INVT SV-DA200-2R0-2, SV-DA200-0R1-2, SV-DA200-1R0-2, SV-DA200-0R7-2, SV-DA200-1R5-2 Operation Manual

...

INVT INDUSTRIAL TECHNOLOGY (SHANGHAI) CO.,LTD.

Serie s

AC ser vo dri ve

SV-DA200 series AC servo drive Preface

-I-

Preface

Thanks for selecting SV-DA200 servo drive.

SV-DA200 servo drive series products adopt modular design with abundant functions and powerful

performance. The upper PC software uses USB communication and the bus control is optional

among Modbus bus, CANopen bus, EtherCAT bus, MotionNet bus and the PROFIBUS-DP bus which

can be selected via extension card. Meanwhile, this product is equipped with online/offline inertia

identification, gain switching, auto/manual notch filter, auto/manual vibration control filter, internal

point-to-point (PTP) control, fully-closed loop control safety terminal STO, 16-bit analog input and

supports multiple types of encoders, etc.

SV-DA200 drive adopts electromagnetic compatibility design to ensure strong anti-electromagnetic

interference capacity while realizing low noise and weakening electromagnetic interference in the

application sites.

This manual presents installation and configuration, parameters setup, fault diagnoses and daily

maintenance and relative precautions to customers. Please read this manual carefully before

installation to ensure SV-DA200 drive is installed and operated properly to give full play to its excellent

performance.

If the product is ultimately used for military affairs or manufacture of weapon, it will be listed on the

export control formulated by Foreign Trade Law of the People's Republic of China. Rigorous

review and necessary export formalities are needed when exported.

Our company reserves the right to update the information of our products.

Note: Models mentioned in this operation manual are standard type unless otherwise specified.

SV-DA200 series AC servo drive Safety precautions

-II-

Safety precautions

Safety symbols:

The safety symbols are marked in the front or side of the servo drive. Users must follow these

safety instructions when operating on the servo drive.

Recycling symbol:

When the life cycle ends, the product should enter the recycling system. Dispose

of it separately at an appropriate collection point instead of placing it in the normal

waste stream.

Following safety precautions should be paid attention to before any installation, configuration,

operation, maintenance and inspection:

Check whether the AC power supply is the same as the rated voltage of the servo drive, otherwise

fire, hurt, damage to the drive may occur.

Do not connect the input power cables to the output terminals, otherwise damage to the drive may

occur.

Do not carry out any insulation and voltage withstand test to the drive directly, and do not test the

control circuit of the drive by megameter.

Connect the drive and motor as correct phase sequence, otherwise drive fault or damage may

occur.

De-couple the motor load and run the motor independently before operation to avoid accidents.

Please ensure the drive can be disconnected from the power supply by E-switch before any

operation.

Set the corresponding parameters before operation, otherwise the drive may run abnormally or

beyond the expectation because of the load.

Only qualified electrical engineers can carry out the wiring, otherwise electric shock or fire may

occur.

Do not touch the conductive parts directly; do not connect any external cables (especially those

SV-DA200 series AC servo drive Safety precautions

-III-

related to electricity) to the enclosure or short connect the external cables, otherwise electric

shock or short circuit may occur.

Rewire the drive after 15 minutes when disconnecting the power supply, otherwise electric shock

may occur.

Do ground with proper techniques because the touch current may be 0.5mA, otherwise electric

shock may occur.

Do not touch the heat sink and external braking resistor during operation, otherwise burning may

occur for the hot sides.

Do install the overcurrent protector, leakage current protector and emergency device and ensure

the normal usage after wiring, otherwise electric shock, hurt and fire may occur.

The leakage current may exceed 3.5mA during the drive running. Do ground with proper

techniques and ensure the grounding resistor is less than 10Ω. The conductivity of PE earth

conductor is the same as the phase conductor (with the same cross area).

The components inside the drive contain heavy metal which should be disposed as industrial

waste.

SV-DA200 series AC servo drive Product overview

-1-

Content

Preface ............................................................................................................................................ I

Safety precautions ......................................................................................................................... II

Content ........................................................................................................................................... 1

1 Product overview ................................ ........................................................................................ 3

1.1 Servo drive ........................................................................................................................... 3

1.2 Servo motor ........................................................................................................................ 10

1.3 Cables ................................................................................................................................ 12

1.4 Braking resistor specification ............................................................................................... 16

2 Installation instruction .............................................................................................................. 17

2.1 Drive dimension .................................................................................................................. 17

2.2 Drive installation ................................................................................................................. 20

2.3 Motor dimension ................................................................................................................. 22

2.4 Motor installation ................................................................................................................. 29

2.5 Technical parameters of servo motor ................................................................................... 29

3 Wiring instruction ..................................................................................................................... 32

3.1 System wiring ................................................................ ..................................................... 32

3.2 Terminal wiring of the main circuit........................................................................................ 36

3.3 Wiring of motor power cables ................................................................ .............................. 39

3.4 Control I/O-CN1 terminal layout .......................................................................................... 41

3.5 Wiring of encoder-CN2 terminals ........................................................................................ 41

3.6 Wiring of 485/CAN-CN3 terminals ....................................................................................... 44

3.7 Wiring of USB-CN4 terminals ................................................................ .............................. 44

3.8 2nd encoder and STO-CN5 terminal wiring........................................................................... 45

3.9 Wiring of PROFIBUS-DP terminals ..................................................................................... 46

3.10 Wiring of motor temperature resistor-CN7 terminal in medium power range (7.5kW–55kW)

...................................................................................................................................................... 47

4 Control mode applications ....................................................................................................... 48

4.1 Standard wiring of the position mode ................................................................................... 48

4.2 Standard wiring of the speed mode ..................................................................................... 49

4.3 Standard wiring of the torque mode ..................................................................................... 50

4.4 CN1 function instruction ...................................................................................................... 51

4.5 CN1 wiring instruction ................................................................ ......................................... 64

4.6 CN5 wiring diagram ............................................................................................................ 70

5 Running and operation ............................................................................................................. 74

5.1 Running .............................................................................................................................. 74

SV-DA200 series AC servo drive Product overview

-2-

5.2 Display and operation ......................................................................................................... 83

6 Function codes ......................................................................................................................... 90

6.1 Basic control (P0 group parameters) ................................................................................... 90

6.2 Autotuning control parameters (P1) ................................................................................... 113

6.3 Motor control parameters (P2)........................................................................................... 119

6.4 I/O management parameters (P3) ..................................................................................... 133

6.5 Extension and application (P4) .......................................................................................... 149

6.6 Program JOG, homing and PTP control (P5) ..................................................................... 165

6.7 Application function (P6) ................................................................................................... 176

6.8 PTP (point-to-point) control (PtP0, PtP1, PtP2) ................................................................. 180

6.9 State monitoring ................................................................................................................ 208

7 Commissioning ....................................................................................................................... 224

7.1 Operation instruction of inertia identification ...................................................................... 224

7.2 General method for parameters adjusting.......................................................................... 224

7.3 Suppression of mechanical resonance .............................................................................. 231

7.4 Gain switching function ..................................................................................................... 232

8 Communication ....................................................................................................................... 236

8.1 Overview .......................................................................................................................... 236

8.2 RS485 communication protocol......................................................................................... 236

8.3 CANopen communication protocol .................................................................................... 240

8.4 PROFIBUS-DP communication protocol ........................................................................... 246

8.5 Upper PC software............................................................................................................ 250

9 Faults and solutions ............................................................................................................... 255

9.1 Meanings of the fault alarm code and countermeasures .................................................... 255

9.2 CANopen communication fault code and countermeasures ............................................... 262

9.3 PROFIBUS-DP communication fault code and countermeasures ...................................... 264

9.4 EtherCAT communication fault code and countermeasures ............................................... 264

10 Appendix ............................................................................................................................... 266

10.1 Setup parameter list ........................................................................................................ 266

10.2 Monitoring parameter table ............................................................................................. 287

10.3 General monitoring parameters ....................................................................................... 291

10.4 Fault code ....................................................................................................................... 292

10.5 Record table of parameter setting ................................................................................... 295

SV-DA200 series AC servo drive Product overview

-3-

1 Product overview

1.1 Servo drive

1.1.1 Instruction to the drive

DA200 series servo drive (100W–55kW)

Specification

Description

Power supply

220V system input voltage

1P/3P AC220V(-15%)–240V(+10%) 47Hz–63Hz

400V system input voltage

3P AC380V(-15%)–440V(+10%) 47Hz–63Hz

Interface

Control signal

Input

10 inputs for standard type, pulse type and

CANopen bus type; 7 inputs for EtherCAT bus type;

5 inputs for MotionNet bus type (the function can be

configured by relevant parameters)

Output

6 single-end outputs for standard type, pulse type

and CANopen bus type; 4 differential outputs for

EtherCAT bus type; 1 single-end output for

MotionNet bus type (the function can be configured

by related parameters)

Analog value

Input

3 inputs for standard type (one 16-bit, two 12-bit

analog inputs), 2 inputs for others (two 12-bit analog

inputs)

Output

2 outputs (analog output)

Pulse signal

Input

1 group (mode: open collector input or differential

input)

Output

1 group (differential outputs (A+, A-;B+, B-;Z+, Z-) or

open collector outputs (A;B;Z))

2nd encoder

Input

Incremental encoder interface (2nd encoder or linear

encoder)

Communication

USB

1:1 communication upper PC software (standard)

RS485

1:n communication (standard)

CANopen

1:n communication (optional)

Profibus-DP

1:n communication (optional)

EtherCAT

1:n communication (optional

Safety terminals

STO

Safe torque off (conform to the latest European

safety standards) (optional)

Control mode

1 Position control; 2 Speed control; 3 Torque

control; 4 Position/Speed mode switching; 5

Speed/Torque mode switching; 6 Position/Torque

mode switching; 7 Fully-closed loop control; 8

CANopen mode; 9 EtherCAT mode; 10 MotionNet

mode

SV-DA200 series AC servo drive Product overview

-4-

DA200 series servo drive (100W–55kW)

Specification

Description

Function

Position

control

Control input

1. Retention pulse clearing;

2. Command pulse input disabled;

3. Electronic gear ratio switching;

4. Vibration control switching, etc

Control output

Positioning completion output, etc

Pulse input

Max. pulse

input

frequency

Optical coupling: differential input

4Mpps, open collector input 200kpps;

Pulse input

mode

1. Pulse + direction;

2. CW+CCW;

3. Quadrature

Electric

gear

1/10000–1000 times

Filter

1. Command smoothing filter;

2. FIR filter

Analog input

Torque limit

command

input

Can independently perform clockwise/

counterclockwise torque limit

Vibration control

Control 5–200Hz forward and whole machine

vibration

Pulse output

1. Can perform arbitrary frequency division settings

under the encoder resolution;

2. B phase reverse function

Speed

control

Control input

1. Internal command speed 1;

2. Internal command speed 2;

3. Internal command speed 3;

4. Zero speed clamp, etc

Control output

Speed reaching, etc

Analog input

Speed

command

input

Can be speed command input after

relevant setting based on analog

voltage DC±10V

Torque limit

input

Can independently arrange clockwise/

counterclockwise torque limit

Internal speed

commands

8 step speed can be switched according to the

external control input

ACC/DEC

adjustment of

speed command

ACC/DEC time setting and S curve setting

SV-DA200 series AC servo drive Product overview

-5-

DA200 series servo drive (100W–55kW)

Specification

Description

Zero speed

clamp

In the speed mode, it can set the operation mode as

the speed mode and position mode

Speed command

filter

A delay filter of analog input speed command

Speed command

zero drift control

Zero drift control against outside interference with

0.3mV precision

Torque

control

Control input

Zero speed clamp input, etc

Control output

Speed reaching, etc

Analog input

Torque

command

input

Analog torque command input, gain

and polarity can be set based on

analog voltage with 4.88mV precision

Speed limit

input

Analog speed limit

Speed limit

Set the speed limit by parameters

Torque command

filter

A delay filter of analog input torque command

Torque command

zero drift control

Zero drift control against the outside interference

with 4.88mV precision

Internal

position plan

Plan bits

128 bits internal position planning, the positioning

can be controlled through communication

Route setting

1. Position; 2. Speed; 3. ACC time; 4. DEC time;

5. Stop timer; 6. Various state output;

7. Operational mode

Homing

1. LS signal; 2. Z phase signal; 3. LS signal+Z

phase signal; 4. Torque limit signal

Protection

Hardware protection

Overvoltage, undervoltage, overcurrent,

overspeed, overload, braking resistor overload,

drive overheat, encoder fault and so on

Software protection

Storage fault, initialization fault, I/O distribution

abnormalities and large position deviation

Protection and fault record

1. Record up to 10 faults

2. Can record the key parameters when fault

occurs

Environment

Operation temperature

0–45

Storage temperature

-20–80(no frozen)

Operation/storage humidity

Operation/storage: ≤90%RH (no condensation)

IP degree

IP20

Elevation

Below 1000m altitude

Vibration

≤5.88m/s2, 10–60Hz(Working at the resonance

point is not allowed)

SV-DA200 series AC servo drive Product overview

-6-

1.1.2 External appearance of the drive

Standard model

CHARGE

MOD E

SET

L3

L1C

L2C

L2

L1

C

N

4

C

N

3

C

N

1

C

N

2

B2

B3

U

V

W

CHARGE light

Power supply of main circuit

Power supply of control circuit

Motor

Grounding

Regenerative resistor

Operation panel

LED display

CN3:CAN/485 communication

CN1:I/O control

CN2:Encoder

CN5:2nd encoder and STO

S1:STO selection

CN4:USB port of up per PC

-

+

Models which carry extension cards with DP function

CHARG E

MODE

L3

L1C

L2

L1

C

N

3

C

N

1

C

N

2

B2

B3

U

V

W

SET

L2C

C

N

4

-

+

CHARGE light

Power supply of main circuit

Power supply of control circuit

Motor

Grounding

Regenerative resistor

Operation panel

LED display

CN3:CAN/485 communication

CN1:I/O control

CN2:Encoder

CN5:2nd encoder and STO

S1:STO selection

CN4:USB port of upper PC

PROFIBUS-DP interface

SV-DA200 series AC servo drive Product overview

-7-

1.1.3 Naming of the drive

SV-DA200-0R4-2-E0-XXXX

① ② ③ ④ ⑤ ⑥ ⑦

Symbol

Instruction

Naming instance

Product category

SV: Servo system product

Product series

DA200: Product series

Power class

0R1: 100W

0R2: 200W

0R4: 400W

0R7: 750W

1R0: 1.0kW

1R5: 1.5kW

2R0: 2.0kW

3R0: 3.0kW

4R4: 4.4kW

5R5: 5.5kW

7R5: 7.5kW

011: 11kW

015: 15kW

022: 22kW

037: 37kW

045: 45kW

055: 55kW

Input voltage class

2: 220VAC; 4: 400VAC

Servo type

E: Pulse type

S: Standard

C: CANopen bus type

P: PROFIBUS-DP bus type

N: EtherCAT bus type

M: MotionNet bus type

K: Customized

Encoder type

0: Photoelectric encoder

(1)

7: Rotary transformer

Lot no.

Manufacturer lot no. used for differentiating models with special

functions. Lot no. is the default one.

Remark:

(1)

: Photoelectric encoder here means 2500-PPR standard incremental type, 17-bit single

turn/multi-turn absolute and 23-bit multi-turn absolute (the same below).

SV-DA200 series AC servo drive Product overview

-8-

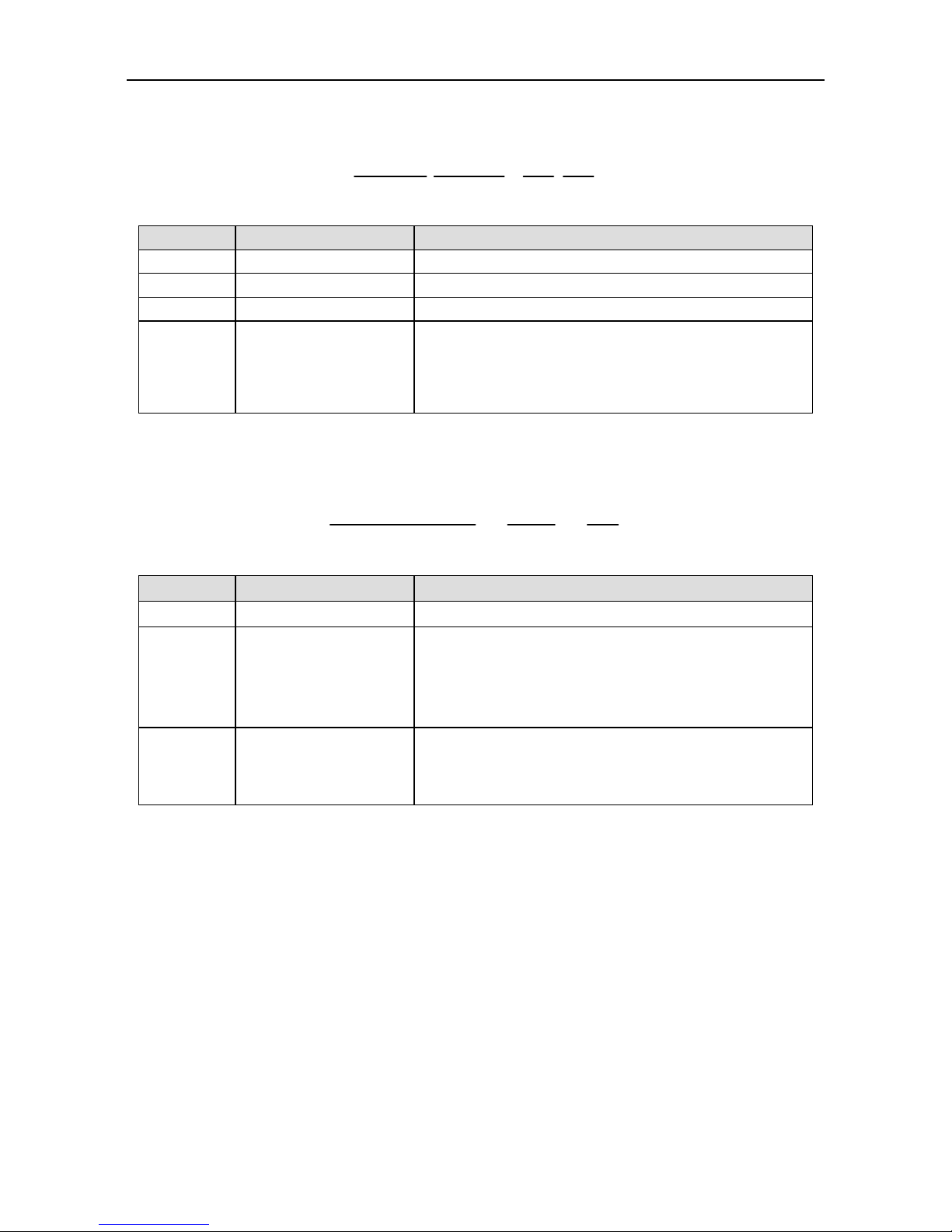

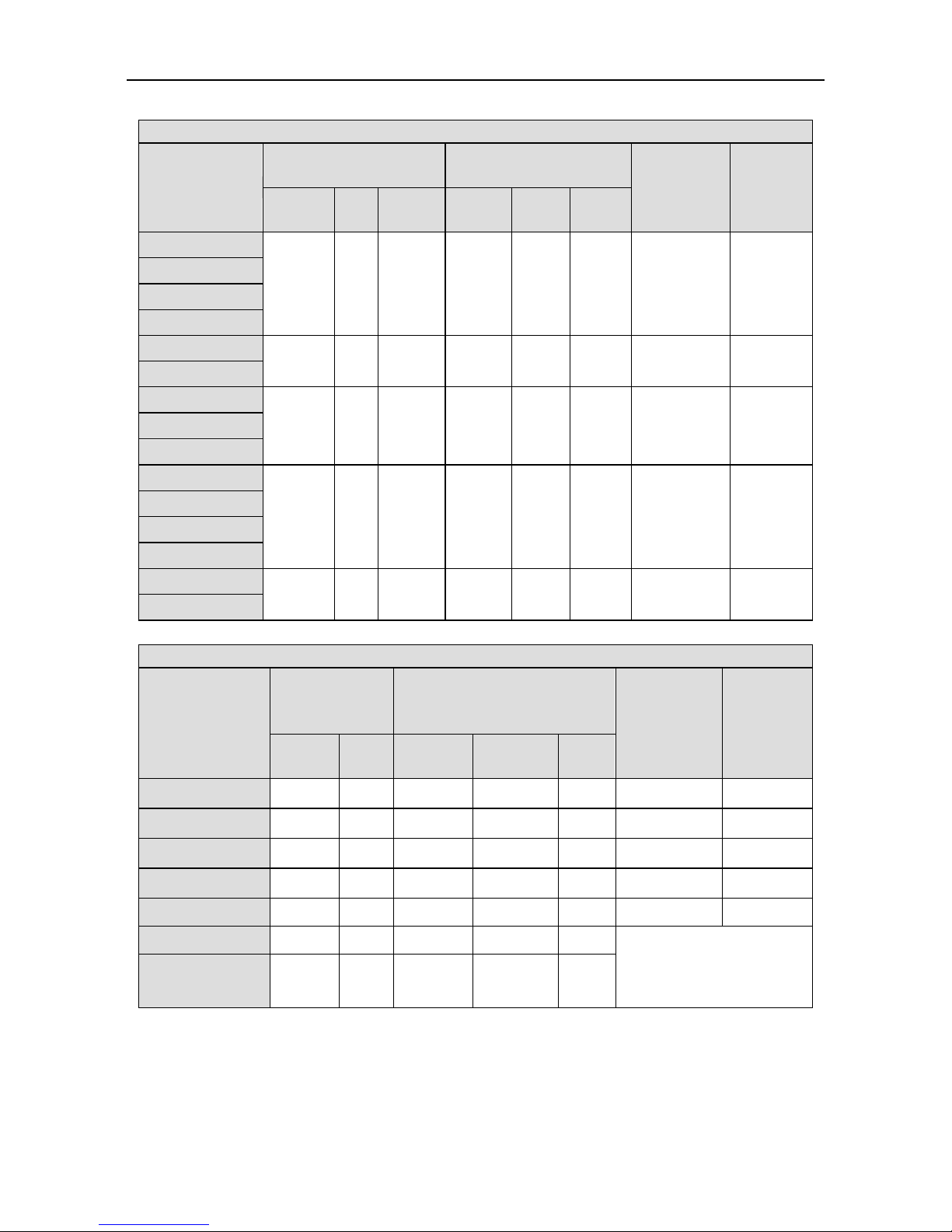

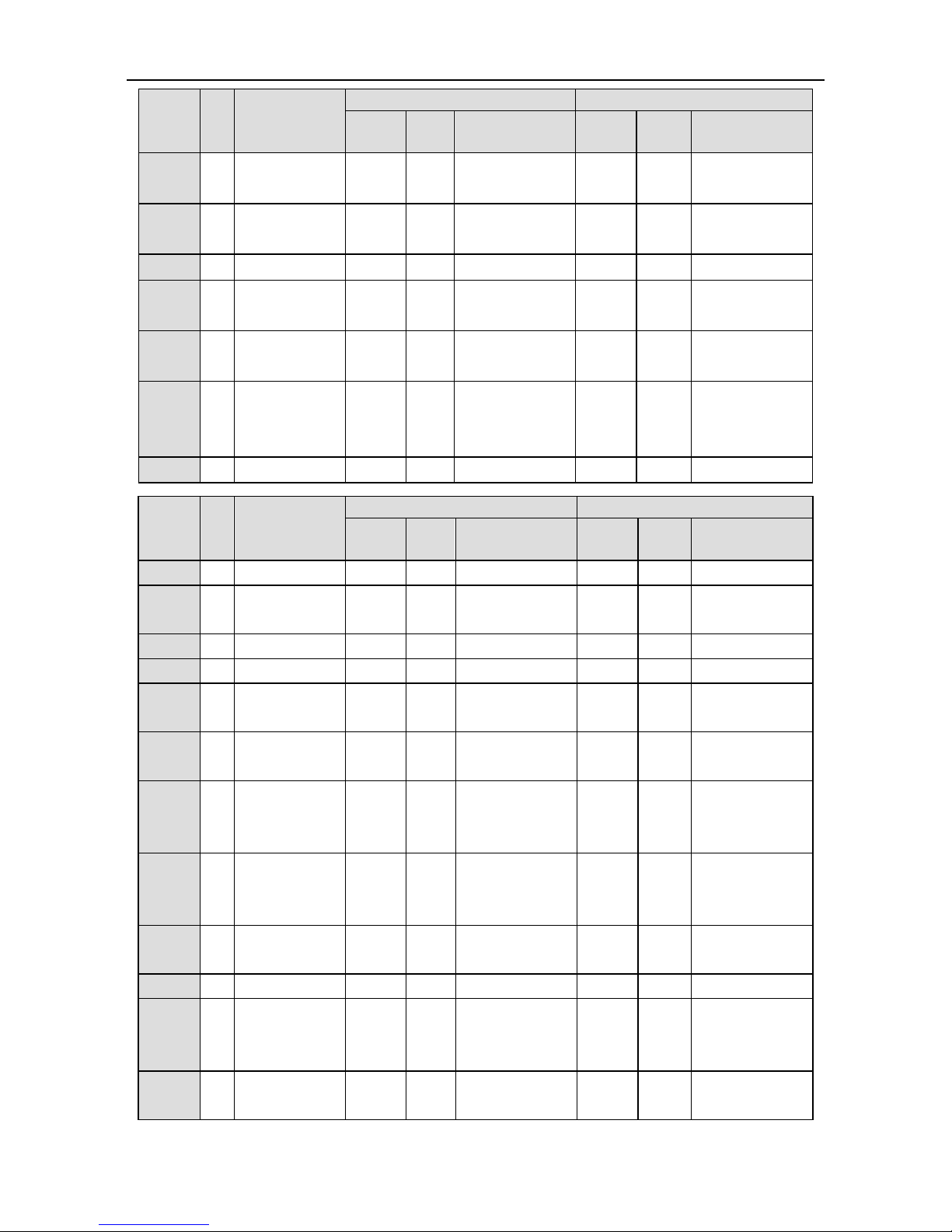

Function difference between different machine types:

Small power range: 100W–5.5kW

Drive type

Symbol

Pulse

input

16-bit

analog

input

2nd

encoder

STO

RS48

5

CAN

open

PROFI

BUS-

DP

Ether

CAT

Motion

Net

Photoelectri

c encoder

Rotary

transfor

mer

Pulse type

E0 ○ × ○ × ○ × × × × ○

×

E7 ○ × ○ × ○ × × × × ×

○

Standard

type

S0 ○ ○ ○ ○ ○ × × × × ○

×

S7 ○ ○ ○ ○ ○ × × × × ×

○

Bus type

C0 × × ○ × × ○ × × × ○

×

P0 × × ○ × × × ○ × × ○

×

N0 × × ○ × × × × ○ × ○

×

M0 × × ○ × ○ × × × ○ ○

×

Customized

K0 ○ × ○ × ○ ○ × × × ○

×

K7 ○ × ○ × ○ ○ × × × ×

○

Medium-power range: 7.5kW–55kW

Drive type

Symbol

Pulse

input

16-bit

analog

input

2nd

encoder

STO

RS48

5

CAN

open

PROF

IBUS-

DP

Ether

CAT

Motion

Net

Photoelectri

c encoder

Rotary

transfor

mer

Standard

type

S0 ○ ○ ○ ○ ○ ○ × × × ○

×

S7 ○ ○ ○ ○ ○ ○ × × × ×

○

Bus type

N0 × × ○ ○ × × × ○ × ○

×

N7 × × ○ ○ × × × ○ × ×

○

Customized

K0 ○ × ○ ○ ○ ○ × × × ○

×

K7 ○ × ○ ○ ○ ○ × × × ×

○

Note: In above table, “○” means this function is available, “×” means this function is unavailable.

1.1.4 Nameplate of the drive

SV-DA200 series AC servo drive Product overview

-9-

1.1.5 Power ratings and cabinet volumes

Model

Input

Output

Cabinet

volume

Voltage (V)

Rated current

(A)

Power

(kW)

Rated

current (A)

SV-DA200-0R1-2

Single/Three phase 220

0.9/0.4

0.1

1.3

A

SV-DA200-0R2-2

Single/Three phase 220

1.8/0.8

0.2

1.8

A

SV-DA200-0R4-2

Single/Three phase 220

3.6/1.5

0.4

2.8

A

SV-DA200-0R7-2

Single/Three phase 220

6.8/2.8

0.75

4.5

B

SV-DA200-1R0-2

Single/Three phase 220

9.1/3.7

1.0 5 B

SV-DA200-1R5-2

Three phase 220

5.6

1.5

7.6

B

SV-DA200-2R0-2

Three phase 220

7.5

2.0

10

D

SV-DA200-3R0-2

Three phase 220

11.2

3.0

13

D

SV-DA200-4R4-2

Three phase 220

16.5

4.4

16.5

D

SV-DA200-1R0-4

Three phase 400

2.1

1.0

3.5

B

SV-DA200-1R5-4

Three phase 400

3.1

1.5

4.5

B

SV-DA200-2R0-4

Three phase 400

4.1

2.0

6.5

C

SV-DA200-3R0-4

Three phase 400

6.2

3.0

8.5

C

SV-DA200-4R4-4

Three phase 400

9.1

4.4

12

D

SV-DA200-5R5-4

Three phase 400

11.3

5.5

16

D

SV-DA200-7R5-4

Three phase 400

15.5

7.5

25

F

SV-DA200-011-4

Three phase 400

22.7

11

33

F

SV-DA200-015-4

Three phase 400

31

15

50

F2

SV-DA200-022-4

Three phase 400

45.4

22

66

G

SV-DA200-037-4

Three phase 400

76.3

37

90

G

SV-DA200-045-4

Three phase 400

92.8

45

112

H

SV-DA200-055-4

Three phase 400

113.4

55

134

H

SV-DA200 series AC servo drive Product overview

-10-

1.2 Servo motor

1.2.1 Nameplate of the motor

INPUT: AC 3PH 220V 2.8A

OUTPUT(RATED): 400W 3000r/min 1.3N·m

IP65 S1 CLASS F NO.3010004(236)

MODEL: SV-ML06-0R4G-2-4A0-3000

Note: “No. 3010004” in the nameplate is the motor model code (motor code for short). Please input

this code into servo parameter P0.00 correctly (P0.00 is long parameter which can be set via keypad.

See details at chapter 5.2.1 (8), otherwise, the servo system may not operate normally and major

fault may occur to the drive and motor.

1.2.2 Naming of the servo motor

① ② ③ ④ ⑤ ⑥ ⑦ ⑧ ⑨ ⑩ ⑪

SV-ML06-0R4G-2-4A0-XXXX

Symbol

Instruction

Naming instance

Product category

SV: Servo system product

Product series

M: M series

C: C series

S: S series

Inertial class

L: Small inertia general servo motor

M: Medium inertia general servo motor

H: Large inertia general servo motor

Base no.

04: 40mm

(2)

06: 60mm

08: 80mm

11: 110mm

13: 130mm

18: 180mm

20: 200mm

26: 263mm

Rated power

0R1: 100W

0R2: 200W

0R4: 400W

SV-DA200 series AC servo drive Product overview

-11-

Symbol

Instruction

Naming instance

0R7: 750W

0R8: 800W/850W

1R0: 1.0kW

1R2: 1.2kW

1R3: 1.3kW

1R5: 1.5kW

1R8: 1.8kW

2R0: 2.0kW

3R0: 3.0kW

4R4: 4.4kW

5R5: 5.5kW

7R5: 7.5kW

011: 11kW

015: 15kW

022: 22kW

037: 37kW

045: 45kW

055: 55kW

……

Rated speed

A: 1000rpm

B: 1500rpm

E: 2000rpm

F: 2500rpm

G: 3000rpm

Voltage class

2: 220VAC

4: 380VAC

Encoder type

1: 2500-PPR standard incremental type

3: 17-bit single-turn absolute value

(1)

4: 17-bit multi-turn absolute value

7: Rotary transformer

9: 23-bit multi-turn absolute value

Shaft end

connection

A: solid with threaded hole and key (standard)

B: Solid optical axis

Optional part

0: with oil seal but no brake

1: without oil seal or brake

(3)

2: with oil seal and permanent magnet brake

3: without oil seal but with permanent magnet brake

(3)

4: with oil seal and electromagnetic brake

5: without oil seal but with electromagnetic brake

(3)

⑪

Lot no.

Manufacturer lot no.

(4)

SV-DA200 series AC servo drive Product overview

-12-

Remark:

(1)

: 17-bit absolute single turn motor belongs to a separate series and its dimension and parameters

are different. Only electromagnetic brake is used. Please pay attention to corresponding series when

selecting models;

(2)

: 40-base motor, only supports 2500-PPR and 17-bit absolute encoder;

(3)

: Non-stock up model, the ordering cycle will be delayed for 3–5 days;

(4)

: No need to fill in for the first-time model selection by customers;

In addition, the non-17 bit single-turn absolute motor with 40 or 60 base supports permanent magnet

brake only.

1.3 Cables

1.3.1 Nameplate of cables

67002-00351

5m power flexible towline cable,0.75mm cable

diameter,4PIN plastic plug,7PIN 20A plug

DAML-075-05-ABF-00

INVT INDUSTRIAL TECHNOLOGY(SHANGHAI) CO.,LTD.

上海英威腾工业技术有限公司

2

1.3.2 Naming of the power cables

DAML-075-05-ABF-00

① ② ③ ④ ⑤ ⑥ ⑦ ⑧

Symbol

Instruction

Naming instance

Product series

For internal use by manufacturer

Power cable

ML: Power cable

Cable diameter

075: 0.75mm2

100: 1.0mm2

150: 1.5mm2

250: 2.5mm

2

400: 4.0mm

2

600: 6.0mm

2

SV-DA200 series AC servo drive Product overview

-13-

Symbol

Instruction

Naming instance

10R: 10mm

2

16R: 16mm

2

25R: 25mm

2

35R: 35mm

2

50R: 50mm2

Cable length

03: 3m

05: 5m

10: 10m

……

Plug on motor end

A: 4PIN plastic plug

B: 4PIN regular aviation plug YD28

C: 4PIN metal plug

D: 7PIN regular aviation plug YD28

E: 4PIN regular aviation plug YD18

N: 4PIN regular aviation plug YD32

S: Copper tube terminal SC

Plug on drive end

B: Euro 7PIN 20A plug

W: No plug

S: Copper tube terminal SC

Cable material

0: Regular cable

A: Shielded normal cable

B: Shielded flexible towline cable

F: Flexible towline cable

Serial no.

00: Standard part

01: Serial no. for non-standard parts

……

1.3.3 Naming of power cable fittings

DAML-AB

① ② ⑤ ⑥

Symbol

Instruction

Naming instance

Product series

For internal use by manufacturer

Power cable

ML: Power cable

Plug on motor end

A: 4PIN plastic plug

B: 4PIN regular aviation plug YD28

C: 4PIN metal plug

D: 7PIN regular aviation plug YD28

SV-DA200 series AC servo drive Product overview

-14-

Symbol

Instruction

Naming instance

E: 4PIN regular aviation plug YD18

N: 4PIN regular aviation plug YD32

S: Copper tube terminal SC

Plug on drive end

B: Euro 7PIN 20A plug

W: No plug

S: Copper tube terminal SC

1.3.4 Naming of the encoder cables

DBEL-15-03-AF-0100

① ② ③ ④ ⑤ ⑥ ⑦ ⑧

Symbol

Instruction

Naming instance

Product series

For internal use by manufacturer

Encoder cable

EL: Encoder cable

Cable number

06: 6-core cable

09: 9-core cable

15: 15-core cable

Cable length

03: 3m

05: 5m

10: 10m

……

Plug on motor end

A: 15PIN DB plug

B: 15PIN regular aviation plug YD28

C: 9PIN metal plug

D: 6PIN plastic head

Cable material

0: regular cable without battery holder

D: regular cable with battery holder

F: Flexible drag chain cable without battery holder

H: Flexible drag chain cable with battery holder

Encoder type

01: 2500-PPR standard incremental type

04: 17-bit single-turn/17-bit multi-turn/23-bit multi-turn

absolute value

07: Rotary transformer

Serial no.

00: Standard part

01: Serial no. for non-standard part

……

SV-DA200 series AC servo drive Product overview

-15-

1.3.5 Naming of encoder cables fittings

DBEL-AA

① ② ⑨ ⑤

Symbol

Instruction

Naming instance

Product series

For internal use by manufacturer

Encoder cable

EL: Encoder cable

Plug on drive end

A: 15PIN DB plug

Plug on motor end

A: 15PIN DB plug

B: 15PIN regular aviation plug YD28

C: 9PIN metal plug

D: 6PIN plastic head

1.3.6 Naming of motor braking cables

BRKL-03-A

① ② ③

Symbol

Instruction

Naming instance

Product series

BRKL: motor brake cable

Cable length

03: 3m

05: 5m

10: 10m

30: 30m

Plug on motor end

A: 2PIN metal plug

B: 3PIN regular aviation plug

C: 3PIN metal plug

SV-DA200 series AC servo drive Product overview

-16-

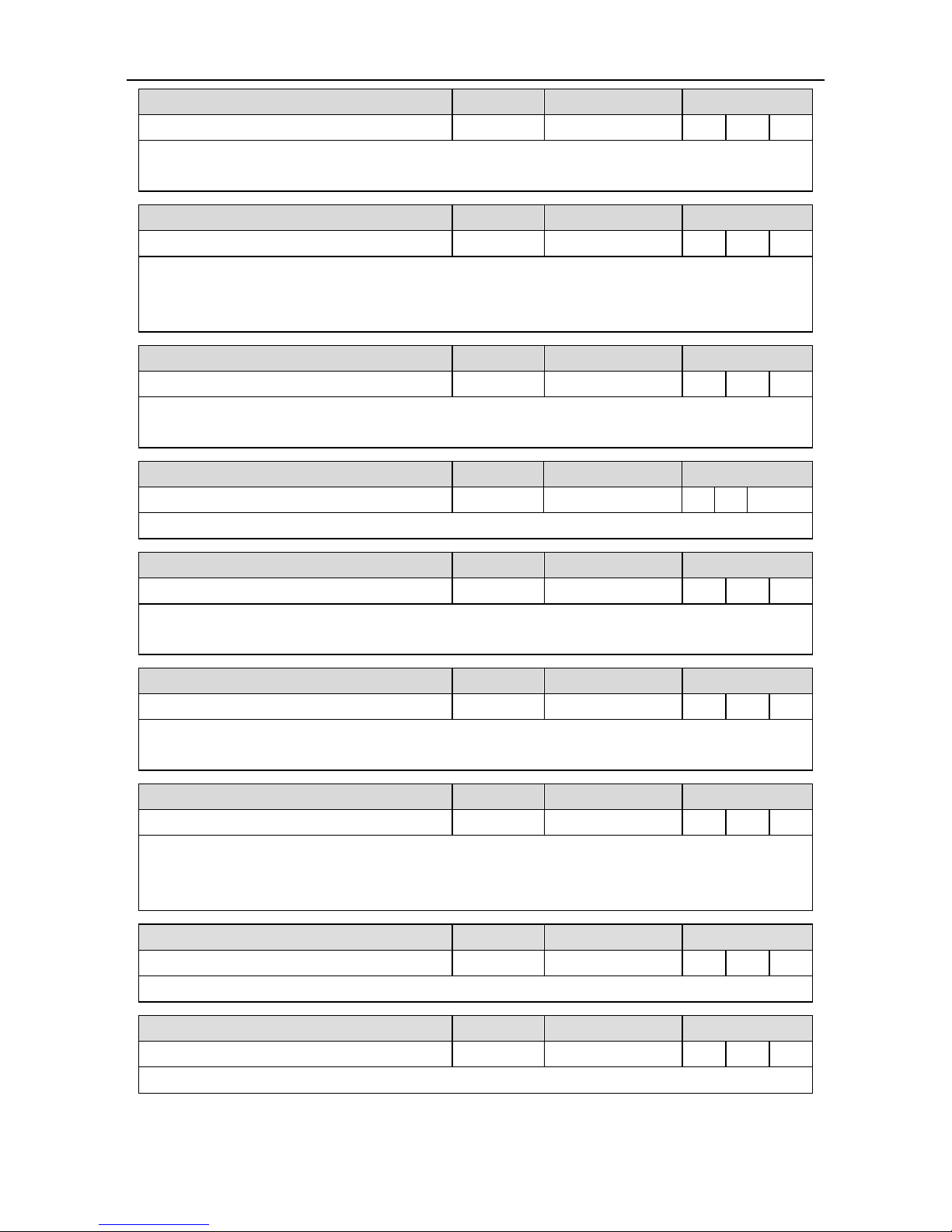

1.4 Braking resistor specification

Drive model

Embedded braking

resistor

Min. resistance of external

braking resistors

SV-DA200-0R1-2

/

60Ω

SV-DA200-0R2-2

/

60Ω

SV-DA200-0R4-2

/

60Ω

SV-DA200-0R7-2

30Ω 60W

30Ω

SV-DA200-1R0-2

30Ω 60W

30Ω

SV-DA200-1R5-2

30Ω 60W

20Ω

SV-DA200-2R0-2

15Ω 120W

15Ω

SV-DA200-3R0-2

15Ω 120W

15Ω

SV-DA200-4R4-2

15Ω 120W

15Ω

SV-DA200-1R0-4

60Ω 60W

60Ω

SV-DA200-1R5-4

60Ω 60W

60Ω

SV-DA200-2R0-4

60Ω 60W

40Ω

SV-DA200-3R0-4

60Ω 60W

30Ω

SV-DA200-4R4-4

30Ω 120W

30Ω

SV-DA200-5R5-4

30Ω 120W

30Ω

SV-DA200-7R5-4

/

30Ω

SV-DA200-011-4

/

20Ω

SV-DA200-015-4

/

15Ω

SV-DA200-022-4

/

10Ω

SV-DA200-037-4

/

10Ω

SV-DA200-045-4

/

5Ω

SV-DA200-055-4

/

5Ω

SV-DA200 series AC servo drive Installation instruction

-17-

2 Installation instruction

2.1 Drive dimension

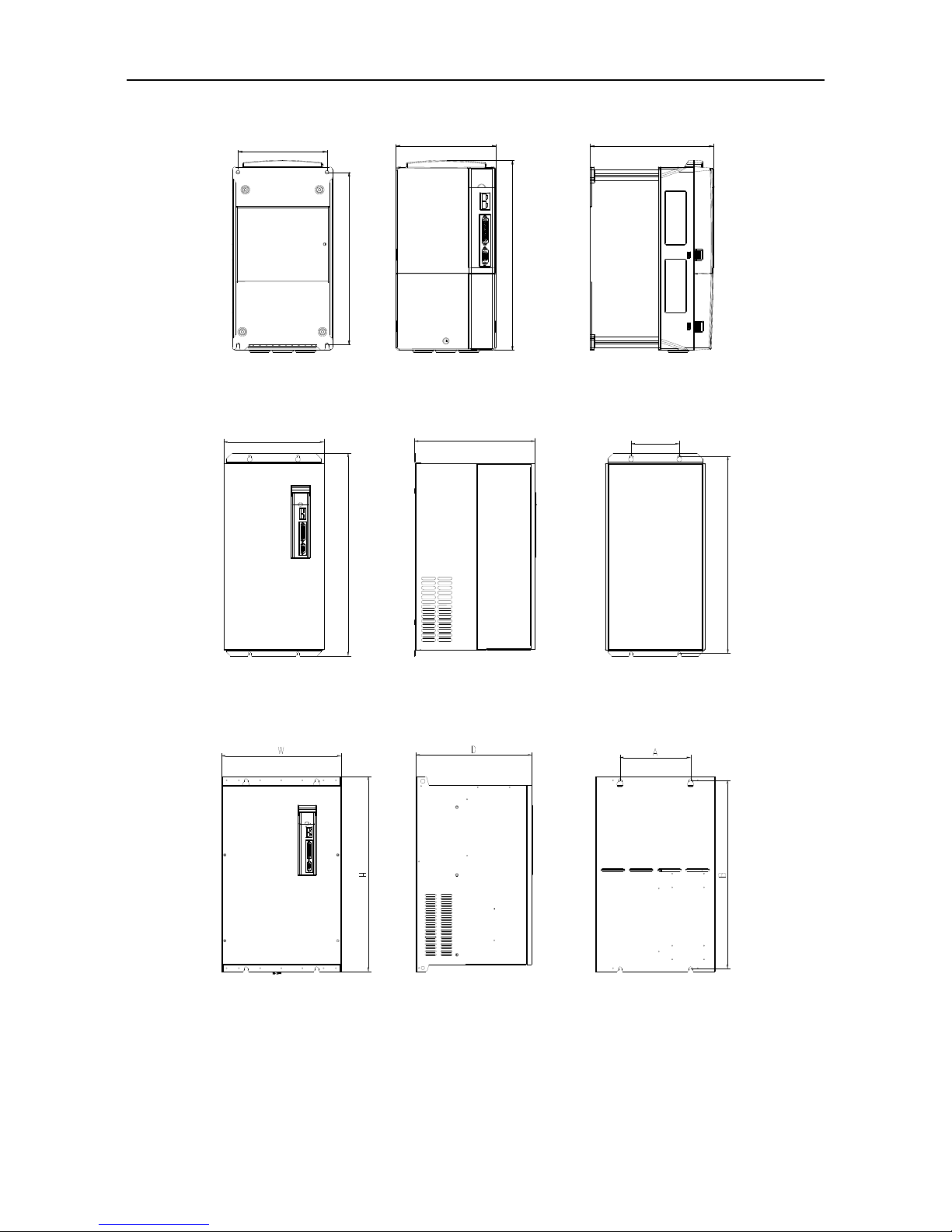

2.1.1 A/B/C size and dimension diagram

2.1.2 Dimension diagram for D size

SV-DA200 series AC servo drive Installation instruction

-18-

2.1.3 Dimension diagram for F/F2 size

D

W

H

A

B

2.1.4 Dimension diagram for G size

H

W

B

A

D

2.1.5 Dimension diagram for H size

SV-DA200 series AC servo drive Installation instruction

-19-

2.1.6 Detailed dimension table

Volume

Model

External dimension

Installation dimension

Installation

hole (mm)

H(mm)

W(mm)

D(mm)

A (mm)

B1 (mm)

B2 (mm)

W1(mm)

A

SV-DA200-0R1-2

170

45

170

33

162

185

22.5

M4(Φ5)

SV-DA200-0R2-2

SV-DA200-0R4-2

B

SV-DA200-0R7-2

170

67

180

54

162

185

25

M4(Φ5)

SV-DA200-1R0-2

SV-DA200-1R5-2

D

SV-DA200-2R0-2

245

92

190

79

237

260

45

M4(Φ5)

SV-DA200-3R0-2

SV-DA200-4R4-2

B

SV-DA200-1R0-4

170

67

180

54

162

185

25

M4(Φ5)

SV-DA200-1R5-4

C

SV-DA200-2R0-4

170

84

180

71

162

185

42

M4(Φ5)

SV-DA200-3R0-4

D

SV-DA200-4R4-4

245

92

190

79

237

260

45

M4(Φ5)

SV-DA200-5R5-4

F

SV-DA200-7R5-4

342

230

208

210

311 / /

M5(Φ6)

SV-DA200-011-4

F2

SV-DA200-015-4

407

255

238

237

384 / /

M6(Φ7)

G

SV-DA200-022-4

555

270

325

130

540 / /

M6(Φ7)

SV-DA200-037-4

H

SV-DA200-045-4

554

338

328

200

535 / /

M8(Φ10)

SV-DA200-055-4

SV-DA200 series AC servo drive Installation instruction

-20-

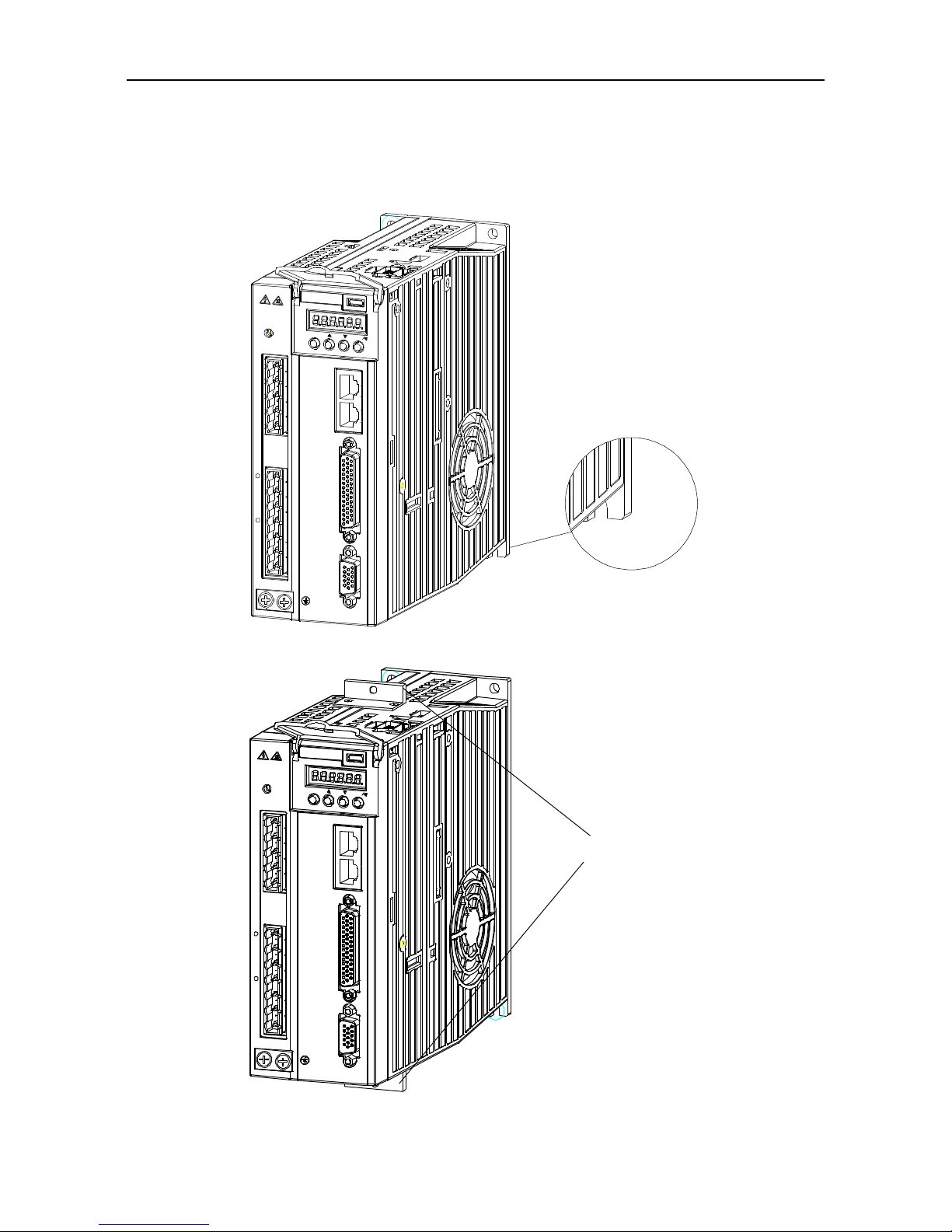

2.2 Drive installation

2.2.1 Installation mode

1) Base installation (there is a Φ5 installation hole at the lower left corner and upper right corner of the

rear board respectively)

CHARGE

MODE

SET

L3

L1C

L2C

L2

L1

C

N

4

C

N

3

C

N

1

C

N

2

B2

B3

U

V

W

-

+

2) Bracket installation (the installation bracket is optional)

CHARGE

MODE

SET

L3

L1 C

L2 C

L2

L1

C

N

4

C

N

3

C

N

1

C

N

2

B2

B3

U

V

W

-

+

Partition bracket

SV-DA200 series AC servo drive Installation instruction

-21-

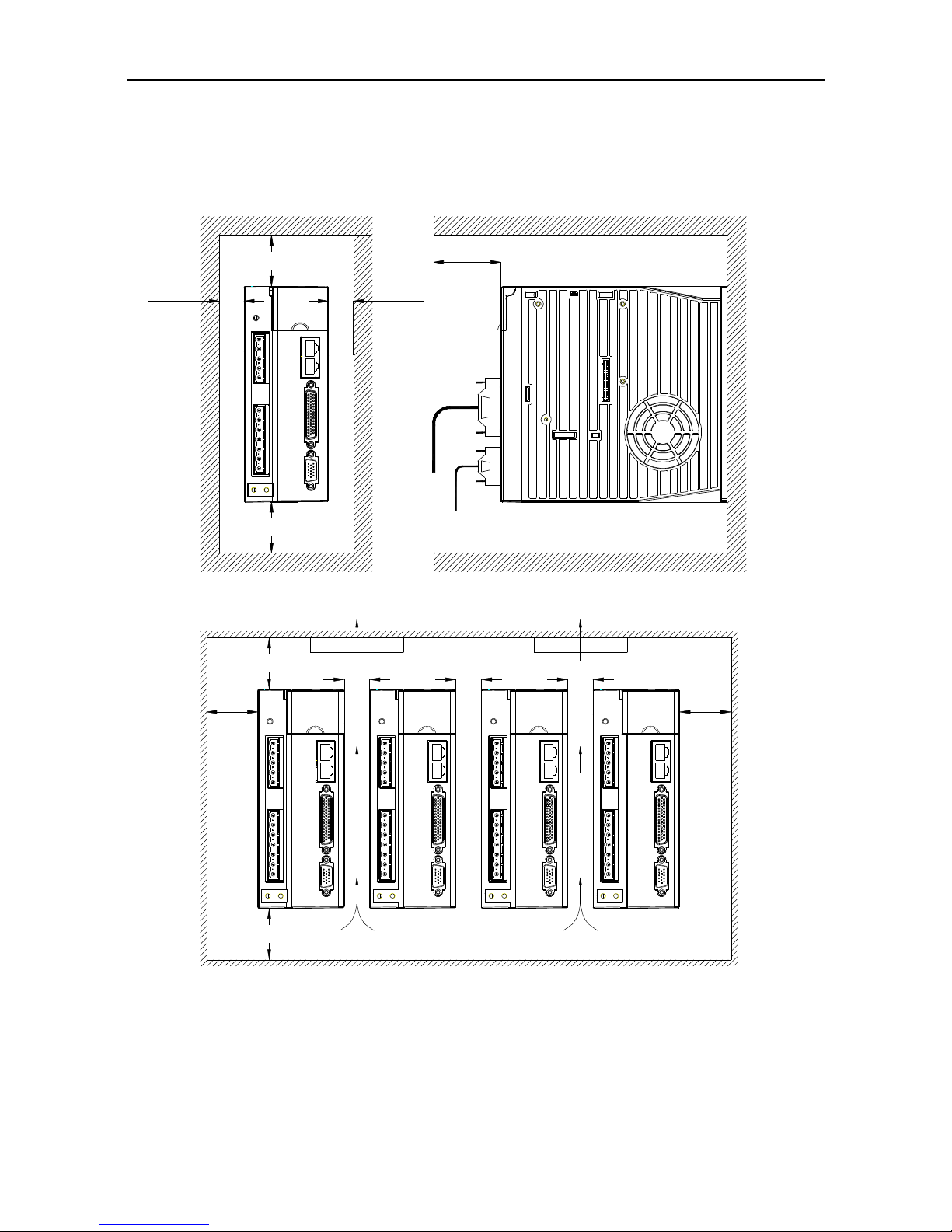

2.2.2 Installation space and direction

Please install the servo drive vertically and keep enough installation space for good ventilation. Install

fans if necessary to ensure the temperature inside the control cabinet is lower than 45.

1) Single drive installation

>100mm

>100mm

>20mm >20mm

>40mm

Up

Down

2) Multiple drives installation

>20mm

>20mm

Up

Down

>20mm

FAN FAN

>20mm

>20mm

>20mm >20mm

SV-DA200 series AC servo drive Installation instruction

-22-

2.3 Motor dimension

Note: As motor structure and dimension may vary slightly with design modification, for those who are

sensitive to the installation length of motor, please confirm the installation length with our business

staff before ordering.

2.3.1 Outline and installation dimension for 40 base (mm)

L25

Φ8h7

Φ30h7

3

4-Φ3.5

Φ46

40

40

15

3h9

9.2

M3 depth 6

A

A

A-A

Motor model

(2500-PPR/multi-turn absolute value)

L(mm)

W/o brake

Permanent magnet brake

SV-ML04-0R1G-2-A

90

124

####

Φ30h7

14

Φ8h7

L

3

25.5 40

40

3h9

9.2

M3 depth 6

2-Φ4.5

Φ46

A

A

A-A

Motor model

(17-bit single-turn encoder)

L(mm)

W/o brake

Electromagnetic brake

SV-ML04-0R1G-2-3A

90.3

123

SV-DA200 series AC servo drive Installation instruction

-23-

2.3.2 Outline and installation dimension for 60 base (mm)

L30

7.5

3

16

5h9

A-A

60.2

60.2

Φ70

Φ50h7

2

2

20.5

M4 depth 10

4-Φ5.5

A

A

Φ14h7

Motor model (2500-PPR/multi-turn absolute

value/rotary transformer)

L(mm)

W/o brake

Permanent magnet brake

SV-ML06-0R2G-2-A

116

164

SV-ML06-0R4G-2-A

141

189

SV-MH06-0R4G-2-A

147

191

4-Φ5.5

##

##

Φ50h7

Φ14h7

A

22.5

M5 depth 15

3

30

L

Φ70

60

60

16

5h9

A-A

A

2

Motor model

(17-bit single-turn encoder)

L(mm)

W/o brake

Electromagnetic brake

SV-ML06-0R2G-2-3A

114

147

SV-ML06-0R4G-2-3A

133

167

SV-DA200 series AC servo drive Installation instruction

-24-

2.3.3 Outline and installation dimension for 80 base (mm)

Φ19h

7

35 L

3

10

Φ70h7

25

M5 depth 10

80

80

Φ90

4-Φ6.3

6h9

A-A

21.5

A

A

2

Motor model (2500-PPR/multi-turn

absolute value/rotary transformer)

L(mm)

W/o brake

Permanent magnet

brake

Electromagnetic

brake

SV-ML08-0R7G-2-A

140

186

186

SV-MH08-0R7G-2-A

151

205

205

####

Φ19h7

35 L

25

Φ70h7

3

A

A

M5 depth 15

80

80

Φ90

4-Φ6.3

6h9

A-A

21.5

Φ19.5×2

Motor model

(17-bit single-turn encoder)

L(mm)

W/o brake

Electromagnetic brake

SV-ML08-0R7G-2-3A

141

173

SV-DA200 series AC servo drive Installation instruction

-25-

2.3.4 Outline and installation dimension for 110 base (mm)

110

110

Φ130

6h9A-A

Φ95h7

2.5

40

Φ19h7

12

5

55 L

M6 depth 20

21.5

4-Φ9

Φ20×2

A

A

Motor model (2500-PPR/multi-turn

absolute value/rotary transformer)

L(mm)

W/o brake

Permanent magnet

brake

Electromagnetic

brake

SV-MM11-0R8E-2-A

189

245

263

SV-MM11-1R2G-2-A

SV-MM11-1R5G-2-A

204

260

278

SV-MM11-1R2E-2-A

219

275

293

SV-MM11-1R8G-2-A

SV-DA200 series AC servo drive Installation instruction

-26-

2.3.5 Outline and installation dimension for 130 base (mm)

130

130

Φ145

Φ110h7

44

Φ22h7

12

6

55 L

M6 depth 22

6h9

A-A

24.5

4-Φ9

A

A

Φ24.4×2

Motor model (2500-PPR/multi-turn

absolute value/rotary transformer)

L(mm)

W/o brake

Permanent magnet

brake

Electromagnetic

brake

SV-MM13-1R0E--A

143

185

185

SV-MM13-1R5E--A

159

201

201

SV-MM13-2R0E--A

175

217

217

SV-MM13-3R0E--A

207

249

249

SV-MH13-0R8B--A

167

209

209

SV-MH13-1R3B--A

202

244

244

Φ110h7

Φ22h7

58

6

L

35

130

Φ145

4-Φ9

130

M6 depth 15

6h9

A-A

24.5

A

A

2

Motor model

(17-bit single-turn encoder)

L(mm)

W/o brake

Electromagnetic brake

SV-MM13-1R0E--3A

165

220

SV-MM13-1R5E--3A

185

240

SV-MM13-2R0E--3A

215

270

SV-MM13-3R0E--3A

265

320

SV-DA200 series AC servo drive Installation instruction

-27-

2.3.6 Outline and installation dimension for 180 base (mm)

L

180

180

Φ200

4-Φ13.5

A-A

38

3.2

65

3

51

Φ114.3h7

Φ38.5×2.5

10h9

M8 depth 25

A

A

Φ35h7

18

Motor model (2500-PPR/multi-turn

absolute value/rotary transformer)

L(mm)

W/o brake

Permanent magnet

brake

Electromagnetic

brake

SV-MM18-3R0B--A

232

314

304

SV-MM18-4R4B--A

262

344

334

SV-MM18-5R5B-4-A

292

382

364

SV-MM18-7R5B-4-A

346

436

418

SV-SM18-7R5B shaft extension dimension (mm):

79

3.2

64

Φ114.3h7

Φ38.5×2.5

19

Φ35h7

M8 depth 25

Motor model (2500-PPR/multi-turn

absolute value/rotary transformer)

L(mm)

W/o brake

Permanent magnet

brake

Electromagnetic

brake

SV-SM18-7R5B-4-A

375

465

455

SV-DA200 series AC servo drive Installation instruction

-28-

2.3.7 Outline and installation dimension for 200 base (mm)

82

Φ180h7

70

Φ42

M10 depth 30

300

Φ42h7

Φ215

A

A

5

L

16.5

110.5

200×200

221×221

4-Φ13.5

246

45

12h9

A-A

Motor model (2500-PPR/multi-turn

absolute value/rotary transformer)

L(mm)

W/o brake

Permanent magnet

brake

Electromagnetic

brake

SV-MH20-011B-4-A

411

547

547

SV-MH20-015B-4-A

446

582

582

2.3.8 Outline and installation dimension for 263 base (mm)

4

110 L

Φ250h7

90

52

14h9

M20 depth 35

320

263×263

292×292

Φ300

4-Φ19

371

146

Φ48h7

A

A

A-A

Motor model (2500-PPR/multi-turn absolute

value/rotary transformer)

L(mm)

W/o brake

SV-SH26-022B-4-A

537

SV-MH26-037B-4-A

537

SV-MH26-045B-4-A

577

SV-MH26-055B-4-A

620

SV-DA200 series AC servo drive Installation instruction

-29-

2.4 Motor installation

Do not pull the motor leads or output shaft during fetching and moving the motor;

Do not beat or hammer during the motor assembly to avoid damage to the encoder or shafts;

Please wipe the slushing oil on the motor shaft before using.

2.5 Technical parameters of servo motor

2.5.1 Motor specification (2500-PPR/multi-turn absolute /rotary transformer)

Motor model

(2500-PPR/multi- turn

absolute/ rotary

transformer)

Rated

power

(kW)

Rated

current

(A)

Max.

transient

current

(A)

Rated

torque

(Nm)

Max.

transient

torque

(Nm)

Rated

speed

(rpm)

Max.

speed

(rpm)

Rotation inertia

standard/ with

brake

(kg·cm²)

Voltage

(V)

Weight

standard/

with brake

(kg)

ML series small inertia

SV-ML04-0R1G-2-A

0.1

0.6

1.2

0.32

0.64

3000

5000

0.051/0.055

220

0.47/0.67

SV-ML06-0R2G-2-A

0.2

1.2

3.6

0.64

1.91

0.175/0.22

1.16/1.66

SV-ML06-0R4G-2-A

0.4

2.8

8.4

1.27

3.9

0.29/0.33

1.6/2.1

SV-ML08-0R7G-2-A

0.75

4.5

13.5

2.39

7.2

1.28/1.51

3.0/3.5

MM/SM series medium inertia

SV-MM11-0R8E-2-A

0.8

3.5

10.5 4 12

2000

3000

5.4/6.7

220

6/7.7

SV-MM11-1R2E-2-A

1.2

4.5

13.5 6 18

7.6/8.9

7.9/9.6

SV-MM11-1R2G-2-A

1.2 5 15 4 12

3000

4000

5.4/6.7

6/7.7

SV-MM11-1R5G-2-A

1.5 6 18 5 15

6.3/7.6

6.8/8.5

SV-MM11-1R8G-2-A

1.8 6 18 6 18

7.6/8.9

7.9/9.6

SV-MM13-1R0E-2-A

1

4.8

14.4

4.78

14.3

2000

3000

6.4/8.3

5.8/7.5

SV-MM13-1R5E-2-A

1.5

7.6

22.8

7.16

21.4

9.3/11.2

7.1/8.8

SV-MM13-2R0E-2-A

2

9.5

28.5

9.55

28.6

12.2/14.1

8.4/10.1

SV-MM13-3R0E-2-A

3

13.6

40.8

14.3

42

18/19.9

10.8/12.5

SV-MM13-1R0E-4-A

1

2.8

8.4

4.78

14.3

6.4/8.3

380

5.8/7.5

SV-MM13-1R5E-4-A

1.5

4.5

13.5

7.16

21.4

9.3/11.2

7.1/8.8

SV-MM13-2R0E-4-A

2

5.5

16.5

9.55

28.6

12.2/14.1

8.4/10.1

SV-MM13-3R0E-4-A

3

7.8

23.4

14.3

42

18/19.9

10.8/12.5

SV-MM18-3R0B-2-A

3

12

29.7

19

47

1500

2000

70/74

220

20.5/25

SV-MM18-4R4B-2-A

4.4

16

39.7

27

67

97/101

25.5/30

SV-MM18-3R0B-4-A

3

7.5

18.7

19

47

70/74

380

20.5/25

SV-MM18-4R4B-4-A

4.4

10

25

27

67

97/101

25.5/30

SV-MM18-5R5B-4-A

5.5

12

24

35

70

86/127

30.5/35.7

SV-MM18-7R5B-4-A

7.5

20

40

48

96

168/179

40/46.5

SV-SM18-7R5B-4-A

7.5

24

62

48

120

1500

3000

190/201

380

46/52.5

SV-DA200 series AC servo drive Installation instruction

-30-

Motor model

(2500-PPR/multi- turn

absolute/ rotary

transformer)

Rated

power

(kW)

Rated

current

(A)

Max.

transient

current

(A)

Rated

torque

(Nm)

Max.

transient

torque

(Nm)

Rated

speed

(rpm)

Max.

speed

(rpm)

Rotation inertia

standard/ with

brake

(kg·cm²)

Voltage

(V)

Weight

standard/

with brake

(kg)

MH/SH series large inertia

SV-MH06-0R4G-2-A

0.4

2.8

8.4

1.27

3.81

3000

5000

0.67/0.77

220

2.0/2.2

SV-MH08-0R7G-2-A

0.75

4.5

13.5

2.39

7.2

2.5/2.73

3.3/3.8

SV-MH13-0R8B-2-A

0.85

5.5

16.5

5.41

16.2

1500

2000

13.4/15.4

6.6/8.3

SV-MH13-1R3B-2-A

1.3

8.2

24.6

8.34

25

23.4/25.4

9.3/11

SV-MH13-0R8B-4-A

0.85

3.2

9.6

5.41

16.2

13.4/15.4

380

6.6/8.3

SV-MH13-1R3B-4-A

1.3

4.8

14.4

8.34

25

23.4/25.4

9.3/11

SV-MH20-011B-4-A

11

22.7

69

70

175

98.3/106.3

49/66

SV-MH20-015B-4-A

15

42.5

107

95.5

240

119/127

56/73

SV-SH26-022B-4-A

22

61

153

140

350

390/412

103/133

SV-MH26-037B-4-A

37

74.6

187

187

468

1800

2300

380

115

SV-MH26-045B-4-A

45

100

250

210

525

2000

2500

447

121

SV-MH26-055B-4-A

55

114

285

290

725

1800

2300

728

150

Insulation class

Class F (155)

Protection class

IP65

Application

environment

Temperature: -20–+40 (non-frozen); RH: below 90%RH (No condensation)

SV-DA200 series AC servo drive Installation instruction

-31-

2.5.2 Motor specification (17-bit single-turn absolute value)

Motor model

(17-bit single-turn absolute

value)

Rated

power

(kW)

Rated

current

(A)

Max.

transien

t current

(A)

Rated

torque

(Nm)

Max.

transient

torque

(Nm)

Rated

speed

(rpm)

Max.

speed

(rpm)

Rotational

inertia

standard/with

brake

(kg·cm²)

Voltage

(V)

Weight

standard/

with brake

(kg)

ML series small inertia

SV-ML04-0R1G-2-3A

0.1

1.1

3.3

0.32

0.96

3000

5000

0.036/0.037

220

0.47/0.67

SV-ML06-0R2G-2-3A

0.2

1.2

3.6

0.64

1.92

3000

5000

0.176/0.179

1.01/1.4

SV-ML06-0R4G-2-3A

0.4

2.3

6.9

1.27

3.81

0.3/0.302

1.37/1.78

SV-ML08-0R7G-2-3A

0.75

4.3

12.9

2.5

7.5

1.015/1.018

2.5/3.4

MM series medium inertia

SV-MM13-1R0E-2-3A

1

4.72

14.2

4.77

14.3

2000

2500

8.71/8.72

220

6.41/7.94

SV-MM13-1R5E-2-3A

1.5

6.87

20.6

7.16

21.5

12.08/12.1

7.9/9.4

SV-MM13-2R0E-2-3A

2

9.18

27.5

9.55

28.6

17.14/17.16

10.12/

11.67

SV-MM13-3R0E-2-3A

3

12.95

38.85

14.3

42.9

25.58/25.59

13.8/15.4

SV-MM13-1R0E-4-3A

1

2.5

7.5

4.77

14.3

8.71/8.72

380

6.41/7.94

SV-MM13-1R5E-4-3A

1.5

4.1

12.3

7.16

21.5

12.08/12.1

7.9/9.4

SV-MM13-2R0E-4-3A

2

6.5

19.5

9.55

28.6

17.14/17.16

10.12/

11.67

SV-MM13-3R0E-4-3A

3

9.6

28.8

14.3

42.9

25.58/25.59

13.8/15.4

Insulation class

Class F(155)

Protection class

IP65

Application

environment

Tempetaure: -20 to +40 (non-frozen); RH: below 90%RH (no condensation)

SV-DA200 series AC servo drive Wiring instruction

-32-

3 Wiring instruction

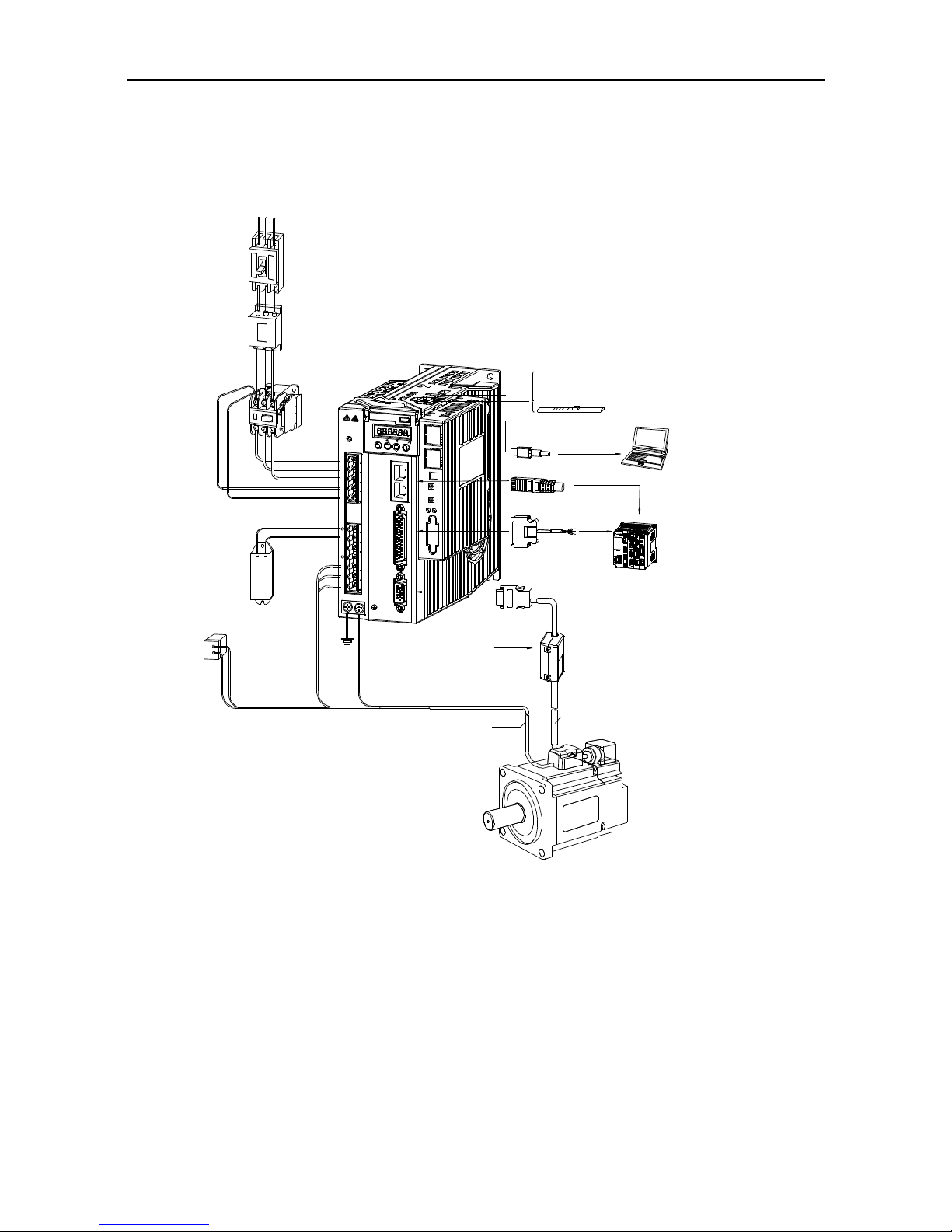

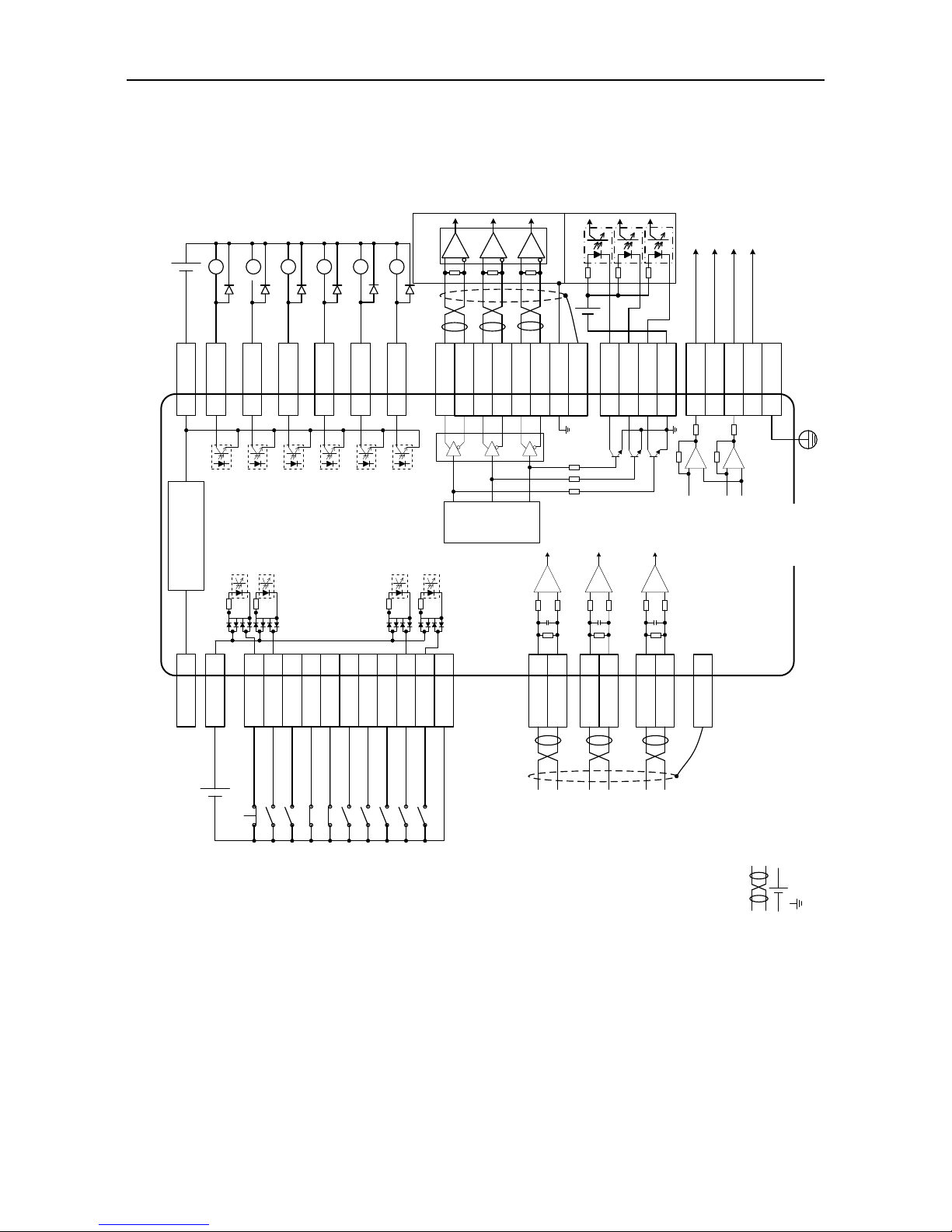

3.1 System wiring

L1 L 2 L3

Electromagnetic

contactor

Turn on/off servo

power.

Please install surge

suppressor duing

usage.

Breaker

Power

ST O

sw itch

PC connection cable

PC

C

N

CHARGE

SET

MODE

4

L2

L1

L1C

L3

3

N

C

CAN/485 communication

Grating ruler or the second encoder

Signal cable (I/O)

Upper device

L2C

+

N

C

-

B3

U

V

B2

1

C

N

2

W

Encoder signal

Safety input signal is valid

and corre ct wirin g is needed

when S TO safety function is

not use d, namely STO is not

set to O N .

Safety input term in al signal is

invalid an d wiring is not needed

when S TO safety prote ction

fun ction is used, nam ely when

STO switch is set to O N

Encoder connection cable

Main circuit cable of motor

Servo motor

Battery unit

(when absolute encoder is used)

Brake power

(

DC 24V, provided by the user

)

Regenerative

brake resistor

Noise filter

Prevent the noise outside

the power cable

Used to cut off the circuit

when p ower cable flows

throu gh o vercurrent

Check to ensure the input power supply indicated on the nameplate is the same as that of the

grid before connecting the input power supply of the drive.

The electromagnetic contactor is used to switch on/off the power supply of the main circuit of

the servo drive. Do not use it to start/stop the servo drive.

In the above figure, the external regenerative brake resistor is connected, and the short

connection wire between B2 and B3 should be removed, refer to chapter 3.2 for details. The

external regenerative brake resistor must be installed on flame-resistance material which has good

cooling effect eg metal.

SV-DA200 series AC servo drive Wiring instruction

-33-

3.1.1 Requirements on input power cable

The dimension of input power cable shall comply with local regulations.

The input power cable must be able to withstand corresponding load current.

The max rated temperature margin of input power cable should not be lower than 70 under

continuous operation.

See IEC/EN 61800-3:2004 for EMC requirements.

It is recommended to use shielded four-core cable for input cable

Conductor

Sleeve

Insulation

PE

Shielded

layer

Four-core cable with shielded layer

In order to protect the conductors, the cross section of shielded cable must the same with that of the

phase conductor when the shielded cable and phase conductor use the same material, which will

help reduce grounding resistor to improve impedance continuity.

In order to suppress the emission and transmission of RF, the conductivity of shielded cable must be

at least 1/10 of phase conductor conductivity. The coverage rate of shielded layer must be above 85%

at least.

3.1.2 Requirements on control cable

All the analog control cables and the cables used for frequency input must use shielded cable. The

analog signal cable uses shielded twisted pair (figure a). Each signal adopts a pair of independent

shielded twisted pair. Different analog signal cannot use the same ground wire.

Multiple double-shielded twisted pairs Multiple single-shielded twisted pairs

For low voltage digital signal, it is recommended to use double-layer shielded cables, single-layer

shielded pairs or shieldless pairs (figure b), however, for pulse input signal, only shielded cable can

be used.

Communication cable must use shielded twisted pairs.

SV-DA200 series AC servo drive Wiring instruction

-34-

3.1.3 Cable diameter of main circuit

Small power range (100W–5.5kW) main circuit cable diameter table

Drive model

Recommended cable

diameter (mm2)

Connectable cable

diameter (mm2)

Terminal

screw

specification

Tightening

torque

(Nm)

L1\L2\L3

UVW

PE

L1C\L2C

L1\L2\L3

UVW

(+), B2,

B3, (-)

PE

SV-DA200-0R1-2

0.75

0.75

0.75

0.75–4

0.75–4

0.75–4

M2.5

0.3–0.6

SV-DA200-0R2-2

SV-DA200-0R4-2

SV-DA200-0R7-2

SV-DA200-1R0-2

1.5

1.5

0.75

1.5–4

1.5–4

1.5–4

M2.5

0.3–0.6

SV-DA200-1R5-2

SV-DA200-2R0-2

2.5

2.5

0.75

2.5–4

2.5–4

2.5–4

M4

1.2–1.5

SV-DA200-3R0-2

SV-DA200-4R4-2

SV-DA200-1R0-4

1.5

1.5

0.75

1.5–4

1.5–4

1.5–4

M2.5

0.3–0.6

SV-DA200-1R5-4

SV-DA200-2R0-4

SV-DA200-3R0-4

SV-DA200-4R4-4

2.5

2.5

0.75

2.5–6

2.5–6

2.5–6

M4

1.2–1.5

SV-DA200-5R5-4

Medium power range (7.5kW–55kW) main circuit cable diameter table

Drive model

Recommended

cable diameter

(mm2)

Connectable cable diameter

(mm2)

Terminal

screw

specification

Tightening

torque

(Nm)

RST

UVW

PE

RST

UVW

(+), PB, (-)

PE

SV-DA200-7R5-4

6 6 6–16

6–10

6–10

M5

2–2.5

SV-DA200-011-4

10

10

10–16

10–16

6–16

M5

2–2.5

SV-DA200-015-4

16

16

16–25

16–25

10–16

M6

4–6

SV-DA200-022-4

25

16

25–50

25–50

16–25

M8

9–11

SV-DA200-037-4

35

16

25–50

25–50

16–25

M8

9–11

SV-DA200-045-4

50

25

35–95

25–95

25–35

The terminal adopts nuts,

users are suggested to use

spanners or sleeves

SV-DA200-055-4

70

35

50–95

50–95

25–35

SV-DA200 series AC servo drive Wiring instruction

-35-

3.1.4 EMI filter

Drive model

EMI filter model

SV-DA200-0R1-2

FLT-P04006L-B

SV-DA200-0R2-2

SV-DA200-0R4-2

SV-DA200-0R7-2

SV-DA200-1R0-4

SV-DA200-1R5-4

SV-DA200-1R0-2

FLT-P04016L-B

SV-DA200-1R5-2

SV-DA200-2R0-4

SV-DA200-3R0-4

SV-DA200-2R0-2

SV-DA200-3R0-2

FLT-P04032L-B

SV-DA200-4R4-4

SV-DA200-4R4-4

SV-DA200-5R5-4

SV-DA200-7R5-4

FLT-P04045L-B

SV-DA200-011-4

SV-DA200-015-4

FLT-P04065L-B

SV-DA200-022-4

FLT-P04100L-B

SV-DA200-037-4

FLT-P04150L-B

SV-DA200-045-4

FLT-P04200L-B

SV-DA200-055-4

FLT-P04250L-B

Note: The EMI filter models in the table are the models of our company and they are used for power

input terminal.

SV-DA200 series AC servo drive Wiring instruction

-36-

3.2 Terminal wiring of the main circuit

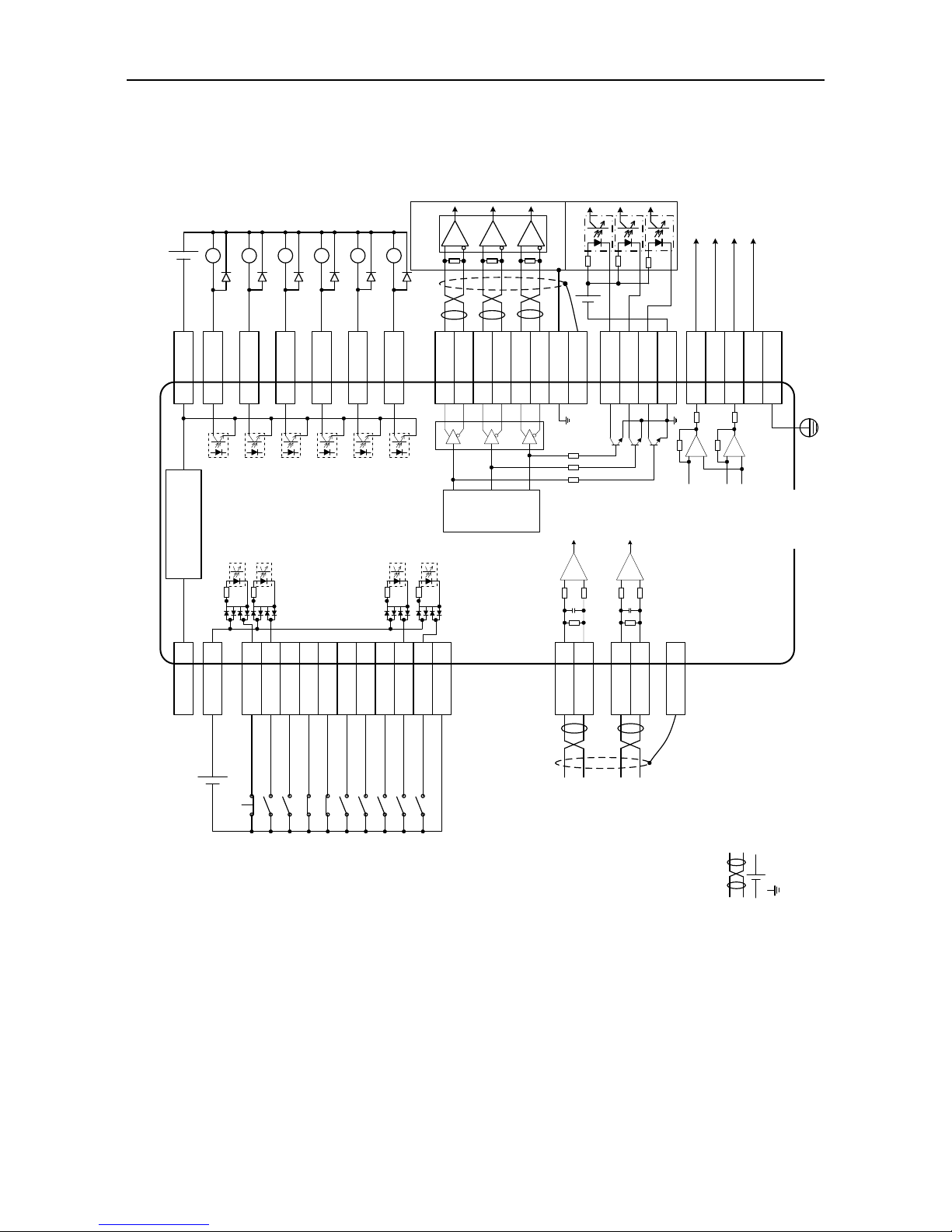

3.2.1 Wiring diagram of single phase 220V (small power range: 100W–5.5kW)

· Do not disconnect the short

connection cable between B2 and

B3, unless external regenerative

brake resistor is used;

· When external regenerative brake

resistor is used, disconnect the short

connection cable between B2 and

B3 and make connection based on

the dotted lines in the diagram.

· Connect output U, V and W to the

drive according to the motor cable

phase sequence of servo motor,

wrong phase sequence will cause

drive fault

· Be sure to ground the servo drive to

avoid accident of electrical shock.

· The electromagnetic brake uses 24V

power supply which should be

provided by the user. Moreover, it

must be isolated from the DC12-24V

power supply which is used by the

control signal.

· Pay attention to the connection of

the freewheeling diode. Reversed

polarity may damage the drive.

· The user is required to make this

emergency stop protection circuit.

· Add surge absorbing devices on

both ends of the electromagnetic

contactor winding.

· The power input voltage range:

AC 220V(-15%)~240V(+10%)

· Connect main circuit to terminal L1

and terminal L3.

· Note: Please use 3-phase input

power for the drive of 1.5kW and

above.

Yellow/Green

Surge absorber

Fuse

Breaker

MC

MC

ALM

CN1

Emergency

stop button

RY

EMI

filter

DC 12~24V

(±10%)

DC 24V

(±10%)

OFF

ALM

ON

+

-

+

-

Motor

L1

L2

L3

L1C

L2C

B3

+

B2

U

V

W

-

COM-

ALM

SV-DA200 series AC servo drive Wiring instruction

-37-

3.2.2 Wiring diagram of three phase 220V/400V (small power range: 100W–5.5kW)

· Input voltage range of 220V system:

AC 220V(-15%)~240V(+10%)

· Input voltage range of 400V system:

AC 380V(-15%)~440V(+10%)

· Do not disconnect the short circuit

wire between B2 and B3 unless an

external regenerative braking

resistor is used.

· When an external regenerative

braking resistor is used, disconnect

the short circuit wire between B2 and

B3, and connect it according to the

dotted line in the figure.

· Connect the output U, V and W of

the drive to the servo motor correctly

according to the phase sequence of

the motor cable of the servo motor.

Wrong phase sequence will cause

drive fault.

· Be sure to ground the servo drive to

avoid accident of electrical shock.

· The electromagnetic brake uses 24V

power supply which should be

provided by the user. Moreover, it

must be isolated with the DC12-24V

power supply which is used by the

control signal.

· Pay attention to the connection of the

freewheeling diode. Reversed

polarity may damage the drive.

· The user is required to make this

emergency stop protection circuit.

· Add surge absorbing devices on both

ends of the electromagnetic

contactor winding.

Surge absorber

Fuse

Breaker MC

MC

ALM

CN1

Emergency

stop button

RY

EMI

filter

DC 12~24V

(±10%)

DC 24V

(±10%)

OFF

ALM

ON

+

-

+

-

Motor

L1

L2

L3

L1C

L2C

B3

+

B2

U

V

W

-

COM-

ALM

Green/Yellow

SV-DA200 series AC servo drive Wiring instruction

-38-

3.2.3 Wiring diagram of three phase 400V (medium power range: 7.5kW–55kW)

· Input voltage range of 400V system:

AC 380V(-15%)~440V(+10%)

· It is necessary to connect external

regenerative brake resistor between

terminal (+) and PB

· Be sure to ground the servo drive to

avoid accident of electrical shock.

· The electromagnetic brake uses 24V

power supply which should be

provided by the user. Moreover, it

must be isolated from the DC12-24V

power supply which is used by the

control signal.

· Pay attention to the connection of the

freewheeling diode. Reversed

polarity may damage the drive.

· The user is required to make this

emergency stop protection circuit.

· Add surge absorbing devices on both

ends of the electromagnetic

contactor winding.

Fuse

Breaker

MC

MC

RY

DC 24V

(±10%)

OFF

ALM

ON

+

-

R

S

T

(+)

PB

(-)

U

V

W

· Connect output U, V and W to the

drive according to the motor cable

phase sequence of servo motor,

wrong phase sequence will cause

drive fault

Motor

ALM

CN1

+

COM-

ALM

Green/Yellow

Emergency

stop button

Surge absorber

EMI

filter

DC 12~24V

(±10%)

SV-DA200 series AC servo drive Wiring instruction

-39-

3.3 Wiring of motor power cables

3.3.1 2500-PPR 40/60/80-base 100W–750W motor power cable

X2

X1

1

2

3

4

6

7

5

A

12

34

A direction view

PE

W

V

U

Wiring relation

Definition

X1

X2

Core wire color

W

X1.7

X2.3

Brown

V

X1.6

X2.1

Red

U

X1.5

X2.2

Blue

PE

Ground terminal

X2.4

Yellow/green

/

X1.4 / / / X1.3

Short connect to X1.2

/

X1.2

Short connect to X1.3

/

X1.1 / /

3.3.2 17-bit or 23-bit 40/60/80-base 100W–750W motor power cable

X2

X1

1

2

3

4

6

7

5

A direction view

PE

W

V

U

A

1234

Wiring relation

Definition

X1

X2

Core wire color

W

X1.7

X2.1

Brown

V

X1.6

X2.3

Red

U

X1.5

X2.4

Blue

PE

Ground terminal

X2.2

Yellow/green

/

X1.4 / / / X1.3

Short connect to X1.2

/

X1.2

Short connect to X1.3

/

X1.1 / /

3.3.3 110/130-base 800W–1.5kW (220V) and 1kW–3kW (380V) motor power cable (except 130

base 17-bit single-turn with brake)

1

2

4

3

X2

X1

1

2

3

4

6

7

5

A

A direction view

PE

W

V

U

SV-DA200 series AC servo drive Wiring instruction

-40-

Wiring relation

Definition

X1

X2

Core wire color

W

X1.7

X2.4

Brown

V

X1.6

X2.3

Red

U

X1.5

X2.2

Blue

PE

Ground terminal

X2.1

Yellow/green

/

X1.4 / /

/

X1.3

Short connect to X1.2

/

X1.2

Short connect to X1.3

/

X1.1 / /

3.3.4 130/180-base 2kW–4.4kW (220V) and 4.4kW–7.5kW (380V) motor power cable (except for

130 base 17-bit single-turn with brake)

1

2

4

3

X2

X1

A

A direction view

PE

Brown

red

Blue

W

V

U

Wiring relation

Definition

X2

Core wire color

W

X2.4

Brown

V

X2.3

Red

U

X2.2

Blue

PE

X2.1

Yellow/green

3.3.5 200/260-base 11kW–55kW (380V) motor power cable

U

V

W

PE

PE

Ye llow

Green

Red

Ye llow

Green

Red

U

V

W

3.3.6 130-base 17-bit single-turn motor power cable with brake

X2

X1

1

2

3

4

6

7

5

A

A direction view

PE

Brake1

Brake2

W

V

U

1

2

3

4

6

7

5

Wiring relation

Definition

X1

X2

Core wire color

W

X1.7

X2.4

Brown

V

X1.6

X2.3

Red U X1.5

X2.2

Blue

PE

Ground terminal

X2.1

Yellow/green

/

X1.4 / /

/

X1.3

Short connect to X1.2

/

X1.2

Short connect to X1.3

/

X1.1 / /

Brake 1

Y shape terminal

X2.6

Red

Brake 2

Y shape terminal

X2.7

Black

SV-DA200 series AC servo drive Wiring instruction

-41-

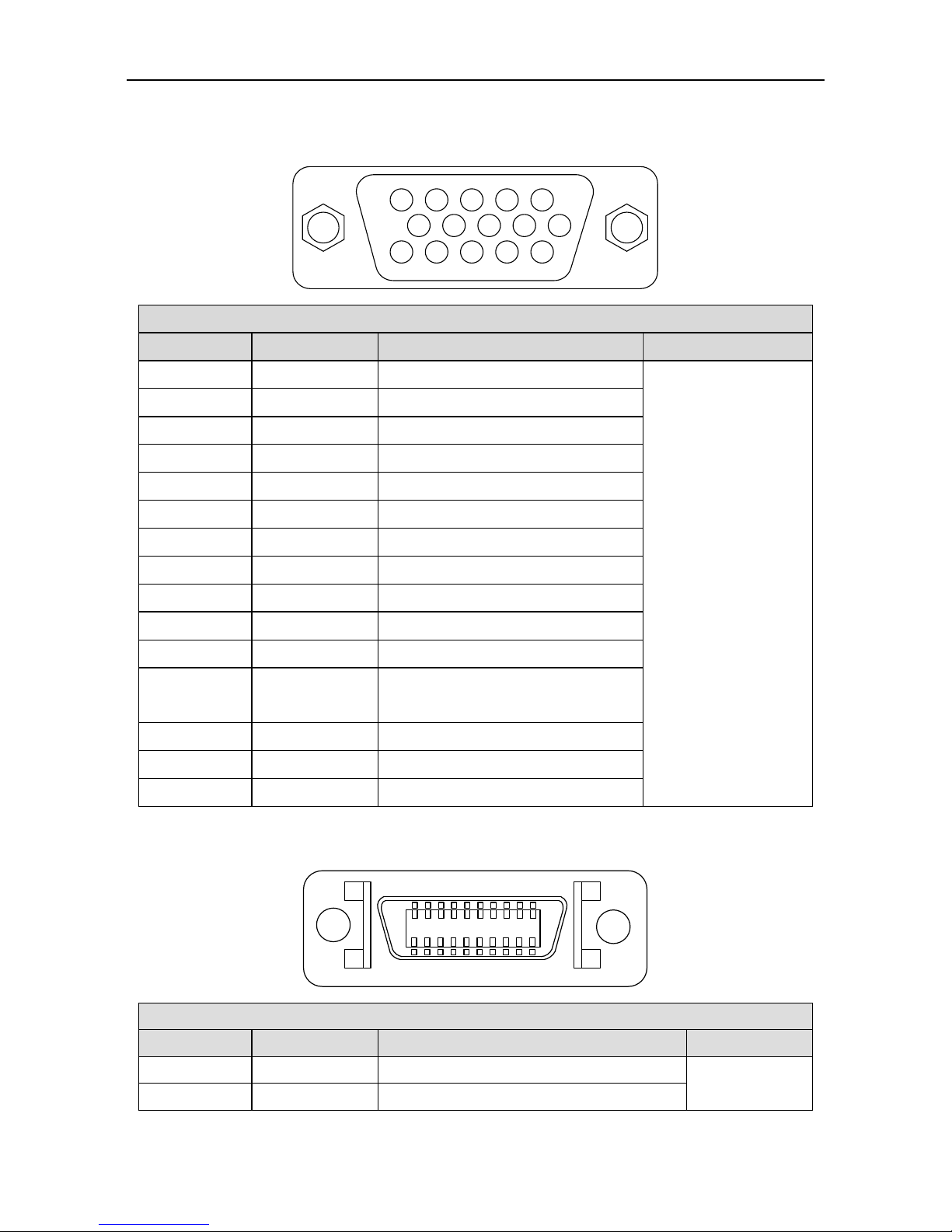

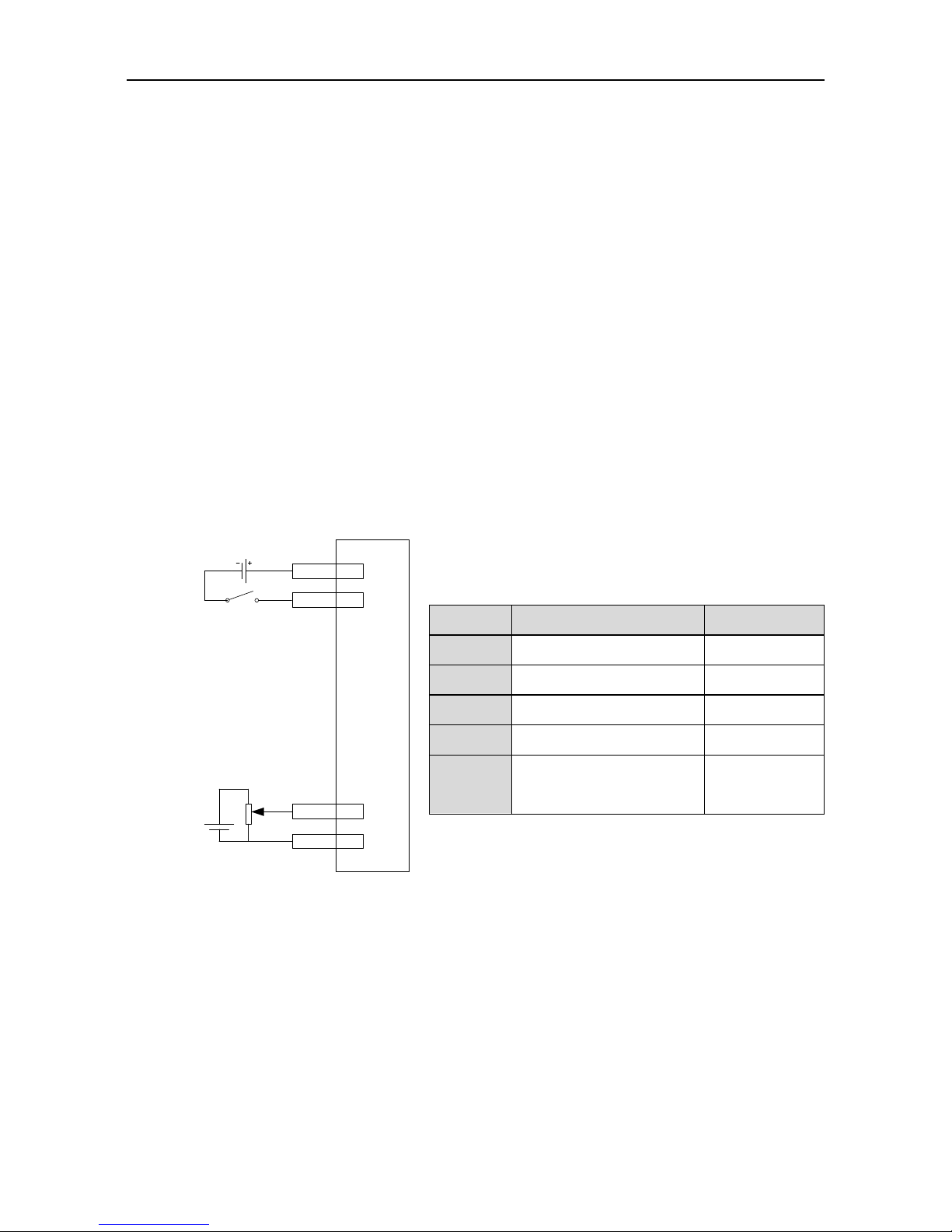

3.4 Control I/O-CN1 terminal layout

CN1 plug pin layout

CN1 plug signal layout

44 43 42 41 40 39 38 37 36 35 34 33 32 31

30 29 28 27 26 25 24 23 22 21 20 19 18 17

15 14 13 12 11 10 9 8 7 6 5 4 3 2161

OA+ OA- OB- OB+ 24V DI4 OCP DI2 OCA GND DI5 SIGN- SIGN+ OCS

OCB DO4 OZ+ OZ- OCZ AO2 PULS-PULS+ DI10 AO1 AD2 GND DI9 DI6

DO2 DO1 DO6 COM- DO3 DI3 DO5 GND AD3 GND GND DI8 DI7 COM+

DI1

AD1

Remark: This is the interface definition for standard model; refer to chapter 4 for terminal

function and application. See corresponding operation guide for EtherCAT bus type.

3.5 Wiring of encoder-CN2 terminals

3.5.1 CN2 terminals

5 4 3 2 1

10 9 8 7 6

15 14 13 12 11

CN2 terminal function

Pin

Name

Function

Remark

1

V+/ SD+

Parallel encoder V+/Serial encoder data+

Different

encoders use

different

cables

2

W+

Signal of parallel encoder W+

3

A+

Signal of parallel encoder A+

4

A-

Signal of parallel encoder A-

5

5V

Encoder power supply

6

U+

Signal of parallel encoder U+

7

V- /SD-

Parallel encoder V-/Serial encoder data-

8

W-

Signal of parallel encoder W-

9

B-

Signal of parallel encoder B-

10

B+

Signal of parallel encoder B+

11

U-

Signal of parallel encoder U-

12

GND

Power ground

13

Z-

Signal of parallel encoder Z-

14

Z+

Signal of parallel encoder Z+

15

-

Unused

SV-DA200 series AC servo drive Wiring instruction

-42-

3.5.2 2500-PPR 40, 60, 80-base encoder cable

1

11

15

5

X2

B

B d irection v iew

1

11

15

5

6

10

X1

A

6

10

A d irection v iew

Wiring relation

Signal

X1

X2

Core wire structure

V+

X1.1

X2.1

Twisted pair

V-

X1.7

X2.7

W+

X1.2

X2.2

Twisted pair

W-

X1.8

X2.8

A+

X1.3

X2.3

Twisted pair

A-

X1.4

X2.4

U+

X1.6

X2.6

Twisted pair

U-

X1.11

X2.11

B-

X1.9

X2.9

Twisted pair

B+

X1.10

X2.10

Z-

X1.13

X2.13

Twisted pair

Z+

X1.14

X2.14

5V

X1.5

X2.5

Twisted pair

GND

X1.12

X2.12

PE

Steel casing

Steel casing

3.5.3 2500-PPR 110, 130, 180, 200 base encoder cable

12

5 3

610

1113

15 14

1

11

15

5

6

10

X1

X2

A

B

B d irection v iew

A d irection v iew

Wiring relation

Signal

X1

X2

Core wire structure

V+

X1.1

X2.11

Twisted pair

V-

X1.7

X2.14

W+

X1.2

X2.12

Twisted pair

W-

X1.8

X2.15

A+

X1.3

X2.7

Twisted pair

A-

X1.4

X2.4

U+

X1.6

X2.10

Twisted pair

U-

X1.11

X2.13

B-

X1.9

X2.8

Twisted pair

B+

X1.10

X2.5

Z-

X1.13

X2.9

Twisted pair

Z+

X1.14

X2.6

5V

X1.5

X2.2

Twisted pair

GND

X1.12

X2.3

PE

Steel casing

Steel casing

SV-DA200 series AC servo drive Wiring instruction

-43-

3.5.4 17-bit and 23-bit 40, 60, 80 base encoder cable

B

7

6

5

4

3

2

1

8

9

X2

B direc tion view

A d irection v iew

1

11

15

5

6

10

X1

A

Wiring relation

Signal

X1

X2

Core wire structure

SD+

X1.1

X2.1

Twisted pair

SD-

X1.7

X2.2

5V

X1.5

X2.3

Twisted pair

GND

X1.12

X2.4

VB-5V / X2.5

Twisted pair

VB-GND / X2.6

PE

Steel casing

Steel casing

Weaving

3.5.5 17-bit and 23-bit 110, 130, 180, 200 base encoder cable

12

35

610

11

13

1415

X2

B

B d irection view

A direc tion view

1

11

15

5

6

10

X1

A

Wiring relation

Signal

X1

X2

Core wire structure

SD+

X1.1

X2.2

Twisted pair

SD-

X1.7

X2.3

5V

X1.5

X2.4

Twisted pair

GND

X1.12

X2.5

VB-5V / X2.6

Twisted pair

VB-GND / X2.7

PE

Steel casing

X2.1

Weaving

3.5.6 Rotary transformer encoder cable

12

3

5

610

11

13

1415

X2

B

A direc tion view

B d irection view

1

11

15

5

6

10

X1

A

Wiring relation

Signal

X1

X2

Core wire structure

SIN+

X1.1

X2.6

Twisted pair

SIN-

X1.7

X2.7

COS+

X1.2

X2.5

Twisted pair

COS-

X1.8

X2.4

R+

X1.5

X2.3

Twisted pair

R-

X1.12

X2.2

PE

Steel casing

X2.1

Weaving

SV-DA200 series AC servo drive Wiring instruction

-44-

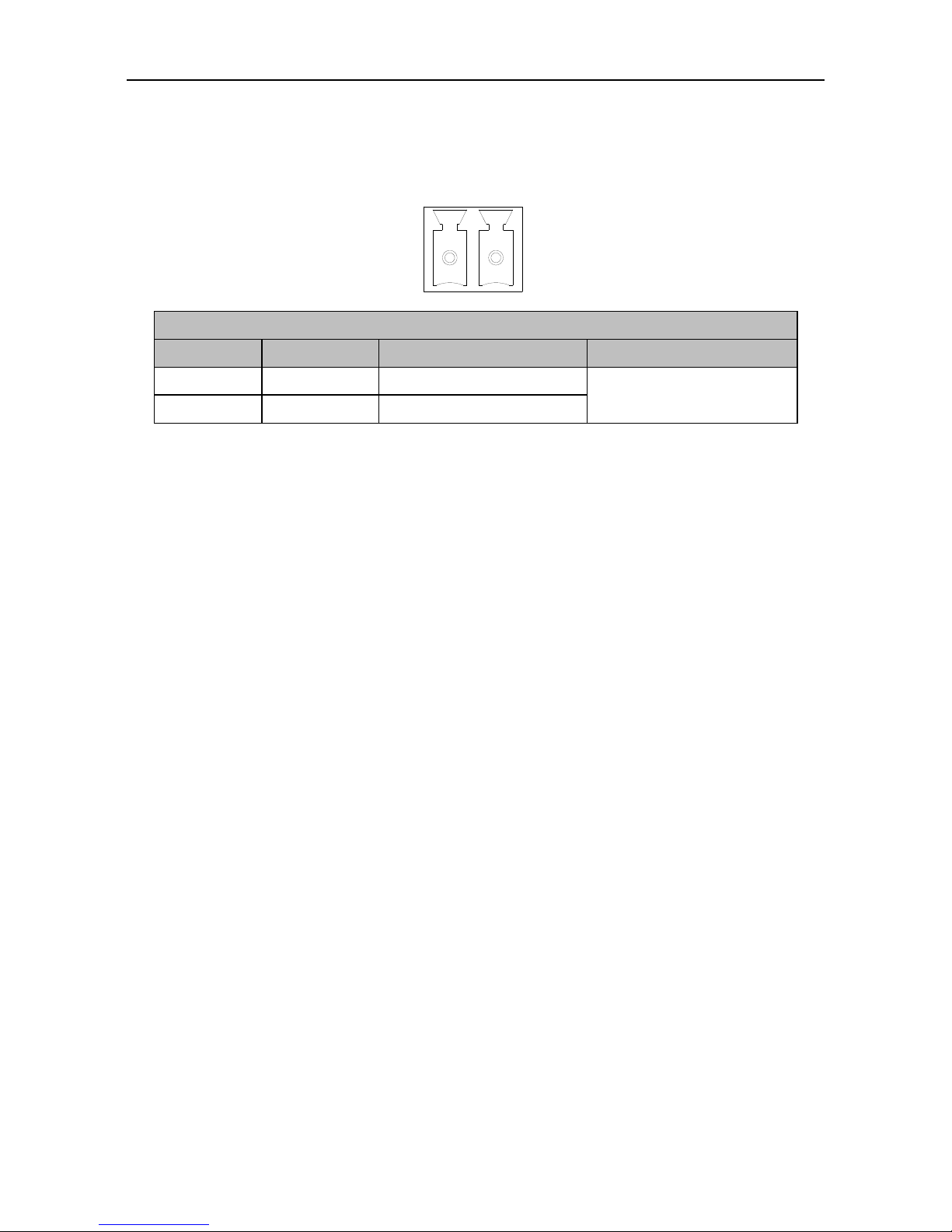

3.6 Wiring of 485/CAN-CN3 terminals

Pin8

Pin1

CN3 terminal function

Pin

Name

Function

Remark

1

GND_CAN

CAN chip power GND

485 and CAN use the

same interface and each

signal has two pins for

multiple networking.

2

GND_485

485 chip power GND

4

RS485+

RS485 data +

5

RS485-

RS485 data -

7

CAN_L

CAN data -

8

CAN_H

CAN data +

3, 6 - Unused

Note: EtherCAT bus-type drive, this port is standard network cable port definition, namely pin 1, 2, 3

and 6 correspond to Tx+, Tx-, Rx+ and Rx- respectively.

3.7 Wiring of USB-CN4 terminals

Pin5

Pin1

CN4 USB port function

Pin

Name

Functions

Remark

2

D-

Data -

The standard cable for USB micro to

USB-A conversion is available.

3

D+

Data +

5

GND

Signal ground

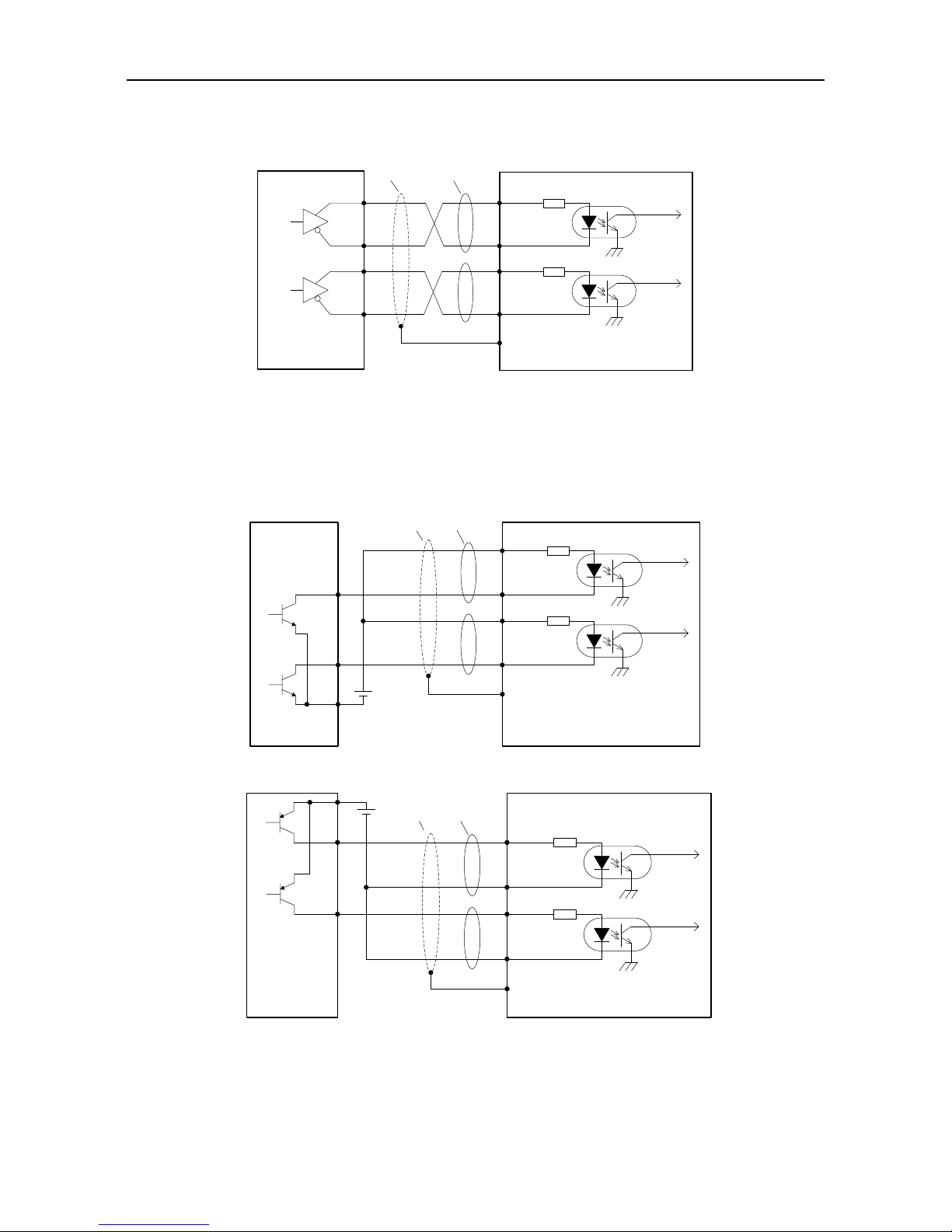

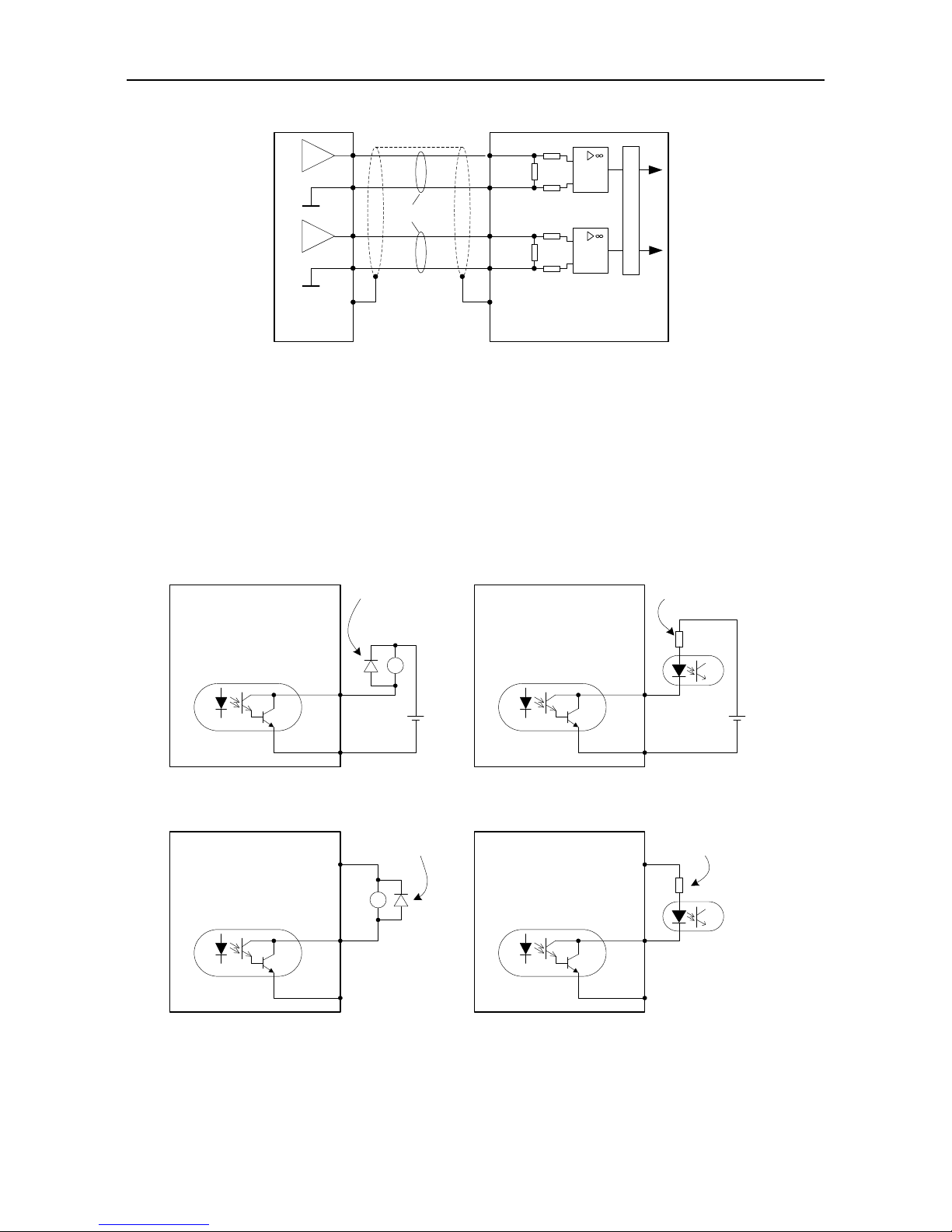

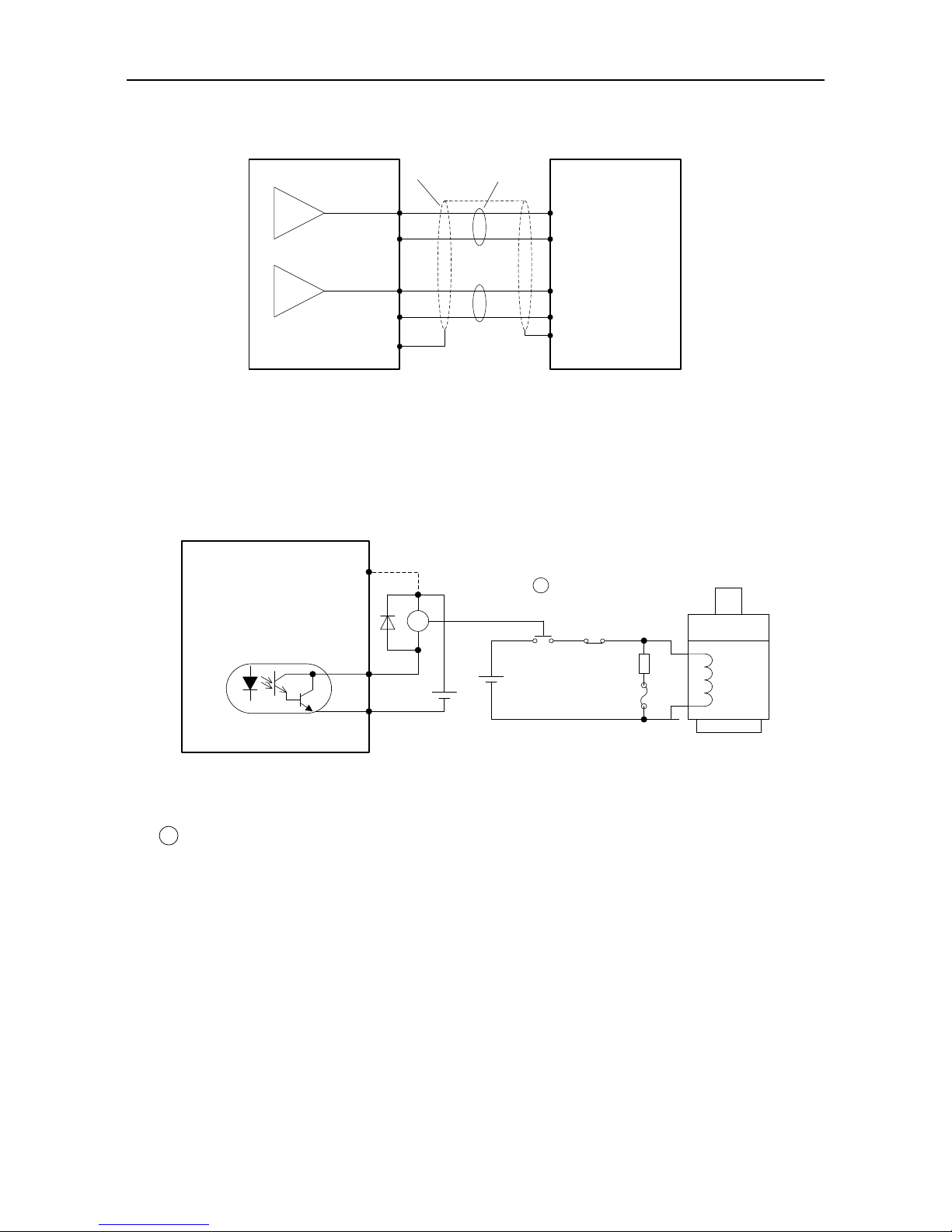

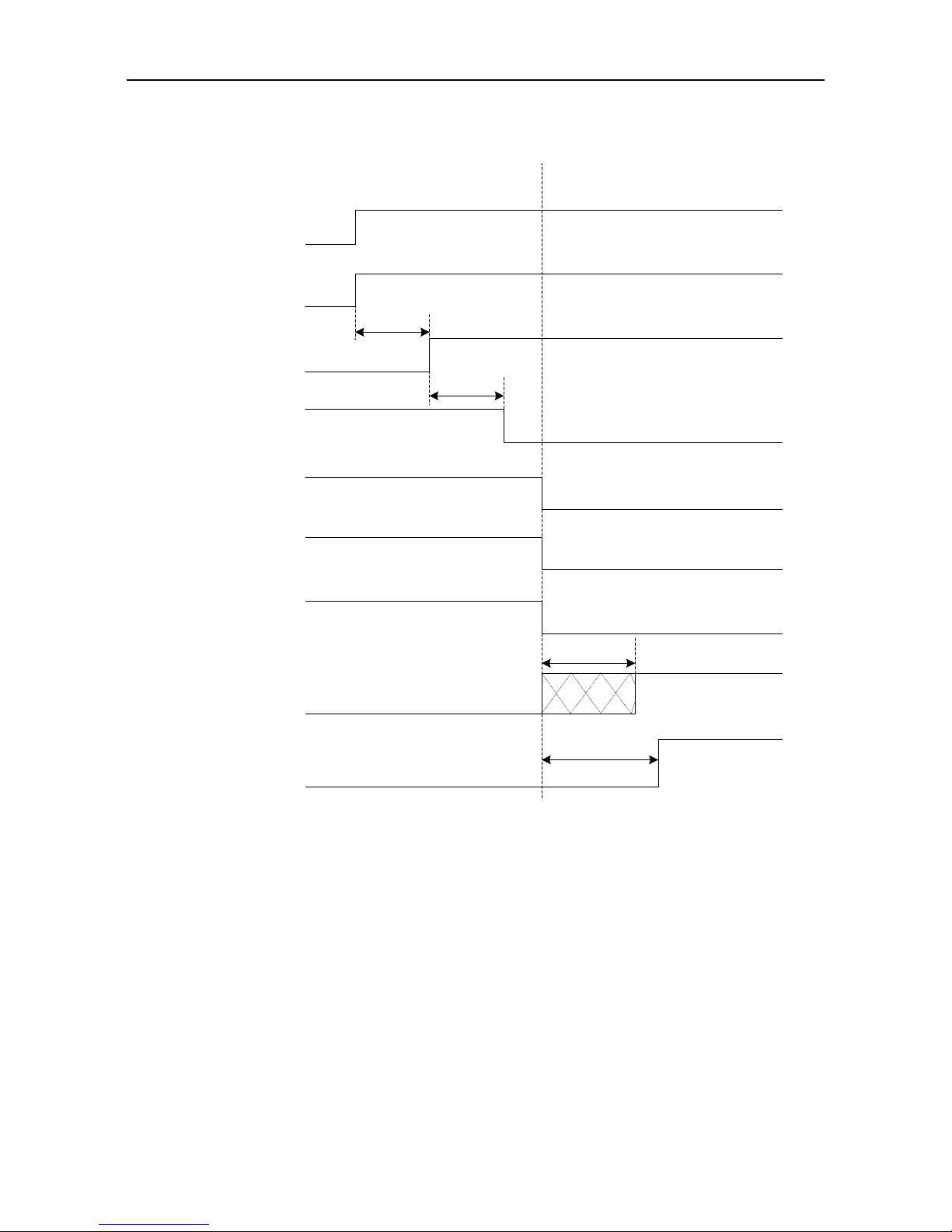

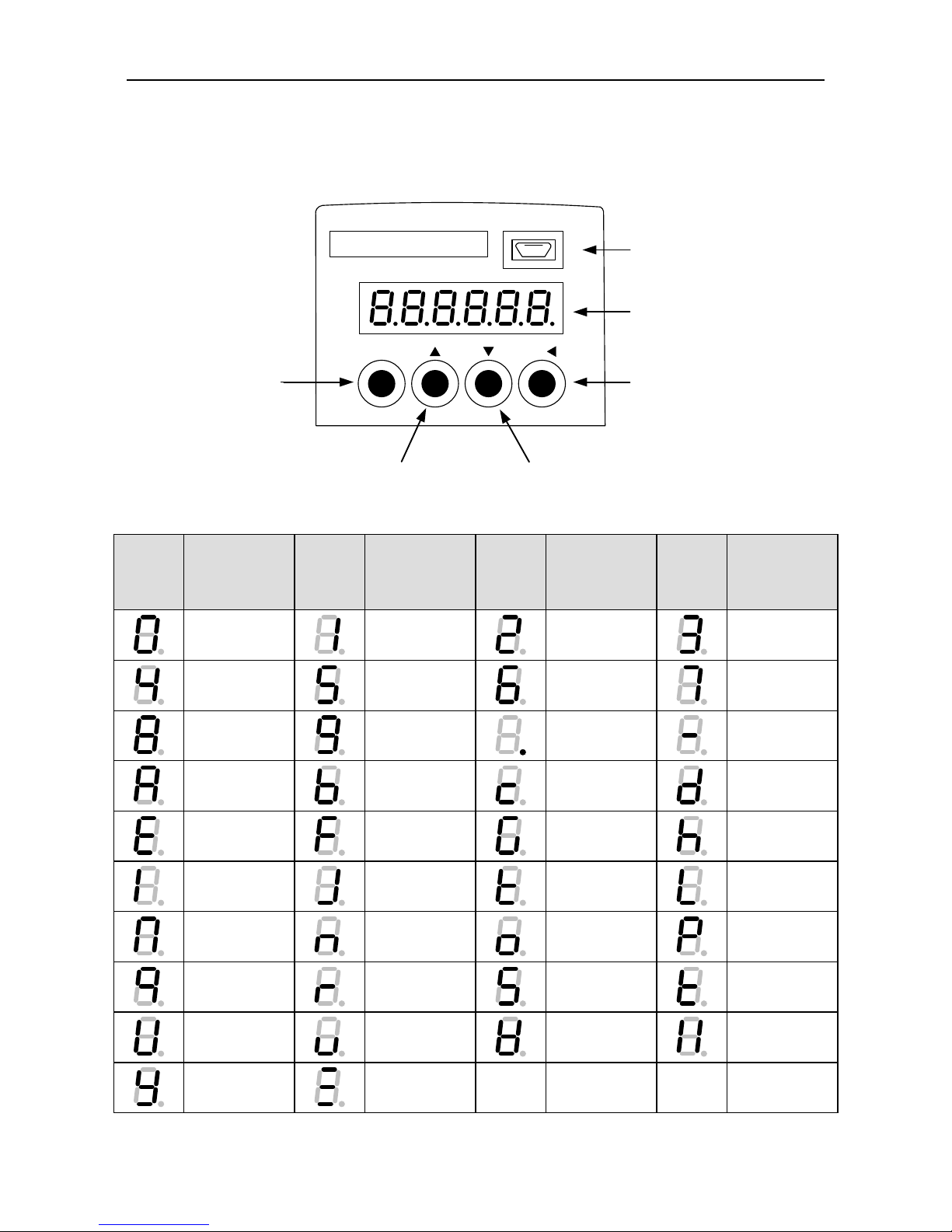

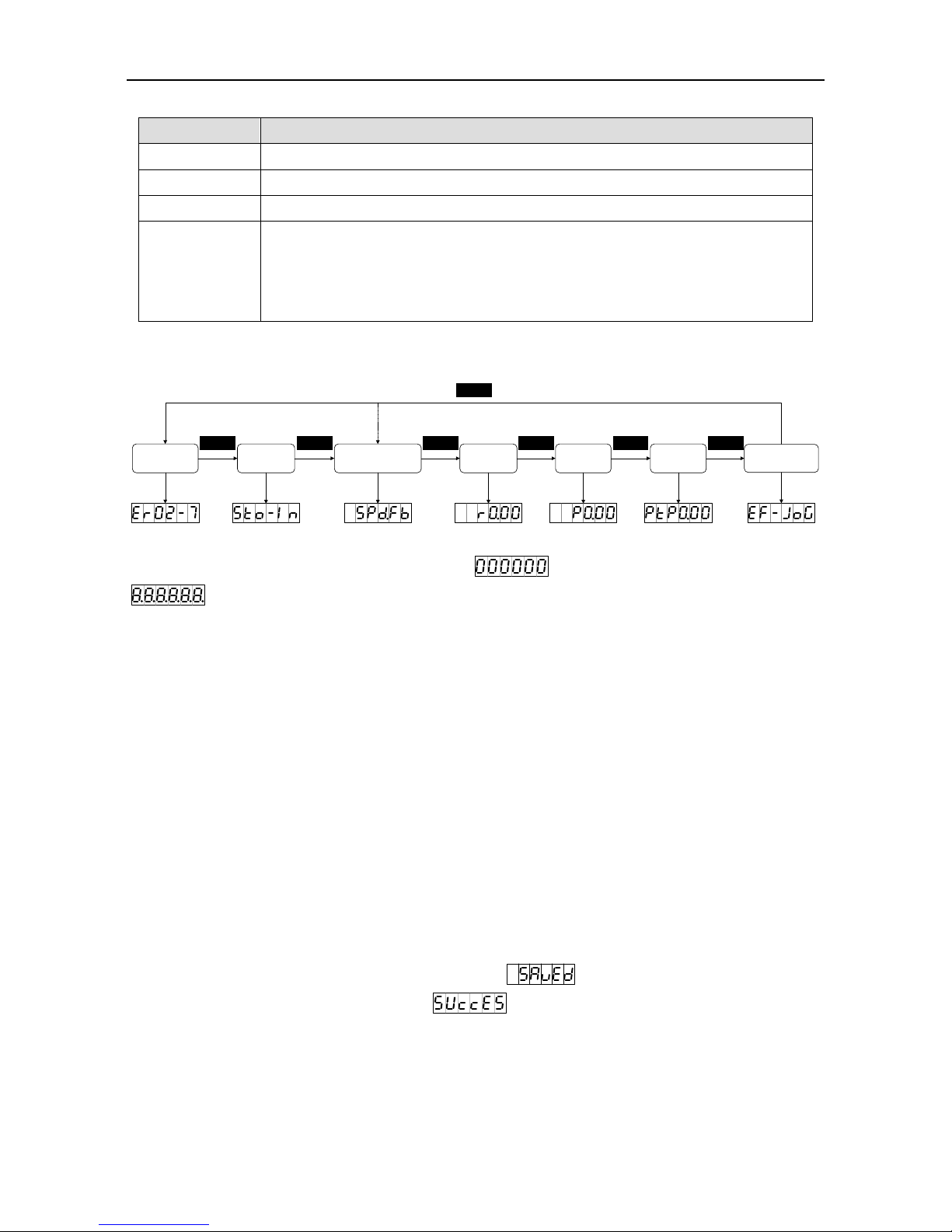

1, 4 - Unused