C1VI - 09 / C1VO - 09

C1VI - 12 / C1VO - 12

a

b

e

2

3

3

7

7

8

8

9

10

11

12

12

12

14

16

16

19

24

24

26

27

28

Simply

29

30

31

31

35

39

39

62

59

...............................................43

.46

..........................................................................44

. 59

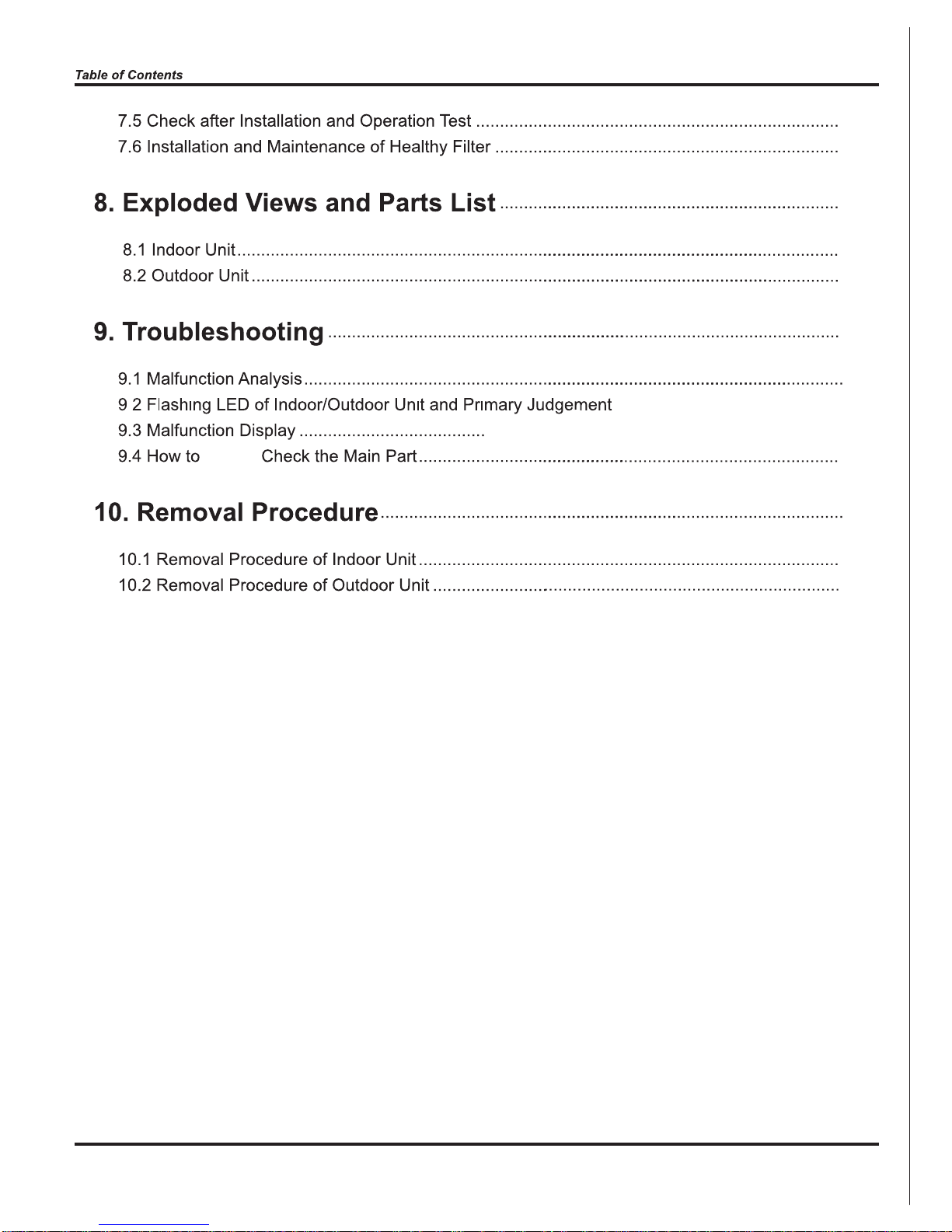

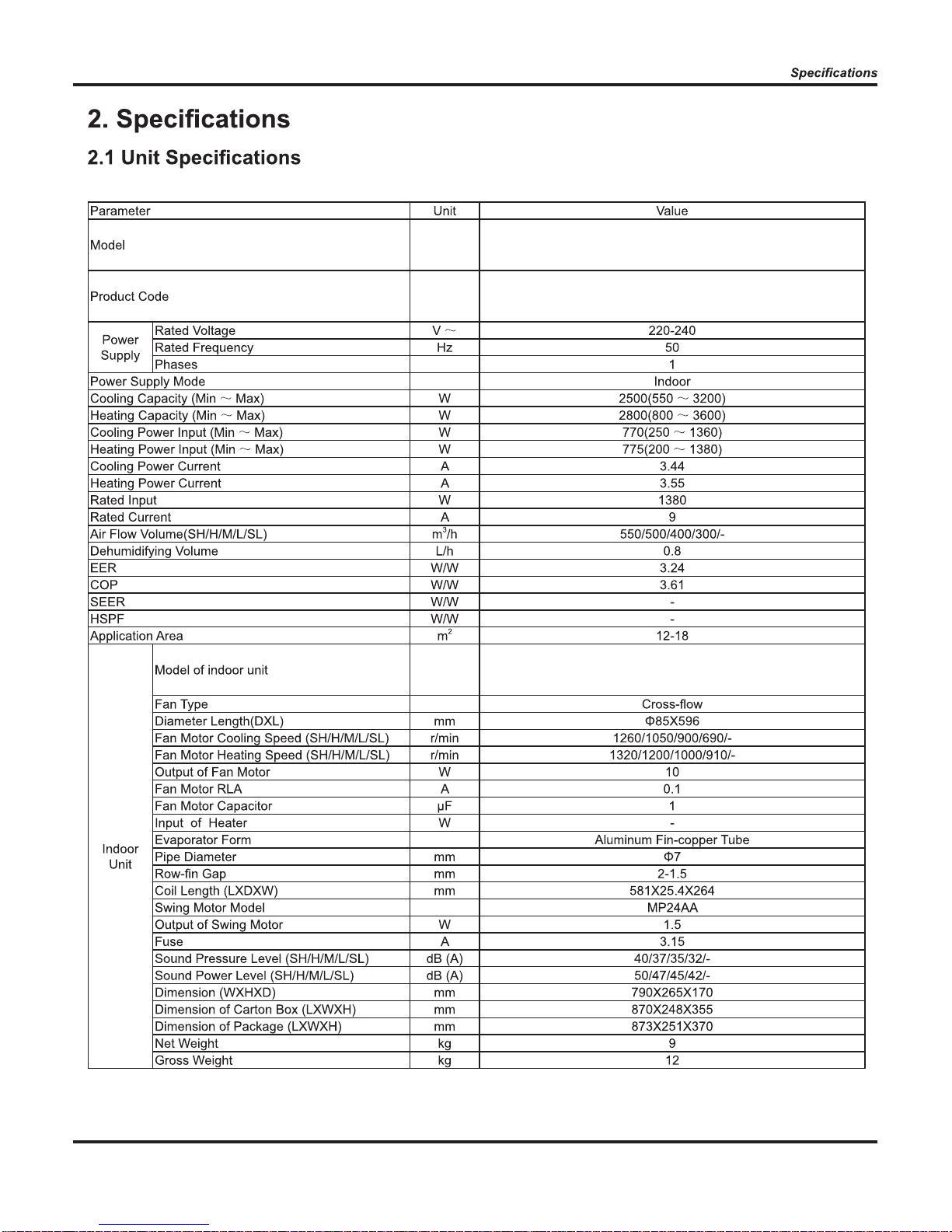

C1VI-09

C1VI-12

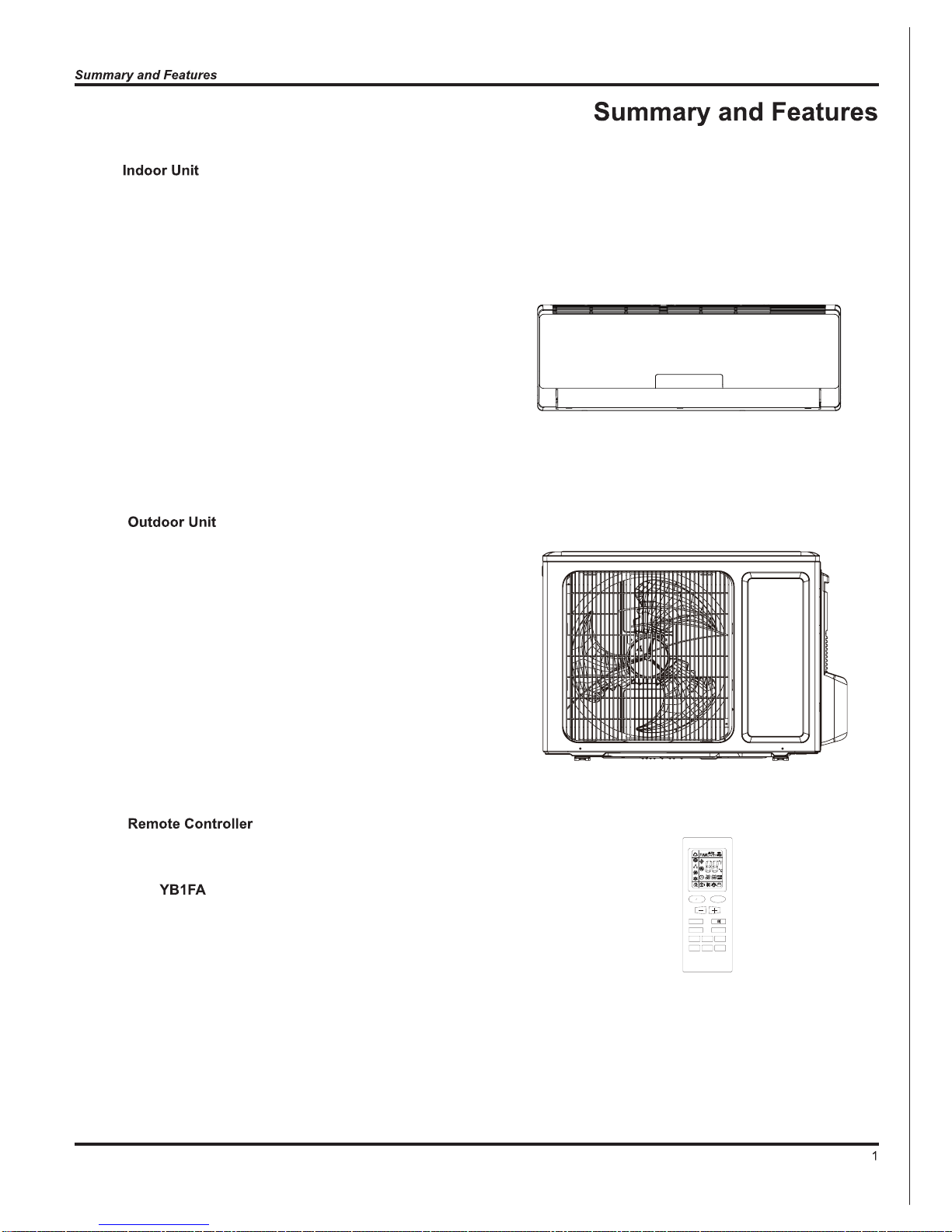

ON OFF

MODE

FAN

CLOCK TIMER ON

X-FAN TEMP

TIMER OFF

TURBO SLEEP LIGH T

C1VO-09

C1VO-12

2

C1VI - 09 / C1VO - 09

C1VI - 09 / C1VO - 09

C1VI - 09

3

C1VO - 09

4

C1VI - 12 / C1VO - 12

C1VI - 12 / C1VO - 12

C1VI - 12

5

C1VO - 12

6

a

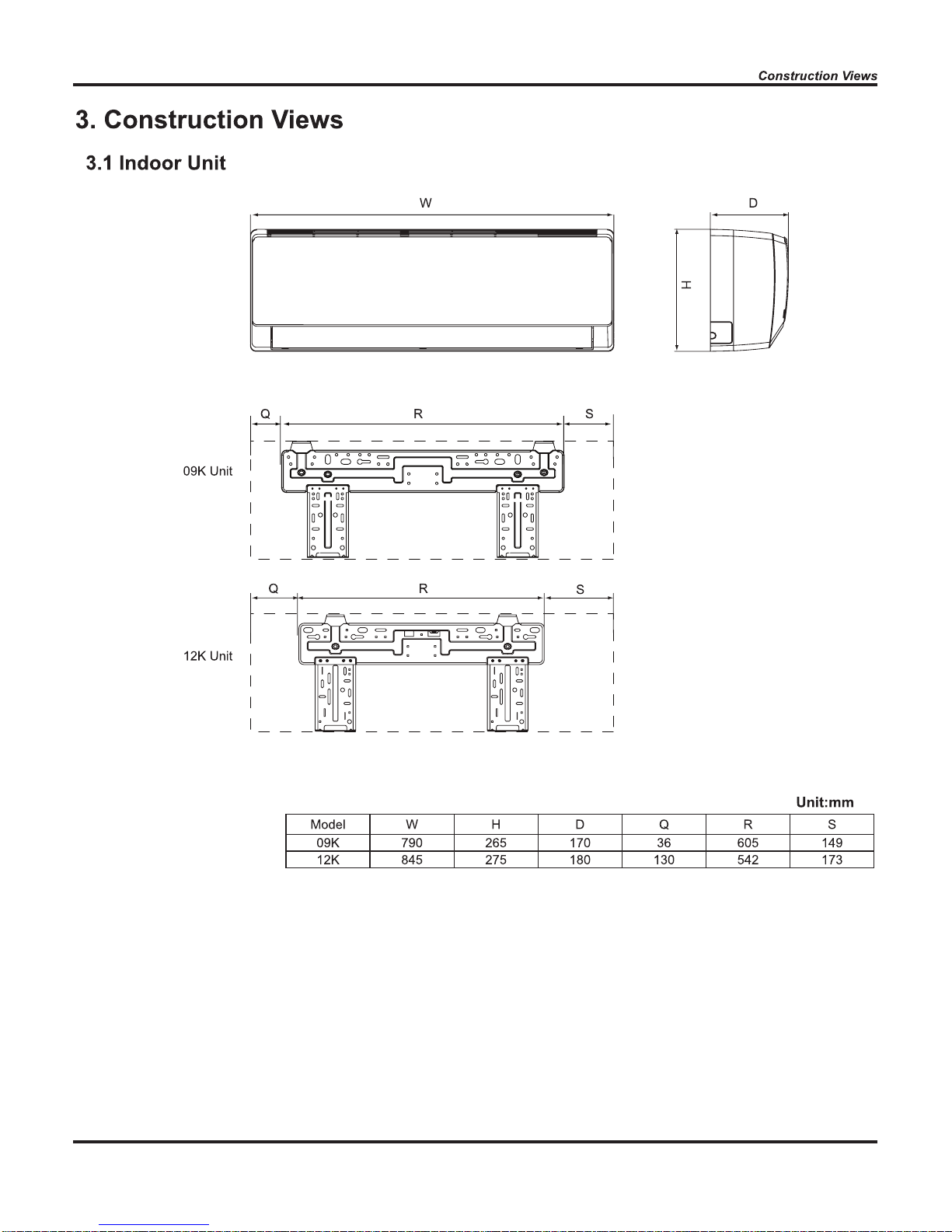

12K

09K

Current(A)

757060504030

1

2

3

4

5

6

7

Compressor Speed (rps)

20

12K

09K

Current(A)

757060

50

4030

1

2

3

4

5

6

7

Compressor Speed (rps)

20

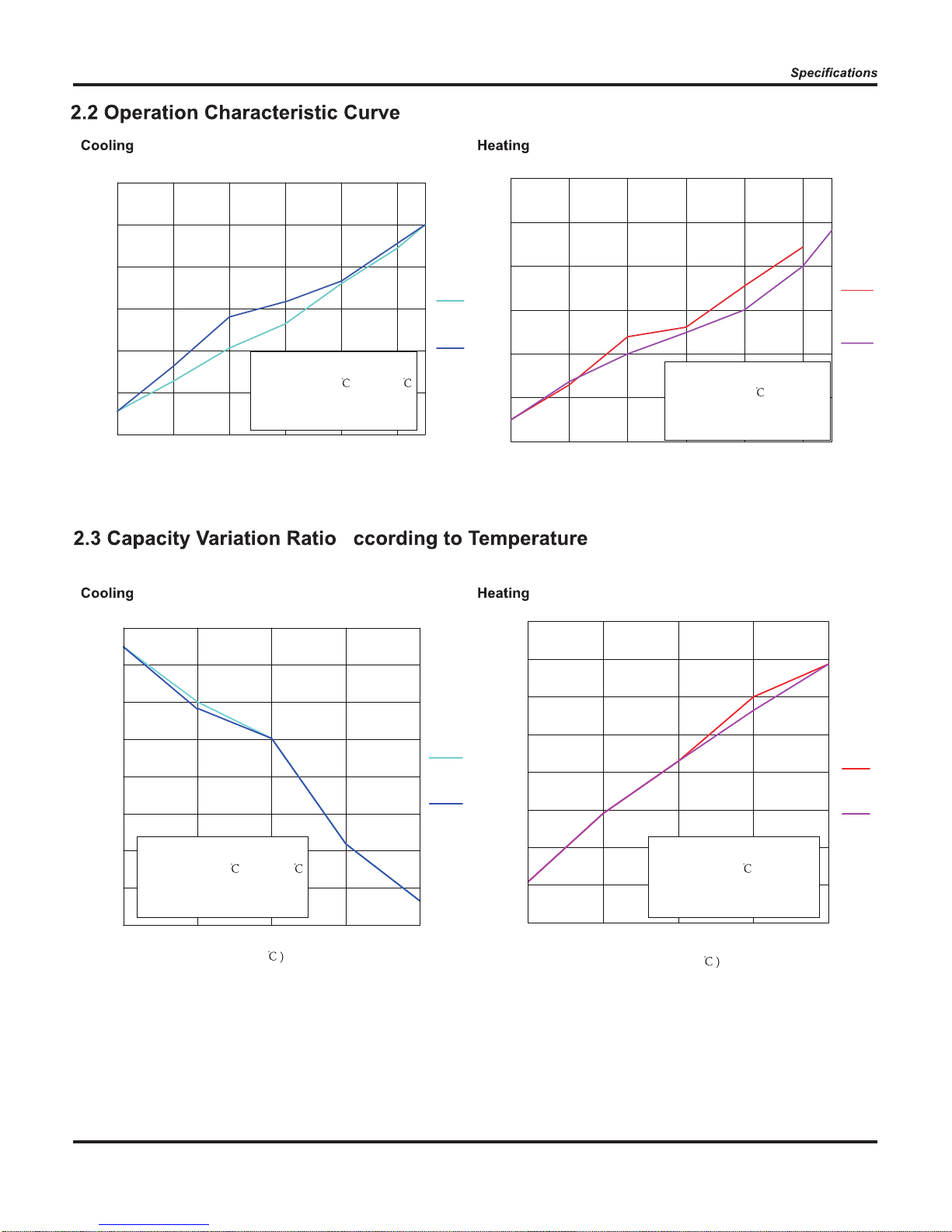

Condition Cooling

Indoor:DB26.7

WB19.4

Indoor air flow: Super High

Pipe length:5m

Condition Heating

Indoor:DB21.1

Indoor air flow: Super High

Pipe length:5m

09K

12K

Capacity ratio(%)

110

60

1070-8

40

50

70

80

90

100

120

Outdoor temp(

-15

09K

12K

Capacity ratio(%)

110

60

48423835

40

50

70

80

90

100

120

Outdoor temp(

32

Condition Heating

Indoor:DB21.1

Indoor air flow: Super High

Pipe length:5m

Condition Cooling

Indoor:DB26.7

WB19.4

Indoor air flow: Super High

Pipe length:5m

7

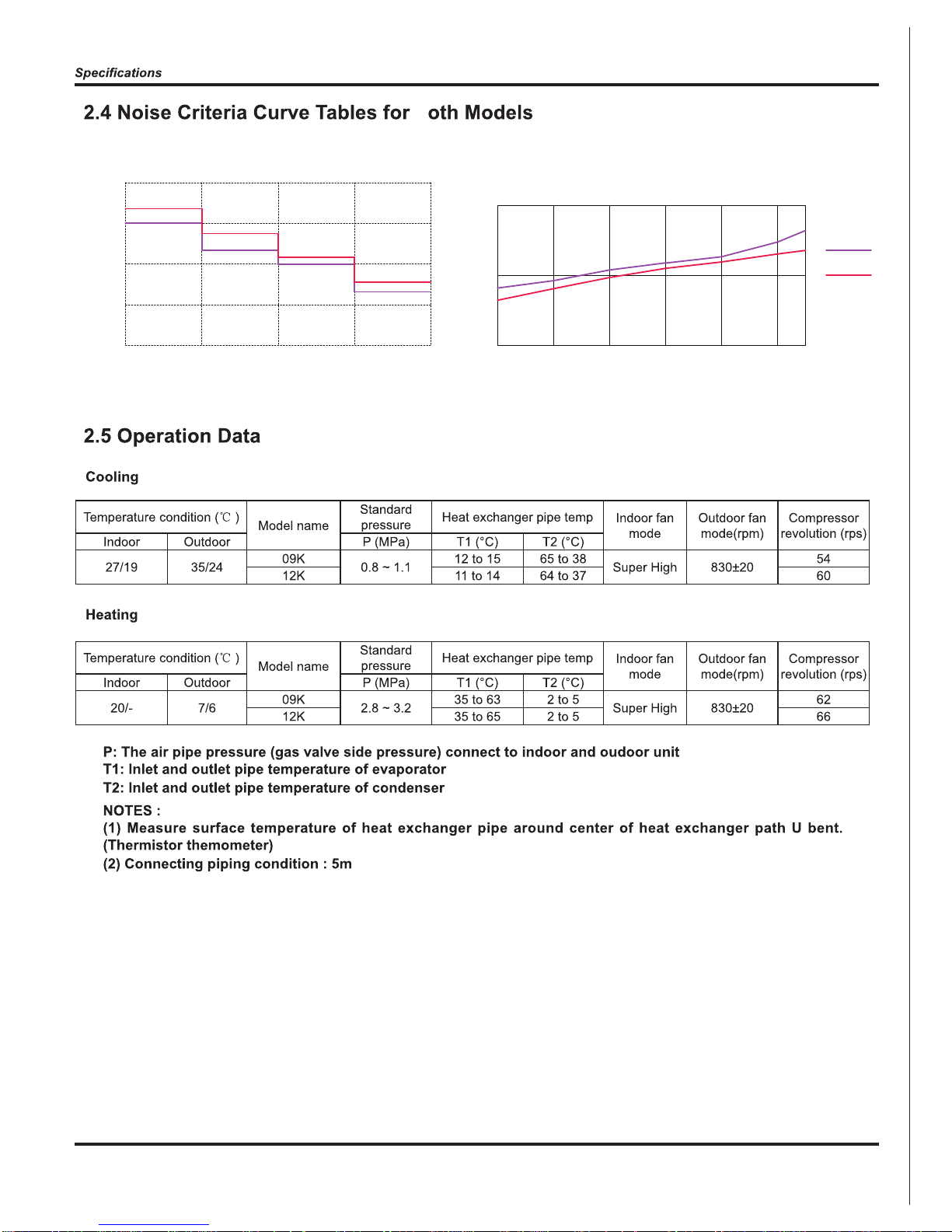

Indoor side noise when blowing

Outdoor side noise when Compressor speed changed

Compressor Speed(rps)

706050403020

45

50

55

Noise/dB(A)

75

09K

12K

Indoor fan motor rotating speed

LowMiddleHighSupper High

25

30

35

40

45

Noise/dB(A)

b

8

9

10

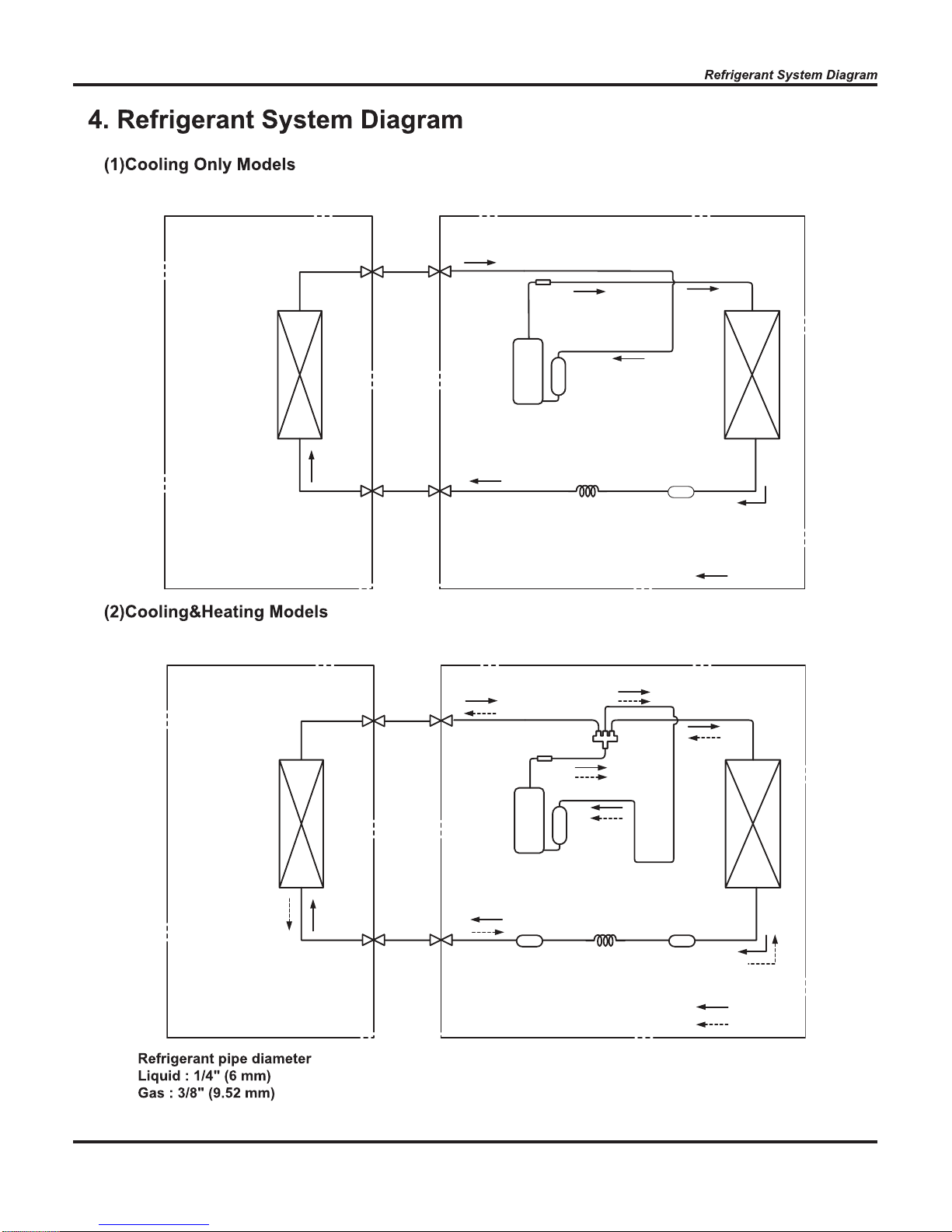

TINU ROODTUOTINU ROODNI

HEAT

EXCHANGE

(EVAPORATOR)

HEAT

EXCHANGE

(CONDENSER)

COMPRESSOR

GAS SIDE

3-WAY VALVE

LIQUID SIDE

2-WAY VALVE

COOLING

Accumlator

Discharge

Suction

Muffler

Strainer

Capillary

TINU ROODTUOTINU ROODNI

HEAT

EXCHANGE

(EVAPORATOR)

HEAT

EXCHANGE

(CONDENSER)

COMPRESSOR

GAS SIDE

3-WAY VALVE

LIQUID SIDE

2-WAY VALVE

COOLING

HEATING

Accumlator

Discharge

Suction

Muffler

4-Way valve

reniartSreniartS

Capillary

11

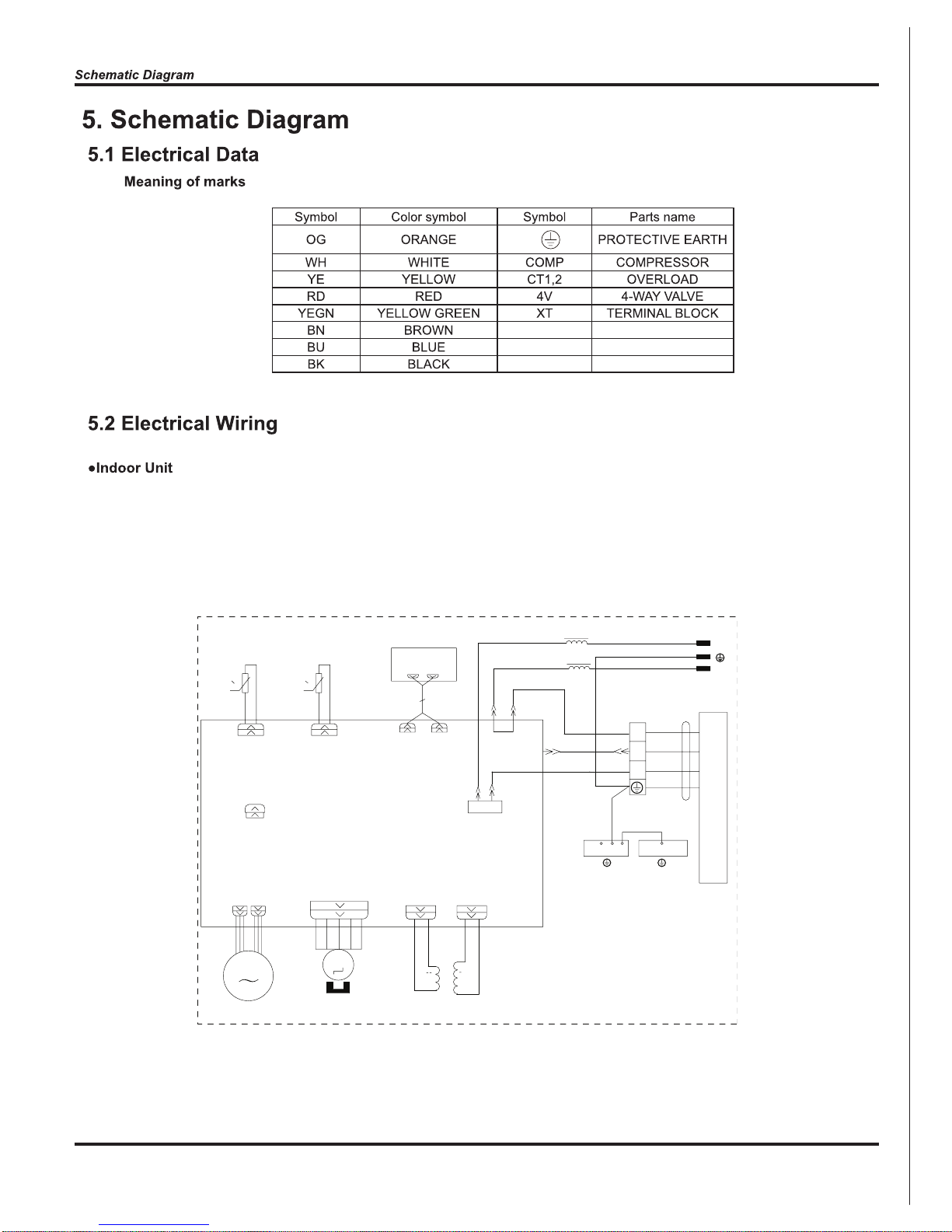

0 0

RT1 RT2

JUMP

CAP

TEM.SENSOR

ROOM

TUBE

TEM.SENSOR

FAN MOTOR

SWING MOTOR(U.D)

AP2

SWING-UD

K4

TUBEROOM

AC-L

PG

PGF

TR_OUT

TR_IN

TC

TRANSFORMER

13

DISPLAY

AP1

CN1

CN2

DISP2

DISP1

M2

M1

PE PE

L1

L1

I

II

L-OUT

ELECTRIC BOX

EVAPORATOR

XT1

W4BU

W3BN

N(1)

OUTDOOR UNIT

2

3

COM-OUT

W1YEGN

W2YEGN

N

W5BK

L

N

BU

YEGN

BN

BN

BU

YEGN

BK

POWER

12

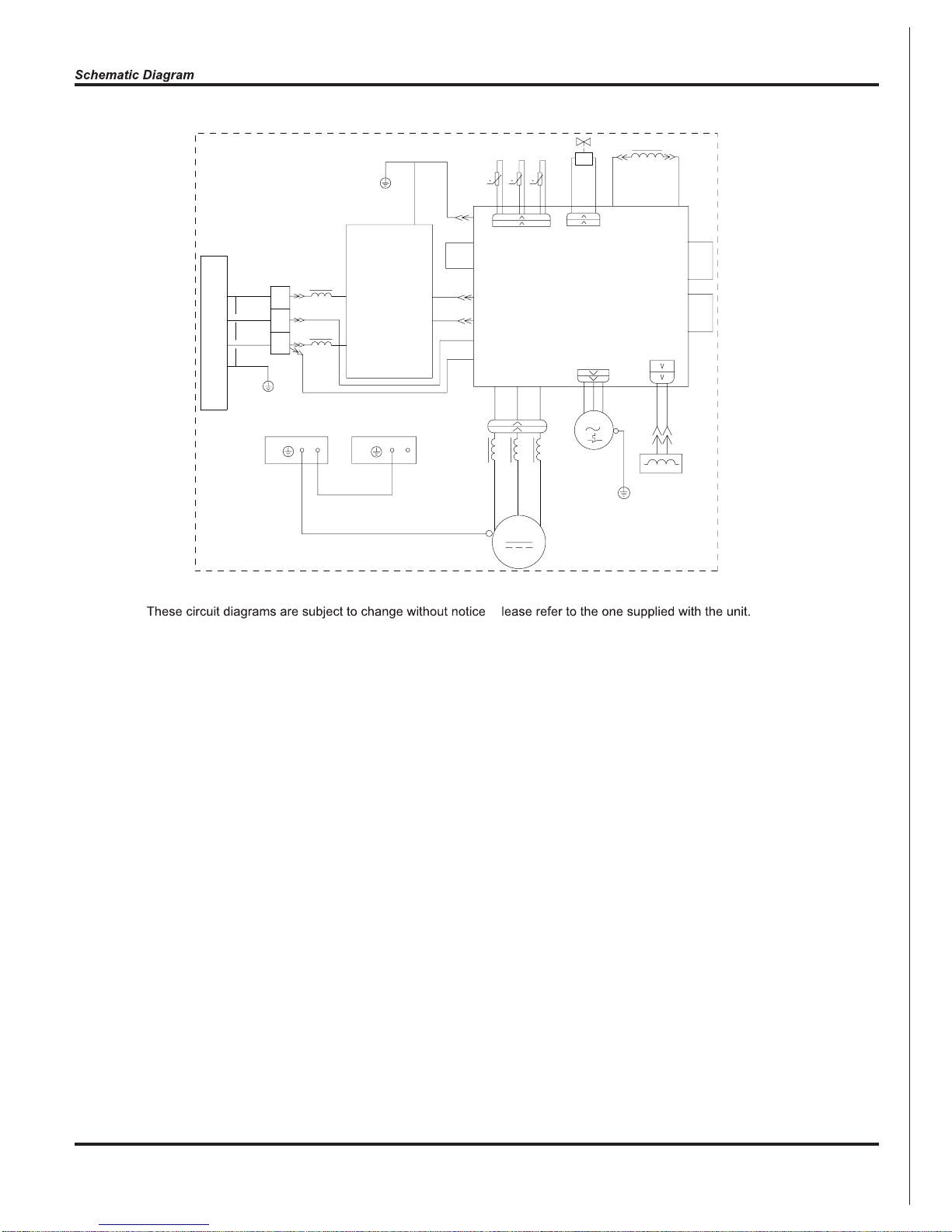

. P

XT

3

2

PE

0

RT1

0

RT2

RT3

0

L

COMP.

PE PE

AP1

AP2

L1

L1

PE

M

TEM.SENSOR

TUBE

OUTROOM

TEM.SENSOR

EXHUAST

TEM.SENSOR

YEGN

W9

YEGN

YEGN

YEGN

YEGN

FAN MOTOR

COMP

BU

YE

RD

YEGN

CT1,2

RD

BN

BU

BU

BN

BN

BN

BU

BU YE

RD

BN

BK

BU

BU

BN

BK

BU

W3

W2

W1

W24

W20

W19

W16

W17

W18

W13

W14

W15

W22

PE

W10 W11

W8

W23

W5

W6

W12

W21

L2

ELECTRIC BOX

MID.ISOLATION SHEET

AC-L5

AC-L4

AC-L

AC-N

COMU

AC-N3

U V W

OFAN

OVC-COMP

AC-N2

AC-N1

AC-L3

AC-L2

LX1-2

LX1-1

CN2

E

AC-L

N

AC-L1

N1

PE

R(W)

S(U)

C(V)

E

N(1)

I

N

D

O

O

R

U

N

I

T

4V

4V

Outdoor Unit

13

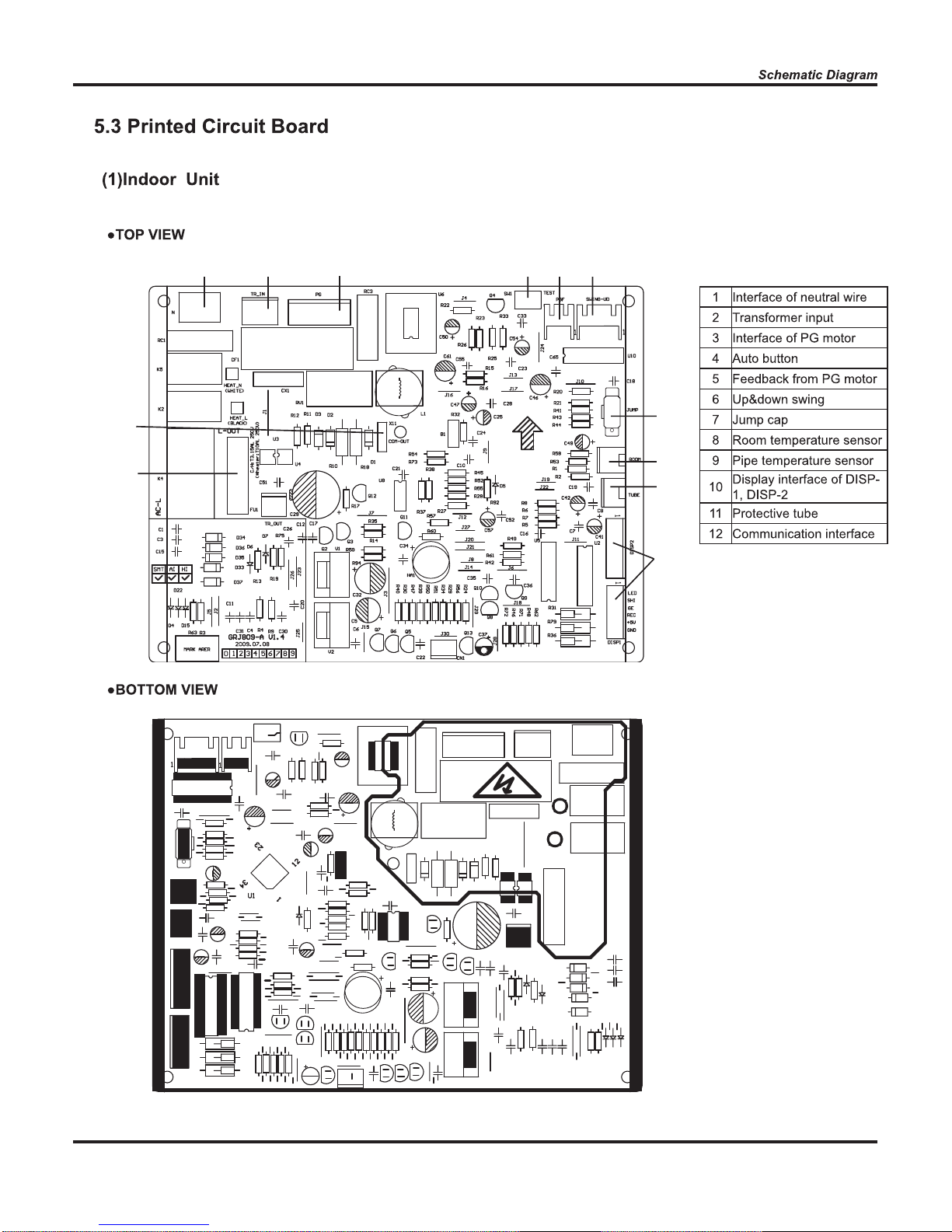

1 2 3

4 5 6

7

8

9

10

11

12

14

11 10 9 8

7

6

13

12

14

5

4

32

1

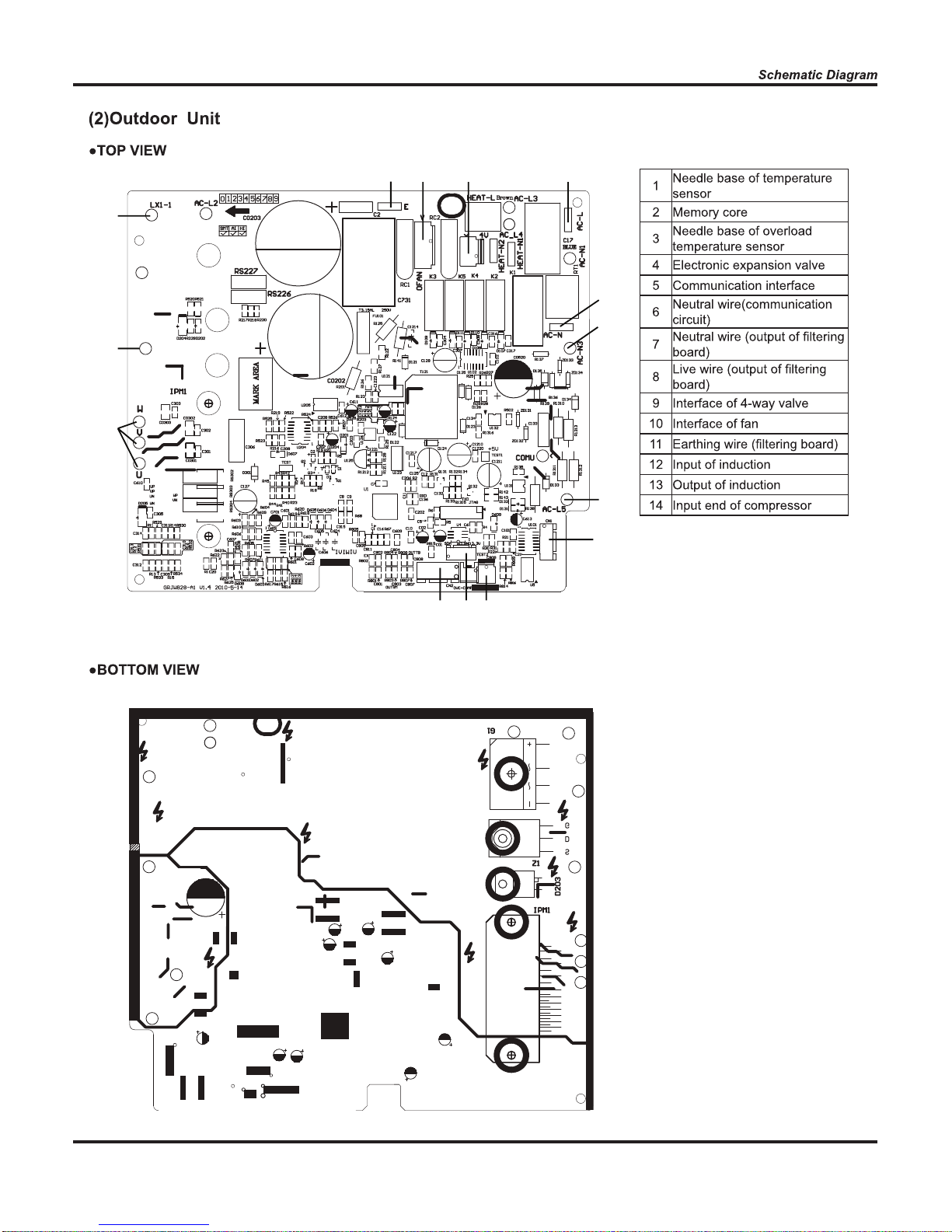

15

1

7

8

4

3

5

6

11

13

12

16

17

18

10

14

9

15

2

2

8

9

10

3

4

11

12

7

6

13

14

5

1

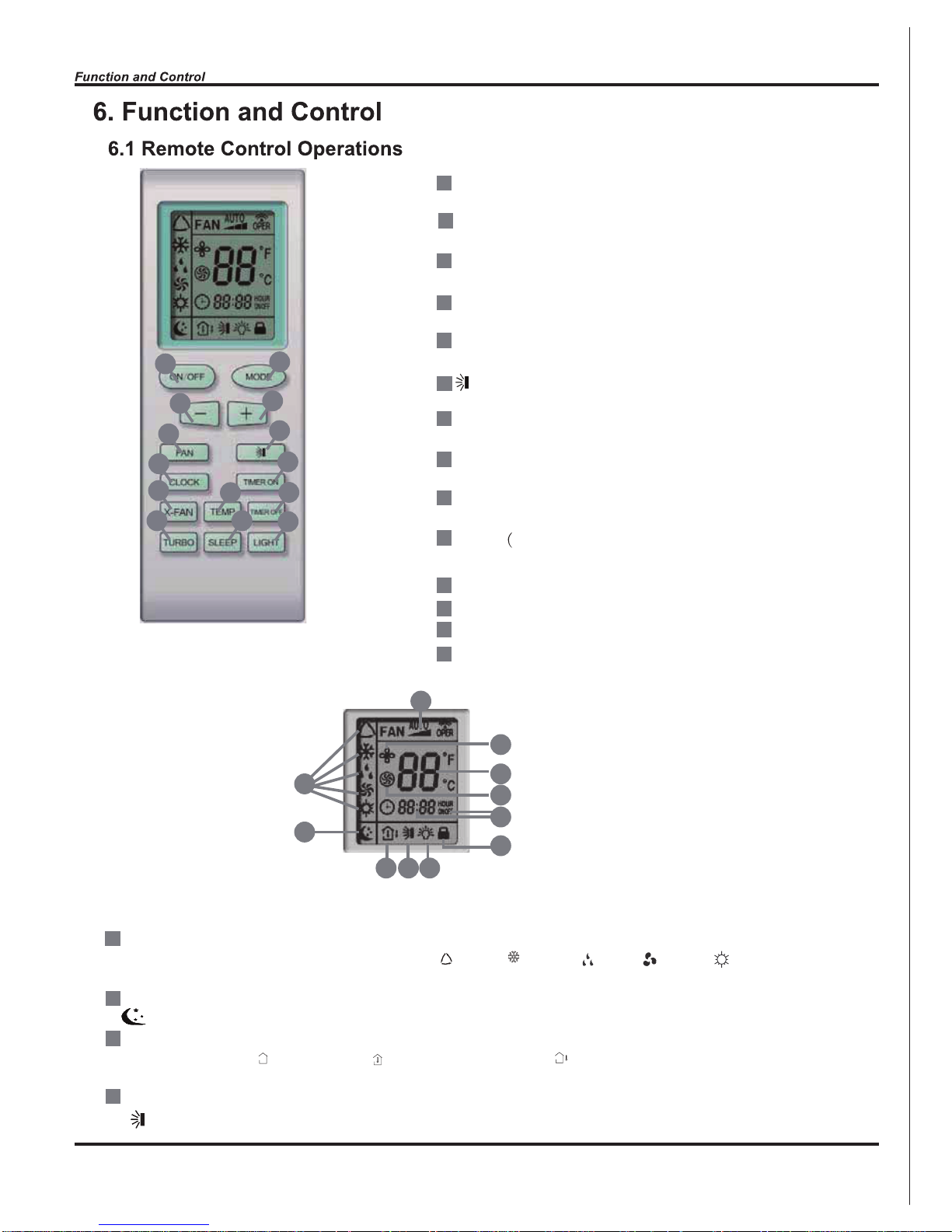

ON/OFF

Press it to start or stop operation.

MODE

Press it to select operation mode (AUTO/COOL/DRY/FAN/HEAT).

+

Press it to increase temperature setting.

-

Press it to decrease temperature setting.

FAN

Press it to set fan speed.

Press it to set swing angle.

TIMER ON

Press it to set auto-on timer.

TIMER OFF

Press it to set auto-off timer.

CLOCK

Press it to set clock.

X-FAN X-FAN is the alternative expression of BLOW for the purpose

of understanding.)

TEMP

TURBO

SLEEP

LIGHT

Press it to turn on/off the light.

171518 19

16

20

21

23

24

22

25

MODE icon:

If MODE button is pressed, current operation mode icon (AUTO), ( COOL), (DRY), (FAN) or (HEAT is only for heat

pump models) will show.

SLEEP icon :

is displayed by pressing the SLEEP button. Press this button again to clear the display.

TEMP icon:

Pressing TEMP button, (set temperature), (indoor ambient temperature), (outdoor ambient temperature) and blank is

displayed circularly.

Up & down swing icon:

is displayed when pressing the up & down swing button. Press this button again to clear the display.

16

20

21

22

23

24

25

1

2

3

4

5

6

19

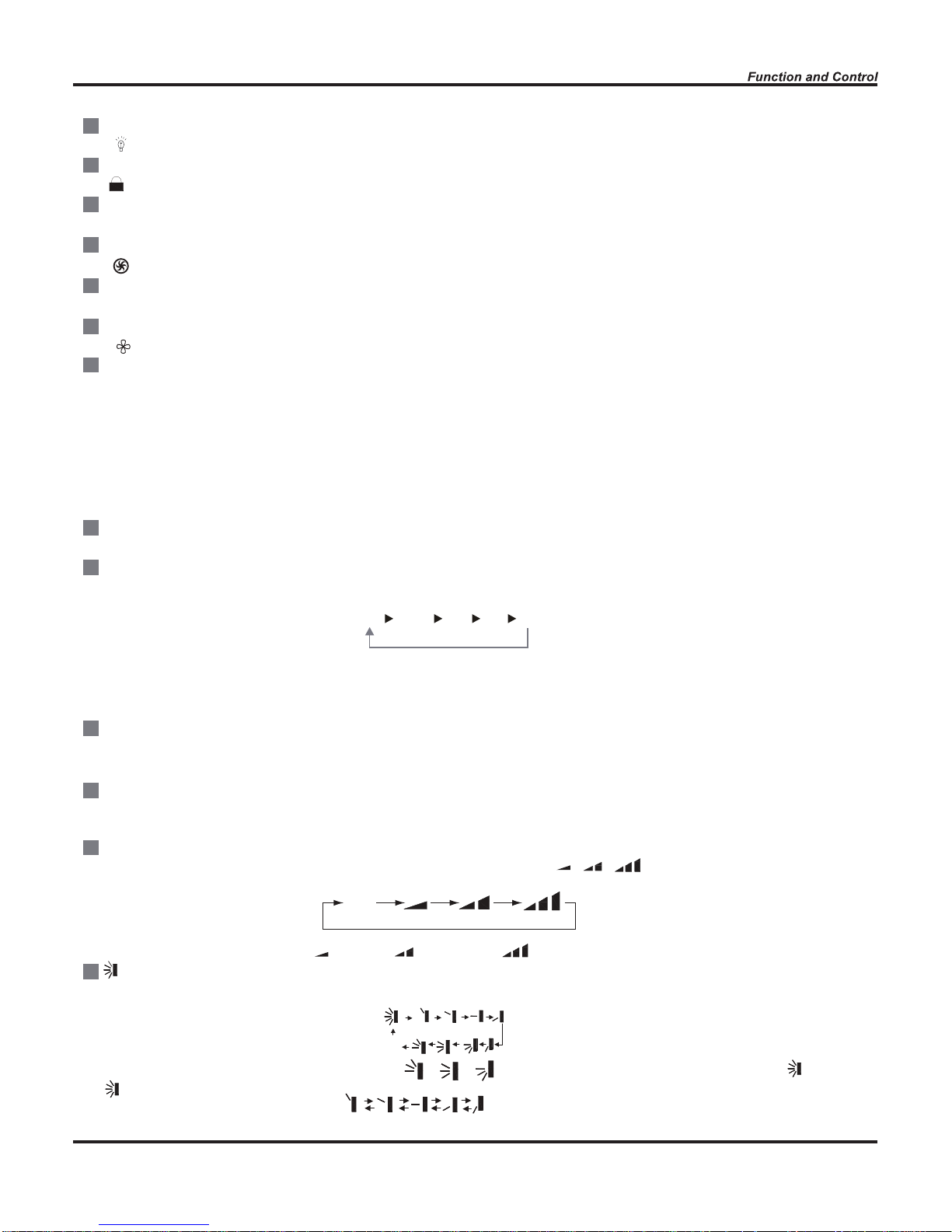

LIGHT icon:

is displayed by pressing the LIGHT button.Press LIGHT button again to clear the display.

LOCK icon:

is displayed by pressing "+" and “-” buttons simultaneously.Press them again to clear the display.

SET TIME display:

After pressing TIMER button, ON or OFF will blink.This area will show the set time.

TURBO icon:

is displayed when pressing theTURBO button.Press this button again to clear the display.

DIGITAL display:

This area will show the set temperature. In SAVE mode,"SE" will be displayed. During defrosting operation, “H1” will be displayed.

X-FAN icon:

is displayed when pressing the X-FAN button. Press this button again to clear the display.

FAN SPEED display:

Press FAN button to select the desired fan speed setting(AUTO Low-Med-High).Your selection will be displayed in the LCD windows,

except the AUTO fan speed.

ON/OFF:

Press this button to turn on the unit. Press this button again to turn off the unit.

MODE:

Each time you press this button,a mode is selected in a sequence that goes from AUTO, COOL,DRY, FAN, and HEAT *, as the

following:

*Note: Only for models with heating function.

After energization, AUTO mode is defaulted. In AUTO mode, the set temperature will not be displayed on the LCD, and the unit will

automatically select the suitable operation mode in accordance with the room temperature to make indoor room comfortable.

+ :

Press this button to increase set temperature. Hold it down for above 2 seconds to rapidly increase set temperature. In AUTO mode,

set temperature is not adjustable.

-:

Press this button to decrease set temperature. Hold it down for above . 2 seconds to rapidly decrease set temperature. In AUTO

mode, set temperature is not adjustable.

FAN :

This button is used for setting fan speed in the sequence that goes from AUTO, , , to then back to Auto.

Press this button to set up & down swing angle, which circularly changes as below:

This remote controller is universal. If any command , or is sent out, the unit will carry out the command as

indicates the guide louver swings as:

AUTO

COOL DRY FAN HEAT*AUTO

Low speed Medium speed High speed

OFF

17

8

9

10

11

12

13

14

15

16

7

TIMER ON:

Press this button to initiate the auto-ON timer. To cancel the auto-timer program, simply press this button again. After pressing this

button, disappears and "ON" blinks . 0 0:00 is displayed for ON time setting. Within 5 seconds, press + or - button to adjust the

time value. Every press of either button changes the time setting by 1 minute. Holding down either button rapidly changes the time

setting by 1 minute and then 10 minutes. Within 5 seconds after setting, press TIMER ON button to confirm.

TIMER OFF:

Press this button to initiate the auto-off timer. To cancel the auto-timer program, simply press the button again.TIMER OFF setting is

the same as TIMER ON.

CLOCK :

Pressing CLOCK button, blinks. Within 5 seconds, pressing + or - button adjusts the present time. Holding down either button

above 2 seconds increases or decreases the time by 1 minute every 0.5 second and then by 10 minutes every 0.5 second. During

blinking after setting, press CLOCK button again to confirm the setting, and then will be constantly displayed.

X-FAN:

Pressing X -FAN button in COOL or DRY mode,the icon is displayed and the indoor fan will continue operation for 10 minutes in

order to dry the indoor unit even though you have turned off the unit.

After energization, X-FAN OFF is defaulted. X-FAN is not available in AUTO, FAN or HEAT mode.

TEMP:

Press this button, could select displaying the indoor setting temperature or indoor ambient temperature.When the indoor unit firstly

power on it will display the setting temperature, if the temperature's displaying status is changed from other status to" ",displays

the ambient temperature, 5s later or within 5s, it receives other remote control signal that will return to display the setting temperature. if the users haven't set up the temperature displaying status,that will display the setting temperature.

TURBO:

Press this button to activate / deactivate the Turbo function which enables the unit to reach the preset temperature in the shortest

time. In COOL mode, the unit will blow strong cooling air at super high fan speed. In HEAT mode, the unit will blow strong heating air

at super high fan speed.

SLEEP:

Press this button to go into the SLEEP operation mode. Press it again to cancel this function. This function is available in COOL,

HEAT (Only for models with heating function) or DRY mode to maintain the most comfortable temperature for you.

LIGHT:

Press LIGHT button to turn on the display's light and press this button again to turn off the display's light. If the light is turned on ,

is displayed. If the light is tunrned off, disappears.

Combination of "+" and "-" buttons: About lock

Press "+ " and "-" buttons simultaneously to lock or unlock the keypad. If the remote controller is locked, is displayed. In this

case, pressing any button, blinks three times.

Combination of "MODE" and "-" buttons:About switch between Fahrenheit and Centigrade At unit OFF, press "MODE" and "- "

buttons simultaneously to switch between

and .

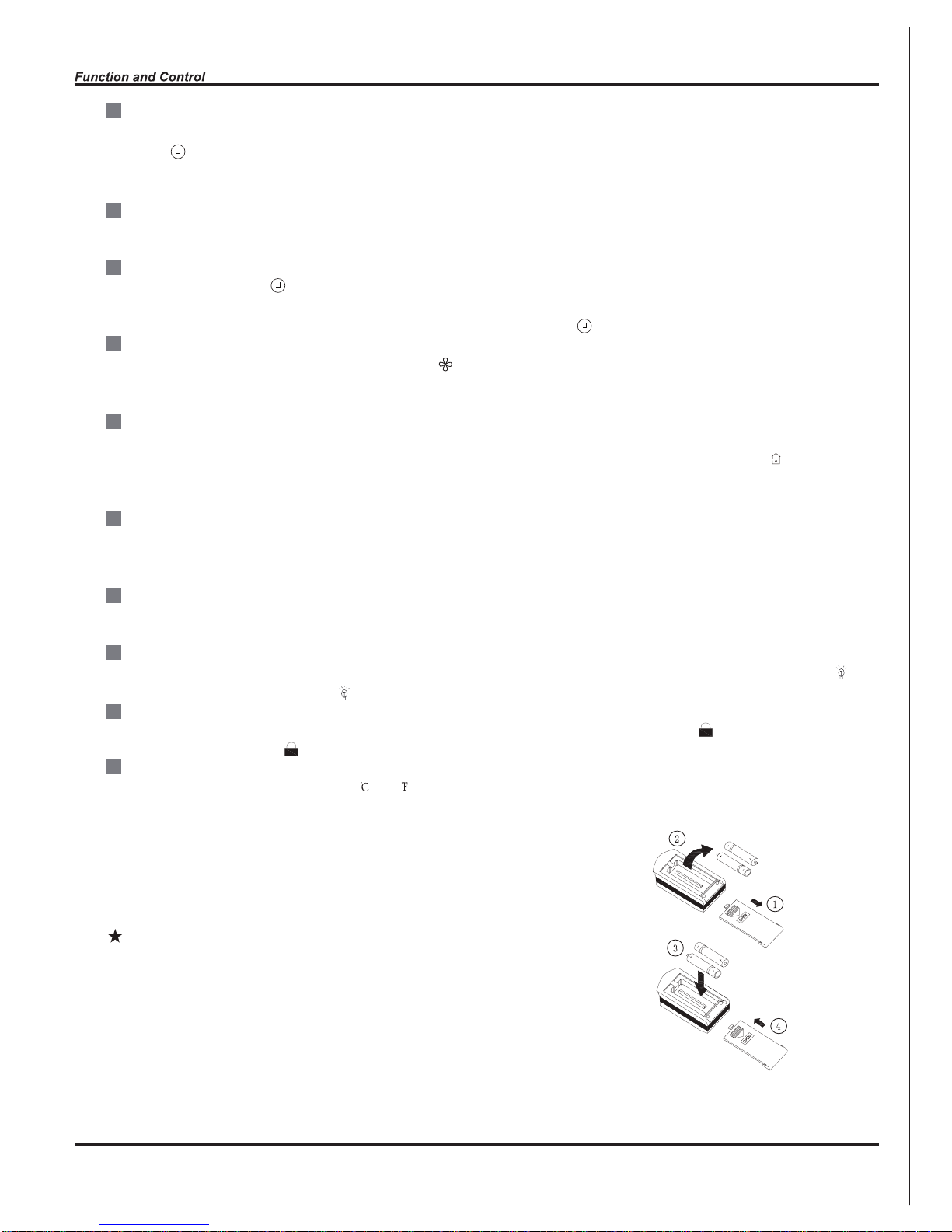

Replacement of Batteries

1.Remove the battery cover plate from the rear of the remote controller.

(As shown in the figure)

2.Take out the old batteries.

3.Insert two new AAA1.5V dry batteries, and pay attention to the polarity.

4. Reinstall the battery cover plate.

Notes:

●When replacing the batteries, do not use old or different types of batteries.

Otherwise, it may cause malfunction.

●If the remote controller will not be used for a long time,

please remove batteries to prevent batteries from leaking.

●The operation should be performed in its receiving range.

●It should be kept 1m away from the TV set or stereo sound sets.

●If the remote controller does not operate normally, please take the

batteries out and reinsert them after 30 seconds. If it still can't operate

properly, replace the batteries.

Sketch map for

replacing batteries

18

Start cooling

Stop cooling

Compresso

r

Original working state

Run

Stop

Outdoor fan

Indoor fan

T

preset

T

amb.

6 minutes 6 minutes3 minutes

T

preset

-3

Preset wind speed

When T indoor amb. =Tpreset-2 , after compressor operates at the frequency which is lower than 15Hz for

continuous 15 minutes, if Tindoor amb.=Tpreset -2

still, compressor stops operation.

When Tindoor amb.

Tpreset-3 , compressor stops operation and outdoor fan stops operation in 30s later. Indoor fan

operates at set speed.

When Tpreset-2

Tindoor amb. Tpreset, the previous operation status will be maintained.

19

(4)-10 . Toutdoor amb. -5 , Toutdoor pipe-Tcompensation Toutdoor amb.-3

(5)Toutdoor amb. -10 , Toutdoorpipe-Tcompensation Toutdoor amb.-3

(After energization, for the first defrosting, Tcompensation=0 ; if it is not first defrosting, Tcompensation is determined

by Toutdoor pipe of last time of quitting defrosting;

a. when Toutdoor pipe

2 , Tcompensation=0 ; b. when Toutdoor pipe 2 , Tcompensation=3

20

21

A

L

B

C

D

O(0

)

O(0 )

L1

A1

B1

C1

D1

heating angle

cooling angle

22

23

24

25

Space to the wall

Space to the ceiling

Space to the wall

Space to the wall

Air outlet side

Space to the floor

Above

Above

15cm Above

15cm Above

30cm Above

50cm Above

50cm Above

30cm Above

200cm Above

Above

Space to the obstruction

Air outlet side

Space to the wall

Air inlet side

The dimensions of the space necessary for correct

installation of the appliance including the minimum

permissible distances to adjacent structures

●

15cm

250

cm

300cm

26

Indoor

Outdoor

Wall pipe

Seal pad

bulge

distortion

outlet pipe of

indoor unit

insulating tube

connected

insulating tube

drain hose

outlet pipe of

indoor unit

drain hose

outlet pipe of

indoor unit

outlet pipe of

indoor unit

rubber belt

rubber belt

rubber belt

Flooded

Fig.2

Wiring Cover

outdoor unit connection

yellowgreen

brown

N(1)

black

2 3

blue

09K UNIT:

12K UNIT:

Wall

Wall

Wall

Above

150 from

the wall

Above

150 from

the wall

Wall

Wall

Wall

Above

150 from

the wall

Above

150 from

the wall

Φ55

Φ55

RightLeft

RightLeft

Φ55

Φ55

Above 150 from the ceiling

Above 150 from the ceiling

27

Fig.5

Mounting

plate

Fixing hook

Mounting

plate

Right

Right rear

Fig.4

Left rear

Left

Fig.3

Tailing 1

Tailing 2

Finally wrap it

with tape

Gas side piping

insulation

Water drainage pipe

Liquid side

Piping insulation

Gas side pipe

External connection

electric wire

Liquid side piping

Spanner

Torque

wrench

Piping

Taper nut

Indoor unit piping

Black

Blue

Yellow-green

signal control wire

N(1) 2 3

Brown

Handle

28

Fig.6

Manifold Valve

Multimeter

-76cmHg

Lo Handle

Charging hose

Manometer

Hi handle

Vacuum pump

Low pressure valve

Drain-water hole

Bottom frame

Hose (available commercially,

inner dia. 16mm)

Drain connecter

29

Fig. a

filter

Air filter

Fig. b

Fig. c

Healthy

30

40

43

42

41

39

15

14

13

12

16

17

18

19

20

21

22

23

24

38

37

36

35

34

33

32

31

30

29

28

27

11

10

9

8

7

6

5

4

3

2

26

1

25

C1VI - 09

31

C1VI - 09

32

36

33

34

37

21

15

14

13

12

16

41

17

18

19

20

23

24

25

26

27

28

29

30

31

32

38

39

40

11

10

9

8

7

6

4

5

3

1

35

22

2

C1VI - 12

33

C1VI - 12

34

1

2

3

4

5

7

8

9

10 11

13

14

15 16

17

18

192021

22

6

12

C1VO - 09

35

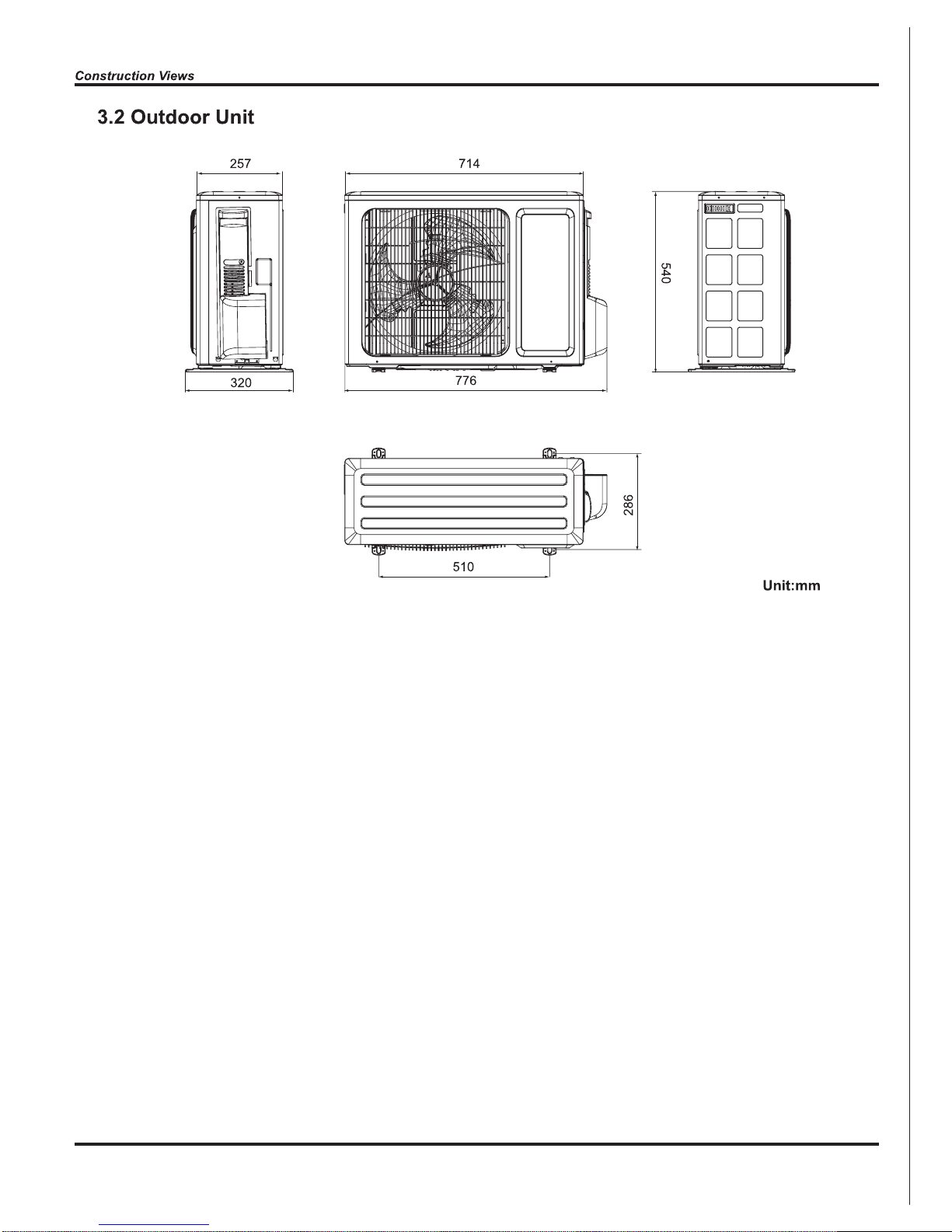

8.2 Outdoor Unit

C1VO - 09

36

1

2

3

4

5

7

8

9

10

11

12

13

14

15 16

17

18

192021

22

23

24

6

C1VO - 12

37

C1V0 - 12

38

The remote

controller does

not receive

signals (after it

is powered, the

buzzer will

sound, unless it

has

malfunction)

Trip of breaker or

blow of fuse

Air conditioner can not

start up

Measure insulation resistance

to ground to see if there is any

leakage.

The circuit or the part of the air

conditioner has malfunction.

They heat and break the insulation and lead to short circuit or

creepage. Measure the insulation resistance or eliminate the

malfunction one by one. If the

breaker itself has malfunction,

then replace the breaker.

The transformer connection is

loose or has bad contact or the

transformer has malfunction.

Fasten the wiring; measure the

output voltage of the transformer , if it is incorrect, change

the transformer.

No power

Check power supply circuit.

Power plug is not well plugged in

and poor connection.

Check if the plug is properly

plugged in and make the loose

contact firm.

Fuse of controller burnt out

The air conditioner does not

react after it is

powered ( after

the plug is

inserted, the

buzzer does not

sound and the

remote startup

has no

response)

Remote controller malfunction

Receiver loose or poor connection

Receiver is broken

Change controller fuse

Controller is broken

Check remote controller

Remote controller is short of power

Change batteries

First, press the manual switch

button AUTO,if there is no

response,check based on the

above methods. If it runs normally after pressing the button,

check again whether the installation position and the connection wire of the reception head

is correct. If it is correct,then replace the receiver or the remote

controller.

Power voltage is too low

Check the voltage. If it is lower than 10% of

the rated voltage, check the cause, improve

the power supply condition and add the stabilized voltage power supply.

The breaker trips at once when it

is set to “ON”.

The breaker trips in few minutes

when it is set to “ON”.

39

Improper set of temperature

Adjust set temperature

If cooling (heating) load is

proper

Check the forecasted load of cooling (heating)

The refrigerant has leakage or is

insufficient

Check and fill the leakage, then

vacuumize it and supplement the refrigerant as required

Leakage between the high pressure and the low pressure inside the compressor

Replace the compressor

Malfunction of four-way valve Replace the four-way valve

Local block of capillary Replace the capillary

Blockage of cooling system

Judge whether the system is blocked by

observing the condensation of evaporator and the pressure value of

the high

pressure manometer and take measures

to deal with the system.

Malfunction of

refrige r an t

flow

Heat insulation for the connection

pipes of the indoor unit and the outdoor unit is bad.

Make sure that heat insulation for the thick and thin pipes

is good. Heat insulation must also be provided for the

joint andthe exposed part of the copper pipe .

Block of outdoor heat exchanger

Clean the dust accumulated on the surface of

the heat exchanger.

Air filter were blocked

Clean the filter

Fan speed was set too slow

To set the fan speed to high or

middle speed

Air circulation

is insufficient

Fan rotation speed becomes

low

Capacitor

damage

Motor damage

Replace the capacitor

Replace the motor

The installation position of the

outdoor unit is not appropriate.

Good ventilation must be provided for the

installation position of the outdoor unit.

The outdoor temperature is too high.

Properly install the rainproof plate or the sunproof plate. If the

maximum cool air still can not meet the requirement, it is suggested to replace the air conditioner.

Keep certain air tightness indoors, try not to use

electricalappliance with large quantity of heat

The air tightness is not enough. People

come in and out too frequently. There

are heating devices indoors.

Poor COOL(HEAT) operation

40

The indoor fan motor is burned or

breaks or has the heat protector

malfunction.

Replace the fan motor or the defective part.

Wrong connection

Make the correction connection based on

the circuit drawing.

The fan capacitor has open circuit or

is damaged.

The fan does not

run when it is set

to supply air.

Replace the fan capacitor of the same type

and same specification.

The outdoor fan motor is damaged.

Replace the fan motor

Wrong connection

Make the correct connection based on the

circuit drawing

The outdoor fan capacitor is damaged.

Replace the fan capacitor

Malfunction of compressor

Replace the compressor

Breakage of running capacitor of

compressor

Replace the capacitor

The voltage is too low or too

high.

Manostat is recommended.

Wrong wir

e connection

Connect the circuit diagram correctly

The built-in heat protector of the

motor breaks frequently because the

motor is abnormal.

Replace the fan motor

Adjust the volume of the refrigerant

The refrigerant is not enough or is too

much.

Replace the capillary

The capillary is blocked and the temperature rises.

The compressor does not run

smoothly or is stuck. The air discharge

valve is damaged

Replace the compressor

The protector itself has malfunction. Replace the protector

The compressor is too hot

and leads to the

action of the

protector.

The protector itself has malfunction.

Use the multimeter to check whether the

contact of the compressor is on when it is

not overheated. If it is not on, then replace

the protector

In the cooling and

heating mode,

the compressor

runs, but the outdoor fan does not

run.

In the cooling

and heating

mode, the

outdoor fan

runs, but the

compressor

does not run.

41

Adjust fan location

Fan of indoor unit contacts other parts

Foreign object in indoor unit

Take out the foreign object

Adjust support washer of compressor, and

tighten loosen screws

Touch of pipeline of outdoor unit Separate the touching pipeline.

Abnormal sound

and shake

Touch of inner plates

1. Tighten connect screw.

2. Stick absorbing clay between plates.

Louver of outdoor unit touched outer

case.

Adjust location of louver.

Abnormal sound inside compressor

Change compressor

Drainage pipe blocked or broken Change drainage pipe

Re-wrap and make it tight.

Wrap of refrigerant pipe joint is not

close enough.

Water leakage

Change controller

Wire loose or wrong connection

In cool, heat

mode, the

outdoor unit

and compressor will not run.

Correctly wire according to the drawing

Improper setting of temperature

Adjust setting temp.

Controller malfunction (IC2003

broken, creepage of parallel capacitor of relay loop, relay is broken etc.)

First, check whether the connection is

wrong. If no, replace the parts

The swing fan

does not run.

The torque of the swing motor is not

enough

Wrong connection

The controller is damaged(IC2003 is

damaged, the swing relay can not

close, etc)

Compressor shakes too much

42

43

44

45

Simply

N

Y

N

Y

N

Y

N

Y

N

Y

Turn on the unit

and wait 1 minute

Use DC voltmeter

to measure the

voltage on the two

ends of electrolytic

capacitor

Voltage higher than 200V?

Fault with the voltage

testing circuit on

control panel AP1

Replace the control

panel AP1

Measure the AC voltage between

terminal

L and N on wiring board

XT(power supply)

Voltage within

210VAC~250VAC?

Shut down the power

and repair the power

supply to restore the

range

210VAC~250VAC

power on and

restart the unit

If the fault is

eliminated?

Shut down the power and wait 20 mi

nutes;

or use DC voltmeter to measure the voltage

on the two ends of capacitor , until the

voltage is lower than 20V

Check the

connection of reactor

(L in the Electrical

Wiring Diagram)

If the wiring of

reactor L

is normal?

Connect the reactor

Laccording to Electrical Wiring Diagram correctly

Re-energize and

turn on the unit

If the fault is

eliminated?

End

Replace the control

panel AP1

46

Energize and

switch on

IPM protection

occurs after the

machine has run for

a

p

eriod of time?

Use AC voltmeter

to measure the

voltage between

terminal L and N

on the wiring

board XT)

If the voltage

between terminal L

and N on wiring

board XT is within

210VAC~250VAC?

Check the supply

voltage and

restore it to

210VAC~250VAC

Voltage between

the two ends of celectrolytic

capacitor is

Restart the unit. Before

protection occurs,

use DC voltmeter to

measure the voltage

between the two

ends of electrolytic

capacitor on control

panel AP1

If the unit can

work

normally?

Please confirm:

1. If the indoor and

outdoor heat

exchangers are

dirty? If they are

obstructed by other

objects which affect

the heat exchange

of indoor and

outdoor unit.

2. If the indoor and

outdoor fans are

working normally?

3. If the environment

temperature is too

high, resulting in

that the system

pressure is too high

and exceeds the

permissible range?

4. If the charge

volume of

refrigerant is too

much, resulting in

that the system

pressure is too

high?

5. Other conditions

resulting in that the

system pressure

becomes too high.

The connection

of capacitor C2

is loose.

Reconnect the

capacitor C2 according

to Electrical Wiring

Diagram. Then,

Restart the

unit.

Stop the unit and

disconnect the power

supply. Wait 20 minutes,

or use DC voltmeter to

measure the voltage

between the two ends of

capacitor C2, until the

voltage is lower than 20V

Replace the capacitor

C2. Then, energize

and start the unit.

Replace the

control panel AP1

Take corrective actions

according to Technical

Service Manual, and

then energize and start

the unit.

If there is any

abnormality

described above?

Replace the

control panel AP1

If the connection

between AP1 and

COMP is unsecure

or the connection

order is wrong?

Connect the control panel

A

P1 and compressor

COMP correctly according

to the Electrical Wiring

Diagram. Then, energize

and start the unit.

Use ohmmeter to

measure the resistance

between the three

terminals on compressor

COMP, and compare the

measurements with the

compressor resistance on

Service Manual.

If the

resistance is

normal?

Use ohmmeter to

measure the resistance

between the two

terminals of compressor

COMP and copper tube.

Replace the

compressor

COMP

Resistance higher

than 500MΩ?

Replace the

control panel

AP1

END

Y N

Y

N

Y

If the unit can

work normallv?

Y

If the unit can

work normally?

Y

N

Y

N

If the unit can

work normally?

Y

Y

N

N

If the unit can

work

normally?

Y

Y

N

N

N

Y

higher than

250V

Remove the wires

on the two ends of

capacitor C2. Then,

use capacitance

meter to measure

the capacitor C2.

Verify as per the

Parameters Sheet.

Stop the unit and

disconnect the power

supply. Then, check

the connection of

capacitor C2

according to Electrical

Wiring Diagram.

If capacitor

C2 is failed?

Refer to the

Electrical Wiring

Diagram and check

if the connection

between AP1 and

COMP is loose and if

the connection order

is correct.

47

End

Y

N

Y

N

Y

N

Overheat and high

temperature protection

Is outdoor ambient temperature higher than 53?

20 minutes after the complete

unit is powered off.

Is heat dissipation of the indoor unit

and outdoor unit abnormal?

Normal protection, please operate

it after the outdoor ambient temperature is normalized.

Improve the heat

dissipation environment of the unit

Does the outdoor fan work normally?

1. Check if the fan terminal OFAN

is connected correctly

2. Resistance between any two

terminals is measure by an ohm

gauge and should be less than 1K

Ohm.

Replace the

control panel

AP1

Replace the fan

capacitor C1

Replace the

outdoor fan

48

Y

N

Y

N

N

Y

Y

N

Power on the unit

Is stop time of the compressor

longer than 3 minutes?

Restart it up after

3 minutes

Does startup fail?

Are the wires for the compressor connected

correctly? Is connection sequence right?

Connect the wires as

per the connection

diagram

Replace the control panel AP1

If the fault is eliminated?

Replace the

compressor

End

49

Out of step occurs once the

unit is powered on.

Is stop time of the

compressor longer than

3 minutes?

Are the wires for the compressor connected

correctly? Is connection sequence right?

Is the connection made in clockwise

direction?

Connect the

wires correctly

Replace the control

panel AP1

If the fault is eliminated?

Replace the

compressor

End

Out of step occurs in

operation

Is the outdoor fan working

normally?

Is the outdoor unit blocked

by foreign objects?

Replace the

control panel AP1

If the fault is eliminated?

Replace the

compressor

End

Check if the fan terminal

OFAN is connected correctly

Remove foreign objects

Replace the fan

capacitor C1

Replace the

outdoor fan

50

20 minutes after the

complete unit is

powered off

Is the terminal FA for the

electronic expansion valve

connected correctly?

Connect the

wires correctly

Resistances between the first four pins

close to the terminal hole and the fifth

pin are almost the same, less than 100

ohm.

Replace the electronic

expansion valve

If the fault is eliminated?

If the fault is eliminated?

Replace the

control panel

AP1

Coolant leakage, refilling

the coolant

End

51

Y

Y

N

N

N

N

N

N

Y

Y

Y

Start

Check wiring of the

reactor (L) of the

outdoor unit and the

PFC capacitor

Whether there is any

damage or

short-circuit?

Replace it as per the

wiring diagram and

reconnect the wires

If the fault is eliminated?

Remove the PFC capacitor

and measure resistance

between the two terminals.

Is the resistance around zero?

The capacitor is

short circuited and

the capacitor

should be replaced

Restart the unit

If the fault is eliminated?

Disconnect the terminals for the

reactor and measure the resistance

between the two terminals of the

reactor by an ohm gauge

Whether there is any damage

or short-circuit?

Replace the reactor

Restart the unit

If the fault is eliminated?

Replace the control

panel AP1

End

Y

52

Y

N

Y

N

N

Y

N

N

Y

N

Y

N

Y

Y

Start

Did the equipment operate

normally before the failure

occurs?

The AP1 voltage

detection circuit

is at fault

Check wiring inside of

the indoor and outdoor

units

Are wires broken?

Check the communication

circuit of the outdoor unit

If the fault is eliminated?

The communication

circuit is abnormal

Replace the main board

of

the indoor unit

End

If the fault is eliminated?

Replace the main board

AP1 of the outdoor unit

If the fault is eliminated?

Is the connection right?

Check the wiring of the indoor and

outdoor units with reference to the

wiring diagram

Correctly connect the

corresponding wires for

the indoor and outdoor

units with reference to

the wiring diagram

53

54

Y

Y

Y

Y

Y

N

N

N

N

Start

Measure voltage at the

Test 10 position as

shown in the diagram

with a voltmeter

Value jumping

Measure voltage at the

Test 15 position as

shown in the diagram

with a voltmeter

Value jumping

Measure voltage at the

Test 11 position as

shown in the diagram

with a voltmeter

Value jumping

Measure voltage at the

Test 12 position as

shown in the diagram

with a voltmeter

Value jumping

The communication

circuit of the outdoor

unit is normal

End

Fault with

outdoor unit

55

56

57

58

59

60

61

2

Handle

2. Remove top cover

1.Remove big handle

Top panel

1 Before disassembly.

Remove the connection screw fixing the big

handle and then remove the handle.

Remove connection screws connecting the

top cover plate with the front panel and the

right side plate, and then remove the top

panel.

62

3.Remove grille and front panel

4.Remove axial flow blade

5.Remove right side plate

Remove connection screws between the front grille

and the front panel. Then remove the front grille.

Remove connection screws connecting the front

panel with the chassis and the motor support, and

then remove the front panel.

Remove the nut fixing the blade and then

remove the axial flow blade.

Remove connection screws connecting the right

side plate with the valve support and the electric

box. Then remove the right side plate.

Grille

Panel

Axial flow blade

Right side plate

63

Remove the 2 screws fixing the cover of electric box. Lift to remove the cover. Loosen the

wire and disconnect the terminal. Lift to remove the electric box assy.

6.Remove electric box assy

Electric box assy

Unscrew the fastening nut of the 4-way Valve

Assy coil and remove the coil. Wrap the 4way Valve Assy with wet cotton and unsolder

the 4 weld spots connecting the 4-way Valve

Assy to take it out.(Note: Refrigerant should

be discharged firstly.) Welding process

should be as quickly as possible and keep

wrapping cotton wet all the time. Be sure not

to burn out the lead-out wire of compressor.

7.Remove 4-way valve assy

8.Remove capillary sub-assy

Unsolder weld point of capillary Sub-assy,

valve and outlet pipe of condensator. Then

remove the capillary Sub-assy. Do not block

the capillary when unsoldering it. (Note: before unsoldering,discharg

e refrigerants

completely)

4-way Valve Assy

Capillary Sub-assy

64

Remove the 4 tapping screws fixing the motor.

Pull out the lead-out wire and remove the

motor. Remove the 2 tapping screws fixing

the motor support. Lift motor support to remove it.

9.Remove motor and motor support

Motor

Motor support

10.Remove clapboard sub-assy

Loosen the screws of the Clapboard Sub-Assy .

The Clapboard Sub-Assy has a hook on the

lower side. Lift and pull the Clapboard Sub-Assy

to remove.

Clapboard Sub-Assy

65

11.Remove Compressor

1 Remove the 2 screws fixing the gas valve.

Unsolder the welding spot connecting gas valve

and air return pipe and remove the gas valve.

(Note: it is necessary to warp the gas valve when

unsoldering the welding spot.) Remove the 2

screws fixing liquid valve. Unsolder the welding spot connecting liquid valve and remove the

liquid valve.

2 Remove the 3 footing screws of the compressor

and remove the compressor.

Compressor

Gas valve

Liquid valve

66

Loading...

Loading...