invebo BC7A Installation Instructions Manual

invebo BC7A

Installation Instructions

Installation of the Bluetooth BC7A

Upgrade KIT in Bose SoundDock

Original Series 1

The installation of the board can be carried out

without any previous experience.

Overview:

Fitting the BC7A kit Replacement is relatively

straight forward but like everything the first time is

more difficult and some may find it extremely fiddly.

These instructions are to show the method of

replacing the BC7A in a detailed step by step

procedure. The Bose SoundDock is still the best

sounding and most affordable compact speaker

around and one of the few things that can’t be

upgraded by going out and buying a better sounding

unit at reasonable cost.

Note the BC7A has the 30-pin legacy iPod docking

connector with USB charge mode support,.

Which docks are compatible?

The BC7A kit is designed to work with all Bose

SoundDock Series 1. If your dock serial number

does not start in digits 0357 or 0402 or 0498 or

052398 then the BC7A is not compatible with your

dock.

Before you Start: It is a good idea to watch the

detailed ‘how to’ videos on YouTube. A full step-bystep video version of these BC7A instructions is

available in the technical guide section of our

website. See the Technical Guides section at

www.invebo.com

For a problem free installation watch the full BC27A

Instruction procedure on YouTube:

https://www.youtube.com/watch?v=hwA8buY7qSc

Tools Required:

1. T8 Torx Driver (from Kit)

2. Sharp craft knife

3. Pliers (flat nose)

General:

1.

The full kit contains the T8 Torx screw

driver, BC7A Main Board.

2.

Initially it is not necessary to remove the

four larger cross-head screws holding the

base moulding on. The half moon moulding

can be removed whilst all of these four

screws are tight.

3.

Three T8 screws hold the dock assembly in

place. These are found on the underside of

the half-round front moulding where the

IPod plugs in. Once removed the assembly

can be pulled out from underneath. You do

this by gently carefully pulling the ribbon

cable which is tucked under the lower cover.

Pull it out so that about 1.5 to 2 inches (3 to

5cm) of ribbon is showing. Then hold onto

the cable to prevent it coming out any

further and pull it from the plug on the

docking board.

4.

You should now have the docking

assembly, including the board and the

plastic moulding, free in your hand. Put the

body of the dock to one side.

5.

Separation of the dock board from the base

moulding requires some sharp flush side

cutters or a sharp craft knife and a great

deal of care. Carefully peel off the black

plastic overlay and put it aside.

6.

You should now see the docking board and

the tops of the plastic pegs that hold the

board in position. These are small pegs that

have been heat-staked. This means that at

the Bose factory the tops of the pegs have

been melted into a mushroom shape.

7.

The head of the mushroom is what holds

the board in place. It is necessary to

carefully cut the tops of the mushrooms with

your sharp craft knife or flush-cutting side

cutters. Trim the mushroom heads back until

the smaller diameter of the body of the peg

is visible, equivalent to roughly the diameter

of the hole in the PCB.

8.

Check that you have done all the pegs.

Then docking PCB can now be gently

levered away from the moulding.

9.

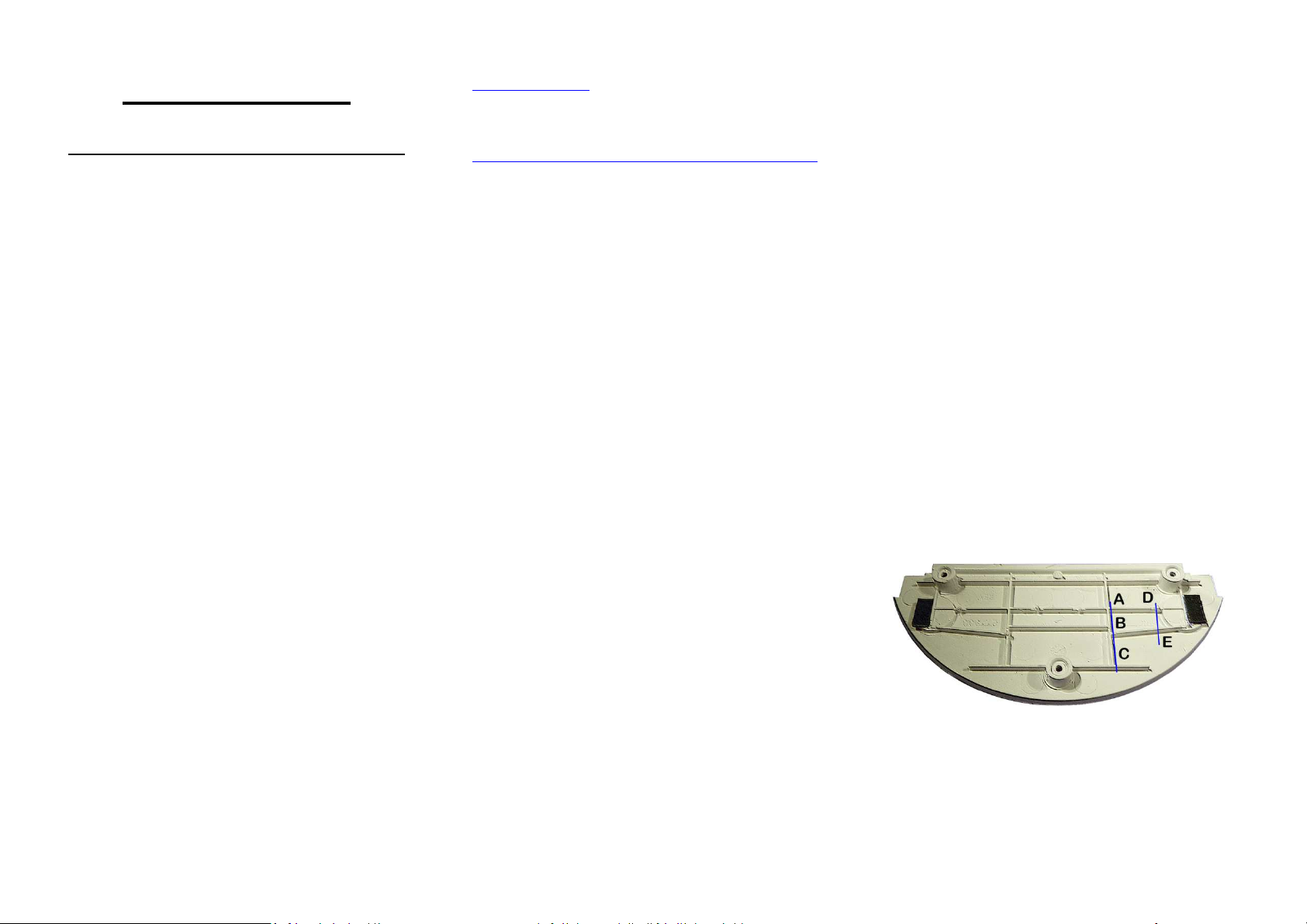

Modification of the Molding: It is

necessary to remove three plastic ribs to

accommodate the electronics module

located on the underside of the BC7A. It is

recommended that you refer to the YouTube

instruction video referenced at the top of

these instructions. . Using the craft knife

make vertical cuts through the horizontal

ribs at A, B C, D. The cut must be through

the full height of the ribs. The position of the

cuts s denoted by the lines on the diagram.

Grip the section of rib between A and D with

flat nosed pliers and Twist to remove this

section of rib. Repeat to remove section B

to E. Repeat the remove the short spar to

the right of C. The root of the removed ribs

must be level with the flat surface of the

molding. If necessary trim of any remnants of the

ribs with the craft knife.

10.

Take the BC7A controller board in your

hand and have a look at it. Notice the ribbon

connector at the edge of the board. See that

there is a small darker section at each end

that can be moved back and forth. This is

the locking mechanism.

11.

Using your fingernail ensure that the

locking mechanism is out at both ends of

the connector. In the out position the tabs

are about 0.08” (2mm) out from the home

position.

12.

If the locking mechanism isn’t in the open

position then the ribbon cannot be inserted.

The insertion force is near to zero when it is

correct. If you have to push to get the ribbon

into the connector then check the lock

mechanism is out at both ends.

13.

A supported foam overlay is supplied with

the kit. Remove the backing from the

adhesive strips and place the overlay over

the docking connector, align and press the

strips so that they adhere to the top of the

docking board.

14.

Place the BC7A board over the pegs and

push down onto the half-moon moulding.

Usually the mushroom heads are an

interference fit which will hold the board in

position. You might even feel it click into

place.

15.

IMPORTANT: Make sure that the board is

sitting flush with the supporting ribs on the

base moulding. If the board is suspended on

the mushroom heads of the pins then you

could have problems with the volume

controls buttons as they will sit too high and

may spontaneously alter the volume. Check

that step 9 has been done correctly noting

that the electronics on the underside of the

BC7A are clear of the removed ribs. Look at

it from the side and make sure that there is

no gap between the board and the

supporting parts of the moulding. If there are

small gaps then simply make sure that the

board moves freely down onto the moulding

with little finger pressure.

16.

Ensure that the board is sitting down flat.

17.

Hold the dock so that the base is horizontal

and uppermost. Loosen the four cross head

screws about one turn each. DO NOT

REMOVE the screws completely.

18.

Bend the ribbon cable backwards so that

the end is parallel to and lying over the flat

base moulding.

19.

Hold the half moon dock assembly with the

base flat on the lower base of the dock.

You will see that when plugged in the half

moon will flip 180 degrees and be in the

correct orientation to be refitted.

20.

Ensure that the ribbon connector locking

tabs/bar are in the fully out position

(unlocked). Feed the end of the ribbon cable

into the connector and when fully engaged

and it is exiting perpendicular to the

connector, push the locking tabs into the

engaged position. You can use your

fingernail. Note that moderate force is

required to do this and it is necessary

engage each side more than once.

Sometimes the other end pops out slightly

when you push the other end in.

21.

When the locking mechanism is fully

engaged, give the ribbon cable a gentle tug

to ensure that the ribbon is securely held in

the connector. You should see a line of 24

bright tin contacts protruding an equal

distance of approximately 1 millimetre out of

the connector. If you can see more at one

end than the other then the ribbon is not

correctly inserted.

22.

Note that if for any reason you want to

unplug the ribbon, you must first disengage

the locking mechanism to let the ribbon slide

out with zero force.

23.

Test fit the BC7A on the support moulding

by placing over the pegs. Look between the

underside of the board and the support ribs

to ensure that there is no gap. i.e. The

board is sitting right down on the support

webs of the half moon base moulding.

24.

During the next operation you must ensure

that the BC7A controller PCB stays located

on the pegs. Be careful. If you have cut the

mushrooms just right then it will snap on

and hold in place nicely. If not it may be a

Loading...

Loading...