Page 1

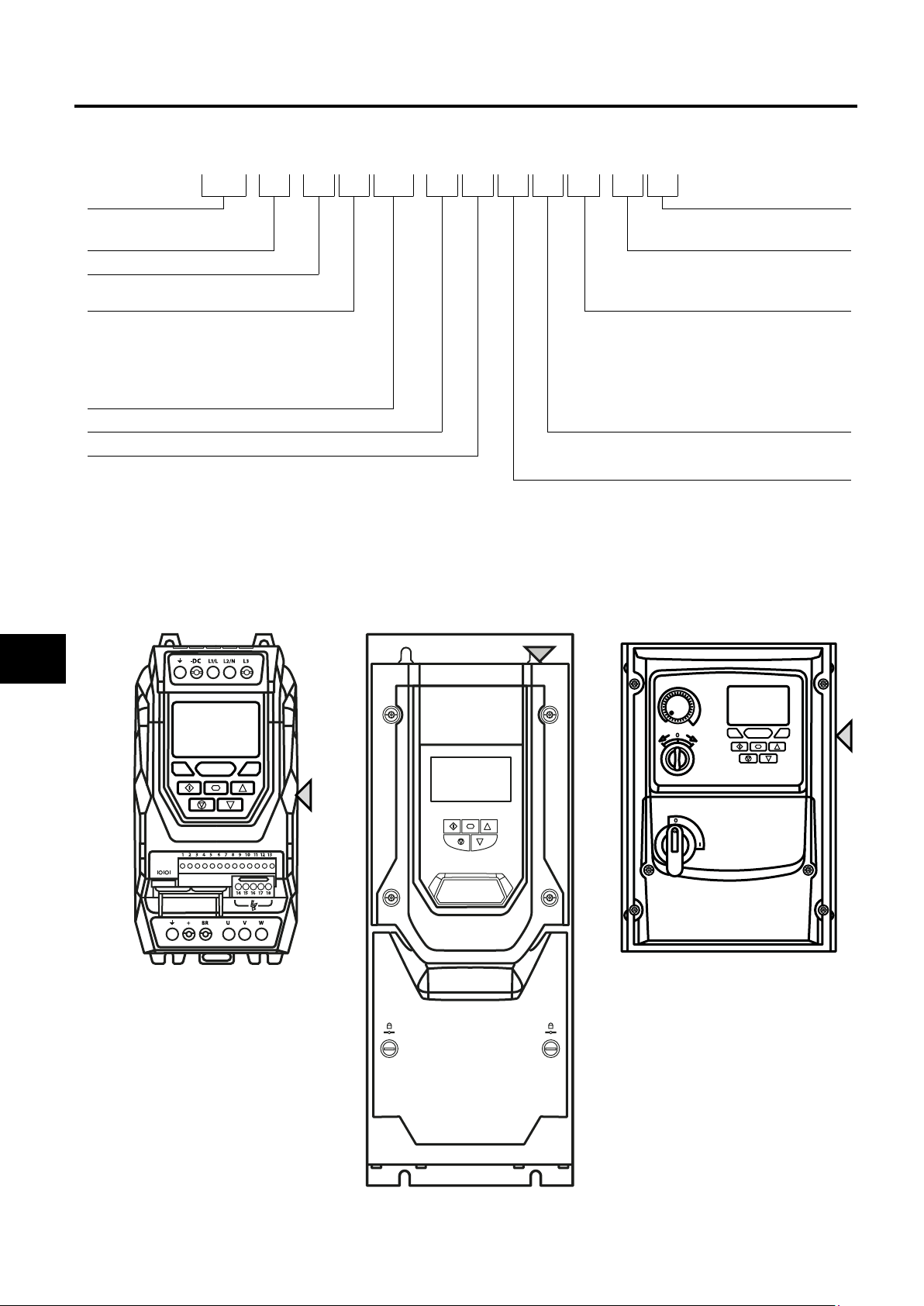

AC Variable Speed Drive

0.75 - 250kW / 1 - 350HP

200 - 600V Single and 3 Phase Input

User Guide

Quick Start Up

General Information

and Ratings

Mechanical Installation

Electrical Installation

Keypad and Display Operation

Parameters

Control Terminal

Functions

Extended

Parameters

1

2

3

4

5

6

7

8

Serial

Communications

Technical Data

Troubleshooting

9

10

11

Page 2

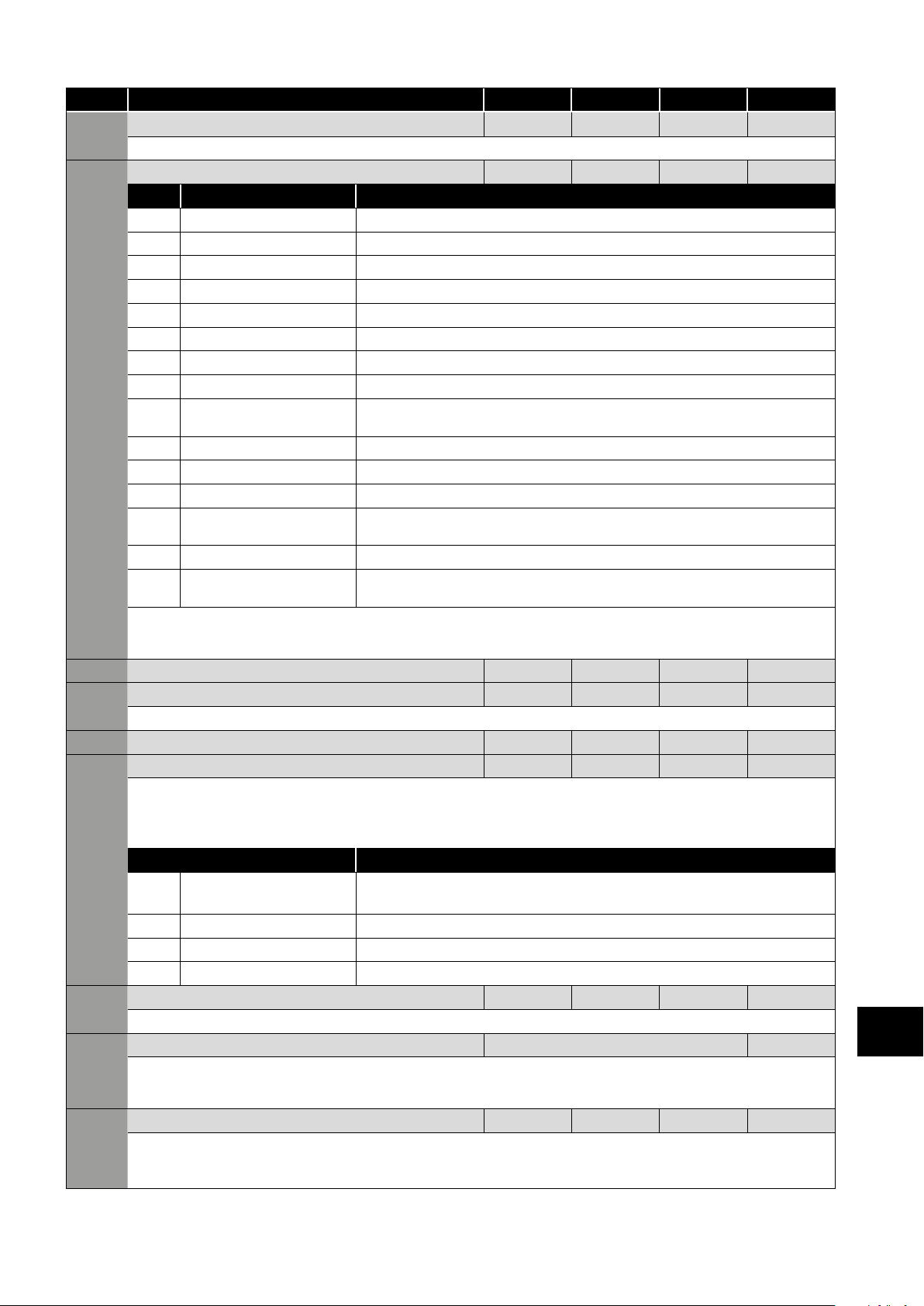

1. Quick Start Up

............................

4

5. Keypad and Display Operation

......................

33

1.1. Important Safety Information

1.2. Quick Start Process

2. General Information and Ratings

2.1. Identifying the Drive by Model Number

2.2. Product Rating Label Location

2.3. Understanding the Rating Label

2.4. Drive Model Numbers – IP20

2.5. Drive Model Numbers – IP55

2.6. Drive Model Numbers – IP66 Non-switched

2.7. Drive Model Numbers – IP66 Switched

3. Mechanical Installation

3.1. General

3.2. Before Installation

3.3. UL Compliant Installation

3.4. Installation Following a Period of Storage

3.5. Mechanical Dimensions and Weight

......................................

.............................

....................

............................

...................

.................

..................

..................

....................

.......................

...........

..........

.....

..........

........

............

4

5

6

6

6

7

7

9

10

11

12

12

12

12

12

13

5.1. Keypad and Display Layout

5.2. Selecting the Language on the TFT and OLED Display

5.3. Additional Display Messages

5.4. Changing Parameters

5.5. Parameter Factory Reset / User Reset

5.6. Resetting the Drive Following a Trip

5.7. Keypad Shortcuts

6. Parameters

6.1. Parameter Set Overview ...................................

6.2. Parameter Group 1 – Basic Parameters ......................

7. Control Terminal Functions ...........................

7.1. Control Source Selection

7.2. Digital Input Configuration Parameter P1-13. . . . . . . . . . . . . . . . . . .

7.3. Example Connection Schematics ............................

8. Extended Parameters

8.1. Parameter Group 2 - Extended Parameters ....................

.......................................

........................................

...............................

.............................

....................................

......................

........................

..................................

..............................

.......

33

34

34

35

35

35

36

37

37

37

40

40

42

43

47

47

3.6. Guidelines for Enclosure Mounting (IP20 Units) .....

3.7. Mounting the Drive – IP20 Units. . . . . . . . . . . . . . . . . . .

3.8. Guidelines for Mounting (IP55 Units)

3.9. Guidelines for Mounting (IP66 Units)

3.10. Removing the Terminal Cover

3.11. Routine Maintenance

4. Electrical Installation

4.1. Connection Diagram

4.2. Protective Earth (PE) Connection

4.3. Incoming Power Connection

4.4. Operation of 3 Phase drives from a Single Phase

Supply

...........................................

4.5. Operation with DC Power Supply or Common DC

Bus

..............................................

4.6. Motor Connection

4.7. Motor Terminal Box Connections

4.8. Connecting a Brake Resistor

4.9. Control Terminal Wiring

..........................

.......................

...........................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

........................

............

............

...................

.................

....................

................

....................

16

17

17

18

19

19

20

20

21

22

23

23

23

23

24

25

8.2. Parameter Group 3 – PID Control ...........................

8.3. Parameter Group 5 – Communication Parameters .............

8.4. Advanced Parameters .....................................

8.5. Parameter Group 0 – Monitoring Parameters (Read Only) ......

9. Serial Communications ........................... 64

9.1. RS-485 Communications

9.2. Modbus RTU Communications ..............................

9.3. CAN Open Communication ...............................

10. Technical Data ................................. 72

10.1. Environmental ...........................................

10.2. Input/Output Power and Current Ratings ....................

10.3. Input Power Supply Requirements ..........................

10.4. Additional Information for UL Approved Installations ...........

10.5. Derating Information .....................................

10.6. Internal EMC Filter and Varistors – Disconnection Procedure ....

11. Troubleshooting ................................ 78

11.1. Fault Messages ..........................................

.................................

52

56

58

62

64

65

67

72

72

75

75

76

76

78

4.10. Control Terminal Connections

4.11. IP66 Switched Version Integrated Control Switch

and Potentiometer Wiring

4.12. Motor Thermal Overload Protection

4.13. EMC Compliant Installation

4.14. Safe Torque Off

2 | Optidrive P2 User Guide | Version 3.04 www.invertekdrives.com

..............................

..................

..........................

.............

....................

26

27

27

28

29

Page 3

Declaration of Conformity

Invertek Drives Ltd hereby states that the Optidrive ODP-2 product range conforms to the relevant safety provisions of the following

council directives:

2014/30/EU (EMC) and 2014/35/EU (LVD)

Designed and manufacture is in accordance with the following harmonised European standards:

EN 61800-5-1: 2007+A1:2017

EN 61800-3: 2004 /A1 2012 Adjustable speed electrical power drive systems. EMC requirements and specific test methods

EN 55011: 2007 Limits and Methods of measurement of radio disturbance characteristics of industrial, scientific

EN60529: 1992 Specifications for degrees of protection provided by enclosures

Adjustable speed electrical power drive systems. Safety requirements. Electrical, thermal and energy.

and medical (ISM) radio-frequency equipment (EMC)

Safe Torque OFF (“STO”) Function

Optidrive P2 incorporates a hardware STO (Safe Torque Off) Function, designed in accordance with the standards listed below.

Standard Classification Independent Approval

EN 61800-5-2:2016 Type 2

EN ISO 13849-1:2015 PL “d”

EN 61508 (Part 1 to 7):2010 SIL 2

EN60204-1:2006 + A1:2009 + AC: 2010 Uncontrolled Stop “Category 0”

EN 62061:2005/A2:2015 SIL CL 2

*TUV

Electromagnetic Compatibility

All Optidrives are designed with high standards of EMC in mind. All versions suitable for operation on Single Phase 230 volt and Three Phase

400 volt supplies and intended for use within the European Union are fitted with an internal EMC filter. This EMC filter is designed to reduce

the conducted emissions back into the mains supply via the power cables for compliance with the above harmonised European standards.

It is the responsibility of the installer to ensure that the equipment or system into which the product is incorporated complies with the

EMC legislation of the country of use, and the relevant category. Within the European Union, equipment into which this product is

incorporated must comply with the EMC Directive 2014/30/EU. This User Guide provides guidance to ensure that the applicable

standards may be achieved.

Copyright Invertek Drives Ltd © 2020

All rights reserved. No part of this User Guide may be reproduced or transmitted in any form or by any means, electrical or mechanical

including photocopying, recording or by any information storage or retrieval system without permission in writing from the publisher.

2 Year Warranty

All Invertek Optidrive units carry a 2 year warranty against manufacturing defects from the date of manufacture. The manufacturer

accepts no liability for any damage caused during or resulting from transport, receipt of delivery, installation or commissioning. The

manufacturer also accepts no liability for damage or consequences resulting from inappropriate, negligent or incorrect installation,

incorrect adjustment of the operating parameters of the drive, incorrect matching of the drive to the motor, incorrect installation,

unacceptable dust, moisture, corrosive substances, excessive vibration or ambient temperatures outside of the design specification.

The local distributor may offer different terms and conditions at their discretion, and in all cases concerning warranty, the local

distributor should be contacted first.

This user guide is the “original instructions” document. All non-English versions are translations of the

“original instructions”.

The contents of this User Guide are believed to be correct at the time of printing. In the interest of a commitment to a policy of

continuous improvement, the manufacturer reserves the right to change the specification of the product or its performance or the

contents of the User Guide without notice.

This User Guide is for use with version 2.50 Firmware. User Guide Revision 3.04.

Invertek Drives Ltd adopts a policy of continuous improvement and whilst every effort has been made to provide accurate and up to

date information, the information contained in this User Guide should be used for guidance purposes only and does not form the part

of any contract.

When installing the drive on any power supply where the phase-ground voltage may exceed the phase-phase voltage

(typically IT supply networks or Marine vessels) it is essential that the internal EMC filter ground and surge protection varistor

ground (where fitted) are disconnected. If in doubt, refer to your Sales Partner for further information.

This manual is intended as a guide for proper installation. Invertek Drives Ltd cannot assume responsibility for the compliance

or the non-compliance to any code, national, local or otherwise, for the proper installation of this drive or associated

equipment. A hazard of personal injury and/or equipment damage exists if codes are ignored during installation.

This Optidrive contains high voltage capacitors that take time to discharge after removal of the main supply. Before

working on the drive, ensure isolation of the main supply from line inputs. Wait ten (10) minutes for the capacitors to

discharge to safe voltage levels. Failure to observe this precaution could result in severe bodily injury or loss of life.

Only qualified electrical personnel familiar with the construction and operation of this equipment and the hazards involved

should install, adjust, operate, or service this equipment. Read and understand this manual and other applicable manuals

in their entirety before proceeding. Failure to observe this precaution could result in severe bodily injury or loss of life.

Version 3.04 | Optidrive P2 User Guide | 3www.invertekdrives.com

Page 4

Quick Start Up

1

1. Quick Start Up

1.1. Important Safety Information

Please read the IMPORTANT SAFETY INFORMATION below, and all Warning and Caution information elsewhere.

Danger: Indicates a risk of electric shock, which,

if not avoided, could result in damage to the

equipment and possible injury or death.

This variable speed drive product (Optidrive) is intended for

professional incorporation into complete equipment or systems

as part of a fixed installation. If installed incorrectly it may present

a safety hazard. The Optidrive uses high voltages and currents,

carries a high level of stored electrical energy, and is used to

control mechanical plant that may cause injury. Close attention

is required to system design and electrical installation to avoid

hazards in either normal operation or in the event of equipment

malfunction. Only qualified electricians are allowed to install and

maintain this product.

System design, installation, commissioning and maintenance must

be carried out only by personnel who have the necessary training

and experience. They must carefully read this safety information

and the instructions in this Guide and follow all information

regarding transport, storage, installation and use of the Optidrive,

including the specified environmental limitations.

Do not perform any flash test or voltage withstand test on the

Optidrive. Any electrical measurements required should be

carried out with the Optidrive disconnected.

Electric shock hazard! Disconnect and ISOLATE the Optidrive

before attempting any work on it. High voltages are present

at the terminals and within the drive for up to 10 minutes after

disconnection of the electrical supply. Always ensure by using a

suitable multimeter that no voltage is present on any drive power

terminals prior to commencing any work.

Where supply to the drive is through a plug and socket connector,

do not disconnect until 10 minutes have elapsed after turning off

the supply.

Ensure correct earthing connections and cable selection as

defined by local legislation or codes. The drive may have a

leakage current of greater than 3.5mA; furthermore the earth

cable must be sufficient to carry the maximum supply fault current

which normally will be limited by the fuses or MCB. Suitably rated

fuses or MCB should be fitted in the mains supply to the drive,

according to any local legislation or codes.

Do not carry out any work on the drive control cables whilst

power is applied to the drive or to the external control circuits.

The “Safe Torque Off” Function does not prevent high voltages

from being present at the drives power terminals.

Within the European Union, all machinery in which this product is used

must comply with the Machinery Directive 2006/42/EC, Safety of

Machinery. In particular, the machine manufacturer is responsible for

ensuring that the electrical equipment complies with EN60204-1 and

providing a disconnecting device which must be one of the following

types:

A switch-disconnector, utilization category AC-23B (EN 60947-3).

A circuit breaker suitable for isolation in accordance with

For installation in other regions, conformance with local electrical

regulations and codes of practice must be adhered to.

The level of integrity offered by the Optidrive control input functions –

for example stop/start, forward/reverse and maximum speed, is not

sufficient for use in safety-critical applications without independent

channels of protection. All applications where malfunction could cause

injury or loss of life must be subject to a risk assessment and further

protection provided where needed.

The driven motor can start at power up if the enable input signal is present.

The STOP function does not remove potentially lethal high voltages.

ISOLATE the drive and wait 10 minutes before starting any work on it.

Never carry out any work on the Drive, Motor or Motor cable whilst

the input power is still applied.

The Optidrive can be programmed to operate the driven motor at

speeds above or below the speed achieved when connecting the

motor directly to the mains supply. Obtain confirmation from the

manufacturers of the motor and the driven machine about suitability for

operation over the intended speed range prior to machine start up.

Do not activate the automatic fault reset function on any systems

whereby this may cause a potentially dangerous situation.

IP55 and IP66 drives provide their own pollution degree 2

environments. IP20 drives must be installed in a pollution degree 2

environment, mounted in a cabinet with IP54 or better.

Optidrives are intended for indoor use only.

When mounting the drive, ensure that sufficient cooling is provided. Do

not carry out drilling operations with the drive in place, dust and swarf

from drilling may lead to damage.

The entry of conductive or flammable foreign bodies should be

prevented. Flammable material should not be placed close to the drive.

Relative humidity must be less than 95% (non-condensing).

Ensure that the supply voltage, frequency and no. of phases (1 or 3

phase) correspond to the rating of the Optidrive as delivered.

Never connect the mains power supply to the Output terminals U, V, W.

Do not install any type of automatic switchgear between the drive and

the motor.

Wherever control cabling is close to power cabling, maintain a

minimum separation of 100 mm and arrange crossings at 90 degrees.

Ensure that all terminals are tightened to the appropriate torque setting.

Do not attempt to carry out any repair of the Optidrive. In the case of

suspected fault or malfunction, contact your local Invertek Drives Sales

Partner for further assistance.

Do not operate the drive with any of the enclosure covers removed.

Danger: Indicates a potentially hazardous situation

other than electrical, which if not avoided, could

result in damage to property.

EN 60947-2.

A disconnector with an integrated auxiliary contact that ensures under

all circumstances the switching devices break the load circuit prior to

opening of the main contacts of the disconnector (EN 60947-3).

4 | Optidrive P2 User Guide | Version 3.04 www.invertekdrives.com

Page 5

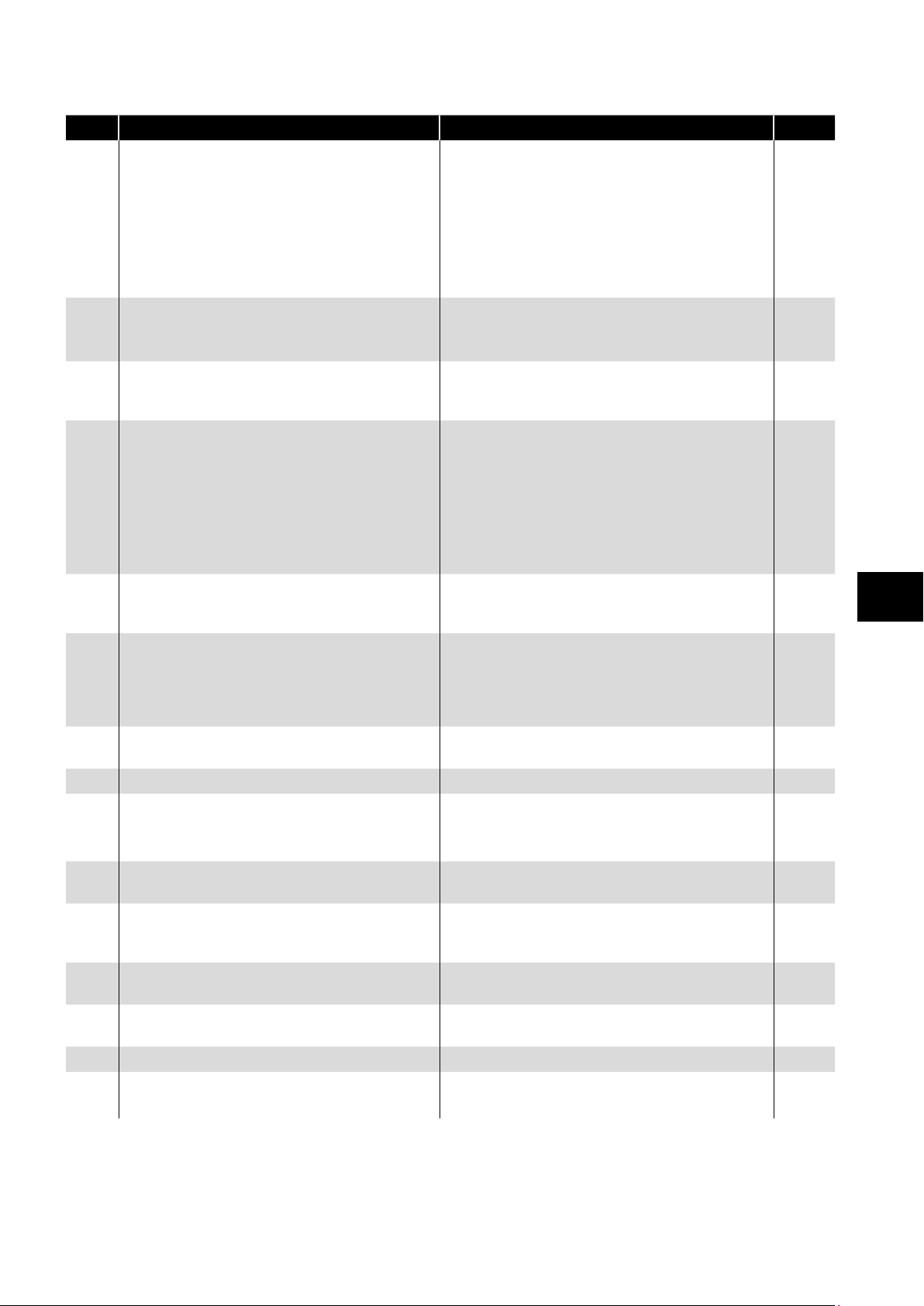

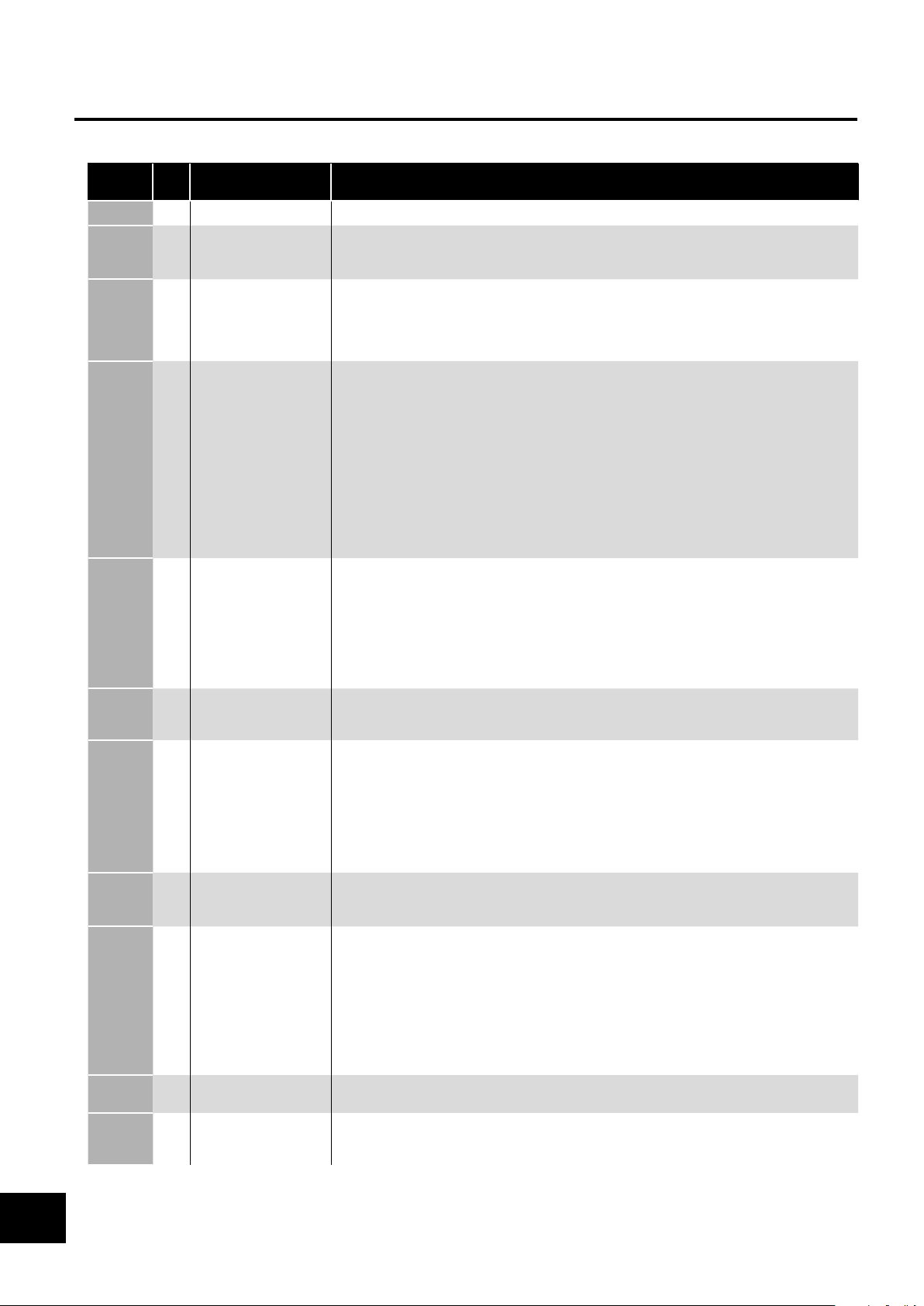

1.2. Quick Start Process

Step Action See Section Page

1 Identify the Model Type and ratings of your drive

from the model code on the label. In particular:

- Check the voltage rating suits the incoming supply

- Check the output current capacity meets or

exceeds the full load current for the intended

motor

- Check the enclosure type is suitable for the

intended mounting location.

2 Unpack and check the drive.

Notify the supplier and shipper immediately of any

damage.

3 Ensure correct ambient and environmental conditions

for the drive are met by the proposed mounting

location.

4 Install the drive in a suitable cabinet (IP20 Units),

ensuring suitable cooling air is available.

Mount the drive to the wall or machine (IP55 &

IP66).

5 Select the correct power and motor cables

according to local wiring regulations or code, noting

the maximum permissible sizes.

6 For IT Supply network, or any power supply type

where the phase – earth voltage may exceed

the phase – phase voltage (such as ungrounded

supplies), disconnect the EMC filter before

connecting the supply.

7 Check the supply cable and motor cable for faults or

short circuits.

8 Route the cables

9 Check that the intended motor is suitable for use,

noting any precautions recommended by the supplier

or manufacturer.

2.1. Identifying the Drive by Model Number

2.3. Understanding the Rating Label

2.4. Drive Model Numbers – IP20

2.5. Drive Model Numbers – IP55

2.6. Drive Model Numbers – IP66 Non-switched

3.1. General

10.1. Environmental 72

3.1. General

3.2. Before Installation

3.5. Mechanical Dimensions and Weight

3.6. Guidelines for Enclosure Mounting (IP20 Units)

3.7. Mounting the Drive – IP20 Units

3.8. Guidelines for Mounting (IP55 Units)

3.9. Guidelines for Mounting (IP66 Units)

10.2. Input/Output Power and Current Ratings 72

10.6. Internal EMC Filter and Varistors – Disconnection

Procedure

4.6. Motor Connection

8.2.3. Parameter Group 4 – High Performance Motor

Control

6

7

7

9

10

12

Quick Start Up

12

12

13

16

17

17

18

1

76

23

53

10 Check the motor terminal box for correct Star or

Delta configuration where applicable.

11 Ensure correct wiring protection is providing, by

installing a suitable circuit breaker or fuses in the

incoming supply line.

12 Connect the power cables, especially ensuring the

protective earth connection is made.

13 Connect the control cables as required for the

application.

14 Thoroughly check the installation and wiring.

15 Commission the drive parameters. 5.4. Changing Parameters

4.7. Motor Terminal Box Connections 23

4.3.3. Fuse / Circuit Breaker Selection 22

4.1. Connection Diagram 20

4.10. Control Terminal Connections 26

6. Parameters

Version 3.04 | Optidrive P2 User Guide | 5www.invertekdrives.com

35

37

Page 6

2. General Information and Ratings

2.1. Identifying the Drive by Model Number

The model number of each Optidrive P2 is constructed according to the following system:

ODP - 2 - 2 4 400 - 3 K F 4 2 - M N

Product Family PCB Coating

General Information & Ratings

Generation Display

Frame Size

Voltage Code

2 : 230 Volt

4 : 400 Volt

5 : 525 Volt

6 : 600 Volt

Three Digit Power Rating

Input Phases Brake Chopper

Power Type

K : kW Rated

H : HP Rated

N : Standard Localised Coating

M: TFT display

T : OLED Text Display

Enclosure

2 : IP20

N : IP55 Non-Switched

A: IP66 Outdoor Non-Switched

B: IP66 Outdoor Switched

4 : Internal Brake Chopper

EMC Filter

0 : No Internal Filer

F : Internal EMC Filter

2

2.2. Product Rating Label Location

All Optidrive P2 models carry a rating label, which can be located as follows:

IP20 Models IP55 Models IP66 Models

On right hand side when viewed from the

front.

On right hand side when viewed from the

front.

On the top surface.

6 | Optidrive P2 User Guide | Version 3.04 www.invertekdrives.com

Page 7

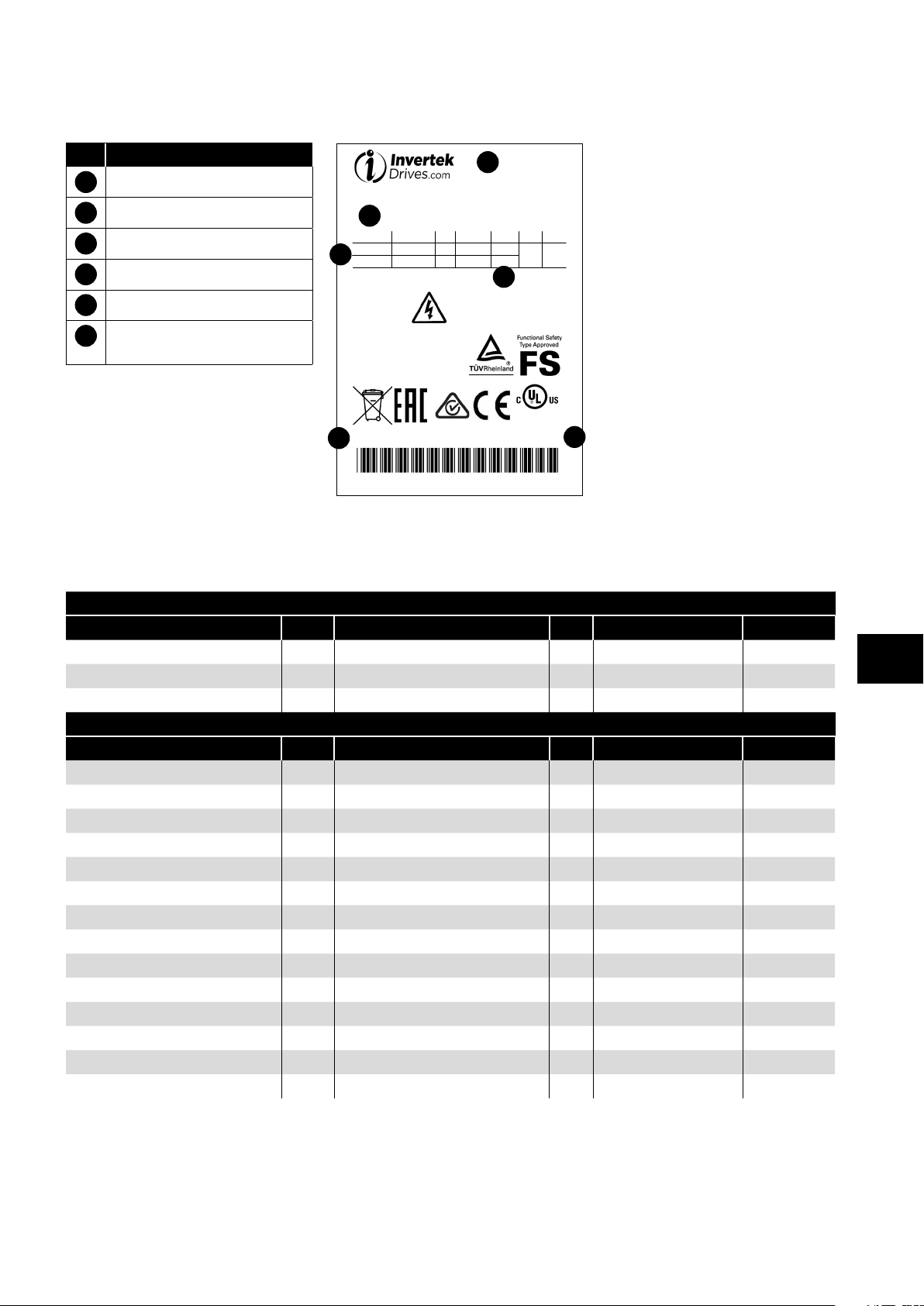

2.3. Understanding the Rating Label

Serial No.:

www.invertekdrives.com

Made in the UK

919011

S/Ware

2.50

HP

/ NEMA 4X

The product rating label provides the following information.

Key

1 Model Code

2 Enclosure Type and IP Rating

3 Firmware Version

4 Serial Number

5 Technical Data – Supply Voltage

Technical Data – Maximum

6

5

OPTIDRIVE P2

ODP-2-64075-3KF42-MN

1

Input

Output

5min before

removing

cover

V

380-480 3 153.2

0-500 150.0

CAUTION

2

20IP

Ø F(Hz) I (A)

50/60

3 0-500

kW

75

6

Read User Guide BeforePower down for

installation or servicing

SCCR: For rating and

protection refer to User Guide

100

continuous output current

Listed 2AD0

Ind.Cont.Eq.

4

11111111111

E226333

3

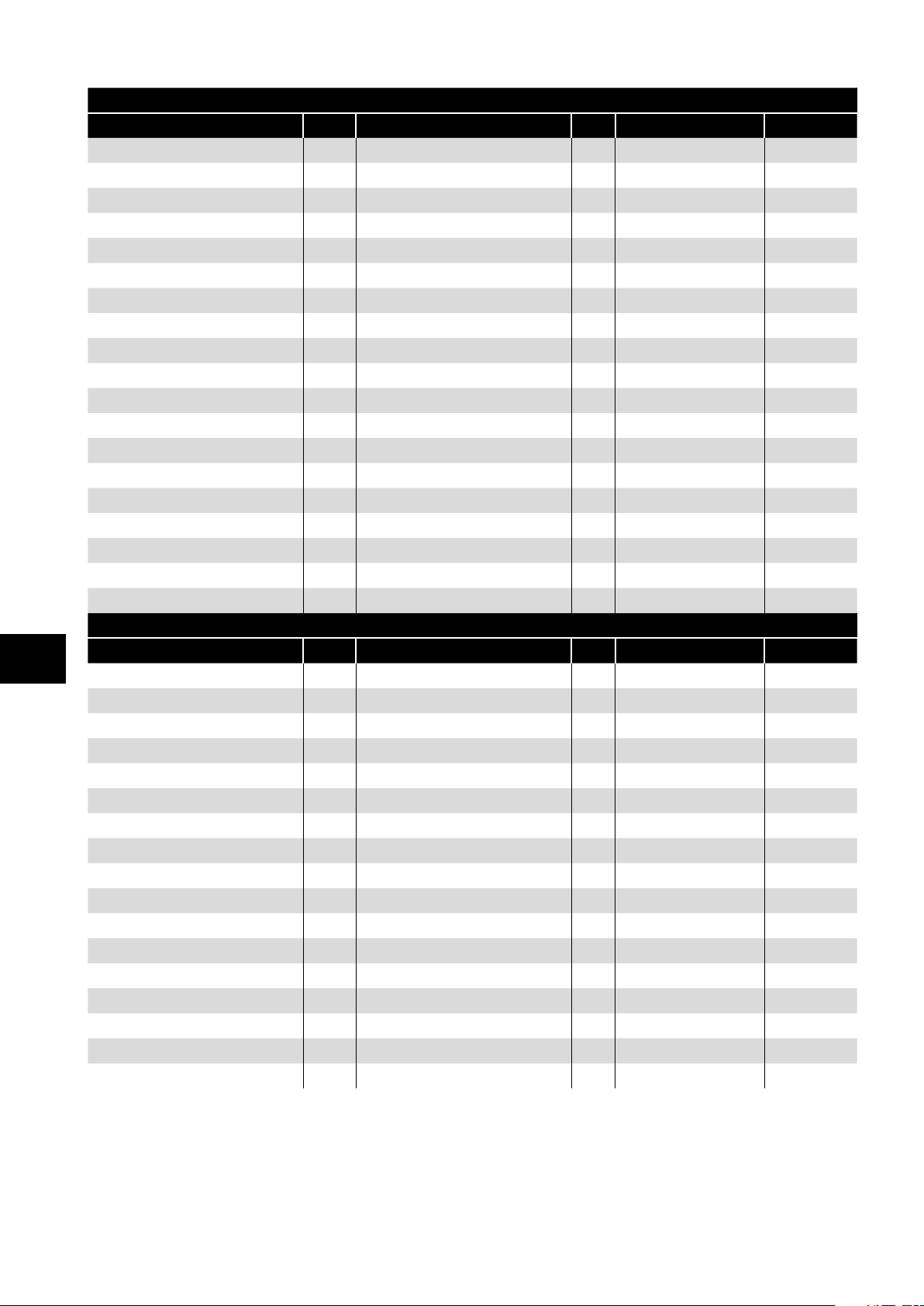

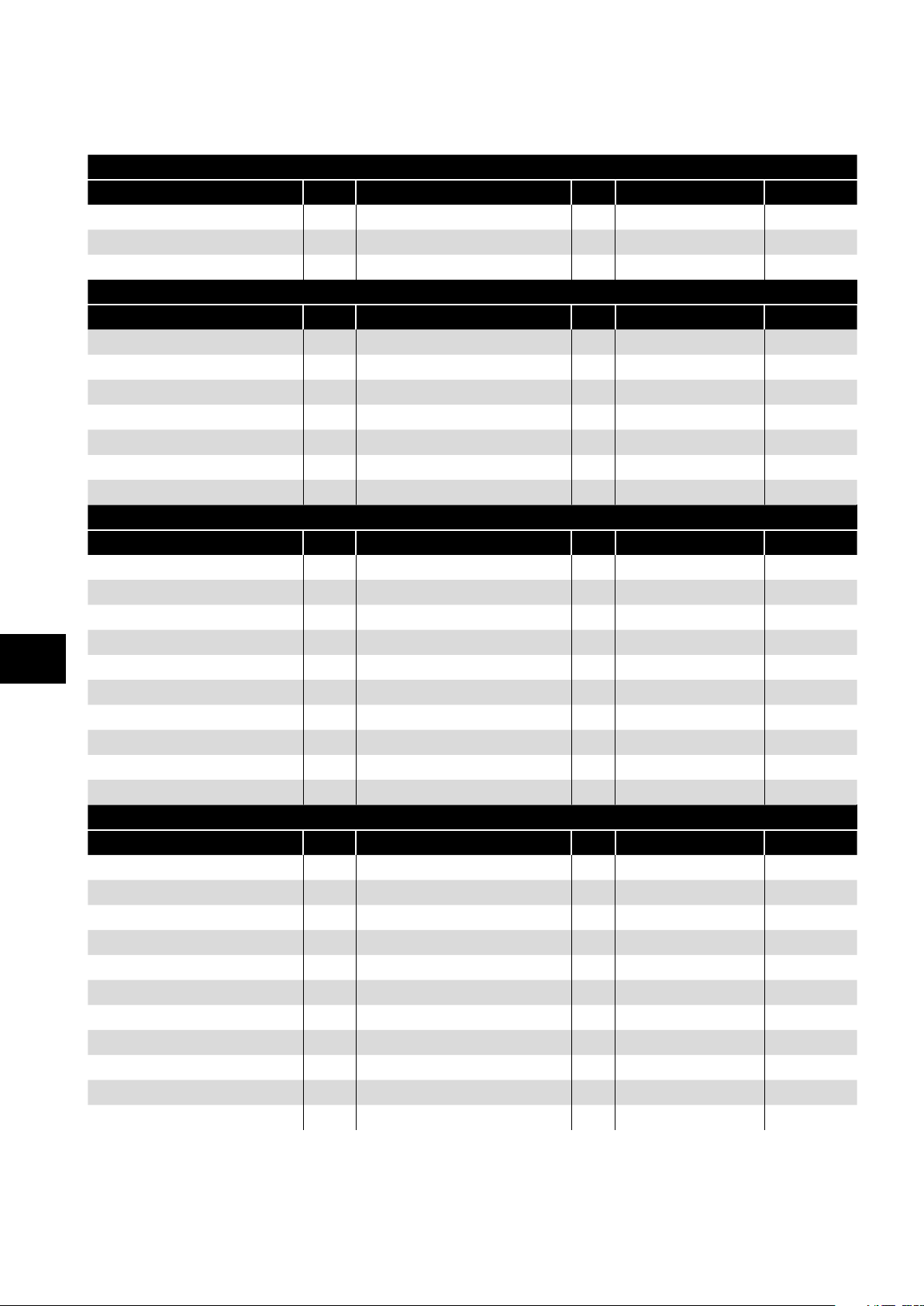

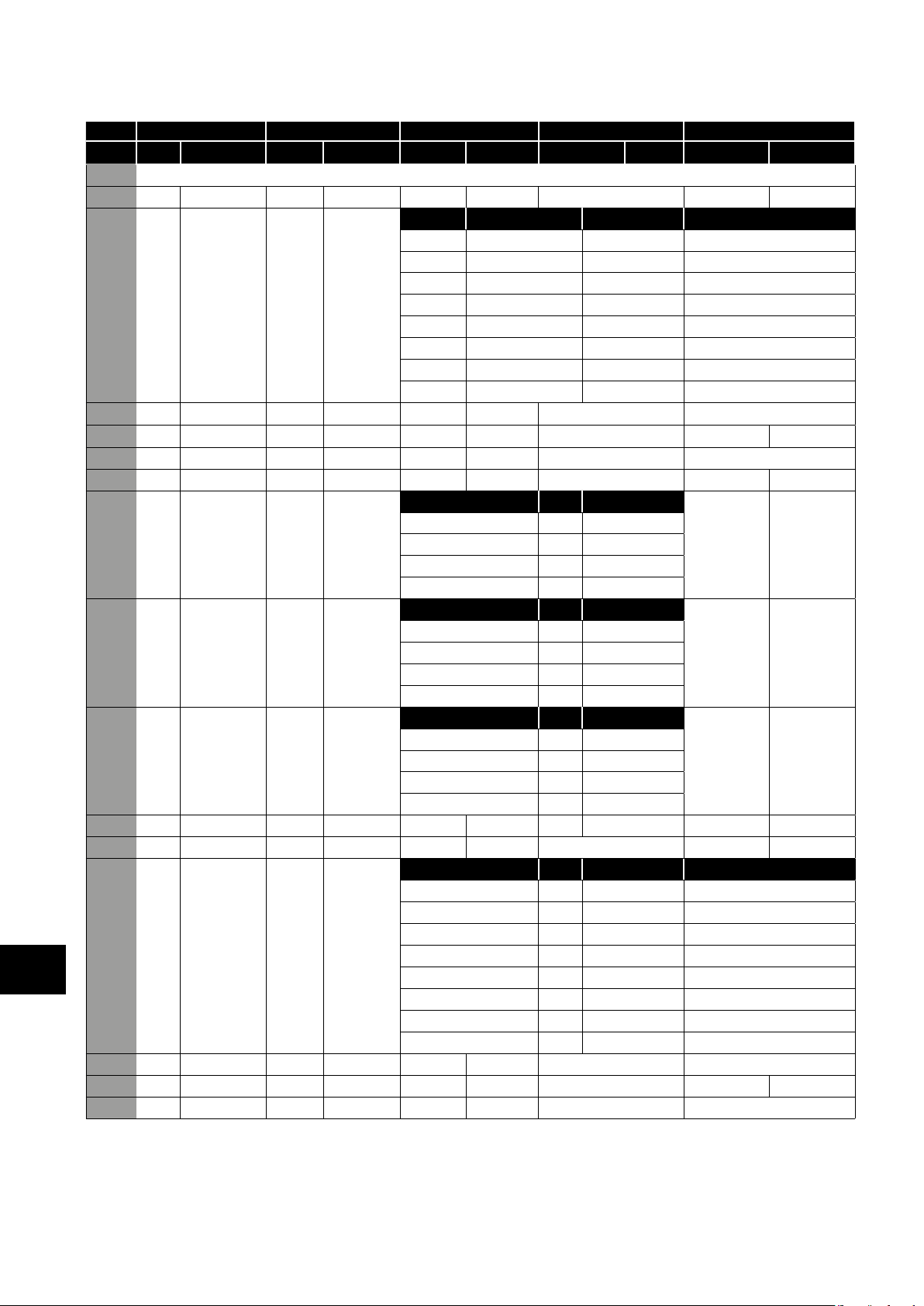

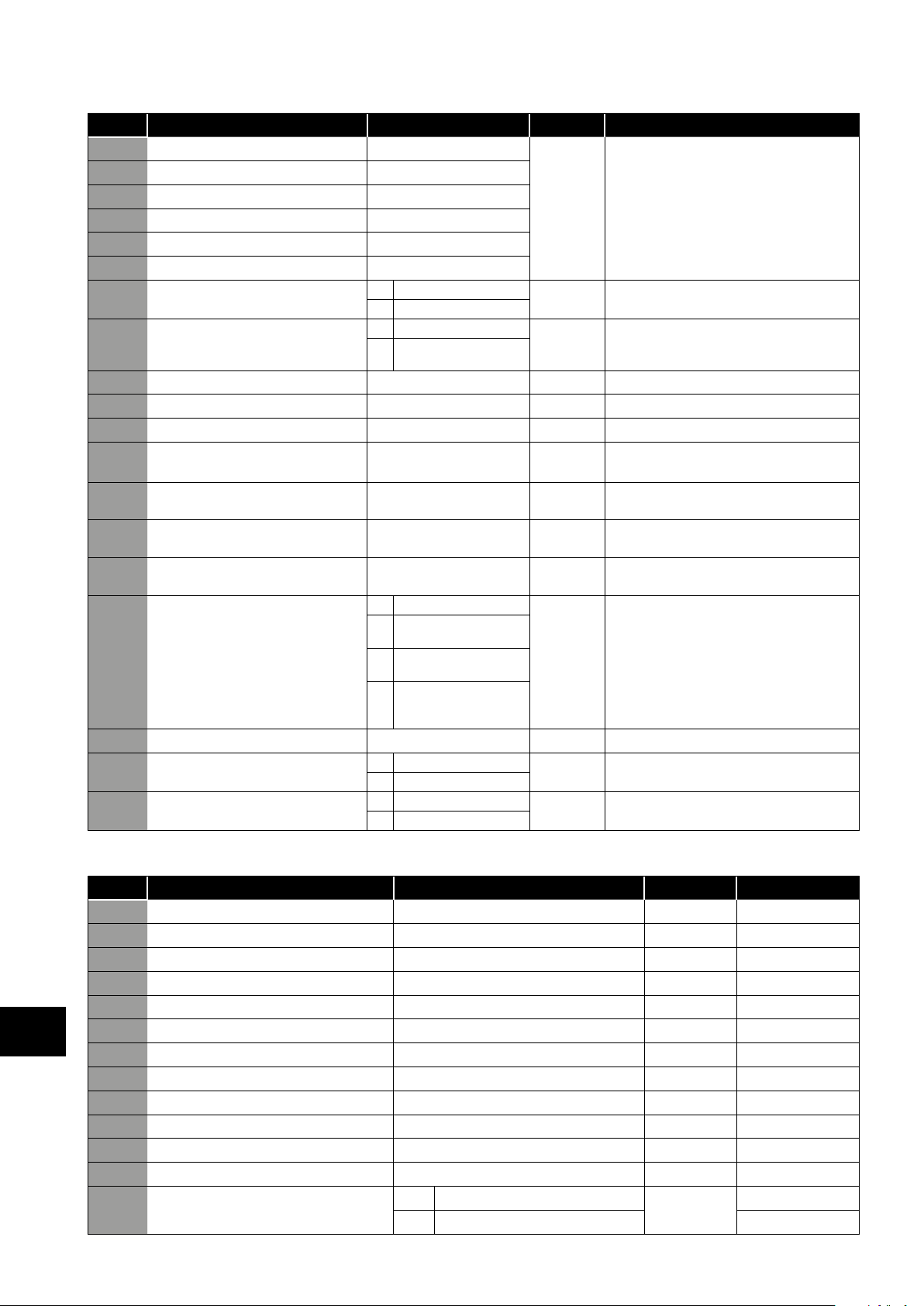

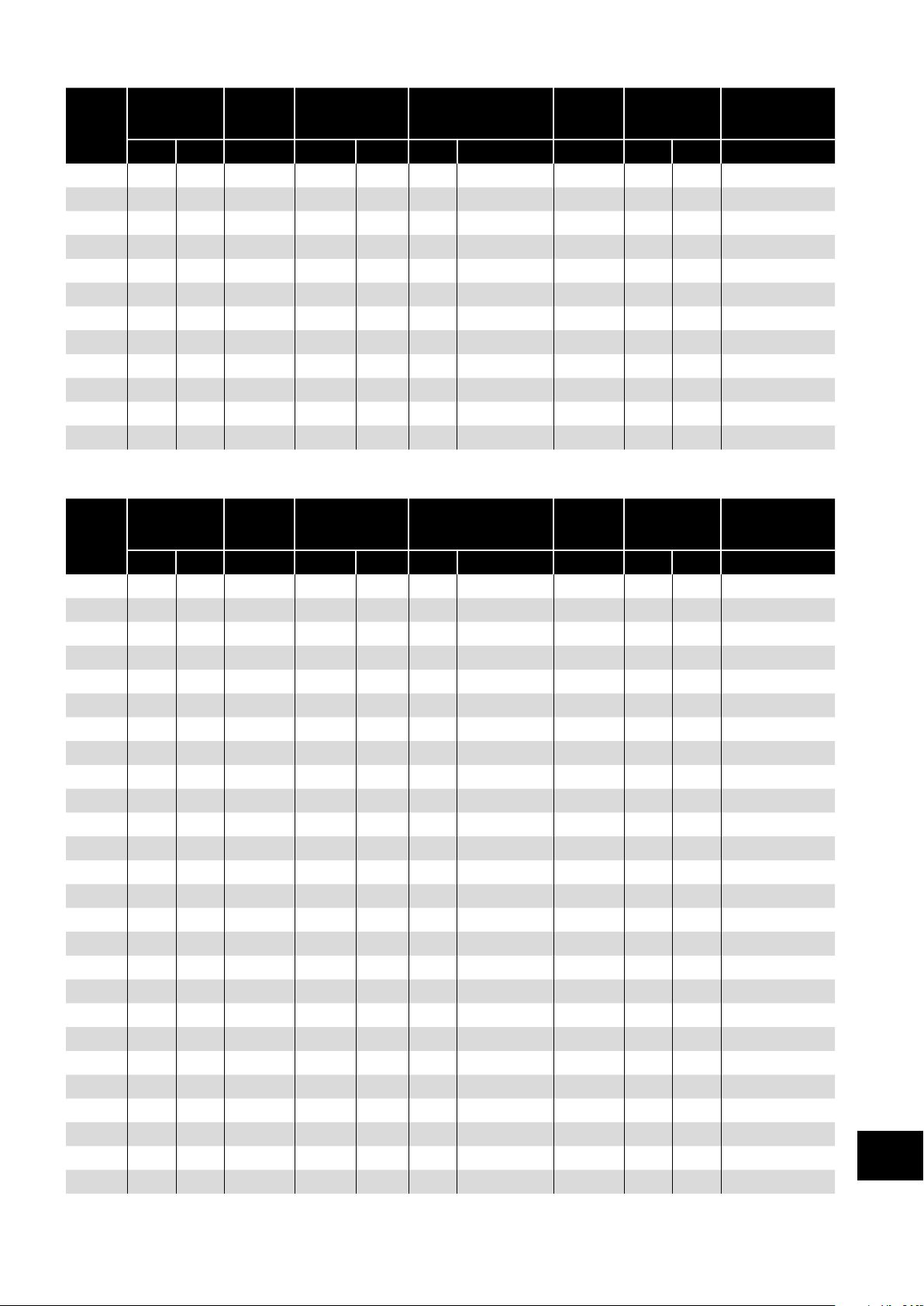

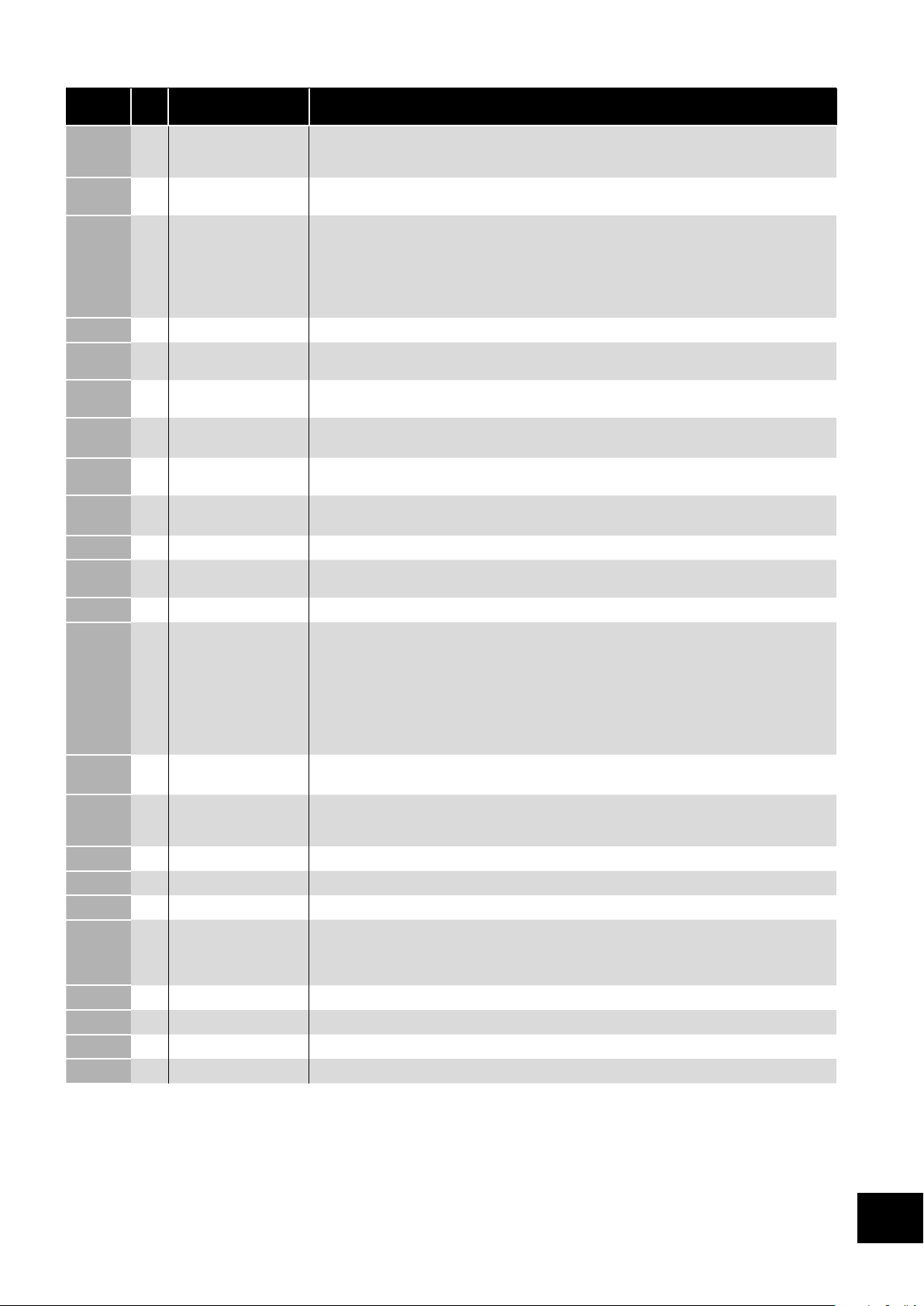

2.4. Drive Model Numbers – IP20

Mechanical Dimensions and Mounting information are shown in section 3.5.1. IP20 Units on page 13.

Electrical Specifications are shown in section 10.2. Input/Output Power and Current Ratings on page 72.

200-240V ±10% - 1 Phase Input

kW Model kW HP Model HP Output Current (A) Frame Size

ODP-2-22075-1KF42-MN 0.75 ODP-2-22010-1HF42-MN 1 4.3 2

ODP-2-22150-1KF42-MN 1.5 ODP-2-22020-1HF42-MN 2 7 2

ODP-2-22220-1KF42-MN 2.2 ODP-2-22030-1HF42-MN 3 10.5 2

200-240V ±10% - 3 Phase Input

kW Model kW HP Model HP Output Current (A) Frame Size

ODP-2-22075-3KF42-MN 0.75 ODP-2-22010-3HF42-MN 1 4.3 2

ODP-2-22150-3KF42-MN 1.5 ODP-2-22020-3HF42-MN 2 7 2

ODP-2-22220-3KF42-MN 2.2 ODP-2-22030-3HF42-MN 3 10.5 2

ODP-2-32040-3KF42-MN 4 ODP-2-32050-3HF42-MN 5 18 3

ODP-2-32055-3KF42-MN 5.5 ODP-2-32075-3HF42-MN 7. 5 24 3

ODP-2-42075-3KF42-MN 7. 5 ODP-2-42100-3HF42-MN 10 30 4

ODP-2-42110-3KF42-MN 11 ODP-2-42150-3HF42-MN 15 46 4

ODP-2-52150-3KF42-MN 15 ODP-2-52020-3HF42-MN 20 61 5

ODP-2-52185-3KF42-MN 18.5 ODP-2-52025-3HF42-MN 25 72 5

ODP-2-62022-3KF42-MN 22 ODP-2-62030-3HF42-MN 30 90 6A

ODP-2-62030-3KF42-MN 30 ODP-2-62040-3HF42-MN 40 110 6A

ODP-2-62037-3KF42-MN 37 ODP-2-62050-3HF42-MN 50 15 0 6B

ODP-2-62045-3KF42-MN 45 ODP-2-62060-3HF42-MN 60 18 0 6B

ODP-2-62055-3KF42-MN 55 ODP-2-62075-3HF42-MN 75 202 6B

General Information & Ratings

2

Version 3.04 | Optidrive P2 User Guide | 7www.invertekdrives.com

Page 8

380-480V ±10% - 3 Phase Input

kW Model kW HP Model HP Output Current (A) Frame Size

ODP-2-24075-3KF42-MN 0.75 ODP-2-24010-3HF42-MN 1 2.2 2

ODP-2-24150-3KF42-MN 1.5 ODP-2-24020-3HF42-MN 2 4.1 2

ODP-2-24220-3KF42-MN 2.2 ODP-2-24030-3HF42-MN 3 5.8 2

General Information & Ratings

2

ODP-2-24400-3KF42-MN 4 ODP-2-24050-3HF42-MN 5 9.5 2

ODP-2-34055-3KF42-MN 5.5 ODP-2-34075-3HF42-MN 7. 5 14 3

ODP-2-34075-3KF42-MN 7. 5 ODP-2-34100-3HF42-MN 10 18 3

ODP-2-34110-3KF42-MN 11 ODP-2-34150-3HF42-MN 15 24 3

ODP-2-44150-3KF42-MN 15 ODP-2-44200-3HF42-MN 20 30 4

ODP-2-44185-3KF42-MN 18.5 ODP-2-44250-3HF42-MN 25 39 4

ODP-2-44220-3KF42-MN 22 ODP-2-44300-3HF42-MN 30 46 4

ODP-2-54300-3KF42-MN 30 ODP-2-54040-3HF42-MN 40 61 5

ODP-2-54370-3KF42-MN 37 ODP-2-54050-3HF42-MN 50 72 5

ODP-2-64045-3KF42-MN 45 ODP-2-64060-3HF42-MN 60 90 6A

ODP-2-64055-3KF42-MN 55 ODP-2-64075-3HF42-MN 75 11 0 6A

ODP-2-64075-3KF42-MN 75 ODP-2-64100-3HF42-MN 100 15 0 6B

ODP-2-64090-3KF42-MN 90 ODP-2-64150-3HF42-MN 15 0 180 6B

ODP-2-64110-3KF42-MN 11 0 ODP-2-64175-3HF42-MN 175 202 6B

ODP-2-84200-3KF42-MN 200 ODP-2-84300-3HF42-MN 300 370 8

ODP-2-84250-3KF42-MN 250 ODP-2-84400-3HF42-MN 400 450 8

500-600V ±10% - 3 Phase Input

kW Model kW HP Model HP Output Current (A) Frame Size

ODP-2-26075-3K042-MN 0. 75 ODP-2-26010-3H042-MN 1 2 .1 2

ODP-2-26150-3K042-MN 1. 5 ODP-2-26020-3H042-MN 2 3.1 2

ODP-2-26220-3K042-MN 2.2 ODP-2-26030-3H042-MN 3 4.1 2

ODP-2-26400-3K042-MN 4 ODP-2-26050-3H042-MN 5 6.5 2

ODP-2-26550-3K042-MN 5.5 ODP-2-26075-3H042-MN 7. 5 9 2

ODP-2-36075-3K042-MN 7. 5 ODP-2-36100-3H042-MN 10 12 3

ODP-2-36110-3K042-MN 11 ODP-2-36150-3H042-MN 15 17 3

ODP-2-36150-3K042-MN 15 ODP-2-36200-3H042-MN 20 22 3

ODP-2-46185-3K042-MN 18.5 ODP-2-46250-3H042-MN 25 28 4

ODP-2-46220-3K042-MN 22 ODP-2-46300-3H042-MN 30 34 4

ODP-2-46300-3K042-MN 30 ODP-2-46400-3H042-MN 40 43 4

ODP-2-56370-3K042-MN 37 ODP-2-56050-3H042-MN 50 54 5

ODP-2-56045-3K042-MN 45 ODP-2-56060-3H042-MN 60 65 5

ODP-2-66055-3K042-MN 55 ODP-2-66075-3H042-MN 75 78 6A

ODP-2-66075-3K042-MN 75 ODP-2-66100-3H042-MN 10 0 10 5 6A

ODP-2-66090-3K042-MN 90 ODP-2-66125-3H042-MN 12 5 13 0 6B

ODP-2-66110-3K042-MN 110 ODP-2-66150-3H042-MN 15 0 15 0 6B

8 | Optidrive P2 User Guide | Version 3.04 www.invertekdrives.com

Page 9

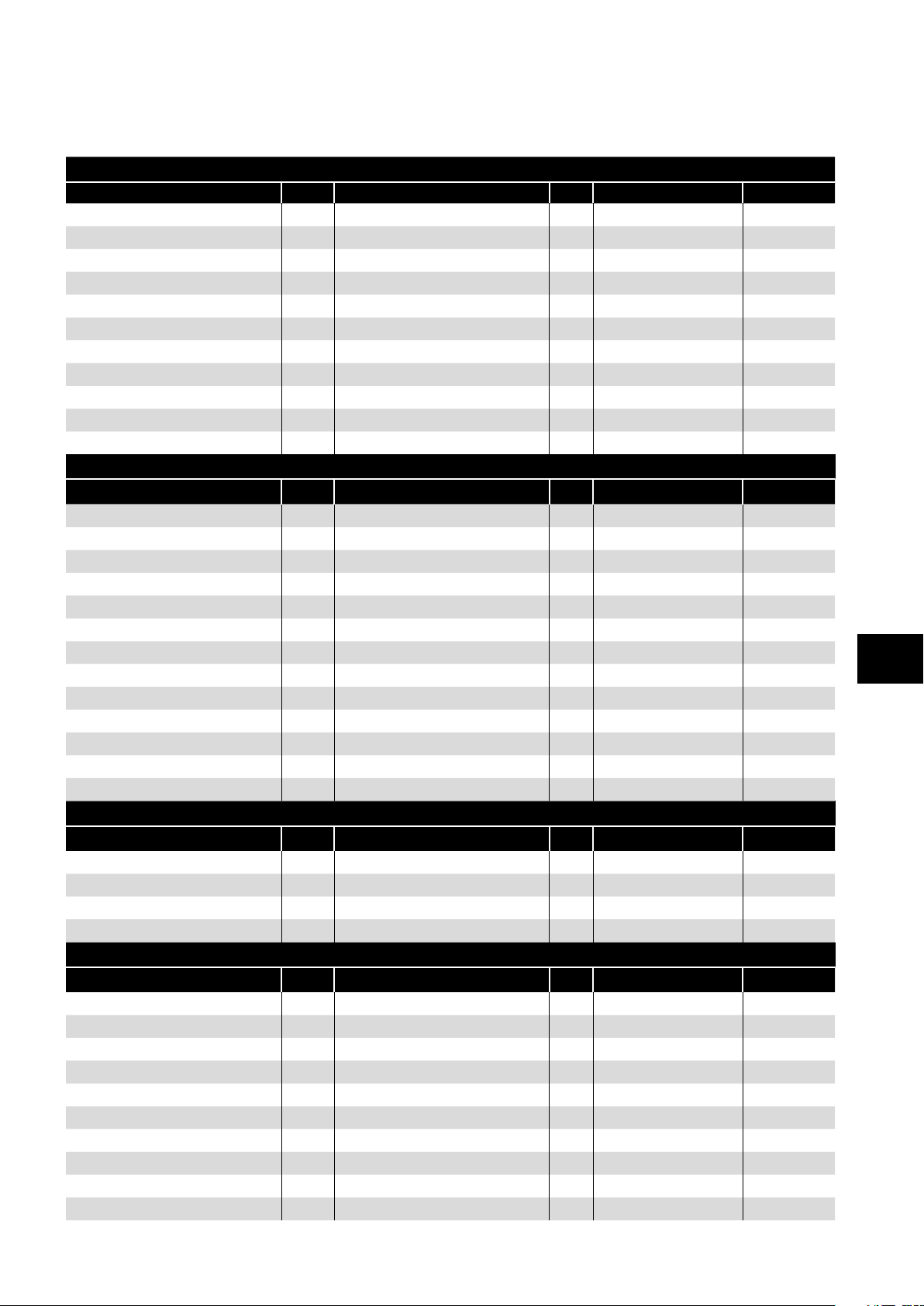

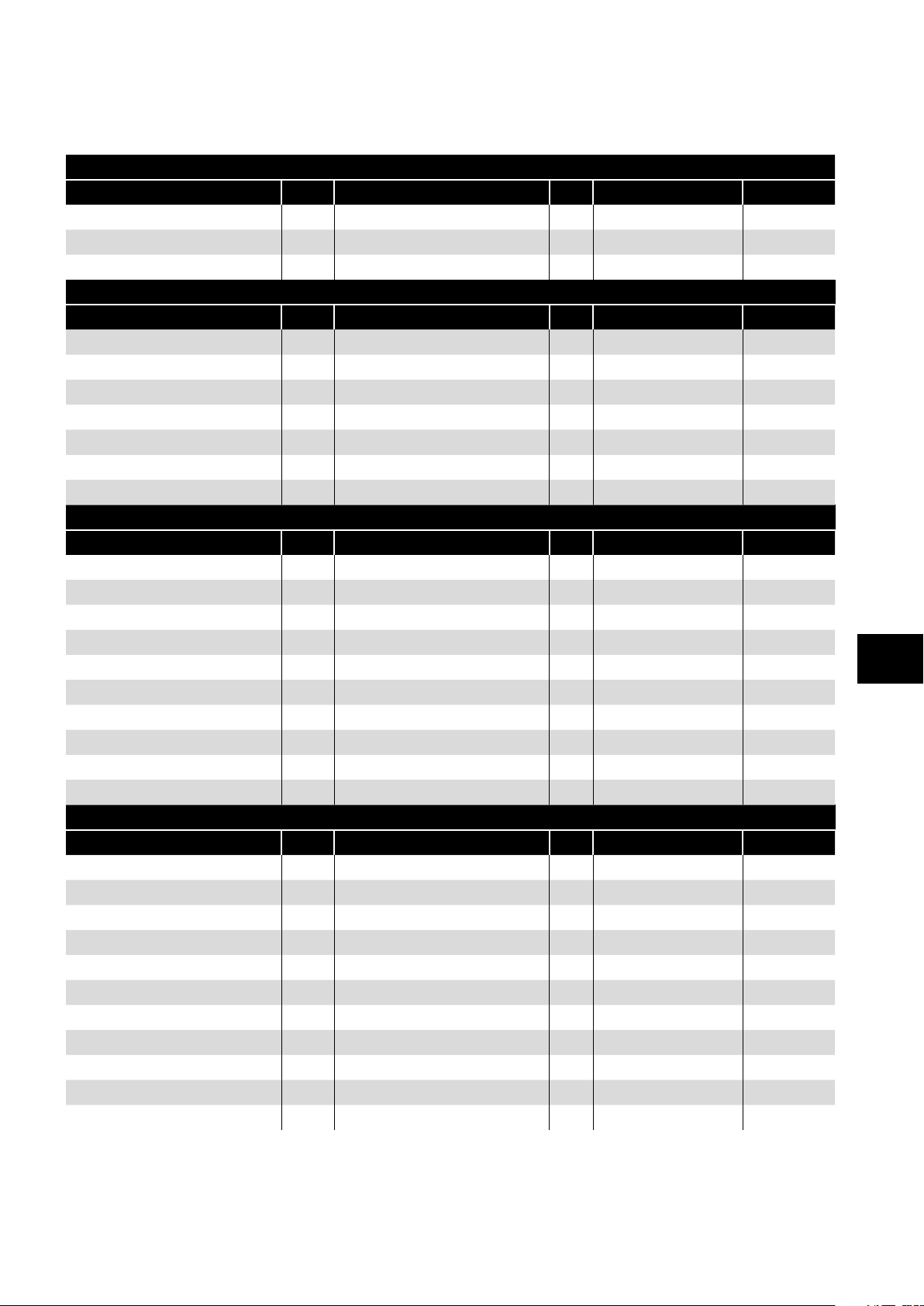

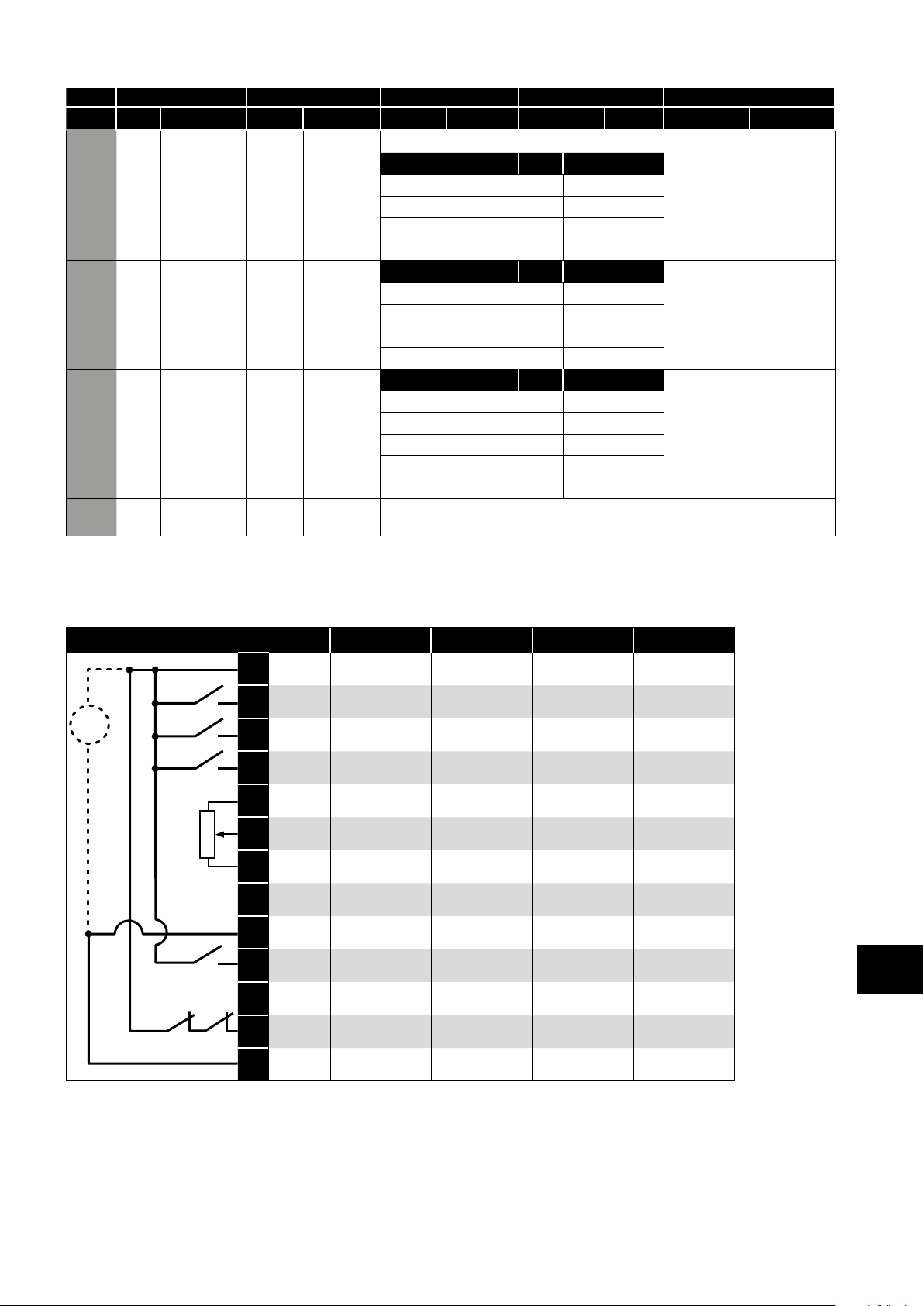

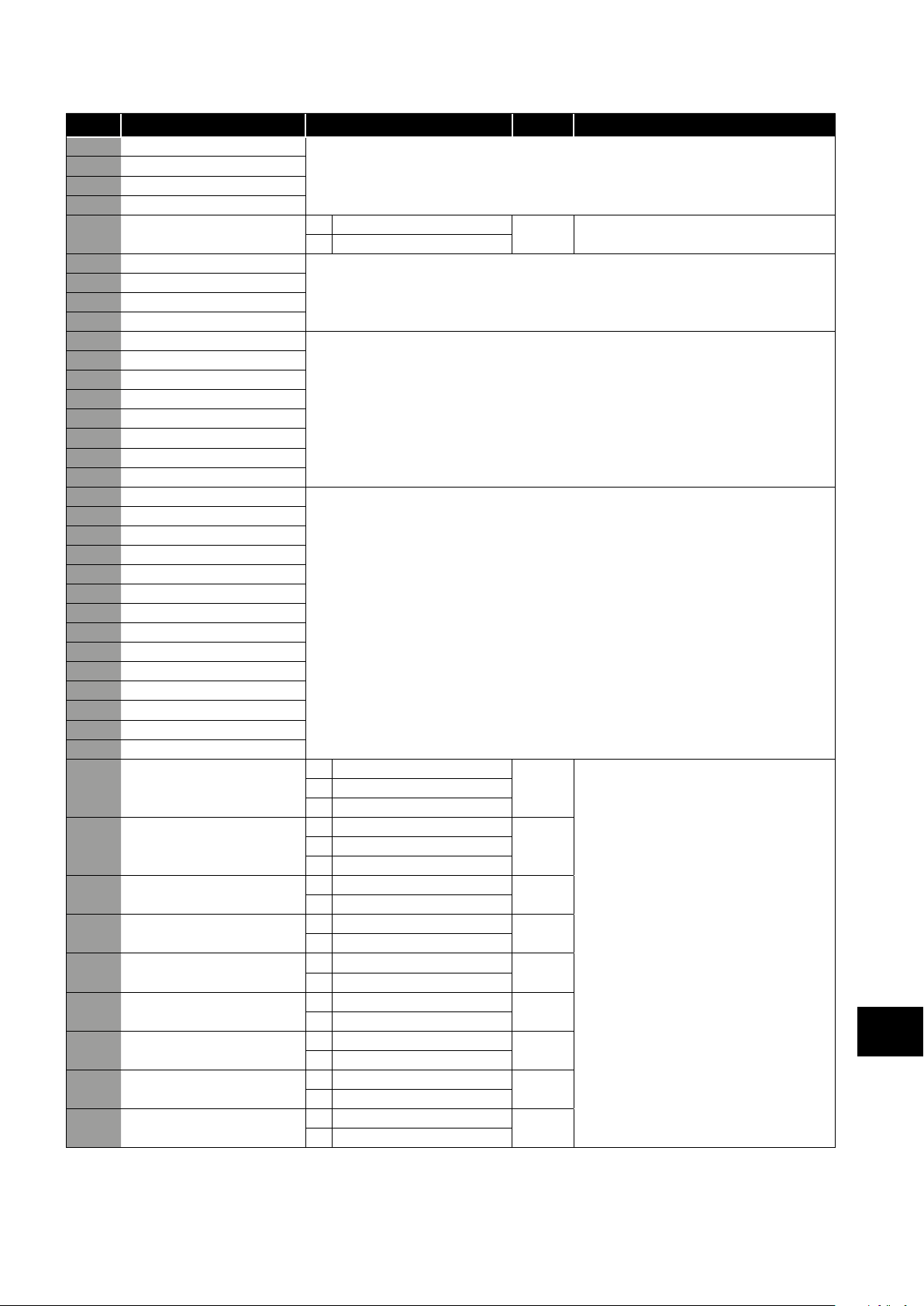

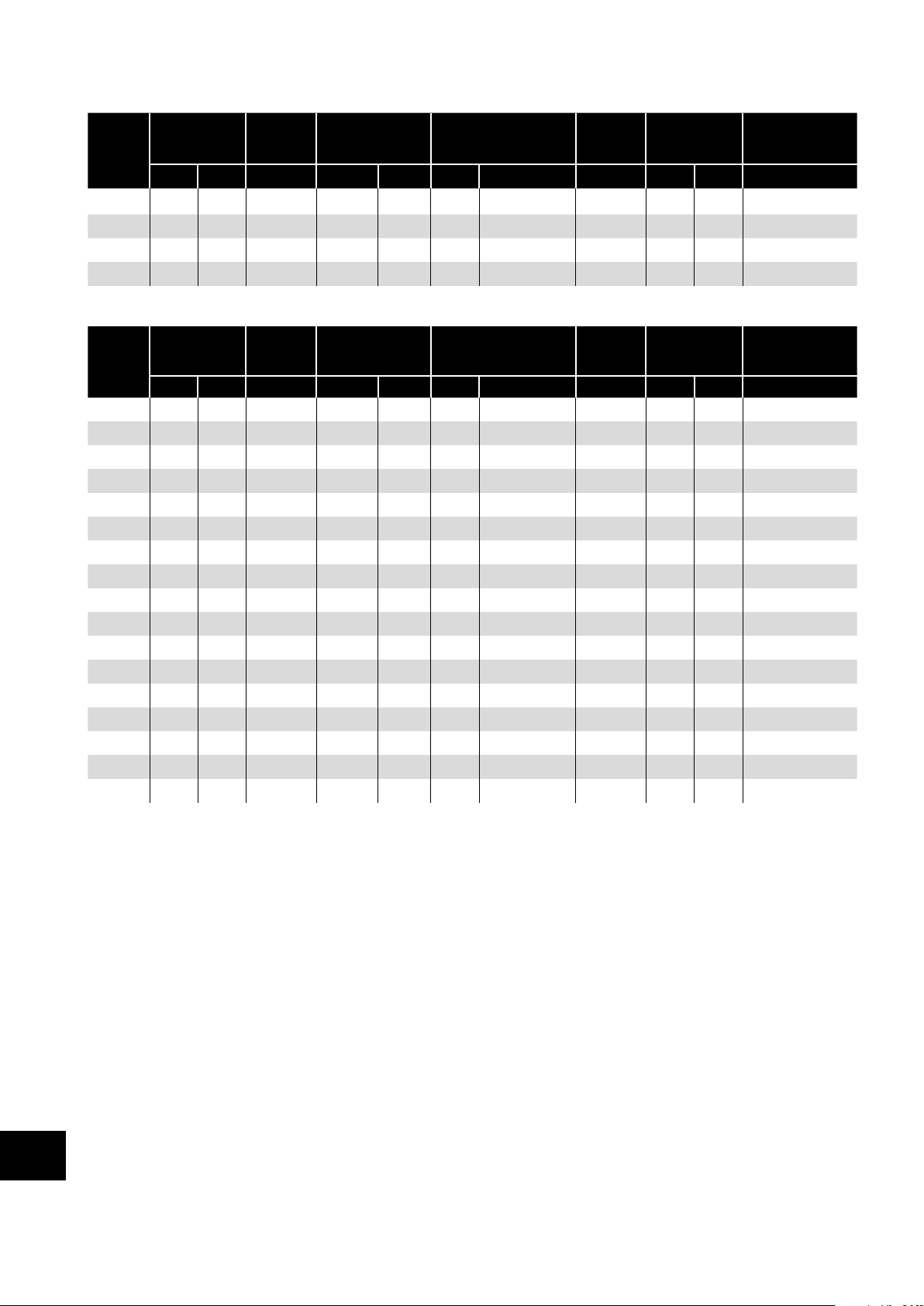

2.5. Drive Model Numbers – IP55

Mechanical dimensions and mounting information are shown from section 3.5.2. IP55 Units on page 14.

Electrical specifications are shown in section 10.2. Input/Output Power and Current Ratings on page 72.

200-240V ±10% - 3 Phase Input

kW Model Number kW HP Model Number HP Output Current (A) Frame Size

ODP-2-42055-3KF4N-TN 5.5 ODP-2-42075-3HF4N-TN 7. 5 24 4

ODP-2-42075-3KF4N-TN 7. 5 ODP-2-42100-3HF4N-TN 10 30 4

ODP-2-42110-3KF4N-TN 11 ODP-2-42150-3HF4N-TN 15 46 4

ODP-2-52150-3KF4N-TN 15 ODP-2-52020-3HF4N-TN 20 61 5

ODP-2-52185-3KF4N-TN 18.5 ODP-2-52025-3HF4N-TN 25 72 5

ODP-2-62022-3KF4N-TN 22 ODP-2-62030-3HF4N-TN 30 90 6

ODP-2-62030-3KF4N-TN 30 ODP-2-62040-3HF4N-TN 40 11 0 6

ODP-2-62037-3KF4N-TN 37 ODP-2-62050-3HF4N-TN 50 15 0 6

ODP-2-62045-3KF4N-TN 45 ODP-2-62060-3HF4N-TN 60 18 0 6

ODP-2-72055-3KF4N-TN 55 ODP-2-72075-3HF4N-TN 75 202 7

ODP-2-72075-3KF4N-TN 75 ODP-2-72100-3HF4N-TN 10 0 248 7

380-480V ±10% - 3 Phase Input

kW Model Number kW HP Model Number HP Output Current (A) Frame Size

ODP-2-44110-3KF4N-TN 11 ODP-2-44150-3HF4N-TN 15 24 4

ODP-2-44150-3KF4N-TN 15 ODP-2-44200-3HF4N-TN 20 30 4

ODP-2-44185-3KF4N-TN 18.5 ODP-2-44250-3HF4N-TN 25 39 4

ODP-2-44220-3KF4N-TN 22 ODP-2-44300-3HF4N-TN 30 46 4

ODP-2-54300-3KF4N-TN 30 ODP-2-54040-3HF4N-TN 40 61 5

ODP-2-54370-3KF4N-TN 37 ODP-2-54050-3HF4N-TN 50 72 5

ODP-2-64045-3KF4N-TN 45 ODP-2-64060-3HF4N-TN 60 90 6

ODP-2-64055-3KF4N-TN 55 ODP-2-64075-3HF4N-TN 75 110 6

ODP-2-64075-3KF4N-TN 75 ODP-2-64100-3HF4N-TN 10 0 15 0 6

ODP-2-64090-3KF4N-TN 90 ODP-2-64150-3HF4N-TN 15 0 18 0 6

ODP-2-74110-3KF4N-TN 110 ODP-2-74175-3HF4N-TN 175 202 7

ODP-2-74132-3KF4N-TN 13 2 ODP-2-74200-3HF4N-TN 200 240 7

ODP-2-74160-3KF4N-TN 16 0 ODP-2-74250-3HF4N-TN 250 302 7

480-525V ±10% - 3 Phase Input

kW Model Number kW HP Model Number HP Output Current (A) Frame Size

ODP-2-75132-3K04N-TN 13 2 175 185 7

ODP-2-75150-3K04N-TN 15 0 200 205 7

ODP-2-75185-3K04N-TN 18 5 250 255 7

ODP-2-75200-3K04N-TN 200 270 275 7

500-600V ±10% - 3 Phase Input

kW Model Number kW HP Model Number HP Output Current (A) Frame Size

ODP-2-46150-3K04N-TN 15 ODP-2-46200-3H04N-TN 20 22 4

ODP-2-46185-3K04N-TN 18.5 ODP-2-46250-3H04N-TN 25 28 4

ODP-2-46220-3K04N-TN 22 ODP-2-46300-3H04N-TN 30 34 4

ODP-2-46300-3K04N-TN 30 ODP-2-46400-3H04N-TN 40 43 4

ODP-2-56370-3K04N-TN 37 ODP-2-56050-3H04N-TN 50 54 5

ODP-2-56450-3K04N-TN 45 ODP-2-56060-3H04N-TN 60 65 5

ODP-2-66055-3K04N-TN 55 ODP-2-66075-3H04N-TN 75 78 6

ODP-2-66075-3K04N-TN 75 ODP-2-66100-3H04N-TN 10 0 10 5 6

ODP-2-66090-3K04N-TN 90 ODP-2-66125-3H04N-TN 12 5 13 0 6

ODP-2-66110-3K04N-TN 110 ODP-2-66150-3H04N-TN 15 0 15 0 6

General Information & Ratings

2

Version 3.04 | Optidrive P2 User Guide | 9www.invertekdrives.com

Page 10

2.6. Drive Model Numbers – IP66 Non-switched

Mechanical dimensions and mounting information are shown from section 3.5.3. IP66 Units on page 15.

Electrical specifications are shown in section 10.2. Input/Output Power and Current Ratings on page 72.

200-240V ±10% - 1 Phase Input

kW Model Number kW HP Model Number HP Output Current (A) Frame Size

ODP-2-22075-1KF4A-MN 1 ODP-2-22010-1HF4A-MN 1 4.3 2

General Information & Ratings

2

ODP-2-22150-1KF4A-MN 2 ODP-2-22020-1HF4A-MN 2 7 2

ODP-2-22220-1KF4A-MN 3 ODP-2-22030-1HF4A-MN 3 10.5 2

200-240V ±10% - 3 Phase Input

kW Model Number kW HP Model Number HP Output Current (A) Frame Size

ODP-2-22075-3KF4A-MN 0.75 ODP-2-22010-3HF4A-MN 1 4.3 2

ODP-2-22150-3KF4A-MN 1.5 ODP-2-22020-3HF4A-MN 2 7 2

ODP-2-22220-3KF4A-MN 2.2 ODP-2-22030-3HF4A-MN 3 10.5 2

ODP-2-32040-3KF4A-MN 4 ODP-2-32050-3HF4A-MN 5 18 3

ODP-2-32055-3KF4A-MN 5.5 ODP-2-32075-3HF4A-MN 7. 5 24 3

ODP-2-42075-3KF4A-MN 7. 5 ODP-2-42100-3HF4A-MN 10 30 4

ODP-2-42110-3KF4A-MN 11 ODP-2-42150-3HF4A-MN 15 46 4

380-480V ±10% - 3 Phase Input

kW Model Number kW HP Model Number HP Output Current (A) Frame Size

ODP-2-24075-3KF4A-MN 0.75 ODP-2-24010-3HF4A-MN 1 2.2 2

ODP-2-24150-3KF4A-MN 1.5 ODP-2-24020-3HF4A-MN 2 4 .1 2

ODP-2-24220-3KF4A-MN 2.2 ODP-2-24030-3HF4A-MN 3 5.8 2

ODP-2-24400-3KF4A-MN 4 ODP-2-24050-3HF4A-MN 5 9.5 2

ODP-2-34055-3KF4A-MN 5.5 ODP-2-34075-3HF4A-MN 7. 5 14 3

ODP-2-34075-3KF4A-MN 7. 5 ODP-2-34100-3HF4A-MN 10 18 3

ODP-2-34110-3KF4A-MN 11 ODP-2-34150-3HF4A-MN 15 24 3

ODP-2-44150-3KF4A-MN 15 ODP-2-44200-3HF4A-MN 20 30 4

ODP-2-44185-3KF4A-MN 18.5 ODP-2-44250-3HF4A-MN 25 39 4

ODP-2-44220-3KF4A-MN 22 ODP-2-44300-3HF4A-MN 30 46 4

500-600V ±10% - 3 Phase Input

kW Model Number kW HP Model Number HP Output Current (A) Frame Size

ODP-2-26075-3K04A-MN 0 . 75 ODP-2-26010-3H04A-MN 1 2.1 2

ODP-2-26150-3K04A-MN 1.5 ODP-2-26020-3H04A-MN 2 3.1 2

ODP-2-26220-3K04A-MN 2.2 ODP-2-26030-3H04A-MN 3 4.1 2

ODP-2-26400-3K04A-MN 4 ODP-2-26050-3H04A-MN 5 6.5 2

ODP-2-26550-3K04A-MN 5.5 ODP-2-26075-3H04A-MN 7. 5 9 2

ODP-2-36075-3K04A-MN 7. 5 ODP-2-36100-3H04A-MN 10 12 3

ODP-2-36110-3K04A-MN 11 ODP-2-36150-3H04A-MN 15 17 3

ODP-2-36150-3K04A-MN 15 ODP-2-36200-3H04A-MN 20 22 3

ODP-2-46185-3KF4A-MN 18.5 ODP-2-46250-3HF4A-MN 25 28 4

ODP-2-46220-3KF4A-MN 22 ODP-2-46300-3HF4A-MN 30 34 4

ODP-2-46300-3KF4A-MN 30 ODP-2-46400-3HF4A-MN 40 43 4

10 | Optidrive P2 User Guide | Version 3.04 www.invertekdrives.com

Page 11

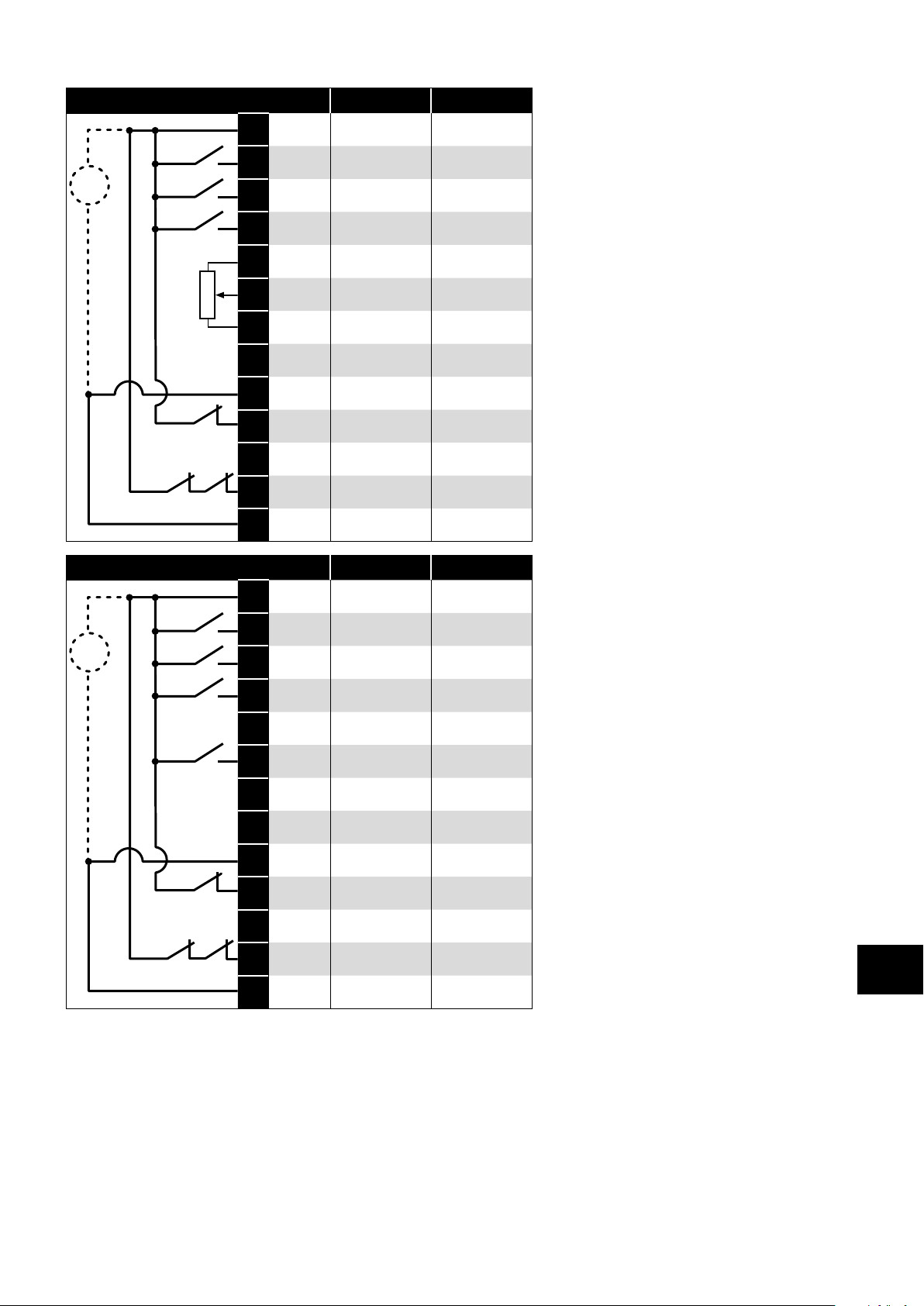

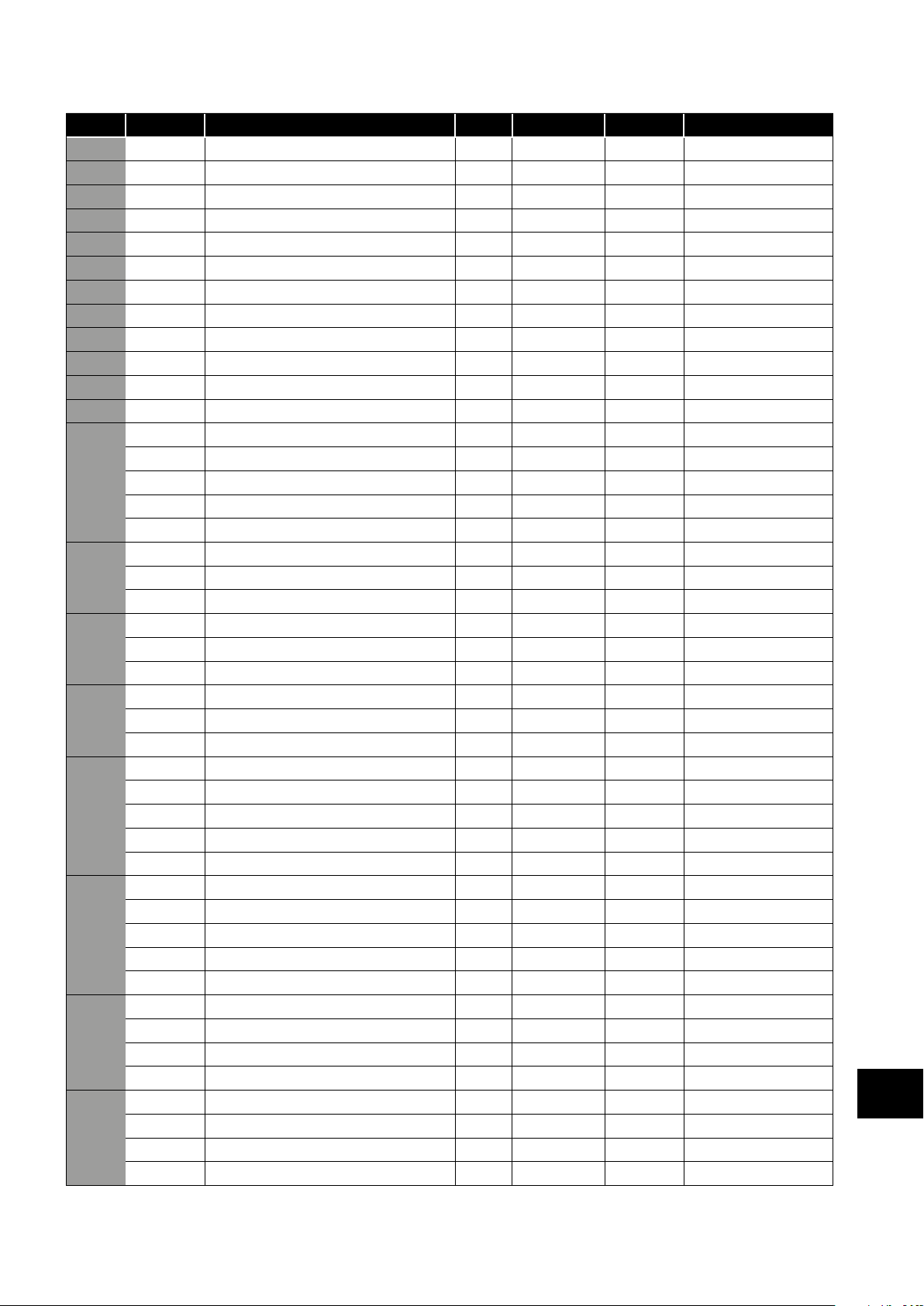

2.7. Drive Model Numbers – IP66 Switched

Mechanical dimensions and mounting information are shown from section 3.5.3. IP66 Units on page 15.

Electrical specifications are shown in section 10.2. Input/Output Power and Current Ratings on page 72.

200-240V ±10% - 1 Phase Input

kW Model Number kW HP Model Number HP Output Current (A) Frame Size

ODP-2-22075-1KF4B-MN 1 ODP-2-22010-1HF4B-MN 1 4.3 2

ODP-2-22150-1KF4B-MN 2 ODP-2-22020-1HF4B-MN 2 7 2

ODP-2-22220-1KF4B-MN 3 ODP-2-22030-1HF4B-MN 3 10.5 2

200-240V ±10% - 3 Phase Input

kW Model Number kW HP Model Number HP Output Current (A) Frame Size

ODP-2-22075-3KF4B-MN 0. 75 ODP-2-22010-3HF4B-MN 1 4.3 2

ODP-2-22150-3KF4B-MN 1.5 ODP-2-22020-3HF4B-MN 2 7 2

ODP-2-22220-3KF4B-MN 2.2 ODP-2-22030-3HF4B-MN 3 10.5 2

ODP-2-32040-3KF4B-MN 4 ODP-2-32050-3HF4B-MN 5 18 3

ODP-2-32055-3KF4B-MN 5.5 ODP-2-32075-3HF4B-MN 7. 5 24 3

ODP-2-42075-3KF4B-MN 7. 5 ODP-2-42100-3HF4B-MN 10 30 4

ODP-2-42110-3KF4B-MN 11 ODP-2-42150-3HF4B-MN 15 46 4

380-480V ±10% - 3 Phase Input

kW Model Number kW HP Model Number HP Output Current (A) Frame Size

ODP-2-24075-3KF4B-MN 0. 75 ODP-2-24010-3HF4B-MN 1 2.2 2

ODP-2-24150-3KF4B-MN 1.5 ODP-2-24020-3HF4B-MN 2 4 .1 2

ODP-2-24220-3KF4B-MN 2.2 ODP-2-24030-3HF4B-MN 3 5.8 2

ODP-2-24400-3KF4B-MN 4 ODP-2-24050-3HF4B-MN 5 9.5 2

ODP-2-34055-3KF4B-MN 5.5 ODP-2-34075-3HF4B-MN 7. 5 14 3

ODP-2-34075-3KF4B-MN 7. 5 ODP-2-34100-3HF4B-MN 10 18 3

ODP-2-34110-3KF4B-MN 11 ODP-2-34150-3HF4B-MN 15 24 3

ODP-2-44150-3KF4B-MN 15 ODP-2-44200-3HF4B-MN 20 30 4

ODP-2-44185-3KF4B-MN 18.5 ODP-2-44250-3HF4B-MN 25 39 4

ODP-2-44220-3KF4B-MN 22 ODP-2-44300-3HF4B-MN 30 46 4

500-600V ±10% - 3 Phase Input

kW Model Number kW HP Model Number HP Output Current (A) Frame Size

ODP-2-26075-3K04B-MN 0 . 75 ODP-2-26010-3H04B-MN 1 2.1 2

ODP-2-26150-3K04B-MN 1.5 ODP-2-26020-3H04B-MN 2 3.1 2

ODP-2-26220-3K04B-MN 2.2 ODP-2-26030-3H04B-MN 3 4.1 2

ODP-2-26400-3K04B-MN 4 ODP-2-26050-3H04B-MN 5 6.5 2

ODP-2-26550-3K04B-MN 5.5 ODP-2-26075-3H04B-MN 7. 5 9 2

ODP-2-36075-3K04B-MN 7. 5 ODP-2-36100-3H04B-MN 10 12 3

ODP-2-36110-3K04B-MN 11 ODP-2-36150-3H04B-MN 15 17 3

ODP-2-36150-3K04B-MN 15 ODP-2-36200-3H04B-MN 20 22 3

ODP-2-46185-3KF4B-MN 18.5 ODP-2-46250-3HF4B-MN 25 28 4

ODP-2-46220-3KF4B-MN 22 ODP-2-46300-3HF4B-MN 30 34 4

ODP-2-46300-3KF4B-MN 30 ODP-2-46400-3HF4B-MN 40 43 4

General Information & Ratings

2

Version 3.04 | Optidrive P2 User Guide | 11www.invertekdrives.com

Page 12

3. Mechanical Installation

3.1. General

The Optidrive should be mounted in a vertical position only, on a flat, flame resistant, vibration free mounting using the integral

mounting holes or DIN Rail clip (Frame Size 2 only).

Do not mount flammable material close to the Optidrive.

Ensure that the minimum cooling air gaps, as detailed in sections 3.6. Guidelines for Enclosure Mounting (IP20 Units) on page

16, 3.8. Guidelines for Mounting (IP55 Units) on page 17 and 3.9. Guidelines for Mounting (IP66 Units) on page 18

are left clear.

Ensure that the ambient temperature range does not exceed the permissible limits for the Optidrive given in section 10.1. Environmental

on page 72.

Provide suitable clean, moisture and contaminant free cooling air sufficient to fulfil the cooling requirements of the Optidrive.

3.2. Before Installation

Mechanical Installation

Carefully Unpack the Optidrive and check for any signs of damage. Notify the shipper immediately if any exist.

Check the drive rating label to ensure it is of the correct type and power requirements for the application.

To prevent accidental damage always store the Optidrive in its original box until required. Storage should be clean and dry and

within the temperature range –40°C to +60°C.

3.3. UL Compliant Installation

Note the following for UL-compliant installation:

For an up to date list of UL compliant products, please refer to UL listing NMMS.E226333.

The drive can be operated within an ambient temperature range as stated in section

For IP20 units, installation is required in a pollution degree 1 environment.

For IP55 units, installation in a pollution degree 2 environment is permissible.

For IP66 units, installation in a pollution degree 4 environment is permissible.

UL Listed ring terminals / lugs must be used for all bus bar and grounding connections.

Refer to section 10.4. Additional Information for UL Approved Installations on page 75.

10.1. Environmental on page 72

.

3

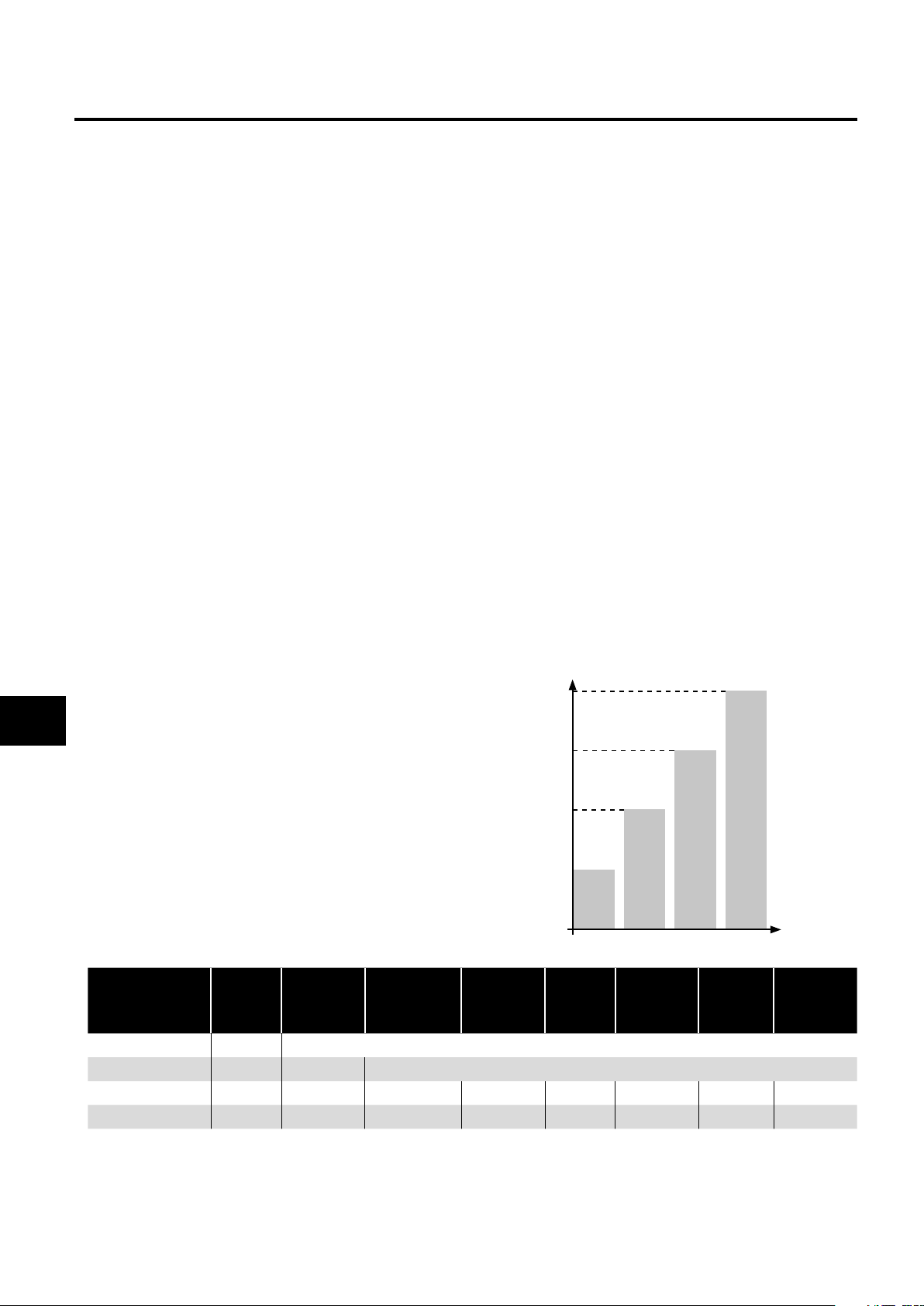

3.4. Installation Following a Period of Storage

100%

Where the drive has been stored for some time prior to installation,

or has remained without the main power supply present for an

extended period of time, it is necessary to reform the DC capacitors

75%

within the drive according to the following table before operation.

For drives which have not been connected to the main power supply

for a period of more than 2 years, this requires a reduced mains

voltage mains voltage to be applied for a time period, and gradually

50%

increased prior to operating the drive. The voltage levels relative to

the drive rated voltage, and the time periods for which they must be

applied are shown in the following table. Following completion of the

25%

procedure, the drive may be operated as normal.

T1 T2 T3 T4

Storage Period

/Power-OFF

Period

Up to 1 Year 100% N/A

1 – 2 Years 100% 1 Hour N/A

2 – 3 Years 25% 30 Minutes 50% 30 Minutes 75% 30 Minutes 100% 30 Minutes

More than 3 Years 25% 2 Hours 50% 2 Hours 75% 2 Hours 100% 2 Hours

Initial

Input

Voltage

Level

Time

Period T1

Secondary

Input

Voltage

Level

Time

Period T2

Third

Input

Voltage

Level

Time

Period T3

Final

Input

Voltage

Level

Period T4

Time

12 | Optidrive P2 User Guide | Version 3.04 www.invertekdrives.com

Page 13

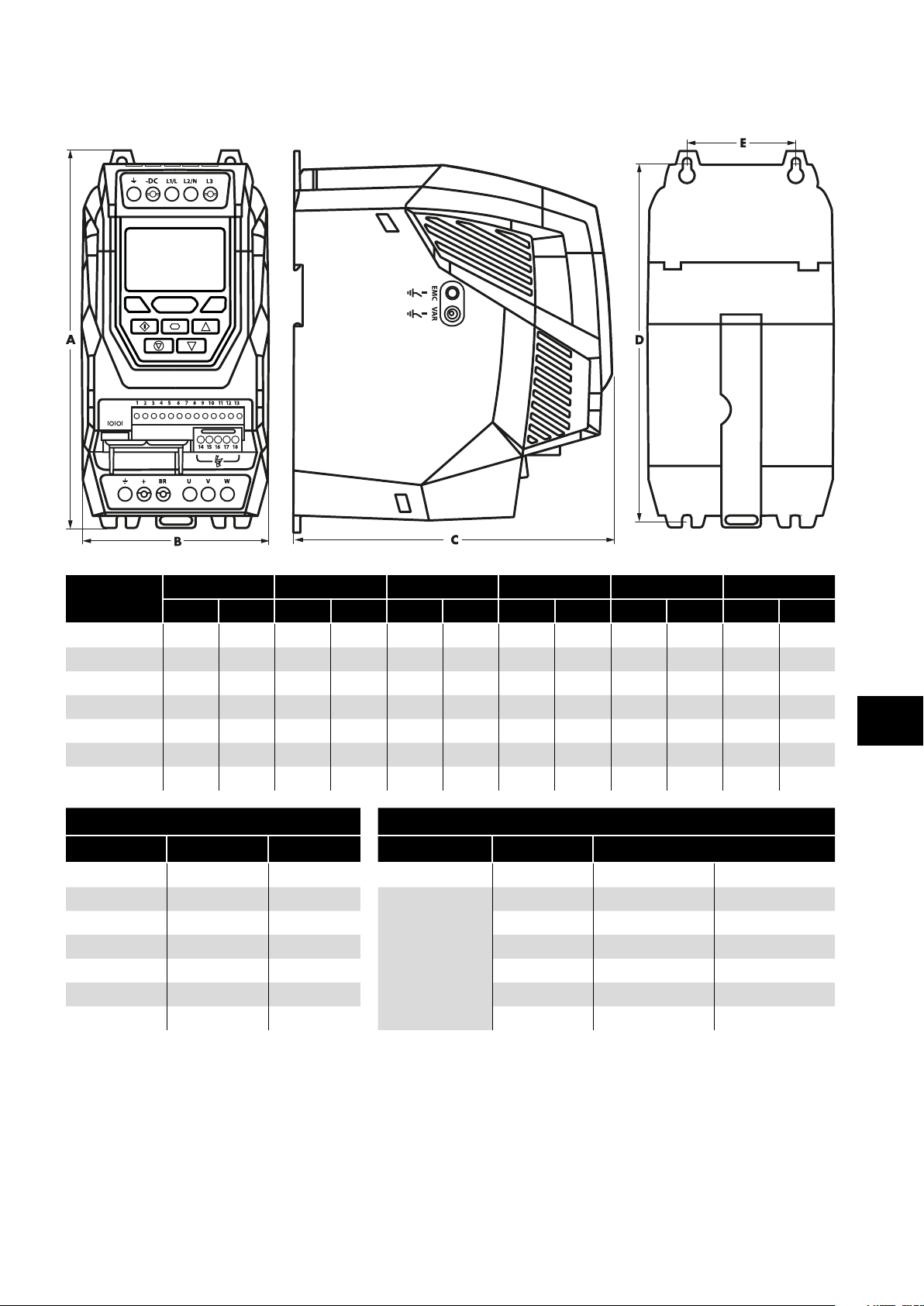

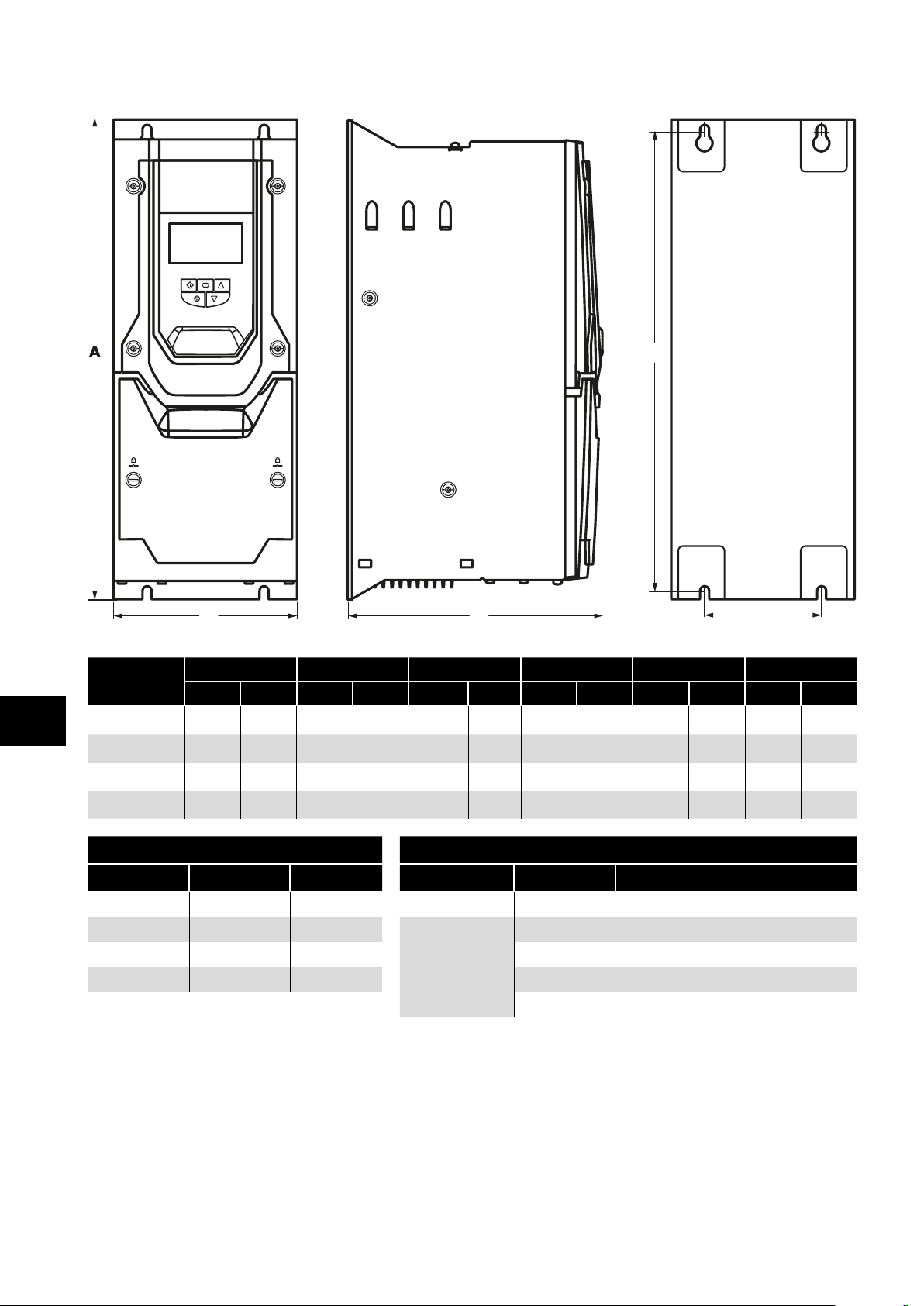

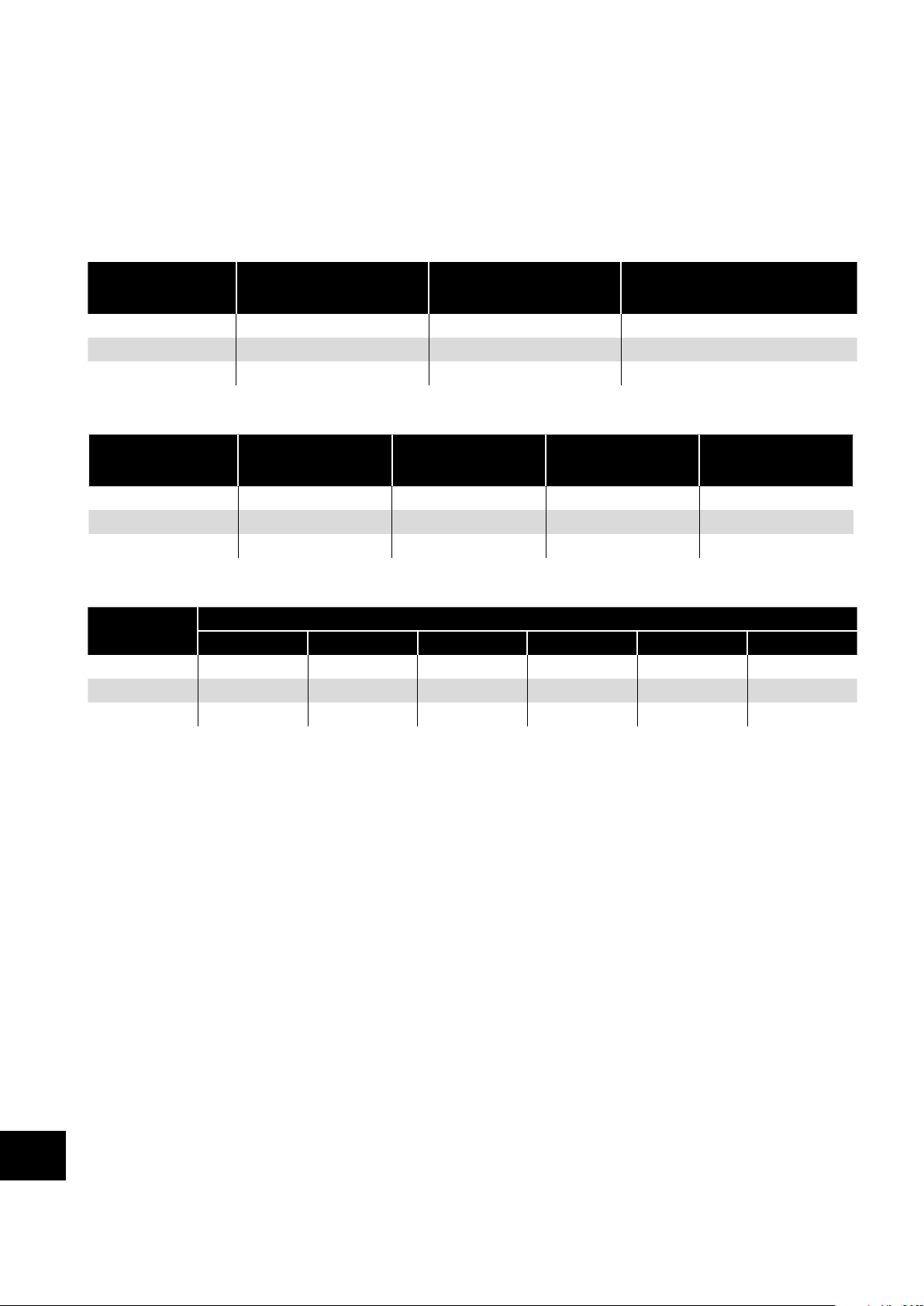

3.5. Mechanical Dimensions and Weight

3.5.1. IP20 Units

Mechanical Installation

Drive Size

2 221 8.70 110 4.33 185 7.28 209 8.23 63 2.48 1.8 4.0

3 2 61 10.28 131 5.16 205 8.07 247 9.72 80 3 .15 3.5 7. 7

4 418 16.46 172 6.77 240 9.45 400 15. 75 125 4.92 9.2 20.3

5 486 19 .13 233 9 .17 260 10.24 460 18.11 175 6.89 18 .1 39.9

6A 614 24.17 286 11 . 25 320 12.59 5 78 22. 75 200 7. 87 32 70.5

6B 726 28.58 330 13 320 12.59 680 26.77 225 8.85 43 94.8

8 995 3 9.17 480 18.89 477 18 .77 942 37.08 432 17 13 0 286.6

Mounting Bolts Tightening Torques

Frame Size Metric UNF Frame Size Required Torque

2 M4 #8 Control Terminals All 0.5 Nm 4.5 lb-in

3 M4 #8

4 M8 5/16 4 2 Nm 18 lb-in

5 M8 5/16 5 4 Nm 35.5 lb-in

6A M8 5/16 6A 12 Nm 9 lb-ft

6B M 10 3/8 6B 15 Nm 11 lb-ft

8 M 12 7/16 8 57 Nm 42 lb-ft

A B C D E Weight

mm in mm in mm in mm in mm in Kg Ib

2 & 3 1 Nm 9 lb-in

Power Terminals

3

NOTE

*The IP20 Frame Size 4 Chassis can obstruct the rotation (tightening) of a bolt or screw with a hex head, a fixing with a round head

will be most suitable for the mounting of this unit.

Version 3.04 | Optidrive P2 User Guide | 13www.invertekdrives.com

Page 14

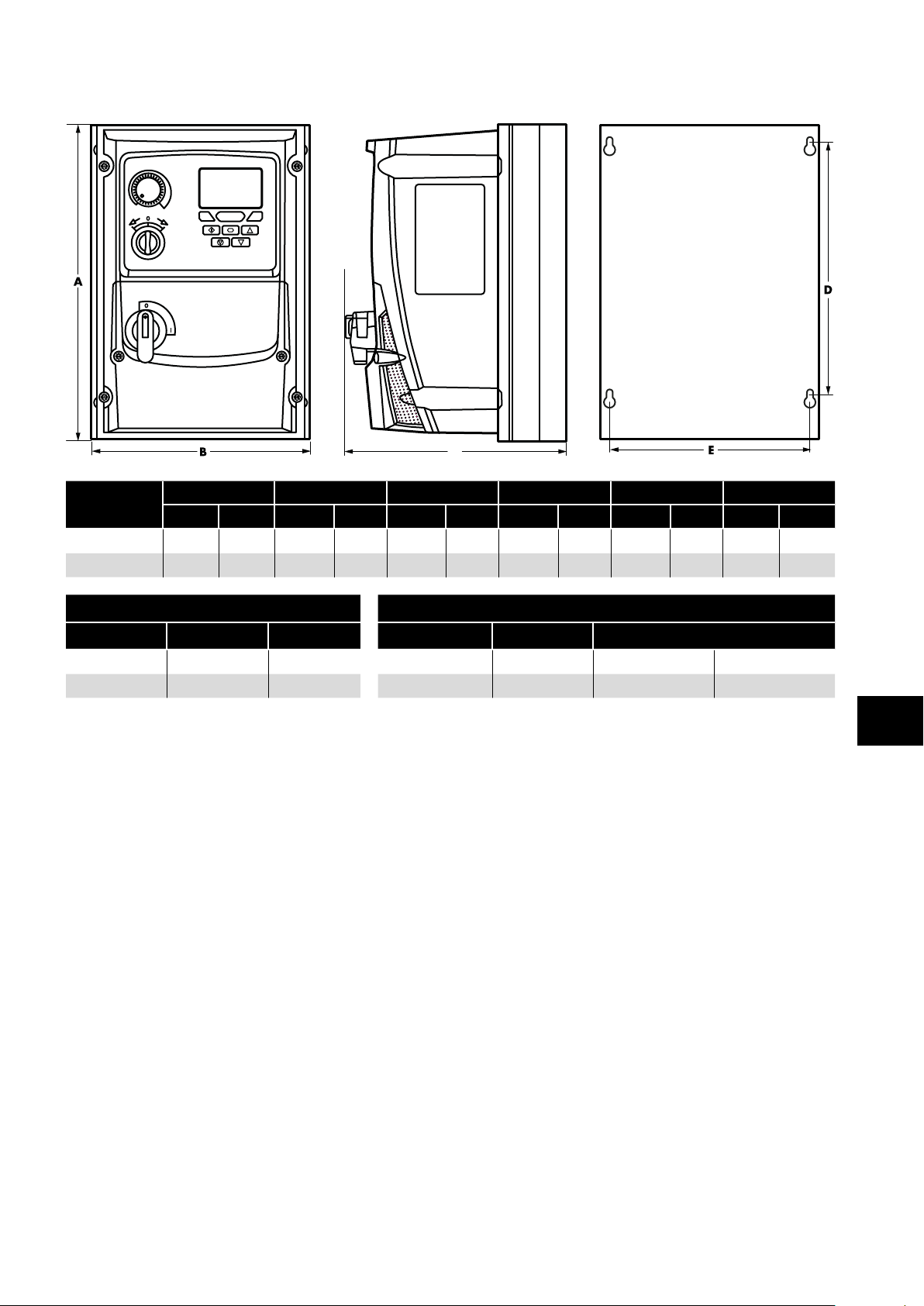

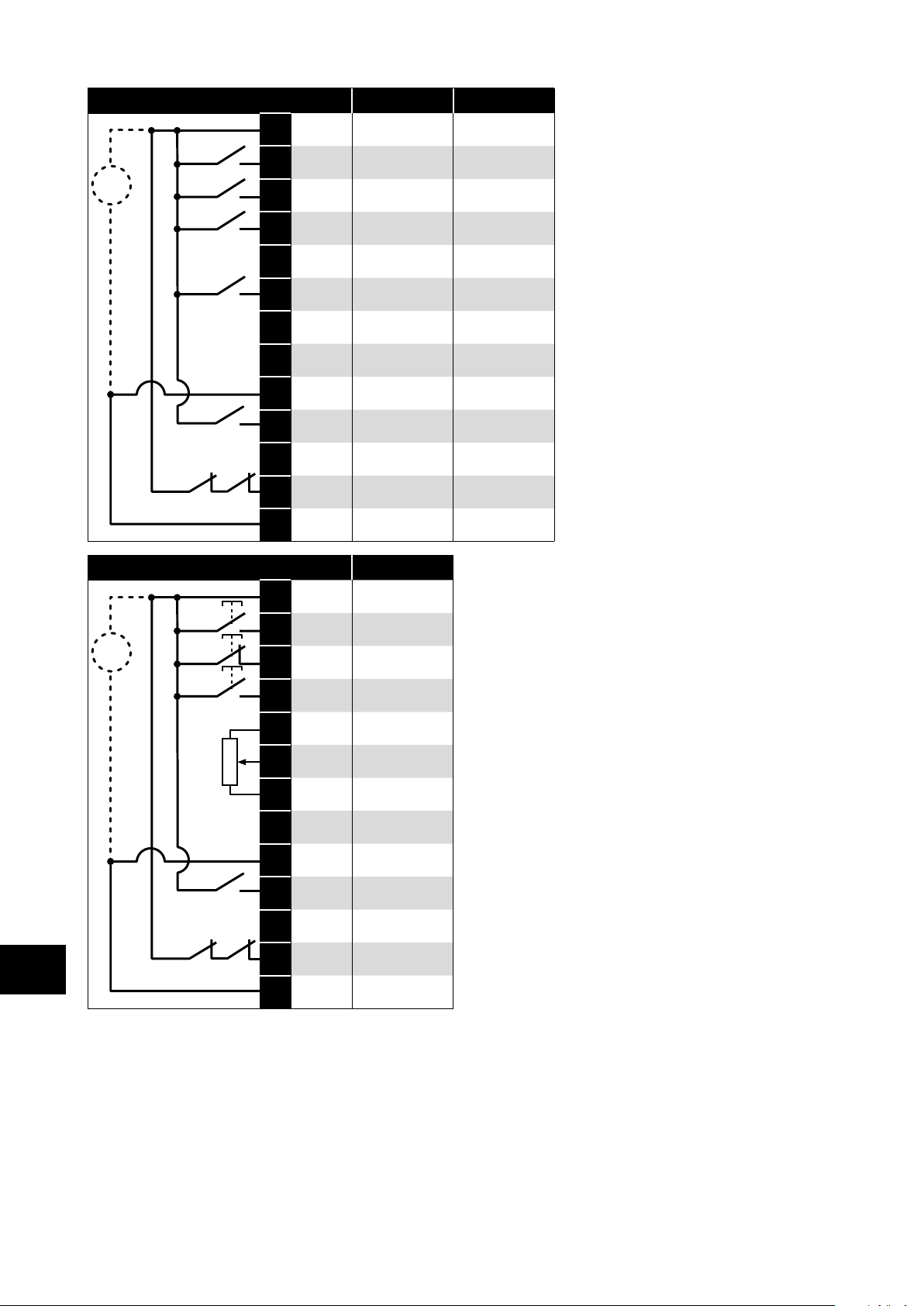

3.5.2. IP55 Units

B

Mechanical Installation

D

3

C

Drive Size

4 450 17. 72 171 6 . 73 252 9.92 428 16.85 110 4.33 11 . 5 25.4

5 540 21.26 235 9.25 270 10.63 515 20.28 175 6.89 23 50.7

6 865 34.06 330 12.99 330 12.99 830 32.68 200 7. 87 55 121. 2

7 1280 50.39 330 12.99 360 14 .17 124 5 49.02 200 7. 87 89

Mounting Bolts Tightening Torques

Frame Size Metric UNF Frame Size Required Torque

4 M8 5/16

5 M8 5/16

6 M10 3/8

7 M10 3/8

A B C D E Weight

mm in mm in mm in mm in mm in kg Ib

Control Terminals All 0.5 Nm 4.5 lb-in

4 2 Nm 18 lb-in

Power Terminals

5 4 Nm 35.5 lb-in

6 15 Nm 11 lb-ft

7 15 Nm 11 lb-ft

E

196.2

14 | Optidrive P2 User Guide | Version 3.04 www.invertekdrives.com

Page 15

3.5.3. IP66 Units

C

Mechanical Installation

Drive Size

2 257 10 .12 188 7.40 239 9 . 41 200 7. 87 178 7. 01 4.8 10.6

3 310 12.20 211 8.29 266 10.47 252

Mounting Bolts Tightening Torques

Frame Size Metric UNF Frame Size Required Torque

2 M4 #8 Control Terminals All 0.5 Nm 4.5 lb-in

3 M4 #8 Power Terminals 2 & 3 1 Nm 9 lb-in

A B C D E Weight

mm in mm in mm in mm in mm in kg Ib

9.90

200 7. 87 7. 7 16.8

3

Version 3.04 | Optidrive P2 User Guide | 15www.invertekdrives.com

Page 16

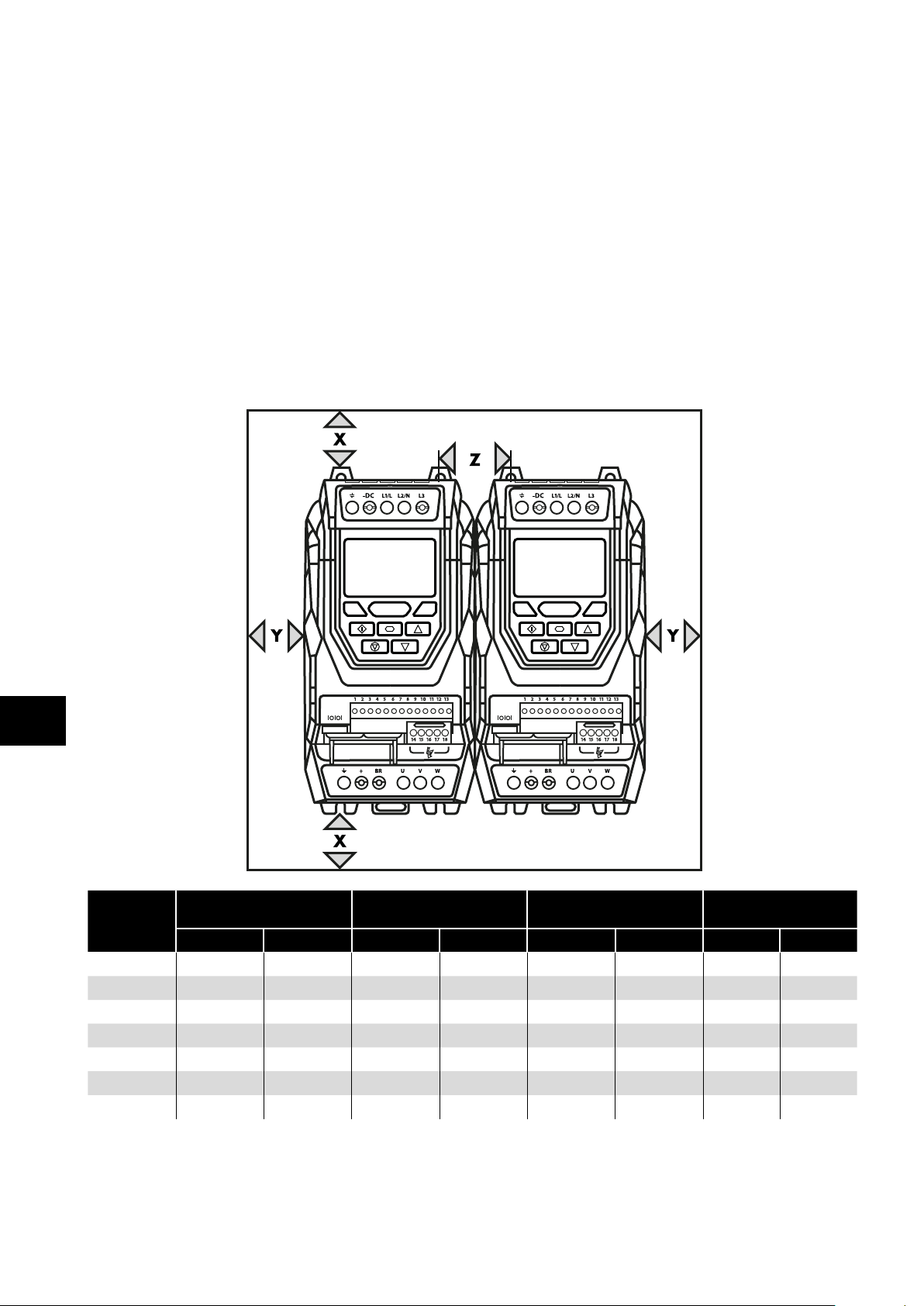

3.6. Guidelines for Enclosure Mounting (IP20 Units)

IP20 drives are suitable for use in pollution degree 1 environments, according to IEC-664-1. For pollution degree 2 or higher

environments, drives should be mounted in a suitable control cabinet with sufficient ingress protection to maintain a pollution

degree 1 environment around the drive.

Enclosures should be made from a thermally conductive material.

Ensure the minimum air gap clearances around the drive as shown below are observed when mounting the drive.

Where ventilated enclosures are used, there should be venting above the drive and below the drive to ensure good air circulation.

Air should be drawn in below the drive and expelled above the drive.

In any environments where the conditions require it, the enclosure must be designed to protect the Optidrive against ingress of

airborne dust, corrosive gases or liquids, conductive contaminants (such as condensation, carbon dust, and metallic particles) and

sprays or splashing water from all directions.

High moisture, salt or chemical content environments should use a suitably sealed (non-vented) enclosure.

The enclosure design and layout should ensure that the adequate ventilation paths and clearances are left to allow air to circulate

through the drive heatsink. Invertek Drives recommend the following minimum sizes for drives mounted in non-ventilated metallic

Mechanical Installation

enclosures:

3

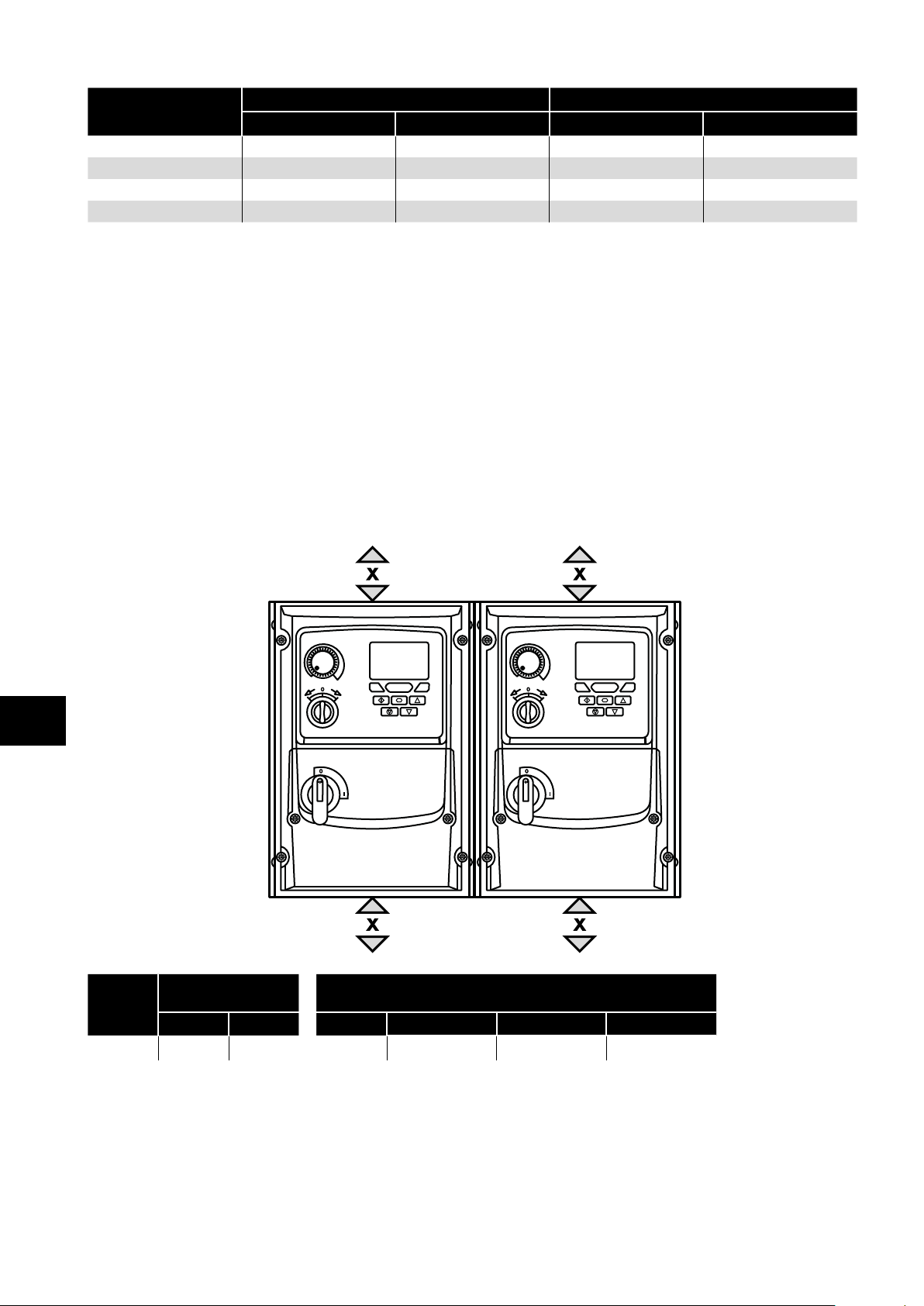

X

Drive Size

2 75 2.95 10 0.39 46 1. 81 0.3 11

3 100 3.94 10 0.39 52 2.05 0.9 31

4 200 7. 87 25 0.98 70 2 . 76 1. 7 62

5 200 7. 87 25 0.98 70 2 . 76 2.9 104

6A 200 7. 87 25 0.98 70 2 . 76

6B 200 7. 87 25 0.98 70 2.76

8 350 11 . 81 50 3.94 412 16.22 20 705

Above & Below

mm in mm in mm in m3/min CFM

Y

Either Side

Z

Between

Recommended

NOTE

Dimension Z assumes that the drives are mounted side-by-side with no clearance.

Typical drive heat losses are <3% of operating load conditions.

Above are guidelines only and the operating ambient temperature of the drive MUST be maintained at all times.

airflow

16 | Optidrive P2 User Guide | Version 3.04 www.invertekdrives.com

Page 17

3.7. Mounting the Drive – IP20 Units

IP20 Units are intended for installation within a control cabinet.

When mounting with screws:

o Using the drive as a template, or the dimensions shown above, mark the locations for drilling.

o Ensure that when mounting locations are drilled, the dust from drilling does not enter the drive.

o Mount the drive to the cabinet backplate using suitable mounting screws.

o Position the drive, and tighten the mounting screws securely.

When Din Rail Mounting (Frame Size 2 Only):

o Locate the DIN rail mounting slot on the rear of the drive onto the top of the DIN rail first.

o Press the bottom of the drive onto the DIN rail until the lower clip attaches to the DIN rail.

o If necessary, use a suitable flat blade screw driver to pull the DIN rail clip down to allow the drive to mount securely on the rail.

o To remove the drive from the DIN rail, use a suitable flat blade screwdriver to pull the release tab downwards, and lift the

bottom of the drive away from the rail first.

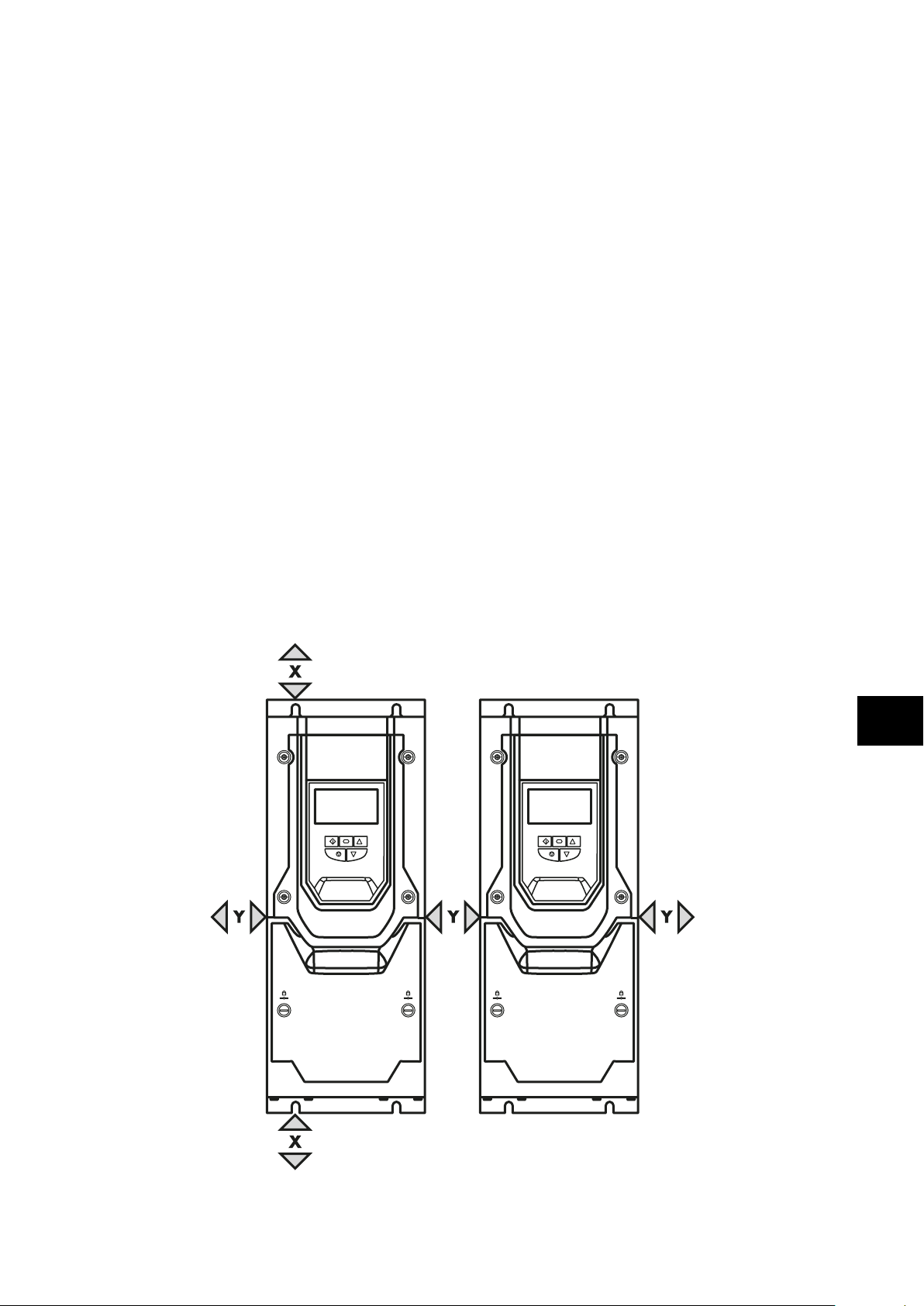

3.8. Guidelines for Mounting (IP55 Units)

Before mounting the drive, ensure that the chosen location meets the environmental condition requirements for the drive shown in

section 10.1. Environmental on page 72.

The drive must be mounted vertically, on a suitable flat surface.

The minimum mounting clearances as shown in the table below must be observed.

The mounting site and chosen mountings should be sufficient to support the weight of the drives.

IP55 units do not require mounting inside an electrical control cabinet; however they may be if desired.

Using the drive as a template, or the dimensions shown above, mark the locations required for drilling.

Suitable cable glands to maintain the IP protection of the drive are required. Gland sizes should be selected based on the number

and size of the required connection cables. Drives are supplied with a plain, undrilled gland plate to allow the correct hole sizes to

be cut as required. Remove the gland plate from the drive prior to drilling.

Mechanical Installation

3

Version 3.04 | Optidrive P2 User Guide | 17www.invertekdrives.com

Page 18

Drive Size

4 200 7. 87 10 0.39

5 200 7. 87 10 0.39

6 200 7. 87 10 0.39

7 200 7. 87 10 0.39

NOTE

Typical drive heat losses are approximately 3% of operating load conditions.

Above are guidelines only and the operating ambient temperature of the drive MUST be maintained at all times.

3.9. Guidelines for Mounting (IP66 Units)

Before mounting the drive, ensure that the chosen location meets the environmental condition requirements for the drive shown in

section 10.1. Environmental on page 72.

Mechanical Installation

The drive must be mounted vertically, on a suitable flat surface.

The minimum mounting clearances as shown in the table below must be observed.

The mounting site and chosen mountings should be sufficient to support the weight of the drives.

Using the drive as a template, or the dimensions shown below, mark the locations required for drilling.

Suitable cable glands to maintain the ingress protection of the drive are required. Gland holes for power and motor cables are

pre-moulded into the drive enclosure, recommended gland sizes are shown below. Gland holes for control cables may be cut as

required.

X –Above & Below Y –Either Side

mm in mm in

3

Drive

Size

2 & 3 200 7. 87 2 & 3 PG21 (M25) PG21 (M25) PG13.5 (M20)

NOTE

Typical drive heat losses are approximately 3% of operating load conditions.

Above are guidelines only and the operating ambient temperature of the drive MUST be maintained at all times.

Alternative metric gland sizes are shown in the brackets.

X

Above & Below

mm in Frame Power Cable Motor Cable Control Cables

Cable Gland Sizes

18 | Optidrive P2 User Guide | Version 3.04 www.invertekdrives.com

Page 19

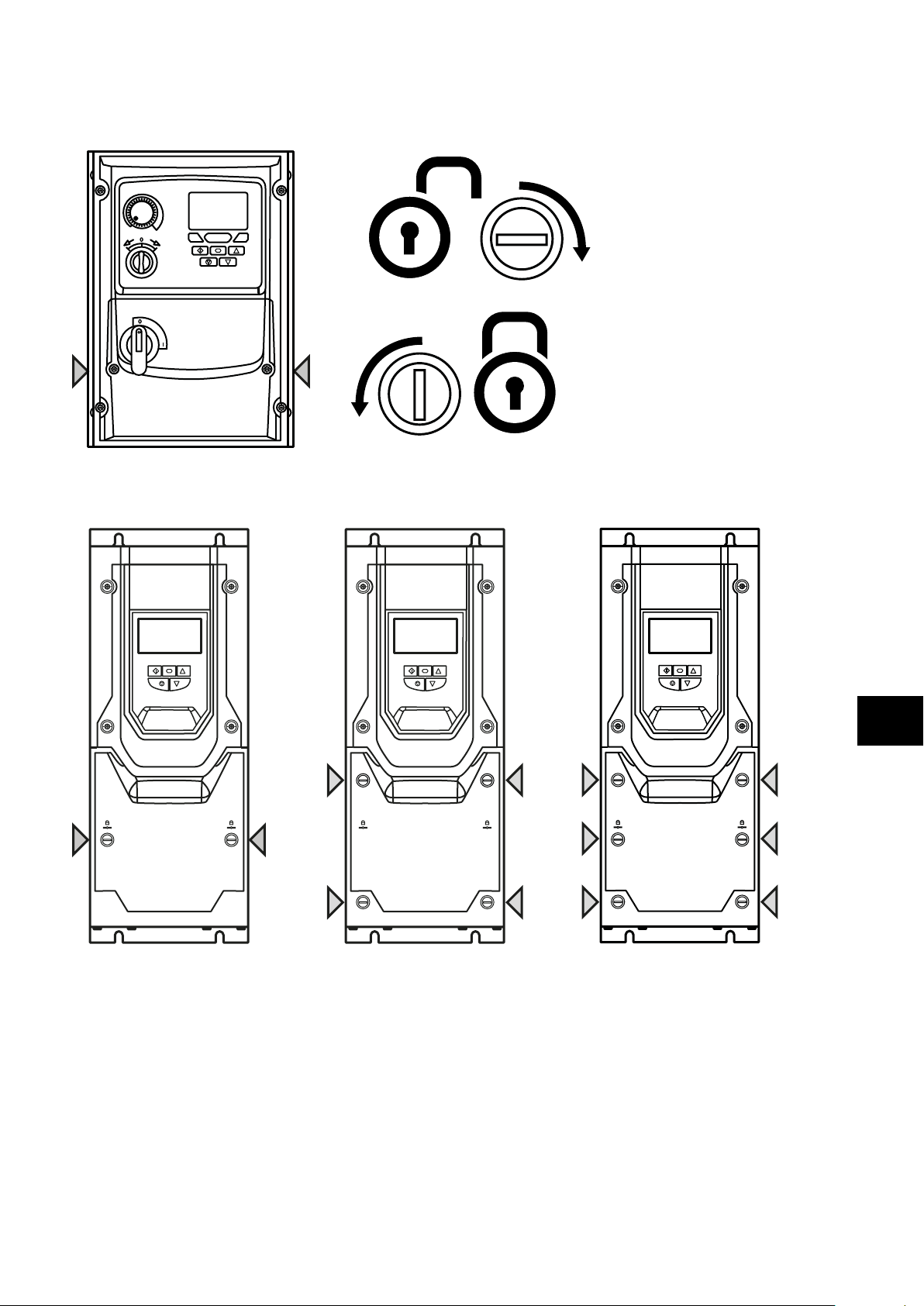

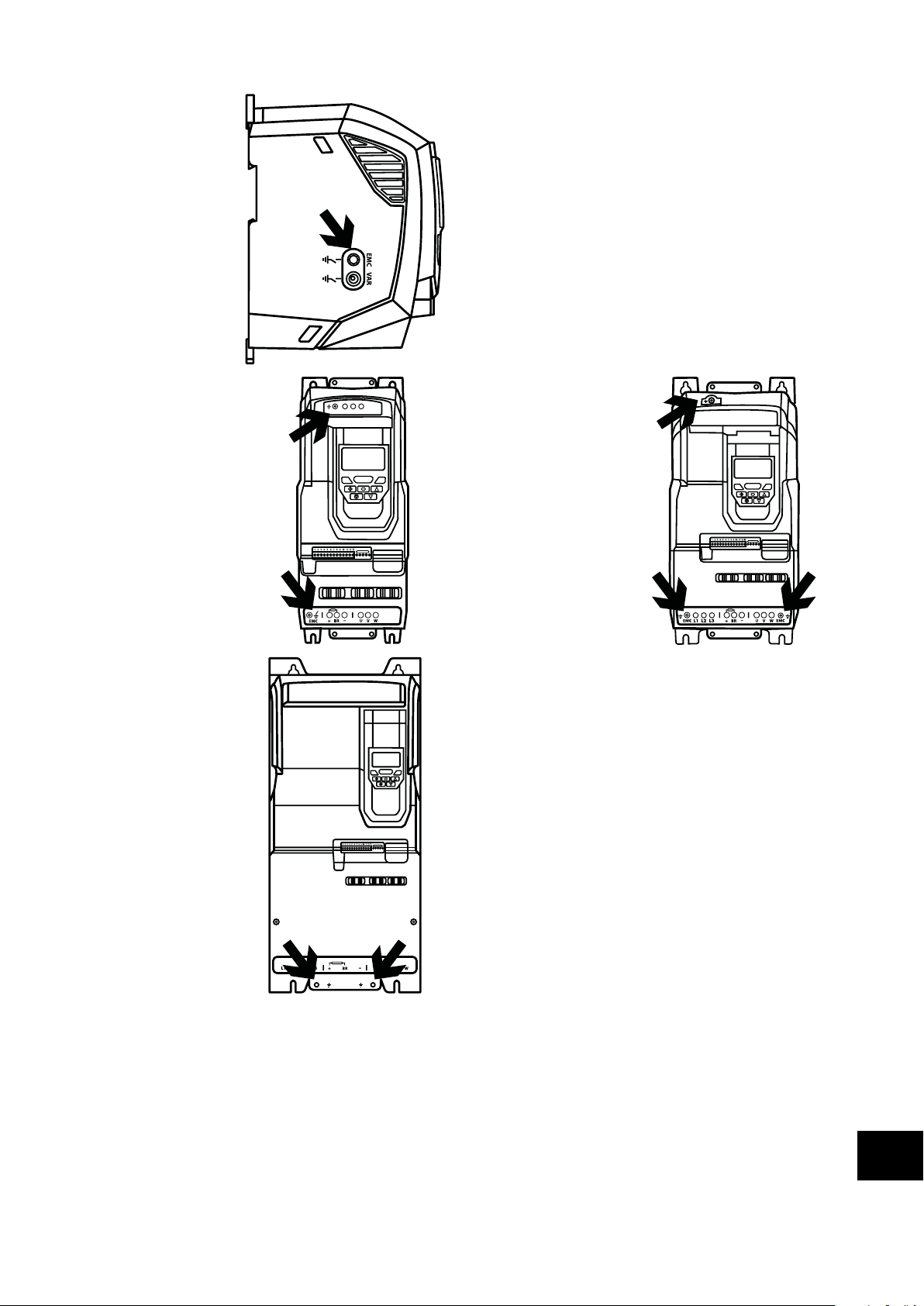

3.10. Removing the Terminal Cover

3.10.1. Frame Sizes 2 & 3

Terminal Cover

Release Screws

Using a suitable flat blade

screwdriver, rotate retaining

screws indicated by arrows until

the screw slot is vertical.

3.10.2. Frame Size 4 3.10.3. Frame Size 5 3.10.4. Frame Sizes 6 & 7

Mechanical Installation

3.11. Routine Maintenance

The drive should be included within the scheduled maintenance program so that the installation maintains a suitable operating

environment, this should include:

Ambient temperature is at or below that set out in section 10.1. Environmental on page 72.

Heat sink fans freely rotating and dust free.

The Enclosure in which the drive is installed should be free from dust and condensation; furthermore ventilation fans and air filters

should be checked for correct air flow.

Checks should also be made on all electrical connections, ensuring screw terminals are correctly torqued; and that power cables

have no signs of heat damage.

3

Version 3.04 | Optidrive P2 User Guide | 19www.invertekdrives.com

Page 20

4. Electrical Installation

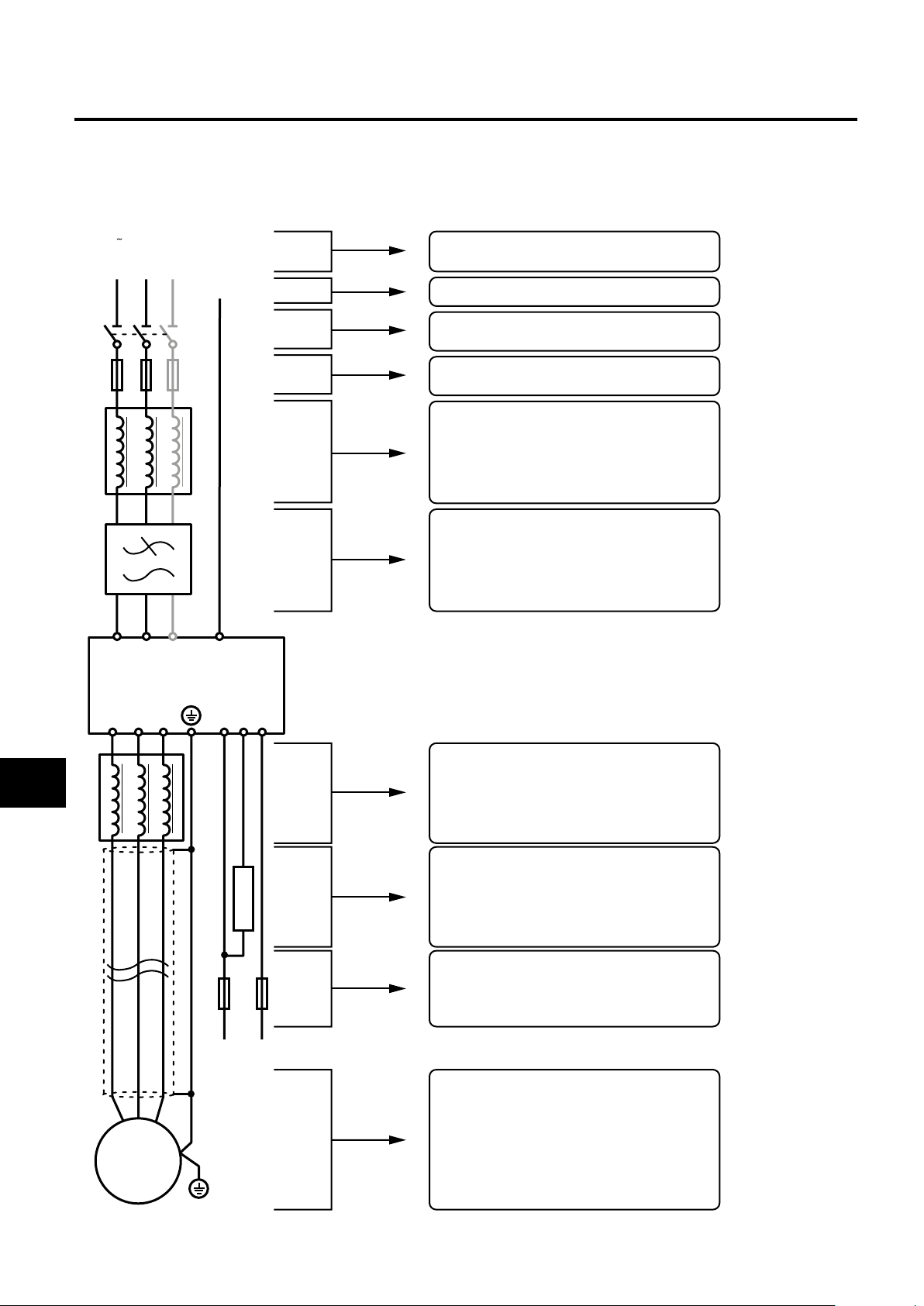

4.1. Connection Diagram

All power terminal locations are marked directly on the product. IP20 Frame Size 2 – 4 units have AC power input located at the top

with the motor and brake resistor connections located at the bottom. All other units have power terminals located at the bottom.

4.1.1. Electrical Power Connections

Mains (1 or 3 phase)

L1/L L2/N L3

PE

Electrical Installation

L1/L L2/N L3

ODP-2

U V W

DC

Additional information in section 4.3. on page 22

Additional information in section 4.2. on page 21

Additional information in section 4.3.3. on page 22

Additional information in section 4.3.4. on page 23

Additional information in section 4.13 . on page 28

DC

-

+

BR

Incoming Power Connection

Protective Earth PE Connection

Isolator/Disconnect

Ensure there is at least 30 seconds

between each power-on!

Fuses/Circuit Breaker

External Line Reactor

NOTE An input choke must be installed

with the IP20 Frame Size 8.

External EMC Filter (optional)

4

VI

UI

M

External Output Filter (optional)

Output Choke (load reactor)

dV/dT filter

Sinewave filter

Brake Resistor with Thermal Overload Protection

Additional information in section 4.8. on page 24

DC Power Supply or Common Bus DC

Additional information in section 4.5. on page 23

DC+ DC-

WI

PE

Shielded Motor Cable with PE Connection

Additional information in section 4.6. on page 23

NOTE Enclosed drives are not suitable for rigid conduit system connection.

20 | Optidrive P2 User Guide | Version 3.04 www.invertekdrives.com

Page 21

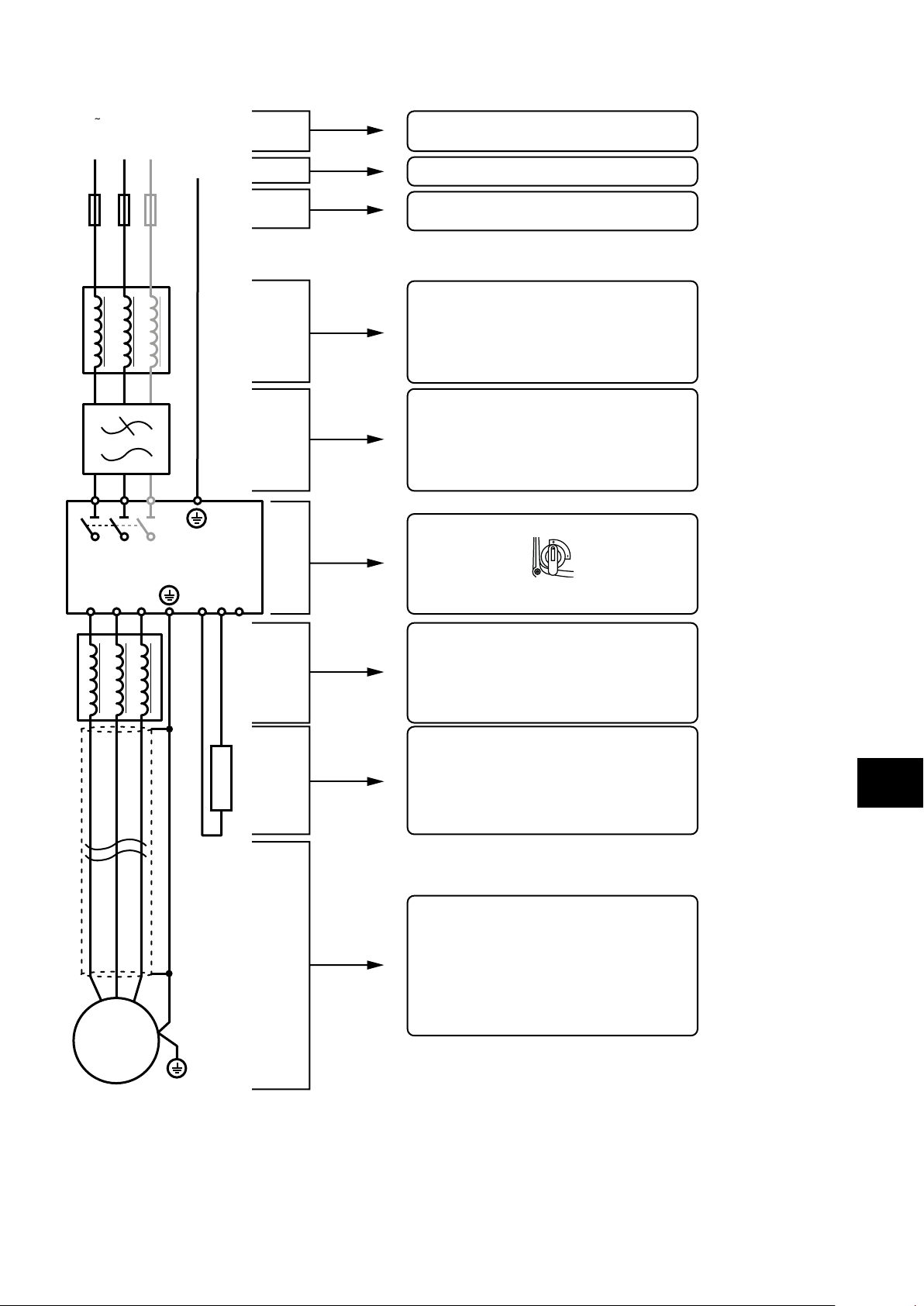

4.1.2. Electrical Power Connections – IP66 (NEMA 4X) Switched Models

Mains (1 or 3 phase)

L1/L L2/N L3

Additional information in section 4.3. on page 22

PE

Additional information in section 4.2. on page 22

Incoming Power Connection

Protective Earth PE Connection

L1/L L2/N L3

ODP-2 IP66 (NEMA 4X) Switched

U V W

DC

+

Additional information in section 4.3.3. on page 22

Additional information in section 4.3.4. on page 24

Additional information in section 4.13 . on page 28

Fuses/Circuit Breaker

External Line Reactor (optional)

External EMC Filter (optional)

Electrical Installation

Built-in mains switch-disconnector

DC

BR

-

Ensure there is at least 30 seconds

between each power-on!

External Output Filter (optional)

Output Choke (load reactor)

dV/dT filter

Sinewave filter

VI

UI

M

Brake Resistor with Thermal Overload Protection

Additional information in section 4.8. on page 24

Shielded Motor Cable with PE Connection

Additional information in section 4.6. on page 23

WI

PE

4

Version 3.04 | Optidrive P2 User Guide | 21www.invertekdrives.com

Page 22

4.2. Protective Earth (PE) Connection

4.2.1. Grounding Guidelines

Adequate safety earthing must be provided in accordance with local wiring rules and codes of practice. The ground terminal of

each Optidrive should be connected back to the common safety earth bar to maintain touch potentials within safe limits. The ground

terminal of each Optidrive should be individually connected DIRECTLY to the site ground bus bar (through the EMC filter if installed).

Optidrive ground connections should not loop from one drive to another, or to, or from any other equipment. Ground impedance must

conform to local industrial safety regulations and/or electrical codes.

To meet UL regulations, UL approved ring crimp terminals should be used for all ground wiring connections.

The integrity of all ground connections should be checked periodically.

4.2.2. Protective Earth Conductor

The Cross sectional area of the PE Conductor must be at least equal to that of the incoming supply conductors.

4.2.3. Motor Ground

The driven motor must be locally connected to a suitable ground location to maintain touch potentials within safe limits. In addition, the

motor ground must be connected to one of the ground terminals on the drive.

4.2.4. Ground Fault Monitoring

As with all inverters, a leakage current to earth can exist. The Optidrive is designed to produce the minimum possible leakage current

whilst complying with worldwide standards. The level of current is affected by motor cable length and type, the effective switching

frequency, the earth connections used and the type of RFI filter installed. If an ELCB (Earth Leakage Circuit Breaker) is to be used, the

following conditions apply:

A Type B Device must be used.

Electrical Installation

Individual device should be used for each Optidrive.

The device must be suitable for protecting equipment with a DC component in the leakage current.

The device should be not sensitive to high frequency leakage current.

4.2.5. Shield Termination (Cable Screen)

The safety ground terminal provides a grounding point for the motor cable shield. The motor cable shield connected to this terminal

(drive end) should also be connected to the motor frame (motor end). Use a shield terminating or EMI clamp to connect the shield to

the safety ground terminal, refer to section 4.13. EMC Compliant Installation on page 28.

4

4.3. Incoming Power Connection

NOTE For IP20 Frame Size 8 it is important that the input supply phase orientation is correct, i.e. L1>L1, L2>L2, L3>L3, failure to do so

will result in a “Ph-Seq" trip.

Ensure there is at least 30 seconds between each power-on.

4.3.1. Suitability

All Optidrive P2 models are designed for use on a single phase or balanced three phase supply depending on the model.

For all models and ratings when working with an IT Supply network, or any power supply type where the phase to earth voltage may

exceed the phase to phase voltage (such as ungrounded supplies), the internal EMC filter and surge protection must be disconnected before

connecting the supply. Refer to section 10.6. Internal EMC Filter and Varistors – Disconnection Procedure on page 76 for further information.

For three phase supply models, a maximum of 3% imbalance is allowed between phases.

4.3.2. Cable Selection

For 1 phase ac supply, power should be connected to L1/L, L2/N.

For a DC Supply, the main power cables should be connected to L1/L, L2/N.

For 3 phase ac supplies, the mains power cables should be connected to L1, L2, and L3. Phase sequence is not important. Neutral

connection is not required.

For compliance with CE and C Tick EMC requirements, refer to section 4.13. EMC Compliant Installation on page 28.

A fixed installation is required according to IEC61800-5-1 with a suitable disconnecting device installed between the Optidrive

and the main Power Source. The disconnecting device must conform to the local safety code / regulations (e.g. within Europe,

EN60204-1, Safety of machinery).

The cables should be dimensioned according to any local codes or regulations. Maximum dimensions for each drive model are

given in section 10.2. Input/Output Power and Current Ratings on page 72.

4.3.3. Fuse / Circuit Breaker Selection

Suitable fuses to provide wiring protection of the input power cable should be installed in the incoming supply line, according to

the data in section 10.2. Input/Output Power and Current Ratings on page 72.

The fuses must comply with any local codes or regulations in place. In general, type gG (IEC 60269) or UL type J fuses are

suitable (exception: Eaton Bussmann FWP series must be used for size 6A & 6B IP20 models); however in some cases type aR

fuses may be required. The operating time of the fuses must be below 0.5 seconds.

Where allowed by local regulations, suitably dimensioned type B MCB circuit breakers of equivalent rating may be utilised in

place of fuses, providing that the clearing capacity is sufficient for the installation.

The maximum permissible short circuit current at the Optidrive Power terminals as defined in IEC60439-1 is 100kA.

The Optidrive provides thermal and short circuit protection for the connected motor and motor cable.

22 | Optidrive P2 User Guide | Version 3.04 www.invertekdrives.com

Page 23

4.3.4. Input Choke

An optional Input Choke is recommended to be installed in the supply line for drives where any of the following conditions occur:

The incoming supply impedance is low or the fault level / short circuit current is high.

NOTE For IP20 Frame Size 8 the input current level will vary according to supply impedance. At minimum a 1% line choke must be

installed. Installing a 4% line choke further helps towards minimising harmonic current distortion and total current levels. 1% and 4% line

chokes are available.

The supply is prone to dips or brown outs.

An unbalanced supply system is used (3 phase drives) where the voltage levels during on load operation exceed the designed 3%

capacity of the Optidrive.

The power supply to the drive is via a busbar and brush gear system (typically overhead Cranes).

In all other installations, an input choke is recommended to ensure protection of the drive against power supply faults.

4.4. Operation of 3 Phase drives from a Single Phase Supply

A special function of Optidrive P2 allows all drives designed for operation on 3 phase supplies to be operated on a single phase

supply of the correct rated voltage at up to 50% of the nominal capacity.

For Example, Model Number ODP-2-64450-3KA4N can be operated on a single phase supply, 380 – 480 volts, with the

maximum output current limited to 45 Amps.

The supply must be connected to the L1 and L2 terminals of the drive.

4.5. Operation with DC Power Supply or Common DC Bus

Optidrive P2 models provide terminals to directly connect to the DC Bus for applications which require this. For further information on

using the DC Bus connections, please refer to your Invertek Drives sales Partner.

4.6. Motor Connection

The drive inherently produces fast switching of the output voltage (PWM) to the motor compared with operation of the motor

directly from the mains supply. Most modern industrial motors are wound for operation with a variable speed drive and will have

insulation rated accordingly. However, on some motors the quality of insulation may be insufficient or unknown. In such cases the

motor manufacturer should be consulted and preventative measures may be required prior to operating with the drive.

The motor should be connected to the Optidrive U, V, and W terminals using a suitable 3 or 4 core cable. Where a 3 core cable

is utilised, with the shield operating as an earth conductor, the shield must have a cross sectional area at least equal to the phase

conductors when they are made from the same material. Where a 4 core cable is utilised, the earth conductor must be of at least

equal cross sectional area and manufactured from the same material as the phase conductors.

Automatic switchgear should not be installed between the drive output and the motor, opening and closing contacts in this circuit

whilst the drive is energised will inevitably reduce the lifetime of the drive and could cause product failure. If an isolator is required

to be placed between the drive and the motor in order to comply with local regulations, the device must not be operated when the

drive is running.

For compliance with the European EMC directive, a suitable screened (shielded) cable should be used. Braided or twisted type

screened cable where the screen covers at least 85% of the cable surface area, designed with low impedance to HF signals are

recommended as a minimum. Installation within a suitable steel or copper tube is generally also acceptable.

The motor earth must be connected to one of the Optidrive earth terminals to provide a low impedance path for common mode

leakage current to return to the drive. This is best achieved in practice by using a cable with suitable shielding which provides a low

impedance path at high frequencies, and ensuring correct, low impedance earth bonding of the motor cable at both ends. For further

information, refer to section 4.13. EMC Compliant Installation on page 28.

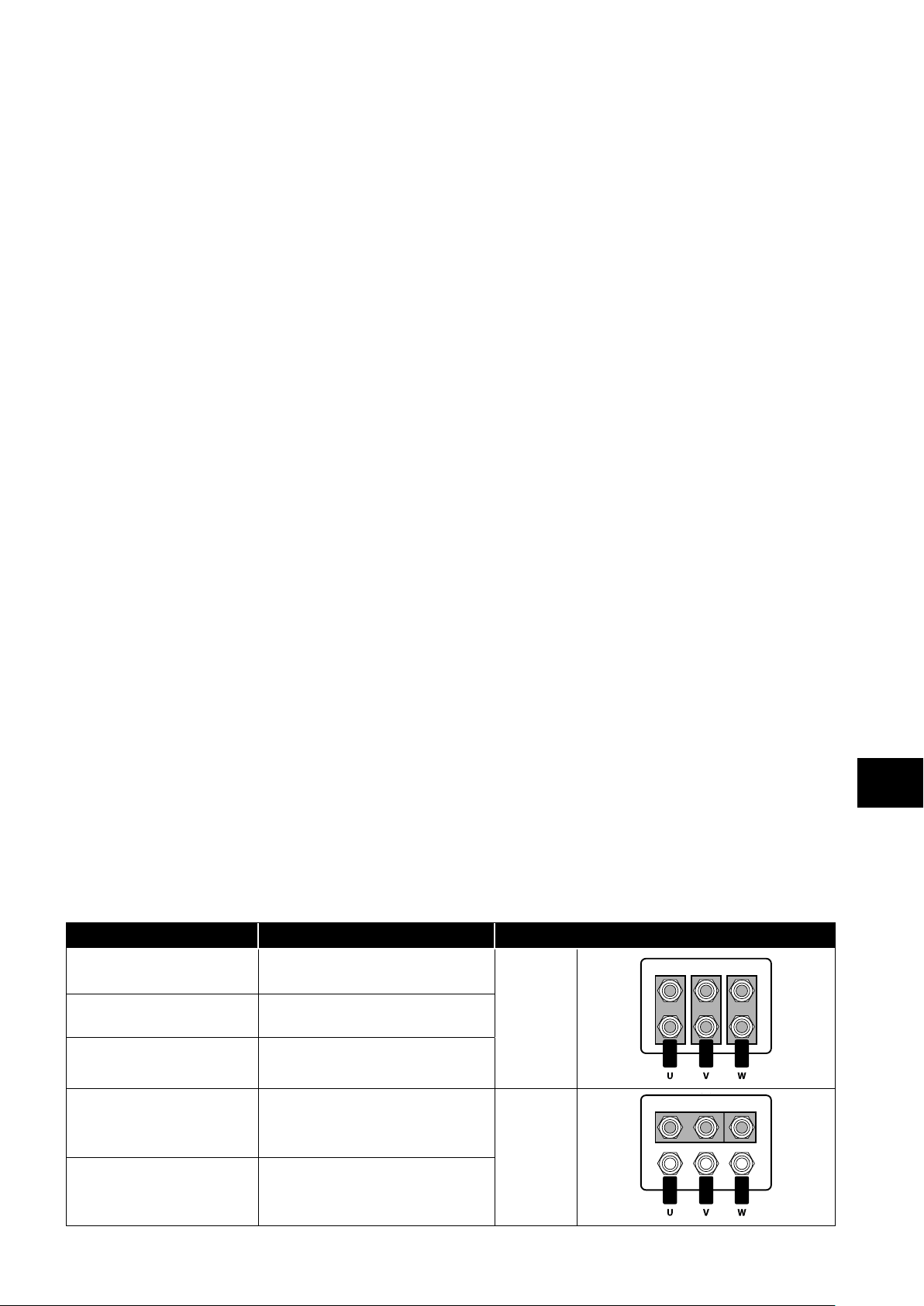

4.7. Motor Terminal Box Connections

Most general purpose motors are wound for operation on dual voltage supplies. This is indicated on the nameplate of the motor. This

operational voltage is normally selected when installing the motor by selecting either STAR or DELTA connection. STAR always gives

the higher of the two voltage ratings.

Incoming Supply Voltage Motor Nameplate Voltages Connection

Electrical Installation

4

230 230 / 400

400 / 460 400 / 690

575 575 / 1000

400 230 / 400

575 330 / 575

Delta

∆

Star

⅄

Version 3.04 | Optidrive P2 User Guide | 23www.invertekdrives.com

Page 24

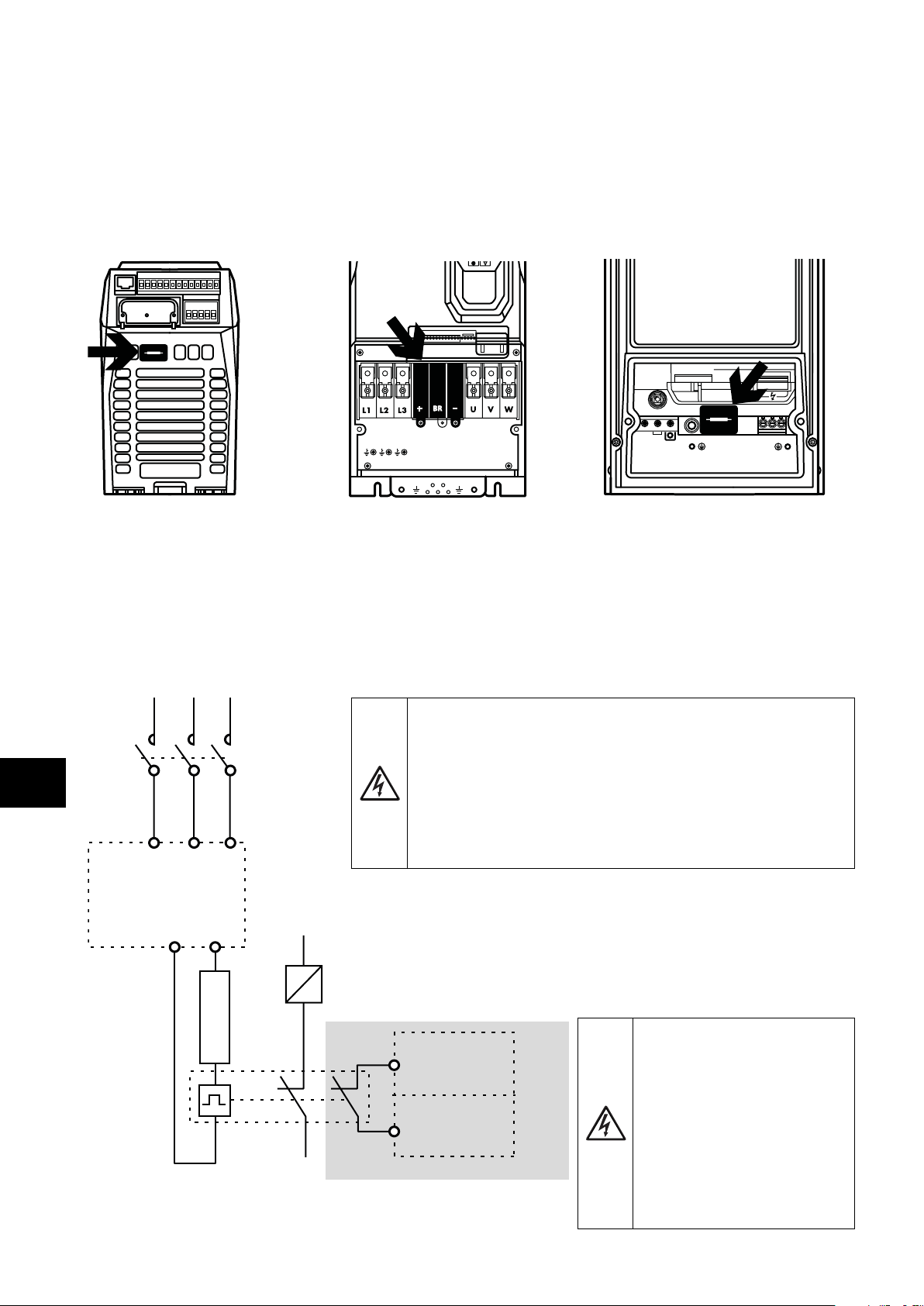

4.8. Connecting a Brake Resistor

Optidrive P2 units feature an internal brake transistor, fitted as standard for all models. The brake resistor should be connected to the

DC+ and BR terminals of the drive. These terminals are shrouded, and the shrouding should be removed to access the terminals.

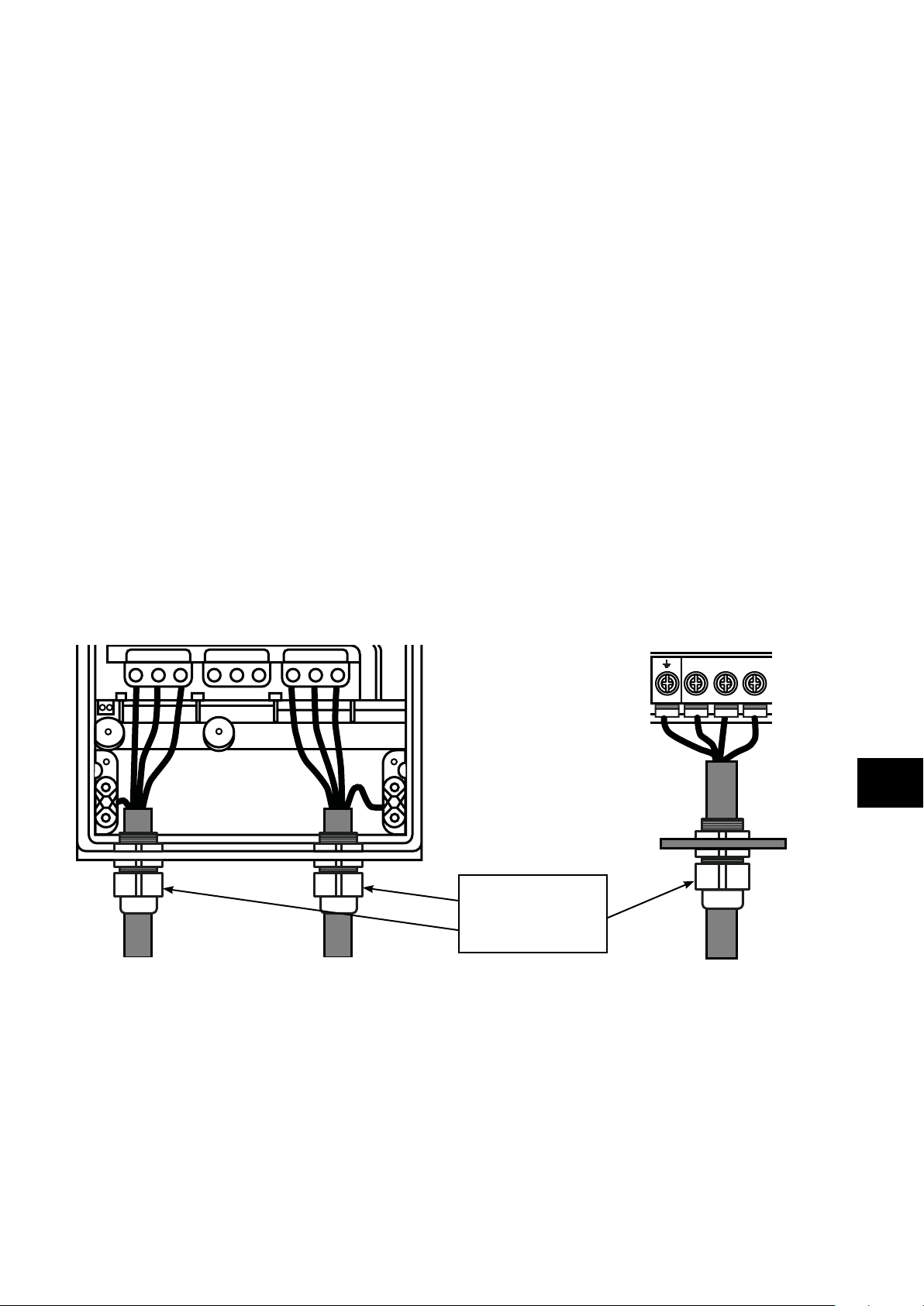

4.8.1. IP20 Drive Models 4.8.2. IP55 & IP66

Frame Sizes 2, 3, 4 & 5

Remove the plastic cover from the base

of the drive as indicated.

Electrical Installation

The brake transistor is enabled using P1-05 (Refer to section 6.2. Parameter Group 1 – Basic Parameters on page 37 for further

information).

Software protection against brake resistor overload is carried out within the drive. For correct protection of the brake resistor, the

following settings are required:

Set P1-14 = 201 (where 201 is the default password setting for advanced parameter access).

Enter the resistance of the brake resistor in P6-19 (Ohms).

Enter the power of the brake resistor in P6-20 (kW).

Dynamic Brake Resistor with Thermal Overload Protection

Frame Sizes 6A/ 6B

Remove the plastic cover from inside the

drive as indicated.

EMC EMC VAR

AC DC

All frame sizes

Remove the plastic cover from inside the

drive as indicated.

1 2 3 4 5 6 7 8 9

I0I0II0I0I

EMC

L3

L2/N

L1

10 11 12 13

14 15 16 17 18

UVW

4

K1

ODP-2

L2/N L3

L1/L

BR

DC+

K1 - Main Contractor

Thermal Overload / Brake Resistor

with internal Over Temperature switch

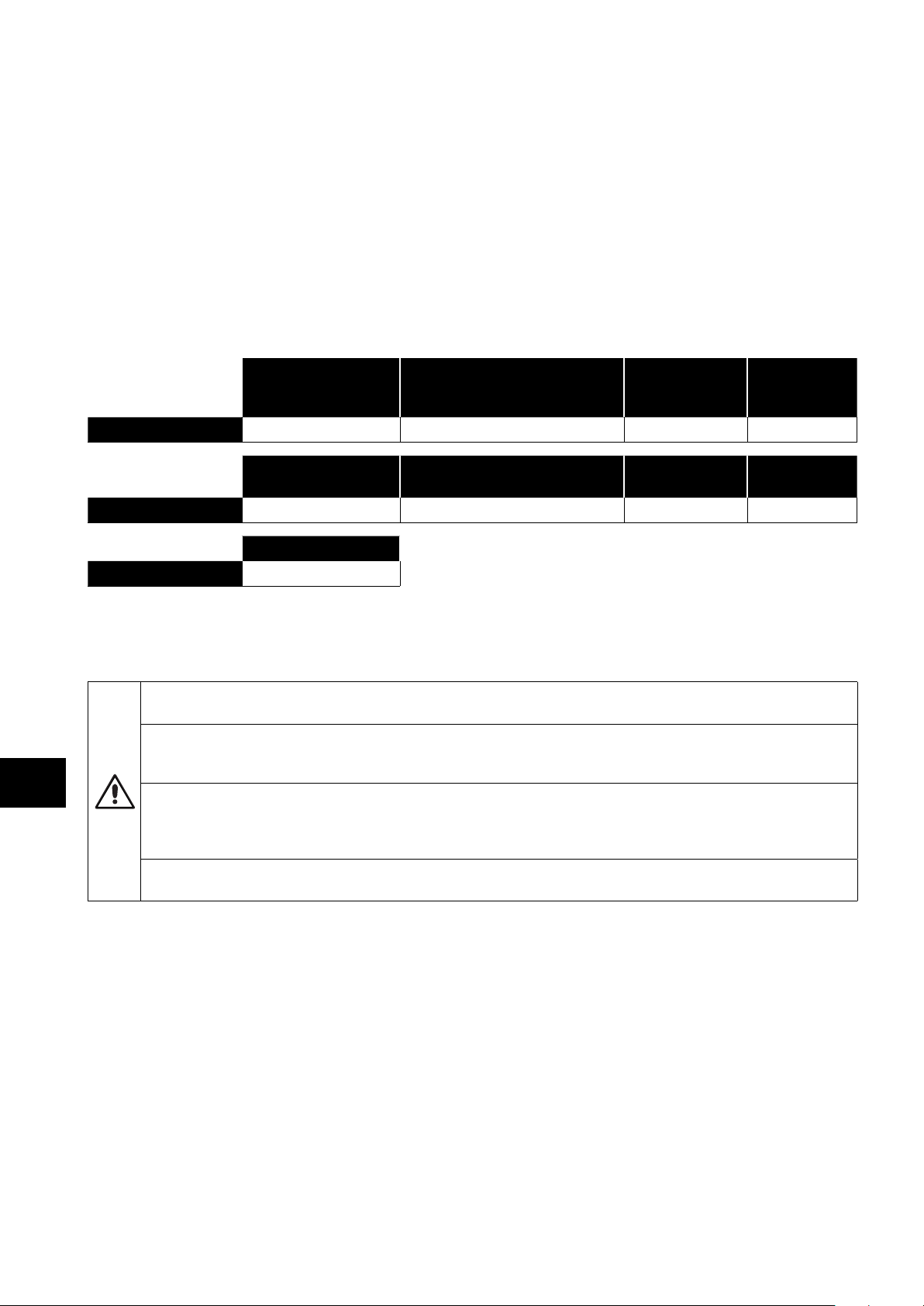

It is highly recommended to equip the drive with a main

contactor in order to provide an additional thermal overload

protection for the braking resistor.

The contactor should be wired so that it will open when the

resistor overheats, otherwise the drive will not be able to

interrupt the main supply if the brake chopper remains closed

(short-circuited) in a fault situation.

It is also recommended to wire the thermal overload

protection to a digital input of the drive as an External Trip.

ODP-2

+ 24 VDC

The voltage level at these

terminals may exceed

800V DC.

Stored charge may be

present after disconnecting

Dlx

the mains power.

Allow a minimum of 5

Optional wiring

minutes discharge after

power off before attempting

any connection to these

terminals.

24 | Optidrive P2 User Guide | Version 3.04 www.invertekdrives.com

Page 25

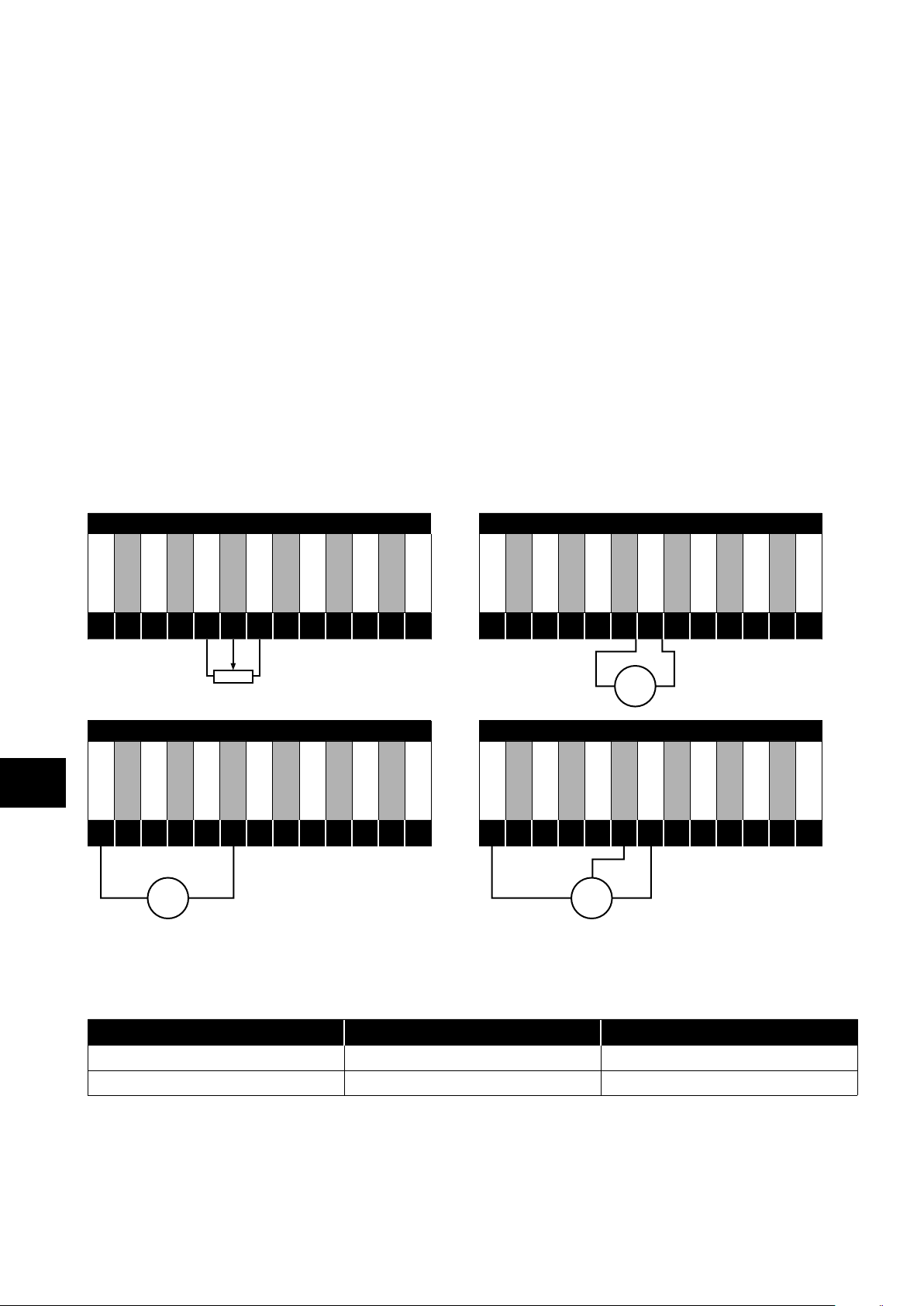

4.9. Control Terminal Wiring

0/4-20 mA

20-4/0 mA

0/4-20 mA

20-4/0 mA

* Dashed lines shows connection for analog inputs in digital mode ** Optional external 24 V DC power supply

All analog signal cables should be suitably shielded. Twisted pair cables are recommended.

Power and Control Signal cables should be routed separately where possible, and must not be routed parallel to each other.

Signal levels of different voltages e.g. 24 Volt DC and 110 Volt AC, should not be routed in the same cable.

Maximum control terminal tightening torque is 0.5Nm.

Control Cable entry conductor size: 0.05 – 2.5mm

4.9.1. Control Connections

2

/ 30 – 12 AWG.

1 (+24V DC/ 100mA)

(AO 1) 8

0-10V

10-0V

+

_

-10 ...10 V

0/4-20 mA

-10 ...10 V

0/4-20 mA

+24 V DC**

0-10 V

10-0 V

20-4 mA

0-10 V

10-0 V

20-4 mA

2 (Dl 1)

3 (Dl 2)

4 (Dl 3)

5 (+10V DC/ 10mA)

6 (AI 1/ DI 4*)

7 (0V/ COM)

10 (AI 2/ DI 5*)

12 (STO+)

13 (STO-)

(0V/ COM) 9

(AO 2) 11

14 (RL1-C)

15 (RL1-NO)

16 (RL1-NC)

17 (RL2-A)

18 (RL2-B)

0-10V

10-0V

NOTE

Key

1 +24V DC 24 Volt DC Input / Output

On-board +24V DC Supply (100mA)

Default Function

Open Closed

or External 24V DC Input

Sec.

Page

4.10 .1 26

2 DI 1 Digital Input 1 (Run Enable) STOP RUN 4.10.2 26

3 DI 2 Digital Input 2 FORWARD REVERSE 4.10.2 26

4 DI 3 Digital Input 3

5 +10V DC +10Volt DC Output On-board +10V DC Supply (10 mA)

P1-12 Reference Preset Speeds 4.10.2 26

6 AI 1 / DI 4 Analog Input 1 / Digital Input 4 Speed Reference 1 (0-10V) 4.10.3 26

7 0V / COM 0 Volt Common 0V Common for AI/AO/DI/DO

8 AO 1 Analog Output 1 Motor Speed (0-10V) 4.10.4 26

9 0V / COM 0 Volt Common 0V Common for AI/AO/DI/DO

10 AI 2 / DI 5 Analog Input 2 / Digital Input 5 P2-01 Speed Ref. P2-02 Speed Ref. 4.10.3 26

11 AO2 Analog Output 2 Motor Current (0-10V) 4.10.4 26

12

13 STO- STO 0 Volt Connection

STO+ STO + 24V DC Connection

InHibit Run Permit 4 .14 29

14 RL1-COM Auxiliary Relay Output 1 Common 4.10.5 26

15 RL1-NO

16 RL1-NC

17 RL2-A Auxiliary Relay Output 2

18 RL2-B Auxiliary Relay Output 2 4.10.5 26

Auxiliary Relay Output 1 Normally Open Drive Healthy Drive Faulty

Auxiliary Relay Output 2 Normally Closed Drive Faulty Drive Healthy

Drive Stopped Drive Running

4.10.5 26

4.10.5 26

4.10.5 26

Electrical Installation

4

NOTE Digital Inputs: Logic High = 8-30V DC (30V DC max) Analog Outputs: 0 – 10 Volt / 4-20mA (20mA max)

SAFE TORQUE OFF input: Logic High = 18-30V DC (Also refer to section 4.14. Safe Torque Off)

Version 3.04 | Optidrive P2 User Guide | 25www.invertekdrives.com

Page 26

4.10. Control Terminal Connections

0/4-20 mA

0/4-20 mA

Example connection schematics are provided in section 7.3. Example Connection Schematics on page 43.

4.10.1. +24V DC Input / Output

When the mains power is applied to the drive, terminal 1 provides a +24V DC output, maximum load 100mA. This may be used to

activate digital inputs or provide power to sensors.

When no mains power is applied to the drive, the drive control electronics may be powered from an external +24V DC source. When

powered in this way, all analog and digital I/O and communication functions remain operative, however the motor may not be

operated, which allows safe testing and commissioning of the installation without risk of high voltage being present. When powered in

this way, the drive requires up to 100mA.

4.10.2. Digital Inputs

Up to five digital inputs are available. The function of the inputs is defined by parameters P1-12 and P1-13, which are explained in

section 7. Control Terminal Functions on page 40.

4.10.3. Analog Inputs

Two analog inputs are available, which may also be used as digital Inputs if required. The signal formats are selected by parameters

as follows:

Analog Input 1 Format Selection Parameter P2-30.

Analog Input 2 Format Selection Parameter P2-33.

These parameters are described more fully in section 8.1. Parameter Group 2 - Extended Parameters on page 47.

Electrical Installation

The function of the analog input, e.g. for speed reference or PID feedback for example is defined by parameters P1-12 and P1-13.

The function of these parameters and available options are described in section 7. Control Terminal Functions on page 40.

Local Potentiometer Connection - AI1 2-wire Analog Voltage or Current signal

4

+24V DC

1

DI 1

2

DI 2

3

DI 3

4

+10V DC

5

AI 1

6

0V / COM

7

0V / COM

9

DI 5

10

AO 2

11

AO 1

8

STO+

12

STO-

13

+24V DC

1

DI 1

2

DI 2

3

0-10 V

10-0 V

-10-10V

20-4 mA

DI 3

4

+10V DC

5

+

V/A

AI 1

6

0V / COM

7

-

0V / COM

9

DI 5

10

AO 2

11

AO 1

8

STO+

12

STO-

13

2-wire or Loop Powered Transducer 3-wire Transducer

+24V DC

1

DI 1

2

+

0/4-20 mA

DI 2

3

24V DC

Sensor

DI 3

4

-

+10V DC

5

AI 1

6

0V / COM

7

0V / COM

9

DI 5

10

AO 2

11

AO 1

8

STO+

12

STO-

13

+24V DC

1

DI 1

2

DI 2

3

+

DI 3

4

24V DC

Sensor

+10V DC

5

-

AI 1

6

0V / COM

7

0V / COM

9

DI 5

10

AO 2

11

AO 1

8

STO+

12

STO-

13

4.10.4. Analog Outputs

Two analog outputs are available, and may be used for 0 – 10 Volt Signal (max load 20mA), 0 – 20mA, 4 – 20mA or a digital

+24Volt DC, 20mA output. The parameters to select function and format are as follows.

Analog Output Function selected by Format selected by

Analog Output 1 P2-11 P2-12

Analog Output 2 P2-13 P2-14

These parameters are described more fully in section 8.1. Parameter Group 2 - Extended Parameters on page 47.

4.10.5. Auxiliary Relay Outputs

Two relay outputs are available, which are intended to be used to switch external resistive loads up to 5A at 230V AC or 30V DC.

Relay 1 has both normally open and normally closed contacts available. Relay 2 provides a simple open or closed contact.

The relay output function may be configured using parameters P2-15 and P2-18, which are described in section 8.1. Parameter

Group 2 - Extended Parameters on page 47.

26 | Optidrive P2 User Guide | Version 3.04 www.invertekdrives.com

Page 27

4.11. IP66 Switched Version Integrated Control Switch and Potentiometer Wiring

Optidrive P2 is optionally available with an integrated mains switch-disconnector and front mounted control switch and potentiometer.

This allows the drive to be operated directly from the front control panel, whilst also providing for options such as Hand / Auto or

Local / Remote Control etc.

The integrated switch in IP66 Outdoor models operates in parallel with drive terminal 2 (T2) and terminal 3 (T3) as digital input 1 and

digital input 2. By default, the integrated switch is enabled.

Integrated Control Switch and Potentiometer Wiring

+10V DC

5

AI 1

6

0V / COM

7

Switch Left Switch Centre Switch Right

DI1 DI2 DI1 DI2 DI1 DI2

1 1 0 0 1 0 Lc-Off

0 0 0 0 0 0 Lc-On

0 1 0 0 1 0 Altern

+24V DC

1

DI 1

2

DI 2

3

DI 3

4

4.11.1. Disabling built-in switches

If required, the built-in control switch may be disabled using the following method:

1) Ensure the drive is stopped (Display shows “Stop”).

2) Enable Advanced Parameter Access by setting the correct value in P1-14 (default : 201).

3) Scroll down to parameter P0-01 (Display shows P0-01).

4) Press and hold “STOP” button for >1s, drive will show:

IP66 Switch Setup

2: Pos >>DI1, Pos<<DI2

1: Switch disabled

0: Pos >>DI1, Pos <<DI1&2

5) Use “UP” or “DOWN” key to select the option:

0: Pos >>DI1, Pos <<DI1&2 means integrated switches are enabled.

1: Switch disabled means the switches are locked/disabled.

2: Pos >>DI1, Pos<<DI2 means that Revers direction is disabled via built-in switch (can be unlocked via external enable signal

connected to DI1 – terminal 2).

6) Press the “STOP” button again to exit.

Electrical Installation

4

4.12. Motor Thermal Overload Protection

4.12.1. Internal Thermal Overload Protection

Optidrive P2 has internal motor overload protection (current limit) set at 150% of FLC. This level may be adjusted using P4-07.

The drive has an in-built motor thermal overload function; this is in the form of an “I.t-trP” trip after delivering >100% of the value set in

P1-08 for a sustained period of time (e.g. 150% for 60 seconds).

4.12.2. Motor Thermistor Connection

Where a motor thermistor is to be used, it should be connected as follows:

Motor Thermistor Connection Additional Information

Compatible Thermistor: PTC Type, 2.5kΩ trip level.

Use a setting of P1-13 that has DI5/AI2 function as E-TRIP

+24V DC

1

DI 1

2

DI 2

3

DI 3

4

+10V DC

5

AI 1

6

0V / COM

7

AO 1

8

0V / COM

9

AI 2

10

AO 2

STO-

STO+

“External Trip”, e.g. P1-13 = 6. Refer to section 7.2. Digital

Input Configuration Parameter P1-13 on page 42 for

further details.

11

12

13

Enable the Motor PTC Thermistor Input function in parameter

P2-33.

Version 3.04 | Optidrive P2 User Guide | 27www.invertekdrives.com

Page 28

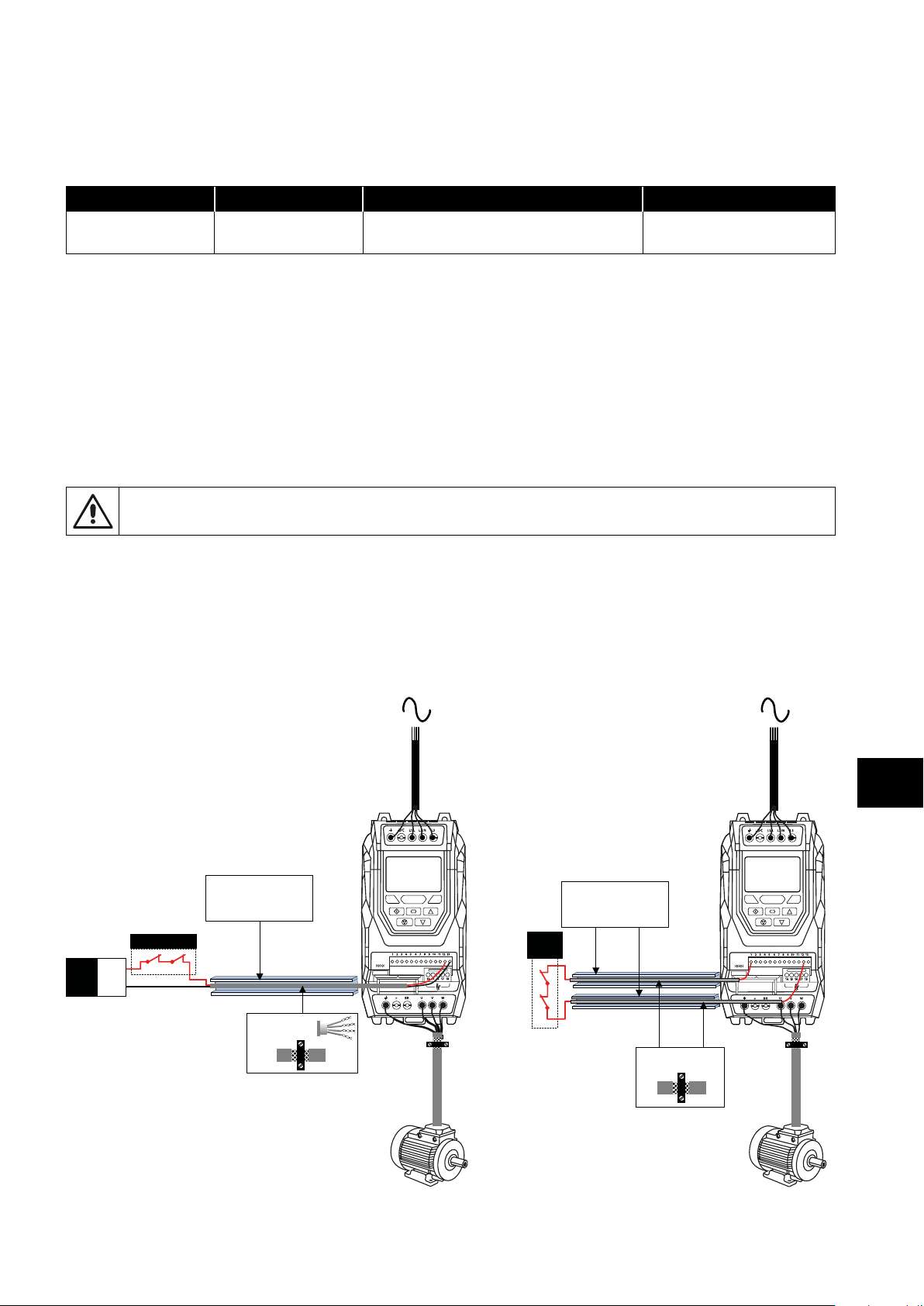

4.13. EMC Compliant Installation

L1

L2

L3

PE

4.13.1. Recommended Installation for EMC Compliance

Electrical Installation

≥ 100mm

Mounting plate

with conductive

service

Control cables

Twisted-Pair shielded

cables for analog

control and motor

feedback signals.

For Best-Practice use

360° bonding EMC

cable gland shielded

to motor chassis.

U V W PE

4

Fuse /

MCB

L1L2L3

Control cablesMains - supply

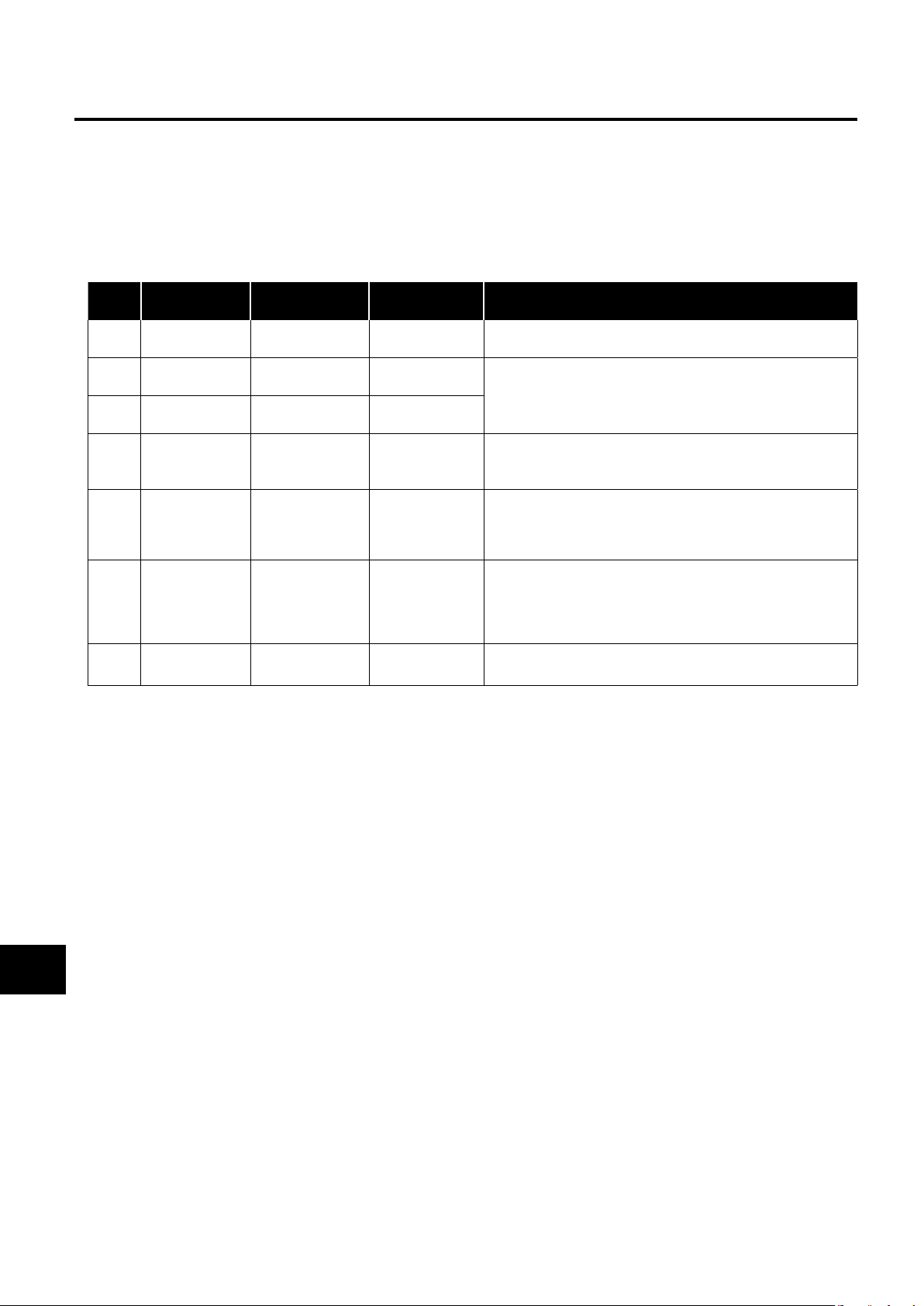

4.13.2. Recommended Cable Types by EMC Category

Number of

Input Phases

1 230 2 IP20, IP66 1 (5) 5 (25) 25 (100)

3 230

3 400

Rated Supply

Voltage

Frame Size IP rating

2, 3 IP20, IP66 1 (5) 5 (25) 25 (100)

4, 5 IP20, IP55 1 (5) 5 (25) 25 (100)

4,5 IP55 - - 25 (100)

6A, 6B IP20 - 10 0 100

6, 7 IP55 - - 25 (100)

2, 3 IP20, IP66 1 (5) 5 (25) 25 (100)

4, 5 IP20, IP55 1 (5) 5 (25) 25 (100)

4,5 IP55 - - 25 (100)

6A, 6B IP20 - 10 0 100

6, 7 IP55 - - 25 (100)

8 IP20 - - 25

Cable shield exposed

and 360° clamped to

grounded metal plate or PE

bar. All other 360° bonding

methods are acceptable.

3-phase and PE shielded cable.

Motor cable