Invertek Drive OPTIDRIVE HVAC Sales Brochure

AC Variable Speed Drive

PUMP CONTROL

Energy efficient pumping with

Pump Control

0.75kW – 250kW / 1HP – 350HP

200 – 480V Single & 3 Phase Input

Pumping Stations

Manufacturing

Treatment Plants

Car Parks

Energy Efficient Pump Control

Energy efficient flow control from reliable, compact drives, ideal for pump systems

Instant Power Savings

With variable speed control, Optidrive HVAC

immediately reduces power usage compared to fixed

speed systems.

Power (%)

100

80

60

40

20

0

0 10 20 30 40 50 60 70 80 90 100

With traditional Damper Control

With Optidrive

HVAC Contro l

Flow (%)

Variable Speed Optimisation

Pump systems are often sized to be most

efficient at an application's maximum

flow rate.

In systems with peak rather than

continuous demand, Optidrive HVAC

matches pump output to the demands of

pump systems. This variable speed control

offers significant savings by maximising

system efficiency at all flow rates.

Traditional means of controlling pump

output involve dissipating or diverting the

output already generated by the pump

running at full speed. In comparison,

Optidrive HVAC saves energy by

generating only the required output.

Invertek’s philosophy to provide innovative

products with easy to use, energy efficient

features ensures that time, set up costs and

operational (energy) savings are maximised

at all times. This results in the shortest

possible payback period, namely the time

taken to recover the initial product and

installation costs through financial savings

achieved through installing Optidrive

HVAC drives.

For simple installation into your pump

management system all Optidrive HVAC

drives are provided with both BACnet

and Modbus RTU as standard across the

product range.

Energy Savings Calculator

Estimate your potential energy savings,

CO2 emissions and financial savings

www.invertekdrives.com/calculator

2 www.invertekdrives.com

Energy efficient pumping with

Save Energy Save Money Save Time

Pump Control

Energy optimisation function minimises

energy usage in real time under partial load

conditions

Advanced sleep & wake functions provide

maximum energy savings by switching off the

pump when not required

Automatic Pump Cleaning ensures

maximum operating efficiency at all times

Control System

Set-point Signal 0-10V

Feedback Signal 4-20mA

Input

Drive Output

technology allows simple

operation of multiple pump sets without the

need for a PLC

Pump blockage detection and cleaning

dramatically reduces pump maintenance

requirements

Built in PLC function allows bespoke

customised applications to be programmed

directly in the drive

Pressure

Sensor

Outputs Outputs

Simple parameter set allows fast

commissioning of pump control systems

Pump operating curve detection

automatically detects and monitors normal pump

behaviour and is able to react when pumping

conditions change

Customisable OLED display provides

excellent visibility of drive status and operation in

all conditions

Optimising EfficiencyControlling Your Pump System

Energy Optimisation

The advanced optimisation function intelligently

matches energy usage to the pump load to ensure

your pump operates at maximum efficiency.

Energy Monitoring

The inbuilt energy consumption meters allow energy

consumption to be clearly displayed and savings to be

calculated.

Outputs Outputs

Optidrive HVAC has a PID controller built in that is fully integrated with both pump

and energy efficient features and is packaged in a user friendly way to ensure ease of

use and fast commissioning. Now in the majority of applications it has become possible

to eliminate the need for external controllers.

Resonance Avoidance

Optidrive HVAC can be easily configured to avoid

frequencies that cause resonance in pumping systems,

preventing unnecessary noise and mechanical damage

to motors and pipework.

In-built Sleep Mode with Auto-boost

Sleep mode saves energy by detecting when a pump

is running inefficiently and producing little useful work.

Optidrive HVAC can be programmed to enter into a

sleep/disabled mode until the demand increases. To

help prevent sleep mode oscillation, Optidrive HVAC

can automatically initiate a boost cycle to increase

pressure on starting or stopping.

3

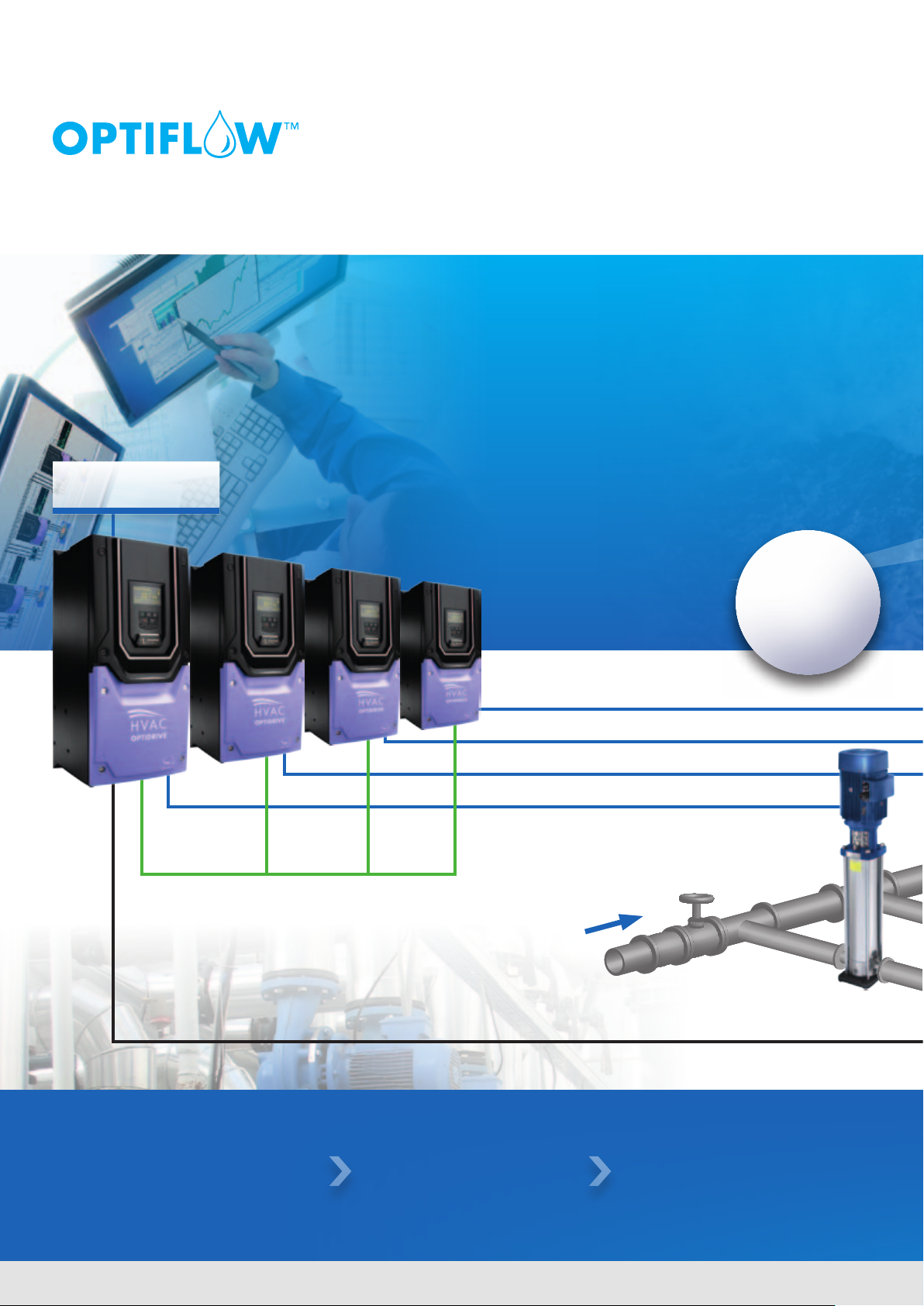

Multi-pump Control

Embedded control technology for multi-pump systems

Flexible pump station control

with no PLCs or pump control units

Setpoint Control

Independent pump

control system

A standard

feature on all

drives

Total Control

A single ‘Master’ drive acts to control

and monitor system operation.

Control connections are made to this

drive only, saving installation time and

reducing costs.

4 www.invertekdrives.com

Optiflow communications

© Feedback signal

Simple Connection

Additional drives connected

on the system require a single

RJ45 connection and basic

commissioning, leading to time

savings and simplified installation.

Flexible Solution

The system can operate with up to five

pumps in any configuration, e.g. Duty

/ Assist / Standby. Duty pumps are

automatically rotated, ensuring maximum

service life and system efficiency.

Loading...

Loading...