Page 1

ITABAR-Sensor Type IBFD Operating Manual

Type IBFD

Contents:

0. Principle of flow measuring with ITABAR-Flow-Sensor............................................2

1. Product Description ......................................................................................................... 2

2. Operating Conditions.......................................................................................................2

3. Pre-Installation Checks....................................................................................................2

4. General Installation Notes ...............................................................................................3

5. Installation of the ITABAR Sensor .................................................................................7

6. Insulation .......................................................................................................................11

8. Measurement Start-Up...................................................................................................13

9. Preventive Maintenance.................................................................................................13

10. Trouble shooting sensors with condensate pots.............................................................13

INTRA-AUTOMATION GmbH

Meß- und Regelinstrumente

Otto-Hahn-Straße 20

41515 Grevenbroich

Tel.: 0 21 81 / 7 56 65 - 0

Fax: 0 21 81 / 6 44 92

Internet: www.intra-automation.de

E-Mail:

info@intra-automation.de Dok.: BA_IBFD_en_041201.DOC

1

Page 2

ITABAR-Sensor Type IBFD Operating Manual

0. Principle of flow measuring with

ITABAR-Flow-Sensor

If there will be insert a sensor rounded on the face in

a parallel stream with velocity w, damming up of the

fluid will be the result. In the middle of this area are

streamlines, called damming up streamlines, which

will be vertical to the sensor. Velocity of the

becomes approximately zero at this significant point.

Everytime damming up streamlines are laminar. In

this case flow measurement can be handle very easy

(no friction):

Using the theme of Bernoulli, you can calculate:

p

ges

= p

+ ½ w².

stat

With the patented profil of the ITABAR-FlowSensor you can measure the total pressure p

upstreams and the and the static pressure p

ges

stat

downstreams. The difference between static and

total pressure is:

w = (2/ρ p

dyn

)½.

By knowing the innerside pipe diameter it applies to

the theme of continuity:

V ∼ w A.

Using a proportional factor, called correction factor

k, you can calculate in accordance with the

following formula:

V = k w A or m = k ρ w A.

This correction factor k is a value only depending on

the ITABAR-Flow-Sensor-Profil. This value had

been find out by INTRA-AUTOMATION

empirically.

Specially for steam-measuring you can not measure

the differencial pressure with electrical or pneumatic

transmitter directly (max. temperature of medium <

100°C). You have to use impulse pipes containing

an identical head of condensate at identical

temperature. To get this result ITABAR-Sensors

will be delivered everytime with condensate

reservoirs. The flow of steam will not demage the

transmitter. But you can only calculate in

accordance with the theme of pressure transmission

(Pascal), if there will be no air in the pressure pipe

and the chambers of the transmitter. If there is air in

it, you can not neglect friction. The dynamic energy

will not be transmitted to the differential transmitter

without faults. You will not get correct measuring

results.

1. Product Description

We congratulate you on your purchase of an

ITABAR Flow Sensor type IBFD.

When installed properly, the ITABAR sensor offers

an array of advantages over other measurement

systems with respect to its accuracy, pressure loss,

and installation. The following guide line is

designed to help you with the sensor installation and

operation.

ITABAR-Flow-Sensors are designed in the way that

the innerside profil diameter will not be smaller than

8 mm. This guarantees condensate drops with a

maximal diameter of 6.5 mm will not prevent a

correct measuring (Prandtl, L.).

2. Operating Conditions

ITABAR Flow sensors type IBFD can be used under

the following conditions:

• Operating pressure: max. 400 bar at 300 °C

max. 160 bar at 590 °C

• Nominal Pipe

Diameters: DN 40 to DN 1000

3. Pre-Installation Checks

Before installation, make sure that all of the

following parts are included in the sensor kit:

• ITABAR-Sensor, Type IBFD

• condensation vessels, flanged or direct welded

on sensor head

• Mounting flange with weld stud

• Gasket for the mounting flange and flanged

model of condensation vessels

• Bolts and nuts (material suitable for temperature

and pressure rating)

• Sensor end support with sealing plug up to

PN 40, for higher pressure closed type

• Instrument valve assembly (if ordered)

NOTE:

The ITABAR type IBFD-26/36 HTG is a

completely welded construction, there are no

flanges, gaskets, stud bolts or nuts needed.

Compare the specifications on the type identification

plate on the sensor with your order form.

The identification plate contains the following information:

• Serial number

• Type name

• Pipe inside diameter

• TAG number

(Measuring location number - if furnished)

• Material

ATTENTION!

You must make sure that the pipe inside diameter

given on the identification plate matches your pipe

diameter.

2

Page 3

ITABAR-Sensor Type IBFD Operating Manual

4. General Installation Notes

In order to obtain optimal measurement results,

follow the notes concerning the installation of the

ITABAR sensor given below.

4.1. Determination of Pipe Arrangement

For design reasons, the pipe arrangement at the

installation location has to be known before the sensor is manufactured. Since the ITABAR sensors for

vertical lines are not interchangeable with those for

horizontal lines.

• Pipe arrangement, horizontal or vertical

• flow direction (only for models with direct

welded condensation vessels)

• Wall thickness of pipe

For horizontal and vertical pipe run the

condensation vessels have to be arranged in the

same horizontal plain.

Compare Fig. 3b and 4b.

Differential pressure tap

4.2. Vertical Pipe Arrangement

The ITABAR sensor for flow measurement of steam

and saturated steam can be installed in vertical pipe

runs at any location, however, the instrument

connections have to be located in the same

horizontal plain (Fig. 3a and 3b).

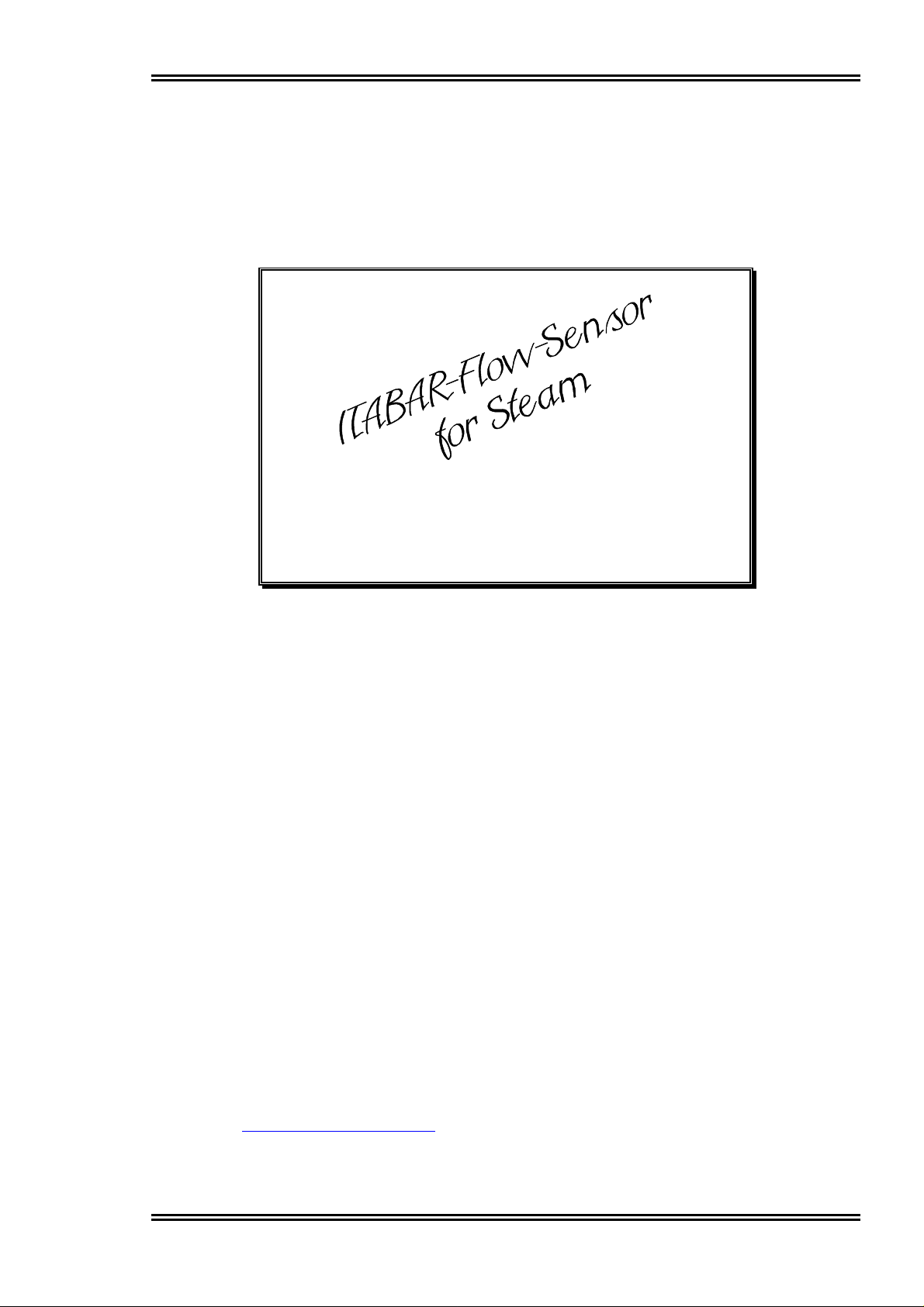

Fig. 3a: Installation for vertical pipe run,

example type IBFD-25…K1H-A81

Fig. 1: Horizontal pipe run

Fig. 2: Vertical pipe run

The flow direction is indicated in each case by the

arrow on the sensor head.

Fig. 3a: Installation for vertical pipe run,

example type IBFD-25….-K5-A16

Fig. 3a: Installation for vertical pipe run,

example type IBFD-26 HTG… -K5-A16

3

Page 4

ITABAR-Sensor Type IBFD Operating Manual

Fig. 3b: Installation for vertical pipe run

example type IBFD-25…-K1H-A81

Fig. 3b: Installation for vertical pipe run

example type IBFD-25…-K7-A18

Fig. 4a: Installation for horizontal pipe run,

example type IBFD-25…-K1H-A81

Fig. 4a: Installation for horizontal pipe run,

example type IBFD-25….-K5-A16

Fig. 3b: Installation for vertical pipe run

example type IBFD-25 HTG….K5-A16

4.3. Horizontal Pipe Arrangement

Always install the ITABAR steam sensor

horizontally with the instrument connections

(condensation vessels) along a horizontal line.

(Fig. 4a and 4b).

Fig. 4a: Installation for horizontal pipe run,

example type IBFD-26-HTG…K5-A16

Fig. 4b: Installation for horizontal pipe run,

example type IBFD-25….-K1H-A81

4

Page 5

ITABAR-Sensor Type IBFD Operating Manual

The tolerances given in the following figures valid

both vertical and horizontal steam lines.

5°

Fig. 4b: Installation for horizontal pipe run,

example type IBFD-25…-K7-A18

Fig. 4a: Installation for horizontal pipe run,

example type IBFD-26-HTG…-K5-A16

3°

Fig. 6: Horizontal pipe run (top view),

example type IBFD-25 without

condensation vessel

1°

Fig. 5: Horizontal pipe run,

example type IBFD-25…-K7-A18

4.4. Misalignment

The ITABAR sensor operates on the basis of simple

physical principles.

Its design incorporates no moving parts which are

subject to wear.

The sensor is not affected by being slightly out of

alignment.

The influence on the accuracy of the measurements

is negligible as long as the limits indicated in

Figures 5, 6 and 7 are not exceeded.

Take care to prevent unequal heights of condensate

in the vessels. The max. deviation from the

horizontal line is 1° (see Fig. 7).

Fig. 7: Horizontal pipe run,

example type IBFD-25…-K7-A18

5

Page 6

ITABAR-Sensor Type IBFD Operating Manual

4.5. Required Undisturbed Pipe Run Lengths

(in multiples of D)

The accuracy of the measurements of the ITABAR

sensor depends on the development of a stream

profile which should be as undisturbed as possible.

Therefore the selection of the installation location

within the pipe run is of considerable importance.

The following tried and true hints regarding the

required pipe lengths ahead of and behind the sensor

are designed to help you in your selection of the

most advantageous installation location.

As a general rule, regulating valves, throttle valves,

and gate-type valves should be installed behind the

sensor.

D=Pipe Diameter

NOTE:

If the recommended straight pipe run lengths are not

available, the measuring accuracy can be adjusted to

the specific conditions of the measuring stretch by

conducting a comparison measurement.

The measurement guarantees that the differential

pressure corresponds to the true flow velocity,

thereby assuring the specified accuracy.

Details can be requested from the manufacturer.

A=Upstream B=Downstream

7

3

Restriction in the Pipe Run

Widening of the pipe Run

Regulating Device

9

17

18

7

7

3

4

4

3

3

24

6

4

Page 7

ITABAR-Sensor Type IBFD Operating Manual

5. Installation of the ITABAR Sensor

In difference to other suppliers the ITABAR-FlowSensor everytime will be build in in the horizontal

line of the pipe and always have condensate pots.

Therefore the influence of condensation and

vaporization is minimized. Please pay attention that

both condensate levels on plus and minus pressure

pipe will be the same. This means both pots must be

on the same horizontal line and there has to be no air

in the pulse tubes and the chambers of the

transmitter.

Following problems will happened by using sensors

of other manufactors who does not use condensate

pots or prefered installation of the sensor on the

lower side of the pipe:

• Condensation and vaporization happened in the

sensor profil. For this reason there is a great

influence to the level of the condensate column.

• There is no energy balance between plus and

minus process connection.

• no equal temperatures in the condensate

columns.

• No chance to correct misalignments

It is not allowed to install ITABAR-Flow-Sensor at

the top of the pipe. If costumer did so, he is not able

to get out all air from the sensor and the condensate

pots. The energy of the system will not be

transmitted without loss to the transmitter. The

kinetic energy will be changed particulary changed

to potential energy. This is eliminated for ITABARFlow-Sensors.

Observe the general installation instructions!

It is particularly important to make sure that the

distance from the gasket surface to the pipe agrees

with the H-dimension you gave in your order (see

Fig. 8).

ITABAR sensors of the type IBFD are supplied with

the following standard H-dimensions:

IBFD-20/21 80 mm

IBFD-25/26 127 mm

IBFD-35/36 150 mm

IBFD-26/36 HT 200 mm

IBFD-26/36 HTG 168 mm

5.1. Installation of Type IBFD-20

H

Fig. 8

3. Observe the H-dimension during the welding of

the mounting flange (see also Fig. 8).

4. Check the alignment of the mounting flange

again - this is importatnt for the exact position of

the condensation vessels.

5. Now the ITABAR sensor can be installed into

the pipe. Place the included gasket on the gasket

surface of the flange. Insert the sensor into the

welded stud and make sure that the arrow on the

sensor flange points in the flow direction.

Tighten the bolts and nuts.

6. Now check the alignment of the condensation

vessel. The condensation vessel have to be

perfectly mounted along a horizontal line.

Check the alignment!

For correction of alignment slightly release stud

bolts on the mounting flange. For correct alignment tighten stud bolts with required torque

according table 1.

H

45°

1. Drill a hole of 18 mm diameter into the pipe.

2. Tack the mounting flange onto the pipe leaving a

clearance of 1-2 mm. The bolt holes of the flange

must be at 45° angles to the pipe axis (see Fig.

9).

Check the alignment of the mounting flange.

Fig. 9

7

Page 8

ITABAR-Sensor Type IBFD Operating Manual

Thread Torque max. Temp.

M12 2,5 - 3 Mkp 300°C

M12 3,5 - 4 Mkp >300°C

M16 5,5 - 6 Mkp 300°C

M16 9 - 9,5 Mkp >300°C

M20 11,5 - 12 Mkp 300°C

M20 18 - 18,5 Mkp >300°C

M24 19 - 19,5 Mkp 300°C

M24 30 - 31,5 Mkp >300°C

Table 1

5.2. Installation of Type IBFD-21

The design of the ITABAR sensor IBFD-21 is

almost identical to the type IBFD-20. The only

difference is the end support for type IBFD-21 (see

Fig. 10), which permits higher stream velocities in

the pipe.

Except for the installation of the sensor end support,

the installation steps are identical to those for type

IBFD-20.

Installation of the closed sensor end support:

1. Install the mounting flange as already described

under chapter 5.1. points 1 to 3.

6. Remove the sensor.

7. Finish welding of mounting flange and end

support can be made.

8. Perform the installation of the sensor into the

pipe according to the instructions given in

chapter 5.1. points 5 and 6.

5.3. Installation of type IBFD-25/35

The installation of the types IBFD-25/35 correspond

to the type IBFD-20.

ATTENTION!

For the installation are following hole-diameters for

mounting stud/flange and end support requested:

IBFD-25 35 mm

IBFD-35 45 mm

IBFD-36-HTG 47 mm mounting stud

41 mm end support

NOTE:

On flanges with eight bolt holes, the welding stud

must be welded on so that the bolt holes in the

flange form an angle of 22.5° with the pipe axis (see

Fig. 11).

2. Take a cord and tie one end around the existing

weld stud. Wrap the other end of the cord around

the pipe so that it forms a loop around the pipe.

Mark the half-way point of the pipe

circumference on the pipe.

3. Now drill a second hole of 18 mm diameter into

the pipe.

4. Insert the ITABAR sensor through the mounting

flange and check correct alignment.

Put the end support on the tip of the sensor.

Fig. 10

5 Tack the sensor end support with 2 mm

clearance onto the pipe.

22,5°

Fig. 11

5.4. Installation of type IBFD-26/36 and IBFD26/36 HTG

The installation of these ITABAR sensors correspond to the installation of type IBFD-21.

Please look at chapter 5.2.

Note that the a.m. sensor types will delivered

normally with a closed sensor end support.

The plugged sensor end support is only up to

pressures of 40 bar available.

ATTENTION!

For the installation are following hole-diameters for

mounting stud/flange and end support requested:

IBFD-26 35 mm

IBFD-26 HTG 35 mm

IBFD-36 45 mm

IBFD-36 HTG 47mm

Installation of the closed end support:

8

Page 9

ITABAR-Sensor Type IBFD Operating Manual

Please refer to chapter 5.2 for installation of closed

sensor end support.

Take care of the diameters of the hole!

Installation of sensor end support with sealing plug:

1. Install the mounting flange as already described

at chapter 5.1. points 1 to 3.

2. Take a cord and tie one end around the existing

weld stud. Wrap the other end of the cord around

the pipe so that it forms a loop around the pipe.

Mark the half-way point of the pipe

circumference on the pipe.

3. Now drill a second hole of 35 mm (IBFD-26)

respectively 45 mm diameter (IBFD-36) into the

pipe.

4. Insert the ITABAR sensor through the mounting

flange and verify the alignment.

Push the end support over the sensor tip of the

opposite side of the pipe.

5 Tack the sensor end support onto the pipe

leaving approximately 2 mm clearance.

6. Remove the sensor from the pipe.

7. Finish welding of mounting flange and end

support can be made.

8. Seal the thread of the sealing plug with a suitable

sealing compound (e.g. PTFE tape). Screw the

plug into the sensor end support and tighten it

firmly.

9. Perform the installation of the sensor into the

pipe according to the instructions given in

chapter 5.1. points 5 and 6.

5.5. Installation of type IBFD-26/36 HTG

The sensor type IBFD-26/36 HTG is a special fully

welded construction for high pressures and

temperatures. Mounting stud and sensor will welded

each another to prevent any leakage.

To remove the sensor if required you have only to

separate mounting stud and sensor by cutting the

weld between this two parts (see Fig. 12).

ATTENTION!

Please take care on the H-dimension in case you did

not co-ordinate the weld preparation of the pipe

system with our work.

To make sure that sensor matches your preparation

consult now our engineers.

Installation of type IBFD-26/36 HTG:

1. Drill a hole of 30 mm (IBFD-26 HTG)

respectively 47 mm diameter (IBFD-36 HTG)

into the pipe.

2. Tack the mounting stud onto the pipe leaving a

clearance of 4 mm. Check the alignment of the

stud.

The stud have to be mounted exact rectangular to

the pipe axis. Verify the correct alignment. Then

the finish weld can be made.

3. Take a cord and tie one end around the existing

weld stud. Wrap the other end of the cord around

the pipe so that it forms a loop around the pipe.

Mark the half-way point of the pipe

circumference on the pipe.

4. Now drill a second hole of 35 mm (IBFD-26

HTG) respectively 41 mm diameter (IBFD-36

HTG) into the pipe.

5. Insert the sensor into the mounting stud. Align

the sensor exactly along a horizontal line. Tack

the sensor with 4 mm clearance to the mounting

stud. Check H-dimension again.

6. Put the end support on the tip of the sensor. Tack

the end support with 4 mm clearance onto the

pipe. Correct the alignment.

7. Now the finish weld between sensor and

mounting stud can be carried out.

8. At least the end support can be finish welded.

Disassembly:

If required the weld between mounting stud and

sensor can be separated for disassembly. While the

tolerance between sensor end endsupport is 0.2 mm,

it can happened that the sensor will be welded

together with the endsupport in inappropriate way.

Then the endsupport has to be seperated also.

Mounting

weld seam

Fig. 12: Disassembly of type IBFD-26/36 HTG

5.6. Installation of Type IBFD-65

9

Page 10

ITABAR-Sensor Type IBFD Operating Manual

The installation of the types IBFD-65 correspond to

the type IBFD-20. The only different is, that the

mounting stud is designed with a weldolet.

1. Drill a hole of 60 mm diameter into the pipe.

2. Tack the mounting flange onto the pipe leaving a

clearance of 4 mm. The bolt holes of the flange

must be at 22,5° angles to the pipe axis (see Fig.

13). Check the alignment of the mounting

flange.

22,5°

Fig. 13

3. Observe the H-dimension during the welding of

the mounting flange (see also Fig. 14).

ment tighten stud bolts with required torque

according table 1.

5.7. Installation of Type IBFD-66

The design of the ITABAR sensor IBFD-66 is

Fig. 14

4. Check the alignment of the mounting flange

again - this is important for the exact position of

the condensation vessels.

5. Now the ITABAR sensor can be installed into

the pipe. Place the included gasket on the gasket

surface of the flange. Insert the sensor into the

welded stud and make sure that the arrow on the

sensor flange points in the flow direction.

Tighten the bolts and nuts.

6. Now check the alignment of the condensation

vessel. The condensation vessel have to be

perfectly mounted along a horizontal line.

Check the alignment!

For correction of alignment slightly release stud

bolts on the mounting flange. For correct align-

10

Page 11

ITABAR-Sensor Type IBFD Operating Manual

almost identical to the type IBFD-65. The only

difference is the end support (with a weldolet for

type IBFD-66 ; see Fig. 15), which permits higher

stream velocities in the pipe.

Except for the installation of the sensor end support,

the installation steps are identical to those for type

IBFD-65.

Installation of the closed sensor end support:

1. Install the mounting flange as already described

under chapter 5.6. points 1 to 6.

2. Take a cord and tie one end around the existing

weld stud. Wrap the other end of the cord around

the pipe so that it forms a loop around the pipe.

Mark the half-way point of the pipe

circumference on the pipe.

3. Now drill a second hole of 60 mm diameter into

the pipe.

4. Insert the ITABAR sensor through the mounting

flange and check correct alignment. Put the

weldolet (item A, fig. 15) on the pipe.

Fig. 15

5. Tack the weldolet (item A) with 4mm clearance

onto the pipe.

6. Remove the sensor.

7. Finish welding of weldolet (item A).

8. Insert the ITABAR sensor through the mounting

flange and install the ring (item B, fig. 15). If it´s

not possible, because the tolerance of welding

are to much, so you are able to machine the ring

(clearence into the weldolet -0,2mm).

9. Now you can weld the endcap (item C, fig. 15)

onto the weldolet (item A).

6. Insulation

It is important for proper operation of the ITABAR

steam sensor that the phase change from vapour to

liquid take place only in the therefore specially

designed condensation vessels and not in the head

of the sensor.

Therefore, the entire sensor head and all other parts

up to the condensation vessels must be insulated

with a suitable material.

Before being insulated, all piping connections

should be checked for leaks and the instrument

connection for the differential pressure have to be

marked ( + and - ) to prevent confusion.

Finally, the ITABAR TAG-plate must hang outside

the insulation for later identification of the flow

station.

ATTENTION!

Do not insulate the condensation vessels, valves and

the lines to the differential pressure transmitter!

The media there have to be in liquid state.

7. Installation of valve block and

the p-transmitter

7.1. Valve block

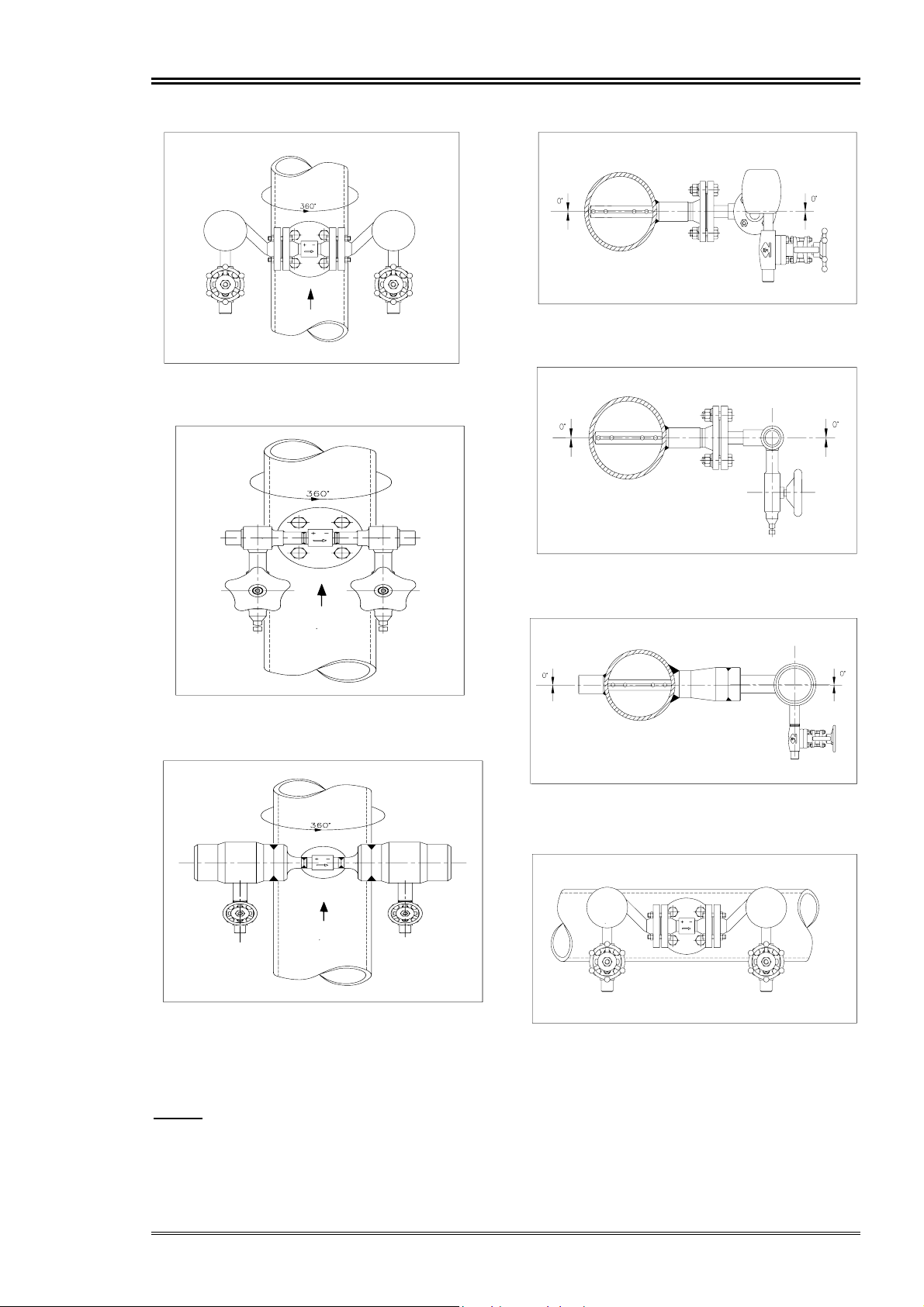

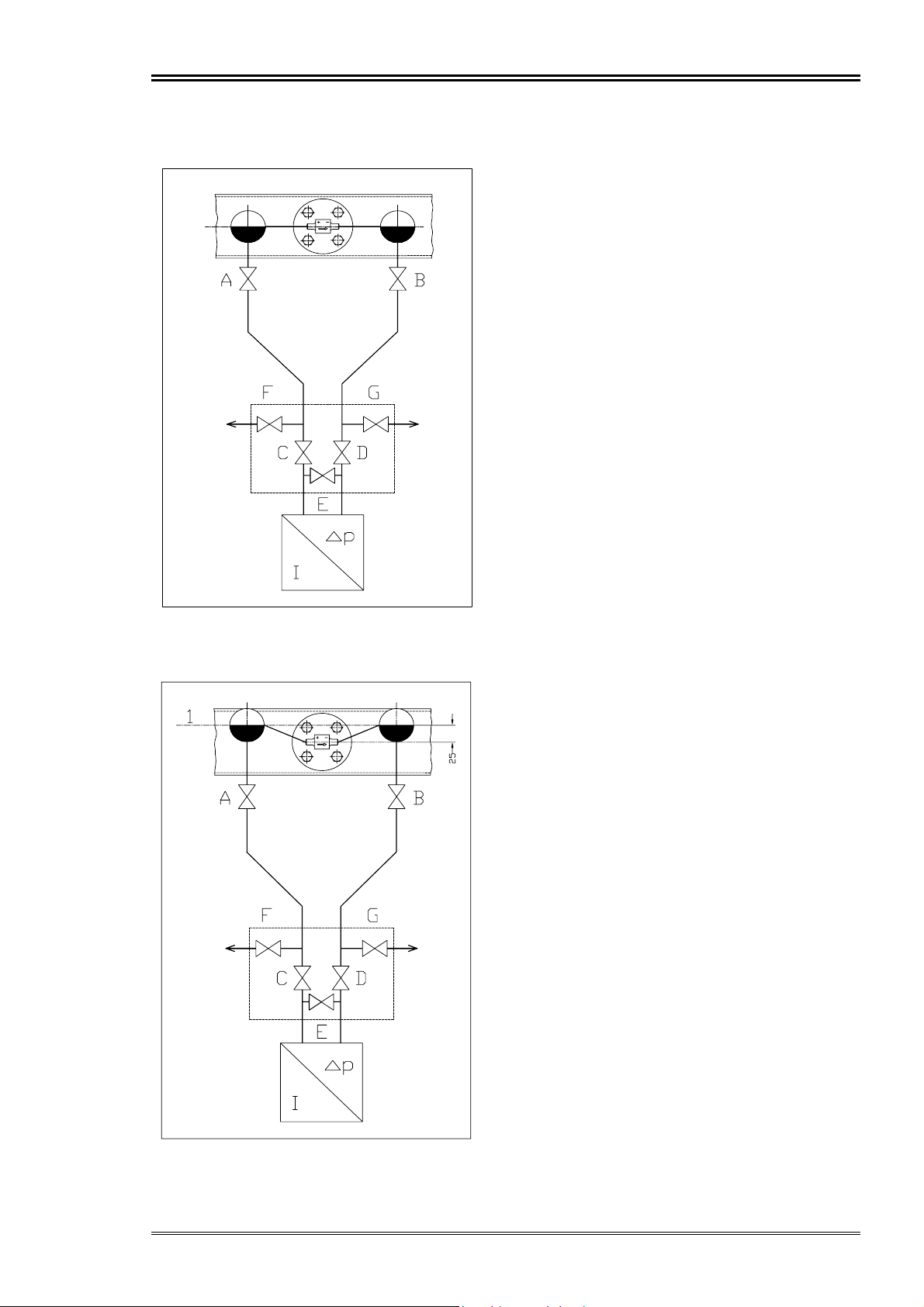

For steam measurement a 3-valve instrument

manifold is recommended. The valves of a 3-valve

manifold has the following functions:

• Valve C and D shut-off to transmitter,

• Valve E Bypass valve (transmitter zero),

If a 5-valve instrument manifold will be used the

valve has additional function:

• valve F and G for drains

See Fig. 13a and b

7.2. ∆p-Transmitter

For steam measurements, the differential pressure

transmitter should always be installed below the

ITABAR sensor in order to avoid the occurrence of

air bubbles in the instrument connections (see

Fig. 13a and b). Take care to mount the dptransmitter exactly horizontal, otherwise a small

difference to alignment is followed by a zero point

error.

We recommend you to install the differential

pressure lines close together (connect hi and lo line

heat conducting) to maintain equal temperature.

11

Page 12

ITABAR-Sensor Type IBFD Operating Manual

Sensor with condensate pots K5/6/7

Fig. 13a

Sensor with condensate pots K1..

Fig. 13b

12

Page 13

ITABAR-Sensor Type IBFD Operating Manual

8. Measurement Start-Up

Make sure that:

- all installation openings are closed,

- all installed parts are securely bolted together,

- all shut-off valve are closed,

- all valves of the 3-valve or 5-valve manifold are

closed

Now the pipe can be cleared for the appropriate

medium.

Check all connections, especially the flange gasket.

It takes about 30-60 minutes that the condensation

vessels will filled with condensate.

Now you can open the primary line valves A and B.

To vent the measuring system open valves F and G.

Close the valves when water without air pockets is

to be seen.

ATTENTION!

Take care that for high pressure application the

vent/drain lines are mounted according to the safety

instructions.

Open now the valves for the

∆p-transmitter (valve C

and D).

Open the valve E for transmitter zero only.

If transmitter zero is O.K. close the valve E. Allow

condensate level to stabilise 1/2 hour before

recording transmitter readings again.

9. Preventive Maintenance

NOTE:

Two-Phase flow or alternating phase flow will cau se

an erratic spiking signal. The ITABAR sensors are

head-measuring devices and will not accurately

measure two-phase flow.

ITABAR-Flow-Sensors for low pressure steam have

condensate pots in which the condensate water line

is 25mm higher than the flange connection of the

sensor is installed precise horizontal.

That means that water column of static and dynamic

pressure side must have the same high to guarantee

zero differential pressure when steam is not flowing.

The arrangment of higher condensate line than

sensor connection has been done to secure the exact

water column onto the d.p. transmitter.

During steam flow the steam will move into the

condensate pots and will condensate to water. The

water level above line 1 will flow back into the

sensor and change again into steam. The steam

pressure from dynamic and static connection is

pressing onto the water level and the difference ot

these pressures will be transmitted into mA- signal

through the differential pressure transmitter.

Please note that 25mm deviation in the line of 1 will

give 25mm WG differential pressure.

ITABAR sensors are insensitive to dirt and soil

build-up and therefore nearly maintenance-free.

However, if cleaning is required:

- remove the sensor

- flush completely

- hand clean with a soft wire brush

10. Trouble shooting sensors with

condensate pots

If, after the start-up of the ITABAR sensor, any

measuring errors occur, they may possibly be

corrected quite easily:

Error:

No differential pressure indication

Correction:

Check whether all instrument valves to the

transmitter are opened.

The valve E must be closed (only for zero).

Check the alignment of the sensor with the pipe. The

arrow on the sensor must point exactly in the flow

direction (downstream).

Error:

Alternating differential pressure

Correction:

Verify that the whole sensor up to the condensation

vessel is insulated.

Remove any insulation from condensation vessels!

∆p

13

Loading...

Loading...