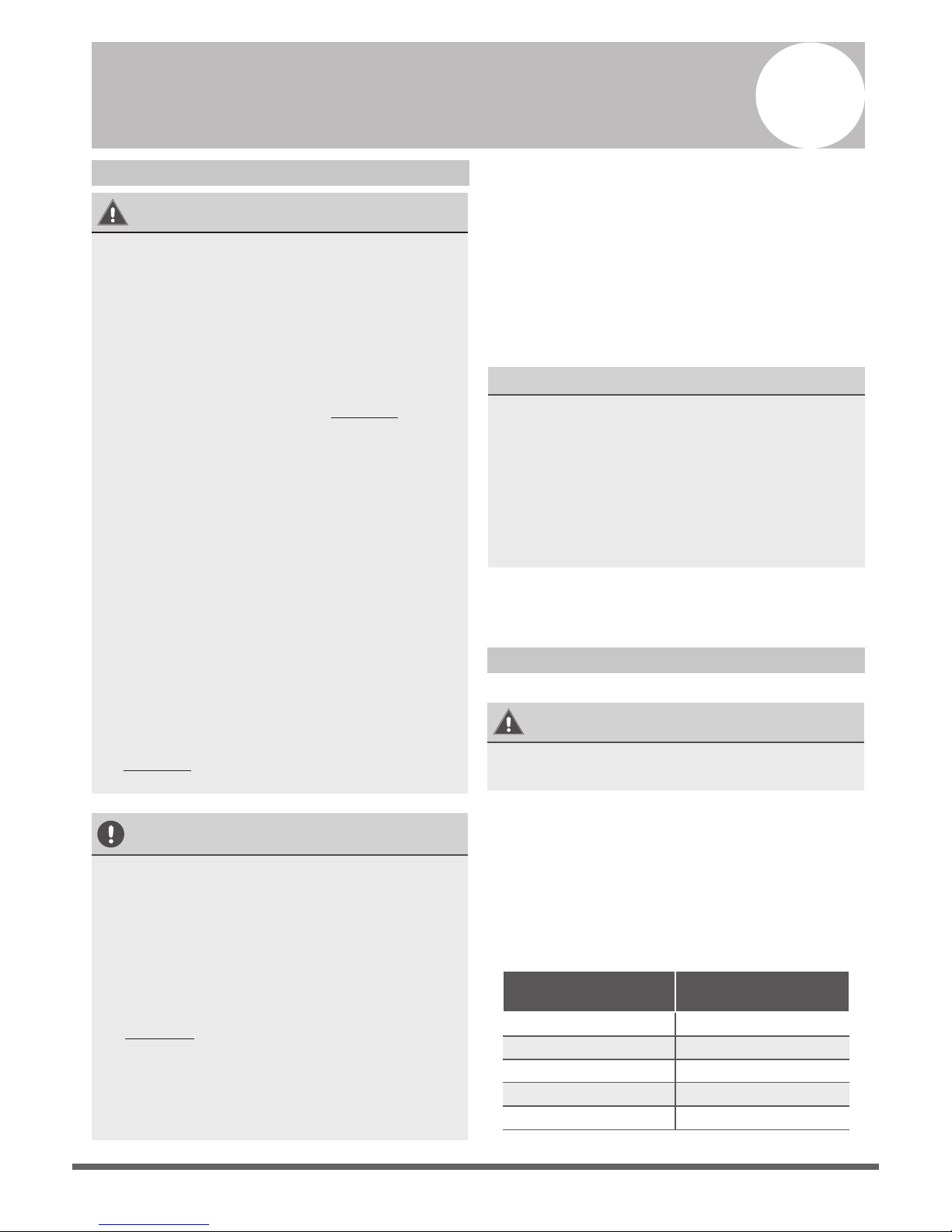

• INSTALLATION MANUAL

• ΕΓΧΕΙΡΙΔΙΟ ΕΓΚΑΤΑΣΤΑΣΗΣ

• MANUAL DE INSTALARE

DUCT TYPE

AIR CONDITIONING SYSTEMS

ENGLISH | ΕΛΛΗΝΙΚΑ | ROMANA

MODELS:

V4MDI-12B

U4MRS-12B

Page 2

Table of Contents

Installation Manual

Accessories .................................................... 04

a. Indoor Unit Parts ........................................ 08

b. Indoor Unit Installation Instructions ....... 09

Safety Precautions ..................................... 05

Outdoor Unit Installation ......................... 12

a. Outdoor Unit Installation Instructions ...... 13

b. Outdoor Unit Types and Specifications .... 14

c. Notes on Drilling Hole in Wall .................... 14

Drain pipe Installation ............................... 15

Indoor Unit Installation

........................... 07

Installation Overview ............................... 07

1

2

5

3

4

6

Page 3

Page 3

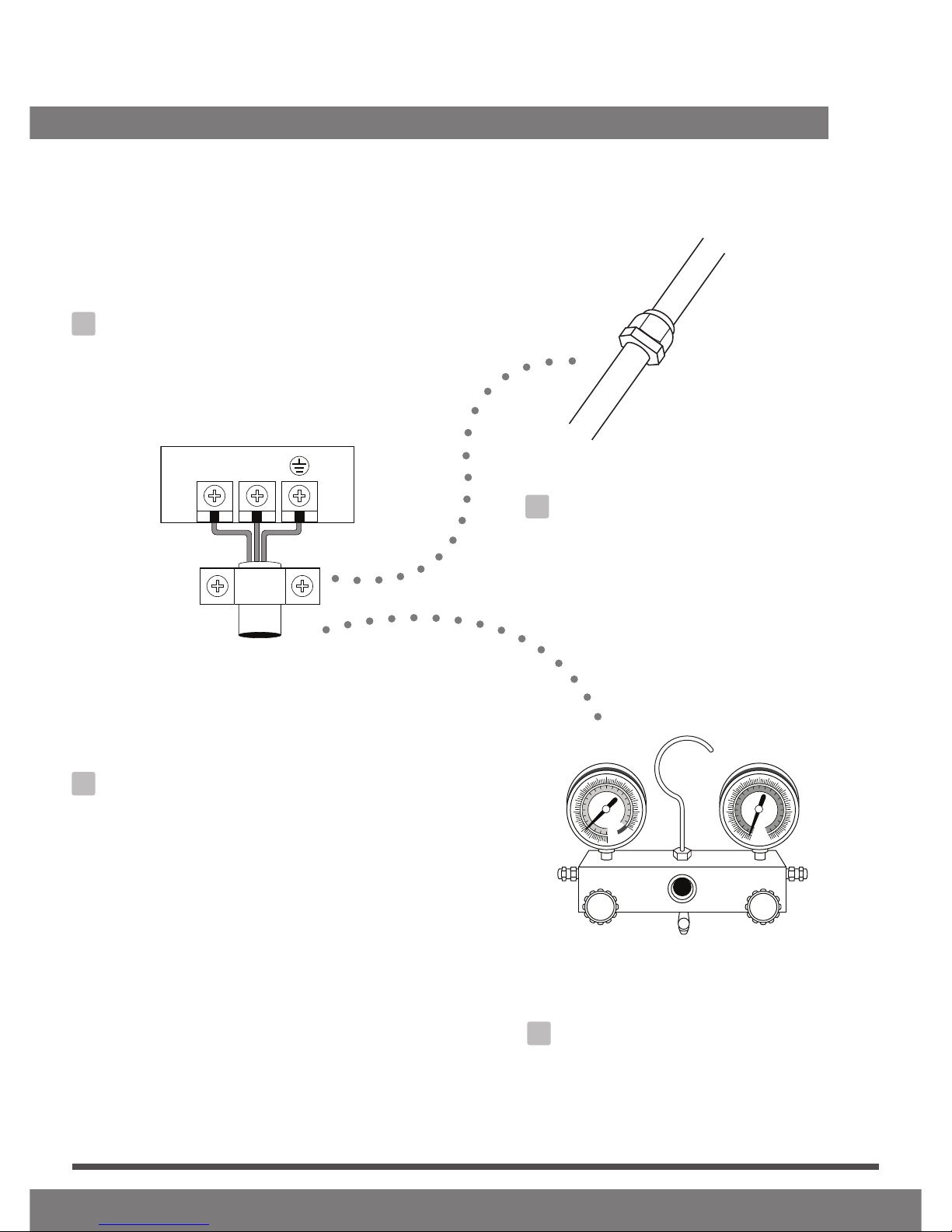

Refrigerant Piping Connection 81.......................

A. Notes on Pipe Length and Elevation .............. 18

B. Refrigerant Piping Connection Instructions ...20

Wiring ................................................. 20

a. Outdoor Uni W iring .................. 22

b. Indoor Uni W iring ..................... 23

c. Power Specificatio ................... 25

Air Evacuation 72..................................................

a. Evacuation Instructio ................................ 27

b. Note on Adding Refrigera ....................... 28

Test Run ............................................. 29

MC MC

7

8

9

10

L N

Page 4

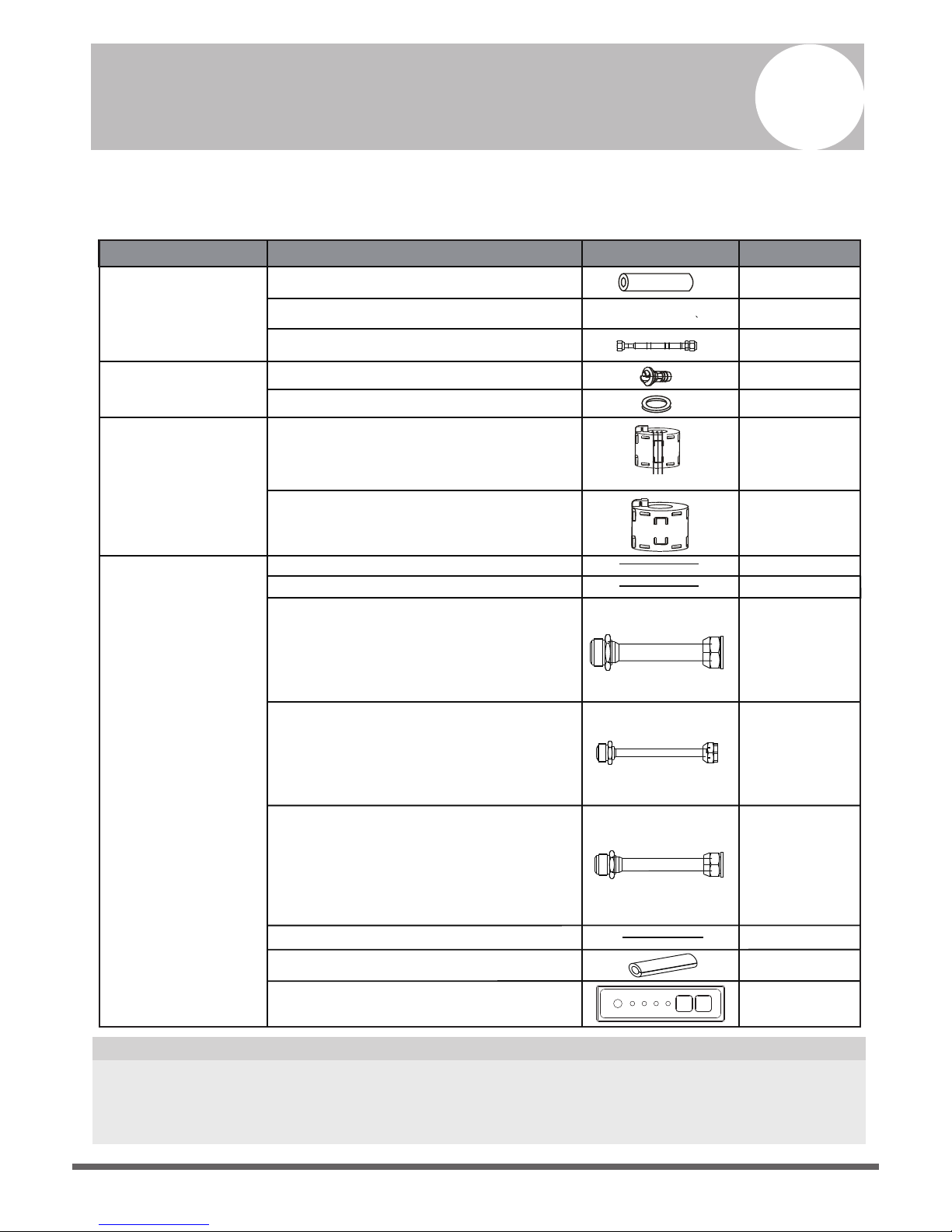

Accessories

1

The air conditioning system comes with the following accessories. Use all of the installation parts

and accessories to install the air conditioner. Improper installation may result in water leakage,

electrical shock and fire, or equipment failure.

There are two types of remote controls: wired and wireless.

Select a remote controller based on customer preferences and requirements and install in an

appropriate place.

Refer to catalogues and technical literature for guidance on selecting a suitable remote controller.

•

Connecting wire for display (2m)

Cord protection rubber ring

QUANTITY

SHAPENAME

Soundproof / insulation sheath

2

1

1

1

Tubing & Fittings

Others

Installation manual

Transfer connector(Φ12.7-Φ15.9)/

Φ0.5in-Φ0.63in

( )(Packed with the indoor unit )

NOTE: Pipe size may dier from appliance to

appliance. To meet dierent pipe size requirements,

sometimes the pipe connections need a transfer

connector installed on the outdoor unit .

Transfer connector(Φ6.35-Φ9.52)/

Φ0.25in-Φ0.375in

( )(Packed with the indoor unit)

NOTE: Pipe size may dier from appliance to

appliance. To meet dierent pipe size requirements,

sometimes the pipe connections need a transfer

connector installed on the outdoor unit .

Transfer connector(Φ9.52-Φ12.7)/

Φ0.375in-Φ0.5in

( ) (Packed with the indoor unit,

used for multi-type models only )

NOTE: Pipe size may dier from appliance to

appliance. To meet dierent pipe size requirements,

sometimes the pipe connections need a transfer

connector installed on the outdoor unit .

1

Owner‘s manual

Drain joint (some models)

Seal ring (some models)

Drainpipe Fittings

(for cooling & heating)

Seal sponge (some models)

EMC Magnetic Ring

(some models)

Magnetic ring

(wrap the electric wires S1 & S2 ( P & Q & E )

around the magnetic ring twice)

Magnetic ring

(Hitch on the connective cable between the indoor

unit and outdoor unit after installation.)

1

1

Orice (some models)

1

1

(on some models)

1

(on some models)

1

(on some models)

1(on some models)

1(on some models)

1

S1&S2(P&Q&E)

Display panel

*Just for testing purposes only

1(on some modelsKJR-120G,KJR-120H)

Page 5

Safety Precautions

2

Read Safety Precautions Before Installation

Incorrect installation due to ignoring instructions can cause serious damage or injury.

The seriousness of potential damage or injuries is classified as either a WARNING or CAUTION.

Failure to observe a warning may result in death. The appliance must be installed in

accordance with national regulations.

Failure to observe a caution may result in injury or equipment damage.

WARNING

CAUTION

WARNING

• Carefully read the Safety Precautions before installation.

• In certain functional environments, such as kitchens, server rooms, etc., the use of specially

designed air-conditioning units is highly recommended.

• Only trained and certified technicians should install, repair and service this air

conditioning unit.

Improper installation may result in electrical shock, short circuit, leaks, fire or other damage to

the equipment and personal property.

• Strictly follow the installation instructions set forth in this manual.

Improper installation may result in electrical shock, short circuit, leaks, fire or other damage to

the equipment.

• Before you install the unit, consider strong winds, typhoons and earthquakes that might aect

your unit and locate it accordingly. Failure to do so could cause the equipment to fail.

• After installation, ensure there are no refrigerant leaks and that the unit is operating properly.

Refrigerant is both toxic and flammable and poses a serious health and safety risk.

Note about Fluorinated Gases

1.

This air-conditioning unit contains fluorinated gases. For specific information on the type of gas

and the amount, please refer to the relevant label on the unit itself.

2.

Installation, service, maintenance and repair of this unit must be performed by a certified

technician.

Product uninstallation and recycling must be performed by a certified technician.3.

If the system has a leak-detection system installed, it must be checked for leaks at least every 12

months.

5.

4.

When the unit is checked for leaks, proper record-keeping of all checks is strongly recommended.

Page 6

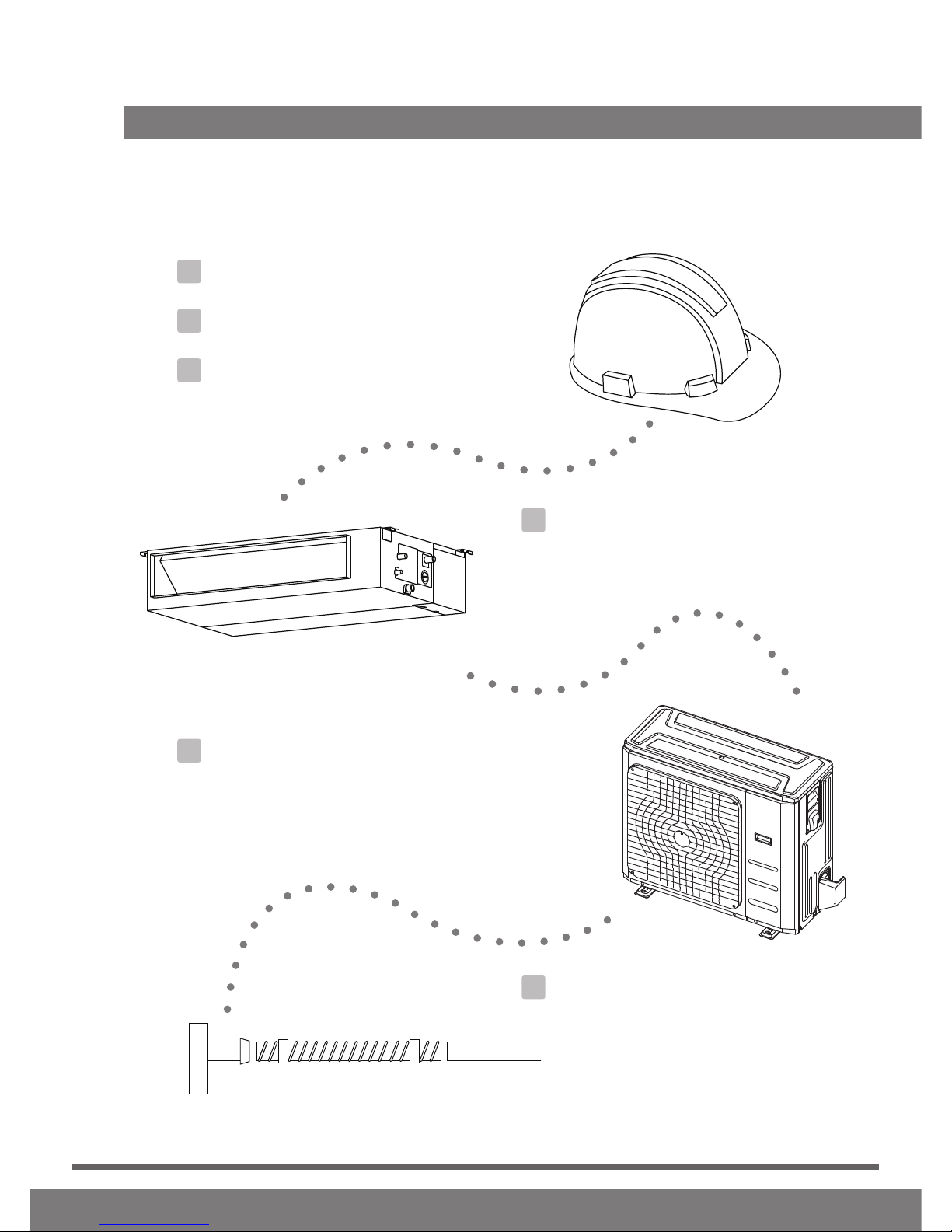

Installation Overview

3

LN

1

2

3

4

5

MC MC

6

7

Install the indoor unit

(Page 8)

INSTALLATION ORDER

Install the outdoor unit

(Page 13)

Install the drainpipe

(Page 15)

Evacuate the refrigeration system

(Page 28)

Connect the wires

(Page 23)

Connect the refrigerant pipes

(Page 18

Perform a test run

(Page 30)

Page 7

Indoor Unit Installation

4

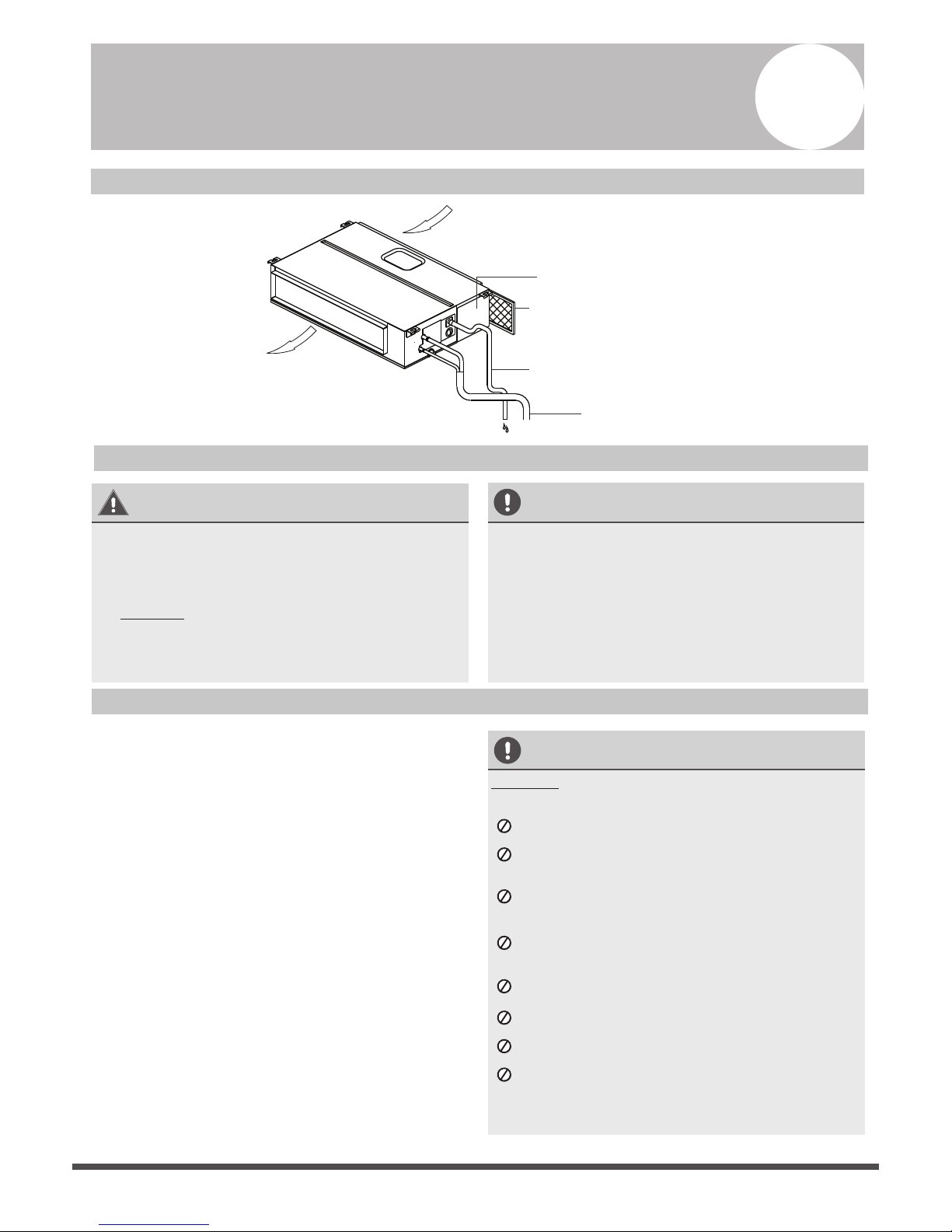

Indoor Unit Parts

Fig. 4.1

WARNING

• Securely install the indoor unit on a structure

that can sustain its weight. If the structure is

too weak, the unit may fall causing personal

injury, unit and property damage or death.

• DO NOT install the indoor unit in the

bathroom or laundry room as excessive

moisture can short the unit and corrode the

wiring.

CAUTION

• Install the indoor and outdoor units, cables

and wires at least 1m (3.2’) from televisions

or radios to prevent static or image

distortion. Depending on the appliances, a

1m (3.2’) distance may not be sufficient.

• If the indoor unit is installed on a metal

part of the building, it must be electrically

grounded.

Indoor Unit Installation Instructions

Step 1: Select installation location

The indoor unit should be installed in a location

that meets the following requirements:

o Enough room exists for installation and

maintenance.

o Enough room exists for the connecting pipe

and drainpipe.

o The ceiling is horizontal and its structure can

sustain the weight of the indoor unit.

o The air inlet and outlet are not impeded.

o The airflow can fill the entire room.

o There is no direct radiation from heaters.

CAUTION

DO NOT install the unit in the following

locations:

In areas with oil drilling or fracking

In coastal areas with high salt content in the

air

In areas with caustic gases in the air, such as

near hot springs

In areas with power fluctuations, such as

factories

In enclosed spaces, such as cabinets

In areas with strong electromagnetic waves

In areas that store flammable materials or gas

In rooms with high humidity, such as

bathrooms or laundry rooms

Air outlet

Air inlet

Air filter(on some models)

Drain hose

Electric control cabinet

Refrigerant connecting pipe

√

√

√

√

√

√

Safety Precautions

o

√

It is embeded installation.

Models with a cooling capacity of 9000Btu to

18000Btu only apply to one room.

o

√

Page 8

Air outlet

Air inlet

Step 2: Hang indoor unit.

1.

Maintenance space

Installation place

Left

side

Right

side

Strong and durable ceiling

Indoor unit

>4in(10cm) >11.8in(30cm)

>0.8in(2cm)

>0.8in(2cm)

>11.8in(30cm)

> 8.2in(250cm)

Floor

Service access Ceiling

(When no ceiling)

B

Fig. 4.2

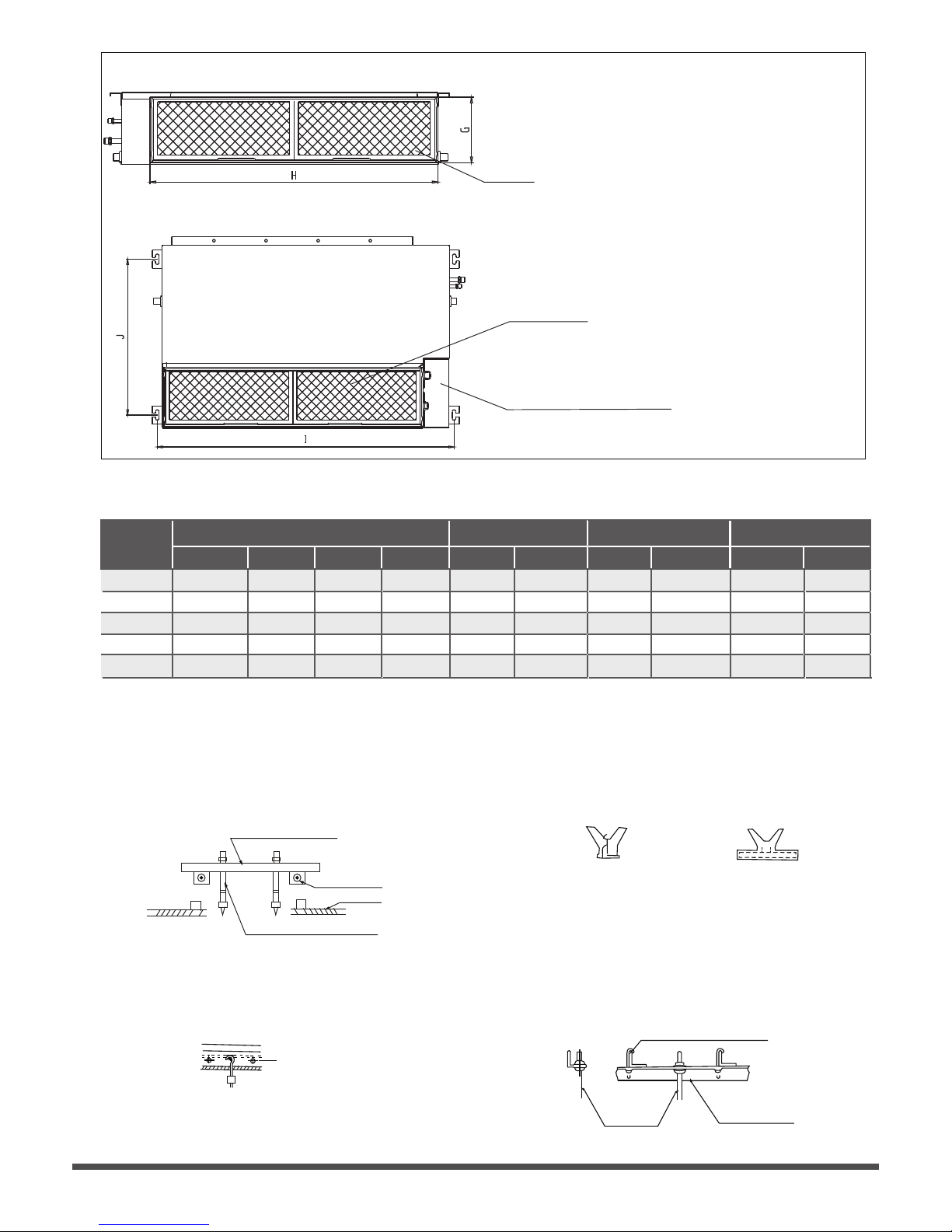

Please refer to the following diagrams to locate the four positioning screw bolt holes on the

ceiling. Be sure to mark the paces where you will drill ceiling hook holes.

Air outlet dimensions

>

7.9

in

(20cm)

11.8in

23.6inx23.6in (60cmx60cm)

checking orifice

> (30cm)

Page 9

Fig. 4.3

Air lter

Descending ventilation opening and mounted hook

Air lter

Electric control box

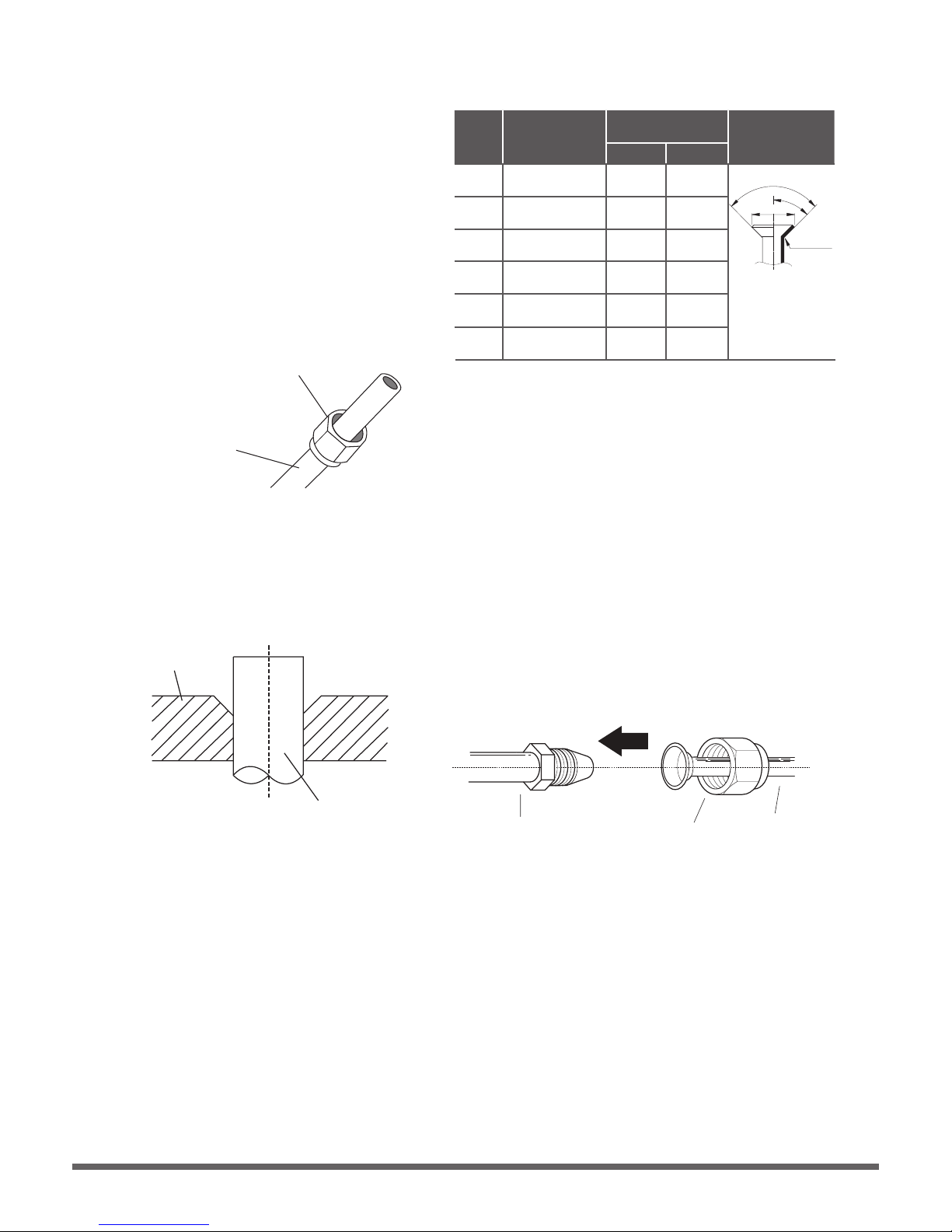

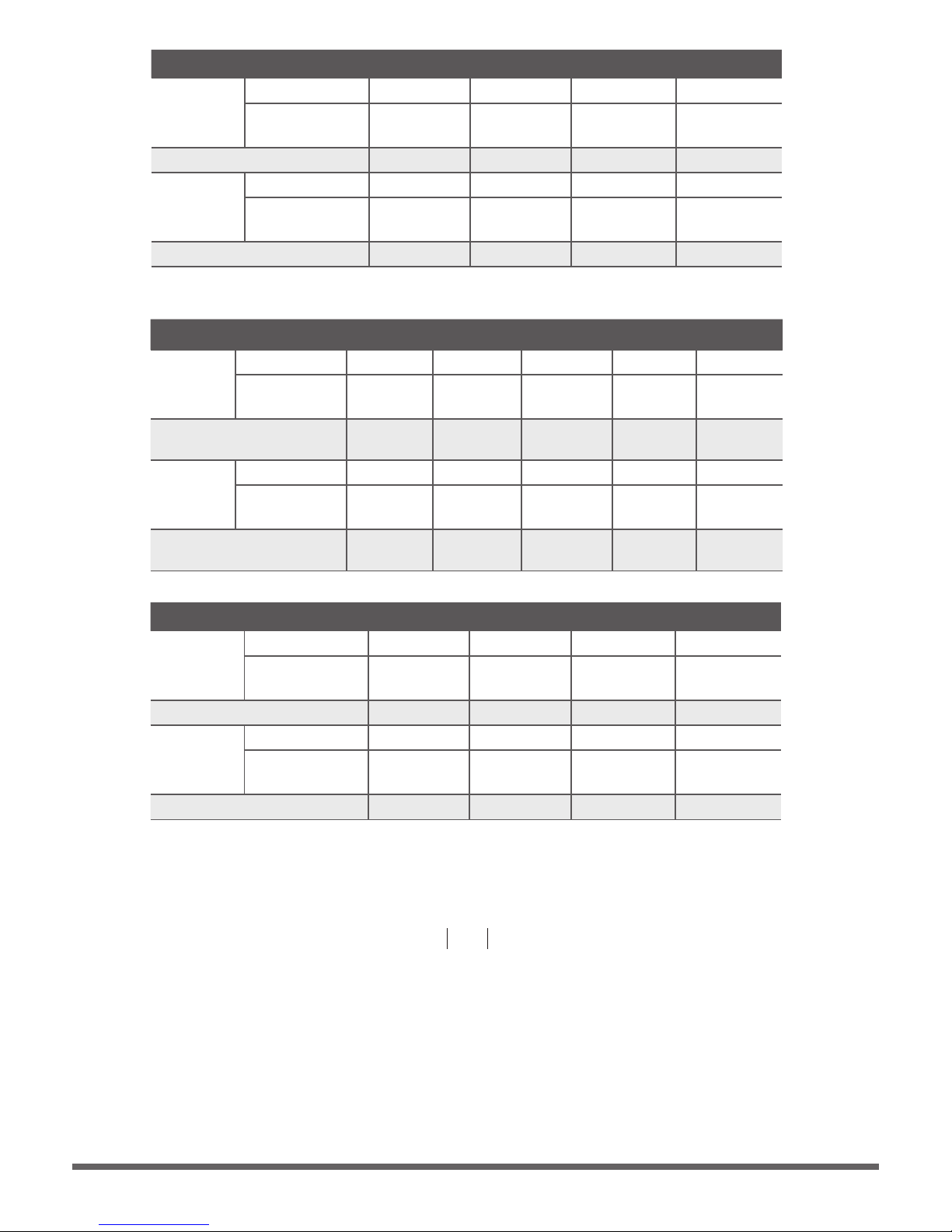

Table.4-1

MODEL

(Btu/h)

Outline dimension

A B C

air outlet opening size

D E F

air return opening size

(unit: mm/inch)

Size of mounted lug

I

J

G

H

18K 210/8.3 674/26.5880/34.6

24K 249/9.8 774/30.51100/43.3

30K~36K 249/9.8 774/30.51360/53.5

36K~60K 300/11.8 874/34.41200/47.2

136/5.4 706/27.8600/23.6

175/6.9 926/36.5700/27.6

175/6.9 1186/46.7700/27.6

227/8.9 1044/41.1800/31.5

190/7.5

228/8.9

228/8.9

280/11

920/36.2782/30.8

1140/44.91001/39.4

1400/55.11261/49.6

1240/48.81101/43.3

508/20

598/23.5

598/23.5

697/27.4

9K/12K

200/7.9 506/19.9700/27.6

152/6 537/21.1450/17.7 186/7.3 741/29.2599/23.6

360/14.2

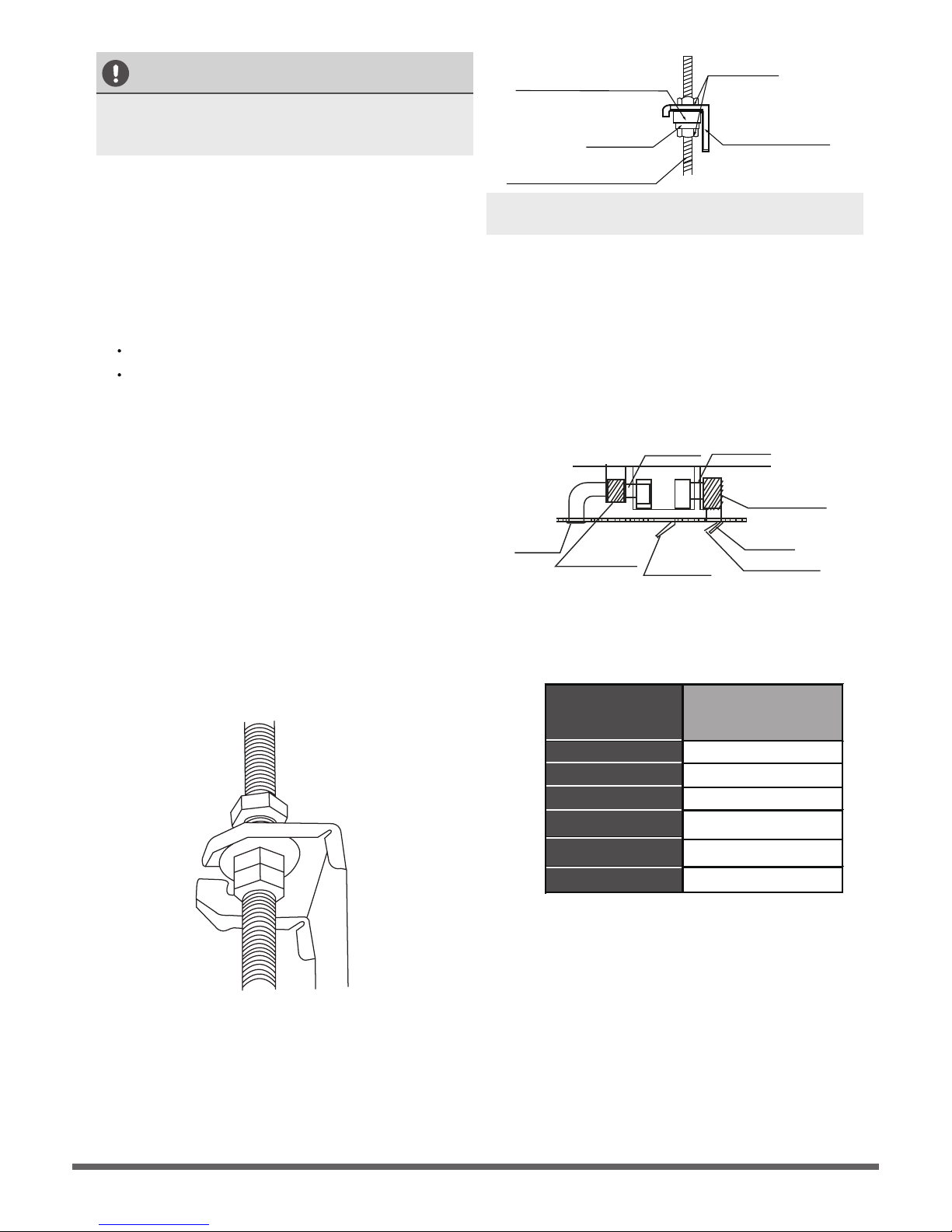

Fig. 4.6

Fig. 4.7

Original concrete bricks

Use an embedding screw bolt, crock, and stick

harness.(See Fig.4.6)

Steel Roof beam structure

Install and use the supporting steel angle.

(See Fig.4.7)

Fig. 4.4

Wood

Place the wood mounting across the roof beam,

then install the hanging screw bolts.(See Fig.4.4)

Wood mounting

Roof beam

Hanging screw bolts

Ceiling

Fig. 4.5

New concrete bricks

Inlay or embed the screw bolts. (See Fig. 4.5)

(Blade shape insertion)

(Slide insertion)

Steel bar

Embedding screw bolt

(Pipe hanging and embedding screw bolt)

Hanging screw bolt

Hanging

bolts

Supporting

steel angle

Air inlet dimensions

Page 10

Fig. 4.10

or more.

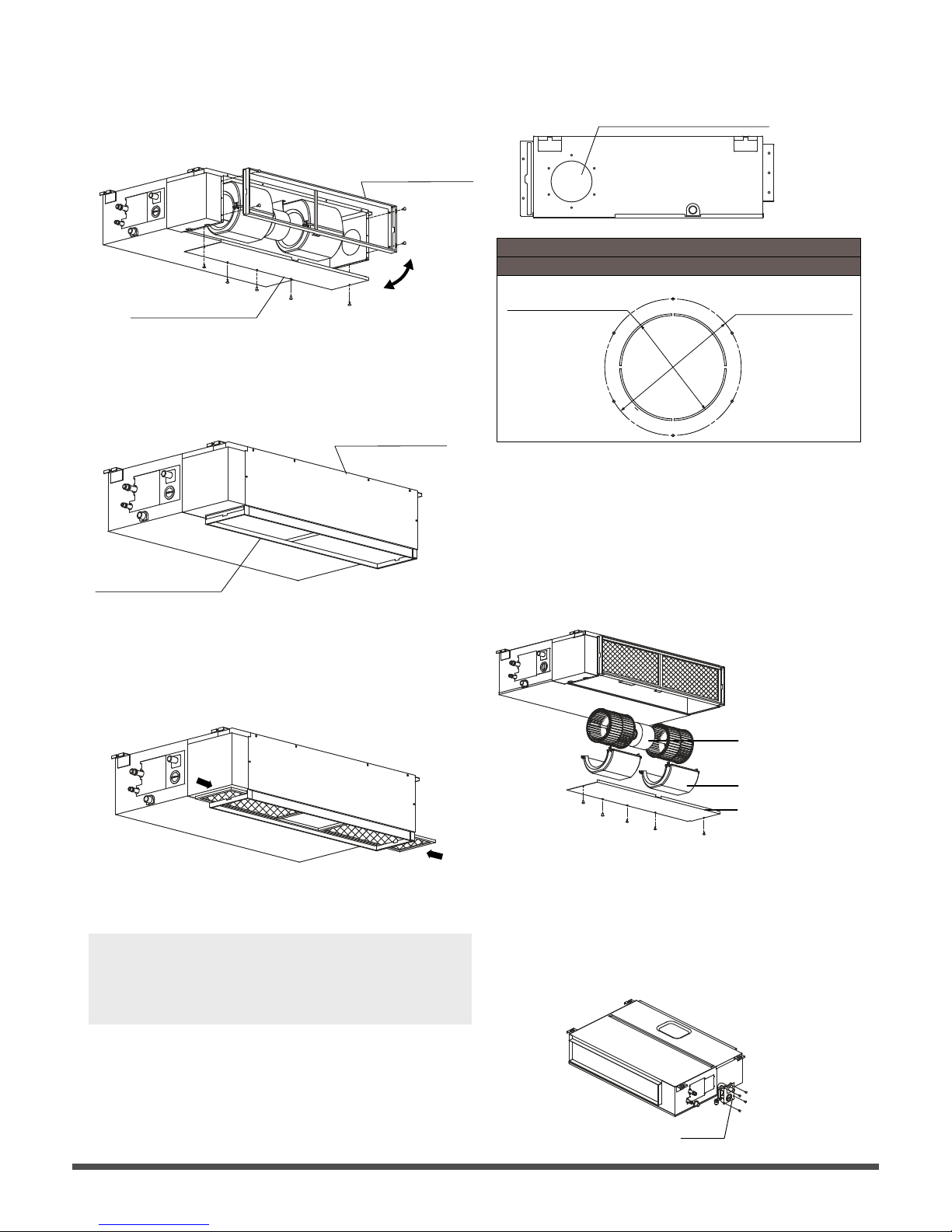

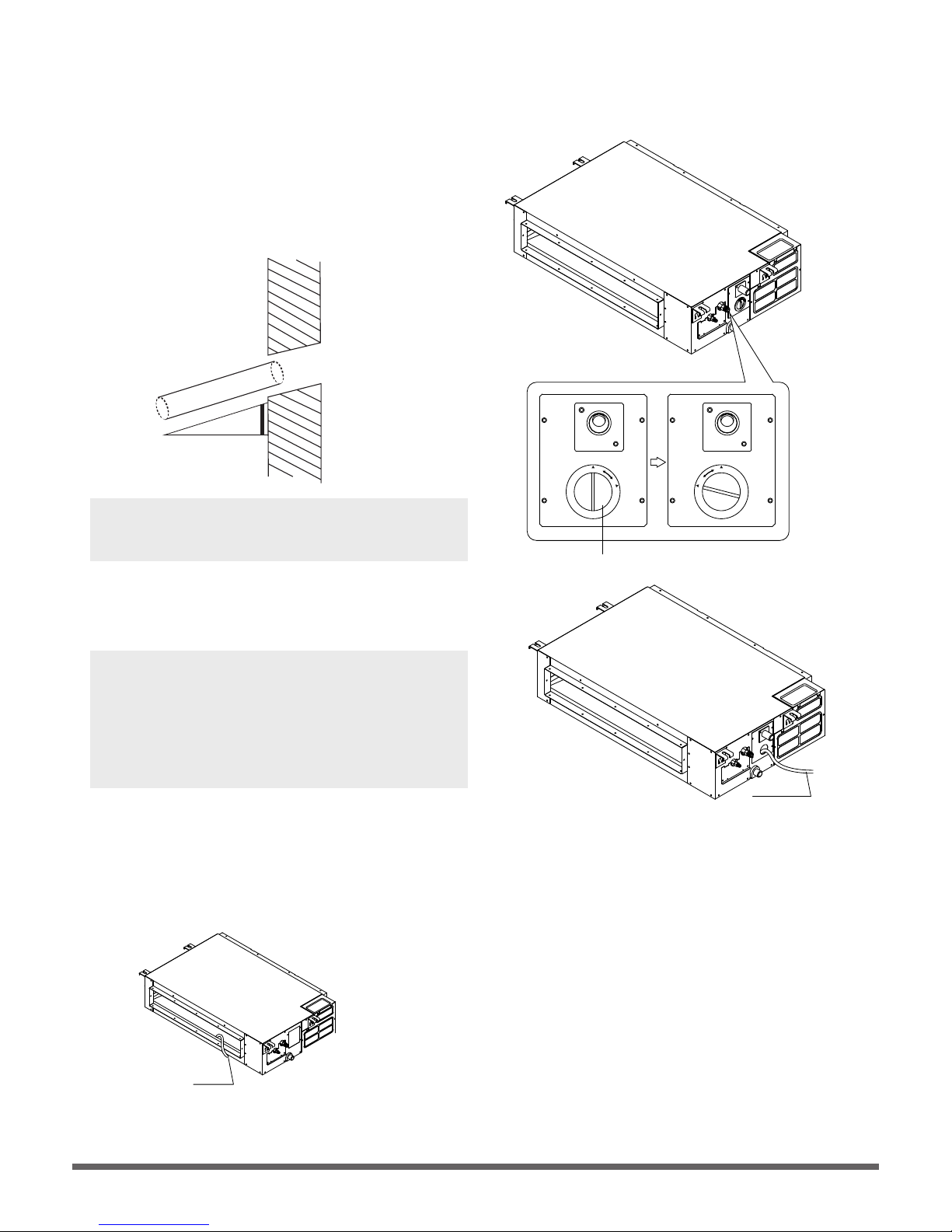

Step 3: Duct and accessories installation

NOTE: 1. Do not place the connecting duct

weight on the indoor unit.

2. When connecting the duct, use an

nonammable canvas tie-in to prevent

vibrating.

3. Insulation foam must be wrapped outside the

duct to avoid condensate. An internal duct

underlayer can be added to reduce noise,

if the end-user requires.

1. Install the lter (optional) according to the size

of the air inlet.

5. Refer to the following static pressure guidelines

when installing the indoor unit.

Change the fan motor static pressure

according to external duct static pressure.

2. Install the canvas tie-in between the body and

the duct.

3. The air inlet and air outlet duct should be far

enough apart enough to a avoid air passage

short-circuit.

4.

Connect the duct according to the following

diagram:

Canvas tie-in Canvas tie-in

Air outlet

Isolation booth

Isolation booth

checking orice

Air inlet

Air dust lter

Table.4-2

MODEL

(Btu/h)

Static Pressure

(Pa/in.wg)

0~100/0~0.4

18K

0~160/0~0.64

24K

0~160/0~0.64

30K~36K

0~160/0~0.64

42K~60K

0~50/0~0.2

9K

0~50/0~0.2

12K

Cut o the roof beam.

Strengthen the point at which the cut

was made. Consolidate the roof beam.

Fig. 4.9

Screw nut

Washer

Hanging screw bolt

Overhang part

Shockproof cushion

NOTE:

Conrm the minimum drain tilt is 1/100

CAUTION

The unit body must be completely aligned with

the hole. Ensure that the unit and the hole are

the same size before moving on.

2.

Install and t pipes and wires after you have

nished installing the main body.When

choosing where to start, determine the

direction of the pipes to be drawn out.

Especially in cases where there is a ceiling

involved, align the refrigerant pipes, drain

pipes, and indoor and outdoor lines with their

connection points before mounting the unit.

3.

Install hanging screw bolts.

4. After you select an installation location,align

the refrigerant pipes, drain pipes, as well as

indoor and outdoor wires with their

connection points before mounting the unit.

5.

Drill 4 holes 10cm (4”) deep at the ceiling

hook positions in the internal ceiling. Be sure

to hold the drill at a 90° angle to the ceiling.

6.

Secure the bolt using the washers and nuts

provided.

7.

Install the four suspension bolts.

8. Mount the indoor unit with at least two

people to lift and secure it. Insert suspension

bolts into the unit’s hanging holes. Fasten

them using the washers and nuts provided.

(See Fig. 4.8).

9. Mount the indoor unit onto the hanging

screw bolts with a block. Position the

indoor unit at using a level indicator to

prevent leaks. (See Fig. 4.9).

Fig. 4.8

Page 11

Step 4: Adjust the air inlet direction

(from rear side to under-side).

1. Take o the ventilation panel and ange.

2. Change the mounting positions of the

ventilation panel and air return ange.

Air return ange

Ventilation panel

3. When installing the lter mesh, t it into the

ange as illustrated in the following gure.

NOTE:

All the gures in this manual are for

demonstration purposes only. The air conditioner

you have purchased may be slightly dierent in

design, though similar in shape.

Step 5: Fresh air duct installation

Dimension :

Duct joint for fresh air

Ø125mm(4.92”)

Ø160mm(6.3”)

MODLE

18-60

Fig. 4.14

Step 6: Motor and drain pump maintenance

Motor maintain:

Take o the ventilated panel.

Take o the blower housing.

Take o the motor.

1.

2.

3.

(the rear ventilated panel is used as an example)

Motor

Blower housing

Ventilated panel

Pump maintainance:

Remove four screws from the drain pump.

Unplug the pump power supply and water

level switch cable.

Detach the pump.

1.

2.

3.

Pump

Fig. 4.11

Fig. 4.12

Fig. 4.13

Fig. 4.15

Fig. 4.16

Air return ange

Ventilation panel

Page 12

Outdoor Unit Installation

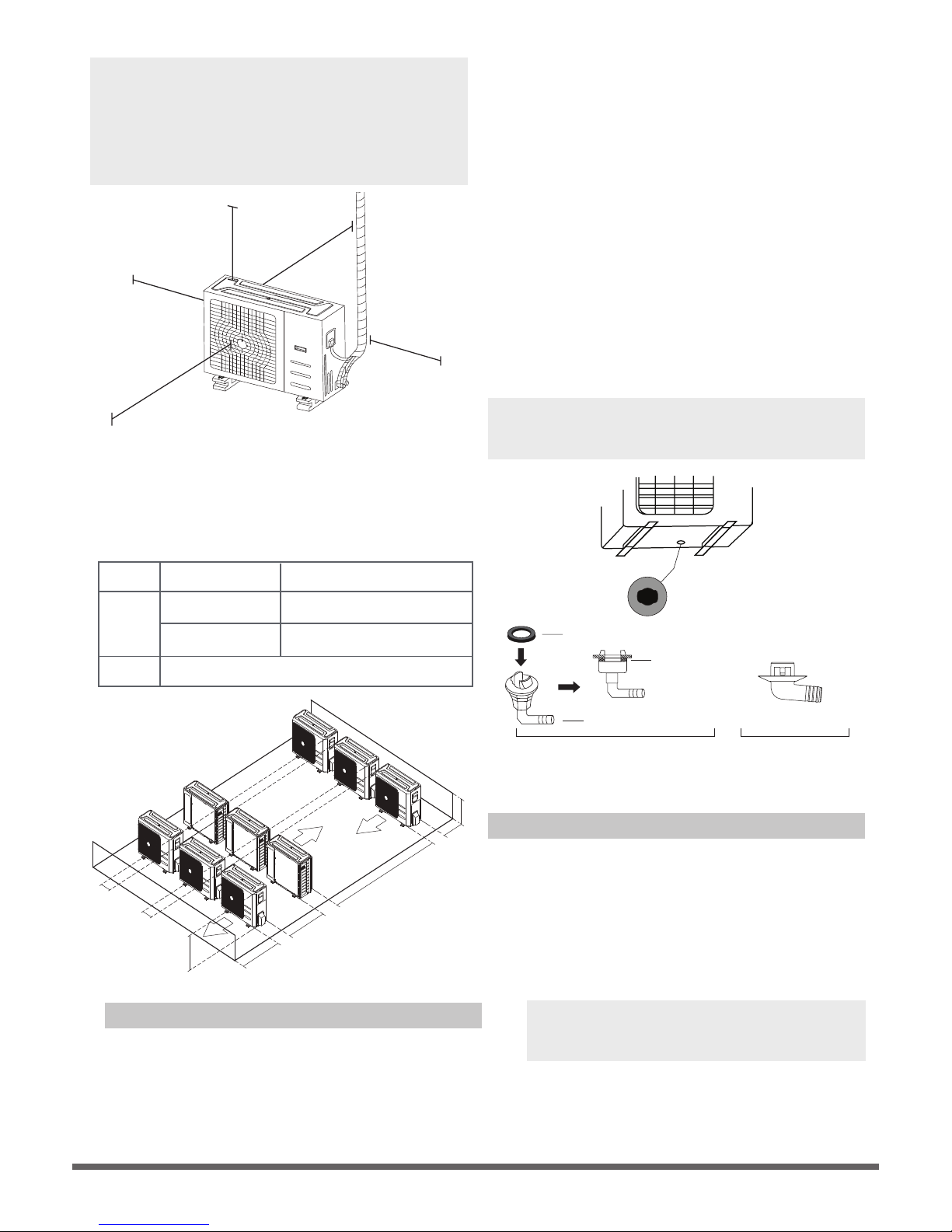

Outdoor Unit Installation Instructions

Step 1: Select installation location.

The outdoor unit should be installed in the

location that meets the following requirements:

o Place the outdoor unit as close to the indoor

unit as possible.

o Ensure that there is enough room for

installation and maintenance.

o The air inlet and outlet must not be

obstructed or exposed to strong wind.

o Ensure the location of the unit will not be

subject to snowdrifts, accumulation of leaves

or other seasonal debris. If possible, provide

an awning for the unit. Ensure the awning

does not obstruct airflow.

o The installation area must be dry and well

ventilated.

o There must be enough room to install the

connecting pipes and cables and to access

them for maintenance.

o The area must be free of combustible gases

and chemicals.

o The pipe length between the outdoor and

indoor unit may not exceed the maximum

allowable pipe length.

o If possible, DO NOT install the unit where it

is exposed to direct sunlight.

o If possible, make sure the unit is located far

away from your neighbors’ property so that

the noise from the unit will not disturb them.

o If the location is exposed to strong winds (for

example: near a seaside), the unit must be

placed against the wall to shelter it from the

wind. If necessary, use an awning.

(See Fig. 5.1 & 5.2)

o Install the indoor and outdoor units, cables

and wires at least 1 meter from televisions or

radios to prevent static or image distortion.

Depending on the radio waves, a 1 meter

distance may not be enough to eliminate all

interference.

Strong wind

Strong wind

Strong wind

Fig. 5.1 Fig. 5.2

Step 2: Install outdoor unit.

Fix the outdoor unit with anchor bolts (M10)

>60cm / 23.6”

Fix with bolts

CAUTION

•

Be sure to remove any obstacles that

may block air circulation.

• Make sure you refer to Length

Specifications to ensure there is

enough room for installation and

maintenance.

Fig. 5.3

5

√

√

√

√

√

√

√

√

√

√

√

√

>120cm / 47”

Air Outlet

(Wall or obstacle)

H

D

W

>30cm / 11.8”

Air inlet

Air inlet

Air inlet

Air inlet

(Wall or obstacle)

>30cm / 11.8”

>30cm / 11.8”

>30cm / 11.8”

Table 5.1: Length Specifications of Split

Type Outdoor Unit (unit: mm/inch)

Table 5.2: Length Specifications of Vertical

Discharge Outdoor Unit (unit: mm/inch)

MODEL

DIMENSIONS

W H D

18 633/25 554/21.8554/21.8

24 633/25 554/21.8554/21.8

36 759/29.8 554/21.8554/21.8

36 633/25 600/23.6600/23.6

48 759/29.8 710/28710/28

60 843/33 710/28710/28

Split Type Outdoor Unit

(Refer to Fig 5.4, 5.5, 5.6, 5.10 and Table 5.1)

Vertical Discharge Type Outdoor Unit

(Refer to Fig 5.7, 5.8, 5.9 and Table 5.2)

Fig. 5.7

Fig. 5.8

Fig. 5.9

Fig. 5.6

Fig. 5.5

A

B

D

W

H

W

H

Fig. 5.4

Outdoor Unit Dimensions

W x H x D

Mounting Dimensions

Distance A Distance B

770x555x300 (30.3x21.85x11.81) 487 (19.2) 298 (11.73)

810x558x310 (31.9x22x12.2) 549 (21.6) 325 (12.8)

845x700x320 (33.27x27.5x12.6) 560 (22) 335 (13.2)

900x860x315 (35.4x33.85x12.4) 590 (23.2) 333 (13.1)

945x810x395 (37.2x31.9x15.55) 640 (25.2) 405 (15.95)

990x965x345 (38.98x38x13.58) 624 (24.58) 366 (14.4)

946x810x420 (37.24x31.9x16.53) 673 (26.5)

403 (15.87)

946x810x410 (37.24x31.9x16.14) 673 (26.5)

403 (15.87)

952x1333x410 (37.5x52.5x16.14) 634 (24.96)

404 (15.9)

952x1333x415 (37.5x52.5x16.34) 634 (24.96)

404 (15.9)

845x702x363 (33.27x27.6x14.3)

540 (21.26)

350 (13.8)

938x1369x392 (36.93x53.9x15.43) 634 (24.96) 404 (15.9)

900x1170x350 (35.4x46x13.8) 590 (23.2) 378 (14.88)

800x554x333 (31.5x21.8x13.1) 514 (20.24) 340 (13.39)

Page 13

>120cm / 47”

Air Outlet

(Wall or obstacle)

H

D

W

>30cm / 11.8”

Air inlet

Air inlet

Air inlet

Air inlet

(Wall or obstacle)

>30cm / 11.8”

>30cm / 11.8”

>30cm / 11.8”

Table 5.1: Length Specifications of Split

Type Outdoor Unit (unit: mm/inch)

Table 5.2: Length Specifications of Vertical

Discharge Outdoor Unit (unit: mm/inch)

MODEL

DIMENSIONS

W H D

18 633/25 554/21.8554/21.8

24 633/25 554/21.8554/21.8

36 759/29.8 554/21.8554/21.8

36 633/25 600/23.6600/23.6

48 759/29.8 710/28710/28

60 843/33 710/28710/28

Split Type Outdoor Unit

(Refer to Fig 5.4, 5.5, 5.6, 5.10 and Table 5.1)

Vertical Discharge Type Outdoor Unit

(Refer to Fig 5.7, 5.8, 5.9 and Table 5.2)

Fig. 5.7

Fig. 5.8

Fig. 5.9

Fig. 5.6

Fig. 5.5

A

B

D

W

H

W

H

Fig. 5.4

Outdoor Unit Dimensions

W x H x D

Mounting Dimensions

Distance A Distance B

770x555x300 (30.3x21.85x11.81) 487 (19.2) 298 (11.73)

810x558x310 (31.9x22x12.2) 549 (21.6) 325 (12.8)

845x700x320 (33.27x27.5x12.6) 560 (22) 335 (13.2)

900x860x315 (35.4x33.85x12.4) 590 (23.2) 333 (13.1)

945x810x395 (37.2x31.9x15.55) 640 (25.2) 405 (15.95)

990x965x345 (38.98x38x13.58) 624 (24.58) 366 (14.4)

946x810x420 (37.24x31.9x16.53) 673 (26.5)

403 (15.87)

946x810x410 (37.24x31.9x16.14) 673 (26.5)

403 (15.87)

952x1333x410 (37.5x52.5x16.14) 634 (24.96)

404 (15.9)

952x1333x415 (37.5x52.5x16.34) 634 (24.96)

404 (15.9)

845x702x363 (33.27x27.6x14.3)

540 (21.26)

350 (13.8)

938x1369x392 (36.93x53.9x15.43) 634 (24.96) 404 (15.9)

900x1170x350 (35.4x46x13.8) 590 (23.2) 378 (14.88)

800x554x333 (31.5x21.8x13.1) 514 (20.24) 340 (13.39)

Page 14

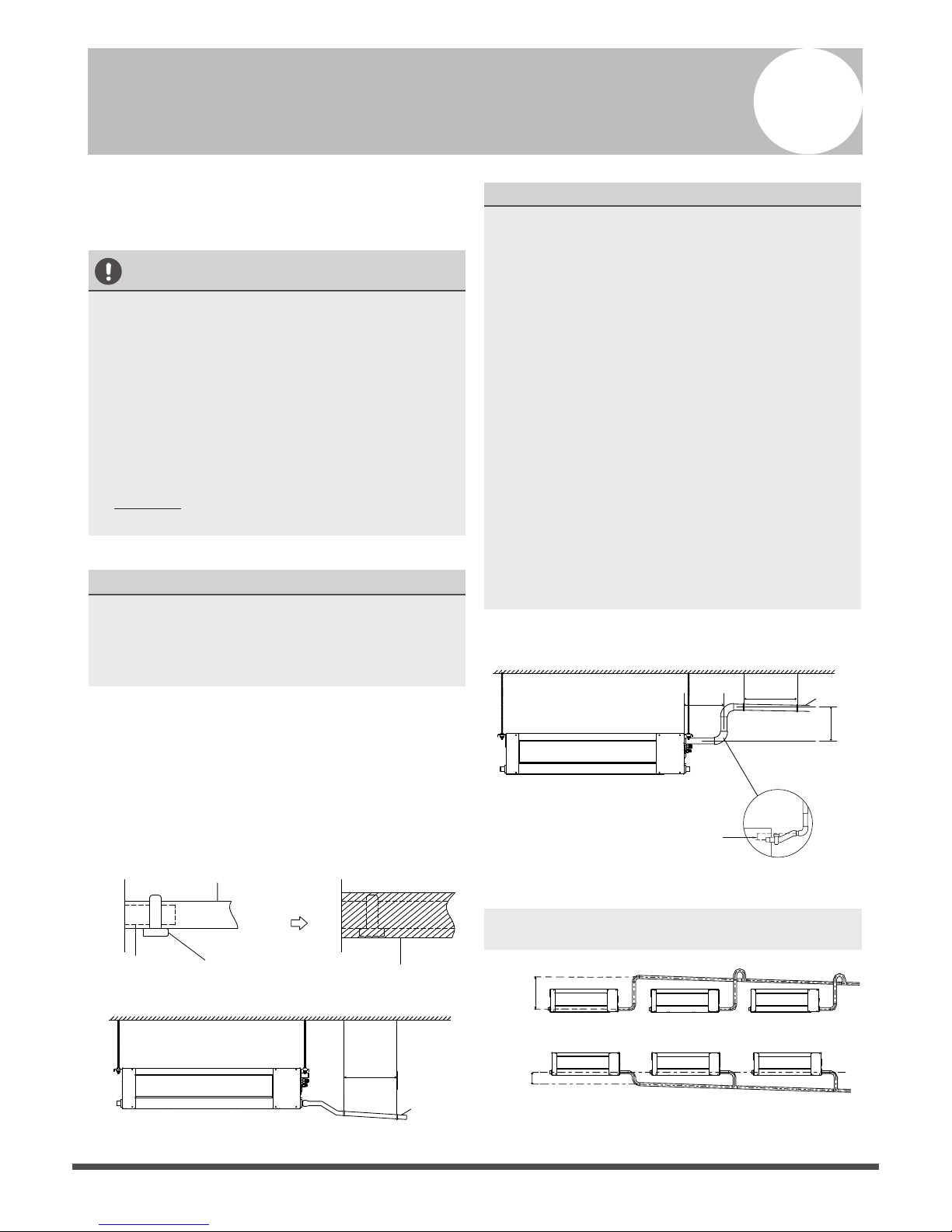

NOTE: The minimum distance between the

outdoor unit and walls described in the

installation guide does not apply to airtight

rooms. Be sure to keep the unit unobstructed

in at least two of the three directions (M, N, P)

(See Fig. 5.10)

M

N

P

30 cm / 11.8” from back wall

60 cm / 23.6” on right

evoba ”6.32 / mc 06

30 cm / 11.8” on left

200 cm / 78” in front

Fig. 5.10

Fig. 5.11

NOTE: Make sure the water drains to a safe

location wher

e it will not cause water damage

or a slipping hazard.

Seal

Drain joint

(A) (B)

Base pan hole of

outdoor unit

Seal

Fig. 5.12

llaW nI eloH gnillirD nO setoN

You must drill a hole in the wall for the

refrigerant piping, and the signal cable that will

connect the indoor and outdoor units.

1. Determine the location of the wall hole

based on the location of the outdoor unit.

2. Using a 65-mm (2.5”) core drill, drill a hole

in the wall.

NOTE: When drilling the wall hole, make

sure to avoid wires, plumbing, and other

sensitive components.

3. Place the protective wall cuff in the hole.

This protects the edges of the hole and will

help seal it when you finish the installation

process.

Fig. 5.11

L

H

300 cm / 118” or more

A

60 cm / 23.6”

or more

150 cm / 59”

or more

25 cm / 9.8”

or more

25 cm / 9.8”

or more

Rows of series installation

L ≤ H

L ≤ 1/2H

L A

25 cm / 9.8” or more

1/2H < L ≤ H

30 cm / 11.8” or more

L > H

Can not be installed

Table 5.3 The relations between H, A and L

are as follows.

Drain Joint Installation

If the drain joint comes with a rubber seal

(see Fig. 5.12 - A ), do the following:

1. Fit the rubber seal on the end of the drain joint

that will connect to the outdoor unit.

2. Insert the drain joint into the hole in the base

pan of the unit.

3. Rotate the drain joint 90° until it clicks in place

facing the front of the unit.

4.

1.

2.

Connect a drain hose extension (not included)

to the drain joint to redirect water from the

unit during heating mode.

If the drain joint doesn’t come with a rubber

seal (see Fig. 5.12 - B ), do the following:

Insert the drain joint into the hole in the base

pan of the unit. The drain joint will click in

place.

Connect a drain hose extension (not included)

to the drain joint to redirect water from the

unit during heating mode.

Page 15

Fig. 6.3

(39-59”)

(7.9”)

<20cm

(21.7”)

<55cm

Lean over 1/50

1-1.5m1-1

Drainpipe installation for units with a pump

Ceiling

0 - 75mm

(3”)

NOTE ON DRAINPIPE INSTALLATION

•

When using an extended drainpipe, tighten

the indoor connection with an additional

protection tube. This prevents it from

pulling loose.

• The drainpipe should slope downward at a

gradient of at least 1/100 to prevent water

from flowing back into the air conditioner.

• To prevent the pipe from sagging, space

hanging wires every 1-1.5m (39-59”).

• If the outlet of the drainpipe is higher than

the body’s pump joint, use a lift pipe for

the indoor unit’s exhaust outlet. The lift

pipe must be installed no higher than

55cm (21.7”) from the ceiling board. The

distance between the unit and the lift pipe

must be less than 20cm (7.9”). Incorrect

installation could cause water to flow back

into the unit and flood.

The drainpipe is used to drain water away from

the unit. Improper installation may cause unit

and property damage.

CAUTION

•

Insulate all piping to prevent condensation,

which could lead to water damage.

•

If the drainpipe is bent or installed

incorrectly, water may leak and cause a

water-level switch malfunction.

•

In HEAT mode, the outdoor unit will

discharge water. Ensure that the drain hose

is placed in an appropriate area to avoid

water damage and slippage.

•

DO NOT pull the drainpipe forcefully. This

could disconnect it.

NOTE ON PURCHASING PIPES

This installation requires a polyethylene tube

(outside diameter = 3.7-3.9cm, inside diameter

= 3.2cm), which can be obtained at your local

hardware store or dealer.

Indoor Drainpipe Installation

Install the drainpipe as illustrated in Figure 6.2.

1.

2.

Drainpipe

connecting port

Drain hose

Pipe clasp

Insulation

Fig. 6.1

Drainpipe Installation

Fig. 6.2

6

Cover the drainpipe with heat insulation to

prevent condensation and leakage.

Attach the mouth of the drain hose to the

unit’s outlet pipe. Sheath the mouth of the

hose and clip it firmly with a pipe clasp.

(Fig 6.1)

NOTE: When connecting multiple drainpipes,

install the pipes as illustrated in Fig 6.4.

(39-59”)

1-1.5m1-1

Lean over 1/50

Ceiling

• To prevent air bubbles, keep the drain hose

level or slightly tiled up (<75mm / 3”).

0-53cm

(20.8”)

≥10cm

(4”)

Fig. 6.4

Page 16

Drainage test

Check whether the drainpipe is unhindered.

This test should be performed on newly built

houses before the ceiling is paved.

Units with a pump.

Units without a pump.

1. Remove the test cover.

Fill the water pan with 2 liters of water.

2. Turn on the unit in COOLING mode. You will

hear the drain pump.Check whether the

water is discharged properly (a 1-minute lag

is possible, depending on the length of the

drain pipe), Check whether water leaks from

the joints.

3. Turn off the air conditioner and put the cap

back on.

3. Using a 65-mm (2.5”) core drill, drill a hole in

the wall. Make sure that the hole is drilled at

a slight downward angle, so that the outdoor

end of the hole is lower than the indoor end

by about 12mm (0.5”). This will ensure proper

water drainage (See Fig. 6.5). Place the

protective wall cuff in the hole. This protects

the edges of the hole and will help seal it

once you finish installation.

Wall

Indoor

Outdoor

≈ 12mm / 0.5 inch

Fig. 6.5

NOTE: When drilling the hole, make sure to

avoid wires, plumbing, and other sensitive

components.

4.

Pass the drain hose through the wall hole.

Make sure the water drains to a safe location

where it will not cause water damage or a

slipping hazard.

NOTE: The drainpipe outlet should be at least

5cm (1.9”) above the ground. If it touches the

ground, the unit may become blocked and

malfunction. If you discharge the water directly

into a sewer, make sure that the drain has a U

or S pipe to catch odors that might otherwise

come back into the house.

Test cap

Fig.6.7

Fig.6.8

C

L

O

S

E

D

O

P

E

N

C

L

O

S

E

D

O

P

E

N

Stow tube

Fig.6.6

Stow tube

Fill the water pan with 2 liters of water.

Check that the drainpipe is unhindered.

Page 17

Refrigerant Piping Connection

Safety Precautions

WARNING

• All field piping must be completed by a

licensed technician and must comply with

the local and national regulations.

• When the air conditioner is installed in a

small room, measures must be taken to

prevent the refrigerant concentration in

the room from exceeding the safety limit

in the event of refrigerant leakage. If the

refrigerant leaks and its concentration

exceeds its proper limit, hazards due to

lack of oxygen may result.

• When installing the refrigeration system,

ensure that air, dust, moisture or foreign

substances do not enter the refrigerant

circuit. Contamination in the system may

cause poor operating capacity, high

pressure in the refrigeration cycle,

explosion or injury.

• Ventilate the area immediately if there is

refrigerant leakage during the installation.

Leaked refrigerant gas is both toxic and

flammable. Ensure there is no refrigerant

leakage after completing the installation

work.

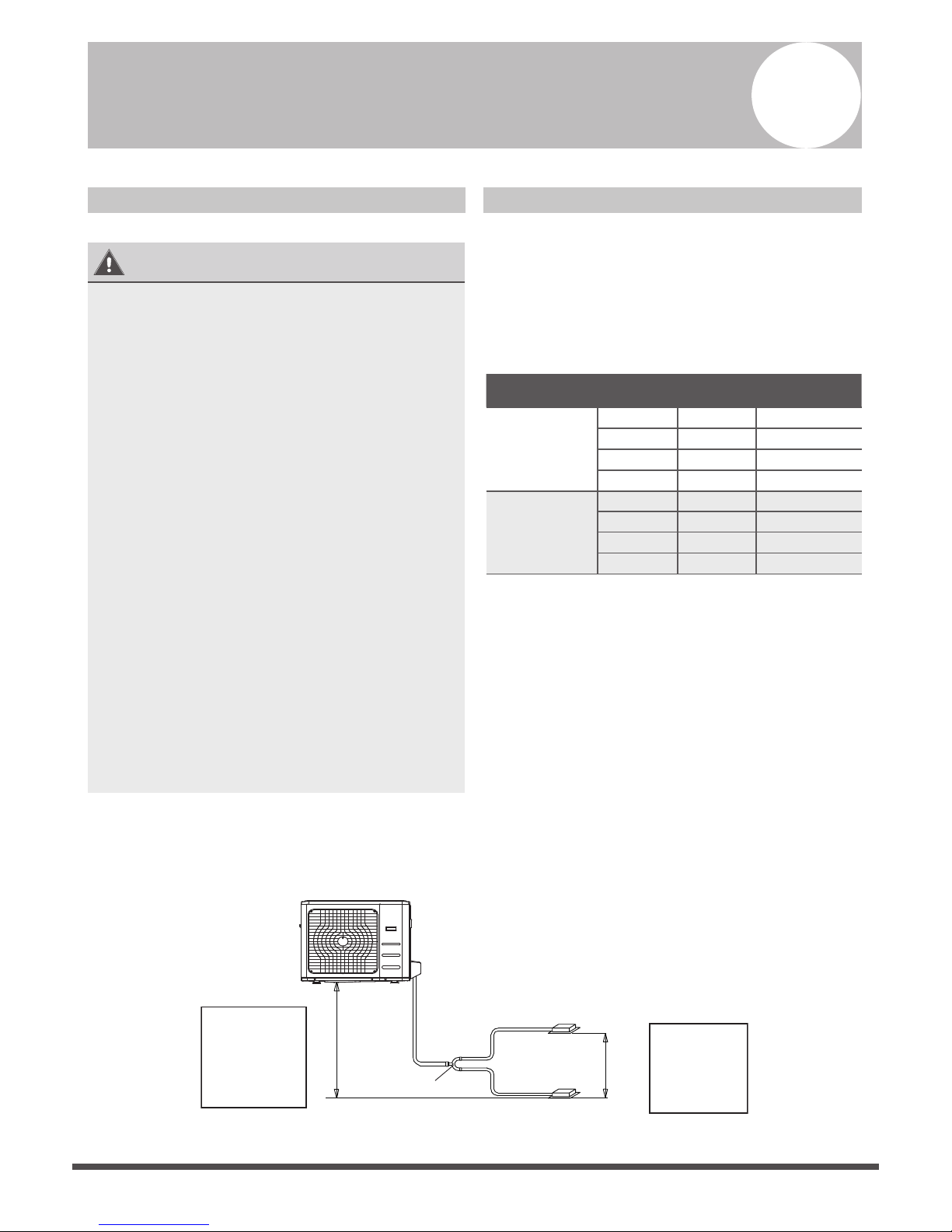

Notes On Pipe Length and Elevation

Ensure that the length of the refrigerant pipe, the

number of bends, and the drop height between

the indoor and outdoor units meets the

requirements shown in Table 7.1:

Table 7.1: The Maximum Length And Drop

Height Based on Models. (Unit: m/ft.)

Type of model Capacity

(Btu/h)

Length of

piping

Maximum drop

height

North America,

Australia and the

eu frequency

conversion Split

Type

<15K 25/82 10/32.8

≥15K - <24K 30/98.4 20/65.6

≥24K - <36K 50/164 25/82

≥36K - ≤60K 65/213 30/98.4

Other Split Type

12K 15/49 8/26

18K-24K 25/82 15/49

30K-36K 30/98.4 20/65.6

42K-60K 50/164 30/98.4

Refrigerant Piping with Twin Indoor Units

When installing multiple indoor units with a single outdoor unit, ensure that the length of the

refrigerant pipe and the drop height between the indoor and outdoor units meet the requirements

illustrated in the following diagram:

L

L1

L2

H2

The line branch pipe

Indoor unit

Outdoor unit

H1

Indoor unit

The drop height

between two

indoor units

must be less

than or equal to

50cm (19.6”)

The drop height

between indoor

unit

and outdoor unit

must be less than

or equal to 20m

(65.6’)

Fig. 7.1

7

Page 18

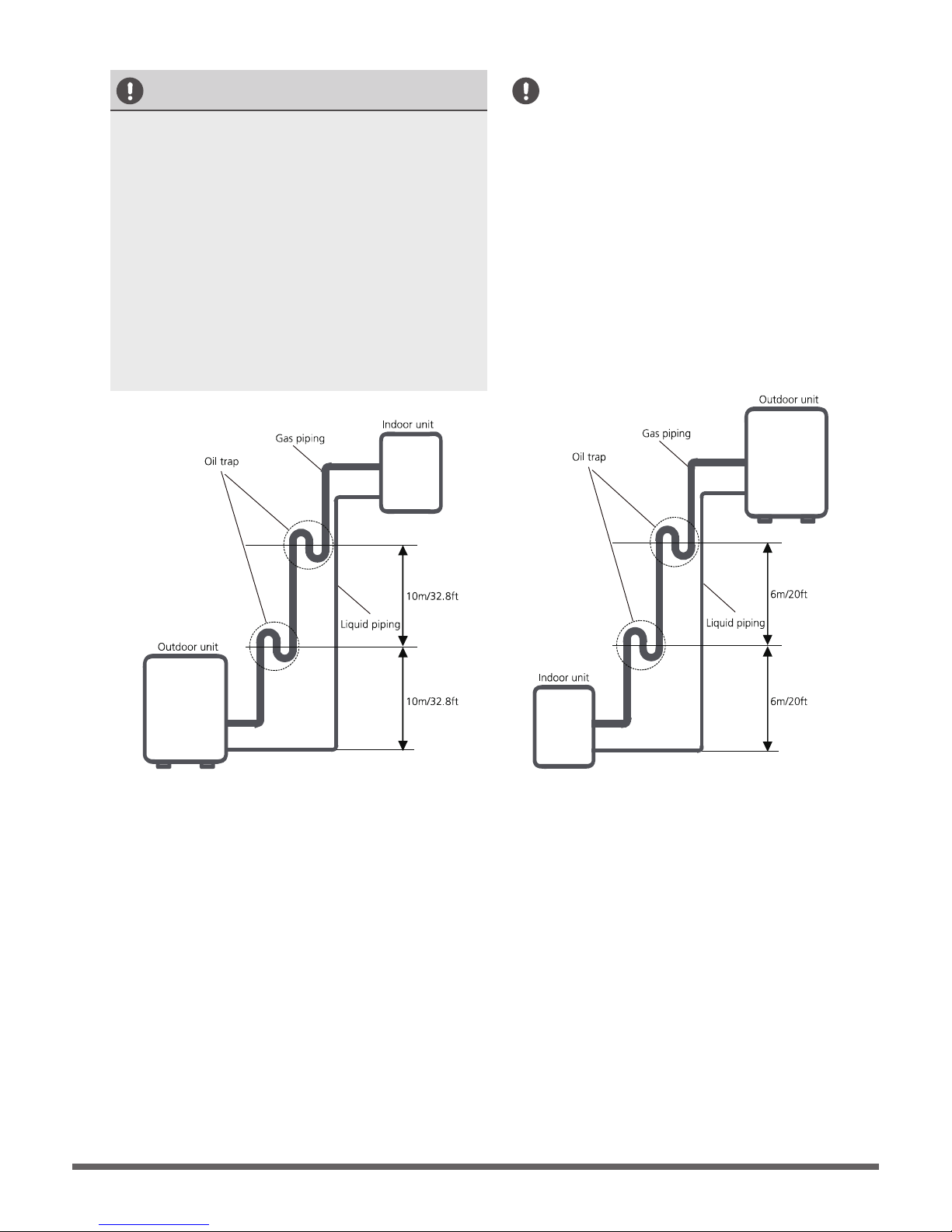

Oil traps

CAUTION

•

If the indoor unit is installed higher than the

outdoor unit:

An oil trap should be installed every 10m

(32.8ft) of vertical suction line riser.

(See Fig. 7.2)

-If oil flows back into the outdoor unit’s

compressor, this might cause liquid

compression or deterioration of oil return.

Oil traps in the rising gas piping can prevent

this.

CAUTION

Fig. 7.2

The indoor unit is installed higher than the

outdoor unit

If the outdoor unit is installed higher than the

indoor unit:

-It is recommended that vertical suction risers

not be upsized. Proper oil return to the

compressor should be maintained with suction

gas velocity. If velocities drop below7.62m/s

(1500fpm (feet per minute)), oil return will be

decreased. An oil trap should be installed every

6m(20ft) of vertical suction line riser.

(See Fig. 7.3)

Fig. 7.3

The outdoor unit is installed higher than the

indoor unit

Page 19

Pipe

Reamer

Point dow n

Fig. 7.5

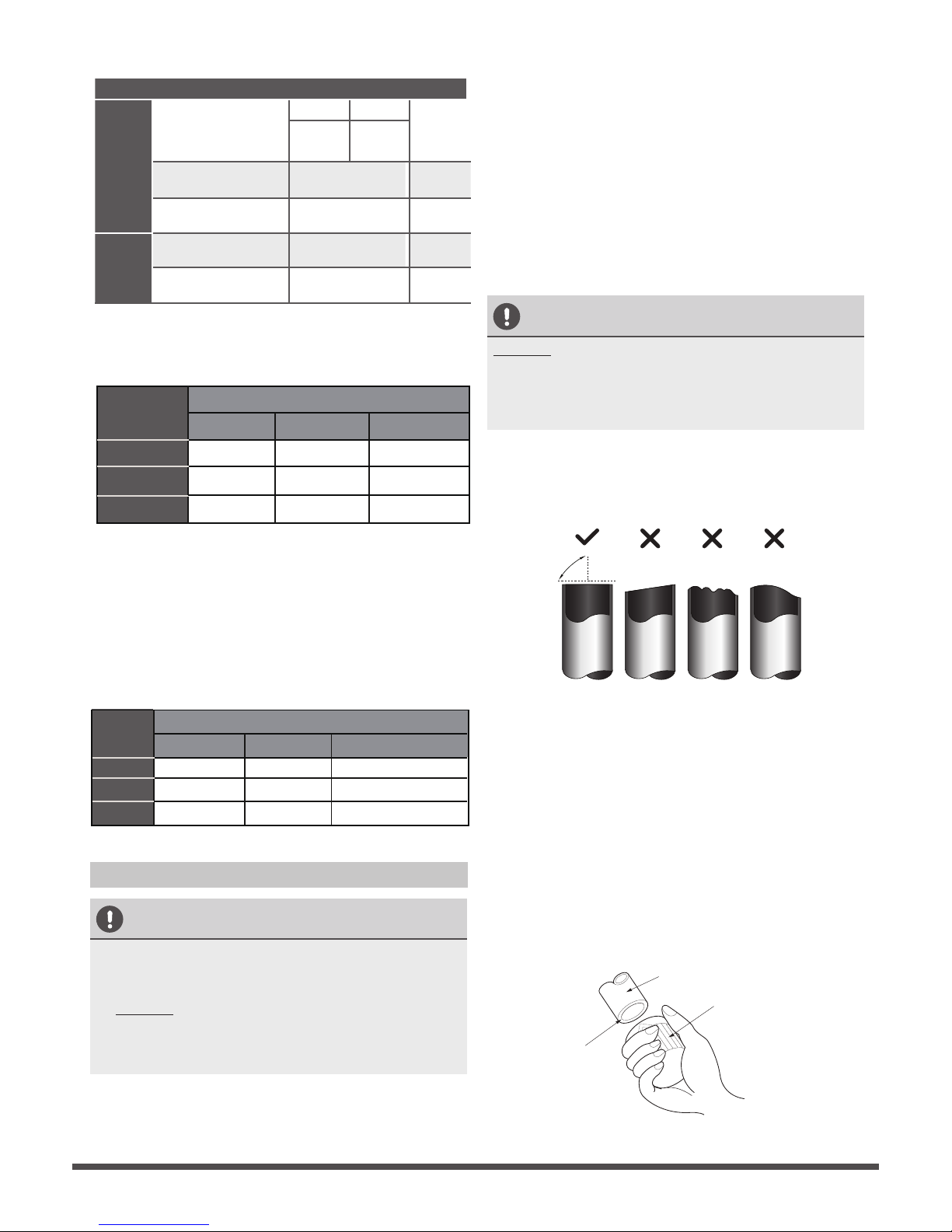

Table 7.2

Piping

length

Total piping length

Permitted length

18K+18K 30m/98’ L+Max

(L1, L2)

24K+24K

30K+30K

50m/164’

(farthest distance from

the line pipe branch)

15m/49’ L1, L2

(farthest distance from

the line pipe branch)

10m/32.8’ L1-L2

Drop

height

Drop height between

indoor and outdoor unit

20m/65.6’ H1

Drop height between

two indoor units

0.5m/1.6’ H2

CAUTION

DO NOT deform pipe while cutting. Be extra

careful not to damage, dent, or deform the pipe

while cutting. This will drastically reduce the

heating efficiency of the unit.

1. Make sure that the pipe is cut at a perfect

90° angle. Refer to Fig. 7.4 for examples

of bad cuts

Oblique

Rough

Warped

90°

Fig. 7.4

Step2: Remove burrs.

Burrs can aect the air-tight seal of refrigerant

piping connection. They must be completely

removed.

1. Hold the pipe at a downward angle to

prevent burrs from falling into the pipe.

2. Using a reamer or deburring tool, remove

all burrs from the cut section of the pipe.

Size of joint pipes for indoor unit

Gas side

Capacity

of indoor

unit (A)

Size of main pipe(mm)

Liquid side

Φ12.7(0.5”)

Φ15.9(0.626

”)

Φ15.9(0.626

”)

Φ6.35(0.25

”)

Φ9.5(0.375

”)

Φ9.5(0.375

”)

18K

24K

30K

Table 7.3

Size of joint pipes for 410A indoor unit

CE-FQZHN-01C

CE-FQZHN-01C

CE-FQZHN-01C

Available

branching pipe

Size of joint pipes for outdoor unit

Base on the following tables, select the diameters

of the outdoor unit connective pipes. In case of the

main accessory pipe larger than the main pipe, take

the larger one for the selection.

Model

Gas side Liquid side

Φ15.9(0.626”)

Φ15.9(0.626

”)

Φ15.9(0.626

”)

Φ9.5(0.375

”)

Φ9.5(0.375

”)

Φ9.5(0.375

”)

the size of main pipe(mm)

36K

48K

60K

Table 7.4

Size of joint pipes for 410A outdoor unit

The 1st branching pipe

CE-FQZHN-01C

CE-FQZHN-01C

CE-FQZHN-01C

Step1: Cut pipes

When preparing refrigerant pipes, take extra

care to cut and flare them properly. This will

ensure efficient operation and minimize the

need for future maintenance.

1. Measure the distance between the indoor

and outdoor units.

2. Using a pipe cutter, cut the pipe a little

longer than the measured distance.

Refrigerant Piping Connection Instructions

CAUTION

• The branching pipe must be installed

horizontally. An angle of more than 10° may

cause malfunction.

• DO NOT install the connecting pipe until both

indoor and outdoor units have been installed.

• Insulate both the gas and liquid piping to

prevent water leakage.

Page 20

TAKE NOTE OF FUSE SPECIFICATIONS

The air conditioner’s printed circuit board(PCB)

is designed with a fuse that provides overcurrent

protection. The specifications of the fuse are

printed on the circuit board, such as:

T5A/250VAC and 10A/250VAC.

Wiring

Safety Precautions

WARNING

• Disconnect the power supply before

working on the unit.

• All wiring must be performed according to

local and national regulations.

• Wiring must be done by a qualified

technician. Improper connections may

cause electrical malfunction, injury, or fire.

•

An i ndependent circuit and single outlet

must be used for this unit. DO NOT plug

another appliance or charger into the

same outlet. If the cannot handle the load

or there is a defect in the wiring, it can

lead to shock, fire, and unit and property

damage.

• Connect the power cable to the terminals

and fasten it with a clamp. An insecure

connection may cause fire.

• Make sure that all wiring is done correctly

and the control board cover is properly

installed. Failure to do so can cause

overheating at the connection points, fire,

and electrical shock.

• Ensure that main power supply connection

is made through a switch that disconnects

all poles, with contact gap of at least 3mm

(0.118”).

• DO NOT modify the length of the power

cord or use an extension cord.

CAUTION

• Connect the outdoor wires before

connecting the indoor wires.

• Make sure you ground the unit. The

grounding wire should be located away

from gas pipes, water pipes, lightning rods,

telephone wires or other grounding wires.

Improper grounding may cause electrical

shock.

• DO NOT connect the unit to the power

source until all wiring and piping is

completed.

• Make sure that you do not cross your

electrical wiring with your signal wiring.

This may cause distortion and interference.

To prevent distortion when the compressor starts

(you can find the unit’s power information on

the rating sticker):

• The unit must be connected to the main

outlet. Normally, the power supply must

have a impedance of 32 ohms.

• No other equipment should be connected

to the same power circuit.

Outdoor Unit Wiring

WARNING

Before performing any electrical or wiring work,

turn off the main power to the system.

1. Prepare the cable for connection

a. You must first choose the right cable size.

Be sure to use H07RN-F cables.

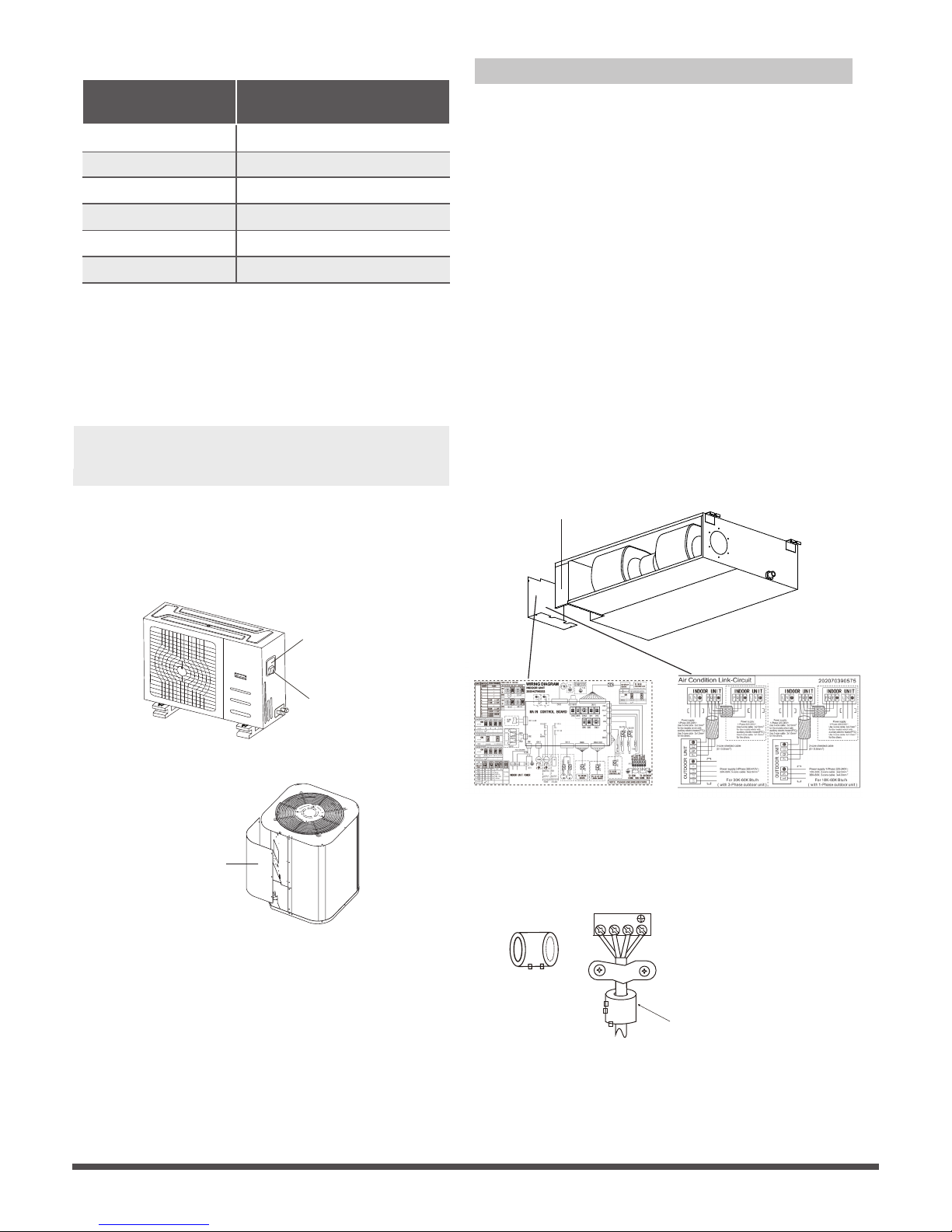

Table 8.1: Minimum Cross-Sectional Area of

Power and Signal Cables in North America

Rated Current of

Appliance (A)

AWG

≤ 7 18

7 - 13 16

13 - 18 14

18 - 25 12

25 - 30 10

8

Page 21

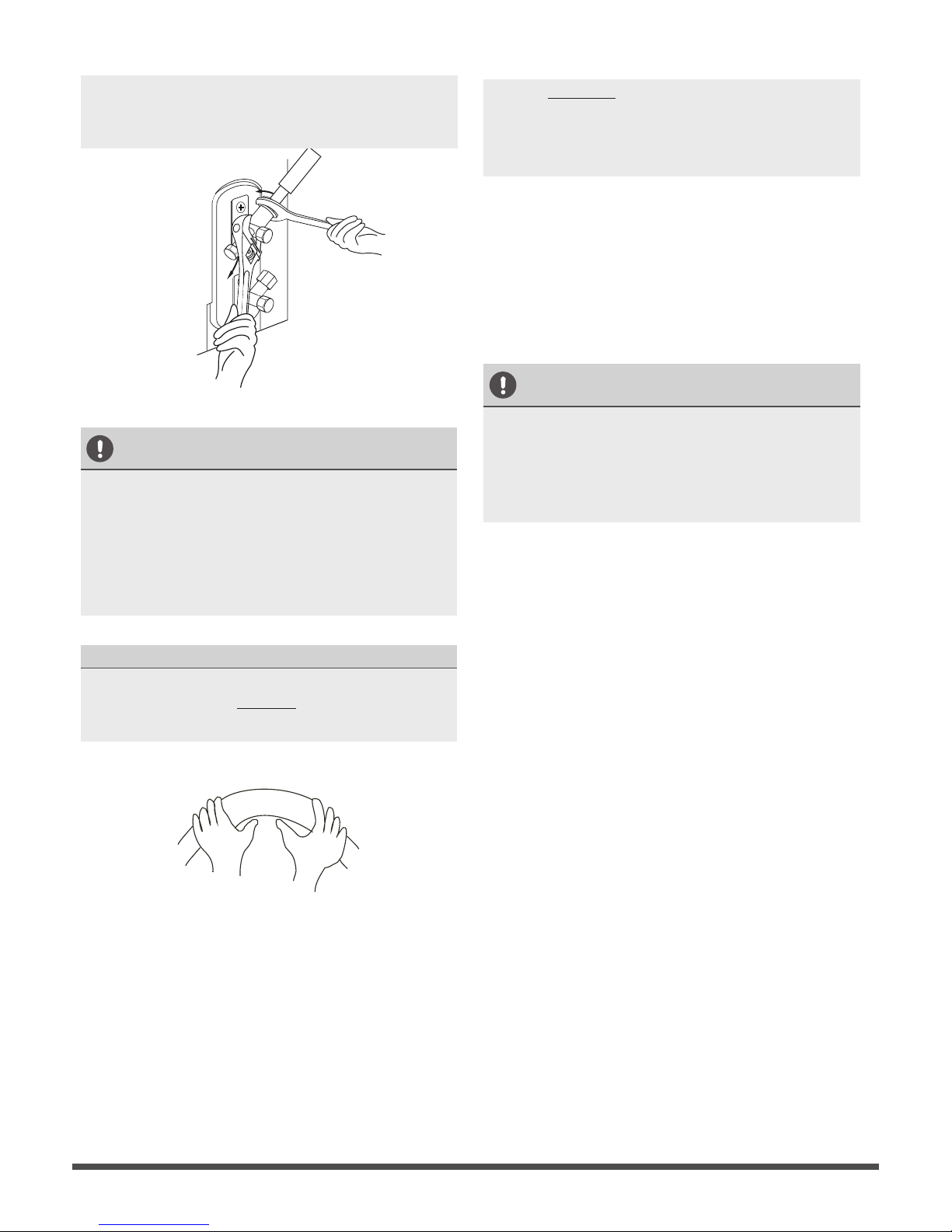

b. Using wire strippers, strip the rubber jacket

from both ends of the signal cable to reveal

approximately 15cm (5.9”) of wire.

c.

Strip the insulation from the ends.

d. Using a wire crimper, crimp u-lugs on the

ends.

NOTE: When connecting the wires, strictly

follow the wiring diagram found inside the

electrical box cover.

2.

Remove the electric cover of the outdoor unit.

If there is no cover on the outdoor unit, take

off the bolts from the maintenance board

and remove the protection board.

(See Fig. 8.1 and 8.2).

Cover

Screw

Fig. 8.1

Protection Board

Fig. 8.2

3.

Connect the u-lugs to the terminals

Match the wire colors/labels with the labels

on the terminal block. Firmly screw the u-lug

of each wire to its corresponding terminal.

4. Clamp down the cable with the cable clamp.

5.

Insulate unused wires with electrical tape.Keep

them away from any electrical or metal parts.

6. Reinstall the cover of the electric control box.

Indoor Unit Wiring

1.

Prepare the cable for connection.

a. Using wire strippers, strip the rubber jacket

from both ends of the signal cable to reveal

about 15cm (5.9”) of the wire.

b.

Strip the insulation from the ends of the

wires.

c.

Using a wire crimper, crimp the u-lugs to

the ends of the wires.

2. Remove the cover of the electric control box

on your indoor unit.

3.

Connect the u-lugs to the terminals.

Match the wire colors/labels with the labels

on the terminal block. Firmly screw the

u-lug of each wire to its corresponding

terminal. Refer to the Serial Number and

Wiring Diagram located on the cover of the

electric control box.

Connective wiring diagram

Wiring diagram

Control box

Fig. 8.3

Table 8.2: Other World Regions

Rated Current of

Appliance (A)

Area (mm²)

Nominal Cross-Sectional

≤ 6 0.75

6 - 10 1

10 - 16 1.5

16 - 25 2.5

25- 32 4

32 - 45 6

Fig. 8.4

Magnetic ring

(if supplied and packed with the accessories)

1 2 3

Pass the belt through

the hole of the Magnetic

ring to fix it on the cable

Page 22

Step 3: Flare pipe ends

Proper flaring is essential to achieve an

airtight seal.

1. After removing burrs from cut pipe, seal

the ends with PVC tape to prevent foreign

materials from entering the pipe.

2. Sheath the pipe with insulating material.

3.

Place flare nuts on both ends of pipe.

Make sure they are facing in the right

direction, because you can’t put them on

or change their direction after flaring.

See Fig. 7.6

Flare nut

Copper pipe

Fig. 7.6

4.

Remove PVC tape from ends of pipe when

ready to perform flaring work.

5.

Clamp flare form on the end of the pipe.

The end of the pipe must extend beyond

the flare form.

Flare form

Pipe

Fig. 7.7

6.

Place flaring tool onto the form.

7.

Turn the handle of the flaring tool

clockwise until the pipe is fully flared.

Flare the pipe in accordance with the

dimensions shown in table 7.5.

8.

Remove the flaring tool and flare form, then

inspect the end of the pipe for cracks and

even flaring.

Step 4: Connect pipes

Connect the copper pipes to the indoor unit first,

then connect it to the outdoor unit. You should

first connect the low-pressure pipe, then the highpressure pipe.

1.

When connecting the flare nuts, apply a thin

coat of refrigeration oil to the flared ends of

the pipes.

2. Align the center of the two pipes that you

will connect.

Indoor unit tubing

Flare nut

Pipe

Fig. 7.9

3.

Tighten the flare nut as tightly as possible by hand.

4.

Using a spanner, grip the nut on the unit tubing.

5.

While firmly gripping the nut, use a torque

wrench to tighten the flare nut according to

the torque values in table 7.5.

Table 7.5: PIPING EXTENSION BEYOND FLARE FORM

Pipe

gauge

Tightening

torque

Flare dimension (A)

(Unit: mm/Inch)

Flare shape

Min. Max.

Ø 6.4

R0.4~0.8

45

°

±

2

90

°

±

4

A

Fig. 7.8

Ø 9.5

Ø 12.7

Ø 15.9

Ø 19.1

Ø 22

65-67 N.m

(663-683 kgf.cm)

23.2/0.91 23.7/0.93

75-85N.m

(765-867 kgf.cm)

26.4/1.04 26.9/1.06

18-20 N.m

(183-204 kgf.cm)

8.4/0.33 8.7/0.34

25-26 N.m

(255-265 kgf.cm)

13.2/0.52 13.5/0.53

35-36 N.m

(357-367 kgf.cm)

16.2/0.64 16.5/0.65

45-47 N.m

(459-480 kgf.cm)

19.2/0.76 19.7/0.78

NOTE: Use both a spanner and a torque wrench

when connecting or disconnecting pipes to/from

the unit.

Fig. 7.10

CAUTION

•

Ensure to wrap insulation around the piping.

Direct contact with the bare piping may result

in burns or frostbite.

•

Make sure the pipe is properly connected.

Over tightening may damage the bell mouth

and under tightening may lead to leakage.

NOTE ON MINIMUM BEND RADIUS

Carefully bend the tubing in the middle according

to the diagram below. DO NOT bend the tubing

more than 90° or more than 3 times.

Bend the pipe with thumb

min-radius 10cm (3.9”)

Fig. 7.11

6.

After connecting the copper pipes to the

indoor unit, wrap the power cable, signal

cable and the piping together with binding

tape.

NOTE: DO NOT intertwine signal cable with

other wires. While bundling these items

together, do not intertwine or cross the signal

cable with any other wiring.

7. Thread this pipeline through the wall and

connect it to the outdoor unit.

8. Insulate all the piping, including the valves

of the outdoor unit.

9. Open the stop valves of the outdoor unit

to start the flow of the refrigerant

between the indoor and outdoor unit.

CAUTION

Check to make sure there is no refrigerant leak

after completing the installation work. If there is

a refrigerant leak, ventilate the area immediately

and evacuate the system (refer to the Air

Evacuation section of this manual).

Page 23

NOTE: Use both a spanner and a torque wrench

when connecting or disconnecting pipes to/from

the unit.

Fig. 7.10

CAUTION

•

Ensure to wrap insulation around the piping.

Direct contact with the bare piping may result

in burns or frostbite.

•

Make sure the pipe is properly connected.

Over tightening may damage the bell mouth

and under tightening may lead to leakage.

NOTE ON MINIMUM BEND RADIUS

Carefully bend the tubing in the middle according

to the diagram below. DO NOT bend the tubing

more than 90° or more than 3 times.

Bend the pipe with thumb

min-radius 10cm (3.9”)

Fig. 7.11

6.

After connecting the copper pipes to the

indoor unit, wrap the power cable, signal

cable and the piping together with binding

tape.

NOTE: DO NOT intertwine signal cable with

other wires. While bundling these items

together, do not intertwine or cross the signal

cable with any other wiring.

7. Thread this pipeline through the wall and

connect it to the outdoor unit.

8. Insulate all the piping, including the valves

of the outdoor unit.

9. Open the stop valves of the outdoor unit

to start the flow of the refrigerant

between the indoor and outdoor unit.

CAUTION

Check to make sure there is no refrigerant leak

after completing the installation work. If there is

a refrigerant leak, ventilate the area immediately

and evacuate the system (refer to the Air

Evacuation section of this manual).

Page 24

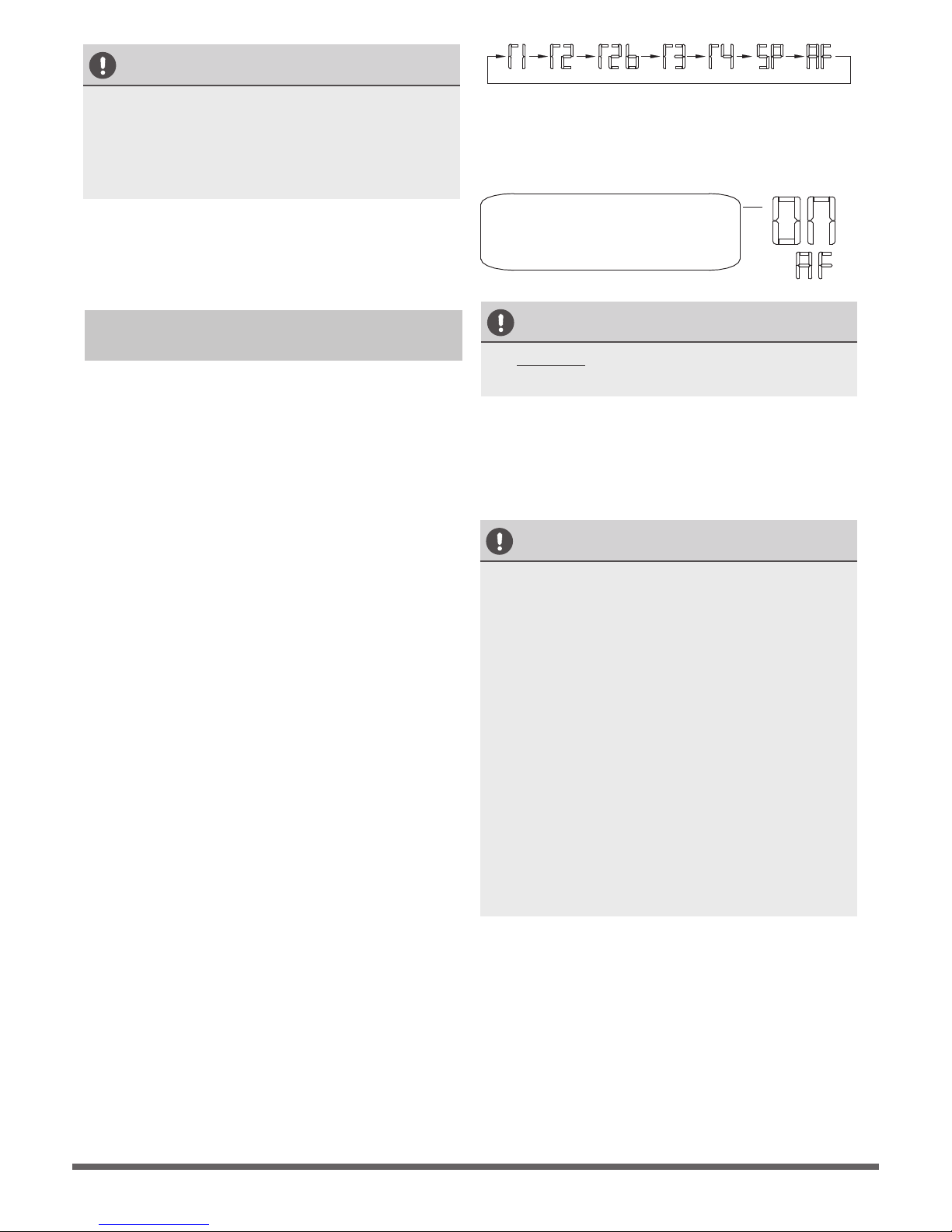

You can use the unit’s automatic airflow

adjustment function to set external static

pressure.

Automatic airflow adjustment is the volume

of blow-off air that has been automatically

adjusted to the quantity rated.

1. Make sure the test run is done with a dry

coil. If the coil is not dry, run the unit for 2

hours in FAN ONLY mode to dry the coil.

2. Check that both power supply wiring and

duct installation have been completed

Check that any closing dampers are open.

Check that the air filter is properly attached

to the air suction side passage of the unit.

3. If there is more than one air inlet and outlet,

adjust the dampers so that the airflow rate

of each air inlet and outlet conforms with

the designed airflow rate. Make sure the

unit is in FAN ONLY mode. Press and set

the airflow adjustment button on the

remote control to change the airflow rate

from H or L.

•

•

4. Set the parameters for automatic airflow

adjustment. When the air conditioning unit

is off, perform the follwoing steps:

- Press“COPY”.

- Press “+” or “-” to select the AF.

- Press “CONFIRM”. The air conditioning

unit will then start the fan for airflow

automatic adjustment.

ON will flash during when the

fan is on during automatic

airflow adjustment.

After 3 to 6 minutes, the air conditioning

unit stops operating once automatic airflow

adjustment has finished.

CAUTION

• DO NOT adjust the dampers when

automatic airflow adjustment is active.

CAUTION

• If there is no change after airflow

adjustment in the ventilation paths, be sure

to reset automatic airflow adjustment.

• If there is no change to ventilation paths

after airflow adjustment,contact your

dealer, especially if this occurs after

testing the outdoor unit or if the unit has

been moved to a different location.

• Do not use automatic airflow adjustment

with remote control,if you are using

booster fans, outdoor air processing unit,

or a HRV via duct.

• If the ventilation paths have been changed,

reset airflow automatic adjustment as

described from step 3 onwards.

CAUTION

• While connecting the wires, please strictly

follow the wiring diagram.

• The refrigerant circuit can become very

hot. Keep the interconnection cable away

from the copper tube.

4.

Clamp down the cable with the cable clamp.

The cable must not be loose or pull on the

u-lugs.

5. Reinstall the electric box cover .

Using the wire controller to set external

static pressure (some models)

Page 25

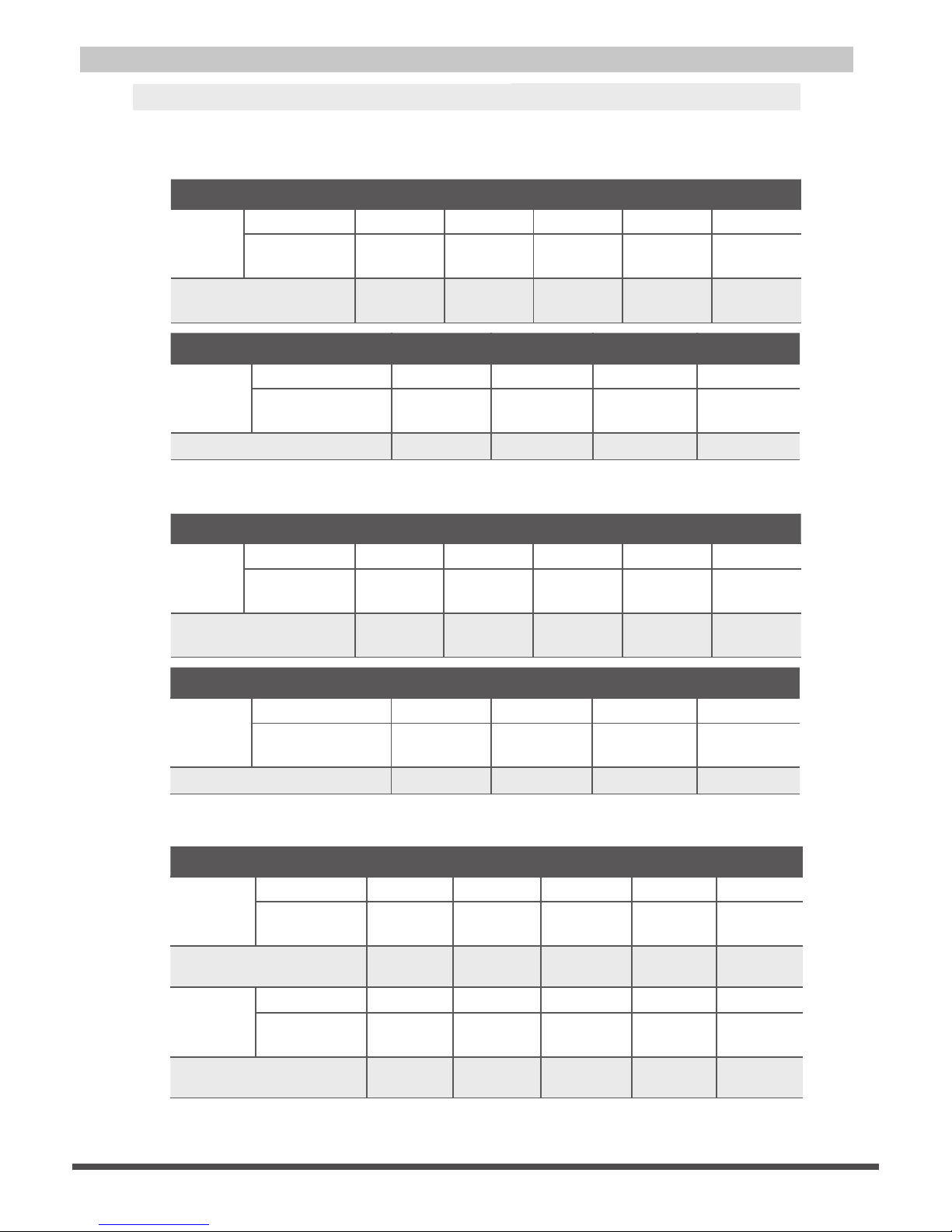

Power Specifications

NOTE: Electric auxiliary heating type circuit bre

aker/fuse need to add more than 10 A.

Indoor Power Supply Specifications

MODEL

(Btu/h)

≤18K 19K~24K 25K~36K 37K~48K 49K~60K

POWER

PHASE 1 Phase 1 Phase 1 Phase 1 Phase 1 Phase

VOLT

VOLT

VOLT

VOLT

VOLT

VOLT

208-240V 208-240V 208-240V 208-240V 208-240V

CIRCUIT BREAKER/

FUSE(A)

25/20 32/25 50/40 70/55 70/60

MODEL

(Btu/h)

≤36K 37K~60K ≤36K 37K~60K

POWER

PHASE 3 Phase 3 Phase 3 Phase 3 Phase

380-420V 380-420V 208-240V 208-240V

CIRCUIT BREAKER/FUSE(A) 25/20 32/25 32/25 45/35

MODEL

(Btu/h)

≤18K 19K~24K 25K~36K 37K~48K 49K~60K

POWER

PHASE 1 Phase 1 Phase 1 Phase 1 Phase 1 Phase

208-240V 208-240V 208-240V 208-240V 208-240V

CIRCUIT BREAKER/

FUSE(A)

25/20 32/25 50/40 70/55 70/60

MODEL

(Btu/h)

≤36K 37K~60K ≤36K 37K~60K

POWER

PHASE 3 Phase 3 Phase 3 Phase 3 Phase

380-420V 380-420V 208-240V 208-240V

CIRCUIT BREAKER/FUSE(A) 25/20 32/25 32/25 45/35

Outdoor Power Supply Specifications

Independent Power Supply Specifications

MODEL

(Btu/h)

≤18K 19K~24K 25K~36K 37K~48K 49K~60K

POWER

(indoor)

PHASE 1 Phase 1 Phase 1 Phase 1 Phase 1 Phase

208-240V 208-240V 208-240V208-240V 208-240V

CIRCUIT BREAKER/

FUSE(A)

15/10 15/10 15/10 15/10 15/10

POWER

(outdoor)

PHASE 1 Phase 1 Phase 1 Phase 1 Phase 1 Phase

208-240V 208-240V 208-240V

208-240V

208-240V

CIRCUIT BREAKER/

FUSE(A)

25/20 32/25 50/40 70/55 70/60

Page 26

MODEL

(Btu/h)

≤18K 19K~24K 25K~36K 37K~48K 49K~60K

POWER

(indoor)

PHASE 1 Phase 1 Phase 1 Phase 1 Phase 1 Phase

220-240V 220-240V 220-240V220-240V 220-240V

CIRCUIT BREAKER/

FUSE(A)

15/10 15/10 15/10 15/10 15/10

POWER

(outdoor)

PHASE 1 Phase 1 Phase 1 Phase 1 Phase 1 Phase

208-240V 208-240V 208-240V

208-240V

208-240V

CIRCUIT BREAKER/

FUSE(A)

25/20 25/20 40/30 50/40 50/40

MODEL

(Btu/h)

≤36K 37K~60K ≤36K 37K~60K

POWER

(indoor)

PHASE 1 Phase 1 Phase 1 Phase 1 Phase

VOLT

VOLT

VOLT

VOLT

VOLT

VOLT

208-240V 208-240V 208-240V 208-240V

CIRCUIT BREAKER/FUSE(A) 15/10 15/10 15/10 15/10

POWER

(outdoor)

PHASE 3 Phase 3 Phase 3 Phase 3 Phase

380-420V 380-420V 208-240V 208-240V

CIRCUIT BREAKER/FUSE(A) 25/20 32/25 32/25 45/35

MODEL

(Btu/h)

≤36K 37K~60K ≤36K 37K~60K

POWER

(indoor)

PHASE 1 Phase 1 Phase 1 Phase 1 Phase

220-240V 220-240V 220-240V 220-240V

CIRCUIT BREAKER/FUSE(A) 15/10 15/10 15/10 15/10

POWER

(outdoor)

PHASE 3 Phase 3 Phase 3 Phase 3 Phase

380-420V 380-420V 208-240V 208-240V

CIRCUIT BREAKER/FUSE(A) 25/20 32/25 32/25 40/30

Inverter Type A/C Power Specifications

NOTE:

To be in compliance with EN61000-3-11, the product shall be connected

= 0.267802236 Ω or less. Before connecting only to a supply of the system impedance: Zsys

the product to public power network, please consult your local power supply authority to

ensure the power network meet above requirement.

Page 27

Air Evacuation

Safety Precautions

CAUTION

• Use a vacuum pump with a gauge reading

lower than -0.1MPa and an air discharge

capacity above 40L/min.

• The outdoor unit does not need vacuuming.

DO NOT open the outdoor unit’s gas and

liquid stop valves.

• Ensure that the Compound Meter reads

-0.1MPa or below after 2 hours. If after

three hours the gauge reading is still above

-0.1MPa, check if there is a gas leak or

water inside the pipe. If there is no leak,

perform another evacuation for 1 or 2 hours.

•

DO NOT use refrigerant gas to evacuate the

system.

Evacuation Instructions

Before using a manifold gauge and a vacuum

pump, read their operation manuals to make

sure you know how to use them properly.

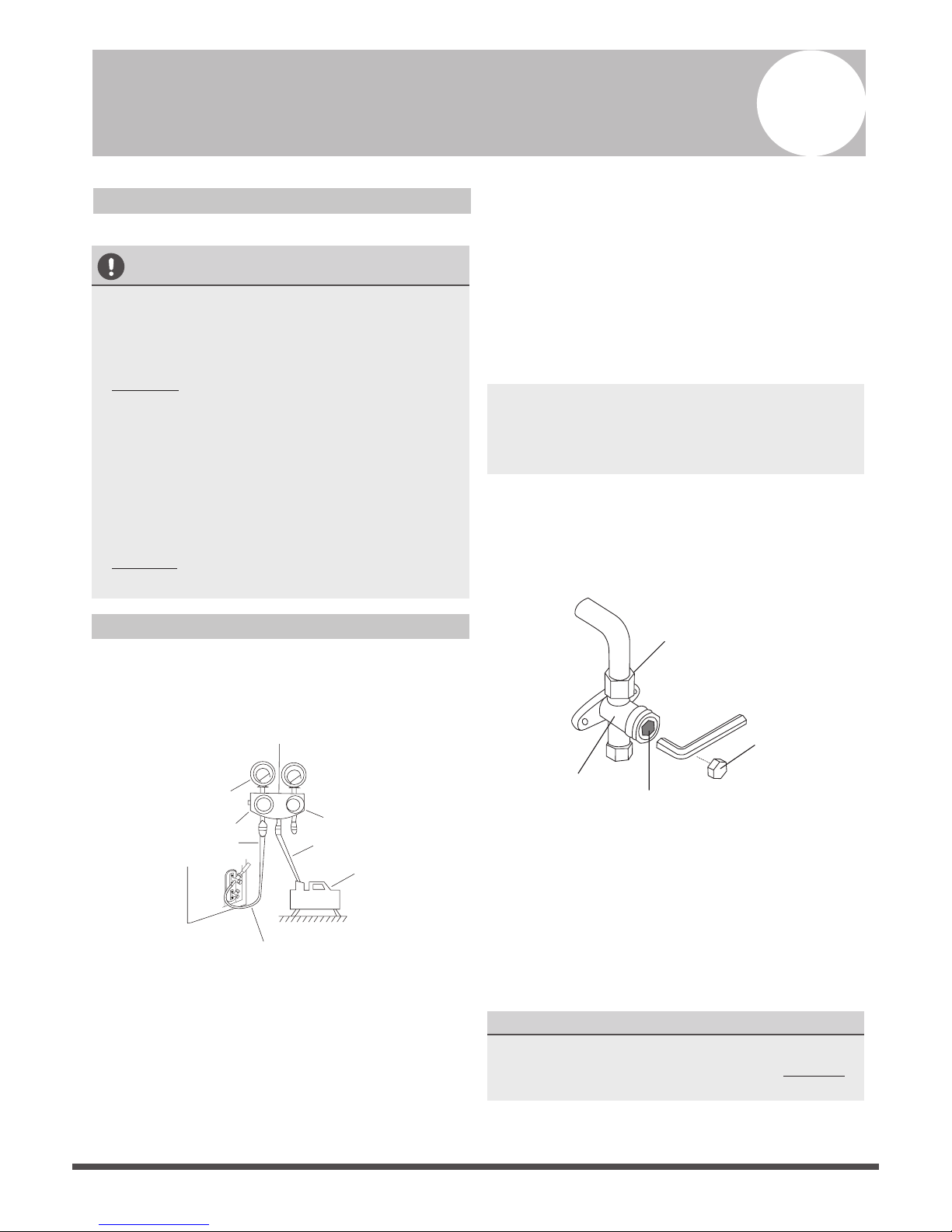

Manifold Gauge

Compound gauge

-76cmHg

Low pressure valve

High pressure valve

Charge hose

Charge hose

Vacuum pump

Pressure gauge

Low pressure valve

Fig. 9.1

1. Connect the manifold gauge’s charge hose to

the service port on the outdoor unit’s low

pressure valve.

2. Connect the manifold gauge’s charge hose

from the to the vacuum pump.

3. Open the Low Pressure side of the manifold

gauge. Keep the High Pressure side closed.

4. Turn on the vacuum pump to evacuate the

system.

5. Run the vacuum for at least 15 minutes, or

until the Compound Meter reads -76cmHG

(-1x105Pa).

6. Close the manifold gauge’s Low Pressure valve

and turn off the vacuum pump.

7. Wait for 5 minutes, then check that there has

been no change in system pressure.

NOTE: If there is no change in system pressure,

unscrew the cap from the packed valve (high

pressure valve). If there is a change in system

pressure, there may be a gas leak.

8. Insert hexagonal wrench into the packed valve

(high pressure valve) and open the valve by

turning the wrench in a 1/4 counterclockwise

turn. Listen for gas to exit the system, then

close the valve after 5 seconds.

Flare nut

Cap

Valve body

Valve stem

Fig. 9.2

9. Watch the Pressure Gauge for one minute to

make sure that there is no change in pressure. It

should read slightly higher than the atmospheric

pressure.

10.Remove the charge hose from the service port.

11.Using hexagonal wrench, fully open both the

high pressure and low pressure valves.

OPEN VALVE STEMS GENTLY

When opening valve stems, turn the hexagonal

wrench until it hits against the stopper. DO NOT

try to force the valve to open further.

12.Tighten valve caps by hand, then tighten it

using the proper tool.

9

Page 28

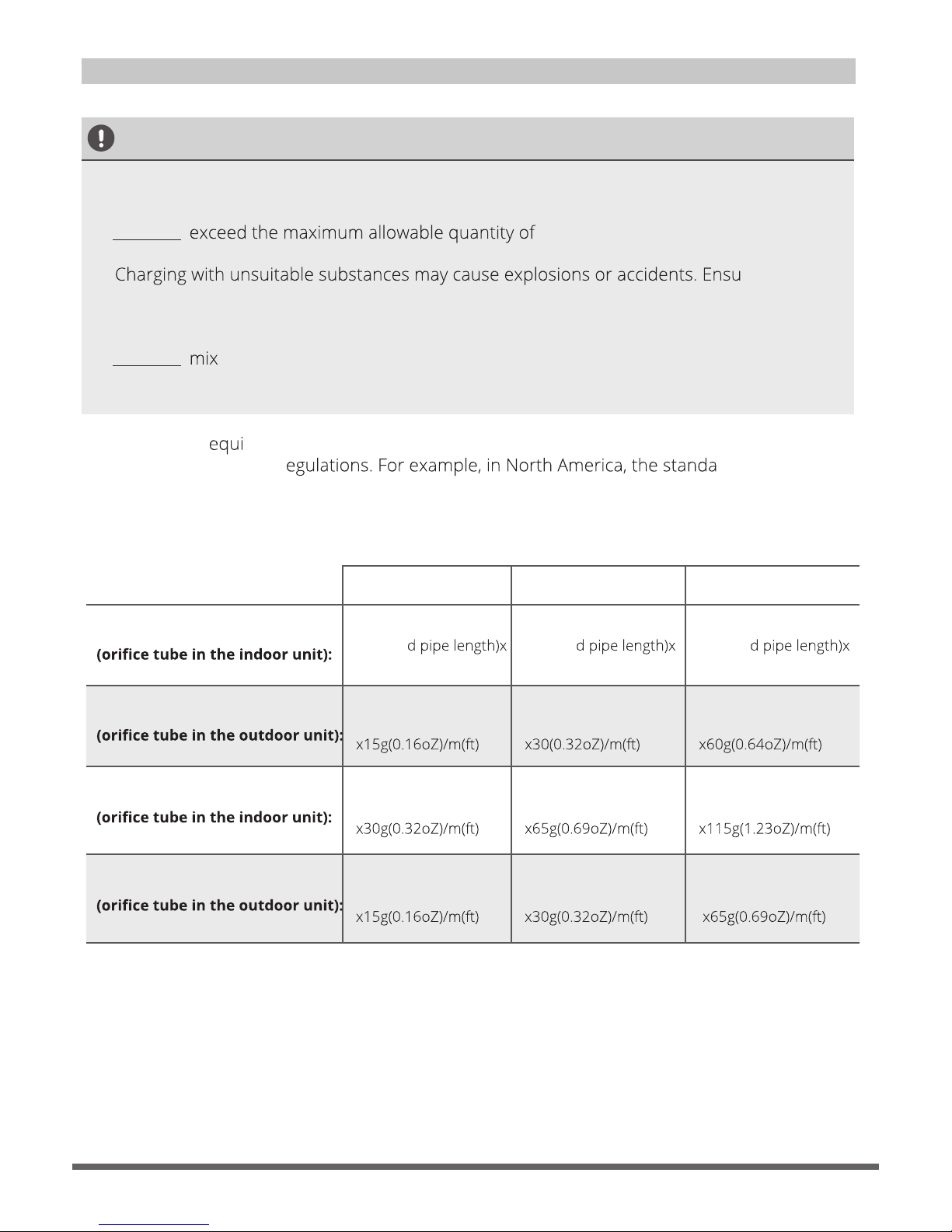

Note On Adding Refrigerant

CAUTION

• Refrigerant charging must be performed after wiring, vacuuming, and the leak testing.

• DO NOT refrigerant or overcharge the system.

Doing so can damage the unit or impact it’s functioning.

•

re that the

appropriate refrigerant is used.

• Refrigerant containers must be opened slowly. Always use protective gear when charging the

system.

• DO NOT refrigerants types.

Some systems r

re additional charging depending on pipe lengths. The standard pipe length

varies according to local r rd pipe length is

7.5m (25’) In other areas, the standard pipe length is 5m (16‘). The additional refrigerant to be

charged can be calculated using the following formula:

Liquid Side Diameter

φ6.35(1/4”) φ9.52(3/8”) φ12.7(1/2”)

R22

(Total pipe length standar

30g (0.32oZ)/m(ft)

(Total pipe length standar

65g(0.69oZ)/m(ft)

(Total pipe length standar

115g(1.23oZ)/m(ft)

R22

(Total pipe length standard pipe length)

(Total pipe length standard pipe length)

(Total pipe length -

standard pipe length)

(Total pipe length -

standard pipe length)

R410A:

(Total pipe length standard pipe length)

(Total pipe length standard pipe length)

(Total pipe length standard pipe length)

R410A:

(Total pipe length standard pipe length)

(Total pipe length standard pipe length)

Page 29

Before Test Run

A test run must be performed after the entire

system has been completely installed. Confirm

the following points before performing the test:

a) Indoor and outdoor units are properly

installed.

b) Piping and wiring are properly connected.

c) No obstacles near the inlet and outlet of the

unit that might cause poor performance or

product malfunction.

d) Refrigeration system does not leak.

e) Drainage system is unimpeded and

draining to a safe location.

f) Heating insulation is properly installed.

Grounding wires are properly connected.

g)

h) Length of the piping and the added

refrigerant stow capacity have been

recorded.

i) Power voltage is the correct voltage for the

air conditioner.

CAUTION

Failure to perform the test run may result in unit

damage, property damage, or personal injury.

Test Run Instructions

1. Open both the liquid and gas stop valves.

2. Turn on the main power switch and allow the

unit to warm up.

3. Set the air conditioner to COOL mode.

4. For the Indoor Unit

a. Ensure the remote control and its buttons

work properly.

b. Ensure the louvers move properly and can

be changed using the remote control.

c. Double check to see if the room

temperature is being registered correctly.

d. Ensure the indicators on the remote

control and the display panel on the indoor

unit work properly.

e. Ensure the manual buttons on the indoor

unit works properly.

f. Check to see that the drainage system is

unimpeded and draining smoothly.

g. Ensure there is no vibration or abnormal

noise during operation.

5. For the Outdoor Unit

a. Check to see if the refrigeration system is

leaking.

b. Make sure there is no vibration or

abnormal noise during operation.

c. Ensure the wind, noise, and water

generated by the unit do not disturb your

neighbors or pose a safety hazard.

6. Drainage Test

a. Ensure the drainpipe flows smoothly. New

buildings should perform this test before

finishing the ceiling.

b. Remove the test cover. Add 2,000ml of

water to the tank through the attached

tube.

c. Turn on the main power switch and run

the air conditioner in COOL mode.

d. Listen to the sound of the drain pump to

see if it makes any unusual noises.

e. Check to see that the water is discharged.

It may take up to one minute before the

unit begins to drain depending on the

drainpipe.

f. Make sure that there are no leaks in any of

the piping.

g. Stop the air conditioner. Turn off the main

power switch and reinstall the test cover.

NOTE: If the unit malfunctions or does not

operate according to your expectations, please

refer to the Troubleshooting section of the

Owner’s Manual before calling customer service.

Test Run

10

Page 30

The design and specifications are subject to change without prior notice for product

improvement. Consult with the sales agency or manufacturer for details.

Page 31

Σελίδα 2

Εγχειρίδιο Εγκατάστασης

Περιεχόμενα

1 Εξαρτήματα........................................04

α. Μέρη εσωτερικής μονάδας..................................08

β. Οδηγίες εγκατάστασης εσωτερικής μονάδας....09

α. Οδηγίες εγκατάστασης εξωτερικής μονάδας……..... 13

β. Τύποι και προδιαγραφές εξωτερικών μονάδων…… 14

γ. Σημειώσεις για τη διάτρηση σε τοίχους.....................14

2 Προφυλάξεις ασφαλείας.................. 05

3 Επισκόπηση εγκατάστασης..............07

6 Εγκατάσταση σωλήνα αποχέτευσης...............15

4 Εγκατάσταση εσωτερικής μονάδας..................07

5 Εγκατάσταση εξωτερικής μονάδας.................... 12

MC MC

L N

Σελίδα 3

MC MC

L N

α. Σημειώσεις για το μήκος και το ύψος των σωλήνων .....18

β. Οδηγίες σύνδεσης σωλήνων ψυκτικού υγρού ...............20

α. Οδηγίες εκκένωσης...........................................................27

β. Σημείωση για την προσθήκη ψυκτικού .........................28

α. Καλωδίωση εξωτερικής μονάδας......... 22

β. Καλωδίωση εσωτερικής μονάδας........ 23

γ. Προδιαγραφές ισχύoς............................. 25

7 Σύνδεση σωληνώσεων ψυκτικού.................................18

9 Εκκένωση του αέρα........................................................27

10 Δοκιμαστική Λειτουργία..................................................29

8 Καλωδίωση..............................................20

Σελίδα 4

S1&S2(P&Q&E)

Εξαρτήματα

1

Το κλιματιστικό μηχάνημα διαθέτει τα εξαρτήματα που παρατίθενται παρακάτω. Χρησιμοποιήστε

όλα τα μέρη και εξαρτήματα εγκατάστασης για να εγκαταστήσετε το κλιματιστικό. Τυχόν εσφαλμένη

εγκατάσταση μπορεί να προκαλέσει διαρροή νερού, ηλεκτροπληξία και πυρκαγιά ή καταστροφή του

εξοπλισμού.

Υπάρχουν δύο τύποι τηλεχειριστηρίων: ενσύρματα και ασύρματα. Επιλέξτε τηλεχειριστήριο με

βάση τις απαιτήσεις και τοποθετήστε το σε κατάλληλο σημείο.

Συμβουλευθείτε καταλόγους και τεχνικά έντυπα για καθοδήγηση ως προς την επιλογή του

κατάλληλου τηλεχειριστηρίου.

ΟΝΟΜΑ ΣΧΗΜΑ ΠΟΣΟΣΤΗΤΑ

Σωληνώσεις και

εξαρτήματα σύνδεσης

Ηχοαπορροφητική / μονωτική επένδυση 2

1

1

1

1

1

1

1

1

1

Αφρώδες υλικό στεγανοποίησης (ορισμένα μοντέλα)

Στόμιο (ορισμένα μοντέλα)

Σύνδεσμος αποχέτευσης (ορισμένα μοντέλα)

Δακτύλιος στεγανοποίησης (ορισμένα μοντέλα)

Εγχειρίδιο χρήστη

Εγχειρίδιο εγκατάστασης

Συνδετήριο καλώδιο για την οθόνη (2m)

Ελαστικός δακτύλιος προστασίας καλωδίου

Μαγνητικός δακτύλιος

(για να περιβάλλει τα καλώδια S1 & S2 ( P & Q & E )

γύρω από το μαγνητικό δακτύλιο δύο φορές)

Μαγνητικός δακτύλιος

(αγκιστρώστε στο καλώδιο σύνδεσης μεταξύ της

εσωτερικής μονάδας και της εξωτερικής μονάδας μετά

από την εγκατάσταση)

Σύνδεσμος μεταφοράς (φ12.7-Φ 15.9)/ (Φ 0.5 i n-Φ 0.63

(συσκευασμένος με την εσωτερική μονάδα)

ΣΗΜΕΙΩΣΗ: Το μέγεθος σωλήνα μπορεί να ποικίλλει

ανάλογα με τη συσκευή. Για να καλυφθούν οι

επιμέρους απαιτήσεις μεγέθους σωλήνα, μερικές

φορές οι συνδέσεις χρειάζονται σύνδεσμο μεταφοράς

τοποθετημένο στην εξωτερική μονάδα.

Σύνδεσμος μεταφοράς (Φ6.35-Φ9.52)/ ( Φ0 .25 i n-Φ

0.375 (συσκευασμένος με την εσωτερική μονάδα)

ΣΗΜΕΙΩΣΗ: Το μέγεθος σωλήνα μπορεί να ποικίλλει

ανάλογα με τη συσκευή. Για να καλυφθούν οι

επιμέρους απαιτήσεις μεγέθους σωλήνα, μερικές

φορές οι συνδέσεις χρειάζονται σύνδεσμο μεταφοράς

τοποθετημένο στην εξωτερική μονάδα.

Σύνδεσμος μεταφοράς (Φ9.52-ΦΊ2.7)/(Φ0.3 75in- Φ 0.5 )in

(συσκευασμένος με την εσωτερική μονάδα , χρησιμοποιείται

μόνο για μοντέλα multi) ΣΗΜΕΙΩΣΗ: Το μέγεθος σωλήνα μπορεί

να ποικίλλει ανάλογα με τη συσκευή. Για να καλυφθούν οι

επιμέρους απαιτήσεις μεγέθους σωλήνα, μερικές φορές οι

συνδέσεις χρειάζονται σύνδεσμο μεταφοράς τοποθετημένο

στην εξωτερική μονάδα.

Εξαρτήματα σωλήνα

αποχέτευσης (για ψύξη

και θέρμανση)

Μαγνητικός δακτύλιος

προστασίας EMC

(ορισμένα μοντέλα)

Λοιπά

Προαιρετικά εξαρτήματα

Οθόνη λειτουργιών

*μόνο για δοκιμαστική λειτουργία

1 (για ορισμένα μοντέλα-

KJR-120G,KJR-120H)

1

(για ορισμένα μοντέλα)

1

(για ορισμένα μοντέλα)

1

(για ορισμένα μοντέλα)

1

(για ορισμένα μοντέλα)

Σελίδα 5

Προφυλάξεις Ασφαλείας

2

Μη συμμόρφωση με μια προειδοποίηση μπορεί να οδηγήσει στον θάνατο.

Η συσκευή θα πρέπει να εγκαθίσταται σύμφωνα με τους εθνικούς κανονισμούς.

ΠΡΟΕΙΔΟΠΟΙΗΣΗ

ΠΡΟΣΟΧΗ

Μη συμμόρφωση με μια σήμανση προσοχής μπορεί να οδηγήσει σε τραυματισμό

ή βλάβη του εξοπλισμού.

Διαβάστε τις προφυλάξεις ασφαλείας πριν από την εγκατάσταση.

Τυχόν εσφαλμένη εγκατάσταση που οφείλεται σε άγνοια των οδηγιών, μπορεί να προκαλέσει

σοβαρή βλάβη ή τραυματισμό. Η σοβαρότητα πιθανής βλάβης ή τραυματισμού αναφέρεται ως

ΠΡΟΕΙΔΟΠΟΙΗΣΗ ή ΠΡΟΣΟΧΗ.

ΠΡΟΕΙΔΟΠΟΙΗΣΗ

Σημείωση σχετικά με τα Φθοριούχα Αέρια

• Διαβάστε προσεκτικά τις Προφυλάξεις Ασφαλείας πριν την εγκατάσταση.

• Σε ορισμένα λειτουργικά περιβάλλοντα, όπως κουζίνες, αίθουσες εξυπηρετήσεων κλπ., συνιστάται η χρήση

ειδικών μονάδων κλιματισμού.

• Μόνο εξειδικευμένοι και πιστοποιημένοι τεχνικοί μπορούν να εγκαταστήσουν, να επισκευάσουν

και να συντηρήσουν το κλιματιστικό.

Η ακατάλληλη εγκατάσταση μπορεί να προκαλέσει ηλεκτροπληξία, βραχυκύκλωμα, διαρροές, πυρκαγιά ή

άλλες ζημιές στον εξοπλισμό και την προσωπική ιδιοκτησία.

• Τηρείτε αυστηρά τις οδηγίες εγκατάστασης που ορίζονται στο παρόν εγχειρίδιο.

Η ακατάλληλη εγκατάσταση μπορεί να προκαλέσει ηλεκτροπληξία, βραχυκύκλωμα, διαρροές, πυρκαγιά ή

άλλες ζημιές στον εξοπλισμό.

• Πριν εγκαταστήσετε τη μονάδα, εξετάστε τους ισχυρούς ανέμους, τους τυφώνες και τους σεισμούς

που μπορεί να προκαλέσουν βλάβες στη μονάδα σας και δράστε ανάλογα. Διαφορετικά ενδέχεται να

προκληθούν ζημιές στο κλιματιστικό σας.

• Μετά την εγκατάσταση, βεβαιωθείτε ότι δεν υπάρχουν διαρροές ψυκτικού μέσου και ότι η μονάδα

λειτουργεί σωστά. Το ψυκτικό μέσο είναι τοξικό και εύφλεκτο και μπορεί να προκαλέσει σοβαρό κίνδυνο

στην υγεία και την ασφάλεια σας.

1. Αυτή η μονάδα κλιματισμού περιέχει φθοριούχα αέρια. Για ειδικές πληροφορίες σχετικά με τον τύπο και

τη ποσότητα του αερίου, ανατρέξτε στη σχετική ετικέτα που φέρει η μονάδα.

2. Η εγκατάσταση, η συντήρηση και η επισκευή αυτής της συσκευής πρέπει να γίνεται από πιστοποιημένο

τεχνικό.

3. Η απεγκατάσταση και η ανακύκλωση του προϊόντος πρέπει να εκτελούνται από πιστοποιημένο τεχνικό.

4. Εάν το σύστημα έχει εγκατεστημένο σύστημα ανίχνευσης διαρροών, πρέπει να ελέγχεται για διαρροές

τουλάχιστον κάθε 12 μήνες.

5. Όταν η μονάδα ελέγχεται για διαρροές, συνιστάται η σωστή καταγραφή όλων των ελέγχων.

Σελίδα 6

LN

1

2

3

4

5

MC MC

6

7

Επισκόπηση εγκατάστασης

3

ΣΕΙΡΑ ΕΓΚΑΤΑΣΤΑΣΗΣ

Τοποθετήστε την

εσωτερική μονάδα

(Σελίδα 9)

Εκκενώστε το ψυκτικό

σύστημα (Σελίδα 27)

Προβείτε σε δοκιμαστική

λειτουργία (Σελίδα 29)

Συνδέστε τα καλώδια

(Σελίδα 22)

Συνδέστε τους σωλήνες

ψυκτικού (Σελίδα 19)

Τοποθετήστε την

εξωτερική μονάδα

(Σελίδα 15)

Τοποθετήστε το

σωλήνα αποχέτευσης

(Σελίδα 17)

Σελίδα 7

Εγκατάσταση εσωτερικής μονάδας

4

Μέρη εσωτερικής μονάδας

Προφυλάξεις Ασφαλείας

Οδηγίες εγκατάστασης εσωτερικής μονάδας

Είσοδος αέρα

Εξαγωγή αέρα

Εικ. 4.1

Ερμάριο ηλεκτρολογικού ελέγχου

Φίλτρο αέρα (σε ορισμένα μοντέλα)

Σωλήνας αποχέτευσης

Σωλήνας σύνδεσης ψυκτικού

ΠΡΟΕΙΔΟΠΟΙΗΣΗ ΠΡΟΣΟΧΗ

ΠΡΟΣΟΧΗ

• Εγκαταστήσετε σταθερά την εσωτερική μονάδα σε

κατασκευή, η οποία να μπορεί να αντέξει το βάρος της.

Εάν η εν λόγω κατασκευή δεν είναι στιβαρή, η μονάδα

ενδέχεται να πέσει και να προκληθεί τραυματισμός, βλάβη

στη μονάδα ή άλλες υλικές ζημίες ή θάνατος.

• ΜΗΝ τοποθετείτε την εσωτερική μονάδα σε μπάνιο ή

πλυσταριό, καθώς η υπερβολική υγρασία από αυτούς

τους χώρους ενδέχεται να προκαλέσει βραχυκύκλωμα της

μονάδας και διάβρωση των καλωδίων.

Βήμα 1: Επιλέξτε τη θέση εγκατάστασης

Η εσωτερική μονάδα θα πρέπει να εγκατασταθεί σε θέση που

να καλύπτει τις παρακάτω προϋποθέσεις:

ΜΗΝ εγκαθιστάτε τη μονάδα στις θέσεις που αναφέρονται

παρακάτω:

Υπάρχει αρκετός χώρος για εγκατάσταση και συντήρηση.

Υπάρχει αρκετός χώρος για τη σύνδεση των σωληνώσεων και

του αγωγού αποχέτευσης.

Η οροφή είναι οριζόντια και η κατασκευή της μπορεί να

δέχεται το βάρος της εσωτερικής μονάδας.

Η εισαγωγή και η εξαγωγή αέρα δεν παρεμποδίζονται.

Η ροή αέρα μπορεί να διοχετευθεί σε ολόκληρο το δωμάτιο.

Δεν υπάρχει απευθείας ακτινοβολία από θερμαντικά σώματα.

Η εγκατάσταση είναι εντοιχισμένη

Σε ένα δωμάτιο μπορούν να εγκατασταθούν κλιματιστικά από

9.000btu/h έως 18.000btu/h.

Περιοχές στις οποίες πραγματοποιείται εξόρυξη

πετρελαίου ή φυσικού αερίου

Παράκτιες περιοχές με υψηλή περιεκτικότητα σε αλάτι

στην ατμόσφαιρα

Θέσεις όπου ο αέρας περιέχει καυστικά αέρια, όπως π.χ.

κοντά σε ιαματικές πηγές

Περιοχές όπου εμφανίζονται διακυμάνσεις του ρεύματος,

π.χ. εργοστάσια

Κλειστοί χώροι, π.χ. ερμάρια

Περιοχές όπου υπάρχουν ισχυρά ηλεκτρομαγνητικά

κύματα

Περιοχές όπου φυλάσσονται εύφλεκτα υλικά ή αέριο

Δωμάτια με υψηλή υγρασία π.χ. μπάνιο ή πλυσταριό

• Εγκαταστήστε την εσωτερική / εξωτερική μονάδα, τα

καλώδια και τους αγωγούς τους σε απόσταση τουλάχιστον

1m (3.2’) από συσκευές τηλεόρασης και ραδιόφωνου

ώστε να μην προκαλούνται παράσιτα ή παραμόρφωση

της εικόνας. Ανάλογα με τις συσκευές, η απόσταση του 1m

(3.2’) ενδέχεται να μην είναι επαρκής.

• Εάν η εσωτερική μονάδα τοποθετηθεί επάνω σε μεταλλικό

μέρος του κτιρίου, θα πρέπει να είναι ηλεκτρικά γειωμένη.

Σελίδα 8

>4in(10cm) >11.8in(30cm)

>0.8in(2cm)

>0.8in(2cm)

>11.8in(30cm)

)mc052(ni2.8 >

B

Εικ. 4.2

>

7.9

in

(20cm)

11.8in

23.6inx23.6in (60cmx60cm)

> (30cm)

Εικ. 4.3

A B C D E F I

J

G

H

18K 210/8.3 674/26.5880/34.6

24K 249/9.8 774/30.51100/43.3

30K~36K 249/9.8 774/30.51360/53.5

36K~60K 300/11.8 874/34.41200/47.2

136/5.4 706/27.8600/23.6

175/6.9 926/36.5700/27.6

175/6.9 1186/46.7700/27.6

227/8.9 1044/41.1800/31.5

190/7.5

228/8.9

228/8.9

280/11

920/36.2782/30.8

1140/44.91001/39.4

1400/55.11261/49.6

1240/48.81101/43.3

508/20

598/23.5

598/23.5

697/27.4

9K/12K

200/7.9 506/19.9700/27.6 152/6 537/21.1450/17.7 186/7.3 741/29.2599/23.6

360/14.2

Εικ. 4.6

Εικ. 4.7

Εικ. 4.4

Εικ. 4.5

Βήμα 2: Ανάρτηση εσωτερικής μονάδας

1. Συμβουλευθείτε τα παρακάτω διαγράμματα για να εντοπίσετε τις οπές των βιδών τοποθέτησης στην

οροφή. Φροντίστε να σημαδέψετε τα σημεία όπου θα γίνει η διάτρηση για τις οπές ανάρτησης οροφής.

Διαστάσεις εξόδου αέρα

Τοποθεσία εγκατάστασης

Τοποθεσία συντήρησης

Στοιβαρή Οροφή

Εξαγωγή Αέρα

Εισαγωγή Αέρα

Έλεγχος

Πρόσβαση

για επισκευή

Οροφή

Δάπεδο

(Όταν δεν υπάρχει οροφή)

Εσωτερική Μονάδα

Αριστερή

Πλευρά

Δεξιά

Πλευρά

Σελίδα 9

Εικ. 4.3

A B C D E F I

J

G

H

18K 210/8.3 674/26.5880/34.6

24K 249/9.8 774/30.51100/43.3

30K~36K 249/9.8 774/30.51360/53.5

36K~60K 300/11.8 874/34.41200/47.2

136/5.4 706/27.8600/23.6

175/6.9 926/36.5700/27.6

175/6.9 1186/46.7700/27.6

227/8.9 1044/41.1800/31.5

190/7.5

228/8.9

228/8.9

280/11

920/36.2782/30.8

1140/44.91001/39.4

1400/55.11261/49.6

1240/48.81101/43.3

508/20

598/23.5

598/23.5

697/27.4

9K/12K

200/7.9 506/19.9700/27.6

152/6 537/21.1450/17.7 186/7.3 741/29.2599/23.6

360/14.2

Εικ. 4.6

Εικ. 4.7

Εικ. 4.4

Εικ. 4.5

Διαστάσεις εισόδου αέρα

Κατερχόμενο άνοιγμα εξαερισμού και τοποθετημένο άγκιστρο

Φίλτρο αέρα

Φίλτρο αέρα

Κιβώτιο ηλεκτρολογικού ελέγχου

Πίνακας.4-1

ΜΟΝΤΕΛΟ

(Btu/h)

(μονάδα: mm/ίντσες)

Ξύλο

Τοποθετήστε το ξύλινο στήριγμα κατά πλάτος της

δοκού οροφής και στη συνέχεια τοποθετήστε τους

κοχλίες ανάρτησης.

(Βλέπε Εικ. 4.4)

Νέα κατασκευή με τούβλο

Διείσδυση ή εγκιβωτισμός των κοχλιών.

(Βλέπε Εικ. 4.5)

Προϋπάρχουσα κατασκευή με τούβλο

Χρησιμοποιήστε βίδα εγκιβωτισμού, τρίψτε και

κολλήστε τον αναρτήρα. (Βλ. Εικ. 4.6)

Κατασκευή οροφής με χαλυβδοδοκούς

Εγκαταστήστε και χρησιμοποιείστε τη χαλυβδογωνία

υποστήριξης. (Βλ. Εικ. 4.7)

Ξύλινο στήριγμα

Δοκός οροφής

Ανάρτηση οροφής

Κοχλίες

(Εισαγωγή σχήματος πτερυγίου)

Αναρτώμενος κοχλίας

Χαλυβδογωνία

στήριξης

Κοχλίες

ανάρτησης

Κοχλίας εγκιβωτισμού (κοχλίας ανάρτησης σωλήνα και εγκιβωτισμού)

(Συρόμενη εισαγωγή)

Διαστάσεις περιγράμματος

Μέγεθος ανοίγματος

εξόδου αέρα

Μέγεθος ανοίγματος

επιστροφής αέρα

Μέγεθος σφιγκτήρα

τοποθέτησης

Σελίδα 10

Εικ. 4.10

or more.

0~100/0~0.4

18K

0~160/0~0.64

24K

0~160/0~0.64

30K~36K

0~160/0~0.64

42K~60K

0~50/0~0.2

9K

0~50/0~0.2

12K

Εικ. 4.9

Εικ. 4.8

Βήμα 3: Εγκατάσταση αεραγωγού και παρελκομένων

1. Τοποθετήστε το φίλτρο (προαιρετικό) ανάλογα με το

μέγεθος της εισόδου αέρα.

2. Τοποθετήστε τον υφασμάτινο σύνδεσμο μεταξύ του κορμού

και του αεραγωγού.

3. Οι αεραγωγοί εισόδου και εξόδου αέρα θα πρέπει να

βρίσκονται σε αρκετή απόσταση μεταξύ τους για να μην

υπάρχει βραχυκύκλωμα στην κυκλοφορία του αέρα.

4. Συνδέστε τον αεραγωγό με βάση το παρακάτω διάγραμμα:

5. Συμβουλευθείτε τις παρακάτω οδηγίες στατικής πίεσης κατά

την εγκατάσταση της εσωτερικής μονάδας.

Αλλάξτε τη στατική πίεση του μοτέρ του ανεμιστήρα

ανάλογα με την εξωτερική στατική πίεση του αεραγωγού.

ΣΗΜΕΙΩΣΗ:

1. Μην αφήνετε την εσωτερική μονάδα να δέχεται το

βάρος του συνδετήριου αεραγωγού.

2. Κατά τη σύνδεση του αεραγωγού, χρησιμοποιήστε

υφασμάτινο μη εύφλεκτο εξάρτημα σύνδεσης για

την αποφυγή κραδασμών.

3. Θα πρέπει να τυλίξετε αφρώδες μονωτικό

(αρμαφλέξ) γύρω από τον αεραγωγό για να

αποφευχθούν συμπυκνώματα. Μπορεί να

προστεθεί εσωτερικό υπόστρωμα στον αεραγωγό

για την ελάττωση του θορύβου.

Πίνακας 4-2

Υφασμάτ. σύνδεσμος Υφασμάτ. σύνδεσμος

Θάλαμος απομόνωσης

Θάλαμος

απομόνωσης

Εξαγωγή

αέρα

Είσοδος αέρα

Φίλτρο σκόνης

Στόμιο ελέγχου

ΜΟΝΤΕΛΟ

(Btu/h)

Στατική πίεση

(Pa)

Ο κορμός της μονάδας θα πρέπει να είναι απολύτως