• USER’S MANUAL

• ΕΓΧΕΙΡΙΔΙΟ ΧΡΗΣΗΣ

• MANUAL DE UTILIZARE

ENGLISH | ΕΛΛΗΝΙΚΑ | ROMANA

AIR CONDITIONING SYSTEMS

MODELS:

RFI-66B/RFO-66B

FLOOR STANDING

Notes prior to use

erutcurtS

ecnanetniaM

2

3

4

5

16

17

18

19

20

21

23

24

25

CONTENTSCONTENTS

Structure

Models & specifications

Control panel

Remote control

Breeze Guided

Care and Maintenance

Trouble shooting

Electric wiring

Notes for piping

noitallatsnI

Installation of indoor unit

Installation of outdoor unit

T

rial running

7

Install slant protection cable

1

NOTES PRIOR TO USE

Power supply requirements:

WARNING

1. Capacity of power supply must be at least 10kw, cross section area of copper core wires must be at

least 2.5mm

2. The air conditioner must be safely earthed! Earth wire must be connected to special device of the

building instead of water pipe or gas pipe.

3. Wiring must be done by special technician according to relevant electrical safety rules and regulations.

4. In fixed circuit, there must be electricity leakage protection switch of enough power capacity and

air switch with enough space.

5. Shut down power supply when not using the air conditioner.

Safety requirements:

Please read this manual carefully prior to using the air conditioner and contact your local dealer or

designated service center for help if there are any questions or problems.

The air conditioner is only suitable for purposes described in this manual.

NEVER use or store petrol or other inflammable gas or liquid near the air conditioner that’s very

dangerous!

The air conditioner is not equipped with a device to bring in fresh air from outdoors, so when you

are using a heater fueled by gas or petrol in the same room, please open the door or window

regularly, as such kind of heater will consume oxygen in the air and may cause people to feel

uncomfortable for lack of oxygen.

2

. Please discuss with the local dealer or professional technician for details.

BE

CAREFUL

Don’t start or stop the air conditioner by turning the power supply on or off and please press the

ON/OFF key instead.

Don’t insert anything into the air intake grille or the air outlet.

Don’t let young children operate the air conditioner.

If there are young children or sick people in the room, please readjust the set temperature

accordingly.

Working temperature range

Working

conditions

Heating

Temp. Indoor temperature Outdoor temperature

Max. 27

Min. 20

dry bulb 24 dry bulb / 18 wet bulb

dry bulb -5 dry bulb / -6 wet bulb

2

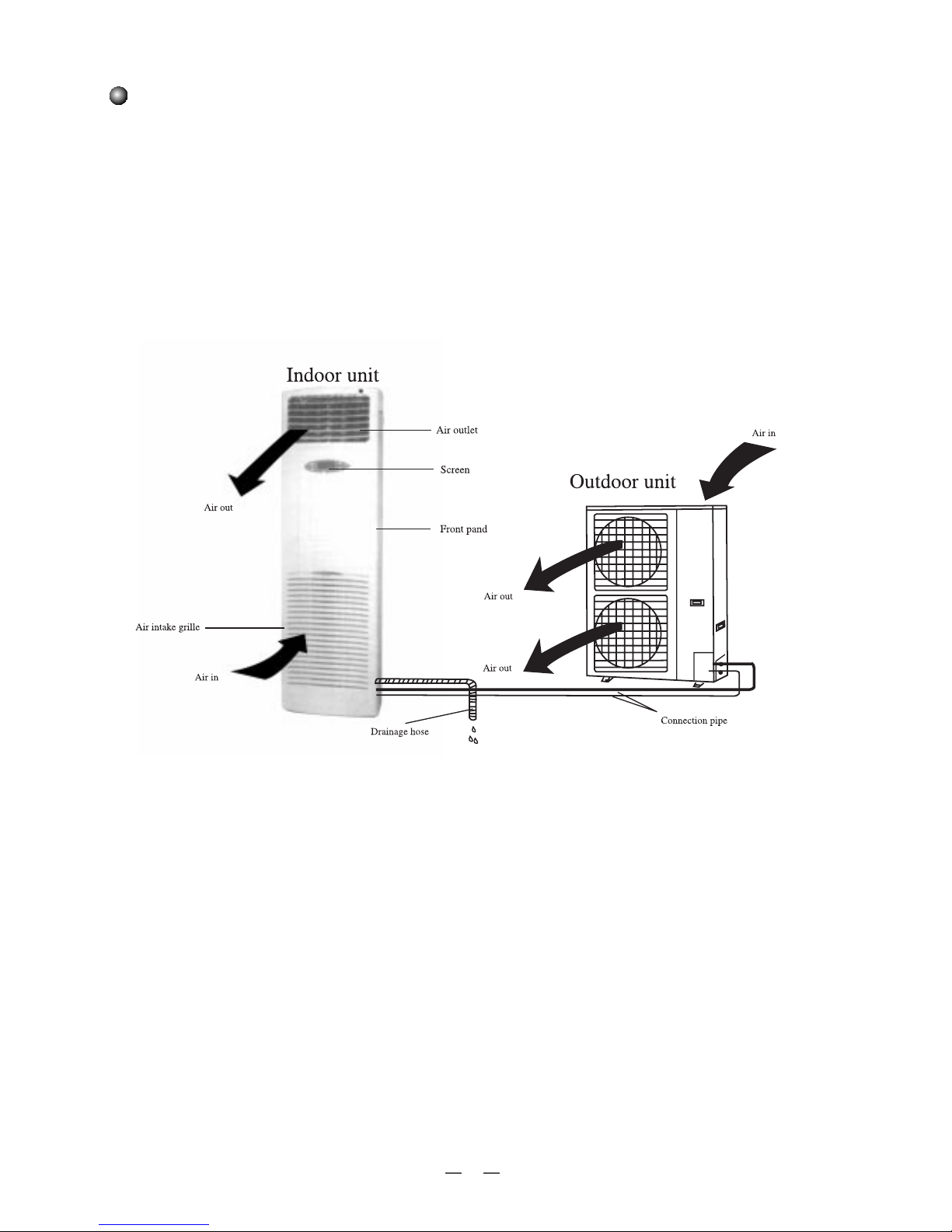

STRUCTURE

3

4

MODELS & SPECIFICATIONS

All above should be changed without notice, there are latest and accurate specifications on the nameplate of your

air conditioner.

Cooling capacity (W)

Heating capacity (W)

Power supply

Input power (W)

Air flow volume (m

3

/h)

Refrigerant

Noise (in/out) dB(A)

Climate

Water resistance level

Isolation

Weight (in/out) (kg)

Dimension(in/out)

(W H D) (mm)

Model

Functions

RFI-66B /RFO-66B

6400/6200(9700)

16000

18000(21500)

380-415V 3N~ 50Hz

2000

58/63

T1

IP24

I

60/115

Indoor:540

1750 380

Outdoor:950

1250

412

Cool Heat

R410A 5.0

5

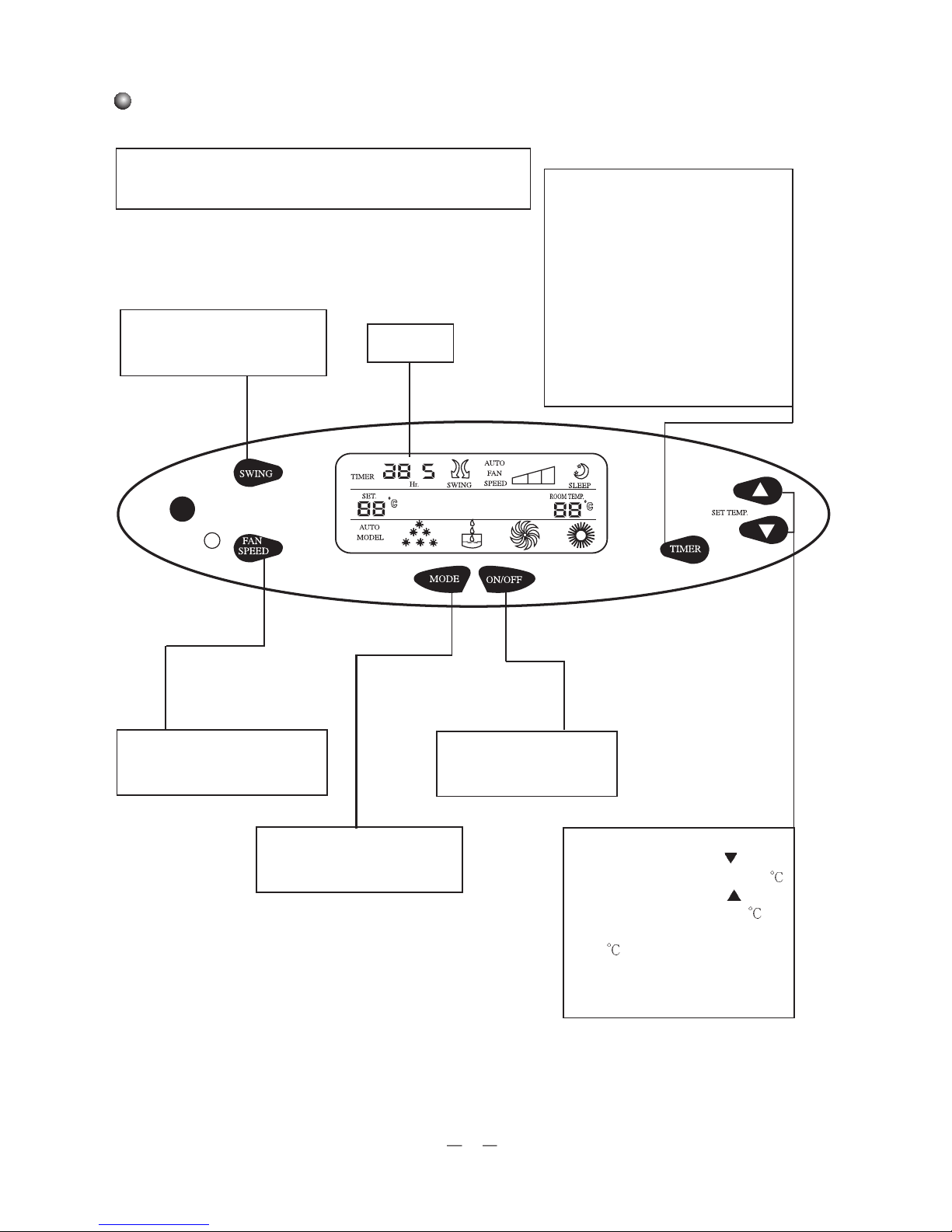

CONTROL PANEL

Floor standing type air conditioner with LCD control panel

SWING key

Choose between SWING and stop

modes.

LCD screen

FAN SPEED key

Choose between AUTO/LO/MED/

HI speeds.

MODE key

Choose between AUTO/COOL/

DRY/FAN/HEAT modes.

ON/OFF key

Press once to start and press

once more to stop the unit.

SET TEMP. key

Every time when pressing

,the set

room temperature is lowered by 1

,

every time when pressing

, the set

room temperature is raised by1

.The

room temperature can be set between

16-30

. In normal operation, pressing

the two keys at the same time will shield

the screen, and pressing the two keys

once more will release the shield.

When the air conditioner is in OFF mode,

the key is used to set the time when the

unit is to be started. and every time when

pressing, the time interval being set will

be 0.5 hour more or less, ranging from

0.5-24 hour (s). when the set time arrives,

the unit will run in the set modes. When

the air conditioner is in ON mode,the key

is used to set the time when the unit is to

be stopped, and the time interval to be set

scrolls between 0.5-24 hour (s). When the

set time arrives,the unit will stop running.

6

SPECIAL FUNCTIONS:

Test function:

Every time when the unit is plugged on and there is not any key signal is accepted:

(1) Press SET TEMP. key

to enter forced cooling mode, the compressor starts and the unit is in

auto swing mode, indoor and outdoor fans run at high speed. LCD displays all symbols. Five

minutes later, the unit stops and enter normal waiting mode.

(2) Press SET TEMP. key

to enter forced heating mode, the compressor and supplementary electric

heater starts and the unit is in auto swing mode, indoor and outdoor fans run at high speed. LCD

displays all symbols. Five minutes later, the unit stops and enter normal waiting mode.

Compressor running protection function:

In all modes, compressor needs 3 minutes to restart once it has been stopped; if there is no changes in

mode, the compressor will keep running for 6 minutes before it can be stopped. Between changes

of modes, compressor will stop for 3 minutes.,

Shielded screen function:

In normal running, pressing the two SET TEMP. keys and at the same time will shield all

functions of keys on the screen, pressing the two key simultaneously once more will release the

shield.

- 7 -

- 8 -

- 9 -

- 10 -

- 11 -

- 12 -

- 13 -

- 14 -

- 15 -

16

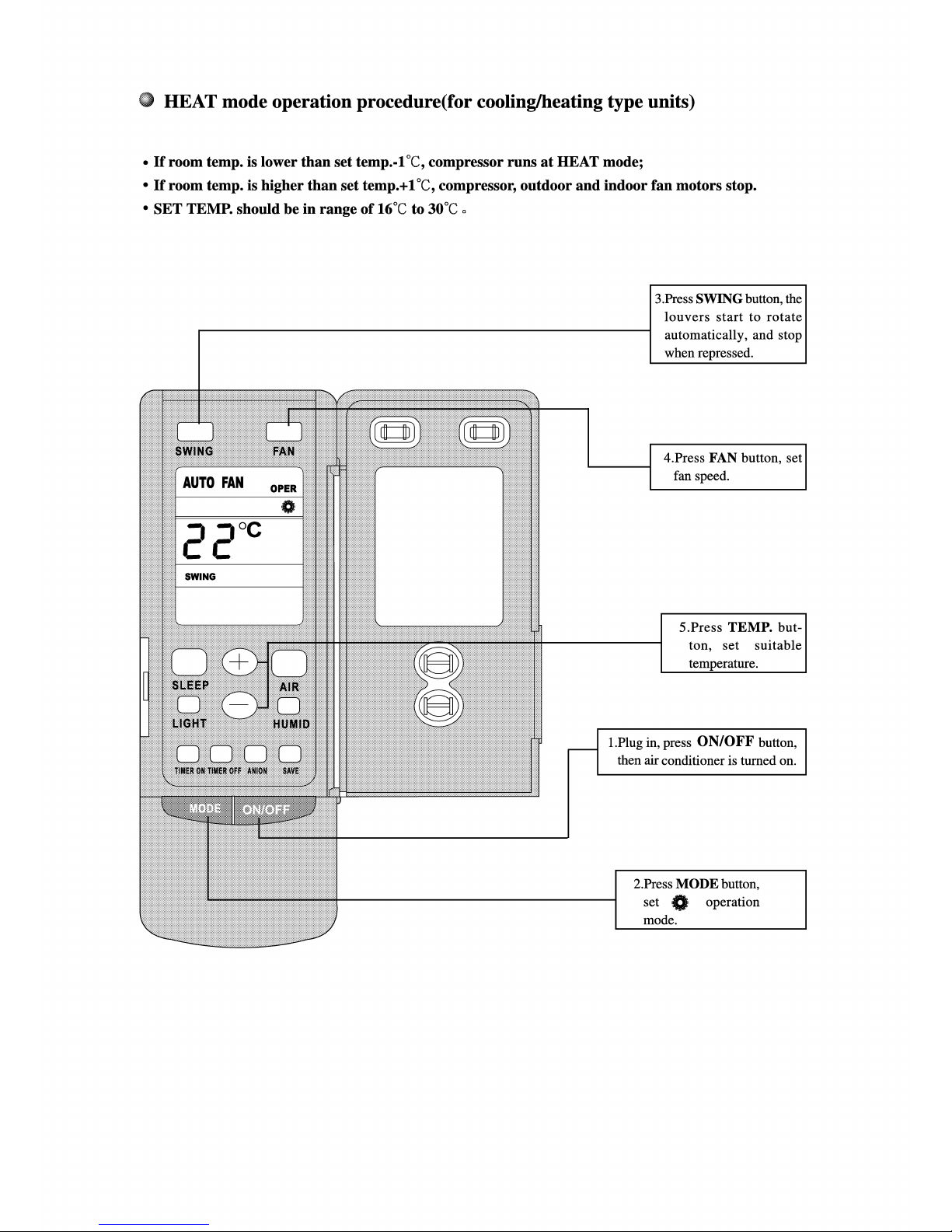

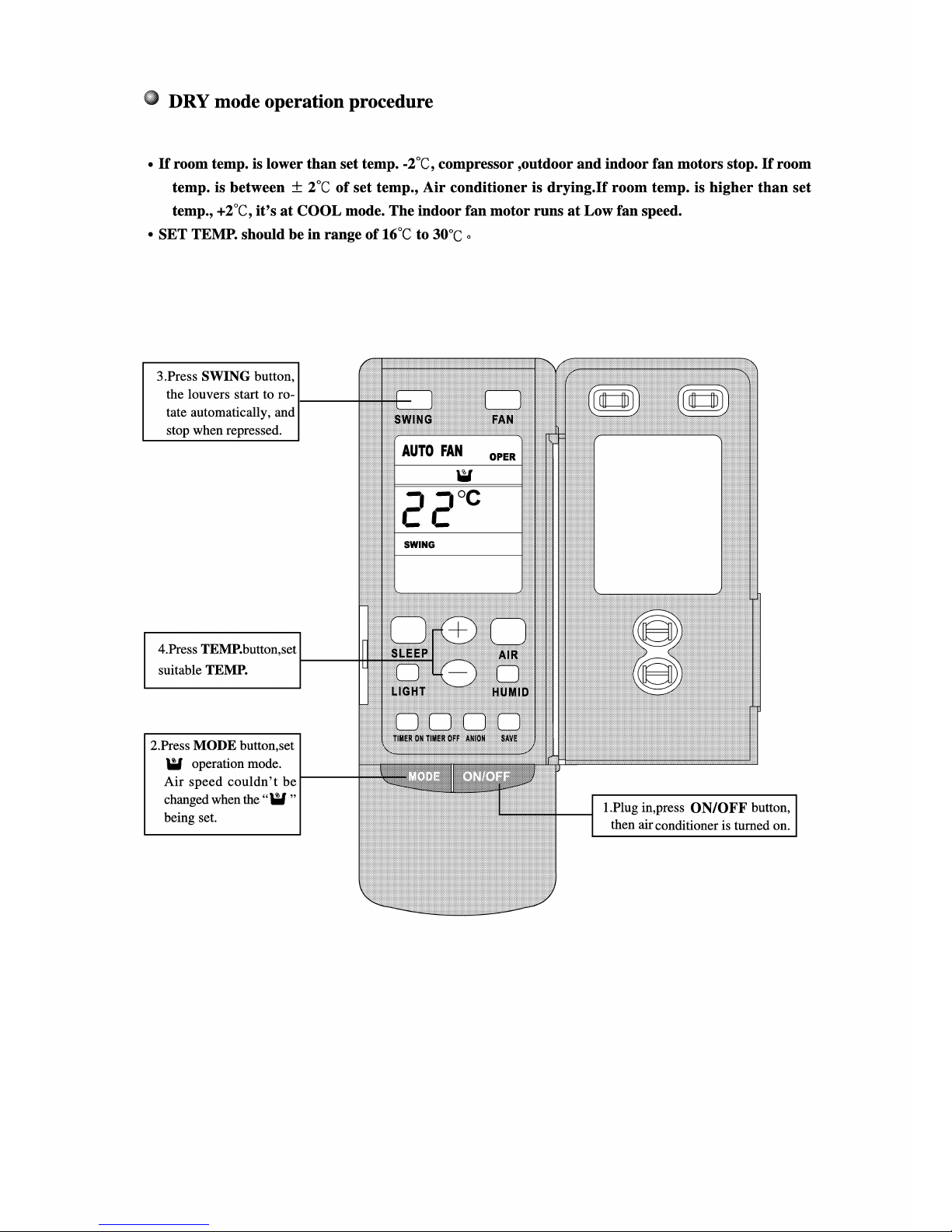

2. Breeze guided up and down

Readjust breezing angles of air louvers with hands. Hold

two ends of the louvers with both hands when doing

the readjustment. When cooling and drying, set to

breeze straightly or upwards; when heating, set to breeze

downwards.

When cooling and drying, set to breeze straightly or upwards

1. Breeze guided left and right

* Press SWING key on control panel

to choose SWING and END SWING, then the swing

louvers will swing left and right or stop swinging

and breeze from a fixed direction.

*

Every time when pressing SWING, “SWING” will appear

on LCD,if indoor fan is already working, then swing motor

will start and breeze left and right ;press the key once more,

“SWING” disappears from LCD, swing motor stops, the

louvers stop swinging and breeze from a fixed direction.

Breeze Guided

Swing louvers

(guide wind breeze

horizontally).

Breeze

straightly

Breeze

upwards

When heating, set to breeze downwards.

Breeze

downwards.

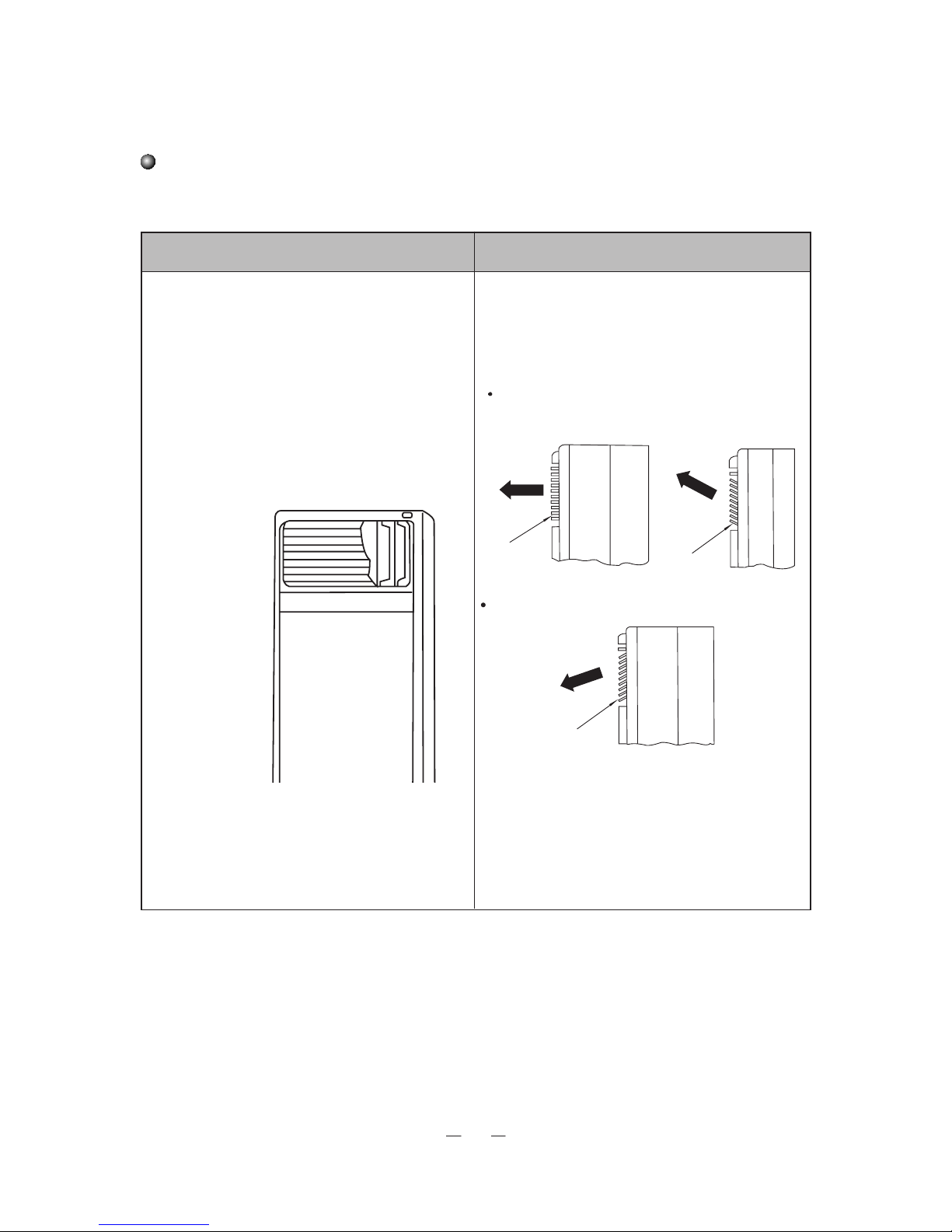

MAINTENANCE

17

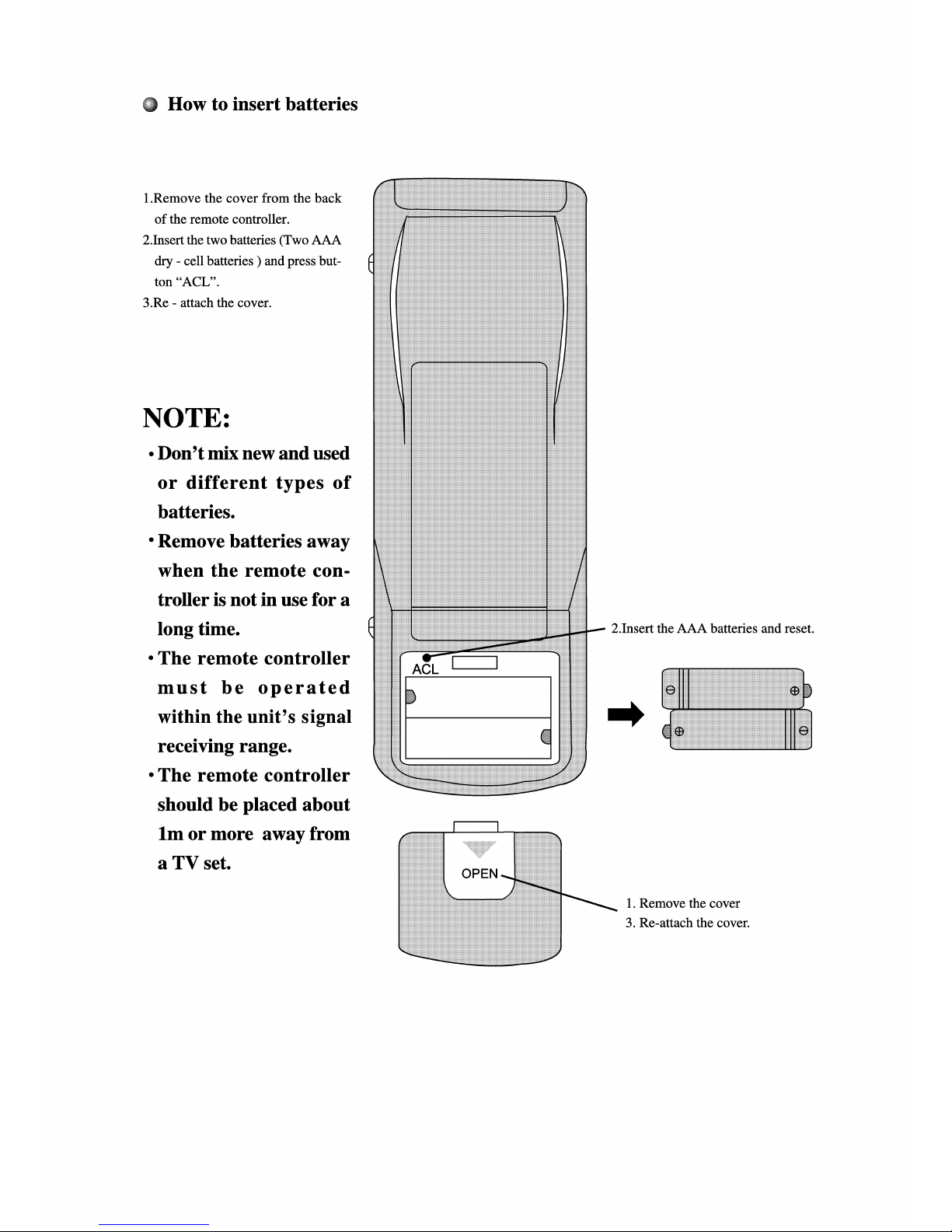

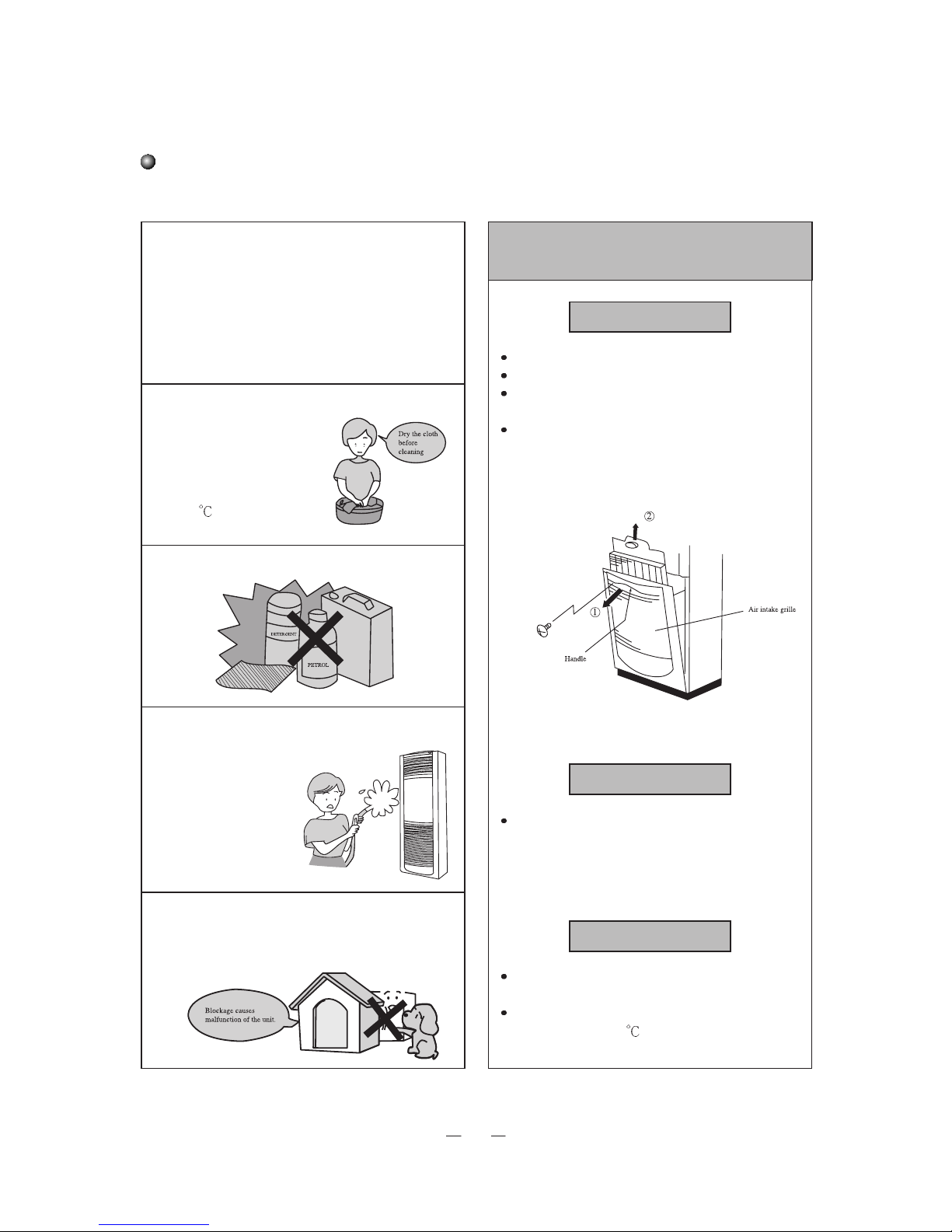

1.Cut power off before cleaning

Cleaning unit Cleaning the air filter

Air filter should be cleaned every two weeks

Removing air filter

Make sure that the A/C has been turned off.

Remove screw from handle of air intake grille.

Pull out air intake grille by the handle towards

direction.

Air filter is attached to the air intake grille. Pull out

the filter towards direction.

Cleaning

Clean by patting the filter softly or use an electric

vacuum. If too much accumulated on the filter, use

water with containing some neutral detergent to

clean, then wash with tap water. Dry after cleaning

and put it back into place.

Note

Do not dry the filter by exposing it under direct sun-

shine or near a heating oven, or it may get deformed.

The filter may get deformed when it is cleaned with

hot water (above 50

).

2.Use soft cloth

when cleaning

cabinet.

If the cabinet is very dirty,

dip cloth into warm water

below 40

, dry the cloth and

then rub off the dirt.

3. Don’t use acid and alkaline solution to clean.

* Make sure there is nothing

blocking the air in and out of the

outdoor unit.

4. Don’t spray water on indoor unit

Care and maintenance

Plug out only after air conditioner stops at all.

18

If your air conditioner is not working properly, please check the following before asking for help. After checking the

following point and the A/C is still not working normally, please contact the nearest service center to examine it.

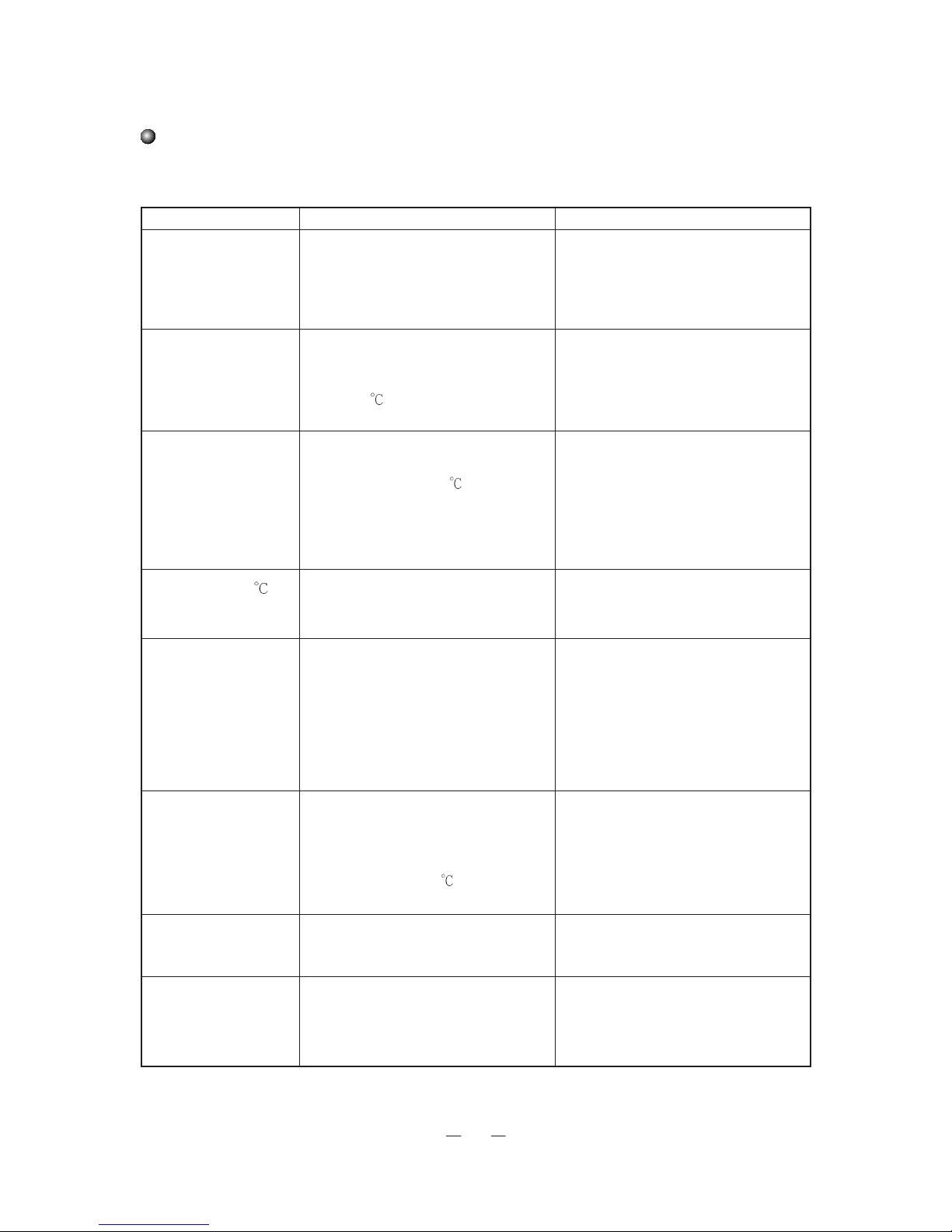

The A/C does not start

The A/C stops soon after

started, screen displays

“E1”

The A/C stops soon after

started, screen displays

“E2”

TEMP. indicates 0

and

the COOL mode is not

working

Poor cooling performance

Poor heating performance

1. No power

2. Electricity leakage switch shut down

3. Voltage too low

4. Operation key turned off

5. Controlling circuit troubles

1. Blocking in front of condenser

2. Controlling circuit troubles

3. Cooling operation when outdoor temp. is

above 43

4. The tube pressure is too high.

1. Indoor fan motor doesn’t work or air outlet

get blocked

2. Indoor temp. is below 18

3. Wire of tube temp. sensor broken

4. Tube temp. sensor not in place

5. Controlling circuit troubles

6. Electricity leakage of capacitor

1. Wire of room temp. sensor broken

2. room temp. sensor not in place

3. Electricity leakage of capacitor

1. Air filter is too dirty or get clogged

2. There are too many people or heating sources

in the room

3. Door or window opened

4. Air in/out is blocked

5. Set temp. too high

6. Leakage of refrigerant

7. Poor performance of room temp. sensor

1. Air filter is too dirty or get clogged

2. Door or window opened

3. Set temp. too low

4. Leakage of refrigerant

5. Outdoor temp. below-5

6. Controlling circuit troubles

1. Connect to power supply

2. Contact service center

3. Contact electrician or dealer

4. Press Operation key again

5. Contact service center

1. Clear blocking

2. Contact service center

3. Put outdoor unit at shady place

4. Contact service center

1. Contact service center

2. Check if there is the need to turn on the A/C

3. Contact service center

4. Fit tube temp. sensor into place

5. Contact service center

6. Contact service center

1. Connect wire of room temp. sensor

2. Fit room temp. sensor into place

3. Contact service center

1. Clean air filter

2. Clear heating sources if possible

3. Close door and window

4. Clear blocking to insure free air flow

5. Set lower temp.

6. Contact service center

7. Replace room temp. sensor

1. Clean air filter

2. Close door and window

3. Set higher temp

4. Contact service center

5. Heating performance is affected

6. Contact service center

Troubles Possible Causes Solution

Trouble shooting

The A/C stops soon after

started, screen displays

“E3”.

The A/C stops soon after

started, screen displays

“E4”.

1.Leakage of refrigerant

2.Controlling circuit troubles

1.Contact service center

2.Contact service center

1.Leakage of refrigerant

2.Controlling circuit troubles

3.wire of sensor broken

4.Voltage is too low

1.Contact service center

2.Contact service center

3.Contact service center

4.Contact service center

19

INSTALLATION

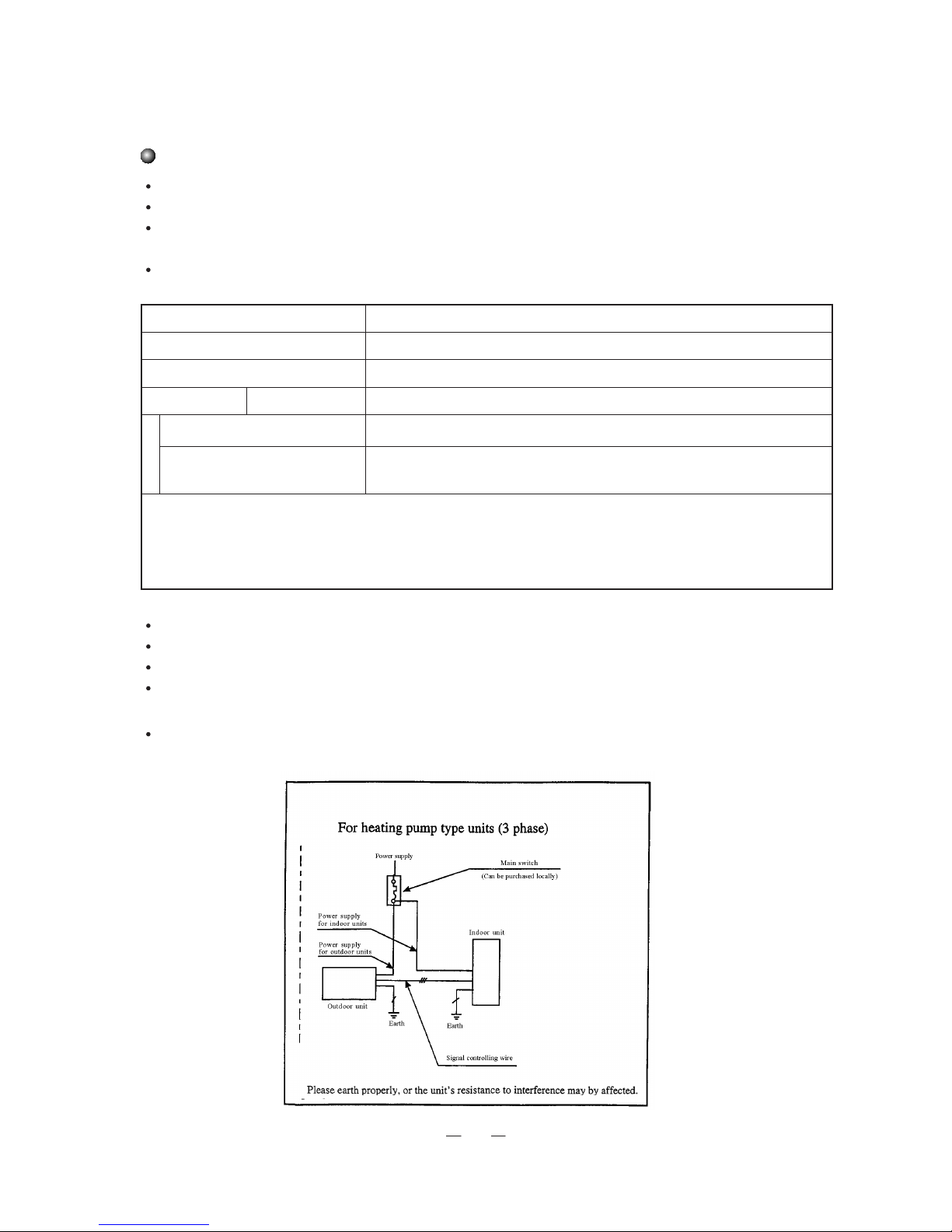

Electric wiring

Please read this manual carefully before installation.

Please strictly follow the instructions of this manual when installing indoor unit and its piping.

First install wire of outdoor unit and then wire of indoor unit. After finishing wiring and piping, connect the unit to the

power supply.

Design of the unit is subject to change without prior notice.

Wiring Example

Model

Power supply

Input capacity Air switch

Lines

Cross section area of

power cord (mm

2

)

Minimum cross section area

of indoor/outdoor power

connecting cable (mm

2

)

Note:

1. Please pay attention to surrounding conditions (eg. ambient temperature, direct sun shine, rain drops etc.).

2. When the voltage declines, please use thicker power conducting wires.

3. Earth wire must be connected to both of indoor and outdoor units.

4. Data listed in this table is for reference only, and please do the wiring according to relevant government rules

a

nd regulations.

25A

2.5/1.5

/

380

RFI-66B/RFO66B

-415V 3N~50Hz

Special circuit must be used for power supply.

The circuit must be installed by special serviceman.

Please do the wiring according to the following wiring diagram. The screws must be tightly fastened.

Connecting wire and power conducting wire between the indoor/outdoor units must be properly arranged so that they

do not touch each other.

Please connect the power phase correctly. If the connection is wrong, the unit will stop automatically in such case,

exchange the connection of two of the three phasewires and the air conditioner can work normally again.

20

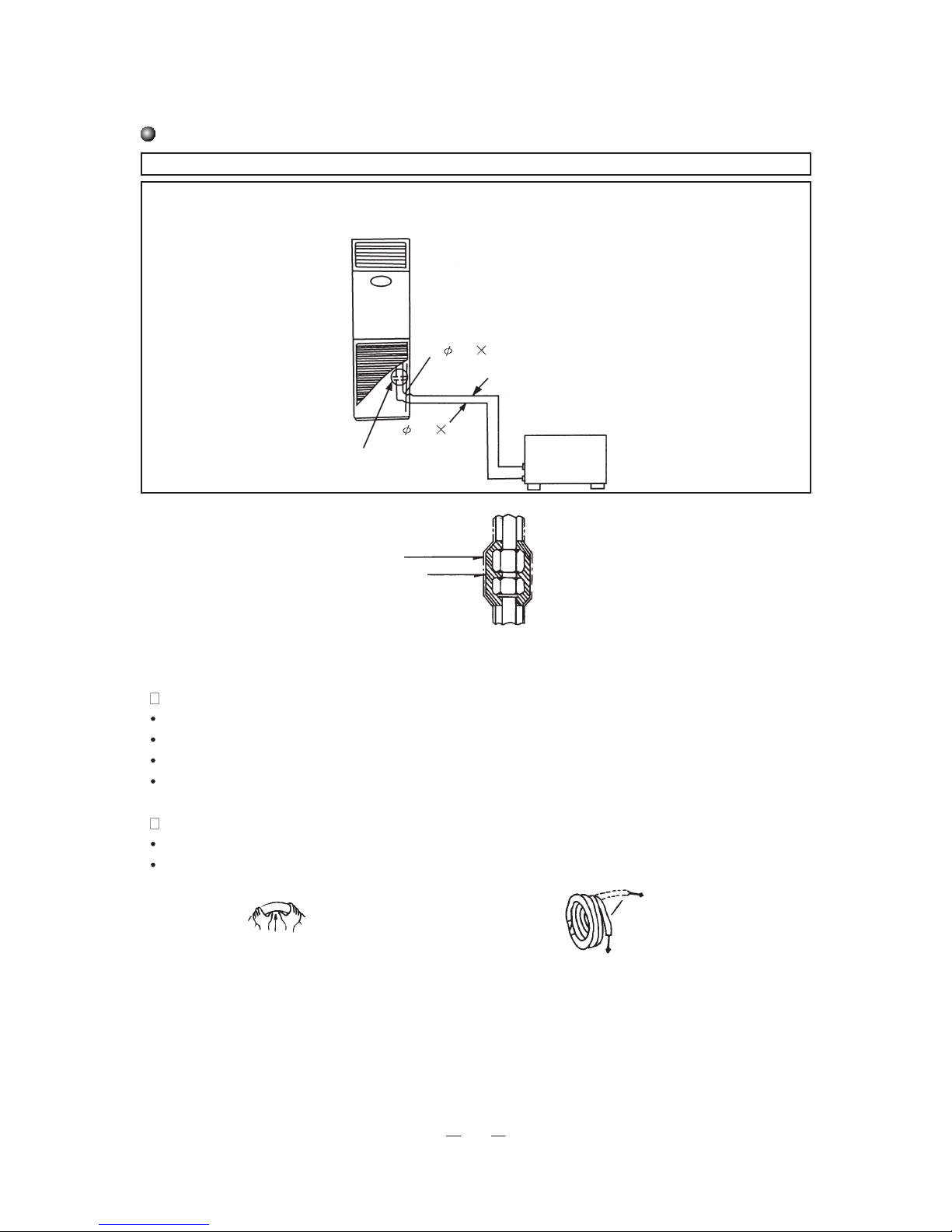

Notes for piping

Pipes for refrigerant and drainage should be insulated to avoid frosting and dripping.

Both of the indoor and outdoor units adopt flare-end connection.

Refrigerant pipe as shown below is used to connect indoor and outdoor units.

Note: Don’t bend the bendable pipe back and forth more than 3 times.

Note: Insulate all exposed parts of the flare-end connection joint and the refrigerant pipe.

2. When using copper pipe bought locally

Check valve of the outdoor unit should be shut (like position unworking). After the refrigerant pipe has been connected to both indoor and outdoor units, exhaust from service mouth on low-pressure check valve of the outdoor

unit. After exhausting, put back nut of the service mouth and fasten.

3. After finishing step 1 and 2, check valve of outdoor unit should be fully open so that there is not blockage between

the indoor and outdoor refrigerant pipe.

Note: before fastening nut of the flare-end pipe, please apply some refrigerant oil to the end of the pipe and the joint.

1. Connecting the pipe

Check valve of the outdoor unit should be shut (like position unworking). Every time when connecting, remove

bonnet from the check valve and connect to flare-end pipe immediately (within five minutes), otherwise dust, moisture and other small things may go into the pipe and cause troubles.

About the bendable pipe

The part with bendable pipe should be used on the indoor side.

The bending angle should not be more than 90.

It’s better for the bend to be in the middle of the pipe, and the radius of the bend is the bigger the better.

Don’t bend the bendable pipe more than three times.

When bending the pipe

Cut some part of the insulation pipe at the place of the bend (and wrap with polythene tape after bending)

Make radius of the bend as big as possible so that the pipe will not get flat or broken.

Indoor unit

Bendable pipe

19 1

Flare-end connection

12 1

Outdoor unit

Polythene tape

Insulation cover

Loosen the roll of pipe

Straighten end of pipe

Bend the pipe with thumb

Minimum radius: 100mm

21

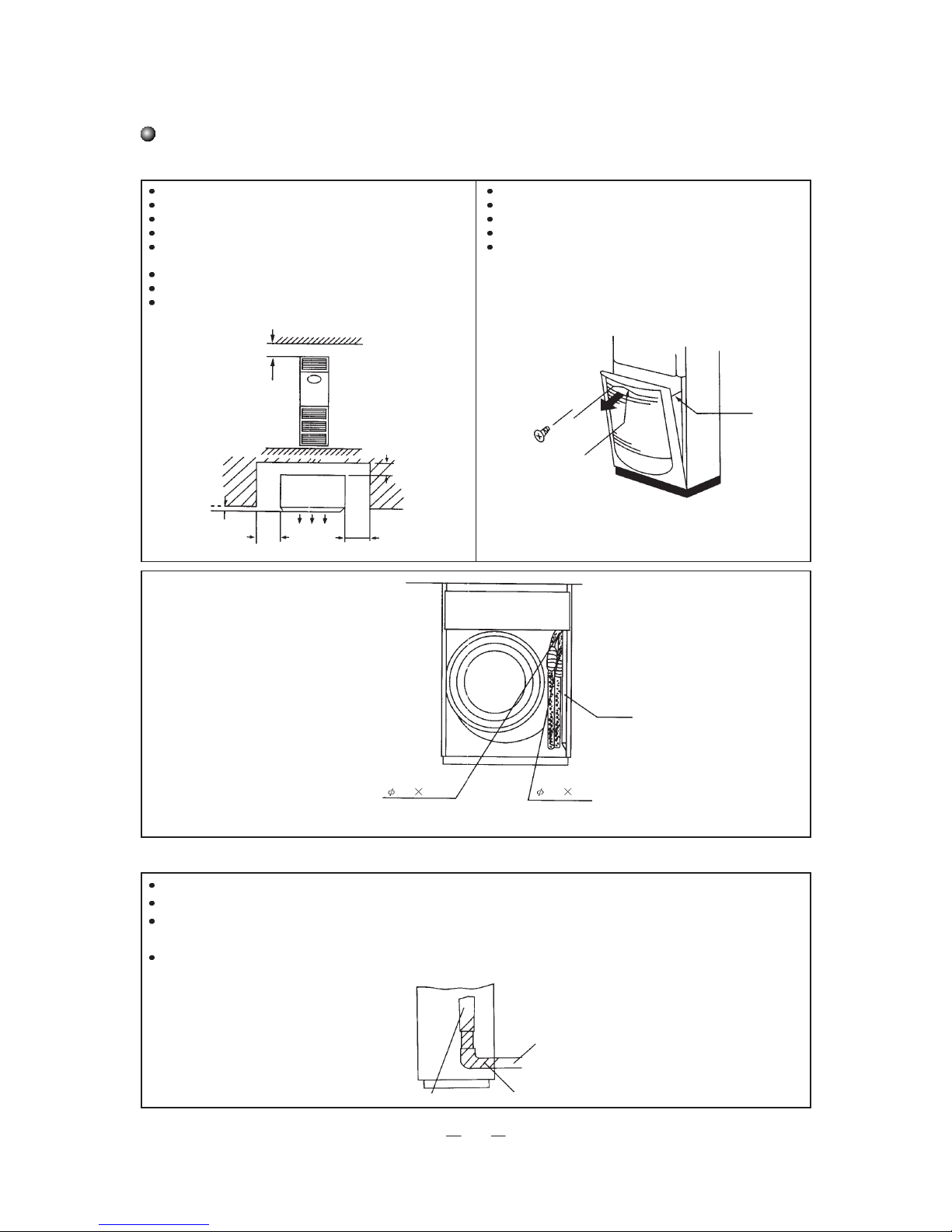

Installation of indoor unit

1. Choose a place 2. Install pipes

Where it’s least likely to be affected by outdoor air.

Where free flow of air in and out of the unit will not be blocked.

Where the refrigerant pipe can be easily lead outdoors.

Where conditioned air can reach every corner of the room.

Where there is not too much moisture and can not be easily splashed

with oil.

Where there inflammable gas is not likely to leak or stay.

Choose a solid and even ground.

Leave enough space for installation and maintenance.

Remove air intake grille.

Before wiring and piping, please remove air intake grille.

Remove screw from the grille.

Open the grille by pulling it out by the handle.

Remove chain and take off the whole grille.

3. Install drainage pipe

Make sure drainage pipe is leading to the outdoor side (discharge side.)

Joint drainage pipe with blow moulding drainage pipe and fix with tape from the accessories.

If the drainage pipe needs to be led indoors, please wrap it with insulation material (at least 9mm thick), and then wrap with tape to prevent

air from going into the pipe and cause congealing.

After connecting, check if water can be discharged properly and if there is any leaking.

>30cm

>4cm

>5cm

>10cm

(Pipe side:30cm min.)

Front

>200cm

>10cm

(Pipe side:

30cm min.)

Chain

Screw

Handle

Drainage pipe

19 1

Refrigerant pipe

12 1

Flare-end connection Flare-end connection

Drainage pipe of indoor unit

Blow moulding drainage pipe

Drainage pipe

Wrapping tape

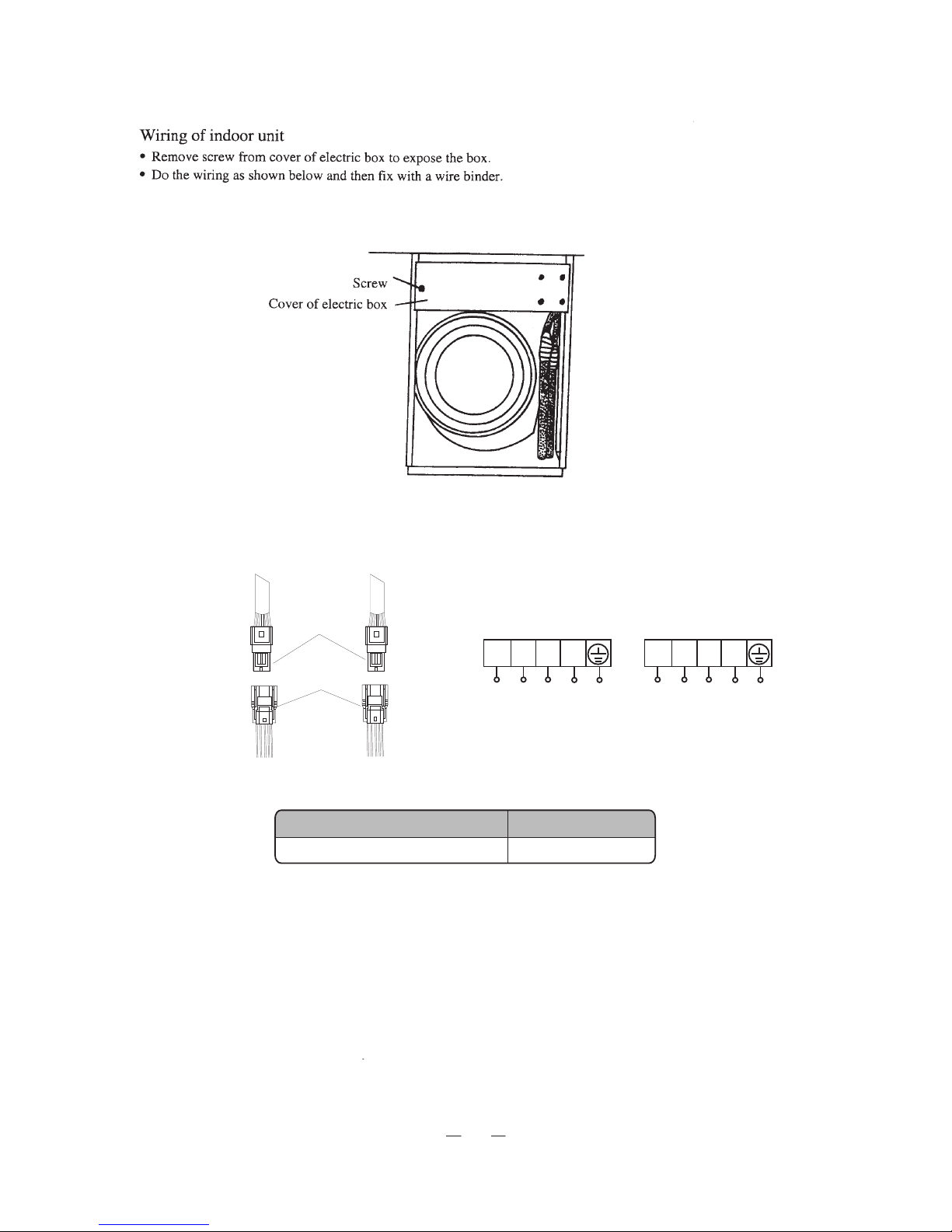

22

Signal wires

(2) For heating pump type units (5 phawe)

Terminal board of indoor units

Power supply

Power supply

Terminal board of outdoor units

Wire interface

L1 L2

L3 N

L1 L2

L3 N

Air switch capacity

Models

RFI-66B/RFO-66B

25A

23

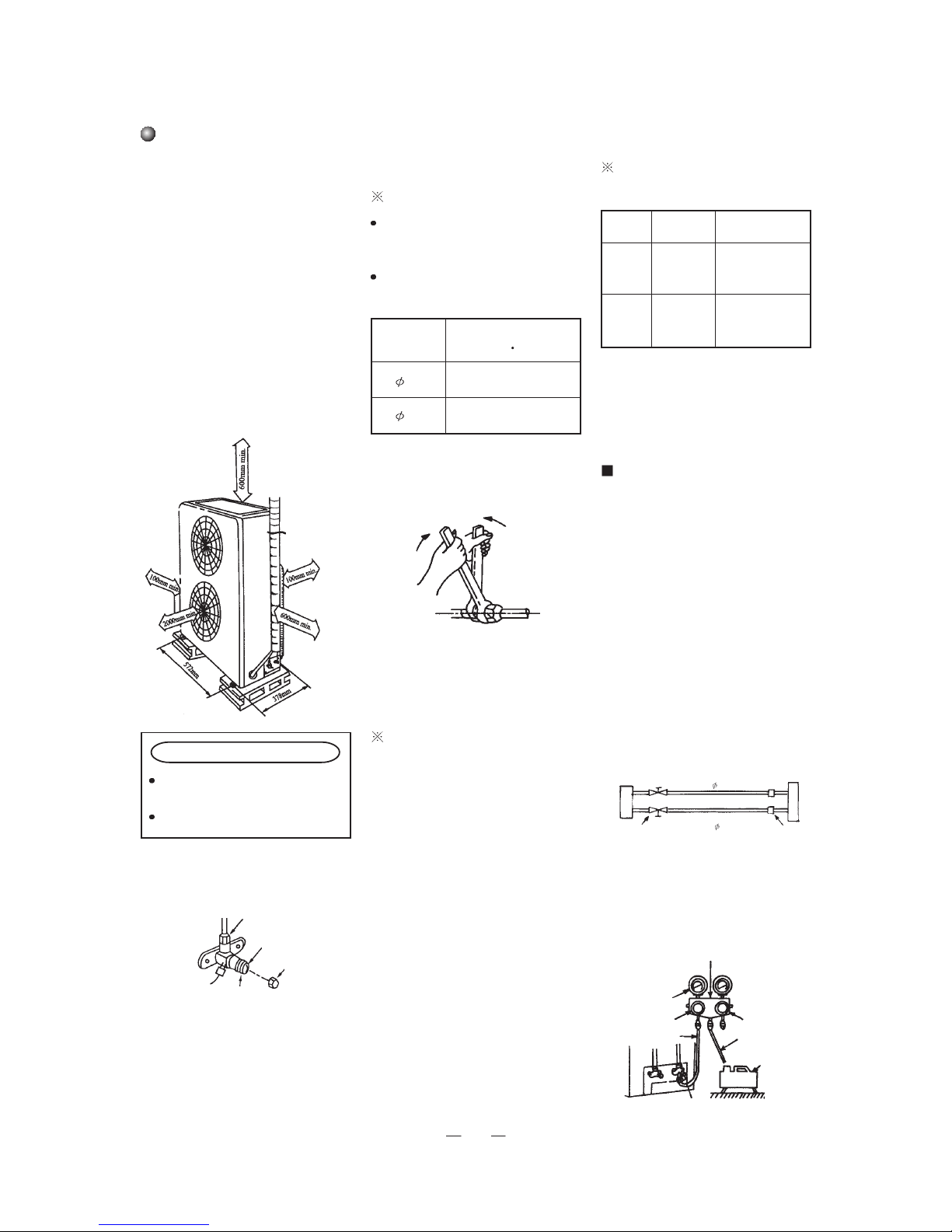

Installation of outdoor unit

1. Choose a place

Note:

The outdoor unit must be installed on

solid foundation to minimize noise and

vibration.

The air outlet must not be blocked.

In coastal area, places of high altitude

or strong wind, please install the unit

against the wall or use wind block.

Install the unit with good ventilation

instead of a sealed space.

Installation hole size: 572x327mm.

2. Connecting of refrigerant pipe

Tightening joint

Match pipes

Screw nut with hand and then tighten

with wrench (see figure below).

Be careful not to twist too tightly or

the nut may get damaged.

Open valve stem until it touches limit

block and don’t open further.

Tighten bonnet with wrench.

When operating the check valve, please note:

Diameter

(mm)

Twisting moment

(N m)

12 45-50

19 70-75

Length of

pipe

Exhausting

Value of refrigerant

charge

5m

5-15m

Use

refrigerant

of outdoor

unit

As value on the

nameplate

Use

vacuum

pump

Nameplate value

+30g/m (charge 30g

more for every meter

added to the pipe

Manifold

Valve

Multimeter

-76cmHg

Lo Handle

Charging hose

Manometer

Hi handle

Charging hose

Vacuum pump

Low pressure valve

Joint nut

Limit block

Bonnet

one-way valve

Valve stem

Exhausting (with

hexagon wrench)

*1.See section about vacuum pump or

refrigerant tank.

*2.Charge refrigerant according to

value listed above. If the unit is to be

moved to other place, please evacuate

with vacuum pump or refrigerant tank.

When using refrigerant of outdoor

unit:

*1.Tighten nuts A,B,C,D substantially.

*2.Remove cover from check valve A.

*3.Twist open core of liquid valve B

with hexagon wrench, and at the same

time hold screw driver against core of

gas valve A to let gas out.

After 15 seconds of exhausting and

refrigerant appears, close one way

valve and tighten bonnet.

*4.Fully open cores of both liquid

valve and gas valve, tighten bonnet,

then check with soap water or leakage

detector to see if there is any leaking

in the joints of piping between indoor

and outdoor units.

*6.Fully open high/low pressure

valves.

*7.Remove charging hose from charging end of low pressure valve.

*8.Tighten bonnet

of low pressure

valve.

When using the vacuum pump

*1.Connect charging hose of manifold

valve to charging end of low pressure

valve (both high/low pressure valves

must be tightly shut).

*2. Connect joint of charging hose to

vacuum pump.

*3.Fully open handle of Lo manifold

valve.

*4.Ope n the vacuum p ump to

evacuate. At the beginning, slightly

loosen joint nut of low pressure valve

to check if there is air coming inside.

(valve of vacuum pump changes from

negative to 0) Then tighten this nut.

*5.After finishing evacuation, shut Lo

handle of manifold valve to stop the

vacuum pump. Keep evacuating for

more than 15 minutes and make sure

the rea

ding of multimeter is -1.0x10

5

pa

(-76cmHg).

Outdoor unit

Gas side

Indoor unit

Check valve

Pipe joint

A

B

C

D

12mm

19mm

24

3.Wiring

Remove front plate.

Open outdoor wiring hole and fit on ring for wiring.

Lead connecting wire from terminal board of outdoor unit, thread it through outdoor wiring

hole and indoor wiring hole, then connect to indoor terminal board.

Connect wires as shown bellow and then fix with wire clamp.

Trial running

After finishing leakage

check, start trial running.

Cooling

Set cooling mode.

See owner’s manual for details.

3-minute protection

If the unit is stopped, it needs 3 minutes to

be restarted.

3~220V 60Hz

Signal wires

Outdoor signal wires

25

Install slant protection cable

Note:

In order to avoid any accidental slant for outdoor unit,please

install slant protection cable.

Installation steps:

1.Take out the screw from the indoor unit top cover (Pic 1)

2.Take out the slant protection cable, put it in the slant protection

hole, fasten it with screws. (Pic 2)

2.Fix another end of cable to the wall by using screw (ST4.2X38)

Take out the screw

protection hole

Fix this end to the wall

Put this end in the

hole,fasten it

Wall

Indoor unit

Pic 1

Pic 2

Abov e scheme for installation referenc e only, indo or uni t may be different .

Activate your warranty.....

in

5

simple

steps!

For the electronic

warranty submission

please use the following link

Scan here for the

warranty form

http://www.inventoraiconditioner.com

/warranty-inventor

Select the product type

(airconditioner or appliance) for

which the warranty will be activated

Choose the warranty that

corresponds to your product

purchase

Fill in the required information

(owner, retailer and appliance)

and press send

You will receive a confirmation

e-mail for the activation of

your warranty

Connect to the following link

http://www.inventorairconditioner.com/warranty-inventor

1

ΠΕΡΙΕΧΟΜΕΝΑ

Σημειώσεις πρίν τη χρήση

Δομή

Συντήρηση

Δομή

Μοντέλα & προδιαγραφές

Πάνελ ελέγχου

Κατεύθυνση αέρα

Φροντίδα & συντήρηση

Έλεγχος σφαλμάτων

2

3

4

5

16

17

18

19

20

21

23

24

25

Ηλεκτρολογική καλωδίωση

Σημειώσεις για την σωλήνωση

Εγκατάσταση της εσωτερικής μονάδας

Εγκατάσταση της εξωτερικής μονάδας

Εγκατάσταση σύρμματος προστασίας κλίσης

Δοκιμαστική λειτουργία

Εγκατάσταση

Τηλεχειριστήριο

7

2

ΣΗΜΕΙΩΣΕΙΣ ΠΡΙΝ ΤΗ ΧΡΗΣΗ

Απαιτήσεις τροφοδοσίας

Εύρος θερμοκρασίας για την σωστή λειτουργία

1. Το φορτίο του παρεχόμενου ρεύματος πρέπει να είναι τουλάχιστον 10kw, και η διατομή των καλωδίων πρέπει

να είναι τουλάχιστον 2.5mm

2.

Συμβουλευτείτε τον προμηθευτή σας για λεπτομέρειες.

2. Το κλιματιστικό πρέπει να γειωθεί με ασφάλεια. Το καλώδιο της γείωσης πρέπει να συνδεθεί στην ειδική συσκευή

του κτιρίου και όχι σε αγωγό ν

ερού ή αερίου.

3.

Η καλωδίωση πρέπει να γίνει από εξειδικευμένο τεχνικό και σύμφωνα με τους αντίστοιχους νόμους και κανονισμούς.

4. Σε ένα σταθερό κύκλωμα, πρέπει να υπάρχει ασφάλεια διαφυγής με επαρκές φορτίο και διακόπτης αέρα με αρκετό χώρο.

5.Αποσυνδέστε το από την παροχή ρεύματος όταν δεν το χρησιμοποιείτε.

Απαιτήσεις ασφαλείας

Διαβάστε αυτό το εγχειρίδιο προσεκτικά πρίν τ

η χρήση της μονάδας και επικοινωνήστε με τον προμηθευτή σας ή με το

τμήμα εξυπηρέτησης πελατών εάν έχετε απορίες ή κάποιο πρόβλημα.

Το κλιματιστικό είναι κατάλληλο προς χρήση μόνο για τον σκοπό που περιγράφεται σε αυτό το εγχειρίδιο.

ΠΟΤΕ μην χρησιμοποιείτε ή αποθηκεύετε βενζίνη ή άλλα εύφλεκ

τα αέρια ή υγρά κοντά στο κλιματιστικό, είναι

πάρα πολύ επικίνδυνο!

Το κλιματιστικ

ό δεν έιναι εξοπλισμένο με συσκευή για να φέρνει φρέσκο αέρα από το εξωτερικό χώρο, επομένως

όταν χρησιμοποιείτε θερμάστρα αερίου στον χώρο, ανοίγετε τα παράθυρα συχνά ώστε να αερίζεται ο χώρος, καθώς

τέτοιου είδους θερμάστρες καταναλώνουν το οξυγόνο του χώρου το οποίο μπορεί να προκαλέσει δυσφορία στους

παρεβρισκόμενους λόγω έλλειψης οξυγόνου.

• Μην εκκινείτε ή σταματάτε την μονάδα ανοιγοκλείνοντας τον διακόπτη παροχής, πιέστε το

πλήκτρο ON/OFF.

• Μην εισάγετε τίποτα στους αεραγωγούς της μονάδας.

•

Μην αφήνετε τα μικρά παιδιά να χειρίζονται τη μονάδα.

• Εάν στον χώρο υπάρχουν μικρά παιδία ή ασθενείς ρυθμίστε τη θερμοκρασία κατάλληλα.

Συνθήκες

λειτουργίας

Θέρμανση

Θερμοκρασία Εσωτερική Θερμοκρασία

27°C

(ξηρό θερμόμετρο) 24°C (ξηρό θερμόμετρο) / 18°C (υγρό θερμόμετρο)

-5°C (ξηρό περιβάλλον) / -6°C (υγρό περιβάλλον)

20°C (ξηρό θερμόμετρο)

Εξωτερική Θερμοκρασία

Μ

έγιστο

Ελάχιστο

ΠΡΟΕΙΔΟΠΟΙΗΣΗ

ΠΡΟΣΟΧΗ

3

ΔΟΜΗ

Έξοδος αέρα

Εσωτερική μονάδα

Εξωτερική μονάδα

Αγωγός

αποστράγγισης

Σωλήνα σύνδεσης

Έξοδος αέρα

Έξοδος αέρα

Εξαγωγή αέρα

Οθόνη

Εμπρόσθιο πάνελ

Είσοδος αέρα

Είσοδος αέρα

Γρίλια εισαγωγής αέρα

4

Μοντέλο & Προδιαγραφές

Ό

λα τα παραπάνω μπορεί να αλλάξουν χωρίς προειδοποίηση, τα αναεωμένα στοιχεία βρίσκοντα στο ταμπελάκι

που βρίσκεται πάνω στην μονάδα.

Λειτουργίες

Απόδοση ψύξης(W)

Απόδοση θέρμανσης(W)

Παροχή ρεύματος

Ισχύς εισόδου(W)

Όγκος ροής αέρα(m3/h)

Ψυκτικό μέσο

Θόρυβος (εσ./εξ.)dB(A)

Κλιματική κλάση

Επίπεδο αντίστασης νερού

Μόνωση

Βάρος(εσ./εξ.)(kg)

Διαστάσεις(εσ./εξ.)

(ΠxΥxΒ) (mm)

Μοντέλο

RFI-66B /RFO-66B

6400/6200(9700)

16000

18000(21500)

380-415 V 3N ~ 50H z

2000

58/63

T1

IP24

I

60/115

Εσωτερική: 540x1750x380

Εσωτερική: 950x1250x412

Ψύξη/Θέρμανση

R410A 5.0

5

Πλήκτρο SWING

Επιλέξτε την κίνηση των

περσίδων ή την στάση τους.

Πλήκτρο FAN SPEED

Επιλέξτε την ταχύτητα του ανεμιστήρα

από αυτ/τη-χαμηλή-μεσαία-υψηλή

Πλήκτρο MODE

Επιλέξτε τo πρόγραμμα λειτουργίας

από Αυτόματη/Ψύξη/

Αφύγρανση/Ανεμιστήρα/Θέρμανση

Πλήκτρο ON/OFF

Πιέστε το μια φορά για να

ενεργοποιήσετε τη μονάδα και

ξανά πιέστε το για να την

απενεργοποιήσετε

Πλήκτρο SET TEMP.

Κάθε φορά που πιέζετε το ,η ρυθμισμένη

θερμοκρασία του χώρου κατεβαίνει κατά 1°C,

κάθε φορά που πιέζετε το ,η ρυθμισμένη

θερμοκρασία του χώρου ανεβαίνει κατά 1°C.

Η ρυθμισμένη θερμοκρασία του χώρου μπορεί

να οριστεί σε εύρος 16~30°C. Υπό κανονική

λειτουργία, πιέζοντας τα δυο πλήκτρα ταυτόχρονα, θα κλειδώσουν τα πλήκτρα της οθόνης,

πιέζοντας τα ξανά μαζί τα πλήκτρα θα ξεκλειδώσουν

Όταν το κλιματιστικό είναι απενεργοποιημένο, το

πλήκτρο χρησιμοποιείται για να οριστεί η ώρα

ενεγοποίησης του κλιματιστικού. Με κάθε πάτημα,

η ώρα αλλάζει κατά 30 λεπτά με εύρος από 30

λεπτά έως 24 ώρες. Όταν φτάσει η ρυθμισμένη

ώρα, η μονάδα θα λειτουργήσει υπό το ορισμένο

πρόγραμμα. Όταν το κλιματιστικό είναι ενεργοποιημένο, το πλήκτρο χρησιμοποιείται για να οριστεί

η ώρα απενεργοποίησης. Με κάθε πάτημα, η ώρα

αλλάζει κατά 30 λεπτά με εύρος από 30 λεπτά έως

24 ώρες. Όταν φτάσει η ρυθμισμένη ώρα, η μονάδα

θα απενεργοποιηθεί.

Πάνελ Ελέγχου

Κλιματιστική μονάδα ντουλάπα εμφανούς τύπου με οθόνη LCD

Οθόνη LCD

6

Ειδικές Λειτουργίες

Λειτουργία προστασίας συμπιεστή

Σε όλες τις λειτουργίες, ο συμπιεστής χρειάζεται 3 λεπτά για να επανεκκινηθεί εάν έχει σταματήσει.

Εάν δεν υπάρχουν αλλαγές στο πρόγραμμα λειτουργίας, ο συμπιεστής θα λειτουργεί για 6 λεπτά

προτού μπορέσει να σταματήσει. Ενδιάμεσα από τις αλλαγές προγράμματος ο συμπιεστής θα

σταματά για 3 λεπτά.

Λειτουργία κλειδώματος των πλήκτρων

Υπό κανονική λειτουργία, πιέζοντας ταυτόχρονα τα πλήκτρα και , θα κλειδώσουν τα πλήκτρα

του πάνελ. Πείζοντάς τα ξανά μαζί τα πλήκτρα θα ξεκλειδώσουν.

Δοκιμαστική Λειτουργία

Κάθε φορά που συνδέεται η μονάδα στο ρεύμα και δεν δέχεται εντολές από τα πλήκτρα:

(1) Πιέστε το πλήκτρο για να μπεί η μονάδα σε αναγκαστική ψύξη, ο συμπιεστής ξεκινά

και οι περσίδες κινούνται αυτόματα, η ταχύτητα του ανεμιστήρα της εσωτερικής και της

εξωτερικής μοναδας είναι υψηλή. Στην οθόνη LCD εμφανίζονται όλα τα σύμβολα.

Μετά από 5 λεπτά, η μονάδα θα σταματήσει και θα είναι σε αναμονή.

(2) Πιέστε το πλήκτρο για να μπεί η μονάδα σε αναγκαστική θέρμανση, ο συμπιεστής

και η βοηθητική ηλεκτρική αντίσταση ενεργοποιούνται και οι περσίδες κινούνται αυτόματα,

η ταχύτητα του ανεμιστήρα της εσωτερικής και της εξωτερικής μονάδας είναι υψηλή. Στην

οθόνη LCD εμφανίζονται όλα τα σύμβολα. Μετά από 5 λεπτά, η μονάδα θα σταματήσει

και θα είναι σε αναμονή.

- 7 -

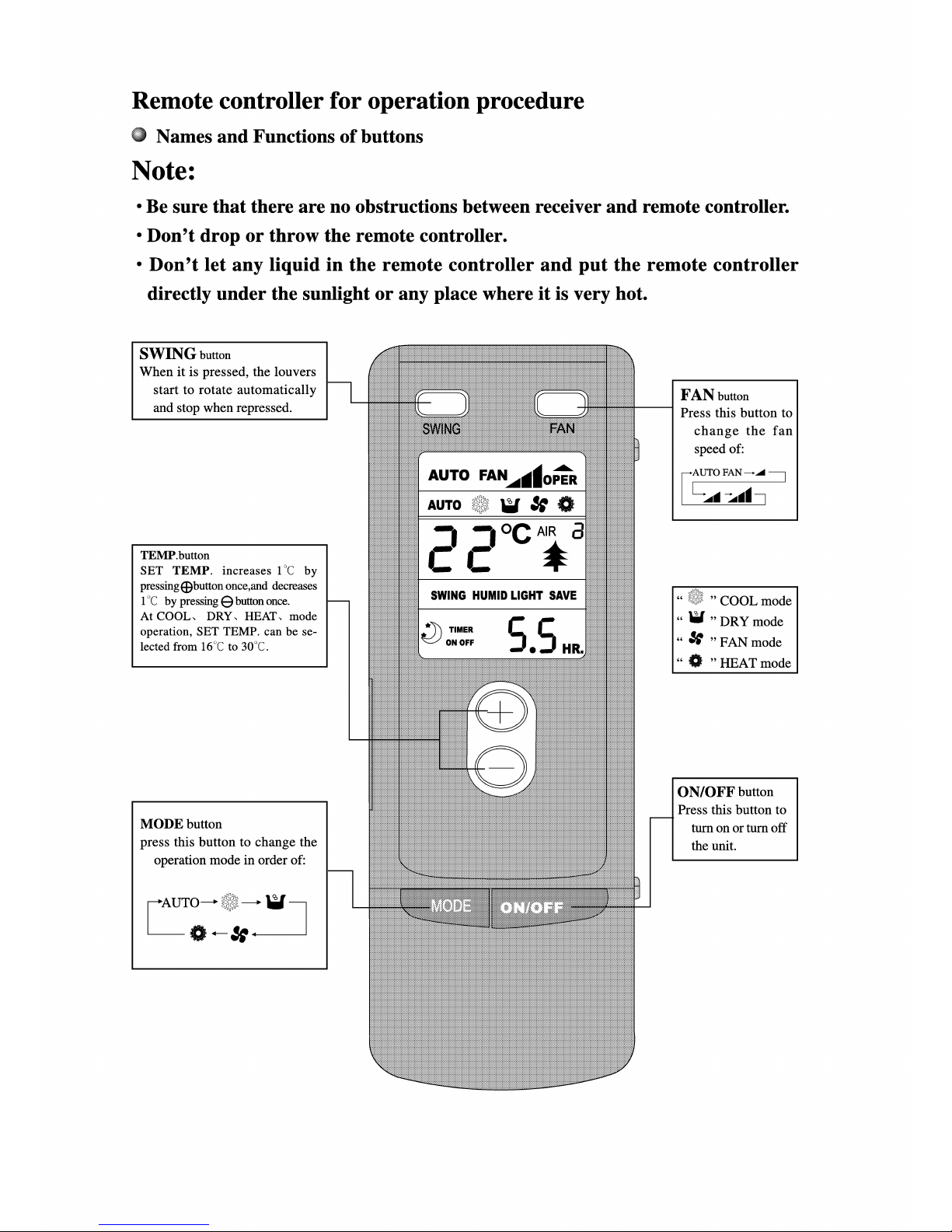

Πλήκτρο MODE

Πιέστε αυτό το πλήκτρο για

να αλλάξετε το πρόγραμμα

λειτουργίας με την ακόλουθη

σειρά:

Πλήκτρο TEMP.

Αυξάνει την θερμοκρασία κατά

1°C πιέζοντας το

+ , και μειώνει

τη θερμοκρασία κατά 1°C

πιέζοντας το

- .

Κατά την Ψύξη, Αφύγρανση,

Θέρμανση, η ορισμένη

θερμοκρασία μπορεί να επιλεγεί

από 16°C~30°C.

Πλήκτρο SWING

Πιέζοντας αυτό το πλήκτρο

ξεκινά η αυτόματη κίνηση των

περσίδων. Πιέζοντάς το ξανά

η κίνηση σταματά.

Τηλεχειριστήριο

Σημείωση:

• Βεβαιωθείτε οτι δεν υπάρχουν εμπόδια μεταξύ του δέκτη και του τηλεχειριστηρίου.

• Μην πετάτε ή χτυπάτε το τηλεχειριστήριο.

• Μην αφήσετε να πέσουν υγρά στο τηλεχειριστήριο και μην το αφήνετε σε σημείο

με απευθείας έκθεση στον ήλιο ή σε πολύ θερμό σημείο.

Ονομασία και λειτουργίες των πλήκτρων.

Πλήκτρο FAN

Πιέστε αυτό το πλήκτρο

για να επιλέξετε την

ταχύτητα του ανεμιστήρα:

Πλήκτρο ON/OFF

Πιέστε αυτό το πλήκτρο για να

ενεργοποιήσετε/απενεργοποιήσετε

τη μονάδα.

Πρόγραμμα Ψύξης

Προγραμμά Αφύγρανσης

Πρόγραμμα Ανεμιστήρα

Πρόγραμμα Θέρμανσης

- 8 -

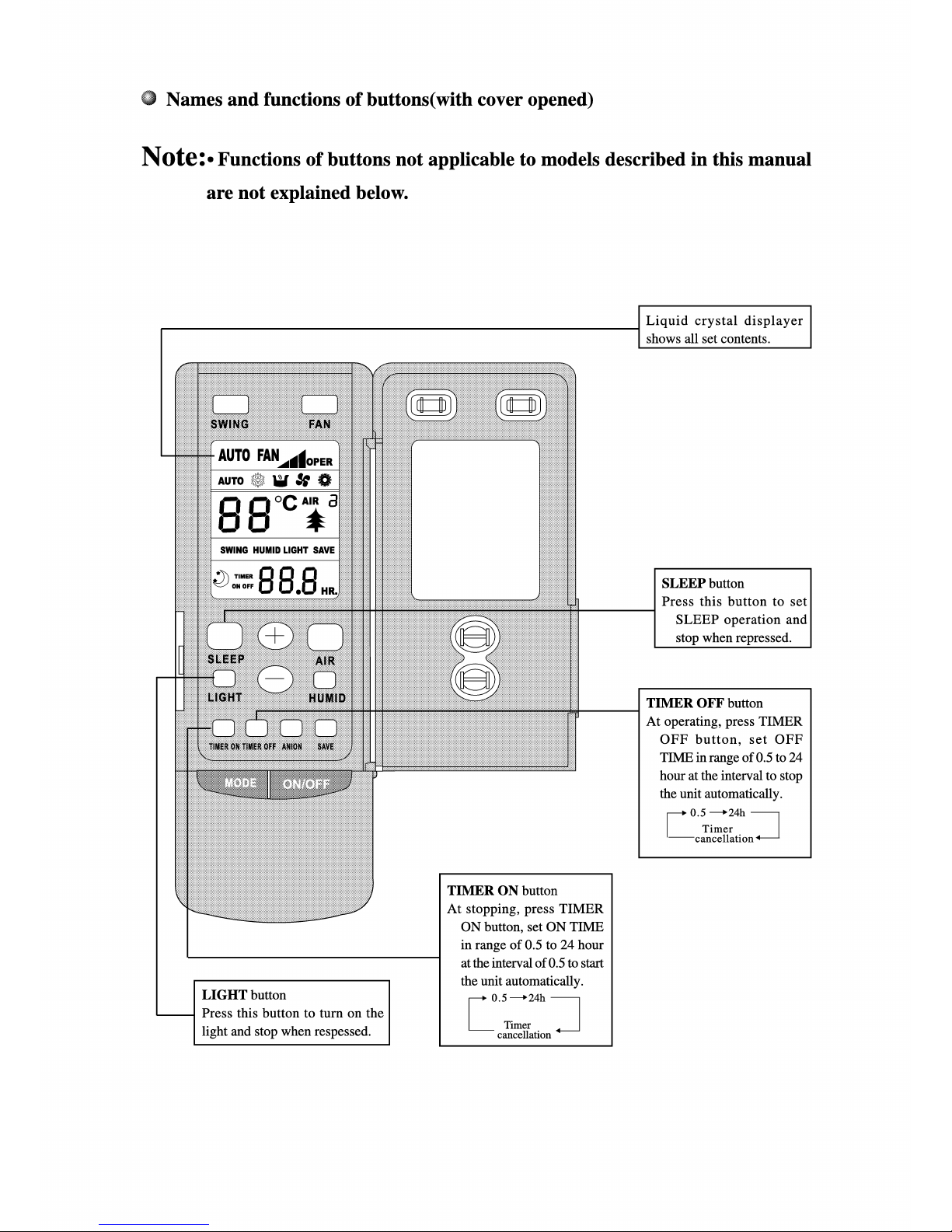

Πλήκτρο LIGHT

Πιέστε αυτό το πλήκτρο

για να ανάψετε το φώς

και ξαναπατήστε το για

να σβήσει.

Πλήκτρο TIMER OFF

Πιέστε αυτό το πλήκτρο

για να ορίσετε την ώρα

απενεργοποίησης σε εύρος

από 30 λεπτά έως 24 ώρες.

Πλήκτρο SLEEP

Πιέστε αυτό το πλήκτρο

για να ενεργοποιήσετε

τη λειτουργία SLEEP.

Ξαναπατήστε το για να την

απενεροποιήσετε.

Οθόνη υγρών κρυστάλλων

Αναγράφει όλες τις ρυθμίσεις

Ονομασίες και λειτουργίες των πλήκτρων (με ανοιχτό το κάλυμμα)

ΣΗΜΕΙΩΣΗ: Η λειτουργία των πλήκτρων δεν εφαρμόζεται σε μοντέλα τα οποία δεν

περιέχονται σε αυτό το εγχειρίδιο.

Ακύρωση

χρονοδιακόπτη

Πλήκτρο TIMER ON

Πιέστε αυτό το πλήκτρο

για να ορίσετε την ώρα

ενεργοποίησης σε εύρος

από 30 λεπτά έως 24 ώρες.

Ακύρωση

χρονοδιακόπτη

- 9 -

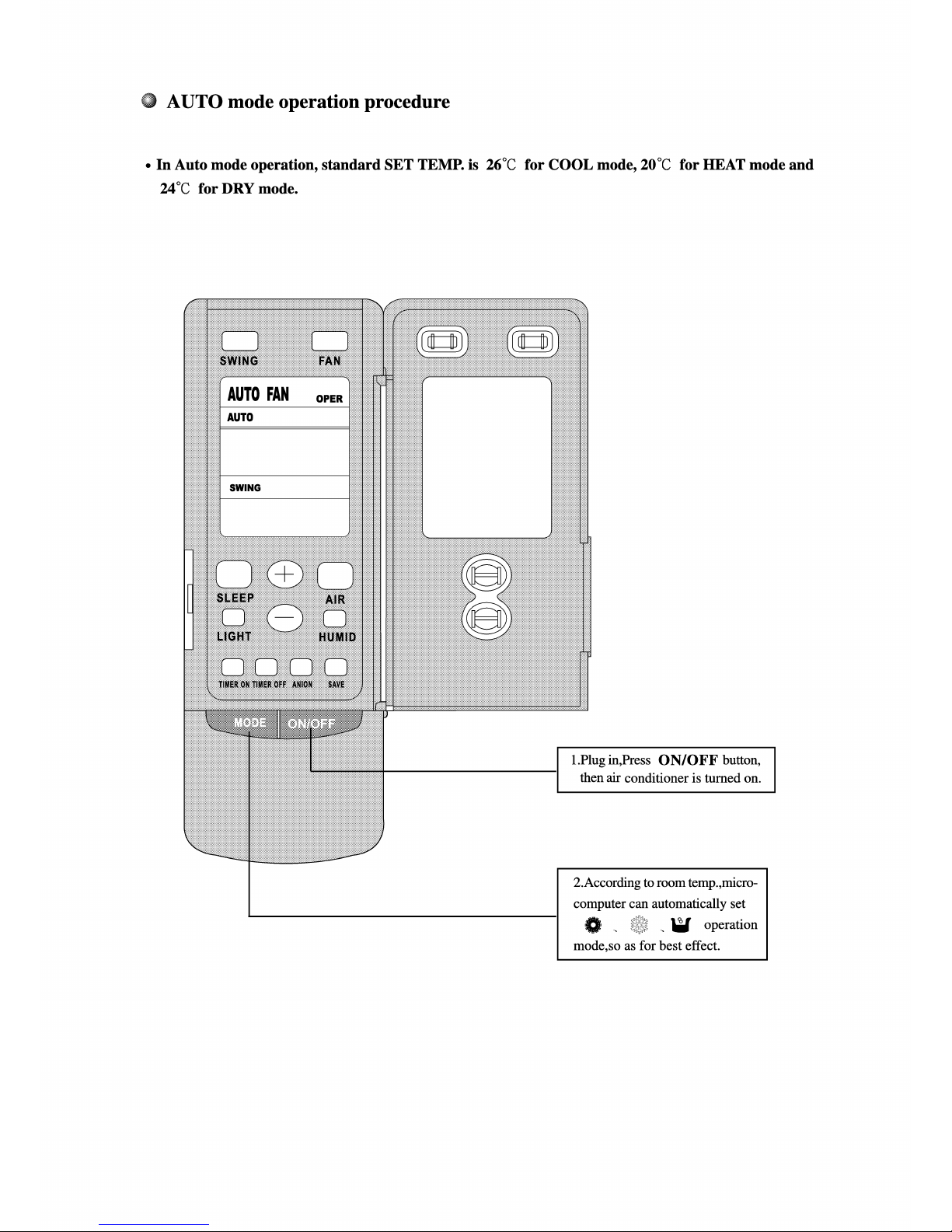

Σύμφωνα με τις συνθήκες του χώρου,

ο επεξεργαστής μπορεί να ορίσει

αυτόματα

για το καλύτερο αποτέλεσμα.

Πιέστε το πλήκτρο ON/OFF

και το κλιματιστικό θα

ενεργοποιηθεί.

ΑΥΤΟΜΑΤΗ ΛΕΙΤΟΥΡΓΙΑ

• Στην αυτόματη λειτουργία, η ρυθμισμένη θερμοκρασία είναι 26°C για την ψύξη, 20°C για τη

θέρμανση και 24°C για την αφύγρανση.

- 10 -

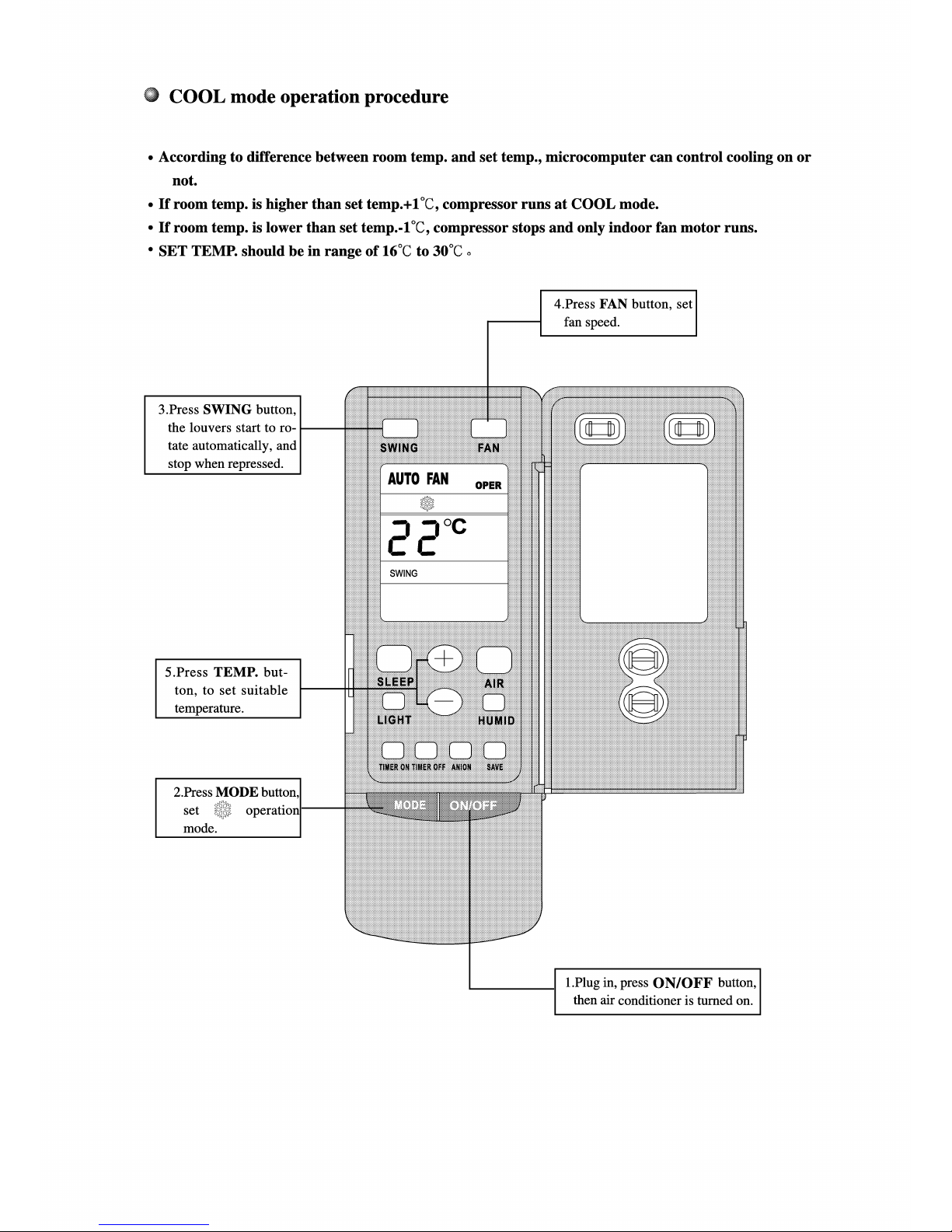

1.Πιέστε το πλήκτρο ON/OFF

και το κλιματιστικό θα ενεργοποιηθεί

2. Πιέστε το πλήκτρο MODE, και

ρυθμίστε τη λειτουργία

5. Πιέστε το πλήκτρο TEMP και

ορίστε την επιθυμητή θερμοκρασία

3. Πιέστε το πλήκτρο SWING για

να ξεκινήσει η κίνηση των περσίδων.

Ξαναπατήστε το για να σταματήσει η

κίνηση

4. Πιέστε το πλήκτρο FAN, για να

ορίσετε την ταχύτητα του ανεμιστήρα.

Λειτουργία ψύξης

• Σύμφωνα με την διαφορά θερμοκρασίας του χώρο με την θερμοκρασία που έχει οριστεί

ο επεξεργαστής μπορεί να ελέγξει την ψύξη.

• Εάν η θερμοκρασία του χώρου είναι κατά 1°C υψηλότερη από την ρυθμισμένη θερμοκρασία,

ο συμπιεστής λειτουργεί στην ψύξη.

• Εάν η θερμοκρασία του χώρου είναι κατά 1°C χαμηλότερη από την ρυθμισμένη θερμοκρασία,

ο συμπιεστής σταματά και λειτουργεί μόνο ο ανεμιστήρας.

• Η ρυθμισμένη θερμοκρασία πρέπει να είναι από 16°C έως 30°C.

- 11 -

1.Πιέστε το πλήκτρο ON/OFF

και το κλιματιστικό θα ενεργοποιηθεί

4. Πιέστε το πλήκτρο FAN, για να

ορίσετε την ταχύτητα του ανεμιστήρα.

2. Πιέστε το πλήκτρο MODE, και

ρυθμίστε τη λειτουργία

5. Πιέστε το πλήκτρο TEMP και

ορίστε την επιθυμητή θερμοκρασία

3. Πιέστε το πλήκτρο SWING για

να ξεκινήσει η κίνηση των περσίδων.

Ξαναπατήστε το για να σταματήσει η

κίνηση

Λειτουργία Θέρμανσης(για τις μονάδες Ψύξης/Θέρμανσης)

• Εάν η θερμοκρασία του χώρου είναι κατά 1°C χαμηλότερη από την ρυθμισμένη θερμοκρασία,

ο συμπιεστής λειτουργεί στην Θέρμανση.

• Εάν η θερμοκρασία του χώρου είναι κατά 1°C υψηλότερη από την ρυθμισμένη θερμοκρασία,

ο συμπιεστής και ο ανεμιστήρας της εσωτερικής/εξωτερικής μονάδας σταματούν.

• Η ρυθμισμένη θερμοκρασία πρέπει να είναι από 16°C έως 30°C.

- 12 -

1.Πιέστε το πλήκτρο ON/OFF

και το κλιματιστικό θα ενεργοποιηθεί

3. Πιέστε το πλήκτρο SWING για

να ξεκινήσει η κίνηση των περσίδων.

Ξαναπατήστε το για να σταματήσει

4. Πιέστε το πλήκτρο TEMP και

ορίστε την επιθυμητή θερμοκρασία

2. Πιέστε το πλήκτρο MODE, και

ρυθμίστε τη λειτουργία

Κατά αυτή τη λειτουργία δεν

μπορείτε να ρυθμίσετε την

ταχύτητα του ανεμιστήρα.

Λειτουργία Αφύγρανσης

• Εάν η θερμοκρασία του χώρου είναι κατά 2°C χαμηλότερη από την ρυθμισμένη θερμοκρασία,

ο συμπιεστής και ο ανεμιστήρας της εσωτερικής και της εξωτερικής μονάδας σταματούν.

• Εάν η θερμοκρασία του χώρου είναι ± 2°C από την ρυθμισμένη θερμοκρασία, το κλιματιστικό

αφυγραίνει. Εάν η θερμοκρασία του χώρου είναι κατά 2°C μεγαλύτερη από την ρυθμισμένη,

το κλιματιστικό περνά σε λειτουργία ψύξης και ο ανεμιστήρας τη εσωτερικής μονάδας λειτουργεί

στη χαμηλή ταχύτητα.

• Η ρυθμισμένη θερμοκρασία πρέπει να είναι από 16°C έως 30°C.

- 13 -

Λειτουργία Χρονοδιακόπτη

Πλήκτρο TIMER OFF

Πιέστε αυτό το πλήκτρο

για να ορίσετε την ώρα

απενεργοποίησης σε εύρος

από 30 λεπτά έως 24 ώρες.

Ακύρωση

χρονοδιακόπτη

Πλήκτρο TIMER ON

Πιέστε αυτό το πλήκτρο

για να ορίσετε την ώρα

ενεργοποίησης σε εύρος

από 30 λεπτά έως 24 ώρες.

Ακύρωση

χρονοδιακόπτη

- 14 -

Πλήκτρο MODE

Πιέστε αυτό το πλήκτρο για

να αλλάξετε το πρόγραμμα

λειτουργίας με την ακόλουθη

σειρά:

ή

Πλήκτρο SWING

Πιέζοντας αυτό το πλήκτρο

ξεκινά η αυτόματη κίνηση των

περσίδων. Πιέζοντάς το ξανά

η κίνηση σταματά.

4. Πιέστε το πλήκτρο FAN, για να

ορίσετε την ταχύτητα του ανεμιστήρα.

1.Πιέστε το πλήκτρο ON/OFF

και το κλιματιστικό θα ενεργοποιηθεί

5. Πιέστε το πλήκτρο TEMP και

ορίστε την επιθυμητή θερμοκρασία

Πλήκτρο SLEEP

Πιέστε αυτό το πλήκτρο

για να ενεργοποιήσετε

τη λειτουργία SLEEP.

Ξαναπατήστε το για να την

απενεροποιήσετε.

Λειτουργία Θέρμανσης(για τις μονάδες Ψύξης/Θέρμανσης)

• Όταν η μονάδα λειτουργεί στην ψύξη ή την αφύγρανση, εάν ενεργοποιηθεί η λειτουργία Sleep, η

θερμοκρασία θα ανέβει κατά 1°C σε μία ώρα και κατά 2°C σε δυο ώρες.

• Όταν η μονάδα λειτουργεί στην θέρμανση, εάν ενεργοποιηθεί η λειτουργία Sleep, η θερμοκρασία θα

πέσει κατά 1°C σε μία ώρα και κατά 2°C σε δυο ώρες.

- 15 -

1. Αφαιρέστε το καπάκι από το

πίσω μέρος του τηλεχειριστηρίου

2. Τοποθετήστε 2 μπαταρίες (ΑΑΑ

ξηρού τύπου) και πιέστε το

πλήκτρο “ACL”.

3. Επανατοποθετήστε το καπάκι.

ΣΗΜΕΙΩΣΗ:

• Μην βάζετε παλιές και νέες

μπαταρίες μαζί ή μπαταρίες

διαφορετικού τύπου.

• Αφαιρέστε τις μπαταρίες

όταν το τηλεχειριστήριο δεν

πρόκειται να χρησιμοποιηθεί

για αρκετό καιρό.

• Το τηλεχειριστήριο πρέπει να

χρησιμοποιείται εντός της

εμβέλειας του.

• Το τηλεχειριστήριο πρέπει να

τοποθετηθεί τουλάχιστον ένα

μέτρο μακρυά από την τηλεόραση

1. Αφαιρέστε το καπάκι

3. Τοποθετήστε το καπάκι

2. Τοποθετήστε τις μπαταρίες ΑΑΑ

Πως να τοποθετήστε τις μπαταρίες

16

• Πιέστε το πλήκτρο SWING στο πάνελ ελέγχου για να

επιλέξετε το Swing ή το End Swing, τότε οι περσίδες θα

κινούνται δεξιά-αριστερά ή θα σταματήσουν και η ροή του

αέρα θα έχει σταθερή κατεύθυνση.

• Καθε φορά που πιέζετε το πλήκτρο στην οθόνη εμφανίζεται

η ένδειξη SWING, εάν λειτουργεί ο ανεμιστήρας της

εσωτερικής μονάδας, θα ξεκινήσει η κίνηση των περσίδων,

πατήστε το ξανά και η κίνηση σταματάει και η ένδειξη σβήνει

από την οθόνη.

Ρυθμίστε την κάθετη κατεύθυνση των περσίδων με το χέρι.

Κρατήστε τα δύο άκρα των περσίδων κατά την ρύθμιση.

Κατά την ψύξη ή αφύγρανση ρυθμίστε τις περσίδες ελαφρώς

προς τα πάνω. Κατά την ψύξη ρυθμίστε τις προς τα κάτω.

(Οριζόντια κίνηση

περσίδων)

Ευθεία

ροή

Κατεύθυνση ροής αέρα

1.Κατεύθυνση ροής αέρα δεξιά-αριστερά 2.Κατεύθυνση ροής αέρα πάνω-κάτω

Ροή προς

τα πάνω

Ροή προς

τα κάτω

Κατά την θέρμανση ρυθμίστε την ροή προς τα κάτω

Κατά την ψύξη ρυθμίστε την ροή προς τα πάνω

ΣΥΝΤΗΡΗΣΗ

17

Καθαρισμός της μονάδας

1. Αποσυνδέστε τη μονάδα από το ρεύμα

3. Μην χρησιμοποιείτε οξύ ή αλκαλικά

διαλύματα

3. Μην ρίχνετε νερό στη μονάδα

• Βεβαιωθείτε ότι δεν υπάρχουν εμπόδια

στους αεραγωγούς της εξωτερικής μονάδας.

2. Χρησιμοποιήστε ένα μαλακό

πανί για τον καθαρισμό.

Εάν το εξωτερικό της μονάδας είναι

πολύ βρώμικο, βρέξτε το πανί με

χλιαρό νερό κάτω των 40°C,

στραγγίξτε το πανί και

καθαρίστε τη μονάδα.

Αποσυνδέστε τη μονάδα από το ρεύμα, μόνο όταν το

κλιματιστικό έχει σταματήσει εντελώς την λειτουργία του.

• Βεβαιωθείτε ότι το κλιματιστικό είναι απενεργοποιημένο.

• Αφαιρέστε τη βίδα από την λαβή στην γρίλια εισαγωγής αέρα.

• Τραβήξτε την γρίλια από την λαβή προς τα έξω.

• Το φίλτρο είναι συνδεδεμένο πάνω στη γρίλια, αφαιρέστε το.

• Καθαρίστε το χτυπώντας το ελαφρώς ή με μια ηλεκτρική

σκούπα. Εάν έχει συσσωρευθεί πολλή σκόνη χρησιμοποιήστε

νερό με ένα ουδέτερο απορρυπαντικό, και ξεβγάλτε το.

Στεγνώστε το μετά τον καθαρισμό και επανατοποθετήστε το.

•

Μην στεγνώσετε το φίλτρο εκθέτοντάς το στον ήλιο ή σε

πηγή θερμότητας, αλλιώς θα παραμορφωθεί.

• Το φιλτρο μπορεί να παραμορφωθεί εάν το καθαρίσετε με

ζεστό νερό( 50°C και πάνω).

στραγγίξτε το

πανί πρίν τον

καθαρισμό

Λαβή

Γρίλια εισαγωγής αέρα

Καθαρισμός του φίλτρου

Το φίλτρο πρέπει να καθαρίζεται

κάθε 2 εβδομάδες

Αφαίρεση του φίλτρου

Καθαρισμός

Σημείωση

Φροντίδα και Συντήρηση

Τα εμπόδια θα προκαλέσουν

βλάβη στη μονάδα.

18

Εάν το κλιματιστικό σας δεν λειτουργεί σωστά, ελέγξτε τα παρακάτω πριν ζητήσετε βοήθεια. Εάν ελέγξετε τα ακόλουθα

σημεία και το κλιματιστικό σας συνεχίζει να μην λειτουργεί σωστά, επικοινωνήστε με το τμήμα επισκευών για να το ελέγξει.

Το κλιματιστικό δεν

ενεργοποιείται

Το κλιματιστικό σταματάει

αμέσως μετά την εκκίνηση

και αναγράφεται ή ένδειξη

“Ε1”

Το κλιματιστικό σταματάει

αμέσως μετά την εκκίνηση

και αναγράφεται ή ένδειξη

“Ε2”

Το κλιματιστικό σταματάει

αμέσως μετά την εκκίνηση

και αναγράφεται ή ένδειξη

“Ε3”

Το κλιματιστικό σταματάει

αμέσως μετά την εκκίνηση

και αναγράφεται ή ένδειξη

“Ε4”

Η ένδειξη θερμοκρασίας

δείχνει 0°C και δεν

δουλεύει η ψύξη.

Χαμηλή απόδοση

Ψύξης

Χαμηλή απόδοση

Θέρμανσης

1. Δεν έχει ρεύμα

2. Ασφάλεια διαρροής ρεύματος

3. Χαμηλή τάση

4. Το πλήκτρο λειτουργίας είναι

απενεργοποιημένο.

5. Πρόβλημα στο κύκλωμα ελέγχου

1. Φραγμένος συμπυκνωτής

2. Πρόβλημα στο κύκλωμα ελέγχου

3. Ψύξη ενώ η εξωτερική θερμοκρασία

είναι πάνω από 43°C

4. Υψηλή πίεση στην σωλήνωση

1. Δεν λειτουργεί ο ανεμιστήρας της εσωτερικής

μονάδας ή έιναι φραγμένη η εξωτερική μονάδα

2. Η εσωτερική θερμοκρασία είναι κάτω από 18°C

3. Κομμένο καλώδιο του αισθητήρα θερμοκρασίας

του στοιχείου

4. Ο αισθητήρας θερμοκρασίας δεν είναι στη

θέση του

5. Πρόβλημα στο κύκλωμα ελέγχου

6. Ηλεκτρική διαρροή στον πυκνωτή

1. Κομμένο καλώδιο στον αισθητήρα

εσωτερικής θερμοκρασίας

2. Ο αισθητήρας εσωτερικής θερμοκρασίας

δεν είναι στη θέση του

3. Ηλεκτρική διαρροή στον πυκνωτή

1. Φραγμένο ή βρώμικο φίλτρο

2. Πολλοί άνθρωποι ή πηγές θερμότητας

στο χώρο.

3. Ανοιχτό παράθυρο ή πόρτα

4. Φραγμένοι αεραγωγοί

5. Υψηλή ρυθμισμένη θερμοκρασία

6. Διαρροή ψυκτικού

7. Βλάβη στον αισθητήρα εσωτερικής

θερμοκρασίας.

1. Φραγμένο ή βρώμικο φίλτρο

2. Ανοιχτό παράθυρο ή πόρτα

3. Χαμηλή ρυθμισμένη θερμοκρασία

4. Διαρροή ψυκτικού

5. Εξωτερική θερμοκρασία μικρότερη από -5°C

6. Πρόβλημα στο κύκλωμα ελέγχου

1. Συνδέστε την παροχή ρεύματος

2. Επικοινωνήστε με το τμήμα επισκευών

3. Επικοινωνήστε με ηλεκτρολόγο

4. Πιέστε ξανά το πλήκτρο

5. Επικοινωνήστε με το τμήμα επισκευών

1. Απομακρύνετε το εμπόδιο

2. Επικοινωνήστε με το τμήμα επισκευών

3. Τοποθετήστε την εξ. μονάδα σε σκιερό

μέρος

4. Επικοινωνήστε με το τμήμα επισκευών

1. Επικοινωνήστε με το τμήμα επισκευών

2. Ελέγξτε εάν πρέπει να ανάψετε το

κλιματιστικό.

3. Επικοινωνήστε με το τμήμα επισκευών

4.Τοποθετήστε τον αισθητήρα στη θέση

του

5. Επικοινωνήστε με το τμήμα επισκευών

6. Επικοινωνήστε με το τμήμα επισκευών

1. Επικοινωνήστε με το τμήμα επισκευών

2. Τοποθετήστε τον αισθητήρα στη θέση του

3. Επικοινωνήστε με το τμήμα επισκευών

1. Καθαρίστε το φίλτρο

2. Απομακρύνετε τις πηγές θερμότητας

3. Κλείστε τα παράθυρα και τις πόρτες

4. Απομακρύνετε τα εμπόδια

5. Ρυθμίστε χαμηλότερη θερμοκρασία

6. Επικοινωνήστε με το τμήμα επισκευών

7. Αντικαταστήστε τον αισθητήρα

1. Καθαρίστε το φίλτρο

2. Κλείστε τα παράθυρα και τις πόρτες

3. Ρυθμίστε χαμηλότερη θερμοκρασία

4. Επικοινωνήστε με το τμήμα επισκευών

5. Επηρεάζεται η θέρμανση

6. Επικοινωνήστε με το τμήμα επισκευών

Πρόβλημα Πιθανά αίτια Λύση

Έλεγχος προβλημάτων

1.Διαρροή ψύκτικού

2.Πρόβλημα στο κύκλωμα ελέγχου

1.Επικοινωνήστε με το τμήμα επισκευών

2.Επικοινωνήστε με το τμήμα επισκευών

1.Διαρροή ψυκτικού

2.Πρόβλημα στο κύκλωμα ελέγχου

3.Κομμένο καλώδιο στον αισθητήρα

4.Πολύ χαμηλή τάση

1.Επικοινωνήστε με το τμήμα επισκευών

2.Επικοινωνήστε με το τμήμα επισκευών

3.Επικοινωνήστε με το τμήμα επισκευών

4.Επικοινωνήστε με το τμήμα επισκευών

19

ΕΓΚΑΤΑΣΤΑΣΗ

Ηλεκτρολογική συνδεσμολογία

Πριν την εγκατάσταση διαβάστε προσεκτικά το εγχειρίδιο

Ακολουθήστε πιστά τις οδηγίες για την εγκατάσταση της εσωτερικής μονάδας και της διασωλήνωσης της

Πρώτα συνδέστε την καλωδίωση της εξωτερικής μονάδας και μετά της εσωτερικής. Όταν τελειώσουν οι

εργασίες καλωδίωσης και διασωλήνωσης, συνδέστε τη μονάδα στο ρεύμα.

Ο σχεδιασμός της μονάδας μπορεί να αλλάξει χωρίς προηγούμενη ειδοποίηση.

Παράδειγμα καλωδίωσης

Μοντέλο

Παροχή ρεύματος

Εισαγώμενη ισχύς Ασφάλεια αέρα

Καλωδιώσεις

Διατομή καλωδίου

παροχής (mm2)

Ελάχιστη διατομή καλωδίου

σύνδεσης εσ./εξ. μονάδας (mm2)

Σημείωση:

1. Δώστε προσοχή στον περιβάλλοντα χώρο (π.χ. ηλιοφάνεια, βροχή κλπ.)

2. Εάν υπάρχει πτώση τάσης, χρησιμοποιήστε μεγαλύτερα καλώδια παροχής

3. Πρέπει να συνδεθεί η γείωση ση εσωτερική και στην εξωτερική μονάδα.

4. Τα δεδομένα σε αυτόν τον πίνακα είναι αναφορικά, εκτελέστε την καλωδίωση σύμφωνα με τους εθνικούς

κανονισμούς καλωδίωσης.

25A

2.5/1.5

/

380

RFI-66B/RFO-66B

-415V 3N~50Hz

Πρέπει να χρησιμοποιηθεί ξεχωριστό κύκλωμα παροχής ρεύματος.

Το κύκλωμα πρέπει να εγκατασταθεί από εξειδικευμένο τεχνικό.

Ακολουθήστε το παρακάτω διάγραμμα καλωδίωσης, οι βίδες πρέπει να τοποθετηθούν σφιχτά.

Το καλώδιο επικοινωνίας και το καλώδιο παροχής ρεύματος πρέπει να τοποθετηθούν έτσι ώστε να μην έρχονται σε επαφή.

Συνδέστε τα καλώδια φάσης σωστά. Εάν η σύνδεση είναι λάθος το κλιματιστικό θα σταματήσει τη λειτουργία του αυτόματα,

σε αυτή τη περίπτωση, αλλάξτε τη θέση των καλωδίων 2 και 3 φάσεων και το κλιματιστικό θα λειτουργήσει σωστά.

Για μονάδες με αντλία θερμότητας (3φασική )

Γειώστε σωστά τις μονάδες αλλίως μπορεί να υπάρχουν παρεμβολές

Παροχή ρεύματος

Κεντρικός διακόπτης

Διαθέσιμο στο εμπόριο

Παροχή ρεύματος

για την εσ. μονάδα

Παροχή ρεύματος

για την εξ. μονάδα

Εσωτερική

μονάδα

Γείωση

Γείωση

Καλώδιο σήματος

Εξωτερική

μονάδα

20

Παρατηρήσεις για σωλήνωση

Οι σωλήνες για ψυκτικό και αποστράγγιση θα πρέπει να μονωθούν ώστε να αποφευχθούν πάγος και σταγόνες.

Η εσωτερική και εξωτερική μονάδα διαθέτουν σύνδεση εκχείλωσης.

Η σωλήνα ψυκτικού όπως φαίνεται παρακάτω χρησιμοποιείται για τη σύνδεση εσωτερικής και εξωτερικής μονάδας.

Σημείωση: Μην λυγίζετε την εύκαμπτη σωλήνα πίσω και μπροστά παραπάνω από 3 φορές.

Σημείωση: Μονώστε όλα τα εκτεθειμένα μέρη των συνδέσμων σύνδεσης εκχείλωσης και της σωλήνας ψυκτικού.

2. Όταν αγοράζετε οι ίδιοι χαλκοσωλήνα

Ελέγξτε τη βαλβίδα της εξωτερικής μονάδας να είναι κλειστή (στη θέση αυτή δεν λειτουργεί). Μετά την ένωση της

σωλήνας ψυκτικού στην εσωτερική και εξωτερική μονάδα, βγάλτε από το στόμιο την βαλβίδας ελέγχου χαμηλής

πίεσης της εξωτερικής μονάδας. Μετά, τοποθετήστε ξανά το παξιμάδι στο και κουμπώστε.

3. Αφότου ολοκληρώσετε τα βήματα 1 και 2, η βαλβίδα ελέγχου της εξωτερικής μονάδας πρέπει να είναι πλήρως ανοιχτή

ώστε να μην υπάρχει εμπόδιο ανάμεσα στην εσωτερική και εξωτερική σωλήνα ψυκτικού.

Σημείωση: πριν σφίξετε το παξιμάδι στην σύνδεση σωλήνας εκχείλωσης, παρακαλούμε εφαρμόστε λίγο λάδι ψυκτικού

υγρού στο τέρμα της σωλήνας και του συνδέσμου.

1. Συνδέστε τη σωλήνα

Ελέγξτε τη βαλβίδα εξωτερικής μονάδας ότι είναι κλειστή (δεν δουλεύει σε αυτή τη θέση). Κάθε φορά που συνδέετε,

αφαιρέστε το κάλυμμα από τη βαλβίδα ελέγχου και ενώστε τη σωλήνα σύνδεσης εκχείλωσης αμέσως (μέσα σε 5 λεπτά),

αλλιώς σκόνη, υγρασία και άλλα μικρά πράγματα μπορεί να εισχωρήσουν μέσα στη σωλήνα και να προκαλέσουν

σφάλματα.

Αναφορικά με την εύκαμπτη σωλήνα

Το μέρος της εύκαμπτης σωλήνας πρέπει να χρησιμοποιηθεί στην εσωτερική πλευρά.

Η γωνία της εύκαμπτης σωλήνας δεν πρέπει να ξεπερνά τις 90

ο

.

Είνια προτιμότερο το λύγισμα να γίνει στη μέση της σωλήνας και η ακτίνα λυγίσματος όσο μεγαλύτερη τόσο το καλύτερο.

Μην λυγίζετε την εύκαμπτη σωλήνα πάνω από 3 φορές.

Όταν λυγίζετε τη σωλήνα

Κόψτε μέρος από τη μόνωση στο μέρος λυγίσματος (και τυλίξτε μετά το λύγισμα με ταινία πολυαιθυνελίου).

Κάντε λύγισμα με ακτίνα όσο μεγαλύτερη γίνεται ώστε να μην είναι ίσια η σωλήνα αλλά και να μην σπάσει.

Εσωτερική μονάδα

Εύκαμπτη σωλήνα

19 1

Σύνδεση εκχείλωσης

12 1

Εξωτερική

μονάδα

Ταινία Πολυαιθυλενίου

Μονωτικό Κάλυμμα

Χαλαρώστε τη τυλιγμένη σωλήνα

Σφίξτε το τέρμα της σωλήνας

Λυγίστε τη σωλήνα με τον αντίχειρα

Ελάχιστη ακτίνα: 100mm

21

Εγκατάσταση εσωτερικής μονάδας

1. Επιλέξτε τοποθεσία 2. Εγκατάσταση σωλήνων

• Εκεί που δεν επηρεάζεται από τον εξωτερικό αέρα.

• Εκεί που δεν εμποδίζεται η εισαγωγή και εξαγωγή αέρα.

• Εκεί που μπορεί εύκολα η σωλήνα ψυκτικού να οδηγηθεί έξω.

• Εκεί που ο αέρας από το κλιματιστικό μπορεί να φτάσει σε κάθε μέρος

του δωματίου.

• Εκεί που δεν υπάρχει πολύ υγρασία και δεν μπορεί να πεταχτεί λάδι

πάνω.

• Εκεί που δεν υπάρχει διαροοή εύφλεκτου αερίου.

• Επιλέξτε σταθερό και στιβαρό έδαφος.

• Αφήστε αρκετό χώρο για εγκατάσταση και συντήρηση.

• Αφαιρέστε την γρίλια εισαγωγής αέρα

• Πριν τη καλωδίωση και τη σωλήνωση, παρακαλούμε αφαιρέστε τη

γρίλια εισαγωγής αέρα.

• Αφαιρέστε τη βίδα από τη γρίλια.

• Ανοίξτε τη γρίλια τραβώντας την από το χερούλι.

• Αφαιρέστε την αλυσίδα και βγάλτε τη γρίλια.

3. Εγκαταστήστε σωλήνα αποστράγγισης

Βεβαιωθείτε ότι η σωλήνα αποστράγγισης οδηγεί στην εξωτερική πλευρά. (μεριά απόλυσης)

Χυτεύστε τη σωλήνα αποστράγγισης και προσαρμόστε ταινία γύρω από αυτή.

Αν η σωλήνα αποστράγγισης χρειάζεται να οδηγηθεί εσωτερικά, παρακαλούμε τυλίξτε την με μονωτικό υλικό (τουλάχιστον 9mm

λεπτό) και μετά τυλίξτε το με ταινία ώστε να αποφύγετε την εισχώρηση αέρα στη σωλήνα που μπορεί να προκαλέσει πήξη.

Μετά την ολοκλήρωση της σύνδεσης, ελέγξτε αν το νερό μπορεί να αποβληθεί σωστά και αν υπάρχει τυχόν διαρροή.

>30cm

>4cm

>5cm

>10cm

(Μέρος σωλήνα:30cm ελαχ..)

Μπροστά

>200cm

>10cm

(Μέρος σωλήνα:

30cm ελαχ.)

Αλυσίδα

Βίδα

Λαβή

Σωλήνα Αποστράγγισης

19 1

Σωλήνα Ψυκτικού

12 1

Σύνδεση εκχείλωσης Σύνδεση εκχείλωσης

Σωλήνα αποστράγγισης εσωτερικής μονάδας

Χύτευση σωλήνα αποστράγγισης

Σωλήνα αποστράγγισης

Τυλίξτε με ταινία

22

Καλώδια σήματος

(2) Για μοντέλα με αντλία θερμότητας (5 φασική)

Τερματικό κουτί στην εσωτερική μονάδα

Παροχή ρεύματος

Παροχή ρεύματος

Τερματικό κουτί στην εξωτερική μονάδα

Σημείο επαφής

καλωδίου

L1 L2

L3 N

L1 L2

L3 N

Ασφάλεια

Μοντέλο

RFI-66B/RFO-66B

25A

Καλωδίωση εσωτερικής μονάδας

• Αφαιρέστε τη βίδα από το κάλυμα του ηλεκτρολογικού πίνακα ώστε να τον ανοίξετε.

• Κάντε τη καλωδίωση όπως φαίνεται παρακάτω και μετά προσαρμόστε με σύνδεσμο καλωδίων.

Βίδα

Κάλυμμα ηλεκτρολογικού πίνακα

23

Εγκατάσταση εξωτερικής μονάδας

1. Επιλέξτε τοποθεσία

Σημείωση:

Η εξωτερική μονάδα πρέπει να εγκατασταθεί

σε σταθερή και στιβαρή βάση ώστε να αποφευχθεί ο θόρυβος και οι δονήσεις.

Η εξαγωγή αέρα δεν πρέπει να εμποδίζεται.

Σε παραθαλάσσιες περιοχές, περιοχές με

μεγάλο υψόμετρο ή δυνατό αέρα, παρακαλούμε εγκαταστήστε τη μονάδα κολλητά στον

τοίχο ή χρησιμοποιήστε προστατευτικό.

Εγκαταστήστε τη μονάδα με καλό εξαερισμό

αντί για κλειστούς χώρους.

Μέγεθος οπής εγκατάστασης: 572x327mm.

2. Σύνδεση ψυκτικής σωλήνας

Σύνδεσμος σφιξίματος

Ταιριάξτε σωληνώσεις

Βιδώστε το παξιμάδι με το χέρι και

μετά σφίξτε με γαλλικό κλειδί

(δείτε σχήμα παρακάτω).

Προσέξτε να μην γυρίσετε υπερβολικά

αλλιώς το παξιμάδι μπορεί να καταστραφεί.

Διάμετρος

(mm)

Ροπή

(N m)

12 45-50

19 70-75

Εκκένωση (με εξαγωνικό κλειδί)

Όγκος

ψυκτικού

Ίδια τιμή με

το ταμπελάκι

Ίδια τιμή με το

ταμπελάκι +30g/m

(επιπλέον 30g για

κάθε επιπλέον μέτρο

της σωλήνας)

Χρήση του

ψυκτικού της

εξωτερικής

μονάδας.

Χρήση

αντλίας

κενού

1. Δείτε το τμήμα για την αντλία κενού ή

την δεξαμενή ψυκτικού

2. Συμπληρώστε το ψυκτικό σύμφωνα με

τα παραπάνω. Εάν η μονάδα πρόκειται

να μετακινηθεί, εκκενώστε το ψυκτικό

υγρό με αντλία κενού ή με δεξαμενή

ψυκτικού.

• Όταν χρησιμοποιείτε το ψυκτικό της

εξωτερικής μονάδας:

1. Σφίξτε επαρκώς τα μπουλόνια A,B,C,D

2. Αφαιρέστε το κάλυμμα από την βαλβίδα Α

3. Στρίψτε το στέλεχος της βαλβίδας Β ώστε

να ανοίξει, με ένα κλειδί ροπής, και ταυτόχρονα

κρατήστε το στέλεχος της βαλβίδας Α με ένα

κατσαβίδι ώστε να εξέλθει το αέριο.

Μετά από 15 δευτερόλεπτα εκκένωσης και

μόλις εμφανιστεί ψυκτικό υγρό, κλείστε τη

βαλβίδα και σφίξτε το κάλυμμα.

4. Ανοίξτε πλήρως τις βαλβίδες υγρού και

αερίου, σφίξτε το κάλυμμα, και ελέγξτε για

διαρροές (με σαπουνόνερο ή με ανιχνευτή

διαρροής) στις ενώσεις των σωλήνων μεταξύ

εσωτερικής και εξωτερικής μονάδας.

Όταν χρησιμοποιείτε αντλία κενού

1. Συνδέστε τον αγωγό πλήρωσης

της βαλβίδας πολλαπλής στην

βαλβίδα πλήρωσης χαμηλής πίεσης.

(οι βαλβίδες υψηλής και χαμηλής

πίεσης πρέπει να είναι κλειστές.)

2. Συνδέστε τον αγωγό πλήρωσης

με την αντλία κενού.

3. Ανοίξτε πλήρως την βαλβίδα LO

της βαλβίδας πολλαπλής.

4. Ενεργοποιήστε την αντλία κενού

για την εκκένωση. Αρχικά χαλαρώστε

τη βαλβίδα χαμηλής πίεσης για να

ελέγξετε εάν υπάρχει αέρας μέσα.

(η βαλβίδα της αντλίας κενού θα

αλλάξει από - στο 0). Τότε σφίξτε

αυτή τη βαλβίδα.

5. Μετά το τέλος της εκκένωσης,

κλείστε την βαλβίδα Lo της βαλβίδας

πολλαπλής για να σταματήσει η

αντλία κενού. Συνεχίστε την εκκένωση

ώστε το πολύμετρο της βαλβίδας

πολλαπλής να δείξει -1.0x10

5

pa

(-76cmHg).

6. Ανοίξτε πλήρως τις βαλβίδες high/low

7. Αφαιρέστε τον αγωγό πληρώτητας

από την βαλβίδα low.

8. Σφίξτε το κάλυμμα της βαλβίδας low.

Εκκένωση

Μήκος

σωλήνα

5m

5-15m

Εξωτερική μονάδα

Πλευρά αερίου

Εσωτερική μονάδα

βαλβίδα ελέγχου

Συνδεση σωληνώσεων

A

B

C

D

12mm

19mm

-76cmHg

Βαλβίδα πολλαπλής εισαγωγής

Μανόμετρο

Μανόμετρο

Λαβή

χαμηλής πίεσης

Σωλήνας φόρτισης

Βαλβίδα

χαμηλής πίεσης

Αντλία κενού

Λαβή

υψηλής πίεσης

Σωλήνας

φόρτισης

Παξιμάδι βαλβίδας

Κατά την χρήση της βαλβίδας ελέγχου προσέξτε:

Ανοίξτε την βαλβίδα έως το όριο ασφάλισης

και όχι περισσότερο

Σφίξτε το κάλυμμα με κλειδί

Όριο ασφάλισης

Κάλυμμα

Στέλεχος βαλβίδας

Βαλβίδα

24

3.Καλωδίωση

Αφαιρέστε το μπροστινό πάνελ.

Ανοίξτε εξωτερική οπή καλωδιώσεων και ενσωματώστε έναν δακτύλιο για τα καλώδια.

Οδηγήστε το καλώδιο σύνδεσης από το τερματικό κουτί της εξωτερικής μονάδας, και προωθήστε το στην

εξωτερική οπή καλωδιώσεων και στην εσωτερική και μετά συνδέστε με το εσωτερικό τερματικό κουτί.

Ενώστε τα καλώδια όπως φαίνεται παρακάτω και μετά προσαρμόστε το με σφιγκτήρα καλωδίων.

Δοκιμαστική λειτουργία

Αφότου ολοκληρώσετε

τον έλεγχο για διαρροή,

ξεκινήστε τον δοκιμαστικό

έλεγχο.

Ψύξη

Ρυθμίστε λειτουργία ψύξης.

Δείτε το εγχειρίδιο χρήστη για λεπτομέρειες.

3- λεπτη προστασία

Αν η μονάδα σταματήσει, χρειάζεται

3 λεπτά να επανεκκινηθεί.

3~220V 60Hz

Εξωτερικά καλώδια σήματος

Καλώδια Σήματος

Καλώδια Σήματος

Καλώδιο σύνδεσης ρεύματος

Καλώδιο ρεύματος

Εξωτερική οπή καλωδίωσης

Οπίσθιο πάνελ

Μπροστινό πάνελ

Τερματικό κουτί

25

Εγκαταστήστε σύρμα προστασίας κλίσης

Σημείωση:

Για να αποφύγετε οποιοδήποτε ατύχημα από τη κλίση της εξωτερικής μονάδας, παρακαλούμε εγκαταστήστε

προστατευτικό σύρμα κλίσης.

Βήματα εγκατάστασης:

Αφαιρέστε τη βίδα από το κάλυμμα της εσωτερικής μονάδας (Εικ 1)

2. Βγάλτε το προστατευτικό από το καλώδιο και βάλτε μέσα στη θήκη που υπάρχει στην οπή και κουμπώστε το με τις βίδες. (Εικ. 2)

3.Στερελωστε την άλλη άκρη του σύρματος στον τοίχο χρησιμοποιώντας βίδα (ST4.2X38)

Βγάλτε τη βίδα

οπή προστασίας

Στρεώστε αυτή την άκρη στον τοίχο

Βάλτε αυτή την άκρη

στην οπή και στερεώστε.

Τοίχος

Εσωτερική μονάδα

Εικ 1

Εικ 2

To παραπάνω σχήμα είναι για επεξηγηματικούς σκοπούς μόνο, η εσωτερική μονάδα μπορεί να διαφέρει.

Ενεργοποιήστε την εγγύηση σας...

σε

5

απλά

Συνδεθείτε στο site της

στον ακόλουθο σύνδεσµο

http://www.inventoraircondition.gr/

egiisi-inventor/

Επιλέξτε τον τύπο του προϊόντος

(κλιµατιστικό ή συσκευή) για το

οποίο θα ενεργοποιηθεί η εγγύηση

Συµπληρώστε τα απαιτούµενα

στοιχεία (κατόχου, εµπόρου και

συσκευής) και πατήστε αποστολή

Επιλέξτε την εγγύηση

που αντιστοιχεί στο προϊόν

που έχετε στην κατοχή σας

Θα λάβετε επιβεβαιωτικό

µήνυµα στο e-mail σας για

την ενεργοποίηση της εγγύησης

Για την υποβολή

ηλεκτρονικών εγγυήσεων

πληκτρολογήστε

την παρακάτω διεύθυνση

https://www.inventoraircondition.gr/egiisi-inventor

Σκανάρετε εδώ

για τα έντυπα

των εγγυήσεων

Inventor

1

CUPRINS

2

3

4

5

16

17

18

19

20

21

23

24

25

7

Note inainte de folosire

Structura

Mentenanta

Structura

Modele si specificatii

Panoul de control

Directionarea fluxului de aer

Intretinere

Depanare

Cablajul

Note privind tubulatura.

Instalarea unitatii interioare

Instalarea unitatii exterioare

Instalarea cablului protector

Testarea

Instalarea

Telecomanda

2

NOTE INAINTE DE FOLOSIRE

Cerinte electrice

Limitele de temperatura

Modul de

functionare

Incalzire

Temperatura Temperatura interioara

27°C

(nivel sczaut al umiditatii) 24°C

(nivel sczaut

al umiditatii)

(nivel sczaut

al umiditatii)

/

18°C

(nivel crescut

al umiditatii)

(nivel crescut

al umiditatii)

-5°C / -6°C

20°C (nivel sczaut al umiditatii)

Temperatura exterioara

Max.

Min.

AVERTIZMENT

ATENTIONARE

1. Capacitatea retelei electrice trebuie sa fie de cel putin 10kw, sectiunea firelor de cupru trebuie sa fie de cel putin 2.5

mm2.

2. Aparatul trebuie impamantat. Impamantarea va fi conectata la sistemul de impamantare al cladirii si nu la conductetele

de gaz sau apa.

3. Lucrarile electrice vor fi efectuate doar de catre un tehnician autorizat si in conformitate cu normele si reglementarile in

vigoare.

4. Circuitul electric va include protectii la scurgeri de curent si un comutator.

5. Opriti alimentarea cu energie electrica atunci cand nu folositi aparatul.

Cerinte privind siguranta:

• Cititi cu atentie manualul de utilizare inainte de a folosi acest aparat si contactati departamentul de servic al magazinul

vanzator pentru mai multe informatii.

• Acest aparat va fi folosit doar in situatilile descrise in acest manual.

• Nu depozitati lichide sau gaze inflamabile in apropierea acestui aparat! Pericol de explozie/incendiu!

• Acest aparat nu foloseste aer proaspat (din exterior). Atunci cand folositi si un incalzitor pe combustibil

lichid sau gazos, lasati usa/fereastra deschisa. Incalzitorul consuma oxigenul din incapere si calitatea

aerului va scadea.

• Pentru a porni sau opri aparatul, folositi doar butonul ON/OFF si nu faceti acest lucru direct

de la reteaua de alimentare cu energie electrica.

• Nu introduceti obiecte in grilele de admisie/evacuare a aerului.

• Copiilor nu le va fi permis sa opereze aparatul de aer conditionat.

• In cazul in care, in incapere, se afla copii sau persoane bolnave, va recomandam sa ajustati

temperatura aparatului.

3

ΔΟΜΗ

Evacuare aer

Unitate interioara

Unitate exterioara

Conducta

scurgere

Conducte de legatura

Evacuare aer

Evacuare aer

Gura evacuare

Afisaj

Panou frontal

Admisie aer

Admisie aer

Gura admisie aer

4

Model si caracteristici

Functii

Racire/Incalzire (W)

Capacitate incalzire (W)

Alimentare electrica

Putere de intrare (W)

Debit aer (m3/h)

Refrigerant

Zgomot (unitate interioara/

exterioara) dB(A)

Zona climatica

Rezistenta apa

Izolatie

Greutate (unitate/

exterioara)(kg)

Dimensiuni (unitate interioara

/exterioara) (LxIxA) (mm)

Μοντέλο

RFI-66B /RFO-66B

6400/6200(9700)

16000

18000(21500)

380-415 V 3N ~ 50H z

2000

58/63

T1

IP24

I

60/115

Unitate interioara: 540x1750x380

Unitate exterioara: 950x1250x412

Racire/Incalzire

R410A 5.0

Toate informatiile de mai sus pot fi schimbate fara o notificare prealabila. Caracteristicile aparatului dvs. vor fi afisate pe

placuta de identificare.

5

Afisajul LCD al aparatului de aer conditionat de tip coloana

Tasta SWING -

Puteti alege modul de

oscilare a fluxului de aer

Tasta FAN SPEED

permite alegerea vitezei ventilatorului.

Alegeti intre modurile

AUTO/LO/MED/HIGH

TASTA MODE

permite alegerea modului

de functionare:

AUTO/COOL/DRY/FAN/HEAT

Tasta ON/OFF

apasati aceasta tasta

pentru a porni/opri aparatul.

Afisaj LCD

Cand aparatul se afla in modul OFF, tasta

TIMER va fi folosita pentru a programa

aparatul sa porneasca la o anumita ora. La

fiecare apasare a tastei, intervalul va fi

ajustat cu 0.5 ore (in intervalul 0.5-24H). La

ora stabilita, aparatul va porni cu setarile

implicite. Pentru a programa oprirea aparatului la o anumita ora repetati acelasi procedeu

cand aparatul este pornit.

Tastele SET TEMP - permit alegerea

temperaturii de functionare. La fiecare

apasare a butonului , temperatura va

scadea cu 1 grad. Temperatura va creste cu

un grad la fiecare apasare a butonului .

Temperatura incaperii poate fi reglata in

intervalul 16-30 grade celsius. In timpul

functionarii normale, daca veti apasa ambele

butoane in acelasi timp, panoul de control va

fi blocat. Deblocarea se va face apasand

aceleasi 2 butoane in acelasi timp.

PANOUL DE CONTROL

6

FUNCTIILE SPECIALE

Functia TEST

De fiecare data cand unitatea este pornita dar nu primeste semnal de la taste:

(1) Apasati tasta SET TEMP pentru a intra fortat in modul racire. Compresorul va porni si aparatul va functiona

in modul de oscilare a fluxlui de aer automat. Ventilatoarele unitatilor interioare si exterioare for functiona la

viteza cea mai mare iar ecranul LCD va afisa toate simbolurile. Dupa 5 minute, aparatul se va opri si va intra in

modul normal de standby.

(2) Apasati tasta SET TEMP pentru a intra fortat in modul incalzire. Compresorul si incalzitorul electric auxiliar

vor porni. Aparatul va functiona in modul de oscilare a fluxlui de aer automat si ventilatoarele unitatilor interioare si exterioare for functiona la viteza cea mai mare iar ecranul LCD va afisa toate simbolurile. Dupa 5 minute,

aparatul se va opri si va intra in modul normal de standby.

Functia de protectie a compresorului:

Orice mod de functionare ati selecta, compresorul va avea nevoie de 3 minute pentru a reporni dupa ce a fost

oprit. Daca nu ati schimat modul de functionare, compresorul va functiona 6 minute pana va putea fi oprit.

Compresorul se va opri 3 minute la schimbarea modurilor.

Functia de blocare a panoului de control :

In timpul functionarii normale a aparatului, apasati tastele SET TEMP si , in acelasi timp, pentru a bloca

panoul central. Apasand inca odata tastele, veti debloca panoul de central.

- 7 -

Folosirea telecomenzii

Butonul SWING.

La apasarea butonului,

flapsurile vor oscila

automat. Apasati inca o

data butonul pentru a opri

oscilarea.

Butonul TEMP

Apasand butonul “+” veti

creste temperatura cu 1

grad celsius. La apasarea

butonului “-”, temperatura

va scadea cu 1 grad

celsius.

In modul de functionare

COOL, DRY, HEAT,

temperatura poate fi reglata

in intervalul 16-30 grade

celsius.

Butonul MODE.

Apasand butonul, puteti

selecta modul de functionare in urmatoarea ordine:

Butonul ON/OFF

Acest buton il veti folosi

pentru pornirea/oprirea

unitatii.

Butonul FAN

Apasati acest buton pentru a

putea seta viteza ventilatorului

conform imaginii de mai jos:

Modul COOL (racire)

Modul DRY (dezumidificare)

Modul FAN (functionarea

ventilatorului)

Modul HEAT (incalzire)

Denumirea si descrierea functiilor butoanelor

Nota:

• Asigurati-va ca nu exista elemente care pot intrerupe transmiterea semnalului

intre telecomanda si unitate.

• Nu trantiti si nu aruncati telecomanda

• Nu lasati telecomanda in bataia luminii solare sau in locuri foarte calde.

De asemenea, evitati contactul lichidelor cu telecomanda.

- 8 -

Denumirea si functiile butoanelor (capacul deschis)

dezactivarea

temporizatorului

dezactivarea

temporizatorului

NOTA: Functiile butoanelor disponibile cu modelele descrise

in acest manual sunt descrise mai jos.

Displayul LCD va fisa functiile

setate

Butonul SLEEP

Apasatia cest buton pentru a

activa functia SLEEP. Apasati

inca o data acest buton pentru

a dezactiva functia.

Butonul TIMER OFF

In timpul functionarii, apasand

acest buton, veti putea

programa temporizatorul (in

intervalul 0.5-24H), pentru a

opri unitatea automat la ora

stabilita.

Butonul TIMER ON

Atunci cand aparatul este

oprit, apasati acest buton

pentru a programa pornirea

automata a aparatului, in

intervalul 0.5-24H.

Butonul Light

Apasand acest buton veti porni

iluminarea telecomenzii. Apasati

inca o data pentru a o opri.

- 9 -

1. Butonul ON/OFF porneste/opreste unitatea

2. In functie de temperatura incaperii,

aparatul poate seta automat modul pentru

a obtine cel mai bun

rezultat.

Modul de functionare AUTO

• In timpul functionarii in modul AUTO, temperatura standard este de 26 de

grade pentru modul HEAT (incalzire), 20 grade pentru modul COOL

(racire) si 24 de grade pentru modul DRY (dezumidificare).

- 10 -

3. Butonul SWING.

La apasarea butonului, flapsurile vor

oscila automat. Apasati inca o data

butonul pentru a opri oscilarea.

5. Puteti alege temperatura dorita

apasant butoanele pentru setarea

temperaturii

2. Apasati butonul MODE

pentru a selecta modul COOL

1. Butonul ON/OFF - porneste/opreste

unitatea

4. Apasati butonul FAN pentru a

selecta viteza ventilatorului

Modul de functionare COOL (racire)

• In functie de diferenta de temperatura intre temperatura incaperii si cea setata pe aparat, sistemul poate

controla modul COOL automat.

• Atunci cand temperatura incaperii este mai mare cu 1 grad celsius decat temperatura aparatului,

compresorul va functiona in modul COOL.

• Daca temperatura incaperii este mai joasa cu 1 grad celsius fata de temperatura sistemului, compresorul

se va opri si vor porni doar ventilatoarele interioare.

• Temperatura setata poate fi aleasa in intervalul 16-30 grade celsius.

- 11 -

4. Apasati butonul FAN pentru a

selecta viteza ventilatorului

5. Puteti alege temperatura dorita

apasant butoanele pentru setarea

temperaturii

1. Butonul ON/OFF - porneste/opreste

unitatea

2. Apasati butonul MODE pentru a

selecta modul HEAT

3. Butonul SWING.

La apasarea butonului, flapsurile vor oscila automat. Apasati

inca o data butonul pentru a opri

oscilarea.

Modul de functionare HEAT (disponibil doar la unitatile

cu functie de racire/incalzire).

• Atunci cand temperatura incaperii este mai joasa cu 1 grad fata de temperatura setata, compresorul va

functiona in modul HEAT.

• Daca temperatura incaperii este mai ridicata cu 1 grad fata de temperatura setata, compresorul si

ventilatoarele interioare si exterioare se vor opri.

• Temperatura poate fi aleasa in intervalul 16-30 grade celsius.

- 12 -

Butonul SWING.

La apasarea butonului, flapsurile vor

oscila automat. Apasati inca o data

butonul pentru a opri oscilarea.

Puteti alege temperatura dorita

apasant butoanele pentru setarea

temperaturii

Butonul ON/OFF - porneste/opreste

unitatea

Modul de functionare DRY

• Atunci cand temperatura incaperii este cu 2 grade celsius mai mica de cat cea a unitatii, compresorul si ventilatoarele interioare si exterioare se vor opri. Daca temperatura incaperii se afla in intervalul +/- 2 grade celsius fata

de temperatura setata, aparatul va functiona in modul de dezumidificare.

Daca temperatura interioara va fi mai ridicata cu 2 grade fata de temperatura setata, aparatul va functiona in

modul COOL. Ventilatorul interior va functiona in viteza LOW.

• Temperatura aleasa se va afa in intervalul 16-30 grade celsius.

Apasati butonul MODE pentru a

selecta modul DRY .

Viteza ventilatorului nu va putea fi

modificata in acest mod.

- 13 -

Dezactivarea

temporizatorului

Dezactivarea

temporizatorului

Butonul TIMER ON

Atunci cand aparatul este oprit,

apasati acest buton pentru a

programa pornirea automata a

aparatului, in intervalul 0.5-24H.

Butonul TIMER OFF

In timpul functionarii, apasand

acest buton, veti putea

programa temporizatorul (in

intervalul 0.5-24H), pentru a

opri unitatea automat la ora

stabilita.

Modul TIMER (temporizator)

- 14 -

4. Apasati butonul FAN pentru a selecta

viteza ventilatorului

3. Butonul SWING.

La apasarea butonului,

flapsurile vor oscila automat.

Apasati inca o data butonul

pentru a opri oscilarea.

6. Butonul Sleep

Apasati butonul pentru a

alege modul de functionare

Sleep

5. Puteti alege temperatura

dorita apasant butoanele

pentru setarea temperaturii

2. Apasati butonul Mode

pentru a alege modul de

functionare.

1. Butonul ON/OFF - porneste/opreste

unitatea

Functionarea in modul SLEEP

• In timpul functionarii in modul COOL sau DRY, daca functia SLEEP este activata , SET TEMP

(temperatura prestabilita) va creste cu 1 grad Celsius in 1 ora si cu 2 grade Celsius in 2 ore.

• In cazul functionarii in modul HEAT, daca functia SLEEP este activata, temperatura prestabilita

va scadea cu 1 grad Celsius in 1 ora si cu 2 grade in 2 ore.

- 15 -

2. Introduceti 2 baterii AAA si

resetati.

1. Scoateti capacul;

3. Puneti capacul la loc.

Deschidere

Introduceti bateriile

1. Scoateti capacul spatiului pentru

baterii.

2. Introduceti 2 baterii (AAA alkalyne) si

apasati butonul ACL.

3. Puneti capacul la loc.

NOTA:

• Nu folositi baterii uzate si baterii noi

in acelasi timp si nu folositi 2

modele diferite de baterii.

• In cazul in care nu veti folosi

telecomanda pentru o perioada

lunga, scoateti bateriile.

• Telecomanda va fi folosita in raza

de actiune a receptorului de semnal

atasat unitatii interioare.

• Pastrati telecomanda la cel putin

1m distanta de televizor.

16

Flapsurile (ghideaza

fluxul de aer orizontal).

Flux de

aer normal

Fluxul de

aer indreptat

in sus

Fluxul de aer

indreptat in jos

Mentenanta

Reglarea fluxului de aer

* Apasati butonul SWING aflat pe panoul de control

pentru a porni oscilarea stanga/dreapta a fluxlui de

aer. Apasand inca o data butonul SWING, veti opri

oscilarea.

* La fiecare apasare a butonului SWING, mesajul

"SWING" va fi afisat pe ecranul LCD. Daca ventilatorul interior este in functiune, motorul flapsurilor va fi

pornit iar fluxul de aer va fi distribuit stanga/dreapta.

Apasand inca o data butonul, flapsurile vor reveni in

pozitia normala si nu vor mai oscila.

1. Reglarea fluxului de aer STANGA/DREAPTA 1. Reglarea fluxului de aer SUS/JOS

Flapsurile vor fi reglate manual. Tineti flapsurile cu

ambele maini atunci cand reglati directia. In timpul

modului COOL/DRY, reglati flapsurile in sus iar in

modul HEAT, reglati-le pentru ca fluxul de aer sa fie

indretpat in jos.

• Reglarea flapsurilor in modul COOL/DRY

• Reglarea flapsurilor in modul HEAT

17

Curatarea unitatii

στραγγίξτε το

πανί πρίν τον

καθαρισμό

Maner

Capacul grilei de admisie

Curatarea filtrului de aer

Curatati filtrul de aer o data

la 2 saptamani

Demontarea filtrului de aer

Curatarea

Nota

Intretinere

Blocajele pot

cauza defectarea

unitatii.

1. Opriti alimentarea cu energie electrica inainte

de inceperea curatirii

Scoateti din priza numai dupa ce aparatul s-a oprit

complet.

2. Folositi o carpa fina atunci cand curatati

carcasa exterioara.

In cazul in care carcasa este

foarte muradara, inmuiati carpa

in apa calduta (sub 40 de grade

celsius), uscati carpa si apoi

stergeti cu grija.

• Asigurati-va ca aparatul este oprit

• Desurubati capacul grilei de admisie a aerului.

• Scoateti capacul grilei de admisie

• Filtrul de aer este atasat capacului grilei de admisie.

Scoati cu grija filtrul de aer.

• Bateti usor filtrul sau folositi un aspirator electric. In

cazul acumularii murdariei intr-un strat gros, puteti

folosi si apa cu detergent neturu pentru curatare.

Uscati bine inainte reintroducerea filtrului.

• Nu uscati filtrul in lumina directa a soarelui sau in

apropierea unei surse de caldura puternica. Filtrul se

poate deforma.

• Filtrul se poate deforma daca este spalat cu apa

foarte fierbinte (peste 50ºC).

3. Nu folositi acizi sau solutii alkaline pentru

curatenie.

4. Nu udati unitatea cu apa.

* Asigurati-va ca grilele de admisie/evacuare a

aerului nu sunt obturate.

18

Problema Cauze posibile Solutia

Depanare

Daca aparatul dumneavoastra nu functioneaza corect, verificati mai intai situatiile mentionate mai jos, inainte de a cere

ajutorul unui specialist. Dupa verificarea tabelului, in cazul in care aparatul tot nu functioneaza, contactati cel mai

apropiat centru de service.

Aparatul nu porneste 1. Nu este alimentat cu energie electrica.

2. Siguranta este sarita.

3. Tensiune scazuta.

4. Este apasat butonul ON/OFF

5. Defectiune a circuitului.

1. Conectati la reteaua electrica.

2. Contactat centrul de service.

3. Contactati un electrician sau dealer-ul.

4. Apasati butonul ON/OFF