Page 1

2U Server System

Service Manual

P47

P/N: 2017-MNU-000016

June, 2018 (Revision A)

Page 2

Copyright Notice

All rights, including copyright, in the content of this manual are owned or controlled by

Inventec and protected by the Taiwan and international copyright act.

No one may, trans m it, adapt, assign, compile, rent, sale, change, copy, reproduce, distribute,

publish, display, br oadc ast, or use in any way the content of this manual, in whole or in part,

for any other purpose whatsoever without the prior written permission of Inventec.

Trademarks

All product names or brands mentioned herein are the trademarks of Inventec, its subsidiaries

or other respective owners in Taiwan, United States and other countries.

Disclaimer

This manual provides the information in relation to the set-up and installation of the product

herein. Nothing herein may be construed as granting any right or license relating to any

intellectual property rights of this manual or product. Unless otherwise provided in the

Purchase and Sale Agreement for this product, manufacturer and distributor of this product

will not be liable whatsoever relating to the distribution and/or use of this product. In addition,

manufacturer and distributor of this product hereby specifically disclaim any express or

implied warranties of merchantability, fitness for a particular purpose, or non-infringemen t of

third party rights in connection with this product.

Manufacturer of this product may have the right to change specifications and product

descriptions at any time without notice.

Page 3

Page 4

Contents

About This Manual ................................................................................................................ i

Conventions .......................................................................................................................................... i

Safety Symbols ..................................................................................................................................... ii

Safety Precautions ............................................................................................................................... iii

Operation Safety .............................................................................................................................. iii

Electrical Safety ............................................................................................................................... iv

Battery Replacement Safety ............................................................................................................ iv

Laser Peripherals or Devices Safety ................................................................................................ v

Intended Application Uses ............................................................................................................... v

Site Selection ................................................................................................................................... vi

Tools Required ................................................................................................................................. vi

Regulatory and Integration Inf ormation .............................................................................................. vii

Regulatory Compliance Identification Numbers .............................................................................. vii

Product Regulatory Com plianc e ..................................................................................................... vii

Power Cords .................................................................................................................................... ix

Rack Mount Instructions ...................................................................................................................... x

1 Introduction................................................................................................................ 1-1

1.1 Audience Assumptions .......................................................................................................... 1-1

1.2 Manual Organization ............................................................................................................. 1-1

1.3 Packing Checklist .................................................................................................................. 1-1

1.4 Specifications ........................................................................................................................ 1-2

1.5 Product Features ................................................................................................................... 1-2

1.6 System Overview ................................................................................................................... 1-4

1.6.1 Server Chassis Layout ................................................................................................... 1-4

1.6.2 Motherboard Layout ....................................................................................................... 1-6

1.6.3 Front View ...................................................................................................................... 1-8

1.6.4 Back View ...................................................................................................................... 1-9

1.6.5 Buttons and System LED Information............................................................................ 1-9

1.6.6 System Thermal Solution ............................................................................................. 1-12

2 Hardware Operations ................................................................................................ 2-1

2.1 Before You Start .................................................................................................................... 2-1

2.1.1 Power Off ....................................................................................................................... 2-1

2.2 Rear Chassis Cover .............................................................................................................. 2-2

2.2.1 To remove the rear chassis cover .................................................................................. 2-2

2.2.2 To install the rear chassis cover ..................................................................................... 2-3

2.3 Front T op Cover ..................................................................................................................... 2-5

2.3.1 To remove the front top cover ........................................................................................ 2-5

2.3.2 To install the front top cover ........................................................................................... 2-6

2.4 Cable Guide ........................................................................................................................... 2-6

2.4.1 To remove the cable guide ............................................................................................. 2-7

2.4.2 To install the cable guide ............................................................................................... 2-7

2.5 Stiffener ................................................................................................................................. 2-8

2.5.1 To remove the stiffener .................................................................................................. 2-8

2.5.2 To install the stiffener ..................................................................................................... 2-9

2.6 Motherboard .......................................................................................................................... 2-9

2.6.1 To remove the motherboard ......................................................................................... 2-10

2.6.2 To install the motherboard ........................................................................................... 2-10

2.7 Processor ............................................................................................................................ 2-11

2.7.1 To remove the heat sink ............................................................................................... 2-12

2.7.2 To install the heat sink ................................................................................................. 2-12

2.7.3 To remove the processor ............................................................................................. 2-13

2.7.4 To install the processor ................................................................................................ 2-14

Page 5

2.8 System Memory ................................................................................................................... 2-15

2.8.1 To remove the system memory .................................................................................... 2-17

2.8.2 To install the system memory ...................................................................................... 2-17

2.9 Power Supplies .................................................................................................................... 2-18

2.9.1 To remove the power supply ........................................................................................ 2-19

2.9.2 To install the power supply ........................................................................................... 2-19

2.10 System Fans ........................................................................................................................ 2-20

2.10.1 To remove the system fans .......................................................................................... 2-21

2.10.2 To install the system fans ............................................................................................. 2-21

2.11 2.5” HDDs ............................................................................................................................ 2-22

2.11.1 To remove the 2.5” HDD .............................................................................................. 2-22

2.11.2 To install the 2.5” HDD ................................................................................................. 2-23

2.12 8x2.5” HDDs Backplane ...................................................................................................... 2-24

2.12.1 To remove the 8x2.5” HDDs backplane ....................................................................... 2-25

2.12.2 To install the 8x2.5” HDDs back plane .......................................................................... 2-25

2.13 Front Panels ........................................................................................................................ 2-26

2.13.1 To remove the front panel ............................................................................................ 2-27

2.13.2 To install the front panel ............................................................................................... 2-27

2.14 OCP Card (Optional) ........................................................................................................... 2-28

2.14.1 To remove the OCP card ............................................................................................. 2-28

2.14.2 To install the OCP card ................................................................................................ 2-29

2.15 Expansion Cards ................................................................................................................. 2-29

2.15.1 To remove the expansion card ..................................................................................... 2-30

2.15.2 To install the expansion card ....................................................................................... 2-31

2.16 Fan Duct .............................................................................................................................. 2-32

2.16.1 To remove the fan duct ................................................................................................ 2-32

2.16.2 To install the fan duct ................................................................................................... 2-33

3 Connectors................................................................................................................. 3-1

3.1 Backplane Connectors .......................................................................................................... 3-1

3.2 OCP Card Connectors ........................................................................................................... 3-2

4 Cable Routing ............................................................................................................ 4-1

Appendix 1 Hazardous Substances Free Regulations and Electromagnetic Emissions

Notices ................................................................................................................................... I

China RoHS Regulations ...................................................................................................................... I

Taiwan BSMI ........................................................................................................................................ II

Electromagnetic Emissions Notices ................................................................................................... III

Federal Communications Commission notice ................................................................................ III

Notices for Canada (Avis Canadien) ............................................................................................... III

Notices for China ............................................................................................................................. III

Notices for European Union ............................................................................................................ IV

Notices for Japan ............................................................................................................................ IV

Notices for Korea ............................................................................................................................ IV

Notices for Taiwan ............................................................................................................................ V

Notices for Russia ............................................................................................................................ V

Appendix 2 BIOS SPEC

Appendix 3 BMC SPEC

Page 6

About This Manual

Conventions

Safety Symbols

Safety Precautions

Regulatory and Integration Information

Rack Mount Instructions

Page 7

Quick Start Guide

i

About This Manual

Conventions

To make sure that you perform certain tasks properly, take note of the following symbols used

throughout this manual.

Warning:

Caution:

Important:

Note:

Information to prevent injury to yourself when trying to complete a

task.

Information to prevent damage to the components when trying to

complete a task.

Information that you must follow to complete a task.

Tips and information to aid in completing a task.

2017-MNU-000016

Page 8

Quick Start Guide

ii

Indicates the potential hazard of energy circuits or electric shock. To reduce

Any surface or area of the equipment marked with this symbol

To reduce the risk of injury from electric shock hazards, do not

open this enclosure.

receptacle.

This symbol, on power supplies or systems, indicates that the equipment is

To reduce the risk of injury from electric shock, remove all power

cords to completely disconnect power from the system.

This symbol indicates that the component exceeds the recommended weight

Safety Symbols

Before troubleshooting, you must be familiar with the safety information listed below. In order

to avoid any potential hazards, the following symbols may be placed on some components of

the server.

The shape and the color of symbols shown below are mainly for your reference. Please take

the actual shipment as standard.

the risk of injury from electric hazards, do not open this enclosure.

Warning:

indicates the presence of electric shock hazards. The enclosed area contains

no operator serviceable parts.

Indicates the potential hazard of electric shock. The enclosed area contains

no user of field serviceable parts. Do not open for any reason.

Warning:

Weight i n kg.

Weight i n lb.

Indicates the presence of a hot surface or hot component.

Warning: To reduce the risk of injury from a hot component, allow the surface

to cool before touching it.

Any RJ45 receptacle marked with this symbol indicates a network interface

connection.

Warning: To reduce the risk of electric shock, fire, or damage to the

equipment, do not plug telephone or telecommunications connectors into this

supplied by multiple sources of power.

Warning:

for one individual to handle safely.

Warning: To reduce the risk of personal injury or damage to the equipment,

observe local occupational health and safety requirements and guidelines for

manual material handling.

2017-MNU-000016

Page 9

Quick Start Guide

iii

Regarding the standards of workstation regulations, do not place the server in the visual

Any operation on this server must be conducted by certified or experienced engineers.

Safety Precautions

Observe the following safety precautions when you are connecting or disconnecting any

device.

field of the user, because of the glossy front of the case.

The product is non-consumer product and for profession technical person used only.

Operation Sa fety

Before operating your server, carefully read all the manuals included with the server

package.

Before using the server, make sure that all cables are correctly connected and power

cords are not damaged. If any damage is detected, contact your dealer as soon as

possible.

T o av oi d short circuits, keep paper clips, screws, and staples away from connectors, slots,

sockets and circuitry.

Before opening the chassis panels, make sure all power cords are unplugged.

Avoid dust, humidity, and extreme temperatures; place the server on a stable surface.

If the power supply is broken, do not try to fix it by yourself. Contact an authorized dealer.

It is recommended that you wear gloves when assembling or disassembling the server to

protect from cuts and scrapes.

W hen the server is powered on, heat sinks and the surfaces of certain IC devices may be

hot. Do not touch them. Check whether the fans are functioning properly.

2017-MNU-000016

Page 10

Quick Start Guide

iv

possible shock from touching two surfaces with different electrical potentials.

If you have an antistatic wrist strap available, use it while handling the device.

it is out of the anti s tatic bag, lay it o n th e antista tic

Electrical Safety

Before installing or removing signal cables, ensure that the power cords for the system

unit and all attached devices are unplugged.

To prevent electric shock hazard, disconnect the power cable from the electrical outlet

before relocating the system.

W hen adding or removing any additional device to or from the system, ensure that the

power cords for those devices are unplugged before the signal cables are connected. If

possible, disconnect all power cords from the existing system before you add a device.

Use one hand, when possible, to connect or disconnect signal cables to prevent a

This product is equipped with a three-wire power cable and plug for user safety. Use the

power cable with a properly grounded electrical outlet to avoid electric shock.

Motherboards, adapters, and disk drives are sensitive to static electricity discharge. These

devices are wrapped in antistatic bags to prevent this damage. Take the following precautions:

Do not remove the device from the antistatic bag until you are ready to install the device in

the system unit.

W ith the device still in its antistatic bag, touch it to a metal frame of the system.

Grasp cards and boards by the edges. Hold drives by the frame. Avoid touching the solder

joints or pins.

If you need to lay the device down while

bag. Before picking it up again, touch the antistatic bag and the metal frame of the system

unit at the same time.

Handle the devices carefully to prevent permanent damage.

Battery Replacemen t Safety

This server is provided with an internal Lithium battery or battery pack. There is a danger of

explosion and risk of personal injury if the battery is incorrectly replaced or mistreated.

For more information about battery replacement or proper disposal, contact an authorized

reseller or your authorized service provider.

2017-MNU-000016

Page 11

Quick Start Guide

v

Return to manufacturer for servicing.

This server contains an internal Lithium Manganese Dioxide, or a Vanadium Pentoxide, or an

alkaline battery pack. There is risk of fire and burns if the battery pack is not handled properly.

To reduce the risk of personal injury:

Do not attempt to recharge the battery.

Do not expose to temperatures higher than 70°C.

Do not disassemble, crush, puncture, shorten external contacts, or dispose in fire or water.

Replace only with the spare parts designated for this product.

Batteries should not be littered along with the general household waste. Please use the public

collection system or return them to the supplier.

Laser Peripherals or De vi ces Safety

To avoid risk of radiation exposure and/or personal injury:

Do not open the enclosure of any laser peripheral or device.

Laser peripherals or devices are not user serviceable.

Intended Application Uses

This product was evaluated as Information Technology Equipment (ITE), which may be

installed in server rooms, computer rooms and similar commercial type locations. The

suitability of this product for other product categories and environments (such as medical,

industrial, residential, alarm systems, and test equipment), other than an ITE application, may

require further evaluation.

2017-MNU-000016

Page 12

Quick Start Guide

vi

Access can only be gained by SERVICE PERSONS about the reasons for the restrictions

controlled by the authority responsible for the location.

hazardous condition is not achieved due to uneven mechanical loading.

Site Selection

Restricted Access Location: location for equipment is intended for installation only in a Server

Room or Computer Room where both of the following apply:

applied to the location and about any precautions that shall be taken.

Access is through the use of a TOOL or lock and key, or other means of securtiy, and is

The system is designed to operate in a typical office environment. Choose a site that is:

Clean, dry, and free of airborne particles (other than normal room dust).

Well-ventilated and away from sources of heat including direct sunlight and radiators.

Away from sources of vibration or physical shock.

Isolated from strong electromagnetic fields produced by electrical devices.

In regions that are susceptible to electrical storms, we recommend you plug your system

into a surge suppresser and disconnect telecommunication lines to your modem durin g an

electrical storm.

Provided with a properly grounded wall outlet.

Provided with sufficient space to access the power supply cord(s), because they serve as

the product's main power.

Mechanical Loading – Mounting of the equipment in the rack should be such that a

Tools Required

A cross screwdriver or a flat screwdriver is needed to install or remove the components in the

server.

2017-MNU-000016

Page 13

vii

Quick Start Guide

Regulatory and Integration Information

Regulatory Compliance Identi fication Numbers

For the purpose of regulatory compliance certifications and identification, this server is

assigned a serial number. This server serial number can be found on the product label, along

with the required approval markings and information. When requesting certification

information for this product, always refer to this serial number. This serial number should not

be confused with the marketing name or model number.

Product Regulatory Compliance

Worldwide Safety approvals can be supplied according to the requirements from Marketing or

Customer.

Product Safety Compliance

The designs of server complies with the following safety requirements:

Table i Product Safety Requirements

IEC 60950-1 Safety of Information Technology Equipment

EN 60950-1 Safety of Information Technology Equipment Including Electrical

Business Equipment, European Committee for Electrotechnical

Standardization (CENELEC)

UL 60950-1 Safety of Information Technology Equipment

UL 94 Tests for Flammability of Plastic Materials for Parts in Devices &

Appliances

GB4943 Safety of Information Technology Equipment

Product EMC Compliance

This product has been tested and verified to comply with the following electromagnetic

compatibility (EMC) regulations.

Communications Commission Notice

Part 15 of the Federal Communications Commission (FCC) Rules and Regulations has

established Radio Frequency (RF) emission limits to provide an interference-free radio

frequency spectrum. Many electronic devices, including computers, generate RF energy

incidental to their intended function and are, therefore, covered by these rules. These rules

place computers and related peripheral devices into two classes, A and B, depending upon

their intended installation. Class A devices are those that may reasonably be expected to be

2017-MNU-000016

Page 14

Quick Start Guide

viii

Table ii European Union EMC Requirements

installed in a business or commercial environment. Class B devices are those that may

reasonably be expected to be installed in a residential environment (for example, personal

computers). The FCC requires devices in both classes to bear a label indicating the

interference potential of the device, as well as additional operating instructions for the user.

The rating label on the device shows which class (A or B) the equipment falls into. Class A

devices do not have an FCC logo or FCC ID on the label. Class B devices have an FCC logo

or FCC ID on the label. Once the class of the device is determined, refer to the following

corresponding statement.

Class A Equipment

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can r adiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference, in which case the user will be required to correct the

interference at personal expense.

Declaration of Conformity for Produ ct s M ar ked with the FCC Logo—United States Only

This device complies with Part 15 of the FCC Rules Operation and is subject to the following

two conditions: (1) this device may not cause harmful interference, and (2) this device must

accept any interference received, including interference that may cause undesired operation.

For questions regarding your product, please contact the supplier.

To identify this product, refer to the Part, Series, or Model number found on the product.

European Union Notice

Products with the CE Marking comply with both the EMC Directive (89/336/EEC) and the

Low-Voltage Directive (73/23/EEC) issued by the Commission of the European Community.

Compliance with these directives implies conformity to the following European Norms (in

brackets are the equivalent international standards):

EN55032 (CISPR 32) Electromagnetic Interference

EN55024 (IEC61000-4-2,3,4,5,6,8,11) Electromagnetic Immunity

EN61000-3-2 (IEC61000-3-2) Power Line Harmonics

EN61000-3-3 (IEC61000-3-3) Power Line Flicker

2017-MNU-000016

Page 15

ix

Canadian Notice (Avis Canadien)

Class A Equipment

Japanese Notice

Quick Start Guide

Taiwanese Notice

Power Cords

The power cord set included in the server meets the requirements for use in the country

where the server was purchased. If this server is to be used in another country, purchase a

power cord that is approved for use in that country.

The power cord must be rated for the product and for the voltage and current marked on the

product's electrical ratings label. The voltage and current rating of the cord should be greater

than the voltage and current rating marked on the product. In addition, the cross-sectional

area of the wires must be a minimum of 1.00mm² or 18AWG, and the length of the cords must

be between 1.8m (6 feet) and 3.6m (12 feet). If you have questions about the type of power

cord to use, contact an authorized service provider.

2017-MNU-000016

Page 16

Quick Start Guide

x

Route power cords so that they will not be walked on or pinched by items placed upon or

against them. Pay particular attention to the plug, electrical outlet, and the point where the

cords exit from the product.

Rack Mount Instructions

The following or similar rack-mount instructions are included with the installation instructions:

Elevated Operating Ambient - If installed in a closed or multi-unit rack assembly, the

operating ambient temperature of the rack environment may be greater than room

ambient. Therefore, consideration should be given to installing the equipment in an

environment compatible with the maximum ambient temperature (Tma) specified by the

manufacturer.

Reduced Air Flow - Installation of the equipment in a rack should be such that the amount

of air flow required for safe operation of the equipment is not compromised.

Mechanical Loading - Mounting of the equipment in the rack should be such that a

hazardous condition is not achieved due to uneven mechanical loading.

Circuit Overloading - Consideration should be given to the connection of the equipment to

the supply circuit and the effect that overloading of the circuits might have on overcurrent

protection and supply wiring. Appropriate consideration of equipment nameplate ratings

should be used when addressing this concern.

Reliable Earthing - Reliable earthing of rack-mounted equipment should be maintained.

Particular attention should be given to supply connections other than direct connections to

the branch circuit (e.g. use of power strips).

2017-MNU-000016

Page 17

Chapter 1

Introduction

Audience Assumptions

Manual Organization

Packing Checklist

Specifications

Product Features

System Overview

Page 18

Introduction

1-1

Table 1-1 Manual Introduction

Table 1-2 Packing Checklist

1 Introduction

1.1 Audi ence Assumptions

This document is for the person who installs, administers, and troubleshoots servers and

storage systems. Inventec assumes you are qualified in the servicing of computer equipment

and trained in recognizing hazards in products with hazardous energy levels.

1.2 Manual Organization

This manual introduces the chassis along with the hardware information, and how to replace

the hardware and connect the cables. This manual is generally organized as follows:

Introduction

Hardware

Operations

Connectors

Cable Connections

Appendix

General server introduction.

The operation of the components on the chassis, such as power

supply, power distribution board, system fans, backplane, and riser

card.

Information about connectors on the various boards in the system.

How to connect cables correctly.

China RoHS Regulations information.

1.3 Packi ng C hecklist

Make sure you have all the co mponents shipped with your sy stem. If any item contained in the

package is damaged or missing, please contact your local dealer for replacement. In addition,

keep the box and packing materials for possible future use. The server is shipped with the

following:

Chassis

Cables

2017-MNU-000016

2U rack-mounted chassis

Main power cable, backplane power cable, SATA/SAS HDD

cable, system fan cables, front panel cables, and so forth

Page 19

1-2

1.4 Specifications

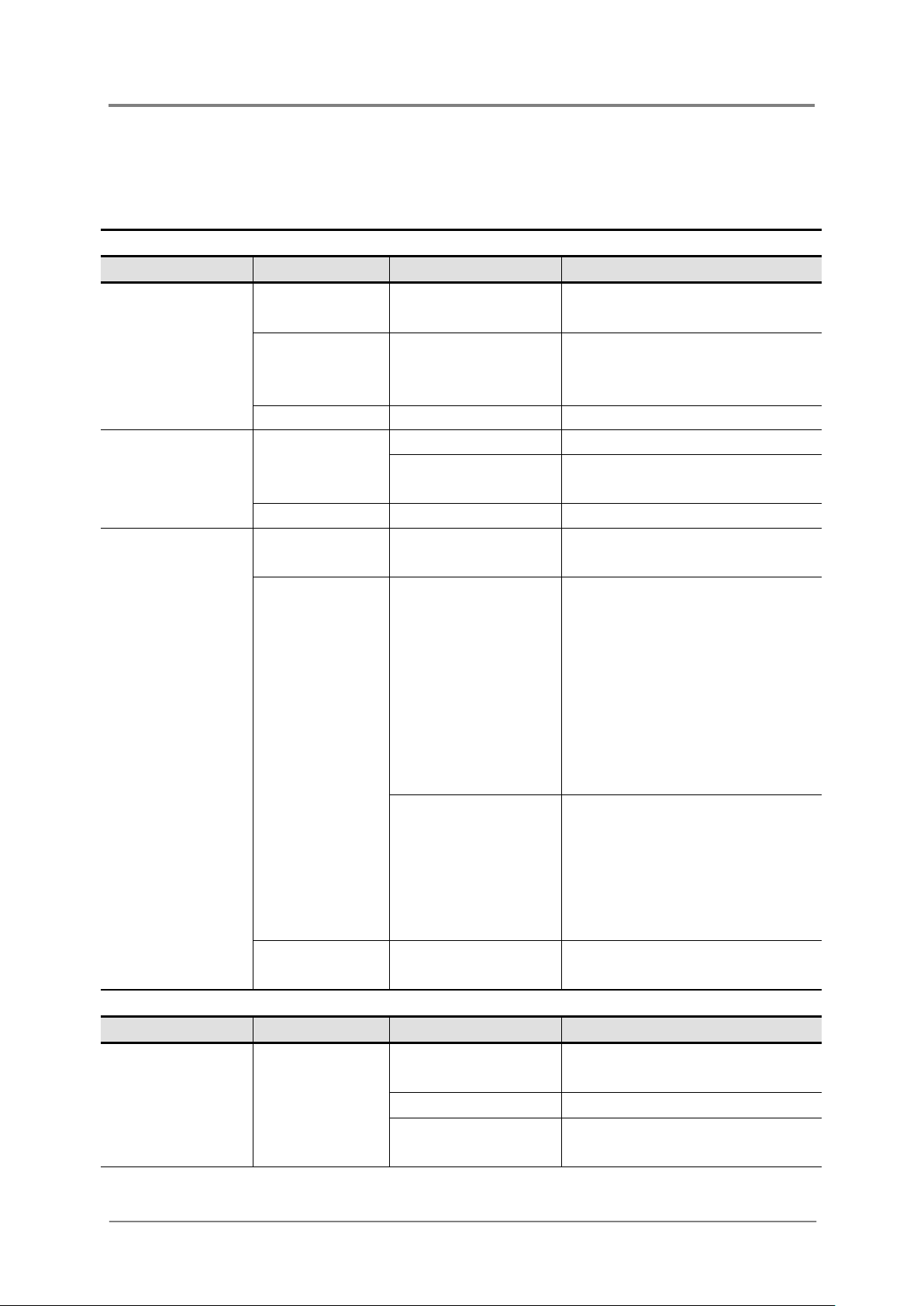

Table 1-3 Specifications

Figure 1-1 Product Introduction with OCP Card

The table below is the technical specifications for the server.

Height: 8.69cm

Introduction

Dimensions

Weight

Temperature

Humidity

Voltage

Current

1.5 Product Features

Width: 43.69cm

Length: 73.66cm

Max. Weight: 24.96KG

Operating System: +5°C ~ +35°C

Non-operating System: -40°C ~ +70°C

Operating System: +20% ~ +80%

Non-operating System: +10% ~ +90%

100-240VAC input, 1600Watt (1 power supply)

100-240VAC input, 3200Watt (2 power supplies)

10-4A (1 power supply)

20-8A (2 power supplies)

2017-MNU-000016

Page 20

1-3

Figure 1-2 Product Introduction without OCP Card

Table 1-4 Product Features

Introduction

Chassis

Power

Storage

Backplane

System Fan

Processor

System

Memory

BMC

Onboard

Storage Ports

2U rack-mounted chassis

1x 1600W/2000W Platinum power supply

Or 2x1600W/2000W redundant Platinum power supplies

8x2.5” hot-pluggable HDDs

8x2.5” HDD Passive Backplanes

Number of fan cage: 6

1x AMD Naples SP3 processor

Up to 150W ~ 200W thermal design power (TDP)

Up to 4 Die 8 core per Die

Up to 8 16-bit IO links

16x DDR4 DIMM slots

8 channels per processor

Supports ECC registered DIMM(RDIMM) at

1866/2133/2400/2667MHz

Aspeed AST2500 BMC

Up to 8x SATA 6Gb/s ports

2x M.2 NVMe Connecors

Rear IO Ports

2017-MNU-000016

2x U.2 NVMe Connecors

1x USB Port 3.0

1x VGA Port

1x management Port

1x Serial Port

Page 21

Introduction

1-4

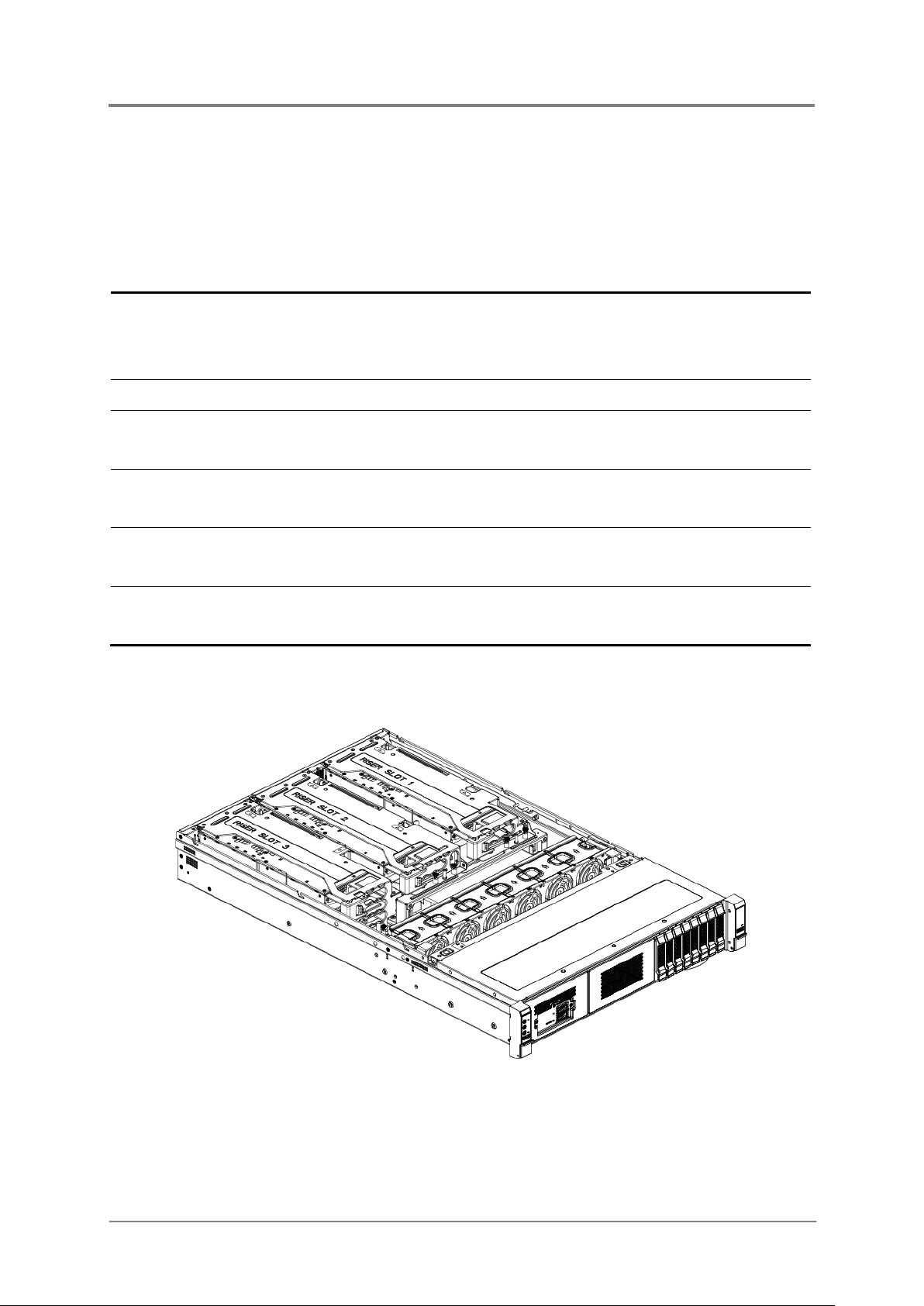

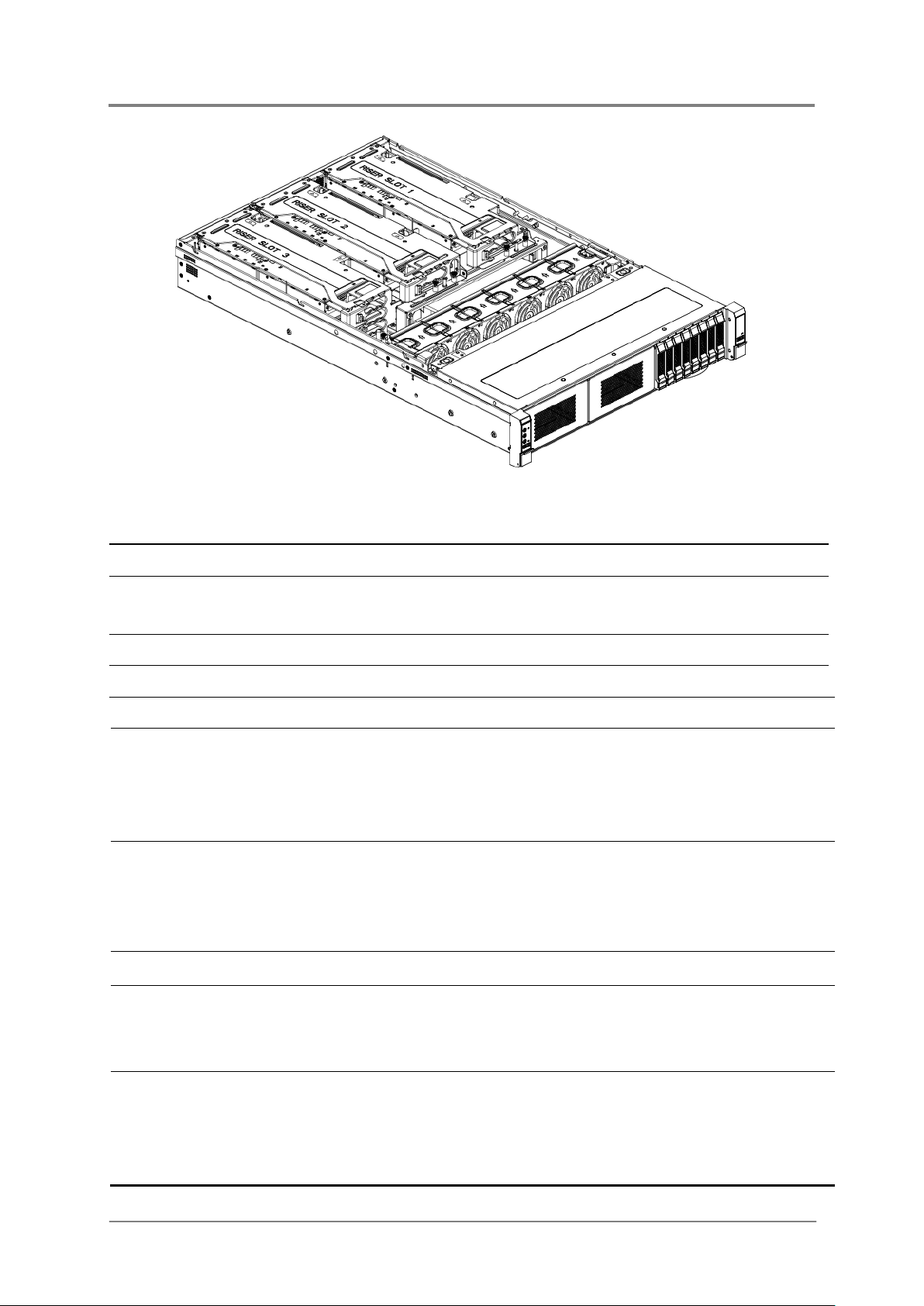

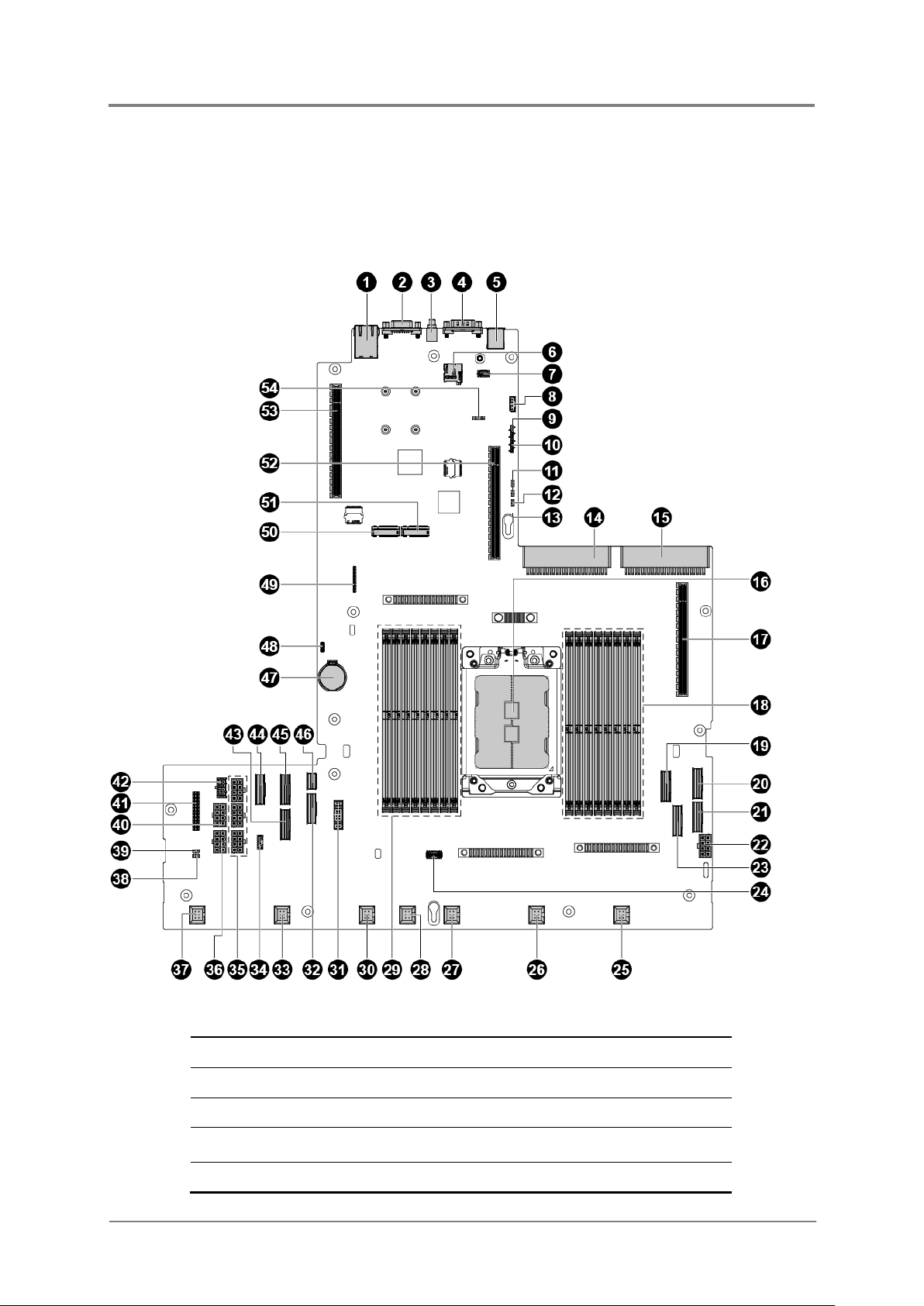

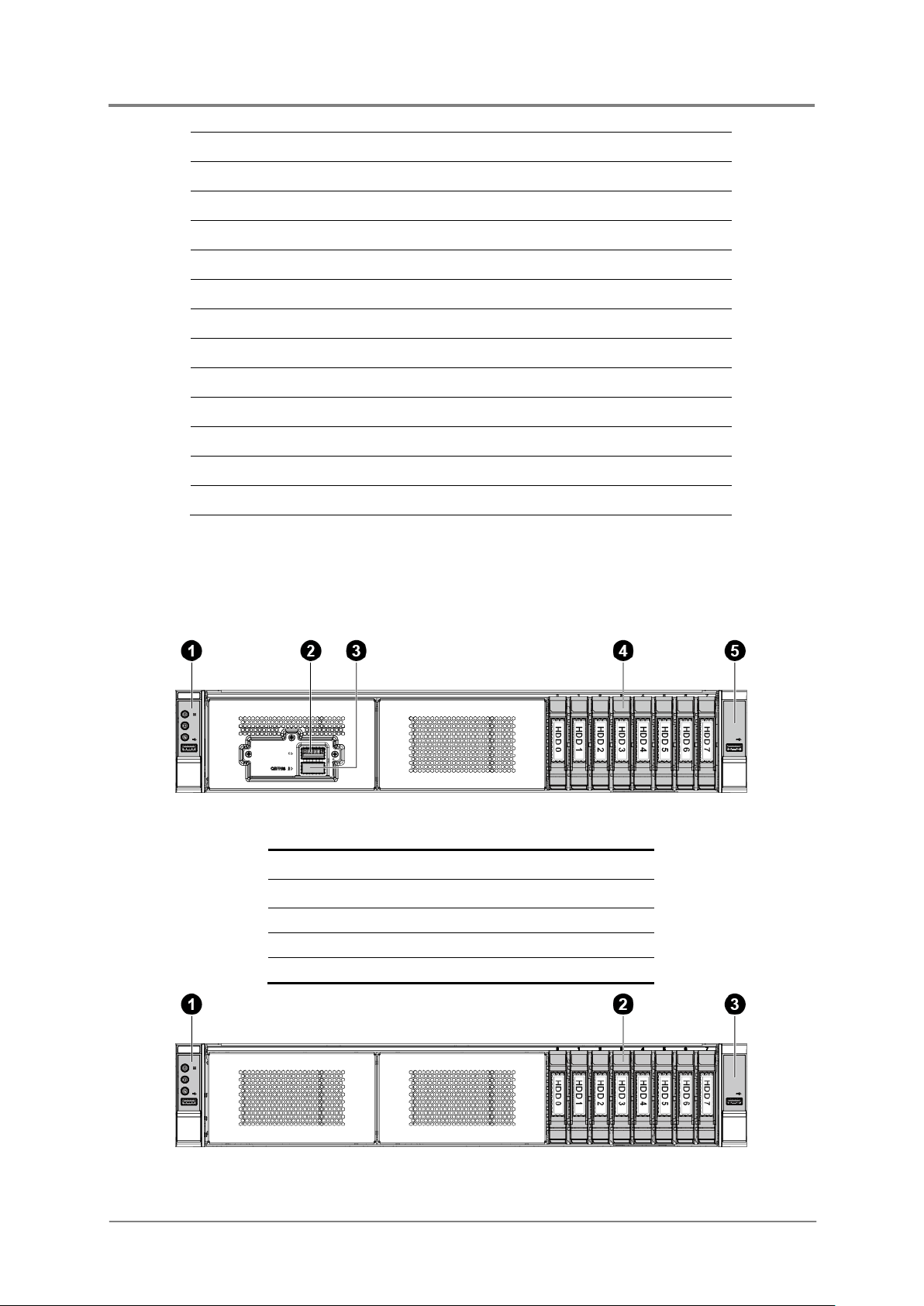

Figure 1-3 System Overview with OCP Card

Front Panel 2

Expansion Card Assembly of GPU 1

Onboard Slots

3xPCI-E x16 Gen3 slots

1.6 System Overview

1.6.1 Server Chassis Layout

1

2

3

4

Fan Duct

System Fans

2.5” HDD Backplane

2.5” HDD Bays

5

6

7

8

9

10

Front Panel 1

OCP Card (Optional)

Motherboard

Expansion Card Assembly of GPU 3&4

Expansion Card Assembly of GPU 2

11

12

13

Power Supply 1

Power Supply 2

2017-MNU-000016

Page 22

Introduction

1-5

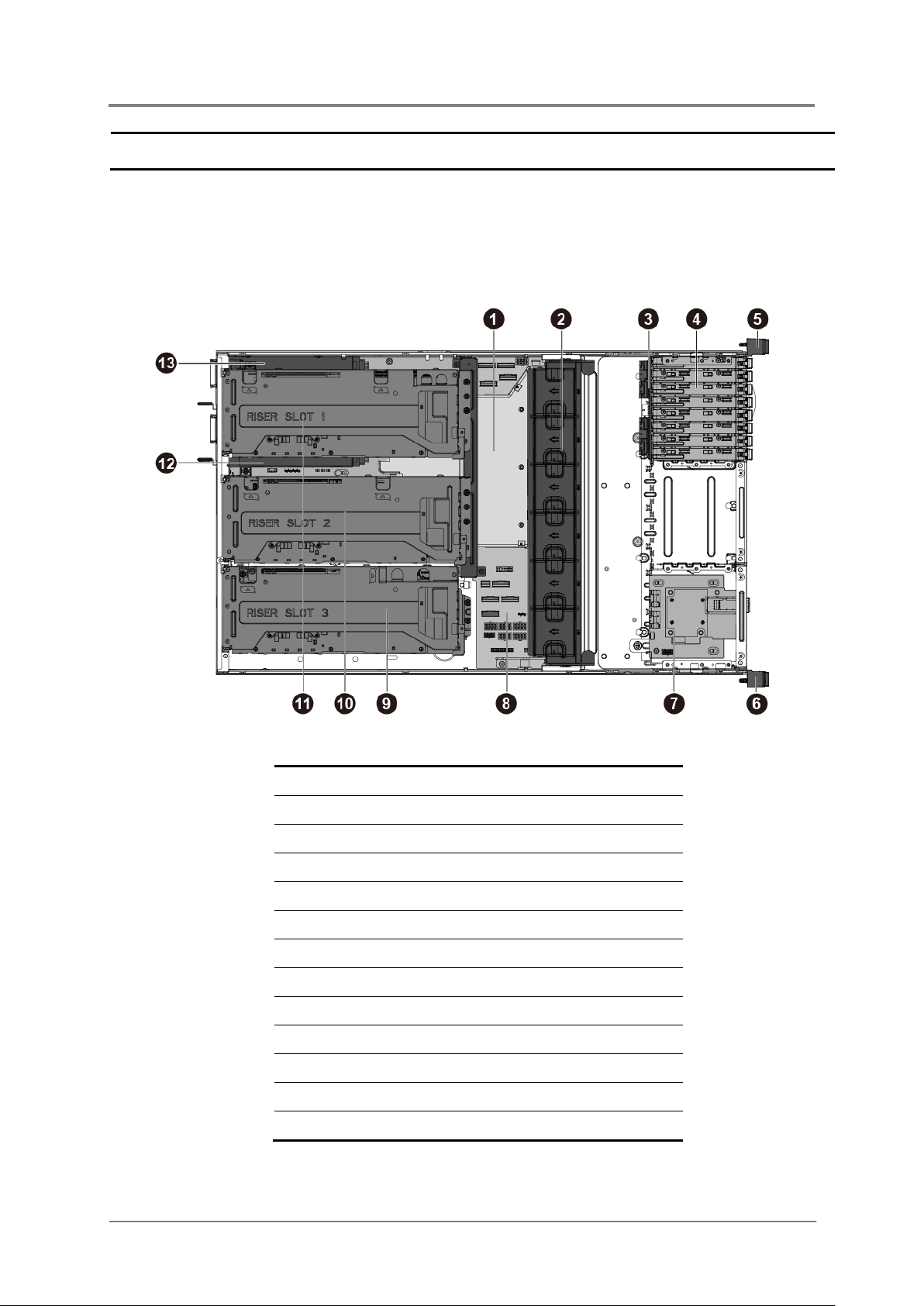

Figure 1-4 System Overview without OCP Card

Fan Duct

2.5” HDD Backplane

Front Panel 2

Motherboard

Expansion Card Assembly of GPU 2

Power Supply 1

1

2

3

4

5

6

7

8

9

10

11

12

System Fans

2.5” HDD Bays

Front Panel 1

Expansion Card Assembly of GPU 3&4

Expansion Card Assembly of GPU 1

Power Supply 2

2017-MNU-000016

Page 23

Introduction

1-6

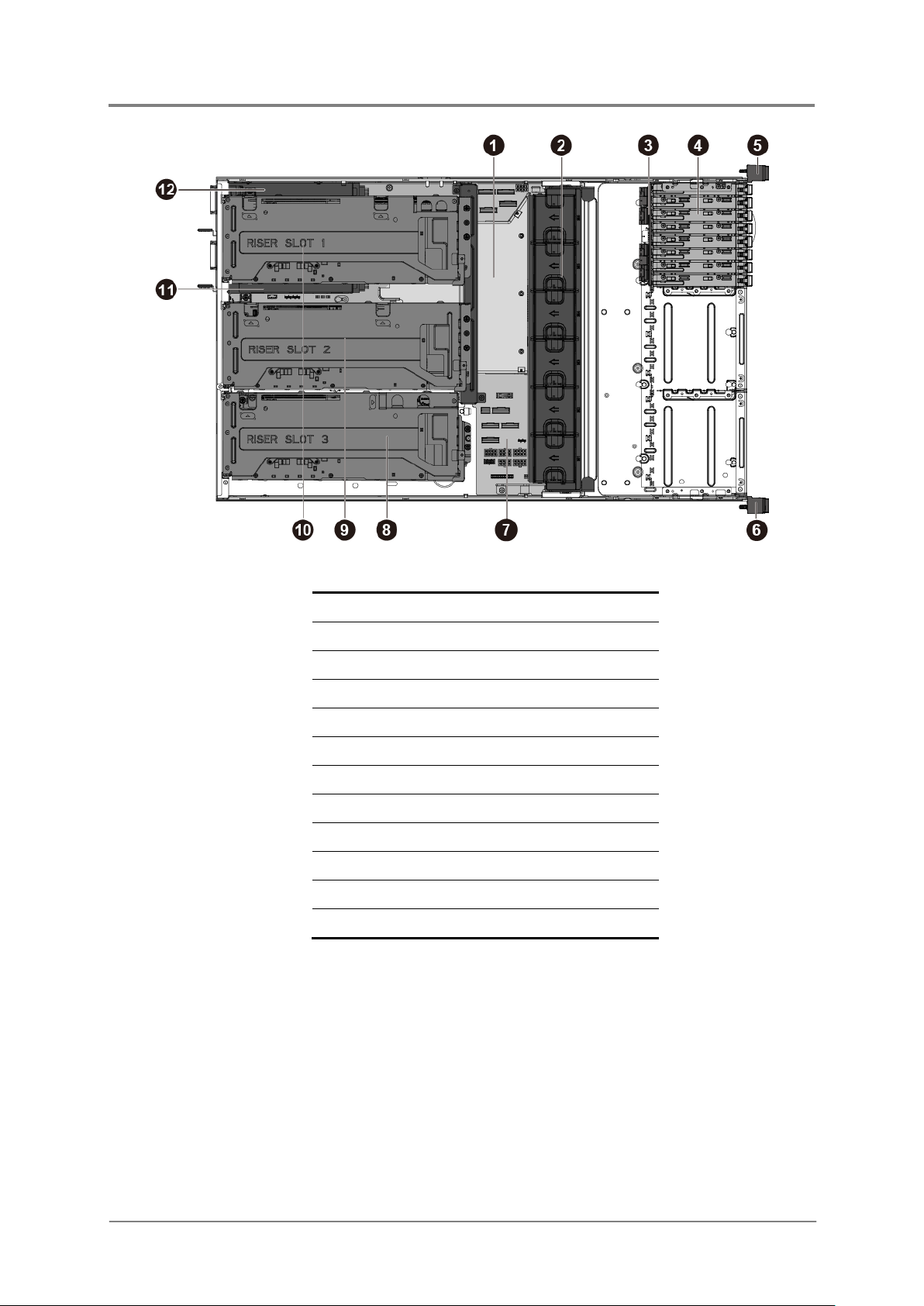

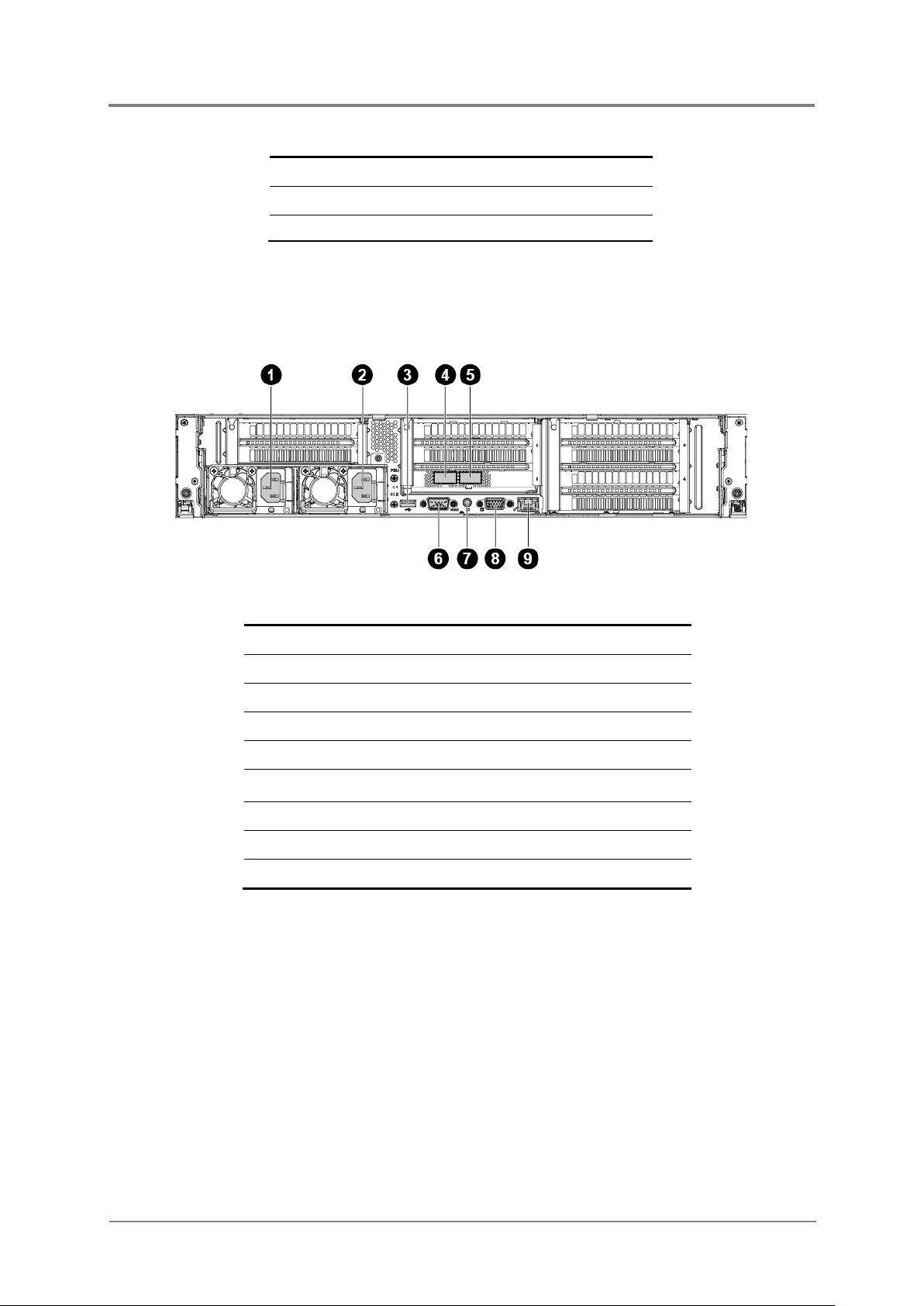

Figure 1-5 Connectors and Component Locations of Motherboard

1.6.2 Motherboard Layout

The layout of the motherboard is shown below. Each connector and major components are

identified by number.

1 Management Port (J34)

2 VGA Connector (J35)

3 UID Button (SW2)

4 Serial Port (J67)

5 Rear Single USB Port (J33)

2017-MNU-000016

Page 24

1-7

6 Micro-SD Card Socket (J50)

8

IPMB Connector (J36)

7 TPM Connector (J58)

9 BMC SIO connector (J66)

10 CPU UART 1x4 connector (J45)

11 BMC Intruder Jumper (J68)

12 BIOS Recovery Jumper (J75)

Introduction

13 Password Clear Jumper (J76)

14 Power Supply Connector (J1)

15 Power Supply Connector (J73)

16 Processor

17 PCI-E X16 Gen3 Slot1 (J21)

18 DIMM Slots (J10, J11, J12, J13, J14, J15, J16, J 17)

19 PCI-E x8 Slimline Connector (G3) (J46)

20 PCI-E x8 Slimline Connector (G2) (J19)

21 PCI-E x8 Slimline Connector (G3) (J20)

22 HDD Backplane Power Connector (J53)

23 SATA Slimline Connector Port 1 (G2) (J71)

24 AMD HDT connector (J47)

25 Fan Connector 1 (J37)

26 Fan Connector 2 (J38)

27 Fan Connector 3 (J39)

28 Fan Connector 7 (J98)

29 DIMM Slots (J3, J61, J5, J60, J6, J7, J8, J9)

30 Fan Connector 4 (J40)

31 Front Panel USB Connector (J57)

32 PCI-E x8 Slimline Connector (G1) (J24)

33 Fan Connector 5 (J41)

34 3.5” HDD Backplane I2C Signals Connector (J101)

35 GPU Power Connectors (J18, J23, J78)

36 HDD Backplane +5V Power Connector (J100)

37 Fan Connector 6 (J42)

38 System Reset Jumper (J65)

39 NMI Jumper (J70)

40 GPU Power Connector (J77)

41 Front Panel Connector (J48)

2017-MNU-000016

Page 25

Introduction

1-8

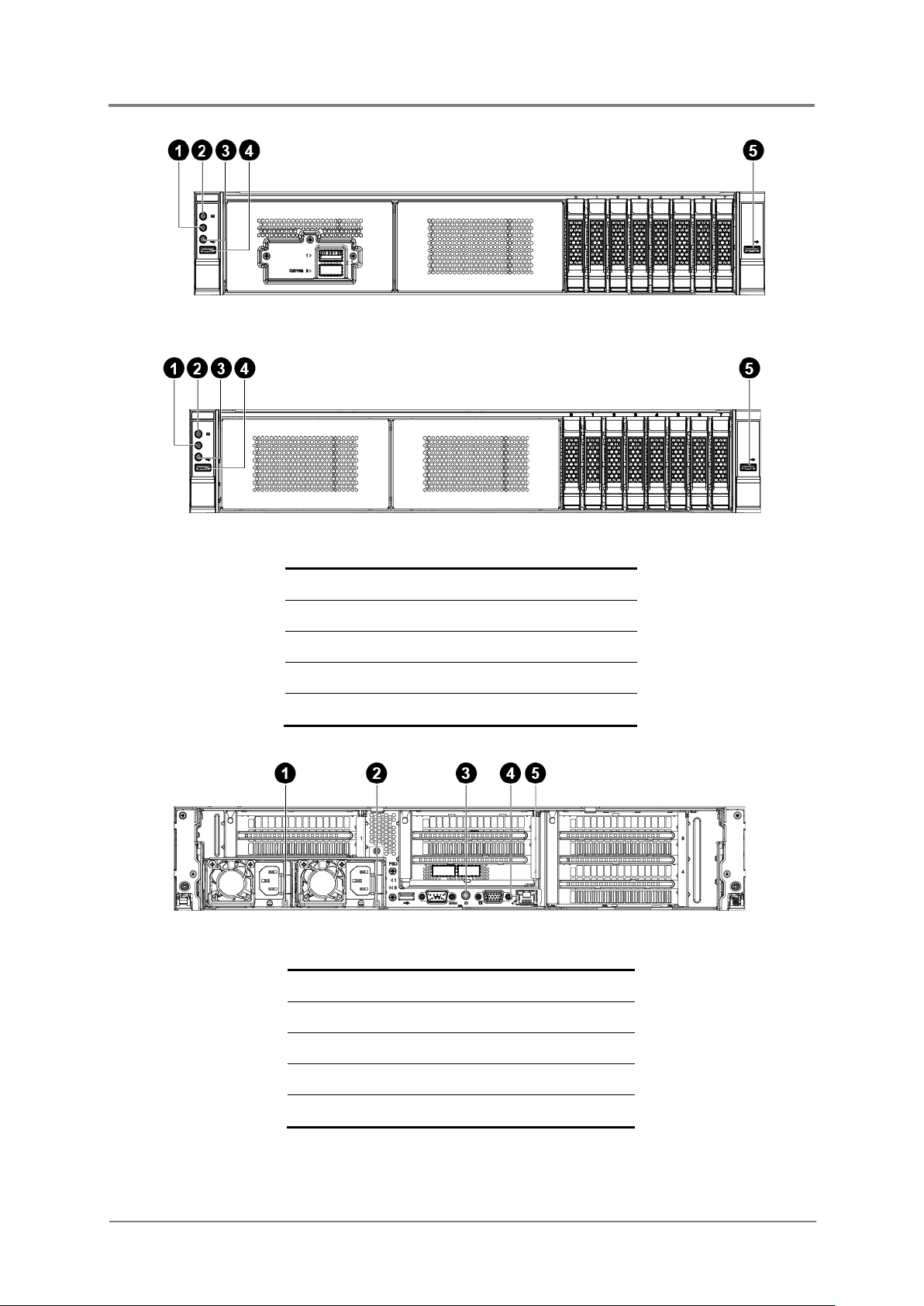

Figure 1-6 Front View with OCP Card

3

QSFP Port 2

4

HDDs

5

Front Panel 2

42 OCP Power Connector (J99)

43 PCI-E x8 Slimline Connector (G0) (J27)

44 PCI-E x8 Slimline Connector (G0) (J32)

45 PCI-E x8 Slimline Connector (G1) (J26)

46 PCI-E x4 Slimline Connector (P0) (J31)

47 System Battery (BH1)

RTC Connector (J56)

48

CPLD JTAG connector (J55)

49

50 M.2 Connector (J51)

51 M.2 Connector (J72)

52 PCI-E X16 Gen3 Slot2 (J28)

PCI-E X16 Gen3 Slot3 (J29)

53

VRD I2C Connector (J115)

54

1.6.3 Front View

The system supports up to 8 2.5” HDDs. The front view of this 2U server allows easy access

to HDDs. In addition, the front panel with buttons and system LEDs is located on the front.

Front Panel 1

1

2 QSFP Port 1

2017-MNU-000016

Figure 1-7 Front View

Page 26

1-9

Front Panel 1

3

Front Panel 2

Figure 1-8 Back View

VGA Connector

1

2 HDDs

1.6.4 Back View

The server back view includes the connectors of the external system devices.

Introduction

AC Power Connector 2

1

AC Power Connector 1

2

Rear Single USB Port

3

QSFP Port 1

4

QSFP Port 2

5

Serial Port (For BMC debug use only)

6

UID Button

7

8

Management Port

9

1.6.5 Buttons and System LED Inform ation

This server is equipped with system LED indicators, and buttons located on the front panels.

The front panel status LEDs allow constant monitoring of basic system functions while the

server is operating. These LEDs provide visual cues to the status of power and ID of

motherboard.

2017-MNU-000016

Page 27

Introduction

1-10

Figure 1-9 Front Panel Buttons and LEDs with OCP Card

Figure 1-10 Front Panel Buttons and LEDs

Figure 1-11 Back View LEDs

1 ID Button/LED

2 Power Button/LED

3 Reset Button

4 USB 3.0 Port 0

5 USB 3.0 Port 1

1 AC Power LED 2

2 AC Power LED 1

3 UID LED

4 Speed LED of Management Port

5 Link/Activity LED of Management Port

2017-MNU-000016

Page 28

1-11

The detailed LED information is shown below:

Front View LEDs

LED Type

Color

Status

Function

System is powered on. (S0, DC

on)

off)

-

Off

AC power is disconnected.

via software.

-

Off

ID LED is off as Default.

operation.

Non-recoverable failure, e.g.

off.

off.

system power off in normal.

Back View LEDs

LED Type

Color

Status

Function

normally.

Blinking (0.5Hz)

Standby mode is normal.

and in offline mode.

Table 1-5 LED Information

Green On

Introduction

Power LED

ID LED

System Health

LED

Amber On

On ID LED is turned on by BMC.

Blue

Blinking

Green On

On

Red

System is powered off. (S5, DC

Unit selected for identification

System i s ready and in normal

Non-recoverable

temperature/voltage

threshold,

VRD hot asserted,

Minimum number of fans

does not present or failed.

It could last even when power

AC Power LED Green

2017-MNU-000016

Blinking

- Off

On

Blinking (2Hz)

Critical alarm, e.g.

Critical temperature/voltage

threshold,

Power fault

It could last even when power

AC power is disconnected or

Output is ON and works

Sleep PSU is in cold redundant

Page 29

1-12

Amber On

-

Off

No AC power.

Green

On

Link at first level speed.

On

Link ON without accessing

Blinking

Link ON with accessing

-

Off

No link.

Introduction

Standby mode with OTP

range

12V Fault (include: OVP,

UVP, OCP, SCP, and OTP).

Fan locks 15 seconds

including standby mode.

Speed LED of

Base-T port 0/1

Amber On Link at others speeds.

- Off No link.

Link/Activity LED

Green

of Base-T port 0/1

1.6.6 System Thermal Solution

This server provides a thermal solution to keep proper cooling. The components in the

following figure must be installed in place.

2017-MNU-000016

Figure 1-12 Thermal Solution

Fan Duct

1

Page 30

Chapter 2

Hardware Operations

Before You Start

Rear Chassis Cover

Front Top Cover

Cable Guide

Stiffener

Motherboard

Power Supplies

System Fans

2.5” HDDs

8x2.5” HDD Backplane

Front Panels

OCP Card

Expansion Cards

Fan Duct

Page 31

Hardware Operations

2-1

Figure 2-1 Pressing the Power Button

The components shown in this chapter are mainly for your reference. Please take the

actual shipment as standard.

To reduce the risk of injury from electric shock, remove the power

disconnect power from the system.

Moving the Power On/Off switch to the Of f position does not completely remov e pow er

from the system. Some portions of the power supply and

remain active. Disconnect all power

power from the system.

2 Hardware Operations

This chapter describes the hardware setup procedures that you have to perform when

replacing system components. It also gives detailed information on the internal components

and how to replace them.

2.1 Before You Start

Take note of the following operations before you start to remove or install internal

components.

2.1.1 Power Off

cord to completely

some internal circuitr y

cords from the server to completely remove

To press the power button:

Press the power button to toggle the server to standby. The power LED in green turns

off.

2017-MNU-000016

Page 32

2-2

To remove the power cords:

Figure 2-2 Unplugging the Power Cords

the server, see “2.1.1 Power Off”.

Figure 2-3 Releasing the Chassis Cover

First unplug the power cords from the AC outlet and then from the server.

2.2 Rear Chassis Cover

Hardware Operations

The server is a 2U form factor designed for easy assembly and disassembly, making the

replacement of internal components very convenient.

Reminder

Before you remove or install the rear chassis cover, please follow the step below:

Step 1:

Make sure the server is not turned on or connected to the AC power. To power off

2.2.1 To remove the rear chassis cover

Release the screw on the chassis cover.

Push the retaining clip along the direction of the arrow.

2017-MNU-000016

Page 33

2-3

Pull up the retaining clip completely to the biggest angle.

Figure 2-5 Locating the Cover onto the Chassis

Simultaneously the cover automatically slides backward.

Remove the cover from the chassis.

Figure 2-4 Removing the Chassis Cover

Hardware Operations

2.2.2 To install the rear c hassis cover

Locate the chassis cover onto the chassis.

Simultaneously pull up the retaining clip completely with the biggest angle, and align the

locking tabs on the cover to the corresponding notches on the chassis.

2017-MNU-000016

Page 34

Hardware Operations

2-4

Figure 2-6 Secure the retaining clip

Figure 2-7 Tightening the Screw

This

cooling.

Secure the retaining clip and simultaneously the cover automatically slides back into place.

Secure the chassis cover with one screw.

system must be operated with the chassis cover installed to ensure proper

2017-MNU-000016

Page 35

Hardware Operations

2-5

Figure 2-8 Removing the Front T op Cover

2.3 Front Top Cover

The server is a 2U form factor designed for easy assembly and disassembly, making the

replacement of internal components very convenient.

Reminder

Before you remove or install the front top cover, please follow the step below:

Step 1:

Step 2:

2.3.1 To remove the front top cover

Press down the retaining clip.

Make sure the server is not turned on or connected to the AC power. To power off

the server, see “2.1.1 Power Off”.

Remove the rear chassis cover. To remove the rear chassis cover, see“2.2 Rear

Chassis Cover”.

Remove the front top cover along the direction of the arrow.

2017-MNU-000016

Page 36

Hardware Operations

2-6

Figure 2-9 Installing the Front Top Cover

This

cooling.

2.3.2 To install the front top cover

Locate the front top cover onto the chassis with the locking tabs on the cover snap into the

corresponding notches on the chassis.

system must be operated with the chassis cover installed to ensure proper

2.4 Cable Guide

The locations of cable guide on the server is shown below:

Figure 2-10 Cable Guide Location

2017-MNU-000016

Page 37

2-7

Step 1:

Make sure the server is not turned on or connected to the AC power. To power off

Step 2:

Remove the rear chassis cover. To remove the rear chassis cover, see“2.2 Rear

Chassis Cover”.

Step 3:

Step 4:

Disconnect all necessary cables.

Figure 2-11 Removing the Cable Guide

Reminder

Before you remove or install the cable guide, please follow the steps below:

the server, see “2.1.1 Power Off”

Remove the fan duct. T o remove the fan duct, see “2.16 Fan Duct”.

2.4.1 To remove the cable guide

Hardware Operations

Remove the two screws that secure the cable guide.

Lift the cable guide out of the chassis.

2.4.2 To install the cable gui de

Reverse the steps above to install the cable guide.

2017-MNU-000016

Page 38

2-8

2.5 Stiffener

Before you remove or install the stiffener, please follow the steps below:

the server, see “2.1.1 Power Off”

Chassis Cover”.

Step 3:

Remove the fan duct. T o remove the fan duct, see “2.16 Fan Duct”.

Figure 2-13 Removing the Stiffener

The locations of stiffener on the server is shown below:

Figure 2-12 Stiffener Location

Hardware Operations

Reminder

Step 1:

Step 2:

Make sure the server is not turned on or connected to the AC power. To power off

Remove the rear chassis cover. To remove the rear chassis cover, see“2.2

2.5.1 To remove the stiffener

Release the screws.

Lift the stiffener out of the chassis.

Rear

2017-MNU-000016

Page 39

2-9

2.5.2 To install the stiffener

Before you remove or install the motherboard, please follow the steps below:

Step 2:

Remove the rear chassis cover. To remove the rear chassis cover, see“2.2 Rear

Chassis Cover”.

Step 3:

Remove the fan duct. T o remove the fan duct, see “2.16 Fan Duct”.

Step 4:

Remove the stiffener. To remove the stiffener see “2.5 Stiffener”.

Step 5:

Step 6:

Disconnect all necessary cables.

Reverse the steps above to install the stiffener.

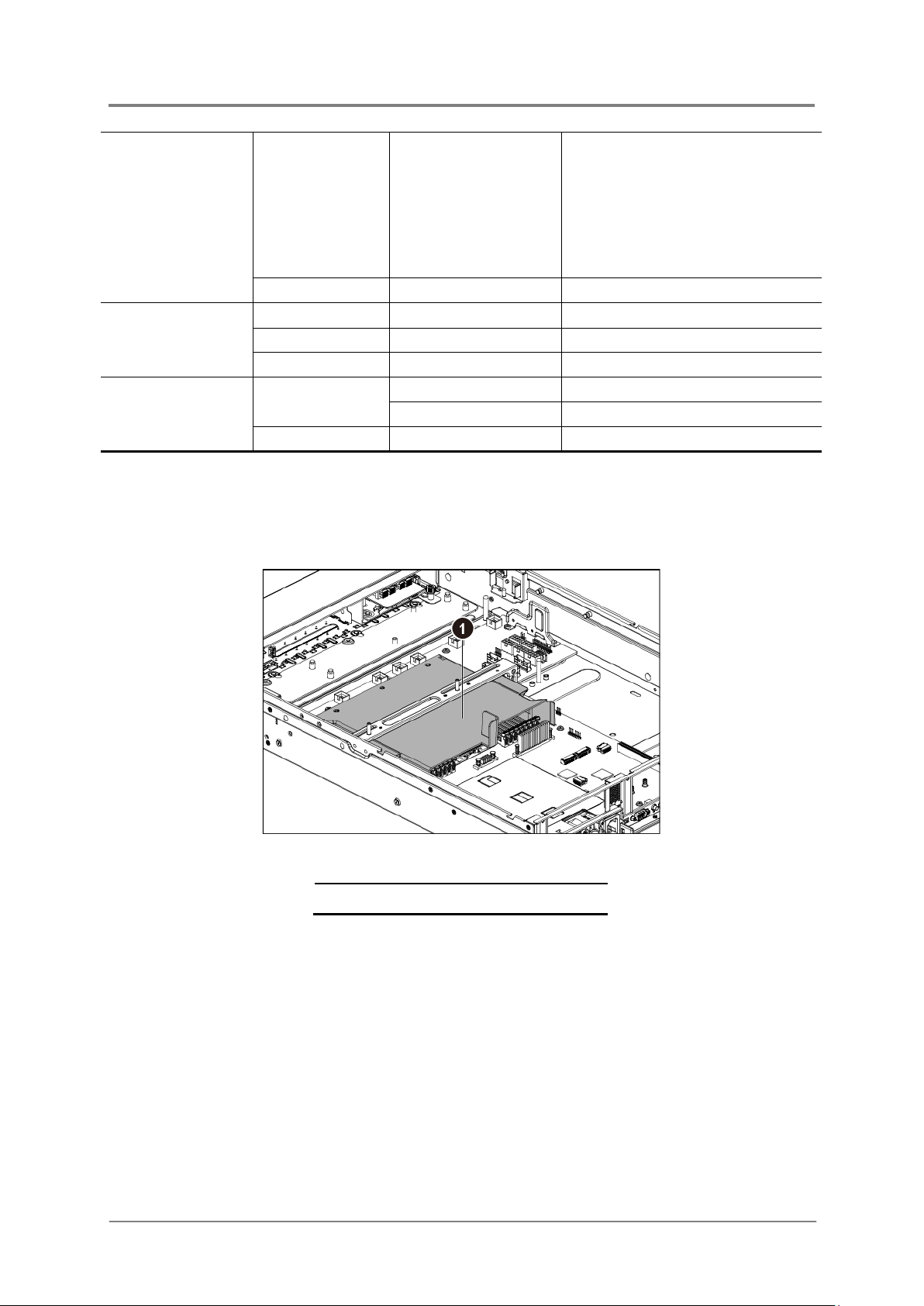

2.6 Motherboard

The location of motherboard on the server is shown below:

Hardware Operations

Figure 2-14 Motherboard Location

Reminder

Step 1:

Make sure the server is not turned on or connected to the AC power. To power off

the server, see “2.1.1 Power Off”

Remove the cable guide. To remove the cable guide, see “2.4 Cable Guide”.

2017-MNU-000016

Page 40

2-10

2.6.1 To remove the motherboard

Figure 2-15 Removing the System Fan Assembly

Figure 2-16 Removing the Motherboard

Hardware Operations

Release the retaining clip that secure the system fan cage.

Lift the system fan assembly out of the chassis.

Remove the 8 screws that secure the motherboard.

Remove the motherboard out of the chassis along the direction of the arrow.

2.6.2 To install the m otherboard

Reverse the steps above to install the motherboard.

2017-MNU-000016

Page 41

2-11

2.7 Processor

Step 1:

Make sure the server is not turned on or connected to the AC power. To power off

the server, see “2.1.1 Power Off”

Chassis Cover”.

Step 3:

Step 4:

Remove the stiffener. To remove the stiffener see “2.5 Stiffener”.

Step 5:

Remove the cable guide. To remove the cable guide, see “2.4 Cable Guide”.

Step 6:

Disconnect all necessary cables.

This motherboard supports one AMD Naples SP3 processor.

The location of processor on the motherboard is shown below:

Hardware Operations

Figure 2-1 Location of Processor

Reminder

Before you remove or install the processor, please follow the steps below:

Step 2:

Remove the rear chassis cover. To remove the rear chassis cover, see“2.2

Remove the fan duct. T o remove the fan duct, see “2.16 Fan Duct”.

Rear

2017-MNU-000016

Page 42

2-12

2.7.1 To remove the heat sink

The heat sink used in the figure below is just for your reference. Please choose an

appropriate heat sink depending on the whole system requirement.

Loosen the four securing screws.

Lift the heat sink up from the installed processor .

Hardware Operations

Figure 2-2 Removing the Heat Sink

2.7.2 To install the heat sink

Reverse the steps above to install the heat sink.

Before you put the heat sink on top of the installed processor, please do not forget

to check if the grease is complete on bottom of the heat sink.

2017-MNU-000016

Page 43

2-13

2.7.3 To remove the processor

Remove the screw marked with “3” around it.

Remove the screw marked with “2” around it.

Remove the screw marked with “1” around it.

To release the force frame, you must remove the screws following the sequence of

“3”, “2” and “1” marked around them.

Hardware Operations

Figure 2-3 Releaing the Force Frame

Open the force frame.

Hold the two clips of the rail frame and lift them up.

Figure 2-4 Opening the Force Frame

2017-MNU-000016

Page 44

2-14

Open the rail frame.

of “1”, “2” and “3” marked around them.

Figure 2-5 Opening the Rail Frame

Pull the CPU package out of the rail frame.

Hardware Operations

Figure 2-6 Removing the CPU Package

2.7.4 To install the processor

Reverse the steps above to install the processor.

When installing the CPU package, make sure to hold the handle but not the

•

processor.

To secure the force frame, you must install the screws following the sequence

•

2017-MNU-000016

Page 45

Hardware Operations

2-15

Before you remove or install the system memory, please follow the steps below:

the server, see “2.1.1 Power Off”

Step 3:

Remove the fan duct. T o remove the fan duct, see “2.16 Fan Duct”.

Step 4:

Remove the stiffener. To remove the stiffener see “2.5 Stiffener”.

Step 5:

Disconnect all necessary cables.

2.8 System Memory

This motherboard supports sixteen DDR4 1866/2133/2400/2667 ECC registered

DIMM/RDIMM.

The locations of the DIMM sockets on the motherboard is shown below:

Figure 2-7 Locations of System Memories

Reminder

Step 1:

Step 2:

Make sure the server is not turned on or connected to the AC power. To power off

Remove the rear chassis cover. To remove the rear chassis cover, see“2.2 Rear

Chassis Cover

”.

2017-MNU-000016

Page 46

Hardware Operations

2-16

There are sixteen DIMMs on the motherboard to support the processor. The DIMM sequence

of the sixteen DIMM sockets is respectively shown below.

Figure 2-8 DIMM Socket Sequence

2017-MNU-000016

Page 47

Hardware Operations

2-17

2.8.1 To remove the system m em ory

Unlock a DIMM socket by pressing the retaining clips outward. This action releases the

module and partially lifts it out of the socket.

Lift out the DIMM.

Figure 2-9 Lifting the DIMM out of the Socket

2.8.2 To install the system m em o r y

Unlock a DIMM socket by pressing the retaining clips outward.

Figure 2-10 Pressing the Retaining Clips Outward

2017-MNU-000016

Page 48

2-18

Hardware Operations

Align the notch on the DIMM to the break on the socket. Carefully insert the DIMM into the

socket until the retaining clips snap back in place.

Figure 2-11 Inserting the DIMM into the Socket

DIMMs fit in only one direction. DO NOT force a DIMM into the socket to avoid

damaging the DIMM.

2.9 Power Supplies

This server is designed with single 1600W/2000W power supply or two 1600W/2000W

redundant power supplies with system throttling mode.

The location of power supplies on the server is shown below:

Figure 2-17 Power Supply Locations

2017-MNU-000016

Page 49

Hardware Operations

2-19

Step 1:

Disconnect all necessary cables.

Figure 2-18 Removing the Power Supply

Reminder

Before you remove or install the power supply, please follow the steps below:

2.9.1 To remove the power supply

Press the retaining clip on the right side of the power supply along the direction of the

arrow.

Pull down the power supply handle.

At the same time, pull out the power supply. (The power supply takes considerable force to

remove.)

2.9.2 To install the power supply

Insert the replacement power supply firmly into the bay. The retaining clip should snap.

Connect the AC power cord to the replacement power supply.

Figure 2-19 Installing the Power Supply

2017-MNU-000016

Page 50

Hardware Operations

2-20

Figure 2-20 System Fan Locations

Before you remove or install the system fan, please follow the steps below:

is not turned on or connected to the AC p ower. To power off

the server, see “2.1.1 Power Off”

Step 3:

Disconnect all necessary cables.

2.10 System Fans

Subdividing the motherboard area and the backplane area is a metal cage that holds the

system fans. This server contains 6 system fans which are located inside the chassis. These

system fans maintain the ideal temperature for the motherboard, backplane and disk drives.

The location of system fans is shown below:

Reminder

Step 1:

Step 2:

Make sure the server

Remove the rear chassis cover. To remove the rear chassis cover, see“2.2 Rear

Chassis Cover”.

2017-MNU-000016

Page 51

2-21

2.10.1 To remove the system f an s

Figure 2-21 Removing the System Fan

Figure 2-22 Installing the System Fan

Unlock the system fan by clamping the locking clip inward.

Take the system fan out of the system fan cage.

Hardware Operations

2.10.2 To install the system fans

Place the system fan into the syste m fan cage.

2017-MNU-000016

Page 52

Hardware Operations

2-22

Figure 2-23 2.5” HDD Locations

•

•

2.11 2.5” HDDs

The server can support 8x2.5” hot-pluggable HDDs. Each HDD is with an adapt er bracket.

You don’t need to power-off the system when removing or installing a HDD.

The location of the 2.5” HDDs on the server is shown below:

Take note of the drive tray orientation before sliding it out.

The tray will not fit back into the bay if inserted incorrectly.

2.11.1 To remove the 2.5” HDD

Push the release button.

Pull the lever open.

Slide the HDD assembly out of the HDD bay.

Figure 2-24 Sliding out the 2.5” HDD Assembly

2017-MNU-000016

Page 53

2-23

Lift the HDD out of the tray.

2.11.2 To install the 2.5” HDD

Figure 2-25 Removing the HDD

Hardware Operations

Place the HDD to the HDD tr a y.

Figure 2-26 Placing the HDD

2017-MNU-000016

Page 54

Hardware Operations

2-24

Figure 2-28 8x2.5” HDDs Backplane Location

Make sure that the HDD is connected to the HDD connector on the backplane.

Carefully insert the HDD assembly into the HDD bay with the lever lifted until it completely

enters the HDD bay.

Push the lever back in place.

Figure 2-27 Installing the HDD Ass e mbly

2.12 8x2.5” HDDs Backplane

The server supports one 8x2.5” HDDs backplanes, which can support up to eight 2.5” HDDs

with adapter bracket in the system. The design incorporates a hot-swappable feature to allow

easy replacement of HDDs. The SATA or SAS connectors on each backplane connect to the

motherboard to provide power and indicate HDD access and failure.

The location of 8x2.5” HDDs backplane is shown below:

2017-MNU-000016

Page 55

2-25

Reminder

Before you remove or install the 8x2.5” HDDs backplane, please follow the steps below:

Make sure the server is not turned on or connected to the AC p ower. To power off

the server, see “2.1.1 Power Off”.

Chassis Cover”.

Front Top

Step 4:

Remove the HDDs.To remove a HDD, see ” 2.11 2.5” HDDs”.

Step 5:

Figure 2-29 Removing the 8x2.5” HDDs backplane

Step 1:

Step 2:

Remove the rear chassis cover. To remove the rear chassis cover, see“2.2 Rear

Step 3:

Remove the front top cover. To remove the front top cover, see “2.3

Cover”.

Disconnect all the necessary cables.

2.12.1 To remove the 8x2.5” HDDs backplane

Remove the screws that secure the backplane.

Remove the backplane along the direction of the arrow.

Hardware Operations

2.12.2 To install the 8x2.5” HD Ds backplane

Reverse the steps above to install the 8x2.5” HDDs backplane.

2017-MNU-000016

Page 56

2-26

2.13 Front Panels

Figure 2-30 Left Front Panel Location

Figure 2-31 Right Front Panel Location

Before you remove or install the front panel, please follow the steps below:

Make sure the server is not turned on or connected to the AC p ower. To power off

The location of left front panel on the server is shown below:

The location of right front panel on the server is shown below:

Hardware Operations

Reminder

Step 1:

the server, see “2.1.1 Power Off”.

2017-MNU-000016

Page 57

2-27

2.13.1 To remove the front panel

Figure 2-32 Removing the Front Panel Assembly

Figure 2-33 Removing the Front Panel

Unscrew the front panel assembly.

Remove the front panel assembly from the chassis.

Hardware Operations

Unscrew the front panel.

Remove the front panel.

2.13.2 To install the front pa nel

Reverse the steps above to install the front panel.

2017-MNU-000016

Page 58

2-28

2.14 OCP Card (Optional)

Figure 2-34 OCP Card Location

Before you remove or install the OCP card, please follow the steps below:

Make sure the server is not turned on or connected to the AC p ower. To power off

the server, see “2.1.1 Power Off”.

Chassis Cover”.

Front Top

Cover”.

Step 4:

Disconnect all the necessary cables.

Figure 2-35 Removing the OCP Card

The location of OCP card on the server is shown below:

Hardware Operations

Reminder

Step 1:

Step 2:

Remove the rear chassis cover. To remove the rear chassis cover, see“2.2 Rear

Step 3:

Remove the front top cover. To remove the front top cover, see “2.3

2.14.1 To remove the OCP card

Unscrew the OCP card.

Remove the OCP card from the chassis.

2017-MNU-000016

Page 59

Hardware Operations

2-29

Figure 2-36 Expansion Card Assembly Locations

Before you remove or install the expansion cards, please follow the steps below:

Make sure the server is not turned on or connected to the AC p ower. To power off

the server, see “2.1.1 Power Off”.

Chassis Cover”.

2.14.2 To install the OCP card

Reverse the steps above to install the OCP card.

2.15 Expansion Cards

The locations of expansion card assemblies on the server are shown below:

Reminder

Step 1:

Step 2:

Remove the rear chassis cover. To remove the rear chassis cover, see“2.2 Rear

2017-MNU-000016

Page 60

2-30

2.15.1 To remove the expan sion card

Figure 2-37 Removing the Expansion Card Assembly

Figure 2-38 Releasing the Clip

Unscrew the expansion card assembly.

Lift the expansion card assembly out of the chassis.

Hardware Operations

Push the locking clip along the direction of the arrow to release the clip.

2017-MNU-000016

Page 61

2-31

Rotate the clip to release the GPU.

Figure 2-39 Removing the GPU

Figure 2-40 Removing the Riser Card

Unscrew the GPU.

Remove the GPU.

Install the slot covers.

Hardware Operations

Remove the screw that secures the riser card.

Remove the riser card.

2.15.2 To install the expansio n card

Reverse the steps above to install the expansion card.

2017-MNU-000016

Page 62

2-32

2.16 Fan Duct

Figure 2-41 Fan Duct Location

Before you remove or install the fan duct, please follow the steps below:

the server, see “2.1.1 Power Off”.

Chassis Cover”.

Step 3:

Remove the stiffener. To remove the stiffener see “2.5 Stiffener”.

Figure 2-42 Removing the Fan Duct

Make sure that the fan duct on the server

The location of fan duct on the server is shown below:

Hardware Operations

Reminder

Step 1:

Step 2:

Make sure the server is not turned on or connected to the AC p ower. To power off

Remove the rear chassis cover. To remove the rear chassis cover, see“2.2 Rear

2.16.1 To remove the fan duct

Lift the fan duct out of the chassis.

is installed in place to keep proper cooling.

2017-MNU-000016

Page 63

2-33

2.16.2 To install the fan duct

Reverse the steps above to install the fan duct.

Hardware Operations

2017-MNU-000016

Page 64

Chapter 3

Connectors

Backplane Connectors

OCP Card Connectors

Page 65

3-1

3 Connectors

3.1 Backplane Connectors

Connectors

Figure 3-1 8x2.5“ HDDs Backplane

2017-MNU-000016

Page 66

3-2

Connectors

1 SATA HDD Connectors 0-7

2 I2C Connector 7 Slimline Connector 1

3 Slimline Connector 4

4 Slimline Connector 3 9

5 Backplane Power Connector

6 Slimline Connector 2

8 Backplane SATA Connectors 2

Backplane SATA Connectors 1

3.2 OCP Card Connectors

Figure 3-2 OCP Card

1 QSFP Ports

2 Slimline Connector 2 4 NCSI Connector

3 Slimline Connector 1

2017-MNU-000016

Page 67

Chapter 4

Cable Routing

Page 68

4-1

4 Cable Routing

Cable Routing

2017-MNU-000016

Page 69

Appendix 1

China RoHS Regulations

Taiwan BSMI

Electromagnetic Emissions Notices

Page 70

Appendix

I

Figure I China RoHS Regulations

Appendix 1 Hazardous Substances Free Regulations and

Electromagnetic Emissions Notices

China RoHS Regulations

2017-MNU-000010

Page 71

II

Taiwan BSMI

Appendix

2017-MNU-000010

Figure II Taiwan BSMI

Page 72

Appendix

III

Electromagnetic Emissions Notices

Federal Communications Commi ssi on notice

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may cause

undesired operation.

Class A Equipment

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instructions, may cause harmful interference to

radio communications. Operation of this equipment in a residential area is likely to cause

harmful interference, in which case the user will be required to correct the interference at

personal expense.

Notices for Canada (Avis Canadien )

Class A Equipment

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing

Equipment Regulations. CAN ICES-3(A)/NMB-3(A) Cet appareil numérique de la class A

respecte toutes les exigences du Règlement sur le materiel brouilleur du Canada.

Notices for Chi n a

Class A Equipment

2017-MNU-000010

Page 73

Appendix

IV

Notices for Europ ean Union

European Union Regulatory Notice

Products bearing the CE marking comply with applicable EU Directives:

Compliance with such directives is assessed using applicable European Harmonized

Standards.

Notices for Japan

VCCI Notice

Class A EMI Warning Message

Power Cord Statement

Notices for Ko re a

Class A EMI Warning Message

2017-MNU-000010

Page 74

V

Notices for Taiwan

BSMI Notices

Class A EMI Warning Message

Notices for Russia

Class A EMI Warning Message

Appendix

2017-MNU-000010

Page 75

Appendix 2

BIOS SPEC

Page 76

BIOS Setup User Manual

K800QG4

rev. 0.01

Mar., 2018

Page 77

BIOS Setup User Manual

Table of Contents

Table of Contents

1 Main ....................................................................................................................... 1

2 Advanced ................................................................................................................ 2

3 Platform.................................................................................................................. 8

4 Socket ................................................................................................................... 10

5 BMC ...................................................................................................................... 19

6 Security ................................................................................................................ 20

7 Boot ...................................................................................................................... 21

8 Save & Exit ............................................................................................................ 22

Page 78

BIOS Setup User Manual

Main

1

1 Main

System brief overview.

Project Version

The current version of BIOS.

Build Date and Time

The date that BIOS image was created.

Platform

Basic info of sytem platform.

Processor

Basic info of system Processor.

Total Memory

Total Memory size.

System Date

Set the Date. Use Tab to switch between Date elements.

Default Ranges:

Year: 1998-9999

Months: 1-12

Days: dependent on month

System Time

Set the Time. Use Tab to switch between Time elements.

Page 79

BIOS Setup User Manual

Advanced

2

2 Advanced

Advanced settings. Includes the driver interface, serail port setting, TPM, CSM,

NVME configuration and USB setting.

iSCSI Configuration

Configure the iSCSI parameters.

Add an Attempt

Use this option to configure an iSCSI boot target.

Delete Attempts

Delete one or more attempts.

Change Attempt Order

Change Attempt Order.

Driver Health

Driver Health status

Trusted Computing

Trusted Computing Settings.

Note: Please remember to install TPM module in advance.

Security Device Support

Enables or Disables BIOS support for security device. O.S. will not show

Security Device. TCG EFI protocol and INT1A interface will not be available.

[Enable]*

[Disable]

TPM State

Enable/Disable Security Device. NOTE: Your Computer will reboot during

restart in order to change State of the Device.

[Enable]*

[Disable]

Pending operation

Page 80

BIOS Setup User Manual

Advanced

3

Schedule an Operation for the Security Device. NOTE: Your Computer will

reboot during restart in order to change State of Security Device.

[None]*

[TPM Clear]

Current Status Information

Current Status Information.

TPM Enabled Status

Enabled Status of TPM.

TPM Active Status

Active Status of TPM.

TPM Owner Status

Owner Status of TPM.

TPM20 Device Found

TPM20 Device Found or not

Serial Port Console Redirection

Serial Port Console Redirection configuration.

Console Redirection

Serial Port Console Redirection.

[Enable]*

[Disable]

Note: POST will not be full screen until this item is disabled.

Console Redirection Settings

The settings specify how the host computer and the remote computer (which

the user is using) will exchange data. Both computers should have the same

or compatible settings.

Terminal Type

Emulation: ANSI: Extended ASCII char set. VT100: ASCII char set. VT100+:

Extends VT100 to support color, function keys, etc. VT-UTF8: Uses UTF8

encoding to map Unicode chars onto 1 or more bytes.

[VT100]

Page 81

BIOS Setup User Manual

Advanced

4

[VT100+]

[VT-UTF8]

[ANSI]*

Bits per second

Selects serial port transmission speed. The speed must be matched on the

other side. Long or noisy lines may require lower speeds.

[9600]

[19200]

[57600]

[115200]*

Data Bits

Data Bits.

[7]

[8]*

Parity

A parity bit can be sent with the data bits to detect some transmission

errors. Even: parity bit is 0 if the num of 1's in the data bits is even. Odd:

parity bit is 0 if num of 1's in the data bits is odd. Mark: parity bit is

always 1. Space: Parity bit is always 0. Mark and Space Parity do not allow

for error detection. They can be used as an additional data bit.

[None]*

[Even]

[Odd]

[Mark]

[Space]

Stop Bits

Stop bits indicate the end of a serial data packet. (A start bit indicates the

beginning). The standard setting is 1 stop bit. Communication with slow

devices may require more than 1 stop bit.

[1]*

[2]

Flow Control

Flow control can prevent data loss from buffer overflow. When sending

data, if the receiving buffers are full, a 'stop' signal can be sent to stop the

Page 82

BIOS Setup User Manual

Advanced

5

data flow. Once the buffers are empty, a 'start' signal can be sent to re-start

the flow. Hardware flow control uses two wires to send start/stop signals.

[None]*

[Hardware RTS/CTS]

EMS

Microsoft Windows Emergency Management Services (EMS) allows for

remote management of a Windows Server OS through a serial port.

[Enable]*

[Disable]

PCI Subsystem Settings

PCI Settings Common for all Devices.

SR-IOV Support

If system has SR-IOV capable PCIe Devices, this option Enables or Disables

Single Root IO Virtualization Support.

[Enable]

[Disable]*

Network Stack Configuration

Network Stack Settings

Network Stack

Enable/Disable UEFI Network Stack.

[Enable]

[Disable]*

Ipv4 PXE Support

Enable Ipv4 PXE Boot Support. If disabled IPV4 PXE boot option will not be

created.

[Enable]*

[Disable]

Ipv4 HTTP Support

Enable Ipv4 HTTP Boot Support. If disabled IPV4 HTTP boot option will not be

created.

[Enable]*

[Disable]

Ipv6 PXE Support

Page 83

BIOS Setup User Manual

Advanced

6

Enable Ipv6 PXE Boot Support. If disabled IPV6 PXE boot option will not be

created.

[Enable]*

[Disable]

Ipv6 HTTP Support

Enable Ipv6 HTTP Boot Support. If disabled IPV6 HTTP boot option will not be

created.

[Enable]*

[Disable]

PXE boot wait time

Wait time to press ESC key to abort the PXE boot.

[0]*

~

[5]

Media detect count

Number of times presence of media will be checked.

[1]*

~

[50]

CSM Configuration

CSM Configuration.

CSM Support

Enable/Disable CSM Support.

[Enable]*

[Disable]

Boot option filter

This option controls Legacy/UEFI ROMs priority.

[UEFI and Legacy]*

[Legacy only]

[UEFI only]

Network

Controls the execution of UEFI and Legacy PXE OpROM.

[UEFI]*

[Legacy]

Page 84

BIOS Setup User Manual

Advanced

7

Storage

Controls the execution of UEFI and Legacy Storage OpROM.

[UEFI]*

[Legacy]

Video

Controls the execution of UEFI and Legacy Video OpROM.

[UEFI]

[Legacy]*

NVMe Configuration

NVMe status and configuration.

USB Configuration

USB devices and configuration.

USB Mass Storage Driver Support

Note: BIOS would no't display info to monitor under legacy OS if you

select UEFI mode.

Enable or Disable USB mass storage driver support.

[Enable]*

[Disable]

Page 85

BIOS Setup User Manual

Platform

8

3 Platform

Platform and PCH configuration options

PCH Configuration

PCH Configuration.

Restore AC Power Loss

Provides the policy whether or not the system should

boot once power returns after a power loss event.

[Power Off]

[Power On]

[Last State]*

P C H SATA Configuration

PCH SATA(Serial Advanced Technology Transport) Configuration.

SATA Controller

Enable or Disable SATA Controller.

[Enable]*

[Disable]