Split Type Floor Ceiling Air Conditioner

V1KI-09

V1KI-12

V1KI-18

V1KI-24

V1KI-30

V1KI-36

V1KI-45

V1KI-50

V1KI-60

Contents

1. Safety Considerations....................................................................................1

2. Displaying Part...............................................................................................3

2.1 LCD Display of Wired controller .........................................................................3

2.2 Instruction to LCD Display ..................................................................................4

3. Buttons............................................................................................................5

4. Installation of Wired Controller...................................................................6

5. Instruction to Operation................................................................................7

5.1 On/Off..................................................................................................................7

5.2 Mode Setting........................................................................................................7

5.3 Temperature Setting .............................................................................................8

5.4 Fan Speed Setting.................................................................................................8

5.5 Swing Control Function .......................................................................................9

5.6 Timer Setting........................................................................................................9

5.7 Air Exchange Setting*......................................................................................11

5.8 Sleep Setting ......................................................................................................12

5.9 Turbo Function Setting.......................................................................................13

5.10 SAVE Function Setting ....................................................................................13

5.11 E-HEATER Setting* ........................................................................................15

5.12 Blow Function Setting........................................................................................16

5.13 Quiet Function Setting .......................................................................................17

5.14 Field Functions...................................................................................................18

5.15 Other Functions..................................................................................................18

6. Error Display................................................................................................20

7. Remote control operation procedure(standard fitting) ............................23

8. Part Names and Their Functions................................................................33

9. Maintenance.................................................................................................34

10. Operating Guide ......................................................................................35

11. Precautions...............................................................................................36

12. Checking Before Contact the Service Man............................................37

12.1 Accessories List for Installation.........................................................................37

12.2 Installation of the Indoor Unit............................................................................39

12.3 Installation of the Outdoor Unit .........................................................................42

12.4 Schematic Diagram of Unit Line Connection ....................................................45

12.5 Connecting Pipe Preparation..............................................................................48

13. Appendix...................................................................................................55

1

1. Safety Considerations

Please read this manual carefully before use and operate correctly as instructed in the manual.

You are specially warned to note the two symbols below.

CAUTION! :

A symbol indicating that improper operation might cause human death or severe

injury.

WARNING! :

A symbol indicating that improper operation might cause human property damage.

WARNING!

1. This unit should be used in offices, restaurants, residences or similar places.

2. Please seek an authorized repair station for installation work. Improper installation might cause

water leakage, electric shock or fire.

3. Please install at a place strong enough to support the weight of air conditioner unit. Otherwise, the

air conditioner unit might fall down and cause human injury or death.

4. To ensure proper drainage, the drainage pipe should be correctly installed according to installation

instructions. Take proper measures for heat preservation to prevent condensing. Improper

installation of pipes might cause leakage and wet the articles in the room.

5. Do not use or store flammable, explosive, poisonous or other dangerous substances beside the air

conditioner.

6. In case of troubles (e.g. burnt smell), please immediately cut off the main power of air conditioner

unit.

7. Keep air flow to avoid shortage of oxygen in the room.

8. Never insert your finger or any objects into the air outlet or the inlet grill.

9. Never plug or unplug the power cable directly to start or stop the air-conditioning unit.

10. Please take constant care to check if the mounting rack is damaged after long time use.

11. Never modify the air conditioner. Please contact the dealer or professional installation workers for

repair or relocation of the air conditioner.

12. The appliance should not be installed in the laundry.

13. Before installation, please check the power supply for compliance with the ratings on nameplate.

Check the power safety as well. (By professionals)

14. Before use, please check and confirm if the cables, drainage pipes and pipelines are correctly

connected, hence to eliminate the risk of water leakage, refrigerant leakage, electric shock or fire.

15. Main power must be securely earthed to ensure effective grounding of the air conditioner unit and

avoid the risk of electric shock. Please do not connect the earth cable to coal gas pipe, water pipe,

lightning rod or telephone line.

16. Once started, the air conditioner should not be stopped until at least five minutes later. Otherwise

the oil return to the compressor may be affected.

17. Do not let the child operate the air conditioner unit.

18. Do not operate the air conditioner unit with wet hands.

19. Please disconnect the main power before cleaning the air conditioner or replacing the air filter. (By

professionals)

20. Please disconnect the main power if the air conditioner is not to be used for al long period of time.

21. Please do not expose the air conditioner unit directly in corrosive environment with water or

moisture.

2

22. Please do not foot on or place any goods on air conditioner unit.

23. After electrical installation, the air conditioner unit should be energized for electrical leakage test.

(By professionals)

24. If the supply cord is damaged, it must be replaced by the manufacturer or its service agent or a

similarly qualified person in order to avoid a hazard.

25. An all-pole disconnection switch with a contact separation of at least 3mm in all poles should be

connected with the fixed wiring.

26. The appliance should be installed in accordance with national wiring regulations.

27. Keep the interconnection cable away from the cooper tube due to the high temperature of the

refrigerant circuit.

28. The power cord must be separated with the communication line.

29. This appliance is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been given

supervision or instruction concerning use of the appliance by a person responsible for their safety.

30. Children should be supervised to ensure that they do not play with the appliance.

3

2. Displaying Part

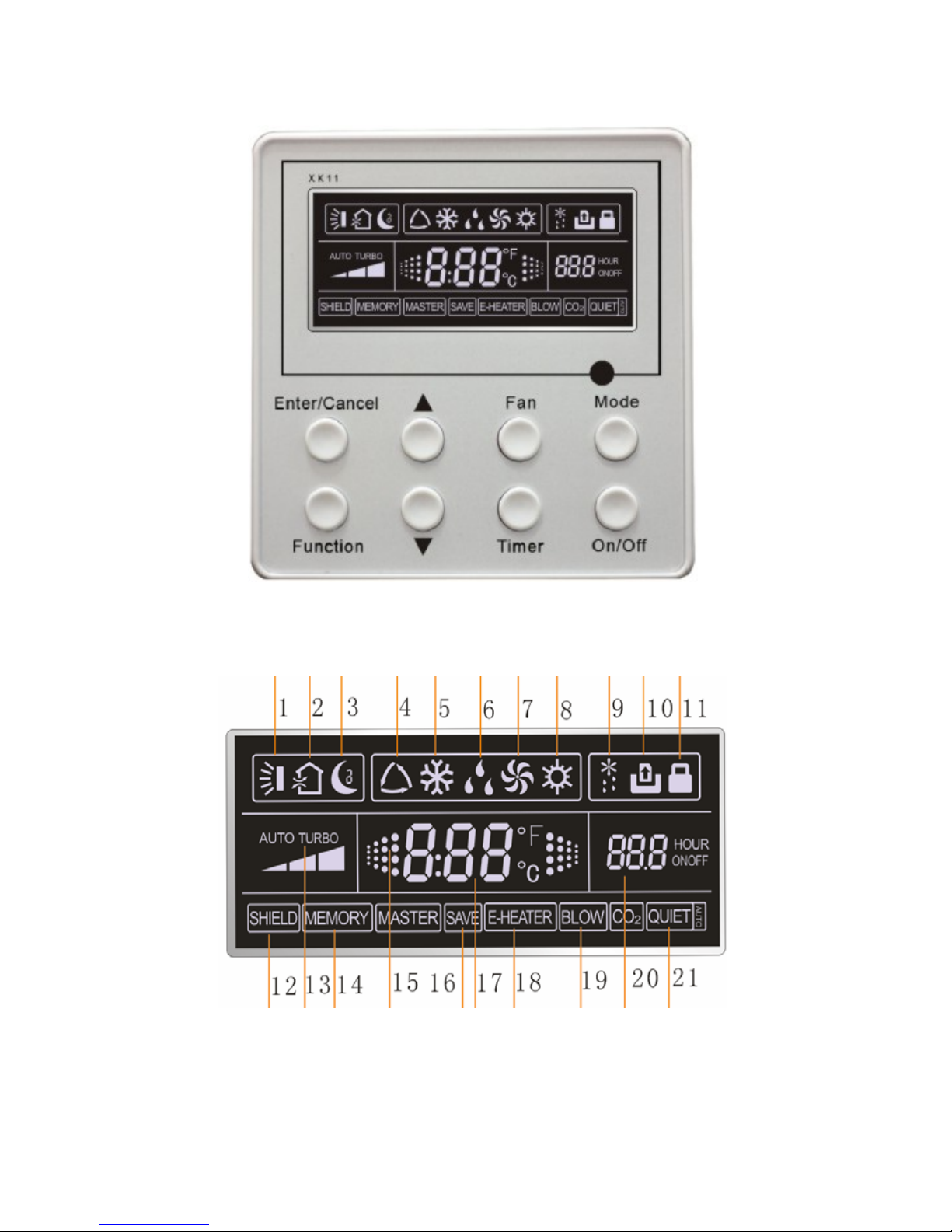

Fig.1 Outline of wired controller

2.1 LCD Display of Wired controller

Fig.2 LCD display

4

2.2 Instruction to LCD Display

Table.1

No. Description Instruction to Displaying Contents

1 Swing Swing function

2

Air *

Air exchange function

3 Sleep Sleeping states

4 Running mode Each kind of running mode of indoor unit (auto mode)

5 Cooling Cooling mode

6 Dry Dry mode

7 Fan Fan mode

8 Heating Heating mode

9 Defrost Defrosting state

10

Gate-control card*

Gate control

11 Lock Lock state

12 Shield

Shielding state (buttons, temperature, on/off, mode or save is

shielded by long-distance monitoring

13 Turbo Turbo function state

14 Memory

Memory state (Indoor unit resumes original setting state

after power failure and then power recovery)

15 Twinkle Flicking when unit is on without operation of button

16 Save Energy-saving state

17 Temperature Ambient/setting temperature value

18

E-Heater*

E-HEATER display means electric- heater is available

19 Blow Blow mark

20 Timer Timer-displayed location

21 Quiet Quiet state(two types: quiet and auto quiet)

Notes: The functions with * are reserved for other models and are not applicable for the models

listed in this manual.

5

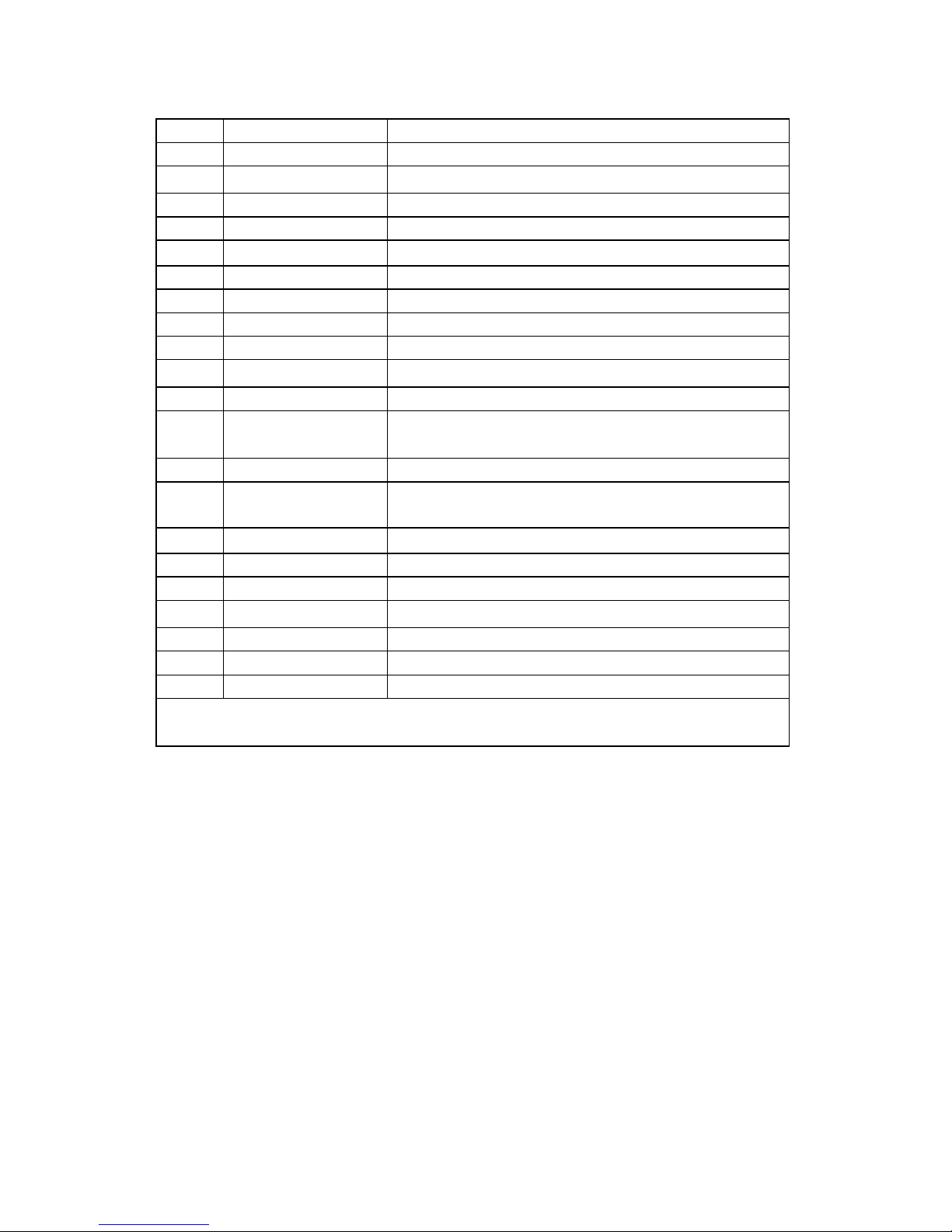

3. Buttons

Silk Screen of Buttons

Fig.3 Silk screen of buttons

Instruction to Function of Buttons

Table.2

No. Description Function of Button

1 Enter/cancel

① Function selection and canceling;

② Press it for 5s to enquiry the outdoor ambient temperature.

2 ▲

6 ▼

① Running temperature setting of indoor unit, range :16~

30°C

②Timer setting, range:0.5-24hr

③Switch over between quiet/auto quiet.

3 Fan Setting of high/middle/low/auto fan speed

4 Mode Setting of cooling/heating/fan/dry mode of indoor unit

5 Function

Switchover among these functions of

air/sleep/turbo/save/e-heater/blow/quite

7 Timer Timer setting

8 On/off Turn on/off indoor unit

4 Mode

and

2 ▲

Memory

function

Press Mode and ▲for 5s under off state of the unit to

enter/cancel key memory function (If memory is set, indoor

unit will resume original setting state after power failure and

then power recovery. If not, indoor unit is defaulted to be off

after power recovery. Memory function is defaulted to be off

before outgoing.)

2 ▲

and

6 ▼

Lock

Upon startup of the unit without malfunction or under off state

of the unit, press ▲ ▼ key at the same time for 5s in to lock

state. In this case, any other buttons won’t respond the press.

Repress ▲ ▼ key for 5s to quit lock state.

6

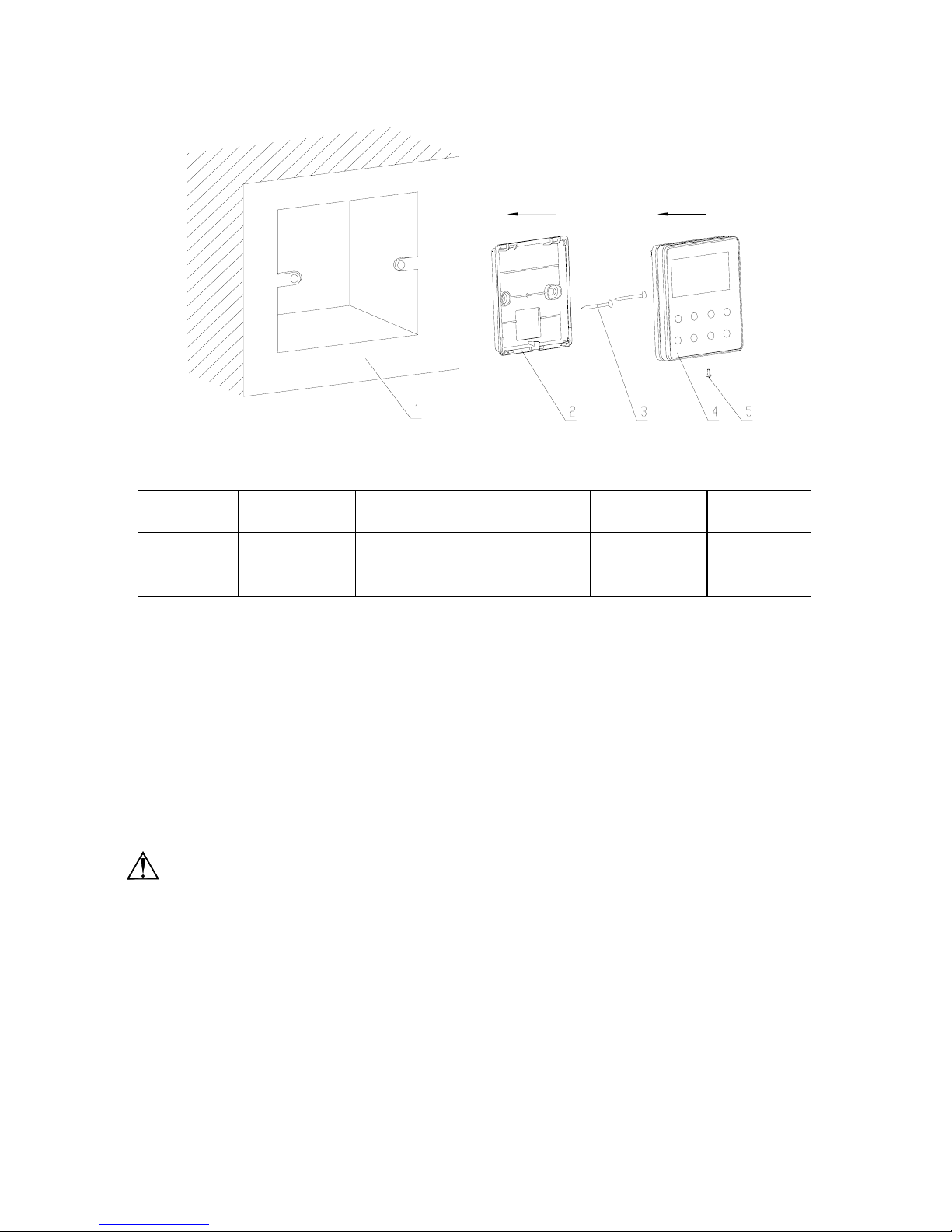

4. Installation of Wired Controller

Fig.4 Sketch for Installation of Wired Controller

No. 1 2 3 4 5

Description Socket’s base

box installed in

the wall

Soleplate of

controller

Screw M4X25 Front panel of

controller

Screw

ST2.2X6.5

Fig.4: Sketch for Installation of Wired Controller. Pay attention to the following items during

installation of wired controller:

1. Cut off power supply of heavy-current wire embedded in mounting hole in the wall before

installation. It is prohibited to perform the whole procedure with electricity.

2. Pull out 4-core twisted pair line in mounting hole and then make it through the rectangle hole at the

back of controller’s soleplate.

3. Joint the controller’s soleplate on wall face and then fix it in mounting hole with screws M4X25.

4. Insert the 4-core twisted pair line through rectangle hole into controller’s slot and buckle the front

panel and soleplate of controller together.

5. At last, fix the controller’s front panel and soleplate with screws ST2.2X6.5.

Caution:

During connection of wirings, pay special attention to the following items to avoid interference of

electromagnetism to unit and even failure of it.

1. To ensure normal communication of the unit, signal line and wiring (communication) of wired

controller should be separate from power cord and indoor/outdoor connection lines. The distance

between them should be kept 20cm in min.

2. If the unit is installed at the place where there is interference of electromagnetism, signal line and

wiring (communication) of wired controller must be shielded by twisted pair lines.

7

5. Instruction to Operation

5.1 On/Off

Press On/Off button to turn on the unit.

Repress this button to turn off the unit.

Note: The state shown in Fig.5 indicates off-state of the unit after energizing

The state shown in Fig.6 indicates on-state of the unit after energizing.

Fig.5 Off state of the unit Fig.6 On state of the unit

5.2 Mode Setting

Under on-state of the unit, press Mode button to switch the operation modes as the following

sequence:

Fig.7

8

5.3 Temperature Setting

Press ▲ or ▼button to increase or decrease of setting temperature under on-state of the unit. If

press either of them continuously, temperature will be increased or decreased by 1°C every 0.5s.

In Cooling, Dry, Fan and Heating mode, temperature setting range is 16°C~30°C.

In Auto mode, the setting temperature is un-adjustable.

As shown in Fig.8

Fig.8

5.4 Fan Speed Setting

Press Fan button, fan speed of indoor unit will change as below:

As shown in Fig.9

Fig.9

9

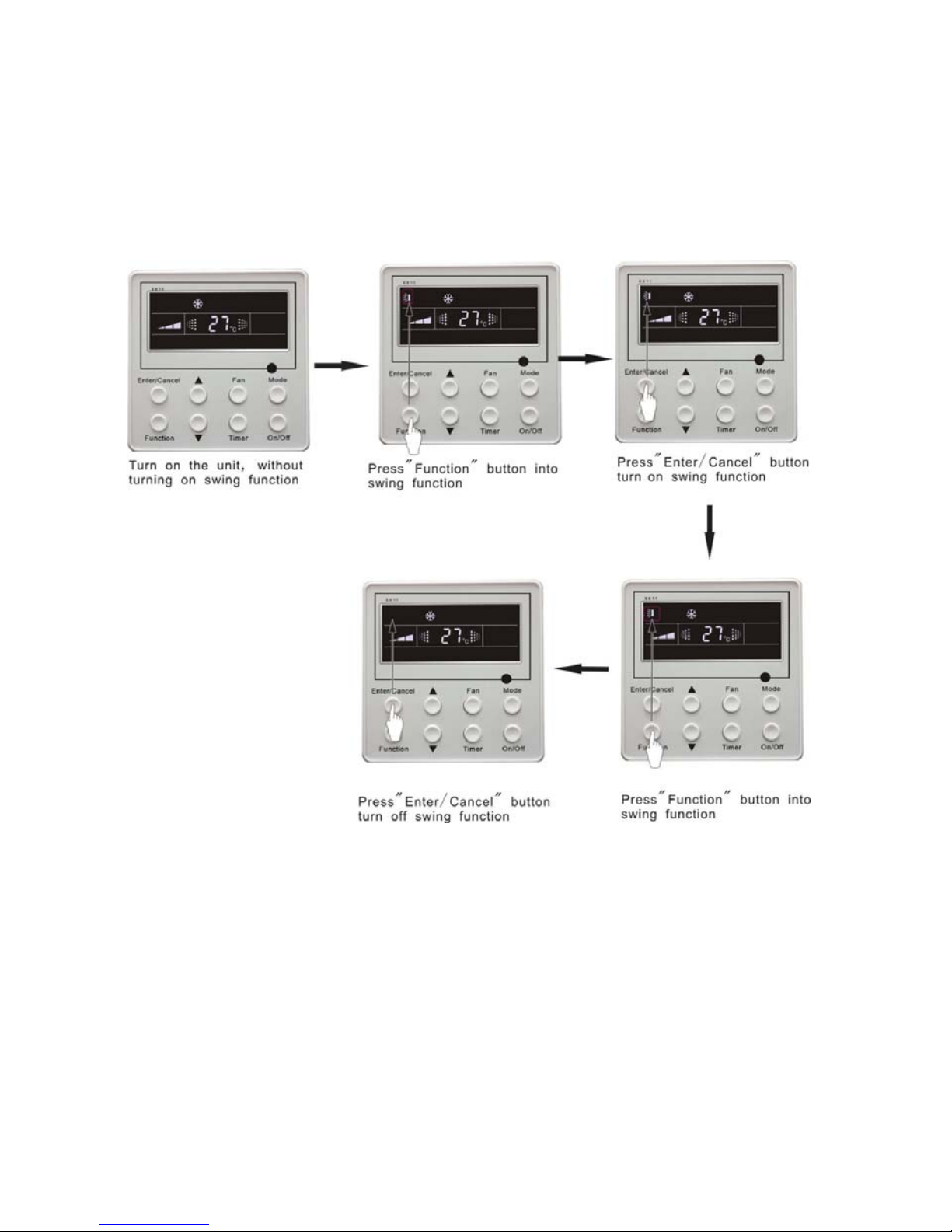

5.5 Swing Control Function

Under on-state of unit, press Function button till the unit enters swing control function and then

press Enter/cancel button to turn on “swing” control function.

During swing function, press Function button till the unit enters swing control function and then

press Enter/cancel button to cancel swing control function.

Swing control function setting is shown in Fig.10

Fig.10

5.6 Timer Setting

Press Timer button to set timer off of the unit. Under off-state of the unit, press Timer button to set

timer on of the unit in the same way.

Timer on setting: Under off-state of the unit without timer setting, if Timer button is pressed,

LCD will display xx hour, with ON blinking. In this case, press▲ or ▼ button to adjust timer on and

then press Timer to confirm. If Mode button is pressed before pressing Timer button to confirm, timer

mode will be switched to timer off setting mode. In this case, LCD displays xx hour, with OFF blinking.

In this case, press▲ or ▼ button to adjust timer off and then press Timer to confirm. When LCD

displays xx hour on off, xx hour means time of timer on, but time of timer off won’t be displayed.

Timer off setting: Under on-state of the unit without timer setting, if Timer button is pressed, LCD

10

will display xx hour, with OFF blinking. In this case, press▲ or ▼ button to adjust timer on and then

press Timer to confirm. If Mode button is pressed before pressing Timer button to confirm, timer mode

will be switched to timer on setting mode. In this case, LCD displays xx hour, with ON blinking. In this

case, press▲ or ▼ button to adjust timer on and then press Timer button to confirm. When LCD

displays xx hour on off, xx hour means time of timer off, but time of timer on won’t be displayed.

Cancel timer: After setting of timer, if Timer button is pressed, LCD won’t display xx. Hour so

that timer setting is canceled.

Timer off setting under on-state of the unit is shown as Fig.11

Fig.11 Timer setting under on state of the unit

Timer range: 0.5-24hr. Every press of▲ or ▼ button will make setting time increased or

decreased by 0.5hr.If press either of them continuously, setting time will automatically increase/

decrease by 0.5hr every 0.5s.

Note:

1. If both timer on and timer off are set in unit on interface, the wired controller only display time of

time off. If both of them are set in unit off-state, only time of timer on is displayed.

2. Timer on in unit on-state is timed from the time of unit off and timer off in unit off-state is timed

from the time of unit on.

11

5.7 Air Exchange Setting*

Turn on air Exchange function:

Under on-state of the unit, press Function button to go to this function setting (Air mark

blinks).AIR 1 displayed at the ambient temperature-displayed location (888) is defaulted (the last type

of AIR will be displayed after adjustment).Press ▲ or ▼ button to adjust air type. Press Enter/Cancel

button to turn on/off air function. After turning on this function, the air mark shows.

There are 10 types of AIR, but only 1-2 types are for remote control. Refer to the following details:

1――The unit continuously runs for 60min, and fresh air valve runs for 6 min.

2――The unit continuously runs for 60min, and fresh air valve runs for 12 min.

3――The unit continuously runs for 60min, and fresh air valve runs for 18 min.

4――The unit continuously runs for 60min, and fresh air valve runs for 2 4 min.

5――The unit continuously runs for 60min, and fresh air valve runs for 30 min.

6――The unit continuously runs for 60min, and fresh air valve runs for 36 min.

7――The unit continuously runs for 60min, and fresh air valve runs for 42 min.

8――The unit continuously runs for 60min, and fresh air valve runs for 48 min.

9――The unit continuously runs for 60min, and fresh air valve runs for 54 min.

10――The unit continuously runs for 60min, and fresh air valve always runs.

Turn off air Exchange function: During Air function, press Function button to go to the Air

function. In this case, air mark is blinking, and then press Enter/cancel button to turn off this function.

Air mark will subsequently disappear.

Air Exchange setting is shown as in Fig.12:

Fig.12 Air exchange device

12

Note:

In air exchange mode, press Function button or there is not any operation within 5s after the last

button operation, the system will be quit from air exchange setting and current energy-saving data won’t

be memorized.

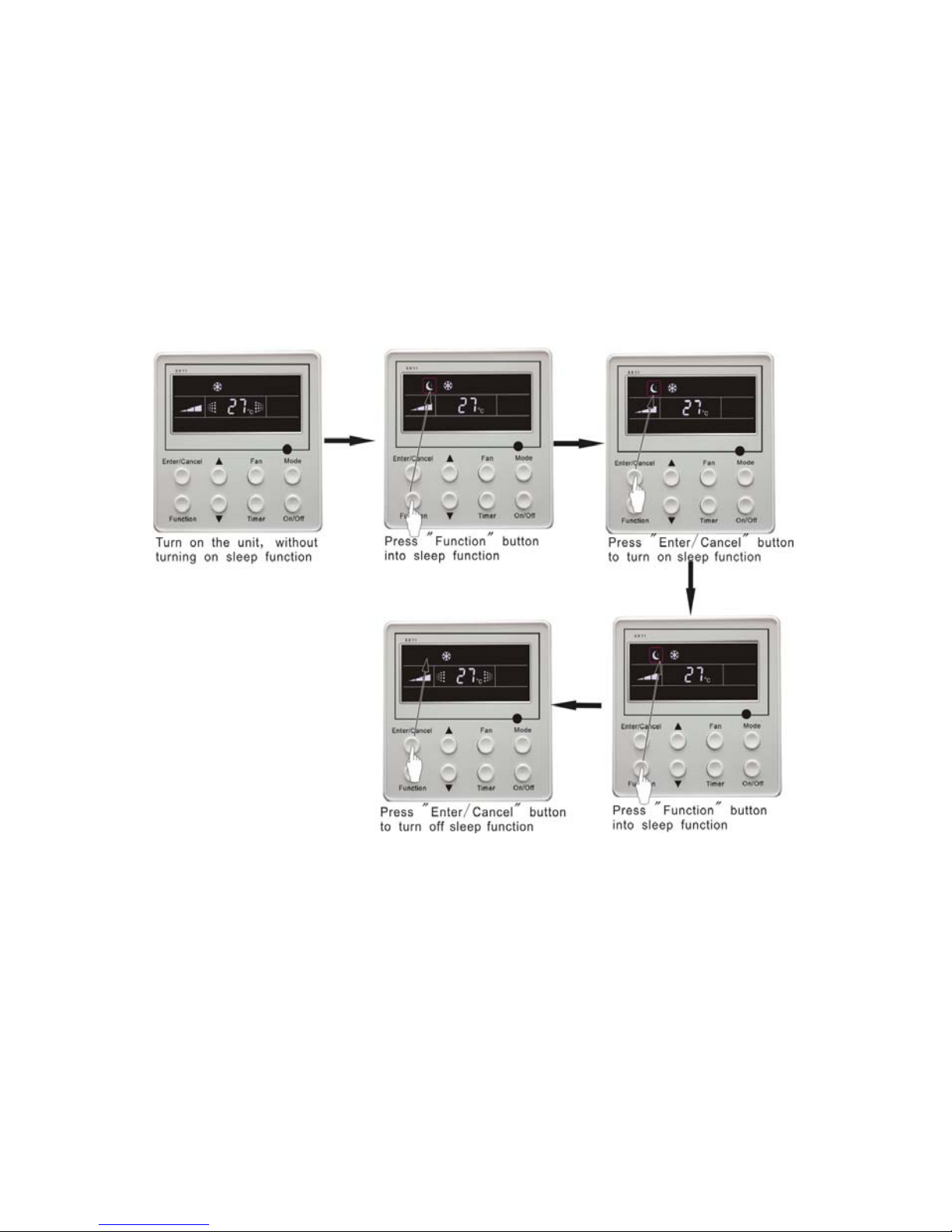

5.8 Sleep Setting

Sleep on: Press Function button under on-state of the unit into sleep function and then press

Enter/cancel button to turn on sleeping function.

Sleep off: During sleep on-state, press Function button to go to the sleep function and then press

Enter/cancel button to turn off this function.

Sleep setting is shown as Fig.13:

Fig.13 Sleep setting

Sleep setting is clear after power failure and then power recovery. There is not sleep function in fan

and auto mode.

Note:

In cooling and dry mode, if the unit with sleep function has run for 1 hour, the preset temperature

will be increased by 1°C and 1°C in another 1 hour. After that, the unit will run at this temperature. In

heating mode, if the unit with sleep function has run for 1 hour, the preset temperature will be decreased

by 1°C and 1°C in another 1 hour. After that, the unit will run at this temperature.

13

5.9 Turbo Function Setting

TURBO function: The unit at high fun speed can realize quick cooling or heating so that room

temperature can quickly approach setting temperature.

In cooling or heating mode, press Function button till the unit enters TURBO function and then

press Enter/cancel button to turn on TURBO function.

During TURBO function, press Function button till the unit enters TURBO function and then

press Enter/cancel button to cancel TURBO function.

TURBO function setting is shown in Fig.14:

Fig.14 Turbo Function Setting

Note:

1. TURBO function will be turned off after power failure and then recovery. In dry, fan and auto mode,

TURBO function can not be set and TURBO mark won’t be displayed.

2. TURBO function will be automatically canceled after setting of quiet function.

5.10 SAVE Function Setting

Energy Saving Function: Energy saving can make the air conditioner runs in a smaller temperature

range by setting lower limited value of setting temperature in cooling or dry mode and upper limited

value in heating mode.

14

Energy Saving Setting for Cooling

Under on-state and in cooling or dry mode of the unit, press Function button into energy saving

function, with SAVE blinking .Press ▲ or ▼ button to adjust lower limited value of setting temperature

in cooing mode. After that press Enter/Cancel button to turn on energy saving function for cooling.

Energy Saving Setting for Heating

Under on state and in heating mode of the unit, press Function button into energy saving function,

with SAVE blinking. Press Mode button into energy saving function for heating and then press▲ or ▼

button to adjust upper limited value of setting temperature in heating mode. After that, press

Enter/Cancel button to turn on energy saving function for heating.

After energy saving function is turned on, press Function button into energy saving function and

press Enter/cancel to cancel this function.

The energy saving setting is shown in the Fig.15:

Fig.15 Energy Saving Setting

Note:

1. In Auto running mode with save function on, the unit will be forcibly quit Auto running Mode and

change to current operation mode, After setting of save, sleep function will be canceled.

2. In save mode, if Function button is pressed or there is not any operation within 5s after the last

button operation, the system will be quit from save function setting and current data won’t be

memorized.

3. After power failure and then recovery, save function setting will be memorized.

4. The lower limited value in cooling mode is 16°C and the upper limited value in heating mode is

30°C.

5. After save setting, if the setting temperature is out of the range in the mode, the limited value will

prevail.

15

5.11 E-HEATER Setting*

E-HEATER: In the heating mode, E-heater is allowed to be turned on for improvement of

efficiency. If heating mode is turned on by button operation, auxiliary electric heating function will be

automatically turned on.

Press Function button in heating mode to go to the auxiliary electric heating function, the

E-HEATER blinking, and press Enter/cancel button to turn on this function. In this case, the

E-HEATER will be displayed, which means E-heater is allowed to be turned on.

If auxiliary electric heating function is on, press Function button to confirm or press Enter/cancel

button to cancel. In this case, E-HEATER won’t be displayed, which means E-heater is prohibited to be

turned on.

The setting of this function is shown as Fig.16 below:

Fig.16 Auxiliary Electric Heating Function Setting

Note:

E-HEATER can not be set in cooling, dry and fan mode, E-HEATER mark won’t be displayed.

The setting is shown in Fig.16

16

5.12 Blow Function Setting

BLOW function: After the unit is turned off, water in evaporator of indoor unit will be

automatically evaporated to avoid mildew.

In cooling and dry mode, press Function button till the unit enters BLOW function, with BLOW

blinking, and then press Enter/cancel button to turn on this function.

In BLOW mode, press Function button till the unit enters BLOW function and then press

Enter/cancel button to cancel this function.

BLOW function setting is shown in Fig.17:

Fig.17 Blow function setting

Note:

1. After setting BLOW function, turn off the unit by pressing On/Off button on remote controller,

indoor fan will run at low fan speed for 10 min. (BLOW shows).Meanwhile, if BLOW function is

canceled indoor fan will be turned off directly.

2. There is not BLOW function in fan or heating mode.

17

5.13 Quiet Function Setting

Quiet function consists of two kinds: QUIET and AUTO QUIET.

Press Function button till the unit enters quiet function setting state, Quiet or Auto Quiet mark

blinks. In this case, press▲ or ▼ button to switch between Quiet and Auto Quiet and then press

Enter/cancel button to turn on this function.

In quiet mode, press Function button till the unit enters quiet function. In this case, Quiet or Auto

Quiet icon blinks and then press Enter/cancel button to cancel this function.

Quiet function setting is shown in Fig.18:

Fig.18 Quiet function setting

Note:

3. During quiet function, fan speed is un-adjustable.

4. When turning on auto quiet function, the unit will enter quiet running state according to

temperature difference between room temperature and setting temperature. In this case, fan speed is

adjustable. If temperature difference between room temperature and setting temperature ≥ 4°C, fan

will keep its current speed; if 2°C≤temperature difference ≤3 ; fan speed will be ℃ reduced by one

grade ,but if it is at minimun. grade, it is un-adjustable.; if temperature difference ≤1°C, fan speed

will be at minimun grade

5. In auto quiet mode, fan speed can not be raised but reduced. If high fan speed is manually adjusted,

auto quiet mode will quit.

6. There is not auto quiet function in fan or dry mode. Quiet off is default after power failure and then

power recovery.

7. If quite function is set, turbo function will be canceled.

18

5.14 Field Functions

Under off-state of the unit, press Function and Timer buttons continuously for 5s to go to the

debugging menu. Press Mode button to adjust the setting items and ▲ or ▼ button to set the actual

value.

5.14.1 Ambient Temperature Sensor Setting

In field setting mode, press Mode button to adjust the temperature displayed location displaying 00,

and press ▲ or ▼ button to adjust setting state at timer displayed location. There are 3 types for

selection:

⑴ Indoor ambient temperature is that at return air inlet (01 is displayed at timer displayed location)

⑵ Indoor ambient temperature is that at the place of screen (02 is displayed at timer displayed location)

⑶ Return air inlet temperature sensor shall be selected for cooling, dry and fan modes and wired

controller temperature sensor (03 is displayed at timer displayed location) shall be selected for heating

and auto modes.

5.14.2 Three Grades of Speed for Indoor Fan

In field setting mode, press Mode button to adjust the temperature displayed location displaying 01

and press ▲ or ▼ button to adjust setting state at timer displayed location. There are 2 types for

selection:

⑴ 3 low grades (LCD displays 01)

⑵ 3 high grades (LCD displays 02)

Three low grades indicate high, medium and low grades and 3 high grades indicate super-high,

high and medium grades.

Press Enter/Cancel button to save the setting and quit after setting. If there is not any operation

within 20s after the system responds to the last button operation in this interface, the system will quit

this menu and display normal off-state; meanwhile, current setting won’t be saved.

5.15 Other Functions

5.15.1 Lock Function

Upon startup of the unit without malfunction or under off-state of the unit, press ▲ and ▼buttons

at the same time for 5s till the wired controller enters lock state. In this case, LCD displays:. After

that, repress these two buttons at the same time for 5s to quit lock state.

Under lock state, any other buttons won’t give any response to the press.

5.15.2 Memory Function

Memory switchover: Under off-state of the unit, press Mode and ▲ buttons at the same time for

5s to switch memory modes. During setting memory mode, Memory will be displayed. If this function

is not set, the unit will be under off state after power failure and then power recovery.

Memory recovery: If memory mode has been set for wired controller, the wired controller after

power failure will resume its original running state upon power recovery.

Note:

It will take about 5 seconds to save all the information, therefore, please do not cut down the power

at this time, or it may fails.

19

5.15.3 Enquiry of Outdoor Ambient Temperature

Under on or off state of the unit, press Enter/Cancel button for 5s, outdoor ambient temperature

will be displayed at temperature displaying location after a sound of click. This enquiry state will quit

by pressing any button. If there is not any operation for 20s, it will automatically quit.

Note:

1. This function will be shielded after energized of 12hr for some models of the units without

outdoor ambient sensors. Please refer to Instruction for details.

2. If malfunction of outdoor ambient sensor occurs, this function will be shielded in 12hr.

5.15.4 Selection of Centigrade and Fahrenheit

Under off state of the unit, press Mode and ▼ at the same time for 5s, the displayer panel will switch

between Centigrade and Fahrenheit.

5.15.5 Master/Slave Wired Controller Setting

Under the off status of the unit, press “Enter/cancel” and “Mode” at the same time for 5 seconds to

go to the master/slave wired controller setting interface, and then press ▲ or ▼ to make the adjustment.

In this case, only in the temperature display is there numbers displayed, 01 for the master wired

controller and 02 for the slave wired controller.

After that, press “Enter/cancel” to save the setting and quit this interface. If there is not any

operation in 20 seconds on this interface after the last button press, the system will quit automatically to

the normal off status without saving the current setting.

Note:

If there is only one wired controller, it only can be set as the master; otherwise the unit won’t run

normally

20

6. Error Display

If there is malfunction during running of the system, the wired controller will display error code at

temperature–displayed location. Once there is more than one malfunction, error codes will be displayed

circularly. If there are multiple circuit systems, the system number of failed system will be displayed

before the colon (not for single system).

If malfunction o·occurs, turn off the unit and contact nearest dealer for help.

As shown in Fig.19, it means high pressure protection of system 2 under unit on.

Fig.19

Error code meaning:

Error code Malfunction

E1 High pressure protection of compressor

E2 Indoor anti-freezing protection

E3 Low pressure protection of compressor

E4 High discharge temperature protection of compressor

E5 Compressor overload protection

E6 Communication malfunction

E9 Water overflow protection

F0 Indoor unit ambient sensor malfunction at air return opening

F1 Evaporator sensor malfunction

F2 Condenser sensor malfunction

F3 Outdoor unit ambient temperature sensor malfunction

F4 Discharge temperature sensor malfunction

F5 Ambient sensor malfunction on Displayer (or LED board)

21

The LED Indicator Display on the Main Board of Outdoor Unit (09K/12K)

This table is applicable to the electric control box of the 09K and 12K C Series DC inverter air

conditioners. Some of the items are not malfunction; they mean the normal running status

Running Status

Outdoor unit

Yellow Lamp

Outdoor unit

Red Lamp

Outdoor unit

Green Lamp

wired

controller

Display

Compressor started Flash once

Defrosting Flash twice Displayed

Anti-freezing protection Flash 3 times E2

IPM protection Flash 4 times E5

Over-current protection Flash 5 times E5

Heat exchanger overload protection Flash 6 times /

Discharge protection Flash 7 times E4

Compressor overload protection Flash 8 times E5

Power protection Flash 9 times E5

Module overheating protection Flash 10 times E5

EEPROM reading error Flash 11 times E5

Low voltage protection Flash 12 times E5

High voltage protection Flash 13 times E5

PFC over-current protection Flash 14 times E5

Unmatched indoor and outdoor

units

Flash 16 times /

Limited frequency(current) Flash once /

Limited frequency (discharge) Flash twice /

Limited frequency (overload) Flash 3 times /

Reduced frequency (anti-freezing) Flash 4 times /

Outdoor ambient temperature

sensor error

Flash 6 times F3

Outdoor pipe temperature sensor

error

Flash 5 times F2

Outdoor discharge temperature

sensor error

Flash 7 times F4

Up to the startup temperature Flash 8 times /

Limited frequency

(module temperature)

Flash 11 times /

Limited frequency (power)

Flash 13

times

/

Communication normal

Flash

continuously

/

Communication error Black out E6

Indoor ambient temperature sensor

error

F0

Indoor pipe temperature sensor

error

F1

22

Definition of Malfunction Codes of DC Inverter General Outdoor Unit (V1.6)

This table is applicable to the electric control box of the other models of C-Series DC inverter air

conditioners.

Malfunction Item

Outdoor unit display of

dual 8 numeral tube

wired controller

Display

DC busbar over voltage protection PH E5

Overheat protection of radiator P8 E5

Current sensor malfunction Pc E5

Carbon fin sensor malfunction P7 E5

Compressor current protection P5 E5

Low voltage protection PL E5

Compressor startup failure Lc E5

PFC abnormality Hc E5

Compressor clogged LE E5

Drive resetting P0 E5

The compressor motor in loss of synchronization H7 E5

Missing phase, Speed discard Ld E5

Malfunction from driving part to main-control

communication

P6 E5

IPM module protection H5 E5

Compressor over speed LF E5

Sensor connection protection Pd E5

Temperature drift protection PE E5

AC contactor protection P9 E5

High-pressure protection E1 E1

Low-pressure protection E3 E3

Exhaust protection E4 E4

Compressor overload protection H3 E5

Communication malfunction (among indoor unit,

outdoor unit and wired controller)

E6 E6

Outdoor ambient temperature sensor malfunction F3 F3

Coil pipe intermediate temperature sensor

malfunction of outdoor unit

F2 F2

Exhaust temperature sensor malfunction F4 F4

Defrosting (non-malfunction) 08 defrost

Oil return (non-malfunction) 09 no display

Mismatch of indoor unit model LP no display

AC current protection (input side) PA E5

Driver board environment temperature sensor

malfunction

PF E5

AC input voltage abnormality * PP E5

Electrification loop malfunction * PU E5

23

7. Remote control operation procedure(standard fitting)

Name and Function-Remote Control

Note:

Be sure that there are no obstructions between receiver and remote controller.

Don’ t drop or throw the remote controller .

Don’ t let any liquid in the remote controller and put the remote controller directly under the

sunlight or any place where is very hot.

Fig.20

24

Name and Function-Remote Control. (Remove the cover)

Note:

This type of remote controller is a kind of new current controller. Some buttons of the controller

which are not available to this air conditioner will not be described below.

Operate on unmentioned buttons would not impact on the normal use.

Fig.21

25

COOL mode operation procedure

According to difference between room temp and set temp, microcomputer can control cooling on

or not.

If room temp is higher than set temp., compressor runs at COOL mode.

If room temp is lower than set temp., compressor stops and only indoor fan motor runs.

Set TEMP should be in range of 16℃ to 30℃.

Fig.22

26

HEAT mode operation procedure

If room temp is lower than set temp, compressor runs at HE AT mode;

If room temp is higher than set temp, compressor and outdoor fan motor stop, only indoor fan

motor runs.

Set TEMP should be in range of 16℃to 30℃

Fig.23

27

DRY mode operation procedure

If room Temp is more than 2℃ below Set TEMP. , compressor and outdoor unit fan motor stop,

indoor unit fan motor runs at low speed.

If room Temp is between 2℃ of Set TEMP, the compressor and outdoor unit fan motor will run for

6 minutes and stop for 4 minutes, and always in such a cycle, the indoor unit fan motor will run at low

speed.

If room Temp is more than 2℃ above Set TEMP. , compressor and outdoor unit fan motor run as

COOL mode , the indoor unit fan motor runs at low speed.

Fig.24

28

AUTO mode operation procedure

According to room temp, microcomputer can automatically set COOL.HEAT.DRY operation mode,

so as far best effect.

At AUTO mode operation, standard TEMP is 26℃ for COOL mode, 24℃ for DRY mode and 20℃

for HEAT mode.

Fig.25

29

FAN mode operation procedure

Connect the unit to power supply.

Press the “ON/OFF” key.

Press the mode key to select the “FAN” mode. The unit shall operate under “FAN” mode.

Press the “FAN” key to select from high, medium and low speed.

Fig.26

30

TIMER operation procedure

Fig.27

31

SLEEP mode operation procedure

When the unit is cooling or drying, if SLEEP operation is set, TEMP. would increase 1℃ in 1 hour

and 2℃ in 2 hours. Indoor fan motor runs at low speed.

When the unit is heating, if SLEEP operation is set, TEMP would decrease 1℃ in 1 hour and 2℃

in 2 hours. Indoor fan motor runs at low speed.

Fig.28

32

How to insert batteries

Fig.29

33

8. Part Names and Their Functions

CAUTION:

Wrong wiring connection will cause electrical malfunction.

Do not pull the wire when fixing it with wire

Notes:

1. If the supply cord is damaged, it must be replaced by the manufacturer or its service agent or a

similarly qualified person in order to avoid a hazard.

2. The appliance will be installed in accordance with national wiring regulations.

States of the Indicating Lamps:

1. Indicating Lamp of “POWER”: The

indicating lamp will shine when power on,

while it will go out when power off.

2. Indicating Lamp of “COOL” :

3. The indicating lamp will shine when

“COOL” is activated, while it will go out

when “COOL” is deactivated.

4. Indicating Lamp of “HEAT”: The indicating

lamp will shine when “HEAT” is activated,

while it will go out when “HEAT” is

deactivated.

5. Indicating Lamp of “TIMER”:

6. The indicating lamp will shine when

“TIMER” is activated, while it will go out

when “TIMER” is deactivated or the set

①

②

③

④

Communication cable

Remote controller

Refrigerant tube

Drain pipe

Fig.30

34

Fig.31

Fig.32

9. Maintenance

Before inspection and maintenance of the unit, please shut down the unit and set the power switch

to “OFF” to cut off the power supply.

Cleaning the Air Filter

Remove the air filter; clean it by a vacuum cleaner or if is very dirty, wash it with soap water and then

wipe off until it is completely dry before reinstallation.

Suggestion

If the air filter is dry, it will cause the reduction of

airflow, and the unit will be easily overloaded and

consumes 6% more energy. So regular cleaning

is necessary.

Cleaning the Unit

Clean the air conditioner and the remote controller

with dry cloth or a vacuum cleaner. If damp cloth is

used, remove moisture by using dry cloth afterward.

CAUTION

1. Do not use benzene gasoline, thinners or

2. polishing products for cleaning.

3. Do not wash with hot water (above 40 ), ℃

4. Otherwise some parts of the unit may be deformed.

Before the Seasonal Use

1. Ensure that nothing blocks the air inlet and outlet of the indoor and outdoor unit.

2. Running the unit without air filters can cause malfunctions due to dirt or dust. Thus, the air filter

should be installed at all times.

3. Ensure that drainage hose is not bent or clogged.

4. Check if the unit is properly installed.

After the Seasonal Use

1. Switch off the main switch of the power supply

2. Clean the air filters and other parts (by professionals)

3. Leave the fan running along for another 2-3 hours to dry the inside of the unit.

CAUTION:

Wrong wiring connection will cause electrical malfunction.

Do not pull the wire when fixing it with wire

Fig31

35

Fig.33

10. Operating Guide

The cleaning and replacement of the filter is only permitted to be done by the professionals. Before

open the grille to clean the filter, please cut off the power supply and wait unit the fan motor stops.

1. The temperature should not be set lower than what you need, otherwise it would result in increased

energy cost.

2. To distribute cool air throughout the room, adjust the air flow direction as shown by the arrows (see

the picture).

3. Clean the air filter every week for higher efficiency.

4. Close the window and door while operating the unit to prevent leakage of cooled air to save energy.

5. Draw close the curtains or close glass windows when cooling to prevent heat load from sun light

which may cause more electricity cost.

6. In case of ineffective ventilation, open the window to ventilate the room air once in a while but not

too long since cooled air will be uselessly drained out.

Fig34

Fig35

36

11. Precautions

1. Turn off the air conditioner if it is not needed, as electricity interference may occurs while it is

running .If the unit is not to be used for a long time, cut off the power supply main switch.

Fig.36

2. Do not insert objects into the air inlet or outlet when the air conditioner is running as it may cause

damage or personal injury .Also pay special attention when children are around.

3. Do not locate any obstacle against the air flow direction of indoor and outdoor unit .Inefficient

performance or malfunction may result.

Fig.37

4. Do not channel the air flow directly at people, especially infants, aged persons, or patients.

5. Do not locate a heater or any other heat source close to the unit. The heat may deform plastic parts.

Fig.38

37

12. Checking Before Contact the Service Man

Check the followings before contact the service man. You may find the solution to your problems.

After checking, if it still does not operate, please contact your local dealer.

Table.3

Problem Solution(s)

The unit does not run

z check if the power supply is in order

z check if the timer switch is on or not

The air conditioner runs but does not cool

enough

z check if the preset temperature is too high

z check if the sunlight shines directly into

the room

z check if the door and window are opened

z check if there is anything blocking the air

discharge

z check if the exhaust fan still operates

z check if the air filter is dirty or clogged

Vapor or mist fume comes out from the

unit when it runs

z check if the hot air in the room is mixed

with cool air, which may cause smog.

The remote controller works abnormally

z check if the batteries are inserted in correct

directions

z check if the batteries are exhausted

12.1 Accessories List for Installation

Table.4

Accessories List for Installation (Outdoor Unit)

Numbe

r

Name Shape Quantity Type Remark

1

Drainage Hole

Cap

for Outdoor

Unit

1(3)

1 for 09K\12K

3for18\24\30\36\42\48\

60K

2

Drainage Joint

for Outdoor

Unit

1

Only for heat pump

units

Notes: See the packing list to check the delivered accessories.

The accessory with * indicates it is not included but should be prepared by the clients themselves.

38

Table.5

Accessories List for Installation (Indoor Unit)

Number Name Shape Quantity Type Remark

1

Nut (with

gasket)

8 M10

2 Tie Line

4 200mm

3

Installation

Paperboard

1

used for

ceiling

drilling

4

Thermal

Insulation Layer

of Discharge

Pipe

1

5

Thermal

Insulation Layer

of Inlet Liquid

Pipe

1

6 Sealing Plaster*

2

7

Remote

Controller

1

8 Battery

2

9 Power Cord *

1

(H05VV-F

)3×1.5mm

2

10

Communication

Cable*

1 AWG#24

11 Drain Hose*

1 Φ17×1.75

12 Pipe Clamp*

1

13 Operation

1

Notes: See the packing list to check the delivered accessories.

The accessory with * indicates it is not included but should be prepared by the clients

themselves.

39

Fig.39

12.2 Installation of the Indoor Unit

When install the indoor unit, you can use a paper pattern for reference and make sure that the

drainage side be 10mm lower than the other side in order to drain the condensation water fluently.

Table.6

Model A B C D E

1220 225 1158 700 280

1420

245

1354

700

280

1700

245

1634

700

280

V1KI-09

V1KI-12

V1KI-18

V1KI-24

V1KI-30

V1KI-36

V1KI-45

V1KI-50

V1KI-60

40

Fig.40

Cautions for Installation Where Air Conditioner Trouble is Likely to Occur

1. Where there is too much of oil.

2. Where it is acid base area.

3. Where there is irregular electrical supply.

Selection of Installation Location

1. Such a place where cool air can be distributed throughout the room.

2. Such a place where condensation water is easily drained out.

3. Such a place that can handle the weight of indoor unit.

4. Such a place which has easy access for maintenance.

5. Such a place where is easy to connect the outdoor unit.

6. Such a place which is 1m or more away from other electric appliances such as television, audio

device, etc.

7. Avoid a location where there is heat source, high humidity or inflammable gas.

8. Do not use the unit in the immediate surroundings of a laundry, a bath, a shower or a swimming

pool.

9. Ensure that the installation conforms to the installation dimension diagram.

10. A space around the unit is adequate for ventilation (See Fig.41)

Fig.41

Insulation

Paper plank

41

There are two types of installation:

Ceiling T ype and Floor Type

Each type is similar to the other as follows:

Determine the mounting position on ceiling or wall by using the paper pattern to indicate the

indoor frame. Mark the pattern and pull out the paper pattern. Remove the return grill, the side panel

and the hanger bracket from the indoor unit as per procedures below.

1. Press the fixing knob of the return grilles and Loosen fixing bolts (M4.2). It will be opened widely,

and then pull it out from the indoor unit.(See Fig.41)

2. Remove the side panel fixing screws and remove it away by pulling it out at the front direction

(arrow direction). (See Fig.42)

3. Loosen two hanger bracket setting bolts (M10) on earth side for less than 10mm. Remove two

hanger bracket fixing bolts (M6) on the rear side. Detach the hanger bracket by pulling it backward

(See Fig.44)

Fig.42

Set the suspension bolt. (Use M10 size suspension bolts)

Adjust the distance between the unit and the ceiling slab beforehand (See Fig.43). Fix the hanger

bracket to the suspension bolt.

WARNING!

1. Make sure that extended suspension bolt from the ceiling stays inside the arrowed position.

Readjust the hanger bracket when it is outside the arrowed position. (See Fig.45)

2. Suspension bolt stays inside the cap of the indoor unit .Never remove the cap. Lift the unit and

slide the hanger bracket in the way that the holes on it will match with the corresponding bolts.

(See Fig.46)

3. Screw tightly both hanger brackets setting bolts (M10.) (See Fig.44)

4. Screw tightly both hanger bracket fixing bolts (M6) to prevent the movement of the indoor unit.

(See Fig.44)

Adjust the height of the unit to incline slightly the rear side of the drain pipe so as to optimize the

drainage.

CAUTION!

Adjust the height by turning the unit with a spanner. Insert the spanner from the hanger bracket

opening. (See Fig.48)

Side panel fixing screw (M4.2)

42

Hanging and Mounting

It is possible to carry out the installation by using inward facing hanger brackets without moving

the brackets from the indoor unit. (See Fig.47)

Be sure to use only the specified accessories and parts for installation.

35mm or less

Hanger bracket

Suspension bol

Fig.43 Fig.46

Fig.44 Fig.47

Fig.45 Fig.48

12.3 Installation of the Outdoor Unit

12.3.1 Installation Location of the Outdoor Unit

1. The foundation must be solid enough to bear the weight and vibration of the unit.

2. The space around the unit is adequate for ventilation.

3. The location is not close to any inflammable gases.

4. The location is sufficiently isolated so that the running noise and the hot exhaust air do not disturb

the users or their neighbors.

5. There is an easy access to check and maintenance.

6. Ensure the spaces indicated by arrows to the wall, ceiling, fence, or other obstacles.

43

Fig.49

CAUTION

Installation in the following places may cause problems

If it is unavoidable to select such places, consult with your distributor or dealer.

1. A place with machine oil

2. A saline place such as a place very close to seashore

3. A place with corrosive gas

4. A place where high-frequency waves are generated by the radio equipment, welder or medical

equipment.

12.3.2 Electric Wiring Connection

Fig.50 Fig.51

CAUTION!

1. Wrong wiring may cause fire or

electric shock.

2. Do not pull the wire when fixing it

3. With wire clamps and clasps.

4. Do not let the wire too loose

5. All the electrical work must be

done by qualified personnel

according to the local rules and this

instruction

6. The rated voltage and the exclusive

Fig.52

U1RS-09

U1RS-12

U1RS-18 U1RS-24

U1RS-45

U1RS-48

U1RS-30

U1RS-36

U1RT-36

U1RT-45

U1RT-50

U1RT-60

44

circuit must be used.

7. Leakage circuit-breaker must be installed.

8. Please use the specified fuse.

9. If the power supply cord of the unit is damaged it must be replaced by the manufacturer or its

service agent or a similarly qualified person in order to avoid a hazard.

10. An all-pole disconnection air switches which have a contact separation of at least 3mm in all poles

is needed

12.3.3 Profile Dimensions of the Outdoor Unit

Fig.53

Table.7

Item

A B C D E

776

320

540

510

286

955 396 700 560 360

980 427 790 610 395

1107

440

1100

631

400

1085

427

1365

620

395

12.3.4 Unit Installation Instructions

Precautions on Installation of the Outdoor Unit

To ensure the unit in proper function, the installation location must be selected in accordance with

following principles:

1. Outdoor unit should be installed in the way that the air discharged by out door unit will not return

and that sufficient space for repair will be provided around the machine.

2. The installation site must have good ventilation, so that the outdoor unit can take in and exhaust

Model

U1RS-09

U1RS-12

U1RS-18

U1RS-24

U1RS-45

U1RS-48

U1RS-30

U1RS-36

U1RT-36

U1RT-45

U1RT-50

U1RT-60

45

enough air. Ensure that there is no obstacle to the air intake and exhaust of the outdoor unit. If

there is any obstacle blocking the air intake or exhaust, remove it.

3. Place of installation should be strong enough to support the weight of outdoor unit, and it should

be able to insulate noise and prevent vibration. Ensure that the wind and noise from the unit will

not affect your neighbors.

4. Avoid direct sunshine over the unit. It is better to set up a sun shield as a protection.

5. Place of installation must be able to drain the rainwater and defrosting water.

6. Place of installation must ensure the machine will not be buried under snow or subject to the

influence of rubbish or oil fog.

7. The installation site must be at a place where the air exhaust outlet does not face strong wind.

12.4 Schematic Diagram of Unit Line Connection

Electric wiring connection

The section area of cables selected by users must not be smaller than the specifications shown in

the following diagram. The signal wire between indoor and outdoor unit will be installed in the shielded

bushing.

Fig.54

1.Power cord 3×2.5 mm2(H07RN-F) 2.Power cord 3×1.0 mm2(H05VV-F)

3.Communication Cords

1.Power cord 3×4 mm2(H07RN-F) 2.Power cord 3×1.0 mm2(H05VV-F)

3.Communication Cords

1.Power cord 3×4 mm2(H07RN-F) 2.Power cord 3×1.5 mm2(H05VV-F)

3.Communication Cords

1.Power cord 3×6 mm2(H07RN-F) 2.Power cord 3×1.5 mm2(H05VV-F)

3.Communication Cords

U1RS-09

U1RS-12

U1RS-18

U1RS-24

U1RS-45

U1RS-48

U1RS-30

U1RS-36

+

+

+

+

+

+

+

+

V1KI-09

V1KI-12

V1KI-18

V1KI-24

V1KI-30

V1KI-36

V1KI-45

V1KI-50

U1RS-09

+

V1KI-09

U1RS-12

+

V1KI-12

U1RS-18

+

V1KI-18

U1RS-24

+

V1KI-24

U1RS-45

U1RS-30

+

+

V1KI-30

V1KI-45

U1RS-36

+

V1KI-36

U1RS-48

+

V1KI-50

46

Fig.55

1.Power cord 5×4 mm2(H07RN-F) 2.Power cord 3×1.5 mm2(H05VV-F)

3.Communication Cords

The following table recommended by the model selection manual is about how to select the air

switch and power cable.

Warning! :

The section area of cables selected by users must not be smaller than the specifications shown in

the table below

Table.8

Model Power Supply

Capability of Air

Switch(A)

(Outdoor/Indoor)

Minimum Sectional Area

Of Earth Wire (mm2)

(Outdoor/Indoor)

16/6 2.5/1.0

16/6 2.5/1.0

20/6 4/1.0

20/10 4/1.5

32/10 6.0/1.5

32/10 6.0/1.5

32/10 6.0/1.5

220-240V~

50HZ

32/10 6.0/1.5

380-415V 3N~

50Hz

20/10 4/1.5

Note: The parameters of the power cord listed above are only applicable to the BV single-core power

cord which is laid within the plastic bushing and used at 40℃, and those of the air switch are applicable

to the one which also is used at 40℃. If the actual installation conditions changes, please refer to the

instructions of the power cord and the air switch.

U1RT-36

U1RT-45

U1RT-50

U1RT-60

+

+

+

+

V1KI-60

V1KI-36

V1KI-45

V1KI-50

U1RT-36

+

V1KI-36

U1RT-50

+

V1KI-50

U1RT-45

+

V1KI-45

U1RT-60

+

V1KI-60

U1RS-09

U1RS-12

U1RS-18

U1RS-24

U1RS-45

U1RS-48

U1RS-30

U1RS-36

20/10 4/1.5

20/10 4/1.5

20/10 4/1.5

U1RT-36

U1RT-45

U1RT-50

U1RT-60

47

Rated Parameters and Outline Dimensions of the Fuse

Table.9

Unit Code

Rated

parameter

Dimensions

46010408/

46010029

250V/15A

250V/3.15A

46010014/

46010023

250V/3.15A、

250V/30A

46010014/

46010023

250V/3.15A、

250V/30A

46010014/

46010023

250V/3.15A、

250V/30A

46010014/

46010023

250V/3.15A、

250V/30A

46010014/

46010023

250V/3.15A、

250V/30A

46010013 250V/5A

All the indoor units 46010013 250V/5A

U1RS-09

U1RS-12

U1RS-18

U1RS-24

U1RS-45

U1RS-48

U1RS-30

U1RS-36

46010014 250V/3.15A

U1RT-36

U1RT-45

U1RT-50

U1RT-60

46010014 250V/3.15A

46010014 250V/3.15A

46010013 250V/5A

48

12.5 Connecting Pipe Preparation

12.51 Pipe Preparation

Pipe & Electrical Wire Cutting

1. Use cutting tools easily found in the market.

2. Measure precisely both outer & inter pipes.

3. The length of the pipe should be a little longer

than the actual measured value.

4. The wire should be 1.5m longer than the

refrigerant tube

Reaming

1. Clean the inside of the inner refrigerant tube.

2. While reaming, the tube end must be on the top of

the reamer to prevent any dust going back into the

tube.

Flaring the Pipe End

Flare both ends of the pipe with flaring kits by

fitting the flare nut on the pipe before flaring. Set the die

on the pipe in the way that the pipe end is 0.5mm above

the top of the die. Then, check if the pipe end is even and

perfectly round or not.

Wire Connecting and Taping

(See the figure on right)

Fig.56

Fig.57

Fig.58

Fig.59

49

12.5.2 Refrigerant Piping work

The refrigerant is R410A for" " series outdoor units,

GWP=2020 ODP=0

The standard pipe length is 5m. When the length (L) of the connecting pipe is less than or equals

7m, there is no need to add refrigerant. If the connecting pipe is longer than 5m, it is required to add

refrigerant. In the below table, the amounts of refrigerant to be added for different models are listed for

each additional meter of pipe length.

Select copper pipes for gas and liquid as informed in specific table (see the pipe table below).For

dust and moisture protection, before assembly of the pipe and its insulation, both ends of the pipe must

be covered.

Table.10

Size of Fitting Pipe

(Inch)

Item

Model

Gas

Pipe

Liquid

Pipe

Max Pipe

Length

(m)

Max Height

Difference

between

Indoor Unit

and Outdoor

Unit(m)

Amount of

Additional

Refrigerant

to Be

Filled For

Extra(Length

of Pipe)

Drainage

Pipe

(Diameter

× Wall

Thickness

)

15 30

15 30

15 30

15 60

15 60

15 60

30 60

30 60

30 60

Φ17×1.75

Avoid pipe bending as mush as possible, if it is necessary, the bending radius must be more than 3

or 4 cm.

Connection between an Indoor unit and an Outdoor Unit

1. Unscrew the flare nut for releasing pressure gas in the indoor unit. If there is no high pressure gas

blowing out, it is the signal of leakage for the indoor unit.

2. Fit the flare nut to the liquid pipe. Flare the pipe’s end with flare tools.

Tighten both flare nuts into gas pipe and liquid pipe at the indoor unit with two spanners.

Liquid pipe

Fig.60

3/8 1/4 20

V1KI-09

V1KI-12

V1KI-18

V1KI-24

V1KI-30

V1KI-36

V1KI-45

V1KI-50

V1KI-60

3/8 1/4 20

1/2 1/4 20

5/8 3/8 30

5/8 3/8 30

5/8 3/8 30

5/8 3/8 50

5/8 3/8 50

3/4 3/8 50

U1RT-**

50

12.5.3 Air Purging

The purpose of the air purging is to get rid of moisture and air in the system, otherwise moisture

and air may cause ineffectiveness of the compressor which directly affects the cooling capacity.

Purging by Using Vacuum

After tightening the flared nuts between the indoor and the outdoor

units

1. Remove the blank cap of a three-way valve by using

a torque wrench, and then check if both high pressure

and low pressure valves are in closed condition or not.

2. Remove the nut at the service port.

3. Connect a gauge into the service port and a vacuum pump.

Remove the gauge and tighten up the nut at the service port.

4. Use a hexagonal wrench to open both high pressure and low pressure valves to the end (counter

clockwise).

5. Tighten the blank cap of the three-way valve.

Gap Leakage Check

1. Check if it leaks or not by applying soapsuds on every

joint and then inspect carefully. After the check, wipe

them off completely.

2. Cover the indoor unit joint with pipe insulation and

four plastic bands to prevent condensing at joints.

Fig.61

Fig.62

51

12.5.4 Liquid Pipe and Drain Pipe

If the outdoor unit is installed lower than the indoor unit

(See Fig.63)

1. A drain pipe should be above ground and the end of the

pipe does not dip into water. All pipes must be restrained

to the wall by saddles.

2. Taping pipes must be done from bottom to top.

3. All pipes are bound together by tape and restrained to

wall by saddles.

If the outdoor unit is installed higher than the indoor unit (See Fig. 64)

1. Taping should be done from lower to the upper part.

2. All pipes are bound and taped together and also should

be trapped to prevent water from returning to the room

(See Fig.64).

3. Restraint all pipes to the wall with saddles.

Fig.63

Fig.64

52

12.5.5 Drain Pipe

CAUTION:

make sure the drain flows out.

Drain pipe

1. The drain pipe outlet direction can be chosen from either the right rear or right.

2. The diameter of the drain pipe should be equal to or greater than the diameter of the connecting

pipe. (Vinyl tube: pipe size:20 mm, outer dimension: 26mm)

3. Keep the drain pipe as short as possible and incline downwards at a gradient of at least 1/100 to

prevent air pockets (See Fig.65)

4. Use the drain hose ④ and clamp ⑤. Insert the drain hose completely into the drain socket, and

tighten the clamp within the range of the gray tape unit the screw head is less than 4mm above the

hose (See Fig.66, 67)

5. Insulate the clamp and drain hose by wrapping the sealing pad over them.

6. No folding of the drain hose is allowed in the indoor unit. (See Fig.68)

Confirm that smooth drainage is achieved after the pipe working.

Inject 600cc water into the drain pan from the air outlet to see if the drainage goes well or not. (See

Fig.69)

Fig.65

Fig.68

Fig.67

Fig.66

Fig.69

53

12.5.6 Routine Checks after Installation

Check after installation

Table.11

Items to be checked Possible Malfunction(s) Items to be checked

Has it been fixed firmly?

The unit may drop, shake or emit

noise.

Has it been fixed firmly?

Have you done the

refrigerant leakage test?

It may cause insufficient

refrigerating capacity.

Have you done the

refrigerant leakage test?

Is the heat insulation

sufficient?

It may cause condensation and

dripping.

Is the heat insulation

sufficient?

Does the unit drain well?

It may cause condensation and

dipping.

Does the unit drain well?

Is the voltage in accordance

with the rated voltage

marked on the nameplate?

It may cause electric malfunction

or damage the part.

Is the voltage in accordance

with the rated voltage

marked on the nameplate?

Is the electric wiring and

piping connection installed

correctly and securely?

It may cause electric malfunction

or damage the part

Is the electric wiring and

piping connection installed

correctly and securely?

Has the unit been connected

to a secure earth

connection?

It may cause electric leakage.

Has the unit been connected

to a secure earth connection?

Is the power cord specified?

It may cause electric malfunction

or damage the part.

Is the power cord specified?

Have the inlet and outlet

been covered?

It may cause insufficient

refrigerating capacity.

Have the inlet and outlet

been covered?

Has the length of the

connection pipes and the

refrigerant charge been

recorded?

The refrigerating capacity may

be not accurate.

Has the length of the

connection pipes and the

refrigerant charge been

recorded?

WARNING! :

1. This appliance is not intended for use by persons (including children) with reduced physical

sensory or capabilities, or lack of experience and knowledge, unless they have been given

supervision or instruction concerning the use the appliance by a person responsible for their safety.

2. Children should be supervised to ensure that they do not play with this appliance.

54

12.5.7 Test Running

Evaluation of the Performance

1. Check the voltage of the main electrical wire.

2. Use a thermometer to measure both inlet and outlet cool air.

3. The difference between inlet air and outlet air

temperature should not be less than 8℃

4. The unit has the function of auto-restart and it

can remember the running mode before power

failure

5. Be sure to use the exclusive accessories listed

above in the installation instructions, or it may

result in water leakage, electric shock, fire, etc.

Fig.70

55

13. Appendix

Air Conditioner Normal Working Conditions and Working Rang:

Notes:

1. The design of this unit conforms to the requirements of EN14511 standard.

2. The air volume is measured at the 0Pa external static pressure.

3. Cooling (heating) capacity stated above is measured under nominal working conditions

corresponding to 0Pa external static pressure. The parameters are subject to change with the

improvement of products, in which case the values on the nameplate will prevail.

This product must not be disposed together with the

domestic waste but disposed at the authorized place for

the recycling of electric and electronic appliances.

Indoor Side Outdoor Side

Test Condition

DB(℃) WB(℃) DB(℃) WB(℃)

Nominal Cooling 27 19 35 24

Nominal Heating 20 — 7 6

Rated Cooling 32 23 43 26

Low Temp.

Cooling

21 15 18 —

Rated Heating 27 - 24 18

Low Temp.

Heating

20 — -7 -8

66129907237

Loading...

Loading...