C1VI - 18 / C1VO - 18

C1VI - 24 / C1VO - 24

Table of Contents

Summary and Features

1.Safety Precautions

2.Specifi cations

2.1 Unit Specifi cations

2.2 Operation Characteristic Curve

2.3 Capacity Variation Ratio According to Temperature

2.4 Operation Data

2.5 Noise Criteria Curve Tables for Both Models

3. Construction Views

3.1 Indoor Unit

3.2 Outdoor Unit

4. Refrigerant System Diagram

5. Schematic Diagram

5.1 Electrical Data

5.2 Electrical Wiring

5.3 Printed Circuit Board

6. Function and Control

6.1 Remote Control Operations

6.2 Description of Each Control Operation

7. Installation Manual

7.1 Notices for Installation

7.2 Installation Dimension Diagram

7.3 Install Indoor Unit

7.4 Install Outdoor Unit

7.5 Check After Installation and Test Operation

7.6 Installation and Maintenance of Healthy Filter

..........................................................................

1

................................................................................2

...........................................................................................3

.....................................................................................3

.................................................................7

..................................8

..........................................................................................8

............................................9

............................................................................10

...............................................................................................10

............................................................................................11

.........................................................12

............................................................................13

..........................................................................................13

.......................................................................................13

................................................................................16

........................................................................19

.....................................................................19

....................................................22

.............................................................................29

.............................................................................29

...............................................................31

.....................................................................................32

..................................................................................33

.............................................34

.........................................35

8. Exploded Views and Parts List

8.1 Indoor Unit

8.2 Outdoor Unit

9. Troubleshooting

9.1 Precautions before Performing Inspection or Repair

9.2 Confi rmation

9.3 Flashing LED of Indoor/Outdoor Unit and Primary Judgement

9.4 How to Check simply the main part

10. Removal Procedure

10.1 Removal Procedure of Indoor Unit

10.2 Removal Procedure of Outdoor Unit

....................................................

36

..............................................................................................36

...........................................................................................40

...................................................................................44

...............................44

............................................................................................45

...............45

.........................................................50

.........................................................................70

.........................................................70

......................................................79

Summary and Features

1

Outdoor Unit

C1VI18

C1VI-24

YB1FA

Remote Controller

C1VI-18

C1VI-24

Summary and Features

Indoor Unit

Safety Precautions

2

Caution

Warning

Warning

Caution

could result in

personal injury

or death.

Incorrect handling

result in

injury

, or damage to product

or property.

Incorrect handling

may

minor

Recognize the following safety information:

Installing, starting up, and servicing air conditioner can be

hazardous due to system pressure, electrical components, and

equipment location, etc.

Only trained, qualified installers and service personnel are

allowed to install, start-up, and service this equipment.

Untrained personnel can perform basic maintenance functions

such as cleaning coils. All other operations should be performed

by trained service personnel.

When handling the equipment, observe precautions in the

manual and on tags, stickers, and labels attached to the equipment. Follow all safety codes. Wear safety glasses and

work gloves. Keep quenching cloth and fire extinguisher nearby

when brazing.

Read the instructions thoroughly and follow all warnings or

cautions in literature and attached to the unit. Consult local

building codes and current editions of national as well as local

electrical codes.

All electric work must be performed by a licensed technician

according to local regulations and the instructions given in this

manual.

Never supply power to the unit unless all wiring and tubing

are completed, reconnected and checked.

This system adopts highly dangerous electrical voltage.

Incorrect connection or inadequate grounding can cause

personal injury or death. Stick to the wiring diagram and all

the instructions when wiring.

Have the unit adequately grounded in accordance with

local electrical codes.

Have all wiring connected tightly. Loose connection may

lead to overheating and a possible fire hazard.

All installation or repair work shall be performed by your dealer

or a specialized subcontractor as there is the risk of fire, electric

shock, explosion or injury.

Make sure the ceiling wall is strong enough to bear the

weight of the unit.

Make sure the noise of the outdoor unit does not disturb

neighbors.

Properly insulate any tubing running inside the room to

prevent the water from damaging the wall.

Make sure the outdoor unit is installed on a stable, level

surface with no accumulation of snow, leaves, or trash

beside.

Follow all the installation instructions to minimize the risk

of damage from earthquakes, typhoons or strong winds.

Avoid contact between refrigerant and fire as it generates

poisonous gas.

Apply specified refrigerant only. Never have it mixed with

any other refrigerant. Never have air remain in the

refrigerant line as it may lead to rupture and other hazards.

Make sure no refrigerant gas is leaking out when

installation is completed.

Should there be refrigerant leakage, the density of

refrigerant in the air shall in no way exceed its limited

value, or it may lead to explosion .

Before installing, modifying, or servicing system, main

electrical disconnect switch must be in the OFF position.

There may be more than 1 disconnect switch. Lock out and

tag switch with a suitable warning label.

Keep your fingers and clothing away from any moving parts.

Clear the site after installation. Make sure no foreign

objects are left in the unit.

Always ensure effective grounding for the unit.

Never install the unit in a place where a combustible gas

might leak, or it may lead to fire or explosion.

Make a proper provision against noise when the unit is

installed at a telecommunication center or hospital.

Provide an electric leak breaker when it is installed in a

watery place.

Never wash the unit with water.

Handle unit transportation with care. The unit should not be

carried by only one person if it is more than 20kg.

Never touch the heat exchanger fins with bare hands.

Never touch the compressor or refrigerant piping without

wearing glove.

Do not have the unit operate without air filter.

Should any emergency occur, stop the unit and disconnect

the power immediately.

1.Safety Precautions

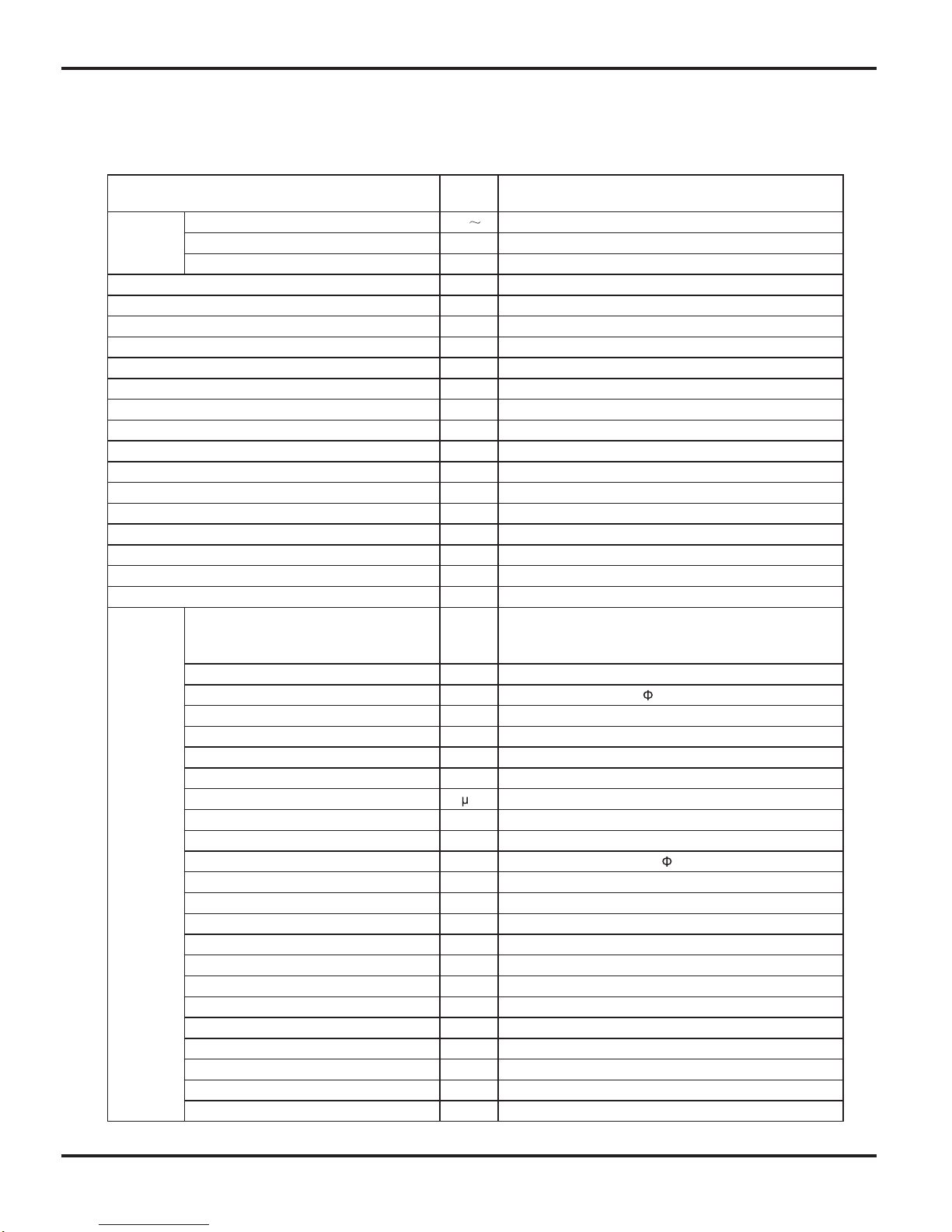

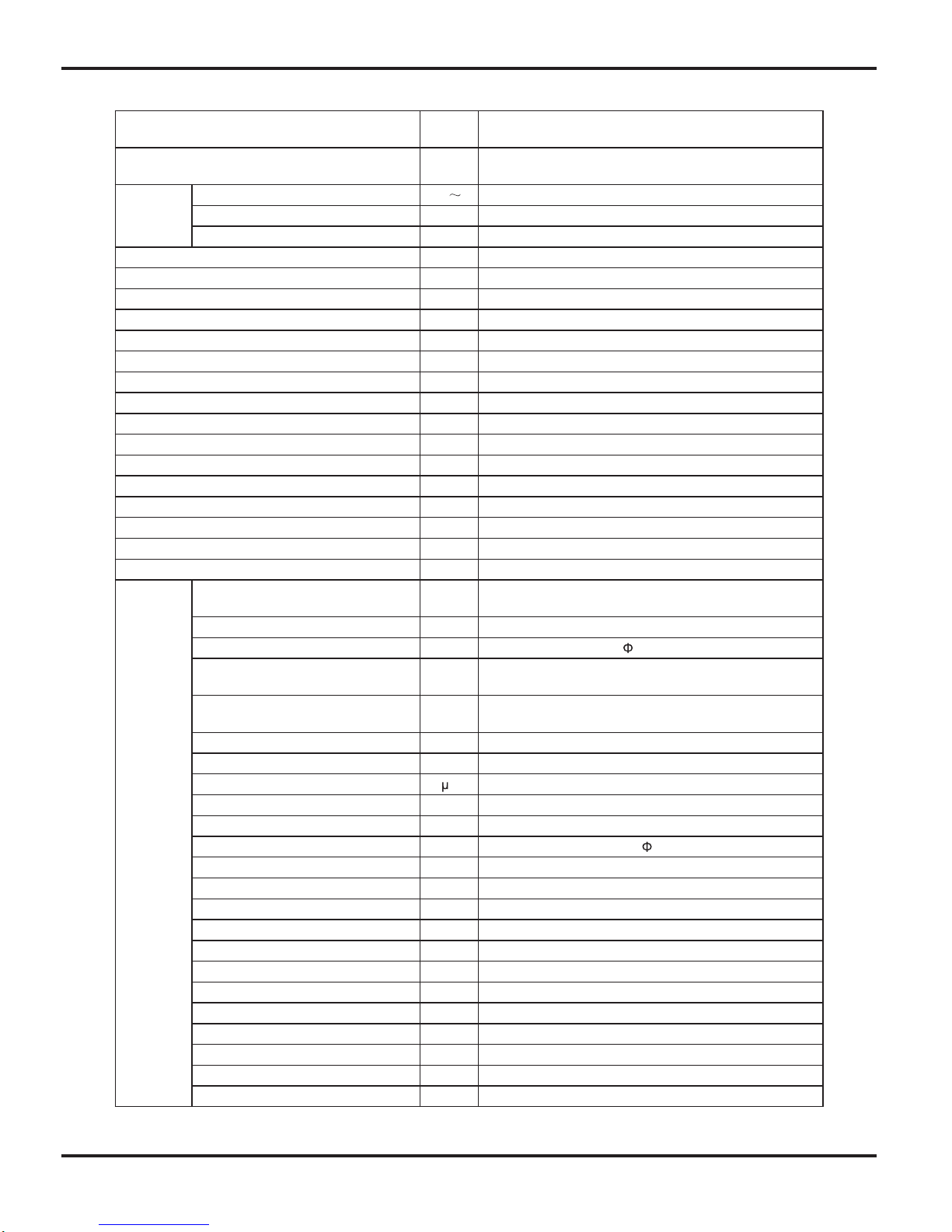

Specifi cations

3

Model

C1VI-18 / C1VO-18

Power

Supply

VegatloV detaR

220-240

05zHycneuqerF detaR

Phases 1

Power Supply Mode Outdoor

)0066~0621(5725WyticapaC gnilooC

)0086~0211(0585WyticapaC gnitaeH

)0562~083(0061WtupnI rewoP gnilooC

)0562~053(0261WtupnI rewoP gnitaeH

52.7AtnerruC rewoP gnilooC

43.7AtnerruC rewoP gnitaeH

0562WtupnI detaR

00.21AtnerruC detaR

m )LS/L/M/H/HS(emuloV wolF riA

3

-/055/056/087/058h/

2h/LemuloV gniyfidimuheD

03.3W/W REE

16.3W/W POC

/W/W REES

/W/W FPSH

maerA noitacilppA

2

23-34

Indoor Unit

Model of indoor unit C1VI-18

wo fl-ssorCepyT naF

mm )LXD(htgneL retemaiD

98X710

Fan Motor Cooling Speed(SH/H/M/L/SL) r/min 1350/1200/1050/900/Fan Motor Heating Speed(SH/H/M/L/SL) r/min 1420/1250/1150/1050/-

02WrotoM naF fo tuptuO

52.0AALR rotoM naF

Fan Motor Capacitor

5.1F

-WretaeH fo tupnI

ebuT reppoc-niF munimulA mroF rotaropavE

mmretemaiD epiP

7

4.1-2mmpaG n fi-woR

8.403X4.52X517mm )WXDXL( htgneL lioC

BV82PMledoM rotoM gniwS

3W rotoM gniwS fo tuptuO

A51.3 BCPA esuF

-/53/04/64/84 )A( Bd )LS/L/M/H/HS( leveL erusserP dnuoS

-/54/05/45/85 )A( Bd )LS/L/M/H/HS( leveL rewoP dnuoS

002X892X049mm )DXHXW( noisnemiD

083X582X0101mm)H/W/L( xoB notraC fo noisnemiD

003X383X3101mm )H/W/L(egakcaP fo noisnemiD

21gk thgieW teN

61gkthgieW ssorG

2.Specifications

2.1 Unit Specifi cations

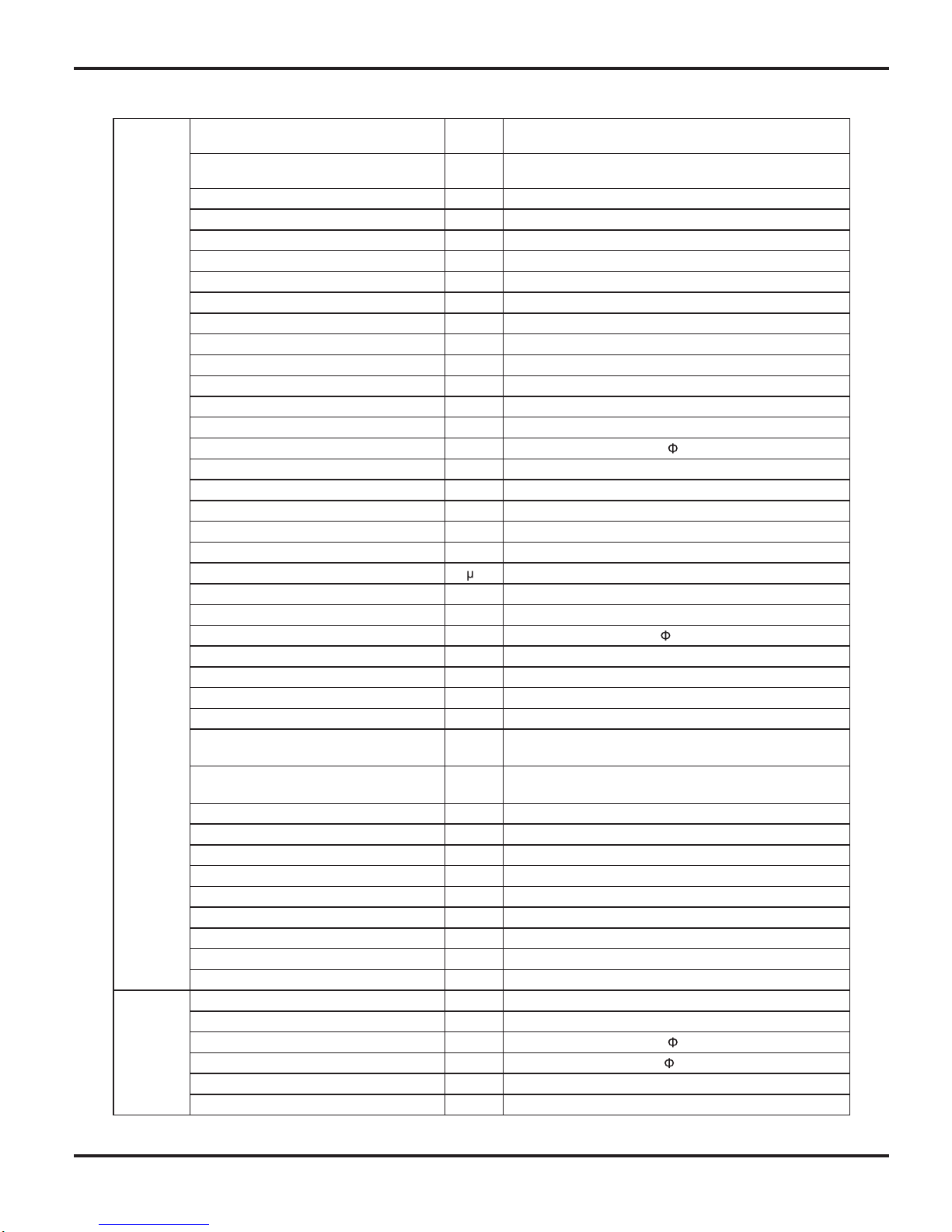

Specifi cations

4

Outdoor

Unit

C1VO-18tinU roodtuO fo ledoM

Compressor Manufacturer/Trademark MITSUBISHI ELECTRIC (GUANGZHOU)COMP

CMYGF031BNSledoM rosserpmoC

S05VPliO rosserpmoC

yratoRepyT rosserpmoC

00.72A .A.R.L

04.8A ALR rosserpmoC

5421WtupnI rewoP rosserpmoC

8756-L11TN1rotcetorP daolrevO

yrallipaCdohteM gnilttorhT

03~61CºpmeT noitarepO

54~81Cº)gnilooC( pmeT tneibmA

42~51- Cº)gnitaeH( pmeT tneibmA

ebuT reppoc-niF munimulA mroF resnednoC

mm retemaiD epiP

7

4.1-2mmpaG n fi-swoR

055X1.83X218mm )WXDXL( htgneL lioC

088mprdeepS rotoM naF

06WrotoM naF fo tuptuO

26.0A ALR rotoM naF

Fan Motor Capacitor

5.3F

Air Flow Volume of Outdoor Unit m

3

0042h/

wo fl-laixAepyT naF

mmretemaiD naF

445

gnitsorfeD citamotuAdohteM gnitsorfeD

1TepyT etamilC

Isolation I

42PInoitcetorP erutsioM

Permissible Excessive Operating Pressure

for the Discharge Side

0.3aPM

Permissible Excessive Operating Pressure

for the Suction Side

9.0aPM

-/-/45 )A( Bd )L/M/H( leveL erusserP dnuoS

-/-/46 )A( Bd )L/M/H( leveL rewoP dnuoS

873X695X998mm )DXHXW( noisnemiD

036X714X549mm)H/W/L( xoB notraC fo noisnemiD

336X234X849mm )H/W/L(egakcaP fo noisnemiD

83gk thgieW teN

34gkthgieW ssorG

A014R tnaregirfeR

02.1gkegrahC tnaregirfeR

Connection

Pipe

5mhtgneL

03m/gegrahC lanoitiddA saG

Outer Diameter Liquid Pipe mm

6

Outer Diameter Gas Pipe mm

12

01mthgieH ecnatsiD xaM

03mhtgneL ecnatsiD xaM

The above data is subject to change without notice. Please refer to the nameplate of the unit.

Specifi cations

5

Model

C1VI-24 / C1VO-24

Power

Supply

VegatloV detaR

220-240

05zHycneuqerF detaR

1sesahP

roodtuOedoM ylppuS rewoP

)0007~0041(0546WyticapaC gnilooC

)0028~0021(0007WyticapaC gnitaeH

)0052~053(5891WtupnI rewoP gnilooC

)0072~053(0391WtupnI rewoP gnitaeH

08.8AtnerruC rewoP gnilooC

65.8AtnerruC rewoP gnitaeH

0072WtupnI detaR

04.21AtnerruC detaR

m )LS/L/M/H/HS(emuloV wolF riA

3

-/055/007/008/009h/

2h/LemuloV gniyfidimuheD

52.3W/W REE

26.3W/W POC

/W/W REES

/W/W FPSH

maerA noitacilppA

2

27-42

Indoor Unit

Model of indoor unit

C1VI-24

wo fl-ssorCepyT naF

Diameter Length(DXL) mm

98X765

Fan Motor Cooling Speed(SH/H/M/L/

SL)

r/min 1250/1100/950/800/-

Fan Motor Heating Speed(SH/H/ML/

SL)

r/min 1300/1100/1000/850/-

53WrotoM naF fo tuptuO

03.0AALR rotoM naF

Fan Motor Capacitor

5.2F

-WretaeH fo tupnI

ebuT reppoc-niF munimulA mroF rotaropavE

mmretemaiD epiP

7

5.1-2mmpaG n fi-woR

9.243X4.52X567mm )WXDXL( htgneL lioC

XX53PMledoM rotoM gniwS

3W rotoM gniwS fo tuptuO

A51.3 BCPA esuF

-/93/24/74/15 )A( Bd )LS/L/M/H/HS( leveL erusserP dnuoS

-/94/25/75/16 )A( Bd )LS/L/M/H/HS( leveL rewoP dnuoS

912X513X7001mm )DXHXW( noisnemiD

313X593X3701mm)H/W/L( xoB notraC fo noisnemiD

823X893X6701mm )H/W/L(egakcaP fo noisnemiD

41gk thgieW teN

91gkthgieW ssorG

Specifi cations

6

Outdoor

Unit

C1VO-24tinU roodtuO fo ledoM

Compressor Manufacturer/Trademark MITSUBISHI ELECTRIC (GUANGZHOU)COMP

CMYGF031BNSledoM rosserpmoC

S05VPliO rosserpmoC

yratoRepyT rosserpmoC

00.72A .A.R.L

04.8A ALR rosserpmoC

5421WtupnI rewoP rosserpmoC

8756-L11TN1rotcetorP daolrevO

yrallipaCdohteM gnilttorhT

03~61CºpmeT noitarepO

54~81Cº)gnilooC( pmeT tneibmA

42~51- Cº)gnitaeH( pmeT tneibmA

ebuT reppoc-niF munimulA mroF resnednoC

mm retemaiD epiP 7

4.1-2mmpaG n fi-swoR

066X1.83X738mm )WXDXL( htgneL lioC

005/096mprdeepS rotoM naF

06WrotoM naF fo tuptuO

26.0A ALR rotoM naF

Fan Motor Capacitor

5.3F

Air Flow Volume of Outdoor Unit m

3

0023h/

wo fl-laixAepyT naF

mmretemaiD naF

520

gnitsorfeD citamotuAdohteM gnitsorfeD

1TepyT etamilC

InoitalosI

42PInoitcetorP erutsioM

Permissible Excessive Operating

Pressure for the Discharge Side

0.3aPM

Permissible Excessive Operating

Pressure for the Suction Side

9.0aPM

-/-/45 )A( Bd )L/M/H( leveL erusserP dnuoS

-/-/46 )A( Bd )L/M/H( leveL rewoP dnuoS

693X007X559mm )DXHXW( noisnemiD

537X554X6201mm)H/W/L( xoB notraC fo noisnemiD

057X854X9201mm )H/W/L(egakcaP fo noisnemiD

84gk thgieW teN

35gkthgieW ssorG

A014R tnaregirfeR

53.1gkegrahC tnaregirfeR

Connection

Pipe

5mhtgneL

03m/gegrahC lanoitiddA saG

Outer Diameter Liquid Pipe mm

6

Outer Diameter Gas Pipe mm

12

01mthgieH ecnatsiD xaM

03mhtgneL ecnatsiD xaM

The above data is subject to change without notice. Please refer to the nameplate of the unit.

Specifi cations

7

gnitaeHgnilooC

0 10 20 30 40 50 60 70 90 0 10 20 30 40 50 60 70 80 90 100 120110

80

11

10

9

8

7

6

5

4

3

2

1

0

Compressor speed (rps)

)A(tnerruC

11

10

9

8

7

6

5

4

3

2

1

0

Compressor speed (rps)

)A(tnerruC

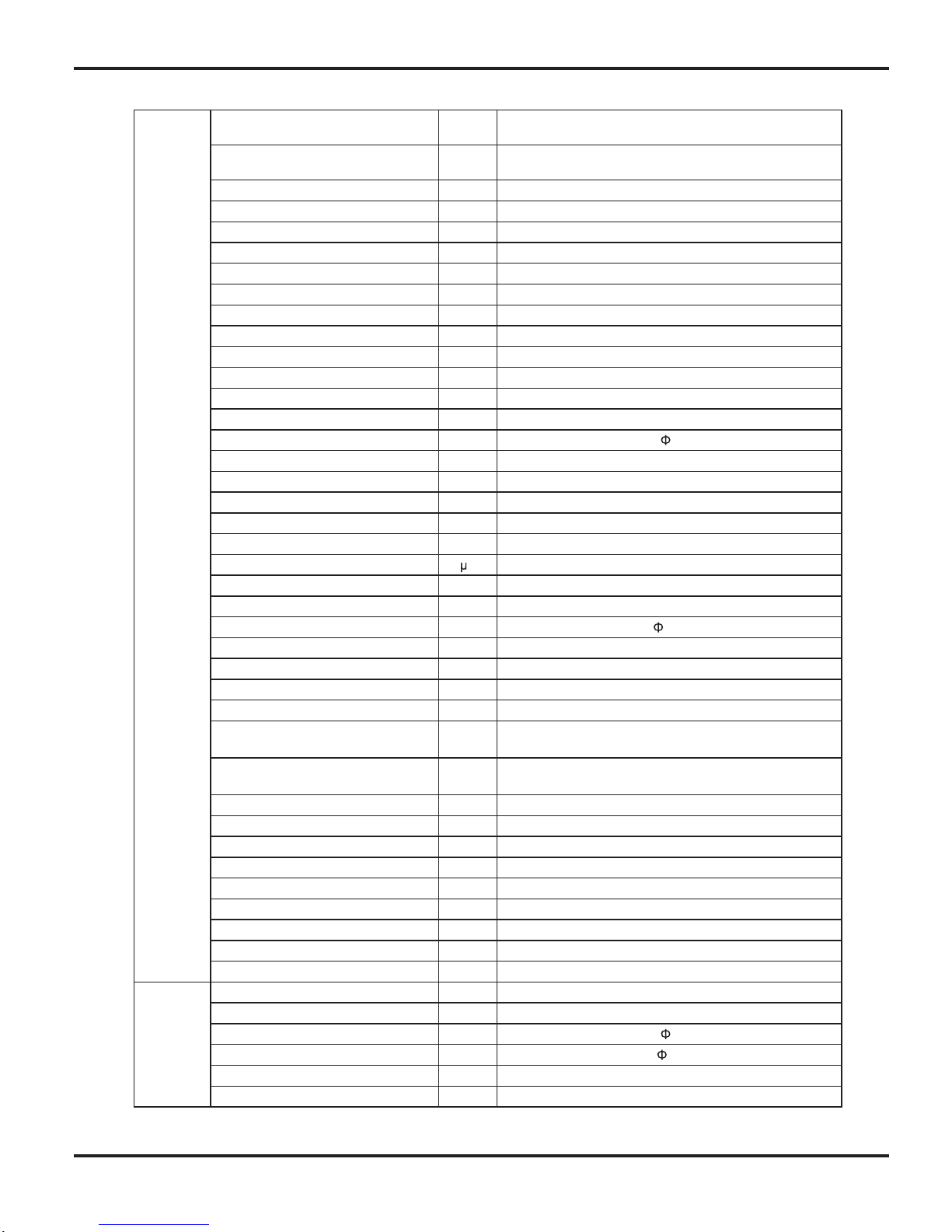

• Conditions

Indoor : DB26.7˚C/WB19.4˚C

Outdoor: DB35˚C/WB23.9˚C

Indoor air flow: Turbo

Pipe length : 5m

• Conditions

Indoor : DB21.1˚C/WB15.6˚C

Outdoor: DB8.33˚C/WB6.11˚C

Indoor air flow: Turbo

Pipe length : 5m

220V

230V

240V

220V

230V

240V

0 10 20 30 40 50 60 70 90 0 10 20 30 40 50 60 70 80 90 100 120110

80

11

10

9

8

7

6

5

4

3

2

1

0

Compressor speed (rps)

)A(tnerruC

11

10

9

8

7

6

5

4

3

2

1

0

Compressor speed (rps)

)A(tnerruC

• Conditions

Indoor : DB26.7˚C/WB19.4˚C

Outdoor: DB35˚C/WB23.9˚C

Indoor air flow: Turbo

Pipe length : 5m

• Conditions

Indoor : DB21.1˚C/WB15.6˚C

Outdoor: DB8˚C/WB6.11˚C

Indoor air flow: Turbo

Pipe length : 5m

220V

230V

240V

220V

230V

240V

gnitaeHgnilooC

2.2 Operation Characteristic Curve

18K

24K

Specifi cations

8

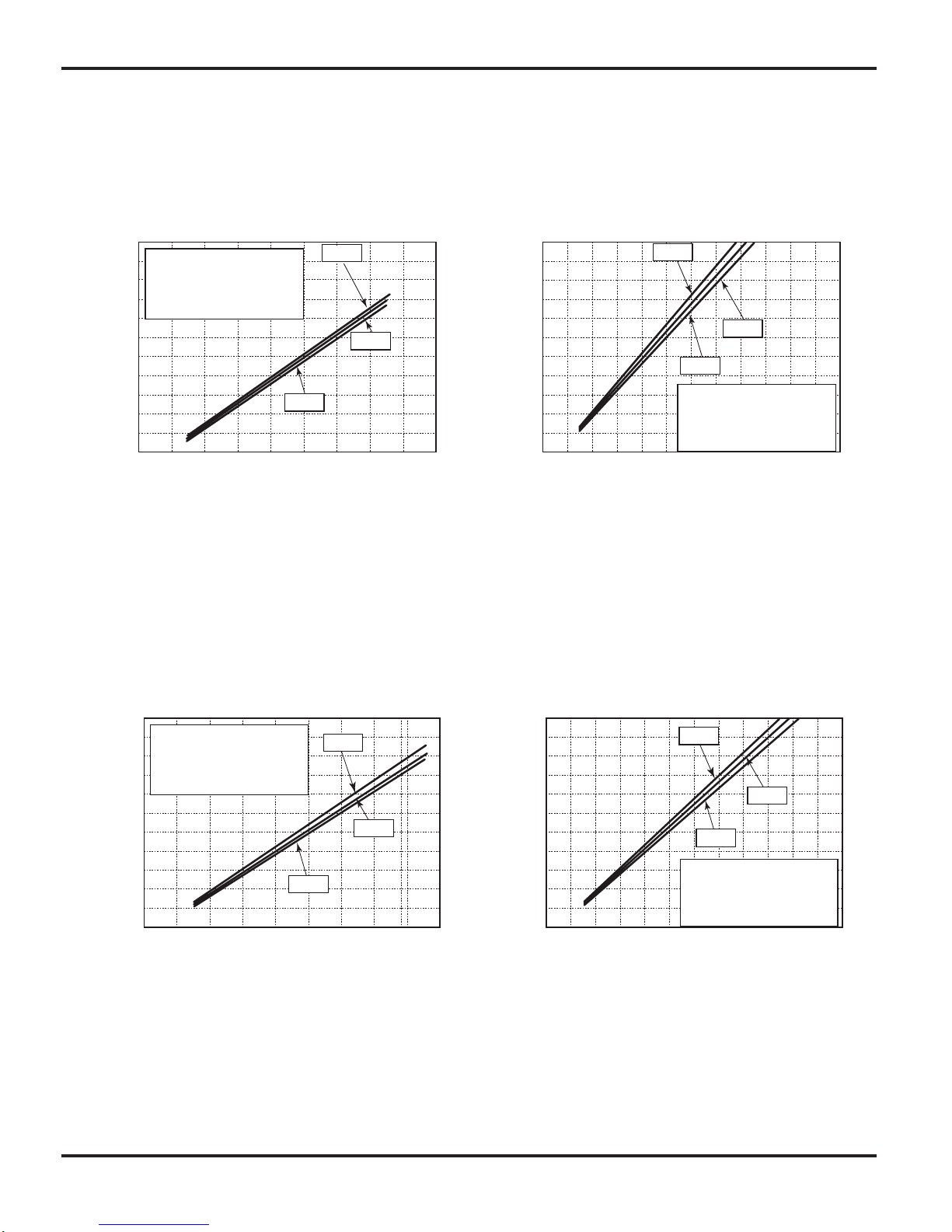

2.3 Capacity Variation Ratio According to Temperature

NOTES :

(1) T1: Inlet and outlet pipe temperature of evaporator

T2: Inlet and outlet pipe temperature of condenser

P: Pressure of air pipe connecting indoor and outdoor units(on the side of gas pipe)

(2) Measure surface temperature of heat exchanger pipe around center of heat exchanger path U bent.

(Thermistor themometer)

(3)

Connecting piping condition : 5 m

t n i looC a e H ig n g

3 2 3 3 3 4 3 5 3 6 3 7 3 8 3 9 4 3 –1 5

–10

5 0 5 7 10

4 0 4 1 42

100

105

95

90

85

80

75

70

65

60

55

50

Outdoor tem p . (˚C)

) %

(

o i t a r y t i c a p a C

110

100

90

80

70

60

50

40

Outdoor tem p . (˚C)

) % ( o i t a r y t i c a p a C

Conditions

Indoor:DB21.1

o

C /WB15.6 oC

Indoor air flow:Turbo

Pipe length:5m

Conditions

Indoor:DB26.7

o

C /WB19.4 oC

Indoor air flow:Turbo

Pipe length:5m

Cooling

Heating

Standard

pressure

Indoor Outdoor

P (MPa)

T1 (°C) T2 (°C)

18K 0.9 to 1.1 12 to 14 70 to 42 High High 62

24K 0.8 to 1.0 10 to 12 70 to 40 High High 78

Outdoor fan

mode

Compressor

Frequency

(Hz)

26.7/19.4 35/–

(°C)

Model

name

temp.

Indoor fan

mode

Standard

pressure

Indoor Outdoor

P (MPa)

T1 (°C) T2 (°C)

18K 2.2 to 2.4 70 to 37 2 to 4 High High 62

24K 2.5 to 2.7 70 to 37 0 to 3 High High 80

Outdoor fan

mode

21.1/

–

8/6.11

Temperature condition

Temperature condition

(°C)

Model

name

Heat exchanger pipe

Heat exchanger pipe

temp.

Indoor fan

mode

Compressor

Frequency

(Hz)

2.4 Operation Data

Specifi cations

9

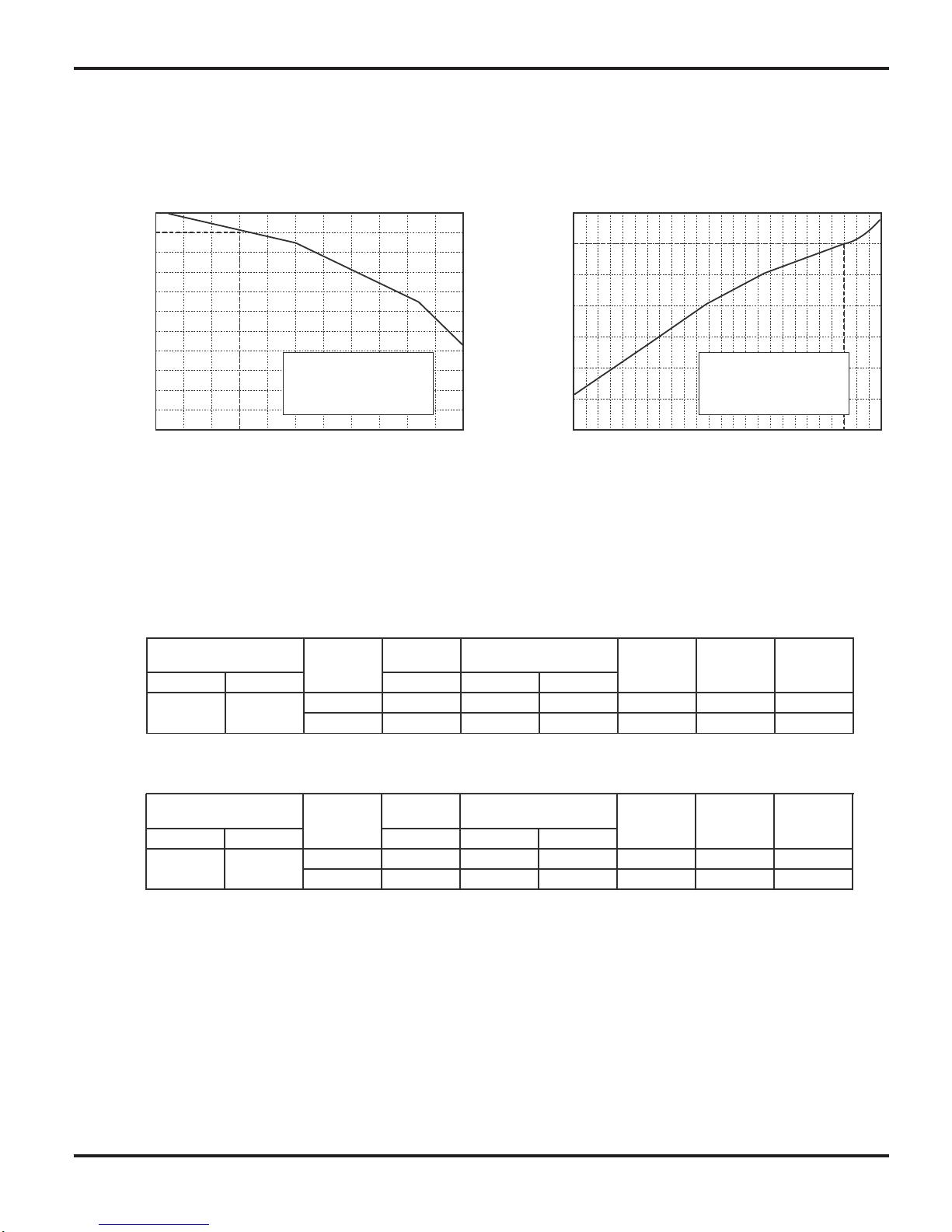

2.5 Noise Criteria Curve Tables for Both Models

Indoor side noise when blowing

Outdoor side noise

18K

24K

60

60

60 80 100

50

50

40

40

40

30

30

20

20

20

10

0

0

Indoor Fan Motor Rotating Speed

Noice/dB(A)

low

Middle

High Super High

Compressor frequency/Hz

)A(Bd/esioN

18 24K

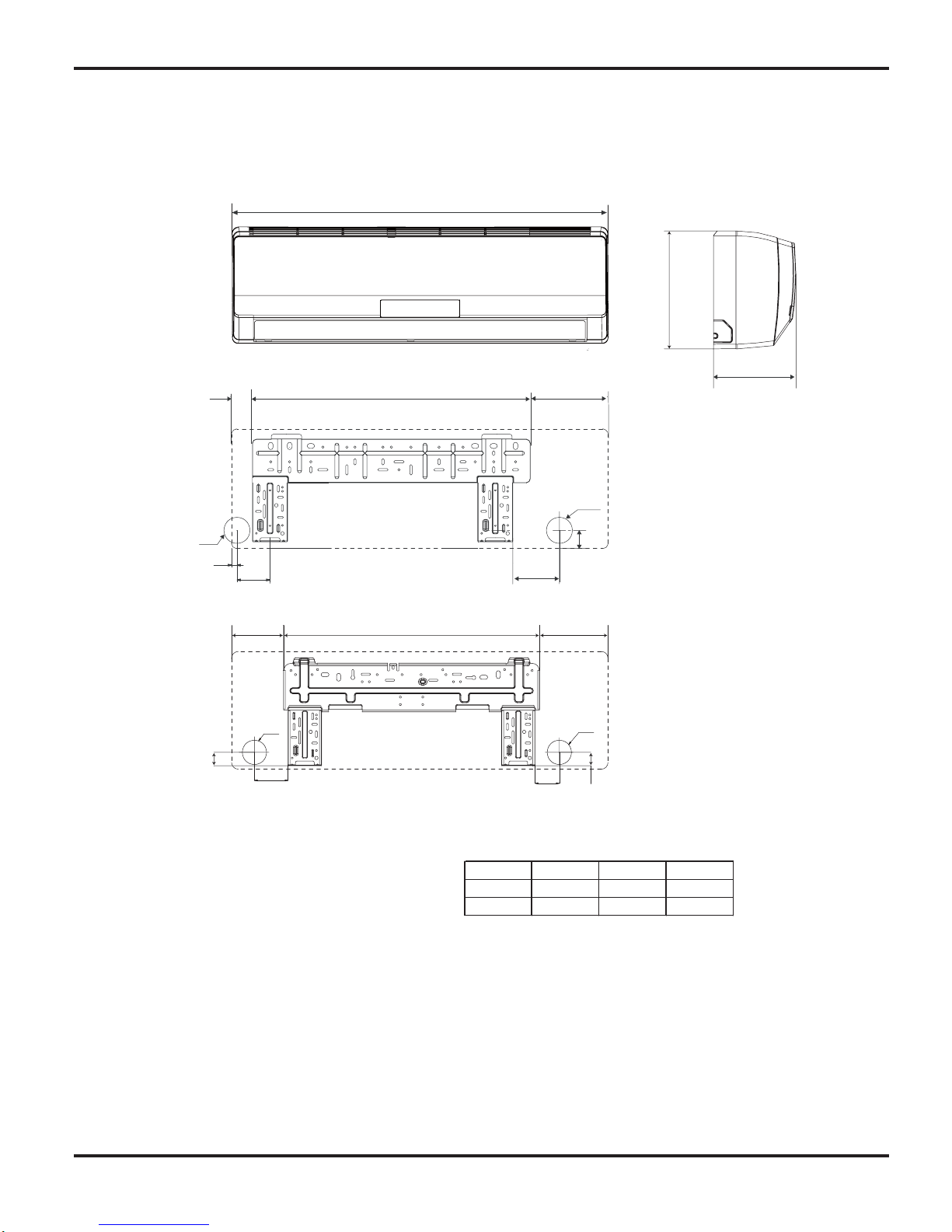

Constrction Views

10

3. Construction Views

3.1 Indoor Unit

139

685

183

Φ55

Φ55

6 3

6 3

90

65

72

45

694

194

D

52

Φ55

Φ55

14

82

18K

24K

Model W H D

W

18K 940 298 200

24K 1007 315 219

Unit:mm

H

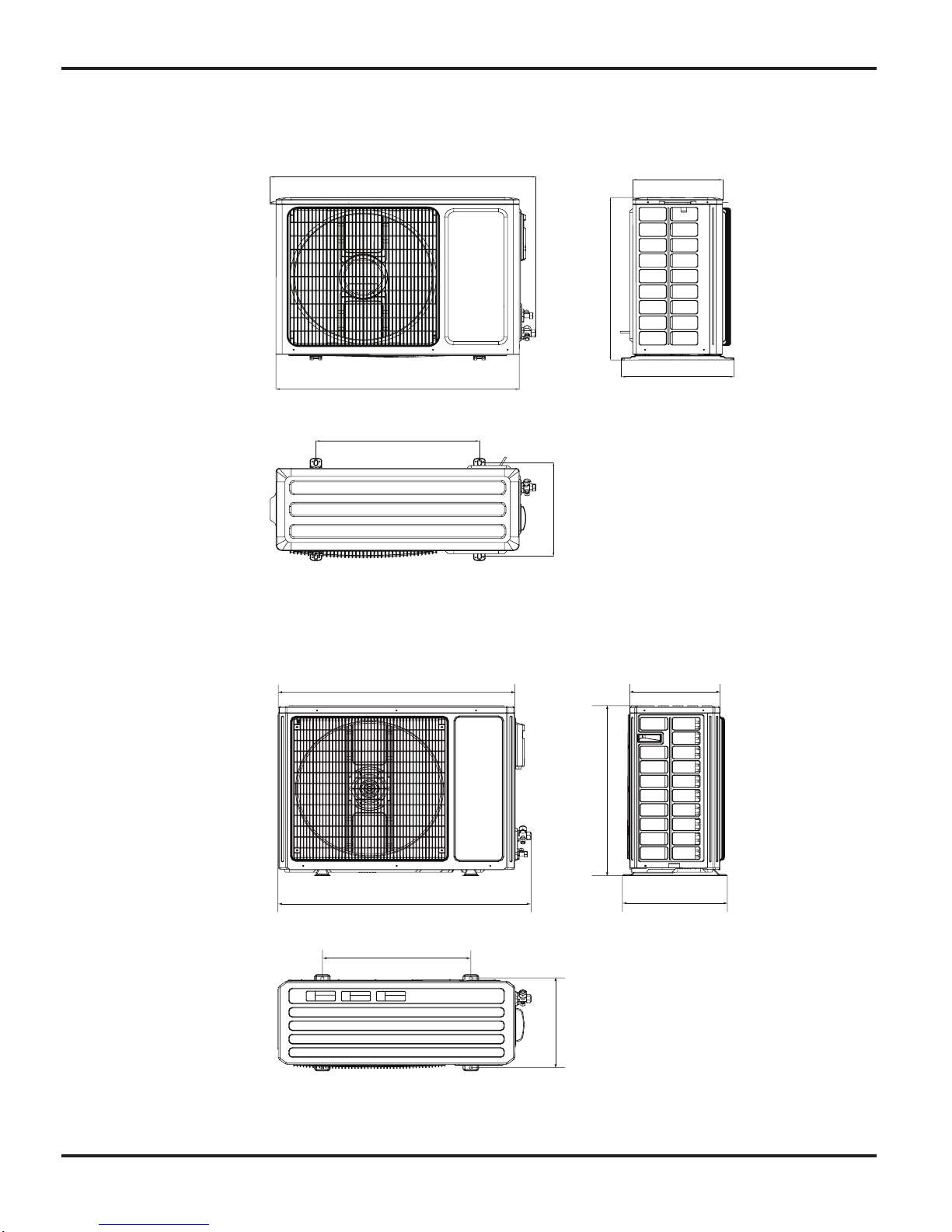

Constrction Views

11

3.2 Outdoor Unit

18K

24K

955

560

043 798

396

3 6 4

7 0 0

899

818

695

378

303

343

550

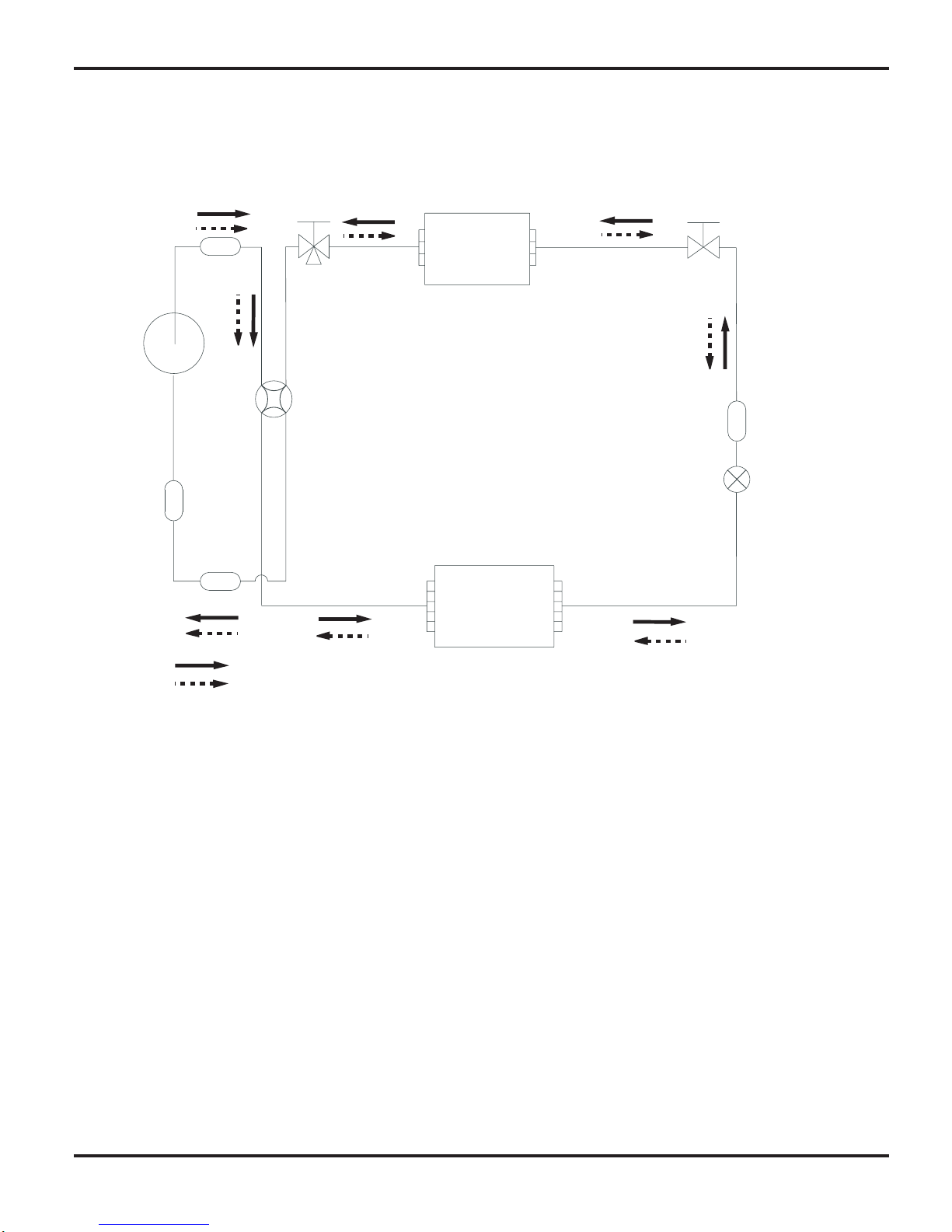

Refrigerant System Diagram

12

4. Refrigerant System Diagram

Refrigerant pipe diameter

Liquid :1/4" (6 mm)

Gas : 1/2" (12mm)

2-Way

valve

Strainer

Strainer

3-Way

valve

Muffler

4-Way valve

Capillary

Heat exchanger

( INDOOR )

Heat exchanger

( OUTDOOR )

rotalumucca-buS

rosserpmoC

Cooling

Heating

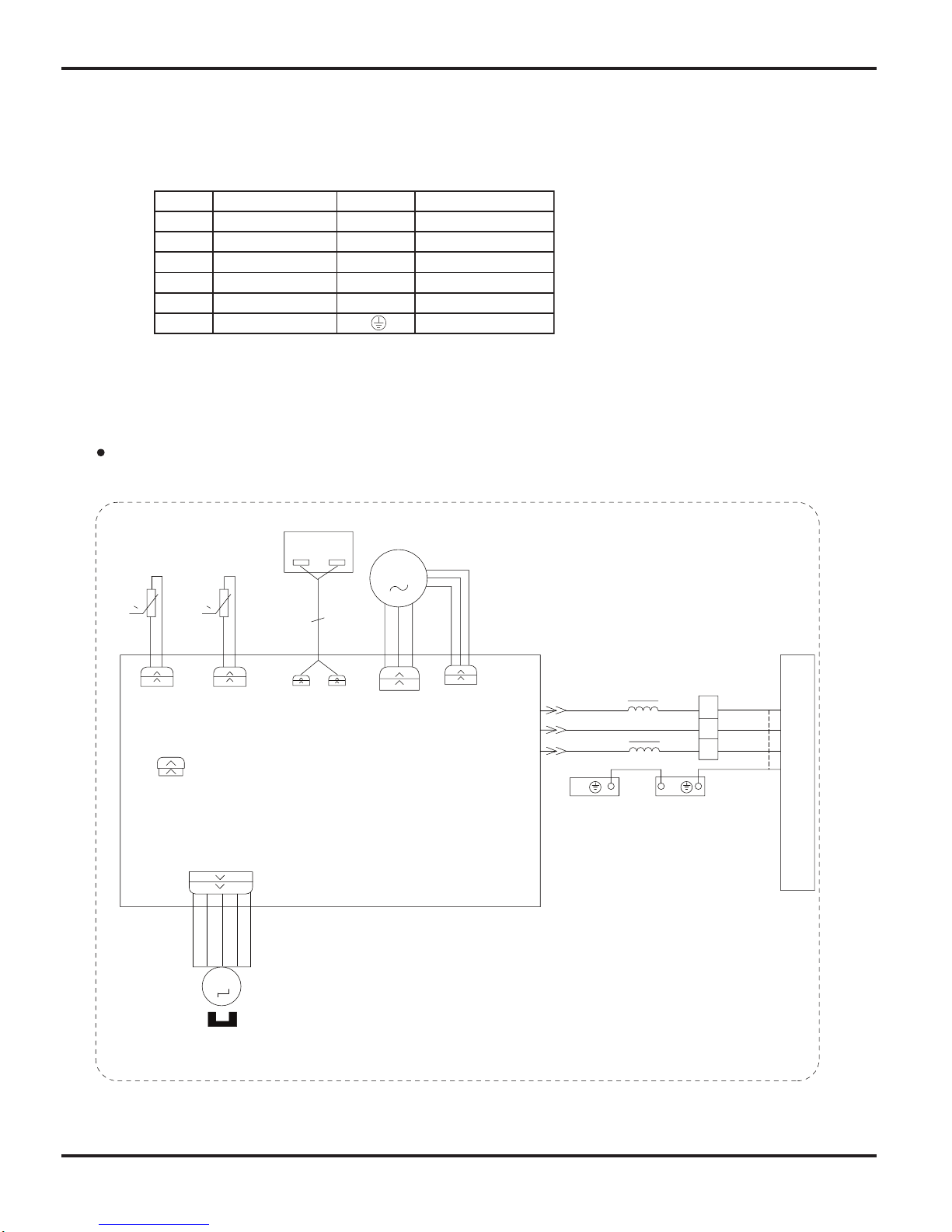

Schematic Diagram

13

5.1 Electrical Data

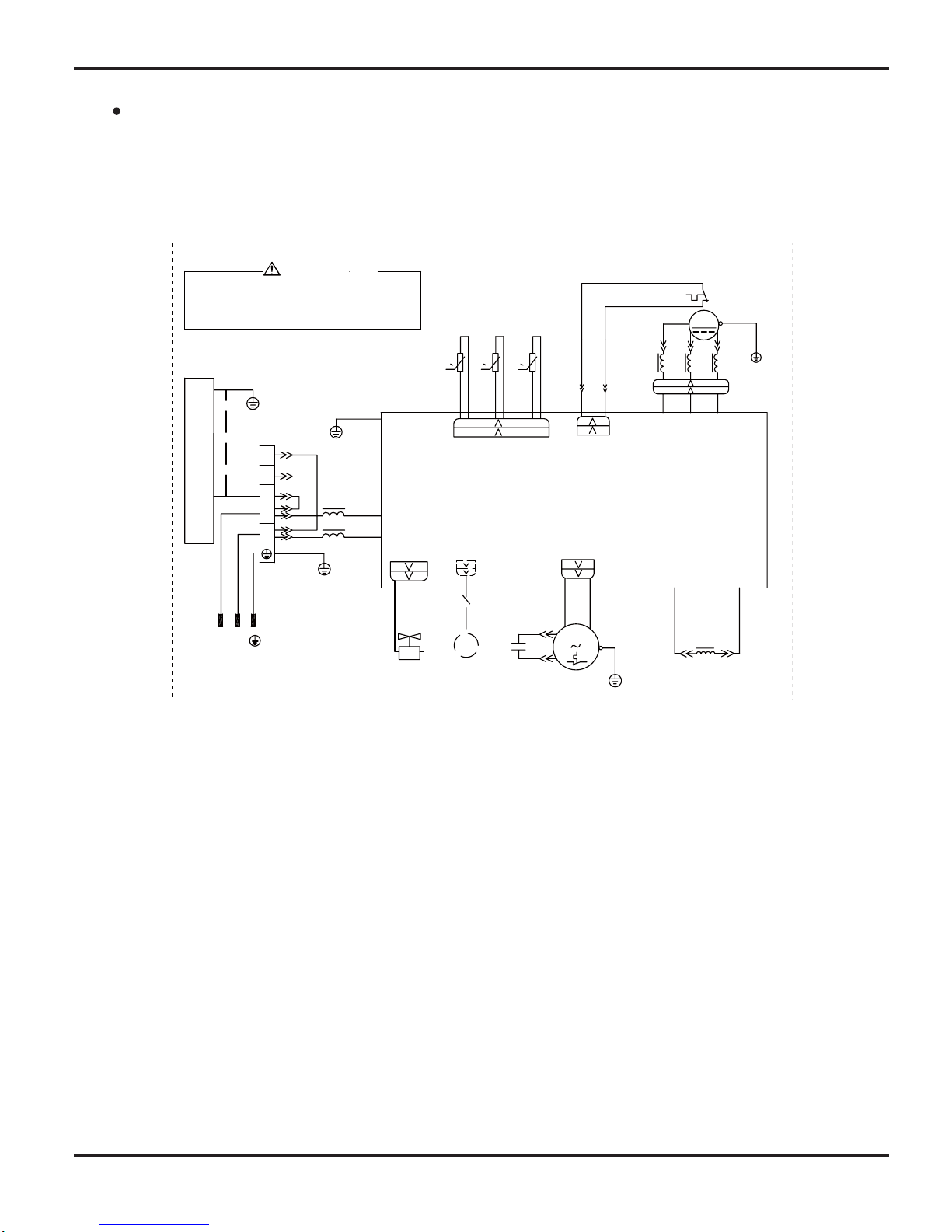

5.2 Electrical Wiring

Indoor unit

5. Schematic Diagram

Symbol Color symbol Symbol Color symbol

Symbol Parts name

BU BLUE

BN BROWN

YE YELLOW

BK BLACK

WHITE

RD RED

YEGN WHYELLOW GREEN

VT VIOLET

PROTECTIVE EARTH

OG ORANGE

RT1

PRINTED CIRCUIT BOARD

EARTHING PANEL

EVAPORATOR

YEGN

BN

BK

BU

OUTDOOR UNIT

M2

ROOM

TUBE

AP1

RT2

BK

BN

3

XT

2

N(1)

BU

YEGN

0

AP2

PEPE

M1

CAP

JUMP

DISP2

PGF

PG

TEM.SENSOR

TUBE ROOM

TEM.SENSOR

MOTOR

SWING

0

AC-L

N

COM-OUT

DISP1

DISPLAY

SWING-UD

Schematic Diagram

14

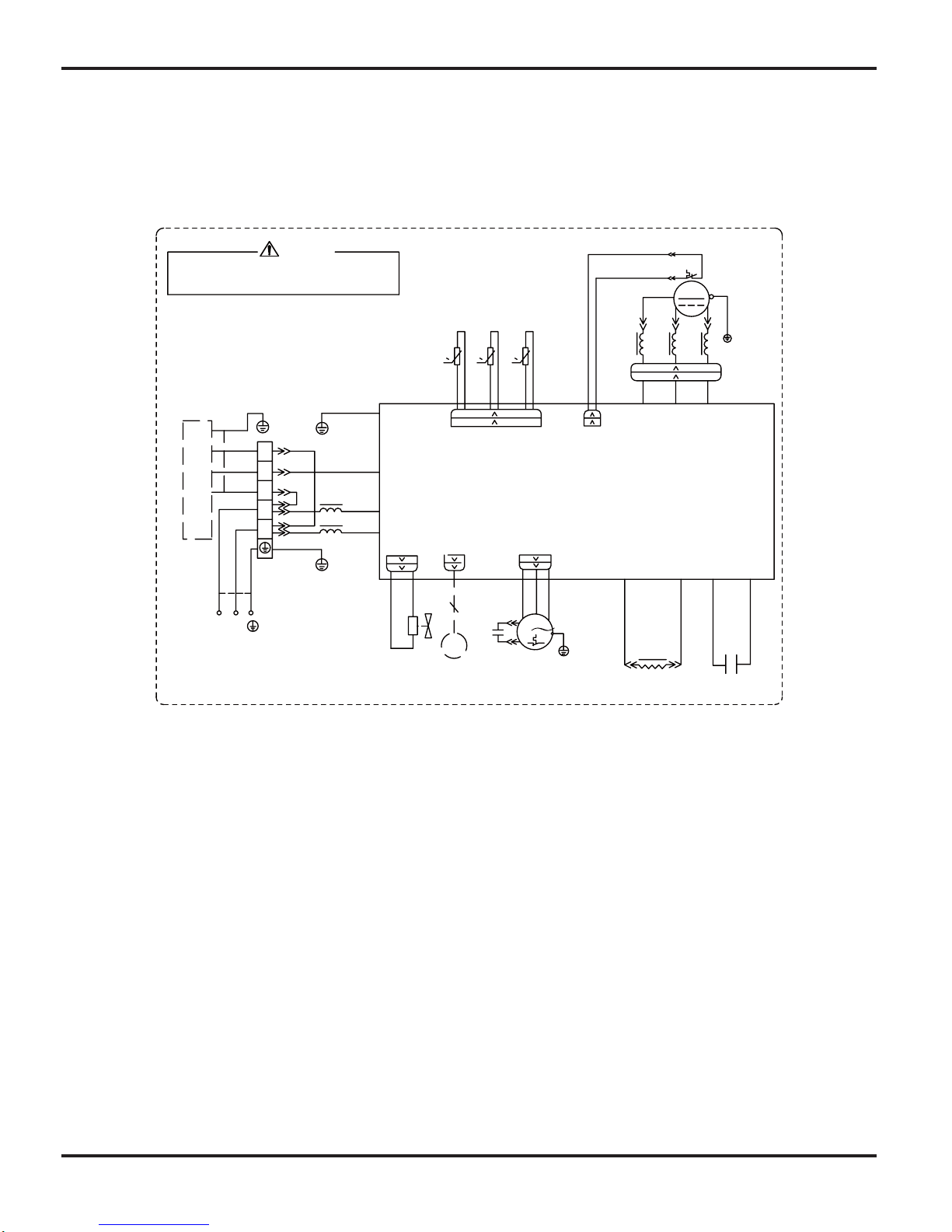

Outdoor unit

INDOOR UNIT

PE

BU

BN

N

L

PE

PE

N(1)

2

3

XT1

BK

BN

BU

YEG N

T- SENSOR

6YEGN

AC-L

N

PE

COMP-W COMP-V COMP-U

YE

BU

RD

U

V

W

PE

PE

COM-INNER

0

RT 1

0

RT 2

RT 3

0

4V

M1

L

INDC1

3RD

WH

PE

OF AN

OVC-COMP

5W H

4W H

SA T

OG

INDC2

COMP

4Y V

X1

CAP .

RD

BN

COMP .

2YE

1BU

WH

BK

TEM.SENSO R

OUTTUBE

OUTROO M

TEM.SENSO R

EXHAUST

TEM.SENSO R

YEG N

PE

FA N MO TO R

TERMINAL

BLOC K

4- WA Y VA LV E

C1

AP1

BU

BK

BN

YEG N

BN

BU

YEG N

EKV

FA

(OPTIONAL)

YEG N

N

L

POWE R

WA RNING

Please don't touch any terminal when the aircondition is

running or during the 15 minutes after the aircondition

stops to prevent the risk of electrical shock!

C1VO-18

Schematic Diagram

15

T-SENSOR

6YEGN

AC-L

N

14YEGN

10BU

PE

9BN

11BK

AP1

XT

3

2

N(1)

COMP-U

16BU

15YE

17RD

U

V

W

E

PE

PE

COM-INNER

0

RT1

0

RT2

RT3

0

4V

L

INDC1

1YE

2BU 3RD

12WH

OVC-COMP

5WH

4WH

SAT

13OG

INDC2

COMP

TEM.SENSOR

EXHAUST

TEM.SENSOR

OUTROOM

TEM.SENSOR

OUTTUBE

INDOOR UNIT

FA

EKV

PE

L

N

8BN

7BU

PE

PFCC2

19YE

18YE

PFCC1

C2

X1

20YEGN

COMP-V COMP-W

BU

BK

BN

YEGN

BN

BU

YEGN

(optional)

YEGN

C

RD

BN

FAN MOTOR

OFAN

PE

4YV

POWER

WARNING

Please don't touch any terminal when the voltage of

terminal P(DC+) and N(DC-) at AP1 is higher than 30V

to prevent the risk of electrical shock!

L

N

M

C1VO-24

Schematic Diagram

16

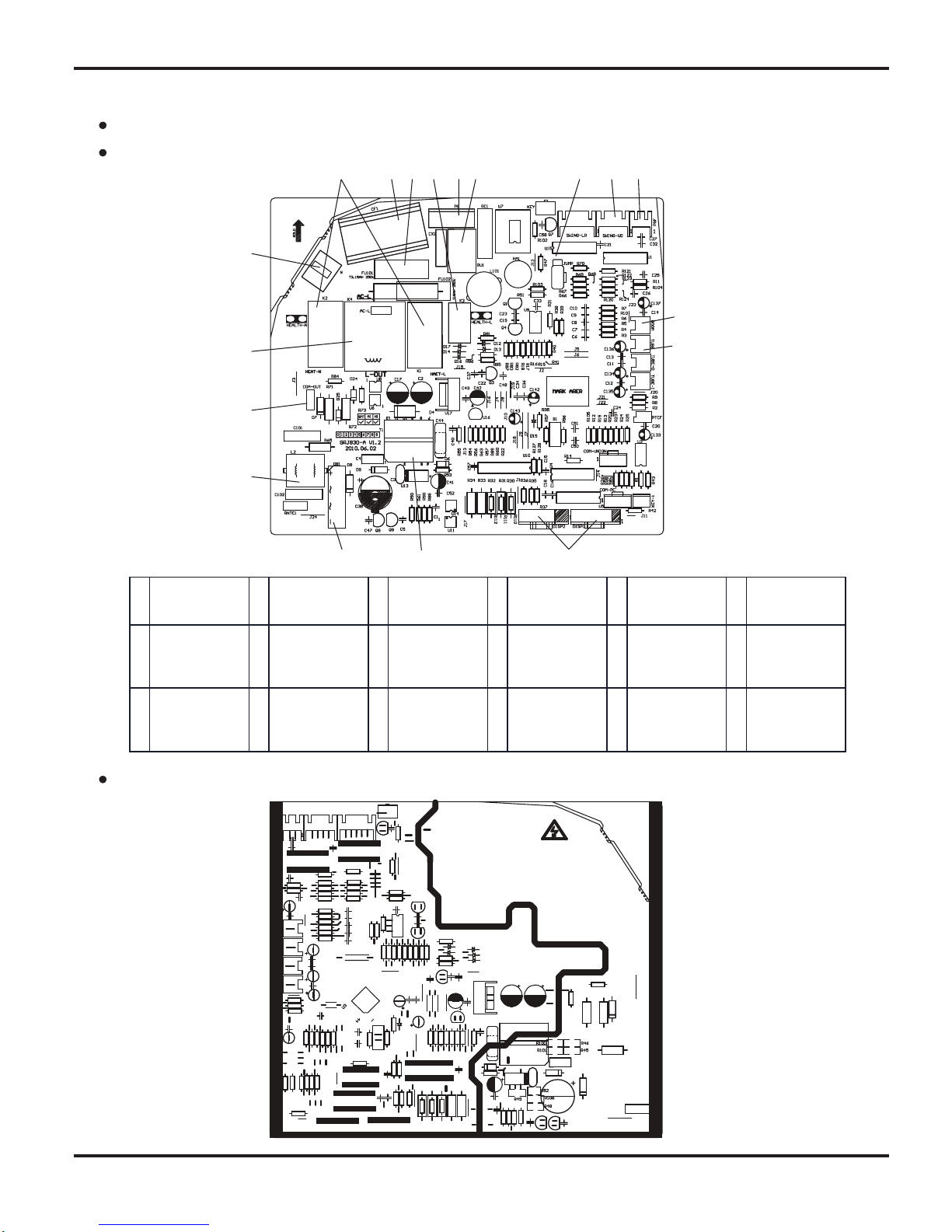

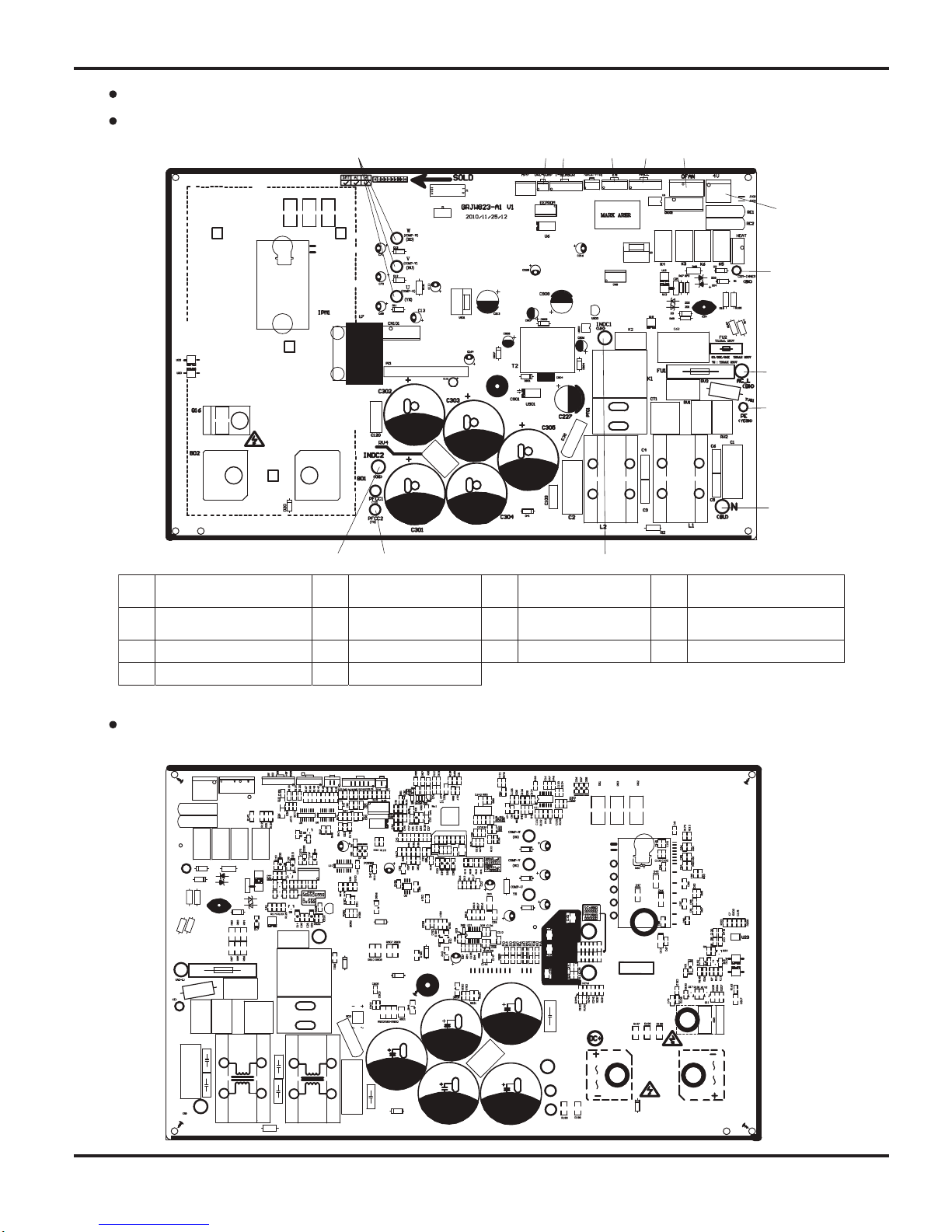

5.3 Printed Circuit Board

TOP VIEW

BOTTOM VIEW

Indoor unit

1

Copper pin

terminal of

neutral wire

2

Auxiliary heating

relay K1, K2

3 Fan capacitor 4 Protective tube 5 Health relay K3 6 PG motor terminal

7 Piezoresistor 8 Jumper cap 9

Up&down swing

terminal

10

PG feedback

terminal

11

Terminal of

ambient

temperature

sensor

12

Terminal of tube

temperature

sensor

13

Connect display

board

DISP1,DISP2

terminals

14

High-frequency

transformer T1

15 Rectifier DB1 16

Strainer

SF2022A-05220

17

Connect copper

terminal of

communication

line for indoor fan

1

8

Supply power for

control relay K4

of outdoor fan

1

2 3 4 5 6 7 8 9

10

11

12

13

1415

16

17

18

Schematic Diagram

17

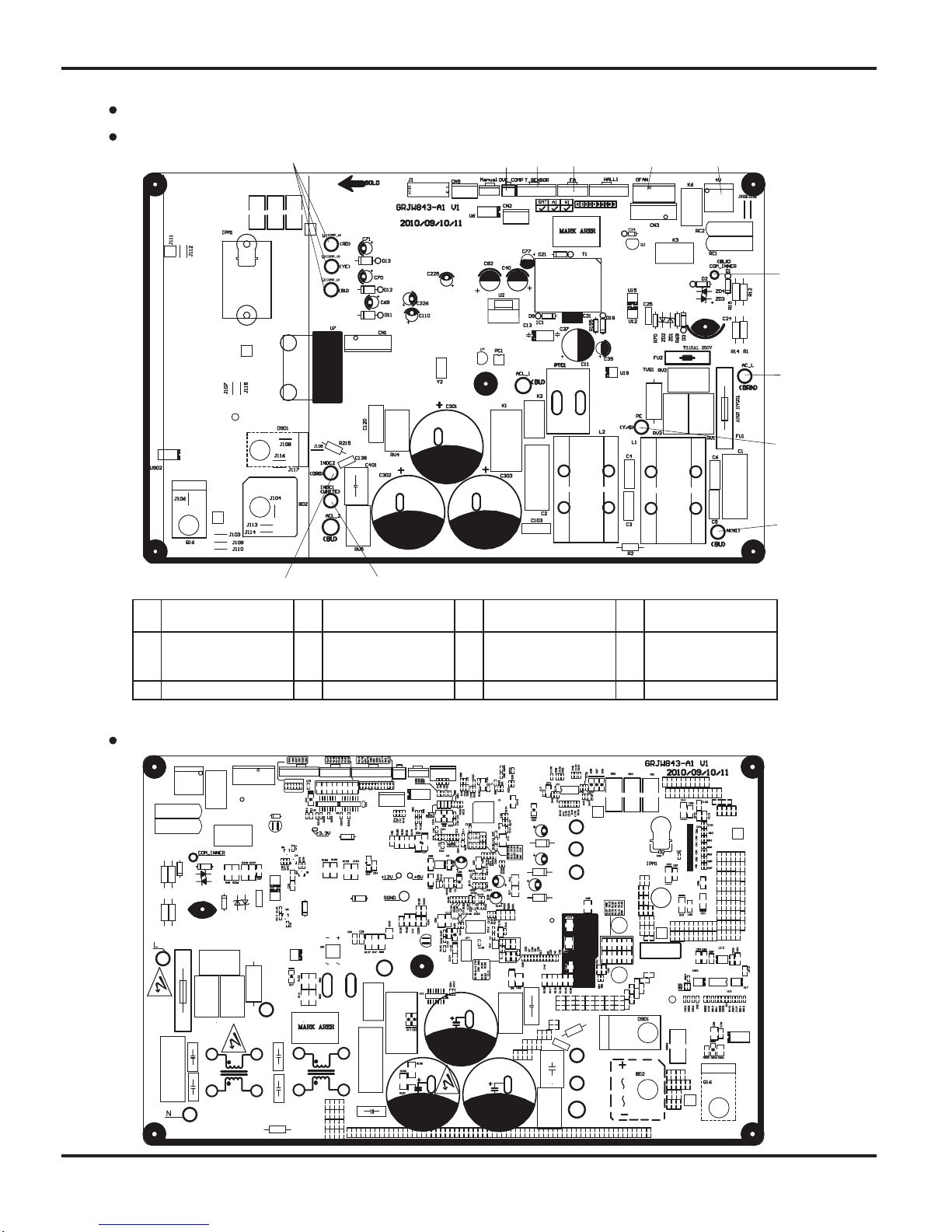

TOP VIEW

BOTTOM VIEW

Outdoor unit(18k)

1

2 3 4

5

6

7

8

9

10

11

12

1 Compressor interface 2

Compressor

overloadprotector

3 Temperature sensor 4

Electric expansion

valve

5

Outdoor fan 6 4-way

valve

6 4-way valve 7

Communication

interface with indoor

unit

8 Live wire

9 Neutral wire 10 Earthing wire 11 Reactor interface 12 Reactor interface 2

Schematic Diagram

18

1

2 3 4 5 6

7

8

9

10

11

13 2141

1 Compressor interface 2

Compressor overload

protector

3 Temperature sensor 4 Electric expansion valve

5 Fan HALL interface 6 Outdoor fan 7 4-way valve 8

Communication interface

with indoor unit

9 Live wire 10 Earthing wire 11 Neutral wire 12 Reactor interface 1

13 PFC capacitor interface 1 14 Reactor interface 2

TOP VIEW

BOTTOM VIEW

Outdoor unit(24k)

Function and Control

19

6. Function and Control

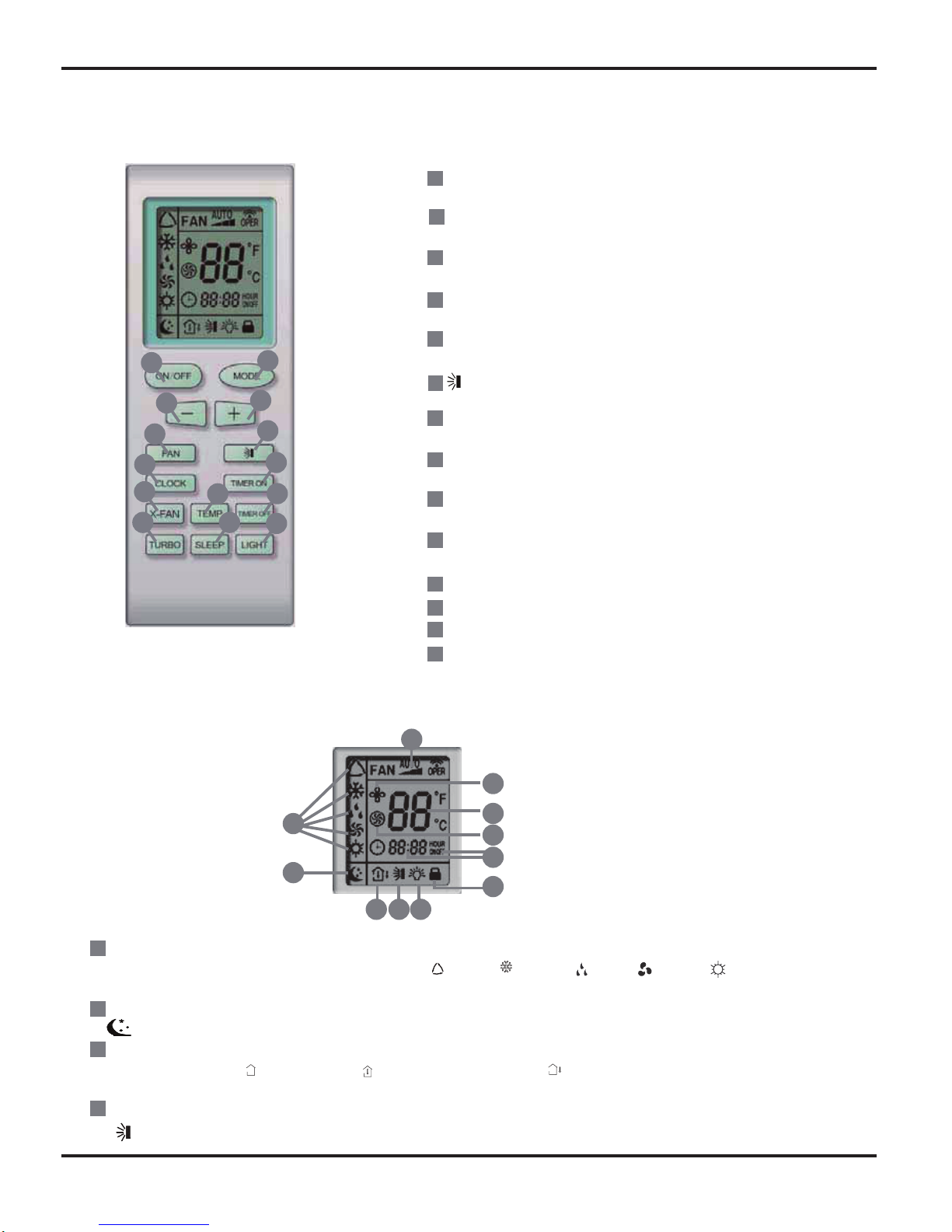

6.1 Remote Control Operations

1

7

8

4

3

5

6

11

13

12

16

17

18

10

14

9

15

2

2

8

9

10

3

4

11

12

7

6

13

14

5

1

ON/OFF

Press it to start or stop operation.

MODE

Press it to select operation mode (AUTO/COOL/DRY/FAN/HEAT).

+

Press it to increase temperature setting.

-

Press it to decrease temperature setting.

FAN

Press it to set fan speed.

Press it to set swing angle.

TIMER ON

Press it to set auto-on timer.

TIMER OFF

Press it to set auto-off timer.

CLOCK

Press it to set clock.

(X-FAN is the alternative expression of BLOW for the

purpose of understanding.)

X-FAN

TEMP

TURBO

SLEEP

LIGHT

Press it to turn on/off the light.

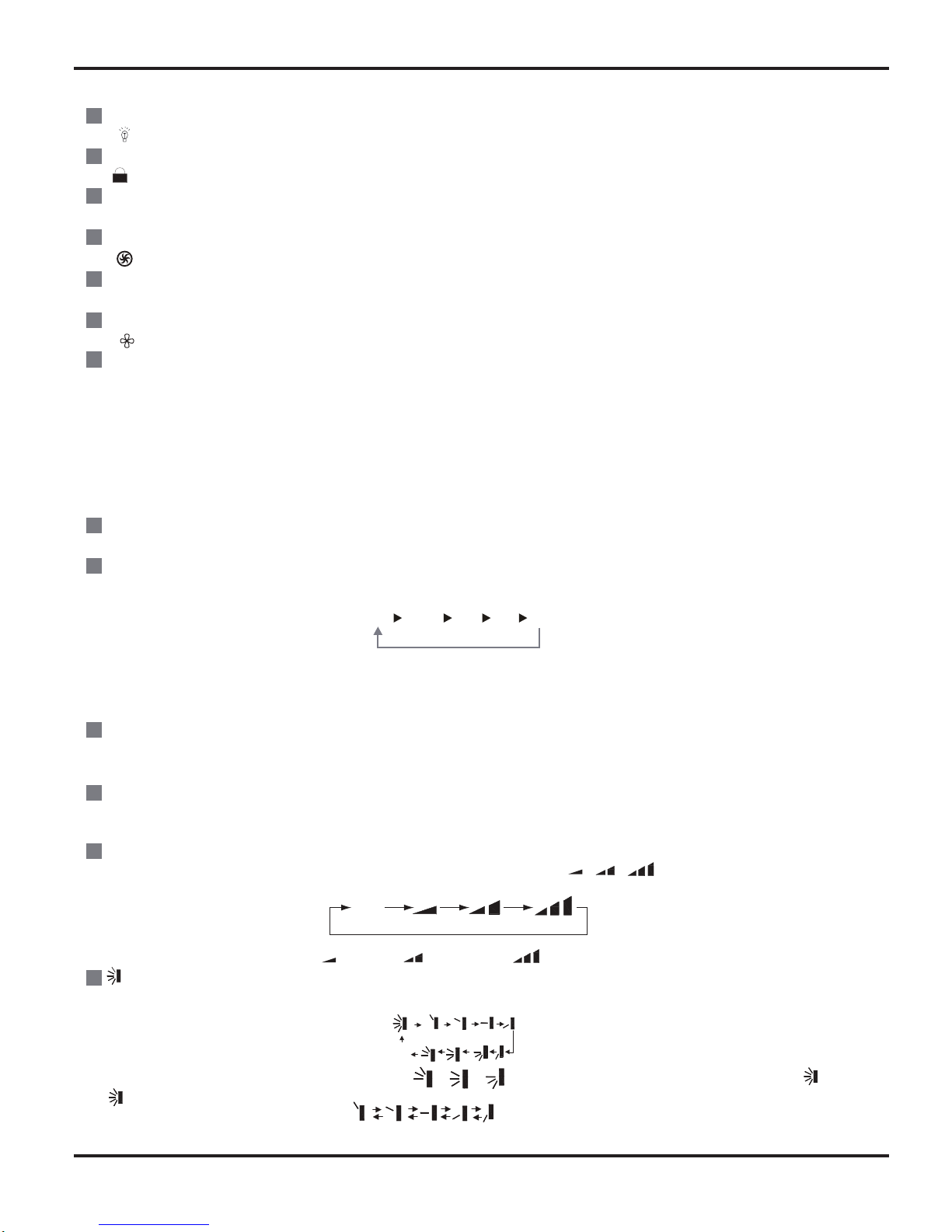

171518 19

16

20

21

23

24

22

25

MODE icon:

If MODE button is pressed, current operation mode icon (AUTO), ( COOL), (DRY), (FAN) or (HEAT is only for heat

pump models) will show.

SLEEP icon :

is displayed by pressing the SLEEP button. Press this button again to clear the display.

TEMP icon:

Pressing TEMP button, (set temperature), (indoor ambient temperature), (outdoor ambient temperature) and blank is

displayed circularly.

Up & down swing icon:

is displayed when pressing the up & down swing button. Press this button again to clear the display.

Function and Control

20

20

21

22

23

24

25

1

2

3

4

5

6

19

LIGHT icon:

is displayed by pressing the LIGHT button.Press LIGHT button again to clear the display.

LOCK icon:

is displayed by pressing "+" and “-” buttons simultaneously.Press them again to clear the display.

SET TIME display:

After pressing TIMER button, ON or OFF will blink.This area will show the set time.

TURBO icon:

is displayed when pressing theTURBO button.Press this button again to clear the display.

DIGITAL display:

This area will show the set temperature. In SAVE mode,"SE" will be displayed. During defrosting operation, “H1” will be displayed.

X-FAN icon:

is displayed when pressing the X-FAN button. Press this button again to clear the display.

FAN SPEED display:

Press FAN button to select the desired fan speed setting(AUTO Low-Med-High).Your selection will be displayed in the LCD windows,

except the AUTO fan speed.

ON/OFF:

Press this button to turn on the unit. Press this button again to turn off the unit.

MODE:

Each time you press this button,a mode is selected in a sequence that goes from AUTO, COOL,DRY, FAN, and HEAT *, as the

following:

*Note: Only for models with heating function.

After energization, AUTO mode is defaulted. In AUTO mode, the set temperature will not be displayed on the LCD, and the unit will

automatically select the suitable operation mode in accordance with the room temperature to make indoor room comfortable.

+ :

Press this button to increase set temperature. Hold it down for above 2 seconds to rapidly increase set temperature. In AUTO mode,

set temperature is not adjustable.

-:

Press this button to decrease set temperature. Hold it down for above . 2 seconds to rapidly decrease set temperature. In AUTO

mode, set temperature is not adjustable.

FAN :

This button is used for setting fan speed in the sequence that goes from AUTO, , , to then back to Auto.

Press this button to set up & down swing angle, which circularly changes as below:

This remote controller is universal. If any command , or is sent out, the unit will carry out the command as

indicates the guide louver swings as:

AUTO

COOL DRY FAN HEAT*AUTO

Low speed Medium speed High speed

OFF

Remote Controller Description

Function and Control

21

8

9

10

11

12

13

14

15

16

7

TIMER ON:

Press this button to initiate the auto-ON timer. To cancel the auto-timer program, simply press this button again. After pressing this

button, disappears and "ON" blinks . 0 0:00 is displayed for ON time setting. Within 5 seconds, press + or - button to adjust the

time value. Every press of either button changes the time setting by 1 minute. Holding down either button rapidly changes the time

setting by 1 minute and then 10 minutes. Within 5 seconds after setting, press TIMER ON button to confirm.

TIMER OFF:

Press this button to initiate the auto-off timer. To cancel the auto-timer program, simply press the button again.TIMER OFF setting is

the same as TIMER ON.

CLOCK :

Pressing CLOCK button, blinks. Within 5 seconds, pressing + or - button adjusts the present time. Holding down either button

above 2 seconds increases or decreases the time by 1 minute every 0.5 second and then by 10 minutes every 0.5 second. During

blinking after setting, press CLOCK button again to confirm the setting, and then will be constantly displayed.

X-FAN:

Pressing X -FAN button in COOL or DRY mode,the icon is displayed and the indoor fan will continue operation for 10 minutes in

order to dry the indoor unit even though you have turned off the unit.

After energization, X-FAN OFF is defaulted. X-FAN is not available in AUTO, FAN or HEAT mode.

TEMP:

Press this button, could select displaying the indoor setting temperature or indoor ambient temperature.When the indoor unit firstly

power on it will display the setting temperature, if the temperature's displaying status is changed from other status to" ",displays

the ambient temperature, 5s later or within 5s, it receives other remote control signal that will return to display the setting temperature. if the users haven't set up the temperature displaying status,that will display the setting temperature.

TURBO:

Press this button to activate / deactivate the Turbo function which enables the unit to reach the preset temperature in the shortest

time. In COOL mode, the unit will blow strong cooling air at super high fan speed. In HEAT mode, the unit will blow strong heating air

at super high fan speed.

SLEEP:

Press this button to go into the SLEEP operation mode. Press it again to cancel this function. This function is available in COOL,

HEAT (Only for models with heating function) or DRY mode to maintain the most comfortable temperature for you.

LIGHT:

Press LIGHT button to turn on the display's light and press this button again to turn off the display's light. If the light is turned on ,

is displayed. If the light is tunrned off, disappears.

Combination of "+" and "-" buttons: About lock

Press "+ " and "-" buttons simultaneously to lock or unlock the keypad. If the remote controller is locked, is displayed. In this

case, pressing any button, blinks three times.

Combination of "MODE" and "-" buttons:About switch between Fahrenheit and Centigrade At unit OFF, press "MODE" and "- "

buttons simultaneously to switch between

and .

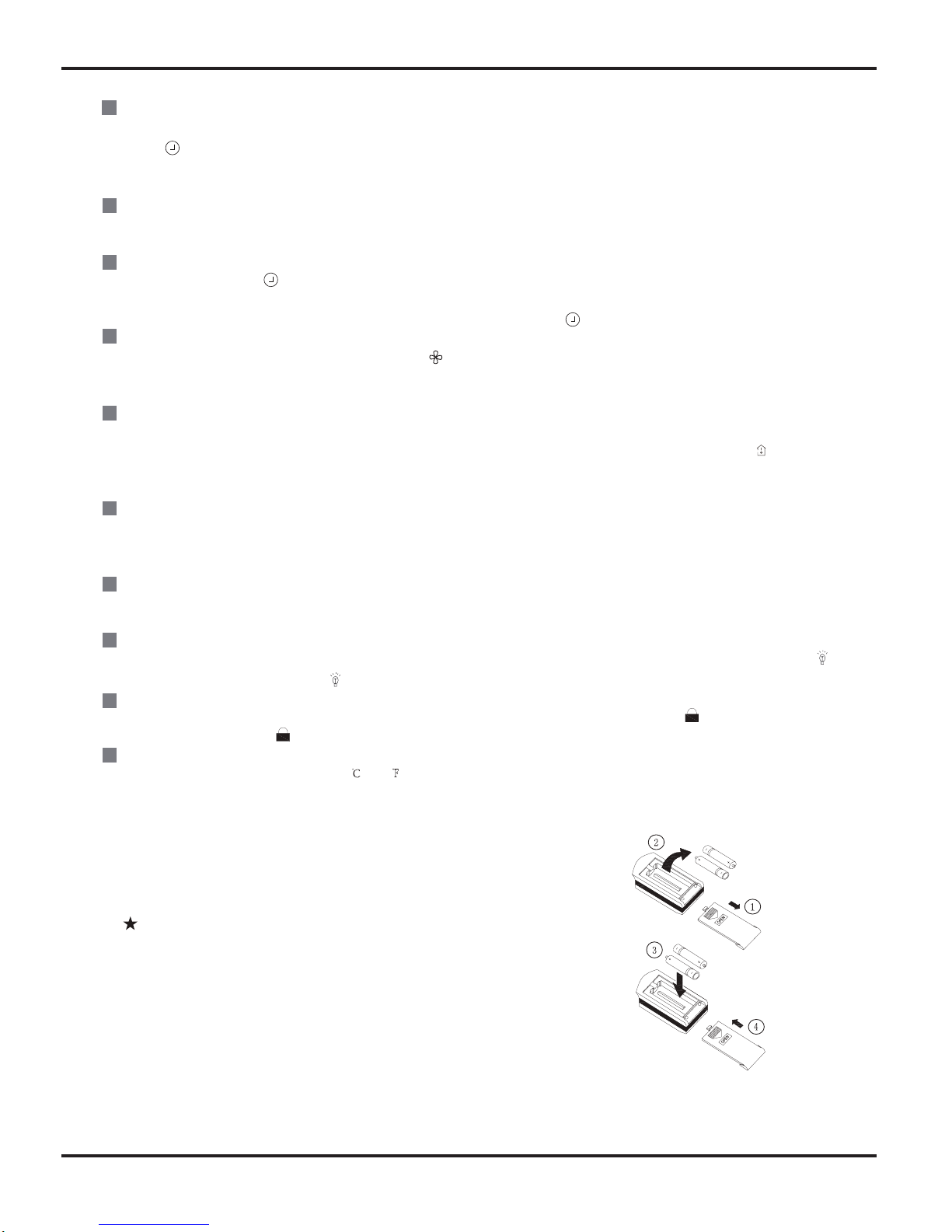

Replacement of Batteries

1.Remove the battery cover plate from the rear of the remote controller.

(As shown in the figure)

2.Take out the old batteries.

3.Insert two new AAA1.5V dry batteries, and pay attention to the polarity.

4. Reinstall the battery cover plate.

Notes:

●When replacing the batteries, do not use old or different types of batteries.

Otherwise, it may cause malfunction.

●If the remote controller will not be used for a long time,

please remove batteries to prevent batteries from leaking.

●The operation should be performed in its receiving range.

●It should be kept 1m away from the TV set or stereo sound sets.

●If the remote controller does not operate normally, please take the

batteries out and reinsert them after 30 seconds. If it still can't operate

properly, replace the batteries.

Sketch map for

replacing batteries

Function and Control

22

6.2 Description of Each Control Operation

1.Basic function of system

(1)

Cooling mode

1.Under this mode, fan motor, swing will work under setting status, the temp. range is 16-30

(61-86 Fahrenheit

scale)

2.Outdoor unit malfunction or unit stop running, indoor unit will keep original running status, malfunction displayed.

3.When 0 (Tset-Tamb.), if indoor fan motor is high speed, that the fan motorist running in middle speed, the

middle speed or low speed will be maintained;(this condition should be executed when compressor start up);the super

high speed will not rotate; When (Tamb-Tset) , the fan will return to the setting fan speed.

(2)Dehumidifying mode

1.Under this mode, fan motor will run at low speed, swing will work at setting status, setting temp. range is 16-30

(61-86 Fahrenheit scale)

2.Outdoor unit malfunction or protection, unit will stop, indoor unit will keep original running status, malfunction

displayed.

(3)Fan mode

Under this mode, indoor fan motor could be setted at high speed, middle speed, low or auto speed, compressor,

outdoor unit and four-way valve will stop to run.

Under this mode, temp. range should be 16-30 (61-86 Fahrenheit scale)

(4)Heating mode

1.Under this mode, temp. range should be 16-30 (61-86 Fahrenheit scale)

2.Working condition

and procedure of heating mode: When unit turn on and enter into Heating mode, indoor unit

enter into anti-cool wind mode, when unit is stop running, and indoor fan motor turns on, blowing heat will act.

3.Protection function, under heating mode, compressor will stop to run due to malfunction happened, indoor fan

motor will blow surplus heat.

4.Defrosting control: When receiving the defrosting signal from outdoor unit, displayer will display H1, 10s later,

indoor fan motor will stop to run.

5.Anti-coold wind function

6.Blow heat air function

a.If heating temp. meets the compressor stop running condition, compressors, outdoor fan motor will stop to run,

the upper and lower guide louver will rotate to horizontal position L, indoor fan motor run at setting fan speed

for 60s, then the indoor fan motor will stop to run.

b.Dueto PG motor block running, the air guide board will keep the position when it

stopping. (under each mode),

other malfunction unit will stop to run, the upper and lower air guide louver will rotate to horizontal position

L, indoor fan unit will run at setting fan speed and run for 60s, indoor fan unit will stop to run.

(5)Auto mode:

1.When Tam

26 , select the cooling mode, at this time, the setting temp. is 25 .(77 Fahrenheit scale)

2.Cooling and heating units: Tamb 22

,will runat heating mode, at this time, the setting temp. is 20

3. Cooling only unit: When Tamb 22 , it will run at Fan mode, the setting temp. is 25 (77 Fahrenheit scale)

4.When 23 Tindoor amb. 25 ,firstly enter into auto mode and run at auto fan speed, other modes will

run at auto mode, will keep the previous running mode. (When entering into Dehumidifying mode, it will run at

auto fan speed)

(6)Auto fan speed control mode

(68Fahrenheit scale)

6.2.1 Functions of Indoor Unit

Function and Control

23

2. Display state of indoor indicators

(1) State of indoor display board

1. When the unit is powered on, all patterns will be displayed and then only power indicator is on. When the unit is turned on

with a remote controller, the operating indicator is on and operation mode which is set currently is displayed.

2. In defrosting mode, "H1" is displayed on "Double 8".

3. Set temperature is displayed on "Double 8".

Display of operation patterns and mode patterns

When the unit is powered on, all patterns will be displayed and the standby operation indicator will become red. When the unit

is turned on through a remote controller, the operation indicator is light. At the same time, operating mode patterns (mode

indicators include cooling, heating and dehumidification modes) set currently are displayed, and dynamic display patterns of

wind speed are displayed. If the light button is switched off, all display will be turned off.

Temperature display control mode of separated air conditioner

1. When user sets the remote controller at set temperature display, currently set temperature will be displayed.

2. Only when remote signals are converted from other display states into indoor ambient temperature display state, the

remote controller will display indoor ambient temperature for 5 seconds and then return to set temperature display.

3. Only when remote signals are converted from other display states into outdoor ambient temperature display state, the

remote controller

will display outdoor ambient temperature for 5 seconds and then return to set temperature display.

4. If the controller is lack of outdoor display functions, as the signal is received, set temperature will be displayed.

5. When the unit is turned off, temperature display will be compulsively set at given temperature by the controller. When the

unit is turned on, patterns as set by remote signals will be displayed.

6. If user does not set up temperature display state, given temperature will be displayed.

(2) Failure display of indoor unit

1. Requirements for failure display

When multiple failures appear at the same time, failure protection codes shall be displayed alternatively.

(1) Hardware failures shall be displayed immediately, referring to requirements in "Failure State Display Table";

(2) Operation states shall be displayed immediately, referring to requirements in "Failure State Display Table";

(3) Other failures shall be displayed 200s after the compressor stops, referring to requirements in "Failure State Display Table".

(Note: in

the case that the unit is switched off with the remote controller, or the compressor is switched on again, failure

display waiting time (200s) shall be cleared.)

(4) Frequency limitation and reduction states shall be displayed by means of remote calling.

3. Failure display control

Indicator failure display shall be kept synchronous with Double 8 failure display, that is, during indicator blinking, failure code

corresponding to such indicator shall be displayed on Double 8.

4. Method of remote calling of failure display

Entering the failure remote calling mode: push the light button four times within 3s to call out relevant failure protection code;

Quit the failure remote calling mode: push the light button four times within 3s or call out failure display to enter it for 5 minutes

and then quit.

3. Other control targets

(1) Up and down wind blow functions: model of stepping motor is MP28EA.

When the unit is powered on, the up and down wind blow motor will turn a wind deflector anti-clockwise to Position 0 to shut

down the air outlet. When the unit is switched on and wind blow function is not preset, under the heating mode, up and down

wind blades will turn clockwise to position D; and under other modes, the up and down wind blades will turn clockwise to

position L. If wind blow function is set at the same time as the unit is switched on, the wind blades will swing between position

L and D. The wind blades can be kept in seven states: position L, position A, position B, position C, position D, swing between

position L and D, stop at one position from L to D. When the unit is turned off, the wind deflector will be closed up to position 0.

Wind blow action is effective only when wind blow commands are set and the indoor unit is running.

Note: When the wind blades are set at position L to B, position A to C, or position B to D through

remote setting,

the wind deflector will swing between position L and D. L—A—B—C—D.

(2) Buzzer

When the controller is powered on, signals from a remote controller are received, or the auto button

is pushed, a buzzer will give out prompt tone.

(3) Auto button

When the button is pushed, the unit will operate in auto mode and the indoor fan will run in auto state. When the indoor fan is

running, the wind blow motor will work. When the button is pushed again, the unit will be switched off. At the same time as the

button is pushed, the whole unit will be powered on and enter into fast test mode; when the unit is powered on and detects for

continuous 20s (such time shall not be fast tested) that the auto button is pushed, and if the unit is currently at fast test state,

the unit will quit the fast test state.

Function and Control

24

(4) Sleep function

This mode is effective only in cooling and heating modes. Proper sleep curves shall be selected for operation according to

preset temperature.

In cooling mode:

(1) When initial temperature is set at 16-23 , an increase of 1 will be gained every hour after the sleep function is activated.

After 3 is raised, the temperature will be maintained. After operation for 7 hours, temperature will go down by 1 ,

afterwards, the unit will operate at such temperature.

(2) When initial temperature is set at 24-27 , an increase of 1 will be gained every hour after the sleep function is activated.

A

fter 2 is raised, the temperature will be maintained. After operation for 7 hours, temperature will go down by 1 ,

afterwards, the unit will operate at such temperature.

(3) When initial temperature is set at 28-29 , an increase of 1 will be gained every hour after the sleep function is activated.

fter 1 is raised, the temperature will be maintained. After operation for 7 hours, temperature will go down by 1 ,

afterwards, the unit will operate at such temperature.

In heating mode:

(1) When initial temperature is set at 16 , the unit will operate at such temperature.

(2) When initial temperature is set at 17-20 , a decrease of 1 will be gained every hour after the sleep function is

activated. After 1 is reduced, the temperature will be maintained.

(3) When initial temperature is set at 21-27 , a decrease of 1 will be gained every hour after the sleep function is

activated. After 2 is reduced, the temperature will be maintained.

(4)

When initial temperature is set at 28-30 , a decrease of 1 will be gained every hour after the sleep function is

activated. After 3 is reduced, the temperature will be maintained.

(5) Timing function

The main board integrates general timing and moment timing. Such two timing functions can be selected through a remote

controller on which different functions are arranged.

1

General timing:

Timing start: timing start can be set when the unit is off. When preset time is reached, the controller will operate in a preset

mode. Timing can be set at an interval of 0.5 hour in a scope of 0.5 - 24 hours.

Timing stop: timing stop can be set when the unit is on. When preset time is reached, the system will be turned off. Timing

can be set at an interval of 0.5 hour in a scope of 0.5 - 24 hours.

2

Moment timing

Timing start: if timing start is set when the system is at operation state, the system will continue to operate; if timing start is set

when the system is at stop, as the preset time is reached, the system will start to run in preset mode.

Timing stop: if timing stop is set when the system is at stop state, the system will keep standby; if timing stop is set when the

system is in operation, as the preset time is reached, the system will stop running.

Timing change:

When the system is in timing mode, start and stop can be set through the On/Off button on the remote controller; or timing

time can be reset and the system will operate according to the latest setting.

When the system is in operation and both timing start and stop are set, the system will stay at currently set operation state.

When preset timing stop time is reached, the system will stop working.

When the

system is at stop state and both timing start and stop are set, the system will keep at stop state. When preset timing

start time is reached, the system will start operation.

From then on, the system will operate in preset mode at a preset start time and stop at a preset stop time everyday. If timing

stop time is set as the same as timing start time, a stop command will be executed.

(6) Dry and mildew proof function

Dry and mildew proof function can be set in cooling and dehumidification modes.

(7) Control of indoor fan

Indoor fan can be set at four levels, super-high, high, middle and low, with a remote controller. When one level is set, the fan

will thus operate at such level. The fan can also be set at auto state.

(8) Power off Memory Function

What will be memorized includes modes, up and down wind blow, light, preset temperature, preset wind speed, general timing

(no memory for moment timing), and Fahrenheit /Celsius degree. When the unit is powered on again after power failure,

operation continues according to memorized content. If timing is not set by the last remote control command, the system will

memorize the last remote control command and operate in the mode specified in the last remote control command. If timing is

set by the last remote control command and power failure happens before the preset time, the system, as powered on again,

will memorize the timing function set by the last remote control command. Timing will be re-counted from the time at which the

system is powered again. If timing is set by the last remote control command and timing of start or stop is reached before

power failure, the system, as powered on again, will memorize operation state before power failure and will not perform timing

action. Moment timing is out the range of memor

y.

Function and Control

25

(9) Locked Protection of PG Motor

When starting up the fans, if the motor has run at a lower speed continuously for a period, for preventing

automatic protection of the motor, stop running, and display the locked operation; if the machine is running at

present, the code of the locked fault---H6 of double-eight digital tubes will be displayed; if the machine is shut

down at present, the information of the locked fault will not be displayed.

(10) Super Power Function

In cooling and heating modes (automatic, dehumidifying and air-supplying modes are without strong power),

press the button of Super Power, the wind speed on the remote controller is displayed as super-high air flow, and

the inner fans are also turned to super-high air flow;

(11) Health Function

When the inner fans are running, the remote controller is set at the Health function at this time (if there is no

Health button on the remote controller, the Health On order is defaulted), then start the Health function device.

5. Fault Detection of Temperature Sensor

(1) Indoor Environment Temperature Sensor:

Detect the fault of thermo-bulb at any time;

(2) Indoor Pipe Temperature Temperature Sensor:

During the defrosting period, the fault of the thermo-bulb will be not detected, which shall be detected in 5

minutes after defrosting is completed; the fault of the thermo-bulb will be detected at other times;

(3) Protecting Treatments of Temperature Sensor:

1.When

the thermo-bulb is detected to be short-circuited continuously for 30 seconds:

It is

regarded that the temperature detected by the thermo-bulb is over-high (or unlimited), then the whole

machine will exert corresponding safety stops according to the over-high temperature sensed by the thermo-bulb,

and display corresponding temperature safety stops and faults of the thermo-bulb simultaneously.

2. When the thermo-bulb is detected in open circuit continuously for 30 seconds: stop the machine in protection,

directly display corresponding faults of the thermo-bulb.

6. Forced Running Function of the Inner Units

(1) Enter into Forced Running Control

Within 5 minutes after power-up, press the Lights Off button on the remote controller continuously for three

times within 3 seconds to enter into the fluorine collecting mode, and display Fo, send the fluorine-collecting

mode for 25 minutes continuously, each load will be treated as cooling when starting the machine (set the air flow

as High, set the temperature as 16

).

(2) Exit from the Forced Running Control

After receiving any remote signal, or signal of keys, the fluorine-collecting mode will exit, and operate in

accordance with the current orders set; or exit the fluorine-collecting mode after running for 25 minutes, and the

machine will be shut down automatically.

(It is refrigerants reclaiming function which is used for the condition that refrigerants cannot be reclaimed by

cooling operation in the season with low temperature.)

Function and Control

26

1. Input Parameter Compensation

(1) Input parameter compensation function

A

s the structure feature of split unit, concerning the comfort, in heating mode, when compressor stops, the indoor ambient

temperature is higher than preset temperature for 3 .

2. Check parameters to effectively make judgment and control

Insert the outdoor discharge temp sensor into corresponding temp sensor jacket of discharge pipe in order to protect safe and

reliable operation of the unit, so that the control system can accurately detect the discharge temp as well as effectively control

and protect it. Otherwise, the unit will stop and display the trouble of “outdoor discharge temp sensor failure ( not be inserted

correctly)” which can be recovered by pressing ON/OFF button.

3. Cooling Mode

3.1 Conditions and processes of cooling operation:

3.1.1 If the compressor stops, and [Tpreset – (Tindoor ambient – ΔTcooling indoor ambient temperature compensation)] ≤0.5 ,

start up the unit for cooling operation;

3.1.2 During cooling operation, if 0

≤ [Tpreset – (Tindoor ambient –ΔTcooling indoor ambient temperature compensation)]< 2 ,

keep the cooling operation;

3.1.3 During cooling operation, if 2

≤ [Tpreset – (Tindoor ambient –ΔTcooling indoor ambient temperature compensation)], the

cooling operation will stop after reaching to the setting temperature.

3.2 Temperature setting range

3.2.1 If Toutdoor ambient ≥ [Tlow-temperature cooling], the temperature can be set at: 16~30

(Cooling at roomemperature);

3.2.2 If Toutdoor ambient < [Tlow-temperature cooling], the temperature can be set at: 25~30

(Cooling at low temperature),

that is, the minimum setting temperature to be judged by outdoor unit is 25

.

4. Dry Mode

4.1 Conditions and processes of dry operation: same as the cooling mode;

4.2 The temperature setting range is: 16~30

;

5. Fan Mode

5.1 The compressor, outdoor fan and four-way valve are switched off;

5.2 The temperature setting range is: 16~30

.

6. Heating Mode

6.1. Conditions and processes of heating operation: (Tindoor ambient is the actual detection temperature of indoor

environment temp sensor, ΔTheating indoor ambient temperature compensation is the indoor ambient temperature compensation

during heating operation)

6.1.1 If the compressor stops, and [(Tindoor ambient –ΔTheating indoor ambient temperature compensation) –Tpreset]≤ 0.5

,

start the unit to enter into heating operation;

6.1.2 During heating operation, if 0

≤ [(Tindoor ambient –ΔTheating indoor ambient temperature compensation)–Tpreset] < 2 ,

keep the heating operation;

6.1.3 During heating operation, if 2

≤ [(Tindoor ambient –ΔTheating indoor ambient temperature compensation)–Tpreset], the

heating operation will stop after reaching the setting temperature.

6.2 The temperature setting range in this mode is: 16~30

.

7. Defrosting Control (heating)

7.1 After the time for defrosting is judged to be satisfied, if the temperature for defrosting is satisfied for continuous 3minutes, the

defrosting operation will start.

7.2 Start defrosting: Compressor stops and starts up 55S later;

7.3 Finish of Defrosting: Compressor stops and starts up 55S later;

7.4 The defrosting operation can exit when any of the conditions below is satisfied:

7.4.1 Toutdoor pipe≥ 12

;

7.4.2 Toutdoor ambient

-5 , and the Toutdoor pipe≥ 6 last more than 80S;

7.4.3The continuous running time of defrosting reaches.

8. Compressor Control

8.1. The frequency of compressor will be controlled according to the relationship of ambient temperature and preset temperature

as well as changing speed of ambient temperature;

8.2 Start the compressor after starting cooling, heating, dry operation, and the outdoor fan for 5s;

8.3 When the unit is off, in safety stops and switching to fan mode, the compressor will stop immediately;

8.4 In all modes: once the compressor starts up, it will not be allowed to stop within 7 min. (Note: except the cases that require

stop of the compressor such as fault protection, remote shutdown, mode switching etc.);

6.2.2 Functions of Outdoor Unit

Function and Control

27

8.5 In all modes: once the compressor stops, it can’t restart within 3-minute (Note: The indoor units with memory function can be

restarted after remote shutdown and powering on again without delay).

9. Outdoor Fan Control

9.1 When the unit is off by remote control in safety stops or stops after reaching the setting temperature, 1min later,the outdoor

fan will stop;

9.2 In fan mode: The outdoor fan stops;

9.3 Start of defrosting: Outdoor fan will stop after compressor stops for 50S;

9.4 Finish of defrosting: Outdoor fan will start up when the compressor stops.

10. 4-way valve control

10.1 The 4-way valve is off under the modes of Cooling, dry and fan;

10.2 In heating mode, the 4-way valve is energized;

10.3 When the unit is off in heating mode or heating mode shifts to other modes, the 4-way valve will be de-energized after

compressor stops for 2min;

10.4. After protection stops, the 4-way valve will be de-energized after 4min;

10.5 Start of defrosting: when entering defrosting mode, 4-way valve will be de-energized after the compressor stops for 50s;

10.6 Finish of defrosting: The 4-way valve will be energized after the compressor stops for 50s.

11. Anti-freezing protection

11.1 In cooling and dry mode, if Tindoor pipe 0 is detected for 3min continuously, the unit will stop; if 6 Tindoor pipe, and

compressor has stopped for 3min, the unit will resume running;

11.2 In cooling and dry mode, if Tindoor pipe

6 , running frequency of compressor will be decreased or stop increasing;

11.3 If the unit stops as anti-freezing protection for 6 times, it can not resume running automatically and display trouble code, it

can resume by pressing ON/OFF button. During operation, if the compressor operates for over 10min, the times of anti-freezing

protection stop will be cleared to zero. When the unit is off/ fan/ heating mode, the malfunction and malfunction times will be

cleared to zero. (If the malfunction can not be removed)

12. Overload protection

12.1 In cooling and dry mode: if 65 ≤Toutdoor pipe, the unit will stop; if Toutdoor pipe 55 , and compressor has stopped for

3min, the unit will resume running;

12.2 In cooling and dry mode: if 55

≤Toutdoor pipe, running frequency of compressor will be decreased or stop increasing;

12.3 In heating mode: if 64

≤Tindoor pipe, the unit will stop; if Tindoor pipe 54 , and compressor has stopped for 3min, the

unit will resume running;

12.4 In heating mode: if 54

≤Tindoor pipe, running frequency of compressor will be decreased or stop increasing;

12.5 If the unit stops as overload protection for 6 times, it can not resume running automatically and display malfunction. It can

resume running by pressing ON/OFF.During operation, if the compressor has operated for over 10 min, the times of overload

protection stop will be cleared to zero. When the unit is off or in Fan mode or shifts to heating mode, the malfunction and

malfunction times will be cleared to zero immediately. (If the malfunction can not be removed)

13. Compressor discharge temperature protection

13.1 If 115 ≤Tdischarge, the unit will stop; if Tdischarge 97 , and compressor has stopped for 3min, the unit will resume

running;

13.2 If 97

≤Tdischarge, running frequency of compressor will be decreased or stop increasing;

13.3 If the unit stops as protection of compressor discharge temperature for 6 times, it can not resume running

automatically and malfunction will be displayed. It can resume running by pressing ON/OFF. During operation, if the compressor

has operated for over 10min, the time of compressor discharge temperature stop will be cleared to zero.When the unit is off/

shifts to fan mode, the malfunction and malfunction times will be cleared. (If the malfunction can not be removed)

14. Current protection

14.1. If 12A≤I alternating-current, running frequency of compressor will be decreased or stop increasing;

14.2. If 17A≤I alternating-current, the unit will stop; and after compressor has stopped for 3min, the unit will resume running;

14.3 If the unit stops as protection for compressor discharge temperature for 6 times, it can not resume running automatically

and malfunction will be displayed. It can resume by pressing ON/OFF button. During operation, if the compressor has operated

for over 10 min, the time of compressor discharge temperature stop will be cleared to zero.

15. Drop off voltage

During compressor operation, the system will stop and malfunction of drop off voltage will occur if voltage downward fluctuates

rapidly, and it will re-start up automatically 3min later.

Function and Control

28

16. Communication malfunction

If the unit does not receive correct signal from indoor unit for 3min continuously, the unit will stop as communication malfunction

protection; if communication malfunction has removed and compressor has stopped for 3min, the unit will resume running.

17. IPM module protection

When the compressor starts, if there is overcurrent or low control voltage for IPM module due to some abnormal results, IPM will

detect module protection signal as the unit is on. Once the module protective signal is detected, stop the unit with module

protection immediately. If the module protection is removed and compressor has stopped for 3min, the unit will be allowed to

operate.If the module protection continuously occurs for three times, it can not be removed automatically, and you should press

the ON/OFF button to resume operation. If the running time of compressor exceeds 10 min, the module protection times will be

cleared.

18. Module overheating protection

18.1 If 80 ≤Tmodule, running frequency of compressor will be decreased or stop increasing;

18.2.If 95

≤Tmodule, the unit will stop; if Tmodule 87 , and compressor has stopped for 3min, the unit will resume running;

18.3 If the unit stops as module overheating protection occurs for 6 times, it can not resume running automatically and

malfunction will be displayed, it can resume by pressing ON/OFF. During operation, if the time exceeds compressor running time,

the time of module overheating protection stop will be cleared. When the unit is off or shifts to fan mode,the malfunction and

malfunction times will be cleared. (If the malfunction can not be removed).

19 Compressor overload protection

19.1 If detect that the overload switch breaks within continuous 3S, the system will stop as protection;

19.2 If detect that the protection has removed and the compressor has stopped for 3min, the unit will be allowed to operate.

19.3 If the unit stops as compressor overload protection occurred for 3 times continuously, it can not resume running

automatically and malfunction will be displayed.

It can resume operation by pressing ON/OFF button; and the times of compressor overload protection will be cleared after the

compressor has run for 30min.

Installation Manual

29

7. Installation Manual

7.1 Notices for Installation

Caution

1.The unit should be installed only by authorized service center according to local or government regulations and in compliance with

this manual.

2.Before installing, please contact with local authorized maintenance center. If the unit isnot installed by the authorized service center,

the malfunction may not be solved due to incovenient contact between the user and the service personnel.

3.When removing the unit to the other place, please firstly contact with the local authorized service center.

4.Warning: Before obtaining access to terminals, all supply circuits must be disconnected.

5.For appliances with type Y attachment, the instructions shall contain the substance of the following. If the supply cord is damaged,

it must be replaced by the manufacturer, its service agent or similarly qualified persons in order to avoid a hazard.

6.The appliance must be positioned so that the plug is accessible.

7.The temperature of refrigerant line will be high; please keep the interconnection cable away from the copper tube.

8.The instructions shall state the substance of the following:

This appliance is not intended for use by persons(including children)with reduced physical, sensory or mental capabilities, or lack

of experience and knowledge, unless they have been given supervision or instruction concerning use of the

appliance by a person

responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

7.1.1 Installation Site Instructions

Proper installation site is vital for correct and efficient operation of the unit. Avoid the following sites where:

strong heat sources, vapours, flammable gas or volatile liquids are emitted.

high-frequency electro-magnetic waves are generated by radio equipment,welders and medical equipment.

salt-laden air prevails (such as close to coastal areas).

the air is contaminated with industrial vapours and oils.

the air contains sulphures gas such as in hot spring zones.

corrosion or poor air quality exists.

7.1.2 Installation Site of Indoor Unit

1.The air inlet and outlet should be away from the obstructions. Ensure the air can be blown through the whole room.

2.Select a site where the condensate can be easily drained out, and where it is easily connected to outdoor unit.

3.Select a place where it is out of reach of children.

4.Select a place where the wall is strong enough to withstand the full weight and vibration of the unit.

5.Be sure to leave enough space to allow access for routine maintenance. The installation site should be 250cm or more above the

floor.

6.Select a place about 1m or more away from TV set or any other electric appliance.

7.Select a place where the filter can be easily taken out.

8.Make sure that the indoor unit is installed in accordance with installation dimension instructions.

9.Do not use the unit in the laundry or by swimming pool etc.

Installation Manual

30

7.1.3

Installation Site of Outdoor Unit

1.Select a site where n oise and outflow air emitted by the unit w ill not annoy neighbors.

2.Select a site where t here is sufficient ventilation .

3.Select a site where there is no obstruction blocking the inlet and outlet .

4 .The site s hould be able to withstand t he f ull weight and v ibration.

5.Select a dry place, but do not expose the unit to direct sunlight or strong wind.

6.Make sure that the outdoor unit is i nstalled in a ccordance with the installation instructions, a nd is convenient for m aintena nc e

and r epair .

7.The height difference between indoor and outdoor units is within 10 m, and the length of the connecting tubing does not exceed

30 m.

8.Select a place where it is out of reach of children.

9.Select a place where t he unit does not have

negative impact on p edestrians or on t he city .

7.1.4 Safety Precautions for Electric Appliances

1.A dedicated power supply circuit s hould be used in a ccordance with local e lectrical safety r egulations.

2.Don't drag the power cord with excessive force .

3.The unit s hould be r eliably earthed and c onnected to an e xclusive earth device by t he professionals .

4 .The air s witch m ust have the f unctions of magnetic tripping and heat tripping to prevent s hort circuit and overload.

5 .The minimum distance between the unit and combustive s urface is 1.5m .

6 .The appliance shall be installed in a ccordance with national wiring regulations .

7.An all-pole disconnection switch with a contact

separation of at least 3 mm in all poles s hould be connected in fixed wiring.

Note:

Make sure the live wire, neutral wire and earth wire in the family power socket are properly connected.

There should be reliable circuit in the diagram.Inadequate or incorrect electrical connections may cause electric s hock or f ire .

7.1.5 Earthing Requirements

1.Air conditioner is type I electric appliance. P lease ensure that t he unit is reliably earthed.

2.The y ellow-green wire in air c onditioner is t he earthing wire which can not be used for other purposes. Improper earthing ma y

cause e lectric shock.

3.The earth resistance should a ccord to the national criterion .

4 .The power must have r eliable earthing terminal. P lease do not connect t he earthing wire with the following:

Water pipe Gas pipe Contamination pipe Other place t hat professional personnel c onsider is unreliable

5. T he model a nd rated values of fuses should a ccord with the silk print on fuse cover or related PCB.

Installation Manual

31

7.2 Installation Dimension Diagram

Space to the wall

Space to the ceiling

Space to the wall

Space to the wall

Air outlet side

Space to the floor

Above

Above

15cm Above

15cm Above

30cm Above

50cm Above

50cm Above

30cm Above

30cm Above

30cm Above

15cm

Above

300

cm

250

cm

Space to the obstruction

Air outlet side

Space to the wall

Air inlet side

The dimensions of the space necessary for proper

installation of the unit includ e the minimum

permissible distances to adjacent parts .

S chematic diagram being reference only (outdoor unit is with variation ) ,

p lease refer to real product for authentic information.

Installation Manual

32

7.3 Install Indoor Unit

1.Mounting plate should be installed horizontally. As the water tray's oulet for the indoor unit is two-way type, during

installation, the indoor unit should slightly slant to water tray's outlet for smooth drainage of condensate.

2.Fix the m ounting plate on the wall with s crews .

3.Be sure that the mounting plate has been fixed firmly enough to withstand about 60 kg. Meanwhile, the weight should

be evenly shared by each screw.

7.3.1 Installingof Mounting Plate

7.3.2 Boring Piping Hole

1.Slant the piping hole ( 55) on the wall slightly downward to the outdoor side.

1. Connect the drain hose to the outlet pipe of the indoor unit.Bind the joint

with rubber belt.

2 .Insert t he p iping-hole s leeve into the hole to prevent t he connection piping and wirin g

from being damaged when passing through t he hole .

7.3.3 Installing of Drain Hose

7.3.4 Connecting Indoor and Outdoor Electric Wire s

1 .Open the front panel .

2.Remove the wiring cover, c onnect and fix power connection

cord to the terminal board shown in Fig 2.

3.Make the power

connection cord pass through the hole at the

back of indoor unit.

4.Reinstall t he cord anchorage and wiring cover.

5.Reinstall the front panel .

55

Indoor

Outdoor

W all pipe

Seal pad

Unit mm

Above 150 from

the celling

Above 150 from

the wall

A

bove 150 from

the wall

Ф

Ф

Above 150 from

the celling

Above 150 from

the wall

Above 150 from

the wall

2.Put the drain hose into insulating tube .

3.Wrap the insulating tube with wide rubber belt to prevent the shift of insulating

tube. Slant the drain hose downward slightly for smooth drainage of condensate.

Note: The insulating tube shoud be connected reliably with the sleeve outside

the outlet pipe. The drain hose should be slanted downward slightly,without distortion, bulge or fluctuation. Do not put the outlet in the water .

bulge

distortio n

outlet pipe of

indoor unit

insulating tube

connecte d

insulating tube

drain hos e

outlet pipe of

indoor uni t

drain hos e

outlet pipe of

indoor uni t

outlet pipe of

indoor unit

rubber belt

rubber bel t

rubber belt

Flooded

Fig. 2

Wr ing Cove r

yellow green

brow n

Outdoor unit connection

N(1 )

2

3

45

Φ55

55Φ55Φ

Φ55

Installation Manual

33

NOTE:

All wires between indoor and outdoor units must be connected by the qualified electric contractor.

Electric wires must be connected correctly. Improper connection may cause malfunction.

Tighten the terminal screws securely.

After tightening the screws, pull the wire sligltly to confirm whether it's firm or not.

Make sure that the electric connections are earthed properly to prevent electric shock.

Make sure that all wiring connections are secure and the cover plates are reinstalled properly. Poor installation

may cause fire or electric shock.

7.3.5 Installing of Indoor Unit

The piping can be output from right, right rear, left or left rear.

1.When routing the piping and wiring from the left or right side of indoor unit, cut off the

tailings from the chassis as necessary(As shown in Fig.3)

(1)Cut off the tailing 1 when routing the wiring only;

(2)Cut off the tailing 1 and tailing 2 when routing both the wiring and piping.

2.Take out the piping from body case, wrap the piping, power cords, drain hose with the

tape and then make them pass through the piping hole. (As shown in Fig.4)

3.Hang the mounting slots of the indoor unit on the upper hooks of the mounting plate

and check if it is firm enough.(As shown in Fig.5)

4.The installation site should be 250cm or more above the floor.

7.3.6 Installing of Connection Pipe

1.Align the center of the pipe flare with the related valve.

2.Screw in the flare nut by hand and then tighten the nut with spanner and

torque wrench by referring to the following:

NOTE: Connect the connection pipe to indoor unit at first and then to outdoor unit. Handle pi-ping bending with care. Do

not damage the connection pipe. Ensure that the joint nut is tightened firmly, otherwise, it may cause leakage.

(N·m)

Ф6

Ф 9.52

Ф 12

31 35

15 20

50 55

Ф 16 60 65

Ф 19 70 75

Hex nut diameter

Tightening torque

Fig.5

Mounting

plate

Fixing hook

Mounting

plate

Right

Right rear

Fig.4

Left rear

Left

Fig.3

Tailing 1

Tailing 2

Finally wrap it

with tape

Gas side piping

insulation

Water drainage pipe

Liquid side

Piping insulation

Gas side pipe

External connection

electric wire

Liquid side piping

1.Remove the handle on the right side plate of outdoor unit.

2.Take off wire cord anchorage. Connect and fix power connection cord

and power cord to the terminal board.Wiring should fit that of indoor unit.

3.Fix the power connection cord and power cord with wire clamps and

then connect the corresponding connector.

4.Confirm if the wire has been fixed properly.

5.Reinstall the handle.

7.4.1 Electric Wiring

NOTE:

Incorrect wiring may cause malfunction of spare part.

After the wire has been fixed, ensure there is free space between the connection and fixing places on the lead wire.

Schematic diagram being reference only, please refer to real product for authentic information.

Spanner

Torque

wrench

Piping

Taper nut

Indoor unit piping

Handle

Indoor unit connection

brown

brown

blue

blue black

yellow-green

yellowgreen

N

N

L

L

7.4 Install Outdoor Unit

Installation Manual

34

1. Connect charging hose of manifold valve to charge end of low pressure valve

(both high/low pressure valves must be tightly shut).

2. Connect joint of charging hose to vacuum pump.

3. Fully open the handle of Lo manifold valve.

4. Open the vacuum pump for vacuumization. At the beginning, slightly loosen joint nut

of low pressure valve to check if there is air coming inside. (If noise of vacuum

pump has been changed, the reading of multimeter is 0) Then tighten the nut.

5. Keep vacuuming for more than 15mins and make sure the reading of multimeter is-1.0

10 pa(-76cmHg).

5

6. Fully open high/low pressure valves.

7. Remove charging hose from charging end of low pressure valve.

8. Tighten lid of low pressure valve. (As shown in Fig.6)

7.4.2 Air Purging and Leakage Test

7.4.3 Outdoor Condensate Drainage (only for Heat pump type )

During heating operation, the condensate water and defrosting water should be

drained out reliably through the drain hose. Install the outdoor drain connector in

a

25 hole on the the base plate and attach the drain hose to the connector,so

that the waste water formed in the outdoor unit can be drained out .The hole diameter

25 must be plugged.

Whether to plug other holes will be determined by the dealers according to actual conditions.

Fig.6

Manifold Valve

Multimeter

-76cmHg

Lo Handle