Invitrogen PowerEase 500, PowerEase 500 EI8600, PowerEase 500 EI8700, PowerEase 500 EI8675 Instructions For Use Manual

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

REMOTE INSPECTION

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

View

Instra

PowerEase® 500

Power Supply

Version D

032202

IM-8634

PowerEase® 500 Power Supply

A programmable power supply for electrophoresis

Catalog nos. EI8600, EI8700, EI8675

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

www.invitrogen.com

tech_service@invitrogen.com

ii

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Warning

Federal

Communications

Commission

Advisory

This equipment has been tested and found to comply with the limits for a Class

A digital device, pursuant to part 15 of the FCC rules. These limits are designed

to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user

will be required to correct the interference at their expense.

Changes or modifications not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

iii

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

iv

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Table of Contents

Warning.................................................................................................................................................................iii

Table of Contents...................................................................................................................................................v

Kit Contents ..........................................................................................................................................................vi

Description...........................................................................................................................................................vii

Safety Information................................................................................................................................................xi

Consignes De Securite ........................................................................................................................................xii

Sicherheits Anweisungen..................................................................................................................................xiii

Accessory Products............................................................................................................................................xiv

Introduction....................................................................................................................1

Overview................................................................................................................................................................ 1

Methods..........................................................................................................................3

Getting Started....................................................................................................................................................... 3

Operational Modes................................................................................................................................................ 4

Using PowerEase® 500.......................................................................................................................................... 5

Printing ................................................................................................................................................................. 12

Custom Methods ................................................................................................................................................. 13

Troubleshooting ..................................................................................................................................................16

Appendix ......................................................................................................................17

Warranty............................................................................................................................................................... 17

Run Conditions for Gels..................................................................................................................................... 18

Repair and Maintenance of PowerEase® 500................................................................................................... 19

Theory of Operation............................................................................................................................................ 20

Technical Service................................................................................................................................................. 21

v

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

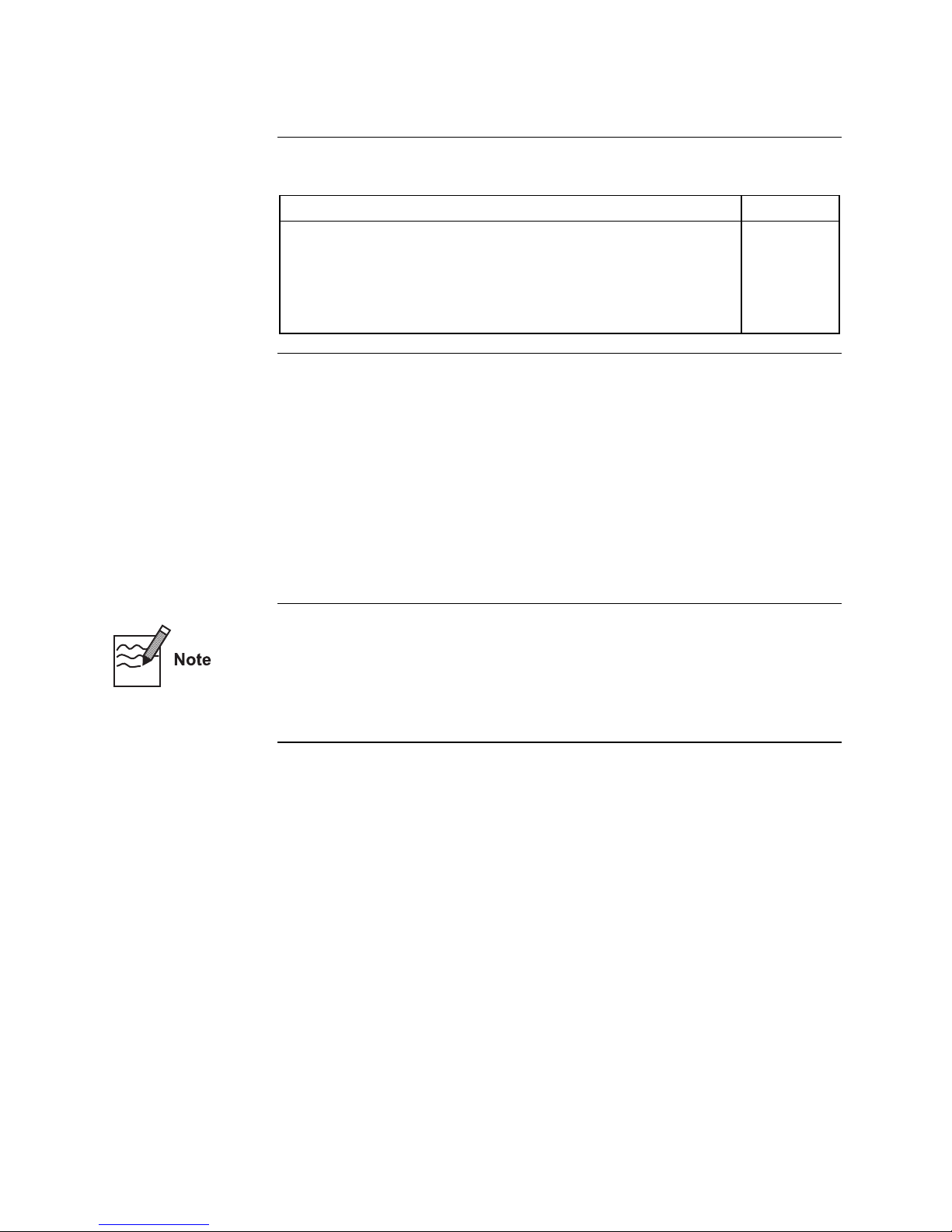

Kit Contents

Types of Kits

Kit Components

This manual is supplied with the following kits:

Kit Catalog no.

PowerEase® 500 Power Supply (100/120 Vac 50/60 Hz) EI8600

PowerEase® 500 Power Supply (220/240 Vac 50/60 Hz) EI8700

PowerEase® 500 Pre-Cast Gel System

includes PowerEase® 500, Temperature Monitoring Probe, XCell

SureLock™ Mini-Cell and XCell II™ Blot Module

EI8675

PowerEase® 500 Power Supply contains:

PowerEase

®

500 Power Supply 1 each

Instruction Manual 1 each

Extra Fuses 2 each

Power Cord (U.S., Canada, Europe, Taiwan and Japan) 1 each

Warranty Card 1 each

Temperature Probe (Optional) 1 each

See next page for specifications and detailed description of PowerEase

®

500

Power Supply.

To ensure safe, reliable operation, always operate the PowerEase® 500 Power

Supply in accordance with the manufacturer’s instructions. Always wear

protective gloves and safety glasses when working in a laboratory environment.

See safety information on pages xi-xiii.

Warranty information is provided on page 17.

vi

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Description

Specifications

Input Power

100/120 VAC 90-132V, 50/60 Hz, 100 watts at maximum load

Fuse One 1A/250V/AGC, fast blow fuse

220/240 VAC 198-264VAC, 50/60 Hz, 260 mA at maximum load

Fuses Two F1A/250V/5x20 mm fast blow fuses

Output Range 1-500 V (minimum step size 1 V)

1-500 mA (minimum step size 1 mA)

0.1-50 W (minimum step size 0.1 W)

Automatic crossover on reaching set limits.

Accuracy Voltage: ± 2% or ± 2 volts

Current: ± 2% or ± 2 mA

Wattage ± 2% or ± 0.2 watt

Drift < 1% in 8 hours after 30 minute warm-up

with constant supply voltage

Circuit Protection Open Circuit; Short Circuit; Thermal Protection

Over Voltage, Current, Wattage

Safety Load Detection

Thermal Shutoff (with optional temperature probe)

Isolated Floating Ground

Memory Control Non-volatile, up to 24 hours

Custom Methods Stored to RAM

Computer Interface RS232C

Display LCD, view area 114 x 64 mm

240 x 128 dots

Temperature Ambient 4-30°C

Dimensions 16.5 cm (w) x 18 cm (h) x 20.5 cm (d)

Weight 2.9 kg (6.4 lbs)

Environmental

Conditions ≤ 100% RH, 75 KPa-106 KPa

vii

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Continued on next page

Description, Continued

Front View of

PowerEase

®

500

1

8

POWER

5

+

2

S

3

R

A

T

T

S

O

P

T

1. LCD Screen

2. Power Output Jacks, Positive (Red)

3. Power Output Jacks, Negative (Black)

4. Temperature Probe Jack

5. Functional Keys (Power, Start, Stop)

6. Directional Keys (Up, Down, Left, Right)

7. High Voltage LED

8. Power LED

P

SELECT

o

w

r

e

HIGH VOLTAGE

5

e

s

a

E

TEMP

7

0

0

6

4

viii

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Continued on next page

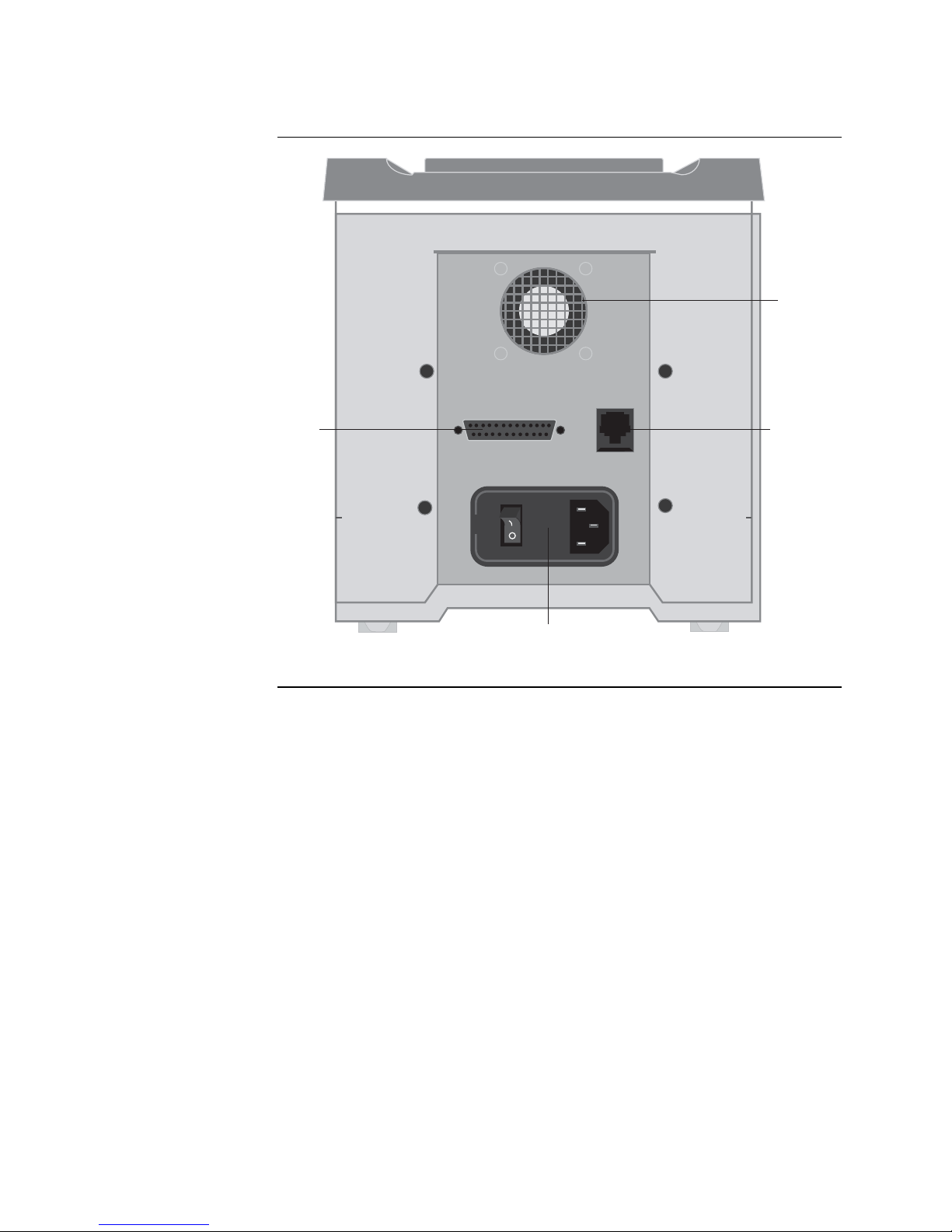

Description, Continued

Rear View of

PowerEase

®

500

Fan

Printer

Port

PRINTER

Power Entry Module

with On/Off

main power switch

RS232

RS232C

Communication

Port

Continued on next page

ix

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

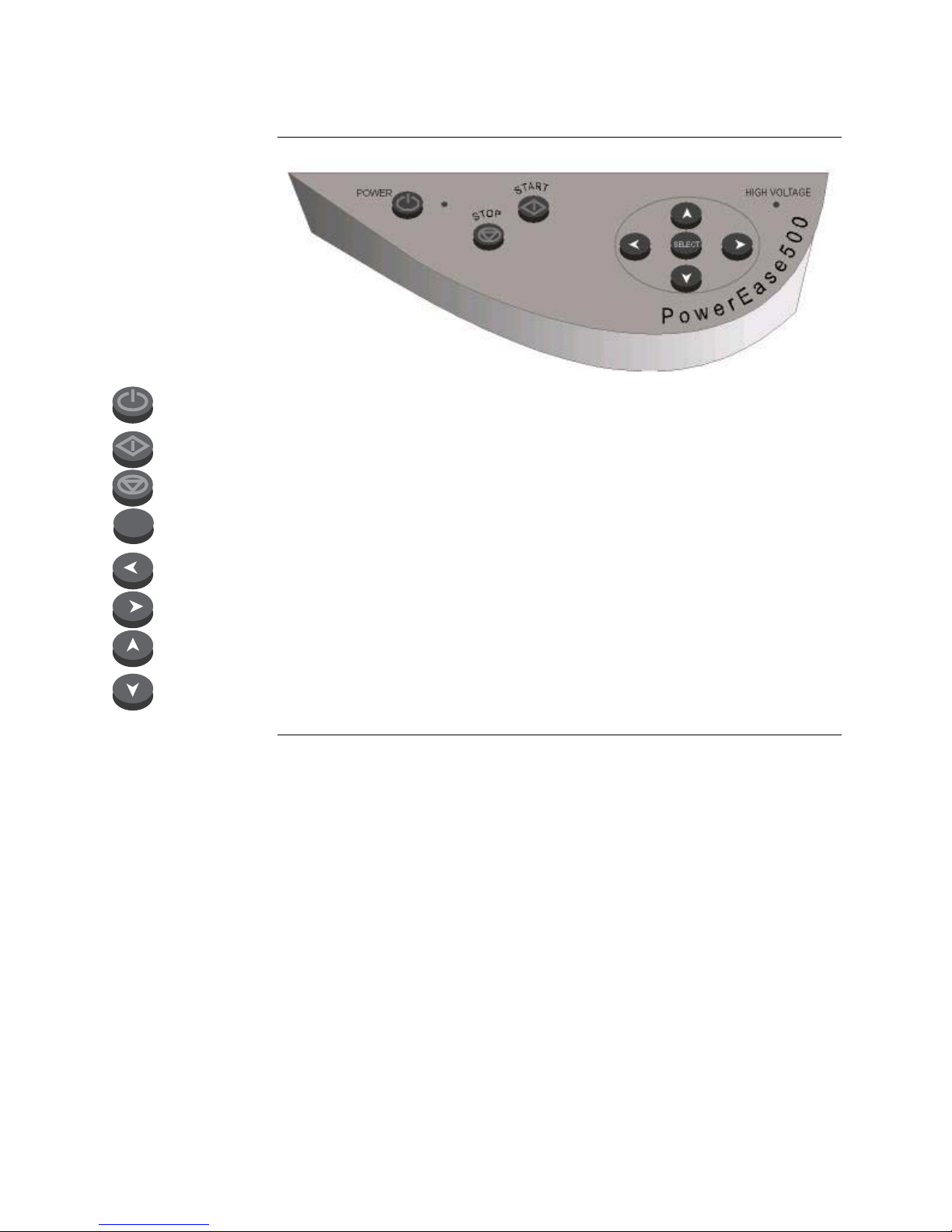

Description, Continued

Key Pad

Power button secondary On/Off switch for the high voltage components, fan, and LCD

SELECT

screen.

Start button used to start a selected method program.

Stop button used to end the selected method and to backup to a previous screen.

Select button used to select a menu choice and to move forward to the next applicable

screen.

Left directional button for moving left around the menu.

Right directional button for moving right around the menu.

Up directional button for moving up around the menu and to adjust numerical and

character values (higher).

Down direction button for moving down around the menu and to adjust numerical and

character values (lower).

x

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Safety Information

Avoiding

Electrical Shock

Avoiding Damage

to the Instrument

The PowerEase® 500 Power Supply produces high voltage outputs which are

electrically isolated from earth ground to reduce the risk of electrical shock to

the user. Observe the following guidelines to ensure safe operation of the unit.

The PowerEase

electrophoresis cells with shielded banana plugs thus minimizing potential

shock hazard to the user. Invitrogen does not recommend use of other

unshielded banana plugs.

To avoid electrical shock:

1. NEVER connect or disconnect wire leads from the power jacks when the

amber high voltage indicator light is on.

2. WAIT at least 5 seconds after stopping a run before handling output leads

or connected apparatus.

3. ALWAYS make sure hands and work area is clean and dry before making

any connections or operating the power supply.

4. ONLY connect the power supply to a properly grounded AC outlet.

1. For proper ventilation, leave at least 10 cm of space behind the instrument,

and at least 5 cm of space on each side.

2. Do not operate the power supply in high humidity environments (> 95%), or

where condensation can occur.

3. To avoid condensation after operating the power supply in a cold room, wrap

the unit in a plastic bag and allow at least 2 hours for the unit to equilibrate to

room temperature before removing the bag and operating the unit.

®

500 Power Supply has been designed for use with

Symbols

The symbols used on the PowerEase® 500 Power Supply are explained below.

Used on the PowerEase® 500 Power Supply to indicate an area where a

potential shock hazard may exist.

Used on the PowerEase® 500 Power Supply to indicate a warning. Consult the

manual to avoid possible personal injury or instrument damage.

Used on the PowerEase

®

500 keypad to indicate the secondary Power button.

Used on the PowerEase

Used on the PowerEase

®

500 keypad to indicate the Start method button.

®

500 keypad to indicate the Stop method button.

xi

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Consignes De Securite

Consignes De

Securite

Pour éviter Tout

Choc électrique

Pour éviter

d’endommager

l’appareil:

Le PowerEase® 500 génère des courants de haut voltage; la construction du

système est faite suivant toutes précautions pour isoler l’utilisateur et éviter

tout choc électrique. Toutefois, il est impératif d’observer les consignes

suivantes pour éviter tout tisque lors de l’utilisation de l’appareil.

PowerEase

équipées avec des fiches banane protégées pour minimiser tout risque de choc

électrique. L’utilisation d’autres types d’équipments n’est pas recommandée

par Invitrogen et se fait aux risques et périls de l’utilisateur.

1. Ne jamais connecter ou déconnecter les cables des fiches quand l’indicateur

haut voltage est allumé..

2. Attendre un minimum de 5 secondes après avoir arrêté le courant avant de

manipuler le système.

3. Vérifier que vos mains sont séches et propres avant d’effectuer toute

connection.

4. Utiliser des prises de courant munies d’une connection à la terre.

1. Assurer une ventilation correcte, en laissant un minimum d’espace derrière

(10 cm) et sur les côtés (5 cm) de l’appareil.

2. N’utilisez pas le générateur dans un environement humide (> 95%) ou avec

des risques de condensation.

3. Pour éviter la condensation lors de l’utilisation de l’appareil en chambre

froide, enveloppez-le dans une poche plastique et laisser l’appareil

s’équilbrer à la température ambiante avant de retirer le sac et de l’utiliser.

®

500 est destiné à être utilisé avec des curves d’electrophorèse

Signification des pictogrammes

Sur le PowerEase® 500, signale les zones où un risque de choc électrique peut

exister.

Sur le PowerEase® 500, signale un risque potentiel pour l’utilisateur ou pour

l’equipement. Veuillez consulter le mode d’emploi.

Sue le panneau du PowerEase

Sur le panneau du PowerEase

Sur le panneau du PowerEase

®

500; bouton d’alimentation secondaire.

®

500; permet de démarrer une méthode.

®

500; bouton d’interruption.

xii

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Sicherheits Anweisungen

Sicherheits

Anweisungen

So verhindern Sie

eine Gefährdung

durch

Stromschlag

Das PowerEase® 500 Stromversorgungsgerät produziert GleichstromHochspannung, die elektrisch getrennt ist vom Erdleiter, um das Risiko des

Benutzers für einen Stromschlag zu minimieren. Trotzdem sollten folgende

Sicherheitsrichtlinien beachtet werden, damit ein einwandfreier Betrieb des

Gerätes gewährleistet ist.

Das PowerEase

Elektrophoresezellen mit isolierten Bananen-Schutzkontaktsteckern. Somit ist

eine Gefährdung durch Stromschlag bei sachgerechter Benutzung ausge

schlossen. Die Verwendung von anderen, ungeschützten Bananensteckern

geschieht auf Risiko des Benutzers und Invitrogen rät ausdrücklich davon ab.

1. Stecken (oder ziehen) Sie niemals Kabel in die Stromausgangsbuchsen am

Gerät, wenn das gelbe Licht (Hochspannungs-Indikator) am

Bedienungsfeld leuchtet.

2. Warten Sie mindestens 5 Sekunden nach Beendigung und Ausschalten

eines Laufs, bevor Sie die Anschlubkabel der Zelle herausziehen.

3. Achten Sie darauf, dab die Arbeitsplatzumgebung der Zelle sauber und

rocken ist. Sie sollten niemals mit nassen Händen Gerät, Kabel oder

Steckverbindungen anfassen.

4. Schlieben Sie das PowerEase

230V Strombuchse an.

®

500 ist entwickelt worden für den Betrieb von

®

500 nur an eine einwandfrei geerdete 220-

Um Beschädigung

des Geräts zu

vermeiden

Symbolerklärung

1. Achten Sie auf wenigstens 10 cm Platz hinter und 5 cm neben dem Gerät,

um seine eingebaute Kühlventilation nicht zu beeinträchtigen.

2. Verwenden Sie das Gerät nicht in Räumen mit hoher Luftfeuchtigkeit

(>95%) oder wo es Wasserdampfkondensation ausgesetzt ist.

3. Ist das Gerät in einem Kühlraum verwendet worden, und soll es nach der

Benutzung wieder unter Normaltemperaur arbeiten, ist es vor der

Umsetzung in eine Kunststoffhülle zu packen. Es soll mindestens 2 Stunden

darin auf die neue Umgebungstemperatur angepasst werden, bevor die

Hülle entfernt und das Gerät wieder in Betrieb genommen wird.

Weist auf eine Zone hin, wo Gefährdung durch Stromschlag besteht.

Lesen Sie die Bedienungsanleitung, um Verletzungen oder Beschädigung des

Gerätes zu vermeiden.

1st der 2. Bertiebsschalter auf dem PowerEase

Start—Knopf auf dem Bedienungsfeld für eine programmierte Methode.

Stop—Knopf auf den Bedienungsfeld für einen Elektophorese—Lauf.

®

500—Bedienungsfeld.

xiii

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Accessory Products

Additional

Products

Additional products that can be used with the PowerEase® 500 Power Supply

or replacement parts for PowerEase

from Invitrogen. For more information, contact Technical Service (see page 21)

or visit our Web site at www.invitrogen.com.

Temperature Monitoring Probe 1 EI8644

RS232 Cable and Adaptor 1 EI8663

Fuses 1A/250V/3AGL Fast Blow (100-120VAC units) 2 EI8670

Fuses F1A/250V/5x20mm Fast Blow (220-240V units) 4 EI8671

XCell SureLock™ Mini-Cell 1 unit EI0001

XCell II™ Blot Module 1 unit EI9051

®

500 Power Supply are available separately

Product Quantity Catalog no

xiv

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Overview

Introduction

Features of

PowerEase® 500

Introduction

The PowerEase® 500 Power Supply is a microprocessor-controlled power supply

for electrophoresis of pre-cast and hand-poured mini-gels. The power supply is

designed to simplify electrophoresis by combining high performance and

programming flexibility with ease of use when running mini-gel and blotting

applications.

The PowerEase

you need to think only about the electrical parameters and limits for a single gel.

This manual describes the setup and operation of PowerEase

including important information on safety and maintaining the unit.

The important features of PowerEase® 500 Power Supply are listed below:

• Large LCD display allows electrical parameters to be displayed in either

graphical or numerical formats

• Eight pre-programmed methods for running and blotting Novex

mini-gels

• Four custom methods for running your custom applications

• Simple three step operating procedure to start running or blotting Novex

pre-cast gels

• Microprocessor control provides highly accurate electrical outputs resulting

in exceptional blotting capability

• Parallel port for printing experimental results to most printers

• Optional Temperature Probe to continuously monitor the buffer temperature

and shut the unit down in the event of overheating

• Two sets of output jacks allows electrophoresis of multiple mini-cell units in

constant voltage, current, or watts

®

500 Power Supply is designed around the single gel concept:

®

500 Power Supply

®

pre-cast

®

1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Continued on next page

Overview, Continued

Flowchart

The flowchart below describes the various screens displayed on the PowerEase®

500 Power Supply and the keypad buttons (Start, Stop or Select) used to

navigate through the screens.

Power ON

Start-Up Screen

Start/Select

Gel Method Screen

Select

Gel Quantity Screen

Method Edit Screen

Method Run Large Display

Select

Method Run Large Display

StopStart

Previous Screen

Method Run Graphic Display

Start

Select, once Select, twice

Method Run Graphic Display

Stop

Previous Screen

Select

Method Run/Edit Screen

Select, onceSelect, twice

Method Run Large Display

2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Getting Started

Installing

PowerEase

®

500

Installing an

Optional Printer

1. Place the PowerEase® 500 Power Supply on a level bench. Keep the area

2. Position the unit properly such that the On-Off switch and the power cord

3. Check the label located near the power entry module to ensure that the unit

The PowerEase® 500 Power Supply has a DB25 parallel connector located on the

rear of the unit. This allows the PowerEase

of your electrophoresis results in ASCII format to most commonly available

printers.

Use the following steps to install a printer:

1. Using a parallel printer cable, connect the male DB25 end of the printer cable

2. Connect the opposite end of the cable into the appropriate connector on the

Methods

around the power supply clear to ensure proper ventilation of the unit.

attachment module located on the rear of the unit are easily accessible.

is of the proper local voltage. Attach the power cord to the power entry

module. Use only properly grounded AC outlets.

®

500 Power Supply to print a report

into the port marked “Printer” located on the rear of the PowerEase

Power Supply.

printer. Refer the user manual of your printer for instructions on connecting

the cable to the printer.

®

500

Installing an

Optional

Temperature

Probe

If you have ordered the Temperature Monitoring Probe, follow the instructions

below to install the probe:

1. Unpack the Temperature Monitoring Probe and inspect for any possible

damage to the wire or connector which may have occurred during shipping.

2. Plug the connector end of the Temperature Monitoring Probe into the port

located at the front lower right corner of the PowerEase

®

500 Power Supply

marked “TEMP”.

3. Place the opposite end of the Temperature Monitoring Probe with the bluecolored bead into an electrophoresis cell buffer chamber to display

temperature on the LCD screen of the PowerEase

can bent the wire, but avoid crimping or pinching the wire. Temperature will

be displayed at all times even when the PowerEase

®

500 Power Supply. You

®

500 Power Supply is

stopped.

3

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Operational Modes

Introduction

Voltage Limiting

Current Limiting

The PowerEase® 500 Power Supply is capable of operating at limiting voltage,

limiting current, and limiting power. We recommend operating the PowerEase

500 Power Supply at limiting voltage for most applications. See below for more

details.

The recommended setting for operating the PowerEase® 500 Power Supply is

voltage limited. For most electrophoresis methods, resistance increases

throughout the run. Using voltage limiting provides the following advantages:

• Current and watts decrease throughout the run, providing a natural safety

margin.

• The same voltage setting can be used regardless of the number or thickness

of gels being electrophoresed.

Discontinuous buffer systems and, to a lesser extent continuous systems,

increase resistance during the run. If you use the current limiting setting on the

PowerEase

to satisfy Ohm’s law (V=IR, see page 20). If no voltage limit is set and a local

fault condition occurs, such as a poor connection, very high local resistance

may cause the voltage to increase to a maximum of the power supply. This will

lead to local overheating and damage to the electrophoresis cell or create unsafe

conditions.

When running under constant current conditions, set a voltage limit on the

power supply at or slightly above the maximum expected voltage.

®

500 Power Supply, the voltage will increase as resistance increases

®

Wattage Limiting

If power is constant, voltage will increase and current will decrease during a

run, but the total amount of heat generated by the system will remain constant

throughout the run. However, locally high resistance can cause a high

proportion of the total heat to be generated over a small distance. This can

damage the electrophoresis cell and/or gel(s).

If operating at wattage limiting, set the voltage limiting to slightly above the

maximum expected for the run.

4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Using PowerEase® 500

Introduction

Starting

PowerEase® 500

You can operate the PowerEase® 500 Power Supply immediately after

installation using three simple steps (see below). For programming custom

settings, see page 13.

1. Plug the power cord of the PowerEase® 500 Power Supply into an available

electrical outlet rated at the appropriate electrical values for the power

supply.

2. Turn on the main power switch located on the rear of the PowerEase

Power Supply (see page ix for rear view of PowerEase

Always leave this switch in the ON position to keep the back-up battery fully

charged.

3. Press the Power button located on the keypad (see page x for a figure of the

keypad). This Power button is a secondary power button and does not

actually shut the instrument down, but shuts down the high voltage, fan,

and LCD screen. When powered back up, the LCD screen will revert to the

same screen as when the secondary power was shut off.

4. A Start-Up screen will appear (see next page).

To avoid condensation, the main power switch located on the rear of the unit

should be left on between use during operation in a cold room or in high

humidity environments.

®

®

500 Power Supply).

500

Operating

PowerEase

®

500

A simple operating procedure of the PowerEase® 500 Power Supply is provided

below. For more details on the different screens and custom methods, see pages

5-13.

1. Turn on the PowerEase

®

500 Power Supply.

2. Press Select once the Start-Up screen appears.

3. Select your gel type from the Gel Method screen.

4. Choose the number of gels to be electrophoresed from the Gel Quantity

screen.

5. Press the Start button to begin electrophoresis.

Note: To reset the PowerEase

®

500 Power Supply, press the Stop button.

The maximum number of Novex® mini-gels that can be electrophoresed at the

same time using PowerEase

®

500 Power Supply and the XCell SureLock™ Mini-

Cell is listed below:

Gel Type Number of Gels

Novex

NuPAGE

NuPAGE

®

Tris-Glycine Gels 10 gels

®

Novex Tris-Acetate Gel 6 gels

®

Novex Bis-Tris Gels 2 gels

Novex® Tricine Gels 4 gels

Novex

®

TBE-Urea gels 10 gels

5

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Continued on next page

Using PowerEase® 500, Continued

Start-Up Screen

Gel Method

Screen

The Start-Up screen is the first screen to appear after pressing the Power button

on the keypad.

Press the Select button to advance to the Gel Method screen.

Note: After first use, the last screen previously in use will appear after shutting

the power off and back on again.

The Gel Method screen (see figure below) allows you to select from a choice of

eight pre-programmed methods for Novex

methods.

1. Use the directional arrow buttons to navigate through the menu.

2. Press the Select button to choose the method. You will advance to the Gel

Quantity screen (see next page) if a pre-programmed method is chosen, or to

the Custom Method Option screen (see page 13) if a user defined method is

selected.

Note: The pre-programmed method durations are set to the shortest run time per

gel type, or buffer level and buffer strength to prevent over-running a gel.

Different percentage gels within a single gel type can cause a gel to take longer to

run. Additional time can be added to the pre-programmed method before,

during, and after a run (see page 11). The estimated durations for different

percentage Novex

®

mini-gels are listed on page 18.

®

mini-gels or four user-defined

6

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Tris-Gly Gel

TBE Gel

IEF Gel

Western Blot

User-Custom1

User-Custom3

SELECT to continue

Tricine Gel

TBE-Urea Gel

NuPAGE Gel

NuPAGE Blot

User-Custom2

User-Custom4

and moves cursor

Continued on next page

Using PowerEase® 500, Continued

Gel Quantity

Screen

The Gel Quantity screen (see figure below) allows you to scale the preprogrammed method’s current and power values by the number of gels that are

to be run.

1. Use the Up and Down arrows on the keypad to increase or decrease the

number of gels from 1 to the maximum allowable quantity of gels which can

be run for the specified method.

2. Press the Start button to begins the electrophoresis. The Method Run Large

Display screen will be displayed.

3. If you need to edit any electrophoresis parameters, press the Select button to

advance to the Method Edit screen (see page 10).

The Stop button returns you to the Gel Method screen (or the Custom Method

Options screen if a custom method is in use).

If the number of gels selected causes the current to be scaled such that the

PowerEase

error message “Power Limit Reached” will be displayed. Similarly, if the current

exceeds 500 mA, an error message “Current Limit Reached” will be displayed.

Change the number of gels appropriately to continue electrophoresis.

Note: Avoid changing the number of gels during the run, unless gels are

removed during the run. If you would prefer to see the total output parameters,

leave the gel number at “1” before starting.

®

500 Power Supply maximum power limit of 50 watts is exceeded, an

Tris-Glycine Gel

Number of

Gels to be run:

START begins; SELECT edits

2

adjust number of gels

Continued on next page

7

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Using PowerEase® 500, Continued

Method Run Large

Display

The Method Run Large Display screen (see figure below) is displayed after the

Start button is pressed from the Gel Quantity screen or the Method Edit

screen. This screen displays the status of the method during a run in an easy to

read format. The screen displays:

• Selected Method

• Status (running or paused)

• Number of Gels

• Run Condition (Limiting Parameters)

• Actual Voltage and Current (large display)

• Step Time Remaining

• Present Step Number

• Actual Wattage (small display)

• Detected Temperature (if installed)

Pressing the Select button once takes you to the Method Run Graphic Display

screen (see next page) and to the Method Run/Edit screen (see page 11) if

pressed twice.

The Stop button pauses the run if pressed once, stops the method if the method

is already in the paused state and takes you to the Method Edit screen.

To resume, press the Start button.

Tris-Glycine Gel

Voltage is constant

125V

30mA

SELECT views; STOP pauses

RUNNING

Time

Left: 0:07

Step:

Power:

Temp:

2

Gels

1

2W

24oC

Continued on next page

8

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Using PowerEase® 500, Continued

Method Run

Graphic Display

The Method Run Graphic Display screen (see figure below) is displayed after

the Select button is pressed from the Method Run Large Display screen. This

screen displays the status of the method during a run in a graphical format. The

screen displays:

• Selected Method

• Status (running or paused)

• Present Run Time

• Voltage, Current, and Wattage (applied during the run)

• Run Condition (Limiting Parameter)

The Select button takes you to the Method Run/Edit screen (see page 11).

The Stop button pauses the run if pressed once, stops the method if pressed

twice and takes you to the Method Edit screen.

To resume, press the Start button.

IEF Gel

RUNNING

500V

c

u

r

r

e

n

t

v

o

l

t

s

p

o

w

e

r

6mA

2:07

2W

SELECT views; STOP pauses

Continued on next page

9

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Using PowerEase® 500, Continued

Method Edit

Screen

The Method Edit screen (see figure below) is displayed after the Select button is

pressed from the Gel Quantity screen. The Method Edit screen allows you to

edit the following method parameters:

• Step Duration

The maximum step duration is 24 hours. If the duration is set to zero, the

step will be deleted and all following steps will be moved up. If you set an

empty step to non-zero, the voltage, current, and wattage settings from the

previous line will be copied.

• Step Voltage Limit

• Step Current Limit

• Step Power Limit

• Load Check State

The Load Check state is either ON or OFF, and determines whether or not

the PowerEase

®

500 Power Supply unit will detect ‘No Load’ conditions. The

default value for Load Check is ON and is the recommended state.

• Gel Quantity

The gel quantity limit determines the maximum voltage, current, and

wattage for the step. Values must be in the range of 1 to 500 volts, 1 to

500 mA, and 0.1 to 50 watts for one gel (the values for current and watts will

be reduced if multiple gels are selected).

If you have changed a pre-programmed method, the method will always run as

edited until you cycle back to the Gel Method screen. At this point the preprogrammed method will revert to the default parameters.

To edit the parameters on this screen:

1. Press the Left or Right arrow buttons to move the cursor between different

fields. As the cursor moves from field to field, a status message on LCD

display is updated to show the affected parameters if changes are made.

2. Use the Up and Down buttons to adjust field values.

3. Press the Start button to begin the run and change the display to the monitor

state. The Stop button takes you to the Gel Quantity screen (see page 7).

10

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Tris-Glycine Gel

Step Time Limits

1

2

3

START begins; STOP for prior

1:30

moves cursor

adjusts run time

125V

Load Check: ON

24oC

100 mA 18.0W

Continued on next page

Using PowerEase® 500, Continued

Method Run/Edit

Screen

The Method Run/Edit screen (see figure below) is displayed after the Select

button is pressed from the Method Run Large Display screen or the Method

Run Graphic Display screen. This screen displays the status of the method

during a run and allows you to edit parameters during the run for the current

step displayed on this screen.

The screen displays:

• Selected Method

• Status (running or paused)

• Number of Gels

• Total Time Elapsed

• Run Condition (limiting parameter or error condition if detected)

• Detected Temperature (if probe is installed)

• Present Step Number

• Present Parameter Set Points

• Step Time Elapsed

• Actual Voltage, Current and Wattage

Make the appropriate change using the directional arrow keys and press the

Start button.

The Select button takes you to the Method Run Large Display if pressed once,

and to the graphic display if pressed twice.

The Stop button pauses the run if pressed once and stops the method if the

method is already paused.

11

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Printing

Print Screen

PowerEase® 500 Power Supply is equipped with a parallel port, allowing you to

print your electrophoresis report.

1. If you wish to print a report, you need to connect the PowerEase

Supply to a printer. See page 3 for Installing an Optional Printer.

2. After a run is completed (time left must be zero), the message “START prints

STOP quits” is displayed at the bottom of the screen.

3. Press the Start button to print a report reflecting voltage, current, watts, and

temperature changes which occurred during the run.

An example of a report is shown below:

Method name: IEF Gel

Run Data:

Time Voltage Current Power Resistance Temp

Step hh:mm V mA W Kohms °C

1 0:05 100 3.7 0.4 27.31 24

0:10 100 3.2 0.4 32.55 24

0:15 100 2.8 0.3 39.23 24

0:20 100 2.3 0.2 45.71 23

0:25 100 2.1 0.1 54.33 23

®

500 Power

12

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Custom Methods

Custom Method

Options Screen

The Custom Method Options screen (see figure below) allows you to program a

custom method. The screen displays the following menu choices:

• Edit or Run Method

• Save Method

• Change Method name

• Reset Method

1. Use the Up and Down arrow buttons to choose from the menu items.

2. Press the Select button to select the current menu choice.

The Stop button returns you to the Gel Method screen (see page 6).

Menu for User-Custom1

Edit or Run Method

Save Method

Change Method name

Reset Method

SELECT chooses; STOP for prior

moves cursor

Edit or Run

Method

The Edit or Run Method option displays the Gel Quantity screen (see figure

below) for the pre-programmed methods. Enter the number of gels to be run and

press Start to begin the run.

User-Custom1

Number of

Gels to be run:

1

adjust number of gels

START begins; SELECT edits

If you need to edit run parameters, press Select to display the Method Edit

screen (see figure below).

User-Custom1

Step Time Limits

1

0:30

2

0:30

3

1:00

100V

200V

500V

Load Check: ON

25mA 2.5W

50mA

110mA

9.0W

50.0W

24oC

13

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

moves cursor

adjusts run time

START begins; STOP for prior

Continued on next page

Custom Methods, Continued

Save Method

Change Method

Name

The Save Method option saves any changes made to the method during the

previous editing session. It is not necessary to save the method before the

method is run. Method is saved to RAM.

The Change Method Name screen (see figure below) allows you to change a

custom method user name. The screen displays the current default custom

method user name (i.e. User-Custom1) and a new name field that is used to

change the default method user name.

1. Use the Left or Right arrow buttons to change the current character (only

capital letters, numbers 0 to 9, and a few other characters such as “-” and “\”

are available).

2. Press the Start button to delete the character directly under the cursor and all

remaining characters to the right of the cursor.

3. Press the Select button to accept the new name as the name of the method

and return you to the Custom Method Options screen. The Stop button

abandons changing the method name and returns you to the Custom

Method Options screen.

Change Method Name

Old Name:

User-Custom1

ZYMOGRAMNew Name:

START erases remaining chars

SELECT to accept; STOP exits

changes letter

moves cursor

Continued on next page

14

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Custom Methods, Continued

Reset Method

The Reset Method screen returns all method parameters including the custom

name back to the original default parameters.

1. To reset, choose “Yes” with the Left button and then press the Select

button.

2. The custom method is cleared and the Gel Method screen is displayed.

Choosing “No” and pressing the Select button, or pressing the Stop button

returns you to the Custom Method Options screen.

User-Custom1

Method will be reset to

default values. Is this OK?

Yes

moves cursor

SELECT choice

NO

15

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Troubleshooting

Introduction

Problem Cause Solution

The LCD screen remains

blank and the fan does not

come on when the main

power is turned on

Display shows PAUSE

and Load Error

Display shows PAUSE

and Hardware Error

Display shows PAUSE and

Temperature Error (if

temperature probe is

connected)

“Current Limit Reached” is

displayed on the Gel

Quantity screen

“Power Limit Reached” is

displayed on the Gel

Quantity screen

Review the information in the table below to troubleshoot your experimental

results.

Power cord not connected or the

fuse has blown

Secondary power off

Electrophoresis cell(s) are not

connected, are disconnected

during the run, or there is a

broken connection in the

electrophoresis cell

High resistance due to tape left on

a pre-cast gel, incorrect buffer

concentration, or incorrect buffer

volumes in the electrophoresis cell

--

Buffer temperature exceeds the

preset temperature limit

Number of gels selected exceeds

the set current limit

Number of gels selected exceeds

the set power limit

Check power cord connections at

both ends or replace the fuse (see

page 19).

Press the Power button on the

keypad.

Check the connections to the power

supply and on your electrophoresis

cell to make sure the connection is

intact.

Press the Stop button.

Correct the condition by making

sure the tape is removed from the

pre-cast gel, buffers are prepared

correctly, and the recommended

volume of buffer is added to the

electrophoresis cell.

Restart the method.

Reset unit by holding front panel

Power button down while switching

rear power switch off and then on

again. Release front Power button.

Check the run conditions for the

correct current and power settings.

Make sure the buffer is prepared

correctly.

Raise the temperature limit.

Number of gels is limited by the

maximum current available.

Decrease the number of gels or

change the current settings.

Number of gels is limited by

maximum power available.

Decrease the number of gels or

change the power settings.

16

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Warranty

PowerEase® 500

Power Supply

Warranty

Appendix

Invitrogen warrants that this product will be free from defects in material and

workmanship for a period of one (1) year from date of purchase. If a defect is

present, Invitrogen will, at its option, repair, replace, or refund the purchase

price of this product at no charge to you, provided it is returned during the

warranty period. This warranty does not apply if the product has been damaged

by accident, abuse, misuse, or misapplication, or from ordinary wear and tear.

For your protection, items being returned must be insured against possible

damage or loss. This warranty shall be limited to the replacement of defective

products. IT IS EXPRESSLY AGREED THAT THIS WARRANTY WILL BE IN

LIEU OF ALL WARRANTIES OF FITNESS AND IN LIEU OF THE WARRANTY

OF MERCHANTABILITY.

17

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Run Conditions for Gels

Introduction

4% Tris-Glycine 125 V 90 minutes

6% Tris-Glycine 125 V 95 minutes

8% Tris-Glycine 125 V 100 minutes

10% Tris-Glycine 125 V 105 minutes

12% Tris-Glycine 125 V 110 minutes

14% Tris-Glycine 125 V 110 minutes

16% Tris-Glycine 125 V 115 minutes

18% Tris-Glycine 125 V 120 minutes

4-12% Tris-Glycine 125 V 105 minutes

4-20% Tris-Glycine 125 V 110 minutes

8-16% Tris-Glycine 125 V 105 minutes

10-20% Tris-Glycine 125 V 120 minutes

10% Tricine 125 V 70 minutes

16% Tricine 125 V 90 minutes

10-20% Tricine 125 V 75 minutes

10% Zymogram 125 V 100 minutes

12% Zymogram 125 V 110 minutes

4-16% Zymogram 125 V 100 minutes

6% TBE 100 V 65 minutes

10% TBE 100 V 100 minutes

20% TBE 200 V 105 minutes

4-20% TBE 200 V 70 minutes

6% TBE-Urea 180 V 45 minutes

10% TBE-Urea 180 V 60 minutes

15% TBE-Urea 180 V 80 minutes

IEF pH 3-7, Step 1 100 V 60 minutes

IEF pH 3-7, Step 2 200 V 60 minutes

IEF pH 3-7, Step 3 500 V 30 minutes

IEF pH 3-10, Step 1 100 V 60 minutes

IEF pH 3-10, Step 2 200 V 60 minutes

IEF pH 3-10, Step 3 500 V 30 minutes

NuPAGE® Novex 10% Bis-Tris with MES SDS Running Buffer 200 V 35 minutes

NuPAGE® Novex 4-12% Bis-Tris with MES SDS Running

Buffer

NuPAGE® Novex 10% Bis-Tris with MOPS SDS Running

Buffer

NuPAGE® Novex 4-12% Bis-Tris with MOPS SDS Running

Buffer

NuPAGE® Novex 7% Tris-Acetate 150 V 60 minutes

NuPAGE® Novex 3-8% Tris-Acetate 150 V 70 minutes

The estimated run duration for Novex® 1.0 mm thick mini-gel is listed below. A

1.5 mm thick gel will take 5-10 minutes longer than similar 1.0 mm thick gel.

Gel Type Voltage Approximate Duration

200 V 35 minutes

200 V 50 minutes

200 V 50 minutes

18

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Repair and Maintenance of PowerEase® 500

Introduction

On Receiving the

Instrument

For a Problem

Requiring Service

Replacing the

Fuse

The PowerEase® 500 Power Supply requires no periodic maintenance program

with the exception of an occasional wipe-down of the instrument to remove salt

deposits which may built up over time.

Examine the unit carefully for any damage inflicted during transit. Any damage

claims must be filed with the carrier. The warranty does not cover in-transit

damage.

1. Check the troubleshooting section on the previous page.

2. Call Technical Service (see page 21).

3. If the unit must be shipped back for repair, contact Invitrogen or the

distributor for a Return Authorization Number and shipping instructions. The

unit will be repaired as quickly as possible and returned to you.

Extra fuses are supplied with PowerEase® 500 Power Supply. For additional

fuses, see page xiv for ordering information.

1. Turn off the main power switch at the rear of the PowerEase

Supply and detach the power cord from the rear of the PowerEase

Power Supply.

2. Open the fuse compartment located inside the Power Entry Module (see

page ix for rear view of the PowerEase

®

500 Power Supply) by inserting a

small flat blade screwdriver into the slot above the ON/OFF switch. Turn

the screwdriver to gently pry open the fuse compartment.

Note: The fuse compartment will not open with the power cord in place.

3. Pull the fuse holder out of the compartment and inspect the fuse. If the fuse

is burned or there is a break in the fuse element, replace the fuse with the

identical type fuse (see figure below).

4. Place the fuse holder(s) back into the compartment, making sure that the

arrow(s) on the fuse holder point in the same direction as the arrows on the

inside of the fuse compartment as shown in the figure below.

5. Snap the cover closed.

SLOT

SLOT

®

500 Power

®

500

100/120V UNIT

19

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

ON/OFF SWITCH

FUSE HOLDER(S)

POWER CORD

CONNECTION

ON/OFF SWITCH

FUSE HOLDER(S)

POWER CORD

CONNECTION

220/240V UNIT

Theory of Operation

Power

Considerations

Resistance

Voltage

Electrophoresis is the migration of a charged particle under the influence of an

electrical field. The influence of various power supply output parameters (volts,

current and watts) is derived from two equations:

Voltage = Current x Resistance (V=IR)

Wattage = Current x Voltage (W=IV)

Resistance of the assembled electrophoresis cell is dependent on the

conductivity of the gel buffer, the thickness of the gel, and the number of gels

being run. Although the resistance is determined by the gel system, the

resistance can vary over the course of the run. For instance, in the Tris-Glycine

buffer system, the fast moving, highly conductive chloride ions in the gel are

gradually replaced by the slower moving, less conductive glycine ions from the

running buffer as the gel runs. As a result, the resistance of the gel increases as

the chloride/glycine front moves down the gel, and the current decreases.

The velocity in which an ion moves in an electric field will vary in proportion to

the field strength (Volts per unit distance). The higher the voltage the faster an

ion will move.

Current

Power

Current is a function of the number of ions passing a given cross-section of the

circuit at a given time. For a given gel/buffer system, at a given temperature,

current will vary in proportion to the field strength (voltage) and/or crosssectional area (number and/or thickness of the gels). Ions in solution and at a

given voltage will move faster as the temperature increases, increasing current.

Watts, or the rate of heat generated by the system, is a function of voltage and

current (W=IV). For a given gel system if either voltage is doubled, watts will

also double (as V=IR, and R is a “constant” determined by the gel system).

20

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Technical Service

World Wide Web

Contact Us

Corporate Headquarters:

Invitrogen Corporation

1600 Faraday Avenue

Carlsbad, CA 92008

USA

Tel: 1 760 603 7200

Tel (Toll Free): 1 800 955 6288

Fax: 1 760 602 6500

E-mail:

tech_service@invitrogen.com

Visit the Invitrogen Web Resource using your World Wide Web browser. At the

site, you can:

• Get the scoop on our hot new products and special product offers

• View and download vector maps and sequences

• Download manuals in Adobe

• Explore our catalog with full color graphics

• Obtain citations for Invitrogen products

• Request catalog and product literature

Once connected to the Internet, launch your web browser (Netscape 3.0 or

newer), then enter the following location (or URL):

...and the program will connect directly. Click on underlined text or outlined

graphics to explore. Don't forget to put a bookmark at our site for easy reference!

For more information or technical assistance, please call, write, fax, or email.

Additional international offices are listed on our Web page (www.invitrogen.com).

®

Acrobat® (PDF) format

http://www.invitrogen.com

Japanese Headquarters:

Invitrogen Japan K.K.

Nihonbashi Hama-Cho Park

Bldg. 4F

2-35-4, Hama-Cho, Nihonbashi

Tel: 81 3 3663 7972

Fax: 81 3 3663 8242

E-mail: jpinfo@invitrogen.com

European Headquarters:

Invitrogen Ltd

3 Fountain Drive

Inchinnan Business Park

Paisley PA4 9RF, UK

Tel: +44 (0) 141 814 6100

Fax: +44 (0) 141 814 6287

E-mail: eurotech@invitrogen.com

©1996-2002 Invitrogen Corporation. All rights reserved.

21

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

REMOTE INSPECTION

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

View

Instra

Loading...

Loading...