INTORQ BFK470 Series, BFK470-10, BFK470-12, BFK470-14, BFK470-06 Translation Of The Original Operating Instructions

...Page 1

setting the standard

INTORQ BFK470

Spring-applied brake with electromagnetic release

Translation of the Original Operating Instructions

www.intorq.com

www.intorq.com

Page 2

This documentation applies to the:

AABCD

A

A

BCD

Product key

Legend for the product key

INTORQ BFK470

Product group Brake

Product type Spring-applied brake

INTORQ B FK -

Type 470

Size 06, 08, 10, 12, 14, 16, 18

Not coded: Supply voltage, hub bore hole, options

INTORQ | BA 14.0199 | 08/2016 2

Page 3

Identification

Packaging label Example

Manufacturer Bar code

Type (see product key) Type No.

Designation Qty. per box

Rated voltage Rated power Rated torque Hub diameter Packaging date

Note CE mark

Name plate Example

Manufacturer CE mark

Type (see product key)

Designation

Rated voltage Rated power Hub diameter

Type No. Rated torque

Date of manufacture

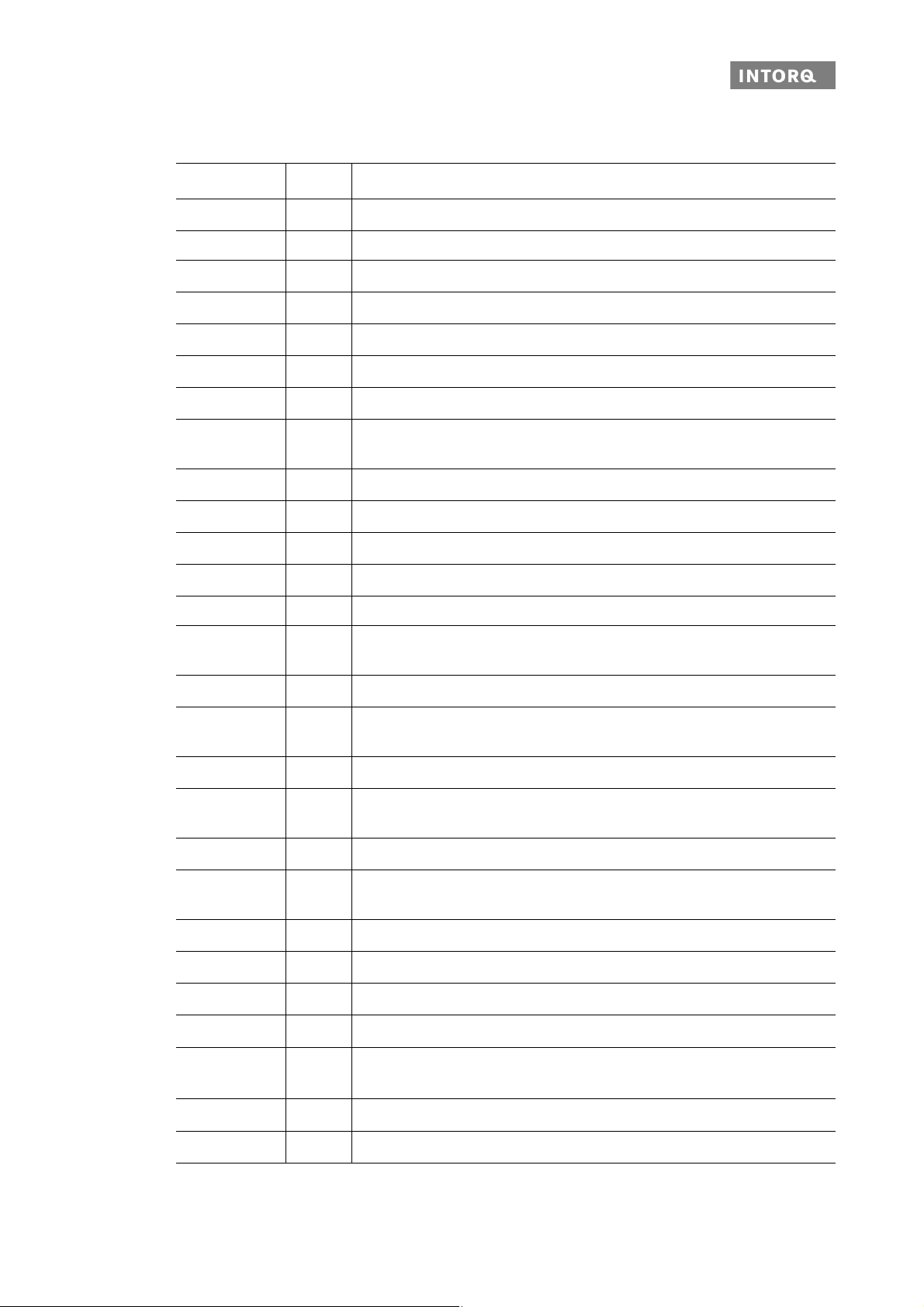

Document history

Material number Version Description

33001439 1.0 01/2012 TD09 First edition

33001439 1.1 03/2012 TD09 Supplemented the technical data

33001439 1.2 10/2012 TD09 Added to the "Brake assembly" chapter

Updated the "Abbreviations used" table

Supplemented the characteristics, rated data and operating times

33001439 2.0 05/2013 TD09 Degree of protection changed

Added note about the end shield characteristics

Shaft characteristic defined, "Mechanical installation" chapter

"Checking the brake" chapter (maintenance and repair) supple-

mented

33001439 3.0 05/2013 TD 09 Text with regard to the disengagement time updated

33001439 3.1 03/2014 SC

Restructured FM; note concerning brake seal 23

33001439 4.0 01/2015 SC Harmonized connection diagrams

33001439 5.0 08/2016 SC Additional sizes: 06, 08, 10, 12

Refer to www.intorq.de for the latest version of these operating instructions.

INTORQ | BA 14.0199 | 08/2016 3

Page 4

Contents

1 Preface and general information ...........................................................................................................................5

1.1 About these Operating Instructions ...............................................................................................................5

1.2 Terminology used ...................................................................... ....................................................................5

1.3 Conventions in use ........................................................................................................................................5

1.4 Abbreviations used ........................................................................................................................................6

1.5 Safety instructions and notices .....................................................................................................................7

1.6 Scope of delivery ...........................................................................................................................................8

1.7 Disposal ........................................................................................................................................................8

1.8 Drive systems ................................................................................................................................................9

1.9 Legal regulations ...........................................................................................................................................9

2 Safety instructions ...............................................................................................................................................10

2.1 General safety instructions ..........................................................................................................................10

2.2 Application as directed ................................................................................................................................11

3 Technical specifications ......................................................................................................................................12

3.1 Product description .....................................................................................................................................12

3.2 Rated data ...................................................................................................................................................14

3.3 Rated data (dimensioning data) electrical data ...........................................................................................16

3.4 Switching energy / operating frequency ......................................................................................................18

3.5 Emissions ....................................................................................................................................................19

4 Mechanical installation ........................................................................................................................................20

4.1 Important notes ...........................................................................................................................................20

4.2 Assembly .....................................................................................................................................................22

5 Electrical installation ............................................................................................................................................25

5.1 Important notes ...........................................................................................................................................25

5.2 Electrical connection ............. .... .... .... ..........................................................................................................25

5.3 Technical data for inductive proximity sensors ...........................................................................................30

5.4 Minimum bend radius for the brake connection line ....................................................................................31

5.5 Bridge/half-wave rectifier (optional) .............................................................................................................31

6 Commissioning and operation ............................................................................................................................34

6.1 Important notes ...........................................................................................................................................34

6.2 Function checks before commissioning ......................................................................................................35

6.3 Brake with proximity sensor ........................................................................................................................36

6.4 Commissioning ............................................................................................................................................37

6.5 During operation ..........................................................................................................................................37

7 Maintenance and repair ......................................................................................................................................38

7.1 Wear of spring-applied brakes ....................................................................................................................38

7.2 Inspections ..................................................................................................................................................39

7.3 Maintenance ................................................................................................................................................40

7.4 Spare-parts list ............................................................................................................................................43

7.5 Electrical accessories .................................................................... .... .... .... ..................................................43

8 Troubleshooting and fault elimination ...............................................................................................................44

INTORQ | BA 14.0199 | 08/2016 4

Page 5

Preface and general information

1 Preface and general information

1.1 About these Operating Instructions

❚ These Operating Instructions will help you to work safely with the spring-applied brake with electromag-

netic release. They contain safety instructions that must be followed.

❚ All persons working on or with electromagnetically released spring-applied brakes must have the Oper-

ating Instructions available and observe the information and notes relevant for them.

❚ The Operating Instructions must always be in a complete and perfectly readable condition.

1.2 Terminology used

Term In the following text used for

Spring-applied brake Spring-applied brake with electromagnetic release

Drive system Drive systems with spring-applied brakes and other drive compo-

1.3 Conventions in use

This document uses the following styles to distinguish between different types of information:

Spelling of numbers

Symbols

nents

Decimal separator Point The decimal point is always used.

For example: 1234.56

Page reference Reference to another page with additional

information

For example: 16 = refer to page 16

Wildcard Wildcard for options, selections

For example: BFK458- = BFK458-10

Note

Important notice about ensuring smooth

operations or other key information.

INTORQ | BA 14.0199 | 08/2016 5

Page 6

Preface and general information

1.4 Abbreviations used

Letter symbol Unit Designation

F

R

N Rated frictional force

I A Current

I

H

I

L

I

N

M

A

M

dyn

M

K

A Holding current, at 20 °C and holding voltage

A Release current, at 20 °C and release voltage

A Rated current, at 20 °C and rated voltage

Nm Tightening torque of fixing screws

Nm Braking torque at a constant speed of rotation

Nm Rated torque of the brake, rated value at a relative speed of rotati on of

100 rpm

n

max

P

H

P

L

P

N

rpm Maximum occurring speed of rotation during the slipping time t

W Coil power during holding, after voltage change-over and 20 °C

W Coil power during release, before voltage change-over and 20 °C

W Rated coil power, at rated voltage and 20 °C

Q J Quantity of heat/energy

Q

E

J Max. permissible friction energy for one-time switching, thermal parameter of

the brake

3

Q

Q

R

S

S

S

s

s

s

s

t

t

N

h

hue

hmax

L

LN

Lmin

Lmax

1

2

R

Smax

J Braking energy, friction energy

J Maximally permissible friction energy for cyclic switching, depending on the

operating frequency

Ohms Rated coil resistance at 20 °C

1/h Switching frequency: the number of switching operations evenly spread over

the time unit

1/h Transition operating frequency, thermal parameter of the brake

1/h Maximum permissible operating frequency, depending on the friction energy

per switching operation

mm Air gap: the lift of the armature plate while the brake is switched

mm Rated air gap

mm Minimum air gap

mm Maximum air gap

ms Engagement time, sum of the delay time and braking torque - rise time

t

= t11 + t

1

ms Disengagement time, time from switching the stator until reaching 0.1 M

12

dyn

t

3

ms Slipping time, operation time of the brake (according to t11) until standstill

INTORQ | BA 14.0199 | 08/2016 6

Page 7

Preface and general information

Letter symbol Unit Designation

t

11

ms Delay during engagement (time from switching off the supply voltage to the

beginning of the torque rise)

t

12

ms Rise time of the braking torque, time from the start of torque rise until reach-

ing the braking torque

t

ue

s Overexcitation time

UVVoltage

U

H

U

L

U

N

V DC Holding voltage, after voltage change-over

V DC Release voltage, before voltage change-over

V DC Rated coil voltage; in the case of brakes requiring a voltage change-over,

U

N

1.5 Safety instructions and notices

The following icons and signal words are used in this document to indicate dangers and important safety information:

Safety instructions

Structure of safety instructions:

equals U

L

SIGNAL WORD

Icon

Indicates the type of danger

Signal word

Characterises the type and severity of danger

Note

Describes the danger

Possible consequences

❚ List of possible consequences if the safety instructions are disregarded.

Protective measure

❚ List of protective measures to avoid the danger.

INTORQ | BA 14.0199 | 08/2016 7

Page 8

Preface and general information

Danger level

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in death or serious

injury.

WARNING

WARNING indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

NOTICE

Notice about a harmful situation with possible consequences: the product itself or surro unding

objects could be damaged.

1.6 Scope of delivery

After receipt of the delivery, check immediately whether the items delivered match the accompanying papers. INTORQ does not accept any liability for deficiencies claimed subsequently.

❚ Claim visible transport da mage immediately to the deliverer.

❚ Claim visible deficiencies or incomplete deliveries immediately to INTORQ GmbH & Co. KG.

1.7 Disposal

The spring-applied brake consists of different types of material.

❚ Recycle metals and plastics.

❚ Ensure professional disposal of assembled PCBs according to the applicable environmental regulations.

INTORQ | BA 14.0199 | 08/2016 8

Page 9

Preface and general information

1.8 Drive systems

Labelling

Drive systems and components are unambiguously designated by the indications on the name plate.

Manufacturer: INTORQ GmbH & Co. KG, Wülmser Weg 5, D-31855 Aerzen, Germany

1.9 Legal regulations

Liability

❚ The information, data and notes in these Operating Instructions met the state of the art at the time of

printing. Claims referring to drive systems which have already been supplied cannot be derived from this

information, illustrations and descriptions.

❚ We do not accept any liability for damage and operating interference caused by:

- inappropriate use

- unauthorised modifications to the product

- improper work on or with the drive system

- operating errors

- disregarding the documentation

Warranty

❚ Terms of warranty: Refer to the terms of sale and delivery for INTORQ GmbH&Co. KG.

❚ Warranty claims must be made to INTORQ immediately after the defects or faults are detected.

❚ The warranty is void in all cases when liability claims cannot be made.

INTORQ | BA 14.0199 | 08/2016 9

Page 10

Safety instructions

2 Safety instructions

2.1 General safety instructions

❚ INTORQ components ...

- ... must only be used as directed.

- ... must not be commissioned if they are noticeably damaged.

- ... must not be technically modified.

- ... must not be commissioned if they are incompletely mounted or connected.

- ... must not be operated wi thout the required covers.

- ... can hold live as well as moving or rotary parts during operation according to their degree of protection. Surfaces may be hot.

❚ For INTORQ components ...

- ... the documentatio n must always be kept at the installation site.

- ... only permitted accessories are allowed to be used.

- ... only original spare pa rts of the manufacturer are allowed to be used.

❚ Follow all specifications and information found in the corresponding enclosed documentation.

These must be followed to maintain safe, trouble-free operation s and to achieve the specified product

characteristics.

❚ Only qualified, skilled personnel are permitted to work on and with INTORQ components.

According to IEC 60364 or CENELEC HD384, qualified, skilled personnel are persons ...

- ... who are familiar with th e installation, mounting, commissioning, and opera tion of the product.

- ... who have the qualific ations necessary for their occupation.

- ... who know and apply all regulations for the prevention of accidents, directives, and laws relevant

on site.

❚ Risk of burns!

- Surfaces may be hot during opera ti on ! Pro vide for protection against accidental contact.

❚ Risk of injury due to a rotating shaft!

- Wait until the motor is at stan dstill before you start working on the motor.

❚ The friction lining and the friction surfaces must never contact oil or grease since e v en small amounts

reduce the braking torque considerably.

❚ The brake is designed for operation under the environmental conditions that apply to IP66 protecti on.

Because of the numerous possibilities of using the brake, it is however necessary to check the functionality of all mechanical components under the corresponding operating conditions.

INTORQ | BA 14.0199 | 08/2016 10

Page 11

Safety instructions

2.2 Application as directed

❚ INTORQ components ...

- ... are intended for use in machinery and systems.

- ... must only be used for the purposes ordered and confirmed.

- ... must only be operated under the ambient conditions prescribed in these Operating Instructions.

- ... must not be operated beyond their corresponding power limits.

Any other use or excessive usage shall be deemed improper!

Possible applications of the INTORQ spring-applied brake

❚ No explosive or aggressive atmosphere.

❚ Humidity: no restrictions

❚ Ambient temperature:

- Standard desig n: -20 °C to +50 °C

- Optional CCV design: -40 °C to +50 °C

INTORQ | BA 14.0199 | 08/2016 11

Page 12

Technical specifications

3 Technical specifications

3.1 Product description

3.1.1 Structure and function

Abb.1 Design of a BFK470 spring-applied brake

1.1 Stator 3 Complete rotor 10 Socket head cap screw, DIN EN ISO 4762

1.2 Pressure springs 4 Hub 12 Complete manual release (optional)

1.3 Plug (check for air gap) 6 Flange (optional) 30 Setting screw for the factory-set adjustment

of the spring force (sealed), applies only to

sizes 12-18

2 Armature plate 8 Coil X Bore holes are optional

The spring-applied brake is designed for converting mechanical work and kinetic energy into heat energy.

Due to the static braking torque, loads can be held at standstill. Emergency braking is possible at high speed

of rotation. The wear increases as the switching energy increases.

INTORQ | BA 14.0199 | 08/2016 12

Page 13

Technical specifications

The spring-applied brakes BFK470 are electrically releas able single-disc brakes with two friction surfaces.

When de-energized, both of the rotor’s friction surfaces are tightened by the force of the compression springs

between the armature plate and the flange. The braking torque is applied over the friction radius of the rotor;

it is transferred to the shaft via a hub that has axial gear teeth. When the brakes are applied, an air gap "s

is present between the stator and the armature plate. To release the brake, the stator´s coil is energized with

DC voltage. The resulting magnetic flux works against the spring force to draw the armature plate to the stator. This releases the rotor from the spring force and allows it to rotate freely.

3.1.2 Brakes

During the braking procedure, the pressure springs (1.2) use the armature plate (2) to press the rotor (3)

(which can be shifted axially on the hub (4)) against the friction surface. The asbestos-free friction linings

ensure high braking torque and low wear. The braking torque is transmitted between the hub (4) and the rotor

(3) via gear teeth.

NOTICE

Due to the structural design of the stator, the air gap cannot be installed downstream. If the

wear limit is reached, the rotor must be replaced.

"

L

3.1.3 Brake release

When the brakes are applied, an air gap "s

To release the brake, the coil of the stator (1.1) is energ ized with the DC voltage provided. The resulting mag netic flux works against the spring force to draw the armature plate (2) to the stator (1.1). This releases the

rotor (3) from the spring force and allows it to rotate freely

3.1.4 Project planning notes

❚ The brakes are dimensioned in such a way that the given rated torques are reached safely after a short

run-in process.

❚ However, as the organic frictio n linings used do not all have identical properties and because environ-

mental conditions can vary, deviations from the specified braking torques are possible. These must be

taken into account in the form of appropriate dimensioning tolerances. Increased breakaway torque is

common in particular after long downtimes in humid environments where temperatures vary.

❚ If the brake is used as a pure holding brake without dynamic load, the friction lining must be reactivated

regularly.

" is present between the stator (1.1) and the armature pl ate (2).

L

INTORQ | BA 14.0199 | 08/2016 13

Page 14

Technical specifications

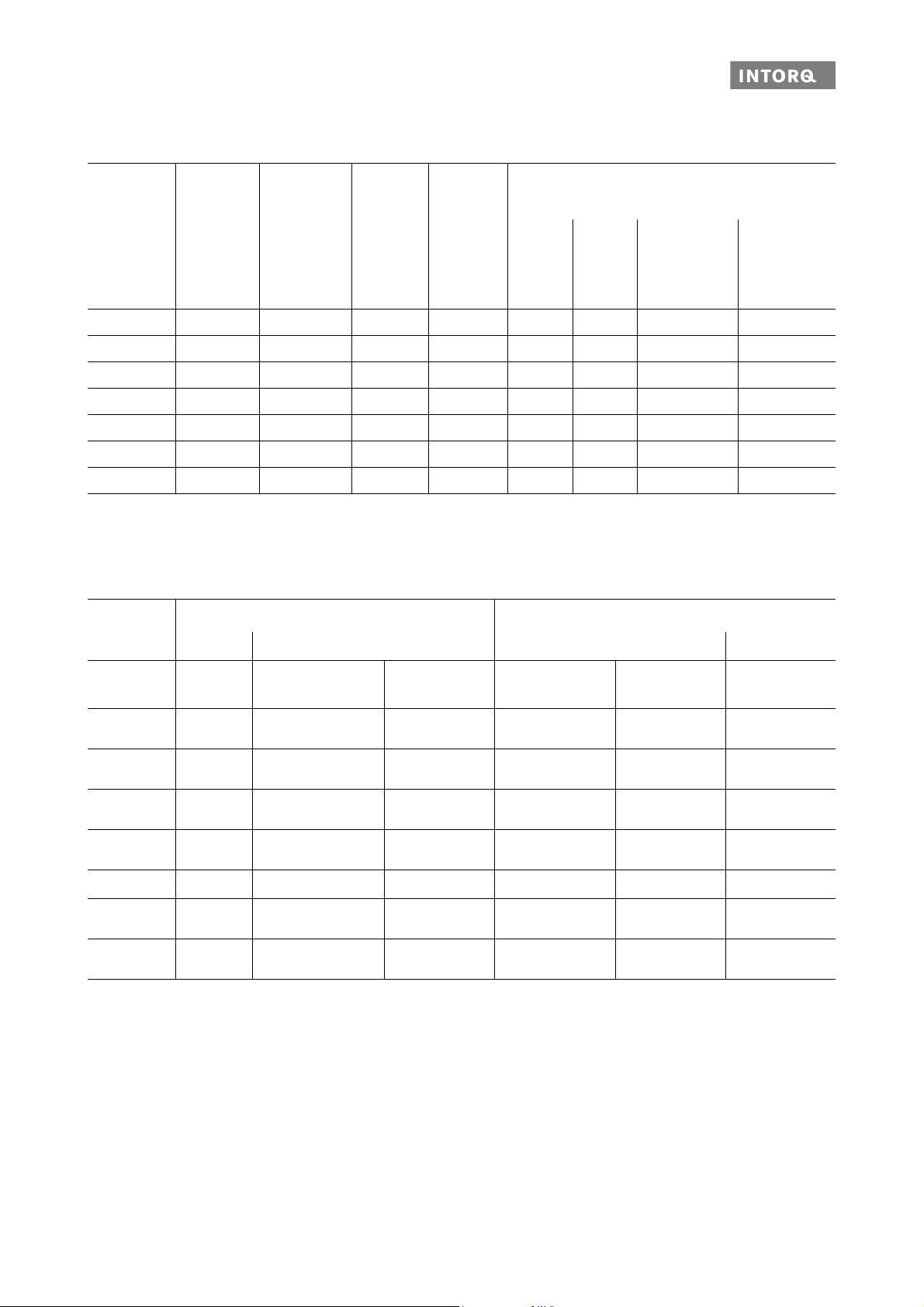

3.2 Rated data

Type Max. speed

of rotation

nmax

[rpm]

Temperature

1)

class

Stator

Operating

time

[%]

Moment of

inertia

Rotor

[kgcm2]

without

flange

[kg]

Mass of brake

with

flange

[kg]

without flange

+ Manual

release

[kg]

with flange

+ Manual

release

[kg]

BFK470-06 6000 F (155°C) 100 0.15 1.3 1.5 1.4 1.6

BFK470-08 5000 F (155°C) 100 0.61 2.0 2.2 2.1 2.3

BFK470-10 4000 F (155°C) 10 0 2.0 3.5 3.9 3.7 4.0

BFK470-12 3600 F (155°C) 10 0 4.5 5.0 5.6 5.3 5.8

BFK470-14 3600 F (155°C) 10 0 6.3 7.7 8.5 8.1 8.9

BFK470-16 3600 F (155°C) 100 15.0 11.9 13.1 12.5 13.7

BFK470-18 3600 F (155°C) 100 29.0 17.6 19.1 18.6 20.0

Tab. 1: General brake characteristics

1)

Maximum speed of rotation when installed horizontally (for higher speeds, contact the manufac-

turer)

Type Air gap Rotor thickness

BFK470-06 0.2

BFK470-08 0.2

BFK470-10 0.2

BFK470-12 0.3

BFK470-14 0.3

BFK470-16 0.3

BFK470-18 0.4

Tab. 2: Air gap / rotor thickness

s

LN

[mm]

+0.08

-0.05

+0.08

-0.05

+0.13

-0.05

+0.08

-0.10

± 0.1

+0.15

-0.05

+0.20

-0.10

operating brake

[mm]

s

L max

holding brake

[mm]

operating brake

[mm]

min. New state

0.5 0.3 5.73 5.93

0.5 0.3 6.73 6.93

0.5 0.35 8.73 8.88

0.6 0.45 9.68 9.83

0.75 0.45 9.55 9.85

0.80 0.50 11.05 11.35

1.0 0.65 12.50 12.85

holding brake

[mm] [mm]

6.0

7.0

9.0

10.0

10.0

11.5

13.0

-0.05

-0.05

-0.1

-0.1

-0.1

-0.1

-0.1

INTORQ | BA 14.0199 | 08/2016 14

Page 15

Technical specifications

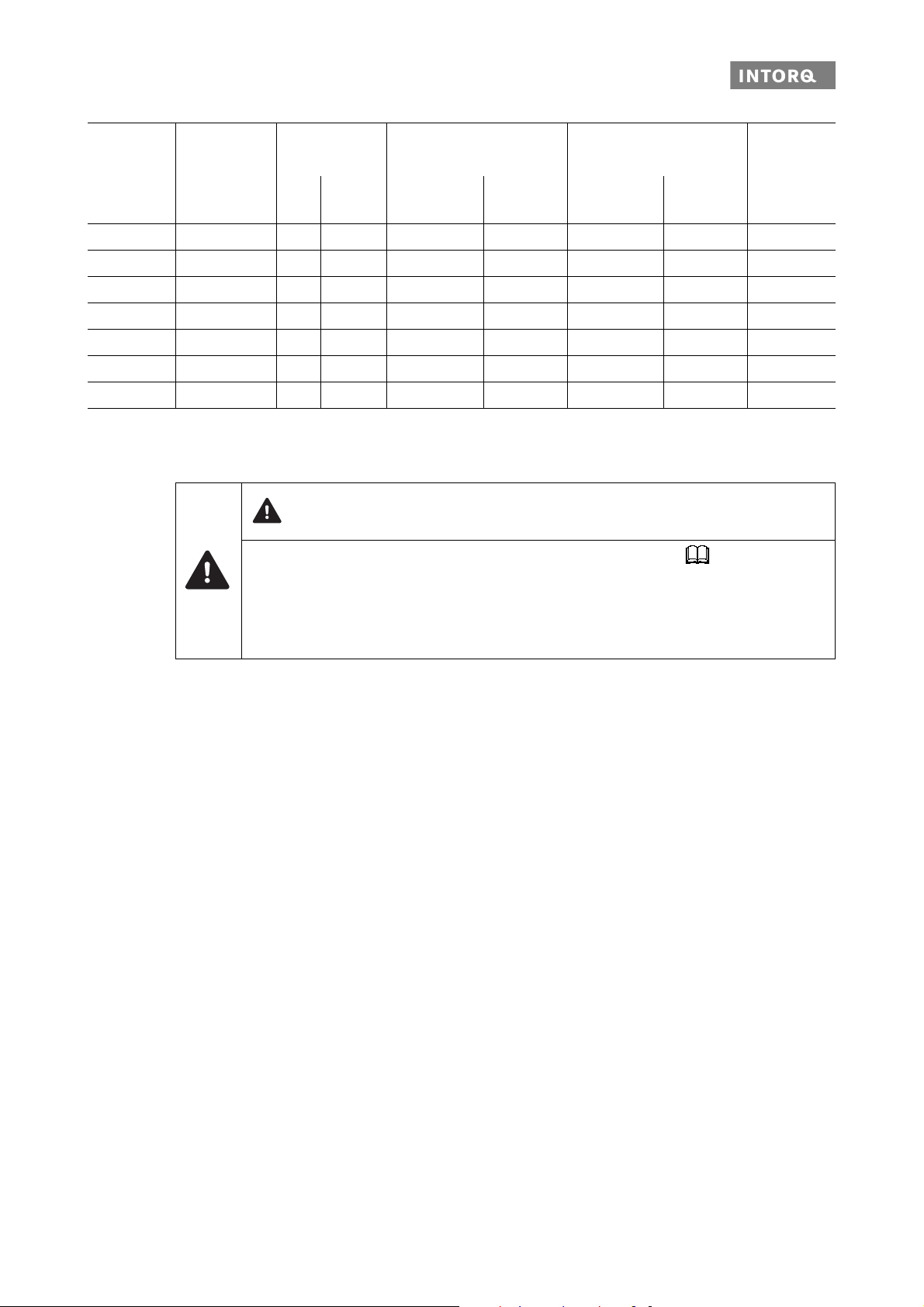

Type

Outer

diameter

[mm]

Pitch

circle

[mm] Thread

Fixing screws

DIN EN ISO 4762

without flange

[mm]

with flange

[mm]

Minimum thread depth Tightening

torque

without flange

[mm]

with flange

[mm]

M

[Nm]

a

BFK470-06 89 72 M4 3 x M4x40 3 x M4x45 7.5 9.0 3.0

BFK470-08 106 90 M5 3 x M5x45 3 x M5x50 10.5 10.0 5.9

BFK470-10 130 112 M6 3 x M6x55 3 x M6x60 14.0 13.5 10.1

BFK470-12 148 132 M6 3 x M6x60 3 x M6x65 12.5 12.5 10.1

BFK470-14 168 145 M8 3 x M8x75 3 x M8x80 19.5 18.5 24.6

BFK470-16 200 170 M8 3 x M8x80 3 x M8x85 18.0 17.0 24.6

BFK470-18 226 196 M8 6 x M8x90 6 x M10x100 19.5 23.0 24.6

Tab. 3: Installation data

CAUTION

❚ The minimum thread depth of the end shield must be maintained! Tab. 3.

❚ If the required thread depth is no t maintained, the fixing screws may run on to the root. This

has the effect that the required pre-load force is no longer established – the brake is no

longer securely fastened!

❚ The material of the end shield must have a tensile strength of R

>= 250 N/mm2.

m

INTORQ | BA 14.0199 | 08/2016 15

Page 16

Technical specifications

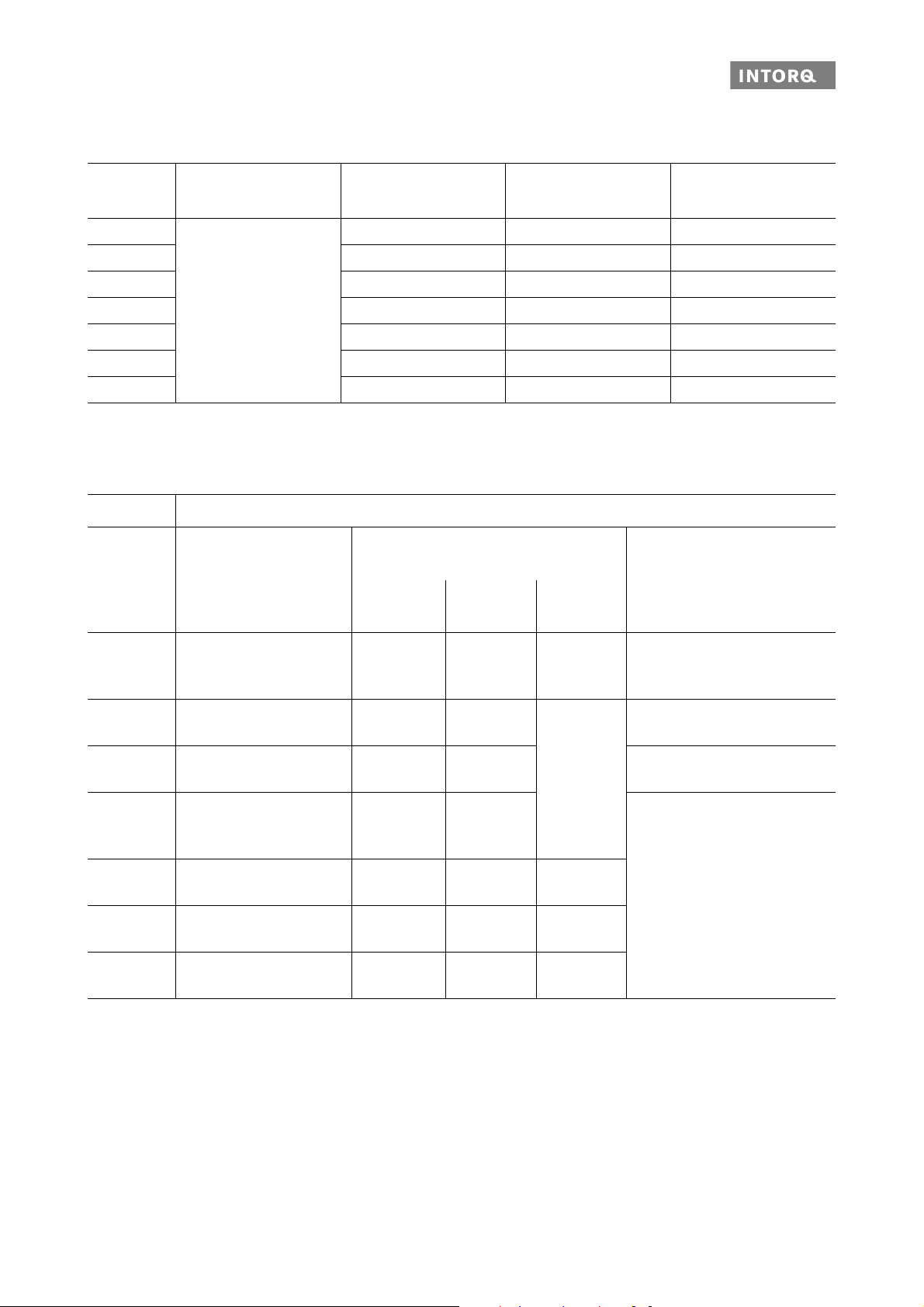

3.3 Rated data (dimensioning data) electrical data

Type Voltage

U [V DC]

BFK470-06

Rated current

[A]

I

N

Power

PN [W]

0.098 20 2101.0

Coil resistance

RN ± 4% []

BFK470-08 0.122 25 1681.0

BFK470-10 0.161 33 1273.0

BFK470-12 0.195 40 1051.0

205

BFK470-14 0.307 60 667.1

BFK470-16 0.332 68 618.0

BFK470-18 0.415 85 494.4

Tab. 4: Coil data at 20°C

Type Braking torques at relative speed of rotation n

Rated torque

[Nm]

100 rpm

Braking torque

X [%] of the rated torque

1500

rpm

3000

rpm

maximum horizontal mounting position

Maximum speed

rpm

BFK470-06 2.0 / 2.5 / 3.0 / 3.5 / 4.0 /

4.5 / 5.5 / 6.0 / 6.5 /

7.0 / 7.5

BFK470-08 3.5 / 5 / 6 / 7 / 8 / 10 /

11 / 12 / 14 / 15

BFK470-10 9 / 11 / 14 / 16 / 18 / 21 /

23 / 25 / 28 / 30 / 33 / 36

BFK470-12 12 / 14 / 15 / 16 / 18 /

23 / 27 / 32 / 36 / 40 /

45 / 46 / 48 / 50 / 55

BFK470-14 40 / 50 / 60 / 65 / 70 /

75 / 80 / 100 / 110

BFK470-16 55 / 80 / 90 / 100 /

105 / 125 / 150

BFK470-18 100 / 150 / 165 / 185 /

200 / 235 / 250

Tab. 5: Rated torques

87 80 74 6000

85 78

83 76 4000

73

5000

81 74

80 73 72

3600

79 72 70

77 70 68

INTORQ | BA 14.0199 | 08/2016 16

Page 17

Technical specifications

Switching times

Abb. 2 Operating/switching times of the spring-applied brakes

t

Engagement time t11Reaction delay of engagement

1

Disengagement time (up to M = 0.1 M

t

2

Rated torque U Voltage

M

dyn

)t

dyn

Rise time of the braking torque

12

Type Rated torque Max. perm.

switching energy

M

K

Q

E

[Nm] [J] [h

Transitional

operating frequency

S

hue

-1

]

Operating times [ms]

at sLN and 0.7 I

DC engagement

t

t

11

12

2)

t

1

1)

N

Disengagement

t

BFK470-06 4 3000 79 16 25 41 32

BFK470-08 8 7500 50 30 26 56 52

BFK470-10 16 12000 40 40 64 104 107

BFK470-12 32 24000 30 47 34 81 121

BFK470-14 60 30000 28 30 47 76 162

BFK470-16 80 36000 27 46 62 109 255

BFK470-18 150 60000 20 62 92 155 343

Tab. 6: Switching energy - operating frequency - operating times

1) Typical values

2) Measured with induced voltage limitation of -800 V DC

2

INTORQ | BA 14.0199 | 08/2016 17

Page 18

Technical specifications

AA

B

Engagement time

The transition from brake-torque free state to holding brakin g torque is not free of time lags.

❚ The engagement time s are valid for DC switching with a spark suppressor.

- Spark suppressors are available for the rated voltages.

- Connect the spark suppressors in parallel to the contact. If this switching is not admissible for safety

reasons (e.g. with hoists and lifts), the spark suppressor can also be connected in parallel to the

brake coil.

- Circuit proposals: 25

❚ The engagement time s are approx. 10 times longer with AC switching.

- Connection: 25

Disengagement time

The disengagement time is the same for DC and AC switchin g. The disengag ement t ime can be shorte ned

by special equipment for fast-response excitation or over-excitation.

3.4 Switching energy / operating frequency

Abb. 3 Switching energy as a function of the operating frequency

Switching energy

Operating frequency

INTORQ | BA 14.0199 | 08/2016 18

Page 19

Technical specifications

S

hmax

S

hue

–

ln 1

Q

R

Q

E

---------

–

--------------------------------=

Q

smaxQE

1e

S

hue

–

S

h

-------------------

–

=

The permissible operating frequency S

set operating frequency S

With high speeds of rotation and switching energy, the wear increases strongly, because very high temperatures occur at the friction surfaces for a short time.

3.5 Emissions

Electromagnetic compatibility

If an INTORQ rectifier is used for the DC switching of the spring-applied brake and if the switching frequency

exceeds five switching operations per minute, the use of a mains filter is required.

If the spring-applied brake uses a rectifier of another manufacturer for the switching, it may become necessary to connect a spark suppressor in parallel with the AC voltage. Spark suppressors are available on request, depending on the coil voltage.

depends on the amount of heat QR (refer to Figure 3). At a pre-

hmax

, the permissible amount of heat is Q

h

smax

.

NOTICE

The user must ensure compliance with EMC Directive 2004/108/EC u sing appro priate contro ls

and switching devices.

Heat

Since the brake converts kinetic energy as well as mechanical and electrical energy into heat, the surface

temperature varies considerably, depending on the operating conditions and possible heat dissipation. Under unfavourable conditions, the surface temperature can reach 130 °C.

Noise

The switching noise during engagement and disengagement varies depending on the air gap, braking torque

and brake size.

Depending on the natural oscillation after installa tion, operating condit ions and state of the frictio n surfaces,

the brake may squeak during braking.

Others

The abrasion of the friction parts produces dust.

INTORQ | BA 14.0199 | 08/2016 19

Page 20

Mechanical installation

4 Mechanical installation

4.1 Important notes

4.1.1 Design of end shield and motor shaft

❚ Comply with the mentioned minimum requirements regarding the end shield and the motor shaft to en-

sure a correct function of the brake.

❚ The diameter of the shaft should er must not be greater than the tooth root diameter of the hub.

❚ The form and position tolerances apply only to the materials mentioned. Contact INTORQ if you are us-

ing other materials.

❚ The brake flange must be supported by the end shield across the full surface.

Design of the end shield

Type Minimum requirements: Use as counter friction surface

Material Evenness Axial runout Roughness Miscellaneous

[mm] [mm]

BFK470-06

BFK470-08

BFK470-10

BFK470-12

BFK470-14

BFK470-16 0.08

BFK470-18 0.10 0.08

Tab . 7: End shield as counter friction surface

S235JR; C15;

EN-GJL-250

0.03

0.05

0.05

without flange with flange

Rz 10 Rz 16

❚ Threaded

holes with

minimum

thread depth

❚ Free of grease

and oil

15

INTORQ | BA 14.0199 | 08/2016 20

Page 21

Mechanical installation

4.1.2 Necessary tools

Type Torque wrench

Measuring range [Nm]

BFK470-06

BFK470-08 4

1 - 12

BFK470-10

BFK470-12

BFK470-14

20 - 100 6 BFK470-16

BFK470-18

* For attaching flange inner bit with pin guide

Multimeter Caliper gauge Feeler gauge

Bit for hexagon socket screws

*

Wrench width [mm]

3

5

INTORQ | BA 14.0199 | 08/2016 21

Page 22

Mechanical installation

4.2 Assembly

4.2.1 Preparation

1. Unpack the spring-applied brake.

2. Check for completeness.

3. Verify the nameplate data (especially the rated voltage).

4.2.2 Brake assembly

NOTICE

The toothed hub and screws must not be lubricated with grease or oil.

Installation of the hub onto the shaft

NOTICE

The customer is responsible for constructing the shaft-hub connection. Make sure that the

bearing length of the key is identical to the length of the hub.

NOTICE

Check the tensile strength of the hub material: When operating with high torque, consult with

INTORQ and use a steel hub with a higher tensile strength.

Abb. 4 Installing the hub onto the shaft

A Circlip B Hub C Keyway

D End shield

1. Press the hub with a moderate amount of force to the shaft.

INTORQ | BA 14.0199 | 08/2016 22

Page 23

Mechanical installation

Secure the hub against axial displacement (for example, by using a circlip).

Mounting the flange

NOTICE

If you are using the spring-applied brake for reverse operations, glue the hub to the shaft.

Abb. 5 Flange and rotor mounting

1. If requ ired, slide the optional flange (6) onto the shaft.

- The chamfer on the flange must point towards the brake!

- Align the through holes of the flange (6) with the fixing holes in the end shield (15).

Abb. 6 Mounting the brake

1Brake 6Flange 15End shield

3 Rotor 10 Socket head cap screws

INTORQ | BA 14.0199 | 08/2016 23

Page 24

Mechanical installation

2. Slide the brake onto the shaft.

- Align supplied so cket head cap screws (10) with fixing holes in the end shield (15).

3. Use a torque key to tighten the socket head cap screws (10) with the required tightening torque, 15.

NOTICE

When using a shaft seal, the brake has to be mounted so that it is centred properly!

The shaft diameter must be implemented in accordance with ISO tolerance h11, with a radial

eccentricity tolerance according to IT8 and an averaged surface roughness of Rz

3.2 µm in

the sealing area.

NOTICE

Please note the following for the version "brake with shaft sealing ring":

❚ Lightly lubricate the lip of the shaft seal with grease.

❚ No grease should be allowed to contact the friction surfaces.

❚ When assembling the stator, push the shaft sealing ring carefully over the shaft. The shaft

should be located concentrically to the shaft seal.

NOTICE

The customer must seal the brake in this position himself if no shaft seal or cover is in use.

NOTICE

If it is necessary to loosen the screws with the seal again, the seals or the complete screw set

must be replaced.

INTORQ | BA 14.0199 | 08/2016 24

Page 25

Electrical installation

5 Electrical installation

5.1 Important notes

DANGER

There is a risk of injury by electrical shock!

❚ Electrical connection must only be carried out by skilled personnel!

❚ Only carry out connection work when no voltage is applied (n o live parts)! There is a risk of

unintended start-ups or electric shock.

NOTICE

❚ It must be ensured that the supply voltage corresponds to the name plate data.

5.2 Electrical connection

Circuit suggestions

NOTICE

The terminal pin sequence shown here does not match the actual order.

INTORQ | BA 14.0199 | 08/2016 25

Page 26

Electrical installation

AA

AA

B

S

AA

AA

B

S

U

U

U

U

U

U

AC switching at the motor – extremely delayed engagement

L1 L2

V

V

L3

4-pole

A

BEG-14x

BEG-24x

BN

3x 39V

BK

R

L

BU

Abb. 7 Supply: Phase-neutral

Bridge rectifiers

BEG-1xx: UN [VDC]=0.9 • [VAC]

Brake

47KΩ

--------

L1 L2

V1U1 W1

U2W2 V2

PNP

v

3

V

V

L3

6-pole

A

BEG-16x

BEG-26x

S

B

U

N

Half-wave rectifiers

v

BEG-2xx: UN [VDC]=0.45 • [VAC]

-------3

Inductive proximity sensor

4-pole

A

BEG-14x

BEG-24x

A

6-pole

BEG-16x

V1U1 W1

U2W2 V2

BEG-26x

Abb. 8 Supply: Phase-phase

1)

Not recommended for most regional/national high-voltage mains systems

BN

3x 39V

BK

R

L

BU

Bridge rectifier

47KΩ

PNP

1)

BEG-1xx: UN [VDC]=0.9 • UV [VAC]

Brake

S

B

U

N

Half-wave rectifiers

BEG-2xx: U

[VDC]=0.45 • UV [VAC]

N

Inductive proximity sensor

INTORQ | BA 14.0199 | 08/2016 26

Page 27

Electrical installation

AA

AA

B

S

AA

AA

B

S

UVU

U

U

U

U

DC switching at the motor – fast engagement

L1 L2

V

L3

BN

3x 39V

BK

R

L

BU

Abb. 9 Supply: Phase-neutral

Bridge rectifiers

BEG-1xx: UN [VDC]=0.9 • [VAC]

Brake

L1 L2

V1U1 W1

U2W2 V2

47KΩ

V

V

L3

PNP

v

-------3

6-pole

BEG-16x

A

BEG-26x

S

B

U

N

Half-wave rectifiers

BEG-2xx: UN [VDC]=0.45 • [VAC]

--------

v

3

Inductive proximity sensor

V1U1 W1

U2W2 V2

BN

3x 39V

BK

R

L

BU

47KΩ

PNP

S

6-pole

BEG-16x

A

BEG-26x

B

U

N

Abb. 10 Supply: Phase-phase

Bridge rectifier

1)

BEG-1xx: UN [VDC]=0.9 • UV [VAC]

Brake

1)

Not recommended for most regional/national high-voltage mains systems

Half-wave rectifiers

BEG-2xx: UN [VDC]=0.45 • UV [VAC]

Inductive proximity sensor

INTORQ | BA 14.0199 | 08/2016 27

Page 28

Electrical installation

AA

AA

B

S

AA

AA

B

S

U

U

AC switching at mains – delayed engagement

V

N

L1

4-pole

BEG-14x

A

BEG-24x

6-pole

BEG-16x

A

BEG-26x

R

L

Abb. 11 Supply: Phase-N

Bridge rectifiers

BEG-1xx: UN [VDC]=0.9 • UV [VAC]

Brake

BN

BK

BU

3x 39V

L1

47KΩ

S

B

U

N

PNP

Half-wave rectifiers

BEG-2xx: UN [VDC]=0.45 • UV [VAC]

Inductive proximity sensor

V

L2

4-pole

BEG-14x

A

BEG-24x

6-pole

A

BEG-16x

BEG-26x

BN

3x 39V

BK

R

L

Abb. 12 Supply: Phase-phase

Bridge rectifier

BU

47KΩ

PNP

1)

S

BEG-1xx: UN [VDC]=0.9 • UV [VAC]

Brake

1)

Not recommended for most regional/national high-voltage mains systems

B

U

N

Half-wave rectifiers

BEG-2xx: UN [VDC]=0.45 • UV [VAC]

Inductive proximity sensor

INTORQ | BA 14.0199 | 08/2016 28

Page 29

Electrical installation

AA

AA

B

S

AA

AA

B

S

U

U

DC switching at mains – fast engagement

V

L2

L1

or

N

L1

6-pole

BEG-16x

A

BEG-26x

BN

3x 39V

BK

R

L

BU

47KΩ

PNP

S

B

U

N

Abb. 13 Supply: Phase-phase or phase-N via 6-pole rectifier

Bridge rectifier

1)

BEG-16x: UN [VDC]=0.9 • UV [VAC]

Brake

1)

For most regional/national high-voltage mains systems, this only makes sense for supplies on L1 and N.

V

L2

L1

or

N

L1

Half-wave rectifiers

BEG-26x: UN [VDC]=0.45 • UV [VAC]

Inductive proximity sensor

4-pole

BEG-14x

A

BEG-24x

14.198.00.xx

BN

3x 39V

BK

R

L

BU

Abb. 14 Supply: Phase-phase or phase-N via 4-pole rectifier

Bridge rectifier

47KΩ

PNP

1)

BEG-14x: UN [VDC]=0.9 • UV [VAC]

Brake

S

B

U

N

Half-wave rectifiers

BEG-24x: U

[VDC]=0.45 • UV [VAC]

N

Inductive proximity sensor

Spark suppressor

14.198.00.xx (required once, select position)

1)

For most regional/national high-voltage mains systems, this only makes sense for supplies on L1 and N.

INTORQ | BA 14.0199 | 08/2016 29

Page 30

Electrical installation

5.3 Technical data for inductive proximity sensors

5.3.1 Proximity sensor for release check

Design PNP, N/O contact

Operating voltage 10 to 30 VDC

Permitted residual ripple 20% U

B

No-load current Max. 10 mA

Output current Max. 200 mA

Voltage drop at outputs Max. 2.0 V at 200 mA

Short circuit protection integrated

Reverse polarity protection integrated

Induction protection integrated

Protection class IP67

Cable configuration and parameters

Cable (diameter / length / AWG) Ø 3.3 mm / L = 2 m / AWG 26

Maximum cable length 100 m

Grey Colour of sheath insulation

Brown (BN) + U

B

Black (BK) Signal (with released armature plate - brake energized)

Blue (BU) - U

B

Operating conditions

Ambient temperature range T

A

from -40 °C to +120 °C (no component damage)

from -25 °C to +120 °C (information analysis)

Shock and vibration IEC 60947-5-2 / 7.4

EMC protection

IEC 60947-5-2 (7.2.3.1) 1 kV

IEC 61000-4-2 Level 2

IEC 61000-4-3 Level 3

IEC 61000-4-4 Level 2

Tab. 8: Technical data for inductive proximity sensors (release check)

INTORQ | BA 14.0199 | 08/2016 30

Page 31

Electrical installation

5.4 Minimum bend radius for the brake connection line

Brake size Wire cross-section Minimum bendradius [mm]

06

08

10

AWG 20 28

12

14

16

AWG 16 46

18

Tab. 9: Minimum bend radius for the brake connection line

5.5 Bridge/half-wave rectifier (optional)

BEG-561- -

The bridge-half-wave rectifiers are used to supply electromagnetic DC spring-applied brakes which are approved for the use with such rectifiers. Other use is only permitted with the approval of INTORQ.

Once a set over-excitation time has elapsed, the bridge-half-wave rectifiers switch over from bridge rectification to half-wave rectification.

Terminals 3 and 4 are located in the DC circuit of the brake. The ind uction voltage peak for DC switching

(see "DC switching - fast engagement" circuit diagram) is limited by an integrated overvoltage protection at

terminals 5 and 6.

5.5.1 Assignment: Bridge/half-wave rectifier – brake size

Rectifier type Supply voltage Over-excitation Holding current reduction

Coil voltage Size Coil voltage Size

[V AC] [V DC] [V DC]

BEG-561-255-030

230 103

BEG-561-255-130 – 14 – 18

BEG-561-440-030-1 400 180 06 – 18 – –

06 – 18

205

06 – 12

INTORQ | BA 14.0199 | 08/2016 31

Page 32

Electrical installation

Abb. 15 BEG-561 attachment options

5.5.2 Technical specifications

Rectifier type Bridge / half-wave rectifier

Output voltage for bridge rectification 0.9 x U

Output voltage for half-wave rectification 0.45 x U

1

1

Ambient temperature (storage/operation) [°C] -25 – +70

Type Input voltage U

(40 Hz – 60 Hz)

Min.

[V ~]

Rated

[V ~]

BEG-561-255-030

1

max.

[V ~]

Max. current I

Bridge

half-wave

[A]

[A]

max

Over-excitation time tue (± 20 %)

at U

1 min

[s]

at U

1 Nom

[s]

at U

[s]

0.430 0.300 0.270

160 230 255 3.0 1.5

BEG-561-255-130 1,870 1,300 1,170

BEG-561-440-030-1 230 400 440 1.5 0.75 0.500 0.300 0.270

1 max

Tab. 10: Data for bridge/half-wave rectifier type BEG-561

U

input voltage (40 – 60 Hz)

1

INTORQ | BA 14.0199 | 08/2016 32

Page 33

Electrical installation

AA

B

C

5.5.3 Reduced switch-off times

AC switching must also be carried out for DC switching (fast engagement)! Otherwise, there will be no overexcitation when it is switched back on.

Delayed engagement Fast engagement

Mains

Bridge

5.5.4 Permissible current load at ambient temperature

1 For screw assembly with metal surface (g ood heat dissipation)

2 For other assembly (e.g. adhesive)

Coil

INTORQ | BA 14.0199 | 08/2016 33

Page 34

Commissioning and operation

6 Commissioning and operation

6.1 Important notes

DANGER

There is a risk of injury by electrical shock!

❚ Electrical connection must only be carried out by skilled personnel!

❚ Only carry out connection work when no voltage is applied (n o live parts)! There is a risk of

unintended start-ups or electric shock.

DANGER

Danger: rotating parts!

The brake must be free of residual torque.

The drive must not be running when checking the brake.

CAUTION

Danger: hot surfaces. Do not touch!

❚ The brake is designed for operation under the environmental conditions that apply to IP66 protecti on.

Because of the numerous possibilities of using the brake, it is however necessary to check the functionality of all mechanical components under the corresponding operating conditions.

NOTICE

Functionality for different operating conditions

❚ The brakes are dimensioned in such a way that the given rated torques are reached safely

after a short run-in process.

❚ However, as the organic friction linings used do not all have identical properties and because

environmental conditions can vary, deviations from the specified braking torques are possible. These must be taken into account in the form of appropriate dimensioning tolerances.

Increased breakaway torque is common, in particular after long downtimes in humid environments where temperatures vary.

NOTICE

Operation without dynamic loads (functioning as a pure holding brake)

❚ If the brake is used as a pure holding brake without dynamic load, the friction lining must be

reactivated regularly.

INTORQ | BA 14.0199 | 08/2016 34

Page 35

Commissioning and operation

6.2 Function checks before commissioning

1. The switching contact for the brake must be open.

2. Remove two bridges from the motor terminals to deenergize the motor.

-Do not disconnect the supply voltage for the brake.

DANGER

There is a risk of electric shock!

If the rectifier is connected to the neutral point of the motor, the neutral conductor must also

be connected to this point.

3. Apply DC voltage to the brake.

4. Measure the AC voltage at the motor terminals. The measured level must be zero.

5. Close the switching contact for the brake.

- The brake is released.

6. Measure the DC voltage at the brake.

- Compare the DC voltage with the voltage indicated on the name plate. A deviation of 10 % is permissible.

- If the measured value deviates: 45

7. Open the switching contact for the brake.

- The brake is applied.

8. Switch off DC voltage for the brake.

9. Screw the bridges onto the motor terminals.

10. If necessary, remove the neutral conductor from the neutral point (step 2).

The preparations for commissioning are completed.

If faults occur, refer to the the error search table, 44. If the fault cannot be fixed or eliminated, please

contact your customer service.

INTORQ | BA 14.0199 | 08/2016 35

Page 36

Commissioning and operation

6.3 Brake with proximity sensor

DANGER

There is a risk of injury by electrical shock!

❚ Electrical connection must only be carried out by skilled personnel!

❚ Only carry out connection work when no voltage is applied (n o live parts)! There is a risk of

unintended start-ups or electric shock.

WARNING

Danger: rotating parts!

The brake must be free of residual torque. The motor must not run!

1. The switching contact for the brake must be open.

2. Remove two bridges from the motor terminals to deenergize the motor.

- Do not switch off the voltage supply to the brake.

- When connecting the rectifier to the neutral point of the motor, the PE conductor must also be connected to this point.

3. Apply DC voltage to the brake.

4. Measure the AC voltage at the motor terminals. The measured level must be zero.

5. Close the switching contact for the brake.

- The brake is released.

6. Measure the DC voltage at the brake:

- Compare the DC voltage with the voltage indicated on the name plate. A deviation of ±10 % is permissible.

7. Check the air gap "s

".

L

- It must be zero and the rotor must rotate freely.

8. Check the switching status of the proximity sensor (refer to Table 11).

9. Open the switching contact for the brake.

- The brake is applied.

10. Check the switching status of the pro ximity sensor (refer to Table 11).

11. Switch off DC voltage for the brake.

12. Screw the bridges onto the motor terminals. Remove additional PE conductor, if necessary.

Contact type Connection Brake released Proximity sensor is closed

N/O contact black / blue no no

Tab. 11: Switching status of the proximity sensor

INTORQ | BA 14.0199 | 08/2016 36

Page 37

Commissioning and operation

6.4 Commissioning

1. Switch on drive system.

2. Carry out a braking test.

6.5 During operation

❚ Checks must be carried out regula rly. Pay special attention to:

- unusual noises or temperatures

- loose fixing elements

- the condition of the electrical cables

- The armature plate must b e attracte d and the rotor must move without residual torque.

❚ Measure the DC voltage at the brake.

- Compare the DC voltage with the voltage indicated on the name plate. A deviation of 10 % is permissible.

❚ If faults occur, refer to the the error search table, 44. If the fault cannot be fixed or eliminated, please

contact your customer service.

INTORQ | BA 14.0199 | 08/2016 37

Page 38

Maintenance and repair

7 Maintenance and repair

7.1 Wear of spring-applied brakes

The table below shows the different causes of wear and their impact on the comp onents of the spring-applied

brake. The influential factors must be quantified so that the service life of the rotor and brake can be calculated and so that the prescribed maintenance intervals can be specified accurat ely. The most important fa ctors in this context are the applied friction energy, the initial speed of rotation of braking and the operating

frequency. If several of the causes of friction lining wear occur in an application at the same time, the influencing factors should be added together when the amount of we ar is calculated.

Component Cause Effect Influencing factors

Friction lining Braking during operation Wear of friction lining Friction work

Emergency stops

Overlapping wear during start and

stop of drive

Active braking via the drive motor

with support of brake (quick stop)

Starting wear in case of motor

mounting position with vertical shaft,

even when the brake is not applied

Armature plate and

counter friction

face

Gear teeth of brake

rotor

Brake support Changing load cycles and shocks in

Springs Axial load cycle and shear stress of

Tab. 12: Causes for wear

Rubbing of brake lining Run-in of armature plate and

Relative movements and shocks

between brake rotor and brake shaft

backlash on reversal between armature plate and cylinder pin

springs through radial backlash on

reversal of armature plate

counter friction face

Wear of gear teeth (primarily

on the rotor side)

Play of armature plate and

cylinder pin

Reduced spring force or

fatigue failure

Number of start/stop

cycles

Friction work

Number of start/stop

cycles

Number of start/stop

cycles, braking torque

Number of switching operations of brake

INTORQ | BA 14.0199 | 08/2016 38

Page 39

Maintenance and repair

7.2 Inspections

7.2.1 Important notes

To ensure safe and trouble-free operations, the spring-applie d brakes must be checked at re gula r intervals

and, if necessary, be replaced. Servicing will be easier at the plant if the brakes are made accessible. This

must be considered when installing the drives in the plant.

Primarily, the required maintenance intervals for industrial brakes result from their load during operation.

When calculating the maintenance interval, a ll causes for wear must be taken into account, 38. For

brakes with low loads (such as holding brakes with emer gency stop function), we recommend a regular inspection at a fixed time interval. To reduce costs, the inspection can be carried out along with other regular

maintenance work in the plant.

Failures, production losses or damage to the system may occur when the brakes are not serviced. Therefore,

a maintenance strategy that is adapted to the particular operating conditions and brake loads must be defined for every application. For the spring-applied brakes, the maintenance intervals and maintenance operations listed in the table below must be followed. The maintenance op erations must be carried out as

described in the detailed descriptions.

7.2.2 Maintenance intervals

Time interval for operating brakes: for holding brakes with emergency

stop:

Inspections with assembled brake

Inspections after removing the brake

❚ according to service life calcula-

tion

❚ or else every six months

❚ after 4000 operating hours at the

latest

❚ Check release function and control

❚ Check rotor

❚ Check hub

❚ Check armature plate and counter friction face

❚ at least every 2 years

❚ after 1 million cycles at the latest

❚ plan shorter intervals for frequent

emergency stops

42

40

INTORQ | BA 14.0199 | 08/2016 39

Page 40

Maintenance and repair

7.3 Maintenance

NOTICE

Brakes with defective armature plates, springs or flanges must be completely replaced.

Observe the following for inspections and maintenance works:

❚ Contamination by oils and greases should be removed using brake cleaner, or the brake

should be replaced after determining the cause. Dirt and particles in the air gap between the

stator and the armature plate endanger the function and should be removed.

❚ After replacing the rotor, the origin al braking torq ue will n ot be reache d until the run -in oper-

ation for the friction surfaces has been completed. Afte r replacing th e rotor, the run-in arma ture plates and the flanges have an increased initial rate of wear.

7.3.1 Check the brake

1. Air gap control (only for sizes12 to 18 ):

- Do not energise the brake when checking the air gap.

- When checking the air gap s

, the plug (item 1.3 in Figure 1) must be levered out manually. Sharp-

L

edged tools will destroy the plug!

- Use a feeler gauge to determine the actual air gap. It can then be compared to the max. permissible

At s

< s

L

air gap s

, the brake remains operational.

Lmax

Lmax

. 14.

NOTICE

After the procedure, the plug (item 1.3) must be pushed in straight so that it is firmly inserted.

Make sure that the plug does not become tilted.

If further tests are required, the brake must be disassembled 41 (only for sizes 6-18).

DANGER

Switch off the voltage. The brake must have no load torque on it when it is being dismantled.

DANGER

There is a risk of injury by electrical shock!

Live connections must not be touched.

WARNING

Danger: rotating parts!

The brake must be free of residual torque. The motor must not run!

INTORQ | BA 14.0199 | 08/2016 40

Page 41

Maintenance and repair

CAUTION

Danger: hot surfaces. Do not touch!

1. Dismantling the brake, 41 .

2. Check rotor: Rotor thickness

- Measure the rotor thickness using a caliper gauge.

- Compare the measured rotor thickness with the minimally permissible rotor thickness, 14.

- If necessary, exchange the roto r.

- Check the gear teeth of the rotor.

- If the gear teeth are damaged, replace the rotor.

7.3.2 Dismantling the brake

Abb. 16 Dismantling the brake

1 Stator 1.2 Shaft seal 1.3 Plug

2 Armature plate 3 Rotor 4 Hub

6 Flange 10 Socket head cap screws 12 Complete manual release

15 End shield

1. Disconnect the connection cable.

2. Loosen the socket head cap screws (10) and remove them.

3. Detach stator (1) from the shaft.

4. Detach rotor (3) from the hub.

5. Check hub: Gear teeth

- Check the gear teeth of the hub.

- If the gear teeth are damaged, dismount and replace the hub.

6. Check armature plate: Thermal damage

- In the case of thermal damage (dark blue tarnishing), replace the stator.

INTORQ | BA 14.0199 | 08/2016 41

Page 42

Maintenance and repair

7. Check counter friction face:

AFlange

- Maximum run-in depth = 30 % of rated air gap 13.

- In the case of strong scoring, repl ace the flange.

- In the case of thermal damage (dark blue tarnishing), replace the flange.

BEnd shield

- Maximum run-in depth = 30 % of rated air gap 13.

- In case of strong scoring, reprocess the end shield 20.

8. Assemble the brake, 22.

9. Connect the supply cable.

10. Recommission the brake, 34.

NOTICE

After replacing the rotor, the original braking torque will not be reached until the run-in operation for the friction surfaces has been completed. After replacing the rotor, the run-in armature

plates and the flanges have an increased initial rate of wear.

7.3.3 Release / voltage

1. Observe the brake functionality while the drive is operating. The armature pl ate must be attracted and

the rotor must move without residual torque.

2. Measure the DC voltage at the brake.

- Compare the DC voltage with the voltage indicated on the name plate. A deviation of 10 % is per-

missible.

INTORQ | BA 14.0199 | 08/2016 42

Page 43

Maintenance and repair

7.4 Spare-parts list

Spring-applied brake INTORQ BFK470-06 to 18

Abb. 17 Spring-applied brake BFK470

_________________ material number of the brake (PLEASE INCLUDE: refer to the nameplate)!

Only parts with item numbers are available.

Item Designation Variant

1.2 Shaft sealing ring Shaft diameter

3 Complete rotor

4 Hub Bore diameter

6 Comple te flange (incl. O-ring)

10 Fixing screws with sealing rings

Socket head cap screw set, DIN EN ISO 4762

7.5 Electrical accessories

Rectifier

Refer to the Operating Instructions "Electrical switching devices and accessories", on page 15.

for mounting to the motor

for flange with through hole

INTORQ | BA 14.0199 | 08/2016 43

Page 44

Troubleshooting and fault elimination

8 Troubleshooting and fault elimination

If any malfunctions should occur during operations, plea se check for possible causes based on the followin g

table. If the fault cannot be fixed or eliminated by one of the listed measures, please contact the customer

service.

Brake malfunctioning

Fault Cause Remedy

Brake does

not release

Coil interruption ❚ Measure coil resistance using a multimeter:

- If resistance is too high, replace the complete stator.

Coil has contact to earth

or between windings

Wiring defective or

wrong

Defective or incorrect

rectifier

❚ Measure coil resistance with multimeter:

- Compare measured value with rated resistance.

- Values: 16

- If resistance is too low, replace the complete stator.

❚ Check coil for short circuit to ground using a multimeter:

- Replace the complete stator if short circuit to ground is detected.

❚ Check brake voltage (refer to "defective rectifier, voltage too low").

❚ Check and correct

- Check cable for continuity using a multimeter:

❚ Replace the complete stator if a cable is defective.

❚ Measure rectifier DC voltage using a multimeter.

If DC voltage is zero:

❚ Check AC rectifier voltage. If AC voltage is zero:

- Switch on power supply

- Check fuse

- Check wiring.

If AC voltage is okay:

- Check rectifier,

- Replace defective rectifier

If DC voltage is too low:

- Check rectifier,

- Diode defective - install an appropriate undamaged rectifier.

❚ Check coil for inter-turn fault or short circuit to ground.

❚ If the rectifier defect occurs again, replace the en tire stator, even if you can-

not find any fault between turns or short circuit to ground. The fault may occur later during heating-up.

Air gap too large

Rotor thickness too

small

INTORQ | BA 14.0199 | 08/2016 44

Replace rotor 41

Replace rotor 41

Page 45

Troubleshooting and fault elimination

Deviations in measured values

Measured value Cause Remedy

Voltage too high Brake voltage does not

match the rectifier

Voltage too low Brake voltage does not

match the rectifier

Defective rectifier diode Replace defective rectifier by a suitable

AC voltage is not mains

voltage

Fuse is missing or defective

Adjust rectifier and brake voltage to each

other.

Adjust rectifier and brake voltage to each

other.

undamaged one.

Install fuse. Exchange fuse.

INTORQ | BA 14.0199 | 08/2016 45

Page 46

Notes

Notes

INTORQ | BA 14.0199 | 08/2016 46

Page 47

Notes

INTORQ | BA 14.0199 | 08/2016 47

Page 48

Notes

INTORQ | BA 14.0199 | 08/2016 48

Page 49

Notes

INTORQ | BA 14.0199 | 08/2016 49

Page 50

Notes

INTORQ | BA 14.0199 | 08/2016 50

Page 51

Page 52

INTORQ GmbH & Co KG

Germany

PO Box 1103

D-31849 Aerzen, Germany

Wülmser Weg 5

D-31855 Aerzen, Germany

+49 5154 70534-444

+49 5154 70534-200

info@intorq.com

应拓柯制动器 (上海)有限责任公司

INTORQ (Shanghai) Co., Ltd.

上海市浦东新区泥城镇新元南路 600 号

6 号楼一楼 B 座

No. 600, Xin Yuan Nan Road,

Building No. 6 / Zone B

Nicheng town, Pudong

201306 Shanghai, China

+86 21 20363-810

+86 21 20363-805

info@cn.intorq.com

INTORQ US Inc.

USA

300 Lake Ridge Drive SE

Smyrna, GA 30082, USA

+1 678 236-0555

+1 678 309-1157

info@us.intorq.com

INTORQ India Private Limited

India

Plot No E-7/3

Chakan Industrial Area, Phase 3

Nighoje, Taluka - Khed

Pune, 410501, Maharashtra, India

+91 2135625500

info@intorq.in

33001439 | BA 14.0199 | EN | 5.0 | © 08/2016 | SC |

www.intorq.com

Loading...

Loading...