ITL 950C

M

KL

D

BC

RS

Q

THE ITL 950C COMPUTER KEY MACHINE

Operations Manual

ITL 950C Operating Manual

TABLE OF CONTENTS

INTRODUCTION PAGE

* Table of content s 1

* Specifications 2

* Key Functions 3

OPERATION

* Starting the ITL950C 4

* Selecting a Manufacturer 4

* Entering a Code 4

* Cutting a Key 4

* Calibrating the ITL950C. 5

* Setting Correction Factor 6- 7

III CUSTOM CONFIGURATION

* Setting the default manufacturer ID 8

* Setting units (metric – inches). 8

* Setting default cut rate 8

* Setting display 8

* Setting the display contrast 8

* Setting Custom Flat Widths 9

* Flat width table 9

IV CREATING A CUSTOM ID TABLE

* Selecting ID T o Be Created 1 0

* Enabling and Disabling Pause 10

* Setting Tip Type 1 0

* T able of reference points 10

* Selecting a Flat 1 0

* Selecting Insert Number 10

* Enabling an Extended T able 11

* Setting Maximum Space 11

* Setting Maximum Depth 1 1

* Setting Minimum Depth 11

* Setting V alues In S pace Table 1 2

* Setting V alues In Depth Table 1 2

* Special cutting instructions 13

VI SETTING SERIAL PORT PARAMETERS

* Setting Serial Port Baud Rate 14

* Error Messages 14-15

VII SPECIAL INSTRUCTIONS

* Half depth mode 0 7

* Flow chart for Medeco Biaxial 16

* Generating a master key system 1 7

1

MACHINE SPECIFICATIONS

Operating Voltage - 120 Volts AC. 2 Amps 60 Hz.

- 12 Volts DC. 10 Amps

Operating Current - AC 1.5 Amp PK. 25 Idle. DC 10 Amp. PK. 1 Idle.

Operating Frequency - 60 Hertz/DC.

Motor Horsepower - 1/8 H.P.

Cutter Speed - 1600 R.P.M.

Motor Bearing Type - Sealed Roller Bearing

Standard Codes - UP TO 800

Custom Codes - 160 (User Modified)

User Definable Flats - 10 with range of 0.001" to 0.140"

Display Format - 4 Line 20 Character Alpha-Numeric

Micro Power LCD

Keyboard Type - 20 Key Sealed Membrane

Computer Interface - RS232C 75-9600 Baud

- Parallel IBM compatible

Repeatable Accuracy - (+/-) 0.002"

Weight - 48 Lbs. Packaged

2

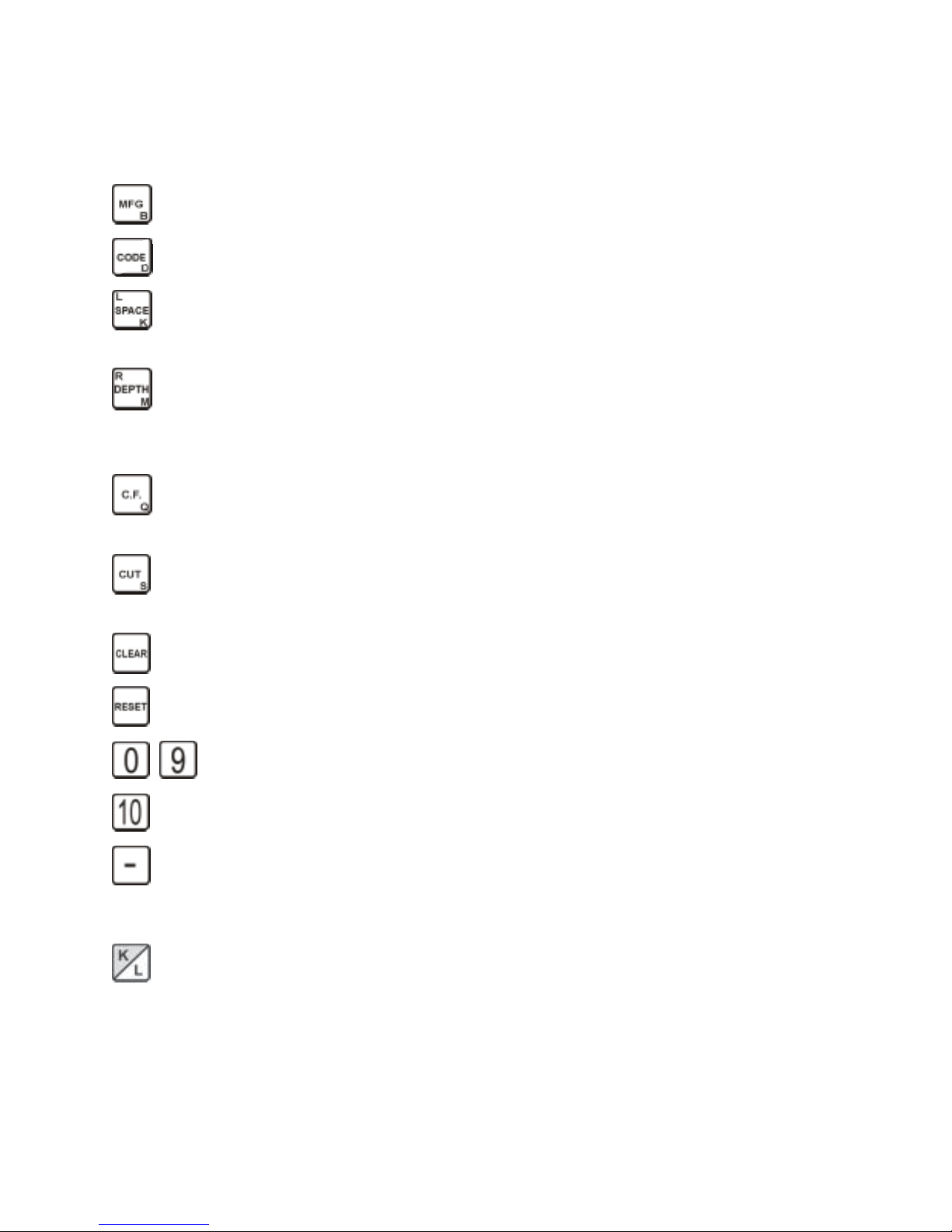

KEY FUNCTIONS

DESCRIPTION

Displays or selects a manufacturer as well as insert and flat number.

Displays or selects key code to be cut. Displays cutter angle where applicable.

Displays Maximum Space to be cut. Also shows tip type and whether key is paused

or not. If paused this key will put an l in the display to indicate a Left cut angle.

Displays Max and Min Depths. Note: there maybe invalid depths between the max

and min values that are invalid, as in Simca. If the table is paused this key will put an

R in the display to indicate a right cut angle.

Displays selected amount of depth correction, flat number , units, plunge mode and

cut feed rate.

Starts cutting operation. If the table is paused this resumes cutting after changing

angles or space position of cutter.

Corrects number entries and aborts functions.

Resets the machine, same as turning power on. Also aborts a cutting operation.

Entry keys for ID’S, Codes, Etc.

Used to enter 11th depth in code i.e. 0-10. (Displays as A)

Used to switch sign of C.F. and Calibration numbers, -5 is negative. Used also to

bypass a cut position in code. (Displays as X)

Alphabetical keys A-Z are arranged in pairs. The top red letters are accessed

directly. The bottom section of each key is accessed by pressing the Alt key first.

3

STARTING THE ITL 950C

The, ITL950C should be plugged in to a switch operated power bar

with surge suppression. Check serial plate for correct machine

voltages and current requirements. Turn on the power switch located on the back of machine. Follow instructions on the display.

(Move vise to right or left.)

12-VOLT POWER INVERTERS

THE USE OF A POWER INVERTER IS NOT RECOMMENDED WITH THE ITL950C.

There is a problem of a stable voltage supply with most inverters. When the voltage drops the

ITL950C will try to reset and can damage the electronics. A low voltage does not matter with a

drill or drive motor but does matter to the ITL950C. WE RECOMMEND CONNECTING THROUGH

A 20 Amp FUSE TO THE VEHICLE 12-VOLT BATTERY FOR MOBILE USE.

SELECTING A MANUF ACTURER

Press the key to display the current lD. number. To load a new lD. number,

enter the required ID number and . T o select Manufacturer 167 (WEISER), press

then . The ITL950C will display MANUF ACTURER 167 INSERT 2 FLA T 8, indicating the new

ID is accepted and has loaded the key specifications.

CUTTING A DIRECT ENTRY CODE (key cuts)

To load a new direct entry code press the desired cuts then press . The ITL950C will

display the desired cuts, indicating it has accepted the cuts.

CUTTING A KEY

In this example we will use MFG number 167 WEISER and cuts 42312.

1) Select Manufacturer 167 by pressing followed by The ITL950C will display

MANUFACTURER 167 INSERT 2 FLAT 8, indicating the new ID is accepted and it has loaded

the key specs. Insert 2 should be used to hold the blank and Flat 8 is the width of each cut.

2) Select key code 42312 by pressing keys then . The ITL950C

will display CODE 42312 indicating the code has been accepted.

3) Using insert 2 put a blank in the vice. Flip up the shoulder reference arm to position the key but

remember to put it down before cutting. T ighten the vice and press then turn the space handle

clockwise until the bar graph disappears and the numbers pass thru “0000”. The cutter motor will

start and the space handle motion should be reversed to counter clockwise. Continue turning the

handle, at about one revolution per second, until the cuts are completed and the cutter motor stops.

**Do not leave the machine motor running when not cutting a key as this may damage the

control transistors.

4

CUTTING A CAR KEY TO CODE

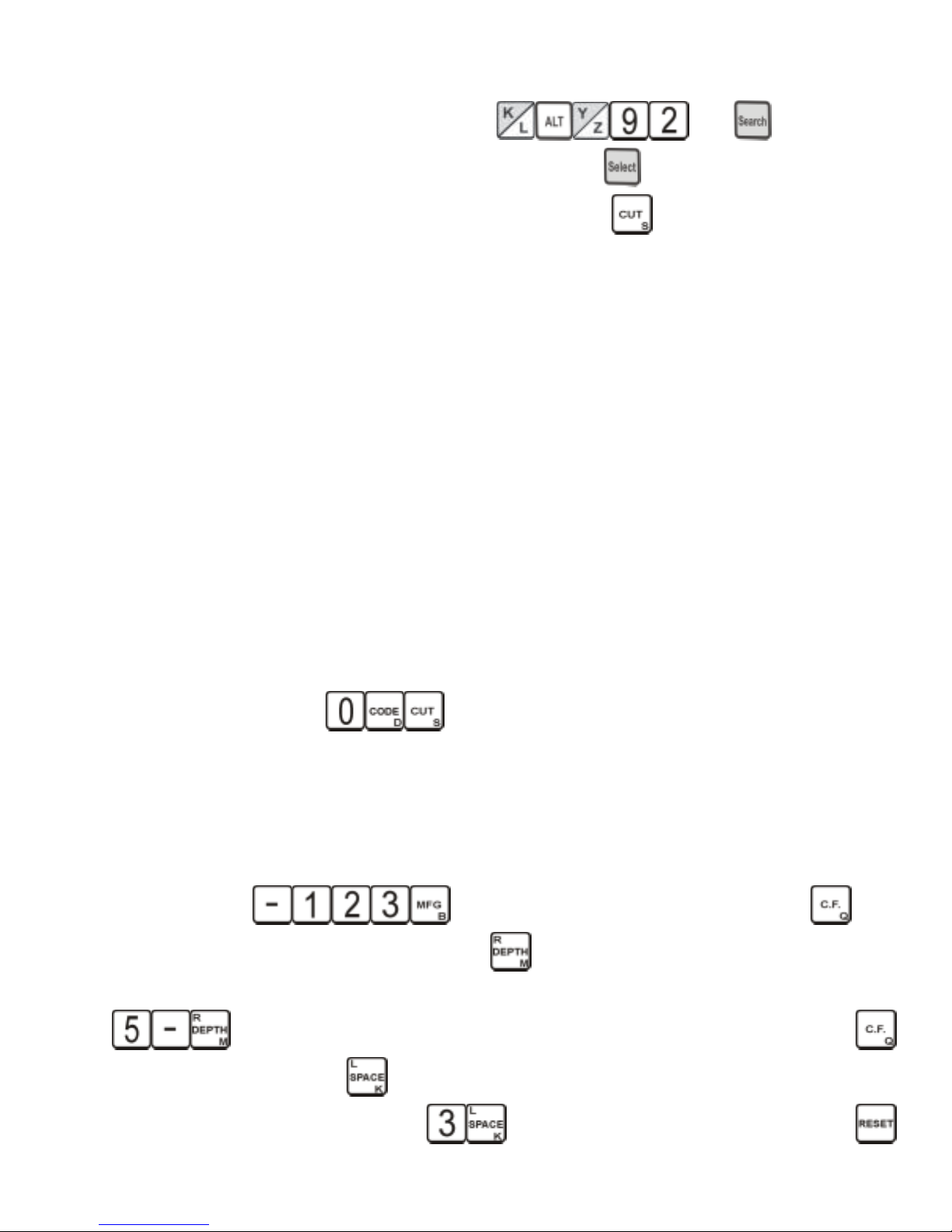

T o cut the sample car key code KZ92 press then then move the

currsor using the up down arrow key to GM 10C 95+ and press . Insert the suggested insert 1FL

and install the suggested key P1 106 or equivalent. Now press Turn the handle clockwise

until the blocks disappear and the numbers count down to 0 and the cutter starts. Now turn the

handle counterclockwise untill the first side of the key is cut and the cutter stops. Turn the key over

and press cut, turn the handle clockwise until the blocks disappear and the numbers count down to 0

and the cutter starts. Now turn the handle counterclockwise untill the second side of the key is cut.

ALWAYS MAKE SURE THE CUTTER HAS STOPPED BEFORE REMOVING A KEY

MAKE SURE THE MOTOR IS OFF BEFORE REMOVING THE KEY.

CALIBRATING THE ITL950C

NOTE Ill IT IS POSSIBLE TO RUN THE CUTTER INTO THE VICE WITH IMPROPER

CALIBRATION. BE CERTAIN OF DEPTH CALIBRATION. YOU MAY ABORT THE CUTTING

OPERA TION A T ANY TIME BY PRESSING THE RESET KEY. THIS WILL STOP THE CUTTER

AND RETURN THE KEY TO THE IDLE POSITION. DO NOT AT ANY TIME ALLOW THE

CUTTER TO TOUCH THE VICE, AS IT WILL DAMAGE THE CUTTER.

TO CHECK CALIBRATIONS

First select MFG 391 this is “Schlage”. Next, place insert #2 in the vice jaw and slide a blank

onto it. Push the key along the top of the insert until the bottom shoulder comes up hard against the

insert. Check the right hand side of the vice. Make sure the insert is tight against the stop screw.

Tighten the vise and press . When the cut is finished, remove the key and measure

the distance from the back of the blank to the bottom of the cut with a micrometer caliper . Subtract

the reading you get from the .335 thousand depth it should be and note the number down. Measure

the distance from the bow of the key to the center of the first cut. As above, subtract the reading from

the .231 thousand space it should be.

TO ADJUST CALIBRA TIONS

Press the keys to enter the EDIT mode and then press . The

display will show EDIT CALIBRATION. Press . Now the display will show ADJUST DP BY

000. If in our sample our depth reading is .340, .335 minus .340, equals -.005. On the keypad enter

. Now the display will read –005.. To return to EDIT CALIBRATION, push the

key twice, and then press the key . In our sample, if the space reading is .229, subtract this from

.231 and the answer is .003. Now press and the display will read 003. Press the key

twice and follow display instructions to return to home.

5

Correct depth calibration is more critical than space calibration, but the more exact they both

are, the better the resulting keys will work. Remember that the allowable range for calibration is from

+0.127 inches to-0.127 inches. The machine is factory set for 0 calibration error so you must be

careful not to enter a depth value that would allow the vise to contact the cutter . Double check your

calibration numbers before entering them and if possible make small changes until you are familiar

with this operation. All calibrations are done using the insert as the stop. When this has been

completed, raise the reference arm up against the shoulder of the key to ensure that it has not been

moved or bent out of position. The reference arm should make light contact with the blank shoulder ,

if not, loosen the two 5/32 allen head machine screws holding the reference block to the vice block

and move the reference arm against the key shoulder and retighten the screws.

Menu of key temporary functions

1. Correction (depth).

2. Flat number (width of root of cut).

3. Cut mode (laser or normal)

4. Half depth mode ( cuts between current and next depth).

5. Plunge mode (cut entry method).

6. Cut feed rate (speed that plunge method uses).

7. Bypass home.

8. Units (inches or metric).

It should be noted if the machine is turned off, the key pressed or the manufacture

I.D. changed, all key functions revert to the default settings.

SETTING TEMPORARY DEPTH CORRECTION

1. The correction function affects the depth of all cuts. A negative correction factor makes cuts

deeper while a positive correction factor makes cuts shallower . The range is from -.009 to +.009

inches in .001 inch steps. Press then a number from through . Use the key

to indicate a negative value. Press to correct your entry and press to set the correction.

A special note regarding the correction function. If the resulting depth is out of the

absolute limits of 0.110 to 0.465 inches, that cut will not be made.

CHANGING FLAT NUMBER

2. The flat number is used to select the width of the bottom of a cut. There are 10 possible flats to

choose from and they are all user definable. The flats listed in the table on page 3 have been preset

at the factory . Refer to setting custom flat widths in the Custom Configuration section for more details.

Press twice. The ITL950C will now display FLA T NUMBER (current flat). To change

the flat number to 2, press , then to set the new flat number. The ITL950C will now display

FLA T NUMBER 2, press to return to READY.

6

TEMPORARY CHANGE TO LASER CUT MODE

In the laser cut mode cuts are made from flat edge to flat

edge without the normal inbetween cut points. From the

ready prompt push the C.F. key three times, the display will

read normal cut mode. Push the (-) key to toggle to the laser cut mode and back to the normal

cut mode.

HALF DEPTH MODE

4. Press four times. The ITL950C will now display HALF-DEPTH = NO This is the normal

mode. Push to switch to the half depth mode and all cuts will be made half way to the next

depth. When cutting the key the second line will read < 1/2 Depth = on >.

PLUNGE CUT MODE

5. Press five times. The ITL950C will now display PLUNGE = NONE (Normal cut method)

PLUNGE = ALL (for keys that require straight in and out movement of the cutter) Safety deposit or

flat steel. PLUNGE = FIRST (for keys that require a vertical entry in the first position to avoid cutting

the key shoulder). Press key to toggle to required function, press to return to READY.

CHANGING CUT RATE

6. The cut rate is a number from 1 through 4 that defines how fast a blank is fed into the cutter . 1 is the

fastest rate and should work for most blanks. However if the cutter becomes dull or thick—blanks are

used you may need to select a slower speed. T o select a cut rate of 3, proceed as follows. Press the

key 6 times. The display will now read CUT FEED RA TE (current rate) press and

, the display will now read CUT FEED RA TE 3. Press to return to READY.

BYPASS HOME MODE

7. Press seven times. The ITL950C will now display BYP ASS HOME = NO This will

reset the space calibration after every cut. Press the key to toggle to BYP ASS HOME =

YES this will temporarily turn off the space calibration. This can be used for impressioning locks

faster . Press to return to READY .

UNITS (METRIC OR INCHES)

8. Press eight times. The ITL950C will now display UNITS (INCHES OR METRIC).

Press key to toggle.

Custom default entries using the key remain in memory when the machine is reset or

turned off.

CUSTOM EDIT MODE

7

SETTING DEFAULT MANUFACTURER ID

The default or power on ID is the MFG ID number the machine selects when reset or turned

on. As with any ID, it must be in the range of 1 through 960, and the t able must be correct. It can be set

by you and remains set until you select a different ID.

1) Press the keys to enter the EDIT mode. The display will show

EDIT.

2) Press the key to display the current default ID. T o change the ID to 23, press

followed by . The ITL950C will display DEF AUL T ID 23.

3) Press the key to return to the EDIT mode. Press the key and follow display

comands and the new ID will be displayed when the ITL950C completes the self-test sequence.

SETTING THE BAUD RATE

See page 14 for table and instructions.

UNITS (INCHES – METRIC)

Press and the key three times and the display will read

UNITS = INCHES. To read the display in metric, press the key . Press the key twice

and follow display instructions.

SETTING DEFAULT CUT RATE

The default cut rate is a number from 1 through 4 that defines how fast the blank is fed into

the cutter. 1 is the fastest rate and should work for most blanks however if the cutter becomes

dull or thick blanks are used, you may need to select a slower speed. Proceed as follows to set

the default cut rate. Press to enter the EDIT mode. Press four

times to display CUT FEED RATE(current feed rate).To change the rate to 2, press

The machine will now display CUT FEED RATE 2. Press and . Follow display

instructions and all plunge cuts will be made at cut rate 2.

SETTING DISPLAY MODE

Press to enter the EDIT mode. Press five times to display

BAR GRAPH DISPLAY MODE SELECTED or NUMERIC DISPLAY MODE SELECTED. Press

key to toggle. Press the key twice and follow display instructions.

8

SETTING THE LCD DISPLAY CONTRAST

Press to enter the EDIT mode. Press the key six times and

the display will read SET LCD CONTRAST 9=DARK..10=LIGHT . Press and hold the key and

the display will darken. Press and hold the key and the display will lighten. Press the

key twice and follow the display instructions.

RESET CODE (for factory use)

SETTING CUSTOM FLAT WIDTHS

The flat width determines the width at the bottom of a cut. There are 10 possible flats to

choose from and they are all user definable. The following section describes how to set your own

flat width.

** CAUTION ** FLAT WIDTHS 1 THRU 8 ARE USED WITH THE MANUFACTURER ID’S AND

CHANGING THESE FLAT WIDTHS WILL CAUSE WRONG FLAT WIDTHS TO BE CUT.

Press to enter the EDIT mode. Press and and the

display will show FLAT 1 = 014. NOTE: Flat 1 is the flat width of the installed cutter and when

cutters are changed, flat 1 must be changed to match the flat width of the new cutter. Pressing

will step through all the 10 flats. To change a flat, enter the desired flat width and press

. For a table of flat numbers and widths refer to the table below .

FLAT WIDTH TABLE

FLAT WIDTH EQUIVALENT CUTTER

1 0.014 INCH CW1012

2 0.024 INCH 37MC USE FOR ASSA

3 0.044 INCH CW1011

4 0.048 INCH 14MC

5 0.036 INCH 4711

6 0.032 INCH Assa

7 0.070 INCH 20MC

8 0.090 INCH CC100

9 INCH USER DEFINED WIDTH

10 INCH USER DEFINED WIDTH

Note: If a CW101 1 cutter is installed, and the manufacture selected calls for a #1 or #2 flat

the display will read the warning FLAT LESS THEN CUTTER INSTALLED.

CREATING A CUSTOM ID TABLE

There are 160 custom IDs you can change yourself the range is 801 to 960. They support

the same features as the fixed IDs. The following sections explain how to create or edit your own

custom ID. The last page of the manual contains a form that should (MUST) be completed before

starting to create a new ID. Photocopy the last page there is only one.

NOTE: The following instructions are set to be followed in a consecutive manner and will

not work properly on an individual basis. Pressing repetitively will cycle you to an

individual function.

9

SELECTING ID TO BE CREATED

Enter the EDIT mode by pressing the keys.

To create ID 803, press followed by The ITL950C will display EDITING ID

803. Y ou have now set the lD number to be edited.

Press

used with keys that require different cut angles as with MEDECO(c), safety deposit box keys and

other flat steel keys. When pause is enabled, the machine will stop the cutter after each cut.

, screen will display ENABLE PAUSE (Y or N) press to toggle. Pause is

SETTING TIP TYPE

Press , screen will display TIP TYPE = 3. The tip type in an ID determines which reference

point is used to cut a key . To enter the new tip type of 2 press .

TABLE OF TIP REFERENCE POINTS

TIP REF # OFFSET RANGE OF SPACES NOTES

0 0.000 INCHES 0.001-1.350 INCHES SHOULDER REFERENCE

1 1.025 INCHES 0.000-0.749 INCHES SAFETY DEPOSIT KEYS

2 1.150 INCHES 0.000-1.149 INCHES USE INSERTS 1A, 1B, 1S.

3 1.350 INCHES 0.000-1.349 INCHES REFERENCE FROM

RIGHT VISE EDGE

SELECTING A FLAT

Press the lTL950C now displays FLAT NUMBER —.

The flat determines how wide the bottom of each cut will be. Note: flat 1 produces the same

width as the cutter being used.

The flat ranges from 1 through 10. To select flat 4, press , followed by . The

display will now show FLAT 4. Refer to the table of flats on page 8.

SELECTING INSERT NUMBER

Press the ITL950C will now show INSERT —. Refer to the following table for further

information on inserts. To select insert 3, press followed by . The display will now show

INSERT 3. Press to continue. Clear may be used to correct entries or return to edit mode.

10

DEPTH LIMITS FOR VISE INSERTS

INSERT NUMBER OFFSET FROM TRUE 0 RANGE OF DEPTHS

1 0.000 INCHES 0.465 - 0.180 INCHES

2 0.035 INCHES 0.430 - 0.145 INCHES

3 0.070 INCHES 0.395 - 0.110 INCHES

4 0.100 INCHES 0.365 - 0.080 INCHES

EXTENDEDTABLE

Press the ITL950C now displays EXTENDED TABLE Y/N Press to toggle.

The table must be set to (Y) for keys requiring 11 or 12 spaces.

When you select the extended table function, the ID # following the one you are currently

editing will contain the extra spaces. For example if you were editing ID 803, and selected the

extended table function, ID 804 would contain the 2 extra spaces. Note: You should not use ID

804 as a valid ID. When using the extended table use the maximum space value in the first

table, in this case 803 should be set to 10 and all 10 spaces must be valid. Edi t the second ID in

this case 804 as with any other custom ID however you need enter only spaces 1 and 2. Space

1 would be the 1 1th space in an extended ID and space 2 would the 12th space.

MAXIMUM SPACE

Press the ITL950C now displays MAXIMUM SP ACE. The range is 1 to 10. To select a

maximum space number of 7, press followed by . The display will now show

MAXIMUM SP ACE 7. The maximum space number is used to verify correct table set-up, define

table limits and determine code length. Enter and for 10th space, not the key.

MAXIMUM DEPTH

Press , the ITL950C now displays MAXIMUM DEPTH. The range is 0 to 10 (not the

key!). To select a maximum depth number of 8, press followed by . The display

will now show MAXIMUM DEPTH 8.

The maximum depth number is used to verify correct table set-up, and define table limits.

MINIMUM DEPTH

Press the ITL950C now displays MINIMUM DEPTH. The range is 0 to 9. To select a

minimum depth number of 1, press followed by . The display now shows MINIMUM

DEPTH 1. The minimum depth number is used to verify correct table set-up, and define table

11

limits. Press

NOTE: P ARAMETER T ABLE IS COMPLETE PLEASE REVIEW THE T ABLE FOR ACCURACY.

to return to EDIT.

T o review the table, continue pressing the

key until the display returns to EDIT.

SETTING VALUES IN SPACE TABLE

Press the ITL950C will display; SP ACE 1 = (0000). Enter the desired space information

in thousandths of and inch e.g. .250. Press on the keyboard, then press

to set entry and to continue to SPACE 2 ect., until all space entries are completed. The

ITL950C will automatically return to EDIT.

SETTING VALUES IN DEPTH TABLE

Press the ITL950C will display DEPTH 0 = ( - - - - ). Enter the desired depth

information in thousandths of and inch e.g. .335. Press . Then to set entry

and to continue to DEPTH 1=0000. Now continue to make entries until all depth entries are

completed. The ITL950C will automatically return to EDIT.

Press key, the ITL950C will display PUSH “—“ TO UPDATE TABLE, CLEAR TO

CANCEL. Press key to set entries. Now follow display commands to return to default.

To sum up be sure your entries are all correct and should your new code fail to work as

expected, DON’T PANIC, recheck the table and you will likely find an error in one of your entries.

T o view or edit your entries press , display will read EDIT . Press

, display will read EDITING ID 0803 continue to press to cycle through

the new ID parameters. To review the numeric entries in the space file, press and ,

then continue pressing the key . To review the depth file, press the number set in the minimum

depth setting and continue pressing the key through all depth settings.

12

Special Cutting Instructions

NOTE For nickel silver blanks our ITL MD1027 CARBIDE CUTTER should be used.

Cutting keys generated by Master Key Program

1. Generate Master Key system. Follow instructions on page 17.

2. Push This will enable use of the Generated system.

3. Select key number from printed chart Press (key number), or continue to press

. to cycle through the generated system.

4. Press when desired key is displayed.

General Motors

General Motors and other keys that have deep cuts close to the shoulder.

1. Input code in the regular fashion.

2. Push key four times, display will read PLUNGE = NONE

3. Push key twice to PLUNGE = FIRST.

4. Push key twice. Move vise right to 0000, the screen will now display CUT TO

CONTINUE. Press , the cutter motor will start, wait until the cutter rests on the

bottom of the cut.

5. Turn the handle counter clockwise to complete the remainder of the cuts in a regular

fashion

Non Biaxial Medeco ( MFG 298,299,302 )

Note CW1012 cutter should be installed for Medeco. 1 flat should be set to 14 thousands.

T o cut a key with a code 1 LEFT, 2 CENTER, 2 RIGHT , 1 CENTER, 2 LEFT push the ,

, , , then . Note the center cuts are set by default. The first

angle ( C ) will flash. Now proceed to cut all center cuts. Push move the vise to 0000 and

push move the vise to 0000 and push The second angle will flash ( L ) turn the cutter

head to the new angle and push . The third angle ( R ) will flash turn the cutter head to the

new angle and push move the vise to 0000 and push . Note the ITL950C will cut all

center cuts first then all left cuts, then all right cuts.

PROGRAMING THE ITL950C

For special instrutions on writing code for the ITL950C Phone 1 888 264-6627.

13

SETTING SERIAL PORT PARAMETERS

SETTING BAUD RATE

Enter the EDIT mode by pressing the keys. Press twice to

enter the Serial port setup routine. Display will read BAUD RATE =8. Use the table

below to select a baud rate. For example to set the baud rate to 4800, locate the correct

baud rate (in this case 7). Now enter the selected baud rate

and press to

save the new baud rate or to erase or correct your entry. Pressing with no

number entered and you will exit the Serial setup routine without changing the baud

rate.

BAUD RA TE SELECT CODE

75 1

150 2

300 3

600 4

1200 5

2400 6

4800 7

9600 8

ERROR MESSAGES

INV ALID MFG ID The ID entered is incorrect; the valid range is 0 through 960.” 0” is a special case used

to load from the serial port.

INV ALID SPACE The space number or value entered is incorrect. See EDITING A CUSTOM ID TABLE

for more information.

CODE TOO LONG The code entered is too long.

SP ACE ERROR 10 Space calibration has failed. Check for obstruction. May also be a machine failure.

DEPTH ERROR 11 Depth calibration has failed. Check for obstruction. May also be a machine failure.

INV ALID C.F. Incorrect correction factor . Range is 9 to -9.

NO CODE SET Y ou must enter both an ID and Code before cutting a key .

OUT OF RANGE Space or depth calibration value exceeds limits. Range is 127 to -127.

INV ALID FLAT # Incorrect fiat # entered. Range is 1 through 10.

INV ALID INSERT # Incorrect insert # entered. Range is 1 through 4.

14

INVALID MAXSPC 11 Incorrect maximum space number. Range is 1 through 10.

INVALID MAXDPT # Incorrect maximum depth number. Range is I through 10

INVALID MINDPT # Incorrect minimum depth number. Range is 0 or 9.

INV ALID BAUD RATE Incorrect baud rate number. Range is 1 through 8.

ERROR LOADING TABLE Remote code load has failed. Check serial port parameters.

INV ALID SPEED Incorrect feed rate number. Range is 1 through 4.

RANGE IS 1 TO 4

INV ALID TIP TYPE The tip number selected is invalid. The range is 0 through 3.

RANGE IS 0 TO 3

INVALID FLAT WIDTH The fiat number selected is invalid. The range is 1 through 10.

RANGE IS 1 TO 10

INVALID DEPTH The depth entered is invalid. The range is 110 T O 465.

RANGE IS 1 10 TO 465

INVALID SPACE VALUE The space entered is out of range. The range is 1 to 10.

RANGE IS 1 TO 10

BAD T ABLE ENTR Y The t able being loaded has invalid entries. If the entry is a custom ID then recheck your entries.

If the entry is in the range of 1 through 800 then check the list of manufacturers and report

the error to your distributor. Note that if you select an ID not in the list it will not be correct.

INV ALID INSER T CF The correction value exceeds the allowed range. Range is .009 to -.009.

15

FLOW CHART TO CUT MEDECO BIAXIAL

1 - Press Display will read MANUFACTURER 300

INSERT 2 FLAT 1

2 - Press Display will read BI-AXIAL ENTERY

M0DE SELECTED

3 - Press Display will read BI-CODE =

4 - Enter code, to use 3B, 4K, 5Q, 6D, 2M, 1S. Press , , ,

, , .

Display will now read: BI-CODE = BKQDMS

3 4 5 6 2 1

5 - Press , display will now read: BI-CODE =

6 - Press , display will read RDY. Press , display will now read: CUT TO CONTINUE

The machine makes center cuts first, then left cuts and last the right cuts. the letter B will be

flashing indicating the first cut to be made. (ignore the cursuor flashing under the S)

7 - Press , display will read MOVE VICE

S > |||||||||||||| BKQDMS The vise direction indicator will be

flashing, turn the space handle clockwise untill the bars disapear, the numbers count down to

0000 and the display reads CUT TO CONTINUE.

8 - Press , cutter motor will start and the first cut will be made. When the cutter motor stops

follow the direction indicator, counterclockwise, to the second cut. When the display

reads 0000 and CUT TO CONTINUE press . When all the center cuts have

been made the display will flash the letter of the first left cut to be made. Remember

to change the head angle.Pull out the lock pin on the back of the cutter head. Rotate

the head clockwise for left cuts and counter clockwise for right cuts. Make sure the

lock pin seats in each location. Press and follow bar graph to

next cut position.

345621

B K Q D M S

BKQDMS

Non biaxial medeco on page 13

16

CREA TING A 950C

MASTER KEYING CHART

Set Manufacturer Id _____

Change System Variables

Change advanced Variables

MACS Limit 6

Max duplicate cuts 3

Rotate sequence 12345

Generate Masterkey System

Toggle MK or GMK

Set Masterkey Set Grandmasterkey

MK = _____

Step control 22222

# of Changekeys

Step control 22222

MK # 1 Number of change keys

GMK =______

MK = 2

Generating Masterkey System

Restore System Defaults

Go to page 13 for instructions on cutting generated keys. Press to exit.

MK #2 Number of change keys

Print Reports to Remote

Send Masterkey Report

to computer for Printing

Send Hardware Report

to computer for Printing

Send Keying Chart to

computer for Printing

17

Need more help?

Our technical support team is committed to helping you.

Email Us:

techsupport@intralocktools.com

or call

toll-free at: 1-888-264-6627

Check our other ITL products

www.intralocktools.com

18

Loading...

Loading...