Page 1

Owner's Operator And Maintenance Manual

®

Excelerator

Li'l Excelerator

Excelerator XLT

Excelerator XLT 2000

DEALER: THIS MANUAL MUST BE GIVEN TO THE USER OF

THE WHEELCHAIR.

USER: BEFORE USING THIS WHEELCHAIR, READ THIS

MANUAL AND SAVE FOR FUTURE REFERENCE.

Page 2

SPECIAL NOTES

SPECIAL NOTES

W

A

R

N

I

N

G

WARNING

DO NOT OPERATE THIS EQUIPMENT WITHOUT FIRST READING

AND UNDERSTANDING THIS MANUAL. IF YOU ARE UNABLE TO

UNDERSTAND THE WARNINGS, CAUTIONS AND

INSTRUCTIONS, CONTACT YOUR INVACARE DEALER OR

INVACARE CUSTOMER SUPPORT AT (800) 532-8677 BEFORE

ATTEMPTING TO USE THIS EQUIPMENT - OTHERWISE INJURY

AND/OR EQUIPMENT DAMAGE MAY RESULT.

WARNING/CAUTION notices as used in this manual apply to hazards or unsafe practices which

could result in personal injury or property damage.

NOTICE

THE INFORMATION CONTAINED IN THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE.

S

P

E

C

A

L

N

O

T

E

S

WARNING

EXCELERATOR USER

As a manufacturer of the Excelerator, Invacare endeavors to supply an Excelerator to meet many

needs of the end user. However, final selection of an Excelerator to be used by an individual rests solely

I

with the user and his/her health care professional capable of making such a selection.

EXCELERATOR TIE-DOWN RESTRAINTS AND SEAT POSITIONING STRAPS

Invacare recommends that the Excelerator users NOT be transported in vehicles of any kind while in an

Excelerator. As of this date, the Department of Transportation has not approved any tie-down systems

for transportation of a user while in an Excelerator, in a moving vehicle of any type.

AS REGARDS RESTRAINTS - SEA T POSITIONING STRAPS - IT IS THE OBLIGATION OF THE DME DEALER, THERAPISTS AND OTHER HEALTH CARE PROFESSIONALS TO DETERMINE IF A SEATING POSITIONING STRAP IS

REQUIRED TO ENSURE THE SAFE OPERATION OF THIS EQUIPMENT BY THE USER. SERIOUS INJURY CAN

OCCUR IN THE EVENT OF A FALL FROM AN EXCELERATOR.

SAVE THESE INSTRUCTIONS

2

Page 3

TABLE OF CONTENTS

TABLE OF CONTENTS

NOTE: When using the term EXCELERATOR, it will pertain to the EXCELERATOR, LI'L EXCELERATOR

EXCELERATOR XLT and EXCELERATOR XLT 2000 except when the instructions specifically note otherwise.

SPECIAL NOTES ........................................................ 2

SPECIFICA TIONS ....................................................... 4

PROCEDURE 1 - GENERAL GUIDELINES ............ 5

OPERATING INFORMATION .......................................... 5

SAFETY/HANDLING OF EXCELERATOR ....................... 6

PROCEDURE 2 - SAFETY INSPECTION/

TROUBLESHOOTING/MAINTENANCE ...............8

SAFETY INSPECTION CHECKLIST ................................ 8

TROUBLESHOOTING .................................................... 9

MAINTENANCE ............................................................. 9

PROCEDURE 3 - ASSEMBL Y PROCEDURES ..... 10

EXCELERATOR/LI'L EXCELERATOR ASSEMBLY

PROCEDURES ......................................................... 10

EXCELERATOR XLT/XLT 2000 ASSEMBLY

PROCEDURES ......................................................... 11

PROCEDURE 4 - REAR WHEELS .......................12

INSTALLING/ADJUSTING THE REAR WHEELS

AND QUICK-RELEASE AXLES - EXCELERATOR

AND LI'L EXCELERATOR .......................................... 12

INSTALLING THE REAR WHEELS WITH THREADED

AXLE OPTION - EXCELERATOR XLT/XLT 2000 ......... 12

TIRE/TUBE REPLACEMENT AND TUNING/

REPLACEMENT OF SPOKES .................................. 12

TIRE PRESSURE ........................................................ 12

DETERMINING/ADJUSTING TOE IN/TOE OUT ............. 12

REPLACING CAMBER INSERTS ................................. 13

PROCEDURE 5 - FORK/ SPRING/CRANK ...........14

EXCELERATOR/LI'L EXCELERATOR

FORK ASSEMBLY INSTALLATION ............................. 14

EXCELERATOR/LI'L EXCELERATOR TENSION

SPRING INSTALLATION ............................................ 14

EXCELERATOR/LI'L EXCELERATOR HAND

CRANK ASSEMBLY INSTALLATION .......................... 14

EXCELERATOR XLT/XLT 2000 FORK/CRANK

ASSEMBLY REPLACEMENT .................................... 15

EXCELERATOR XLT/XLT 2000 TENSION SPRING OR

ROAD CROWN COMPENSATOR REPLACEMENT/

ADJUSTMENT .......................................................... 16

PROCEDURE 6 - SPEED SHIFTERS .................. 18

LI'L EXCELERATOR - THREE (3) SPEED

SHIFTER CABLE INSTALLATION ............................... 18

LI'L EXCELERATOR - THREE (3) SPEED

SHIFTER CABLE ADJUSTMENT ............................... 18

EXCELERATOR/EXCELERATOR XLT - SEVEN

(7) SPEED SHIFTER INSTALLATION .......................... 19

EXCELERATOR/EXCELERATOR XLT - SEVEN (7)

SPEED SHIFTER ADJUSTMENT/REPLACEMENT -

BEFORE 1997 ONLY................................................. 19

PROCEDURE 7 - CHAIN.....................................20

EXCELERATOR/LI'L EXCELERATOR CHAIN

INSTALLATION w/ SEVEN (7) SPEED HUB .............. 20

EXCELERATOR/LI'L EXCELERATOR CHAIN

ADJUSTMENT ......................................................... 20

EXCELERATOR CHAIN STAY ADJUSTMENT ............. 20

EXCELERATOR XLT/XLT 2000 CHAIN

ADJUSTMENT ......................................................... 20

EXCELERATOR XLT/XLT 2000 CHAIN INSTALLATION

WITH TWENTY-FOUR (24) OR TWENTY-SEVEN

(27)SPEED CASSETTE ............................................ 21

PROCEDURE 8 - P ARKING BRAKE ...................22

USING PARKING BRAKE ........................................... 22

PARKING BRAKE ADJUSTMENT/REPLACEMENT ....... 22

PROCEDURE 9 - BACK/SEA T............................23

BACK HEIGHT ADJUSTMENT (ADJUSTABLE

BACKS ONLY) ......................................................... 23

SLIDING SEAT ADJUSTMENT .................................... 23

EXCELERATOR XLT/XLT 2000 BACK ANGLE

ADJUSTMENT ........................................................24

PROCEDURE 10 - UPHOLSTERY ...................... 25

SEAT UPHOLSTERY REPLACEMENT ....................... 25

BACK UPHOLSTERY REPLACEMENT ....................... 25

PROCEDURE 11 - FOOTREST .......................... 26

EXCELERATOR/LI'L EXCELERATOR FOOTREST

ADJUSTMENT/REPLACEMENT .............................. 26

EXCELERATOR XLT/XLT 2000 FOOTREST AND LEG

GUARD REPLACEMENT ......................................... 27

EXCELERATOR XLT/XLT 2000 USING/REPLACING

FOOTREST STRAP ................................................. 28

PROCEDURE 12 - OPERA TION ......................... 29

HAND CRANK ASSEMBLY ......................................... 29

SHIFTING GEARS ...................................................... 29

BACKING UP .............................................................. 30

BRAKING ................................................................... 30

PARKING BRAKE ....................................................... 30

STEERING/CORNERING ............................................ 31

MOUNTAIN DRIVE OPTION - SEVEN (7) SPEED

SHIFTER ONLY ........................................................ 31

PROCEDURE 13 - OPTIONS .............................. 33

WATER BOTTLE INSTALLATION ................................ 33

TOW BAR INSTALLATION .......................................... 33

REAR SAFETY LIGHT ................................................ 33

COMPUTER INSTALLATION ....................................... 33

SEAT POSITIONING STRAP INSTALLATION............... 33

HORIZONTAL HANDLES ............................................ 33

TRI-PIN QUAD HANDLES ........................................... 33

GLOVES .................................................................... 33

SAFETY FLAG INSTALLATION ................................... 33

SAFETY HELMET ....................................................... 34

LATERAL SUPPORT .................................................. 34

LIMITED WARRANTY.........................................35

T

A

B

L

E

O

F

C

O

N

T

E

N

T

S

3

Page 4

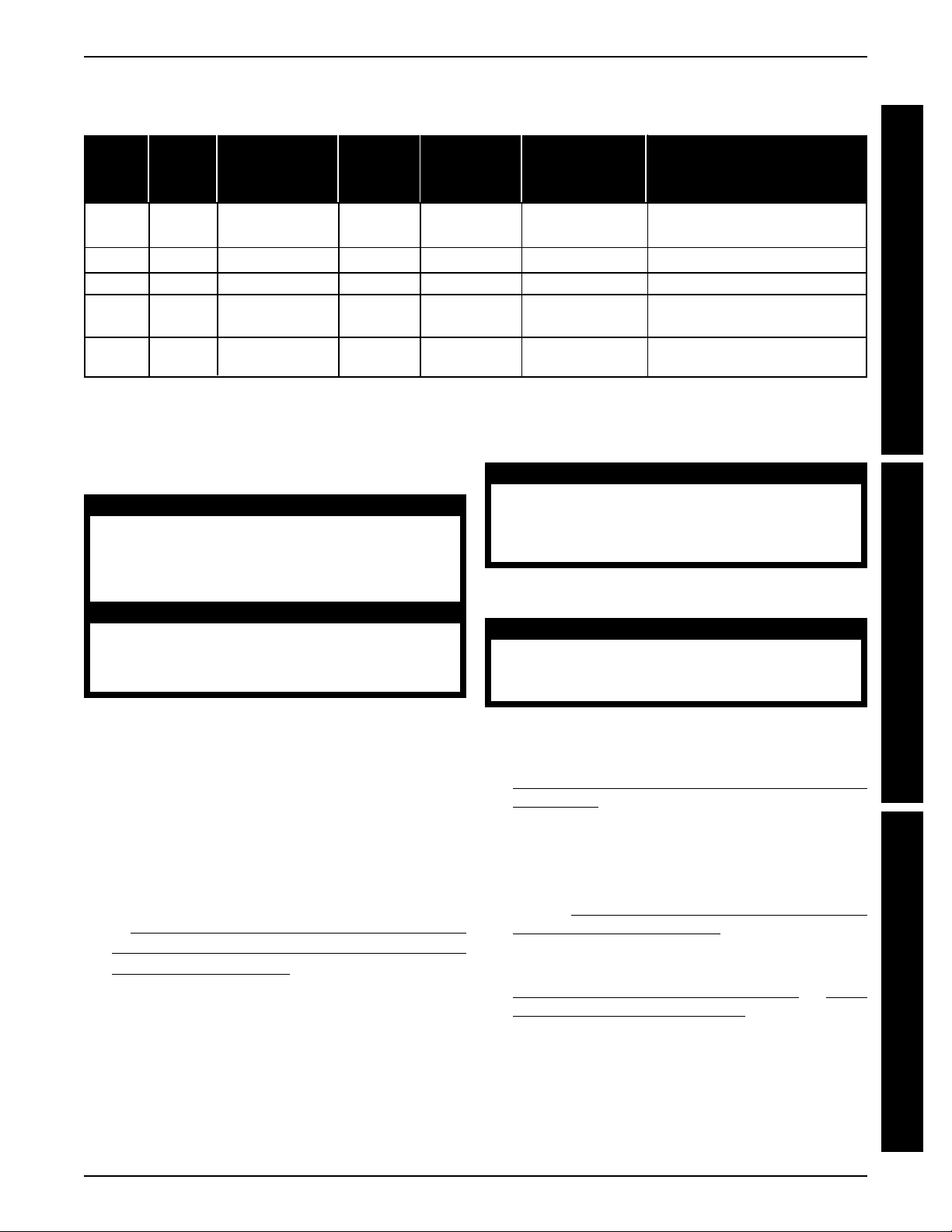

SPECIFICATIONS

SPECIFICATIONS

EXCELERA TOR

14 to 20-inches

15

Fixed 20/18-inches

Rigid

C

S

P

E

F

I

I

Seat Width:

Seat Depth:

Seat-to-Floor

(approx.):

Back Style:

C

A

T

O

N

S

Back Height

(Fixed or Adjustable):

Footrest:

I

Side - Wheel

Clearance:

Rear Axle:

Rear Wheel Camber:

Wheels:

Brakes:

Handles:

Hub:

Spokes:

Shift Levers:

Gears:

Seat Cushion:

Back Upholstery:

Weight:

Shipping Weight:

Options:

* Knobby Tires will reduce side wheel clearance to approximately 1-inch.

Shimano

®

, Nexus®, and Ultegra®- Registered trademarks of Shimano American Corp.

12-16 or 14-18-inches

Adjustable Height/Angle

2-inches - * 2.5-inches

Quick-Release

o

9

- Standard

24-inch Spoke

(Cruiser Tires)

Hand Crank (Internal)

Parking Brake

Ergonomic, Vertical

FRONT - Shimano

Nexus® 7 Speed Hub

REAR - Precision

Black Anodized w/1/2inch Quick Release

Stainless Axles

14 Gauge Stainless

Shimano

7 Speed

Foam Insert

Nylon-Adjustable Tension

50 lbs.

80 lbs.

Computer, Tow Bar,

Horizontal Handles,

Safety Light, Helmet and

Flag, Custom Color, Seat

Positioning Strap, Quad

Cuffs & Gloves, 24-inch

Knobby Tires, Mountain

Drive, Bike Rack,

Water Bottle and Cage,

Tripin Quad Handles.

LI'L EXCELERATOR

12 or 14-inches

12 or 14-inches

Fixed 17.5/15.5

inches

Rigid

12 to 16-inches

Adjustable Height/Angle

2-inches - * 2.5-inches

Quick-Release

9o - Standard

Front - 20-inch Spoke

Rear - Mag (Knobby

Tires)

Hand Crank (Internal)

Parking Brake

Ergonomic, Vertical

®

FRONT - Shimano 3

Speed Hub

REAR - Precision

Black Anodized w/1/2inch Quick Release

Stainless Axles

14 Gauge Stainless

Shimano

3 Speed

Foam Insert

Nylon-Adjustable Tension

40 lbs.

70 lbs.

7 Speed Hub, Helmet,

Horizontal Handles,

Quad Cuffs & Gloves,

Computer, Custom

Color, Seat positioning

Strap, Safety Flag and

Light, Water Bottle and

Cage.

4

EXCELERATOR XLT

14 to 20-inches

15-inches

Fixed 12.5-inches

Adjustable Back

Angle 90O - 110

13-inches (Fixed)

20-inches (Narrow, Tall)

Adjustable Fore and Aft

2-inches - * 2.5-inches

Quick-Release

15o - Standard

24-inch Spoke

(High Performance,

Cruiser or *Knobby)

Hand Crank - (Internal)

Parking Brake

Ergonomic, Vertical

FRONT - Shimano

Nexus 7 Speed Hub

REAR - Precision

Black Anodized w/1/2inch Quick Release

Stainless Axles

14 Gauge Stainless

Shimano

7 Speed

Foam Insert - Optional

Nylon-Adjustable Tension

35 lbs.

80 lbs.

NOTE: Same options

as Excelerator including the following:

24 Speed External

Gearing, Threaded

Axles, Leg Guard

Attachments, Lateral

Supports.

O

EXCELERAT OR

XLT 2000

14 to 20-inches

15-inches

Fixed 12.5-inches

Adjustable Back

Angle 90O - 110

13-inches (Wide)

20-inches (Narrow, Tall)

Adjustable Fore and Aft

2-inches - * 2.5-inches

Quick-Release or

Threaded

o

15

- Standard

24-inch Spoke

(High Performance,

Cruiser or *Knobby)

Dual Hand Caliper

Brakes

Ergonomic, Vertical

FRONT - Shimano 27

Speed External

Cassette XT/Ultegra

REAR - Precision Black

Anodized w/1/2-inch

Quick Release Stainless

or Threaded Axles

14 Gauge Stainless

Shimano - STI

indexed/brake levers

27 Speed

Foam Insert - Optional

Nylon

30 lbs.

80 lbs.

NOTE: Same options

as Excelerator including the following:

Composite Wheels,

Leg Guard Attachments, Lateral Supports, Welded Seat

O

®

Page 5

GENERAL GUIDELINES

This Procedure Includes the Following:

PROCEDURE 1

Operating Information

Safety/Handling of Excelerator

OPERATING INFORMATION

WARNING

Wear your helmet at ALL times when riding the Excelerator.

The bicycle must be adjusted to fit the rider. Check the seat position, back height, quick release threaded

axles, footrest height, hand crank adjustment for smooth operation of your Excelerator.

Before riding your Excelerator, check your brakes. Be sure that the brakes and all other features of your

Excelerator are operating properly.

The user is responsible for normal upkeep and maintaining the Excelerator in proper operating condi-

tion.

The manufacturer is not responsible for failure, damage or injury caused by improper operation or

maintenance by the end-user.

To determine and establish your particular safety limits, practice transferring activities in the presence of

a qualified health care professional BEFORE attempting active use of the Excelerator.

Before attempting to transfer IN or OUT of the Excelerator, every precaution should be taken to reduce

the gap distance. Position the Excelerator on level ground and as close as possible to the object you

are transferring INTO or OUT of. The parking brake of the Excelerator MUST be engaged and the object

you are transferring INTO or OUT of MUST also be secured before attempting any transfers.

Care MUST BE taken when operating on roads, streets or highways.

Operation of the Excelerator is subject to all traffic rules and regulations. (This may include the use of a

safety light and reflectors for dusk/night riding.)

Give pedestrians the right of way.

Slow down at all street interprocedures and observe to the left, to the right and back to left again before

proceeding.

Use proper hand signals when turning.

DO NOT attempt to move up or down an incline with an ice or oil film.

DO NOT attempt to ride over curbs or obstacles. Doing so may cause your Excelerator to turn over and

cause bodily harm or damage to the Excelerator.

DO NOT use parts, accessories, or adapters other than those authorized by Invacare.

G

E

N

E

R

A

L

G

U

I

D

E

L

I

N

E

S

DO NOT attempt to lift the Excelerator by any removable (detachable) parts. Lifting by means of

any removable (detachable) parts of an Excelerator may result in injury to the user or damage to

the Excelerator.

DO NOT stand on the seat or frame of the Excelerator.

If a seat positioning strap is deemed necessary by your health care professional (doctor - therapist),

ALWAYS wear a seat positioning strap.

Avoid all surface hazards.

DO NOT carry any riders.

DO NOT carry any items that may obstruct your view or prohibit you from operating the Excelerator

properly.

DO NOT clean gear hubs with pressure water (e.g. strong water jet, high-pressure cleaner etc.). Water

that penetrates into the hub could lead to function problems. The hub has been adequately lubricated.

However, if the response of the hand crank brake should become too sharp, the brake cylinder MUST

be greased by a brake professional, using special SACHS grease Type A (F & S Part No. 0369135100).

5

Page 6

G

E

N

E

R

A

L

G

U

I

D

E

L

I

N

E

S

TIRE PRESSURE

DO NOT use your Excelerator unless it has the proper tire pressure (p.s.i.). DO NOT overinflate the tires.

Failure to follow these suggestions may cause the tire to explode and cause bodily harm.

DO NOT ride on a flat or underinflated tires. Riding on flat or underinflated tires can cause injury, as well

as, damage to the tire, tube and bicycle.

WEIGHT LIMITATION

The Invacare Excelerator and Excelerator XLT/XLT 2000 have a maximum weight limitation of 250 lbs.

The Invacare Li'l Excelerator has a maximum weight limitation of 150 lbs.

SAFETY/HANDLING OF

EXCELERATOR

“Safety and Handling” of the Excelerator requires the

close attention of the user as well as the assistant. This

manual points out the most common procedures and

techniques involved in the safe operation and maintenance of the Excelerator. It is important to practice and

master these safe techniques until you are comfortable

in maneuvering the Excelerator.

Use this information only as a “basic” guide. The techniques that are discussed on the following pages have

been used successfully by many.

Individual users often develop skills to deal with daily

living activities that may differ from those described in

this manual. Invacare recognizes and encourages each

individual to try what works best for him/her in overcoming obstacles that they may encounter. Techniques in

this manual are a starting point for the new Excelerator

user and assistant with “safety” as the most important

consideration for all.

GENERAL GUIDELINESPROCEDURE 1

WARNING

When you are assisting with a transfer to / from the

Excelerator, remember to use good body mechanics.

Keep your back straight and bend your knees whenever

lifting or positioning the Excelerator for the end-user.

Also, be aware of detachable parts. These must NEVER

be used for lifting supports, as they may be inadvertently

released, resulting in possible injury to the user and/or

assistant.

Percentage of Weight Distribution

Transferring in and out of the Excelerator will cause a

change to the normal balance, the center of gravity, and

the weight distribution of the Excelerator. To determine

and establish your particular safety limits, practice transferring activities in several combinations in the presence

of a qualified health care professional BEFORE attempting a transfer alone.

Proper positioning is essential for your safety.

Transferring into/out of the Excelerator

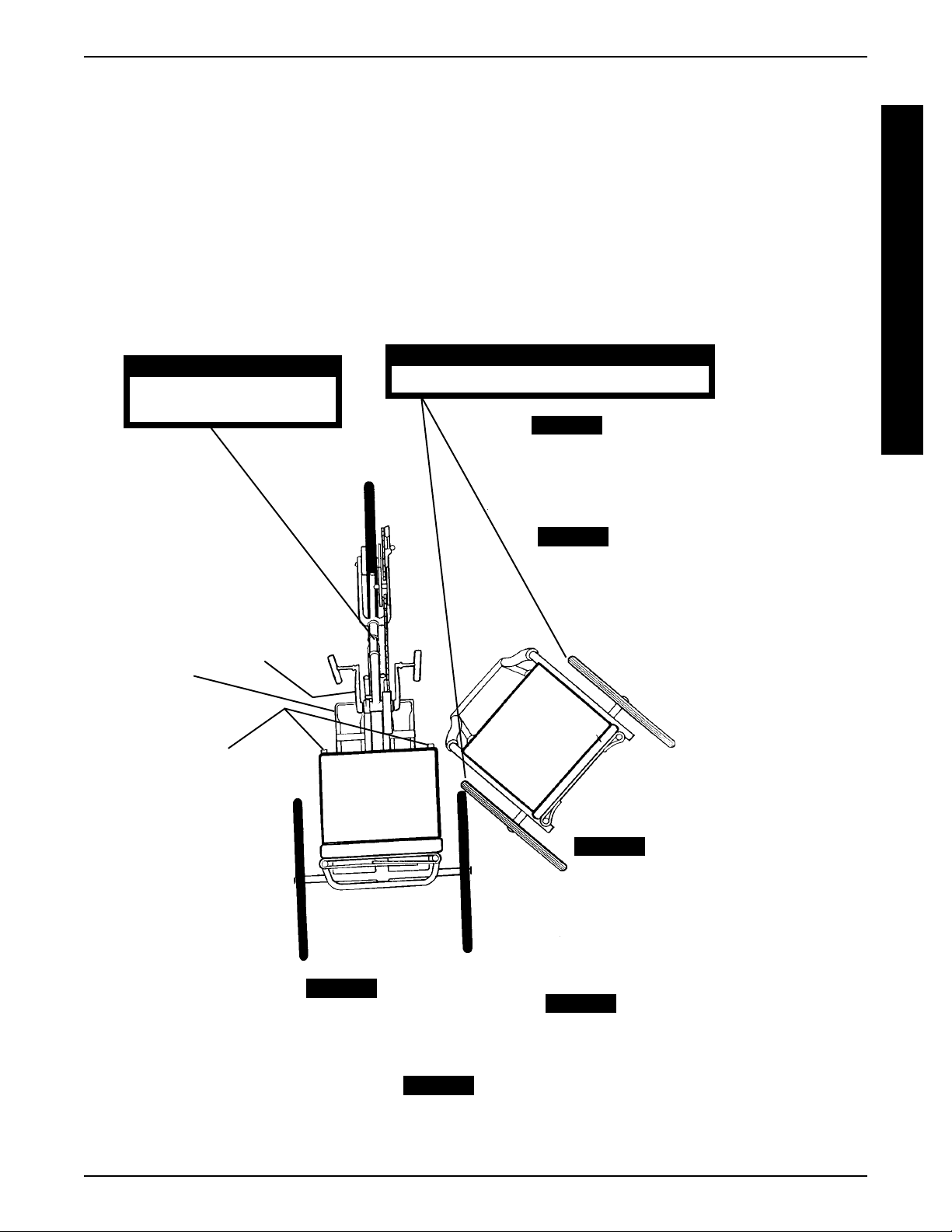

(FIGURE 1)

Stability and Balance

For stability and proper operation of your Excelerator, you

must at all times maintain proper balance. Your Excelerator

should remain upright and stable during normal daily activities when operated correctly.

Invacare recommends using seat positioning straps for

additional safety.

A Note to Excelerator Assistants

When learning assistance techniques for the Excelerator,

have an experienced assistant help you before attempting it alone.

WARNING

Before attempting to transfer IN or OUT of the

Excelerator, every precaution should be taken

to reduce the gap distance. Position the Excelerator on level ground and as close as possible

to the object you are transferring INTO or OUT of.

The parking brake of the Excelerator MUST be engaged and the object you are transferring INTO

or OUT of MUST also be secured before attempting any transfer.

CAUTION

When transferring, position yourself as far back

as possible in the seat. This will prevent damage

to the upholstery.

6

Page 7

GENERAL GUIDELINES

NOTE: This activity may be performed independently

provided you have adequate mobility and upper body

strength.

Position the Excelerator on level ground and as close as

possible along side the object to which you are transferring. Apply parking brake on Excelerator and secure

object that you are transferring into or out of. Shift body

weight onto object with transfer.

During independent transfer, little or no seat platform will

be beneath you. Use a transfer board if at all possible.

WARNING

Parking Brake MUST be

secured.

Wheel Locks MUST be engaged.

PROCEDURE 1

WARNING

STEP 1:

of the wheelchair upholstery closest to

the Excelerator.

Shift body weight to the edge

G

E

N

E

R

A

L

G

U

I

D

E

L

I

N

E

S

Footrest

Hand

Crank

Seat

Frame

STEP 2:

Lift and place LEFT

leg past front frame over center tube.

STEP 3:

Place LEFT hand on

the Excelerator seat frame, NOT

on hand crank.

STEP 6:

Excelerator footrests.

Place both legs onto

STEP 4:

Place RIGHT hand on

the wheelchair frame.

STEP 5:

Lift and shift weight into

Excelerator seat.

FIGURE 1 - TRANSFERRING INTO AND OUT OF THE EXCELERATOR

7

Page 8

PROCEDURE 2

SAFETY INSPECTION/TROUBLESHOOTING/MAINTENANCE

This Procedure Includes the Following:

S

Safety Inspection Checklist Troubleshooting Maintenance

A

SAFETY INSPECTION CHECKLIST

F

E

NOTE: Every six (6) months, take your Excelerator to a qualified technician for a thorough inspection and servicing. Regular

cleaning will reveal loose or worn parts and enhance the smooth operation of your Excelerator. For safe and proper operation, your

T

Excelerator must be cared for just like any other vehicle. Routine maintenance will extend the life and efficiency of your Excelerator.

Y

NOTE: Invacare recommends that the following adjustments be performed by a qualified technician. Initial adjustments should be

I

made to suit your personal body structure and preference. Thereafter follow these maintenance procedures.

N

S

P

E

C

T

O

N

T

R

O

U

B

L

E

S

H

O

O

T

N

G

M

A

N

T

E

N

A

N

C

E

ITEM INITIALLY INSPECT/ INSPECT/ INSPECT/

FRAME

Check for bent or broken frame. Frame damage can cause

other parts to fail. X X X

I

BRAKES (PROCEDURE 8)

Parking Brake - Adjust brake shoes to front rim. Check for

worn or missing shoes. Check for wax or oil on rim. X X X

Cable anchor attached securely to brake arm. X X X

Internal Stopping Brakes - engages easily. X X X

SEAT AND BACK UPHOLSTERY (PROCEDURE 10)

Inspect for rips or sagging. X X

REAR WHEELS (PROCEDURE 4)

Axle nut and wheel mounting nuts are secure. X X X X

No excessive side movement or binding when lifted and spun. X X X

CAUTION: As with any vehicle, the wheels and tires

should be checked periodically for cracks and wear, and

should be replaced.

SPOKES (PROCEDURE 4)

Inspect for bent or broken spokes. X X

All spokes uniformly tight. X X

FRONT WHEEL/FORK (PROCEDURE 5)

Keep axle nuts tight. Wheel should be centered in fork. Keep

wheel bearings adjusted and keep spokes tight and wheel

in proper alignment. X X X

Check rim and fork assembly for damage. X X X

I

CAUTION: As with any vehicle, the wheels and tires

should be checked periodically for cracks and wear, and

should be replaced.

TIRES (PROCEDURE 4)

Inspect for flat spots and wear. Check for proper inflation. X X X

CAUTION: As with any vehicle, the wheels and tires

should be checked periodically for cracks and wear, and

should be replaced.

CHAIN/CHAIN GUARD (PROCEDURE 7)

Check for damage, rust, tension and stretch. Adjust if

necessary. Lubricate each link often (3-in-1 oil or a quality

I

bike lubricant). Check for damage or looseness. X X X

CONTROL CABLES (PROCEDURE 6)

Adjust accordingly. X X X

FRONT FORK (GOOSE NECK) (PROCEDURE 5)

Keep tight and lubricate (All purpose grease). X X X

FOOTREST (PROCEDURE 11)

Check that mounting hardware is tight and footrest secure. X X

Check footrest straps for wetness and/or damage. X X X X

UPHOLSTERY (PROCEDURE 10)

Clean upholstery with light detergent and water. X X

MOUNTAIN DRIVE OPTION (PROCEDURE 12)

Oil Hand crank. X

Adjust bearing play X

ADJUST ADJUST ADJUST

WEEKL Y MONTHLY PERIODICALL Y

8

Page 9

SAFETY INSPECTION/TROUBLESHOOTING/MAINTENANCE

PROCEDURE 2

TROUBLESHOOTING

SLUGGISH WHEEL SQUEAKS LOOSENESS SOLUTIONS

VEERS VEERS TURN OR FLUTTERS AND IN

RIGHT LEFT PERFORMANCE RATTLES EXCELERATOR

XXXX Check tires for correct and

equal pressure.

XXX XCheck for loose axle nuts.

XXCheck spokes and nipples.

XXXCheck chain for proper ten-

sion and adjustment.

XXCheck that goose neck fitt-

ings are secure.

MAINTENANCE

S

A

F

E

T

Y

I

N

S

P

E

C

T

I

O

N

Maintenance Safety Precautions

WARNING

After ANY adjustments, repair or service and BEFORE use, make sure all attaching hardware is tightened securely - otherwise injury or damage may

result.

CAUTION

DO NOT overtighten hardware attaching to the

frame. This could cause damage to the frame tubing.

Suggested Maintenance Procedures

1. Before using your Excelerator, make sure all nuts and

bolts are tight. Check all parts for damage or wear and

replace. Check all parts for proper adjustment.

2. Check parking brake cable and shifter adjustment

cables for proper adjustment and operation. Refer to

PROCEDURES 6 AND 7 of this manual.

3. If equipped, keep quick release axles free of dirt and

lint to ensure positive locking and proper operation. Refer

INSTALLING/ADJUSTING THE REAR WHEEL

to

AND QUICK-RELEASE AXLES - EXCELERATOR

AND LI'L EXCELERATOR in PROCEDURE 4 of this

manual. Oil quick-release axles at least once (1) a month

(3-in-1® oil or equivalent).

WARNING

Do not use the wheelchair unless it has the proper

tire pressure (p.s.i.). DO NOT overinflate the tires.

Failure to follow these suggestions may cause the

tire to explode and cause bodily harm.

4. Recommended tire pressure is listed on the side wall

of the tire. If tire needs replaced, see local bike shop.

CAUTION

As with any vehicle, the wheels and tires should

be checked periodically for cracks and wear,

and should be replaced.

5. The wheels and tires should be checked periodically for cracks and wear, and should be replaced.

6. Check chain for slack and readjust. Refer to

EXCELERATOR / LI'L EXCELERATOR CHAIN ADJUSTMENT in PROCEDURE 7 of this manual.

7. Regularly check for loose spokes in the front and

rear wheels. If loose, have them aligned at your local

bike shop.

8. If equipped, check tension spring for proper operation.

Refer to

SION SPRING INSTALLATION in PROCEDURE 5 of

this manual.

9. Check Upholstery for sagging, rips or tears Refer to

BACK UPHOLSTERY REPLACEMENT or SEAT

UPHOLSTERY REPLACEMENT in PROCEDURE

10 of this manual.

10. Check alignment of front wheel. If it wobbles or takes

too much effort to turn by hand, have it aligned at

your local bike shop.

EXCELERATOR/LI'L EXCELERATOR TEN-

T

R

O

U

B

L

E

S

H

O

O

T

I

N

G

M

A

I

N

T

E

N

A

N

C

E

3-in-1® - Registered trademark of American Home Products

Corporation.

9

Page 10

PROCEDURE 3

ASSEMBL Y PROCEDURES

This Procedure Includes the Following:

Excelerator/Li'l Excelerator Assembly Procedures

A

S

Excelerator XLT/XLT 2000 Assembly Procedures

S

E

M

B

L

Y

P

R

O

C

E

D

U

R

E

S

After ANY adjustments, repair or service and BEFORE use, make sure all attaching hardware is tightened securely - otherwise injury or damage may

result.

DO NOT operate the Excelerator if the hand crank

obstructs your view. If the hand crank obstructs

your view, adjust the hand crank height BEFORE

using the Excelerator - Otherwise injury or damage may occur.

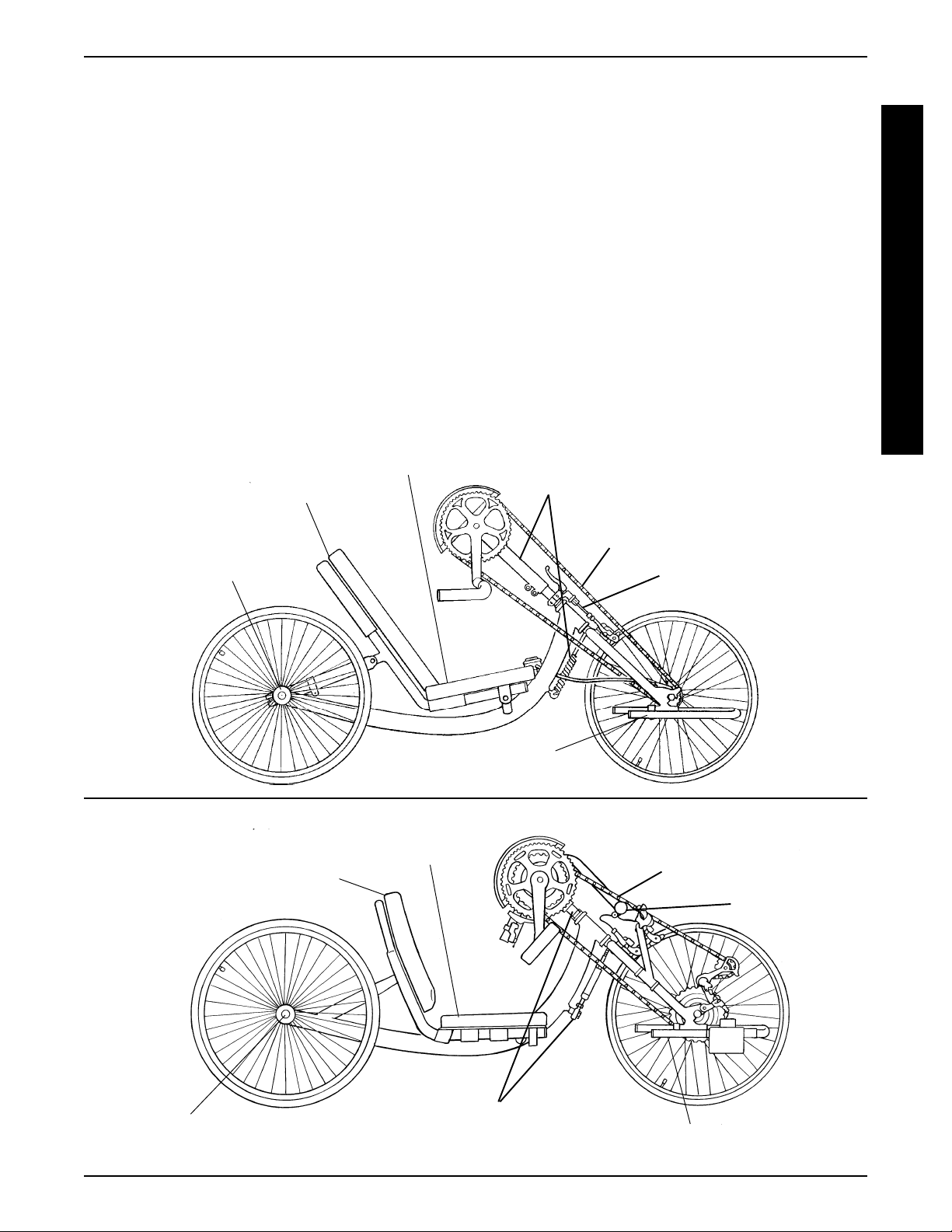

EXCELERATOR/LI'L

EXCELERATOR ASSEMBLY

WARNING

PROCEDURES (FIGURE 1)

NOTE: Invacare recommends that the following procedures be performed by a qualified technician.

T ools required:

Adjustable wrench (10-12-inches)

6, 8 and 9mm wrench

1/8-inch allen wrench

1/2-inch box wrench

Two (2) medium srewdrivers (flathead and phillips)

1. Secure and adjust rear wheels (PROCEDURE 4).

2. Secure the fork assembly (PROCEDURE 5).

3. Secure and adjust tension spring (PROCEDURE 5).

4. Secure and adjust hand crank assembly (PROCEDURE 5).

5. Secure and adjust STANDARD three (3) speed shifter

or Seven (7) speed shifter (PROCEDURE 6).

6. Adjust chain (PROCEDURE 7).

7. Tension and adjust cantilever brake cable (Optional

[PROCEDURE 8]).

8. Fasten and adjust parking brake (PROCEDURE 8).

9. Secure and adjust back height (PROCEDURE 9).

10. Secure and adjust seat position/upholstery (PROCEDURE 10).

11. Secure and adjust footrest (PROCEDURE 11).

12. Check that all hardware is tight.

PROCEDURE 9

PROCEDURE 4

PROCEDURE 10

PROCEDURE 6

PROCEDURE 5

PROCEDURE 8

PROCEDURE 6

PROCEDURE 11

FIGURE 1 - EXCELERATOR/LI'L EXCELERATOR ASSEMBLY PROCEDURES

10

Page 11

ASSEMBL Y PROCEDURES

PROCEDURE 3

EXCELERATOR XLT/XLT 2000

ASSEMBLY PROCEDURES

(FIGURE 2)

NOTE: Invacare recommends that the following procedures be performed by a qualified technician.

Tools required:

Adjustable Wrench (10-12-inches)

5, 8 and 32 mm Wrench

3/16-inch Allen Wrench

1/4-inch Allen Wrench

1/2-inch Box Wrench

1/2-inch Socket Wrench

Two (2) Medium Screwdrivers (Flathead and Phillips)

EXCELERA TOR XL T

PROCEDURE 10

PROCEDURE 9

1. Secure and adjust rear wheels (PROCEDURE 4).

2. Adjust hand crank assembly (PROCEDURE 5).

3. Adjust chain (PROCEDURE 7).

4. Adjust the optional cantilever brake cable (PROCEDURE 8).

5. Adjust parking brake (PROCEDURE 8).

6. Adjust back height and/or angle (PROCEDURE 9).

7. Adjust seat position/upholstery (PROCEDURE 10).

8. Adjust footrest (PROCEDURE 11).

9. Check that all hardware is tight.

PROCEDURE 5

A

S

S

E

M

B

L

Y

P

R

O

C

E

D

U

R

E

S

PROCEDURE 4

PROCEDURE 9

PROCEDURE 7

PROCEDURE 8

PROCEDURE 11

EXCELERA TOR XLT 2000

PROCEDURE 10

PROCEDURE 7

PROCEDURE 8

PROCEDURE 4

PROCEDURE 5

PROCEDURE 11

FIGURE 2 - EXCELERA TOR XLT/XLT 2000 ASSEMBLY PROCEDURES

11

Page 12

PROCEDURE 4 REAR WHEELS

This Procedure includes the following:

Installing/Adjusting the Rear Wheels and Quick-

Release Axles

R

Installing the Rear Wheels with Threaded Axle

E

Option - Excelerator XL T/XLT 2000

A

Tire/Tube Replacement and Tuning/Replacement

R

of Spokes

W

Tire Pressure

Determining/Adjusting Toe In/T oe Out

H

Replacing Camber Inserts

E

E

WARNING

S

L

After ANY adjustments, repair or service and BEFORE use, make sure all attaching hardware is tightened securely - otherwise injury or damage may

result.

INSTALLING/ADJUSTING THE

REAR WHEEL AND QUICKRELEASE AXLES (FIGURE 1)

5. Reinstall rear wheel on the Excelerator.

6. Tilt Excelerator onto either rear wheel and spin raised

wheel. It should spin freely with no excessive drag.

7. Repeat procedure for opposite rear wheel.

NOTE: If drag to either side occurs, repeat the procedure until the Excelerator rolls correctly.

INSTALLING THE REAR WHEELS

WITH THREADED AXLES EXCELERATOR XLT/XLT 2000

(FIGURE 2)

1. Apply a small amount of grease onto the axle.

2. Insert the axle into the axle mounting hole on the chair

frame.

3. Securely tighten the axle to the frame.

Axle Mounting

Hole

1/4-inch Allen

Wrench

1. Make sure that the axle receiver hex nut is securely

tightened before installing the rear wheels.

2. Depress detent pin in the quick-release axle and slide

axle through the axle receiver.

3. Release detent pin ensuring that the locking pins are

fully released.

NOTE: Locking pins MUST protrude past the end of the

axle receiver to fully release. Any excessive play MUST

also be eliminated.

4. Increase or decrease end play by adjusting the locknut on the end of the quick-release axle.

WARNING

Make sure detent pin is fully released BEFORE operating the Excelerator, Li'l Excelerator or

Excelerator XL T.

Keep locking pins clean.

Axle Receiver Hex Nut

Locknut

Frame

Axle

FIGURE 2 - INSTALLING THE REAR WHEELS WITH

THREADED AXLES - EXCELERA TOR XL T/XL T 2000

Rear Wheel

TIRE/TUBE REPLACEMENT AND

TUNING/REPLACEMENT OF SPOKES

NOTE: Invacare recommends that these procedures be

performed by a qualified technician.

TIRE PRESSURE

WARNING

DO NOT use the Excelerator unless it has the

proper tire pressure (p.s.i.). DO NOT overinflate the

tires. Failure to follow these suggestions may cause

the tire to explode and cause bodily harm. Tire

p.s.i. is printed on the tire wall.

DETERMINING/ADJUSTING

TOE IN/TOE OUT (FIGURE 3)

Locking Pins

Axle Receiver

FIGURE 1 - INSTALLING/ADJUSTING THE REAR WHEEL

AND QUICK-RELEASE AXLES

Detent Pin

Determining Toe In/Toe Out

1. Inflate all pneumatic tires to recommended tire pressures (listed on the sidewall of the tire).

12

Page 13

PROCEDURE 4REAR WHEELS

2. Measure the distance between the center lines at the

rear and front of the rear wheels at approximately 12inches from the ground/floor (FIGURE 3).

NOTE: For optimum accuracy, perform STEP 2 with the

wheelchair occupied.

3. Determine the difference between the two (2) measurements. If the difference between the two (2)

measurements is GREA TER than 1/2-inch (0

4-inch for maximum rollability), one (1) of two (2)

conditions exists:

a. If the back centerline measurement of the rear

wheels is SMALLER than the front centerline

measurement of the rear wheels, a TOE-OUT

condition exists (FIGURE 3).

b. If the back centerline measurement of the rear

wheels is LARGER than the front centerline

measurement of the rear wheels, a TOE-IN condition exists (FIGURE 3).

4. If the difference between the measurements is greater

than 1/2-inch, correct the toe-in/toe-out condition. Refer to

ADJUSTING TOE-IN/TOE-OUT in this proce-

dure of the manual.

Clamp

Camber

Insert

FRONT OF WHEELCHAIR

Socket Screw

Toe-out

+ 1/

Camber

Bar

Adjusting Toe In/Toe Out

1. Loosen, but do not remove the socket screws and

clamps that secure camber inserts to the camber bar.

2. Slowly rotate the camber insert until the rear wheels

are approximately in a straight line.

3. Securely tighten the socket screws and clamps that

secure the camber inserts to the camber bar.

4. Measure the distance between the center lines at the

rear and front of the rear wheels at approximately 12inches from the ground/floor. Refer to

ING TOE IN/TOE OUT in this procedure of the

manual.

5. Repeat STEPS 1-4 until the toe in/toe out measurement is less than 1/2-inch (0

rollability).

+ 1/4-inch for maximum

DETERMIN-

REPLACING CAMBER INSERTS

(FIGURE 4)

1. Loosen, but do not remove the socket screws and

clamps that secure the camber inserts to the camber

bar.

2. Remove the existing camber insert from the camber

bar.

3. Install the new camber insert into the camber bar.

4. Adjust the toe in/toe out of the wheelchair. Refer to

DETERMINING/ADJUSTING TOE IN/TOE OUT in

this procedure of the manual.

R

E

A

R

W

H

E

E

L

S

Toe-in

Top View of

Wheelchair

Smaller Than

Front

Larger Than Front

FIGURE 3 - DETERMINING/ADJUSTING TOE IN/TOE OUT

13

Frame

Clamp

Camber

Insert

FIGURE 4 - REPLACING CAMBER INSERTS

Socket

Screw

Camber Bar

Page 14

PROCEDURE 5 FORK/SPRING/CRANK

This Procedure includes the following:

EXCELERA TOR/LI'L EXCELERA TOR:

F

O

Fork Assembly Installation

R

K

Tension Spring Installation

/

Hand Crank Assembly Installation

S

EXCELERA TOR XL T/XLT 2000:

P

R

Fork /Crank Assembly Replacement

I

Tension Spring or Road Crown Compensator

N

G

Replacement/Adjustment

/

C

R

A

N

K

After ANY adjustments, repair or service and BEFORE use, make sure all attaching hardware is

tightened securely - otherwise injury or damage

may result.

DO NOT operate the Excelerator if the hand crank

obstructs your view. If the hand crank obstructs

your view, adjust the height BEFORE using the

Excelerator - Otherwise injury or damage may

occur.

WARNING

EXCELERATOR/LI'L

EXCELERATOR FORK ASSEMBLY

INSTALLATION (FIGURE 1)

1. Remove the fork assembly from the packaged container.

2. Slide fork assembly through the opening in the front

frame (Goose Neck) making sure to seat washer

and ball bearing housing.

3. Seat ball bearings on fork assembly.

4. Place locknut over fork assembly and tighten.

5. Tighten locknut setscrews.

EXCELERATOR/LI'L

EXCELERATOR TENSION SPRING

INSTALLATION (FIGURE 1)

NOTE: The tension spring is NOT intended to keep the

Excelerator straight when pedaling but to keep the

Excelerator from leaning excessively to one side or another.

Ball Bearings

Locknut

Goose Neck

Front Frame

Opening

Ball Bearing Housing

Eye Bolt

Washer

Fork Assembly

Tension Spring

Eye Bolt

FIGURE 1 - EXCELERATOR/LI'L EXCELERATOR FORK

ASSEMBL Y/TENSION SPRING INST ALLA TION

Adjustable

Chain Idler

EXCELERATOR/LI'L

EXCELERATOR HAND CRANK

ASSEMBLY INSTALLATION

(FIGURE 2)

1. Remove the chain from the front wheel hub so it moves

with the hand crank assembly.

2. Slide the hand crank assembly over and completely

down the fork stem.

3. Position the chain on the hand crank sprocket assembly and the front wheel hub.

4. Move the hand crank assembly up or down on the

fork stem until you are comfortable with the position

for operational purposes.

NOTE: Positioning of the hand crank assembly loosens

or tightens the chain in an UP/DOWN position.

5. Tighten hex nut to secure the hand crank assembly.

6. Adjust the tautness of the chain by moving the adjustable chain idler IN or OUT.

7. Tighten the hex screw to secure the adjustable chain

idler in place.

1. Tighten eye bolts into fork assembly and front frame.

2. Using a medium flat head screwdriver, hook the tension spring to the fork assembly and front frame eye

bolts.

NOTE: Tension is applied by loosening or tightening the

eye bolts. This should be done before installation of the

tension spring.

Fork

Stem

FIGURE 2 - EXCELERATOR/LI'L EXCELERATOR HAND

CRANK ASSEMBL Y INST ALLA TION

Hex Nut

Step 5

14

Page 15

FORK/SPRING/CRANK PROCEDURE 5

EXCELERATOR XLT/XLT 2000

FORK/CRANK ASSEMBLY

REPLACEMENT (FIGURE 3)

NOTE: Invacare recommends that the following procedure be performed by a qualified technician.

1. Note the position of the crank handles.

STEPS 1, 2, 3, 38, 39 STEPS 6, 36 STEPS 7, 8, 35

Fork

Socket

Screws

Fork

Crank

Handles

Half

Clamp

Socket

Screws

2. Loosen, but do not remove the two (2) socket screws

that secure the crank handles to the existing fork.

3. Slide the crank handles down towards the front wheel.

4. Remove the chain from the crank handles.

5. Remove the crank handles from the existing fork.

6. Remove the two (2) socket screws and half clamp

that secure the brake handle to the existing fork.

7. Remove the socket nut on the BACK of the existing

fork that secures the brake assembly.

Brake

Handle

Fork

Hardware

Socket

Nut

Brake Assembly

F

O

R

K

/

S

P

R

I

N

G

/

C

R

A

N

K

STEPS 9, 34

Fork

Road Crown Compensator

STEPS 13, 14, 27, 28, 29, 30

Non-Turn

Fork

Washer - Must

Be Installed

as Shown

Washer

Front

Cap Nuts

Wheel

STEPS 10, 33

Seat Frame

STEPS 16, 17, 24, 25

Fork

Hex

Bolts,

Locknuts

and

Footrest

Footrest

Clamps

Shifter

STEPS 11, 12, 31, 32

Locknut

Brake

Hex Bolt

Arm

STEPS 5, 18, 19, 20, 21, 22, 23, 37

Crank Handles

Top

Nuts

Bearing

O-Ring

Bottom Bearing

Frame

Fork

Brake

Arm

Clamp

FIGURE 3 - EXCELERA TOR XL T/XLT 2000 FORK/CRANK ASSEMBL Y REPLACEMENT

15

Page 16

FORK/SPRING/CRANKPROCEDURE 5

8. Note brake assembly hardware position and remove

the brake assembly from the existing fork.

F

9. Remove the tension spring or road crown compen-

O

R

K

/

S

P

R

I

N

G

/

C

R

A

N

K

sator from the existing fork. Refer to

XLT/XLT 2000 TENSION SPRING OR ROAD

CROWN COMPENSATOR REPLACEMENT in this

procedure of the manual.

10. Loosen, but do not remove the socket screw that

secures the shifting lever to the seat frame.

11. Remove the hex bolt and locknut that secure the brake

arm to the brake arm clamp.

12. Remove the brake arm clamp from the existing fork.

13. Loosen, but do not remove the two (2) cap nuts that

secure the front wheel to the existing fork.

14. Remove the front wheel from the existing fork.

EXCELERATOR

15. Lay the chain flat.

NOTE: Laying the chain flat will prevent kinks in the chain.

16. Remove the two (2) hex bolts, locknuts and clamps

that secure the footrests to the existing fork.

17. Note the position of the footrests and remove the footrests from the existing fork.

18. Remove the two (2) top nuts that secure the existing

fork to the frame.

19. Note the o-ring and bearing position and remove the

existing fork from the frame.

30. Torque the two (2) cap nuts 260-390 inch-pounds.

31. Install the brake arm clamp onto the new fork.

32. Secure the brake arm to the brake arm clamp with

the hex bolt and locknut. Torque to 22-26 inch-pounds.

33. Reinstall the shifting lever onto the seat frame and

secure with the socket screw.

34. Install the tension spring or road crown compensator

onto the new fork. Refer to

EXCELERATOR XLT/

XLT 2000 TENSION SPRING OR ROAD CROWN

COMPENSATOR REPLACEMENT/ADJUSTMENT

in this procedure of the manual.

NOTE: EXCELERATOR XLT BUILT BEFORE 9/99

ONLY- Make sure the shifting cable is between the spring

and the frame.

35. Install the brake assembly onto the new fork. Refer to

the hardware position noted in STEP 8 and tighten

securely with the socket nut.

36. Install the brake handle and half clamp onto the new

fork and secure with the two (2) socket screws.

37. Slide the crank handles onto the new fork.

NOTE: Make sure the sprocket on the crank handles is in

line with the sprocket on the front wheel.

38. Reinstall the chain onto the crank handle sprocket.

39. Move the crank handle to the position determined in

STEP 1 and tighen the two (2) socket screws securely.

20. Slide the bottom bearing onto the new fork. Refer to

FIGURE 3 for correct orientation.

21. Slide the new fork into the frame.

22. Position the o-ring and bearing on the new fork. Refer to FIGURE 3 for correct orientation.

23. Install the two (2) nuts onto the new fork and tighten

securely. Refer to FIGURE 3 for correct orientation.

24. Position the footrest clamps on the new frame.

25. Install the footrests onto the new fork to the position

noted in STEP 17 and secure with the two (2) hex

bolts and locknuts.

26. Position the chain around the hub of the front wheel.

27. Install the front wheel onto the new fork.

NOTE: Make sure the washer and the non-turn washer

are on the OUTSIDE of the new fork.

28. Line up the projecting ends of the non-turn washer

with the slot in the new fork.

29. Repeat STEPS 27-28 until the projecting ends of the

non-turn washer line up with the slot in the new fork.

EXCELERATOR XLT/XLT 2000

TENSION SPRING OR ROAD

CROWN COMPENSATOR

REPLACEMENT/ADJUSTMENT

NOTE: Excelerator XLTs built before 9/99 have the tension spring. All Excelerator XLTs built after 9/99 have the

road crown compensator.

NOTE: The tension spring or road crown compensator is

NOT intended to keep the Excelerator XLT/XLT 2000

straight when pedaling but to keep the Excelerator XLT/

XLT 2000 from leaning excessively to one side or another.

Tension Spring Replacement/Adjustment

(FIGURE 4)

REMOVING TENSION SPRING.

1. Using a medium flat head screwdriver, unhook the

existing tension spring from fork and frame eye bolt.

16

Page 17

FORK/SPRING/CRANK PROCEDURE 5

ADJUSTING TENSION SPRING.

NOTE: Adjustments should be performed BEFORE

installation of the tension spring.

1. Rotate the frame eye bolt to adjust the tension.

CLOCKWISE - INCREASES tension.

COUNTERCLOCKWISE - DECREASES tension.

INSTALLING TENSION SPRING.

1. Using a medium flat head screwdriver, hook the new

tension spring onto the fork eye bolt and frame eye bolt.

Fork

Fork Eye

Bolt

Frame Eye Bolt

Tension Spring

FIGURE 4 - TENSION SPRING REPLACEMENT/

ADJUSTMENT

Road Crown Compensator Replacement/

Adjustment (FIGURE 5)

4. Rotate the fork to ensure the front wheel is pointing directly forward.

5. Position the fork end of the road crown compensator on the fork bolt.

NOTE: If necessary, lengthen or shorten the road

crown compensator to position the fork end onto the

fork bolt. Refer to the

ADJUSTING procedure in this

section.

6. Secure the road crown compensator to the fork

bolt with the locknut. Tighten securely.

Fork Bolt

Locknut

REMOVED

Frame

Mounting

Hole

Frame

Fork End

Road Crown

Compensator

Frame End

INST ALLED

Bolt

Spacer

F

O

R

K

/

S

P

R

I

N

G

/

C

R

A

N

K

REMOVING ROAD CROWN COMPENSATOR.

1. Remove the locknut securing the fork end of the

road crown compensator to the fork bolt.

2. Remove the fork end of the the road crown compensator from the fork bolt.

3. Remove the bolt and spacer securing the frame

end of the road crown compensator to the frame.

ADJUSTING ROAD CROWN COMPENSATOR.

1. Rotate the fork end of the road crown compensator to adjust the length.

CLOCKWISE - shortens the road crown compensator and pulls the front wheel to the left.

COUNTERCLOCKWISE - lengthens the road crown

compensator and pushes the front wheel to the right.

INSTALLING ROAD CROWN COMPENSATOR.

1. Position the bolt through the frame end of the road

crown compensator.

2. Position the spacer on the bolt.

3. Install the bolt with spacer and road crown compensator into the mounting hole on the frame.

Frame

Fork

Road Crown

Compensator

ADJUSTING

Fork

End

Road Crown Compensator

FIGURE 5 - ROAD CROWN COMPENSATOR

REPLACEMENT/ADJUSTMENT

17

Page 18

SPEED SHIFTERSPROCEDURE 6

This Procedure includes the following:

LI'L EXCELERA TOR:

S

Three (3) Speed Shifter Cable Installation

P

Three (3) Speed Shifter Cable Adjustment

E

EXCELERA TOR/EXCELERA TOR - XL T :

E

D

Seven (7) Speed Shifter Cable Installation

Seven (7) Speed Shifter Cable Adjustment/

S

Replacement

H

I

F

T

E

R

S

After ANY adjustments, repair or service and BEFORE use, make sure all attaching hardware is tightened securely - otherwise injury or damage may

result.

LI'L EXCELERATOR - THREE (3)

SPEED SHIFTER CABLE

WARNING

INSTALLATION (FIGURE 1)

NOTE: The THREE (3) SPEED Shifter Cable runs from

the LEFT-SIDE of the FRONT FRAME to its mounting

position on the HAND CRANK Assembly Shaft.

1. Run the cable from the left-side of the fork assembly

to mounting position just below the hand crank assembly.

2. Attach the three (3) speed cable to the hand crank

assembly extension.

3. Secure with hardware provided.

FIGURE 1 - LI'L EXCELERATOR THREE (3) SPEED

SHIFTER CABLE INSTALLATION

LI'L EXCELERATOR - THREE (3)

SPEED SHIFTER CABLE

ADJUSTMENT

CAUTION

DO NOT ride the Excelerator if the hub is out of

adjustment. This will damage the internal parts

and cause hub to malfunction.

3. Shift gears to check for correct adjustment.

NOTE: If gears do NOT shift, increase cable tension and

retest proper shifting of gears. If the chain skips a gear,

loosen the cable tension until correct operation is achieved.

CAUTION

DO NOT overtighten the cables. Doing so may

cause the cable to break. If PROCEDURE A does

NOT solve the problem, take your Li'l Excelerator

to an authorized Invacare Dealer or qualified

technician for proper adjustment.

NOTE: Shift gears when pedals are stationary or when

minimum amount of pedaling is being done to avoid wear

on rotating parts of hub.

Clamp

Hex Nut

Cable

FIGURE 2 - LI'L EXCELERATOR THREE (3) SPEED

SHIFTER CABLE ADJUSTMENT

Procedure B (FIGURE 3)

NOTE: If the following procedure does not enable all three

(3) gears, contact a qualified technician or Invacare for

assistance.

1. Ensure that the indicator chain is fully screwed into

the axle. Turn back a maximum of half a turn.

2. Check that the indicator chain runs freely through the

indicator protector if fitted.

3. Select third gear and loosely connect the cable adjuster onto the indicator coupling.

4. Select second gear position on the gear control. Looking through the window in the right-hand axle nut,

turn the cable adjuster until the end of the indicator is

exactly level with the end of the axle.

5. Tighten the locknut against the adjuster.

Indicator Protector

Right- Hand

Indicator Chain

Indicator Coupling

Locknut

Cable Adjuster

Axle

Axle Nut

S

P

E

E

D

S

H

I

F

T

E

R

S

Procedure A (FIGURE 2)

1. Loosen the hex nut.

2. Using a pair of pliers, pull cable to increase tension.

Retighten hex nut.

Indicator Chain

FIGURE 3 - LI'L EXCELERATOR THREE (3) SPEED

INDICATOR CHAIN ADJUSTMENT

18

Page 19

PROCEDURE 6SPEED SHIFTERS

EXCELERATOR/EXCELERATOR

XLT - SEVEN (7) SPEED SHIFTER

CABLE INSTALLATION (FIGURE 4)

S

P

NOTE: The SEVEN (7) SPEED Shifter Cable runs from

E

the RIGHT-SIDE of the FRONT FRAME to its mounting

E

position on the HAND CRANK Assembly Shaft.

D

1. Run the cable from the right-side of the fork assem-

S

H

I

F

T

bly to mounting position on the left side just below the

hand crank assembly.

2. Attach the seven (7) speed cable to the hand crank

assembly extension.

3. Secure with hardware provided.

E

R

Shifter Cable

S

FIGURE 4 - EXCELERA TOR/EXCELERATOR XLT SEVEN

(7) SPEED SHIFTER CABLE INST ALLATION

EXCELERATOR/EXCELERATOR

XLT SEVEN (7) SPEED SHIFTER

ADJUSTMENT/REPLACEMENT BEFORE 1997 ONLY (FIGURE 5)

NOTE: Excelerator/Excelerator XLTs manufactured AFTER 1997 are equipped with SHIMANO hubs. If equipped

with a SHIMANO hub, it MUST be serviced and adjusted

by a qualified technician.

NOTE: QUALIFIED TECHNICIANS ONLY - Contact

Invacare, 1-800-532-8677 for complete SHIMANO hub

instructions.

NOTE: There is no cable adjustment for the seven (7)

speed shifter cable. Loosening the knurled screw will enable you to pull the gear box from the hub axle.

It is recommended that you take your Excelerator to a

qualified technician for any shifter adjustment.

If adjustment or replacement of internal parts is required,

i.e., won't shift into ALL seven (7) gears, perform the following replacement:

1. Ensure that the hub and shifter are properly installed.

NOTE: Shifter is installed with a 4 mm hex key to a torque

of 1.8 to 2.1 ft. lbs.

2. Loosen knurled screw and pull gearbox (clickbox) from

the hub axle.

3. Run the cable and clickbox along the frame and above

the bottom bracket until it reaches the rear axle.

Shifter

4. Ensure that there are no extreme bends in the cable

and there is ample slack for the handlebars to turn

without binding the cable.

5. Use a light oil and lubricate shift rod and the shift tube.

CAUTION

Ensure that the inner lug of the guiding rib is run into

the shift tube slot until it snaps into place.

6. Push the rod and tube into the drive side of the axle as

far as it will go. The shift rod should fit inside of the shift

tube.

7. Position the shifter in gear number one.

8. Push the RED adjusting sleeve (guiding rib first) over

the axle.

9. Position the guiding rib above the axle and slide it onto

the clickbox.

NOTE: The guiding rib complete MUST be seated into the

clickbox housing groove.

10. Ensure that the guiding rib fits into the slot in the top of

the clickbox.

CAUTION

Ensure that knurled screw is secure.

11. Finger tighten knurled screw on clickbox.

12. If more technical assistance is required, contact the

manufacturer direct at (800) 346-2928.

13. To maintenance, periodically lubricate the shift rod

and shift tube.

Bracket

Gearbox

(Clickbox)

Adjusting

Sleeve

(Insert into

slot in

clickbox

opening)

Knurled

Screw

FIGURE 5 - EXCELERA TOR/EXCELERATOR XLT SEVEN

(7) SPEED SHIFTER CABLE ADJUSTMENT/

REPLACEMENT - SACHS HUB ONLY

Internal Peg

(Align with

slot in shift

tube opening)

Shift Tube

(EXCELERATOR

ONLY)

Guiding Rib

Axle Bore

Shift Rod

Slot for

Internal

Peg

Groove for

Knurled Screw

Hub

Axle

S

P

E

E

D

S

H

I

F

T

E

R

S

19

Page 20

CHAINPROCEDURE 7

This Procedure includes the following:

EXCELERA TOR/LI'L EXCELERA TOR:

Chain Installation w/Seven (7) Speed Hub

Chain Adjustment

Chain Stay Adjustment

C

H

A

EXCELERA TOR XLT/XLT 2000:

Chain Adjustment

Chain Installation w/Twenty-Four (24) or T wentySeven (27) Speed Cassette

I

N

Chain MUST be tight. If noisy, loosen. After chain

is assembled, start in first gear and on straightaway.

After ANY adjustments, repair or service and BEFORE use, make sure all attaching hardware is tightened securely - otherwise injury or damage may

result.

WARNING

EXCELERATOR/ LI'L EXCELERATOR

/CHAIN INSTALLATION W/SEVEN (7)

SPEED HUB (FIGURE 1)

5. Place chain over the top of the bottom chain tensioner.

6. Attach the chain together using the master link (w/

clip) provided.

EXCELERATOR/LI'L EXCELERATOR

CHAIN ADJUSTMENT

1. Move the hand crank assembly up and down on the

fork stem until you are comfortable with the position

for operational purposes (PROCEDURE 2).

NOTE: Positioning of the hand crank assembly loosens

or tightens the chain in an UP/DOWN position.

2. Tighten the hex screw to secure the hand crank assembly (PROCEDURE 2).

3. Adjust the tautness of the chain by moving the adjustable chain idler IN or OUT (PROCEDURE 2).

4. Tighten the hex screw to secure the adjustable chain

idler in place (PROCEDURE 2).

EXCELERATOR CHAIN STAY

ADJUSTMENT (FIGURE 2)

C

H

A

I

N

1. Spread the chain out flat and run it over the BOTTOM chain tensioner upwards to the hand crank

sprocket assembly.

2. Position chain over the hand crank assembly sprocket.

NOTE: It may be necessary to turn the hand crank in a

clockwise motion to position the chain on the sprocket.

3. Run the chain over the top chain tensioner.

4. Position the chain around the wheel sprocket and

back up towards the bottom chain tensioner.

Chain

Tensioners

Step 2

Hand Crank

Sprocket Assembly

Wheel Sprocket

FIGURE 1 - EXCELERATOR / LI'L EXCELERATOR/

CHAIN INSTALLATION W/SEVEN (7) SPEED HUB

Top Chain

Tensioner

Bottom

Chain

Tensioner

Step 4

1. Loosen button screw and adjust bracket upward.

Retighten button screw.

Button

Screw

Bracket

FIGURE 2 - EXCELERATOR CHAIN STAY ADJUSTMENT

EXCELERATOR XLT/XLT 2000

CHAIN ADJUSTMENT (FIGURE 3)

1. Loosen, but do not remove the two (2) socket screws

that secure the crank handles to the fork.

2. Slide the crank handles up and/or down until the

proper tension on the chain is achieved.

NOTE: The proper chain tension will be approximately 1/

2-inch of chain slack.

NOTE: If crank is in desired position but chain tension is

not correct, links must be added to or removed from the

chain to correct the tension.

3. Tighten the two (2) socket screws that secure the

crank handles to the fork securely.

20

Page 21

CHAIN PROCEDURE 7

Step 5

Crank

Handles

Hand Crank Sprocket

Fork

Assembly

C

H

A

I

N

Socket

Screws

FIGURE 3 - EXCELERATOR - XLT CHAIN ADJUSTMENT

C

H

A

I

N

EXCELERATOR XLT/XLT 2000

CHAIN INSTALLATION - TWENTYFOUR (24) OR TWENTY-SEVEN (27)

SPEED CASSETTE (FIGURE 4)

1. Spread the chain out flat and run it around the chain

ring on the crank and the sprocket on the hub.

NOTE: It may be necessary to turn the hand crank in a

clockwise motion to position the chain on the small

sprocket.

2. Ensure that crank assembly is loosened and movable.

3. Lift UP on the chain derailleur and thread the chain

under the derailleur.

4. Thread the chain around the wheel sprocket.

5. Run the chain around the BOTTOM of the wheel

sprocket and back up towards the hand crank

sprocket.

6. Attach the chain together using the master link (w/

clip) provided.

7. To tension chain, refer to

2000 FORK/CRANK ASSEMBLY REPLACEMENT

in PROCEDURE 5 of this manual.

EXCELERATOR XLT/XLT

Step 3

Step 4

Chain Derailleur and

Wheel Sprocket

FIGURE 4 - EXCELERA TOR XL T/XLT 2000 CHAIN

INST ALLA TION- TWENTY-FOUR (24) OR TWENTY-

SEVEN (27) SPEED CASSETTE

21

Page 22

P ARKING BRAKEPROCEDURE 8

This Procedure includes the following:

Using Parking Brake

P

Parking Brake Adjustment/Replacement

A

R

K

N

G

After ANY adjustments, repair or service and BE-

I

FORE use, make sure all attaching hardware is tightened securely - otherwise injury or damage may

result.

WARNING

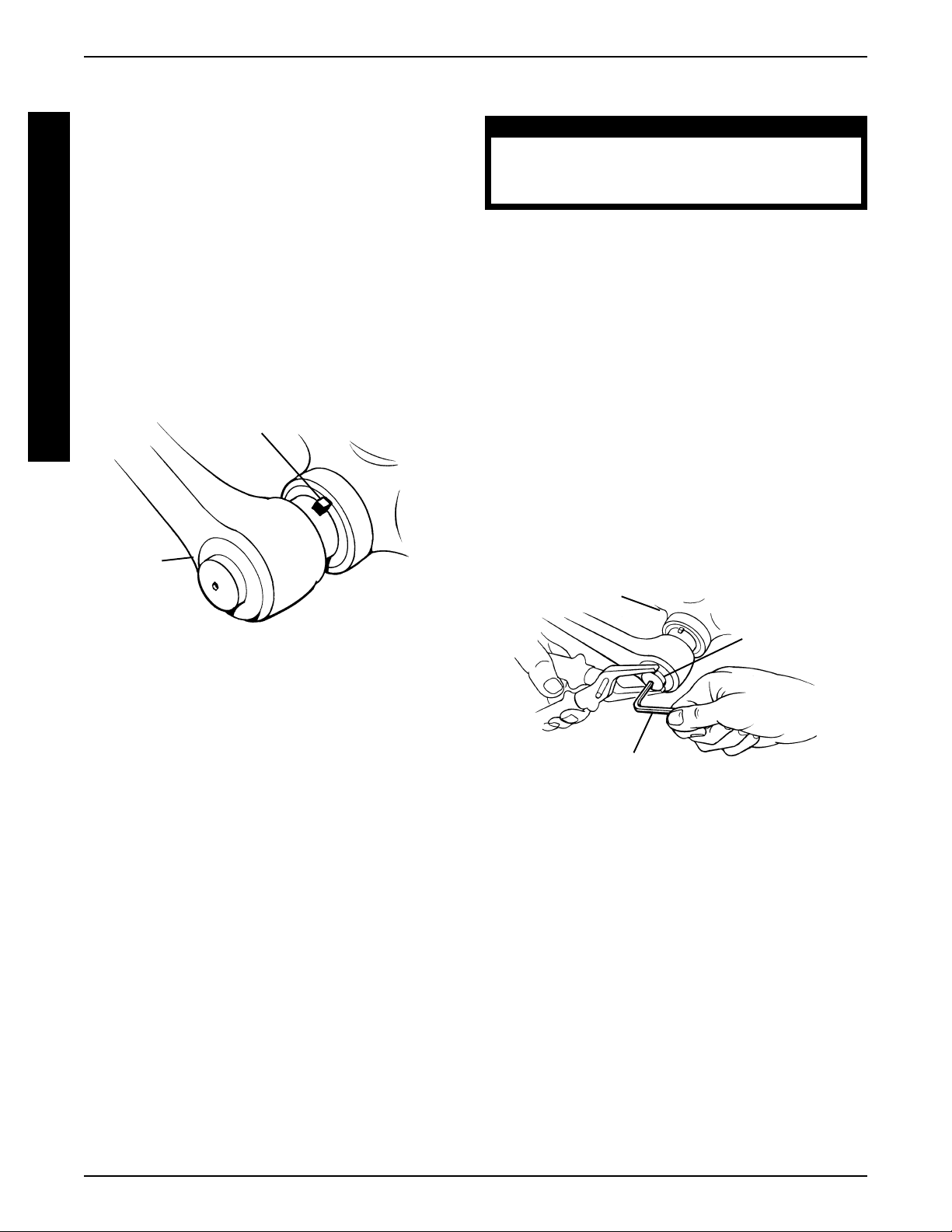

USING PARKING BRAKE (FIGURE 1)

B

NOTE: The parking brake on the Excelerator, Li'l

R

Excelerator and Excelerator XLT is factory installed. No

A

installation is necessary.

K

E

1. To engage the parking brake, squeeze the handle

and push in the stop button on the side of the parking

brake or move stop lever to the highest position.

2. To disengage the parking brake, release the handle.

PARKING BRAKE ADJUSTMENT/

REPLACEMENT (FIGURE 1)

Adjustment

CABLE.

1. Loosen the hex nut and turn the adjuster barrel clockwise (tighten) or counterclockwise (loosen) to adjust

the cable. Retighten hex nut.

BRAKE PADS.

1. Adjust the brake pad assembly so that when the parking brake is engaged the brake pads rest solely on

the rim of the wheel.

Replacement

PARKING BRAKE PADS.

1. Remove the mounting nuts and replace brake pads.

2. Secure with existing hardware and adjust.

PARKING BRAKE.

WARNING

Replacement of the parking brake MUST be

performed by a qualified technician.

P

A

R

K

I

N

G

B

R

A

K

E

WARNING

Before using your particular Excelerator,

inspect the parking brake for proper operation.

Rim of Wheel

Brake

Pads

TO ENGAGE: Squeeze

Handle Closed and

Push in Stop Button or

Move Lever to Stop

Position.

TO DISENGAGE:

Squeeze Handle

Closed until Stop

Button Releases, Then

Release Handle

TO ENGAGE: Squeeze

Handle Closed and Push in

Stop Button or Move Lever to

Stop Position.

TO DISENGAGE: Squeeze

Handle Closed until Stop

Button Releases, Then

Release Handle

Stop Button

Brake Pads

EXCELERATOR/LI'L EXCELERATOR EXCELERATOR XLT

FIGURE 1 - PARKING BRAKE INSTALLATION/ADJUSTMENT/REPLACEMENT

22

Page 23

BACK/SEAT PROCEDURE 9

This Procedure includes the following:

Back Height Adjustment (Adjustable Backs Only)

Sliding Seat Adjustment

Excelerator XL T/XLT 2000 Back Angle Adjustment

WARNING

After ANY adjustments, repair or service and BEFORE use, make sure all attaching hardware is tightened securely - otherwise injury or damage may

result.

BACK HEIGHT ADJUSTMENT

(ADJUSTABLE BACKS ONLY)

(FIGURE 1)

1. Unlatch the two (2) fastening flaps that secure the top

of the back upholstery to the back canes.

WARNING

Push pin MUST protrude thr ough hole in back cane.

Ensure that both back cane inserts are at the same

height BEFORE reassembling the chair.

2. Press the push pin on the back cane insert tube in and

adjust the back height to one (1) of three (3) heights

depending on original back height.

4. Secure the top of the back upholstery to the fastening

flaps ensuring the top of the back upholstery is even

with the top of the back canes.

SLIDING SEAT ADJUSTMENT

(FIGURES 2 AND 3)

Excelerator/Li'l Excelerator (FIGURE 2)

NOTE: The seat is supported on adjustment rails to

allow forward/rearward adjustment. The adjustment

lever is located on the underside of the seat, at the

front left.

1. Activate parking brake.

2. Grasp forward/rearward adjustment lever and push

it to the right and slide seat forward or rearward.

3. Ensure that seat is properly engaged into the seating

position you desire by "jiggling" the seat, making sure

that the seat engages into the locking notch and adjustment lever returns to its original forward facing

position.

NOTE: User need not be in seat to slide seat forward

or rearward.

REPLACEMENT.

1. Remove the locknuts, bolts, and coved spacers

from both sliding seat rail brackets.

2. Remove sliding seat and seat rails from brackets.

B

A

C

K

/

S

E

A

T

3. Reinstall the fastening flaps onto the back canes, ensuring the fastening strips face towards the front of

the Excelerator.

NOTE: The fastening flap with the

left back cane.

Top of Back

Upholstery

Fastening Flaps

Back Canes

Cane

Insert

Push

Pin

Back

Invacare

logo is for the

Seat

Back

Seat Rails

Adjustment Lever

Seat Rail

Locknuts

and

Threaded

Studs (Both

Sides)

Seat Rail Bracket Locknuts, Bolts, and

Coved Spacers (Both Sides)

FIGURE 1 - BACK HEIGHT ADJUSTMENT

(ADJUSTABLE BACKS ONLY)

FIGURE 2 - SLIDING SEAT ADJUSTMENT -

EXCELERATROR/LI'L EXCELERATOR

23

Page 24

BACK/SEATPROCEDURE 9

3. Remove the locknuts from the threaded studs from

seat rails on both sides of seat.

4. Remove seat from seat rails.

5. Reverse STEPS 3-4 to install NEW seat onto seat

B

A

C

K

/

S

E

A

T

rails.

6. Reverse STEPS 1-2 to install sliding seat and seat

rails onto the seat frame.

Excelerator XLT/XLT 2000 (FIGURE 3)

1. Activate parking brake.

2. Loosen, but do not remove the six (6) socket screws

that secure the seat frame to the handcycle frame.

NOTE: There are three (3) socket screws on the right

and left side of the handcycle.

3. Loosen, but do not remove the hex bolts and locknuts that secure the two (2) seat angle adjustment

clamps to the rear seat supports.

NOTE: There is one (1) clamp on the right and left

side of the handcycle.

6. Tighten the hex bolts and locknuts that secure the

two (2) seat angle adjustment clamps to the rear seat

supports securely.

EXCELERATOR XLT/XLT 2000

BACK ANGLE ADJUSTMENT

(FIGURE 4)

1. Activate parking brake.

2. Loosen, but do not remove the four (4) rear socket

screws that secure the seat frame to the handcycle

frame.

NOTE: There are two (2) socket screws on the right and

left side of the handcycle.

3. Loosen, but do not remove the hex bolts and locknuts that secure the two (2) seat angle adjustment

clamps to the rear seat supports.

NOTE: There is one (1) clamp on the right and left side of

the handcycle.

4. Perform one (1) of the following:

4. Perform one (1) of the following:

A. Moving the seat rearward - While lifting up on

the back support tubes, push the seat rearward

to the desired position.

B. Moving the seat forward - While pushing

down on the back support tubes, pull the seat

forward to the desired position.

5. Tighten the six (6) socket screws that secure the

seat frame to the handcycle frame securely.

Seat Angle Adjustment Clamps

Seat Frame

A. Increasing Back Angle - While lifting up on the

back support tubes, pull the seat upward to the

desired position.

B. Decreasing Back Angle - While pushing down

on the back support tubes, push the seat down

to the desired position.

5. Tighten the three (3) socket screws that secure the

seat frame to the handcycle frame securely.

6. Tighten the hex bolts and locknuts that secure the

two (2) seat angle adjustment clamps to the rear seat

supports securely.

Seat Angle Adjustment Clamps

Seat

Socket Screws

FIGURE 3 - SLIDING SEA T ADJUSTMENT -

EXCELERA TROR XLT/XLT 2000

Handcycle Frame

Socket

Screw

Socket

Screws

FIGURE 4 - EXCELERA TROR XL T/XL T 2000 BACK

ANGLE ADJUSTMENT

Handcycle Frame

24

Page 25

PROCEDURE 10UPHOLSTERY

This Procedure includes the following:

Seat Upholstery Replacement

Back Upholstery Replacement

W ARNING

After ANY adjustments, repair or service and BEFORE

use, make sure all attaching hardware is tightened

securely - otherwise injury or damage may result.

Upholstery MUST be inspected BEFORE each use.

Exposure to moisture (ie.- wet weather or puddles)

will damage fastening straps/flaps/strips. DO NOT

operate excelerator if upholstery is wet or damaged, otherwise severe injury may occur.

SEAT UPHOLSTERY REPLACEMENT

(FIGURE 1)

1. Remove seat cushion and back upholstery from chair.

2. Unlatch the four (4) fastening flaps that secure the

seat upholstery to the seat frame.

3. Remove the existing seat upholstery.

4. Install the new seat upholstery making sure that the

three (3) fastening flaps that are in close proximity to

one another are to the rear of the seat frame.

5. Secure the four (4) fastening flaps together.

6. Reinstall back upholstery and seat cushion onto chair.

Back Upholstery

Large

Strap

Toward

Rear of

Seat

Frame

Towards

Front of

Chair

4. Install the new back upholstery onto the wheelchair.

5. Securely latch the fastening flaps on the bottom of

the new back upholstery to the back canes.

Back Upholstery

Fastening

Flap

Fastening

Flap

Back

Canes

FIGURE 2 - BACK UPHOLSTERY REPLACEMENT -

ALL EXCELERA TORS EXCEPT XL T/XLT 2000

NARROW BACK

EXCELERATOR XLT/XLT 2000 Narrow Back

(FIGURE 3)

1. Pull the back cushion off the back frame.

2. Align the fastening strips on the back frame with

the fastening strips on the new back cushion.

3. Press the back cushion firmly against the back

frame to secure.

U

P

H

O

L

S

T

E

R

Y

Three (3) Seat Upholstery Fastening Straps

Towards Rear of Seat Frame

FIGURE 1 - SEAT UPHOLSTERY REPLACEMENT

BACK UPHOLSTERY REPLACEMENT

All Excelerators Except XLT/XLT 2000

Narrow Back (FIGURE 2)

1. Unlatch the two (2) fastening flaps that secure the

bottom of existing back upholstery to the back canes.

2. Unlatch the top of the existing back upholstery.

3. Lift up on the existing back upholstery and remove

from the wheelchair.

25

Back

Frame

Fastening Strips

FIGURE 3 - EXCELERA TOR XL T/XL T 2000

Back

Cushion

Page 26

FOOTRESTPROCEDURE 11

This Procedure includes the following:

EXCELERA TOR LI'L EXCELERA TOR:

Footrest Adjustment/Replacement

EXCELERA TOR - XLT/XLT 2000: Footrest and Leg

Guard Replacement

F

O

Using/Replacing Footrest Strap

O

R

E

S

T

After ANY adjustments, repair or service and BEFORE use, make sure all attaching hardware is tightened securely - otherwise injury or damage may

T

result.

WARNING

EXCELERATOR/LI'L EXCELERATOR

FOOTREST ADJUSTMENT/

REPLACEMENT (FIGURE 1)

NOTE: Range of the Footrest is 0 to 4-1/2-inches.

Adjusting Footrest Height:

Replacing Individual Footplates

1. Remove the two (2) button screws and locknuts that

secure the footrests to the footplate clamps.

2. Align new footplates on the footplate clamps at the desired depth.

3. Line up the mounting holes in the footplates with the

mounting holes in the footplate clamps.

4. Install the button screws into the mounting holes and

tighten securely with the locknuts.

Height Adjustment

Socket

Screws

Footplate

1. Loosen the socket screws on both footrests.

2. Slide the footplate up or down to desired height.

3. Retighten the socket screw that secures the footplate.

4. Secure straps over top of feet before using your

Excelerator.

Adjusting Footrest Angle

1. Loosen the button screws and locknuts that secure

the half clamps to the footrest weldment.

NOTE: The footplate clamps are located under the

footplates.

2. Position footplates to an appropriate angle for user.

3. Securely tighten the button screws and locknuts that

secure the half clamps to the footrest weldment.

Adjusting Footrest Depth

1. Remove the two (2) button screws and locknuts that

secure the footplates to the half clamps.

2. Adjust the footplates to one (1) of five (5) depths.

Depth Adjustment

Button

Screws

Footplate

Locknuts

Angle Adjustment or Replacement

Footplate

Button Screws

3. Line up the mounting holes in the footplates with the

mounting holes in the footplate clamps.

4. Install the button screws into the mounting holes and

tighten securely with the locknuts.

Locknuts

FIGURE 1 - FOOTREST ADJUSTMENT/REPLACEMENT

26

Page 27

FOOTREST PROCEDURE 11

EXCELERATOR XLT/XLT 2000

FOOTREST AND LEG GUARD

REPLACEMENT (FIGURE 2)

Footrest

1. Note the position of the existing footrest.

2. Remove the hex bolt and locknut that secure the existing footrest to the fork.

3. Remove the existing footrest from the clamp on the

fork.

4. Slide the new footrest into the clamp on the fork to

the position noted in STEP 1.

5. Reinstall the hex bolt and locknut. Tighten securely.

6. Repeat STEPS 1-5 for the opposite footrest, if necessary.

Leg Guard

1. Loosen the two (2) allen screws on each mounting clamp.

2. Position each mounting clamp onto the fork under

the brake cable as shown in FIGURE 2.

Fork

Clamp,

Hex Bolt

and

Locknut

Footrest Replacement

F

O

O

T

R

E

S

T

Footrest

Leg Guard Replacement

Fork

NOTE: The leg guard should surround, but not touch

the REAR of the front tire.

3. Tighten the two (2) allen screws on each mounting

clamp securely.

Brake

Cable

Rear of

Front

Tire

Leg Guard

FIGURE 2 - EXCELERA TOR XLT/XLT 2000 FOOTREST

AND LEG GUARD REPLACEMENT

Allen

Screws

Mounting

Clamp

27

Page 28

PROCEDURE 11 FOOTREST

EXCELERATOR XLT/XLT 2000 USING/REPLACING FOOTREST

STRAP

WARNING

F

O

O

T

R

E

S

T

Footrest straps MUST be inspected BEFORE each

use. Exposure to moisture (ie.- wet weather or

puddles) will damage fastening strips. Footrest

strap will not hold feet securely in footrest if fastening strips are damaged. DO NOT operate

excelerator if footrest straps are wet or damaged,

otherwise severe injury may occur.

Always wear shoes and securely strap feet in

using straps provided. Severe injury may occur if feet are not secured while the Excelerator

is in motion.