INVT GD300L-2R2G-S2, GD300L-004G-4, GD300L-5R5G-4, GD300L-011G-4, GD300L-7R5G-4 Operation Manual

...Page 1

Goodrive 3 0 0 - L I F T S e r i e s I nver t e r

Page 2

Goodrive300-LIFT series inverter Preface

Preface

Goodrive300-LIFT (GD300L for short) series inverters for lifts are the new generation of lift-dedicated

inverters, which use the GD control platform for development based on CHV180 series inverters.

Applying advanced variable frequency vector control and modular interface design, the product

improves the security reliability, control performance, and ease of commissioning and features the

following:

Compatible with asynchronous and synchronous motors.

Starting torque compensation control with weighing sensors: implements slide prevention by

setting parameters.

Starting torque compensation control without weighing sensors: implements precise control on

gearless synchronous-tractor lifts, which achieves stable startup.

Static identification on initial pole angles of synchronous motors: For permanent magnet

synchronous motors, autotuning can be executed when the motors are static. This simplifies the

commissioning process and is applicable to commission the motors in mechanical connection.

S-curve function: Acceleration (ACC) and deceleration (DEC) S curve algorithms improve the

comfortability during motor ACC, DEC, and stop.

Brake and contactor control function: controls contactors and braking based on lift running logic,

enhancing lift security.

ASR optimization: ASR uses variable proportional and integral gain control, providing dynamic

response in startup and stop states and improving comfortability during constant-speed running.

Forced DEC handling: prevents top-hitting and bottom-clashing during the upward or downward

running of lifts.

Emergency operation function: implements stop at convenient leveling for the equipment of

UPS and storage battery input interfaces.

Energy-saving operation: implemented for using the optional RBU series energy feedback unit.

i

Page 3

Goodrive300-LIFT series inverter Contents

Contents

Preface ............................................................................................................................................ i

Contents ......................................................................................................................................... ii

1 Safety precautions ...................................................................................................................... 1

1.1 What this chapter contains .................................................................................................... 1

1.2 Safety definition .................................................................................................................... 1

1.3 Warning signs ....................................................................................................................... 1

1.4 Safety guide .......................................................................................................................... 2

2 Precautions for quick application .............................................................................................. 5

2.1 What this chapter contains .................................................................................................... 5

2.2 Unpacking inspection ............................................................................................................ 5

2.3 Application confirmation ........................................................................................................ 5

2.4 Environment confirmation ...................................................................................................... 5

2.5 Installation confirmation ......................................................................................................... 6

2.6 Basic commissioning ............................................................................................................. 7

3 Product overview ........................................................................................................................ 8

3.1 What this chapter contains .................................................................................................... 8

3.2 Basic principles ..................................................................................................................... 8

3.3 Product specifications ........................................................................................................... 9

3.4 Name plate ......................................................................................................................... 11

3.5 Type designation key ........................................................................................................... 11

3.6 Rated specifications ............................................................................................................ 12

3.7 Structure diagram ................................................................................................................ 12

4 Installation guide ...................................................................................................................... 14

4.1 What this chapter contains .................................................................................................. 14

4.2 Mechanical installation ........................................................................................................ 14

4.3 Wiring ................................................................................................................................. 20

4.4 Wiring protection ................................................................................................................. 26

5 Keypad operation procedure .................................................................................................... 28

5.1 What this chapter contains .................................................................................................. 28

5.2 Keypad ............................................................................................................................... 28

5.3 Keypad displaying ............................................................................................................... 30

5.4 Keypad operation ................................................................................................................ 31

6 Function parameters ................................................................................................................. 34

6.1 What this chapter contains .................................................................................................. 34

6.2 Function parameters ........................................................................................................... 34

7 Commissioning guidelines ....................................................................................................... 76

7.1 What this chapter contains .................................................................................................. 76

7.2 Wiring between the lift controller and inverter ...................................................................... 77

7.3 Setting basic parameters ..................................................................................................... 77

7.4 Debugging running .............................................................................................................. 79

7.5 Lift running mode ................................................................................................................ 82

8 Fault tracking ................................ ............................................................................................ 95

8.1 What this chapter contains .................................................................................................. 95

8.2 Alarm and fault indications ................................................................................................... 95

ii

Page 4

Goodrive300-LIFT series inverter Contents

8.3 How to reset ........................................................................................................................ 95

8.4 Fault history ........................................................................................................................ 95

8.5 Inverter faults and solutions ................................................................................................. 95

8.6 Common fault analysis ...................................................................................................... 102

9 Maintenance and hardware diagnosis ................................................................................... 108

9.1 What this chapter contains ................................................................................................ 108

9.2 Maintenance intervals ....................................................................................................... 108

9.3 Cooling fan ........................................................................................................................ 110

9.4 Capacitors .......................................................................................................................... 111

9.5 Power cable ...................................................................................................................... 112

10 Communication protocol ...................................................................................................... 113

10.1 What this chapter contains .............................................................................................. 113

10.2 Brief instruction to Modbus protocol ................................................................................. 113

10.3 Application of the inverter ................................................................................................ 114

10.4 RTU command code and communication data illustration ................................................ 119

10.5 Common communication faults ........................................................................................ 134

Appendix A Expansion cards .................................................................................................... 135

A.1 What this chapter contains ................................................................................................ 135

A.2 I/O expansion card ............................................................................................................ 135

A.3 Asynchronous motor PG card ........................................................................................... 137

A.4 Synchronous motor PG card ............................................................................................. 140

A.5 STO instructions ............................................................................................................... 143

Appendix B Technical data ........................................................................................................ 151

B.1 What this chapter contains ................................................................................................ 151

B.2 Ratings ............................................................................................................................. 151

B.3 Grid specifications ............................................................................................................ 152

B.4 Motor connection data ...................................................................................................... 152

B.5 Applicable standards ......................................................................................................... 153

B.6 EMC regulations ............................................................................................................... 153

Appendix C Dimension drawings .............................................................................................. 155

C.1 What this chapter contains ................................................................................................ 155

C.2 Keypad structure .............................................................................................................. 155

C.3 Inverter structure .............................................................................................................. 156

C.4 Dimensions for inverters of AC 3PH 380V(-15%)–440V(+10%) ......................................... 156

Appendix D Peripheral optional parts ....................................................................................... 158

D.1 What this chapter contains ................................................................................................ 158

D.2 Peripheral wiring ............................................................................................................... 158

D.3 Power supply .................................................................................................................... 159

D.4 Cables .............................................................................................................................. 159

D.5 Breaker and electromagnetic contactor ............................................................................. 162

D.6 Reactors ........................................................................................................................... 163

D.7 Filter ................................................................................................................................. 164

D.8 Braking system ................................................................................................................. 166

D.9 Emergency operation systems .......................................................................................... 168

Appendix E Further information................................................................................................ 169

iii

Page 5

Goodrive300-LIFT series inverter Safety precautions

Danger:

Serious physical injury or even death may be caused if related

requirements are not followed.

Warning:

Physical injury or damage to the devices may be caused if related

requirements are not followed.

Note:

Steps to take for ensuring the proper running of the product.

Qualified electricians:

People working on the device must have taken part in professional

electrical and safety training, obtained the certification, and been

familiar with all steps and requirements for installing, performing

commissioning on, operating, and maintaining the device, and are

capable of preventing or dealing with all kinds of emergencies.

Sign

Name

Description

Abbreviation

Danger

Danger

Serious physical injury or even

death may be caused if related

requirements are not followed.

Warning

Warning

Physical injury or damage to the

devices may be caused if

related requirements are not

followed.

Electrostatic discharge

Electrostatic

discharge

Damage to the PCBA board

may be caused if related

requirements are not followed.

Hot sides

Hot sides

The base of the device may

become hot. Do not touch it.

Note

Note

Steps to take for ensuring the

proper running of the device.

Note

1 Safety precautions

1.1 What this chapter contains

Read this manual carefully and follow all safety precautions before moving, installing, operating, and

servicing the product. Otherwise, physical injury or death or damage to the devices may be caused.

For any physical injury or damage to the devices caused by you or your customers due to your

neglect of the safety precautions, our company shall not be held liable.

1.2 Safety definition

1.3 Warning signs

Warning signs are used to warn you about the conditions that may cause severe injury or damage to

the device. They instruct you to exercise caution to prevent danger. The following table describes the

warning signs used in this manual.

-1-

Page 6

Goodrive300-LIFT series inverter Safety precautions

Only qualified electricians are allowed to operate the device.

Do not perform any wiring, inspection, or component replacement operations

when power is applied. Before wiring or inspection, ensure that all input

power supplies are disconnected and wait for at least the waiting time

specified on the inverter, or ensure that the DC bus voltage is lower than 36

V. The following table describes the waiting time.

Inverter model

Minimum waiting time

380V

4kW-30kW

10 minutes

Do not refit the product unauthorizedly; otherwise fire, electric shocks or

other injury may be caused.

The base may become hot when the machine is running. Do not touch it.

Otherwise, you may get burnt.

The electronic parts and components inside the inverter are electrostatic

sensitive parts. Take measurements to prevent electrostatic discharge when

performing operations involving them.

Do not install the inverter on inflammables. Prevent it from coming into

contact with or adhering to inflammables.

Connect the optional brake components (brake resistor, brake unit, or

feedback unit) according to the wiring diagram.

Do not operate the inverter if it is damaged or lack of components.

Do not touch the inverter with wet objects or any of your body parts.

Otherwise, electric shocks may be caused.

1.4 Safety guide

1.4.1 Delivery and installation

Note:

Use proper handling and installation tools to avoid damage to the device or physical injury.

Installers must take mechanical protective measures, such as wearing anti-smashing shoes and

work clothes, to protect personal safety.

Ensure that no physical impact or vibration occurs on the inverter during its transport and

installation.

Do not carry the machine only by its front cover. Otherwise, the machine may fall down.

Install the inverter in a place that will prevent children or other people from touching it.

The inverter cannot meet the low- and medium-voltage protection requirements stipulated in

IEC61800-5-1 if it is installed on a site where the altitude is higher than 2000 m.

Operate the inverter in environments that meet the operation requirements (for details, see

section 4.2.1 "Installation environment").

-2-

Page 7

Goodrive300-LIFT series inverter Safety precautions

Before wiring the terminals of the inverter, disconnect all power supplies

applied to it and wait for at least the waiting time specified on it..

The voltage is high inside the inverter when it is running. Except settings

through the keypad, do not perform any other operations on it.

The inverter cannot be used independently as an "emergency-stop device".

The product cannot be used for motor emergency braking. You need to

configure a mechanical brake device.

When the inverter is used to drive a permanent-magnet synchronous motor

(PMSM), ensure the following in addition to the preceding precautions:

1. All the input power supplies, including the main power supply and

control power supply, are disconnected.

2. The running of the PMSM is stopped, and the voltage on the output

side of the inverter is lower than 36 V.

3. The waiting time after the PMSM is stopped is not shorter than the

waiting time specified on the inverter, and the voltage between (+) and

(-) is lower than 36 V.

4. During the operation, ensure that the PMSM will not rotate again due

to external loads. It is recommended that you configure an effective

external brake device or disconnect the electrical connection between

the PMSM and the inverter.

Prevent screws, cables, and other conductive items from dropping into the inverter.

The leakage current of the inverter may be larger than 3.5 mA during operation. Perform reliable

grounding and ensure that the grounding resistance is lower than 10 Ω. The conductivity of the

PE grounding conductor is the same as that of the phase conductor (with the same sectional

area).

R, S and T are the power input terminals, while U, V and W are the the terminals for output to the

motor. Connect the input power cables and motor cables properly. Otherwise, damage to the

inverter may be caused.

1.4.2 Commissioning and operation

Note:

Do not switch on or off the input power supply of the inverter frequently.

If the inverter has been stored for a long time, check, set the capacity of, and perform a test run

on it before using it. For details about inspection and capacity setting, see chapter 9.

"Maintenance and hardware fault diagnosis".

Close the front cover of the inverter before running it. Otherwise, electric shocks may be caused.

-3-

Page 8

Goodrive300-LIFT series inverter Safety precautions

Only trained and qualified electricians are allowed to maintain, check, and

replace components of the inverter.

Before wiring the terminals of the inverter, disconnect all power supplies

applied to it and wait for at least the waiting time specified on it.

During the maintenance and replacement of components, take measures to

prevent screws, cables, and other conductive items from dropping into the

inverter.

There are heavy metals in the inverter. Deal with it as industrial effluent.

When the life cycle ends, the inverter should enter the recycling system.

Dispose of it separately at an appropriate collection point instead of

placing it in the normal waste stream.

1.4.3 Component maintenance and replacement

Note:

Tighten the screws with proper torque.

During the maintenance and replacement of components, prevent the inverter and its

components from coming into contact with or being attached with inflammables.

Do not perform any insulation or withstand voltage tests on the inverter. Do not use a megameter

to measure the control circuit of the inverter.

During the maintenance and replacement of components, take measurements to prevent

electrostatic discharge for the inverter and its internal components.

1.4.4 What to do after scrapping

-4-

Page 9

Goodrive300-LIFT series inverter Precautions for quick application

1. Whether the packing box is damaged or dampened.

2. Whether the model identifier on the exterior surface of the packing box is consistent with

the purchased model.

3. Whether the interior surface of the packing box is abnormal, for example, in wet condition,

or whether the enclosure of the product is damaged or cracked.

4. Whether the nameplate of the product is consistent with the model identifier on the exterior

surface of the packing box.

5. Whether the accessories (including the user manual, control keypad, and extension cards)

inside the packing box are complete.

1. Mechanical type of the load to be drived by the inverter. Check whether the inverter will be

overloaded in actual operation and whether the power level needs to be raised.

2. Whether the actual running current of the to-be-loaded motor is lower than the rated current

of the inverter.

3. Whether control precision implemented by the inverter meets the requirement of the actual

load.

4. Whether the grid voltage is consistent with the rated voltage of the inverter.

5. Whether you need to configure an extension card to implement the required communication

mode.

1. Whether the ambient temperature in the application is higher than 40°C. If yes, derate the

machine by 3% for every increased 1°C. Do not use the inverter in environments where the

temperature is higher than 50°C.

Note: If the inverter is installed in a cabinet, the ambient temperature is the air temperature

2 Precautions for quick application

2.1 What this chapter contains

This chapter describes the basic principles for the installation and commission of the inverter, which

helps you to quickly complete the installation and commissioning.

2.2 Unpacking inspection

Check the following items after receiving the product.

If any of the problems described in the check items are found, contact the local dealer or our

company.

2.3 Application confirmation

Confirm the following items before using the inverter.

2.4 Environment confirmation

Check the following items before you install and use the inverter.

-5-

Page 10

Goodrive300-LIFT series inverter Precautions for quick application

inside the cabinet.

2. Whether the ambient temperature in application is lower than –10°C. If yes, configure a

heating device.

Note: If the inverter is installed in a cabinet, the ambient temperature is the air temperature

inside the cabinet.

3. Whether the altitude on the site is higher than 1000 m. If yes, derate the machine by 1% for

every increased 100 m.

4. Whether the ambient humidity is higher than 90% or condensation occurs. If yes, take extra

protective measures.

5. Whether there is direct sunlight or biological invasion in the application environment. If yes,

take extra protective measures.

6. Whether there is dust or inflammable and explosive gas in the application environment. If

yes, take extra protective measures.

1. Whether the input power cables and motor cables meet the current-carrying capacity

requirements of the actual load.

2. Whether the peripheral accessories are correctly selected and properly installed, and

whether the installation cables meet the current-carrying capacity requirements of the

accessories, including the input reactor, input filter, output reactor, output filter, DC reactor,

brake unit, and brake resistor.

3. Whether the inverter is installed on non-flammable materials, and whether its heat-emitting

accessories (such as reactor and brake resistor) are kept away from inflammable materials.

4. Whether all the control cables are wired separately from power cables, and whether

electromagnetic compatibility (EMC) specification requirements are taken into full account

during the wiring.

5. Whether all the grounding systems are properly grounded according to the requirements of

the inverter.

6. Whether all the installation spacings of the inverter meet the requirements stated in the

manual.

7. Whether the installation of the inverter meets the requirements stated in the manual.

8. Check that the external connection terminals are tightly fastened and whether the torque

meets the requirements.

9. Whether screws, cables, or other conductive items drop into the inverter. If yes, take them

out.

2.5 Installation confirmation

Check the following items after the installation of the inverter is complete.

-6-

Page 11

Goodrive300-LIFT series inverter Precautions for quick application

1. Select the motor type and set the motor parameters according to the actual motor

parameters, and set the control mode of the inverter.

2. Perform autotuning if required. Remove the motor load, if possible, to perform dynamic

parameter autotuning; and if the load cannot be removed, you can perform static

autotuning.

3. Adjust the ACC/DEC time according to the actual operation conditions of the load.

4. Perform commissioning on the machine in jogging mode and check whether the rotating

direction of the motor meets the requirement. If no, exchange the wires of any two phases

of the motor to change the running direction of the motor.

5. Set all control parameters and then run the machine.

2.6 Basic commissioning

Complete the basic commissioning as follows before using the inverter.

-7-

Page 12

Goodrive300-LIFT series inverter Product overview

3 Product overview

3.1 What this chapter contains

The chapter briefly describes the operation principle, product characteristics, layout, name plate and

type designation information.

3.2 Basic principles

GD300L series inverters special for lifts are wall mountable devices for controlling asynchronous AC

induction motors and permanent magnet synchronous motors.

The diagram below shows the simplified main circuit diagram of the inverter. The rectifier converts

three-phase AC voltage to DC voltage. The capacitor bank of the intermediate circuit stabilizes the

DC voltage. The converter transforms the DC voltage back to AC voltage for the AC motor. The brake

pipe connects the external brake resistor to the intermediate DC circuit to consume the feedback

energy when the voltage in the circuit exceeds its maximum limit.

Figure 3-1 Main circuit for 4–5.5kW inverters

Figure 3-2 Main circuit for 7.5–15kW inverters

-8-

Page 13

Goodrive300-LIFT series inverter Product overview

(-)

(+)

Built-in

reactor

Function

Specifications

Power

input

Input voltage (V)

Rated voltage: AC 380V (Available voltage degrees:

220, 380, 400, 415, 440, which can be set by the

function code)

Allowed input working voltage range:

AC 1PH 220V(-15%)–240V(+10%)

AC 3PH 380V(-15%)–440V(+10%)

Input current (A)

Refer to the rated value.

Input frequency (Hz)

50Hz or 60Hz

Allowed range: 47–63Hz

Power

output

Output voltage (V)

0–input voltage

Output current (A)

Refer to 3.6 Rated specifications.

Output power (kW)

Refer to 3.6 Rated specifications.

Output frequency (Hz)

0–400Hz

Technical

control

feature

Control mode

SVPWM, sensorless vector control

Motor type

Asynchronous motor and permanent magnet

synchronous motor

Adjustable-speed ratio

For open-loop vector control: 1:200

For closed-loop vector control: 1:1500

Speed control

accuracy

± 0.5%(open-loop vector); ± 0.05% (closed-loop vector)

Figure 3-3 Main circuit for 18.5–30kW inverters

Note:

• The inverters ≤15kW contain built-in brake units and supports external brake resistors which are

optional.

• The 18.5–30kW inverters contain built-in DC reactors and support external brake units which are

optional.

3.3 Product specifications

-9-

Page 14

Goodrive300-LIFT series inverter Product overview

Function

Specifications

Speed fluctuation

± 0.3%(sensorless vector control)

Torque response

<20ms(sensorless vector control)

Torque control

accuracy

10% (sensorless vector control)

Starting torque

For asynchronous motor sensorless vector control:

0.3Hz/150%

For sensor-included vector control: 0 Hz/200%

Overload capability

150% of rated current: 1 minute

180% of rated current: 10 seconds

200% of rated current: 1 second

Running

control

feature

Frequency setting

method

Digital setting, analog setting, multi-step speed running

setting, and MODBUS communication setting

implement switching between channels.

Voltage

auto-adjustment

Keep constant voltage automatically when the grid

voltage transients.

Fault protection

Provide more than 30 fault protection functions against

faults such as overcurrent, overvoltage, undervoltage,

overheating, phase loss and overload.

Peripheral

interface

Analog input

1 input (AI1): 0–10V/0–20mA

Resolution: ≤20mV

Analog output

1 output (AO1): 0–10V/0–20mA

Resolution: ≤20mV

Digital input

8 common inputs; Max. frequency: 1kHz; internal

impedance: 3.3kΩ;

1 high speed input; Max. frequency: 50kHz

Resolution: ≤2ms

Digital output

1 terminal Y for open collector output

Relay output

3 NO programmable relay outputs;

RO1A NO, RO1C common terminal

RO2A NO, RO2C common terminal

RO3A NO, RO3C common terminal

Contactor capability: 3A/AC250V,1A/DC30V

Power output

Provides 24V/200mA and 10V/50mA power output.

PG expansion card

(optional)

Incremental 5–24V; sine and cosine; absolute value;

UVW

-10-

Page 15

Goodrive300-LIFT series inverter Product overview

Function

IO expansion cards

(optional)

3 common digital inputs

1 analog input AI2

1 NO/NC relay output

1 HDO output

1 Y output

1 RS485 interface (supporting RTU)

1 CAN communication interface

STO expansion card

(optional)

Provides STO security terminal functions.

Bluetooth/Ethernet

expansion card

(optional)

Others

Mountable method

Running environment

temperature

MTBF

Protective degree

Cooling

Brake unit

DC reactor

DC reactors are standard configuration for inverters

≥18.5kW.

EMC filter

Optional filters C2 can be configured, meeting

IEC618000-3 C2 requirements.

Specifications

Commissions devices through Bluetooth or Ethernet

communication.

Wall mounting

-10–50˚C. The inverter must be derated if temperature

is above 40˚C.

100,000 hours

IP20

Forced air cooling

Built in inverters ≤15kW; optional for others

3.4 Name plate

Model: GD300L-5R5G-4

Power(Output): 5.5kW

Input: AC 3PH 380V(-15%)-440V(+10%) 19.5A 47Hz-63Hz

Output: AC 3PH 0V-Uinput 14A 0Hz-400Hz

S/N: Made in China

Shenzhen INVT Electric Co., Ltd.

Figure 3-4 Name plate

Note: The certification mark such as "CE" can be placed only after the product is certified.

3.5 Type designation key

The type designation contains inverter information. You can find the type designation on the type

designation label attached to the inverter or the simple name plate.

-11-

Page 16

Goodrive300-LIFT series inverter Product overview

GD300L – 5R5G – 4 –LIFT

①

② ③

④

Key

Sign

Description

Remarks

Abbreviation

①

Product abbreviation

GD300L is short for Goodrive300-LIFT,

special for lifts.

Rated power

②

Power range + Load

type

5R5: 5.5kW

G: Constant torque load

Voltage degree

③

Voltage degree

S2: AC 2PH 220V (-15%)–240V(+10%)

4: AC 3PH 380V (-15%)–440V(+10%)

No. for market

management

④

Number for market

management

LIFT: inverter special for lifts

Model

Rated output

power(kW)

Rated input

current(A)

Rated output

current(A)

GD300L-1R5G-S2

1.5

14.2

7

GD300L-2R2G-S2

2.2

23

10

GD300L-004G-4

4

13.5

9.5

GD300L-5R5G-4

5.5

19.5

14

GD300L-7R5G-4

7.5

25

18.5

GD300L-011G-4

11

32

25

GD300L-015G-4

15

40

32

GD300L-018G-4

18.5

47

38

GD300L-022G-4

22

56

45

GD300L-030G-4

30

70

60

Operation panel

Control board terminals

PG card expansion

Main circuit terminals

Main circuit cable port

Control cable

port

CHARGE LED

Function card

expansion

Whole-unit

mounting hole

Cover

Cover buckling

position

Vent hole

Figure 3-5 Product type

3.6 Rated specifications

Note: For inverters of 380 V, 4 kW–30 kW, the STO rating is SIL3 PLe CAT.3.

3.7 Structure diagram

Figure 3-6 Components of inverters ≤15 kW

-12-

Page 17

Goodrive300-LIFT series inverter Product overview

Fixed hook for cover

Keypad panel

Control board

Control terminals

PG card expansion

Keypad bracket

Shield plate

Function card expansion

Main circuit terminals

Control cable port

Whole-unit

mounting hole

Fixed hook for cover

Keypad panel

Control board

Control terminals

PG card expansion

Keypad bracket

Shield plate

Function card expansion

Main circuit terminals

Control cable port

Whole-unit

mounting hole

Cover

Cover mounting hole

Vent hole

Figure 3-7 Components of inverters ≥18.5 kW

-13-

Page 18

Goodrive300-LIFT series inverter Installation guide

Only qualified electricians are allowed to carry out what described in this chapter.

Please operate as the instructions in Safety precautions. Ignoring these may

cause physical injury or death or damage to the devices.

Ensure the power supply of the inverter is disconnected during the operation.

Wait for at least the time designated until the CHARGE indicator is off after the

disconnection if the power supply is applied. It is recommended to use the

multimeter to monitor whether the drive DC bus voltage is under 36V.

The installation and design of the inverter should comply with the requirement of

the local laws and regulations in the installation site. If the installation infringes

the requirement, our company will exempt from any responsibility. Additionally, if

users do not comply with the suggestion, some damage beyond the assured

maintenance range may occur.

Environment

Conditions

Installation site

Indoor

Environment

temperature

-10–+50˚C

If the ambient temperature of the inverter is above 40˚C, derate 3% for

every additional 1˚C.

It is not recommended to use the inverter if the ambient temperature is

above 50˚C.

In order to improve the reliability of the device, do not use the inverter

if the ambient temperature changes frequently.

Please provide cooling fan or air conditioner to control the internal

ambient temperature below the required one if the inverter is used in a

closed space such as in the control cabinet.

When the temperature is too low, if the inverter needs to restart to run

after a long stop, it is necessary to provide an external heating device

to increase the internal temperature, otherwise damage to the devices

4 Installation guide

4.1 What this chapter contains

The chapter describes the mechanical installation and electric installation.

4.2 Mechanical installation

4.2.1 Installation environment

The installation environment is the safeguard for a full performance and long-term stable functions of

the inverter. Check the installation environment as follows:

-14-

Page 19

Goodrive300-LIFT series inverter Installation guide

Environment

Conditions

may occur.

Humidity

RH≤90%

No condensation is allowed.

The maximum relative humility should be equal to or less than 60% in

corrosive air.

Storage temperature

-30–+60˚C

Running environment

The inverter installation site should:

keep away from the electromagnetic radiation source;

keep away from contaminative air, such as corrosive gas, oil mist

and flammable gas;

ensure foreign objects, such as metal power, dust, oil, water cannot

enter into the inverter (do not install the inverter on the flammable

materials such as wood);

keep away from radioactive and flammable materials, direct

sunlight, contaminative liquids, salty and vibration environments.

Altitude

<1000m

When the altitude exceeds 1000m but is lower than 3000m, derate 1%

for every additional 100m;

When the altitude exceeds 2000m, configure an isolation transformer

on the input end of the inverter.

When the altitude exceeds 3000m but is lower than 5000m, contact

our company for technical consultation. Do not use the inverter at an

altitude higher than 5000m.

Pollution level

Level 2

Vibration

≤ 5.8m/s2(0.6g)

Installation direction

The inverter needs to be installed on an upright position to ensure

good cooling conditions.

Note:

• GD300L series inverters should be installed in a clean and ventilated environment according to

enclosure classification.

• Cooling air must be clean, free from corrosive materials and electrically conductive dust.

4.2.2 Installation direction

The inverter may be installed on the wall or in a cabinet.

The inverter must be installed in an upright position. Check the installation direction according to the

requirements below. Refer to Appendix C "Dimension drawings" for frame details.

-15-

Page 20

Goodrive300-LIFT series inverter Installation guide

a. Vertical b. Horizontal

c. Transverse

OK NG NG

Cool air

Warm air

Figure 4-1 Inverter installation direction

4.2.3 Installation manner

The inverter is wall mountable.

Figure 4-2 Installation manner

(1) Mark the hole locations, which are shown in the dimension drawings in the appendix.

(2) Fix the screws or bolts to the marked locations.

(3) Put the inverter against the wall.

(4) Tighten the screws in the wall securely.

4.2.4 Single-inverter installation

Note: The minimum space of B and C is 100mm.

Figure 4-3 Single installation

-16-

Page 21

Goodrive300-LIFT series inverter Installation guide

Warm air

Cool air

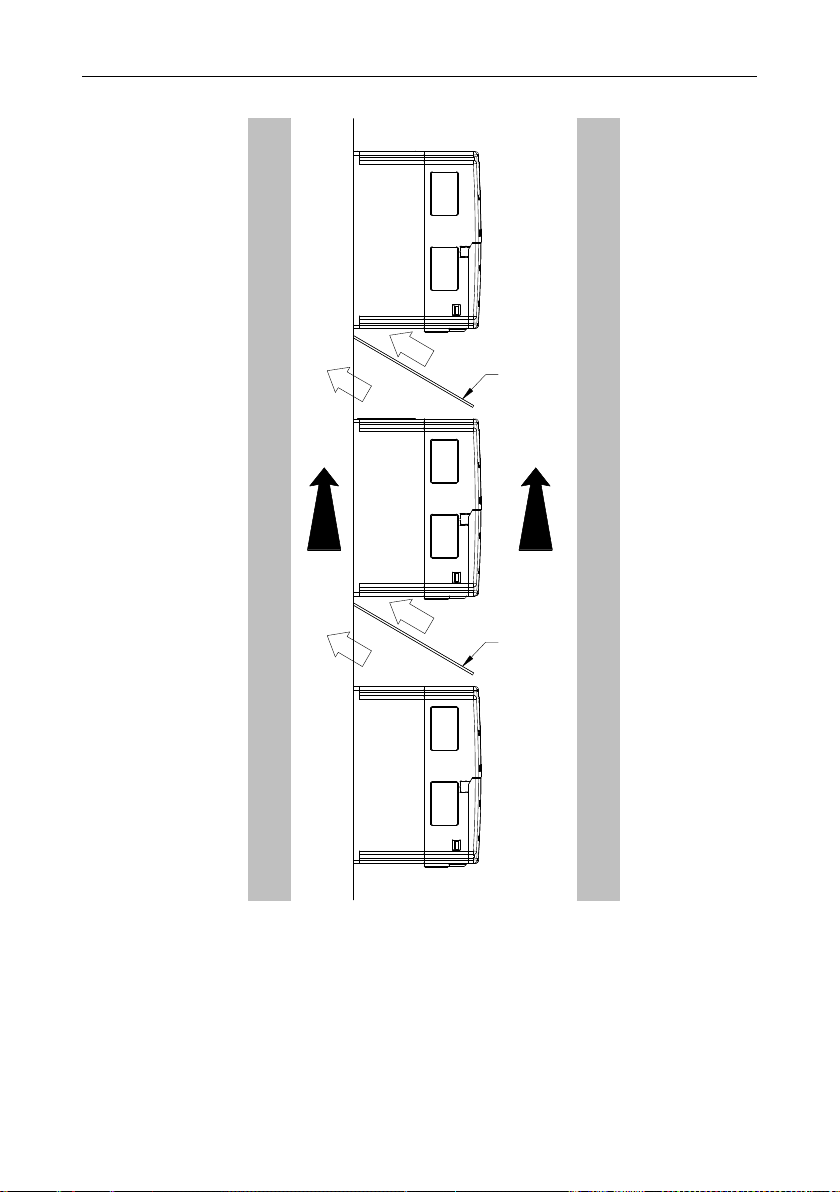

4.2.5 Multiple-inverter installation Parallel installation

Figure 4-4 Parallel installation

Note:

• Before installing inverters in different sizes, align their top positions for the convenience of later

maintenance.

• The minimum space of B, D and C is 100mm.

-17-

Page 22

Goodrive300-LIFT series inverter Installation guide

Cool air

Warm air

Wind screen

Cool air

Warm air

Wind screen

4.2.6 Vertical installation

Note: Windscreens are needed in vertical installation to avoid insufficient cooling due to mutual

Figure 4-5 Vertical installation

impact.

-18-

Page 23

Goodrive300-LIFT series inverter Installation guide

Cool air

Cool air

Cool air

Warm air

Warm air

Warm air

4.2.7 Tilt installation

Figure 4-6 Tilt installation

Note: Ensure the separation of the wind input and output channels in tilt installation for avoiding

mutual impact.

-19-

Page 24

Goodrive300-LIFT series inverter Installation guide

Earth

Breaker or RCCB

Motor

DC reactor

Output

noise filter

Earth

Output AC

reactor

Inverter

Input

interference

filter

Brake resistor

MAgnetic

contactor (MC)

Input AC

reactor

Power supply

4.3 Wiring

4.3.1 Connection to peripheral devices

Figure 4-7 Connection to peripheral devices

-20-

Page 25

Goodrive300-LIFT series inverter Installation guide

R

S

T

W

V

U

PE

M

Inverter of 15kW or lower

(+)

PB

3PH

380V±15%

50/60Hz

Braking resistor

Input

reactor

Input

filter

Fuse

(-)

R

S

T

W

V

U

PE

M

18.5~30kW

P1

(+)

DC reactor

(built-in)

3PH

380V±15%

50/60Hz

(-)

Input

reactor

Input

filter

Fuse

DC-

Braking resistor

DC+

Braking unit

KM1

KM1

4.3.2 Connection diagram of main circuit

Figure 4-8 Connection diagram of main circuit for 380V inverters

Note:

• The fuse, DC reactor, brake unit, brake resistor, input reactor, input filter, output reactor, output

filter are optional parts. Refer to Peripheral optional parts for detailed information.

• The inverters of 18.5–30kW contain built-in DC reactors.

4.3.3 Terminals in main circuit

Figure 4-9 Terminals of main circuit for the inverters of 380V 4–5.5kW

-21-

Page 26

Goodrive300-LIFT series inverter Installation guide

Terminal

Name

Function

R, S, T

Power input of main circuit

3PH AC input terminals, connected to the

grid

(+), (-)

Reserved terminal for connecting

external brake units

Reserved terminal for connecting external

brake units

(+), PB

Reserved terminals for

connecting external brake

resistors

Reserved terminals for connecting

external brake resistors

P1, (+)

Reserved terminals for

connecting external DC reactors

Reserved terminals for connecting

external DC reactors

(-)

DC negative bus output terminal

DC negative bus output terminal

U, V, W

Inverter output

3PH AC output terminals, generally

connected to the motor

Grounding terminal

Grounding terminal

Figure 4-10 Terminals of main circuit for the inverters of 380V 7.5–15 kW

Figure 4-11 Terminals of main circuit for the inverters of 380V 18.5–30kW

Note:

• Do not use an asymmetrically constructed motor cable. If there is a symmetrically constructed

-22-

Page 27

Goodrive300-LIFT series inverter Installation guide

Screw not fastened Screw fastened

grounding conductor in the motor cable in addition to the conductive shield, connect the

grounding conductor to the grounding terminal at the inverter and motor ends.

• Brake resistor, brake unit, and DC reactor are optional parts.

• Route the motor cable, input power cable, and control cables separately.

4.3.4 Wiring of terminals in main circuit

1. Connect the ground wire of the input power cable to the ground terminal (PE) of the inverter, and

connect the 3PH input cable to the terminals R, S, and T, and fasten them up.

2. Connect the ground wire of the motor cable to the ground terminal of the inverter, and connect

the 3PH motor cable to the terminals U, V, and W, and fasten them up.

3. Connect the brake resistor and other accessories that are equipped with cables to the specified

positions.

4. Fasten all the cables outside of the inverter mechanically, if possible.

Figure 4-12 Proper screw fastening

-23-

Page 28

Goodrive300-LIFT series inverter Installation guide

GD300L inverters

special for lifts

Multi-function input terminal 1

Multi-function input terminal 2

Multi-function input terminal 3

Multi-function input terminal 4

Multi-function input terminal 5

Multi-function input terminal 6

S6

S5

S4

S3

S2

S1

COM

Analog output

0-10V/4-20mA

+24V

Relay 1 output

24V

S7

Multi-function input terminal 7

GND

AI1

+10V

Analog speed

adjustment

0~10V/0-20mA

PW

R03C

Y1

CME

AO1

GND

High-speed input terminal

HDI

Multi-function input terminal 8

S8

R03A

R02C

R02A

R01C

R01A

Relay 2 output

Relay 3 output

CN3

M

U

V

W

PE

R

S

T

P1

(+) (-)

P1

(+)

DC reactor

(built-in for

18.5-30kW)

(-)

-

Braking resistor

+

RB2

RB1

(Inverters of 18.5kW or

higher connect

external braking units)

3PH

50Hz/60Hz

380V(-15%)

~440V(+10%)

CN13

CN14

Multi-function expansion

card interface

External keypad interface

Open collector output Y

S1 S2 S3 S4

+24V COM HDI AO1

R03C

CMEY1PW COM

GND

AI1

S5 S6 S7 S8

R03A

RO1C

+10V

PE

R01A R02A

RO2C

Terminal

Description

S1-S7

Common digital input terminals

1. Internal impedance: 3.3kΩ

2. 12–30V voltage input acceptable

3. Dual-direction input terminals, supporting both NPN and PNP

4. Max input frequency: 1kHz

4.3.5 Connection diagram of control circuit

4.3.6 Terminals in control circuit

Figure 4-13 Connection diagram of control circuit

Figure 4-14 Terminals in control circuit

-24-

Page 29

Goodrive300-LIFT series inverter Installation guide

Terminal

Description

5. All are programmable digital input terminals. Terminal functions can be set by

function codes.

HDI

1. It can serve as the high-frequency pulse input channel, besides the functions of

S1–S8.

2. Max. input frequency: 50kHz

COM

Common terminal of +24V

PW

To provide the input digital power supply from external to internal. Voltage range:

12–24V

+10V

+10V power provided by the local device

AI1

1. Input range: 0–10V/0–20mA for AI1 voltage/current, switched by J3

2. Input impedance: 20kΩ for voltage input; 500Ω for current input

4. Resolution: 5mV as the min. resolution when 10V corresponds to 50Hz.

5. Deviation ±1%, 25˚C

GND

Reference zero potential of +10V

AO1

1. Input range: 0–10V/0–20mA for AO1 voltage/current, switched by J1

2. Deviation ±1%, 25˚C

Y1

1. Switch capacity: 200mA/30V

2. Output frequency range: 0–1kHz

CME

Common terminal of open connector output

RO1A

RO1 relay output, RO1A NO, RO1C common terminal

Contact capacity: 3A/AC250V, 1A/DC30V

RO1C

RO2A

RO2 relay output, RO2A NO, RO2C common terminal

Contact capacity: 3A/AC250V, 1A/DC30V

RO2C

RO3A

RO3 relay output, RO3A NO, RO3C common terminal

Contact capacity: 3A/AC250V, 1A/DC30V

RO3C

4.3.7 Input/Output signal connection

Use the U-shaped contact tag to set the NPN mode or PNP mode and the internal or external power

supply. The default setting is NPN internal mode.

-25-

Page 30

Goodrive300-LIFT series inverter Installation guide

RPB U

POWER

S

T

MOTOR

V

W

(+) (-)

U-shaped short

connector between

+24V and PW

U-shaped short

connector between

COM and CME

S1

S2

COM

PW

+ 24V

COM

+ 24V

Internal power supply (NPN mode)

S1

S2

COM

PW

+ 24V

COM

+24V

+ 24V

External power supply (NPN mode)

S1

S2

COM

PW

+ 24V

COM

+24V

S1

S2

COM

PW

+ 24V

COM

+24V

Internal power supply (PNP mode) External power supply (PNP mode)

Internal power supply (PNP mode)

External power supply (PNP mode)

Figure 4-15 U-shaped contact tag

If the signal is from NPN transistor, please set the U-shaped contact tag between +24V and PW as

below according to the used power supply.

Figure 4-16 NPN modes

If the signal is from PNP transistor, please set the U-shaped contact tag as below according to the

used power supply.

Figure 4-17 PNP modes

4.4 Wiring protection

4.4.1 Protecting the inverter and input power cable in short-circuit situations

Protect the inverter and input power cable against thermal overload in short circuit situations.

Arrange the protection according to the following guidelines.

-26-

Page 31

Goodrive300-LIFT series inverter Installation guide

Input cable

Inverter

Fuse

M3~

If the inverter is connected to multiple motors, a separate thermal overload switch

or a circuit breaker must be used for protecting each cable and motor. These

devices may require a separate fuse to cut off the short-circuit current.

Figure 4-18 Fuse configuration

Note: Select the fuse as the manual indicated. The fuse will protect the input power cable from

damage in short-circuit situations. It will protect the surrounding devices when the internal of the

inverter is short circuited.

4.4.2 Protecting the motor and motor cable in short-circuit situations

The inverter protects the motor and motor cable in a short-circuit situation when the motor cable is

dimensioned according to the rated current of the inverter. No additional protection devices are

needed.

4.4.3 Protecting the motor against thermal overload

According to regulations, the motor must be protected against thermal overload and the current must

be switched off when overload is detected. The inverter includes a motor thermal protection function

that protects the motor and closes the output to switch off the current when necessary.

-27-

Page 32

Goodrive300-LIFT series inverter Keypad operation procedure

No.

Name

Description

1

State LED

RUN/TUNE

LED off means that the inverter is in the

stopping state; LED blinking means the

inverter is in the parameter autotune

state; LED on means the inverter is in the

running state.

FWD/REV

FED/REV LED

LED off means the inverter is in the

forward rotation state; LED on means the

inverter is in the reverse rotation state

LOCAL/REMOT

LED for keypad operation, terminals

operation and remote communication

control

5 Keypad operation procedure

5.1 What this chapter contains

This chapter describes:

Buttons, indicating lights and the screen as well as the methods to inspect, modify and set function

codes by keypad

5.2 Keypad

The keypad is used to control GD300L series inverters special for lifts, read the state data, and adjust

parameters.

Note: The LED keypad is provided as standard configuration. There is another optional LCD keypad

which supports various languages, parameter copy, and 10-line displaying, and is compatible with the

LED keypad in installation dimensions.

Figure 5-1 Keypad

-28-

Page 33

Goodrive300-LIFT series inverter Keypad operation procedure

No.

Name

Description

LED off means that the inverter is in the

keypad operation state; LED blinking

means the inverter is in the terminals

operation state; LED on means the

inverter is in the remote communication

control state.

TRIP

LED for faults

LED on when the inverter is in the fault

state; LED off in normal state; LED

blinking means the inverter is in the alarm

state.

2

Unit LED

Mean the unit displayed currently

Hz

Frequency unit

RPM

Rotating speed unit

A

Current unit

%

Percentage

V

Voltage unit

3

Code

displaying

zone

5-digit LED display displays various monitoring data and alarm code such as

set frequency and output frequency.

0

3

6

9

C

F

L

O

S

v

1

4

7

A

d

H

N

P

t

.

2

5

8

b

E

l

n

r

U

-

Displayed

character

Displayed

character

Displayed

character

Corresponding

character

Corresponding

character

Corresponding

character

4

Digital

potentiom

Reserved

-29-

Page 34

Goodrive300-LIFT series inverter Keypad operation procedure

No.

Name

Description

eter

5

Buttons

PRG

ESC

Programming key

Enter or escape from the first level menu

and remove the parameter quickly.

DATA

ENT

Entry key

Enter the menu step-by-step.

Confirm parameters.

UP key

Increase data or function code

progressively.

DOWN key

Decrease data or function code

progressively.

SHIFT

Right-shift key

Move right to select the displaying

parameter circularly in stopping and

running mode.

Select the parameter modifying digit

during the parameter modification.

Run key

This key is used to operate on the

inverter in key operation mode.

Stop/

Reset key

This key is used to stop in running state

and it is limited by function code P07.05

This key is used to reset all control

modes in the fault alarm state.

QUICK

JOG

Quick key

The function of this key is confirmed by

function code P07.04.

5.3 Keypad displaying

The keypad displaying state of Goodrive300L series inverters is divided into stopping state parameter,

running state parameter, function code parameter editing state and fault alarm state and so on.

5.3.1 Displayed state of stopping parameters

When the inverter is in the stopping state, the keypad will display stopping parameters as shown in

Figure 5-2.

In the stopping state, various kinds of parameters can be displayed. Select the parameters to be

displayed or not by P07.08. See the instructions of P07.08 for the detailed definition of each bit.

In the stopping state, there are 9 stopping parameters can be selected to be displayed or not. They

are: set speed, set frequency, bus voltage, input terminals state, output terminals state, AI1, AI2, and

magnetic pole position. P07.08 determines whether to display the parameters by bit. 》/SHIFT can

shift the parameters form left to right, while QUICK/JOG (P07.04=2) can shift the parameters form

-30-

Page 35

Goodrive300-LIFT series inverter Keypad operation procedure

PRG

ESC

DATA

ENT

SHIFT

RUN

STOP

RST

QUICK

JOG

PRG

ESC

DATA

ENT

SHIFT

RUN

STOP

RST

QUICK

JOG

PRG

ESC

DATA

ENT

SHIFT

RUN

STOP

RST

QUICK

JOG

Parameter displayed in the

stop state

Parameter displayed in the

running state

Faulty state displayed

right to left.

5.3.2 Displayed state of running parameters

After receiving valid running commands, the inverter will enter the running state and the keypad will

display the running parameters. RUN/TUNE LED on the keypad is on, while the FWD/REV is

determined by the current running direction, as shown in Figure 5-2.

In the running state, there are 16 parameters that can be displayed. They are: running speed, set

speed, bus voltage, output voltage, output current, running frequency (Hz on), running rotation speed,

output power, output torque, input terminals state, output terminals state, AI1, AI2, torque

compensation, magnetic pole position, and linear speed. P07.06 determines whether to display the

parameters by bit. 》/SHIFT can shift the parameters form left to right, while QUICK/JOG (P07.04=2)

can shift the parameters from right to left.

5.3.3 Displayed state of fault

If the inverter detects the fault signal, it will enter the fault alarm displaying state. The keypad will

display the fault code by blinking. The TRIP LED on the keypad is on, and the fault reset can be

operated by STOP/RST on the keypad, control terminals or communication commands.

5.3.4 Displayed state of function codes editing

In the state of stopping, running or fault, press PRG/ESC to enter into the editing state (if there is a

password, see P07.00).The editing state is displayed on two classes of menu, and the order is:

function code group/function code number→function code parameter, press DATA/ENT into the

displayed state of function parameter. On this state, you can press DATA/ENT to save the parameters

or press PRG/ESC to exit.

5.4 Keypad operation

Operate the inverter via operation panel. See the detailed structure description of function codes in

the brief diagram of function codes.

Figure 5-2 Displayed state

-31-

Page 36

Goodrive300-LIFT series inverter Keypad operation procedure

The units place is

blinking.

All digits are

blinking.

The units place is

blinking.

The units place is blinking.

The units place is blinking.

Note: When setting the value, you can press and + to modify the value.

PRG

ESC

DATA

ENT

PRG

ESC

PRG

ESC

PRG

ESC

DATA

ENT

DATA

ENT

5.4.1 How to modify the function codes of the inverter

The inverter has three levels menu, which are:

1. Group number of function code (first-level menu)

2. Tab of function code (second-level menu)

3. Set value of function code (third-level menu)

Remarks: Press both PRG/ESC or DATA/ENT to return to the second-level menu from the third-level

menu. The difference is: pressing DATA/ENT will save the set parameters into the control panel, and

then return to the second-level menu with shifting to the next function code automatically; while

pressing PRG/ESC will directly return to the second-level menu without saving the parameters, and

keep staying at the current function code.

Under the third-level menu, if the parameter has no blinking bit, it means the function code cannot be

modified. The possible reasons could be:

1) This function code is not modifiable parameter, such as actual detected parameter, operation

records and so on;

2) This function code is not modifiable in running state, but modifiable in stop state.

Example: Set function code P00.01 from 0 to 1.

Figure 5-3 Sketch map of modifying parameters

5.4.2 How to set the password of the inverter

Goodrive300L series inverters special for lifts provide password protection function to users. Set

P07.00 to gain the password and the password protection becomes valid instantly after quitting from

the function code editing state. Press PRG/ESC again to the function code editing state, "0.0.0.0.0"

will be displayed. Unless using the correct password, you cannot enter it.

Set P07.00 to 0 to cancel password protection function.

The password protection becomes effective 1 minute later after retreating from the function code

editing state. Press PRG/ESC again to the function code editing state, "0.0.0.0.0" will be displayed.

Unless using the correct password, you cannot enter it.

-32-

Page 37

Goodrive300-LIFT series inverter Keypad operation procedure

The units place is

blinking.

All digits are

blinking.

The units place is blinking.

The units place

is blinking.

Note: When setting the value, you can press and + to modify the value.

The units place is

blinking.

The units place

is blinking.

PRG

ESC

PRG

ESC

PRG

ESC

PRG

ESC

DATA

ENT

DATA

ENT

DATA

ENT

The units place is

blinking.

All digits are

blinking.

The units place is blinking.

The units place

is blinking.

Note: When setting the value, you can press and + to modify the value.

The units place is

blinking.

The units place is

blinking.

DATA

ENT

DATA

ENT

DATA

ENT

PRG

ESC

PRG

ESC

PRG

ESC

PRG

ESC

Figure 5-4 Sketch map of password setting

5.4.3 How to watch the inverter state through function codes

Goodrive300L series inverters special for lifts provide group P17 as the state inspection group. You

can enter P17 directly to view the state.

Figure 5-5 Sketch map of state viewing

-33-

Page 38

Goodrive300-LIFT series inverter Function parameters

6 Function parameters

6.1 What this chapter contains

This chapter lists and describes the function parameters.

6.2 Function parameters

The function parameters of GD300L series inverters special for lifts are divided into 30 groups

(P00–P29) by function, of which P18–P19 and P22–P28 are reserved. Each function group contains

certain function codes applying 3-level menus. For example, "P08.08" means the eighth function code

in the P8 group function. P29 group is factory reserved and inaccessible for users.

For the convenience of function codes setting, the function group number corresponds to the first

level menu, the function code corresponds to the second level menu and the function code

corresponds to the third level menu.

1. Below is the instruction of the function lists:

The first line "Function code": codes of function parameter group and parameters;

The second line "Name": full name of function parameters;

The third line "Detailed illustration of parameters": detailed illustration of the function parameters

The fourth line "Default value": the original factory values of the function parameter;

The fifth line "Modify": the modifying character of function codes (the parameters can be modified or

not and the modifying conditions), below is the instruction:

"○": means the set value of the parameter can be modified on stop and running state;

"◎": means the set value of the parameter cannot be modified on the running state;

"●": means the value of the parameter is the real detection value which cannot be modified.

(The inverter has limited the automatic inspection of the modifying character of the parameters to help

users avoid misadjustment.)

2. "Parameter radix" is decimal (DEC), if the parameter is expressed by hex, then the parameter is

separated from each other when editing. The setting range of certain bits are 0–F (Hex).

3. "The default value" means the function parameter will restore to the default value during default

parameters restoring, but the detected parameter or recorded value is not restored.

4. For a better parameter protection, the inverter provides password protection to the parameters.

After setting the password (set P07.00 to any non-zero number), the system will come into the state of

password verification firstly after the user press PRG/ESC to come into the function code editing state.

And then "0.0.0.0.0." will be displayed. Unless the user input right password, they cannot enter into

the system. For the factory setting parameter zone, it needs correct factory password (remind that the

users cannot modify the factory parameters by themselves, otherwise, if the parameter setting is

incorrect, damage to the inverter may occur). If the password protection is unlocked, the user can

modify the password freely and the inverter will work as the last setting one. When P07.00 is set to 0,

-34-

Page 39

Goodrive300-LIFT series inverter Function parameters

Function

code

Name

Detailed instruction of parameters

Default

value

Modify

P00 Group Basic function group

P00.00

Speed control

mode

0: Sensorless vector control (SVC) mode 0

1: SVC mode 1

2: V/F control

3: Closed-loop vector control

2 ◎ P00.01

Run command

channel

0: Keypad ("LOCAL/REMOT" off)

1: Terminal ("LOCAL/REMOT" blinking)

2: Communication ("LOCAL/REMOT" on)

3: CAN ("LOCAL/REMOT" on)

1

◎

P00.02

Lift rated speed

0.100–4.000m/s

1.500m/

s

◎

P00.03

Speed command

selection

0: Keypad

1: AI1

2: AI2

3: Multi-step speed running

4: Remote communication

5: AI1 tracking running

6: CAN communication-based setting

7: CAN communication-based reference

3

◎

P00.04

Max. output

frequency

10.00–600.00Hz

50.00

Hz

◎

P00.05

Keypad set

speed

0–P00.02 (lift rated speed)

1.500m/

s

○

P00.06

Running

direction

0: Default direction

1: Reverse direction

2: Forbid to run in reverse direction

0

◎

P00.07

Carrier

frequency mode

0: Fixed carrier frequency, set by P00.08

1: Auto adjustment

0

◎

the password can be canceled. If P07.00 is not 0 during powering on, then the parameter is protected

by the password. When modify parameters by serial communication, the password function also

follows the above rules.

-35-

Page 40

Goodrive300-LIFT series inverter Function parameters

Function

code

Name

Detailed instruction of parameters

Default

value

Modify

P00.08

Carrier

frequency

setting

Carrier

frequency

Electromagnetic

noise

Noise and leakage

current

Heat

dissipation

High

LowHigh

Low

High

Low

1 kHz

10 kHz

15 kHz

Mapping between models and carrier

frequencies

Model

Default carrier

frequency

380V

1.5–11kW

8 kHz

15–55kW

4 kHz

>75kW

2 kHz

660V

22–55kW

4 kHz

>75kW

2 kHz

Advantage of high carrier frequency: ideal

current waveform, little current harmonic wave

and motor noise.

Disadvantage of high carrier frequency:

increasing switch loss, increasing inverter

temperature, and impact to output capacity. The

inverter needs to derate on high carrier

frequency. Besides, the leakage and electrical

magnetic interference increases. Applying low

carrier frequency is contrary to the above. Too

low carrier frequency will cause unstable

running, torque decreasing and surge.

A reasonable carrier frequency has been set in

factory. In general, you do not need to modify

the parameter. When the frequency used

exceeds the default one, the inverter needs to

derate 20% for each additional 1kHz carrier

frequency. Setting range: 1.2–15.0kHz

Depend

on

model

◎

-36-

Page 41

Goodrive300-LIFT series inverter Function parameters

Function

code

Name

Detailed instruction of parameters

Default

value

Modify

P00.09

Motor parameter

autotuning

0: No operation

1: Rotating parameter autotuning on empty-load

asynchronous motor

2: Static parameter autotuning on asynchronous

motor

3: Rotating parameter autotuning on empty-load

synchronous motor

4: Static parameter autotuning on synchronous

motor

5: Rotating parameter autotuning on

synchronous motor with load

0

◎

P00.10

Function

restore

parameter

0: No operation

1: Restore the default value

2: Delete the fault records

3: Roll back function parameters, reading

function parameters that are saved when the

LSB of P07.01 is set to 5.

0

◎

P00.11

AVR function

0: Invalid

1: Valid

1

◎

P00.12

Reserved

0-65535

0 ○ P00.13

Reserved

0-65535

0

○

P01 Group Startup and stop control

P01.00

Start mode

0: Start-up directly: start from the starting

frequency P01.01

1: Start-up after DC braking: start the motor from

the starting frequency after DC braking (setting

P01.04 and P01.05)

It is suitable in the cases where reverse rotation

may occur to the low inertia load during starting.

0

◎

P01.01

Starting

frequency of

direct start

Starting frequency of direct start-up means the

original frequency during the inverter starting.

See P01.03 for detailed information.

Setting range: 0.00–50.00Hz

0.00Hz

◎

P01.02

ACC time of start

0.000–0.100s

0.010s

◎

-37-

Page 42

Goodrive300-LIFT series inverter Function parameters

Function

code

Name

Detailed instruction of parameters

Default

value

Modify

P01.03

Retention time of

the starting

frequency

Frequency (f)

f

max

t1

Time (t)

f1 is set through P01.01.

t1 is set through P01.02.

f1

Set a proper starting frequency to increase the

torque of the inverter during starting. During the

retention time of the starting frequency, the

output frequency of the inverter is the starting

frequency. And then, the inverter will run from

the starting frequency to the set frequency. If the

set frequency is lower than the starting

frequency, the inverter will stop running and

keep in the stand-by state. The starting

frequency is not limited in the lower limit

frequency.

Setting range: 0.0–50.0s

0.0s

◎

P01.04

Pre-start braking

current

The inverter will carry out DC braking at the

braking current set before starting and it will

speed up after the DC braking time. If the DC

braking time is set to 0, the DC braking is invalid.

Stronger braking current indicates bigger

braking power. The DC braking current before

starting means the percentage of the rated

current of the inverter.

Setting range of P01.04: 0.0–100.0%

Setting range of P01.05: 0.0–30.0s

0.0%

◎

P01.05

Braking time

before starting

0.0s

◎

-38-

Page 43

Goodrive300-LIFT series inverter Function parameters

Function

code

Name

Detailed instruction of parameters

Default

value

Modify

P01.06

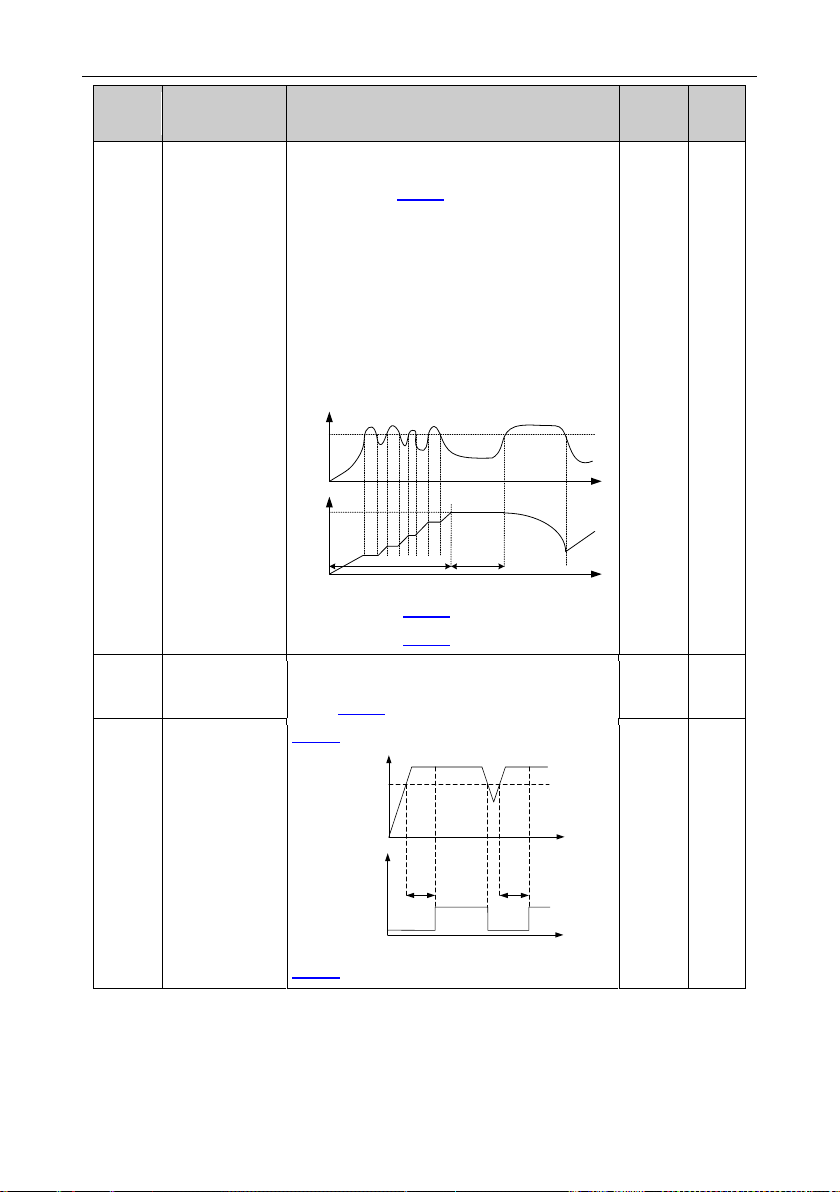

ACC/DEC

selection

Changing mode of the frequency during start-up

and running.

0: Linear type

The output frequency increases or decreases

linearly.

f

max

Output frequency (f)

t1 t2

Time (t)

1: S curve, indicating the output frequency

increases or decreases according to the S

curve.

Generally, S curve is used in scenarios such as

lifts and conveyers which require smooth startup

and stop.

Output frequency (f)

Time (t)

f

max

t1 t2

0

◎

P01.07

Stop mode

0: Decelerate to stop. After the stop command

becomes valid, the inverter decelerates to

decrease the output frequency during the set

time. When the frequency decreases to P01.15,

the inverter stops.

1: Coast to stop: after the stop command

becomes valid, the inverter ceases the output

immediately. And the load coasts to stop at the

mechanical inertia.

0

○

P01.08

Start frequency

in stop braking

Starting frequency of stop braking: The inverter

will carry on stop DC braking when the

frequency is arrived during decelerating to stop.

Demagnetizing time: Before the stop DC

0.00Hz

○

P01.09

Demagnetizing

time

0.00s

○

P01.10

Stop DC braking

current

0.0%

○

-39-

Page 44

Goodrive300-LIFT series inverter Function parameters

Function

code

Name

Detailed instruction of parameters

Default

value

Modify

P01.11

DC braking time

braking, the inverter will close output and begin

to carry on the DC braking after the waiting time.

This function avoids the overcurrent fault caused

by DC braking when the speed is too high.

Stop DC braking current: DC brake added.

Stronger current indicates bigger DC braking

effect.

Braking time of stop braking: Retention time of

DC brake. If the time is 0, the DC brake is

invalid. The inverter will stop at the set

deceleration time.

Running

command

Pre-start

braking

command

Constant speed

ON

OFF

Braking waiting time

during stop

Time t

ACC