INVT CHE100-0R7G-2, CHE100-1R5G-S2, CHE100-2R2G-2, CHE100-004G-2, CHE100-1R5G-2 Operation Manuals

...

CHE Series Sensorless Vector

Control Inverter

Operation Manual

z Thank you very much for your buying CHE series sensorless vector control

inverter.

z

Before use, please read this manual thoroughly to ensure proper usage. Keep this

manual at an easily accessible place so that can refer anytime as necessary.

I

WARNING

CAUTION

WARNING

CAUTION

Safety Precautions

Please read this operation manual carefully before installation, operation, maintenance or

inspection

In this manual, the safety precautions were sorted to “WARNING” or “CAUTION”.

Indicates a potentially dangerous situation which, if can not

avoid will result in death or serious injury.

Indicates a potentially dangerous situation which, if can not

avoid will cause minor or moderate injury and damage the

device. This

Symbol is also used for warning any un-safety operation.

In some cases, even the contents of “CAUTION” still can cause serious accident.

Please follow these important precautions in any situation

★ NOTE indicate the necessary operation to ensure the device run properly.

Warning Marks are placed on the front cover of the inverter.

Please follow these indications when using the inverter.

WARNING

z May cause injury or electric shock.

z Please follow the instructions in the manual before installation or operation.

z Disconnect all power line before opening front cover of unit. Wait at least 1

minute until DC Bus capacitors discharge.

z Use proper grounding techniques.

z Never connect AC power to output UVW terminals

II

TABLE OF CONTENTS

TABLE OF CONTENTS ............................................................................................ II

LIST OF FIGURES ...................................................................................................IV

1. INTRODUCTION................................................................................................. 1

1.1 Technology Features .................................................................................... 1

1.2 Description of Name Plate ........................................................................... 2

1.3 Selection Guide ............................................................................................ 2

1.4 Parts Description .......................................................................................... 4

1.5 External Dimension ...................................................................................... 5

2. INSPECTION ...................................................................................................... 8

3. INSTALLATION................................................................................................... 9

3.1 Environmental Requirement....................................................................... 10

3.2 Installation Space ........................................................................................11

3.3 Dimension of External Keypad ................................................................ 12

3.4 Disassembly ............................................................................................... 12

4. WIRING ............................................................................................................. 14

4.1 Connection of Peripheral Devices.............................................................. 15

4.2 Terminal Configuration ............................................................................... 16

4.2.1 Main Circuit Terminals............................................................................ 16

4.2.2 Control Circuit Terminals ........................................................................ 17

4.3 Typical Wiring Diagram .............................................................................. 18

.4.4 Specifications of Breaker, Cable, Contactor and Reactor......................... 19

4.4.1 Specifications of breaker, cable and contactor....................................... 19

4.4.2 Specifications of AC input reactor, AC output reactor and DC reactor... 21

4.4.3 Specification of braking resistor ............................................................. 22

4.5 Wiring Main Circuits ................................................................................... 23

4.5.1 Wiring at input side of main circuit ......................................................... 23

4.5.2 Wiring at inverter side of main circuit ..................................................... 24

4.5.3 Wiring at motor side of main circuit........................................................ 25

4.5.4 Wiring of regenerative unit ..................................................................... 25

4.5.5 Wiring of Common DC bus .................................................................... 26

4.5.6 Ground Wiring (PE)................................................................................ 26

4.6 Wiring Control Circuits................................................................................ 26

4.6.1 Precautions ............................................................................................ 26

4.6.2 Control circuit terminals.......................................................................... 27

4.6.3 Jumpers on control board ...................................................................... 27

4.6.4 Wiring description of size A (1AC 0.4~0.75kW) ..................................... 28

4.7 Installation Guidline to EMC Compliance................................................... 28

4.7.1 General description of EMC ................................................................... 28

4.7.2 EMC features of inverter ........................................................................ 29

4.7.3 EMC Installation Guideline..................................................................... 29

5. OPERATION ..................................................................................................... 32

5.1 Keypad Description .................................................................................... 32

5.1.1 Keypad schematic diagram.................................................................... 32

5.1.2 Key function description......................................................................... 32

5.1.3 Indicator light description ....................................................................... 33

5.2 Operation Process...................................................................................... 34

III

5.2.1 Parameter setting................................................................................... 34

5.2.2 Fault reset ..............................................................................................35

5.2.3 Motor parameter autotuning................................................................... 35

5.2.4 Password setting.................................................................................... 36

5.3 Running State .............................................................................................36

5.3.1 Power-on initialization ............................................................................36

5.3.2 Stand-by................................................................................................. 36

5.3.3 Motor parameter autotuning................................................................... 36

5.3.4 Operation ............................................................................................... 36

5.3.5 Fault .......................................................................................................37

5.4 Quick Testing ..............................................................................................37

6. DETAILED FUNCTION DESCRIPTION ............................................................38

6.1 P0 Group--Basic Function ..........................................................................38

6.2 P1 Group--Start and Stop Control............................................................... 45

6.3 P2 Group--Motor Parameters ..................................................................... 47

6.4 P3 Group—Vector Control.......................................................................... 49

6.5 P4 Group-- V/F Control...............................................................................50

6.6 P5 Group--Input Terminals..........................................................................52

6.7 P6 Group--Output Terminals .......................................................................57

6.8 P7 Group--Display Interface ....................................................................... 59

6.9 P8 Group--Enhanced Function...................................................................64

6.10 P9 Group--PID Control .............................................................................68

6.11 PA Group-- Multi-step Speed Control........................................................ 71

6.12 PB Group-- Protection Function ...............................................................73

6.13 PC Group--Serial Communication ............................................................76

6.14 PD Group—Supplementary Function .......................................................78

6.15 PE Group—Factory Setting ......................................................................81

7. TROUBLE SHOOTING .....................................................................................81

7.1 Fault and Trouble shooting.........................................................................81

7.2 Common Faults and Solutions....................................................................83

8. MAINTENANCE ...................................................................................................84

8.1 Daily Maintenance ......................................................................................85

8.2 Periodic Maintenance ................................................................................. 85

8.3 Replacement of wearing parts ....................................................................86

8.4 Warranty......................................................................................................86

9. LIST OF FUNCTION PARAMETERS.................................................................. 87

Special parameter for CHE150 series high speed inverter: ...........................100

Parameters display on LCD keypad ...............................................................101

10. COMMUNICATION PROTOCOL.....................................................................108

IV

LIST OF FIGURES

Figure 1.1 Nameplate of inverter....................................................................................... 2

Figure 1.2 Parts of inverters (15kw and below)................................................................. 4

Figure 1.3 Parts of inverters (18.5kw and above). ............................................................ 5

Figure 1.4 Dimension (0.4~0.75kW 1AC 220V). ............................................................... 5

Figure1.5 Dimension (0.75~15kW). .................................................................................. 6

Figure 1.6 Dimension (18.5~110kW). ............................................................................... 6

Figure 1.7 Dimension (132~315kW). ................................................................................ 6

Figure 1.8 Dimension (350~630kW). ................................................................................ 7

Figure 3.1 Relationship between output current and altitude.......................................... 10

Figure 3.2 Safe space. .................................................................................................... 11

Figure 3.3 Installation of multiple inverters...................................................................... 11

Figure 3.4 Dimension of small keypad. ........................................................................... 12

Figure 3.5 Dimension of big keypad................................................................................ 12

Figure 3.6 Disassembly of plastic cover.......................................................................... 12

Figure 3.7 Disassembly of metal plate cover. ................................................................. 13

Figure 3.8 Open inverter cabinet..................................................................................... 13

Figure 4.1 Connection of peripheral devices................................................................... 15

Figure 4.2 Main circuit terminals (0.4~0.75kW 1AC 220V). ............................................16

Figure 4.3 Main circuit terminals (1.5~2.2kW)................................................................. 16

Figure 4.4 Main circuit terminals (4.0~5.5kW) ................................................................ 16

Figure 4.5 Main circuit terminals (7.5~15kW).................................................................. 16

Figure 4.6 Main circuit terminals (18.5~110kW).............................................................. 16

Figure 4.7 Main circuit terminals (132~315kW)............................................................... 16

Figure 4.8 Main circuit terminals (350~630kW)............................................................... 16

Figure 4.9 Control circuit terminals (0.4~0.75kW 1AC 220V). ........................................ 17

Figure 4.10 Control circuit terminals (1.5~2.2kW)........................................................... 17

Figure 4.11 Control terminals (4.0kW and above). ......................................................... 17

Figure4. 12 Wiring diagram. ............................................................................................ 18

Figure 4.13 Wiring at input side of main circuit. .............................................................. 24

Figure 4.14 Wiring at motor side of main circuit.............................................................. 25

Figure 4.15 Wiring of regenerative unit. .......................................................................... 25

Figure 4.16 Wiring of common DC bus. .......................................................................... 26

V

Figure 4.17 Wiring of size A (0.4~0.75kW 1AC). ............................................................ 28

Figure 5.1 Keypad schematic diagram............................................................................ 32

Figure 5.2 Flow chart of parameter setting...................................................................... 35

Figure 5.3 Quick testing diagram. ................................................................................... 38

Figure 6.1 Acceleration and deceleration time. ............................................................... 42

Figure 6.2 Effect of carrier frequency. ............................................................................. 43

Figure 6.3 Starting diagram............................................................................................. 45

Figure 6.4 DC braking diagram. ......................................................................................47

Figure 6.5 FWD/REV dead time diagram........................................................................ 47

Figure 6.6 ASR diagram.................................................................................................. 49

Figure 6.7 PI parameter diagram. ................................................................................... 50

Figure6.8 V/F curve diagram........................................................................................... 51

Figure 6.9 Manual torque boost diagram. ....................................................................... 51

Figure 6.10 2-wire control mode1.................................................................................... 55

Figure 6.11 2-wire control mode 2................................................................................... 55

Figure 6.12 3-wire control mode 1................................................................................... 55

Figure 6.13 3-wire control mode2.................................................................................... 56

Figure 6.14 Relationship between AI and corresponding setting. ................................... 57

Figure 6.15 Relationship between AO and corresponding setting. ................................. 59

Figure 6.16 Skip frequency diagram. .............................................................................. 65

Figure 6.17 Traverse operation diagram. ........................................................................ 65

Figure 6.18 FDT level and lag diagram. .......................................................................... 67

Figure 6.19 Frequency arriving signal diagram. .............................................................. 67

Figure 6.20 PID control diagram. .................................................................................... 68

Figure 6.21 Reducing overshooting diagram. ................................................................. 69

Figure 6.22 Rapidly stabilizing diagram. ......................................................................... 70

Figure 6.23 Reducing long-cycle oscillation diagram. ..................................................... 70

Figure 6.24 Reducing short-cycle oscillation diagram..................................................... 70

Figure 6.25 Relationship between bias limit and output frequency. ................................ 71

Figure 6.26 Multi-steps speed operating diagram. .......................................................... 72

Figure 6.27 Motor overload protection curve................................................................... 73

Figure 6.28 Over-voltage stall function............................................................................ 75

Figure 6.29 Current limiting protection function............................................................... 76

Figure 6.30 Meaning of PC.06. ..................................................................................... 78

Introduction

1

1. INTRODUCTION

1.1 Technology Features

● Input & Output

◆Input Voltage Range: 380/220V ±15%

◆Input Frequency Range: 47~63Hz

◆Output Voltage Range: 0~rated input voltage

◆Output Frequency Range: 0~400Hz

● I/O features

◆Programmable Digital Input:

Provide 4 terminals which can accept ON-OFF inputs

◆Programmable Analog Input:

AI1 can accept input of 0 ~10V; AI2 can accept input of 0~10V or 0~20mA.

◆Programmable Open Collector Output:

Provide 1 output terminal (open collector output or high-speed pulse output)

◆Relay Output: Provide 1 output terminal.

◆Analog Output: Provide 1 analog output terminal, whose output scope can be

0/4~20 mA or 0~10 V, as chosen..

● Main Control Function

◆Control Mode: Sensorless Vector Control (SVC), V/F Control.

◆Overload Capacity:

60s with 150% of rated current, 10s with 180% of rated current.

◆Starting Torque: 150% of rated torque at 0.5Hz (SVC).

◆Speed Adjusting Range: 1:100 (SVC)

◆Speed Accuracy: ± 0.5% of maximum speed (SVC)

◆Carrier Frequency: 0.5kHz ~15.0kHz.

◆Reference Frequency Source: keypad, analog input, serial communication,

multi-step speed, PID and so on. The combination of multi- modes and switching

between different modes can be realized.

◆Torque Control Function: Provide multiple torque setting source.

◆PID Control Function

◆Multi-Step Speed Control Function: 8 steps speed can be set.

◆Traverse Control Function

◆None-Stop when instantaneous power off.

◆Speed trace Function: Start the running motor smoothly.

◆QUICK/JOG Key: User defined shortcut key can be realized.

◆Automatic Voltage Regulation (AVR) Function:

Automatically keep the output voltage stable when input voltage fluctuating.

◆ Up to 24 fault protections:

Protect from over current, over voltage, under voltage, over heat, phase failure,

over load etc.

Introduction

2

1.2 Description of Name Plate

Figure 1.1 Nameplate of inverter.

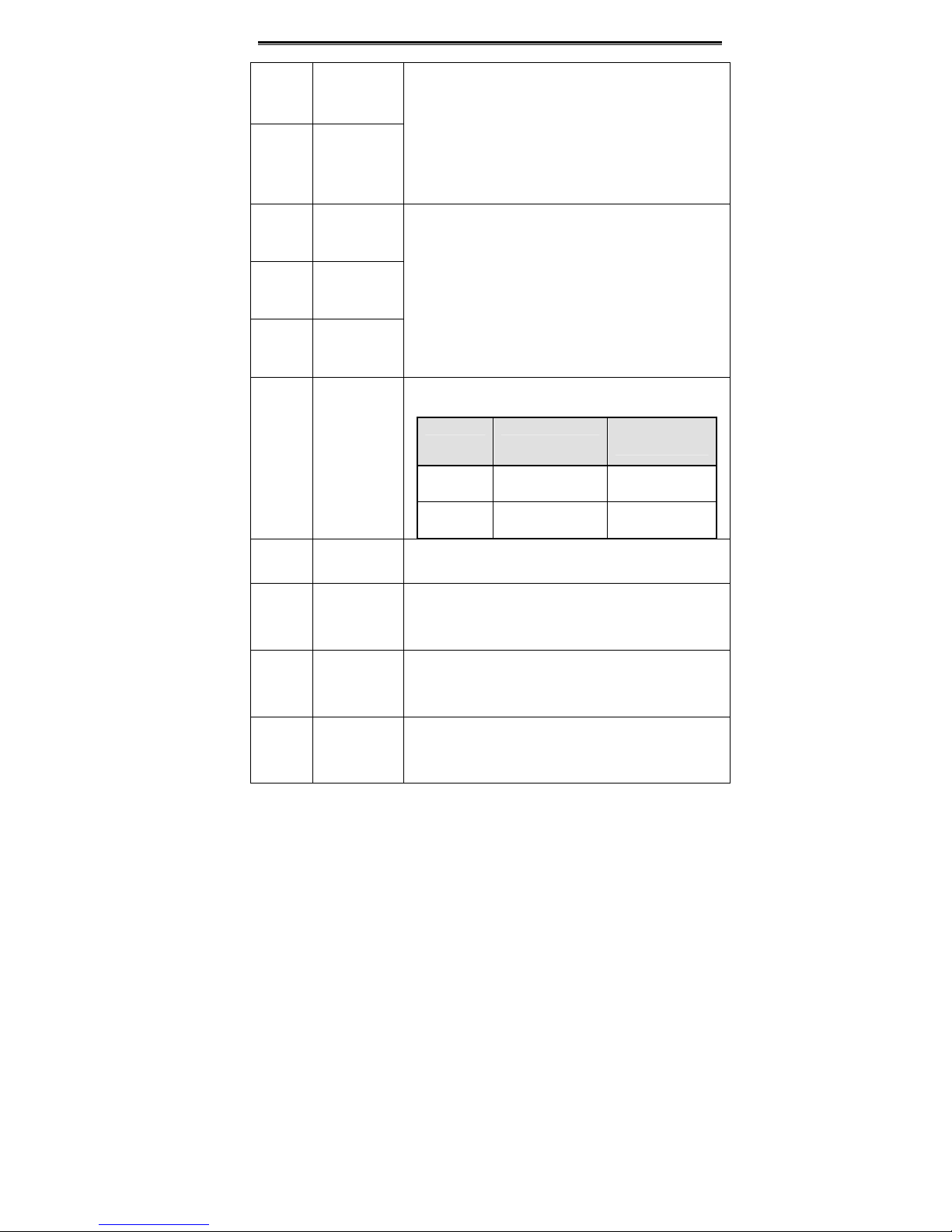

1.3 Selection Guide

Model No.

Rated

Output

Power

(kW)

Rated

Input

current

(A)

Rated

Output

current

(A)

Motor

Power

(KW)

Size

1AC 220V ±15%

CHE100-0R4G-S2 0.4 5.4 2.3 0.4 A

CHE100-0R7G-S2 0.75 8.2 4.5 0.75 A

CHE100-1R5G-S2 1.5 14.2 7.0 1.5 B

CHE100-2R2G-S2 2.2 23.0 10 2.2 B

3AC 220V ±15%

CHE100-0R7G-2 0.75 5.0 4.5 0.75 A

CHE100-1R5G-2 1.5 7.7 7 1.5 B

CHE100-2R2G-2 2.2 11.0 10 2.2 B

CHE100-004G-2 4.0 17.0 16 3.7 C

CHE100-5R5G-2 5.5 21.0 20 5.5 C

CHE100-7R5G-2 7.5 31.0 30 7.5 D

CHE100-011G-2 11.0 43.0 42 11.0 E

CHE100-015G-2 15.0 56.0 55 15.0 E

CHE100-018G-2 18.5 71.0 70 18.5 E

CHE100-022G-2 22.0 81.0 80 22.0 F

CHE100-030G-2 30.0 112.0 110 30.0 F

CHE100-037G-2 37.0 132.0 130 37.0 F

CHE100-045G-2 45.0 163.0 160 45.0 G

Introduction

3

3AC 380V ±15%

CHE100-0R7G-4

0.75 3.4 2.5 0.75

B

CHE100-1R5G-4

1.5 5.0 3.7 1.5

B

CHE100-2R2G-4

2.2 5.8 5 2.2

B

CHE100-004G/5R5P-4

4.0/5.5 10/15 9/13 4.0/5.5

C

CHE100-5R5G/7R5P-4

5.5/7.5 15/20 13/17 5.5/7.5

C

CHE100-7R5G/011P-4

7.5/11 20/26 17/25 7.5/11

D

CHE100-011G/015P-4

11/15 26/35 25/32 11/15

D

CHE100-015G/018P-4

15/ 18.5 35/38 32/37 15/ 18.5

D

CHE100-018G/022P-4

18.5/ 22 38/46 37/45 18.5/ 22

E

CHE100-022G/030P-4

22/30 46/62 45/60 22/30

E

CHE100-030G/037P-4

30/37 62/76 60/75 30/37

E

CHE100-037G/045P-4

37/45 76/90 75/90 37/45

F

CHE100-045G/055P-4

45/55 90/105 90/110 45/55

F

CHE100-055G/075P-4

55/75 105/ 140 110/ 150 55/75

F

CHE100-075G/090P-4

75/90 140/ 160 150/ 176 75/90

G

CHE100-090G/110P-4

90/110 160/ 210 176/ 210 90/110

G

CHE100-110G/132P-4

110/132 210/ 240 210/ 250 110/132

G

CHE100-132G/160P-4

132/160 240/ 290 250/ 300 132/160

H

CHE100-160G/185P-4

160/185 290/ 330 300/ 340 160/185

H

CHE100-185G/200P-4

185/200 330/ 370 340/ 380 185/200

H

CHE100-200G/220P-4

200/220 370/ 410 380/ 415 200/220

I

CHE100-220G/250P-4

220/250 410/ 460 415/ 470 220/250

I

CHE100-250G/280P-4

250/280 460/ 500 470/ 520 250/280

I

CHE100-280G/315P-4

280/315 500/ 580 520/ 600 280/315

I

CHE100-315G/350P-4

315/350 580/ 620 600/ 640 315/350

I

Introduction

4

1.4 Parts Description

Figure 1.2 Parts of inverters (15kw and below).

Introduction

5

Figure 1.3 Parts of inverters (18.5kw and above).

1.5 External Dimension

Figure 1.4 Dimension (0.4~0.75kW 1AC 220V).

Introduction

6

Figure1.5 Dimension (0.75~15kW).

Figure 1.6 Dimension (18.5~110kW).

Figure 1.7 Dimension (132~315kW).

Introduction

7

Figure 1.8 Dimension (350~630kW).

A

(mm)B (mm)H (mm)W (mm)D (mm)

Power

(kW)

Size

Installation

Dimension

External Dimension

Installation

Hole

(mm)

0.4~0.75

(1AC 220V)

A 76.8 131.6 140 85 115 4

0.75~2.2 B 110.4 170.2 180 120 140 5

4~5.5 C 147.5 237.5 250 160 175 5

7.5~15 D 206 305.5 320 220 180 6.0

18.5~30 E 176 454.5 467 290 215 6.5

37~55 F 230 564.5 577 375 270 7.0

75~110 G 320 738.5 755 460 330 9.0

H(without

base)

270 1233 1275 490 391 13.0

132~185

H(with base) — — 1490 490 391 —

I(without

base)

500 1324 1358 750 402 12.5

200~315

I(with base) — — 1670 750 402 —

Inspection

8

2. INSPECTION

● Don’t install or use any inverter that is damaged or have fault part, otherwise

may cause injury.

Check the following items when unpacking the inverter,

1. Inspect the entire exterior of the Inverter to ensure there are no scratches or other

damage caused by the transportation.

2. Ensure there is operation manual and warranty card in the packing box.

3. Inspect the nameplate and ensure it is what you ordered.

4. Ensure the optional parts are what you need if have ordered any optional parts.

Please contact the local agent if there is any damage in the inverter or optional parts.

CAUTION

Installation

9

3. INSTALLATION

● The person without passing the training manipulate the device or any rule in the

“Warning” being violated, will cause severe injury or property loss. Only the

person, who has passed the training on the design, installation, commissioning

and operation of the device and gotten the certification, is permitted to operate

this equipment.

● Input power cable must be connected tightly, and the equipment must be

grounded securely.

● Even if the inverter is not running, the following terminals still have dangerous

voltage:

- Power Terminals: R, S, T

- Motor Connection Terminals: U, V, W.

●When power off, should not install the inverter until 5 minutes after, which can

ensure the device discharge completely.

● The section area of grounding conductor must be no less than that of power

supply cable.

●When moving the inverter please lift by its base and don’t lift by the panel.

Otherwise may cause the main unit fall off which may result in personal injury.

● Install the inverter on the fireproofing material (such as metal) to prevent fire.

● When need install two or more inverters in one cabinet, cooling fan should be

provided to make sure that the air temperature is lower than 45°C. Otherwise it

could cause fire or damage the device.

WARNING

CAUTION

WARNING

Installation

10

3.1 Environmental Requirement

3.1.1 Temperature

Environment temperature range: -10°C ~ +40°C. Inverter will be derated if ambient

temperature exceeds 40°C.

3.1.2 Humidity

Less than 95% RH, without dewfall.

3.1.3 Altitude

Inverter can output the rated power when installed with altitude of lower than

1000m. It will be derated when the altitude is higher than 1000m. For details, please

refer to the following figure:

Figure 3.1 Relationship between output current and altitude.

3.1.4 Impact and Vibration

It is not allowed that the inverter falls down or suffers from fierce impact or the

inverter installed at the place that vibration frequently.

3.1.5 Electromagnetic Radiation

Keep away from the electromagnetic radiation source.

3.1.6 Water

Do not install the inverter at the wringing or dewfall place.

3.1.7 Air Pollution

Keep away from air pollution such as dusty, corrosive gas.

3.1.8 Storage

Do not store the inverter in the environment with direct sunlight, vapor, oil fog and

vibration.

Installation

11

3.2 Installation Space

Figure 3.2 Safe space.

Figure 3.3 Installation of multiple inverters.

Notice: Add the air deflector when apply the up-down installation.

Installation

12

3.3 Dimension of External Keypad

Figure 3.4 Dimension of small keypad.

Figure 3.5 Dimension of big keypad.

3.4 Disassembly

Figure 3.6 Disassembly of plastic cover.

Installation

13

Figure 3.7 Disassembly of metal plate cover.

Figure 3.8 Open inverter cabinet.

Wiring

14

4. WIRING

● Wiring must be performed by the person certified in electrical work.

● Forbid testing the insulation of cable that connects the inverter with high-voltage

insulation testing devices.

● Cannot install the inverter until discharged completely after the power supply is

switched off for 5 minutes.

● Be sure to ground the ground terminal.

(200V class: Ground resistance should be 100Ω or less, 400V class: Ground

resistance should be 10Ω or less, 660V class: Ground resistance should be 5Ω or

less). Otherwise, it might cause electric shock or fire.

● Connect input terminals (R, S, T) and output terminals (U, V, W) correctly.

Otherwise it will cause damage the inside part of inverter.

● Do not wire and operate the inverter with wet hands.

Otherwise there is a risk of electric shock.

●Check to be sure that the voltage of the main AC power supply satisfies the rated

voltage of the Inverter.

Injury or fire can occur if the voltage is not correct.

● Connect power supply cables and motor cables tightly.

WARNING

C

A

UTION

Wiring

15

4.1 Connection of Peripheral Devices

Figure 4.1 Connection of peripheral devices.

Wiring

16

4.2 Terminal Configuration

4.2.1 Main Circuit Terminals (380VAC)

Figure 4.2 Main circuit terminals (0.4~0.75kW 1AC 220V).

R S T U V W

(+) PB

POWER MOTOR

Figure 4.3 Main circuit terminals (1.5~2.2kW).

R S T U V W

(+) PB (-)

POWER MOTOR

Figure 4.4 Main circuit terminals (4.0~5.5kW) .

R S T U V W

(+) PB (-)

POWER MOTOR

Figure 4.5 Main circuit terminals (7.5~15kW).

R S T U V W

POWER

P1 (+) (-)

MOTOR

Figure 4.6 Main circuit terminals (18.5~110kW).

R S T U V W

POWER MOTOR

P1 (+) (-)

Figure 4.7 Main circuit terminals (132~315kW).

R S T U V W

POWER MOTOR

P1 (+) (-)

Figure 4.8 Main circuit terminals (350~630kW).

Wiring

17

Main circuit terminal functions are summarized according to the terminal symbols in the

following table. Wire the terminal correctly for the desired purposes.

4.2.2 Control Circuit Terminals

485+ 485- S1 S2 S3 S4 COM AI2 AO Y +24V ROA ROB ROC

Figure 4.9 Control circuit terminals (0.4~0.75kW 1AC 220V).

485+ 485- +10V AO COM Y +24V ROA ROB ROC

AI1 GND AI2 S1 S2 S3 S4

Figure 4.10 Control circuit terminals (1.5~2.2kW).

485+ 485- AO AI1 GND AI2 +10V S1 S2 S3 S4 COM Y +24V ROA ROB ROC

Figure 4.11 Control terminals (4.0kW and above).

Terminal Symbol Function Description

R、S、T Terminals of 3 phase AC input

(+)、(-) Spare terminals of external braking unit

(+)、PB Spare terminals of external braking resistor

P1、(+) Spare terminals of external DC reactor

(-) Terminal of negative DC bus

U、V、W Terminals of 3 phase AC output

Terminal of ground

Wiring

18

4.3 Typical Wiring Diagram

Figure4. 12 Wiring diagram.

Notice

1. Inverters between 18.5KW and 90KW have built-in DC reactor which is used to

improve power factor. For inverters above 110KW, it is recommended to install DC

reactor between P1 and (+).

2. Inverters below 15KW have built-in braking unit. If need braking, only need to

install braking resistor between PB and (+).

3. For inverters above 18.5KW, if need braking, should install external braking

unit between (+) and (-).

Wiring

19

.4.4 Specifications of Breaker, Cable, Contactor and Reactor

4.4.1 Specifications of breaker, cable and contactor

Model No.

Circuit Breaker

(A)

Input/Output

Cable (mm2)

AC Contactor

(A)

1AC 220V ±15%

CHE100-0R4G-S2 16 2.5 10

CHE100-0R7G-S2 16 2.5 10

CHE100-1R5G-S2 20 4 16

CHE100-2R2G-S2 32 6 20

33AACC 222200VV ±±1155%%

CHE100-0R4G-2 16 2.5 10

CHE100-0R7G-2 16 2.5 10

CHE100-1R5G-2 20 4 16

CHE100-2R2G-2 32 6 20

CHE100-004G-2 40 6 25

CHE100-5R5G-2 63 6 32

CHE100-7R5G-2 100 10 63

CHE100-011G-2 125 25 95

CHE100-015G-2 160 25 120

CHE100-018G-2 160 25 120

CHE100-022G-2 200 35 170

CHE100-030G-2 200 35 170

CHE100-037G-2 200 35 170

CHE100-045G-2 250 70 230

Wiring

20

3AC 380V ±15%

CHE100-0R7G-4 10 2.5 10

CHE100-1R5G-4 16 2.5 10

CHE100-2R2G-4 16 2.5 10

CHE100-004G/5R5P-4 25 4 16

CHE100-5R5G/7R5P-4 25 4 16

CHE100-7R5G/011P-4 40 6 25

CHE100-011G/015P-4 63 6 32

CHE100-015G/018P-4 63 6 50

CHE100-018G/022P-4 100 10 63

CHE100-022G/030P-4 100 16 80

CHE100-030G/037P-4 125 25 95

CHE100-037G/045P-4 160 25 120

CHE100-045G/055P-4 200 35 135

CHE100-055G/075P-4 200 35 170

CHE100-075G/090P-4 250 70 230

CHE100-090G/110P-4 315 70 280

CHE100-110G/132P-4 400 95 315

CHE100-132G/160P-4 400 150 380

CHE100-160G/185P-4 630 185 450

CHE100-185G/200P-4 630 185 500

CHE100-220G/250P-4 800 150x2 630

CHE100-250G/280P-4 800 150x2 700

CHE100-280G/315P-4 1000 185x2 780

CHE100-315G/350P-4 1200 240x2 900

Wiring

21

4.4.2 Specifications of AC input reactor, AC output reactor and DC reactor

AC Input reactor AC Output reactor DC reactor

Model No.

Current

(A)

Inductance

(mH)

Current

(A)

Inductance

(mH)

Current

(A)

Inductance

(mH)

3AC 380V ±15%

CHE100-0R7G-4 - - - - - -

CHE100-1R5G-4

5 3.8 5 1.5

- -

CHE100-2R2G-4

7 2.5 7 1

- -

CHE100-004G/5R5P-4

10 1.5 10 0.6

- -

CHE100-5R5G/7R5P-4

15 1.4 15 0.25

- -

CHE100-7R5G/011P-4

20 1 20 0.13

- -

CHE100-011G/015P-4

30 0.6 30 0.087

- -

CHE100-015G/018P-4

40 0.6 40 0.066

- -

CHE100-018G/022P-4

50 0.35 50 0.052 80

0.4

CHE100-022G/030P-4

60 0.28 60 0.045 80

0.4

CHE100-030G/037P-4

80 0.19 80 0.032 80

0.4

CHE100-037G/045P-4

90 0.19 90 0.03 110

0.25

CHE100-045G/055P-4

120 0.13 120 0.023 110

0.25

CHE100-055G/075P-4

150 0.11 150 0.019 110

0.25

CHE100-075G/090P-4

200 0.08 200 0.014 180

0.18

CHE100-090G/110P-4

200 0.08 200 0.014 180

0.18

CHE100-110G/132P-4

250 0.065 250 0.011

250

0.2

CHE100-132G/160P-4

290 0.065 290 0.011

326 0.215

CHE100-160G/185P-4

330 0.05 330 0.01

494 0.142

CHE100-185G/200P-4

400 0.044 400 0.008

494 0.142

CHE100-200G/220P-4

400 0.044 400 0.008

494 0.142

CHE100-220G/250P-4

490 0.035 490 0.005

494 0.126

CHE100-250G/280P-4

530 0.04 530 0.005

700 0.1

CHE100-280G/315P-4

600 0.04 600 0.005

700 0.1

CHE100-315G/350P-4

660 0.025 660 0.004

800 0.08

Wiring

22

4.4.3 Specification of braking unit and braking resistor

Braking unit

Braking resistor

(100% braking torque) Model No.

Order No. Quantity Specification Quantity

3AC 220V ±15%

CHE100-0R4G-2

275Ω/75W 1

CHE100-0R7G-2

275Ω/75W 1

CHE100-1R5G-2

138Ω/150W 1

CHE100-2R2G-2

91Ω/220W 1

CHE100-004G-2

52Ω/400W 1

CHE100-5R5G-2

37.5Ω/550W 1

CHE100-7R5G-2

Built-in 1

27.5Ω/750W 1

CHE100-011G-2

1 19Ω/1100W 1

CHE100-015G-2

1 13.6Ω/1500W 1

CHE100-018G-2

1 12Ω/1800W 1

CHE100-022G-2

1 9Ω/2200W 1

CHE100-030G-2

DBU-055-2

1 6.8Ω/3000W 1

CHE100-037G-2

2 11Ω/2000W 2

CHE100-045G-2

DBU-055-2

2 9Ω/2400W 2

3AC 380V ±15%

CHE100-0R7G-4 900Ω/75W 1

CHE100-1R5G-4 460Ω/150W 1

CHE100-2R2G-4 315Ω/220W 1

CHE100-004G/5R5P-4 175Ω/400W 1

CHE100-5R5G/7R5P-4 120Ω/550W 1

CHE100-7R5G/011P-4 100Ω/750W 1

CHE100-011G/015P-4 70Ω/1100W 1

CHE100-015G/018P-4

Built-in 1

47Ω/1500W 1

CHE100-018G/022P-4

38Ω/2000W 1

CHE100-022G/030P-4

32Ω/2200W 1

CHE100-030G/037P-4

23Ω/3000W 1

CHE100-037G/045P-4

DBU-055-4 1

19Ω/3700W 1

Wiring

23

CHE100-045G/055P-4

16Ω/4500W 1

CHE100-055G/075P-4

13Ω/5500W 1

CHE100-075G/090P-4

19Ω/3700W 2

CHE100-090G/110P-4

16Ω/4500W 2

CHE100-110G/132P-4

DBU-055-4 2

13Ω/5500W 2

CHE100-132G/160P-4

1

5Ω/15000W 1

CHE100-160G/185P-4

DBU-160-4

1

3.5Ω/20000W 1

CHE100-185G/200P-4

1

3.5Ω/20000W 1

CHE100-200G/220P-4

1

3Ω/25000W 1

CHE100-220G/250P-4

DBU-220-4

1

3Ω/25000W 1

CHE100-250G/280P-4

1

2.5Ω/30000W 1

CHE100-280G/315P-4

1

2.5Ω/30000W 1

CHE100-315G/350P-4

DBU-315-4

1

2Ω/35000W 1

Notice:

1. Above selection is based on following condition: 700V DC braking voltage

threshold, 100% braking torque and 10% usage rate.

2. Parallel connection of braking unit is helpful to improve braking capability.

3. Wire between inverter and braking unit should be less than 5m.

4. Wire between braking unit and braking resistor should be less than 10m.

5. Braking unit can be used for braking continuously for 5 minutes. When braking

unit is working, temperature of cabinet will be high, user is not allowed to touch to

prevent from injure.

For more details, please refer to DBU and RBU user manual.

4.5 Wiring Main Circuits

4.5.1 Wiring at input side of main circuit

4.5.1.1 Circuit breaker

It is necessary to connect a circuit breaker which is compatible with the capacity of

inverter between 3ph AC power supply and power input terminals (R, S, T). The

capacity of breaker is 1.5~2 times to the rated current of inverter. For details, see

<Specifications of Breaker, Cable, and Contactor>.

4.5.1.2 Contactor

In order to cut off the input power effectively when something is wrong in the system,

contactor should be installed at the input side to control the on/off of the main circuit

Wiring

24

power supply.

4.5.1.3 AC reactor

In order to prevent the rectifier damage resulted from the large current, AC reactor

should be installed at the input side. It can also prevent rectifier from sudden

variation of power voltage or harmonic generated by phase-control load.

4.5.1.4 Input EMC filter

The surrounding device may be disturbed by the cables when the inverter is working.

EMC filter can minimize the interference. Just like the following figure.

Figure 4.13 Wiring at input side of main circuit.

4.5.2 Wiring at inverter side of main circuit

4.5.2.1 DC reactor

Inverter from 18.5kW to 90kW have built-in DC reactor which can improve the

power factor.

4.5.2.2 Braking unit and braking resistor

• Inverter of 15KW and below have built-in braking unit. In order to dissipate the

regenerative energy generated by dynamic braking, the braking resistor should

be installed at (+) and PB terminals. The wire length of the braking resistor should

be less than 5m.

• Inverter of 18.5KW and above need connect external braking unit which should be

installed at (+) and (-) terminals. The cable between inverter and braking unit

should be less than 5m. The cable between braking unit and braking resistor

should be less than 10m.

• The temperature of braking resistor will increase because the regenerative energy

will be transformed to heat. Safety protection and good ventilation is

recommended.

Wiring

25

Notice: Be sure that the electric polarity of (+) (-) terminals is right; it is not allowed

to connect (+) with (-) terminals directly, otherwise damage or fire could occur.

4.5.3 Wiring at motor side of main circuit

4.5.3.1 Output Reactor

When the distance between inverter and motor is more than 50m, inverter may be

tripped by over-current protection frequently because of the large leakage current

resulted from the parasitic capacitance with ground. And the same time to avoid

the damage of motor insulation, the output reactor should be installed.

4.5.3.2 Output EMC filter

EMC filter should be installed to minimize the leak current caused by the cable and

minimize the radio noise caused by the cables between the inverter and cable.

Just see the following figure.

Figure 4.14 Wiring at motor side of main circuit.

4.5.4 Wiring of regenerative unit

Regenerative unit is used for putting the electricity generated by braking of motor to the

grid. Compared with traditional 3 phase inverse parallel bridge type rectifier unit,

regenerative unit uses IGBT so that the total harmonic distortion (THD) is less than 4%.

Regenerative unit is widely used for centrifugal and hoisting equipment.

Figure 4.15 Wiring of regenerative unit.

Wiring

26

4.5.5 Wiring of Common DC bus

Common DC bus method is widely used in the paper industry and chemical fiber industry

which need multi-motor to coordinate. In these applications, some motors are in driving

status while some others are in regenerative braking (generating electricity) status. The

regenerated energy is automatically balanced through the common DC bus, which means

it can supply to motors in driving status. Therefore the power consumption of whole

system will be less compared with the traditional method (one inverter drives one motor).

When two motors are running at the same time (i.e. winding application), one is in driving

status and the other is in regenerative status. In this case the DC buses of these two

inverters can be connected in parallel so that the regenerated energy can be supplied to

motors in driving status whenever it needs. Detailed wiring is shown in the following

figure:

Figure 4.16 Wiring of common DC bus.

Notice: Two inverters must be the same model when connected with Common DC

bus method. Be sure they are powered on at the same time.

4.5.6 Ground Wiring (PE)

In order to ensure safety and prevent electrical shock and fire, PE must be grounded with

ground resistance. The ground wire should be big and short, and it is better to use copper

wire (>3.5mm

2

). When multiple inverters need to be grounded, do not loop the ground

wire.

4.6 Wiring Control Circuits

4.6.1 Precautions

z Use shielded or twisted-pair cables to connect control terminals.

z Connect the ground terminal (PE) with shield wire.

Wiring

27

z The cable connected to the control terminal should leave away from the main

circuit and heavy current circuits (including power supply cable, motor cable, relay

and contactor connecting cable) at least 20cm and parallel wiring should be avoided.

It is suggested to apply perpendicular wiring to prevent inverter malfunction caused

by external interference.

4.6.2 Control circuit terminals

Terminal

No.

Function

S1~S4

ON-OFF signal input, optical coupling with PW and COM.

Input voltage range: 9~30V

Input impedance: 3.3kΩ

+24V

Provide output power supply of +24V.

Maximum output current: 150mA

AI1

Analog input: 0~10V

Input impedance: 10kΩ

AI2

Analog input: 0~10V/ 0~20mA, switched by J16.

Input impedance:10kΩ (voltage input) / 250Ω (current input)

GND

Common ground terminal of analog signal and +10V.

GND must isolated from COM.

+10V Supply +10V to inverter.

COM

Common ground terminal for digital signal and +24V (or external

power supply).

AO

Provide voltage or current output which can be switched by J15.

Output range: 0~10V/ 0~20mA

Y

Open collector output terminal, the corresponding common

ground terminal is COM.

ROA、ROB、

ROC

Relay output: ROA--common; ROB--NC, ROC—NO.

Contact capacity: AC 250V/3A, DC 30V/1A

4.6.3 Jumpers on control board

Jumper Function

J2, J4

Default setting: J2 and J4 are disconnected. It is prohibited to be

connected together, otherwise it will cause inverter malfunction.

J7

Default setting: 2 and 3 connected. Do not change default setting

otherwise it will cause communication malfunction.

Wiring

28

J16

Switch between (0~10V) voltage input and (0~20mA) current input.

V connect to GND means voltage input;

I connect to GND means current input.

J15

Switch between (0~10V) voltage output and (0~20mA) current

output.

V connect to OUT means voltage output;

I connect to OUT means current output.

4.6.4 Wiring description of size A (1AC 0.4~0.75kW)

AI2 can work in three modes (0~24V/0~10V/0~20mA) depend on the configuration of

J16.

0~24V input 0~10V input 0~20mA input

Figure 4.17 Wiring of size A (0.4~0.75kW 1AC).

To the external potentiometer, resistance should be greater than 3kΩ and power should

greater than 1/4W. Its resistance is recommended to be 5~10kΩ.

Notice:

The terminal will use the internal circuit to adjust the input signal. To the first two

work mode, the relative internal voltage range is 0~10V. And to the third work mode,

the relative internal voltage range is 0~5V.

4.7 Installation Guidline to EMC Compliance

4.7.1 General description of EMC

EMC is the abbreviation of electromagnetic compatibility, which means the device or

system has the ability to work normally in the electromagnetic environment and will not

generate any electromagnetic interference to other equipments.

EMC includes two subjects: electromagnetic interference and electromagnetic

anti-jamming.

According to the transmission mode, Electromagnetic interference can be divided into two

Wiring

29

categories: conducted interference and radiated interference.

Conducted interference is the interference transmitted by conductor. Therefore, any

conductors (such as wire, transmission line, inductor, capacitor and so on) are the

transmission channels of the interference.

Radiated interference is the interference transmitted in electromagnetic wave, and the

energy is inverse proportional to the square of distance.

Three necessary conditions or essentials of electromagnetic interference are:

interference source, transmission channel and sensitive receiver. For customers, the

solution of EMC problem is mainly in transmission channel because of the device

attribute of disturbance source and receiver can not be changed

4.7.2 EMC features of inverter

Like other electric or electronic devices, inverter is not only an electromagnetic

interference source but also an electromagnetic receiver. The operating principle of

inverter determines that it can produce certain electromagnetic interference noise. And

the same time inverter should be designed with certain anti-jamming ability to ensure the

smooth working in certain electromagnetic environment. The following is its EMC

features:

4.7.2.1 Input current is non-sine wave. The input current includes large amount of

high-harmonic waves that can cause electromagnetic interference, decrease

the grid power factor and increase the line loss.

4.7.2.2 Output voltage is high frequency PMW wave, which can increase the

temperature rise and shorten the life of motor. And the leakage current will also

increase, which can lead to the leakage protection device malfunction and

generate strong electromagnetic interference to influence the reliability of other

electric devices.

4.7.2.3 As the electromagnetic receiver, too strong interference will damage the

inverter and influence the normal using of customers.

4.7.2.4 In the system, EMS and EMI of inverter coexist. Decrease the EMI of inverter

can increase its EMS ability.

4.7.3 EMC Installation Guideline

In order to ensure all electric devices in the same system to work smoothly, this section,

Wiring

30

based on EMC features of inverter, introduces EMC installation process in several

aspects of application (noise control, site wiring, grounding, leakage current and power

supply filter). The good effective of EMC will depend on the good effective of all of these

five aspects.

4.7.3.1 Noise control

All the connections to the control terminals must use shielded wire. And the shield layer of

the wire must ground near the wire entrance of inverter. The ground mode is 360 degree

annular connection formed by cable clips. It is strictly prohibitive to connect the twisted

shielding layer to the ground of inverter, which greatly decreases or loses the shielding

effect.

Connect inverter and motor with the shielded wire or the separated cable tray. One side

of shield layer of shielded wire or metal cover of separated cable tray should connect to

ground, and the other side should connect to the motor cover. Installing an EMC filter can

reduce the electromagnetic noise greatly.

4.7.3.2 Site wiring

Power supply wiring: the power should be separated supplied from electrical transformer.

Normally it is 5 core wires, three of which are fire wires, one of which is the neutral wire,

and one of which is the ground wire. It is strictly prohibitive to use the same line to be both

the neutral wire and the ground wire

Device categorization: there are different electric devices contained in one control cabinet,

such as inverter, filter, PLC and instrument etc, which have different ability of emitting and

withstanding electromagnetic noise. Therefore, it needs to categorize these devices into

strong noise device and noise sensitive device. The same kinds of device should be

placed in the same area, and the distance between devices of different category should

be more than 20cm.

Wire Arrangement inside the control cabinet: there are signal wire (light current) and

power cable (strong current) in one cabinet. For the inverter, the power cables are

categorized into input cable and output cable. Signal wires can be easily disturbed by

power cables to make the equipment malfunction. Therefore when wiring, signal cables

and power cables should be arranged in different area. It is strictly prohibitive to arrange

them in parallel or interlacement at a close distance (less than 20cm) or tie them together.

If the signal wires have to cross the power cables, they should be arranged in 90 angles.

Power input and output cables should not either be arranged in interlacement or tied

Wiring

31

together, especially when installed the EMC filter. Otherwise the distributed capacitances

of its input and output power cable can be coupling each other to make the EMC filter out

of function.

4.7.3.3 Ground

Inverter must be ground safely when in operation. Grounding enjoys priority in all EMC

methods because it does not only ensure the safety of equipment and persons, but also is

the simplest, most effective and lowest cost solution for EMC problems.

Grounding has three categories: special pole grounding, common pole grounding and

series-wound grounding. Different control system should use special pole grounding, and

different devices in the same control system should use common pole grounding, and

different devices connected by same power cable should use series-wound grounding.

4.7.3.4 Leakage Current

Leakage current includes line-to-line leakage current and over-ground leakage current.

Its value depends on distributed capacitances and carrier frequency of inverter. The

over-ground leakage current, which is the current passing through the common ground

wire, can not only flow into inverter system but also other devices. It also can make

leakage current circuit breaker, relay or other devices malfunction. The value of

line-to-line leakage current, which means the leakage current passing through distributed

capacitors of input output wire, depends on the carrier frequency of inverter, the length

and section areas of motor cables. The higher carrier frequency of inverter, the longer of

the motor cable and/or the bigger cable section area, the larger leakage current will

occur.

Countermeasure:

Decreasing the carrier frequency can effectively decrease the leakage current. In the

case of motor cable is relatively long (longer than 50m), it is necessary to install AC

reactor or sinusoidal wave filter at the output side, and when it is even longer, it is

necessary to install one reactor at every certain distance.

4.7.3.5 EMC Filter

EMC filter has a great effect of electromagnetic decoupling, so it is preferred for customer

to install it.

For inverter, noise filter has following categories:

z Noise filter installed at the input side of inverter;

z Install noise isolation for other equipment by means of isolation transformer or

Wiring

32

power filter.

5. OPERATION

5.1 Keypad Description

5.1.1 Keypad schematic diagram

Figure 5.1 Keypad schematic diagram.

5.1.2 Key function description

Button

Symbol

Name Function Description

Programming

Key

Entry or escape of first-level menu.

Enter Key Progressively enter menu and confirm parameters.

Operation

33

UP Increment

Key

Progressively increase data or function codes.

DOWN

Decrement Key

Progressive decrease data or function codes.

+

Combination

Key

Cyclically displays parameters by left shift, In the

stop or running status. Note that when operation,

should firstly press and hold the DATA/ENT key and

then press the QUICK/JOG key.

Shift Key

In parameter setting mode, press this button to

select the bit to be modified. In other modes,

cyclically displays parameters by right shift

Run Key Start to run the inverter in keypad control mode.

STOP/RESET

Key

In running status, restricted by P7.04, can be used to

stop the inverter.

When fault alarm, can be used to reset the inverter

without any restriction.

Shortcut

Multifunction

Key

Determined by Function Code P7.03:

0: Jog operation

1: Switch between forward and reverse

2: Clear the UP/DOWN settings.

3: Quick debugging mode1 (by menu)

4: Quick debugging mode2 (by latest order)

5: Quick debugging mode3 (by non-factory setting

parameters)

+

Combination

Key

Pressing the RUN and STOP/REST at the same

time can achieve inverter coast to stop.

5.1.3 Indicator light description

5.1.3.1 Function Indicator Light Description

Indicator Light

Name

Indicator Light Description

RUN/TUNE

Extinguished: stop status

Flickering: parameter autotuning status

Light on: operating status

FWD/REV

Extinguished: forward operation

Operation

34

Light on: reverse operation.

LOCAL/REMOT

Extinguished: keypad control

Flickering: terminal control

Light on: communication control

TRIP

Extinguished: normal operation status

Flickering: overload pre-warning status

5.1.3.2 Unit Indicator Light Description

Symbol Description

Hz Frequency unit

A Current unit

V Voltage unit

RPM Rotation speed unit

% Percentage

5.1.3.3 Digital Display

Have 5 digit LED , which can display all kinds of monitoring data and alarm codes such as

reference frequency, output frequency and so on.

5.2 Operation Process

5.2.1 Parameter setting

Three levels of menu are:

z Function code group (first-level);

z Function code (second-level);

z Function code value (third-level).

Remarks:

Press both the PRG/ESC and the DATA/ENT can return to the second-class menu from

the third-class menu. The difference is: pressing DATA/ENT will save the set parameters

into the control panel, and then return to the second-class menu with shifting to the next

function code automatically; while pressing PRG/ESC will directly return to the

second-class menu without saving the parameters, and keep staying at the current

function code

Operation

35

Figure 5.2 Flow chart of parameter setting.

Under the third-class menu, if the parameter has no flickering bit, it means the function

code cannot be modified. The possible reasons could be:

z This function code is not modifiable parameter, such as actual detected parameter,

operation records and so on;

z This function code is not modifiable in running status, but modifiable in stop status

5.2.2 Fault reset

If the inverter has fault, it will prompt the related fault information. User can use

STOP/RST or according terminals determined by P5 Group to reset the fault. After fault

reset, the inverter is at stand-by state. If user does not reset the inverter when it is at fault

state, the inverter will be at operation protection state, and can not run.

5.2.3 Motor parameter autotuning

If “Sensorless Vector Control” mode is chosen, motor nameplate parameters must be

input correctly as the autotuning is based on it. The performance of vector control

depends on the parameters of motor strongly, so to achieve excellent performance, firstly

must obtain the parameter of motor exactly.

The procedure of motor parameter autotuning is as follows:

Firstly, choose the keypad command channel as the operation command channel

(P0.01).

And then input following parameters according to the actual motor parameters:

P2.00: motor rated power.

P2.01: motor rated frequency;

P2.02: motor rated speed;

P2.03: motor rated voltage;

P2.04: motor rated current

Notice: the motor should be uncoupled with its load; otherwise, the motor

parameters obtained by autotuning may be not correct.

Set P0.12 to be 1, and for the detail process of motor parameter autotuning, please refer

to the description of Function Code P0.12. And then press RUN on the keypad panel, the

inverter will automatically calculate following parameter of the motor:

Operation

36

P2.05: motor stator resistance;

P2.06: motor rotor resistance;

P2.07: motor stator and rotor inductance;

P2.08: motor stator and rotor mutual inductance;

P2.09: motor current without load;

then motor autotuning is finished.

5.2.4 Password setting

CHE series inverter offers user’s password protection function. When P7.00 is set to be

nonzero, it will be the user’s password, and After exiting function code edit mode, it will

become effective after 1 minute. If pressing the PRG/ESC again to try to access the

function code edit mode, “0.0.0.0.0”will be displayed, and the operator must input correct

user’s password, otherwise will be unable to access it.

If it is necessary to cancel the password protection function, just set P7.00 to be zero.

5.3 Running State

5.3.1 Power-on initialization

Firstly the system initializes during the inverter power-on, and LED displays “-CHE-”. After

the initialization is completed, the inverter is on stand-by status.

5.3.2 Stand-by

At stop or running status, parameters of multi-status can be displayed. Whether or not to

display this parameter can be chosen through Function Code P7.06(Running status

display selection ) and P7.07 (Stop status display selection) according to binary bits, the

detailed description of each bit please refer the function code description of P7.06 and

P7.07.

In stop status, there are nine parameters which can be chosen to display or not. They are:

reference frequency, DC bus voltage, ON-OFF input status, open collector output status,

PID setting, PID feedback, analog input AI1 voltage, analog input AI2 voltage, step

number of multi-step speed. Whether or not to display can be decided by setting the

corresponding binary bit of P7.07. Press the 》/SHIFT to scroll through the parameters in

right order . Press DATA/ENT + QUICK/JOG to scroll through the parameters in left

order.

5.3.3 Motor parameter autotuning

For details, please refer to the description of P0.12.

5.3.4 Operation

In running status, there are fourteen running parameters: output frequency, reference

frequency, DC bus voltage, output voltage, output current, output power, output torque,

PID setting, PID feedback, ON-OFF input status, open collector output status, length

value, count value, step number of PLC and multi-step speed, voltage of AI1, voltage of

AI2 and step number of multi-step speed. Whether or not to display can be decided by the

Operation

37

bit option of Function Code P7.06 (converted into binary system). Press the 》/SHIFT to

scroll through the parameters in right order . Press DATA/ENT + QUICK/JOG to scroll

through the parameters in left order.

5.3.5 Fault

CHE series inverter offers a variety of fault information. For details, see inverter faults and

their troubleshooting.

5.4 Quick Testing

Operation

38

Figure 5.3 Quick testing.diagram

6. DETAILED FUNCTION DESCRIPTION

6.1 P0 Group--Basic Function

Function

Code

Name Description

Setting

Range

Factory

Setting

P0.00

Control

mode

selection

0:Sensorless vector control

1:V/F control

2:Torque control

0~2 0

0: Sensorless vector control: It is widely used for the application which requires high

torque at low speed, higher speed accuracy, and quicker dynamic response, such as

machine tool, injection molding machine, centrifugal machine and wire-drawing machine,

etc.

1: V/F control: It is suitable for general purpose application such as pumps, fans etc.

2: Torque control: It is suitable for the application with low accuracy torque control, such

as wired-drawing. In torque control mode, the speed of motor is determined by load, the

rate of ACC/DEC has nothing to do with the value of P0.08 and P0.09 (or P8.00 and

P8.01).

Notice:

z Inverter can drive only one motor when P0.00 is set to be 0 or 2. When P0.00

is set to be 1, inverter can drive multi motors.

z The autotuning of motor parameters must be accomplished properly when

P0.00 is set to be 0 or 2.

z In order to achieve better control characteristic, the parameters of speed

regulator (P3.00~P3.05) must be adjusted according to actual situation when

P0.00 is set to be 0 or 2.

Function

Code

Name Description

Setting

Range

Factory

Setting

P0.01

Run

command

source

0: Keypad (LED extinguished)

1: Terminal (LED flickering)

2: Communication (LED lights

on)

0~2 0

The control commands of inverter include: start, stop, forward run, reverse run, jog, fault

Detailed Function Description

39

reset and so on.

0: Keypad (LED extinguished);

Both RUN and STOP/RST key are used for running command control. If Multifunction

key QUICK/JOG is set as FWD/REV switching function (P7.03 is set to be 1), it will be

used to change the rotating orientation. In running status, pressing RUN and

STOP/RST in the same time will cause the inverter coast to stop.

1: Terminal (LED flickering)

The operation, including forward run, reverse run, forward jog, reverse jog etc. can be

controlled by multifunctional input terminals.

2: Communication (LED lights on)

The operation of inverter can be controlled by the host through communication.

Function

Code

Name Description

Setting

Range

Factory

Setting

P0.02

UP/DOWN

setting

0: Valid, save UP/DOWN

value when power off

1: Valid, do not save

UP/DOWN value when

power off

2: Invalid

3: Valid during running, clear

when stop.

0~3 0

0: User can adjust the reference frequency by UP/DOWN. The value of UP/DOWN can

be saved when power off.

1: User can adjust the reference frequency by UP/DOWN, but the value of UP/DOWN will

not be saved when power off.

2: User can not adjust the reference frequency by UP/DOWN. The value of UP/DOWN

will be cleared if P3.05 is set to 2.

3: User can only adjust the reference frequency by UP/DOWN during the inverter is

running. The value of UP/DOWN will be cleared when the inverter stops.

Notice:

z UP/DOWN function can be achieved by keypad (∧ and ∨) and

multifunctional terminals.

z Reference frequency can be adjusted by UP/DOWN.

z UP/DOWN has highest priority which means UP/DOWN is always active no

matter which frequency command source is.

z When the factory setting is restored (P1.03 is set to be 1), the value of

UP/DOWN will be cleared

Function

Code

Name Description

Setting

Range

Factory

Setting

Detailed Function Description

40

P0.03

Frequency A

command

source

0: Keypad

1: AI1

2. AI2

3: AI1+AI2

4. Multi-Step speed

5: PID

6: Communication

0~6 0

0: Keypad: Please refer to description of P3.00

1: AI1

2: AI2

3:AI1+AI2

The reference frequency is set by analog input. CHE series inverter provides 2 analog

input terminals. AI1 is 0~10V voltage input terminal, while AI2 is 0~10V voltage input or

0~20mA current input. Voltage input or current input of AI2 can be selected by Jumper

J16.

Notice:

z When AI2 is set as 0~20mA current input, the corresponding voltage range is

0~5V. For detailed relationship between analogue input voltage and frequency,

please refer to description of P5.07~P5.11.

z 100% of AI is corresponding to maximum frequency(P0.04)

4: Multi-step speed

The reference frequency is determined by PA group. The selection of steps is determined

by combination of multi-step speed terminals.

Notice:

z Multi-step speed mode will enjoy priority in setting reference frequency if

P0.03 is not set to be 4. In this case, only step 1 to step 15 are available.

z If P0.03 is set to be 4, step 0 to step 15 can be realized.

Jog has highest priority.

5: PID

The reference frequency is the result of PID adjustment. For details, please refer to

description of P9 group

6: Communication

The reference frequency is set through RS485. For details, please refer to description of

Chapter 10.

Function

Code

Name Description Setting Range

Factory

Setting

P0.04

Maximum

frequency

P0.05~400.00Hz P0.05~400.00 50.00Hz

Notice:

z The frequency reference should not exceed maximum frequency.

Detailed Function Description

41

z Actual acceleration time and deceleration time are determined by maximum

frequency. Please refer to description of P0.08 and P0.09.

Function

Code

Name Description Setting Range

Factory

Setting

P0.05

Upper frequency

limit

P0.06~ P0.04 P0.06~P0.04 50.00Hz

Notice:

z Upper frequency limit should not be greater than the maximum frequency

(P0.04).

z Output frequency should not exceed upper frequency limit.

Function

Code

Name Description Setting Range

Factory

Setting

P0.06

Lower frequency

limit

0.00 Hz ~ P0.05 0.00~P0.05 0.00Hz

Notice:

z Lower frequency limit should not be greater than upper frequency limit

(P0.05).

z If frequency reference is lower than P0.06, the action of inverter is determined

by P1.12. Please refer to description of P1.12.

Function

Code

Name Description

Setting

Range

Factory

Setting

P0.07

Keypad reference

frequency

0.00 Hz ~

P0.04

0.00~P0.04 50.00Hz

When P0.03 is set to be 0, this parameter is the initial value of inverter reference

frequency

Function

Code

Name Description Setting Range

Factory

Setting

P0.08 Acceleration time 0 0.0~3600.0s 0.0~3600.0

Depend on

model

P0.09 Deceleration time 0 0.0~3600.0s 0.0~3600.0

Depend on

model

Acceleration time is the time of accelerating from 0Hz to maximum frequency (P0.04).

Deceleration time is the time of decelerating from maximum frequency (P0.04) to 0Hz.

Please refer to following figure.

Detailed Function Description

42

Figure 6.1 Acceleration and deceleration time.

When the reference frequency is equal to the maximum frequency, the actual

acceleration and deceleration time will be equal to the P0.08 and P0.09 respectively.

When the reference frequency is less than the maximum frequency, the actual

acceleration and deceleration time will be less than the P0.08 and P0.09 respectively.

The actual acceleration (deceleration) time = P0.08 (P0.09) * reference frequency/P0.04.

CHE series inverter has 2 groups of acceleration and deceleration time.

1st group: P0.07, P0.08

2nd group: P8.00, P8.01

The acceleration and deceleration time can be selected by combination of multifunctional

ON-OFF input terminals determined by P5 Group. The factory setting of acceleration and

deceleration time is as follow:

z 5.5kW and below: 10.0s

z 7.5kW~30kW: 20.0s

z 37kW and above: 40.0s

Function

Code

Name Description

Setting

Range

Factory

Setting

P0.10

Running

direction

selection

0: Forward

1: Reverse

2: Forbid reverse

0~2 0

Notice:

z The rotation direction of motor is corresponding to the wiring of motor.

z When the factory setting is restored (P0.13 is set to be 1), the rotation

direction of motor may be changed. Please be cautious to use.

z If P0.10 is set to 2, user can not change rotation direction of motor by

QUICK/JOG or terminal.

Function

Code

Name Description

Setting

Range

Factory

Setting

P0.11 Carrier frequency 0.5~15.0kHz 0.5~15.0

Depend on

model

Detailed Function Description

43

Figure 6.2 Effect of carrier frequency.

The following table is the relationship between power rating and carrier frequency.

Carrier f

Model

Highest Carrier f

( kHz )

Lowest Carrier f

( kHz )

Factory setting

( kHz )

G Model: 0.4kW~11kW

P Model: 0.75kW~15kW

15 1 8

G Model: 15kW~55kW

P Model: 18.5kW~75kW

8 1 4

G Model: 75kW~300kW

P Model: 90kW~315kW

6 1 2

Carrier frequency will affect the noise of motor and the EMI of inverter.

If the carrier frequency is increased, it will cause better current wave, less harmonic

current and lower noise of motor.

Notice:

z The factory setting is optimal in most cases. Modification of this parameter is

not recommended.

z If the carrier frequency exceeds the factory setting, the inverter must be

derated because the higher carrier frequency will cause more switching loss,

higher temperature rise of inverter and stronger electromagnetic

interference.

If the carrier frequency is lower than the factory setting, it is possible to cause less output

torque of motor and more harmonic current.

Function

Code

Name Description

Setting

Range

Factory

Setting

P0.12

Motor parameters

autotuning

0: No action

1: Rotation autotuning

2: Static autotuning

0~2 0

0: No action: Forbidding autotuning.

1: Rotation autotuning:

z Do not connect any load to the motor when performing autotuning and ensure

the motor is in static status.

Detailed Function Description

44

z Input the nameplate parameters of motor (P2.01~P2.05) correctly before

performing autotuning. Otherwise the parameters detected by autotuning will be

incorrect; it may influence the performance of inverter.

z Set the proper acceleration and deceleration time (P0.08 and P0.09) according

to the motor inertia before performing autotuning. Otherwise it may cause

over-current and over-voltage fault during autotuning.

z The operation process is as follow:

a. Set P0.12 to be 1 then press the DATA/ENT, LED will display “-TUN-” and

flickers. During “-TUN-” is flickering, press the PRG/ESC to exit autotuning.

b. Press the RUN to start the autotuning. LED will display “TUN-0”.

c. After a few seconds the motor will start to run. LED will display “TUN-1” and

“RUN/TUNE” light will flicker.

d. After a few minutes, LED will display “-END-”. That means the autotuning is

finished and return to the stop status.

e. During the autotuning, press the STOP/RST will stop the autotuning.

Notice: Only keypad can control the autotuning. P0.12 will restore to 0

automatically when the autotuning is finished or cancelled.

2: Static autotuning:

z If it is difficult to disconnect the load, static autotuning is recommended.

z The operation process is the same as rotation autotuning except step c.

Notice: The Mutual inductance and current without load will not be detected by

static autotuning, if needed user should input suitable value according to

experience.

Function

Code

Name Description

Setting

Range

Factory

Setting

P0.13

Restore

parameters

0: No action

1: Restore factory setting

2: Clear fault records

0~2 0

0: No action

1: Inverter restores all parameters to factory setting except P2 group.

2: Inverter clear all fault records.

This function code will restore to 0 automatically when complete the function operation.

Function

Code

Name Description

Setting

Range

Factory

Setting

P0.14 AVR function

0: Disabled

1: Enabled all the time

0~2 1

Detailed Function Description

45

2: Disabled during

deceleration

AVR ( Auto Voltage Regulation) function ensure the output voltage of inverter stable no

matter how the DC bus voltage changes. During deceleration, if AVR function is disabled,

the deceleration time will be short but the current will be big. If AVR function is enabled all

the time, the deceleration time will be long but the current will be small.

6.2 P1 Group--Start and Stop Control

Function

Code

Name Description

Setting

Range

Factory

Setting

P1.00

Start

Mode

0: Start directly

1: DC braking and start

0~1 0

0: Start directly: Start the motor at the starting frequency determined by P1.01.

1: DC braking and start: Inverter will output DC current firstly and then start the motor at

the starting frequency. Please refer to description of P1.03 and P1.04. It is suitable for the

motor which have small inertia load and may reverse rotation when start.

Function

Code

Name Description

Setting

Range

Factory

Setting

P1.01 Starting frequency 0.00~10.00Hz 0.00~10.00 1.5Hz

P1.02

Hold time of starting

frequency

0.0~50.0s 0.0~50.0 0.0s

z Set proper starting frequency can increase the starting torque.

z If the reference frequency is less than starting frequency, inverter will be at

stand-by status. The indicator of RUN/TUNE lights on, inverter has no output.

z The starting frequency could be less than the lower frequency limit (P0.06).

z P1.01 and P1.02 take no effect during FWD/REV switching.

Figure 6.3 Starting diagram.

Function

Code

Name Description