Invertek Drive Variable Speed Drives Catalog

Stock Drives Catalogue

Variable Speed Drives

& Accessories

Company Overview

UK Head Office

Welshpool

The OrganisationInvertek Drives

Invertek Drives is dedicated

to the design and manufacture

of sophisticated electronic

variable speed drives, used

to control motors in a wide

variety of industrial and energy

saving applications.

State of the art UK headquarters

house specialist facilities for innovation,

manufacturing and global marketing.

All operations, including innovation, are

accredited to the exacting customer

focused ISO 9001:2000 quality standard.

The company’s products are sold globally

by a network of specialist distributors

in over 80 different countries. Invertek

Drives’ unique and innovative Optidrive

range is designed for ease of use and

meets recognised international design

standards for CE (Europe), UL (USA) and

CTick (Australia).

Innovative Products

Easy to use variable speed drives

Incredible performance

Robust & reliable

Low cost of installation & ownership

Wide power range

0.37 – 250kW, 115V – 60 0V

ii

USA

Global sales, service & application support

network in over 80 countries

UK

Head Office

RUSSIA

CZECH REPUBLIC

SPAIN

CHINA

Service Centre

SINGAPORE

Online

Support

Pre-sales

Support

Customer

Service

Technical

Support

SOUTH AFRICA

Knowledge

Management

Field

Service

Logistics &

Distribution

Spare Parts

& Repair

AUSTRALASIA

Service

Contracts

International

Support

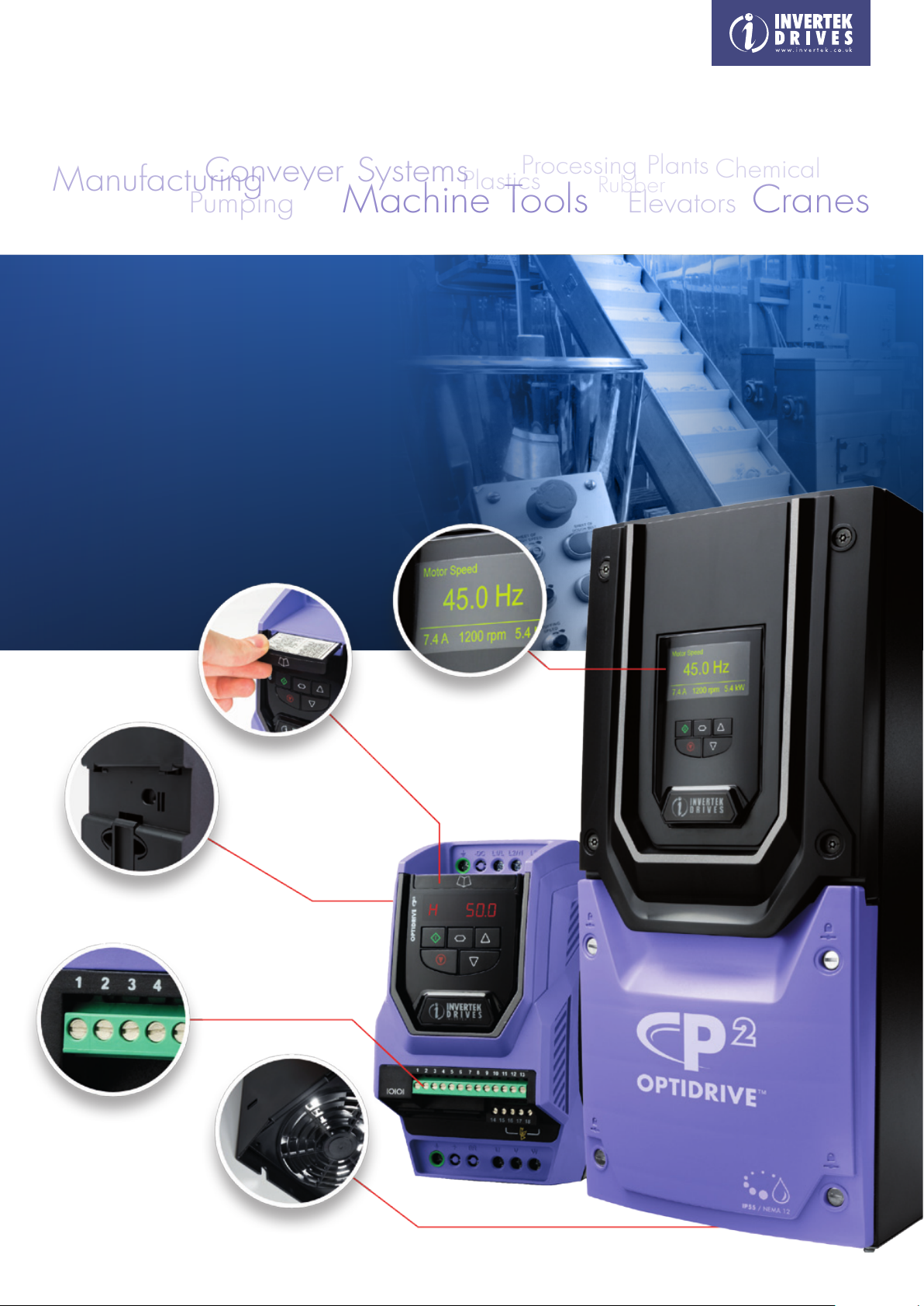

Conveyors

HVAC

Machine Tools

Manufacturing

Pumping

Process Control

Elevators

Cranes

iii

Global Drive Solutions

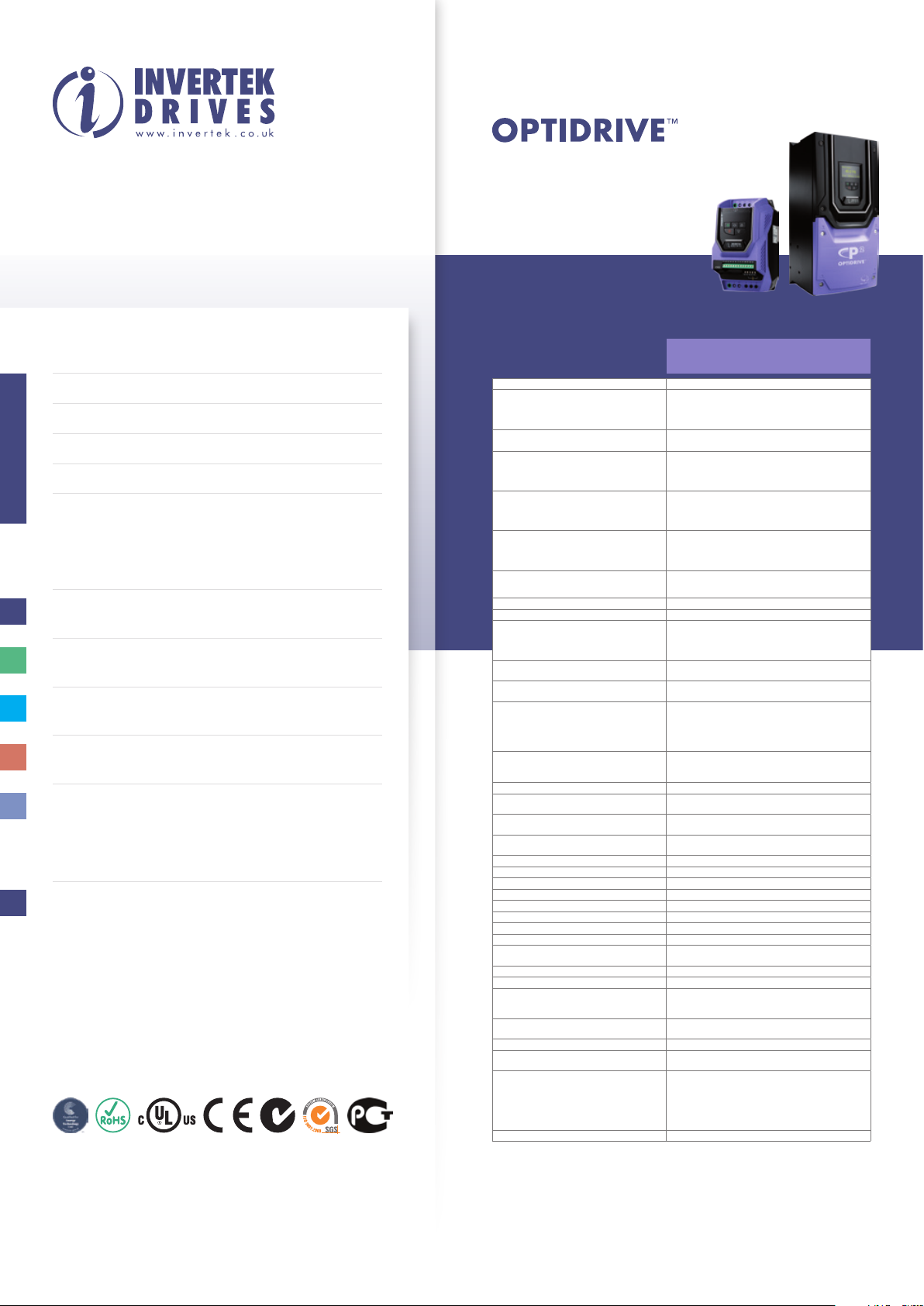

AC Variable Speed Drives

Pages 2–7 Pa ges 8 –13 Pages 14 –17 Page s 18 –19 Pa ges 2 0 –21

AC Variable Speed Drives

OPTIDRIVE P2

OPTIDRIVE HVAC

OPTIDRIVE E2

OPTIDRIVE E2 Single Phase

OPTIDRIVE PCE

Options

OPTIDRIVE P2 & HVAC OPTIONS

Plug-in Modules, Mains Isolator

CONFIGURATION / MONITORING

Optiport 2, Optipad

SOFTWARE / COMMISSIONING

OptiTools Studio, Optistick

DATA CABLES & ACCESSORIES

PC Connection Kit, Cable Splitter, Cables

INSTALLATION OPTIONS

Optifilter, Optibrake, Input Chokes,

Output Filters

COMPATIBILITY REFERENCE

Options Compatibility

2 – 7

8 – 13

14 – 17

18 – 19

20 – 21

22

23

24

25

26

27

Product Range

Previous Optidrive Version

IP20

Suppl y / Power Range

IP40

Suppl y / Power Range

IP55

Suppl y / Power Range

IP66

Suppl y / Power Range

Operating Ambient Rating

Control Modes

Maxi mum Outpu t Hz

Linear / Variable Torque Control

Motor Overload Capacity

Internal EMC Filter Unit Available

Internal Brake Transistor

I/O Connections

Factory Fit Controls

(Spee d Potentiomete r, FWD - 0 - R EV, Power

Isolator)

Pulse Frequency Speed Reference

Power Supplies

Display Type

Keypad

Service/Maintenance Indication

PI / PID Con trol

Energy Optimiser

Spin Start

Safe Torque Off Function

Pluggable Terminals

Fire Mode

Pump Cascade

Mains Pow er Discon nect

Bluetooth

Param eter Copy Modul e

Communications

PC Software

Simple PLC Functionality

Remote Keypad

Options

Conformance

P2 HVAC E2 E2 Single Phase PCE

Optidrive Plus Optidrive VTC Optidrive E & EF Optidrive E1 & EF1 None

200–240V, 1ph, 4.3 to 10.5A (0.75 to 2.2kW / 1.0 to 3.0HP)

200–240V, 3ph, 4.3 to 24A (0.75 to 5.5kW / 1.0 to 7.5HP)

380–480V, 3ph, 2.2 to 24A (0.75-11kW / 1.0 to 15HP)

380–480V, 3ph, 370 to 450A (200 to 250kW / 300 to

350HP)

200–240V, 3ph, 24 to 248A (5.5 to 75kW / 7.5 to 100HP)

380–480V, 3ph, 24 to 302A (11 to 160kW / 15 to 250HP)

200–240V, 1ph, 4.3 to 10.5A (0.75 to 2.2kW / 1.0 to 3.0HP)

200–240V, 3ph, 4.3 to 18A (0.75 to 4.0kW / 1.0 to 5HP)

380–480V, 3ph, 2.2 to 18A (0.75 to 7.5kW / 1.0 to 10HP)

IP20 : –10 to 50°C

IP40 : –10 to 50°C

IP55 : –10 to 50°C

IP66 : –10 to 50°C

V/F, Energy Optimised, Sensorless & Closed Loop

Vector, Open Loop Permanent Magnet

500 120 500 120 500

Linear Linear & Variable Linear Linear Linear

150% - 60 Secs

200% - 3.75 Secs

250% - 1.8 Secs

300% (max) - 1.25 Secs

All models provided with Internal EMC filter All models provided with Internal EMC filter Optional, refer to product page

Standard Frame Sizes 2-5

Optional Frame Sizes 6 and above

3 x Programmable Digital Inputs

2 x User-selectable Digital or Analog Inputs

2 x User-selectable Digital or Analog Outputs

2 x Programmable Relays (1 x change-over, 1 x single pole)

Safe Torque Off inputs

Optional on IP66 Models Optional on IP66 Models IP66: Optional Factory Fit

Yes - Digital Input 3 (20kHz Max) No No No No

24VDC @ 100mA

10VDC @ 10mA (for potentiometer)

IP20: 7 Segment LED

IP55 & IP66: Optional 7 Segment LED or OLED

7-Seg =

5 Buttons (start, stop, navigate, up, down)

OLED = 5 Buttons (start, stop, navigate, up, down)

Yes Yes No No No

Yes (PID) Yes (PID) Yes (PI) Yes (PI) Yes (PID)

Yes Yes Yes No Yes

Yes Yes Yes, Frames 2-3 No Yes

Yes Yes No No No

Yes Yes No No Yes

No Yes No No No

No Yes No No No

IP55: External Option

IP66: Factory Fit Option

Yes (Requires Optistick) Yes (Requires Optistick) Yes (Requires Optistick) Yes (Requires Optistick) No

Optistick Optistick Optistick Optistick No

Modbus RTU, CAN Open on board

Profibus, DeviceNet, Ethernet IP, Modbus TCP, Profinet,

Ethercat with plug in interface

OptiTools Studio OptiTools Studio

Licensed Software Tool Licensed Software Tool No No No

LED : OPT-2-OPORT-IN

OLED : OPT-2-OPPAD-IN

OPT-2-CASCD-IN

OPT-2-ENCOD-IN

OPT-2-EXTIO-IN

OPT-2-PROFB-IN

OPT-2-ETHNT-IN

OPT-2-DEVNT-IN

CE, UL, cUL, CTick CE, UL, cUL, CTick CE, UL, cUL, C-Tick, Gost CE, UL, cUL, C-Tick, Gost CE, UL, cUL, C-Tick, Gost

Easy to use, reliable products

with incredible performance

200–240V, 1ph, 4.3 to 10.5A (0.75 to 2.2kW / 1.0 to 3.0HP)

200–240V, 3ph, 4.3 to 24A (0.75 to 5.5kW / 1 to 7.5HP)

380–480V, 3ph, 2.2 to 24A (0.75-11kW / 1.0 to 15HP)

380–480V, 3ph, 370 to 450A (200 to 250kW / 300 to

350HP)

200–240V, 3ph, 24 to 248A (5.5 to 75kW / 7.5 to 100HP)

380–480V, 3ph, 24 to 302A (11 to 160kW / 15 to 250HP)

200–240V, 1ph, 4.3 to 10.5A (0.75 to 2.2kW / 1.0 to 3.0HP)

200–240V, 3ph, 4.3 to 18A (0.75 to 4.0kW / 1.0 to 5HP)

380–480V, 3ph, 2.2 to 18A (0.75 to 7.5kW / 1.0 to 10HP)

IP20 : –10 to 50°C

IP40 : –10 to 50°C

IP55 : –10 to 50°C

IP66 : –10 to 50°C

110% - 60 Secs

125% - 7.5 Secs

150% - 3.9 Secs

165% (max) - 2.9S

Not Available Frame Sizes 2-3 Frame Size 2 Only No

3 x Programmable Digital Inputs

2 x User-selectable Digital or Analog Inputs

2 x User-selectable Digital or Analog Outputs

2 x Programmable Relays (1 x change-over, 1 x single pole)

Safe Torque Off inputs

V/F

Energy Optimised

110–115V, 1ph, 2.3 to 5.8A (0.5 to 1.5HP)

200–240V, 1ph, 2.3 to 15A (0.37 to 4kW / 0.5 to 5HP)

200–240V, 3ph, 2.3 to 18A (0.37 to 4kW / 0.5 to 5HP)

380–480V, 3ph, 2.2 to 24A (0.75 to 11kW / 1 to 15HP)

110–115V, 1ph, 2.3 to 5.8A (0.5 to 1.5HP)

200–240V, 1ph, 2.3 to 10.5A (0.37 to 2.2kW / 0.5 to 3HP)

200–240V, 3ph, 2.3 to 18A (0.37 to 4kW / 0.5 to 5HP)

380–480V, 3ph, 2.2 to 18A (0.75 tp 7.5kW / 1 to 10HP)

110–115V, 1ph, 2.3 to 5.8A (0.5 to 1.5HP)

200–240V, 1ph, 2.3 to 15A (0.37 to 4kW / 0.5 to 5HP)

200–240V, 3ph, 2.3 to 18A (0.37 to 4kW / 0.5 to 5HP)

380–480V, 3ph, 2.2 to 18A (0.75 to 7.5kW / 1 to 10HP)

IP20 : 50°C

IP66 : 40°C

V/F

Energy Optimised

150% - 60 Secs

175% - 2 Secs

2 x Programmable Digital Inputs

2 x User-selectable Digital or Analog Inputs

1 x User-selectable Digital or Analog Output

1 x Programmable Relay (single pole)

110–115V, 1ph, 7 to 10.5A (0.5 to 0.75HP)

200–240V, 1ph, 4.3 to 10.5A (0.37 to 1.1kW / 0.5 to 1.5HP)

110–115V, 1ph, 7 to 10.5A (0.5 to 0.75HP)

200–240V, 1ph, 4.3 to 10.5A (0.37 to 1.1kW / 0.5 to 1.5HP)

110–115V, 1ph, 7 to 10.5A (0.5 to 0.75HP)

200–240V, 1ph, 4.3 to 10.5A (0.37 to 1.1kW / 0.5 to 1.5HP)

IP20 : 50°C

IP66 : 40°C

V/F V/F, Energy Optimised, Sensorless Vector

150% - 60 Secs

175% - 2 Secs

110V not available with Filter

All other models available with or without filter

2 x Programmable Digital Inputs

2 x User-selectable Digital or Analog Inputs

1 x User-selectable Digital or Analog Output

1 x Programmable Relay (single pole)

IP66: Optional Factory Fit

Note : Reverse motor rotation is not possible

200–240V, 1ph, 4.5 to 7A (0.75 to 1.5kW / 1 to 2HP)

380–480V, 3ph, 2.2 to 4.1A (0.75 to 1.5kW / 1 to 2HP)

IP55 : 40°C

150% - 60 Secs

175% - 2 Secs

All models available with or without filter

2 x Programmable Digital Inputs

2 x User-selectable Digital or Analog Inputs

1 x Programmable Relay (single pole)

Optional Factory Fit

24VDC @ 100mA

10VDC @ 10mA (for potentiometer)

IP20: 7 Segment LED

IP55 & IP66: OLED

7-Seg =

5 Buttons (start, stop, navigate, up, down)

OLED = 7 Button (start, stop, navigate, up, down, hand, auto)

IP55: External Option

IP66: Factory Fit Option

Modbus RT, BACnet MS/TP on board

BACnet IP, Modbus TCP, Ethernet IP, Profibus, Profinet,

DeviceNet, EtherCat optional plug in interface

LED : OPT-2-OPORT-IN

OLED : OPT-2-OPPAD-IN

OPT-2-CASCD-IN

OPT-2-EXTIO-IN

OPT-2-BACNT-IN

OPT-2-PROFB-IN

OPT-2-ETHNT-IN

OPT-2-DEVNT-IN

24VDC @ 100mA

10VDC @ 10mA (for potentiometer)

7 Segment led 7 Segment LED None

5 Buttons (start, stop, navigate, up, down) 5 Buttons (start, stop, navigate, up, down)

IP66: Factory Fit Option IP66: Factory Fit Option No

Modbus RTU on board

Profibus, DEviceNet or Ethernet IP via external gateway

Optistore V3

OptiTools Studio (OTS)

OPT-2-OPORT-IN, OPT-2-OPPAD-IN OPT-2-OPORT-IN, OPT-2-OPPAD-IN OD-OPRTP

OPT-HVACO-IN

ODP-2ROUT-IN

OPT-LOGIP-11-IN

OPT-LOGIP-23-IN

24VDC @ 100mA

10VDC @ 10mA (for potentiometer)

Modbus RTU on board

Profibus, DeveiceNet, EtherNet IP via external gateway

OptiTools Studio (OTS) Optistore V3

OPT-HVACO-IN

ODP-2ROUT-IN

OPT-LOGIP-11-IN

OPT-LOGIP-23-IN

24VDC @ 100mA

Optional Remote

No

None Available

Global service and support network

Leading edge design & technology

1.03

1

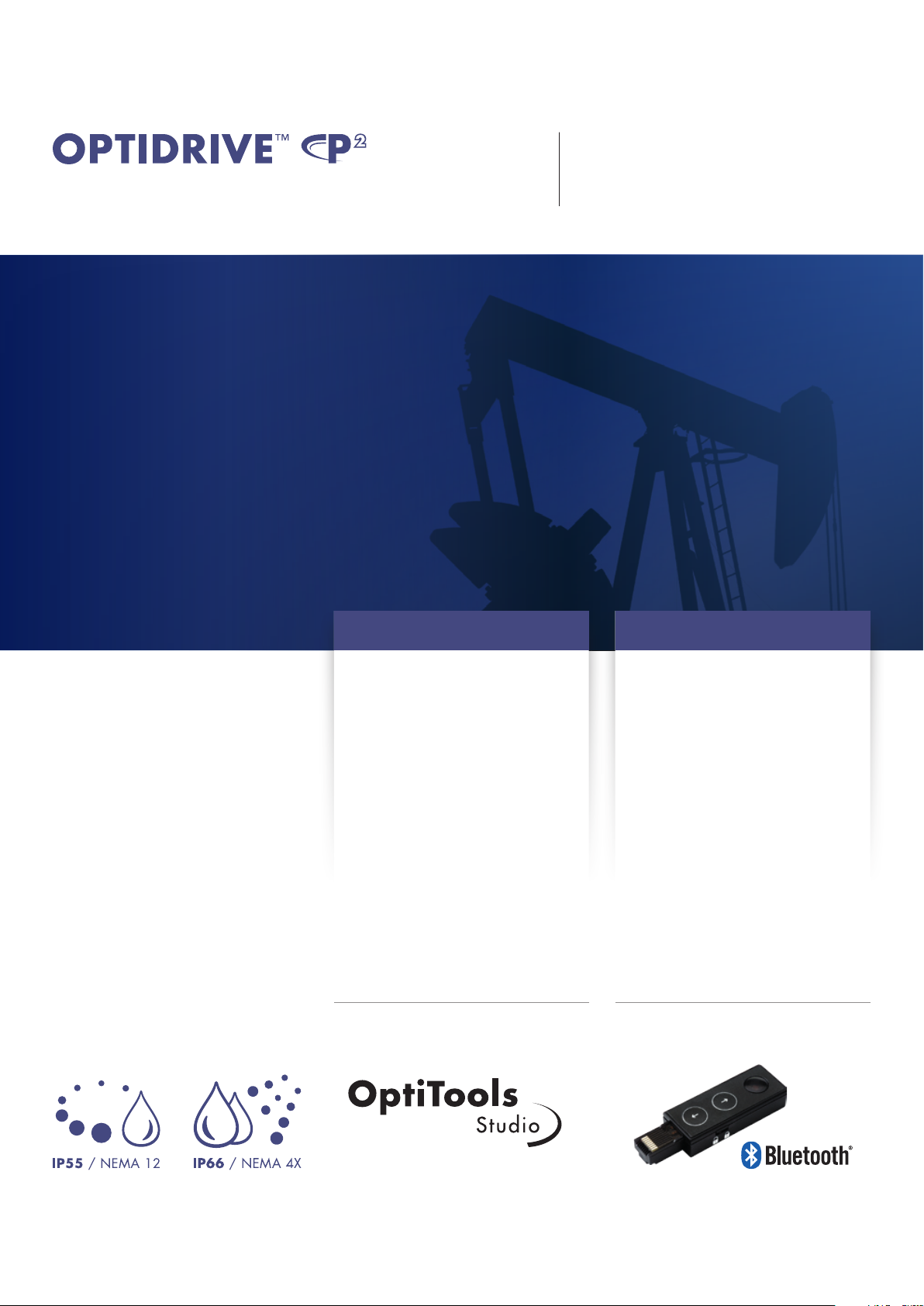

AC Variable Speed Drive

World Leading Motor Control

Controlling the latest generation of permanent

magnet motors and standard induction motors

0.75kW – 250kW / 1HP – 350HP

200 – 480V Single & 3 Phase Input

Optidrive P2 offers the perfect

combination of high performance

together with ease of use to

allow even the most demanding

applications to be tackled easily.

Low ambient operation (−10°C)

Dedicated Hoist Mode

CAN and Modbus RTU

communication as standard

High Performance Low Cost Installation

Sensorless Vector Control

Up to 200% torque from zero speed

ensures reliable starting and accurate

speed control under all load conditions.

PM Motor Control

Future proof. Allows upgrade to the latest

generation of high efficiency permanent

magnet motors.

I/O & Communications

Optidrive P2 supports a wide range of

interfaces to machine control systems.

Powerful PC based

commissioning software

Built-in EMC Filter

An internal filter in every Optidrive P2

saves cost and time for installation.

Integral Brake Transistor

Saves space, cost and time for installation.

OPTISTICK

Product Code: OPT-2-STICK-IN

OptiTools Studio allows parameter

Up to 7.5kWUp to 160kW

2

upload, download and storage and access

to Optidrive P2 Simple PLC functionality.

See Page 24

Fast parameter copying between drives

Bluetooth PC interface for OptiTools

Studio commissioning software

150% overload for 60 seconds

Cranes

Manufacturing

Rubbe r

Chemical

Elevators

Plastics

Machine Tools

Conveyer Systems

Processing Plants

Pumping

200% overload for 4 seconds

Industrial heavy duty rating for every model

Optional LED or OLED

(IP55 & IP66)

Convenient

Help Card

DIN Rail Mount

(IP20)

Pluggable

Terminals

High Quality

Long-life Fans

3

High Performance | Easy to Use

Simple PLC Functionality

A wide range of function types available

including:

Programmable Logic Functions

Comparators

Timers

Mathematical Functions

Drive specific functions

All blocks can be easily combined to create

flexible programs.

Programs can be protected to prevent

unauthorised copying.

Complete control over the drive including

all inputs and outputs.

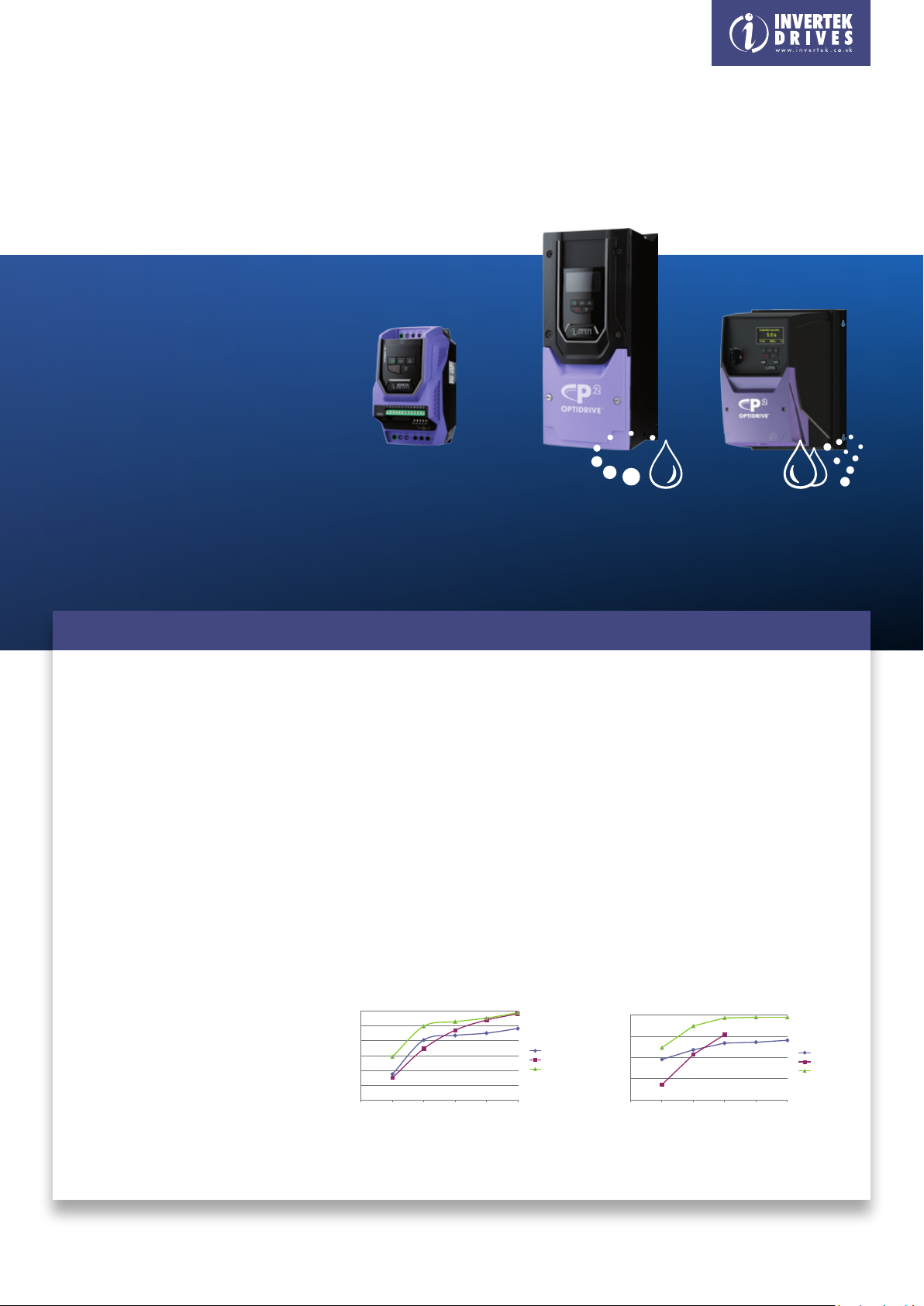

Safe Torque Off (provided as standard)

Optidrive P2 features a safe torque off function to allow

simple integration into machine critical safety circuits.

Simple machine design reduces component costs, saves panel space and

minimises installation time

Faster shut down and reset procedures reduce system maintenance time

Better safety standard compared to mechanical solution

Better motor connection. Single cable with no interruption.

4

With Without

Supply Supply

Input Contactor

NOT required

Optidr ive

P2

Safet y

Relay

Machine

Safety Circuit

Safet y

Relay

Machine

Safety Circuit

Variable

Speed Drive

Input

Contactor

Advanced Motor Control

53.0%

58.0%

63.0%

68.0%

73.0%

78.0%

83.0%

0 20 40 60 80 100

Standard IM

Typical PM Drive

Optidrive P2 PM

17.0%

27.0%

37.0%

47.0%

57.0%

0 20 40 60 80 100

Standard IM

Typical PM Drive

Optidrive P2 PM

Invertek has developed advanced

mathematical algorithms and uses the

very latest hardware technology to ensure

Optidrive P2 provides exceptional motor

control with a simple interface to help

users easily apply the benefits to their

applications.

IP20

IP55

IP66

Drive System Efficiency

With today’s ever increasing energy costs, ef ficiency

has long been a key factor in relation to drive system

component selection. In many cases, an efficiency

figure can be arrived at by simply multiplying the

efficiencies of the various components together

to find a combined efficiency figure, however this

may not tell the whole story. The efficiency of

components such as drives, motors and gearboxes

can vary considerably with speed and load, hence

simply combining the ‘headline’ efficiency figures can

often be very misleading. In reality, the efficiency

curves for the whole system should be overlaid, to

provide a true efficiency figure for the system across

the desired speed and load range.

Modern AC inverters will typically have an electrical

efficiency of around 98%, which represents the

different between the electrical output power

compared to electrical input power only. A further

factor that is often overlooked is the efficiency of the

motor control strategy employed by the drive. This

can have a significant effect on the overall system

efficiency, and is often not considered when energy

saving calculations are made.

Panel mount units

available up to 11kW

Wall mount units

available up to 160kW

Furthermore, Optidrive P2 has been designed and

developed to work with all PM motors, and control

them with Optimum efficiency, providing the most

efficient PM motor control available.

The graphs below clearly demonstrate these two

factors:

The overall efficiency of the system varies with

speed and load and is not a constant

Motor control efficiency significantly affects

overall system efficiency

The graphs are generated by measuring the electrical

power drawn from the mains supply compared to

the torque generated at the output shaft. These

are based on a system requirement of 2.2kW

motor power.

Improvement in Efficiency at

100% Rated Speed Output

Wall mount units

available up to 7.5kW

The blue line represents what will be considered a

“high efficiency” solution using an efficient IM motor,

a modern AC drive and efficient gearbox.

The red line represents eff iciency of a typical PM

motor and drive solution. Eff iciency is improved at

high speeds and loads, however it is actually reduced

at very low loads, and output torque cannot be

maintained at low speeds.

The green line represents the Optidrive P2

controlling the same PM motor. Efficiency is

improved at all speeds and loads.

In simple terms, Optidrive P2 PM motor control

produces the maximum amount of output shaft

torque per electrical kW consumed across all speed

and torque ranges.

Improvement in Efficiency at

10% Rated Speed Output

Optidrive P2 has been designed to work with

both standard induction motors, which typically

meet the IE2 efficiency standards currently in

place in Europe, and the latest generation of high

efficiency PM motors designed to meet the future

IE4 requirements. This means that an eff icient drive

can be purchased now, allowing for a future update

of the motor without requiring a change to the

installed drive.

Comparative Efficiency

Load (%) Load (%)

Comparative Efficiency

5

kW HP Amps Size

kW Model Code

Product Range

Generation

Frame S ize

Supply Voltage

Power Rating

Input Phases

Po wer Ty pe

Factory Build Options

HP Model Code

Product Range

Generation

Frame S ize

Supply Voltage

Power Rating

Input Phases

Po wer Ty pe

Brake Transistor

EMC Filter

No Brake Tran sistor

Interna l EMC Filter

Factory Build Options

Factory Build Options

Internal Brake Transistor

IP20

Enclosure

IP40

IP66 Non-switched

IP55

IP66 Switched

Display

OLED Dis play

7 Segmen t LED Displ ay

Full Conformal Coating

Standard Coating

PCB Coating

200 – 240V ± 10 %

1 Phase I nput

200 – 240V ± 10 %

3 Phase I nput

380 – 48 0V ± 10%

3 Phase I nput

0.75 1 4.3 2 ODP - 2 - 2 2 075 - 1 K F 4 # -# # ODP - 2 - 2 2 010 - 1 H F 4 # -# # F 4 2 X Y S T N C

1.5 2 7 2 ODP - 2 - 2 2 150 - 1 K F 4 #- ## ODP - 2 - 2 2 020 - 1 H F 4 #-# # F 4 2 X Y S T N C

2.2 3 10.5 2 ODP - 2 - 2 2 220 - 1 K F 4 #-# # ODP - 2 - 2 2 030 - 1 H F 4 #- ## F 4 2 X Y S T N C

0.75 1 4.3 2 ODP - 2 - 2 2 075 - 3 K F 4 # -# # ODP - 2 - 2 2 010 - 3 H F 4 #- ## F 4 2 X Y S T N C

1.5 2 7 2 ODP - 2 - 2 2 15 0 - 3 K F 4 #- ## ODP - 2 - 2 2 020 - 3 H F 4 # -# # F 4 2 X Y S T N C

2.2 3 10.5 2 ODP - 2 - 2 2 220 - 3 K F 4 # - ## ODP - 2 - 2 2 030 - 3 H F 4 #- ## F 4 2 X Y S T N C

4 5 18 3 ODP - 2 - 3 2 040 - 3 K F 4 # - ## ODP - 2 - 3 2 050 - 3 H F 4 #- ## F 4 2 X Y S T N C

5.5 7.5 24 3 ODP - 2 - 3 2 055 - 3 K F 4 2 - ## ODP - 2 - 3 2 075 - 3 H F 4 2 - ## F 4 2 S T N C

5.5 7.5 24 4 ODP - 2 - 4 2 055 - 3 K F 4 N -## ODP - 2 - 4 2 075 - 3 H F 4 N -

7.

5 10 30 4 ODP - 2 - 4 2 075 - 3 K F 4 N - ## ODP - 2 - 4 2 10 0 - 3 H F 4 N -# # F 4 N S T N C

## F 4 N S T N C

11 15 46 4 ODP - 2 - 4 2 110 - 3 K F 4 N-# # ODP - 2 - 4 2 150 - 3 H F 4 N- ## F 4 N S T N C

15 20 61 5 ODP - 2 - 5 2 150 - 3 K F 4 N- ## ODP - 2 - 5 2 020 - 3 H F 4 N- ## F 4 N S T N C

18.5 25 72 5 ODP - 2 - 5 2 185 - 3 K F 4 N- ## ODP - 2 - 5 2 025 - 3 H F 4 N-# # F 4 N S T N C

22 30 90 6 ODP - 2 - 6 2 022 - 3 K F #N- ## ODP - 2 - 6 2 030 - 3 H F # N- ## F 1 4 N S T N C

30 40 11 0 6 ODP - 2 - 6 2 030 - 3 K F #N- ## ODP - 2 - 6 2 040 - 3 H F #N-# # F 1 4 N S T N C

37 50 150 6 ODP - 2 - 6 2 037 - 3 K F # N - ## ODP - 2 - 6 2 050 - 3 H F # N- ## F 1 4 N S T N C

45 60 180 6 ODP - 2 - 6 2 045 - 3 K F #N -# # ODP - 2 - 6 2 060 - 3 H F # N- ## F 1 4 N S T N C

55 75 202 7 ODP - 2 - 7 2 055 - 3 K F #N -# # ODP - 2 - 7 2 075 - 3 H F # N-# # F 1 4 N S T N

7

5 10 0 248 7 ODP - 2 - 7 2 075 - 3 K F # N- ## ODP - 2 - 7 2 100 - 3 H F #N -# # F 1 4 N S T N C

0.75 1 2.2 2 ODP - 2 - 2 4 075 - 3 K F 4 #-## ODP - 2 - 2 4 010 - 3 H F 4 # -# # F 4 2 X Y S T N C

1.5 2 4.1 2 ODP - 2 - 2 4 150 - 3 K F 4 #-# # ODP - 2 - 2 4 020 - 3 H F 4 # -# # F 4 2 X Y S T N C

2.2 3 5.8 2 ODP - 2 - 2 4 220 - 3 K F 4 # -# # ODP - 2 - 2 4 030 - 3 H F 4 # -# # F 4 2 X Y S T N C

4 5 9.5 2 ODP - 2 - 2 4 400 - 3 K F 4 #- ## ODP - 2 - 2 4 050 - 3 H F 4 #-# # F 4 2 X Y S T N C

5.5 7.5 14 3 ODP - 2 - 3 4 055 - 3 K F 4 # -## ODP - 2 - 3 4 075 - 3 H F 4 # -# # F 4 2 X Y S T N C

7.5 10 18 3 ODP - 2 - 3 4 075 - 3 K F 4 #-# # ODP - 2 - 3 4 100 - 3 H F 4 # -# # F 4 2 X Y S T N C

11 15 24 3 ODP - 2 - 3 4 110 - 3 K F 4 2 - ## ODP - 2 - 3 4 15 0 - 3 H F 4 2 - ## F 4 2 S T N C

11 15 24 4 ODP - 2 - 4 4 110 - 3 K F 4 N- ## ODP - 2 - 4 4 150 - 3 H F 4 N- ## F 4 N S

15 20 30 4 O

DP - 2 - 4 4 150 - 3 K F 4 N - ## ODP - 2 - 4 4 200 - 3 H F 4 N- ## F 4 N S T N C

T N C

18.5 25 39 4 ODP - 2 - 4 4 185 - 3 K F 4 N -# # ODP - 2 - 4 4 250 - 3 H F 4 N-# # F 4 N S T N C

22 30 46 4 ODP - 2 - 4 4 220 - 3 K F 4 N- ## ODP - 2 - 4 4 300 - 3 H F 4 N - ## F 4 N S T N C

30 40 61 5 ODP - 2 - 5 4 300 - 3 K F 4 N - ## ODP - 2 - 5 4 040 - 3 H F 4 N -# # F 4 N S T N C

37 50 72 5 ODP - 2 - 5 4 370 - 3 K F 4 N -# # ODP - 2 - 5 4 050 - 3 H F 4 N-# # F 4 N S T N C

45 60 90 6 ODP - 2 - 6 4 045 - 3 K F #N -# # ODP - 2 - 6 4 060 - 3 H F # N- ## F 1 4 N S T N C

55 75 110 6 ODP - 2 - 6 4 055 - 3 K F # N-# # ODP - 2 - 6 4 075 - 3 H F # N -## F 1 4 N S T N C

75 120 150 6 ODP - 2 - 6 4 075 - 3 K F #N- ## ODP - 2 - 6 4 120 - 3 H F #N -# # F 1 4 N S T N C

90 15 0 180 6 ODP - 2 - 6 4 090 - 3 K F # N -## ODP - 2 - 6 4 150 - 3 H F # N- ## F 1 4 N S T N C

110 175 202 7 ODP -

2 - 7 4 11

0 - 3 K F # N- ## ODP - 2 - 7 4 175 - 3 H F #N- ## F 1 4 N S T N C

132 200 24 0 7 ODP - 2 - 7 4 132 - 3 K F #N-# # ODP - 2 - 7 4 200 - 3 H F # N- ## F 1 4 N S T N C

160 250 302 7 ODP - 2 - 7 4 160 - 3 K F # N- ## ODP - 2 - 7 4 250 - 3 H F #N- ## F 1 4 N S T N C

200 300 370 8 ODP - 2 - 8 4 200 - 3 K F # 4 -# # ODP - 2 - 8 4 300 - 3 H F # 4 - ## F 1 4 4 S T N C

250 350 450 8 ODP - 2 - 8 4 250 - 3 K F # 4 -# # ODP - 2 - 8 4 350 - 3 H F # 4 - ## F 1 4 4 S T N C

kW Models: Factor y Settings

Motor Rated Frequency: 50Hz

Motor Rated Voltage: 4 00V

HP Mode ls: Factory Sett ings

Motor Rated Frequency: 60Hz

Motor Rated Voltage: 460V

Replace # in model code with colour-coded option

IP20 units are available wit h 7 Segment LED Display only

C

6

NOT TO SCA LE

Size 2 2 3 3 4 5 6 7 8

Enclosure IP20 IP66 IP20 IP66 IP55 IP55 IP55 IP55 IP4 0

Height (mm) 2 21 257 261 310 440 540 865 128 0 2000

Width (mm) 11 2 188 131 211 171 235 330 330 500

Depth (mm) 185 239 205 2 51 240 270 330 360 516

Weight (kg) 1. 8 4.8 3.5 7. 3 11. 5 22.5 50 80 270

H

W

D

Loading...

Loading...