INVENTOR IMCR8WZNa-M, IMCR10WZNa-M, IMCR22SNa-M, IMCR25SNa-M, IMCR12.5WZNa-M Service Manual

...

Service Manual

Service Manual

Service Manual

Mini Chiller

MINI CHILLER PRODUCT

2

PRODUCT INTRODUCTION ................................................................................... 3

1 MODELS LIST ............................................................................................................................. 3

1.1 Split Type ........................................................................................................................... 3

1.2 Integral Type ...................................................................................................................... 4

2 NOMENCLATURE ...................................................................................................................... 5

1.1 Split Type ........................................................................................................................... 5

1.2 Integral Type ...................................................................................................................... 5

3FUNCTION ................................................................................................................................... 5

4 PRODUCT DATA ......................................................................................................................... 6

4.1 Product Data at Rated C

ondition ........................................................................................ 6

4.2 Operation Range ................................................................................................................. 8

4.3 Pressure-loss Conversion C

hart ......................................................................................... 8

4.4 Electrical Data .................................................................................................................... 8

5 PIPING DIAGRAM ...................................................................................................................... 9

UNITS CONTROL .................................................................................................... 11

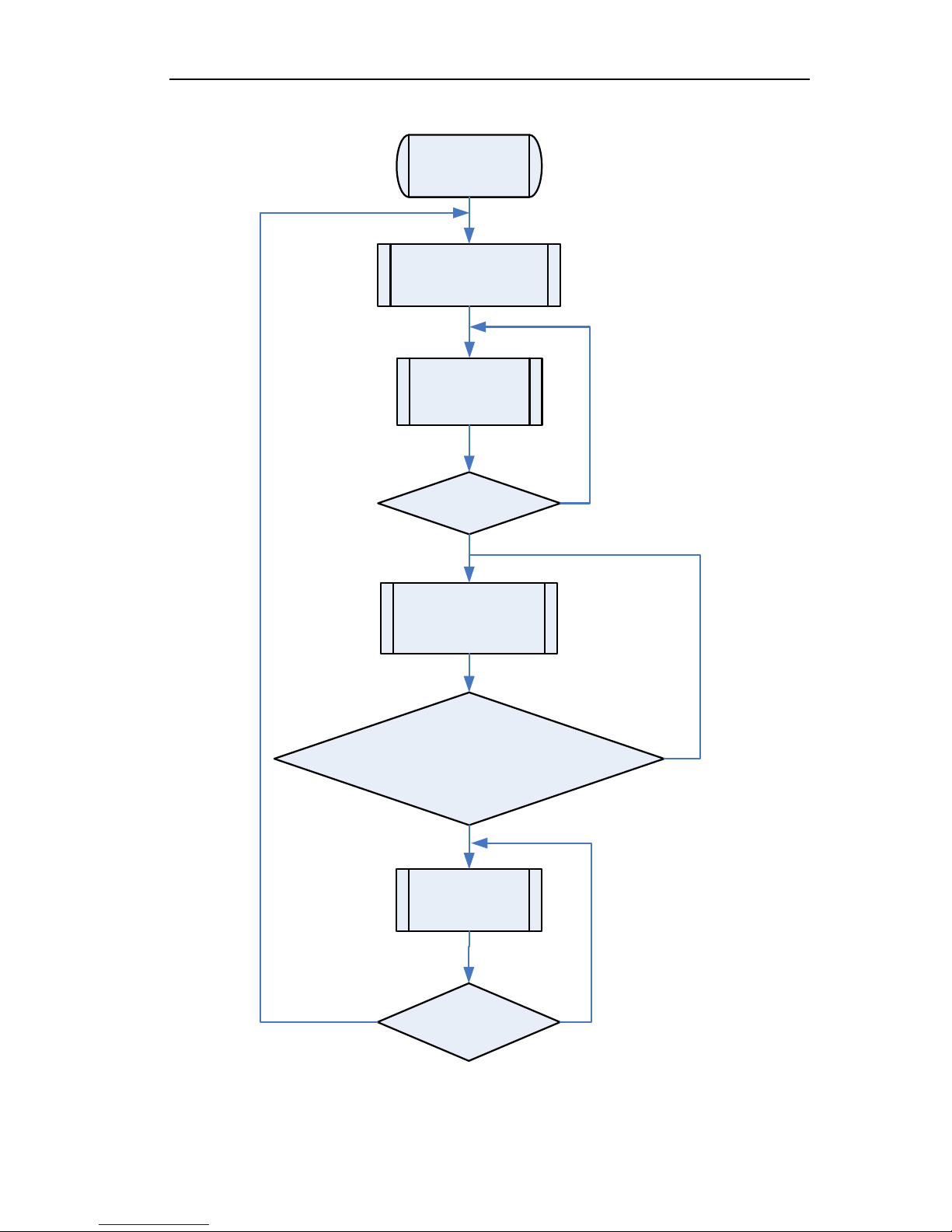

1 OPERATION FLOWCHAR

T ..................................................................................................... 11

1.1 Cooling Operation ............................................................................................................ 11

1.2 Heating Operation ............................................................................................................ 12

2 MAIN LOGIC ............................................................................................................................. 13

3 WIRED CONTROLLER ............................................................................................................ 15

3.2.2 Display View ................................................................................................................. 17

4 CONTROL WIRING DESIGN

................................................................................................... 19

UNITS INSTALLATION .......................................................................................... 22

1 UNITS INST

ALL ........................................................................................................................ 22

1.1 Installation Positions ........................................................................................................ 22

1.2 Matters need Attention ..................................................................................................... 22

1.3 DIMENSION DA

TA ........................................................................................................ 22

1.2 INSTALLATION CLEARANCE DA

TA ......................................................................... 25

2 WATER PIPING WORK

............................................................................................................ 28

2.1 Installation Procedure ....................................................................................................... 28

2.2 Matters of Attention ......................................................................................................... 28

2.3 Antifreeze ......................................................................................................................... 28

3 ELECTRIC WIRING WORK ..................................................................................................... 28

3.1 Wiring Principle

............................................................................................................... 28

3.2 Electric Wiring Design ..................................................................................................... 28

3.3 SPECIFICATION OF POWER CORD &

AIR SWITCH ................................................ 28

3.4 WIRING DIAGRAM ....................................................................................................... 29

3.4.1 Wiring Diagram-Split T

ype .......................................................................................... 29

3.4.2 Wiring Diagram- Integral Type ..................................................................................... 31

UNITS MAINTENANCE .......................................................................................... 34

1 ERROR CODE LIST .................................................................................................................. 34

2 FLOW CHART OF TROUBLESHOOTING.............................................................................. 34

3 DISASSEMBLY AND ASSEMBLY PROCEDURE OF MAIN P

ARTS .................................... 36

3.1 Split Type ......................................................................................................................... 36

3.2 Integral Type .................................................................................................................... 46

4 EXPLODED VIEWS AND P

ART LIST ..................................................................................... 50

4.1 Exploded Views and Par

ts List- Split Type ...................................................................... 50

4.2 Exploded Views and Parts List- Integral Type ................................................................. 61

MINI CHILLER PRODUCT

3

PRODUCT INTRODUCTION

1 MODELS LIST

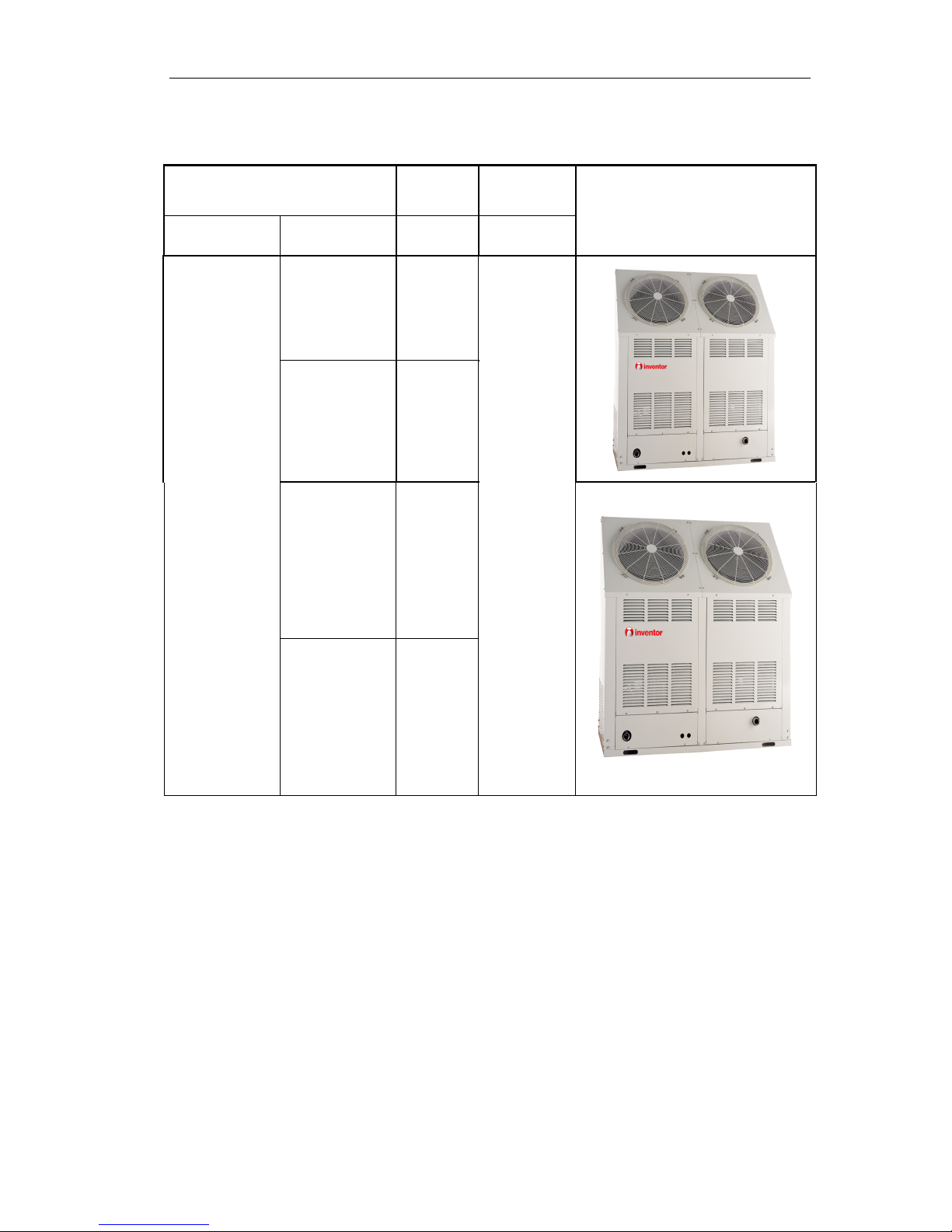

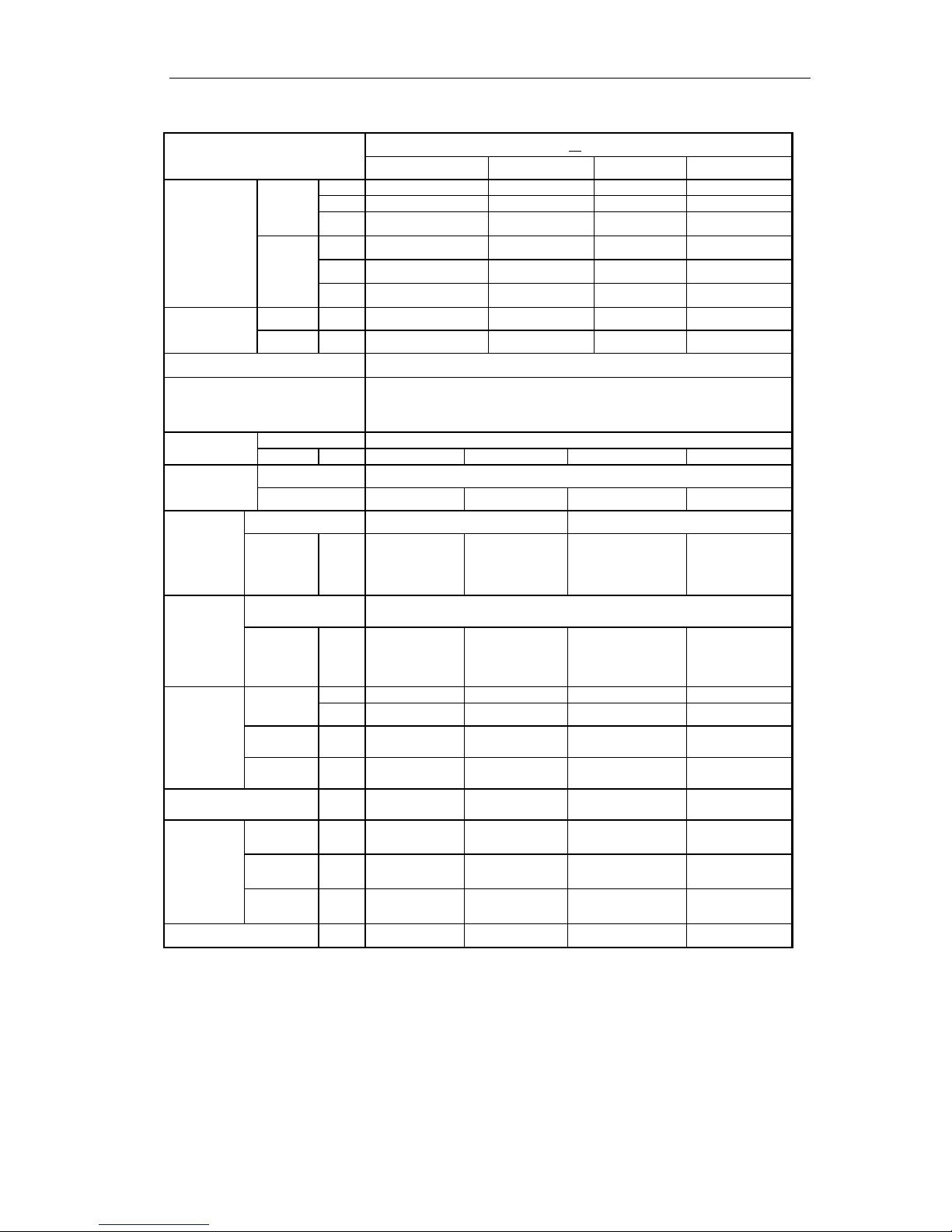

1.1 Split Type

Model

Nominal

Capacity

Power Supply

Appearance

Refrigerant Model Name kW (V,Ph,Hz)

Outdoor Unit indoor Unit

R410A

IMCR8WZNa-M

8.0

380~415V

3Ph 50Hz

IMCR10WZNa-M 10.0

IMCR12.5WZNa-M

12.5

IMCR15WZNa-M

15.0

Note:1Ton =12000Btu/h = 3.517kW

MINI CHILLER PRODUCT

4

1.2 Integral Type

Model

Nominal

Capacity

Power Supply

Appearance

Refrigerant Model Name kW (V,Ph,Hz)

R410A

IMCR22SNa-M 22

380~415V

3Ph 50Hz

IMCR25SNa-M

25

IMCR35SNa-M

35

IMCR45SNa-M

45

Note:1Ton =12000Btu/h = 3.517kW

MINI CHILLER PRODUCT

5

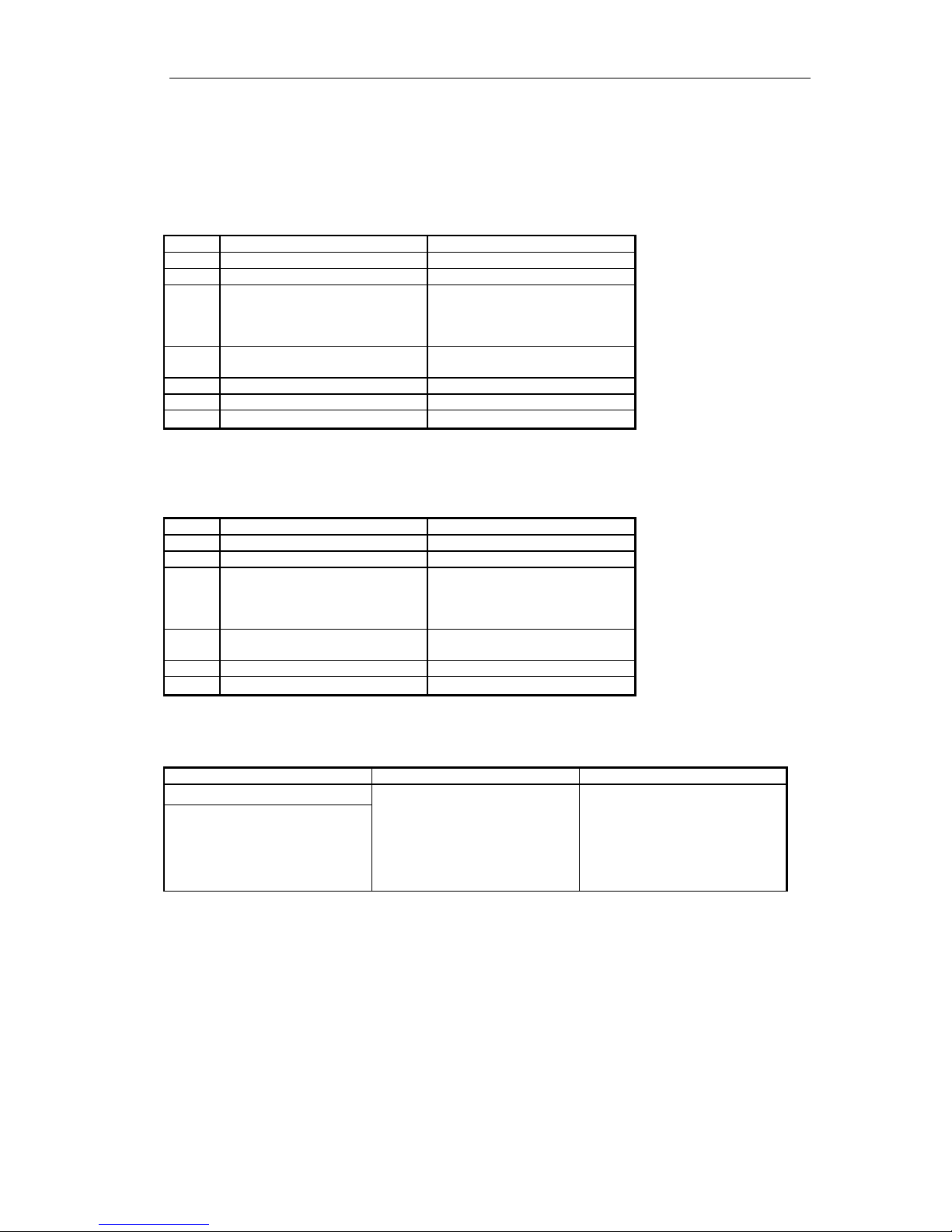

2 NOMENCLATURE

1.1 Split Type

IMC R 15 W Z Na - M

1 2 3 4 5 6 7

NO. Description Options

1 Mini chiller 2 Product type R=Heat pump

3 Nominal Cooling Capacity

8=8kW

10=10 kW

12.5= 12.5kW

15= 15kW

4 Struct type

Default=Vertical type

W=Horizontal type

5 Product configuration Z=Combination

6 Refrigerant Na=R410A, Default=R22

7 Voltage

M=380~415V 3Ph 50Hz

1.2 Integral Type

IMC R 35 S Na - M

1 2 3 4 5 6

NO. Description Options

1 Mini chiller 2 Product type R=Heat pump

3 Nominal Cooling Capacity

22=22kW

25=25kW

35=35kW

45=45kW

4 Refrigeration Circuits

Default=One circuit

S=Twin circuit

5 Refrigerant Na=R410A, Default=R22

6 Voltage

M=380~415V 3Ph 50Hz

3FUNCTION

Indoor Unit Type Function Description

Split Type

Heating

Interface kit for up to 16 indoor

units

Memory restart

Two circuits optimized design

Low noise design

Safety and reliability thanks to

advance compressor balance control

Integral Type

MINI CHILLER PRODUCT

6

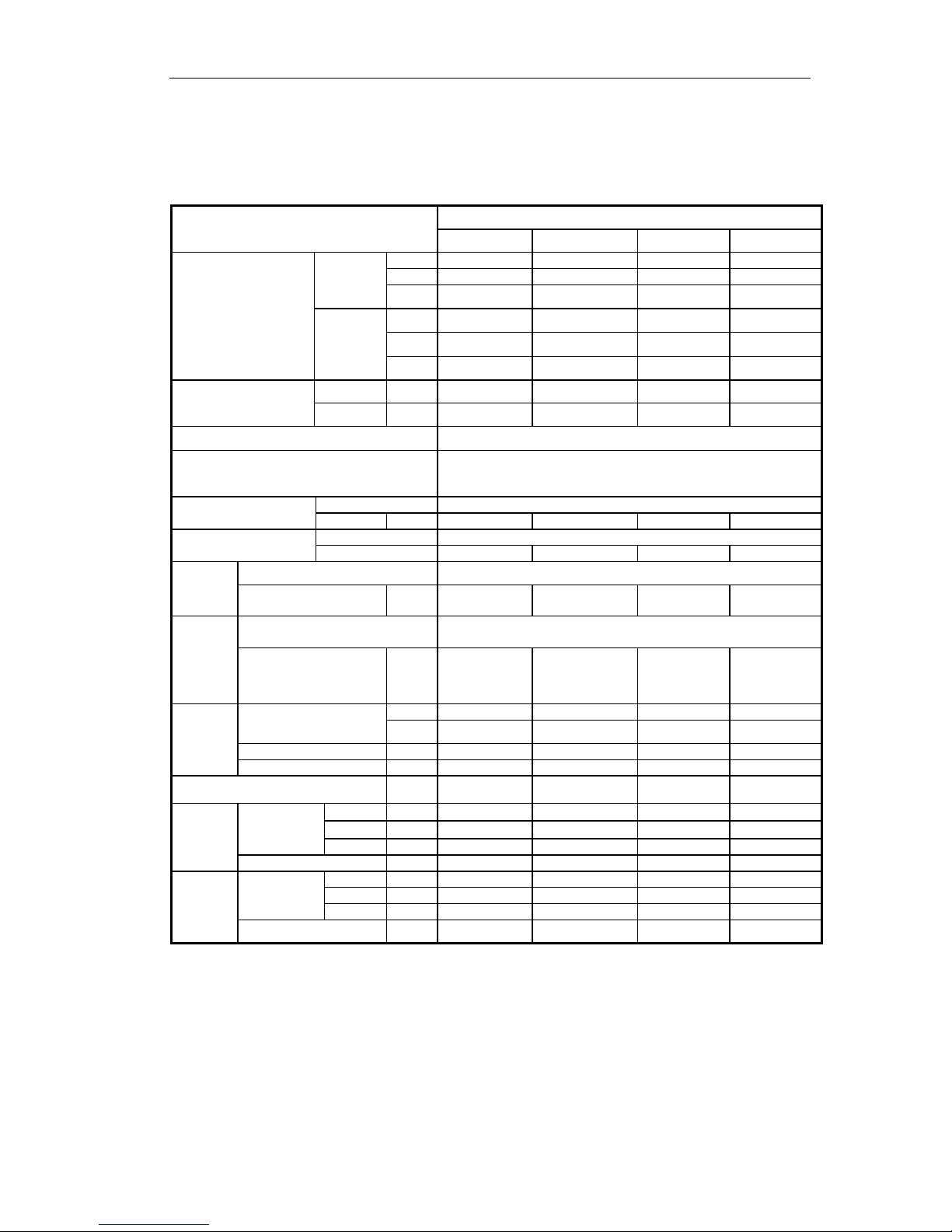

4 PRODUCT DATA

4.1 Product Data at Rated Condition

4.1.1 Split Type

Models

IMCR_WZNa-M

8 10 12.5 15

Nominal Capacity

Cooling

kW 8 10 13 15

Btu/h 27300 34120 42650 51180

RT 2.3 2.9 3.6 4.3

Heating

kW 9 11 15.5 16

Btu/h 307000 37550 44356 54600

RT 2.6 3.1 3.7 4.6

Power

Consumption

Cooling kW 3.3 4.4 5.2 5.6

Heating kW 3.2 4.2 5.0 5.5

Power Supply 380~415V,3Ph,50Hz

Safeties

High/Low pressure switch, compressor thermal protection, over

current protection, lose of phase/anti-phase protection,

antifreeze protection, water flow switch

Refrigerant

Type R4 10A

Charge kg 3.1 3.55 3.6 5.5

Compressor

Type scroll

NO. 1 1 1 1

Evaporator

Heat Exchanger Tube-in-Tube

Water In/Out Pipe

Diameter

Inch 1’ 1’ 1’ 1’

Condenser

Heat Exchanger Aluminum fin-copper tube

Fan Motor Power Input

kW 0.2 0.14 0.14 0.2

Pump

Water Flow

L/s 0.36 0.5 0.56 0.72

GPM 5.78 7.94 8.83 11.48

Delivery Lift m 18 18 18 18

Power Input kW 0.55 0.55 0.55 0.55

Expansion Vessel Volume L 5 5 5 5

Indoor

Unit

Unit /

Packing

Dimension

Height mm 288/385 288/385 288/385 288/385

Width mm 1100/1285 1100/1285 1100/1285 1100/1285

Depth mm 450/682 450/682 450/682 450/682

Net/Gross Weights 84/96 84/96 84/96 84/96

Outdoor

Unit

Unit /

Packing

Dimension

Height mm 840/985 1250/1385 1250/1385 1250/1385

Width mm 950/1100 950/1110 950/1110 1100/1260

Depth mm 412/450 412/450 412/450 412/450

Net / Gross Weights

90/100 112/123 115/126 123/134

MINI CHILLER PRODUCT

7

4.1.2 Integral Type

Models

IMCR

SNa-M

22 25 35 45

Nominal

Capacity

Cooling

kW 22 25 35 43

Btu/h 64828 85300 119420 153540

RT 5.4 7.1 10 13

Heating

kW 26 27 37 50

Btu/h 71650 92124 126250 184248

RT 6 7.7 10.6 15.4

Power

Consumption

Cooling kW 8.7 9.0 11.8 17.1

Heating kW 8.8 8.85 12.3 16.6

Power Supply 380~415V 3Ph 50Hz

Safeties

High/Low pressure switch, compressor thermal protection, over current

protection, lose of phase/anti-phase protection, antifreeze protection,

water flow switch

Refrigerant

Type R4 10A

Charge kg 3.6X2 4.8X2 6.5X2 7.3X2

Compressor

Type scroll

NO. 2 2 2 2

Evaporator

Heat Exchanger Tube-in-Tube Shell and tube

Water

In/Out

Pipe

Diameter

Inch 1’ 1’ 1-1/2’ 1-1/2’

Condenser

Heat Exchanger Aluminum fin-copper tube

Fan

Motor

Power

Input

kW 0.4 0.4 0.6 0.8

Pump

Water

Flow

L/s 0.9 1.2 1.4 2.2

GPM 14.5 18.9 22.9 35.2

Delivery

Lift

m 22 24 25 27

Power

Input

kW 0.75 0.75 1.5 1.5

Expansion Vessel

Volume

L 8 8 8 8

Unit / Packing

Dimension

Height mm 1850/1960 1850/1960 1760/1870 1761/1870

Width mm 1460/1540 1460/1540 1750/1830 1750/1830

Depth mm 530/610 530/610 800/880 800/880

Net/Gross Weights

kg

370/380 390/400 680/690 755/765

NOTE:

1、Cooling capacity is based on the following conditions:leaving chilled water temp.7℃,outdoor air temp.35℃

2、Heating capacity is based on the following conditions:leaving warmed water temp.45℃, outdoor air

temp.7℃

3、Water flow range for operation must be from 70% to 120% of the rated water flow。

4、The maximum allowable pressure for water pipe is 0.9MPa

MINI CHILLER PRODUCT

8

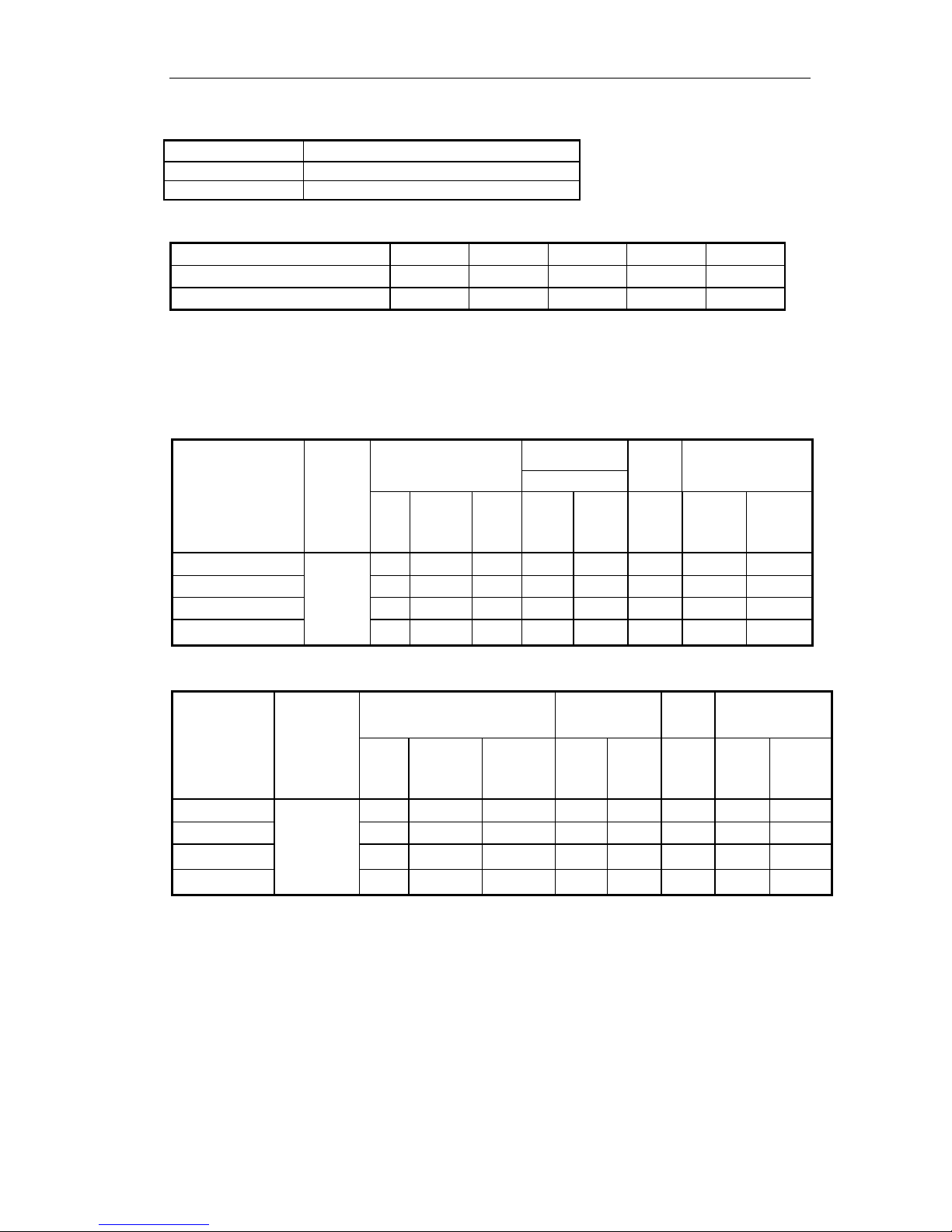

4.2 Operation Range

Mode

Range of Outdoor Temperature℃ (℉)

Cooling 16~48

Heating -15~28

4.3 Pressure-loss Conversion Chart

Water F l o w (m3/h) 1.2 1.4 1.7

1.9 2.0

The percentage (%) 70 80 100 110 120

Loss of Pressure (kPa) 200 100 0

100 200

NOTE:

The percentage is contrasted to nominal water flow.

4.4 Electrical Data

4.4

.1 Split Type

Model

Rated

Power

Supply

Compressor

Fan Motor

Pump Total

Outdoor

NO.

LRA

each

(A)

MRC

each

(A)

NO.

MRC

(A)

MRC

(A)

MRC

(A)

NRC

(A)

IMCR8WZNa-M

380~41

5V 3Ph

50Hz

1 97 21.2 1 1.5 1.0 23.4 17

IMCR10WZNa-M

2 49 13.2 2 2 1.0 31 22

IMCR12.5WZNa-M

2 52 16.1 2 3 1.0 39 28

IMCR15WZNa-M

2 69 17 2 3 1.0 47 33.5

4.4.2 Integral Type

Model

Rated

Power

Supply

Compressor Fan Motor Pump Total

NO.

LRA

each

(A)

MRC

each

(A)

NO.

MRC

(A)

MRC

(A)

MRC

(A)

NRC

(A)

IMCR22SNa-M

380~415V

3Ph 50Hz

2 42 9.5 2 5 1.3 19.5 14

IMCR25SNa-M`

2 56 11.2 2 5 1.3 23.5 16.8

IMCR35SNa-M

2 101 15.3 2 7.5 2.7 42 30

IMCR45SNa-M

2 110 21.4 2 7.5 2.7 54 38.5

Notes:

LRA: Locked rotor amps (A)

MRC: Maximum running current (A)

NRC: Nominal running current (A)

MINI CHILLER PRODUCT

9

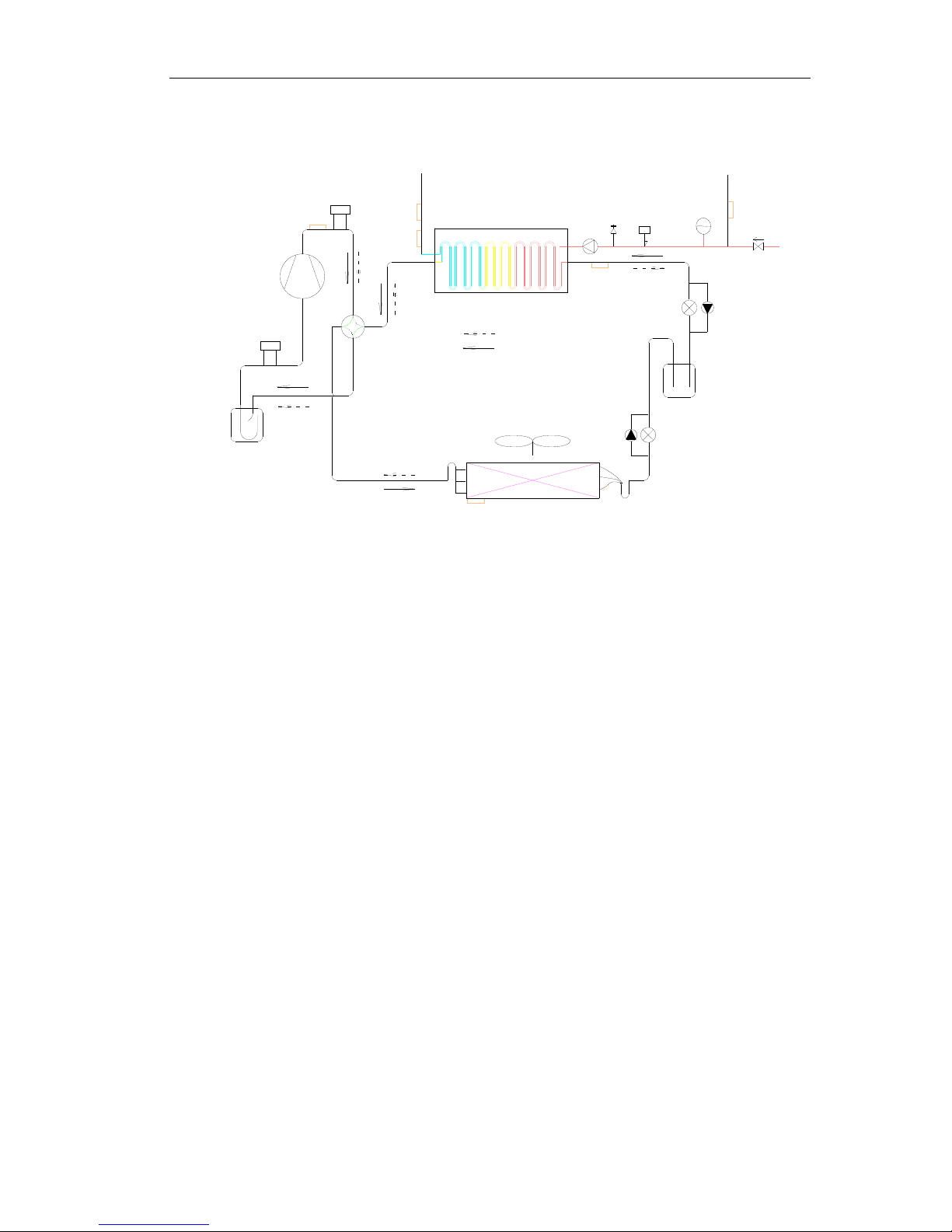

5 PIPING DIAGRAM

Heating circuit

Cooling circuit

Pump

Relief

valve

Flow

switch

Expansion

drum

High pressure

tank

Aluminum fin-copper tube

coil

Four-way valve

Shell and tube heat

exchanger

Inlet

Outlet

High-pressure

switch

Compressor

Low-pressure

switch

Liquid-gas separator

F

INVENTOR COMMERCIAL AIR CONDITIONERS MINI

CHILLER

10

CONTROL

MINI CHILLER CONTROL

11

UNITS CONTROL

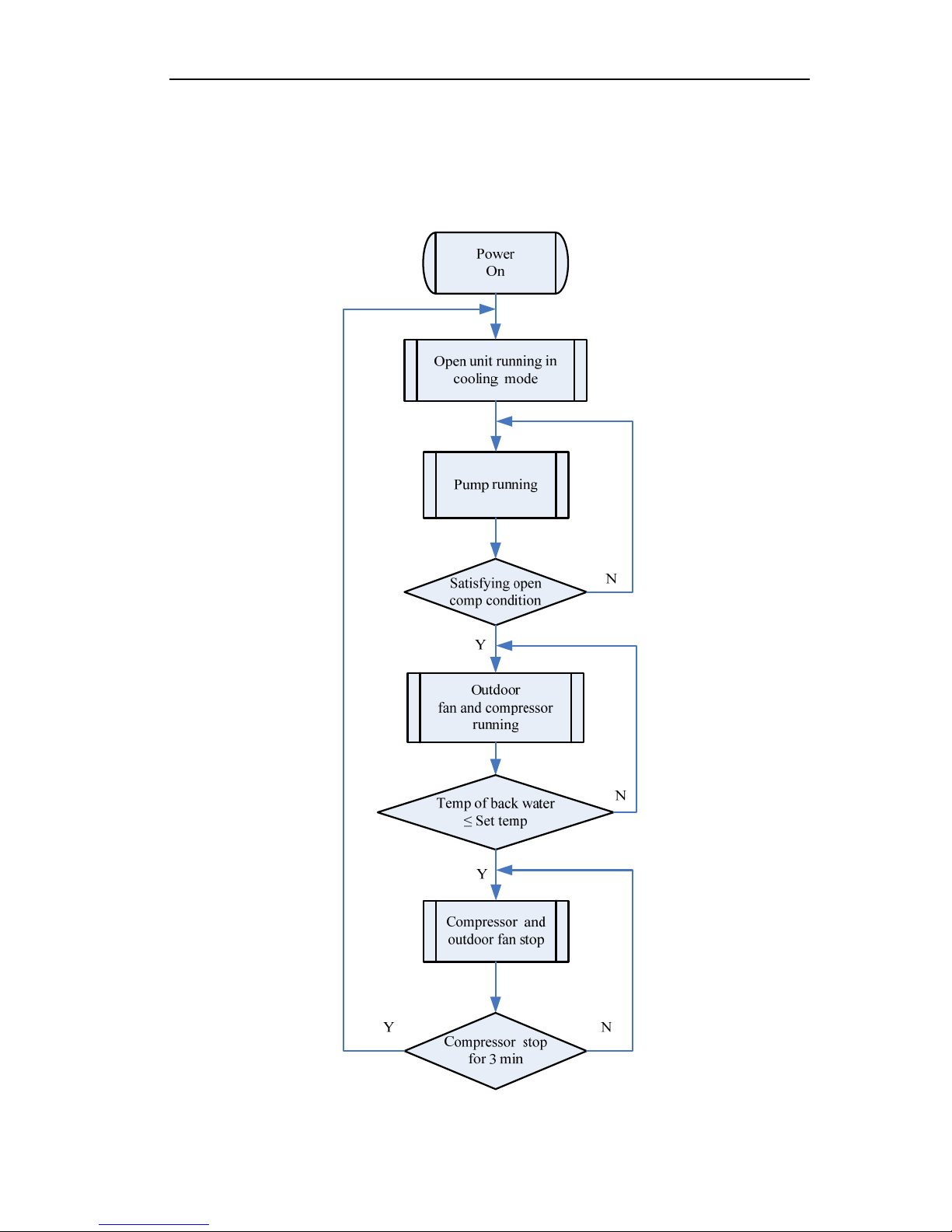

1 OPERATION FLOWCHART

1.1 Cooling Operation

MINI CHILLER CONTROL

12

1.2 Heating Operation

Power

On

Open unit running in

heating mode

Satisfying open

comp condition

Pump running

Outdoor

fan, compressor and

valve running

Temp of back water

≥ (Set temp + 5) (spilt type)

Temp of back water

≥ (Set temp + 6) (Integral type)

Compressor and

outdoor fan stop

Compressor stop

for 3 min

NY

N

Y

Y

N

MINI CHILLER CONTROL

13

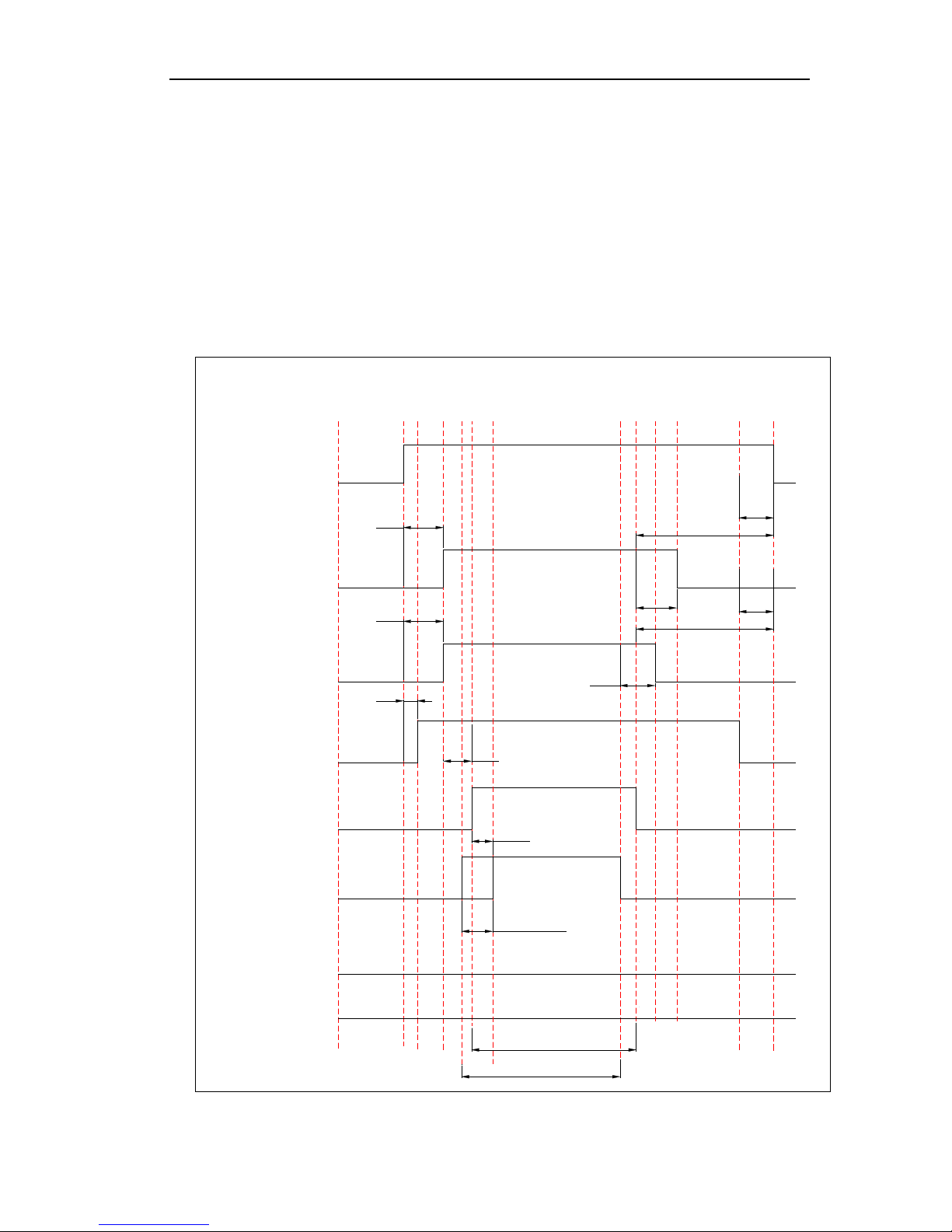

2 MAIN LOGIC

2.1 Cooling Mode

When press ON button, if the outdoor temperature is over 16℃, it starts the water pump first After

30s, if the outlet water temperature meets the cooling running requirements, it starts the fans of outdoor

unit. Then the compressor will run after 15s. During the period of cooling, the unit will turn off if the

outlet water temperature meets the stopping requirements and the running time of compressor is over

the shortest running time required. The fans of outdoor unit will stop after 15s.

If the outdoor temperature is below 16℃, the unit will stop, and turn off all loads except the water

pump.

Turn on

Turn off

Pump

1

Fan 1

Fan 2

Flow Switch

Compr essor

1

Compr ess or 2

Four-way valve 1

Four-way valve 2

30S

30S

5S

15S

10min

15>Tout>12

14>Tout>7

15>Tout>8

Check if flow switch is ok

15S

15S

5S

3min

3min

5S

When it is turned off

When it is turned off

MINI CHILLER CONTROL

14

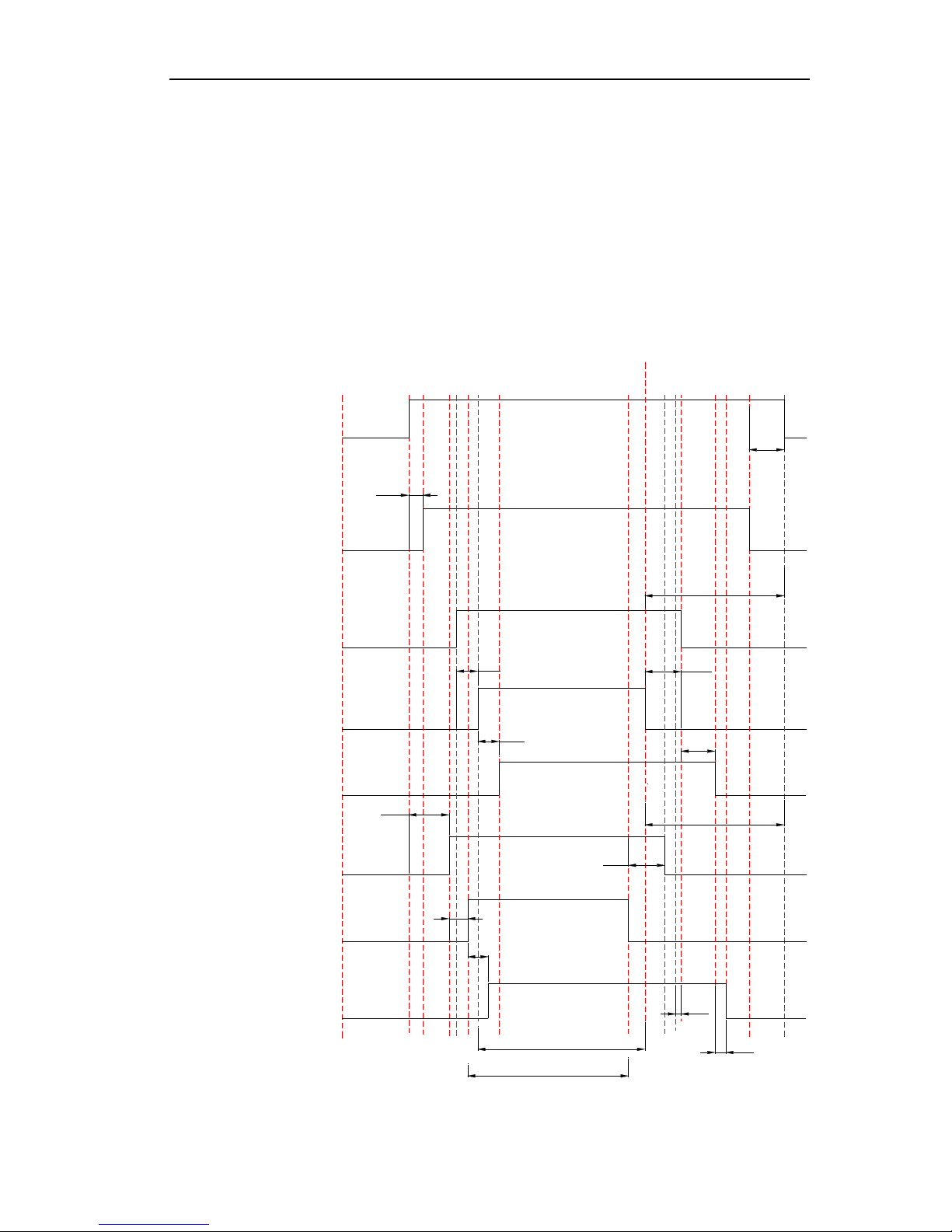

2.2 Heating Mode

When press ON button, if the outdoor temperature is below 28℃, it starts the water pump first After

30s, if the outlet water temperature meets the heating running requirements, it starts the fans of outdoor

unit. Then the compressor will run after 15s. During the period of cooling, the unit will turn off if the

outlet water temperature meets the stopping requirements and the running time of compressor is over

the shortest running time required. The fans of outdoor unit will stop after 15s.

If the outdoor temperature is over 28℃, the unit will stop, and turn off all loads except the water

pump.

Pump

Turn

off

Turn

on

Flow Switch

Fan 1

Compressor 1

Four-way Valve1

Fan 2

Compressor 2

Four-way Valve 2

15S

Check if flow switch is ok

5S

3min

When it is turned off

15S

30S

3min

When it is turned off

5S

15S

30S

5S

15S

2S

5S

15S

48<Tout<54

46<Tout<52

MINI CHILLER CONTROL

15

2.3 Defrosting Mode

The condition of start defrosting mode:

Under heating mode, if the accumulative running time of compressor is over the set interval time

of defrosting( default 45min),and the defrosting temperature is lower than the set starting

temperature(default -4℃) ,the unit will start running defrosting mode, and the 4-way valve will shut

off and the outdoor fan will stop after 2s.

The condition of quit defrosting mode:

Under defrosting mode, if the continual defrosting time is over the set continual time of defrosting

(default 8min),and the defrosting temperature is over the set stopping temperature(default 20℃) ,the

unit will restart running heating mode, and the 4-way valve will turn on and the outdoor fan will run.

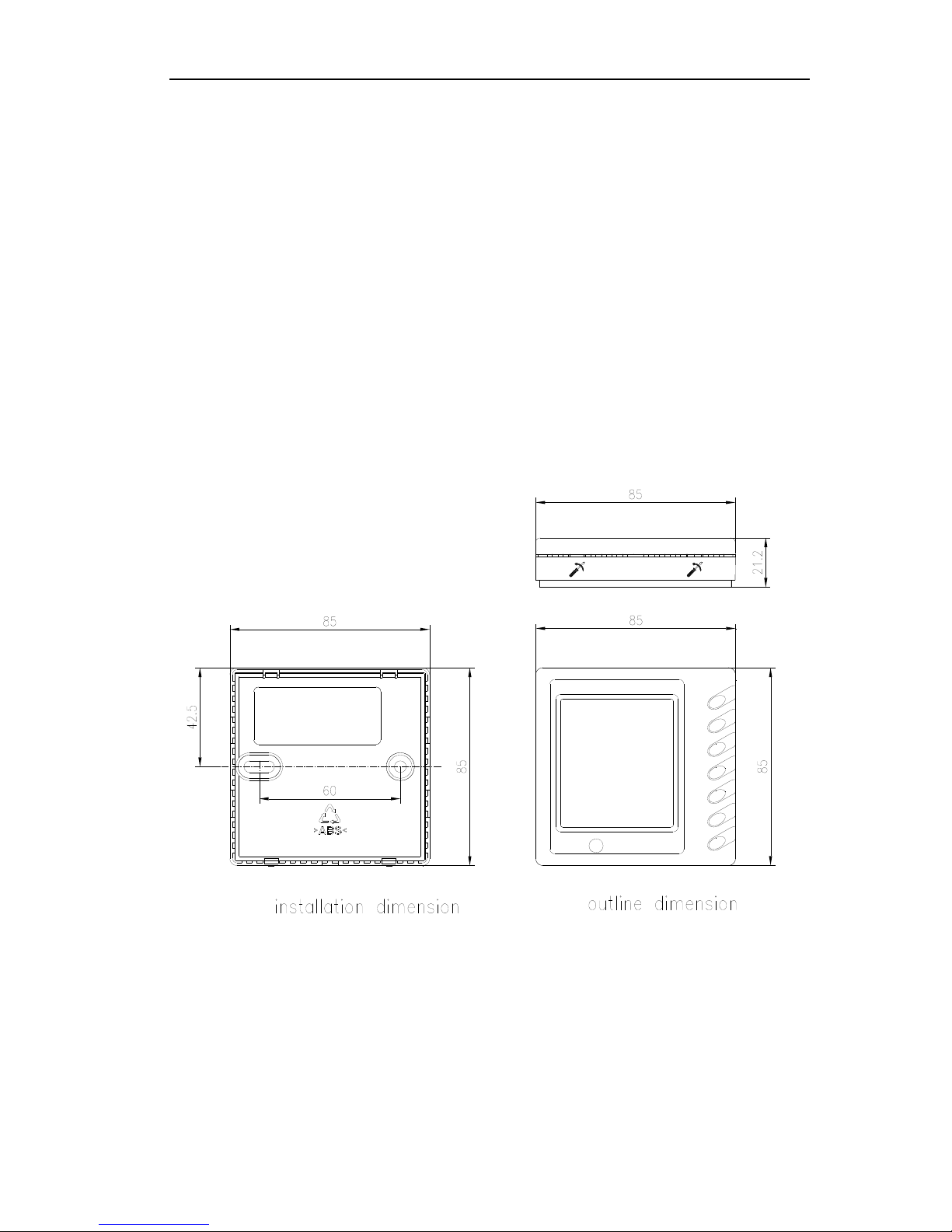

3 WIRED CONTROLLER

3.1 Dimension

3.2 Function

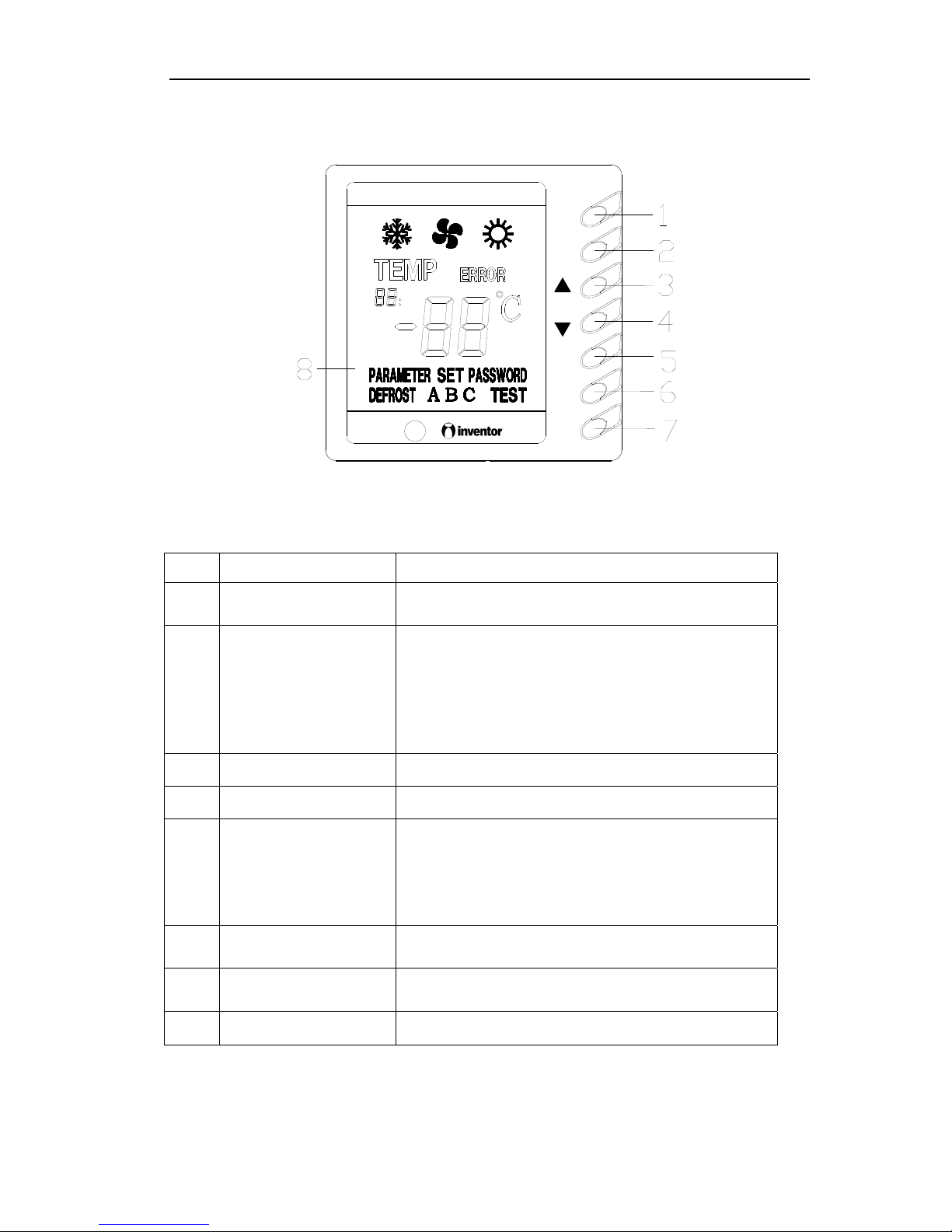

3.2.1 Operation View

MINI CHILLER CONTROL

16

MODE

CHECK

ON

QUIT

OFF

NO. Name Function description

1 MODE button

It can switch between cooling and heating, this button is

available only on cooling and heating unit.

2 CHECK button

Press it once under normal state to enter check mode,

under check mode, press this button when “17” is

displayed can change the value of “17”. Under parameter

set mode, press this once can switch the adjusting objection

between parameter and value, press this button for long

(about 5s) to save and quit this parameter setting.

3 Increasing button

To increase present set value or change set/check object.

4 Decreasing button

To decrease present set value or change set/check object.

5 QUIT button

Under Set and Check mode, press it once to quit this mode.

Under parameter set mode, this set value would not be

saved. Press this button for long (about 5s) to set sound,

and make sound switches between always on and always

off.

6 ON button

To turn on the unit; when under compel operation, press

once to quit compel operation.

7 OFF button

To turn off the unit; press it once to quit compel operation

when the unit is under compel operation.

8 LCD display Display information of the unit.

Note:

(1) Turn On, Off Auxiliary Heater: It is only available for heat pump unit. Press CHECK once to

MINI CHILLER CONTROL

17

enter Check mode. Press ▲ and ▼ to change check object, press CHECK again till the present

check object becomes “17”, value “17” switches between 01/03 (auxiliary heater on) and 00/02

(auxiliary heater off). That is 00 Off —>01 On —>00 Off, or 02 Off —>03 On —>02 Off.

(2) Check Parameter: After electrify for 20s, press QUIT then ▲ to enter parameter checking mode.

Under this mode, Auxiliary display area shows the checking object, Main display area displays

the value for the checking object. Press ▲ and ▼ to change the checking object. Press QUIT to

quit from the check mode.

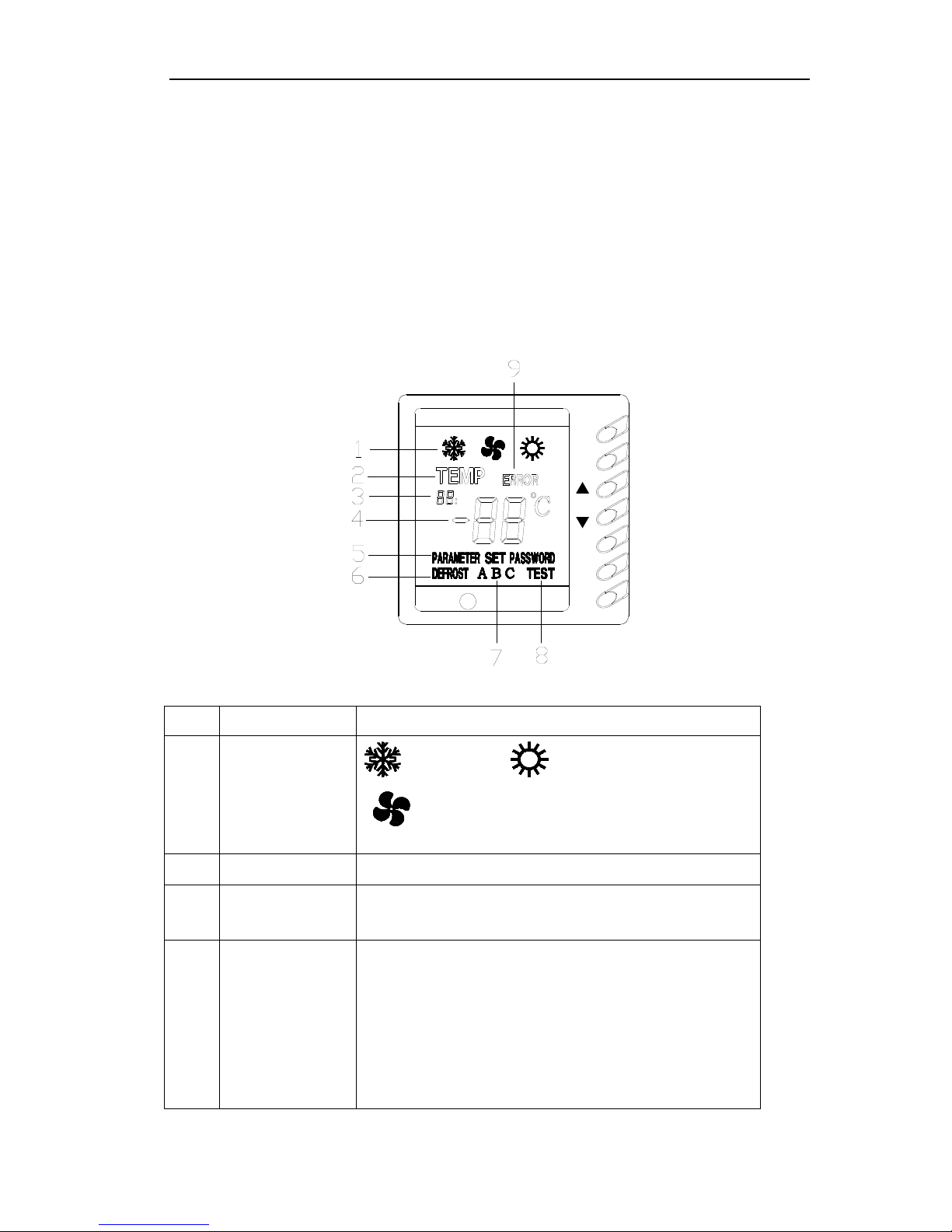

3.2.2 Display View

OFF

QUIT

ON

CHECK

MODE

NO. Name Function description

1 Running mode display

: cooling mode, : heating mode,

: reserved

2 Temp display It shows temperature value displays at main display area.

3 Auxiliary display area

It contains 2 numbers and a comma, for showing temperature and

number of parameter at main display area. It only displays when under

Check mode and Parameter checking mode.

4 Main display area

It contains a minus, 2 numbers and 1 temperature unit, for displaying

value of temperature and parameter (temperature or time value) and error

code. When temperature value is displayed, it shows value in algorism

and temperature unit; when time is displayed, it shows algorism value but

no temperature unit (default unit is min); when it is code, it displays

specific error (refer to Malfunction Error List) but no temperature unit.

Individual temperature or parameter may exceed 99, then adopt AX for

100~109, bX for 110~119, CX for 120~129, dX for 130~139, EX for

140~149, FX for 150~159, and X stands for a number between 0~9.

MINI CHILLER CONTROL

18

Under normal state, it shows temperature for back water.

5 Parameter display

It means the value shown at present main display area is parameter. It

shows only under Parameter Check mode.

6 Defrost display It displays when defrosting, otherwise it doesn’t displays.

7 System ID

It displays when system or compressor orders, for showing which system

is defrosting.

8 Testing display For testing, it displays under compel operation.

9 Error code display

It shows the error code displayed on Main Display Area. It displays when

there is error at system or communication.

Caution:

(1) When unit is off, it displays only temperature of back water. When unit is on, under normal state,

if there is no error, it displays temperature of back water, if there is error, it displays error code;

when there is no operation after 60s of pressing the button, it quit back to normal state display

automatically.

(2) Auto antifreeze operation display (only for heat pump unit)

When auto antifreeze function is started and relevant conditions are satisfied, unit begins auto

antifreeze operation. At this time, LCD main display area displays code d2 (if there is error it

displays error code).

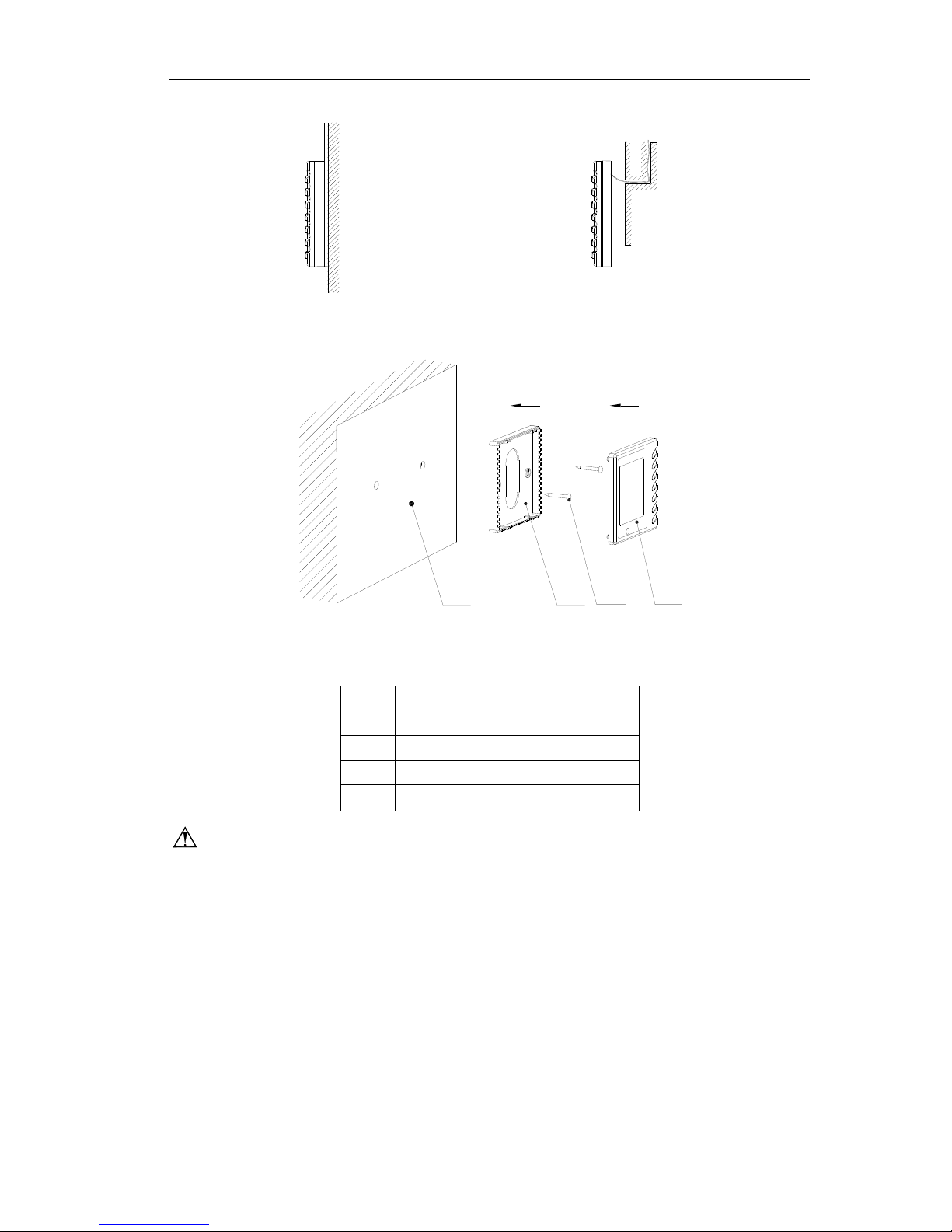

3.3 Installation

1. First select an installation position. According to the size of the communication line of the wire

controller, leave a recess or a embedded wire hole to bury the communication line.

2. If the communication line between the wire controller (85×85×20) and the indoor unit is

surface-mounted, use 1# PVC pipe and make matching recess in the wall (refer to Figure 6); If

concealed installation is adopted, 1# PVC pipe can be used (Refer to Figure 7).

3. No matter if surface mounting or concealed mounting is selected, it is required to drill 2 holes (in

the same level) which distance shall be the same as the distance (60mm) of installation holes in

the bottom plate of the wire controller. Then insert a wood plug into each hole. Fix the bottom

plate of the wire controller to the wall by using the two holes. Plug the communication line onto

the control panel. Lastly install the panel of the wire controller.

Caution:

During the installation of the bottom plate of the wire controller, pay attention to the direction of

the bottom plate. The plate’s side with two notches must be at the lower position, and otherwise the

panel of the wire controller cannot be correctly installed.

MINI CHILLER CONTROL

19

PVC pipe

Fig6:Surface Mounting of Cable Fig7:Concealed mounting of Cable

1 324

Fig 8 Schematic Diagram of Installation

No. Name

1 Wall Surface

2 Bottom Plate of Wire Controller

3 Screw M4X10

4 Panel of Wire Controller

Caution:

1. The communication distance between the main board and the wire controller can be as far as 20m

(The standard distance is 8m).

2. The wire controller shall not be installed in a place where there is water drop or large amount of

water vapor.

4 CONTROL WIRING DESIGN

MINI CHILLER CONTROL

20

twisted-pair

twisted-pair

X17J1

CN2

CN1

Outdoor Unit Controller

Manual Unit Controller

Indoor Unit Controller

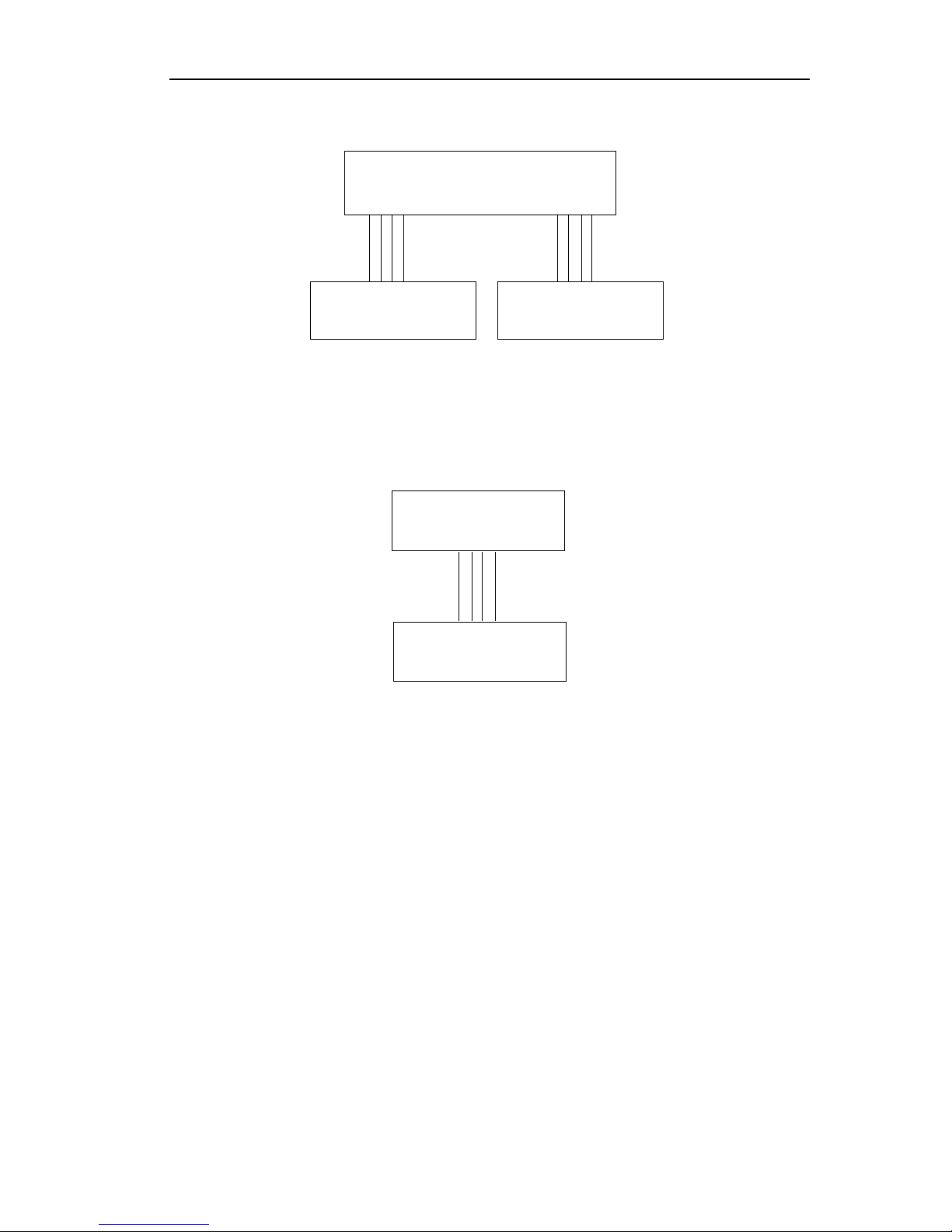

The controllers of the split type unit include manual controller, indoor unit controller and outdoor

unit controller. The indoor unit controller communications with manual controller and outdoor unit

controller in RS485. The indoor unit controller connects manual controller with 4-line twisted-pair.

Similarly, the indoor unit controller connects outdoor unit controller with 4-line twisted-pair.

Indoor Unit Controller

Manual Unit Controller

Outdoor Unit Controller

J1

X17

twisted-pair

The controllers of the Integral type unit include manual controller and outdoor unit controller. The

manual controller communications with outdoor unit controller in RS485. The manual controller

connects outdoor unit controller with 4-line twisted-pair.

Loading...

Loading...