Invertek Drive OPTIDRIVE Catalog

Stock Drives Catalogue

Variable Speed Drives

& Accessories

The OrganisationInvertek Drives

UK Headquarters, Welshpool

Invertek Drives is dedicated to

the design and manufacture of

sophisticated electronic variable

speed drives, used to control motors

in a wide variety of industrial and

energy savingapplications.

State of the art UK headquarters house

specialist facilities for innovation,

manufacturing and globalmarketing.

The company pledges to implement and

operate the ISO 14001 Environmental

Management System to enhance

environmentalperformance.

All operations, including innovation,

are accredited to the exacting customer

focused ISO 9001 quality standard.

The company’s products are sold globally

by a network of specialist distributors

in over 80 different countries. Invertek

Drives’ unique and innovative Optidrive

range is designed for ease of use and

meets recognised international design

standards for CE(Europe), UL(USA) and

RCM(Australia).

Innovative Products

y Easy to use variable speeddrives

y Incredible performance

y Robust & reliable

y Low cost of installation & ownership

y Wide power range

0.37 – 250kW, 115V – 600V

ii

www.invertekdrives.com

Company Overview

Invertek Office

Sales Partner

Service Centre

USA

IRELAND

UK

Headquarters

GERMANY

SPAIN

SOUTH AFRICA

POLAND

CZECH REPUBLIC

Global sales, service & application support

in over 80 countries

CHINA

MALAYSIA

INDONESIA

SINGAPORE

AUSTRALASIA

Online

Support

y Conveyors

y HVAC

y Machine Tools

Pre-sales

Support

Customer

Service

y Manufacturing

y Pumping

y Process Control

Technical

Support

y Elevators

y Cranes

Knowledge

Management

Field

Service

Logistics &

Distribution

Spare Parts

& Repair

Service

Contracts

International

Support

iii

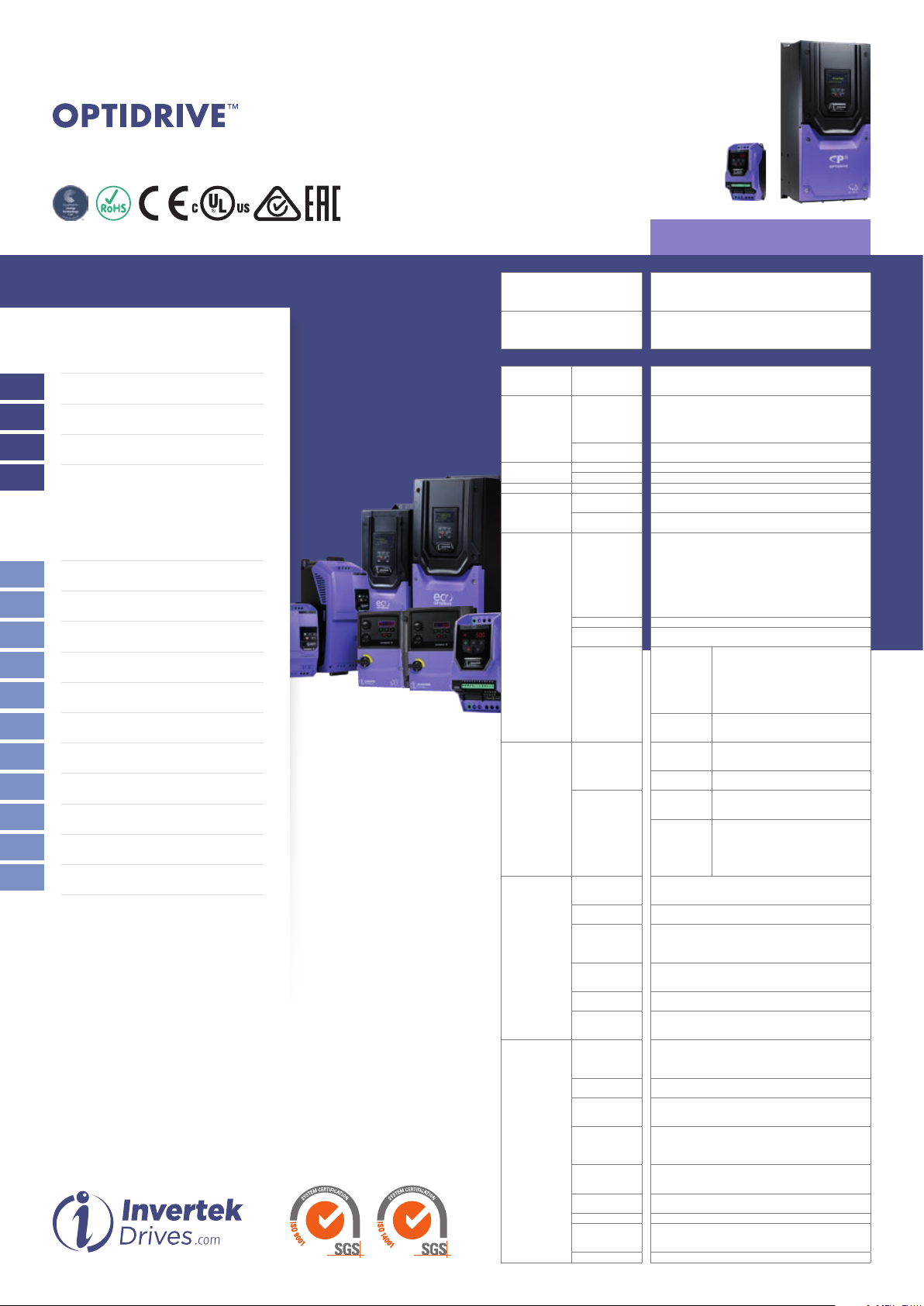

AC Variable Speed Drives

Page

AC Variable Speed Drives

2

OPTIDRIVE P2

8

OPTIDRIVE E3

12

OPTIDRIVE E3 Single Phase

14

OPTIDRIVE Eco

Options

22

Keypads & Displays

23

Plug-in Options

24

Software / Commissioning

25

Networking Options

26

Input Chokes

27

Output Chokes

28

EMC Filters

29

Brake Resistors

30

Local Isolator

30

Through Hole MountKits

31

Options Compatibility

Easy to use,

reliable products

with incredible

performance

Global service and

support network

leading edge design

& technology

Specification

Motor Types 3 Phase Induction Motor (IM)

Typical Applications

Input Ratings Supply Voltage 200 – 240 Volts ± 10%

Output Ratings Output Power 230 Volt 1 Phase Input : Up to 10.5A / 2.2kW / 3HP

Overload Capacity 150% for 60 Seconds

Ambient Conditions Tempe rature -10 – 50°C -20 – 50°C -20 – 50°C -10 – 50°C

Enclosure Ingress Protection IP20, IP55, IP66 IP20, IP66 IP20, IP66 IP20, IP55, IP66

Programming Keypad Built-in Keypad as standard

Control Specification Control Method V/F Control

Fieldbus Connectivity Built In

I/O Specification Programmable Inputs 5 Total as standard (Optional additional 3)

Application Features PI(D) Control Internal PID Controller

Humidity 95% Max, non condensing 95% Max, non condensing 95% Max, non condensing 95% Max, non condensing

Display Built-in multi language text display (IP55 & IP66)

PWM Freque ncy 4 – 32kHz Effective 4 – 32kHz Effective 4 – 32kHz Effective 4 - 32kHz Effective

Braking Motor Flux Braking

Setpoint Control

Optional

Digital Inpu ts 8 – 30 Volt DC, internal or external supply

Analog Inputs Resolution : 12 bits

Programmable

Outputs

Relay Outputs Maximum Voltage : 250 VAC, 30 VDC

Analog Outputs 0 to 10 Volt

Fire Mode Bidirectional

Load Monitoring Over Torque Protection (Fan / Bump Blocked)

P2 E3 (3ph Out) E3 (1ph Out) Eco

Permanent Magnet AC Motor (PM)

Brushless DC Motor (BLDC)

Synchronous Reluctance Motor (SynRM)

Fans

Pumps

380 – 480 Volts ± 10%

500 – 600 Volts ± 10%

230 Volt 3 Phase Input : Up to 248A / 75kW / 100HP

400 Volt 3 Phase Input : Up to 450A / 250kW / 350HP

460 Volt 3 Phase Input : Up to 450A / 250kW / 350HP

575 Volt 3 Phase Input : Up to 150A / 110kW / 150HP

200% for 4 seconds

Optional remote mountable keypad

7 Segment LED (IP20)

Energy Optimised V/F

3GV Sensorless Vector Speed Control

3GV Sensorless Vector Torque Control

Closed Loop (Encoder) Speed Control

Closed Loop (Encoder) Torque Control

PM Vector Control

BLDC Control

Synchronous Reluctance Motor Control

Built-in Braking Transistor

Analog Signal

Digital

CANopen 125 – 1000kbps

Modbus RTU

Other

3 Digital (Optional additional 3)

2 Analog / Digital Selectable

Response time < 4ms

Response time : < 4ms

Accuracy : <1% full scale

Parameter adjustable scaling and offset

4 Total (Optional additional 3)

2 Analog / Digital

2 Relays (Optional additional 3)

Switching Current Capacity : 6A AC, 5A DC

0 to 20mA

4 to 20mA

Multi Setpoint Select

Standby / Sleep Mode

Boost Function

0 to 10 Volts

10 to 0 Volts

-10 to + 10 Volts

0 to 20mA

20 to 0mA

4 to 20mA

20 to 4 mA

Motorised Potentiometer (Keypad)

Modbus RTU

CANopen

9.6 – 115.2 kbps selectable

8N1, 8N2, 8E1, 8O1

PROFIBUS DP (DPV1)

PROFINET IO

DeviceNet

EtherNet/IP

EtherCat

Modbus TCP

Pages 2– 7

Duty / Ass ist /

Satndby

Hoist Mode Dedicated Hoist Mode

Pump Blockage

Detection

Pump Cleaning Adjustable Bidirectional Pump Cleaning Cycle operation

Multi-pump control Control of fixed speed assist pumps (with cascade control module)

Pump Stir Automatic pump stir function

Motor Holding Brake Pre-Torque & Control

Over Limit Protection

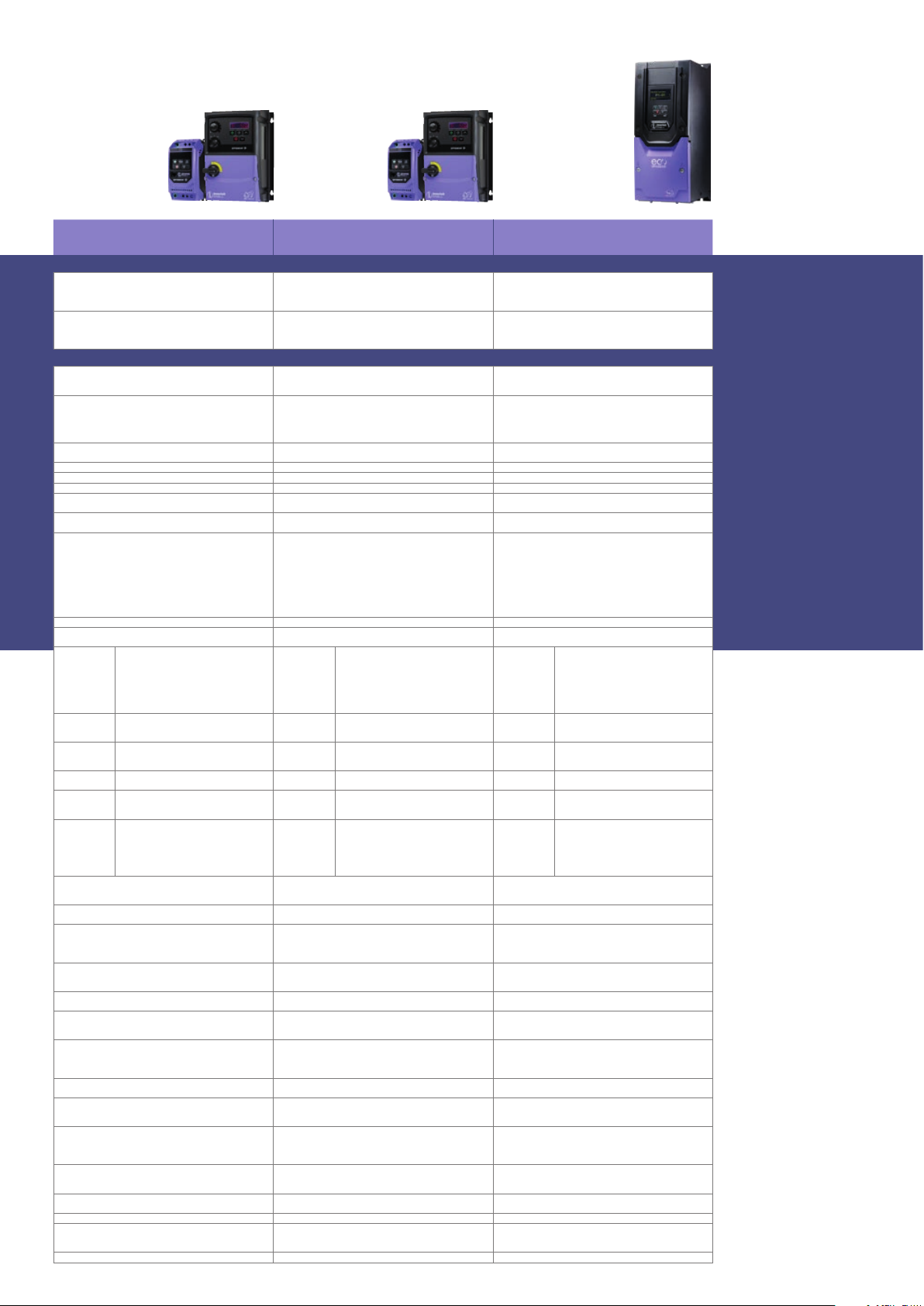

Pag es 14 –19Pa ge s 12–13Pa ge s 8 –11

3 Phase Induction Motor (IM)

Permanent Magnet AC Motor (PM)

Brushless DC Motor (BLDC)

Synchronous Reluctance Motor (SynRM)

General Industrial

Fans

Pumps

Crane & Hoist

110 – 115 Volts ± 10%

200 – 240 Volts ± 10%

380 – 480 Volts ± 10%

110 Volt 1 Phase Input : Up to 5.8A / 1.1kW / 1.5HP

230 Volt 1 Phase Input : Up to 15.3A / 4kW / 5HP

230 Volt 3 Phase Input : Up to 18A / 4kW / 5HP

400 Volt 3 Phase Input : Up to 46A / 22kW / 30HP

460 Volt 3 Phase Input : Up to 46A / 22kW / 30HP

150% for 60 Seconds

175% for 2.5 seconds

Built-in Keypad as standard

Optional remote mountable keypad

7 Segment LED 7 Segment LED

V/F Control

Energy Optimised V/F

Sensorless Vector Speed Control

PM Vector Control

BLDC Control

Synchronous Reluctance Motor Control

Motor Flux Braking

Built-in Braking Transistor (Not Frame Size 1)

Analog Signal

Digital

CANopen 125 – 1000kbps CANopen 125 – 1000kbps BACnet MS/ TP

Modbus RTU 9.6 – 115.2 kbps selectable Modbus RTU 9.6 – 115.2 kbps selectable Modbus RTU

4 Total

2 Digital

2 Analog / Digital Selectable

8 – 30 Volt DC, internal or external supply

Response time < 4ms

Resolution : 12 bits

Response time : < 4ms

Accuracy : ± 2% full scale

Parameter adjustable scaling and offset

2 Total

1 Analog / Digital

1 Relay

Maximum Voltage : 250 VAC, 30 VDC

Switching Current Capacity : 6A AC, 5A DC

0 to 10 Volt 0 to 10 Volt

Internal PI Controller

Standby / Sleep Function

Selectable Speed Setpoint (Fixed / PID / Analog / Fieldbus)

0 to 10 Volts

10 to 0 Volts

0 to 20mA

20 to 0mA

4 to 20mA

20 to 4 mA

Motorised Potentiometer (Keypad)

Modbus RTU

CANopen

Single Phase AC Motor

Permanent Split Capacitor (PSC)

Shaded Pole

General Industrial

Fans

Pumps

110 – 115 Volts ± 10%

200 – 240 Volts ± 10%

110 Volt 1 Phase Input : Up to 10.5A / 0.55kW / 0.75HP

230 Volt 1 Phase Input : Up to 10.5A / 1.1kW / 1.5HP

150% for 60 Seconds

175% for 2.5 seconds

Built-in Keypad as standard

Optional remote mountable keypad

V/F Voltage Vector

Energy Optimised V/F

Motor Flux Braking

Built-in Braking Transistor (Frame Size 2)

Analog Signal

Digital

4 Total

2 Digital

2 Analog / Digital Selectable

8 – 30 Volt DC, internal or external supply

Response time < 4ms

Resolution : 12 bits

Response time : < 4ms

Accuracy : ± 2% full scale

Parameter adjustable scaling and offset

2 Total

1 Analog / Digital

1 Relay

Maximum Voltage : 250 VAC, 30 VDC

Switching Current Capacity : 6A AC, 5A DC

Internal PI Controller

Standby / Sleep Function

Selectable Speed Setpoint (Fixed / PID / Analog / Fieldbus)

0 to 10 Volts

10 to 0 Volts

0 to 20mA

20 to 0mA

4 to 20mA

20 to 4 mA

Motorised Potentiometer (Keypad)

Modbus RTU

CANopen

3 Phase Induction Motor (IM)

Permanent Magnet AC Motor (PM)

Brushless DC Motor (BLDC)

Synchronous Reluctance Motor (SynRM)

General Industrial

Fans

Pumps

200 – 240 Volts ± 10%

380 – 480 Volts ± 10%

500 – 600 Volts ± 10%

230 Volt 1 Phase Input : Up to 10.5A / 2.2kW / 3HP

230 Volt 3 Phase Input : Up to 248A / 75kW / 100HP

400 Volt 3 Phase Input : Up to 450A / 250kW / 350HP

460 Volt 3 Phase Input : Up to 450A / 250kW / 350HP

575 Volt 3 Phase Input : Up to 150A / 110kW / 150HP

110% for 60 seconds

165% for 4 seconds

Built-in Keypad as standard

Optional remote mountable keypad

Built-in multi language text display (IP55 & IP66)

7 Segment LED (IP20)

Eco Sensorless Vector Control

Open Loop Permanent Magnet Vector

Open Loop BLDC Vector

Open Loop Synchronous Reluctance Vector

Motor Flux Braking

Analog Signal

Digital

BACnet/IP

Other

5 Total as standard (Optional additional 3)

3 Digital (Optional additional 3)

2 Analog / Digital Selectable

8 – 30 Volt DC, internal or external supply

Response time < 4ms

Resolution : 12 bits

Response time : < 4ms

Accuracy : <1% full scale

Parameter adjustable scaling and offset

4 Total (Optional additional 3)

2 Analog / Digital

2 Relays (Optional additional 3)

Maximum Voltage : 250 VAC, 30 VDC

Switching Current Capacity : 6A AC, 5A DC

0 to 10 Volt

0 to 20mA

4 to 20mA

Internal PID Controller

Multi Setpoint Select

Standby / Sleep Mode

Boost Function

Bidirectional

Selectable Speed Setpoint (Fixed / PID / Analog / Fieldbus)

Under Torque Protection (Broken Belt / Shaft)

Pump Blockage Detection with Cleaning

Built-in Multi Pump Support

Automatic Changeover on Fault

Automatic Changeover on Run Time

Fully Redundant

0 to 10 Volts

10 to 0 Volts

-10 to + 10 Volts

0 to 20mA

20 to 0mA

4 to 20mA

20 to 4 mA

Motorised Potentiometer (Keypad)

Modbus RTU

BACnet MS/TP

BACnet Application Specific Controller

9.6 – 76.8 kbps selectable

Data Format : 8N1, 8N2, 8E1, 8O1

9.6 – 115.2 kbps selectable

8N1, 8N2, 8E1, 8O1

Plug-in BACnet/IP Interface

Dual LAN Ports

Device Level Ring

PROFIBUS DP (DPV1)

PROFINET IO

DeviceNet

EtherNet/IP

EtherCat

Modbus TCP

Pump load monitoring with autotune function, user configurable

Control of Duty, Assist and Standby variable speed pumps via

internal Master – Slave network

AC Variable Speed Drive

World Leading Motor Control

Controlling the latest generation of permanent magnet motors

and standard inductionmotors

0.75 – 250kW / 1 – 350HP

200 – 600V Single & 3 Phase Input

Optidrive P2 offers the perfect

combination of high performance

together with ease of use to allow even

the most demanding applications to be

tackledeasily.

y Low ambient operation (−10°C)

y Dedicated Hoist Mode

y CAN and Modbus RTU

communication as standard

High Performance Low Cost Installation

Sensorless Vector Control

Up to 200% torque from zero speed

ensures reliable starting and accurate

speed control under all load conditions.

PM Motor Control

Future proof. Allows upgrade to the latest

generation of high efficiency permanent

magnet motors.

I/O & Communications

Optidrive P2 supports a wide range of

interfaces to machine control systems.

Powerful PC based

commissioning software

Built-in EMC Filter

An internal filter in every OptidriveP2

saves cost and time for installation.

Integral Brake Transistor

Saves space, cost and time for installation.

OPTISTICK Smart

OPT-3-STICK-IN

2

www.invertekdrives.com

y Allows copying, backup and restore of

OptiTools Studio allows parameter upload,

Up to 11kWUp to 160kW

download and storage and access to

Optidrive P2 Simple PLC functionality.

See Page 24

drive parameters

y Provides Bluetooth interface to a PC

running OptiTools Studio or the OptiTools

Mobile app on a smartphone

y Onboard NFC (Near Field

Communication) for rapid data transfer

150% overload for 60 seconds

Cranes

Manufacturing

Rubber

Chemical

Elevators

Plastics

Machine Tools

Conveyer Systems

Processing Plants

Pumping

200% overload for 4 seconds

Industrial heavy duty rating for every model

Multi Language Text Display

(IP20 size 4-7, IP55 & IP66)

Convenient Help

Card

DIN Rail Mount

(IP20)

Pluggable Terminals

High Quality

Long-life Fans

3

High Performance | Easy to Use

Simple PLC Functionality

A wide range of function types available

including:

y Programmable Logic Functions

y Comparators

y Timers

y Mathematical Functions

y Drive specific functions

All blocks can be easily combined to

create flexible programs.

Programs can be protected to prevent

unauthorised copying.

Complete control over the drive including

all inputs and outputs.

Safe Torque Off (provided as standard)

Optidrive P2 features a safe torque off function to allow simple

integration into machine critical safety circuits.

y Simple machine design reduces component costs, saves panel space and

minimises installation time

y Faster shut down and reset procedures reduce system maintenance time

y Better safety standard compared to mechanical solution

y Better motor connection. Single cable with no interruption.

4

www.invertekdrives.com

With Without

Supply Supply

Input Contactor

NOT required

Optidrive

P2

Safety

Relay

Machine

Safety Circuit

Safety

Relay

Machine

Safety Circuit

Contactor

Variable

Speed

Drive

Input

IP20

IP55

IP66

Up to 250kW

Up to 160kW

Advanced Motor Control

Optidrive P2 has been uniquely developed to allow a wide range of different motor types to be used, with only parameter

changes being required. This technology allows the same drive to be used in a wide range of applications, allowing OEMs

and end user alike to take advantage of the energy saving provided by using the latest motor technologies.

AC Induction Motors

The majority of AC motors in

use today around the world are

standard induction motors. These

motors are relatively low cost,

readily available and provide good

performance with long service

life. With the ever increasing

focus on energy efficiency, motor

manufacturers have refined

and improved their designs in

recentyears.

Optidrive P2 has been developed

to provide optimum control

and maximum efficiency

when operating with older

motors designs, or newer high

efficiencydesigns.

Operation can be in simple

V/F control mode or in High

Performance Third Generation

Vector Mode, which provides up

to 200% torque from zero speed

without requiring anencoder.

Permanent Magnet ACMotors

Permanent magnet AC motors

provide improved efficiency

compared to standard induction

motors. Using permanent magnets

in the motor construction eliminates

the need for any magnetising

current, reducing electrical losses.

PM motors have been used for

many years in high performance

applications, however this has

always required the use of a

feedback device, such as a

resolver or encoder. Optidrive P2

has been designed to operate with

AC PM motors without requiring

any feedback device, allowing

them to be used for their energy

efficiency benefits without incurring

extra cost and complexity in

applications which do not require

positionfeedback.

Brushless DC Motors

BLDC motors are similar to AC

PM motors, however the design

requires a slightly different

control method to optimise the

performance. Optidrive P2 has

the flexibility to control this type

of motor, requiring only simple

parameter changes. This provides

much greater flexibility for OEMs,

allowing Optidrive P2 to be used

in a variety of applications, with

various motor types.

Synchronous ReluctanceMotors

Synchronous Reluctance Motors

(SynRM), not to be confused with

Switched Reluctance Motors,

share a similar stator construction

to standard induction motors,

however the rotor is substantially

different, in order to improve the

overall efficiency of the motor.

SynRM motors are ideally suited to

variable torque applications.

Optidrive P2 can control

synchronous reluctance motors,

allowing the energy saving benefits

to be realised.

Up to 11kW

5

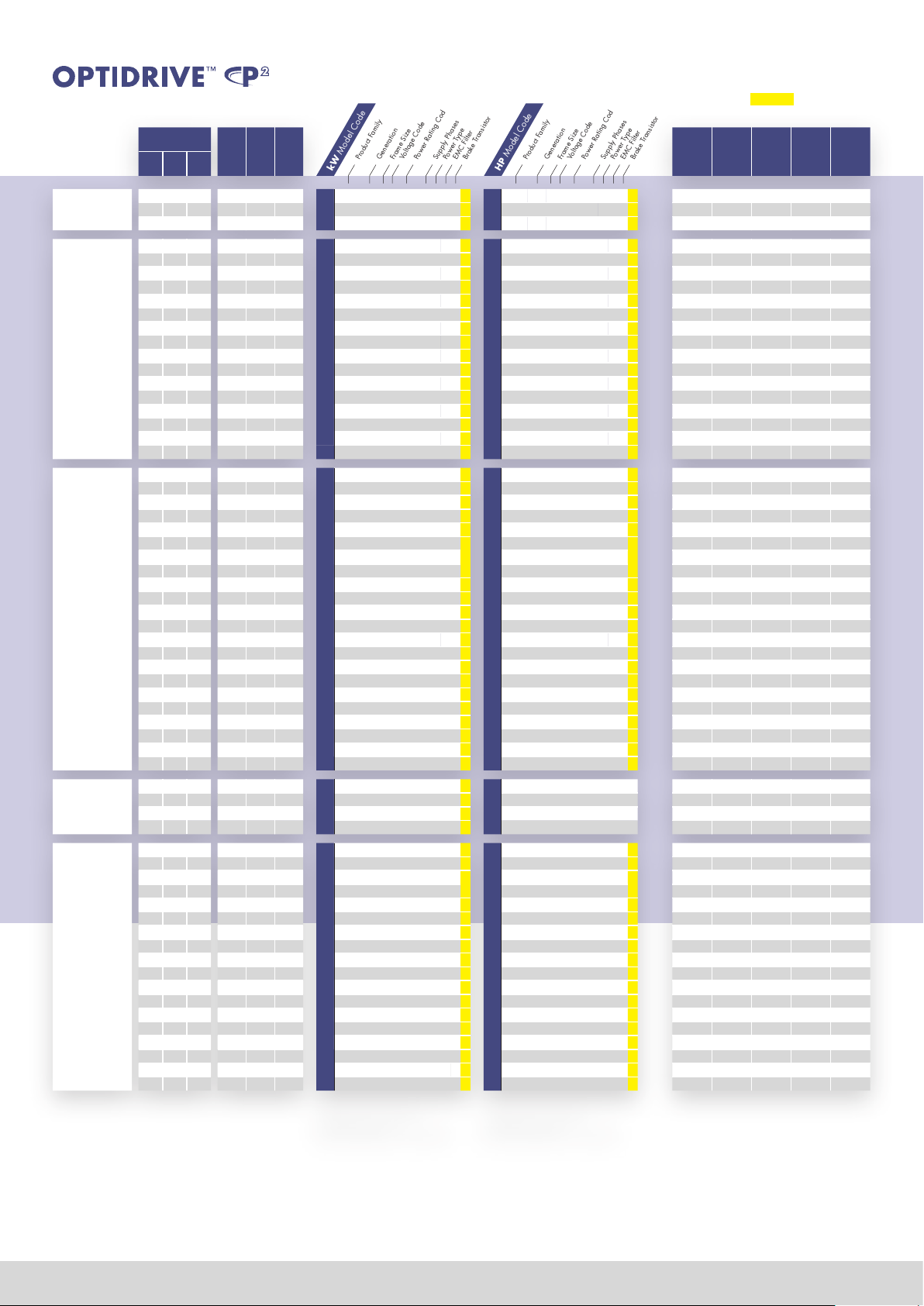

Replace #

in model co de with

enclosure/displayoption

200 – 240V ± 10%

1 Phase Input

200 – 240V ± 10%

3 Phase Input

380 – 480V ± 10%

3 Phase Input

480 – 525V ± 10%

3 Phase Input

500 – 600V ± 10%

3 Phase Input

Frame Size

IP20 IP55 IP66

kW HP Amps

kW Model Code

Product Family

Generation

Frame Size

Voltage Code

Power Rating Code

Supply Phases

Power Type

EMC Filter

Brake Transistor

HP Model Code

Product Family

Generation

Frame Size

Voltage Code

Power Rating Code

Supply Phases

Power Type

EMC Filter

Brake Transistor

IP20

LED

Display

IP20

TFT

Display

IP55

OLED

Display

IP66

OLED

Display

2 2 0.75 1 4.3 ODP - 2 - 2 2 075 - 1 K F 4 # ODP - 2 - 2 2 010 - 1 H F 4 # 2-SN X-TN Y-TN

2 2 1.5 2 7 ODP - 2 - 2 2 150 - 1 K F 4 # ODP - 2 - 2 2 020 - 1 H F 4 # 2-SN X-TN Y-TN

2 2 2.2 3 10.5 ODP - 2 - 2 2 220 - 1 K F 4 # ODP - 2 - 2 2 030 - 1 H F 4 # 2-SN X-TN Y-TN

2 2 0.75 1 4.3 ODP - 2 - 2 2 075 - 3 K F 4 # ODP - 2 - 2 2 010 - 3 H F 4 # 2-SN X-TN Y-TN

2 2 1.5 2 7 ODP - 2 - 2 2 150 - 3 K F 4 # ODP - 2 - 2 2 020 - 3 H F 4 # 2-SN X-TN Y-TN

2 2 2.2 3 10.5 ODP - 2 - 2 2 220 - 3 K F 4 # ODP - 2 - 2 2 030 - 3 H F 4 # 2-SN X-TN Y-TN

3 3 4 5 18 ODP - 2 - 3 2 040 - 3 K F 4 # ODP - 2 - 3 2 050 - 3 H F 4 # 2-SN X-TN Y-TN

3 5.5 7.5 24 ODP - 2 - 3 2 055 - 3 K F 4 # ODP - 2 - 3 2 075 - 3 H F 4 # 2-SN

4 5.5 7.5 24 ODP - 2 - 4 2 055 - 3 K F 4 # ODP - 2 - 4 2 075 - 3 H F 4 # N-TN

4 4 7.5 10 30 ODP - 2 - 4 2 075 - 3 K F 4 # ODP - 2 - 4 2 100 - 3 H F 4 # 2-MN N-TN

4 4 11 15 46 ODP - 2 - 4 2 110 - 3 K F 4 # ODP - 2 - 4 2 150 - 3 H F 4 # 2-MN N-TN

5 5 15 20 60 ODP

- 2 - 5 2 150 - 3 K F 4 # ODP - 2 - 5 2 020 - 3 H F 4 # 2-MN N-TN

5 5 18.5 25 72 ODP - 2 - 5 2 185 - 3 K F 4 # ODP - 2 - 5 2 025 - 3 H F 4 # 2-MN N-TN

6A 6 22 30 90 ODP - 2 - 6 2 022 - 3 K F 4 # ODP - 2 - 6 2 030 - 3 H F 4 # 2-MN N-TN

6A 6 30 40 110 ODP - 2 - 6 2 030 - 3 K F 4 # ODP - 2 - 6 2 040 - 3 H F 4 # 2-MN N-TN

6B 6 37 50 150 ODP - 2 - 6 2 037 - 3 K F 4 # ODP - 2 - 6 2 050 - 3 H F 4 # 2-MN N-TN

6B 6 45 60 180 ODP - 2 - 6 2 045 - 3 K F 4 # ODP - 2 - 6 2 060 - 3 H F 4 # 2-MN N-TN

7 55 75 202 ODP - 2 - 7 2 055 - 3 K F 4 # ODP - 2 - 7 2 075 - 3 H F 4 # N-TN

7 75 100 240 ODP - 2 - 7 2 075 - 3 K F 4 # ODP - 2 - 7 2 100 - 3 H F 4 # N-TN

2 2 0.75 1 2.2 ODP - 2 - 2 4 075 - 3 K F 4 # ODP - 2 - 2 4 010 - 3 H F 4 # 2-SN X-TN Y-TN

2 2 1.5 2 4.1 ODP - 2 - 2 4 150 - 3 K F 4 # ODP - 2 - 2 4 020 - 3 H F 4 # 2-SN X-TN Y-TN

2 2 2.2 3 5.8 ODP - 2 - 2 4 220 - 3 K F 4 # ODP - 2 - 2 4 030 - 3 H F 4 # 2-SN X-TN Y-TN

2 2 4 5 9.5 ODP - 2 - 2 4 400 - 3 K F 4 # ODP - 2 - 2 4 050 - 3 H F 4 # 2-SN X-TN Y-TN

3 3 5.5 7.5 14 ODP - 2

- 3 4 055 - 3 K F 4 # ODP - 2 - 3 4 075 - 3 H F 4 # 2-SN X-TN Y-TN

3 3 7.5 10 18 ODP - 2 - 3 4 075 - 3 K F 4 # ODP - 2 - 3 4 100 - 3 H F 4 # 2-SN X-TN Y-TN

3 11 15 24 ODP - 2 - 3 4 110 - 3 K F 4 # ODP - 2 - 3 4 150 - 3 H F 4 # 2-SN

4 11 15 24 ODP - 2 - 4 4 110 - 3 K F 4 # ODP - 2 - 4 4 150 - 3 H F 4 # N-TN

4 4 15 20 30 ODP - 2 - 4 4 150 - 3 K F 4 # ODP - 2 - 4 4 200 - 3 H F 4 # 2-MN N-TN

4 4 18.5 25 39 ODP - 2 - 4 4 185 - 3 K F 4 # ODP - 2 - 4 4 250 - 3 H F 4 # 2-MN N-TN

4 4 22 30 46 ODP - 2 - 4 4 220 - 3 K F 4 # ODP - 2 - 4 4 300 - 3 H F 4 # 2-MN N-TN

5 5 30 40 61 ODP - 2 - 5 4 300 - 3 K F 4 # ODP - 2 - 5 4 040 - 3 H F 4 # 2-MN N-TN

5 5 37 50 72 ODP - 2 - 5 4 370 - 3 K F 4 # ODP - 2 - 5 4 050 - 3 H F 4 # 2-MN N-TN

6A 6 45 60 90 ODP - 2 - 6 4 045 - 3 K F 4 # ODP - 2 - 6 4 060 - 3 H F 4 # 2-MN N-TN

6A 6 55 75 110 ODP - 2 - 6 4 055 - 3 K F 4 # ODP - 2 - 6 4 075 - 3 H F 4 # 2-MN N-TN

6B 6 75 100 150 ODP - 2 - 6 4 075 - 3 K F 4 # ODP - 2 - 6 4 10 0 - 3 H F 4 # 2-MN N-TN

6B 6 90 150 180 ODP - 2 - 6 4 090 - 3

K F 4 # ODP - 2 - 6 4 150 - 3 H F 4 # 2-MN N-TN

7 110 175 202 ODP - 2 - 7 4 110 - 3 K F 4 # ODP - 2 - 7 4 175 - 3 H F 4 # N-TN

7 132 200 240 ODP - 2 - 7 4 132 - 3 K F 4 # ODP - 2 - 7 4 200 - 3 H F 4 # N-TN

7 160 250 302 ODP - 2 - 7 4 160 - 3 K F 4 # ODP - 2 - 7 4 250 - 3 H F 4 # N-TN

8 200 300 370 ODP - 2 - 8 4 200 - 3 K F 4 # ODP - 2 - 8 4 300 - 3 H F 4 # 2-MN

8 250 350 450 ODP - 2 - 8 4 250 - 3 K F 4 # ODP - 2 - 8 4 350 - 3 H F 4 # 2-MN

7 132 – 185 ODP - 2 - 7 5 132 - 3 K 0 4 # – N-TN

7 150 – 205 ODP - 2 - 7 5 150 - 3 K 0 4 # – N-TN

7 185 – 255 ODP - 2 - 7 5 185 - 3 K 0 4 # – N-TN

7 200 – 275 ODP - 2 - 7 5 200 - 3 K 0 4 # – N-TN

2 2 0.75 1 2.1 ODP - 2 - 2 6 075 - 3 K 0 4 # ODP - 2 - 2 6 010 - 3 H 0 4 # 2-SN X-TN Y-TN

2 2 1.5 2 3.1 ODP - 2 - 2 6 150 - 3 K 0 4 # ODP - 2 - 2 6 020 - 3 H 0 4 # 2-SN X-TN Y-TN

2 2 2.2 3 4.1 ODP - 2 - 2 6 220 - 3 K 0 4 # ODP - 2 - 2 6 030 - 3 H 0 4 # 2-SN X-TN Y-TN

2 2 4 5 6.5 ODP - 2 - 2 6 400 - 3 K 0 4 # ODP - 2 - 2 6 050 - 3 H 0 4 # 2-SN X-TN Y-TN

2 2 5.5 7.5 9 ODP - 2 - 2

6 550 - 3 K 0 4 # ODP - 2 - 2 6 075 - 3 H 0 4 # 2-SN X-TN Y-TN

3 3 7.5 10 12 ODP - 2 - 3 6 075 - 3 K 0 4 # ODP - 2 - 3 6 100 - 3 H 0 4 # 2-SN X-TN Y-TN

3 3 11 15 17 ODP - 2 - 3 6 110 - 3 K 0 4 # ODP - 2 - 3 6 150 - 3 H 0 4 # 2-SN X-TN Y-TN

3 15 20 22 ODP - 2 - 3 6 150 - 3 K 0 4 # ODP - 2 - 3 6 200 - 3 H 0 4 # 2-SN

4 15 20 22 ODP - 2 - 4 6 150 - 3 K 0 4 # ODP - 2 - 4 6 200 - 3 H 0 4 # N-TN

4 4 18.5 25 28 ODP - 2 - 4 6 185 - 3 K 0 4 # ODP - 2 - 4 6 250 - 3 H 0 4 # 2-MN N-TN

4 4 22 30 34 ODP - 2 - 4 6 220 - 3 K 0 4 # ODP - 2 - 4 6 300 - 3 H 0 4 # 2-MN N-TN

4 4 30 40 41 ODP - 2 - 4 6 300 - 3 K 0 4 # ODP - 2 - 4 6 400 - 3 H 0 4 # 2-MN N-TN

5 5 37 50 54 ODP - 2 - 5 6 370 - 3 K 0 4 # ODP - 2 - 5 6 050 - 3 H 0 4 # 2-MN N-TN

5 5 45 60 65 ODP - 2 - 5 6 450 - 3 K 0 4 # ODP - 2 - 5 6 060 - 3 H 0 4 # 2-MN N-TN

6 55 75 78 ODP - 2 - 6 6 055 - 3 K 0 4 # ODP - 2 - 6 6 075 - 3 H 0 4 # N-TN

6 75 100 105 ODP - 2 - 6 6 075 - 3 K 0 4 # ODP - 2 - 6 6 100 - 3 H 0 4 # N-TN

6 90 125 130 ODP - 2 - 6 6 090 - 3 K 0 4 # ODP -

2 - 6 6 125 - 3 H 0 4 # N-TN

6 110 150 150 ODP - 2 - 6 6 110 - 3 K 0 4 # ODP - 2 - 6 6 150 - 3 H 0 4 # N-TN

IP66

Switched

OLED

Display

6

www.invertekdrives.com

kW Models: Factory Settings

Motor Rated Frequency: 50Hz

Motor Rated Voltage: 230/400/575V

HP Models: Factory Settings

Motor Rated Frequency: 60Hz

Motor Rated Voltage: 230/460/575V

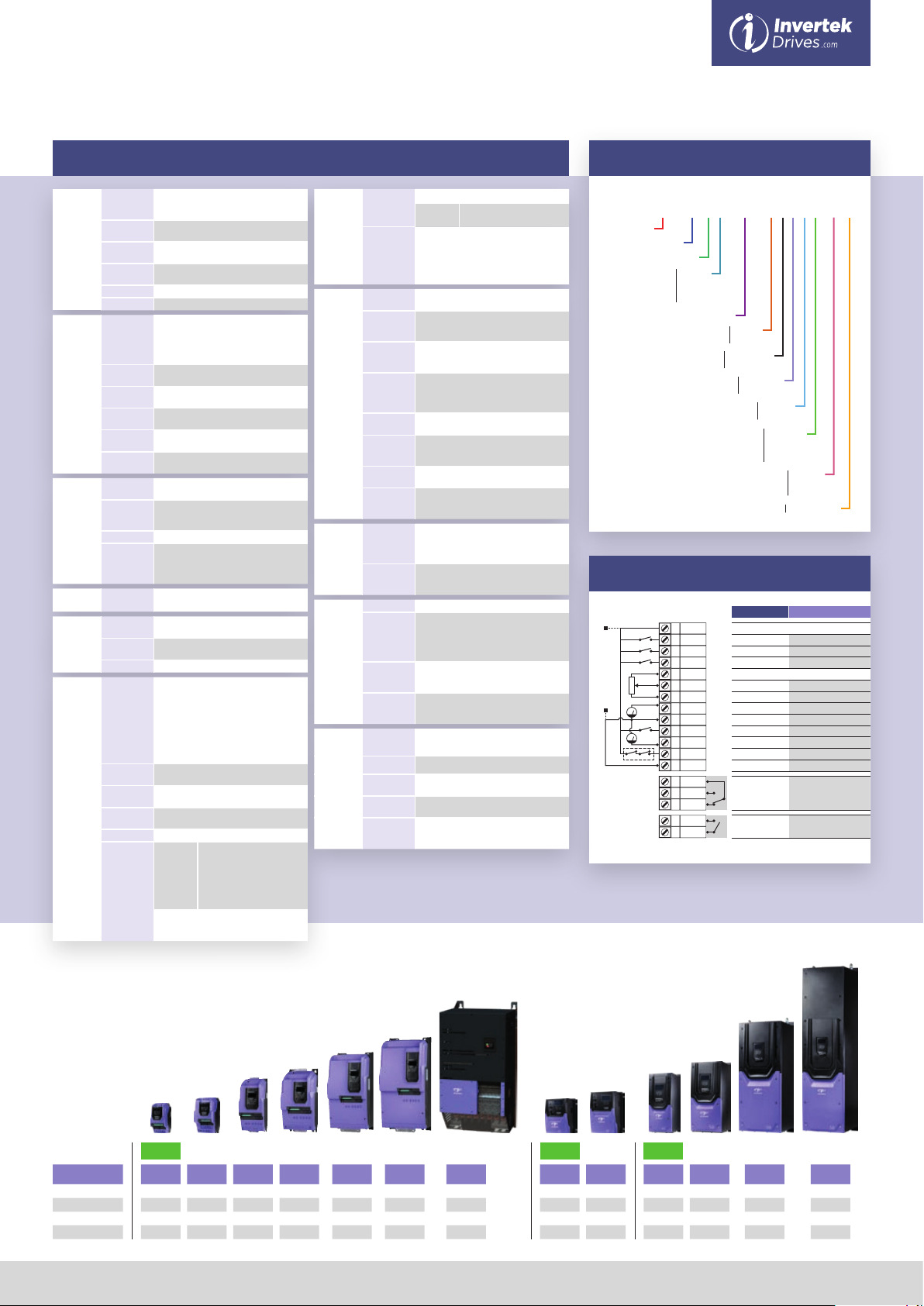

Drive Specification Model Code Guide

Input Ratings

Output

Ratings

Ambient

Conditions

Enclosure

Programming

Control

Specification

Supply Voltage

Supply

Frequenc y

Displacement

Power Factor

Phase

Imbalance

Inrush Current < rated c urrent

Power Cycles 120 per hour maximum, evenly sp aced

Output Power

Overload

Capacity

Output

Frequenc y

Acceleration

Time

Deceleration

Time

Typic al

Efficiency

Tempe rature

Altitude

Humidity 95% Max, non condensing

Vibration

Ingress

Protection

Keypad

Display

PC OptiTools Studio

Control

Method

PWM

Frequenc y

Stopping

Mode

Braking

Skip Frequ ency Single point, user adjustable

Setpoint

Control

200 – 240V ± 10%

380 – 480V ± 10%

500 – 600V ± 10%

48 – 62Hz

> 0.98

3% Maximum all owed

230V 1Ph. Input: 0.75–2.2kW (1–3HP)

230V 3Ph. Input: 0.75–75kW (1–100HP)

400V 3Ph. Input: 0. 75–250 kW

460V 3Ph. Input: 1– 350HP

575V 3Ph. Input: 0.75–110kW (1–150HP)

150% for 60 seconds

0 – 500Hz, 0.1Hz resolution

0.01 – 600 seconds

0.01 – 600 seconds

> 98%

Storage: −40 to 60°C

Operating: −10 to 50°C

Up to 1000m ASL wit hout derating

Up to 2000m m aximum UL Approved

Up to 4000 m maximum (non UL)

Conforms to I EC 60068-2-6

Sinusoidal Vibration

10 - 57Hz @ 0.075mm Pk

57 - 150Hz @ 1g Pk

IP20, IP55, IP66

Built-in key pad as standard

Optional remote mountable keypad

Built-in m ulti language text disp lay (IP55 & IP66)

7 Segment LED ( IP20)

V/F Voltage Vector

Energy Optims ied V/F

3GV Sensorless Vector Speed Control

3GV Sensorless Vector Torque Control

Closed Loop (Encoder) Speed Control

Closed Loop (Encoder) Torque Control

PM Vector Control

BLDC Control

Synchronous Reluctance

4 – 32kHz Eff ectiv e

Ramp to Stop: User A djustable 0.01 – 600 se cs

Coast to Stop

Motor Flux Braking

Built-in Braking Transisto r

0 to 10 Volts

10 to 0 Volts

−10 to +10 Volts

Analog

0 to 20mA

Signal

20 to 0mA

4 to 20mA

20 to 4mA

Motorised Potentiometer (Keypad)

Digital

Modbus RTU

CANopen

Fieldbus

Connectivity

I/O

Specification

Application

Features

Maintenance

&Diagnostics

Standards

Compliance

Built-in

Optional Other

Power Supply

Programmable

Inputs

Digital Inpu ts

Analog Inputs

PTC Inp ut

Programmable

Outputs

Relay Outputs

Analog

Outputs

PID Control

Hoist Mode

Fault Memory Last 4 Trips stored w ith time stamp

Data Logging

Maintenance

Indicator

Monitoring

Low Voltage

Directive

EMC Directive 2 014/30/E U

Additional

Conformance

Marine

Certification

Environmental

Conditions

CANopen 125 – 1000kbps

Modbus

9.6 - 115.2 kbps selectable

RTU

8N1, 8N2, 8E1, 8O1

PROFIBUS DP (DPV1)

PROFINET IO

DeviceNet

EtherNet/IP

EtherCAT

Modbus TCP

24 Volt DC, 100mA, Sho rt Circuit Protected

10 Volt DC, 10mA for Potentiom eter

5 Total as standa rd (Optional additional 3)

3 Digital (Optional additional 3)

2 Analog / Digit al Selectable

Opto - Isolated

8 – 30 Volt DC, intern al or external supply

Response tim e < 4ms

Resolution: 12 bits

Response tim e: < 4ms

Accuracy: < 1% full s cale

Parameter adju stable scaling and of fset

Motor PTC / Thermistor Input

Trip Level : 3kΩ

4 Total (Optional additional 3)

2 Analog / Digit al

2 Relays (Opt ional additional 3)

Maximum Volta ge: 250 VAC, 30 VDC

Switching Curre nt Capacity: 5A AC , 5A DC

0 to 10 Volt

0 to 20mA

4 to 20mA

Internal PID Controller

Multi Setpoint Select

Standby / Sle ep Mode

Boost Function

Dedicated Hoist Mode

Motor Holding Brake Pre-Torque & Control

Over Limit Prot ection

Logging of da ta prior to trip for diagno stic

purposes:

Output Current

Driv e Tempera ture

DCBusVoltage

Maintenance Indicator with user adjustable

maintenance inte rval

Onboard service life monitoring

Hours Run Met er

Resettab le & Non Resettable kWh m eters

Cooling Fan Run Tim e

2014/ 35/E U

UL, cUL, EAC, RCM

DNV Type Approva l

Designed to m eet IEC 60721-3-3, in operation:

IP20 Dri ves: 3S2/3C2

IP55 & 66 Drives: 3S3/3C3

ODP-2-22075-1KF4#-#N

Product Family

Generation

Frame Size

200–240V = 2 Supply

380–480V = 4

480–525V = 5

500–600V = 6

Connection Diagram

+24Vdc

Optional

External

Power

Supply

0Vdc

Voltage

Power Rating Code

Single Phase = 1 Supply

3 Phase = 3

No Internal EMC Filter = 0 EM C Filter

Internal EMC Filter = F

Internal Brake Transistor = 4 Bra ke

IP66 Non-switched = X

Phases

kW = K Po wer Ty pe

HP = H

IP20 = 2 Enclosure

IP55 = N

IP66 Switched = Y

7 Segment LE D = S Display

OLED = T

TFT = M

Transistor

Standard Coating = N PCB Coating

Function Default Setting

24 Volt DC Output, 100mA m ax / 24 Volt DC Input

Digital Input 1 D rive Enable

DI 1

Digital Input 2 Forward / Reverse Select

DI 2

Digital Input 3 Pr eset Speed 1 Selec t

DI 3

+10 Volt Power Supply 5mA

Analog Input 1 Spe ed Reference 0–10 Volt

0 Volt

0V

Analog Output 1 Motor Speed

AO1

0 Volt

0V

Analog Input 2

Analog Output 2 Motor Current

AO2

Safe Torque Off I nput

Safe Torque Off I nput

Output Relay 1 Drive Healt hy / Fault

Output Relay 2 Drive Running

10

11

12

13

14

15

16

17

18

1

2

3

4

5

6

7

8

9

+24V

+10V

DI 4/AI 1

DI 5/AI 2

STO +

STO -

RL1-C

RL1-NO

RL1-NC

RL2-A

RL2-B

NOT TO SCALE

Size

mm Height

mm Width

mm Depth

kg Weight

IP20

2 3 4 5 6A 6B 8

221 261 418 486 614 726 995

110 131 16 0 222 286 330 482

185 205 240 260 320 320 480

1.8 3.5 9. 2 18 .2 32 43 128

IP66 IP55

2 3

257 310

188 2 11

239 266

4.8 7. 7

4 5 6 7

450 540 865 12 80

171 235 330 330

252 270 330 360

11. 5 23 55 89

7

Loading...

Loading...