INVERTEC optidrive E IP20, optidrive E IP66 User Manual

Optidrive ODE-3 1Ph Output User Guide Revision 1.00

www.invertekdrives.com

1

1

Quick Start Up

User Guide

Single Phase Output

IP20 & IP66 (NEMA 4X)

AC Variable Speed Drive

0.37 – 1.1kW (0.5 – 1.5HP)

110 – 230V

Installation and Operating Instructions

Optidrive ODE-3 1Ph Output User Guide Revision 1.00

2

www.invertekdrives.com

1

Quick Start Up

1. Quick Start Up...................................................................................................................................................................... 4

1.1. Important Safety Information 4

1.2. Quick Start Process 5

2. General Information and Ratings ......................................................................................................................................... 7

2.1. Identifying the Drive by Model Number 7

2.2. Drive Model Numbers 7

3. Mechanical Installation ........................................................................................................................................................ 8

3.1. General 8

3.2. UL Compliant Installation 8

3.3. Mechanical Dimensions and Mounting – IP20 Open Units 8

3.4. Guidelines for Enclosure Mounting – IP20 Units 8

3.5. Mechanical Dimensions – IP66 (Nema 4X) Enclosed Units 9

3.6. Guidelines for mounting (IP66 Units) 9

3.7. Gland Plate and Lock Off 10

3.8. Removing the Terminal Cover 10

3.9. Routine Maintenance 10

4. Power Wiring ..................................................................................................................................................................... 11

4.1. Grounding the Drive 11

4.2. EMC Filter Disconnect 11

4.3. Wiring Precautions 11

4.4. Incoming Power Connection 12

4.5. Drive and Motor Connection 12

4.6. Motor Thermal overload Protection 12

4.7. Control Terminal Wiring 12

4.8. Connection Diagram 13

4.9. Using the REV/0/FWD Selector Switch (Switched Version Only) 14

4.10. Control Terminal Connections 14

5. Operation .......................................................................................................................................................................... 15

5.1. Managing the Keypad 15

5.2. Changing Parameters 15

5.3. Read Only Parameter Access 15

5.4. Resetting Parameters 15

5.5. Resetting A Fault 15

6. Parameters ........................................................................................................................................................................ 16

6.1. Standard Parameters 16

6.2. Extended Parameters 17

6.3. P-00 Read Only Status Parameters 20

6.4. Single Phase Motor - Boost Starting cycle 21

7. Analog and Digital Input Macro Configurations ................................................................................................................. 22

7.1. Overview 22

7.2. Macro Functions Guide Key 22

7.3. Macro Functions – Terminal Mode (P-12 = 0) 22

7.4. Macro Functions - Keypad Mode (P-12 = 1 or 2) 23

7.5. Macro Functions - Fieldbus Control Mode (P-12 = 3, 4, 7, 8 or 9) 23

7.6. Macro Functions - User PI Control Mode (P-12 = 5 or 6) 23

7.7. Fire Mode 24

8. Modbus RTU Communications ........................................................................................................................................... 25

8.1. Introduction 25

8.2. Modbus RTU Specification 25

8.3. RJ45 Connector Configuration 25

8.4. Modbus Telegram Structure 25

8.5. Modbus Register Map 25

9. Technical Data ................................................................................................................................................................... 26

9.1. Environmental 26

9.2. Rating Tables 26

9.3. Additional Information for UL Compliance 27

10. Trouble Shooting ........................................................................................................................................................... 28

10.1. Fault Code Messages 28

Optidrive ODE-3 1Ph Output User Guide Revision 1.00

www.invertekdrives.com

3

1

Quick Start Up

Declaration of Conformity

Invertek Drives Ltd hereby states that the Optidrive ODE-3 product range conforms to the relevant safety provisions of the following council

directives:

2004/108/EC (EMC) and 2006/95/EC (LVD) (Valid until 20.04.2016)

2014/30/EU (EMC) and 2014/35/EU (LVD) (Valid from 20.04.2016)

Designed and manufacture is in accordance with the following harmonised European standards:

EN 61800-5-1: 2003

Adjustable speed electrical power drive systems. Safety requirements. Electrical, thermal and energy.

EN 61800-3 2nd Ed: 2004

Adjustable speed electrical power drive systems. EMC requirements and specific test methods

EN 55011: 2007

Limits and Methods of measurement of radio disturbance characteristics of industrial, scientific and

medical (ISM) radio-frequency equipment (EMC)

EN60529 : 1992

Specifications for degrees of protection provided by enclosures

Electromagnetic Compatibility

All Optidrives are designed with high standards of EMC in mind. All versions suitable for operation on Single Phase 230 volt and Three Phase 400

volt supplies and intended for use within the European Union are fitted with an internal EMC filter. This EMC filter is designed to reduce the

conducted emissions back into the supply via the power cables for compliance with the above harmonised European standards.

It is the responsibility of the installer to ensure that the equipment or system into which the product is incorporated complies with the EMC

legislation of the country of use. Within the European Union, equipment into which this product is incorporated must comply with the EMC

Directive 2004/108/EC. When using an Optidrive with an internal or optional external filter, compliance with the following EMC Categories, as

defined by EN61800-3:2004 can be achieved:

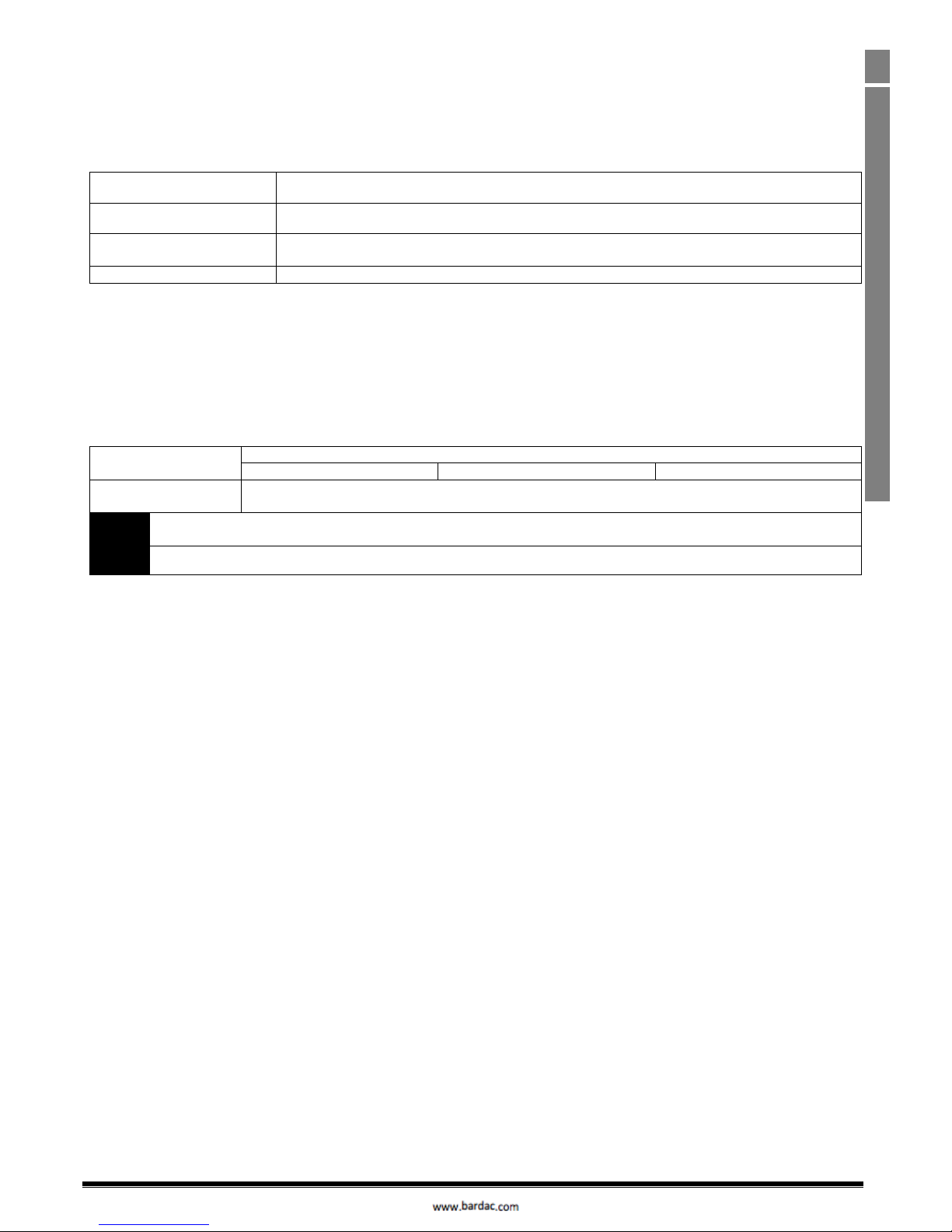

Drive Type / Rating

EMC Category

Cat C1

Cat C2

Cat C3

1 Phase, 230 Volt Input

ODE-3-x2xxxx-1Fxx

No additional filtering required

Use shielded motor cable

Note

Compliance with EMC standards is dependent on a number of factors including the environment in which the drive is installed,

motor switching frequency, motor, cable lengths and installation methods adopted.

Compliance with EMC directives is achieved with the factory default parameter settings

All rights reserved. No part of this User Guide may be reproduced or transmitted in any form or by any means, electrical or mechanical including

photocopying, recording or by any information storage or retrieval system without permission in writing from the publisher.

Copyright Invertek Drives Ltd © 2015

All Invertek Optidrive units carry a 2 year warranty against manufacturing defects from the date of manufacture. The manufacturer accepts no

liability for any damage caused during or resulting from transport, receipt of delivery, installation or commissioning. The manufacturer also

accepts no liability for damage or consequences resulting from inappropriate, negligent or incorrect installation, incorrect adjustment of the

operating parameters of the drive, incorrect matching of the drive to the motor, incorrect installation, unacceptable dust, moisture, corrosive

substances, excessive vibration or ambient temperatures outside of the design specification.

The local distributor may offer different terms and conditions at their discretion, and in all cases concerning warranty, the local distributor

should be contacted first.

This user guide is the “original instructions” document. All non-English versions are translations of the “original instructions”.

The contents of this User Guide are believed to be correct at the time of printing. In the interest of a commitment to a policy of continuous

improvement, the manufacturer reserves the right to change the specification of the product or its performance or the contents of the User

Guide without notice.

This User Guide is for use with version 3.02 Firmware.

User Guide Revision 1.00

Invertek Drives Ltd adopts a policy of continuous improvement and whilst every effort has been made to provide accurate and up to date

information, the information contained in this User Guide should be used for guidance purposes only and does not form the part of any

contract.

All Bardac drives

Bardac Drives

Optidrive ODE-3 1Ph Output User Guide Revision 1.00

4

www.invertekdrives.com

1

Quick Start Up

1. Quick Start Up

1.1. Important Safety Information

Please read the IMPORTANT SAFETY INFORMATION below, and all Warning and Caution information elsewhere.

Danger : Indicates a risk of electric shock, which, if not

avoided, could result in damage to the equipment and

possible injury or death.

Danger : Indicates a potentially hazardous situation

other than electrical, which if not avoided, could

result in damage to property.

This variable speed drive product (Optidrive) is intended for professional incorporation into complete equipment or systems as

part of a fixed installation. If installed incorrectly it may present a safety hazard. The Optidrive uses high voltages and currents,

carries a high level of stored electrical energy, and is used to control mechanical plant that may cause injury. Close attention is

required to system design and electrical installation to avoid hazards in either normal operation or in the event of equipment

malfunction. Only qualified electricians are allowed to install and maintain this product.

System design, installation, commissioning and maintenance must be carried out only by personnel who have the necessary

training and experience. They must carefully read this safety information and the instructions in this Guide and follow all

information regarding transport, storage, installation and use of the Optidrive, including the specified environmental limitations.

Do not perform any flash test or voltage withstand test on the Optidrive. Any electrical measurements required should be carried

out with the Optidrive disconnected.

Electric shock hazard! Disconnect and ISOLATE the Optidrive before attempting any work on it. High voltages are present at the

terminals and within the drive for up to 10 minutes after disconnection of the electrical supply. Always ensure by using a suitable

multimeter that no voltage is present on any drive power terminals prior to commencing any work.

Where supply to the drive is through a plug and socket connector, do not disconnect until 10 minutes have elapsed after turning

off the supply.

Ensure correct earthing connections. The earth cable must be sufficient to carry the maximum supply fault current which

normally will be limited by the fuses or MCB. Suitably rated fuses or MCB should be fitted in the mains supply to the drive,

according to any local legislation or codes.

Ensure correct earthing connections and cable selection as per defined by local legislation or codes. The drive may have a

leakage current of greater than 3.5mA; furthermore the earth cable must be sufficient to carry the maximum supply fault current

which normally will be limited by the fuses or MCB. Suitably rated fuses or MCB should be fitted in the mains supply to the drive,

according to any local legislation or codes.

Do not carry out any work on the drive control cables whilst power is applied to the drive or to the external control circuits.

Within the European Union, all machinery in which this product is used must comply with Directive 2006/42/EC, Safety of

Machinery. In particular, the machine manufacturer is responsible for providing a main switch and ensuring the electrical

equipment complies with EN60204-1.

The level of integrity offered by the Optidrive control input functions – for example stop/start, maximum speed, etc. is not

sufficient for use in safety-critical applications without independent channels of protection. All applications where malfunction

could cause injury or loss of life must be subject to a risk assessment and further protection provided where needed.

The driven motor can start at power up if the enable input signal is present.

The STOP function does not remove potentially lethal high voltages. ISOLATE the drive and wait 10 minutes before starting any

work on it. Never carry out any work on the Drive, Motor or Motor cable whilst the input power is still applied.

The Optidrive can be programmed to operate the driven motor at speeds above or below the speed achieved when connecting

the motor directly to the mains supply. Obtain confirmation from the manufacturers of the motor and the driven machine about

suitability for operation over the intended speed range prior to machine start up.

Do not activate the automatic fault reset function on any systems whereby this may cause a potentially dangerous situation.

IP20 drives must be installed in a pollution degree 2 environment, mounted in a cabinet with IP54 or better.

Optidrives are intended for indoor use only.

When mounting the drive, ensure that sufficient cooling is provided. Do not carry out drilling operations with the drive in place,

dust and swarf from drilling may lead to damage.

The entry of conductive or flammable foreign bodies should be prevented. Flammable material should not be placed close to the

drive

Relative humidity must be less than 95% (non-condensing).

Ensure that the supply voltage, frequency and no. of phases (1 or 3 phase) correspond to the rating of the Optidrive as delivered.

Never connect the mains power supply to the Output terminals U, V, W.

Do not install any type of automatic switchgear between the drive and the motor

Wherever control cabling is close to power cabling, maintain a minimum separation of 100 mm and arrange crossings at 90

degrees

Ensure that all terminals are tightened to the appropriate torque setting

Do not attempt to carry out any repair of the Optidrive. In the case of suspected fault or malfunction, contact your local Invertek

Drives Sales Partner for further assistance.

Bardac

Optidrive ODE-3 1Ph Output User Guide Revision 1.00

www.invertekdrives.com

5

1

Quick Start Up

1.2. Quick Start Process

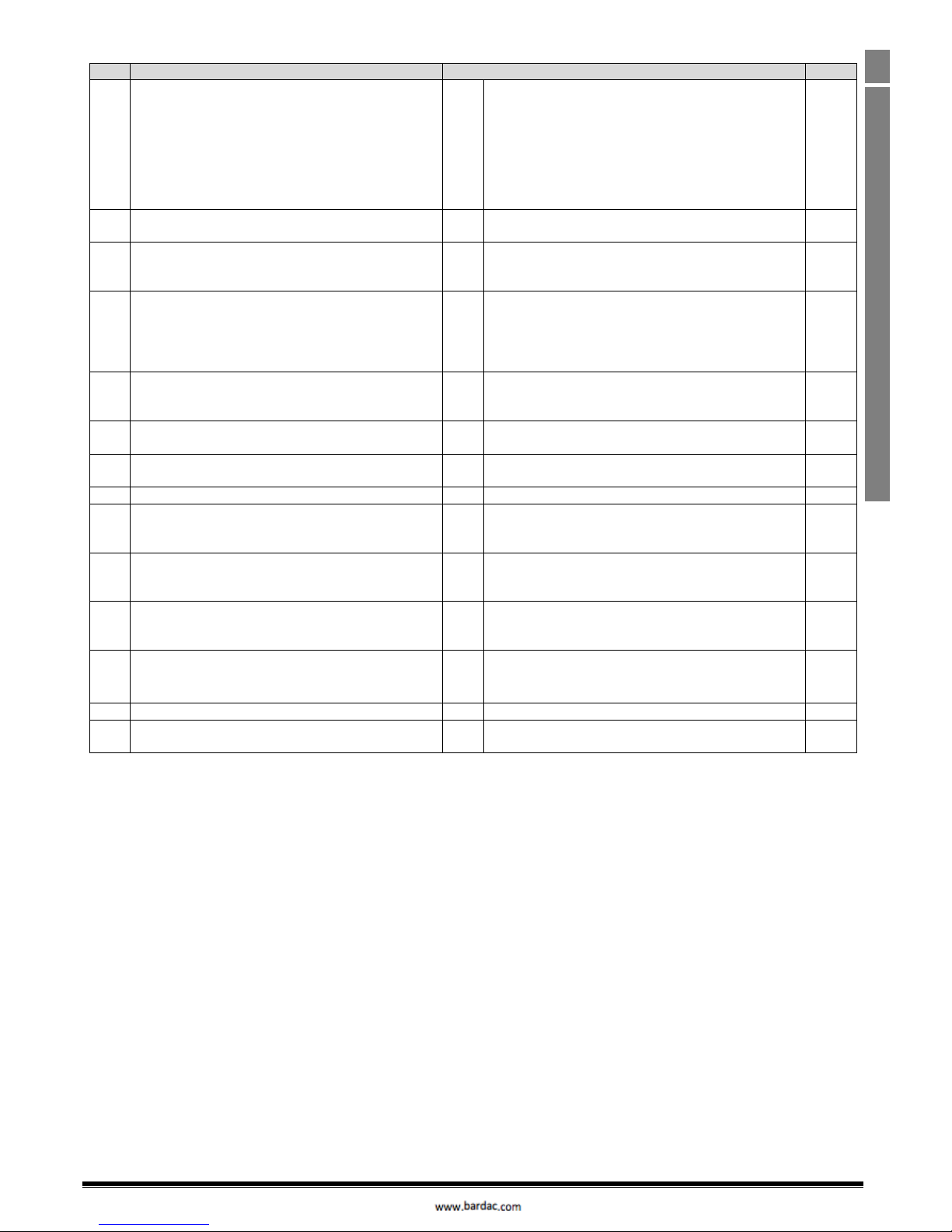

Step

Action

See Section

Page

1

Identify the Enclosure Type, Model Type and ratings of

your drive from the model code on the label. In

particular

- Check the voltage rating suits the incoming

supply

- Check the output current capacity meets or

exceeds the full load current for the intended

motor

2.1

Identifying the Drive by Model Number

7

2

Unpack and check the drive. Notify the supplier and

shipper immediately of any damage.

3

Ensure correct ambient and environmental conditions

for the drive are met by the proposed mounting

location.

9.1

Environmental

26

4

Install the drive in a suitable cabinet (IP20 Units),

ensuring suitable cooling air is available. Mount the

drive to the wall or machine (IP66).

3.1

3.3

3.4

3.5

3.6

General

Mechanical Dimensions and Mounting – IP20 Open Units

Guidelines for Enclosure Mounting – IP20 Units

Mechanical Dimensions – IP66 (Nema 4X) Enclosed Units

Guidelines for mounting (IP66 Units)

8

8

8

9

5

Select the correct power and motor cables according

to local wiring regulations or code, noting the

maximum permissible sizes

9.2

Rating Tables

26

6

If the supply type is IT or corner grounded, disconnect

the EMC filter before connecting the supply.

4.2

EMC Filter Disconnect

11 7 Check the supply cable and motor cable for faults or

short circuits.

8

Route the cables

9

Check that the intended motor is suitable for use,

noting any precautions recommended by the supplier

or manufacturer.

10

Ensure suitable wiring protection is providing, by

installing a suitable circuit breaker or fuses in the

incoming supply line

9.2

Rating Tables

26

11

Connect the power cables, especially ensuring the

protective earth connection is made

4.1

4.3

4.4

Grounding the Drive

Wiring Precautions

Incoming Power Connection

11

11

12

12

Connect the control cables as required for the

application

4.7

4.8

7

Control Terminal Wiring

Connection Diagram

Analog and Digital Input Macro Configurations

12

12

22

13

Thoroughly check the installation and wiring

14

Commission the drive parameters

5.1 6 Managing the Keypad

Parameters

15

16

Optidrive ODE-3 1Ph Output User Guide Revision 1.00

6

www.invertekdrives.com

1

Quick Start Up

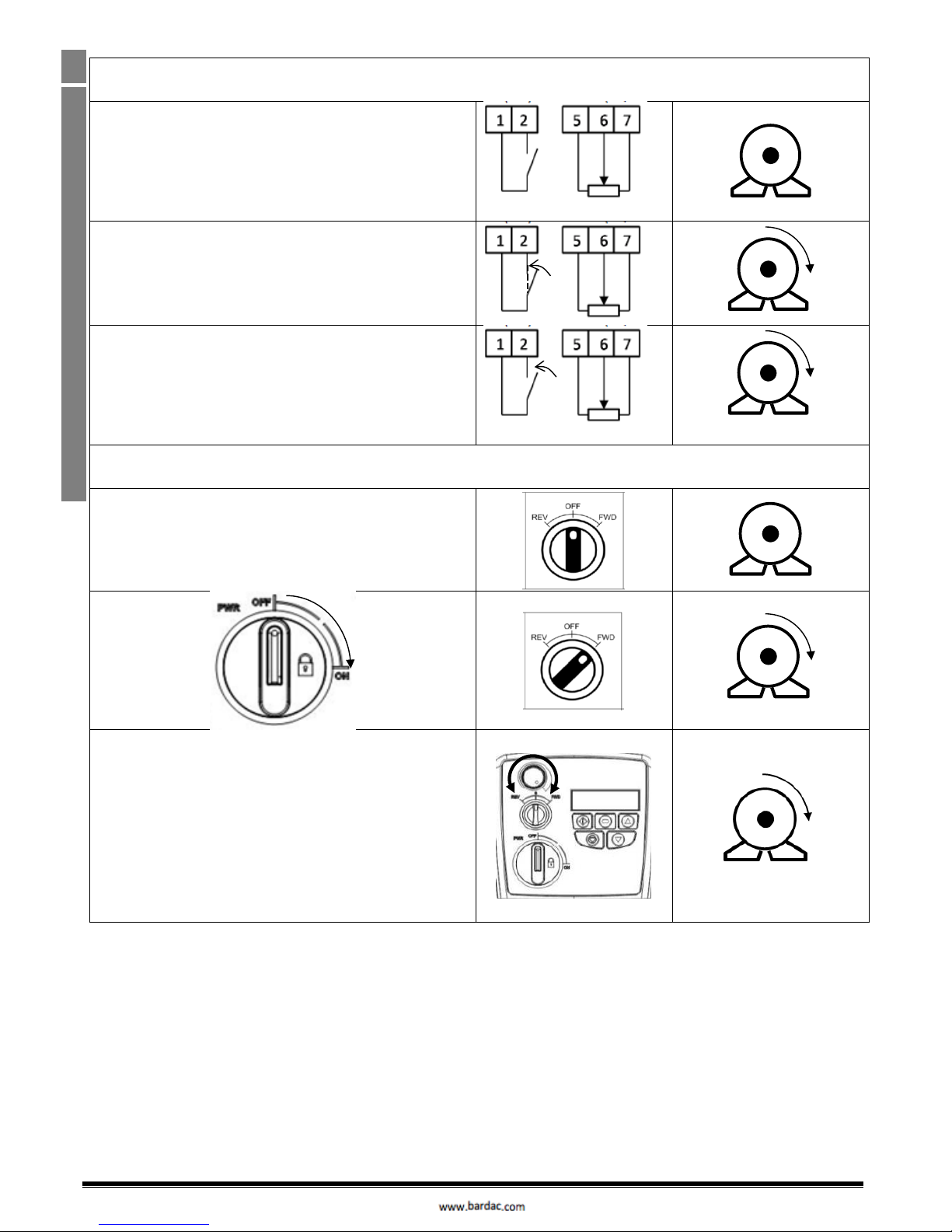

Quick Start – IP20 & IP66 Non Switched

Connect a Start / Stop switch between control terminals 1 & 2

5k – 10k

Close the Switch to Start

Open to Stop

Connect a potentiometer (5k – 10kΩ) between terminals as shown

to vary the speed from P-2 (0Hz default) to P-01 (50 / 60 Hz default)

0....10V

0.......50/60Hz

Quick Start – IP66 Switched

Switch the unit on using the isolator switch on the panel.

The OFF/REV/FWD will enable the output to the motor.

NOTE : With single phase motors, forward rotation only is possible.

The potentiometer will control the speed.

0.......50/60Hz

Optidrive ODE-3 1Ph Output User Guide Revision 1.00

www.invertekdrives.com

7

2

General Information and Ratings

2. General Information and Ratings

This chapter contains information about the Optidrive E3 including how to identify the drive

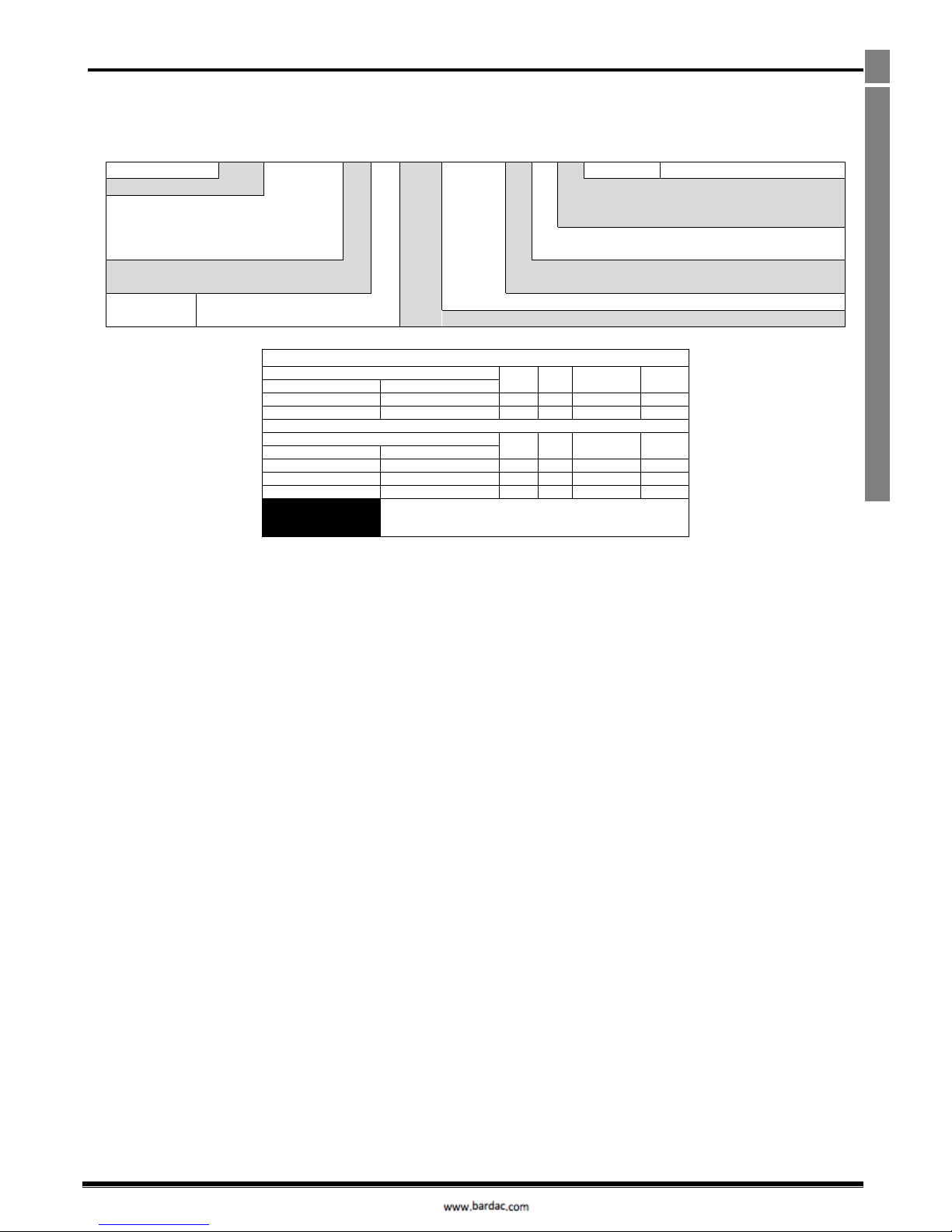

2.1. Identifying the Drive by Model Number

Each drive can be identified by its model number, as shown in the table below. The model number is on the shipping label and the drive

nameplate. The model number includes the drive and any options.

ODE

-

3

-

1

2

0021

-

1

F

1

2

-01

Single Phase Output

Product Family

IP Rating

2 = IP20

X = IP66 Non Switched

Y = IP66 Switched

Generation

Dynamic Brake

Transistor

1 = Not Fitted

4 = Internal Transistor

Frame Size

Filter Type

0 = No Filter

F = Internal EMC Filter

Input Voltage

1 = 110 – 115

2 = 200 – 240

No. Of Input Phases

Output Current x 10

2.2. Drive Model Numbers

110 – 115V + / - 10% - 1Phase Input – 1 Phase 110V Output (Voltage Doubler)

Model Number

kW

HP

Output

Current (A)

Frame

Size

With Filter

Without Filter

N/A

ODE-3-110070-101#-01

0.5

7.0 1 N/A

ODE-3-210105-104#-01

0.75

10.5

2

200 – 240V + / - 10% - 1Phase Input – 1 Phase Output

Model Number

kW

HP

Output

Current (A)

Frame

Size

With Filter

Without Filter

ODE-3-120043-1F1#-01

ODE-3-120043-101#-01

0.37

0.5

4.3

1

ODE-3-120070-1F1#-01

ODE-3-120070-101#-01

0.75 1 7.0

1

ODE-3-120105-1F4#-01

ODE-3-120105-104#-01

1.1

1.5

10.5

2

NOTE

For IP20 units, replace ‘#’ with ‘2’

For IP66 Non Switched Units, replace ‘#’ with ‘X’

For IP66 Switched Units, replace ‘#’ with ‘Y’

Optidrive ODE-3 1Ph Output User Guide Revision 1.00

8

www.invertekdrives.com

3

Mechanical Installation

3. Mechanical Installation

3.1. General

The Optidrive should be mounted in a vertical position only, on a flat, flame resistant, vibration free mounting using the integral mounting

holes or DIN Rail clip.

IP20 Optidrives must be installed in a pollution degree 1 or 2 environment only.

Do not mount flammable material close to the Optidrive

Ensure that the minimum cooling air gaps, as detailed in section 3.5 and 3.7 are left clear

Ensure that the ambient temperature range does not exceed the permissible limits for the Optidrive given in section 9.1

Provide suitable clean, moisture and contaminant free cooling air sufficient to fulfil the cooling requirements of the Optidrive

3.2. UL Compliant Installation

Refer to section 9.3 on page 27 for Additional Information for UL Compliance.

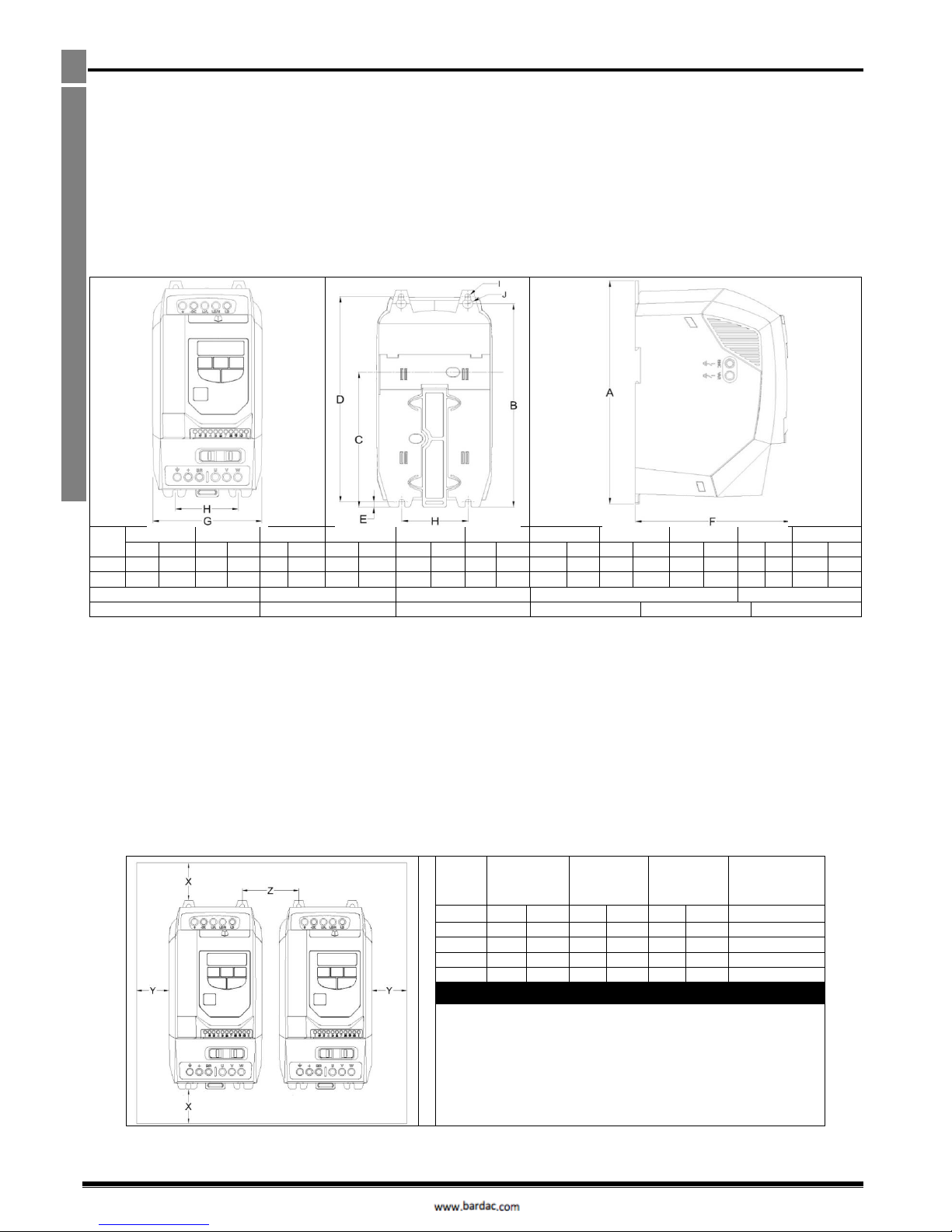

3.3. Mechanical Dimensions and Mounting – IP20 Open Units

Drive

Size

A B C D E F G H I J Weight

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

Kg

lb

1

173

6.81

160

6.30

109

4.29

162

6.38 5 0.20

123

4.84

83

3.27

50

1.97

5.5

0.22

10

0.39

1.0

2.2

2

221

8.70

207

8.15

137

5.39

209

8.23

5.3

0.21

150

5.91

110

4.33

63

2.48

5.5

0.22

10

0.39

1.7

3.8

Mounting Bolts

Frame Size 1 – 2

4 x M5 (#8)

Frame Size 4

4 x M8

Tightening Torques

Frame Sizes 1 – 2

Control Terminals

0.5 Nm (4.5 lb-in)

Power Terminals

1 Nm (9 lb-in)

3.4. Guidelines for Enclosure Mounting – IP20 Units

IP20 drives are suitable for use in pollution degree 1 environments, according to IEC-664-1. For pollution degree 2 or higher environments,

drives should be mounted in a suitable control cabinet with sufficient ingress protection to maintain a pollution degree 1 environment

around the drive.

Enclosures should be made from a thermally conductive material.

Ensure the minimum air gap clearances around the drive as shown below are observed when mounting the drive.

Where ventilated enclosures are used, there should be venting above the drive and below the drive to ensure good air circulation. Air

should be drawn in below the drive and expelled above the drive.

In any environments where the conditions require it, the enclosure must be designed to protect the Optidrive against ingress of airborne

dust, corrosive gases or liquids, conductive contaminants (such as condensation, carbon dust, and metallic particles) and sprays or

splashing water from all directions.

High moisture, salt or chemical content environments should use a suitably sealed (non-vented) enclosure.

The enclosure design and layout should ensure that the adequate ventilation paths and clearances are left to allow air to circulate through the

drive heatsink. Invertek Drives recommend the following minimum sizes for drives mounted in non-ventilated metallic enclosures:-

Drive

Size X Above &

Below

Y

Either

Side

Z

Between

Recommended

airflow

mm

in

mm

in

mm

in

CFM (ft3/min)

1

50

1.97

50

1.97

33

1.30

11

2

75

2.95

50

1.97

46

1.81

22

Note :

Dimension Z assumes that the drives are mounted side-by-side with

no clearance.

Typical drive heat losses are 3% of operating load conditions.

Above are guidelines only and the operating ambient temperature of

the drive MUST be maintained at all times.

Bardac Drives

Optidrive ODE-3 1Ph Output User Guide Revision 1.00

www.invertekdrives.com

9

3

Mechanical Installation

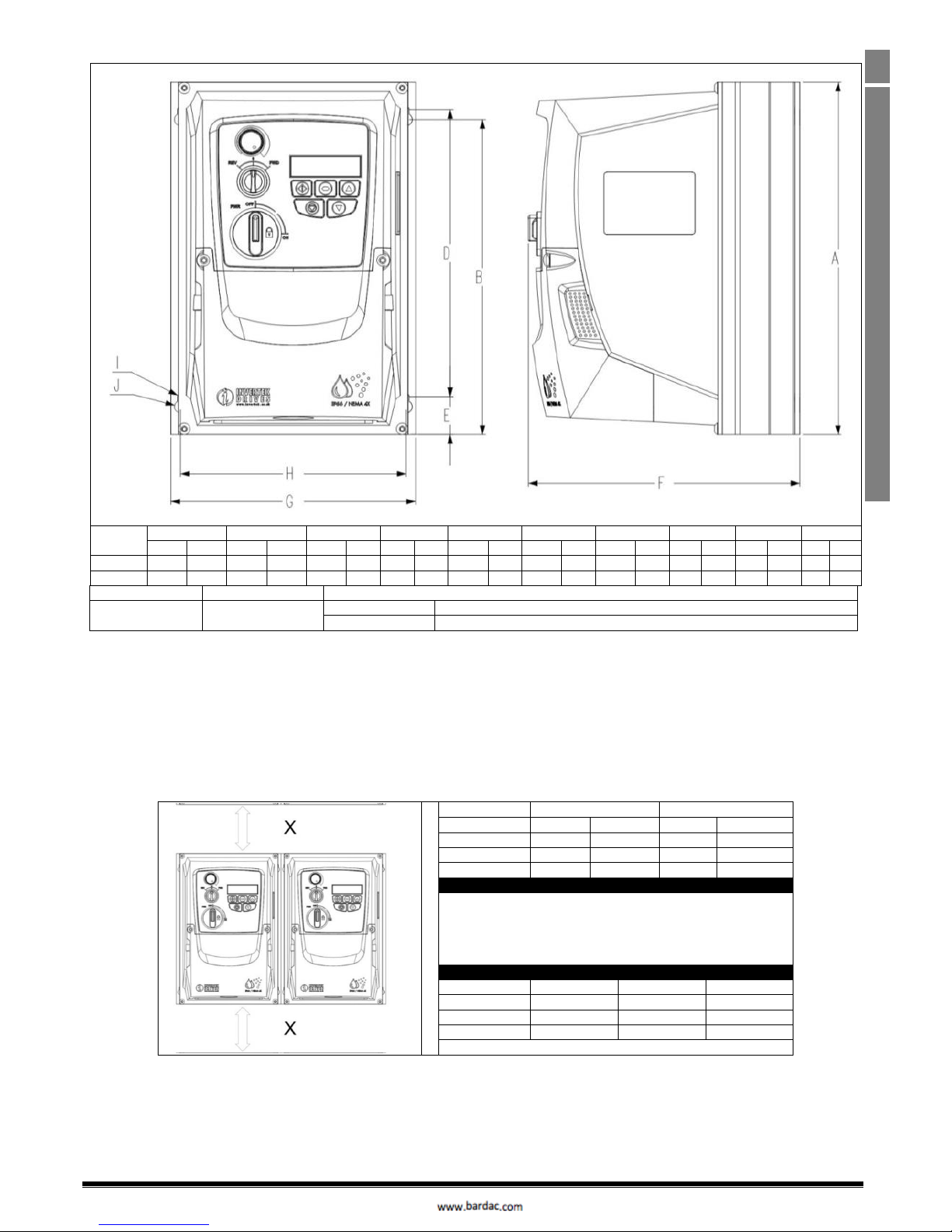

3.5. Mechanical Dimensions – IP66 (Nema 4X) Enclosed Units

Drive Size

A B D E F G H I J

Weight

mm

in

mm

in

mm

in

mm

in

mm

In

mm

in

mm

in

mm

in

mm

in

kg

lb

1

232.0

9.13

207.0

8.15

189.0

7.44

25.0

0.98

179.0

7.05

161.0

6.34

148.5

5.85

4.0

0.16

8.0

0.31

3.1

6.8

2

257.0

10.12

220.0

8.67

200.0

7.87

28.5

1.12

187.0

7.36

188.0

7.40

176.0

6.93

4.2

0.17

8.5

0.33

4.1

9.0

Mounting Bolts

All Frame Sizes

4 x M4 (#8)

Tightening Torques

All Frame Sizes

Control Terminals

0.5 Nm (4.5 lb-in)

Power Terminals

1 Nm (9 lb-in)

3.6. Guidelines for mounting (IP66 Units)

Before mounting the drive, ensure that the chosen location meets the environmental condition requirements for the drive shown in

section 9.1

The drive must be mounted vertically, on a suitable flat surface

The minimum mounting clearances as shown in the table below must be observed

The mounting site and chosen mountings should be sufficient to support the weight of the drives

Using the drive as a template, or the dimensions shown above, mark the locations required for drilling

Suitable cable glands to maintain the ingress protection of the drive are required. Gland holes for power and motor cables are pre-

moulded into the drive enclosure, recommended gland sizes are shown above. Gland holes for control cables may be cut as required.

Drive Size

X Above & Below

Y Either Side

mm

in

mm

in

1

200

7.87

10

0.39

2

200

7.87

10

0.39

Note:

Typical drive heat losses are approximately 3% of operating load

conditions.

Above are guidelines only and the operating ambient temperature of

the drive MUST be maintained at all times.

Cable Gland Sizes

Drive Size

Power Cable

Motor Cable

Control Cables

1

M20 (PG13.5)

M20 (PG13.5)

M20 (PG13.5)

2

M25 (PG21)

M25 (PG21)

M20 (PG13.5)

Loading...

Loading...