intrepid 350 WALKAROUND Owner's Manual

OWNER’S MANUAL

11700 SOUTH BELCHER ROAD

350

WALKAROUND

INTREPID POWERBOATS, INC.

LARGO, FL 33773

PHONE (727)548-1260

FAX (727)544-1796

TABLE OF CONTENTS

BOAT DATA

OWNER’S DATA A-1

BOAT DATA A-2

A WORD OF WELCOME A-3

WARRANTY INFORMATION

WARRANTY B-1

CUSTOMER’S RESPONSIBILITY B-4

CONTROL HELM

SPEED AND MANEUVERING CONTROLS C-1

ENGINE THROTTLE AND SHIFTER C-1

IGNITION SWITCHES C-2

STEERING C-3

BOAT AND ENGINE TRIM C-4

TRIM TAB SYSTEM C-4

ENGINE TILT AND TRIM C-6

ENGINE INSTRUMENTATION C-7

THE IMPORTANCE OF ENGINE INSTRUMENTATION C-7

BASIC ENGINE INSTRUMENTATION C-7

TACHOMETER C-7

VOLTMETER C-7

FUEL GAUGE C-7

TRIM GAUGE C-7

HOURMETER C-8

ENGINE MANUFACTURER SUPPLIED INSTRUMENTATION C-8

ELECTRICAL SYSTEM CONTROL C-9

BATTERY SWITCH PANEL OPERATION C-10

NAVIGATIONAL SYSTEMS C-11

COMPASS C-11

ELECTRONICS C-11

ACCESSORIES

HELM DC PANEL D-1

SWITCH PANEL POWER D-1

NAVIGATION LIGHTS D-2

NAVIGATION LIGHTS D-2

ANCHOR LIGHT D-2

TRIM TABS D-3

BAITWELL PUMP (WITHOUT OPTIONAL GENERATOR) D-3

BAITWELL PUMP (WITH OPTIONAL GENERATOR) D-5

FRESH WATER SYSTEM D-7

FISH BOX MACERATOR D-8

FISH BOX MACERATOR SYSTEMS D-10

SALTWATER PUMP D-12

ELECTRONICS D-13

BILGE PUMP SYSTEMS D-13

ACCESSORIES (continued)

BILGE PUMP #1 D-13

BILGE PUMP #2 D-14

CABIN BILGE PUMP D-14

COCKPIT LIGHTS D-16

ACCESSORY # 1 D-16

ACCESSORY # 2 D-17

OVERHEAD LIGHT OPTION D-17

ACCESSORY # 3 D-17

SPREADER LIGHT OPTION D-18

ACCESSORY # 4 D-18

ACCESSORY # 5 D-19

COCKPIT REFRIGERATOR D-19

ACCESSORY # 6 D-19

ELECTRIC HELM SEAT OPTION D-19

ACCESSORY #7 D-20

CABIN DC PANEL D-20

CABIN BILGE PUMP D-20

SUMP PUMP D-21

REFRIGERATOR D-21

WASTE SYSTEM D-22

HEAD LIGHT D-25

CABIN LIGHTS D-26

OVERHEAD LIGHTS D-27

FUEL SYSTEM

FUEL SYSTEM E-1

FUEL TANK PICKUPS E-1

FUEL FILTERS E-2

SHUTOFF VALVES E-2

PRIMER BULBS E-3

TANK FILL E-3

TANK VENT E-3

FUEL LEVEL SENDER E-3

BONDING E-4

SYSTEM INSPECTION E-4

DECK HARDWARE

ANCHOR ROLLER F-1

MOORING CLEATS F-2

ANCHOR LOCKER F-2

CABIN HATCH F-2

COCKPIT SCUPPERS F-2

OIL TANK FILLS F-2

BOW AND STERN EYES F-3

TOW EYE OPTION F-3

THRU HULL LOCATIONS

THRU HULL LOCATIONS G-1

120VAC ACCESSORIES

120VAC ELECTRICAL SYSTEM H-1

120VAC SOURCE H-3

120VAC DISTRIBUTION H-3

AC DISTRIBUTION PANEL H-3

GROUNDED NUETRAL BUS BAR H-5

GROUNDING BOND BUS BAR H-5

GALVANIC ISOLATOR H-6

120VAC ACCESSORIES H-6

AC OUTLETS H-6

MICROWAVE H-6

BATTERY CHARGER H-6

AIR CONDITIONING OPTION H-7

WATER HEATER H-8

REFRIGERATOR H-9

SPARE H-10

OPTIONAL COCKPIT COOLER H-10

BONDING H-11

OPTIONAL SYSTEMS

WINDLASS SYSTEM

DC DISTRIBUTION I-1

WINDLASS CONTROL I-1

WINDLASS OPERATION I-2

GENERATOR SYSTEM J-1

DC DISTRIBUTION J-2

AC DISTRIBUTION J-2

FUEL SYSTEM J-4

RAW WATER J-5

EXHAUST J-6

GENERATOR CONTROLS J-6

ACCESSORIES J-7

HALON FIRE EXTINGUISHER J-7

CO MONITOR J-7

BOW THRUSTER SYSTEM

DC DISTRIBUTION K-1

THRUSTER CONTROL K-2

THRUSTER OPERATION K-2

OPERATING YOUR INTREPID

OPERATING YOUR INTREPID L-1

STARTING THE ENGINES L-1

RUNNING YOUR INTREPID L-1

PERFORMANCE L-2

ENGINE EFFICIENCY L-2

ATMOSPHERIC CONDITIONS L-2

PERSONAL EQUIPMENT AND ACCESSORIES L-2

MARINE GROWTH L-2

BILGE WATER L-2

PROPELLERS L-2

MAINTAINING YOUR INTREPID

MAINTAINING YOUR INTREPID M-1

DAILY / WEEKLY MAINTENANCE M-1

100 HOURS OR 60 DAYS M-1

EXTERIOR M-1

INTERIOR M-2

BILGE AREAS M-2

CONTROL HELM M-2

FIBERGLASS AND GELCOAT CARE M-2

LEAVING YOUR INTREPID

LEAVING YOUR INTREPID N-1

SHORT TERM N-1

LONG TERM N-1

STORING N-1

DRY STORAGE N-1

WET STORAGE N-1

LAUNCHING YOUR INTREPID N-2

PRE LAUNCH N-2

AFTER LAUNCH N-2

RULES OF THE ROAD

RULES OF THE ROAD O-1

A WORD OF WELCOME

We are pleased that you have chosen Intrepid.

Intrepid’s unique step-lift bottom design will give you excellent performance and many years of

boating pleasure.

The step-lift hull is a state-of-the-art design that reduces the wetted surface of the hull bottom,

which means less drag and higher performance.

Your Intrepid is built of the finest, most modern materials and is manufactured under rigid quality

controls. The hull is constructed of high-impact hand laid up multi-laminate fiberglass. Your boat

comes to you as the most thoroughly tested and trouble free boat on the market today. Each boat

is thoroughly sea-trialed before delivery.

While durable in its construction, your Intrepid will benefit from reasonable care, maintenance and

adjustments. Repairs may be required from time to time with certain components as with all

mechanical items. This manual has been specially prepared for your particular model to guide

you in keeping it in the best possible condition.

To fully enjoy your Intrepid you should understand it completely and we suggest you read this

manual thoroughly. If any points arise that you do not completely understand, your dealer will be

able to help you.

It is also recommended that you read all the associated instruction manuals for the components

installed on your Intrepid. These manuals are included in your Owner’s Pack.

When your Intrepid requires service, contact your dealer. They are there to assist you in every

way possible.

We wish you many years of safe and pleasurable boating with your new Intrepid.

A-3

WARRANTY

Below is a copy of the Warranty statement that you signed at the closing of your boat:

Intrepid Powerboats, Inc. is proud of its heritage and reputation for producing products with high

standards of quality and workmanship. Product excellence serves as the cornerstone of our

commitment to customer satisfaction. Intrepid Powerboats, Inc.’s Limited Warranty (“Warranty”) is

your assurance of this commitment. This warranty provides you with protection against certain

repair expenses resulting from defects in materials or workmanship. When maintained and

utilized in the prescribed manner, you can count on your Intrepid boat to provide reliable service.

This Warranty provides you with specific coverage and notes your responsibilities in maintaining

and operating your Intrepid boat. Please take time to read and become familiar with this

Warranty.

WARRANTY PERIOD. For the period of three (3) years from the date of first purchase at retail

(except for a defect in the paint or gelcoat finish which shall be limited to ninety days from the

date of first purchase at retail) Intrepid Powerboats, Inc. warrants to the first purchaser at retail

that the Intrepid Boat shall be free from defects in material or workmanship, subject to the

following conditions, exclusions and provisions.

CONDITIONS OF WARRANTY. As a condition of Intrepid Powerboat, Inc.’s obligations under

this Warranty the first purchaser at retail shall:

1. Within ten (10) days of the date of sale, complete and mail to Intrepid Powerboats, Inc. the

Owner’s Warranty Registration attached hereto:

2. Make any claim under this Warranty, and any notification and/or communications in

connection therewith, to and through the authorized Intrepid Powerboats, Inc. dealer who

sold the Intrepid Boat to the first purchaser at retail, or if such authorized dealer is not readily

available, to and through another authorized Intrepid Powerboats, Inc. dealer:

3. Upon request by Intrepid Powerboats, Inc., promptly return the Intrepid Powerboat to Intrepid

Powerboats, Inc. transportation charges prepaid, and:

4. Not permit any repair and/or replacement services covered under this Warranty to be

preformed by any unauthorized party.

EXCLUSIONS FROM WARRANTY. This warranty shall not apply to:

1. Any Intrepid Boat that has been used at any time for commercial purposes, including, but not

limited to, use in or for the production of revenue or income;

2. Any Intrepid Boat, which has been subject to abuse or neglect in use or service, including,

but not limited to careless or improper hauling, loading, use or operation (a) for racing

purposes, (b) contrary to load or horsepower capacity recommended by Intrepid Powerboats,

Inc., (c) contrary to Intrepid Powerboats, Inc. operation and maintenance instructions, or (d)

in connection with accessories not recommended by Intrepid Powerboats, Inc.;

3. Any observable defect in windshield, upholstery material or convertible top discovered after

deliver to the first purchaser at retail;

4. Any defect caused by, resulting from or in connection with installation of any engine by any

party other than Intrepid Powerboats, Inc.;

5. Engines, outdrives, controls, propellers, pumps, trim tabs, breakers, lights, and other

products not manufactured by Intrepid Powerboats, Inc.; provided, however to the extent

possible, Intrepid Powerboats, Inc. shall pass on to the first purchaser at retail the warranties

of the manufacturers of such items;

6. Any repair or replacement made necessary by normal wear and tear;

7. Any party other than the first purchaser at retail; and

8. Any incidental or consequential damages arising out of , or as a result of, any defect part or

parts, including, but not limited to, loss of use.

B-1

OTHER PROVISIONS OF THIS WARRANTY

1. No Intrepid Powerboats, Inc. dealer or any other party is or shall be authorized to assume,

create, or amend any obligation or responsibility, on behalf of or in the name of Intrepid

Powerboats, Inc. or to bind Intrepid Powerboats, Inc. in any manner in connection with this

Warranty, unless specifically authorized to do so in writing by Intrepid Powerboats, Inc. and

such written authorization shall only be effective for the claim and to the extent expressly

specified therein.

2. Intrepid Powerboats, Inc. reserves the right to change the design, materials, and equipment

of Intrepid Boats without assuming any responsibility or obligation to incorporate such

changes in the repair or replacement of or to Intrepid Boats, pursuant to this Warranty, which

were manufactured prior to any such changes.

EXCLUSIVE REMEDY OF WARRANTY. As the original purchaser’s sole and exclusive remedy

under this Warranty, Intrepid Powerboats, Inc. will repair or replace without charge any part or

parts covered under this Warranty, which, in the sole discretion of Intrepid Powerboats, Inc. or an

authorized dealer of Intrepid Powerboats, Inc., is found to be defective in material and

workmanship.

Intrepid Powerboats, Inc. makes no other warranty of any kind. This Warranty displaces and is in

lieu of all other express or implied warranties of any kind regarding Intrepid Powerboats, Inc.

products, including any implied warranties of merchantability and fitness for a particular purpose

which are hereby disclaimed and negated in all respects.

This Warranty gives you specific rights, you may also have other rights which vary from state to

state.

B-2

WARRANTY ADDENDUM

NOTICE TO FIRST PURCHASER FROM INTREPID POWERBOATS, INC.

PURCHASER NAME:

ADDRESS:

CITY:

ZIP:

BOAT S/N:

ENGINE MFG:

S/N:

S/N:

PURCHASE DATE:

I,

item number 5 under “Exclusions from Warranty” and fully understand that if and when there is

any warranty, or service needed for the outboard or inboard motors, I must make arrangements

with my local factory authorized service center, as INTREPID is not an authorized service center

for motors or related parts.

The balance of number 5 will be handled by Intrepid Boats through the warranty extended by that

specific manufacturer.

All Yamaha engines rigged by Intrepid Powerboats use a custom rig tube receiver at the engine

that does not allow the tube to fall out as other rig tube receivers do.

It is most important that when the engines are trimmed all the way up in the out of water position,

that the engines must be turned hard over to port or starboard (preferable port), before trimming

them up so that you will not kink the rigging tube.

On triple engine installations, care must be taken not to turn the engines hard over prior to tilting

as damage to engine cowling may occur.

SIGNED:

DATE:

have read the INTREPID Limited Warranty and specifically

B-3

CUSTOMER’S RESPONSIBILITY

Read your warranty certificate carefully and promptly mail in the warranty registration with all the

requested information.

The warranty is specific as to what is covered by warranty and how to obtain repair.

It is important to realize that there is a difference between warranty work, routine maintenance

and damage caused by misuse or negligence.

If you experience a problem with your Intrepid or any of the factory installed components, contact

the Intrepid factory with a complete description of what is occurring for assistance. We will then

advise you of the quickest and best way to resolve the problem.

The engine(s) are covered separately under warranty by the Engine Manufacturer. Any engine

warranty or service work must be performed by an Engine Manufacturer’s authorized service

center.

Do not operate your Intrepid or any system or component until you have read and understand this

manual or the manuals supplied by equipment suppliers. Supplied equipment manuals are

included in your Owner’s Pack.

The delivering representative or dealer should familiarize you with the operation and handling of

your Intrepid so that you will have a complete understanding of your boat. If you have any

questions regarding your Intrepid or its operation, contact us and we will answer all questions.

B-4

CONTROL HELM

The Helm on your Intrepid is the control and monitor center for the engine and electrical, steering,

and navigational systems installed on your boat.

THE CONTROL HELM

(TWIN ENGINE MERCURY OPTIMAX WITH SMARTCRAFT GAUGE PACKAGE SHOWN)

SPEED AND MANEUVERING CONTROLS

Located on the helm are all the controls necessary to control your engine and maneuvering

functions. These controls include:

1. Engine Throttle & Forward/Reverse Controls

2. Ignition/Start Switches

3. Steering System

4. Boat & Engine Trim

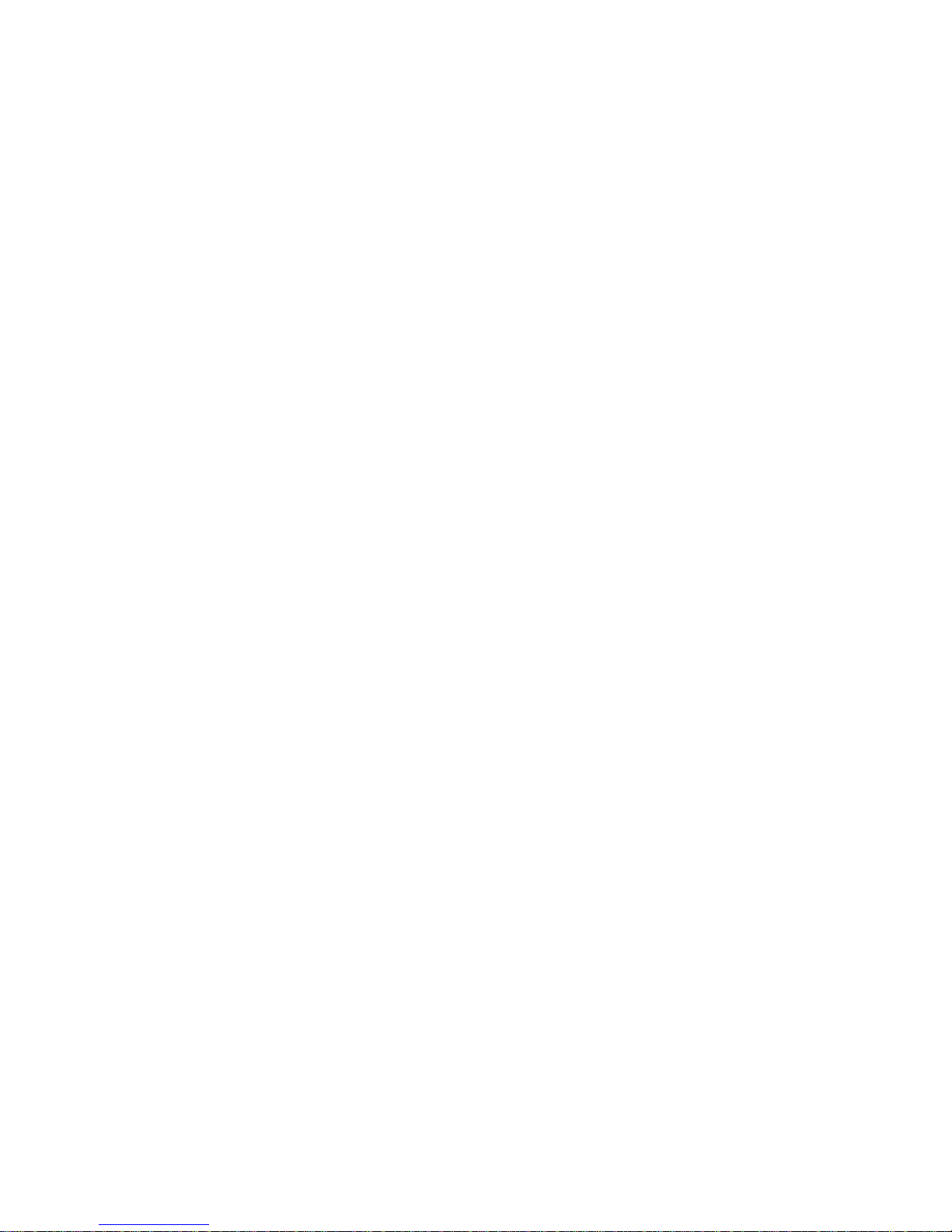

1. Engine Throttle / Shift Control (Outboard)

Throttle and Shift controls are installed on the starboard side of the steering helm. They are pushpull controls and are connected to the engine throttle and shift mechanisms through push-pull

cables.

NOTE

Refer to the Engine Control manufacturer’s manual for proper operation and maintenance of the

Engine Control system. This manual is included in your Owner’s packet.

The Shift Control shifts the engine in the same direction the lever is moved, forward to go forward

and aft to move backwards.

C-1

The Throttle Control controls the engine speed or RPM by pushing the levers forward to increase

speed and pulling the lever back to decrease speed in forward gear.

TWIN ENGINE THROTTLE / SHIFT CONTROLS

NOTE

It is recommended that you check for proper throw of the shift mechanism when you first take

delivery and periodically to ensure full throw into forward and reverse. If the gears are not fully

engaged while running, extensive damage can occur which is not covered under the engine

manufacturer's warranty. If you find your controls are not adjusted correctly, contact your dealer

immediately to have them adjusted.

NOTE

Avoid high RPM operation out of gear in the same manner you would with your personal

automobile.

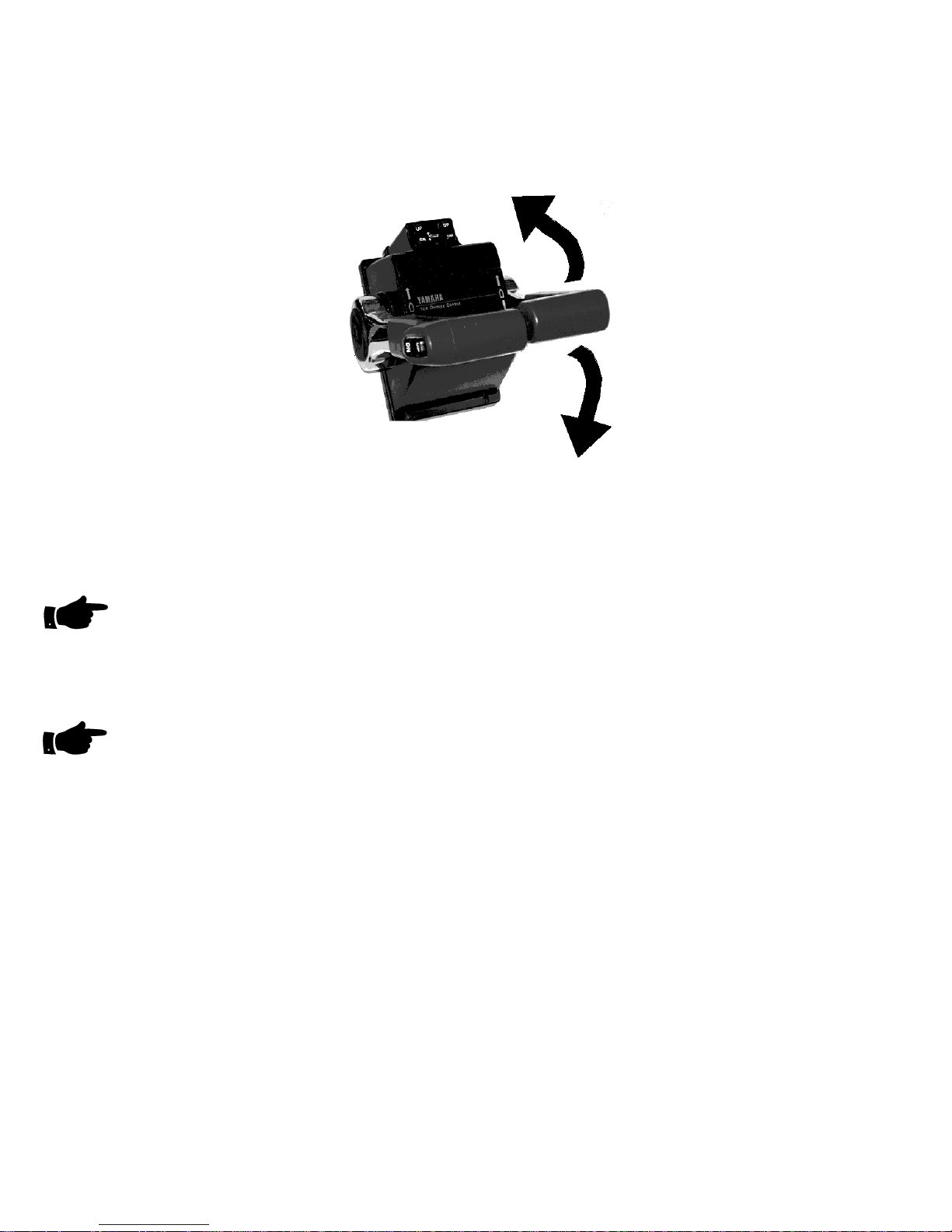

2. Ignition Switches

The Ignition Switches are provided by the Engine Manufacturer. Refer to the information on the

operation of the Ignition Switch that is located in your Owner’s Pack.

The Ignition Switches provides you with the ability to:

1. Energize the engine electrical system

2. Energize the engine instrumentation

3. Crank the engine.

4. Choke the engine during starting

5. Turning off the engines, engine electrical systems, and instrumentation.

C-2

IGNITION ON

ENGINE AND

IGNITION OFF

YAMAHA

KILL SWITCH

AND LANYARD

ENGINE START

PUSH KEY TO

CHOKE

YAMAHA IGNITION SWITCH

NOTE

The Lanyard connected to the Engine Kill Switch should be attached to the boat’s helmsman

whenever underway. If the helmsman is thrown or rolled away from the helm, the Lanyard will

unclip from the Engine Kill Switch and shutdown the engines.

If extra Ignition Switch keys are required, contact Intrepid Powerboats. Key numbers can be

found in this Owner’s Manual.

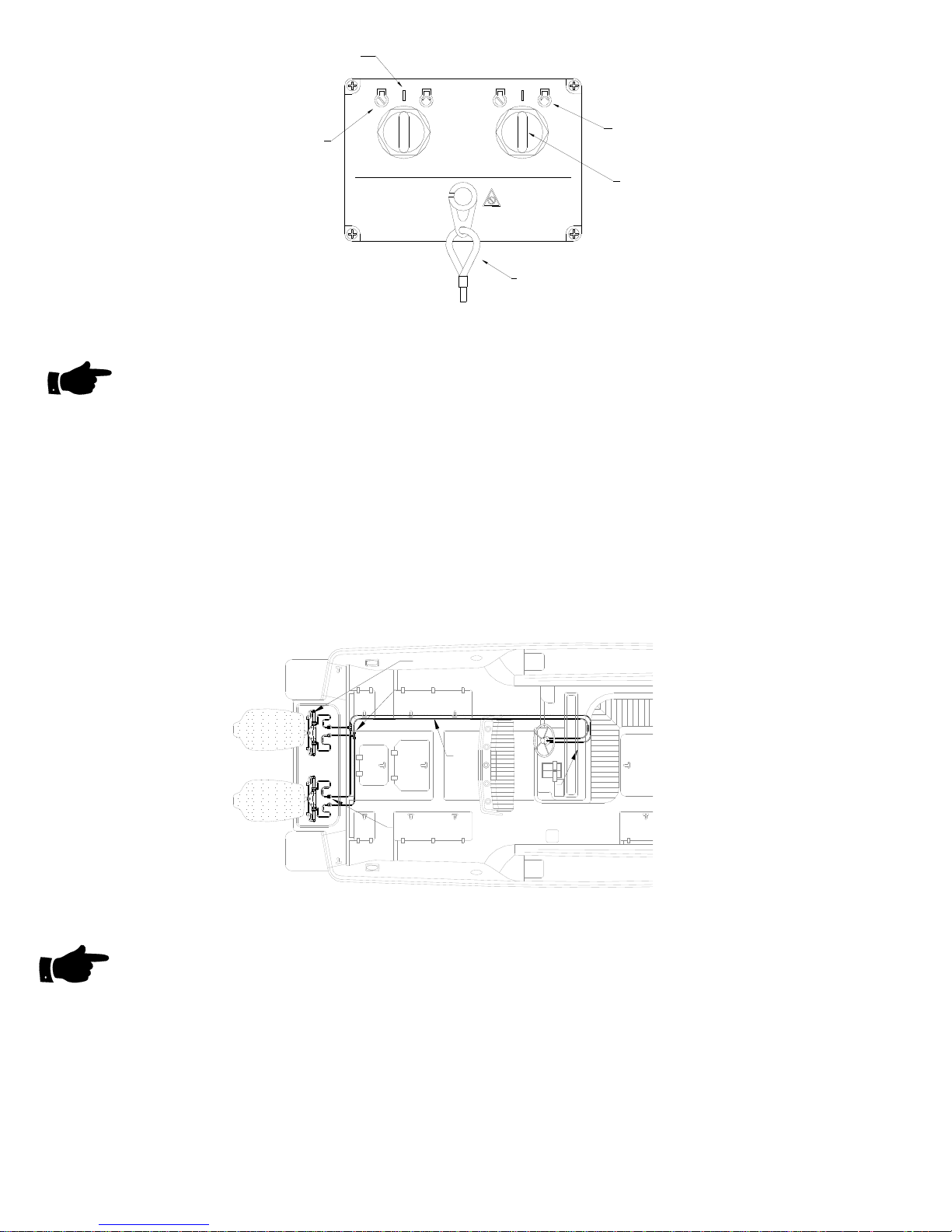

3. STEERING SYSTEM

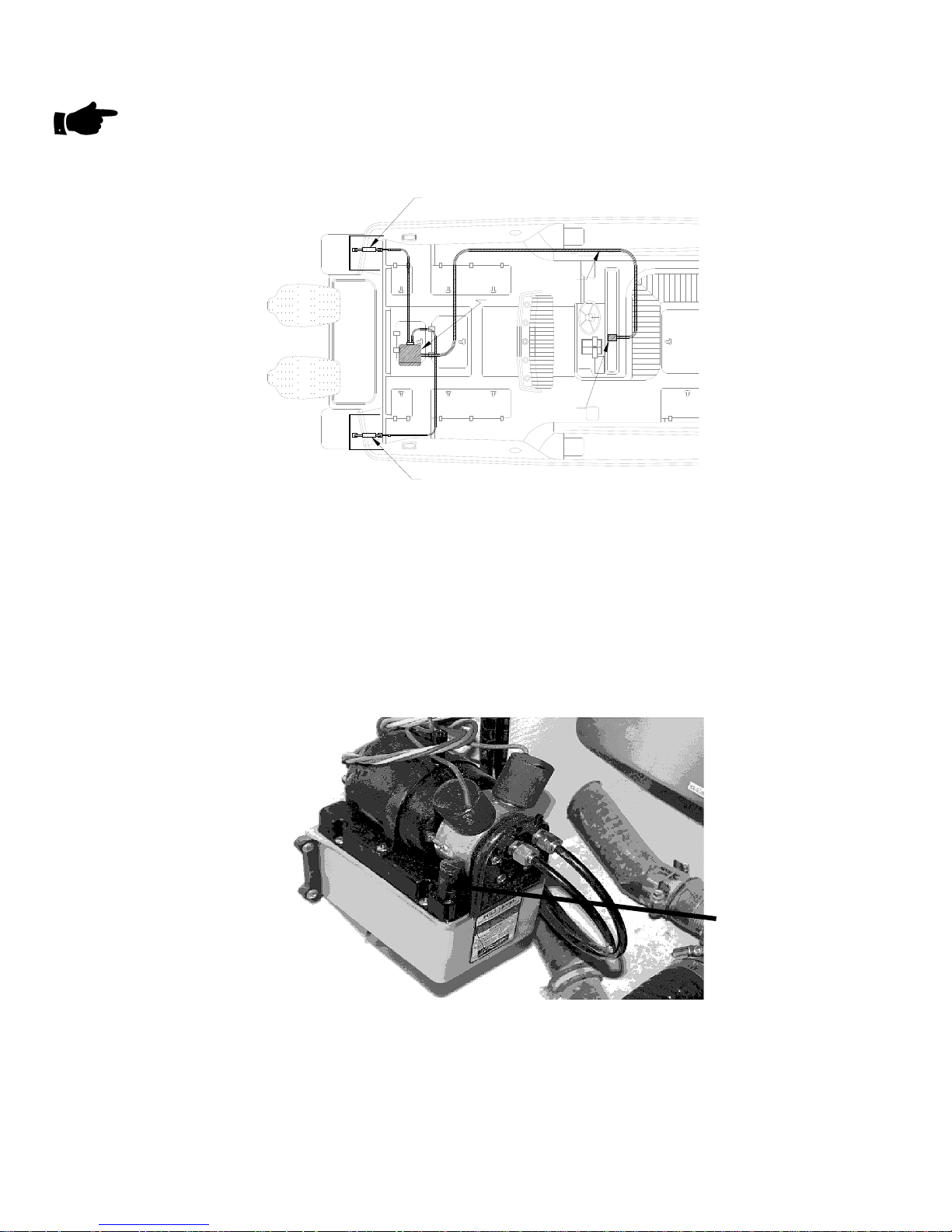

The hydraulic steering system transmits power from the steering wheel to the steering ram

mounted on the engines to control the turning of the engines. The system gives instant steering

response to the engines to control the direction of the boat while under way.

STEERING CYLINDER

TEES

HYDRAULIC

LINES

STEERING HELM

SPLASHWELL

FITTINGS

HYDRAULIC STEERING SYSTEM DIAGRAM

NOTE

Refer to the Steering Control manufacturer’s manual for proper operation and maintenance of the

teering system. This manual is included in your Owner’s packet. S

The helm unit under the steering wheel contains the hydraulic fluid that supplies the complete

steering system. Periodic checks of the fluid level should be performed to insure an adequate

Supply is always available to prevent air from entering the system and causing a degradation or

loss of steering.

C-3

The steering system uses hydraulic fluids as outlined in literature for the steering supplied in the

Owner’s packet.

NOTE

The Steering Helm is the hydraulic pump for the system. The direction that the helm is turned

controls check valves in the helm, which in turn determines the direction of flow to the steering

cylinders. When refilling the helm with hydraulic fluid care must be taken to ensure no small

particles of debris enters the system. Debris can affect the operation of the check valves, which

may mean a degradation of or loss of steering capability.

4. BOAT & ENGINE TRIM

TRIM TAB SYSTEM

The Trim Tab System is operated with the switches on the Control Helm. These switches control

the direction and amount the transom mounted trim tabs move.

Power to these switches is supplied from the "TRIM TAB" switch and re-settable circuit breaker

located on the switch panel.

This electric-hydraulically-operated system is used to trim the running attitude of the boat while

under way. If used properly, the trim tabs will aid in trimming the boat in fore and aft and side to

side position, providing a better view for the helmsman and allowing an overall smoother ride and

with increased efficiency.

The operator should be aware that each trim tab does not operate as a unit, but are individually

controlled to allow trimming to correct a listing position while under way.

The double rocker switch located on the helm console actuates the trim tabs. Depressing the top

of the switches lowers the tabs, which causes the bow of the boat to go down while underway.

Depressing the bottom of the switches to the "UP" position allows the bow to rise.

BOW

STERN

LOWERS

RISES

TABS

DOWN

The speed of your boat and conditions of the water will determine the extent of lowering your trim

tabs.

The trim tabs should always be in the "UP" position when dockside and during slow operation

such as docking or slow trolling.

Trim tab position in a following sea must be up. If the trim tabs are down excessively, it can affect

handling characteristics and decrease steering ability and response.

C-4

NOTE

When backing down hard such as can occur in fishing, the extreme force on the tabs from the

water can damage the trim tabs or cylinders if they are not in the full "UP" position

PORT TRIM TAB

& CYLINDER

ELECTRICAL

HARNESS

TRIM TAB

PUMP

TRIM TAB

SWITCH

STBD TRIM TAB

& CYLINDER

.

TRIM TAB SYSTEM DIAGRAM - TYPICAL

The pump/reservoir for the trim tabs is located in aft center bilge area, under the aft center cockpit

hatch. Check the fluid level in the reservoir before operating the trim tabs. The hydraulic fluid level

can be seen through the translucent reservoir container mounted on the bottom of the pump.

Hydromatic transmission fluid is used in this system to actuate the cylinders. If addition of fluid is

necessary, remove the screw in the center of the top cover and lift the cover off. The small plug is

removed from the corner of the pump / reservoir and fluid is added using a small funnel to bring

fluid level to correct height.

C-5

PUMP RESERVIOR FILL

TRIM TAB PUMP

Consult the trim tab owner’s manual supplied in your owner’s packet for complete instructions on

the operation and maintenance of the units.

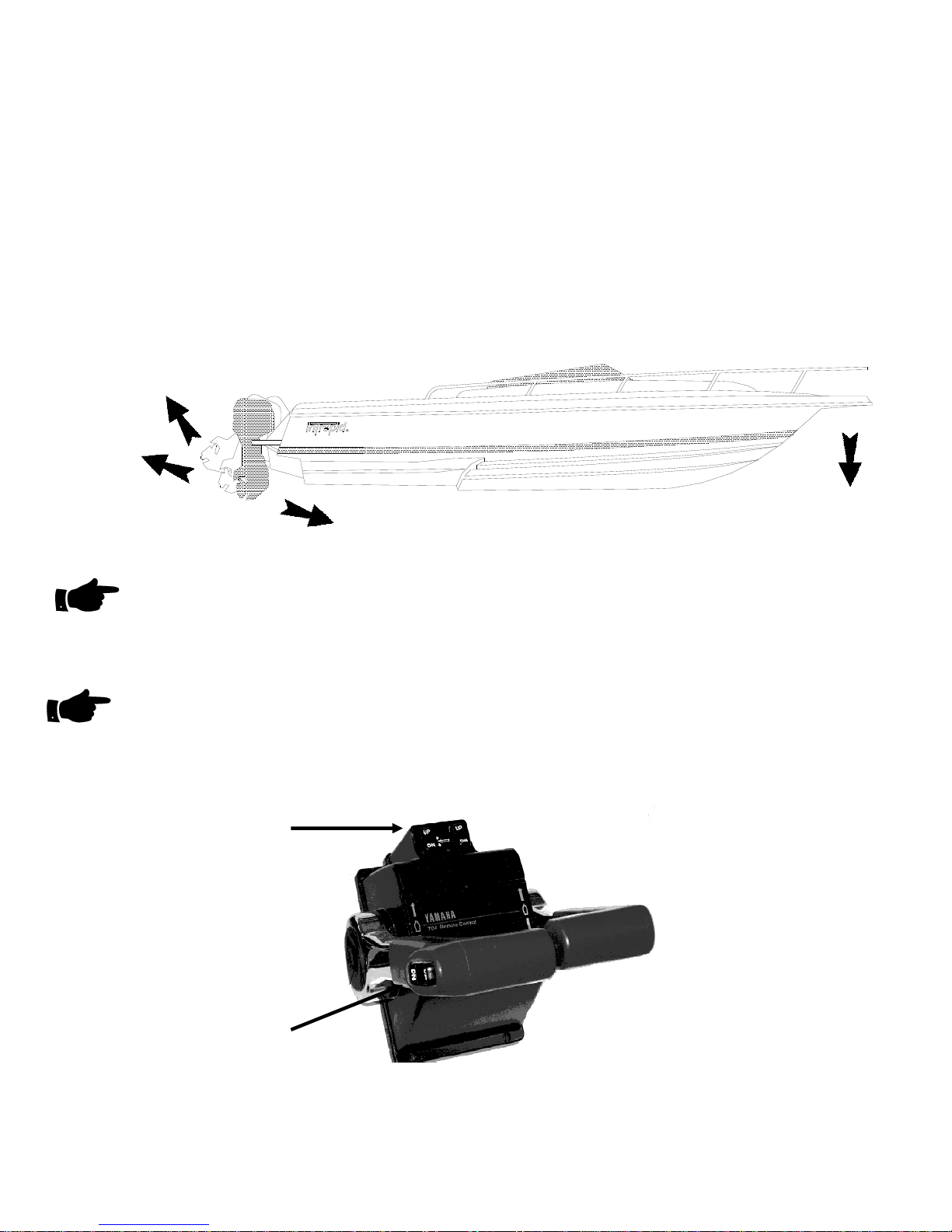

ENGINE TRIM & TILT

The engines Tilt/Trim system is provided by the Engine Manufacturer. Refer to the information on

the operation of the Tilt/Trim system that is located in your Owner’s Pack.

The Trim Buttons next to Engine Throttle/Transmission Control operates the system. Trimming

the engine DOWN has the affect of lowering the bow.

ENGINE TILT

POSITION

ENGINE UP

POSITION

NOTE

In normal conditions only a few seconds of DOWN Trim from the full UP position is necessary.

The Trim button also controls the Tilt position. The engine’s electrical system must be on to tilt the

engine from the Helm.

NOTE

When tilting an engine, observe the rigging tubes from the engine to the boat. If tilting the engine

causes a tight bend in one of these tubes, it may be necessary to steer the engine one turn in a

direction to relieve the tight bend.

INDIVIDUAL ENG TRIM

BOW DOWN IN ENGINE

DOWN POSITION

ENGINE DOWN

POSITION

SIMALTANEOUS ENG TRIM

C-6

ENGINE TRIM/TILT SWITCHES

ENGINE INSTRUMENTATION

1. THE IMPORTANCE OF ENGINE INSTRUMENTATION

To avoid the possibility of mechanical damage to your Engine basic instrumentation for each

Engine is provided on your Intrepid. Unless specified at the time an Intrepid was ordered from the

factory, your boat will be fitted with instrumentation provided by the Engine Manufacturer.

The operator of this boat should become accustomed to checking the instrumentation frequently

when running and particularly when first starting the Engine.

Engine instrumentation gives indications as to what is happening to the engines while they are

being operated. It is important that you become familiar with the appropriate reading for each

instrument. This information is provided by the Engine Manufacturer and is located in your

Owner’s Packet.

Power is provided to an engine’s instrumentation by that engine’s electrical system. The engine’s

Ignition Switch must be on for the instruments to operate.

2. BASIC ENGINE INSTRUMENTATION

TACHOMETER

This instrument provides a reading of Revolutions Per Minute (RPM) of the engine. There is no

set correlation of RPM’s to the speed of the boat. Speeds at various RPM’s should be determined

by using a Speedometer or an electronic device.

VOLTMETER

This instrument monitor’s the amount of charge available in the engine battery. A low voltage

reading when the engine is not running indicates that the battery is not at full charge. A voltage

indication of 13 to 15 volts when the engine is running indicates that the battery is charging.

FUEL GAUGE

The electric fuel gauge indicates the amount of fuel remaining in the fuel tank in terms of

percentage of tank capacity.

The fuel gauge provides a convenient but approximate indication of remaining fuel. Safe

operation of this boat requires filling the fuel tank after each use and becoming familiar with fuel

usage under various conditions.

NOTE

If your Intrepid is equipped with an auxiliary Fuel Tank but has only one Fuel Gauge, your boat

has been fitted with a Main Tank / Auxiliary Tank Selector switch located on your console.

Selecting MAIN will provide a fuel level reading for the Main Tank and an AUX selection will

provide a fuel level reading on the Auxiliary Tank.

NOTE

The fuel senders mounted into the tanks are located under access plates in the cockpit deck.

These senders control the electric gauge on the helm and incorporate a mechanical indication of

Fuel Level on top of each sender.

TRIM GAUGE

The trim gauge provides an indication of the amount an engine is trimmed up or down. Monitoring

this gauge will provide you with the ability to set the amount of engine trim for optimum

performance.

C-7

Hour Meter (Optional)

This meter registers the amount of time in hours that the engine’s ignition system has been on. It

is activated when the Ignition Switch is turned ON. If the hour meter is to be replaced, note the

hours on the old Hour Meter. This figure must be added to the hours shown on the new Hour

Meter to determine the amount of total hours an engine has run.

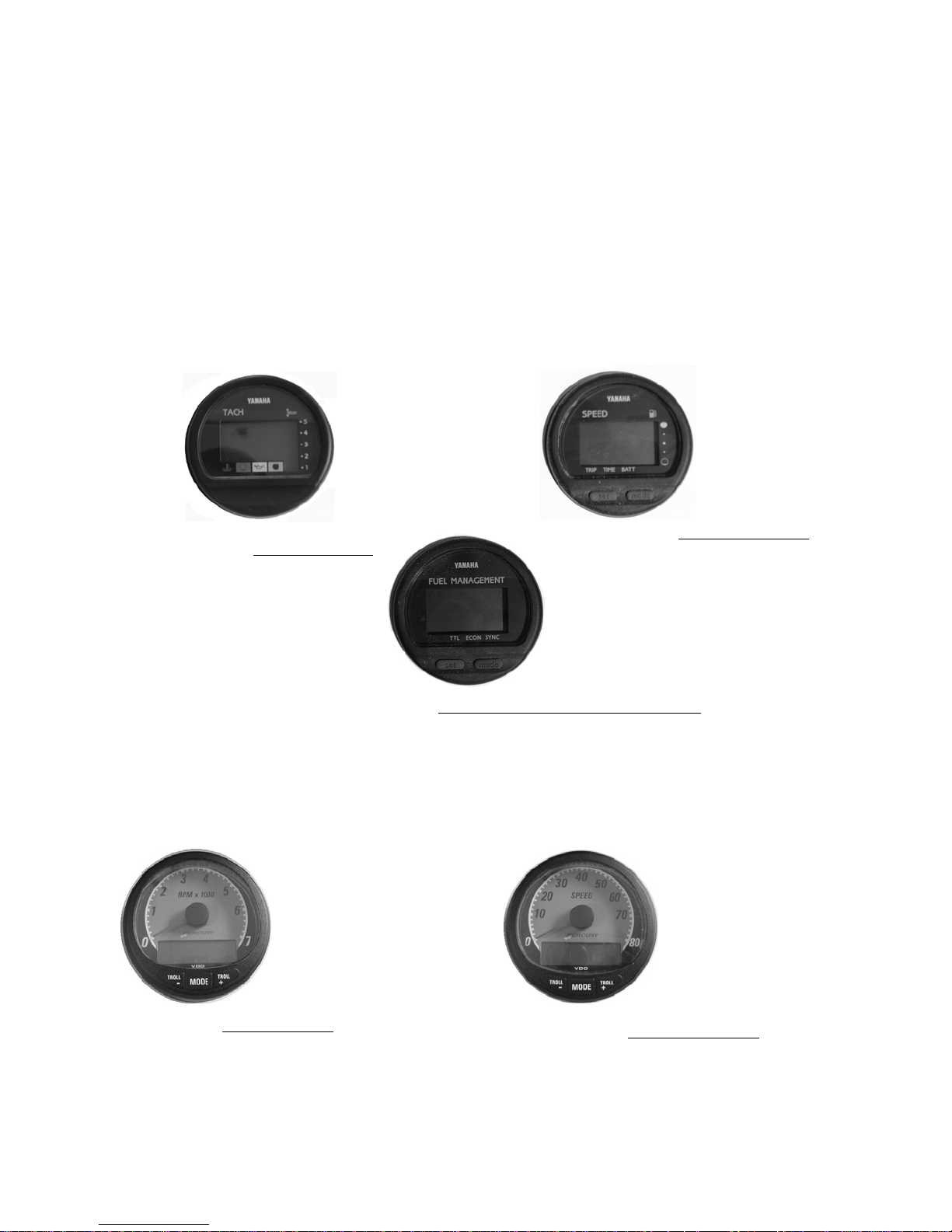

3. ENGINE MANUFACTURER SUPPLIED INSTRUMENTATION

Unless specifically requested at the time a boat was ordered Intrepid has installed

instrumentation that is provided by the Engine Manufacturer.

Information on the use of Engine Manufacturer Instrumentation and the range of normal operating

indications is found in the Engine Owners Manual. This manual is located in your Owner’s Pack.

TACHOMETER

DIGITAL TACHOMETER

HOUR METER

POWER TRIM ANGLE

ENGINE TEMPERATURE

BATTRY VOLTAGE

WATER PRESSURE

SMART TACH

MERCURY SMARTCRAFT INSTRUMENTATION

TRIM GAUGE

TACHOMETER

ENGINE ALARMS

FUEL GALLONS/HOUR

TRIP

OPTIONAL FUEL MANAGEMENT

YAMAHA MULTIFUNCTION INSTRUMENTATION

CLOCK & TEMPERATURE

FUEL TANK LEVEL (S)

FUEL FLOW

DIGITAL SPEEDOMETER

BAROMETER READING

SPEEDOMETER

FUEL GAUGE

SPEED DISPLAY

TRIP & TIME

VOLT METER

SPEEDOMETER

OIL TANK LEVEL(S)

FUEL ECONOMY

FUEL RANGE

TRIP ODOMETER

C-8

ELECTRICAL SYSTEM CONTROL

DC Electrical power is supplied to the Engine electrical system and the boat’s accessories by the

batteries. This power is controlled by Battery Disconnect Switches. The Batteries and Battery

Switches are located @ or under the Helm.

Proper use of the Battery Switches will help lengthen battery life and help provide optimum

charge of the batteries.

If your boat is equipped with optional accessories (Bow Thruster, or Generator, for example)

there will be additional switches on your boat. Specifics on the use of these switches can be

found in the section of this Owner’s Manual that pertains to that accessory.

The battery disconnect switches are located on the side of the helm console.

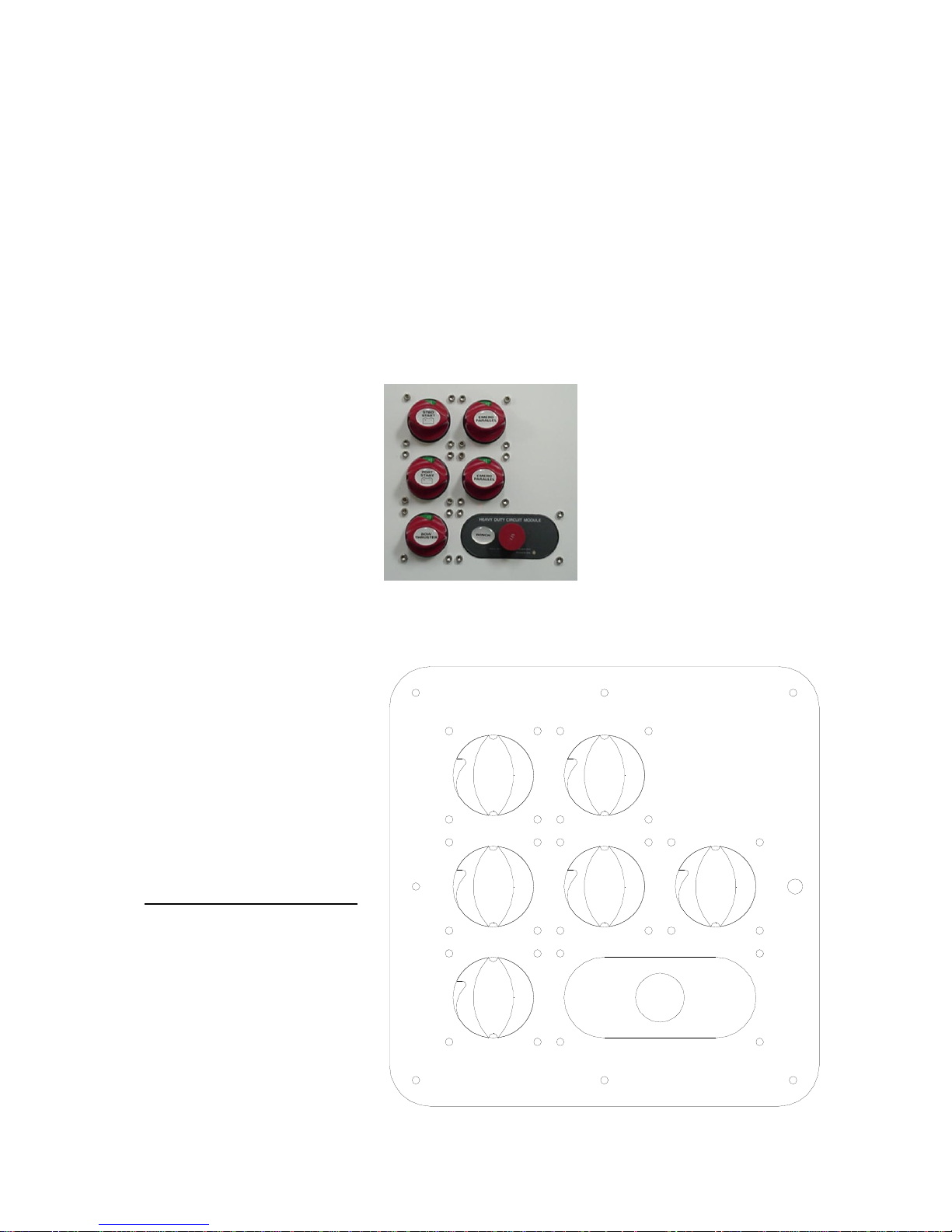

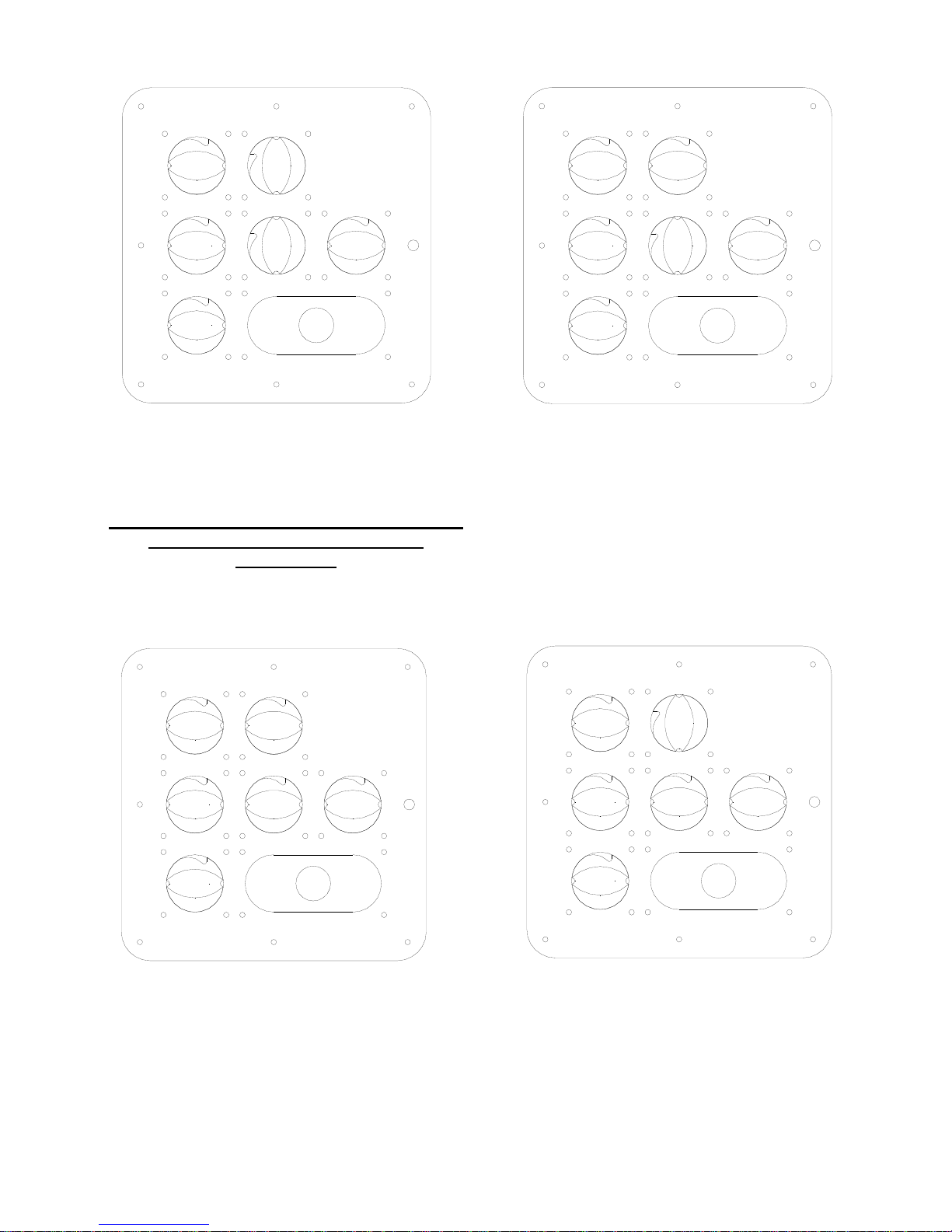

(SHOWN W/BOW THRUSTER & WINDLASS

ALL BATTERIES OFF

OPTIONS SHOWN INCLUDE:

BOW THRUSTER

WINDLASS

GENERATOR

BATTERY SWITCH PANEL

OPTION )

ALL SWITCHES IN ON POSITION

STBD

START

PORT

START

BOW

THRUSTER

WINCH

EMERG

PARALLEL

GEN

EMERG

PARALLEL

135

START

C-9

`

STBD

START

PORT

START

BOW

THRUSTER

NOR ERY

MAL OPERATION BATT

EMERG

EMERG

WINCH

PARALLEL

GEN

PARALLEL

START

135

SWITCH POSITIONS

ALL BATTERIES ON WITH

PARALLEL SWITCHES OFF

EMERGENCY PARALLEL SWITCHES MUST

REMAIN “OFF” DURING NORMAL

OPERATION

STBD

START

PORT

START

BOW

THRUSTER

EMERG

PARALLEL

EMERG

PARALLEL

WINCH

135

GEN

START

STBD START PARALLEL

CIRCUIT TURNED ON

AUX. BATTERY WILL BE PLACED

IN SERIES WITH STBD START

BATTERY TO INCREASE POWER

AVAILABLE FOR ENGINE

CRANKING

ONCE ENGINE IS RUNNING RETURN EMERGENCY PARALLEL SWITCH TO OFF POSITION

STBD

START

PORT

START

BOW

THRUSTER

EMERG

PARALLEL

EMERG

PARALLEL

WINCH

135

GEN

START

STBD & PORT PARALLEL CIRCUIT

TURNED ON

AUX. BATTERY WILL BE PLACED IN

SERIES WITH BOTH THE STBD AND

THE PORT START BATTERY TO

INCREASE POWER AVAILABLE FOR

ENGINE CRANKING

STBD

START

PORT

START

BOW

THRUSTER

EMERG

PARALLEL

EMERG

PARALLEL

WINCH

GEN

START

135

PORT START PARALLEL

CIRCUIT TURNED ON

AUX. BATTERY WILL BE PLACED

IN SERIES WITH PORT START

BATTERY TO INCREASE POWER

AVAILABLE FOR ENGINE

CRANKING

ONCE ENGINE IS RUNNING RETURN EMERGENCY PARALLEL SWITCH TO OFF POSITION

C-10

NOTE

A battery will be charged by the Alternator of the engine it is connected to or the Battery Charger

regardless of the position of its battery switch. The Auxiliary battery of the battery system will be

charged by the alternator of an engine or by the Battery Charger.

NOTE

When all the batteries are disconnected from the electrical system by turning all the switches

OFF, all Engines and Accessories are inoperative with the exception of the Automatic Bilge Pump

circuits

CAUTION

Never disconnect a running engine from the batteries. Ensure that at least one battery is

connected to a running engine at all times. Failure to do so may cause damage to the diodes of a

disconnected running engine’s alternator.

NAVIGATIONAL SYSTEMS

1. COMPASS

Your Intrepid may be supplied with an optional compass.

The compass is located on the Control Helm just forward of the steering helm. Compass internal

lighting is controlled by the NAV/ANCHOR Light Switch located on the Control Helm Switch

Panel.

The compass was calibrated at the compass manufacturer’s facility. Intrepid makes no attempt to

further calibrate (swing) the compass.

To ensure accurate compass readings, the owner must calibrate the compass to eliminate

deviations caused by the geographical area that the boat will operate in and after the owner has

installed any metal or electrical/electronic equipment on the Control Helm.

Information on calibrating the compass is included in the literature provided by the compass

manufacturer. This literature can be found in your Owner Pack.

2. ELECTRONICS

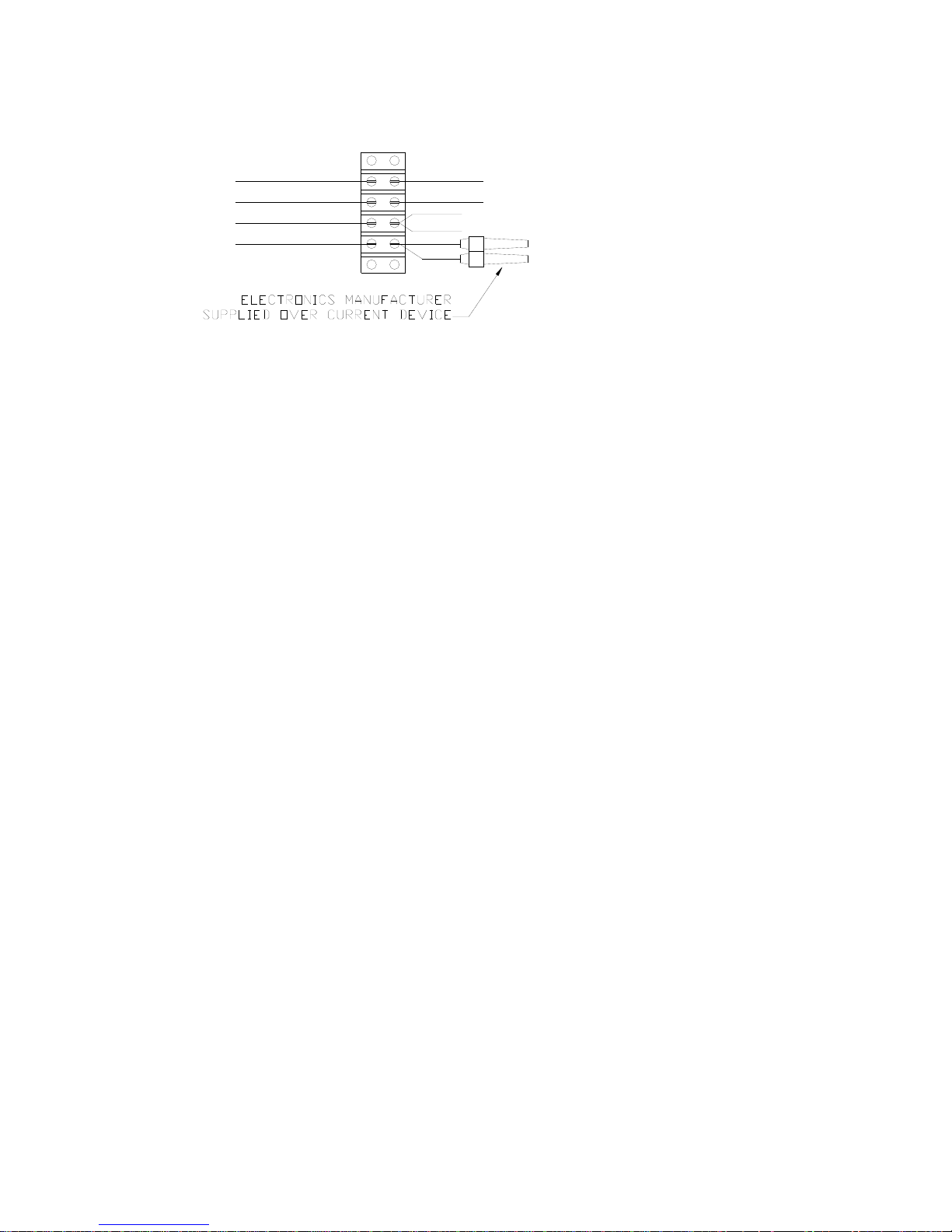

Your Intrepid is provided with a switch and a 30 AMP circuit breaker on the Control Helm Switch

Panel. This ON/OFF switch supplies a small 4 position terminal block located on the underside of

the Control Helm face. Ground is also provided at this small terminal block. Any owner-installed

electronics should be powered from this terminal block.

NOTE

When installing electronics, always use the current protection devices supplied or required by the

manufacturer of the electronics. These over current protection devices should be connected to

the 12AWG Red wire on this terminal block.

C-11

16 RED

16 BLK

12 BLK

12 RED

TO COMPASS AND

GAUGE LIGHTS

TO ELECTRONICS NEGATIVE

TO ELECTRONICS POSITIVE

A second Electronics power supply is provided for electronics added to a Hard or T-Top If a top

was installed by Intrepid this lead (12AWG Red and Black) connects to terminal block in the

Electronics Box. If your boat was not supplied with a Hard or T-Top the lead is coiled under the

small deck access hatch to the PORT of the Control Helm.

C-12

ACCESSORIES

HELM DC PANEL

Your Intrepid has been fitted with many accessories, most as standard equipment; others as

customer ordered options.

The switch panel on the Control Helm controls some of these accessories.

The Switch panel is powered by the boat’s Battery System. The Battery Switches described in the

Control Helm section of this manual control this power. The PORT Battery System supplies

power to the upper side of the Switch Panel while the STBD Battery System powers the lower

side of the Switch Panel.

BILGE 1

MACERATOR

AUT

MAN

FRESHW ATER

ACCESSORIES POWERED BY PORT BATTERY SYSTEM AND BATTERY SWITCH

NOTE

The Bilge Pump circuit on the upper side of the Switch Panel is powered by the Port Battery

System but is not controlled by the Port Battery Disconnect Switch. This Bilge Pump Automatic

and Manual circuits will remain active even if the Battery Switch is turned OFF.

BAITWELL

CABIN LT

ACC 5ACC 2NAV

ANCHOR

ACCESSORIES POWERED BY STARBOARD BATTERY SYSTEM AND BATTERY SWITCH

NOTE

The Bilge Pump circuit on the lower side of the Switch Panel is powered by the Stbd Battery

System but is not controlled by the Stbd Battery Disconnect Switch. This Bilge Pump’s Automatic

and Manual circuits will remain active even if the Battery Switch is turned OFF.

NOTE

The Switch Panel is constructed such that all the switch handles are pointing down in the OFF

position with the exception of NAV/ANCHOR switch that is OFF in the center position (as shown).

Next to each switch is a waterproof circuit breaker for that switch’s circuit. The circuit breaker is

supplied to protect the boat’s wiring and components. If an electrical problem dev elops in a

circuit, that circuit’s breaker will disconnect the circuit from its power source. Once the problem

has been corrected push the center of the breaker IN to reset the circuit.

D-1

1. NAVIGATION LIGHTS

Your Intrepid has been fitted with Navigation Lighting that is suitable for International Rules and

complies with federal regulations in effect at the time of manufacture.

Navigation Lights should be used between the times of ½ hour before dusk and ½ hour after

dusk, or at times of low visibility.

The Navigation Light circuit is composed of the following lights:

1. One GREEN 10-point side light with a 2-mile visibility located on the starboard side of

the cabin.

2. One RED 10-point side light with a 2-mile visibility located on the port side of the

cabin.

3. One White 360° Masthead/Anchor light with a 2-mile visibility located at least 1 meter

above the side lights.

MASTHEAD / ANCHOR LIGHT

360° WHITE ALL_AROUND

10 POINT SIDE LIGHTS

GREEN - STARBOARD

RED - PORT

When underway during the times required both Side Lights (Port and Starboard) and the

Masthead/Anchor Light should be illuminated.

When anchored during the times required only the Masthead/Anchor Light should be illuminated.

NAV LIGHTS

This portion of the Navigation Light circuit is powered by the Port Battery System and is protected

by a 10-amp circuit breaker. Placing the switch handle to the NAV position will do the following:

1. Turn ON both the Port and Starboard Side Lights

2. Turn ON the Masthead/Anchor Light

3. Turn ON the backlighting for the Switch Panel

4. Turn ON the lights for the Engine Instrumentation

5. Turn ON the lights for the compass (if installed)

ANCHOR LIGHT

This portion of the Navigation’ Light circuit is powered by the Port Battery System and is

protected by the same 10-amp circuit breaker as the NAV light circuit. Placing the switch handle

to the ANCHOR position will turn ON the Masthead/Anchor Light only.

A spare positive wire and a ground wire are marked as STERN SPARE and coiled at the

transom. This red positive wire is controlled by the ANCHOR position of the NAV/ANCHOR

Switch.

D-2

2. TRIM TABS

The Trim Tabs are powered by the Starboard Battery System and its circuitry is protected by a

20-amp circuit breaker.

By placing the Trim Tab switch handle to the ON position (up) power is provided to the Trim Tab

Switches located on the Helm.

Refer to the Trim Tab section in the Control Helm chapter of this Owner’s Manual for instructions

on the use and maintenance of the Trim Tab System.

3. BAITWELL PUMP

STANDARD WITHOUT GENERATOR

The Baitwell Pump is powered by the Port Battery System and a 20-amp fuse protects its

circuitry.

By placing the Baitwell Pump switch handle to the ON position (up) power is provided to the

Baitwell Pump.

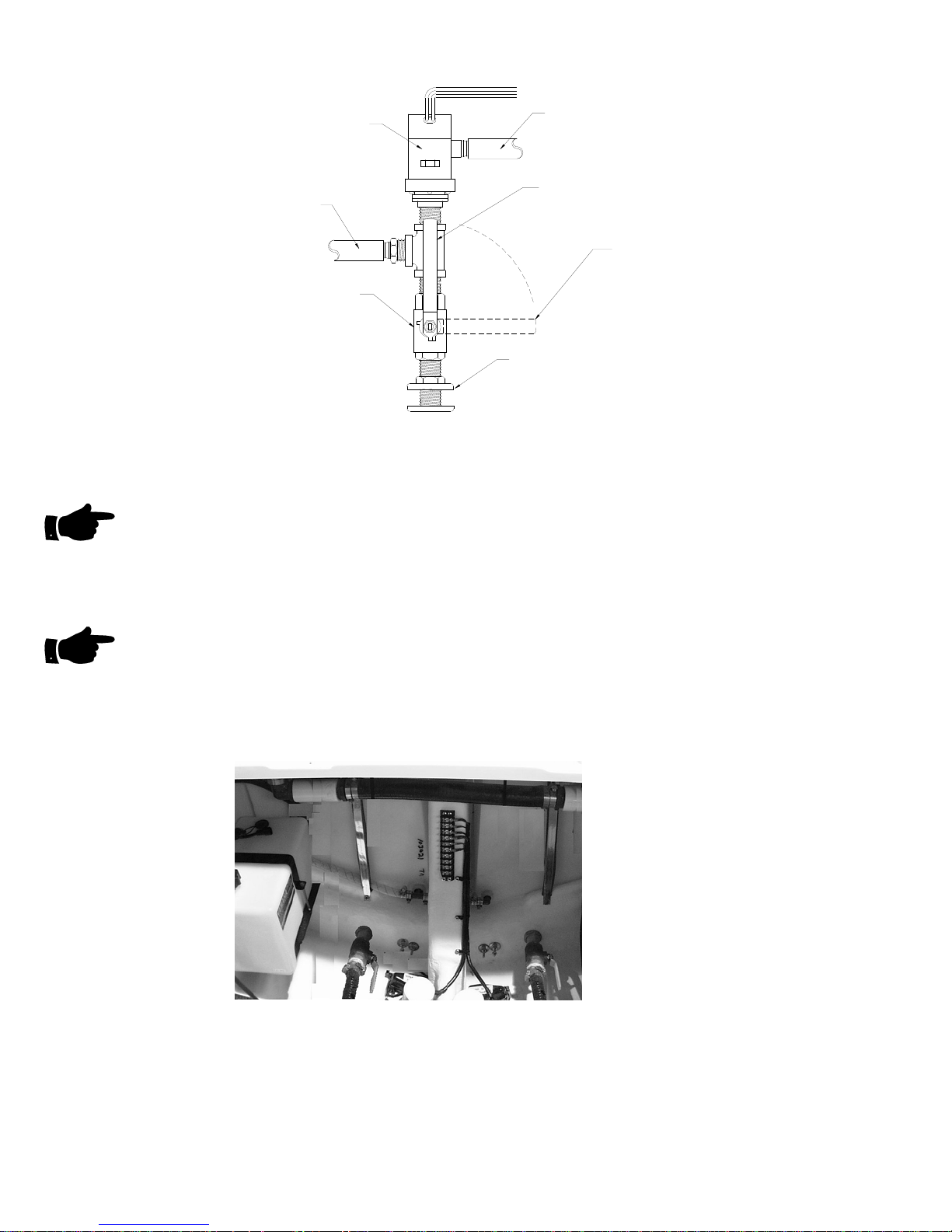

The Baitwell Pump, thru-hull, and seacock are located in the bilge under the Aft Center Bilge

Access Hatch. The Baitwell drain thru-hull and seacock are located further aft in the same

compartment.

BAITWELL PUMP, SEACOCK,

AND THRU-HULL

BAITWELL AERATOR

BAITWELL

BAITWELL DRAIN

BAITWELL DRAIN

SEACOCK AND THRU-HULL

BAITWELL SYSTEM DIAGRAM

The Baitwell Pump draws raw water through the thru-hull and seacock. Water will not be supplied

to the pump if the seacock is closed.

D-3

BAITWELL

PUMP

HOSE TO

BAITWELL

HOSE TO SALT

WATER PUMP

SEACOCK

3/4" NPT

HANDLE IN

OPEN POSITION

HANDLE IN

CLOSED POSITION

THRU HULL

3/4" NPT

The level of water in the Baitwell is maintained by the height of the drain tube, which fits within the

drain fitting.

NOTE

The Baitwell will fill beyond capacity if the Baitwell Pump is ON and The Baitwell Drain Seacock

Valve is OFF.

To drain the Baitwell the drain tube must be removed from the drain fitting in the Baitwell and the

Baitwell Drain Seacock Valve must be opened.

NOTE

The Baitwell will not drain completely when not underway. The Baitwell Drain and the Drain Thruhull are both below the waterline of the boat. The Baitwell will only drain to the level of the

waterline of the boat. To completely drain the Baitwell the Drain Seacock must be opened while

the boat is underway (on plane) or when the boat is out of the water. After draining the Baitwell

close the Baitwell Drain Seacock while underway.

BA K ITWELL DRAIN THRU-HULL & SEACOC

D-4

(VALVES SHOWN IN OPEN POSITION)

Loading...

Loading...