Intramech SWC-04-V-ECM, SWC-06-V-ECM, SWC-12-V-ECM, SWC-15-V-ECM, SWC-18-V-ECM Operation And Service Manual

...

SK2013-SON-002-TechMnl-SWC-002

HYDRONIC HIGH-WALL FAN COILS

INSTALLATION OPERATION AND

SERVICE MANUAL

SWC~EC SERIES

Page 2 of 67

SK2013-SON-002-TechMnl-SWC-002

INVESTING IN QUALITY, RELIABILITY & PERFORMANCE.

ISO 9001 QUALITY

Every product is manufactured

to meet the stringent

requirements of the

internationally recognized ISO

9001 standard for quality

assurance in design,

development and production.

CE SAFETY STANDARDS

All products conform to the

Certificate Europe directives

(Machinery Safety,

Electromagnetic Compatibility

and Low Voltage), as required

throughout the European

Community, to guarantee correct

standards of safety.

WEEE MARK

All products conform to the “WEEE”

directive to guarantee correct standards

of environmental solutions.

World Leading Design and Technology

Equipped with the latest CAD/CAM computer

aided design and manufacturing technology, our

factories in China and Thailand produce over

2,000,000 air conditioning units each year, all

conforming to the highest international standards

of quality and safety.

The Highest Standards of Manufacturing

In order to guarantee the very highest

standards and performance, we manage every

stage in the manufacturing of our products.

Throughout the production process we maintain

strict control, originating with our extensive

resources in research and development through

to the design and manufacture of almost every

individual component, from molded plastics to

the assembly of units and controllers.

Quality Controlled from Start to Finish

Our highly trained staff and strict quality

control methods enable us to produce

products with an exceptional reputation for

reliability and efficiency, maintained over

many years. As well as full CE certification

and ISO 9001, several products have

UL/CSA (NRTL) safety approval plus ARI

Certification in the USA, ROHS compliance for

Europe, giving you the confidence of knowing our

company is the right choice when selecting air

conditioning equipment.

ALWAYS MAKE SURE THIS MANUAL REMAINS WITH THE SWC-ECM WATER HIGH-WALL UNIT. READ

THIS MANUAL BEFORE PERFORMING ANY OPERATION ON THE SWC-EC WATER HIGH-WALL UNIT.

Page 3 of 67

SK2013-SON-002-TechMnl-SWC-002

Table of Content

MODEL CODE NOMENCLATURE .......................................................................................................... 5

A. GENERAL DESCRIPTION ............................................................................................................... 6

B. TECHNICAL DATA ........................................................................................................................ 7

B.1. GENERAL SPECIFICATION .................................................................................................................................. 7

B.1.1. SWC–V–EC Series 3-Speed Specifications ..........................................................................................................7

B.2. COIL DATA ..................................................................................................................................................... 9

B.2.1. 2-pipe systems ...................................................................................................................................................9

B.3. PERFORMANCE TABLES .................................................................................................................................. 10

B.3.1. Cooling Capacity Tables – 2-pipe systems .......................................................................................................10

B.3.2. Heating Capacity Table – 2-pipe systems ........................................................................................................14

B.4. DIMENSIONAL DRAWINGS .............................................................................................................................. 18

B.5. VALVE INFORMATION .................................................................................................................................... 20

B.5.1. 2-Way Valve Body ............................................................................................................................................20

C. SERVICE AND INSTALLATION ..................................................................................................... 21

C.1. INSTALLATION OF HIGH-WALL UNIT ................................................................................................................. 21

C.1.1. Selecting a Location .........................................................................................................................................21

C.1.2. Mounting Plate Dimensions.............................................................................................................................22

C.1.3. Installing the Mounting Plate ..........................................................................................................................23

C.1.4. Drilling the Condensate Drainage Hole ............................................................................................................23

C.1.5. Installing the Hydronic Unit .............................................................................................................................24

C.1.6. Drainage Piping Works .....................................................................................................................................24

C.2. UNIT MAINTENANCES AND PREPARATIONS ........................................................................................................ 25

C.2.1. Opening and Closing Of Lift-Up Grille Cover ....................................................................................................25

C.2.2. Removing Front Cover Assembly .....................................................................................................................25

C.2.3. Air Purging .......................................................................................................................................................25

C.2.4. Wiring Connections..........................................................................................................................................25

C.3. PIPE CONNECTIONS WITH VALVE ..................................................................................................................... 26

D. CONTROL SPECIFICATIONS ........................................................................................................ 27

D.1. SK-NCSWC-001 COMPLETE FUNCTION FCU CONTROLLER ................................................................................. 27

D.1.1. Abbreviations ...................................................................................................................................................27

D.1.2. Definition of Input/Output ..............................................................................................................................27

D.1.3. Wiring Diagram SK-NCSWC-001 .......................................................................................................................28

D.1.4. Configuration Settings .....................................................................................................................................29

D.1.5. Control Logics For 2-Pipe System.....................................................................................................................31

D.1.6. Control Logics For 4-Pipe System.....................................................................................................................35

D.1.7. Auto Fan Speed ................................................................................................................................................38

D.1.8. Louver ..............................................................................................................................................................39

D.1.9. Buzzer ..............................................................................................................................................................39

D.1.10. Auto Restart .....................................................................................................................................................39

D.1.11. Operation Of Control Panel On High-Wall Unit ...............................................................................................40

D.2. LED LIGHTS .................................................................................................................................................. 41

D.2.1. LED Indication and Error Description ...............................................................................................................42

D.2.2. LED indication on Master/Slave connection ....................................................................................................43

D.3. NETWORKING SYSTEM ................................................................................................................................... 44

D.3.1. Master-Slave Network .....................................................................................................................................44

D.3.2. Master – Slave Network Setup ........................................................................................................................45

D.3.3. Master-Slave Communication Method ............................................................................................................48

D.3.4. Unit Network Wiring Scheme ..........................................................................................................................49

D.4. SK-NCSWC-002 LIMITED FUNCTION FCU CONTROLLER .................................................................................... 50

D.4.1. Definition of Input/Output ..............................................................................................................................50

D.4.2. Wiring diagram SK-NCSWC-002 .......................................................................................................................51

D.4.3. Onboard configuration ....................................................................................................................................52

Page 4 of 67

SK2013-SON-002-TechMnl-SWC-002

D.4.4. Control Logics ..................................................................................................................................................52

D.4.5. LED Indication ..................................................................................................................................................53

D.4.6. Error Description ..............................................................................................................................................53

D.5. OPEN MODBUS PROTOCOL ............................................................................................................................. 54

E. USERS INTERFACE ..................................................................................................................... 58

E.1. REMOTE CONTROL HANDSET .......................................................................................................................... 58

E.2. WIRED WALL PAD ......................................................................................................................................... 59

E.2.1. Wall Pad Display ..............................................................................................................................................59

E.2.2. Wall Pad Operation Guidelines ........................................................................................................................60

E.2.3. EC unit RPM setting .........................................................................................................................................63

E.3. SENSOR RESISTANCE R-T CONVERSION TABLE.................................................................................................... 64

E.4.

T

ROUBLESHOOTING GUIDE

.............................................................................................................................. 66

Page 5 of 67

SK2013-SON-002-TechMnl-SWC-002

Model Code Nomenclature

SWC

-

06

- V S - ECM

ECM

EC motor configuration

S

Complete function onboard PCB with

integrated group control functionality.

W

Limited function onboard PCB with

drain-pump, louver and zone control

functionality.

V

2-pipe system

04

Model. See General Specification

(section B) for cooling/heating Sizes

capacities

06

12

15

18

20

24

SWC

Hydronic high-wall C Series

Page 6 of 67

SK2013-SON-002-TechMnl-SWC-002

A. General Description

This High-Wall Unit is designed to meet and exceed demanding requirements for efficiency, quiet

operation and good looks. The sleek profile and elegantly styled cabinet complements any interior

design theme, and the microprocessor assures accurate environmental control.

Cabinet ~ the cosmetically attractive cabinet is constructed of durable flame resistant acrylonitrilebutadiene-styrene (ABS) plastic. The silver white color and rounded corners provide its

contemporary appearance.

Water Coil ~ the water coil has a large heat transfer surface and utilizes the latest technology in fin

profile. It combines an advanced technology approach with the security of a traditional tube

thickness design. The water coil is also equipped with an air vent valve and a water purge valve.

Integral Hoses ~ an integral hose is a synthetic elastomer tube, with stainless steel outer

braiding and brass connectors, which enables quick, low cost connections with no brazing.

Blower and Motor ~ the High-wall unit incorporates only specially designed and tested high

power-factor, permanent split capacitor type blower motors, allowing the tangential blower wheel to

provide optimum performance in airflow-efficiency and quiet operation.

Filters ~ washable, easy-to-remove, fine mesh air filters are standard to all High-wall models. Tabs

located on the front of the unit can be unsnapped, allowing the filter to be easily slid downward

and removed. No tools are required, nor are dismantling of any equipment.

Air Grille Distribution ~ all High-wall units are equipped with both deflector blades and

independent directional vanes, enabling supply air to be automatically distributed, and air flow and

direction customized.

Microprocessor Control ~ see D. Controls Specifications (pages 27 - 54) for complete

control specifications and details. The main design features include:

~ FCEER rating class: A/B.

~ FCCOP rating class: B/C.

~ High efficiency brushless DC motor with PID algorithmic processing in auto-mode.

~ 2-pipe, 2-pipe and booster electric heat, 2-pipe and primary electric heat, 4-pipe with 4x2

device installed.

~ Cool, Heat, Auto, Dehumidifier and Fan modes.

~ Sleep, Auto-Fan, Daily Timer, Auto-Restart with memory functions.

~ User friendly remote control handset.

~ Heat and cool temperature protections and safety cut out.

~ 2-way and 3-way on/off valve control.

~ Addressable control and error diagnostics (Master-Slave) for sub-networks of up to 32

units, with IR handset as global control interface.

~ Wired wall pad controller (optional) with 7-day programmable timer, real-time clock, network

control (global and addressable) and error diagnostics.

~ Manual control panel in cabinet.

~ Auxiliary switch for cooling and heating signal.

~ Occupancy (remote on/off) contacts / economy mode contacts.

~ Open Modbus communication protocol.

~ Local PC host control solution (optional).

Page 7 of 67

SK2013-SON-002-TechMnl-SWC-002

B. Technical Data

B.1. General Specification

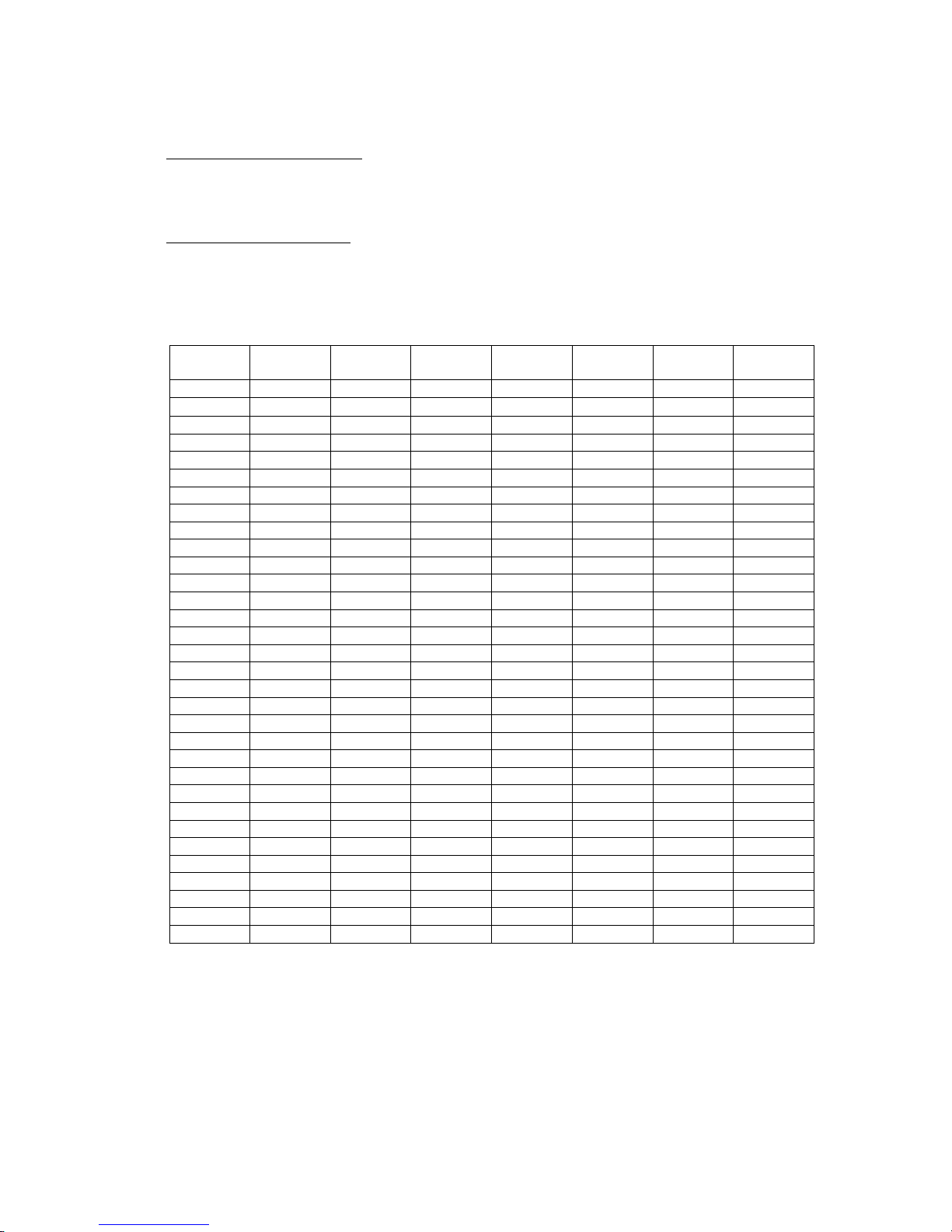

B.1.1. SWC–V–EC Series 3-Speed Specifications

Product range: SWC-ECM Hydronic High Wall with EC Motor

SWC-V~-ECM Hydronic High Wall 2-pipe with EC Motor

SWC-[Size]-V~-ECM

04

06

12

15

Unit Configuration

Configuration

2-pipe

Number Of Fan Blowers

Single

Power Supply

(V/Ph/H

z)

230/1/50

220/1/60

Operation Control

~S: Complete function onboard PCB with integrated group control functionality, incl. 1 pc return air sensor

and 2 pcs temperature sensors.

~W: Limited function onboard PCB with drain-pump, louver and zone control functionality, incl. 1 pc coil

temperature sensors.

Performance Data

Air

Total Air Flowe

H

m3/hr

370

500

500

645

M

290

370

370

445

L

220

290

290

370

Cooling

Cooling Capacitye

H

kW

1.31

2.17

2.59

3.16

M

1.09

1.71

2.03

2.36

L

0.88

1.43

1.68

2.03

Sensible Cooling

Capacitye

H

0.97

1.59

1.88

2.31 M 0.80

1.25

1.46

1.71

L

0.64

1.04

1.2

1.46

FCEERe

Rating

142

175

207

192

Class B B A A

Heating

Heating Capacitye

H

kW

1.60

2.64

3.12

3.83 M 1.33

2.08

2.44

2.83

L

1.06

1.71

1.98

2.44

Max. Electric Heater Capacity

0.6

1.2

FCCOPe

Rating

172

211

246

232

Class B B B B

Sound

Sound PressureLevel ( Outlet )

dB(A)

27/24/21

35/27/24

35/27/24

41/32/27

Sound Power Level ( Outlet )e

38/35/32

46/38/35

46/38/35

52/43/38

Electrical

Fan Motor Powere

H W 10

13

13

20

M 8 10

10

13

L

6 8 8

10

Fan Motor Apparent Power @ H

20

32

32

50

Fan Motor Running Current @ H

A

0.08

0.142

0.142

0.182

Hydraulic

Cooling Water Flow Rate

H

L/h

225

370

446

543

M

187

294

348

406

L

150

244

288

348

Cooling Pressure Drope

H

kPa

10.1

12

10

14.1 M 7.4

8.06

6.62

8.58

L

5.1

5.9

4.8

6.62

Heating Water Flow Rate

@H/M/L

L/h

Same as "Cooling Water Flow Rate"

Heating Pressure Drope

H

kPa

9 9 11

12 M 4.5

4.5 7 7

L

3.5

3.5 4 5

Water Content

L

0.045

0.0789

0.124

0.124

Construction

and Packing Data

Water

Connections

Type

Socket (Threaded Female)

In

mm [in]

12.70 [1/2]

Out

Condensate Drainage Connection

16 [0.63]

Dimensions

L

mm

876

W

228

H

300

Net Weight

Kg

11

12

13

13

1."e" refers to technical information listed on the Eurovent website. Eurovent testing

conditions:

a. Cooling mode (2-pipe):

b. Heating mode (2-pipe):

- Return air temperature: 27C DB/ 19C WB.

- Return air temperature: 20C.

- Inlet/ outlet water temperature: 7C/ 12C.

- Inlet water temperature: 50C.

- Water flow-rate: variable.

- Water flow-rate: same as 2-pipe

cooling.

Page 8 of 67

SK2013-SON-002-TechMnl-SWC-002

Product range: SWC-ECM Hydronic High Wall with EC Motor

SWC-V~-ECM Hydronic High Wall 2-pipe with EC Motor

SWC-[Size]-V~-ECM

18

20

24

Unit Configuration

Configuration

2-pipe

Number Of Fan Blowers

Single

Power Supply

(V/Ph/Hz)

230/1/50

220/1/60

Operation Control

~S: Complete function onboard PCB with integrated group control functionality, incl. 1 pc

return air sensor and 2 pcs temperature sensors.

~W: Limited function onboard PCB with drain-pump, louver and zone control functionality,

incl. 1 pc coil temperature sensors.

Performance Data

Air

Total Air Flowe

H

m3/hr

876

980

1240

M

740

760

1080

L

570

600

760

Cooling

Cooling Capacitye

H

kW

4.38

5.19

6.25

M

3.84

4.23

5.61 L 3.12

3.50

4.23

Sensible Cooling Capacitye

H

3.18

3.73

4.52

M

2.78

3.03

4.04

L

2.24

2.49

3.03

FCEERe

Rating

213

180

126

Class A B

B

Heating

Heating Capacitye

H

kW

5.25

6.14

7.44

M

4.58

4.97

6.65 L 3.68

4.09

4.97

Max. Electric Heater Capacity

1.6

FCCOPe

Rating

255

212

153

Class B B

C

Soun

d

Sound PressureLevel ( Outlet )

dB(A)

46/40/34

41/35/30

48/45/35

Sound Power Level ( Outlet )e

57/51/45

52/46/41

59/56/46

Electrical

Fan Motor Powere

H

W

30

45

83

M

20

24

60

L

13

18

24

Fan Motor Apparent Power @ H

83

90

200

Fan Motor Running Current @ H

A

0.272

0.4

0.75

Hydraulic

Cooling Water Flow Rate

H

L/h

752

889

1072

M

658

727

961

L

536

601

727

Cooling Pressure Drope

H

kPa

19.4

19.8

27.2 M 15.5

14

22.6

L

10.8

10.1

14

Heating Water Flow Rate

@H/M/L

L/h

Same as "Cooling Water Flow Rate"

Heating Pressure Drope

H

kPa

16

16

25 M 13

12

19 L 8 8 13

Water Content

L

0.192

0.252

0.252

Construction

and Packing Data

Water

Connections

Type

Socket (Threaded Female)

In

mm [in]

12.70 [1/2]

Out

Condensate Drainage Connection

16 [0.63]

Dimensions

L

mm

876

1063

W

228

240

H

300

310

Net Weight

Kg

14

16

16

1."e" refers to technical information listed on the Eurovent website. Eurovent testing conditions:

a. Cooling mode (2-pipe):

b. Heating mode (2-pipe):

- Return air temperature: 27C DB/ 19C WB.

- Return air temperature: 20C.

- Inlet/ outlet water temperature: 7C/ 12C.

- Inlet water temperature: 50C.

- Water flow-rate: variable.

- Water flow-rate: same as 2-pipe cooling.

Page 9 of 67

SK2013-SON-002-TechMnl-SWC-002

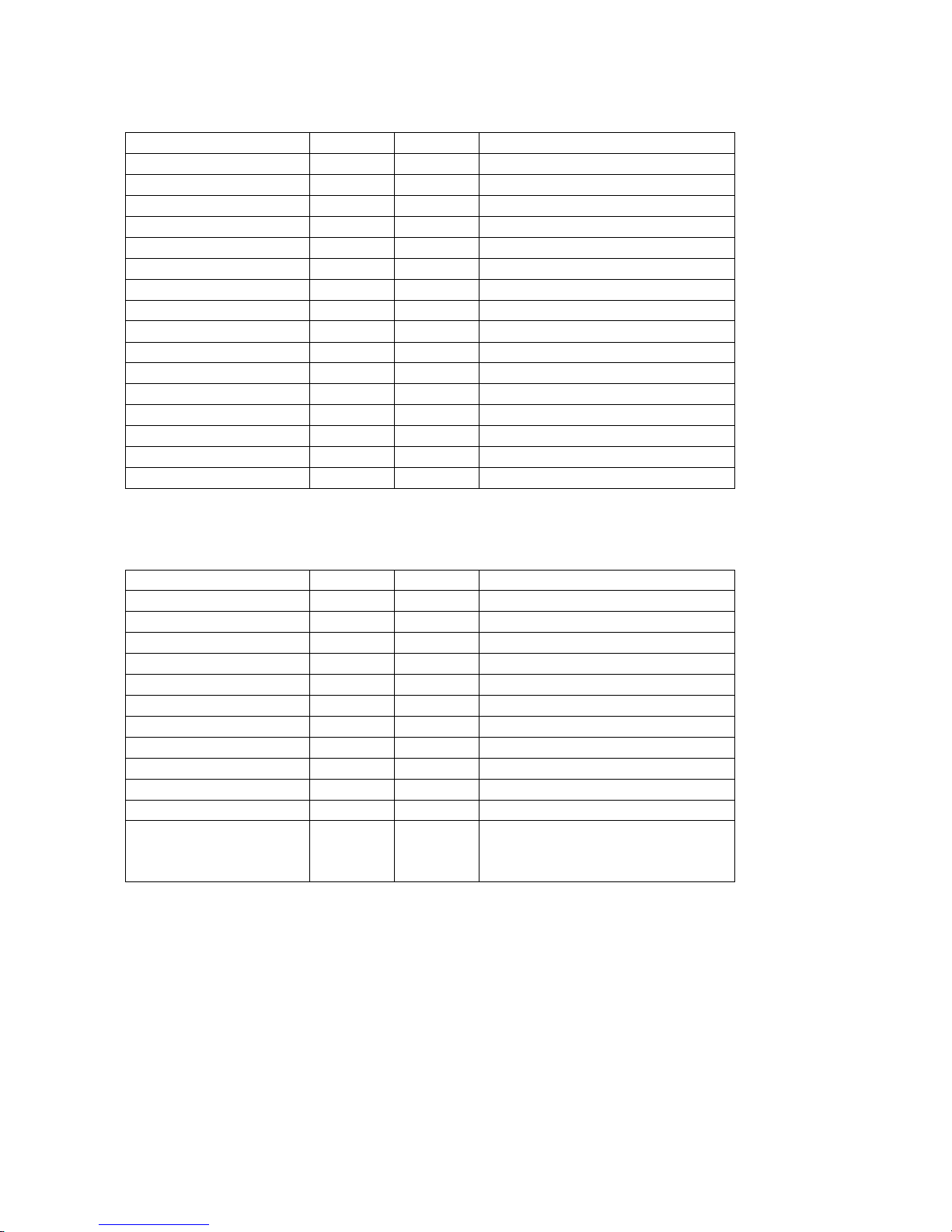

B.2. Coil Data

B.2.1. 2-pipe systems

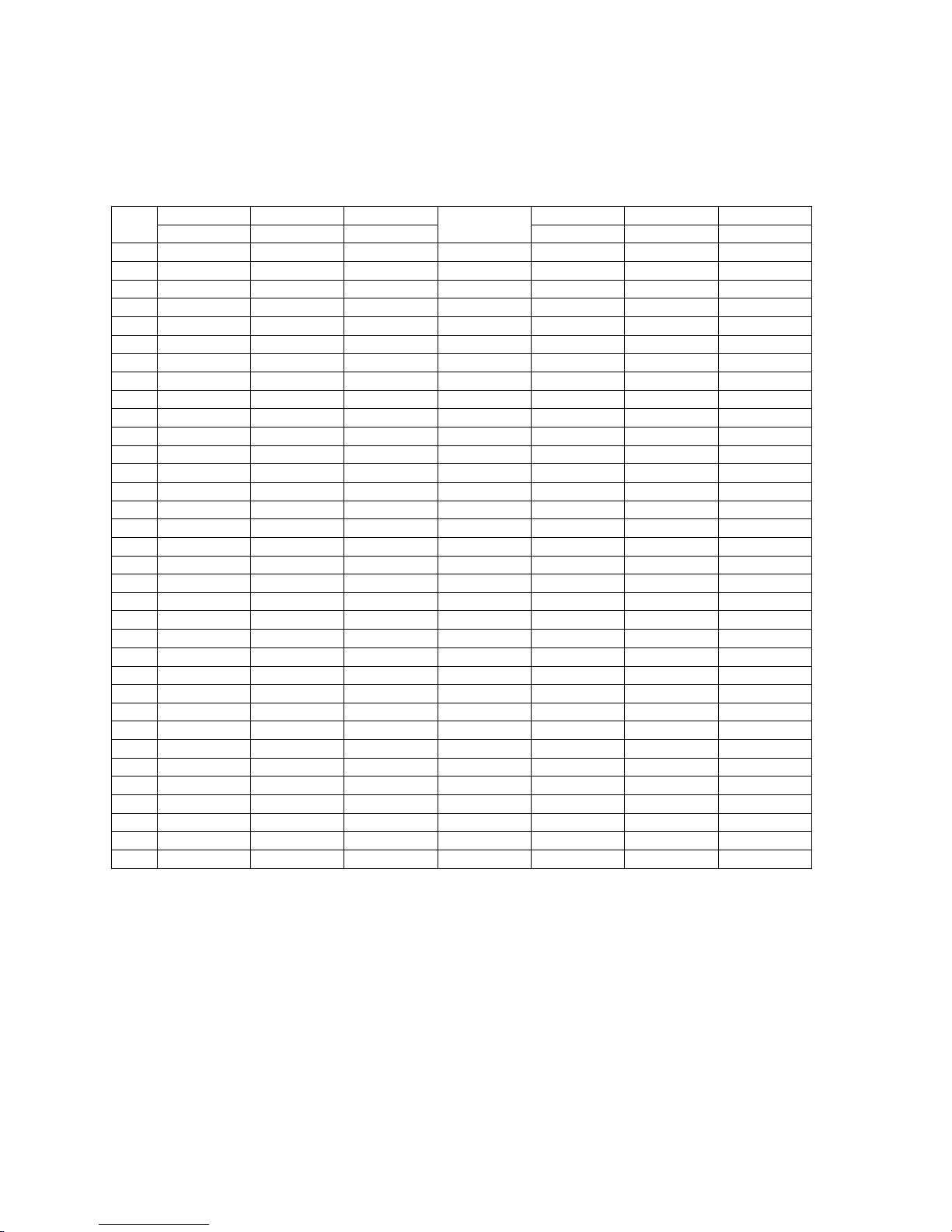

Model

Fin Height

(mm.)

Fin Length

(mm.)

Fins per Inch

No. of Rows

No. of

Copper

No. of

Circuits

Tube

Diameter

(mm)

SWC-04

230

680

19.5

2 8 2

7

SWC-06

357

680 2 20 4 7

SWC-12

357

680 2 26 5 7

SWC-15

357

680 2 26 5 7

SWC-18

357

680 2 34 5 7

SWC-20

378

845 2 36 6 7

SWC-24

378

845 2 36 6 7

Page 10 of 67

SK2013-SON-002-TechMnl-SWC-002

B.3. Performance Tables

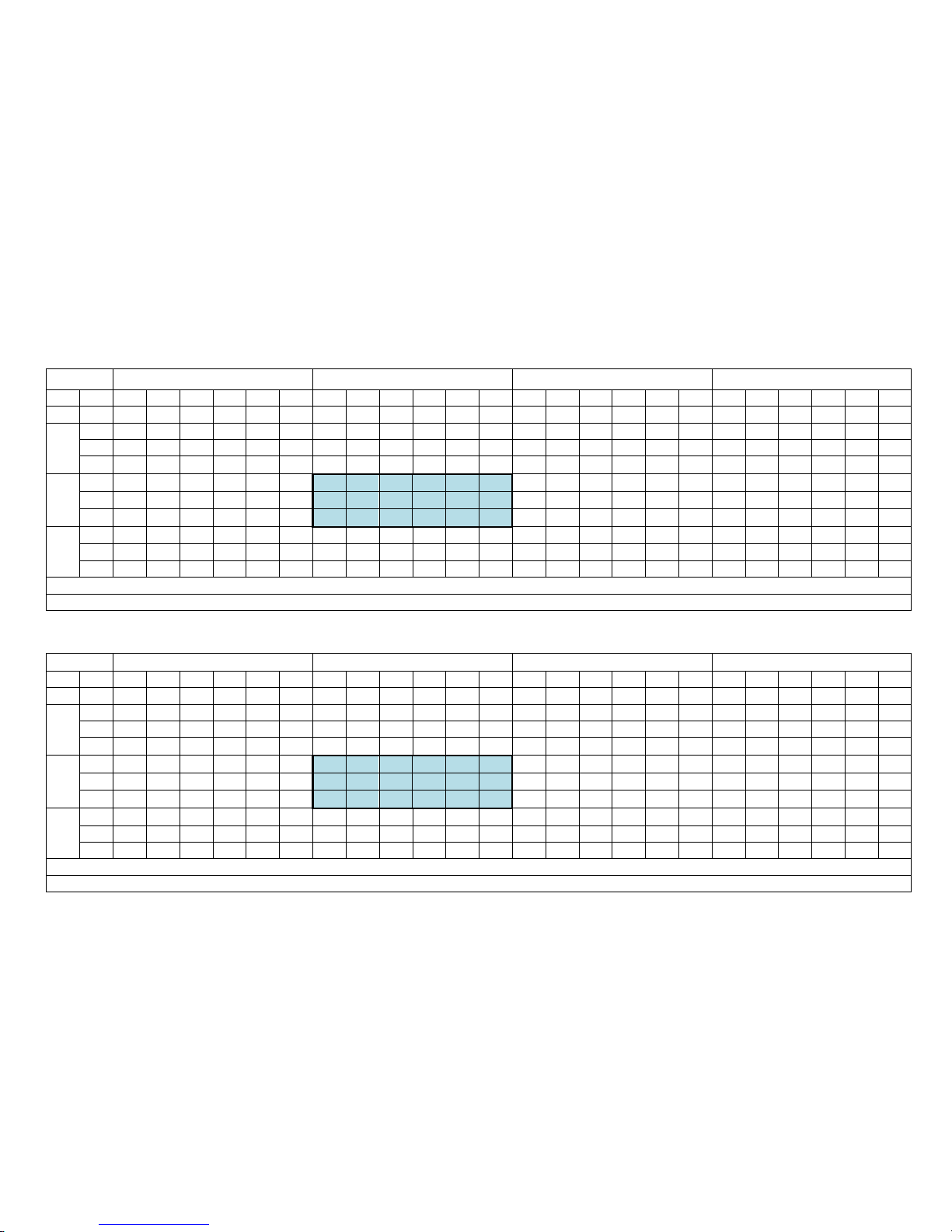

B.3.1. Cooling Capacity Tables – 2-pipe systems

SWC-04-V-ECM

TAI DB24°C-WB17.4°C

TAI DB27°C-WB19°C

TAI DB27°C-WB19.5°C

TAI DB28°C-WB21°C

Twi

qa

Pf

Pfs

Tad

Taw

dPw

Qw

Pf

Pfs

Tad

Taw

dPw

Qw

Pf

Pfs

Tad

Taw

dPw

Qw

Pf

Pfs

Tad

Taw

dPw

Qw

°C

m3/h

kW

kW

°C

°C

kPa

l/s

kW

kW

°C

°C

kPa

l/s

kW

kW

°C

°C

kPa

l/s

kW

kW

°C

°C

kPa

l/s 5 370

1.3

0.913

16.1

13.3

10.1

0.0618

1.58

1.09

17.5

14.2

14.1

0.0754

1.68

1.09

17.5

14.5

15.6

0.08

1.97

1.15

18

15.4

20.7

0.094

290

1.08

0.757

15.7

13

7.36

0.0514

1.31

0.902

17

13.9

10.3

0.0626

1.39

0.902

17

14.1

11.4

0.0664

1.64

0.95

17.4

15

15

0.078

220

0.867

0.605

15.1

12.7

5.07

0.0413

1.05

0.72

16.3

13.4

7.06

0.056

1.12

0.721

16.3

13.7

7.8

0.0532

1.31

0.759

16.7

14.5

10.2

0.0624

7

370

1.02

0.793

17.2

14.2

6.6

0.0487

1.31

0.971

18.6

15.1

10.1

0.0625

1.41

0.0971

18.6

15.4

11.4

0.0671

1.7

1.03

19

16.2

15.8

0.0813

290

0.853

0.658

16.8

14

4.86

0.0407

1.09

0.804

18.1

14.8

7.4

0.052

1.17

0.804

18.1

15.1

8.33

0.0559

1.42

0.853

18.5

15.9

11.5

0.0675

220

0.687

0.526

16.2

13.7

2.04

0.0328

0.877

0.642

17.4

14.5

5.1

0.0418

0.94

0.642

17.4

14.7

5.73

0.0448

1.13

0.681

17.8

15.5

7.89

0.0541

9

370

0.721

0.67

18.2

15.2

3.6

0.0344

1.02

0.85

19.6

16

6.44

0.0485

1.11

0.851

19.6

16.3

7.54

0.0532

1.41

0.91

20.1

17.1

11.3

0.0675

290

0.604

0.556

17.9

15

1.7

0.0288

0.849

0.705

19.2

15.8

4.75

0.0405

0.93

0.705

19.2

16

5.54

0.0444

1.18

0.754

19.6

16.8

8.28

0.0562

220

0.49

0.445

17.4

14.8

1.37

0.0234

0.684

0.563

18.6

15.5

3.3

0.0327

0.749

0.563

18.6

15.7

3.84

0.0357

0.945

0.603

19

16.5

5.7

0.0451

Pf: total cooling capacity Tal: in flow air temperature dpw: pressure drop standard coil Twi: entering water temperature, water temperature arise 5°C.

Qw: fluid flow rate in heat exchanger Qa: air flow Pfs: sensible cooling capacity Tad: discharge air dry temperature Taw: discharge air wet temperature

Page 11 of 67

SK2013-SON-002-TechMnl-SWC-002

SWC-06-V-ECM

TAI DB24°C-WB17.4°C

TAI DB27°C-WB19°C

TAI DB27°C-WB19.5°C

TAI DB28°C-WB21°C

Twi

qa

Pf

Pfs

Tad

Taw

dPw

Qw

Pf

Pfs

Tad

Taw

dPw

Qw

Pf

Pfs

Tad

Taw

dPw

Qw

Pf

Pfs

Tad

Taw

dPw

Qw

°C

m3/h

kW

kW

°C

°C

kPa

l/s

kW

kW

°C

°C

kPa

l/s

kW

kW

°C

°C

kPa

l/s

kW

kW

°C

°C

kPa

l/s 5 500

2.14

1.5

14.4

12.3

12

0.102

2.61

1.79

15.4

13

16.8

0.124

2.77

1.79

15.4

13.2

18.6

0.132

3.25

1.88

15.8

13.9

24.5

0.155

370

1.71

1.19

13.7

11.9

8.14

0.0814

2.07

1.42

14.7

12.5

11.3

0.0989

2.2

1.42

14.7

12.7

12.5

0.105

2.58

1.49

15

13.4

16.4

0.123

290

1.41

0.978

13.2

11.5

5.87

0.0672

1.71

1.16

14.1

12.1

8.14

0.0814

1.81

1.16

14.1

12.3

8.98

0.0862

2.12

1.22

14.4

12.9

11.7

0.101 7 500

1.69

1.3

15.6

13.4

7.9

0.0808

2.17

1.59

16.7

14.1

12

0.103

2.33

1.59

16.7

14.3

13.6

0.111

2.81

1.69

17.1

15

18.8

0.134

370

1.36

1.03

15.1

13.1

5.41

0.0646

1.71

1.25

16

13.7

8.06

0.0817

1.85

1.26

16

13.9

9.2

0.0884

2.23

1.34

16.4

14.5

12.7

0.107

290

1.12

0.85

14.6

12.8

3.93

0.0535

1.43

1.04

15.5

13.4

5.9

0.068

1.53

1.04

15.5

13.6

6.63

0.0729

1.84

1.1

15.8

14.1

9.09

0.0877 9 500

1.2

1.1

16.9

14.6

4.33

0.0573

1.69

1.4

18

15.2

7.72

0.0805

1.85

1.4

18

15.5

9.02

0.0882

2.34

1.5

18.3

16.1

13.5

0.112

370

0.967

0.874

16.5

14.4

1.82

0.0461

1.35

1.11

17.4

14.9

5.29

0.0644

1.48

1.11

17.4

15.1

6.16

0.0705

1.86

1.19

17.7

15.7

9.16

0.0889

290

0.805

0.719

16.1

14.2

1.52

0.0384

1.12

0.908

16.9

14.7

3.85

0.0534

1.22

0.91

16.9

14.8

4.47

0.0583

1.54

0.973

17.2

15.4

6.6

0.0734

Pf: total cooling capacity Tal: in flow air temperature dpw: pressure drop standard coil Twi: entering water temperature, water temperature arise 5°C.

Qw: fluid flow rate in heat exchanger Qa: air flow Pfs: sensible cooling capacity Tad: discharge air dry temperature Taw: discharge air wet temperature

SWC-12-V-ECM

TAI DB24°C-WB17.4°C

TAI DB27°C-WB19°C

TAI DB27°C-WB19.5°C

TAI DB28°C-WB21°C

Twi

qa

Pf

Pfs

Tad

Taw

dPw

Qw

Pf

Pfs

Tad

Taw

dPw

Qw

Pf

Pfs

Tad

Taw

dPw

Qw

Pf

Pfs

Tad

Taw

dPw

Qw

°C

m3/h

kW

kW

°C

°C

kPa

l/s

kW

kW

°C

°C

kPa

l/s

kW

kW

°C

°C

kPa

l/s

kW

kW

°C

°C

kPa

l/s 5 500

2.56

1.78

12.6

11.2

9.98

0.122

3.1

2.11

13.3

11.7

13.9

0.148

3.29

2.11

13.3

11.8

15.3

0.157

3.85

2.22

13.6

12.4

20.1

0.183

370

2.02

1.4

12

10.7

6.69

0.0964

2.45

1.66

12.6

11.2

9.24

0.117

2.59

1.66

12.6

11.3

10.2

0.123

3.03

1.75

12.8

11.8

13.3

0.144

290

1.66

1.14

11.4

10.4

4.77

0.079 2 1.35

12

10.7

6.56

0.0953

2.12

1.35

12

10.9

7.22

0.101

2.47

1.42

12.2

11.3

9.39

0.118

7

500

2.04

1.54

14.1

12.6

6.65

0.0971

2.59

1.88

14.8

13

10

0.124

2.78

1.88

14.8

13.2

11.3

0.132

3.34 2 15.1

13.7

15.5

0.159

370

1.62

1.21

13.5

12.2

4.5

0.771

2.03

1.46

14.1

12.6

6.62

0.0968

2.19

1.48

14.2

12.7

7.54

0.105

2.63

1.57

14.4

13.2

10.3

0.126

290

1.33

0.991

13.1

11.9 2 0.0634

1.68

1.2

13.6

12.2

4.8

0.0801

1.8

1.21

13.6

12.4

5.38

0.0857

2.15

1.28

13.8

12.8

7.32

0.103

9

500

1.46

1.3

15.6

14

3.71

0.0695

2.03

1.65

16.3

14.4

6.51

0.0968

2.22

1.65

16.3

14.6

7.58

0.106

2.79

1.77

16.6

15

11.2

0.133

370

1.16

1.03

15.2

13.7

1.66

0.0555

1.61

1.3

15.7

14.1

4.4

0.0769

1.76

1.3

15.7

14.2

5.11

0.84

2.21

1.39

15.9

14.6

7.52

0.105

290

0.963

0.837

14.8

13.5

1.37

0.0459

1.33

1.06

15.3

13.8

1.9

0.0633

1.45

1.06

15.2

13.9

3.67

0.069

1.81

1.13

15.4

14.2

5.36

0.083

Pf: total cooling capacity Tal: in flow air temperature dpw: pressure drop standard coil Twi: entering water temperature, water temperature arise 5°C.

Qw: fluid flow rate in heat exchanger Qa: air flow Pfs: sensible cooling capacity Tad: discharge air dry temperature Taw: discharge air wet temperature

Page 12 of 67

SK2013-SON-002-TechMnl-SWC-002

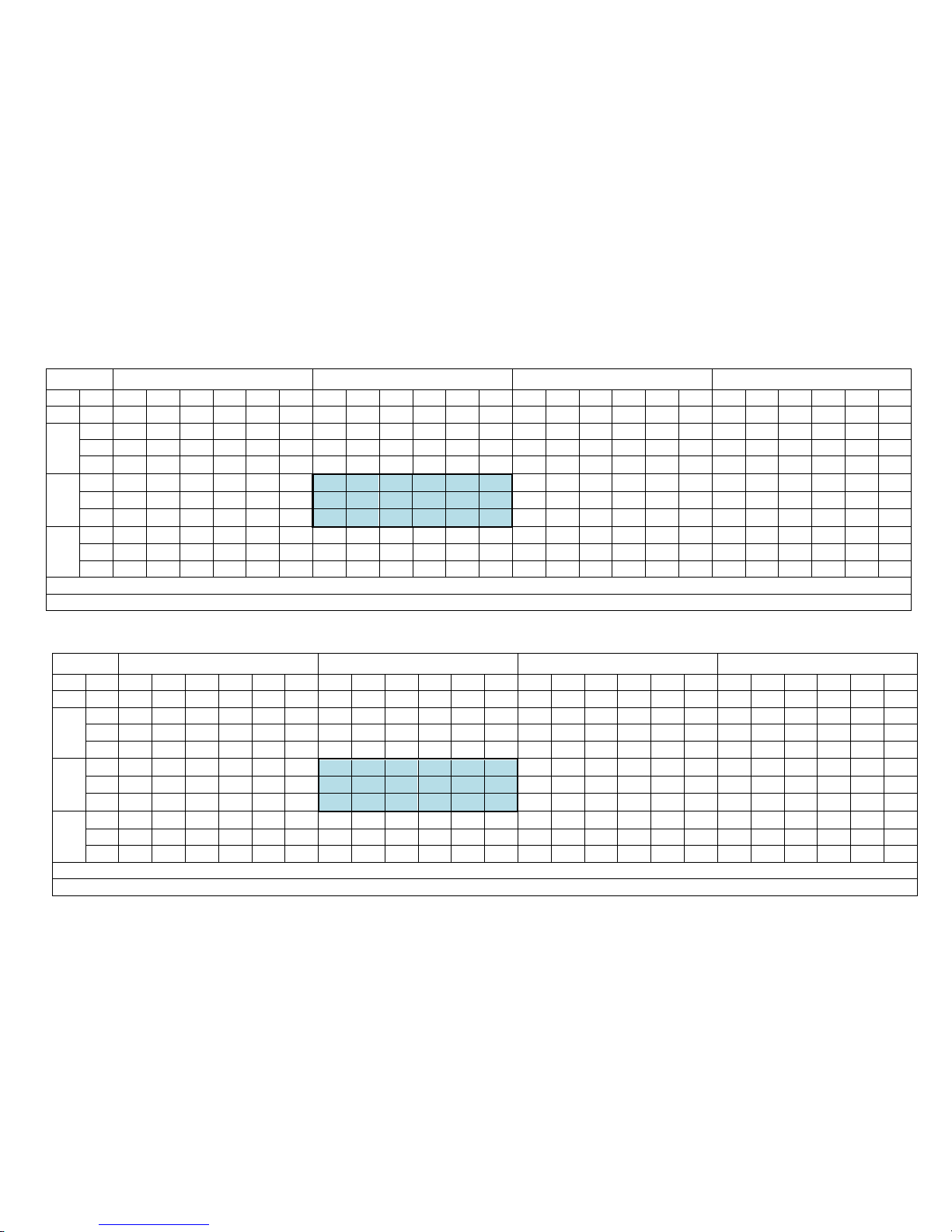

SWC-15-V-ECM

TAI DB24°C-WB17.4°C

TAI DB27°C-WB19°C

TAI DB27°C-WB19.5°C

TAI DB28°C-WB21°C

Twi

qa

Pf

Pfs

Tad

Taw

dPw

Qw

Pf

Pfs

Tad

Taw

dPw

Qw

Pf

Pfs

Tad

Taw

dPw

Qw

Pf

Pfs

Tad

Taw

dPw

Qw

°C

m3/h

kW

kW

°C

°C

kPa

l/s

kW

kW

°C

°C

kPa

l/s

kW

kW

°C

°C

kPa

l/s

kW

kW

°C

°C

kPa

l/s 5 645

3.12

2.18

13.2

11.5

14

0.149

3.79

2.59

14

12.1

19.6

0.181

4.02

2.59

14

12.3

21.6

0.192

4.71

2.73

14.3

12.9

28.5

0.225

445

2.34

1.62

12.4

11

8.54

0.111

2.83

1.92

13.1

11.5

11.8

0.135 3 1.92

13.1

11.6

13.1

0.143

3.51

2.02

13.3

12.1

17.1

0.167

370

2.02

1.4

12

10.7

6.69

0.0964

2.45

1.66

12.6

11.2

9.24

0.117

2.59

1.66

12.6

11.3

10.2

0.123

3.03

1.75

12.8

11.8

13.3

0.144

7

645

2.47

1.89

14.6

12.9

9.26

0.118

3.16

2.31

15.4

13.4

14.1

0.151

3.39

2.31

15.4

13.6

15.9

0.161

4.08

2.45

15.7

14.1

21.9

0.195

445

1.86

1.41

13.9

12.4

5.71

0.0888

2.36

1.71

14.6

12.9

8.58

0.113

2.53

1.72

14.6

13

9.65

0.121

3.05

1.82

14.8

13.5

13.2

0.145

370

1.62

1.21

13.5

12.2

4.5

0.0771

2.03

1.46

14.1

12.6

6.62

0.0968

2.19

1.48

14.2

12.7

7.54

0.105

2.63

1.57

14.4

13.2

10.3

0.126

9

645

1.76

1.6

16.1

14.2

5.1

0.0839

2.46

2.02

16.8

14.7

9.06

0.118

2.7

2.02

16.8

14.9

10.6

0.129

3.41

2.17

17.1

15.4

15.8

0.162

445

1.34

1.19

15.5

13.9

1.9

0.0637

1.86

1.5

16.1

14.3

5.6

0.0886

2.03

1.5

16.1

14.4

6.5

0.0968

2.55

1.61

16.3

14.9

9.62

0.122

370

1.16

1.03

15.2

13.7

1.66

0.0555

1.61

1.3

15.7

14.1

4.4

0.0769

1.76

1.3

15.7

14.2

5.11

0.084

2.21

1.39

15.9

14.6

7.52

0.105

Pf: total cooling capacity Tal: in flow air temperature dpw: pressure drop standard coil Twi: entering water temperature, water temperature arise 5°C.

Qw: fluid flow rate in heat exchanger Qa: air flow Pfs: sensible cooling capacity Tad: discharge air dry temperature Taw: discharge air wet temperature

SWC-18-V-ECM

TAI DB24°C-WB17.4°C

TAI DB27°C-WB19°C

TAI DB27°C-WB19.5°C

TAI DB28°C-WB21°C

Twi

qa

Pf

Pfs

Tad

Taw

dPw

Qw

Pf

Pfs

Tad

Taw

dPw

Qw

Pf

Pfs

Tad

Taw

dPw

Qw

Pf

Pfs

Tad

Taw

dPw

Qw

°C

m3/h

kW

kW

°C

°C

kPa

l/s

kW

kW

°C

°C

kPa

l/s

kW

kW

°C

°C

kPa

l/s

kW

kW

°C

°C

kPa

l/s 5 876

4.33 3 13

11.4

19.3

0.206

5.25

3.57

13.8

12

26.9

0.25

5.56

3.57

13.8

12.2

29.7

0.265

6.51

3.76

14.1

12.7

39

0.31

740

3.79

2.62

12.6

11.2

15.4

0.181

4.59

3.11

13.4

11.7

21.3

0.219

4.86

3.12

13.4

11.9

23.5

0.232

5.68

3.28

13.7

12.4

30.8

0.271

570

3.08

2.12

12.1

10.8

10.8

0.147

3.72

2.51

12.7

11.2

14.9

0.177

3.94

2.51

12.7

11.4

16.4

0.188

4.6

2.65

13

11.9

21.4

0.219

7

876

3.45

2.61

14.4

12.7

12.9

0.164

4.38

3.18

15.2

13.2

19.4

0.209

4.7

3.18

15.2

13.4

21.9

0.224

5.65

3.38

15.5

14

30.1

0.27

740

3.03

2.28

14

12.5

10.3

0.144

3.84

2.78

14.9

13

15.5

0.183

4.11

2.78

14.9

13.2

17.4

0.196

4.94

2.95

15.1

13.7

23.9

0.236

570

2.47

1.84

13.6

12.2

7.26

0.118

3.12

2.24

143

12.6

10.8

0.149

3.34

2.24

14.3

12.8

12.2

0.159 4 2.38

14.5

13.2

16.6

0.191

9

876

2.47

2.21

15.9

14.1

7.18

0.118

3.44

2.79

16.7

14.6

12.6

0.164

3.76

2.79

16.7

14.7

14.7

0.179

4.73

2.99

17

15.2

21.8

0.226

740

2.18

1.93

15.7

14

5.79

0.104

3.02

2.44

16.4

14.4

10.1

0.144

3.3

2.44

16.4

14.5

11.7

0.157

4.14

2.61

16.6

15

17.3

0.198

570

1.78

1.56

15.2

13.7

4.13

0.0852

2.46

1.97

15.8

14.1

7.12

0.117

2.68

1.97

15.8

14.2

8.26

0.128

3.36

2.11

16

14.6

12.1

0.16

Pf: total cooling capacity Tal: in flow air temperature dpw: pressure drop standard coil Twi: entering water temperature, water temperature arise 5°C.

Qw: fluid flow rate in heat exchanger Qa: air flow Pfs: sensible cooling capacity Tad: discharge air dry temperature Taw: discharge air wet temperature

Page 13 of 67

SK2013-SON-002-TechMnl-SWC-002

SWC-20-V-ECM

TAI DB24°C-WB17.4°C

TAI DB27°C-WB19°C

TAI DB27°C-WB19.5°C

TAI DB28°C-WB21°C

Twi

qa

Pf

Pfs

Tad

Taw

dPw

Qw

Pf

Pfs

Tad

Taw

dPw

Qw

Pf

Pfs

Tad

Taw

dPw

Qw

Pf

Pfs

Tad

Taw

dPw

Qw

°C

m3/h

kW

kW

°C

°C

kPa

l/s

kW

kW

°C

°C

kPa

l/s

kW

kW

°C

°C

kPa

l/s

kW

kW

°C

°C

kPa

l/s 5 980

5.13

3.53

12.5

11

19.7

0.244

6.19

4.18

13.2

11.5

27.2

0.295

6.55

4.19

13.2

11.7

30

0.312

7.65

4.41

13.5

12.2

39.3

0.365

760

4.18

2.86

11.9

10.7

13.9

0.199

5.04

3.39

12.6

11.1

19.1

0.24

5.33

3.39

12.6

11.3

21

0.254

6.21

3.57

12.8

11.7

27.4

0.296

600

3.46

2.36

11.4

10.3

10

0.165

4.16

2.79

12

10.7

13.8

0.198

4.39

2.79

12

10.8

15.1

0.209

5.12

2.94

12.2

11.3

19.7

0.244

7

980

4.1

3.07

14

12.4

13.2

0.196

5.19

3.73

14.7

12.9

19.8

0.247

5.55

3.74

14.7

13

22.3

0.265

6.66

3.96

14.9

13.5

30.5

0.318

760

3.36

2.49

13.5

12.1

9.4

0.16

4.23

3.03

14.1

12.5

14

0.202

4.53

3.03

14.1

12.7

15.7

0.216

5.42

3.21

14.3

13.1

21.4

0.258

600

2.78

2.06

13

11.8

6.84

0.133

3.5

2.49

13.6

12.2

10.1

0.167

3.74

2.5

13.6

12.3

11.3

0.178

4.47

2.64

13.8

12.7

15.4

0.213

9

980

2.97

2.6

15.5

13.9

7.53

0.142

4.1

3.28

16.2

14.3

13

0.195

4.47

3.28

16.2

14.4

15.1

0.213

5.59

3.51

16.4

14.9

22.2

0.267

760

2.44

2.11

15.1

13.6

5.4

0.117

3.35

2.66

15.7

14

9.24

0.16

3.65

2.66

15.7

14.1

10.7

0.174

4.56

2.85

15.9

14.5

15.7

0.218

600

2.04

1.74

14.7

13.4

3.97

0.0972

2.78

2.19

15.2

13.7

6.7

0.133

3.03

2.19

15.2

13.8

7.77

0.144

3.77

2.35

15.4

14.2

11.3

0.18

Pf: total cooling capacity Tal: in flow air temperature dpw: pressure drop standard coil Twi: entering water temperature, water temperature arise 5°C.

Qw: fluid flow rate in heat exchanger Qa: air flow Pfs: sensible cooling capacity Tad: discharge air dry temperature Taw: discharge air wet temperature

SWC-24-V-ECM

TAI DB24°C-WB17.4°C

TAI DB27°C-WB19°C

TAI DB27°C-WB19.5°C

TAI DB28°C-WB21°C

Twi

qa

Pf

Pfs

Tad

Taw

dPw

Qw

Pf

Pfs

Tad

Taw

dPw

Qw

Pf

Pfs

Tad

Taw

dPw

Qw

Pf

Pfs

Tad

Taw

dPw

Qw

°C

m3/h

kW

kW

°C

°C

kPa

l/s

kW

kW

°C

°C

kPa

l/s

kW

kW

°C

°C

kPa

l/s

kW

kW

°C

°C

kPa

l/s 5 1240

6.17

4.27

13

11.4

27.1

0.294

7.47

5.06

13.8

11.9

37.7

0.356

7.91

5.07

13.8

12.1

41.6

0.377

9.24

5.33

14.1

12.7

54.6

0.44

1080

5.54

3.82

12.7

11.2

22.5

0.264

6.69

4.53

13.4

11.7

31.2

0.319

7.09

4.53

13.5

11.9

34.4

0.338

8.28

4.77

13.7

12.4

45.1

0.395

760

4.18

2.86

11.9

10.7

13.9

0.199

5.04

3.39

12.6

11.1

19.1

0.24

5.33

3.39

12.6

11.3

21

0.254

6.21

3.57

12.8

11.7

27.4

0.296

7

1240

4.93

3.71

14.4

12.7

18.1

0.235

6.25

4.52

15.2

13.2

27.2

0.298

6.69

4.52

15.2

13.4

30.7

0.319

8.04

4.79

15.5

13.9

42.2

0.383

1080

4.43

3.32

14.2

12.5

15.1

0.211

5.61

4.04

14.9

13

22.6

0.267 6 4.05

14.9

13.2

25.5

0.286

7.21

4.29

15.2

13.7

34.9

0.344

760

3.36

2.49

13.5

12.1

9.4

0.16

4.23

3.03

14.1

12.5

14

0.202

4.53

3.03

14.1

12.7

15.7

0.216

5.42

3.21

14.3

13.1

21.4

0.258

9

1240

3.55

3.14

15.9

14.1

10.2

0.169

4.91

3.96

16.7

14.5

17.8

0.234

5.36

3.97

16.7

14.7

20.7

0.256

6.73

4.24

16.9

15.2

30.7

0.321

1080

3.2

2.81

15.7

14

8.54

0.153

4.42

3.55

16.4

14.4

14.8

0.211

4.82

3.55

16.4

14.5

17.2

0.23

6.04

3.8

16.6

15

25.4

0.288

760

2.44

2.11

15.1

13.6

5.4

0.117

3.35

2.66

15.7

14

9.24

0.16

3.65

2.66

15.7

14.1

10.7

0.174

4.56

2.85

15.9

14.5

15.7

0.218

Pf: total cooling capacity Tal: in flow air temperature dpw: pressure drop standard coil Twi: entering water temperature, water temperature arise 5°C.

Qw: fluid flow rate in heat exchanger Qa: air flow Pfs: sensible cooling capacity Tad: discharge air dry temperature Taw: discharge air wet temperature

Page 14 of 67

SK2013-SON-002-TechMnl-SWC-002

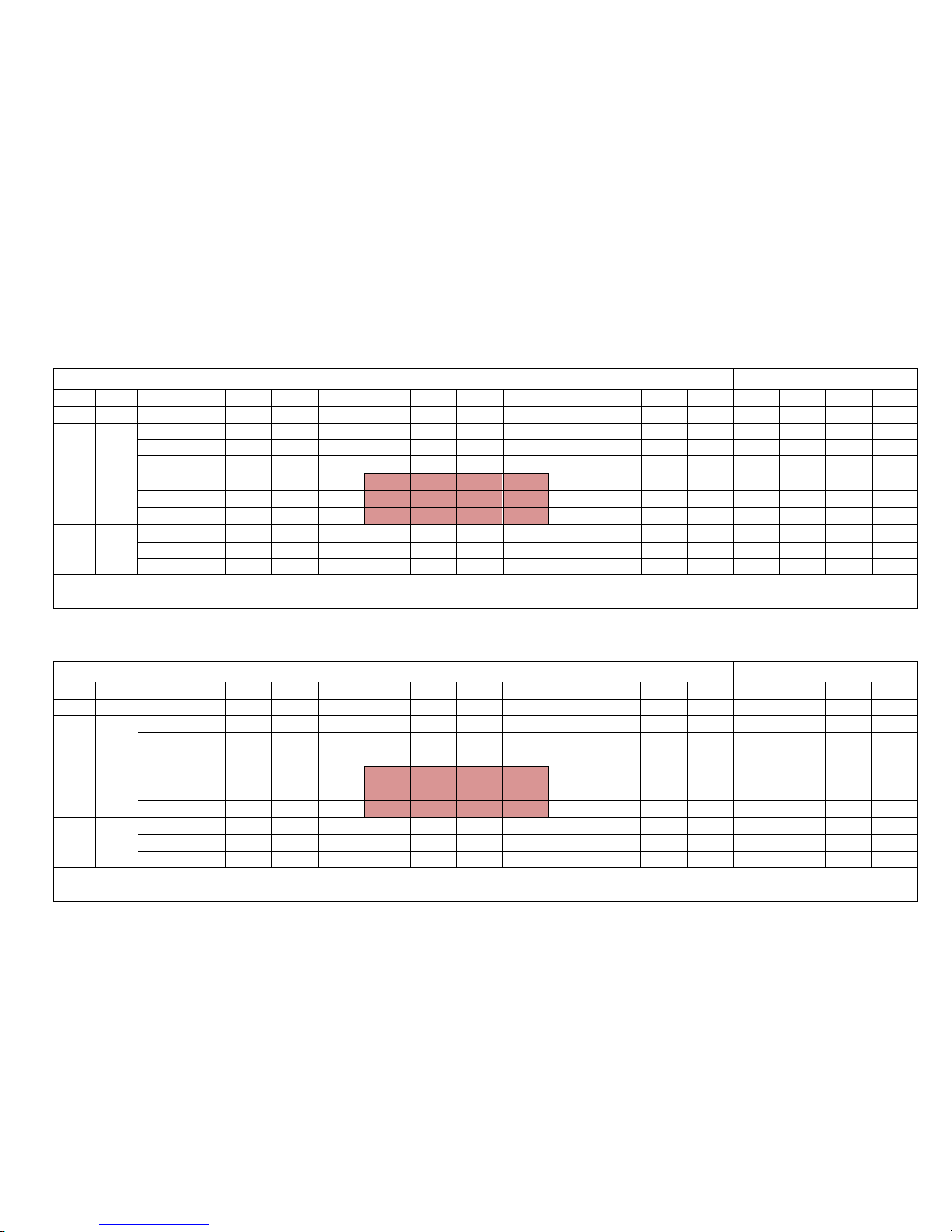

B.3.2. Heating Capacity Table – 2-pipe systems

SWC-04-V-ECM

TAI 18°C

TAI 20°C

TAI 22°C

TAI 24°C

Twi

Two

qa

Pf

Tad

Qw

dPw

Pf

Tad

Qw

dPw

Pf

Tad

Qw

dPw

Pf

Tad

Qw

dPw

°C

°C

m3/h

kW

°C

l/s

kPa

kW

°C

l/s

kPa

kW

°C

l/s

kPa

kW

°C

l/s

kPa

45

40

370

1.47

30.4

0.0701

10.02

1.34

31.4

0.064

8.64

1.21

32.4

0.0579

7.26

1.08

33.4

0.0518

5.88

290

1.22

31.2

0.0579

7.2

1.11

32.1

0.0529

6.21 1 33

0.0479

5.22

0.89

33.9

0.0429

4.23

220

0.966

32.1

0.0462

4.87

0.882

32.9

0.0422

4.2

0.798

33.7

0.0382

3.53

0.714

34.5

0.0342

2.86

60

40

370

1.58

31.5

0.0378

3.48

1.45

32.4

0.0347 3 1.32

33.3

0.0316

2.52

1.19

34.2

0.0285

2.04

290

1.3

32.2

0.0314

2.47

1.2

33.1

0.0288

2.15

1.1

34

0.0262

1.83 1 34.9

0.0236

1.51

220

1.8344

33.1

0.025

1.69

0.961

34

0.023

1.47

0.876

34.9

0.021

1.25

0.791

35.8

0.019

1.03

70

60

370

2.83

42

0.0676

8.74

2.7

43

0.0644

8.05

2.57

44

0.0612

7.36

2.44

45

0.058

6.67

290

2.34

43.3

0.056

6.26

2.23

44.3

0.0533

5.77

2.12

45.3

0.0506

5.28

2.01

46.3

0.0479

4.79

220

1.87

45.1

0.0445

4.21

1.78

46

0.0424

3.88

1.69

46.9

0.0403

3.55

1.6

47.8

0.0382

3.22

Pf: total heating capacity dpw: pressure drop standard coil Qw: fluid flow rate in heat exchanger Tad: discharge air dry temperature

Tai: in flow air temperature Twi: in flow fluid temperature Two: out flow fluid temperature Qa: air flow

Page 15 of 67

SK2013-SON-002-TechMnl-SWC-002

SWC-06-V-ECM

TAI 18°C

TAI 20°C

TAI 22°C

TAI 24°C

Twi

Two

qa

Pf

Tad

Qw

dPw

Pf

Tad

Qw

dPw

Pf

Tad

Qw

dPw

Pf

Tad

Qw

dPw

°C

°C

m3/h

kW

°C

l/s

kPa

kW

°C

l/s

kPa

kW

°C

l/s

kPa

kW

°C

l/s

kPa

45

40

500

2.41

33.1

0.1148

11.81

2.2

33.9

0.105

10.2

1.99

34.7

0.0952

8.59

1.78

35.5

0.0854

6.98

370

1.91

34.1

0.091

7.87

1.74

34.8

0.0831

6.79

1.57

35.5

0.0752

5.71

1.4

36.2

0.0673

4.63

290

1.55

34.8

0.0746

5.57

1.42

35.5

0.0681

4.81

1.29

36.2

0.0616

4.05

1.16

36.9

0.0551

3.29

60

40

500

2.62

34.4

0.0624

4.05

2.4

35.2

0.0573

3.53

2.18

36

0.0522

3.01

1.96

36.8

0.0471

2.49

370

2.07

35.5

0.0495

2.71

1.9

36.2

0.0455

2.37

1.73

36.9

0.0415

2.03

1.56

37.6

0.0375

1.69

290

1.69

36.3

0.0407

1.95

1.56

37

0.0374

1.7

1.43

37.7

0.0341

1.45

1.3

38.4

0.0308

1.2

70

60

500

4.66

47.3

0.111

10.35

4.44

48.1

0.106

9.53

4.22

48.9

0.101

8.71 4 49.7

0.096

7.89

370

3.67

49

0.0877

6.84

3.5

49.8

0.0836

6.3

3.33

50.6

0.0795

5.76

3.16

51.4

0.0754

5.22

290

3.01

50.6

0.0719

4.83

2.87

51.3

0.0685

4.45

2.73

52

0.0651

4.07

2.59

52.7

0.0617

3.69

Pf: total heating capacity dpw: pressure drop standard coil Qw: fluid flow rate in heat exchanger Tad: discharge air dry temperature

Tai: in flow air temperature Twi: in flow fluid temperature Two: out flow fluid temperature Qa: air flow

SWC-12-V-ECM

TAI 18°C

TAI 20°C

TAI 22°C

TAI 24°C

Twi

Two

qa

Pf

Tad

Qw

dPw

Pf

Tad

Qw

dPw

Pf

Tad

Qw

dPw

Pf

Tad

Qw

dPw

°C

°C

m3/h

kW

°C

l/s

kPa

kW

°C

l/s

kPa

kW

°C

l/s

kPa

kW

°C

l/s

kPa

45

40

500

2.83

35.8

0.136

9.61

2.59

36.4

0.124

8.29

2.35

37

0.112

6.97

2.11

37.6

0.1

5.65

370

2.22

36.8

0.1063

5.37

2.03

37.3

0.0971

5.42

1.84

37.8

0.0879

5.47

1.65

38.3

0.0787

5.52

290

1.81

37.6

0.0863

4.38

1.65

38

0.0789

3.79

1.49

38.4

0.0715

3.2

1.33

38.8

0.0641

2.61

60

40

500

3.1

37.6

0.0742

3.33

2.85

38.1

0.0682

2.91

2.6

38.6

0.0622

2.49

2.35

39.1

0.0562

2.07

370

2.43

38.6

0.0585

2.21

2.24

39.1

0.0537

1.93

2.05

39.6

0.0489

1.65

1.86

40.1

0.0441

1.37

290

1.99

39.4

0.0474

1.57

1.83

39.9

0.0437

1.37

1.67

40.4

0.04

1.17

1.51

40.9

0.0363

0.97

70

60

500

5.49

52.5

0.131

8.37

5.23

53.1

0.125

7.71

4.97

53.7

0.119

7.05

4.71

54.3

0.113

6.39

370

4.29

54.2

0.1024

5.45

4.09

54.8

0.0976

5.02

3.89

55.4

0.0928

4.59

3.69

56

0.088

4.16

290

3.48

55.7

0.0832

3.8

3.32

56.2

0.0793

3.5

3.16

56.7

0.0754

3.2

Pf: total heating capacity dpw: pressure drop standard coil Qw: fluid flow rate in heat exchanger Tad: discharge air dry temperature

Tai: in flow air temperature Twi: in flow fluid temperature Two: out flow fluid temperature Qa: air flow

Page 16 of 67

SK2013-SON-002-TechMnl-SWC-002

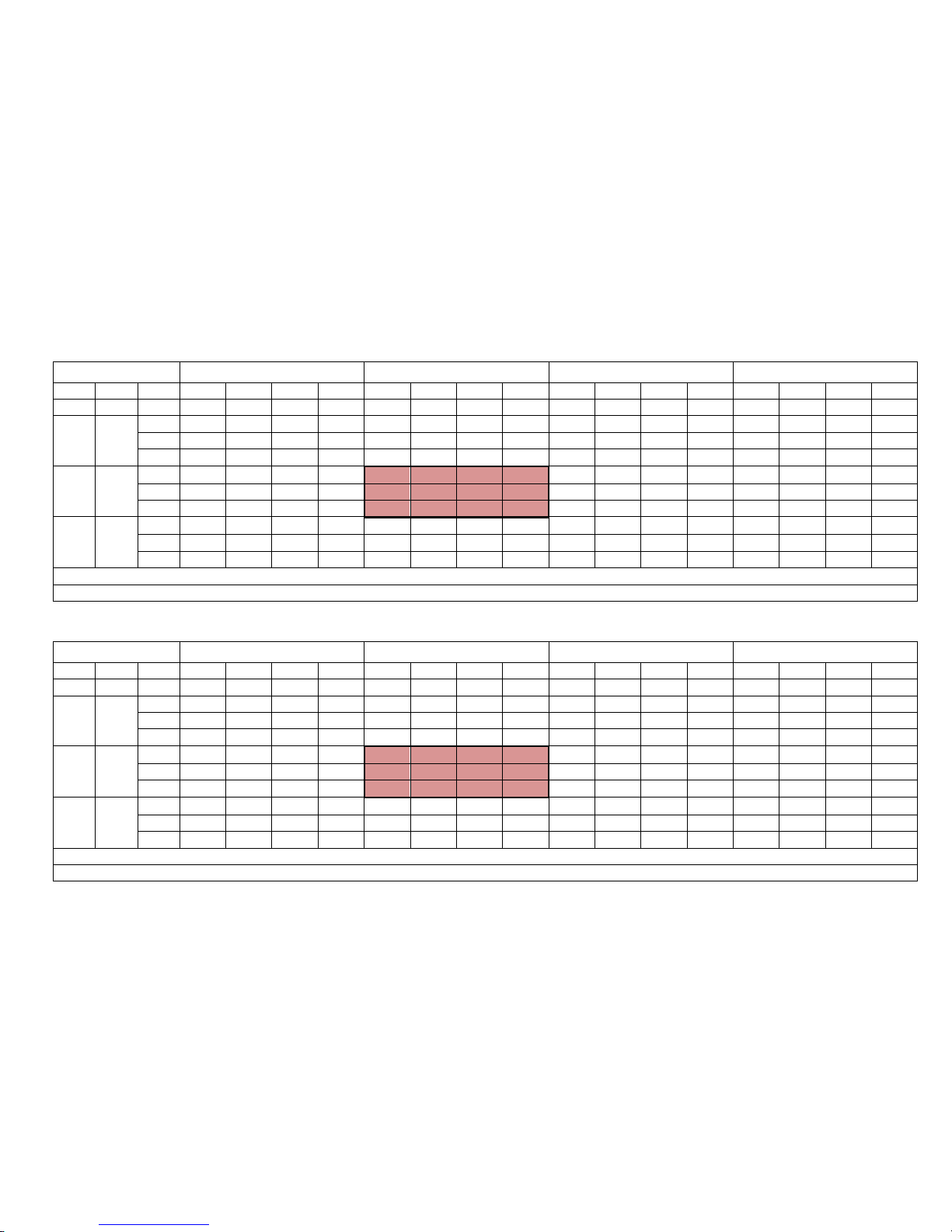

SWC-15-V-ECM

TAI 18°C

TAI 20°C

TAI 22°C

TAI 24°C

Twi

Two

qa

Pf

Tad

Qw

dPw

Pf

Tad

Qw

dPw

Pf

Tad

Qw

dPw

Pf

Tad

Qw

dPw

°C

°C

m3/h

kW

°C

l/s

kPa

kW

°C

l/s

kPa

kW

°C

l/s

kPa

kW

°C

l/s

kPa

45

40

645

3.5

35.1

0.166

13.82

3.19

35.7

0.152

11.9

2.88

36.3

0.138

9.98

2.57

36.9

0.124

8.06

445

2.59

36.3

0.124

8.14

2.36

36.8

0.113

7.03

2.13

37.3

0.102

5.92

1.9

37.8

0.091

4.81

370

2.22

36.8

0.1063

6.27

2.03

37.3

0.0971

5.42

1.84

37.8

0.0879

4.57

1.65

38.3

0.0787

3.72

60

40

645

3.8

36.6

0.0907

4.74

3.49

37.2

0.0834

4.13

3.18

37.8

0.0761

3.52

2.87

38.4

0.0688

2.91

445

2.83

38

0.0675

2.84

2.6

38.5

0.0621

2.48

2.37

39

0.0567

2.12

2.14

39.5

0.0513

1.76

370

2.43

38.6

0.0583

2.21

2.24

39.1

0.0536

1.93

2.05

39.6

0.0489

1.65

1.86

40.1

0.0442

1.37

70

60

645

6.75

51.1

0.16

12.1

6.43

51.7

0.153

11.1

6.11

52.3

0.146

10.1

5.79

52.9

0.139

9.1

445

4.98

53.2

0.118

7.09

4.75

53.8

0.113

6.53

4.52

54.4

0.108

5.97

4.29

55

0.103

5.41

370

4.29

54.2

0.1024

5.45

4.09

54.8

0.0976

5.02

3.89

55.4

0.0928

4.59

3.69

56

0.088

4.16

Pf: total heating capacity dpw: pressure drop standard coil Qw: fluid flow rate in heat exchanger Tad: discharge air dry temperature

Tai: in flow air temperature Twi: in flow fluid temperature Two: out flow fluid temperature Qa: air flow

SWC-18-V-ECM

TAI 18°C

TAI 20°C

TAI 22°C

TAI 24°C

Twi

Two

qa

Pf

Tad

Qw

dPw

Pf

Tad

Qw

dPw

Pf

Tad

Qw

dPw

Pf

Tad

Qw

dPw

°C

°C

m3/h

kW

°C

l/s

kPa

kW

°C

l/s

kPa

kW

°C

l/s

kPa

kW

°C

l/s

kPa

45

40

876

4.78

35.2

0.229

18.7

4.37

35.8

0.209

16.1

3.96

36.4

0.189

13.5

3.55

37

0.169

10.9

740

4.17

35.7

0.199

14.7

3.81

36.3

0.182

12.7

3.45

36.9

0.165

10.7

3.09

37.5

0.148

8.7

570

3.36

36.6

0.161

10.06

3.07

37.1

0.147

8.69

2.78

37.6

0.133

7.32

2.49

38.1

0.119

5.95

60

40

876

5.22

36.8

0.125

6.44

4.8

37.4

0.115

5.62

4.38

38

0.105

4.8

3.96

38.6

0.095

3.98

740

4.57

37.5

0.1084

5.1

4.2

38

0.1

4.45

3.83

38.5

0.0916

3.8

3.46

39

0.0832

3.15

570

3.68

38.5

0.0883

3.54

3.39

38.9

0.0812

3.09

3.1

39.3

0.0741

2.64

2.81

39.7

0.067

2.19

70

60

876

9.24

51.2

0.22

16.3

8.81

51.9

0.21

15

8.38

52.6

0.2

13.7

7.95

53.3

0.19

12.4

740

8.06

52.3

0.192

12.8

7.68

52.9

0.183

11.8

7.3

53.5

0.174

10.8

6.92

54.1

0.165

9.8

570

6.49

53.9

0.156

8.75

6.18

54.4

0.148

8.06

5.87

54.9

0.14

7.37

5.56

55.4

0.132

6.68

Pf: total heating capacity dpw: pressure drop standard coil Qw: fluid flow rate in heat exchanger Tad: discharge air dry temperature

Tai: in flow air temperature Twi: in flow fluid temperature Two: out flow fluid temperature Qa: air flow

Page 17 of 67

SK2013-SON-002-TechMnl-SWC-002

SWC-20-V-ECM

TAI 18°C

TAI 20°C

TAI 22°C

TAI 24°C

Twi

Two

qa

Pf

Tad

Qw

dPw

Pf

Tad

Qw

dPw

Pf

Tad

Qw

dPw

Pf

Tad

Qw

dPw

°C

°C

m3/h

kW

°C

l/s

kPa

kW

°C

l/s

kPa

kW

°C

l/s

kPa

kW

°C

l/s

kPa

45

40

980

5.58

35.9

0.267

18.5

5.1

36.5

0.244

16

4.62

37.1

0.221

13.5

4.14

37.7

0.198

11

760

4.52

36.7

0.217

12.86

4.13

37.2

0.198

11.1

3.74

37.7

0.179

9.34

3.35

38.2

0.16

7.58

600

3.71

37.4

0.177

9.1

3.39

37.9

0.162

7.87

3.07

38.4

0.147

6.64

2.75

38.9

0.132

5.41

60

40

980

6.13

37.6

0.147

6.47

5.64

38.2

0.135

5.65

5.15

38.8

0.123

4.83

4.66

39.4

0.111

4.01

760

4.98

38.6

0.12

4.52

4.58

39.1

0.11

3.95

4.18

39.6

0.1

3.38

3.78

40.1

0.09

2.81

600

4.09

39.4

0.0981

3.23

3.77

39.9

0.0903

2.83

3.45

40.4

0.0825

2.43

3.13

40.9

0.0747

2.03

70

60

980

10.83

52.6

0.257

22.1

10.3

53.2

0.245

17.9

9.77

53.8

0.233

13.7

9.24

54.4

0.221

9.5

760

8.72

54.2

0.207

11.19

8.31

54.7

0.198

10.3

7.9

55.2

0.189

9.41

7.49

55.7

0.18

8.52

600

7.17

55.5

0.171

7.89

6.83

56

0.163

7.28

6.49

56.5

0.155

6.67

6.15

57

0.147

6.06

Pf: total heating capacity dpw: pressure drop standard coil Qw: fluid flow rate in heat exchanger Tad: discharge air dry temperature

Tai: in flow air temperature Twi: in flow fluid temperature Two: out flow fluid temperature Qa: air flow

SWC-24-V-ECM

TAI 18°C

TAI 20°C

TAI 22°C

TAI 24°C

Twi

Two

qa

Pf

Tad

Qw

dPw

Pf

Tad

Qw

dPw

Pf

Tad

Qw

dPw

Pf

Tad

Qw

dPw

°C

°C

m3/h

kW

°C

l/s

kPa

kW

°C

l/s

kPa

kW

°C

l/s

kPa

kW

°C

l/s

kPa

45

40

1240

6.78

35.2

0.324

26.1

6.19

35.8

0.296

22.5

5.6

36.4

0.268

18.9

5.01

37

0.24

15.3

1080

6.05

35.6

0.29

21.5

5.53

36.2

0.265

18.5

5.01

36.8

0.24

15.5

4.49

37.4

0.215

12.5

760

4.52

36.7

0.217

12.86

4.13

37.2

0.198

11.1

3.74

37.7

0.179

9.34

3.35

38.2

0.16

7.58

60

40

1240

7.4

36.8

0.177

8.99

6.81

37.4

0.163

7.84

6.22

38

0.149

6.69

5.63

38.6

0.135

5.54

1080

6.63

37.3

0.159

7.42

6.1

37.9

0.146

6.48

5.57

38.5

0.133

5.54

5.04

39.1

0.12

4.6

760

4.98

38.6

0.12

4.52

4.58

39.1

0.11

3.95

4.18

39.6

0.1

3.38

3.78

40.1

0.09

2.81

70

60

1240

13.2

51.3

0.313

22.8

12.5

51.9

0.298

21

11.8

52.5

0.283

19.2

11.1

53.1

0.268

17.4

1080

11.6

52.1

0.279

18.7

11.1

52.7

0.266

17.2

10.6

53.3

0.253

15.7

10.1

53.9

0.24

14.2

760

8.72

54.2

0.207

11.19

8.31

54.7

0.198

10.3

7.9

55.2

0.189

9.41

7.49

55.7

0.18

8.52

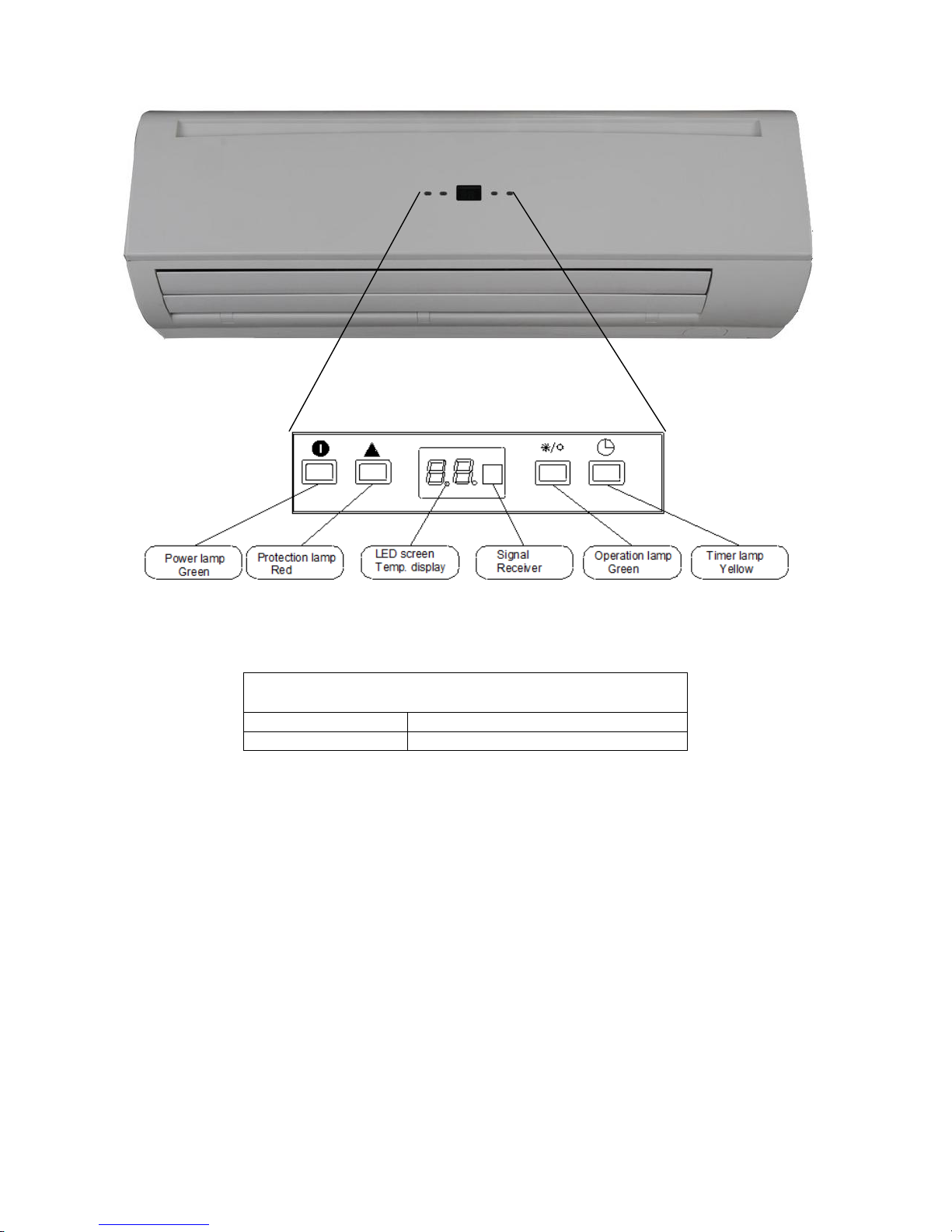

Pf: total heating capacity dpw: pressure drop standard coil Qw: fluid flow rate in heat exchanger Tad: discharge air dry temperature

Tai: in flow air temperature Twi: in flow fluid temperature Two: out flow fluid temperature Qa: air flow

Page 18 of 67

SK2013-SON-002-TechMnl-SWC-002

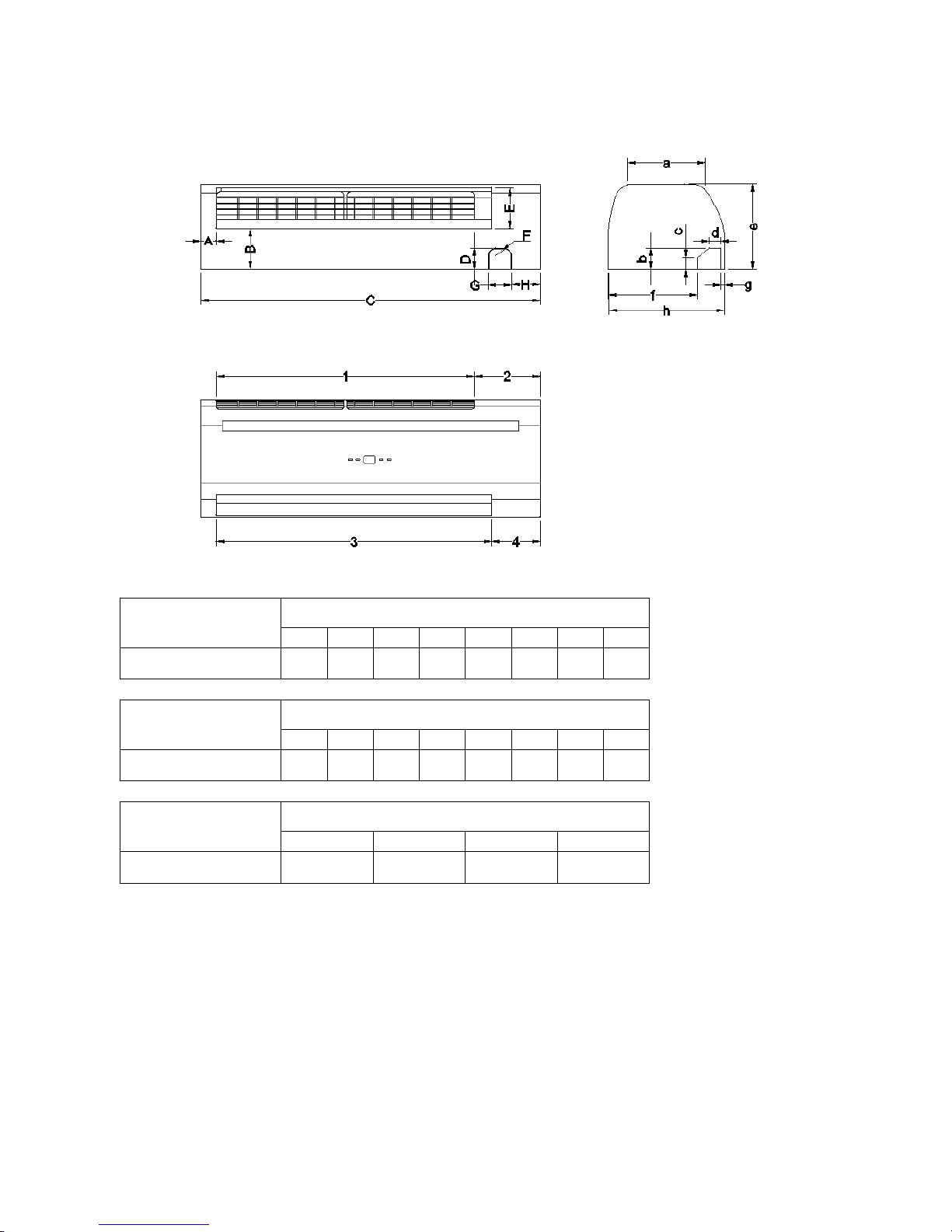

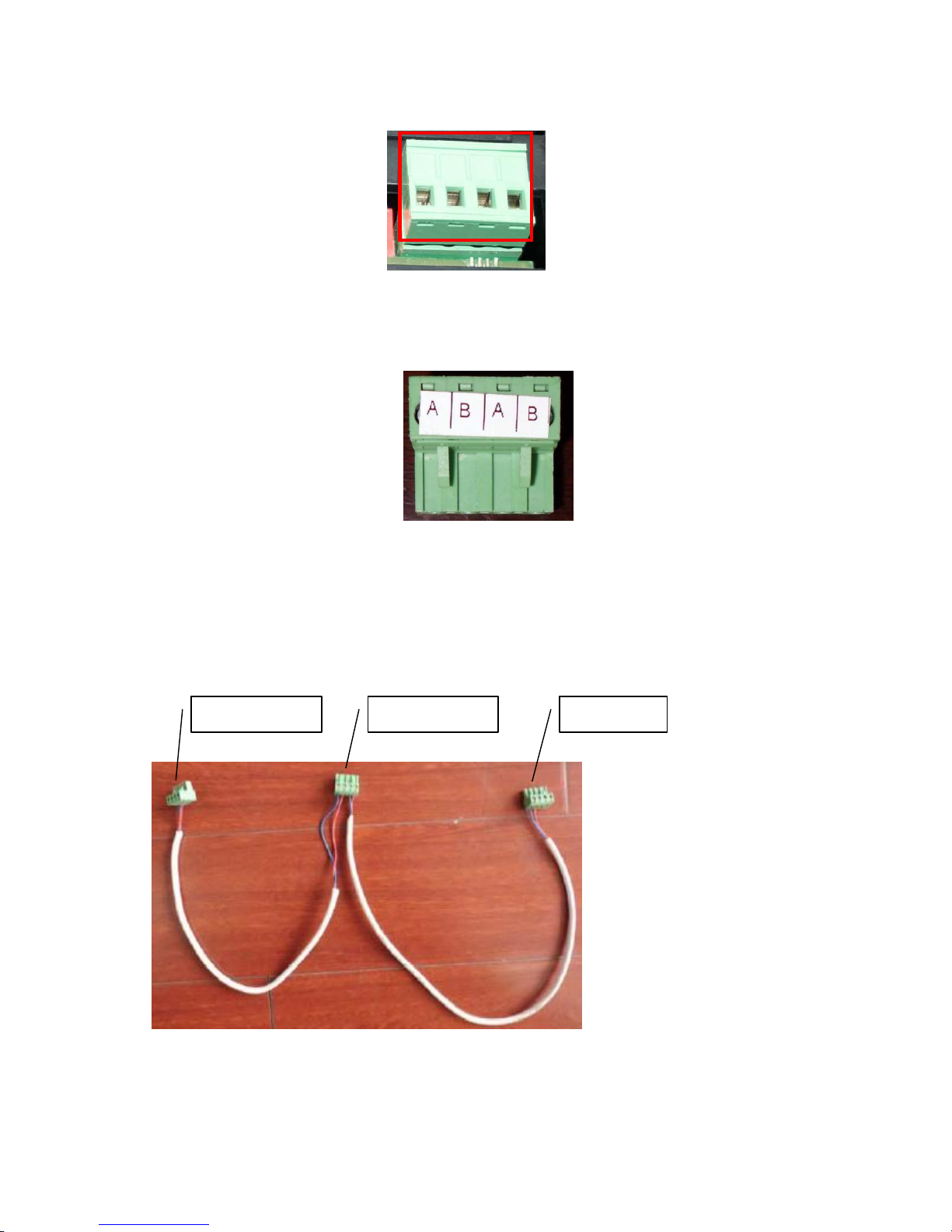

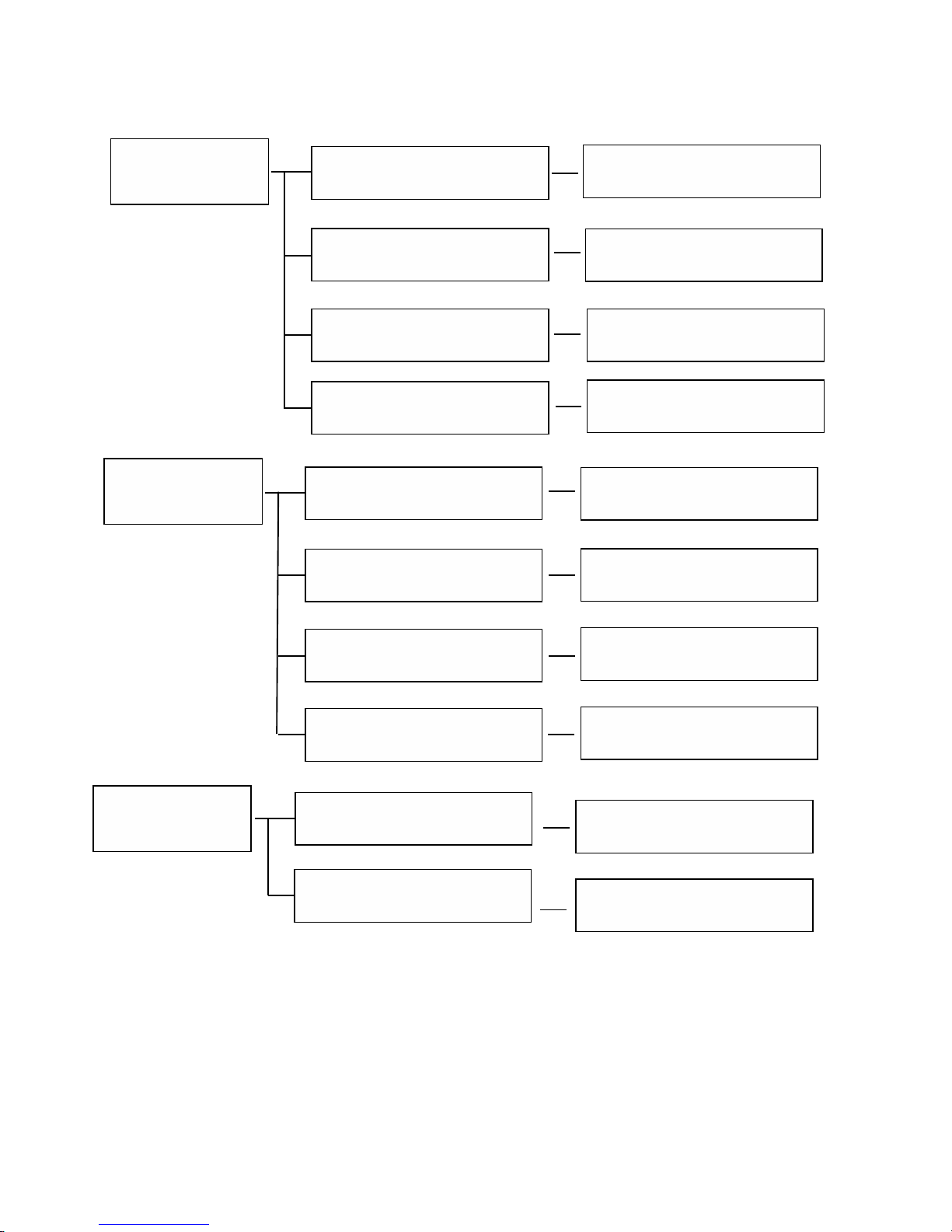

B.4. Dimensional Drawings

Dimensional drawing for SWC-04/06/12/15/18-ECM

Model

Unit Dimensions (mm)

A B C D E F G

H

SWC-04/06/12/15/18

40

105

875

55

105

R20

60

74

Model

Unit Dimensions (mm)

a b c d e f g

h

SWC-04/06/12/15/18

200

55

30

30

220

229

10

300

Model

Unit Dimensions (mm)

1 2 3

4

SWC-04/06/12/15/18

665

170

710

125

(All dimensions shown in mm)

Page 19 of 67

SK2013-SON-002-TechMnl-SWC-002

Dimensional drawing for SWC-20/24-ECM

Model

Unit Dimensions (mm)

A B C D E F G

SWC-20/24

90

1050

51

90

15

73

74

Model

Unit Dimensions (mm)

a b c d e f g

h

SWC-20/24

215

52

30

32

235

310

58

13

Model

Unit Dimensions (mm)

1 2 3

4

SWC-20/24

855

155

820

175

(All dimensions shown in mm)

Page 20 of 67

SK2013-SON-002-TechMnl-SWC-002

B.5. Valve Information

B.5.1. 2-Way Valve Body

Valve Dimensions (mm)

DN A B C D

D15

(G1/2”)

52

47

19.5

63

Page 21 of 67

SK2013-SON-002-TechMnl-SWC-002

C. Service and Installation

C.1. Installation of High-Wall Unit

C.1.1. Selecting a Location

Select the location for the High-wall unit with the following considerations:

1. The front of the air inlet and outlet should be free from any obstructions. The air

should flow freely.

2. The wall where the unit is to be mounted should be stiff enough not to resonate

and produce noise.

3. The location should allow easy access to install the connecting water pipes, and

be where drainage can be easily obtained.

4. Ensure the clearance on every side of the fan coil unit conforms to the following

drawing.

5. From the floor the height should be more than eye level.

6. Avoid installing the unit in direct sunlight.

* Required clearance for maintenance and servicing is as shown above.

** All dimensions shown in mm.

7. The signal receiver on the unit must be kept away from any high frequency

emission source.

8. Keep the unit away from fluorescent lamps, which may affect the control system.

9. To avoid electromagnetic control system interference, ensure control wires

are installed separately from 220-240 VAC power wires.

10. Where electromagnetic waves exist use shielded sensor cables.

11. Install a noise filter if any harmful noise exists in the power supply.

Higher than eye level

Page 22 of 67

SK2013-SON-002-TechMnl-SWC-002

C.1.2. Mounting Plate Dimensions

SWC-04/06/12/15/18 –ECM

SWC-20/24 –ECM

(All dimensions shown in mm)

Page 23 of 67

SK2013-SON-002-TechMnl-SWC-002

C.1.3. Installing the Mounting Plate

1. Select the structural position (e.g. a pillar or lintel) on the wall.

2. Then temporarily fasten the mounting plate on the wall with a steel nail.

3. Mount the mounting plate horizontally as shown in the

above figure or by means of gradiometer. Fail to

follow this may cause indoor water dripping and

abnormal noise.

4. Fix the mounting plate by means of expansion screws

or tapping screws.

C.1.4. Drilling the Condensate Drainage Hole

1. Ensure that the hole for condensate drainage is correctly positioned. The height should be lower

than the below edge of the indoor unit.

2. Drill a 65mm diameter hole with a descending slope.

3. Seal it off with putty after installation.

Page 24 of 67

SK2013-SON-002-TechMnl-SWC-002

C.1.5. Installing the Hydronic Unit

1. Pass the piping through the hole in the wall and hook the indoor unit on the mounting plate at the

upper hooks.

2. Move the body from side to verify if it is securely fixed.

3. While pushing the unit onto the wall from the underside, hook it up on the mounting plate at the

lower part.

4. Make sure the units are firmly hooked up on the mounting plate.

C.1.6. Drainage Piping Works

1. Install the drain hose so that it slopes downward slightly for free drainage. Avoid installing it as

shown in the below illustration marked with “X”.

2. Put water in the drain pan and make sure that the water is drained outdoors.

3. If the flexible drain hose provided in the indoor unit is not long enough, please extend

it by joining it to an extension hose (not provided). Be sure to insulate the connecting

part of the extension drain hose with a shield pipe as shown.

4. In case that the attached (if it is attached) drain hose passes through an indoor area,

insulate it with heat insulation material.

Page 25 of 67

SK2013-SON-002-TechMnl-SWC-002

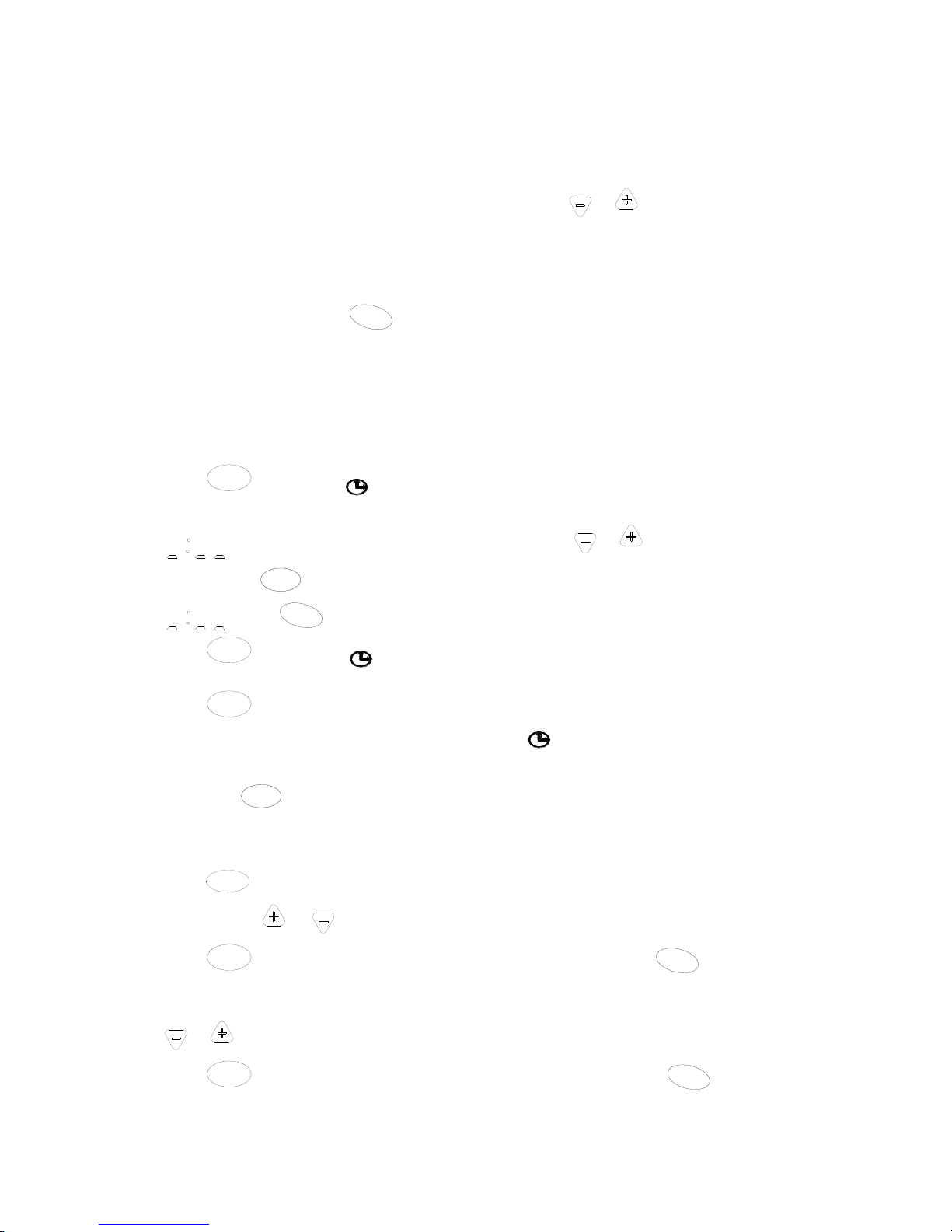

Open the lift-up grilled cover by lifting

from the bottom position indicated by the

arrow

C.2. Unit Maintenances and Preparations

C.2.1. Opening and Closing Of Lift-Up Grille Cover

C.2.2. Removing Front Cover Assembly

1. Set the horizontal louver to horizontal position.

2. Remove the screw caps below the louver, and then remove the mounting screws.

3. Open the lift-up grille cover by grasping the panel at both sides as shown above.

4. Remove the remaining screws located at the centers.

5. Grasp the lower part of the front cover and pull the entire assembly out and up towards you.

C.2.3. Air Purging

1. After connecting the water inlet and outlet pipes to the main supply lines turn on the main breaker

and operate the unit in COOLING mode.

2. Open the water inlet valve and flood the coil.

3. Check all connections for water leakage, if no leak is found open the purging valve by using hand

and support the unit with an open end wrench. Then purge the air trapped inside the coil. When

performing this activity, take care not to touch the electrical parts.

4. Close the purging valve when no bubbles appear.

5. Open the water outlet valve.

C.2.4. Wiring Connections

1. Unit components are wired to the terminal block of indoor unit. Wirings can be accessed from

the terminal block inside the control box.

Close the lift-up grilled cover by pressing

the two sides down at the position of the

arrow.

Page 26 of 67

SK2013-SON-002-TechMnl-SWC-002

C.3. Pipe Connections with Valve

Pre-assembly

Complete Assembly

Flexible copper

Valve body

with actuator

½” gasket

Coil connector

Page 27 of 67

SK2013-SON-002-TechMnl-SWC-002

D. Control Specifications

D.1. SK-NCSWC-001 Complete function FCU Controller

Used in all High-wall [V/P] ~S unit configurations.

D.1.1. Abbreviations

Ts = Setting temperature

Tr = Room air temperature

Ti1 = Chilled water coil temperature

Ti2 = Hot water coil temperature

AUX1 = Hot water free contact

AUX2 = Chilled water free contact

MTV1 = Chilled Motorized valve

MTV2 = Hot Motorized valve

D.1.2. Definition of Input/Output

I/O

Code

2-Pipe

4-Pipe

Analogue Input

Return air sensor

AI1

Return air temperature (Tr)

2-pipe coil circuit sensor

AI2

Chilled / hot water coil

circuit (Ti1)

Chilled water coil

circuit (Ti1)

Hot water sensor

AI3

N/A

Hot water coil circuit

(Ti2)

Input

LED display / IR receiver

X-DIS1

Digital communication port to LED display / IR

receiver board.

Wired wall pad

TTL1

Digital communication port to wired wall pad board.

Digital input

Occupancy contact

On/Off

Window contacts: for remote ON/OFF (when DIPB

SW1 = 1).

Economy contacts: for remote activation of

economy mode (when DIPB SW1 = 0).

Electrical heater safety switch

EH

Voltage-free (NC). The contact is closed before the

EH is turned on.

Power input

Phase

L1

Power supply to the PCB and all the loads

connected to the voltage outputs. Max length: 5 m.

Neutral

N1

Power supply to the PCB and all the loads

connected to the voltage outputs. Max length: 5 m.

Earth

PE1

Power supply to the PCB and all the loads

connected to the voltage outputs. Max length: 5 m.

Voltage output

Fan

CN4

Fan driver

Valve 1

MTV1

2-pipe coil circuit valve

output – chilled / hot

water valve.

Voltage output (L)

2-pipe coil circuit valve

output – chilled water

valve.

Voltage output (L)

Valve 2

MTV2

Reserved

4-pipe coil circuit valve

output – hot water

valve.

Voltage output (L)

Voltage of electrical heater

(Live)

HEAT

Voltage output (L), maximum 25 A

Output

Stepping motor

CN1 / CN2

Louver stepping motor relay

Auxiliary contact 2

AUX2

Cooling mode signal relay (NO). Voltage free

contact.

To ensure the sensitivity of the connection, please

make sure max wiring length < 5 m, 5 A

Auxiliary contact 1

AUX1

Heating mode signal switch (NO). Voltage free

contact.

To ensure the sensitivity of the connection, please

make sure max wiring length < 5 m. 5 A

Serial BUS port

CN3

Master-slave network serial connection OR

MODBUS / local PC host network serial

connection.

Page 28 of 67

SK2013-SON-002-TechMnl-SWC-002

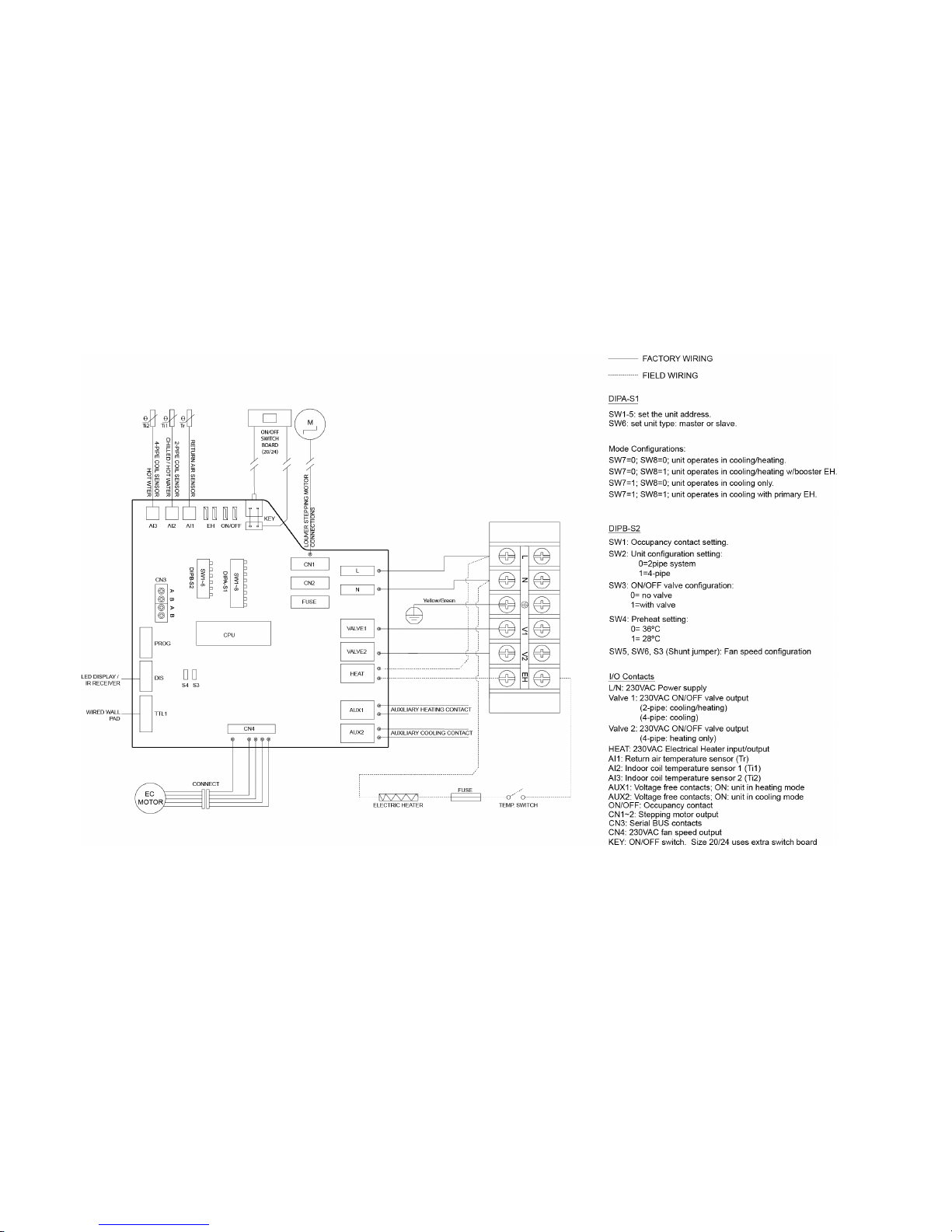

D.1.3. Wiring Diagram SK-NCSWC-001

Page 29 of 67