Page 1

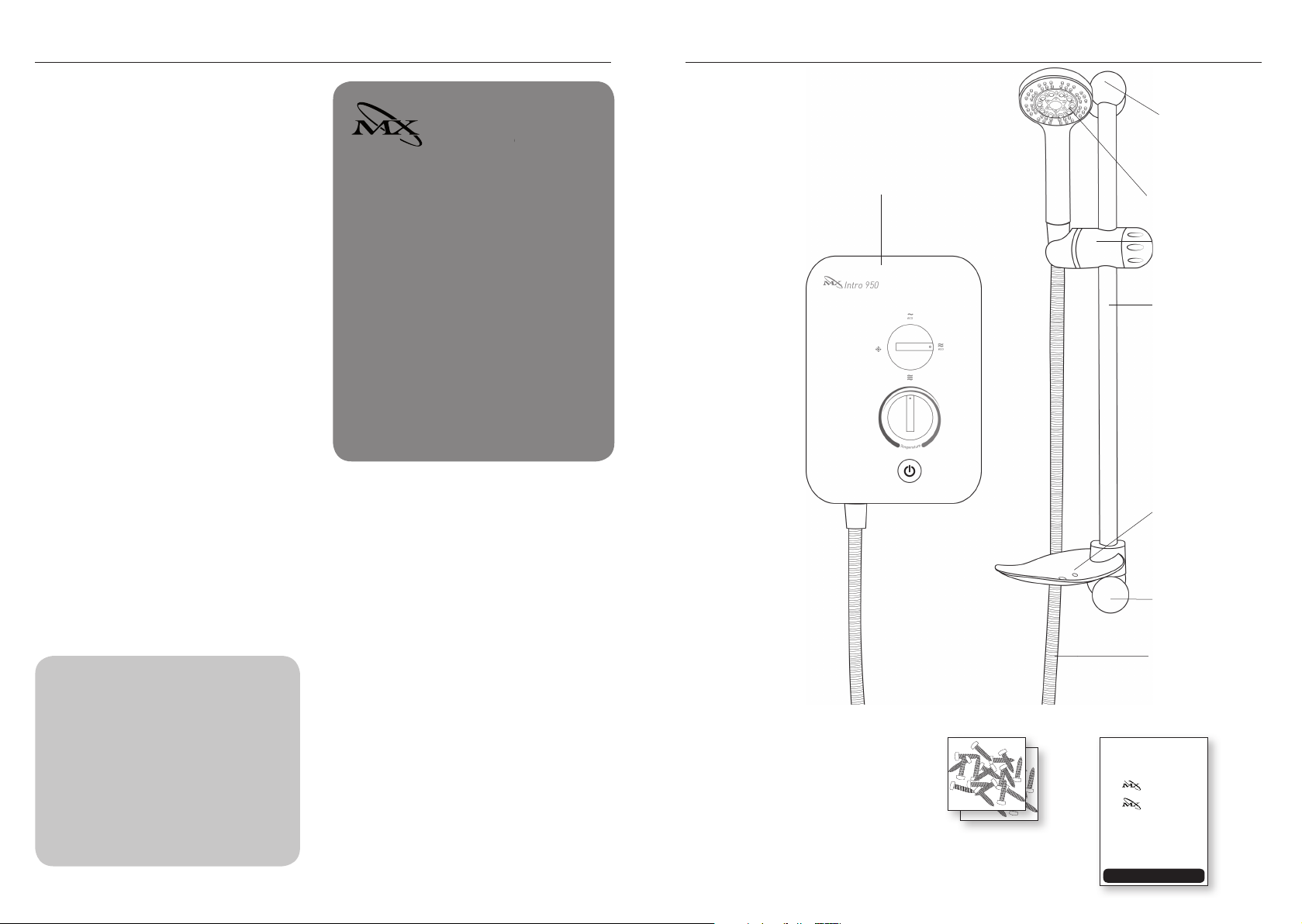

Intro 850

Intro 950

Instantaneous Electric Shower

Installation and User Instructions

This Step-by-Step guide should be given to the customer

IMPORTANT!

after installation and demonstration.

Page 2

CONTENTS 1. PACK CONTENTS

Intro 850

Intro 850

1. Pack Contents 3

2. Installation Check List 4

3. Important Safety Information 5

Installation

4. General Installation Layout Guide 7

5. Important Installation Information 8

6. Fixing the Shower to the Wall 8

7. Product Positioning Guide 9

8. Plumbing Connections 10

9. Electrical Connections 11

10. Fitting the Front Cover 12

11. Riser Rail Fitting Instructions 13

12. Commissioning the Shower 14

User Guide

13. Operating the Shower 15

14. How Your Shower Works 16

15. Routine Maintenance 16

16. Troubleshooting and FAQs 17

17. Troubleshooting Checklist for the Installer 18

18. Product Warranty 19

19. Service Policy 20

MX Intro 850 and 950 – a guide for installers

The compact MX Intro 850 (8.5 kW) and

950 (9.5 kW) shower models are designed for

quick installation. Both water and electrics enter

the shower unit from the right hand side of the

back plate with top bottom and rear options.

A removable corner section allows easy access

for the plumbing connection. The screw wall

mounting hole positions are visible when the front

cover is removed. The top two fixing holes are

vertical key hole slots and the bottom fixing hole is

a horizontal slot to allow for alignment.

The MX Intro 850 and 950 electric showers are

designed for Domestic and light commercial

applications.

• 1. Shower Unit

Please make sure ALL

components are included

before starting the

installation.

1. Shower Unit

2. Shower Handset

3. Riser Rail Tube

4. Riser Rail Brackets x2

These instructions contain

all the necessary fitting and

operating instructions for

your electric shower. Care

taken during the installation

will provide a long, trouble

free life from your shower.

2 3

5. Riser Rail Height Adjuster

6. Flexible Shower Hose

7. Soap Dish

8. Hose Retaining Ring

9. Screw Packs

10. Installation and User

Instructions plus

Guarantee Card

• 9. Screw Packs

• 4. Riser Rail Bracket

• 2. Shower Handset

• 5. Riser Rail

Height Adjuster

• 3. Riser Rail Tube

• 7. Soap Dish

• 4. Riser Rail Bracket

• 6. Flexible Shower Hose

• 10. Fitting Instructions

& Guarantee Card

Intro 950

Instantaneous Electric Shower

Installation Instructions

IMPORTANT!

This Step-by-Step guide should be given to the customer

after installation and demonstration.

Page 3

!

!

!

!

!

!

!!!

!

!

!!!

!

!

2. INSTALLATION CHECK LIST

3. PLEASE READ THIS IMPORTANT SAFETY INFORMATION

1. Check that the water supply will satisfy requirements .....................................

2. Check that water and cable entry points of the unit meet requirements ......

3. Check that the electric supply will satisfy requirements ..................................

4. Select a suitable position for the shower .............................................................

5. Plumbing installation ..............................................................................................

6. Electrical installation ...............................................................................................

7. Fit to the wall and connect the shower supplies ................................................

8. ONLY Commission the shower in the way described ......................................

9. Fitting the front cover and aligning the controls .................................................

10. Familiarise yourself with the user operating instructions ...............................

Products manufactured by the MX Group are safe and without risk provided

they are installed, used and maintained in good working order in accordance

Tick off as you complete

with our instructions and recommendations.

FOR THE USER:

WARNING: DO NOT operate shower if frozen, or suspected of being frozen.

It must thaw out before using.

DO NOT operate the unit if the showerhead or spray hose becomes

damaged.

DO NOT restrict flow out of shower by placing showerhead in direct contact

with your body or ther solid object.

WARNING: the outlet of the shower acts as a vent and must not be

connected to anything other than the flexible shower hose and handset

supplied or approved by the manufacturer.

DO NOT operate the shower if water ceases to flow during use or if water

has entered inside the unit because of an incorrectly fitted cover.

DO NOT place items such as soap, shampoo or other such bottles on top of

the unit as liquid could leak through the joint between the cover and back

plate and damage the sealing rubber.

The shower spray head MUST be cleaned regularly to remove scale and

debris. The frequency of the cleaning will vary according to the local water

quality. If the water outlet temperature becomes hot and you are unable to

obtain cooler water, immediately check the shower handset for blockage.

See section 15 for cleaning instructions.

IMPORTANT: This appliance is not intended for use by persons (including

children) with reduced physical, sensory or mental capabilities, or lack of

experience and knowledge, unless they have been given supervision or

instruction concerning use of the appliance by a person responsible for

their safety. Children should be supervised to ensure they do not play with

the appliance.

4 5

Page 4

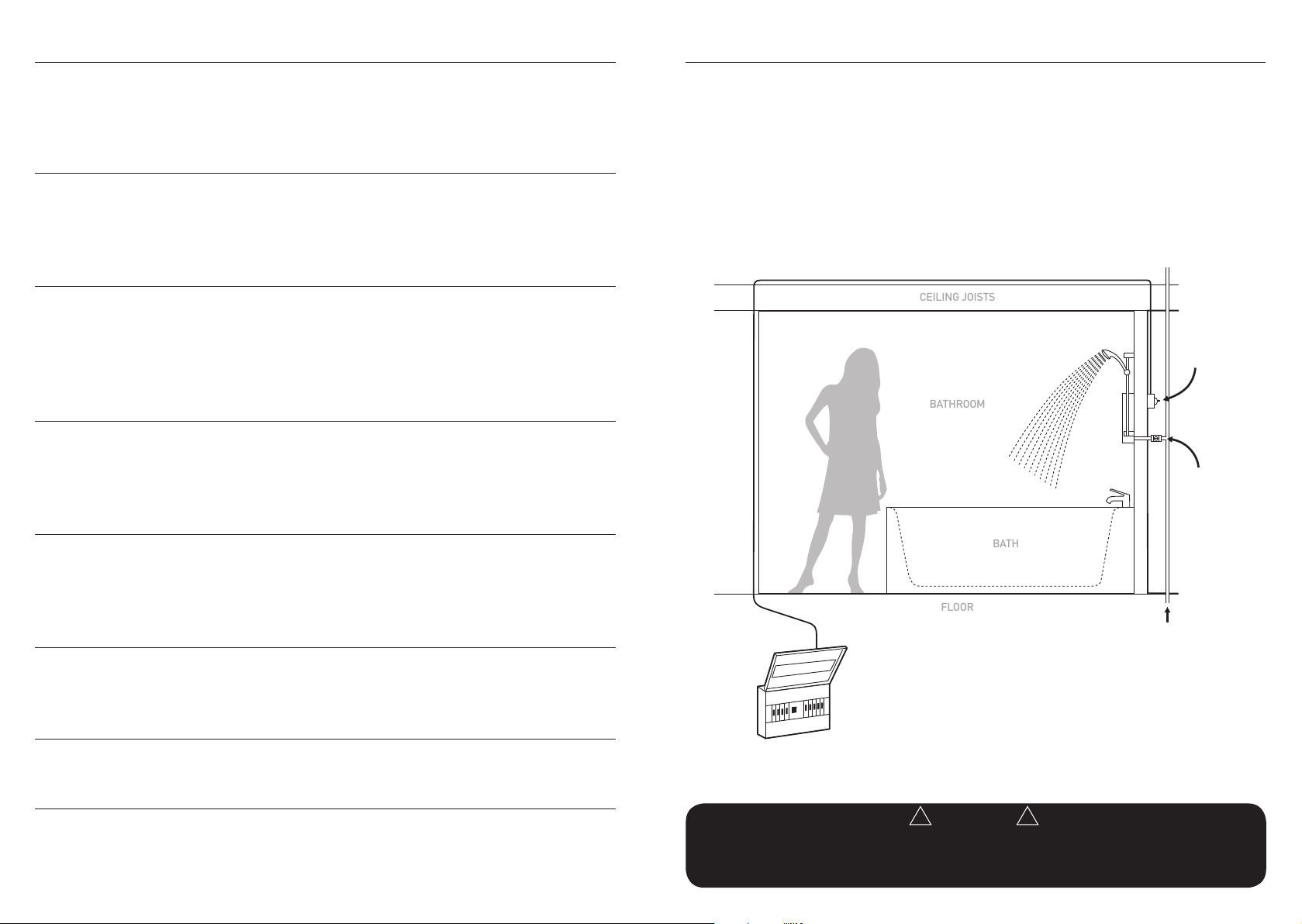

PLEASE READ THIS IMPORTANT SAFETY INFORMATION (CONT.) 4. GENERAL INSTALLATION LAYOUT GUIDE

BATH

BATHROOM

FLOOR

CEILING JOISTS

!!!

!

FOR THE INSTALLER:

MAINS SERVICE CONNECTIONS: The shower unit is supplied for right hand

mains water and electrical connection.

IMPORTANT: To comply with water regulations, building regulations or any specific

local water company regulations and in accordance with BS EN 806 a double check

valve should be fitted where it is possible that the shower head may come into

contact with used water, for example in the bath or a shower tray.

IMPORTANT: Check that there are no hidden cables or pipes before drilling

holes for the wall plugs. Choose a flat piece of wall to avoid the possibility of

distorting the back plate and making the front cover a poor fit. Exercise great care

when using power tools near water. The use of a residual current device (RDC) is

recommended.

IMPORTANT: Before connecting the water supply to the shower

unit the water supply pipe should be flushed out to remove all debris. After

flushing the pipe work make the connection to shower inlet and ensure the

shower is positioned squarely on the wall and all fixing screws are tightened.

Plan your installation carefully. Check on the nearest

and most accessible rising main water supply, this

may be beneath the bath or in the loft, where it feeds

the water storage tank. Use only the cold rising

water main.

Avoid connecting the shower unit if possible where

it will be affected by water drawn off by another

appliance.

For example from the mains feed to the toilet as this

may cause a drop in pressure to a level that is too low

for the shower unit to work correctly.

A WRAS (Water Regulations Advice Scheme) listed

isolating valve must be fitted between the rising main

and the unit to comply with water regulations and to

allow for routine maintenance and servicing.

DOUBLE POLE

HEATER SWITCH

WALL MOUNTED

IN ACCORDANCE

WITH LOCAL

AUTHORITY

REGULATIONS

SHOWER

UNIT

ISOLATING

STOP TAP

IT IS VERY IMPORTANT to ensure that the terminal block screws are FULLY

tightened and that no cable insulation is trapped under the screws. The earth

continuity conductor of the electrical installation must be effectively bonded to

earth on the fuse board.

SEPARATE PERMANENTLY

CONNECTED SUPPLY

FROM CONSUMER UNIT

COLD WATER

MAINS SUPPLY

IMPORTANT: Ensure that the flow / temperature control knob is turned to FULL

flow and the commissioning instructions are followed before switching the unit on.

This will make sure that the unit is full of water when first activated.

IMPORTANT: The shower unit MUST be full of water before the heat settings

are used.

IMPORTANT

This appliance is not intended for use by persons (Including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge, unless they have been given supervision or

instruction concerning use of the appliance by a person responsible for their safety. Children should be

6 7

supervised to ensure that they do not play with the appliance.

Page 5

5. IMPORTANT INSTALLATION INFORMATION

7. PRODUCT POSITIONING GUIDE

n Shower installation must be carried out by a

suitably qualified person and be in accordance with

BS 7671 (IEE wiring regulations) building regulations,

water regulations and or any specific local water

n The shower unit must not be fitted where it may

be exposed to frost, for example in an outdoor area.

The shower must not be used if suspected of being

frozen. Frost damage is not covered by the guarantee.

company regulations in force and should be in

accordance with BS EN 806.

n Plumbers jointing compound must not be used.

In instances of difficult joints use P.T.F.E. Tape.

n This shower unit is designed to be connected to a

15mm cold water mains supply.

n To make sure the heating elements are activated

the shower must be connected to mains water supply

with a minimum running pressure of 100kPa (15lb/

The use of jointing compound will invalidate the

product guarantee.

n DO NOT solder fittings near the shower unit

as heat can travel along pipe work and damage

components.

sq in) – 1 Bar at a minimum flow rate of 8 litres per

minute. The maximum static pressure is 1000kPa

(150lb/sq in) 10 Bar.

n DO complete all plumbing connections before

making the electrical connections.

NOTE: For the Intro 950 9.5kW model, the minimum

running pressure must be obtained at 9 L/min.

6. FIXING THE SHOWER TO THE WALL

Position your shower on the wall so that it will NOT

be in the direct water spray from the shower handset

when fixed.

You may wish to consider mounting the unit so that

the shower handset could be used over a sink for

washing hair.

The shower unit should be positioned so that the

shower head cannot be immersed in the bath or

shower tray when hanging down. A shower hose

retainer is supplied with the accessories (see pages

3 and 9).

Remove the four front cover fixing screws and lift

the cover off complete with the control knobs and

start /stop push button.

Having decided on the water and cable entry points

and chosen a flat piece of wall, hold the shower

vertically against the wall and mark the top two

fixing holes.

Carefully drill the two holes as marked using a sharp

5.5mm masonry drill after first making certain there

are no pipes or wires behind the proposed holes.

Insert the wall plugs and screws provided leaving the

screw head proud by approximately 5mm. The shower

can now be hung on these screws.

Make sure that the shower is positioned vertically now

mark and drill the lower slotted fixing hole. Then fix

the shower to the wall. Do not fully tighten the screws

at this stage.

The shower back plate and removable corner

moulding have moulded knock out sections which

are clearly indicated to allow the chosen service entry

option to be removed prior to final fix.

Shower unit can be mounted

either side of riser rail

Intro 950

eco

eco

T

e

e

r

m

u

t

a

e

p

r

25mm minimum

Outline of bath or

shower tray

Height of

showerhead

and shower

to suit user’s

requirements

Soap dish

Hose retaining ring

Spillover level

Spillover level

8 9

Page 6

!!!

!

!!!

!

8. PLUMBING CONNECTIONS

!!!

!

9. ELECTRICAL CONNECTIONS

The shower back plate incorporates into the lower

right side a removable corner section to allow easy

access when deciding on and connecting to the water

mains supply.

Remove the bottom right hand side corner section

giving access to the water inlet spigot.

The shower unit is supplied for right hand installation.

IMPORTANT: Before connecting the mains water

supply to the shower flush out the pipe work to

remove all swarf and system debris. This is achieved

by connecting a hose to the pipe work and turning on

the mains water supply at the isolating stop tap long

enough to clear the debris to waste.

Turn off the mains water supply at the isolating

stop tap.

Check that the inline filter is fitted to the inlet pipe.

Having decided on the direction of the water inlet

supply: Top (falling) Bottom (rising) or rear inlet it

is necessary to remove the appropriate knock out

(thinned out plastic) cross section from the back

plate before commencing with the installation. The

connection to the unit is made using a 15mm copper,

stainless or plastic pipe with a 15mm compression

elbow or 15mm push fit elbow.

IMPORTANT: Do not use excessive force when

making the connection to the unit.

Now tighten the back plate fixing screws so the

unit is firmly fixed to the wall.

If rear entry pipe work is used we recommend the use

of a suitable sealant to seal around the incoming pipe

NOTE!

PLUMBING THE SHOWER

UNIT MUST PRECEDE WIRING!

IMPORTANT

To comply with water regulations, building regulations or any specific local water company regulations and

should be in accordance with BS EN 806. A double check valve must be fitted with all flexible

shower accessories where it is possible that the showerhead may come into contact with used water

work to prevent water entering the wall.

Turn on the mains water supply and check for leaks.

At this stage no water can flow through the unit.

IMPORTANT: Remember to replace the lower corner

section before refitting the front cover.

Top knock out section for

mains water and cable entry

Water inlet with

removable filter for

cleaning.

Bottom

knock out

section for

mains water

and cable

Removable cover plate for

bottom inlet, accessible once

the cover is removed. Simply

slide this back into place

before replacing the cover.

entry.

The electrical installation must be in accordance with

the current BS 7671 (I.E.E. wiring regulations) and

part P of the building and / or local regulations.

The shower unit is designed for a single phase 50 Hz

a.c. electrical supply.

ELECTRICAL SPECIFICATIONS

Nominal Power rating at 240V

8.5kW - (40A MCB rating)

9.5kW - (40A MCB rating)

IMPORTANT: The heating elements on the UK

models are manufactured to 240V specification and

will give a lower kW rating if the voltage supply is

below 240V.

The shower unit must be permanently connected

to the electrical supply, direct from the consumer

unit via a double pole linked switch with a minimum

contact gap of 3 mm. The switch must be readily

accessible and clearly identifiable and sited out of

reach of a person using the shower over a fixed

bath or shower tray, unless the switch is pull cord

operated. The wiring must be connected to the

switch without the use of a plug or socket outlet.

The supply cable size is determined by the kW rating

of the product (as detailed on the rating plate fixed

to the back plate) and the distance between the

shower and the consumer unit. The table below is

for guidance only but will help you choose the correct

cable for your installation. If you are in any doubt

consult an electrician.

KW

NOMINAL

RATING

AT 240V

7.5 31.25amps 40amps 40amps 29m 48m

8.0 33.33amps 40amps 40amps 27m 44m

8.5 35.41amps 40amps 40amps 23m 38m

9.5 39.58amps 40amps 40amps 21m 32m

10.5 43.75amps 45amps 45amps 18m 30m

Nominal Power rating at 230V

7.8kW - (40A MCB rating)

8.7kW - (40A MCB rating)

MINIMUM

RATING OF

ISOLATING

SWITCH

FUSE

RATING

MAX CABLE

RUN

6mm 10mm

The incoming cable should be hidden. Connect as

follows:

Earth cable to terminal marked

Neutral cable to terminal marked N

Live cable to terminal marked L

The outer sheath of the supply cable must be striped

back to a suitable length and the earth conductor

must have an earthing sleeve fitted.

Connect the cable to the terminal block. Ensure that

ALL the retaining screws are VERY tight and that NO

cable insulation is trapped under the screws. Loose

connections can result in cable overheating.

IMPORTANT: Failure to ensure that the retaining

screws are VERY tight could result in a failure of the

terminal block.

IMPORTANT: DO NOT switch on the electricity supply

until the shower cover has been fitted.

N

L

i.e. In the bath or shower tray.

IMPORTANT

IMPORTANT

Before turning on the water supply to the shower unit the water supply pipe should be flushed out to remove

debris. After flushing the pipework ensure that the shower unit is positioned squarely on the wall and tighten

the screws. Tighten all plumbing connections and check the pipework for leaks.

Ensure that the terminal block screws are fully tightened and that no cable insulation is trapped under

screws. Ensure the cable clamp is used to secure the cable. The earth continuity conductor of the electrical

installation must be effectively connected to all exposed metal parts of other appliances and services in the

room in which the shower unit is installed to confirm

10 11

Terminal

block

Page 7

ELECTRICAL CONNECTIONS (CONT.)

!!!

!

!

!

11. RISER RAIL FITTING INSTRUCTIONS

The diagram below shows a schematic wiring

diagram.

IMPORTANT: The use of connections within the unit

or other points in the shower circuit to supply power

to other equipment such as an extractor fan or pump

etc will invalidate the guarantee.

1. Thermal cut-out

2. Pressure switch

3. Heater body

3

2

1. Establish position for the riser rail, and mark

the wall for the lower mounting bracket. Make

allowances for the tallest person likely to use the

shower regularly.

2. Remove covers from the wall brackets.

3. Position the lower bracket and mark the wall forthe

screw fixing. Then drill and plug the wall and fix the

lower bracket without the rail location notch.

1

L

N

E

10. FITTING THE FRONT COVER

IMPORTANT: it is necessary to align the control

knobs on the cover with the opposite control spindles

mounted of the back plate before the front cover is

fitted.

First turn the power selector knob to the cold position.

Intro 950

Then turn the flow / temperature controlknob

anti-clock wise to the mechanical stop position

(maximum flow).

On the shower back plate make sure that the power

selector spindle key way is pointing down and the

temperature spline spindle is rotated fully anti-

clockwise until it reaches the mechanical stop.

The front cover can now be fitted carefully ensuring

the controls are aligned and secured with the four

fixing screws provided.

Following the installation of the riser rail (see section

11) attach the flexible hose to the shower outlet

positioned centrally on the back plate making sure

that you use the seal washer provided. The shower is

now ready for commissioning.

12 13

STOP

4. Fit the rail into the lower bracket. Place the

remaining bracket with the rail location notch

on top of the rail, making sure that the rail slot is

located into the notch. Ensure the hole position is

vertically aligned and mark the wall. Remove the

rail and bracket, then drill and plug the wall.

5. Slide the height adjuster onto the rail. Tighten to

the rail by turning the locking cap. Then fit the

soap dish, dampening the rail will make it easier to

slide on. Finally fit the hose retaining ring onto the

bottom of the rail below the soap dish.

6. Replace the rail assembly into the lower bracket.

Refit the top bracket, ensuring the slot in the rail is

located into the bracket notch and fix to the wall.

7. Slide covers onto both brackets.

8. Firmly attach flexible hose to showerhead making

sure sealing washer is in place after first passing

through the hose retaining ring.

NOTE: The adjustable height adjuster grips the conical

ends of the hose, not the handle of the showerhead.

CAUTION

Check there are no hidden cables or pipes before drilling holes for wall plugs.

Exercise great care when using power tools near water.

The use of a residual current device (RCD) is recommended.

TIPS

• A piece of insulating or masking tape applied

to the wall before marking out the fixing

holes will help stop the drill from wandering,

particularly on tiled surfaces.

• When working near a basin or bath, insert the

plug in the waste fitting so that small parts

cannot be lost.

• Take care not to drop accessories or tools into

basin or bath.

Page 8

12. COMMISSIONING THE SHOWER

!!!

!

!!!

!

13. OPERATING THE SHOWER

1. Make sure that the electricity supply has been

isolated at the double pole isolating switch.

2. Turn the top rotary power selector knob to the Cold

setting.

3. Turn the rotary flow / temperature control fully

anti-clockwise to the maximum flow position

(direction of blue graphic).

4. Ensure that the water supply is fully on at the mains

stop cock and isolating service valve (if fitted).

5. Check that water is not leaking from the bottom of

the case.

6. Push the start / stop button and check that water

flows freely from the shower within a few seconds.

At this point the water from the showerhead will be

at full force and at a cool temperature.

7. Rotate the bottom flow / temperature control

knob slowly clockwise. This will gradually reduce

the flow of water through the shower. The water

temperature will remain cool.

8. Return the flow / temperature knob to the

maximum flow position (fully anti-clockwise).

9. Switch on the electrical supply at the double pole

switch or pull cord. The power on neon indicator

will light at the switch.

12. Now adjust the bottom rotary flow / temperature

control knob clockwise for hotter water allowing

a few seconds for the temperature to stabilise.

Set the control to a comfortable showering

temperature.

13. Push the start / stop button to switch the unit off.

14. Switch off at the pull cord or wall mounted switch.

15. Finally we recommend that the shower head is

removed to make sure no debris has worked into

it. Clean and re-fit.

eco

eco

• Power selector

1. Switch on the electrical supply at the pull cord

or wall mounted switch. The power on neon will

illuminate indicating the switch is on.

NOTE: We recommend that you do not stand under

the spray from the shower handset when switching

on – wait until the water has reached a stable warm

temperature.

2. Push the start / stop button for immediate water

flow.

3. Select your power setting using the top rotary

control. There are four power settings:

High – Indicated by three red lines

Eco 2 – Indicated by two red lines

eco

Eco1 – Indicated by one red line

eco

Cold – Indicated by blue graphic symbol

NOTE: Eco 1 and Eco 2 settings

These are the low power settings for increased

economy in the warmer months or when a cooler

shower is preferred. Fine tune outlet temperature

adjustment is via the bottom rotary flow / temperature

control.

4. The flow / temperature control knob alters the

outlet temperature by increasing or reducing the

flow rate of water through the shower unit.

5. To increase the temperature turn the control knob

clockwise (in the direction of the red graphic)

and this will decrease the flow. To reduce the

temperature turn the control knob anti clockwise

(in the direction of the blue graphic) and this will

increase the flow.

6. To turn off the shower unit push the start / stop

button.

NOTE: A small amount of water will be retained in the

shower head after the shower has been turned off.

This may drain over a few minutes.

7. Finally switch off at the pull cord or wall mounted

switch.

IMPORTANT: Once the power and temperature

controls are set the shower can be switched on

and off by the separate start / stop push button.

Only occasional adjustment of the rotary flow /

temperature control will be necessary for winter /

summer changes in the incoming cold water ambient

temperatures.

10. Now turn the top power selector knob to the

Eco 1 power setting indicated by one red line.

Allow a few seconds for the warmer temperature

to reach the shower head. This shows that the

Eco 1 power setting is working correctly.

11. Now turn the top power selector to the high

power setting indicated by three red lines. The

temperature should rise further. This shows that

the full power setting is working correctly.

• Flow /

T

e

e

r

m

u

t

a

p

r

e

Temperature

control

• Start / Stop

button

NOTE: High Power setting

This is the full power setting. Fine tune outlet

temperature adjustment is via the bottom rotary flow

/ temperature control.

NOTE: If cold setting is selected the heating elements

are not energised so the water temperature will be

at the incoming water mains ambient which will be

warmer in summer and colder in the winter months.

Adjustment of the rotary flow / temperature control

on this setting will only alter the flow of water not the

water temperature.

IMPORTANT

Turn the flow / temperature control knob anti-clockwise until the valve is fully open before switching

on the unit. This will ensure a fast fill up of the unit when the shower is first switched on.

IMPORTANT: When making a temperature

adjustment the unit can take up to 20–30 seconds to

stabilize at the new temperature. Please wait before

making further adjustments.

IMPORTANT

The shower unit must be full of water before heat settings are used.

14 15

Page 9

14. HOW YOUR SHOWER WORKS

16. TROUBLESHOOTING AND FREQUENTLY ASKED QUESTIONS

1. The cold incoming water is heated instantaneously

as it flows over the heaters in the heat exchanger

assembly.

2. At the start up the shower will reach temperature in

20–30 seconds.

3. The amount of hot water available at the set

temperature is limited by the total power of the

heater.

4. The water is turned on and off by the solenoid valve

built into the shower.

5. A stabiliser built into the water flow valve

automatically compensates for small fluctuations in

water pressure that frequently occur in households.

There are two further controls that cater for

exceptional restrictions in water pressure to prevent

the shower from getting too hot.

6. A two stage mechanical cut-out is mounted on top

of the heat exchanger.

Stage 1 switches the power off to the elements if

it senses an excessive temperature. The switch

operates with an audible click and will re-set if cold

water is run through the shower.

Stage 2 only operates if an extreme temperature

is sensed. The cut-out will permanently switch off

and will then have to be replaced.

7. A pressure relief device is fitted to the bottom of the

heat exchanger body to safeguard against a build

up of pressure in the heater. It provides protection

to the heater should there be an excessive build

up of pressure occur. If this device operates then a

replacement part will be required.

15. ROUTINE MAINTENANCE

SHOWER HANDSET CLEANING INSTRUCTIONS

The shower handset should be cleaned periodically to remove lime scale or debris which will reduce the

performance of the shower. The frequency of the cleaning will vary according to local water quality.

PERIODICAL MAINTENANCE

1. To break away scale

deposits on a daily basis

simply rub your thumb

over the surface whilst

the shower is running.

2. If scale deposits are

stubborn, soak the

showerhead in a

proprietary limescale

remover and rinse

thoroughly before use.

ATTENTION!

DO NOT OPERATE THE SHOWER UNIT IF THE SHOWERHEAD

OR HOSE BECOMES DAMAGED.

THE SHOWER IS DESIGNED AND APPROVED TO EN-60335 WITH THE SHOWERHEAD

PROVIDED. UNDER NO CIRCUMSTANCES MUST ANY SHOWERHEAD THAT IS NOT

APPROVED BY THE MANUFACTURER BE USED WITH THIS PRODUCT.

If the performance of your shower deteriorates in service please follow the self help items detailed below before

seeking professional advice from the installer.

If the actions below fail to restore the shower performance you should initially contact the person or company

that installed the shower.

Q. Water does not flow when start / stop button is

pressed.

A. Three things to check:

1. Check the mains water supply is fully open at

the stop cock.

2. Check that the local isolating valve is fully open.

3. Check that the front cover is correctly mounted

on the back plate and all cover screws are fitted

correctly.

Q. Water too HOT.

A. Five possible reasons:

1. Reduce the temperature by adjusting the rotary

flow / temperature control.

2. Clean the shower handset of any dirt or debris.

3. Check that the mains water stop valve is fully

open.

4. Check that the local isolating valve is fully open.

5. Select a lower power setting.

6. Clean inline filter of any dirt or debris.

Q. Water is dripping from the bottom of the shower.

A. Safety pressure relief may have operated. This

will need to be replaced. Please contact the MX

service line.

Check the inlet mains water connection.

If the pressure relief valve has operated check the

hose and handset are NOT partially or fully blocked.

These would need to be replaced. Please contact

MX Customer Care.

Q. Water too COLD.

A. Eight things to check:

1. Check the mains circuit breaker and/or fuse.

2. Check the isolation pull cord or surface mounted

switch is on.

3. Check the rotary power selector is set to full

power (indicated by three red lines).

4. Increase the water temperature by adjusting the

rotary flow / temperature control in the direction

of the red graphic.

5. Confirm that there is sufficient mains water

pressure.

6. Restart the shower on the full power setting.

7. Allow cold water to run through the shower to

re-set the cyclic over temperature cut-out.

8. If there is still no hot water contact MX

Customer Care.

Q. Spray pattern from the handset is poor.

A. Clean the spray plate. If the handset is adjustable

select a different mode by rotating the spray plate.

Q. The shower filter and/or the handset keeps

blocking or filling up with solid material.

A. Following the initial installation no solid

materials should remain in your cold water supply

or the electric shower unit. There is a problem with

your water supply. Contact a plumber for advice.

Q. The shower hose or shower hand set become

damaged or is leaking.

A. Contact MX Customer Care and they will advise

of a suitable replacement.

16 17

Page 10

TROUBLESHOOTING AND FREQUENTLY ASKED QUESTIONS (CONT.)

18. THE MARLETON CROSS LTD (MX GROUP) - 1 YEAR GUARANTEE

Q. My electric shower is out of the warranty period

and is no longer working.

A. Please contact MX Customer Care for advice.

Q. The shower cycles from hot to cold.

A. If the temperature in the electric shower

has exceeded the safe maximum, then the unit

automatically shuts off the power to the heating

elements. When a safe temperature returns the

elements will turn back on. An audible click can be

heard. See also ‘Water too hot’ above.

17. TROUBLESHOOTING CHECKLIST FOR THE INSTALLER

IMPORTANT: The following check list is provided for the benefit of the qualified installer.

WARNING: SWITCH OFF THE ELECTRICITY AT THE ISOLATOR BEFORE REMOVING THE FRONT COVER TO

MAKE CHECKS.

Q. Water too cold.

A. Check the circuit through the thermal cut out.

Check circuit through the two sheathed heating

elements.

NOTE: Test to be done using a low voltage

resistance meter whilst the power is switched OFF

at the isolating switch.

Check working voltage.

Q. Poor or no control over water flow.

A. Replace the water flow valve head works.

Customer Care Department

Telephone: 0845 505 2211 Fax: 0845 850 0757

9.00 am - 5.00 pm Monday to Friday

Q. No water when start / stop button is pressed.

A. Check the water supply isolating valves are fully

open.

Check the mechanical solenoid is latching.

Q. Pressure relief valve operated.

A. Check for cause of high pressure such as

blocked shower hose or shower handset. Replace

pressure relief valve disc. (Note: this is not covered

under the product guarantee.)

Marleton Cross Limited (MX Group) hopes you are satisfied with your

purchase and in the unlikely event that you encounter a problem which

is caused exclusively by the MX Group manufactured product (the

“product”) we will take responsibility on the terms set out here.

We aim to supply components which have been manufactured to

the highest standards. In respect of the product you have a one year

guarantee which covers any defect in manufacture.

Any part found to be defective during the guarantee period will be

replaced without charge providing that the product has been installed

in accordance with our instructions, used as intended and maintained/

serviced as recommended.

In the unlikely event that any problems are encountered with this

component’s performance on installation, please contact our Customer

Care Department for help, as below.

Please supply proof and date of purchase when contacting MX Group.

The company reserves the right, in the event of a claim not covered by

the guarantee, to charge the claimant for parts and labour at current

rates. This guarantee is given in addition to and does not affect your

statutory rights.

Exclusions:

1. Any product found to be defective during this period, as the result of

misuse, neglect or damage, will not be covered by this guarantee

such as:

• Damage caused by accident

• Those components subject to wear and tear such as ‘O’ rings and

washers etc.

• Effects of scaling

• Damage caused by faulty installation.

• Damage caused by waterborne debris.

• Damage caused by improper cleaning components.

• The components being used for a purpose other than intended.

2. Breakdown due to:

a) Use other than domestic use by you or your resident family

b) Wilful act or neglect

c) Any malfunction resulting from the incorrect use or quality of water

or incorrect setting of controls; and

d) Faulty installation.

3. Repair costs for damage caused by foreign objects of substances or

the inappropriate use of jointing compounds or blow torches.

4. Total loss of the product due to non-availability of parts or other

reason, (MX Group will maintain stocks of spare parts for repair for at

least 5 years from end of product line to cover this guarantee).

5. Compensations for loss of use of the product or consequential loss of

any kind.

6. Call out charges

7. The cost of routine maintenance, adjustments, overhaul

modifications or loss or damage arising there from, including the cost

of repairing damage, breakdown, malfunction caused by corrosion,

furring, pipe scaling, limescale, system debris or frost.

8. Components and/or units including components purchased and

installed other than in the United Kingdom.

Limitations

1. This guarantee lasts for a single continuous period of 1 year from

the date of delivery to you the customer.

2. This guarantee is personal to the original purchaser of the product

and is not transferable.

3. Original proof of purchase(s) must be shown for any claim under

this guarantee.

4. This guarantee does not cover any components that have been

modified, altered or transformed in any way.

5. This guarantee applies to an original installation in accordance

to our fitting instructions and does not cover previously installed

components (showroom displays etc) or components that have been

moved from their original installation position for any reason.

6. This guarantee applies only to manufacturing or material defects.

It does not apply to normal wear and tear, accidental damage,

inappropriate use (including inappropriate cleaning) or other events

outside the manufacturer’s control.

7. This guarantee applies only to the product itself and as a result any

liability attributed to MX Group is limited to the cost of the component.

8. If a product is deemed to be of faulty manufacture MX Group will at

their discretion replace the component. Any related consequential

loss or damage is excluded.

9. No claim will be accepted if a product is installed with a fault (ours or

otherwise) that would have been clearly evident before installation.

10. We make no representations, and exclude any and all liability, in

respect of any third party products or services supplied by way of

extensions to this guarantee.

Liability

1. Except as required or agreed by us, you will not in any circumstances

return any of the product to us, and where the property in any of the

goods returned to us has passed to you, they will nevertheless remain

your property and at your risk unless we have agreed otherwise in

writing before their return.

2. Except as stated above, we will not be liable for any direct,

consequential or other loss, damage or injury suffered or incurred by

you, and you will indemnify us fully against any claims made by third

parties, in respect of the goods or otherwise arising from the contract.

3. Nothing contained in the contract will be treated as excluding or

restricting any liability on our part for death or personal injury

resulting from our negligence.

4. Except as stated above, and to the fullest extent permitted by law,

all conditions, warranties and representations, whether express or

implied, statutory or otherwise in relation to the product (other than

such as relate to title to the component) are excluded.

5. You acknowledge that our prices for the goods reflect these Terms

and Conditions, and accordingly that you accept the above limitations

on and exclusions of liability in exchange for those prices.

6. When providing information to MX-Group you understand that you

are doing this subject to our terms and other policies (including data

protection) we have in place from time to time, copies of which are

available on our website www.mx-group.com or on request as per

the MX Group contact details given herein.

7. This guarantee does not affect your statutory rights.

In the interest of continuous product development we reserve the right

to alter the specification as necessary.

In the unlikely event that you need to make a claim on our guarantee

please contact MX Customer Care on 0845 505 2211 or

sales@mx-group.com

18 19

Page 11

19. SERVICE POLICY

In the event of you needing to contact the MX Group

Customer Care Department, the following procedure

should be followed:-

1. Before telephoning the MX Group Customer Care

Department you should ensure that you have the

model number, power rating, serial number,

this can be found on the bottom of the shower unit

plus the date of purchase.

2. The MX Group Customer Care Department will be

able to inform you whether the fault can be rectified

by the provision of a replacement part or an on site

visit by a Qualified Service Engineer.

Customer Care Department

Telephone: 0845 505 2211 Fax: 0845 850 0757

9.00 am - 5.00 pm Monday to Friday

3. If a service call is booked, you or a representative

must be present during the Engineers visit.

4. A charge will be made where a call under the terms

of the guarantee has been booked and a failure was

not product related, or an engineer arrives and is

not able to gain access.

5. If the product is no longer covered by the

Guarantee, a charge will be made for the site

visit and for any parts supplied.

MXINTRO KL/MAY2016

Marleton Cross Limited Trading as The MX Group

Alpha Close, Delta Drive, Tewkesbury Industrial Estate, Tewkesbury, Gloucestershire GL20 8JF

Tel: 01684 293311 Fax: 01684 293900 Email: sales@mx-group.com www.mx-group.com

CUSTOMER CARE: 0845 5052211

TRADE DESCRIPTIONS ACT

Variations in terms of colour finish, materials and all other aspects of appearance may occur on occasions, either

through non-availability of materials or due to our policy of continuing technical improvement. Therefore the Company

reserves the right to change specification or withdraw products from this list without prior notice being given.

Loading...

Loading...