Page 1

j

setting the standard

INTORQ BFK468

Electromagnetically released spring−applied brake

Operating Instructions

www.intorq.com

Page 2

j | BA 14.0190 | 11/2012

This documentation applies to ...

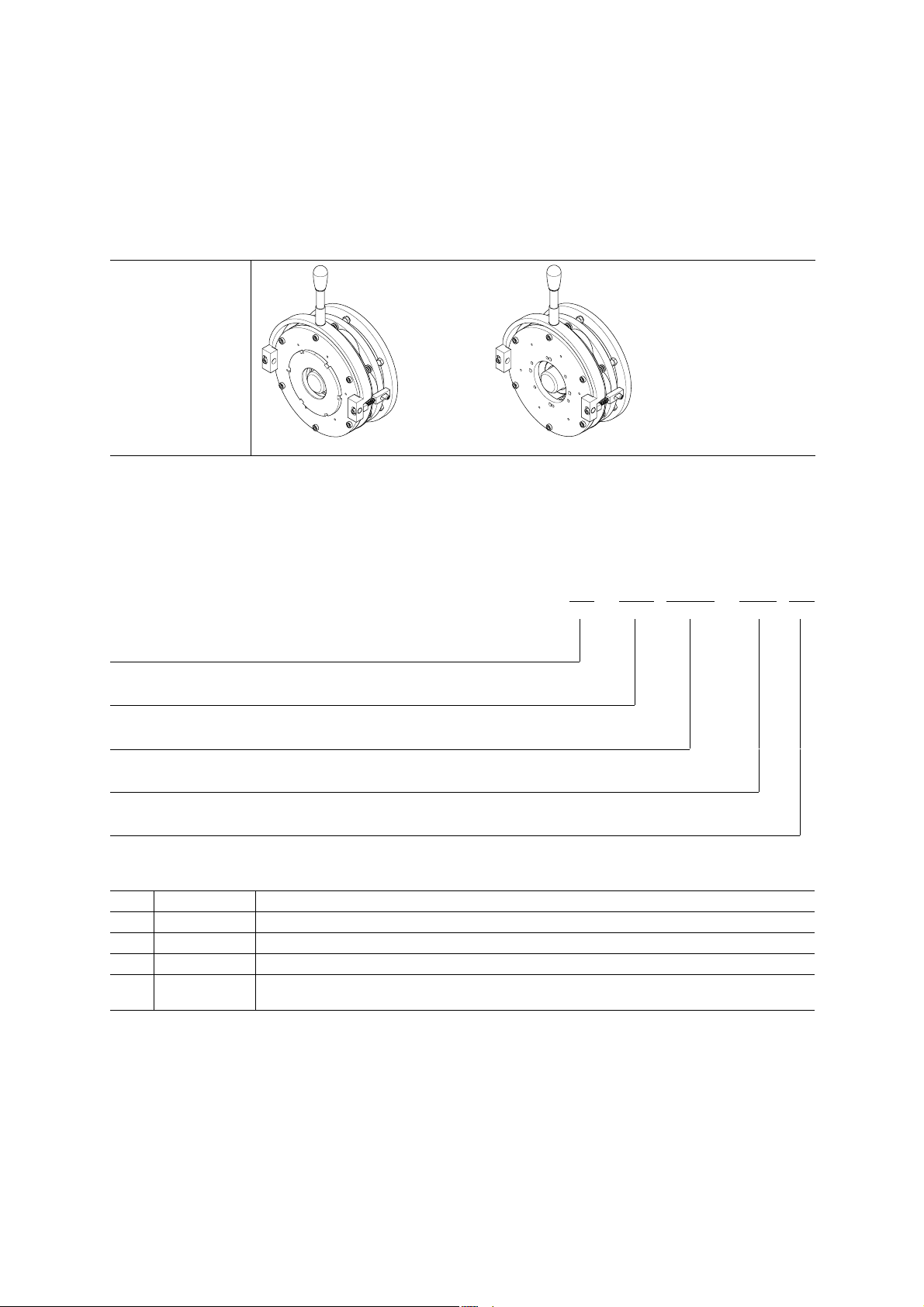

BFK468

BFK46825−002.iso/dms

Product key

Product key INTORQ B FK LLL

Legend for INTORQ BFK468 product key

Product group Brakes

Product family Spring−applied brake

Type 468

Size 18, 20, 25, 31

Design E − adjustable (brake torque can be reduced via adjuster nut)

N − not adjustable

Not coded: Supply voltage, hub bore, options

−

LL L

2

Page 3

i

Identification

j | BA 14.0190 | 11/2012

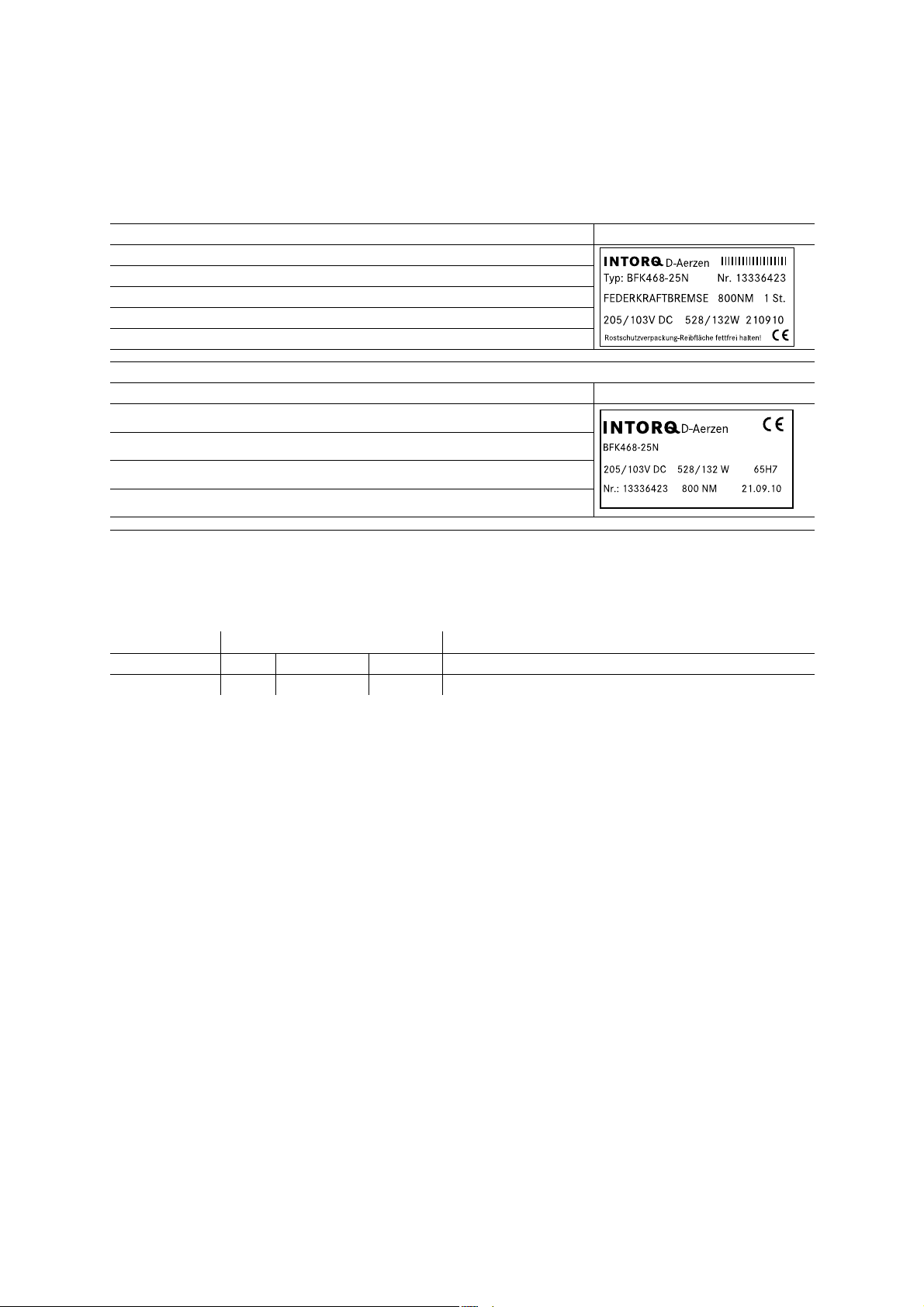

Package label

Manufacturer Bar code

Type (see product key) Type No.

Name Rated torque Quantity per box

Release/holding voltage Release/holding power Packing date

Additional information CE designation

Nameplate

Manufacturer CE designation

Type (see product key)

Rated voltage Rated power Hub diameter

Type No. Rated torque Production date

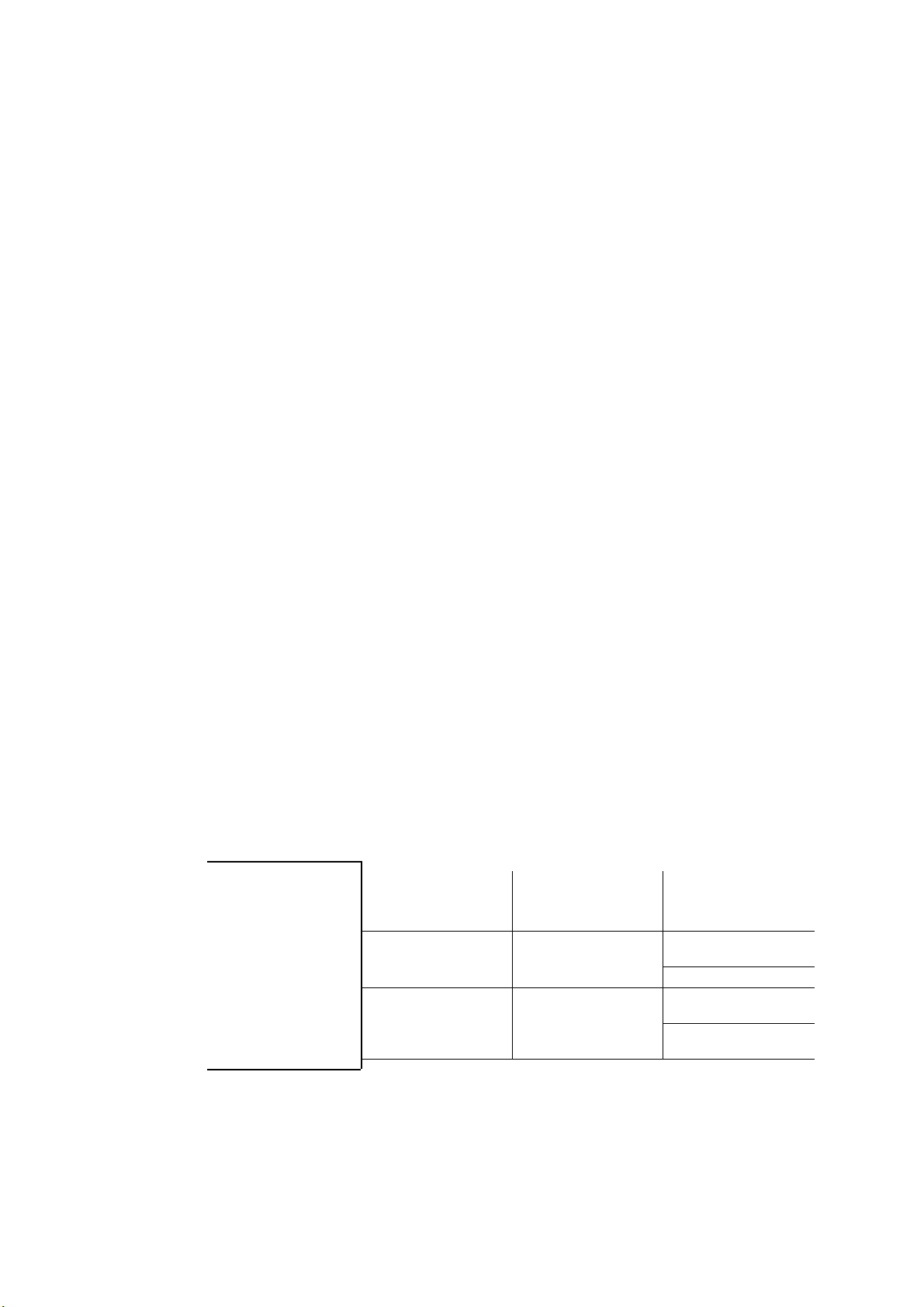

Document history

Material number Version Description

13190474 1.0 01/2007 TD09 First edition

33002357 2.0 11/2012 TD09 Complete revision

0Fig. 0Tab. 0

Example

BFK458−002.iso/dms

Example

BFK468−001.iso/dms

3

Page 4

j | BA 14.0190 | 11/2012

Contentsi

1 Preface and general information 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 About these Operating Instructions 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Terminology used 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Conventions used 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Abbreviations used 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 Notes used 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6 Scope of supply 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7 Disposal 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.8 Drive systems 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.9 Legal regulations 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Safety instructions 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 General safety information 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Application as directed 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Technical data 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Product description 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Brake torques 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Rated data 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Operating times 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Operating frequency / friction work 19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 Emission 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Mechanical installation 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Necessary tools 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Mounting 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Installation 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Electrical installation 29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Bridge/half−wave rectifiers (option) 29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Electrical connection 31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Commissioning and operation 34 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Functional test 34 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Reducing the brake torque 38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 During operation 39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Maintenance/repair 40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Wear of spring−applied brakes 40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Inspections 41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 Maintenance operations 42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 Spare−parts list 44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5 Spare parts order 45 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Troubleshooting and fault elimination 46 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

Page 5

i

j | BA 14.0190 | 11/2012

Preface and general information1

1 Preface and general information

1.1 About these Operating Instructions

| These Operating Instructions will help you to work safely on and with the

spring−applied brake with electromagnetic release. They contain safety instructions

that must be followed.

| All persons working on or with the electromagnetically released spring−applied brakes

must have the Operating Instructions available and observe the information and notes

relevant for them.

| The Operating Instructions must always be in a complete and perfectly readable

condition.

1.2 Terminology used

Term In the following text used for

Spring−applied brake Spring−applied brake with electromagnetic release

Drive system Drive systems with spring−applied brakes and other drive

components

1.3 Conventions used

This documentation uses the following conventions to distinguish different types of

information:

Spelling of numbers Decimal separator Point The decimal point is always used.

Symbols

For example: 1234.56

Page reference Reference to another page with additional information

For example: 16 = see page 16

Document reference Reference to another documentation with additional

information

For example: Operating instructions

Wildcard Wildcard for options, selections

For example: BFK458− = BFK458−10

5

Page 6

j | BA 14.0190 | 11/2012

Preface and general information1

1.4 Abbreviations used

Abbreviation Unit Name

I [A] Current

I

N

M

A

M

N

n

max

P

N

Q [J] Quantity of heat/energy

Q

E

Q

R

Q

Smax

R

N

S

h

S

hue

S

hmax

s

L

s

LN

s

Lmin

s

Lmax

t

1

t

2

t

11

t

11

t

12

U [V] Voltage

U

N

[A] Rated current at 20 °C and rated voltage

[Nm] Tightening torque of the fixing screws

[Nm] Characteristic torque of the brake / clutch

[r/min] Maximum speed during the slipping time t3

[W] Rated coil power at rated voltage and at 20 °C

[J] Maximally permissible friction energy for one−time switching

[J] Braking energy, friction energy

[J] Maximally permissible friction energy for cyclic switching

[Ohm] Rated coil resistance at 20 °C

[1/h] Operating frequency, i.e. the number of periodical switching opera-

tions

[1/h] Transition operating frequency for thermal characteristic of the

brake / clutch

[1/h] Maximally permissible operating frequency, depending on the fric-

tion energy per switching operation

[mm] Air gap, i.e. lift of the armature plate while the brake is switched, or

lift of the armature part when the clutch is switched

[mm] Rated air gap

[mm] Minimum air gap

[mm] Maximum air gap

[s] Engagement time, i.e. sum of the delay time and the braking torque

exit time t

= t11 + t

1

12

[s] Disengagement time, i.e. time between switching the stator and

reaching 0.1 M

K

[s] Slipping time, i.e. engagement time of the brake (after t11) until

standstill

[m] Delay during engagement, i.e. time from switching off the supply

voltage to the beginning of the torque rise

[m] Rise time of the braking torque, i.e. time from the start of the torque

rise until reaching the braking torque

[V] Rated coil voltage

6

Page 7

i

j | BA 14.0190 | 11/2012

Preface and general information1

1.5 Notes used

The following pictographs and signal words are used in this documentation to indicate dangers

and important information:

Safety instructions

Structure of safety instructions:

Danger!

Characterises the type and severity of danger

Note

Describes the danger

Possible consequences:

| List of possible consequences if the safety instructions are disregarded.

Protective measure:

| List of protective measures to avoid the danger.

Pictograph and signal word Meaning

Danger of personal injury through dangerous electrical voltage

Danger!

Danger!

Stop!

Application notes

Pictograph and signal word Meaning

Note!

Tip!

Reference to an imminent danger that may result in death or serious

personal injury if the corresponding measures are not taken.

Danger of personal injury through a general source of danger

Reference to an imminent danger that may result in death or serious

personal injury if the corresponding measures are not taken.

Danger of property damage

Reference to a possible danger that may result in property damage if the

corresponding measures are not taken.

Important note to ensure troublefree operation

Useful tip for simple handling

Reference to another documentation

7

Page 8

j | BA 14.0190 | 11/2012

Preface and general information1

1.6 Scope of supply

1.7 Disposal

1.8 Drive systems

After receipt of the delivery, check immediately whether it corresponds to the accompanying

papers. INTORQ does not grant any warranty for deficiencies claimed subsequently.

| Claim visible transport damage immediately to the forwarder.

| Claim visible deficiencies / incompleteness immediately to INTORQ GmbH & Co.KG.

The spring−applied brake consists of different types of material.

| Recycle metals and plastics.

| Ensure professional disposal of assembled PCBs according to applicable

environmental regulations.

Labelling

Drive systems and components are unambiguously designated by the indications on the

nameplate.

Manufacturer: INTORQ GmbH & Co KG, Wülmser Weg 5, D−31855 Aerzen

| The spring−applied INTORQ brakeis also delivered in single modules and individually

combined to its modular design. The data − package labels, nameplate, and type code

in particular − apply to one complete stator.

| If single modules are delivered, the labelling is missing.

8

Page 9

i

j | BA 14.0190 | 11/2012

Preface and general information1

1.9 Legal regulations

Liability

| The information, data and notes in this documentation met the state of the art at the

time of printing. Claims referring to products which have already been supplied cannot

be derived from the information, illustrations and descriptions.

| We do not accept any liability for damage and operating interference caused by:

– inappropriate use

– unauthorised modifications to the product

– improper working on and with the product

– operating faults

– disregarding the documentation

Warranty

| Terms of warranty: see terms of sale and delivery of INTORQ GmbH & Co. KG.

| Warranty claims must be made to INTORQ immediately after detecting defects or

faults.

| The warranty is void in all cases where liability claims cannot be made.

9

Page 10

j | BA 14.0190 | 11/2012

Safety instructions2

2 Safety instructions

2.1 General safety information

| INTORQ components ...

– ... must only be applied as directed.

– ... must not be commissioned if they are noticeably damaged.

– ... must not be technically modified.

– ... must not be commissioned if they are mounted incompletely.

– ... must not be operated without the required covers.

– ... can hold live as well as moving or rotary parts during operation according to their

degree of protection. Surfaces may be hot.

| For INTORQ components ...

– ... the documentation must always be kept at the installation site.

– ... only permitted accessories are allowed to be used.

– ... only original spare parts of the manufacturer are allowed to be used.

| All specifications of the corresponding enclosed documentation must be observed.

This is vital for a safe and trouble−free operation and for achieving the specified product

features.

| Only qualified, skilled personnel are permitted to work on and with INTORQ

components.

In accordance with IEC 60364 or CENELEC HD 384, qualified, skilled personnel are

persons ...

– ... who are familiar with the installation, mounting, commissioning, and operation of

the product.

– ... who have the qualifications necessary for their occupation.

– ... who know and apply all regulations for the prevention of accidents, directives, and

laws relevant on site.

| Risk of burns!

– Surfaces may be hot during operation! Provide for protection against accidental

contact.

| Risk of injury due to a rotating shaft!

– Wait until the motor is at standstill before you start working on the motor.

| The friction lining and the friction surfaces must by no means have contact to oil or

grease since even small amounts reduce the brake torque considerably.

10

| The brake is designed for operation under the environmental conditions that apply to

IP54. Because of the numerous possibilities of using the brake, it is however necessary

to check the functionality of all mechanical components under the corresponding

operating conditions.

Page 11

i

j | BA 14.0190 | 11/2012

Safety instructions2

2.2 Application as directed

| INTORQ components ...

– ... are intended for use in machinery and systems.

– ... must only be used for the purposes ordered and confirmed.

– ... must only be operated under the ambient conditions prescribed in these

Operating Instructions.

– ... must not be operated beyond their corresponding power limits.

Any other use shall be deemed inappropriate!

Possible applications of the INTORQ spring−applied brake

| Humidity: no restrictions

– In case of formation of condensed water and moisture: provide for appropriate

ventilation to ensure that all components will dry quickly.

| Ambient temperature:

– −20 °C to +40 °C (standard)

| At high humidity and low temperature:

– Take measures to protect armature plate and rotor from freezing.

| Protect electrical connections against contact.

11

Page 12

j | BA 14.0190 | 11/2012

Technical data3

3 Technical data

3.1 Product description

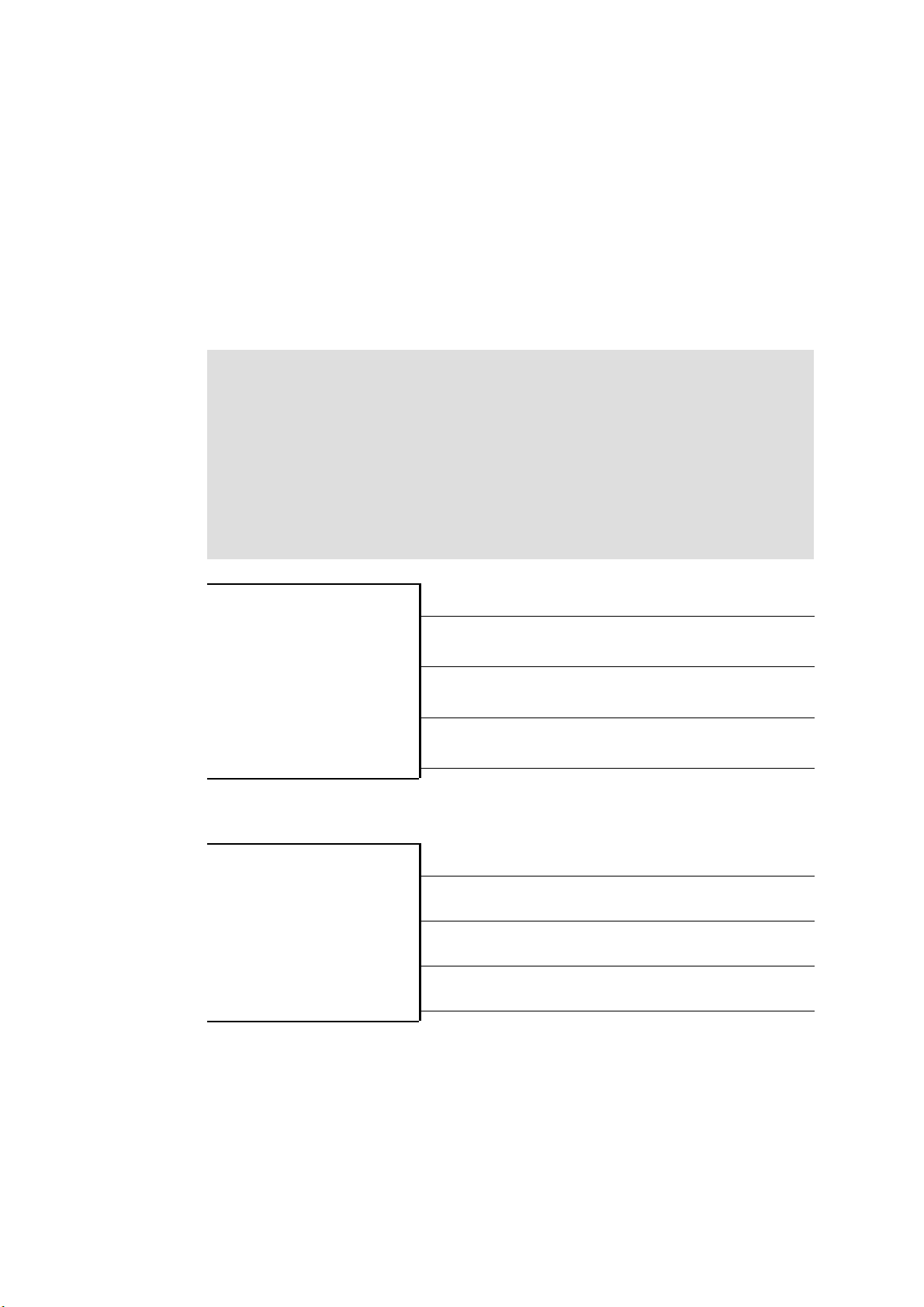

BFK46820−003.iso/dms

Fig. 1 Design of the BFK468 spring−applied brake: basic module E (complete stator) + rotor + hub +

flange

1 Complete stator 3 Complete rotor 6 Flange

1.2 Compression springs 4 Hub 9 Sleeve bolts

2 Armature plate 5 Shaft 31 Torque adjustment ring

KL 46820−001.iso/dms

Fig. 2 Design of the BFK468 spring−applied brake: basic module N (complete stator) + rotor + hub +

flange

1 Complete stator 3 Complete rotor 6 Flange

1.2 Compression springs 4 Hub 9 Sleeve bolts

2 Armature plate 5 Shaft

12

Page 13

i

j | BA 14.0190 | 11/2012

Technical data3

3.1.1 General information

The spring−applied brake is designed for the conversion of mechanical work and kinetic energy

into heat. Due to the static brake torque, the brake can hold loads without speed difference.

Emergency braking is possible at high speed. The more friction work, the higher the wear.

(Operating speeds 16)

The BFK468− spring−applied brake is a single−disk brake with two friction surfaces.

Several compression springs (1.2) generate the braking torque by friction locking. The brake

is released electromagnetically by a reduction of the holding current via an INTORQ bridge

half−wave rectifier.

The stator (1) is designed to be of thermal class F. The limit temperature of the coils is 155°C.

3.1.2 Braking

During braking the rotor (3) axially slidable on the hub (4) is pressed against the friction

surface by the inner and outer springs (1.2) via the armature plate. The asbestos−free

friction linings ensure a high braking torque and low wear. The braking torque transmission

between hub (4) and rotor (3) is effected by means of toothing.

3.1.3 Brake release

In braked state, there is an air gap "s

To release the brake, the coil of the stator (1.1) is excited with the DC voltage provided. The

magnetic force generated attracts the armature plate (2) towards the stator (1.1) against the

spring force. The rotor (3) is then released and can rotate freely.

3.1.4 Brake torque reduction

For basic module E (adjustable), the spring force and thus the brake torque can be reduced

by unscrewing the adjuster nut (8), ( 38).

3.1.5 Manual release (optional for sizes 18 to 25)

The manual release is optionally available for short−term releases when no voltage is applied.

The manual release can be retrofitted.

" between the stator (1.1) and the armature plate (2).

L

13

Page 14

j | BA 14.0190 | 11/2012

Technical data3

3.1.6 Microswitch (optional)

The manufacturer offers the microswitch for air−gap or wear monitoring. The user must provide

the corresponding electrical connection ( 31et seqq.).

When air−gap monitoring, the motor does not start before the brake has been released. With

this set−up, all possible faults are monitored. For example, in the event of defective rectifiers,

interrupted connection cables, defective coils, or excessive air gaps the motor will not start.

When checking the wear, no current will be applied to the brake and the motor if the air gap

is too large.

3.1.7 Encapsulated design (optional)

This design not only avoids the penetration of spray water and dust, but also the spreading

of abrasion particles outside the brake. This is achieved by:

| a cover seal over the armature plate and rotor,

| a cover in the adjuster nut,

| a shaft seal in the adjuster nut for continuous shafts (option).

14

Page 15

i

j | BA 14.0190 | 11/2012

Technical data3

3.2 Brake torques

Stop!

Please observe that engagement times and disengagement times change

depending on the brake torque.

Size 18 20 25 31

Rated torques [Nm],

relating to the

relative speed Dn =

100 rpm

Depending on the

rated torque (spring

assembly), the angle

of rotation for the

braking torque

reduction can be

60°, 120° or 180°

for basic module E.

Characterist

ic torque

[Nm] [Nm] [Nm] [Nm] [Nm] [Nm] [Nm]

100 N/E 6.4 170 N/E 19.8 260 N/E 16.5

115 N/E 6.4 200 N/E 19.8 300 N/E 8.2 720 N

130 N/E 6.4 230 N/E 9.9 350 N/E 8.2 960 N

150 N/E 3.2 260 N/E 9.9 400 N/E 8.2 1200 N

165 N/E 3.2 300 N/E 19.8 445 N/E 16.5 1440 N

185 N/E 6.4 345 N/E 19.8 490 N/E 8.2 1680 N

200 N/E 6.4 400 N/E 19.8 520 N/E 16.5 1920 N

235 N/E 6.4 440 N/E 19.8 600 N/E 16.5 2160 N

265 N/E 6.4 480 N/E 19.8 700 N/E 16.5 2400 N

300 N/E 6.4 520 N/E 19.8 800 N/E 16.5

Torque

reduction E

per detent

position

Characterist

ic torque

Torque

reduction E

per detent

position

Characterist

ic torque

230 N

Torque

reduction E

per detent

position

Characterist

ic torque

Tab. 1 N.....Brake torque for module N (without torque adjustment ring)

E......Brake torque for module E (with torque adjustment ring)

Holding brake with emergency stop operation (s

Service brake (s

Standard braking torque

approx. 4.0 x sLN)

L max.

3.2.1 Basic module E, brake torque reduction

For basic module E, the braking torque can be reduced by means of the torque adjustment

ring in the stator. The torque adjustment ring must only be screwed out up to the maximum

projection "h

", 16 and 38.

Emax.

approx. 2.0 x sLN)

L max.

15

Page 16

j | BA 14.0190 | 11/2012

Technical data3

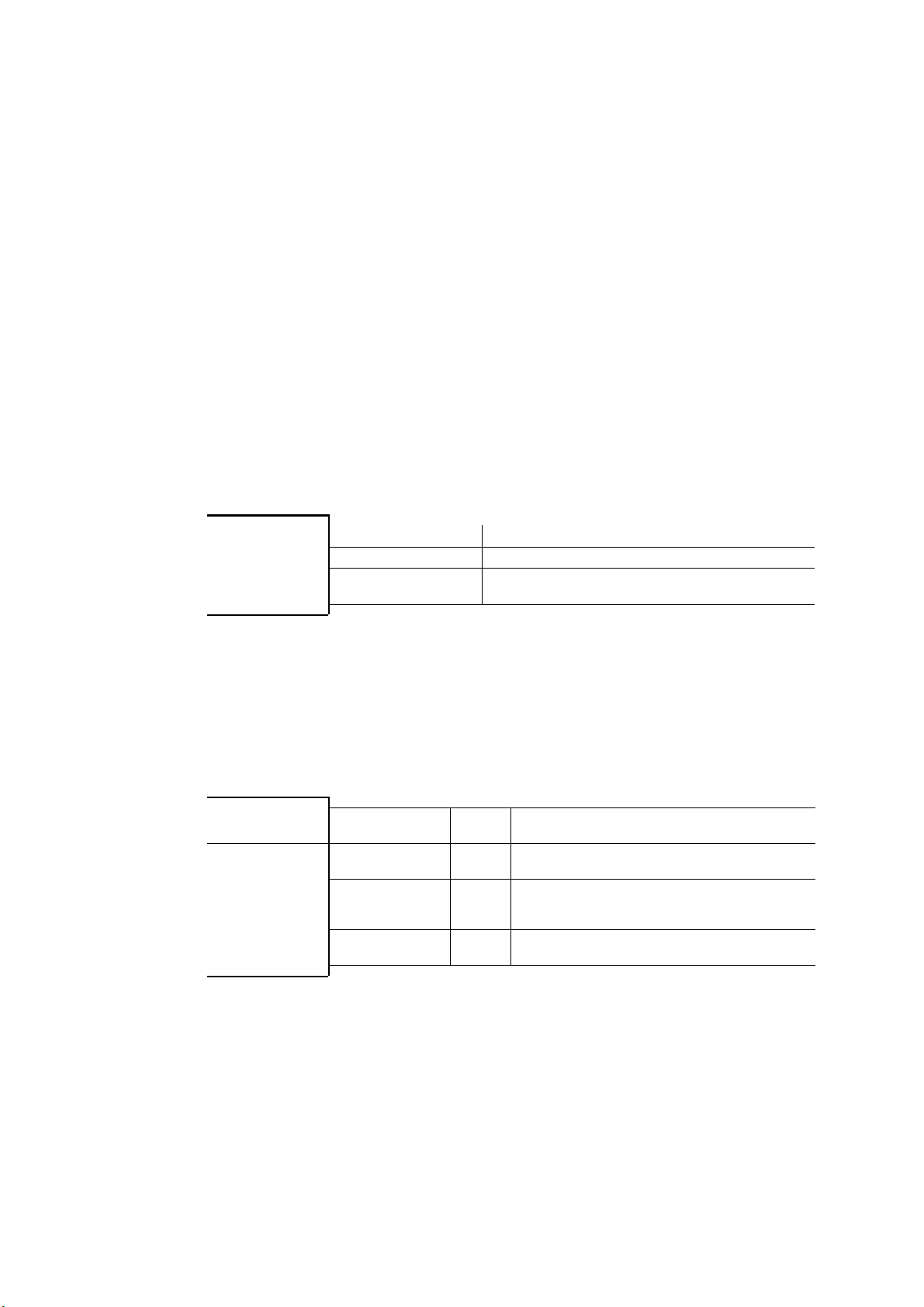

3.2.2 Brake torques depending on the speed and permissible limit speeds

Type Rated torque at

BFK468−18

BFK468−20 75 68 3700

BFK468−25 73 66 3000

BFK468−31 69 −−−−− 2300

Dn = 100 rpm

[%] 1500 3000 maximum [rpm]

100

Tab. 2 Brake torques depending on the speed and permissible limit speeds

Braking torque at Dn0 [rpm] [%] max. speed

mounting position

77 70

66

Dn

0max.

horizontal

4400

with

3.3 Rated data

Type sLN

BFK468−18

BFK468−20

BFK468−25

BFK468−31 1.5 1.0 3.0 15.0 18.0 −−−−

+0.1 mm

−0.05 mm

[mm] [mm] [mm] [mm] min. 1) [mm] max. [mm] [mm]

0 4

0 5

s

L max.

service

brake

1 0 0.6 3.0 10.0 13.0 15

1 25

s

Lmax.

holding

brake

0.75 4.5 15.5 20.0 19.5

Max.

adjustment,

permissible

wear

distance

4.0 12.0 16.0 17

Rotor thickness Excess

of the torque

adjustment

ring h

Emax.

1) The friction lining is designed such that the brake can be adjusted at least 5 times.

Type Pitch circle Tightening torque Weight

[mm] Thread Screws [Nm] Complete

BFK468−18 196 6 x M8 36.1 23 13.4

BFK468−20 230

BFK468−25 278 31.0

BFK468−31 360 8 x M16 302 −−−−− 55.1

Tab. 3 Characteristics of BFK468 spring−applied brake

6 x M10 71 40

lever [Nm]

of complete stator

[kg]

20.0

16

Page 17

i

j | BA 14.0190 | 11/2012

Technical data3

Type Electrical power P

[W] [V] [W]

BFK468−18 85 / 340

BFK468−20 100 / 408

BFK468−25 132 / 528

BFK468−31 230 / 920 360 / 180 140.9

1)

Coil power at 20 _C

Tab. 4 Coil voltage/coil resistance of BFK468

3.3.1 Project planning notes

| The brakes are dimensioned in such a way that the given characteristic torques are

reached safely after a short run−in process.

1)

Release voltage/holding voltage

U

205 / 103 123.5

360 / 180 381.5

205 / 103 106.1

360 / 180 317.6

205 / 103 79.6

360 / 180 245.5

Coil resistance RN ±8 %

| Due to the fluctuating properties of the organic friction linings used and the alternating

environmental conditions, deviations of the given braking torques may occur. These

must be considered by corresponding safety measures in the dimensioning process.

Especially with humidity and alternating temperatures, an increased breakaway torque

may occur after a long downtime.

| Check the braking torque if the brake is inserted on the customer’s friction surfaces.

| If the brake is used as a pure holding brake without dynamic load, the friction lining

must be reactivated regularly.

17

Page 18

j | BA 14.0190 | 11/2012

Technical data3

3.4 Operating times

BFKXXX−011.iso/dms

Fig. 3 Operating times of the spring−applied brakes

Engagement time t

t

1

Disengagement time (up to M = 0.1 Mr)t12Rise time of the brake torque

t

2

Characteristic torque U Voltage

M

K

Type Rated torque at

Dn = 100 rpm

MK 1) Q

[Nm] [J] [h−1] t

BFK468−18 150 60000 20 26 30 56 70

BFK468−20 260 80000 19 102 112 168 106

BFK468−25 400 120000 15 60 135 197 120

BFK468−31 1200 300000 13 65 133 198 250

1) Minimum braking torque when all components are run in

Tab. 5 Switching energy − operating frequency − operating times

Max. permissible

friction work per

operation only

E

Transition

operating

frequency

s

hue

Reaction delay during engagement

11

Operating times [ms] at s

DC engagement Disengage

11

t

12

LN

t

1

t

Engagement time

The transition from brake−torque free state to holding braking torque is not free of time lags.

2

18

A braking torque reduction via the torque adjustment ring prolongs the engagement time and

reduces the disengagement time.

| The engagement times are valid for DC switchingwith a spark suppressor.

– Spark suppressors are available for the rated voltages.

– Connect the spark suppressors in parallel to the contact. If this is not admissible for

safety reasons, e.g. with hoists and lifts, the spark suppressor can also be

connected in parallel to the brake coil.

– Circuit proposals: 31, Fig. 15

| The engagement times are approx. 5 times longer with AC switching.

– Connection: 31, Fig. 14

Page 19

i

j | BA 14.0190 | 11/2012

Technical data3

Disengagement time

The disengagement time is the same for DC and AC switching.

3.5 Friction work / operating frequency

Q [J]

1000000

31

10000

1000

25

18

20

100000

A

100

1

Fig. 4 Switching energy as a function of the operating frequency

Switching energy Q Operating frequency s

S

+

hmax

lnǒ1 *

B

* S

10

hue

Q

Q

The permissible operating frequency "S

If the operating frequency "S

100

R

Ǔ

E

" is given, the permissible heat quantity "Q

h

1000 10000

Q

smax

+ Q

hmax

ǒ

1 * e

E

" depends on the heat quantity "QR" (see Fig. 4).

-1

S [h ]

h

h

*S

hue

S

h

BFK468−003.des/dms

Ǔ

" can be

smax

calculated.

With high speed and friction work, the wear increases strongly, because very high

temperatures occur at the friction faces for a short time.

19

Page 20

j | BA 14.0190 | 11/2012

Technical data3

3.6 Emission

Electromagnetic compatibility

Note!

If an INTORQ rectifier is used for the DC switching of the spring−applied brake and if the

operating frequency exceeds five switching operations per minute, the use of a mains filter

is required.

If the spring−applied brake uses a rectifier of another manufacturer for the switching, it

may become necessary to connect a spark suppressor in parallel with the AC voltage.

Spark suppressors are available on request, depending on the coil voltage.

The user must ensure compliance with EMC Directive 2004/108/EC using

appropriate controls and switching devices.

Heat

Since the brake converts kinetic energy as well as mechanical and electrical energy into heat,

the surface temperature varies considerably, depending on the operating conditions and

possible heat dissipation. Under unfavourable conditions, the surface temperature can reach

130 _C.

Geräusche

Das Schaltgeräusch beim Verknüpfen und Trennen ist unterschiedlich groß. Einflussgrößen

sind Lüftweg, Bremsmoment und Bremsengröße.

Je nach Eigenschwingung im eingebauten Zustand, Betriebsbedingungen und Zustand der

Reibflächen kann Quietschen während des Abbremsvorganges auftreten.

Others

The abrasion of the friction parts produces dust.

In case of high load, the friction face will become so hot that odours may occur.

20

Page 21

i

j | BA 14.0190 | 11/2012

Mechanical installation4

4 Mechanical installation

Stop!

Toothed hub and screws must not be lubricated with grease or oil!

4.1 Necessary tools

Type Torque key

Insert for hexagon socket

Measuring

range [Nm]

BFK468−18

BFK468−20

BFK468−25 14 155 − 165

BFK468−31 40 − 200

20 − 100

screws

Wrench size

[mm]

6 x 1/2"

square

1

8 x

/2"

square

14 x 1/2"

square

Wrench size of open−jawed spanner [mm] Hook wrench

*

Sleeve bolts Nuts / bolts 2kt lever Diameter

15

17

24 − / − −−−−− −−−−−

Manual

release

− / 10

10 110 − 115

12 135 − 145

DIN 1810

design A

[mm]

Box spanner

for flange

installation,

outside

Wrench size

[mm]

13 x 1/2"

square

17 x 1/2"

square

24 x 1/2"

square

* for flange mounting insertion with journal guide

Feeler gauge Caliper gauge Multimeter

21

Page 22

j | BA 14.0190 | 11/2012

Mechanical installation4

4.2 Mounting

4.2.1 Preparation

1. Unpack spring−applied brake.

2. Check for completeness.

3. Check nameplate data, especially rated voltage.

4.3 Installation

When you have ordered a version with manual release or flange, attach these units first.

4.3.1 Installation of the hub onto the shaft

Stop!

In reverse operation, it is recommended to additionally glue the hub to the shaft!

KL BFK46825−001−a.iso

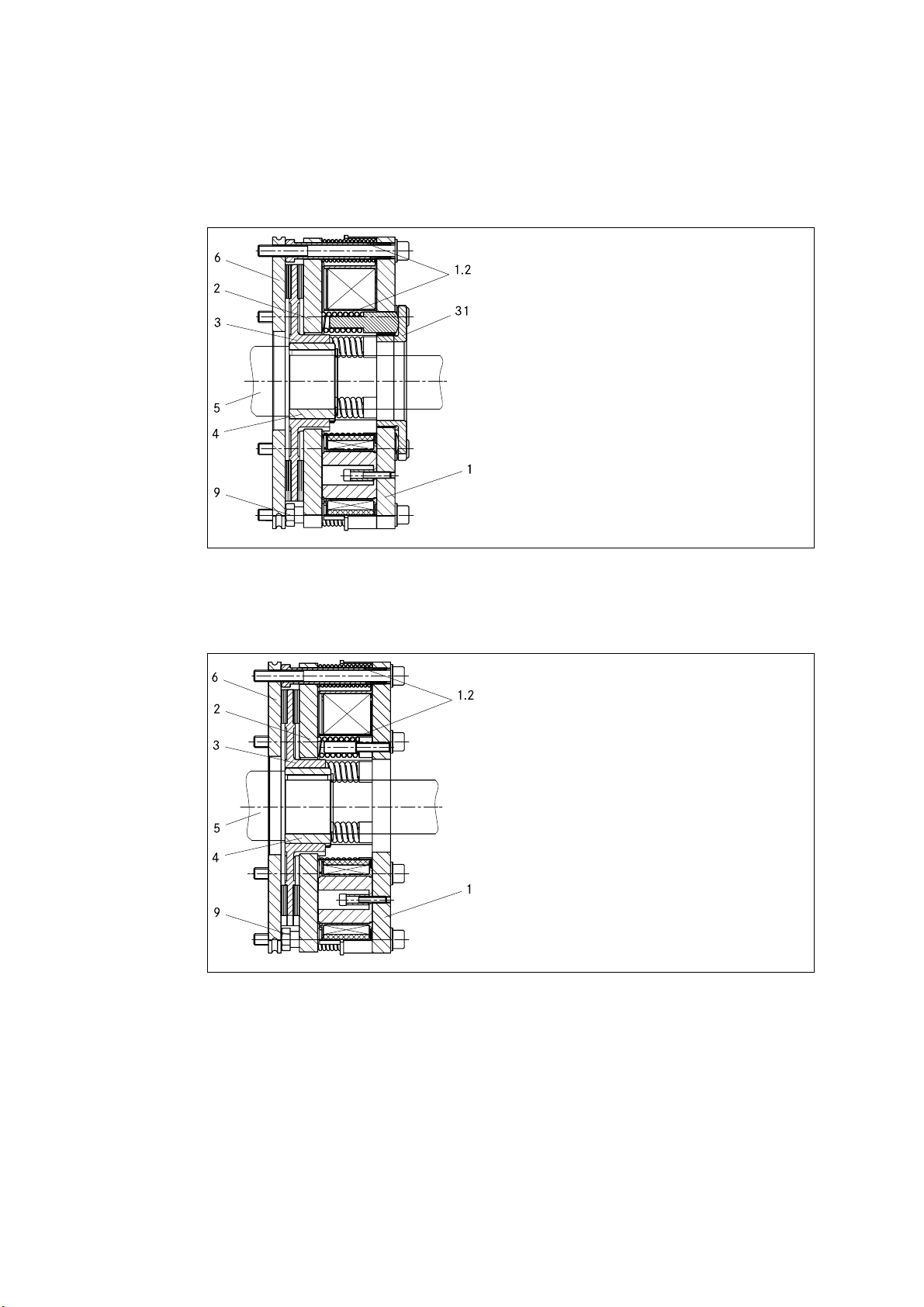

Fig. 5 Mounting the hub onto the shaft

4 Hub 4.2 Circlip 15 End shield

4.1 Keyway

1. Press hub (4) onto the shaft.

2. Secure hub against axial displacement, e.g. using a circlip (4.2).

22

Page 23

i

j | BA 14.0190 | 11/2012

Mechanical installation4

4.3.2 Installation of the brake

Stop!

| Minimum requirement of the end shield (15):

–Material S235 JR or C15 (other materials after consultation with INTORQ),

–Levelness 0.10 mm,

–Axial runout 0.10 mm,

–Roughness Rz 10 to Rz 16

| When dimensioning the thread depth in the end shield (15), the permissible

wear distance must be taken into consideration, 16.

| Condition of the end shield (15):

–It has to be free of grease and oil.

Mounting the flange without additional screws

KL BKF46825−001−d.iso

Fig. 6 Flange assembly BFK468

6 Flange 15 End shield

1. Hold the flange (6) against the end shield (15) and check the pitch circle and retaining

screw drill hole threading.

2. Assemble the brake with the corresponding screw set (see chapter 4.3.2).

23

Page 24

j | BA 14.0190 | 11/2012

Mechanical installation4

Fig. 7 Mounting the brake

BFK46825−008.iso/dms

3 Complete rotor 6 Flange 15 End shield

4 Hub

1. Push the rotor (3) onto the hub (4) and check whether it can be moved by hand

(Fig. 7).

Stop!

Please note the following for the version "brake with shaft sealing ring in torque

adjustment ring":

2. Lightly lubricate the lip of the shaft seal with grease.

3. When assembling the stator (1), push the shaft sealing ring carefully over the shaft.

– The shaft should be located concentrically to the shaft seal.

24

Page 25

i

j | BA 14.0190 | 11/2012

Mechanical installation4

Fig. 8 Mounting of the complete stator

1 Complete stator 7 Connector block

10 Cheese head screw 15 End shield

BFK46825−003.iso

4. Screw the complete stator (1) onto the end shield (15) using the set of screws (10)

provided and a torque key.

5. Remove and dispose of the connector blocks (7).

BFK46825−005.iso/dms

Fig. 9 Inspection of the air gap s

s

AR

1 Stator 10 Cheese head screws

L

9 Sleeve bolts 15 End shield

1. Check the air gap "sL" near the screws (10) using a feeler gauge and compare the

values to the values for "s

" in the table ( 16).

LN

Note!

Do not insert feeler gauge more than 10 mm between armature plate (2) and

stator (1.1)!

25

Page 26

j | BA 14.0190 | 11/2012

Mechanical installation4

Fig. 10 Adjusting the air gap

BFK46825−006.iso

1 Stator 10 Cheese head screw

9 Threaded sleeves

Please adjust if the value for "sL" is outside the tolerance of "sLN":

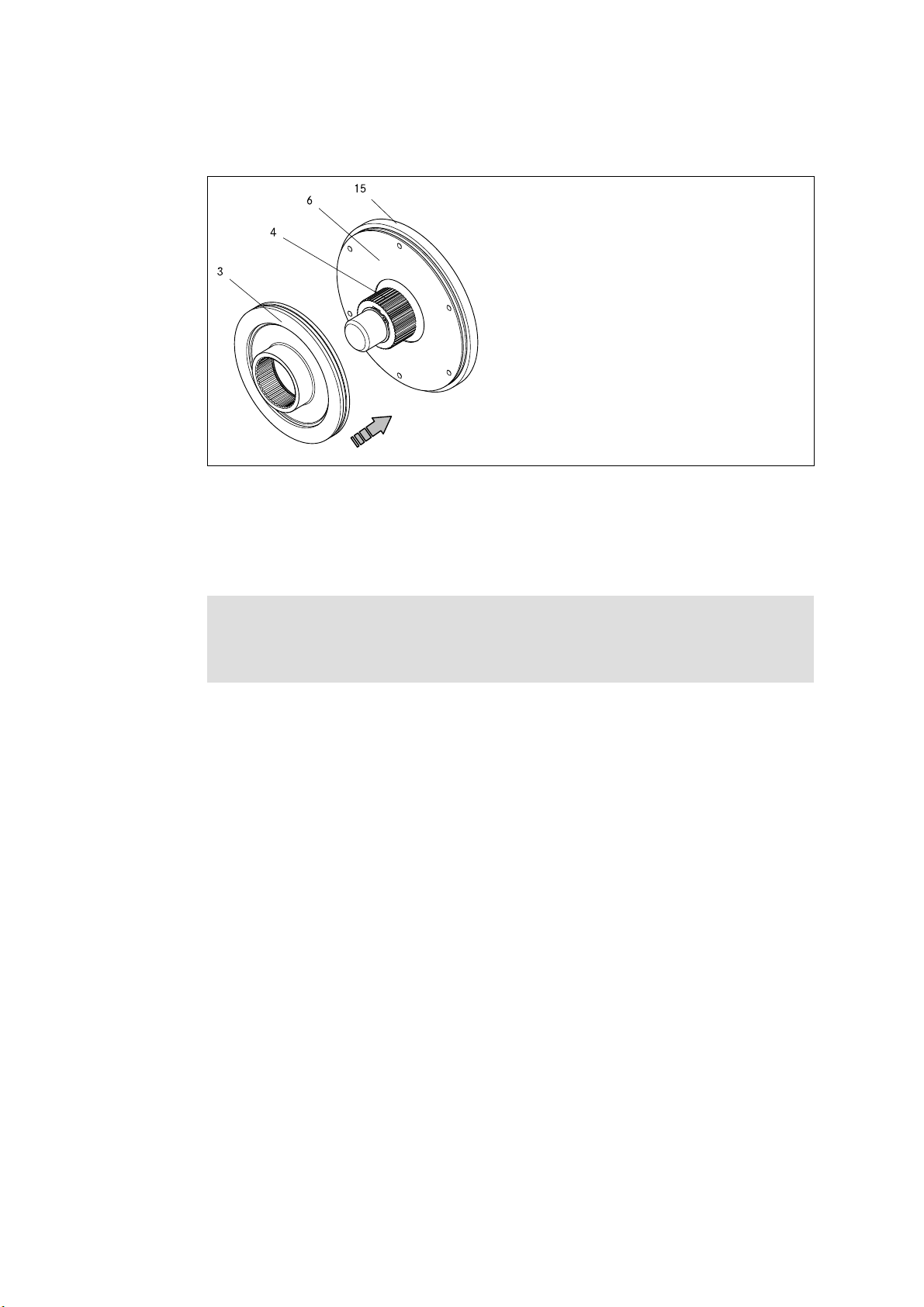

4.3.3 Assembly of the cover seal

BFK46825−007.iso/dms BFK46820−008.iso/dms

Fig. 11 Assembly of the cover ring

1 Stator 6 Flange 13 Cover ring

2 Armature plate 10 Cheese head screw

1. Pull the cable through the seal (13).

26

2. Push the seal (13) over the complete stator (1).

3. Press the lips of the cover seal (13) into the groove of complete stator (1) and flange

(6)/end shield.

Page 27

i

j | BA 14.0190 | 11/2012

Mechanical installation4

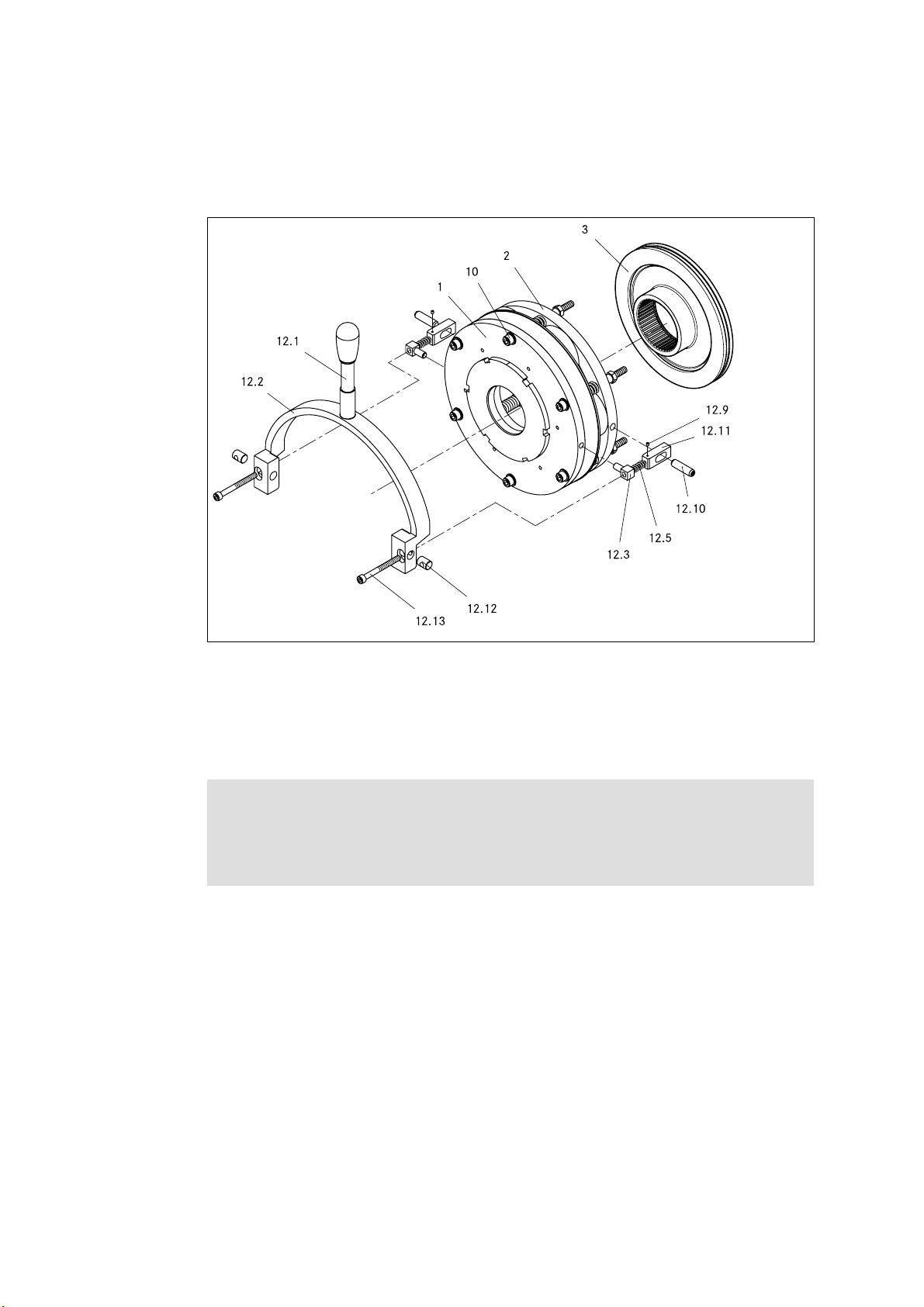

4.3.4 Assembly of the manual release sizes 18 to 25

BFK46825−009.iso

Fig. 12 Assembly of the manual release for brake sizes 18−25

1 Stator (here: design E) 12.1 Manual release lever with control

button

2 Armature plate 12.2 Manual release shackle 12.11 Clip

3 Complete rotor 12.3 Eyebolts 12.12 Trunnion

10 Cheese head screw 12.5 Compression spring

12.10 Pin

Stop!

Before assembly of the manual release, the brake must be mounted onto the

motor end shield and the air gap must be adjusted correctly, further

documentation for BKF468.

1. Hammer the pins (12.10) into the bore holes of the armature plate (2). (When the

brake has already been installed, cushion the impact energy by pressing against the

opposite side of the armature plate).

2. Screw the eyebolts (12.3) into the stator (1) and align them according to the hole

spacing of the manual release shackle (12.2).

3. Put clips (12.11) with elongated hole onto the pins (12.10), align thread towards the

eyebolts (12.3).

4. Insert the compression springs (12.5) between clips (12.11) and eyebolts (12.3).

5. Push the trunnions (12.12) into the bore holes of the shackle (12.2), cross hole to the

outside.

27

Page 28

j | BA 14.0190 | 11/2012

Mechanical installation4

6. Push the cheese head screws (12.13) through the cross holes of the trunnions

(12.12).

7. Locate the shackle (12.2) with trunnions (12.12) and cheese head screws (12.13)

such onto the back of the stator (1) that the cheese head screws (12.13) are led

through the eyebolts (12.3) and the compression springs (12.5).

8. Screw the cheese head screws (12.13) into the clip threads (12.11).

9. Adjust gap "s" using the cheese head screws (12.13), (values for "s " 28.

10. Secure the adjustment of the cheese head screws (12.13) using the threaded pin

(12.9) in the clip (12.11).

Note!

Dimension "s + sL" can be checked through the difference of the fitting length

of the compression springs when the armature plate is attracted towards the

stator and the manual release has been adjusted.

11. If necessary, screw the lever (12.1) into the shackle (12.2).

Type sL (mm) s +

BFK468−18 0.4 2.0 2.4

BFK468−20 0.4 2.0 2.4

BFK468−25 0.5 2.5 3.0

Tab. 6 Adjustment setting for manual release

0.1

(mm) s + sL (mm)

Stop!

Dimension "s" must be observed! Check air gap "sL".

BFK46820−006.iso

28

Page 29

i

j | BA 14.0190 | 11/2012

Electrical installation5

5 Electrical installation

5.1 Bridge/half−wave rectifiers (option)

BEG−561

After a defined overexcitation time, the bridge/half−wave rectifiers change from bridge

rectification to half−wave rectification. Depending on the dimensioning of the load, the

switching performance can thus be improved or the power can be derated.

Fig. 13 BEG−561 attachment features

5.1.1 Technical data

Rectifier type Bridge/half−wave rectifier

Output voltage for bridge rectification 0.9 x U

Output voltage for half−wave rectification 0.45 x U

Ambient temperature (storage/operation) [°C] −25 ... +70

Type Input voltage U

BEG−561−255−030

BEG−561−255−130 1.870 1.300 1.170

BEG−561−440−030−1

BEG−561−440−130 3.0 1.5 2.300 1.300 1.200

Input voltage U1 (40 ... 60 Hz)

Tab. 7 Data for bridge/half−wave rectifier type BEG−561

min.

[V ~ ]

160

230

(40 Hz ... 60 Hz)

rated

[V ~ ]

230 255 3.0 1.5

400 440

1

max.

[V ~ ]

Max. current I

bridge

[A]

1.5 0.75 0.500 0.300 0.270

1

1

max.

half−wave

[A]

Overexcitation time tue ( ±20%)

with U

[s]

0.430 0.300 0.270

1 min

with U

[s]

rated

with U

1

max

[s]

1

29

Page 30

j | BA 14.0190 | 11/2012

Electrical installation5

5.1.2 Reduced switch−off times

When switching on the DC side (fast engagement), switching on the AC side is also required!

Otherwise, there will be no overexcitation during power−on.

Delayed engagement Fast engagement

1234 65

Mains Bridge Coil

5.1.3 Permissible current load − ambient temperature

12 34 65

1 For screw assembly with metal surface (good heat dissipation)

2 For other assembly (e.g. glue)

5.1.4 Assignment: Bridge/half−wave rectifier − brake size

Rectifier type AC voltage Coil voltage

[V AC] [V DC]

BEG−561−255−030

BEG−561−255−130 BFK468−25

BEG−561−440−030−1

BEG−561−440−130

230

400

±10%

±10%

release/holding

205 / 103

360 / 180

BFKXXX−008.iso

Assigned brake

BFK468−18

BFK468−20

BFK468−18

BFK468−20

BFK468−25

BFK468−31

30

Page 31

i

j | BA 14.0190 | 11/2012

Electrical installation5

5.2 Electrical connection

Danger!

The brake must only be electrically connected when no voltage is applied!

5.2.1 Circuit proposals

Fig. 14 AC switching, delayed engagement

Bridge rectifier/half−wave rectifier

Fig. 15 DC switching, normal engagement

Bridge rectifier/half−wave rectifier

BFKXXX−007.iso

BFKXXX−002.iso

Stop!

For switching on the DC side the brake must be operated with a spark

suppressor to avoid impermissible overvoltages.

31

Page 32

j | BA 14.0190 | 11/2012

Electrical installation5

KL−BFKXXX−003.iso

Fig. 16 With microswitch (release check); connection diagram also valid for star connection

DC voltage depending on coil voltage Spark suppressor

KL−BFKXXX−004.iso

Fig. 17 With microswitch / wear check addition for all circuits; connection diagram also valid for star

connection

32

Page 33

i

j | BA 14.0190 | 11/2012

Tip!

During operation according to Fig. 17 the air gap is only monitored when no voltage is applied

to the brake. This makes sense because it is possible that when the current flows only one

side of the armature plate is attracted at first. This misalignment may cause a simulation of the

maximum air gap and the actuation of the microswitch. If there is no closed contact in parallel

to the microswitch contact, motor and brake will be switched off. The microswitch contact is

closed again when the armature plate is completely released − the release is repeated again −

because of the small difference−contact travel of the microswitch.

To avoid this misinterpretation of the microswitch signal, the signal should only be processed

when no voltage is applied to the brake.

Electrical installation5

1. Mount the rectifier in the terminal box. With motors of the insulation class "H", mount

the rectifier in the control cabinet. Permissible ambient temperature for the rectifier

−25 _C to +70 _C.

2. Compare the coil voltage of the stator to the DC voltage of the rectifier installed.

Conversion of supply voltage to DC voltage:

– Bridge rectifier: U

– Half−wave rectifier: U

– Permissible deviation of U

3. Select suitable circuit diagram ( 31).

= UAC ¯ 0.9

DC

= UAC ¯ 0.45

DC

and UDC up to ±10%.

coil

Note!

Selection of the rectifier at voltages ³ 460 V AC catalogue "Electronic

switchgear and accessories" Chapter spark suppressors and rectifiers.

4. Motor and brake must be wired according to the requirements of the engagement

time.

33

Page 34

j | BA 14.0190 | 11/2012

Commissioning and operation6

6 Commissioning and operation

Danger!

The live connections and the rotating rotor must not be touched.

The drive must not be running when checking the brake.

6.1 Functional test

In the event of failures, refer to the troubleshooting table, 46. If the fault cannot be

eliminated, please contact the aftersales service.

6.1.1 Release / voltage check

For brakes without microswitch only

Danger!

The brake must be free of residual torque. The motor must not rotate.

Danger!

Live connections must not be touched.

1. Remove two bridges from the motor terminals. Do not switch off the DC brake supply.

When connecting the rectifier to the neutral point of the motor, the PE conductor must

also be connected to this point.

2. Connect the mains supply.

3. Measure the DC voltage at the brake.

– Compare the DC voltage measured with the voltage specified on the nameplate. A

10 % deviation is permissible.

4. Check air gap "s

5. Switch off the current.

". It must be zero and the rotor must rotate freely.

L

34

6. Bolt bridges to the motor terminals. Remove additional PEN conductor.

Page 35

i

j | BA 14.0190 | 11/2012

Commissioning and operation6

6.1.2 Microswitch − release check

Danger!

The brake must be free of residual torque. The motor must not rotate.

Danger!

Live connections must not be touched.

1. The switching contact for the brake must be open.

2. Remove two bridges from the motor terminals to deenergise the motor.

– Do not switch off the DC brake supply.

– When connecting the rectifier to the neutral point of the motor, the PE conductor

must also be connected to this point.

3. Apply DC voltage to the brake.

4. Measure the AC voltage at the motor terminals. It must be zero.

5. Close the switching contact for the brake.

– The brake is released.

6. Measure the DC voltage at the brake:

– Compare the DC voltage measured with the voltage specified on the nameplate. A

±10 % deviation is permissible.

7. Check air gap "s

– It must be zero and the rotor must rotate freely.

.

L"

35

Page 36

j | BA 14.0190 | 11/2012

Commissioning and operation6

6.1.3 Microswitch − wear check

Danger!

The brake must be free of residual torque. The motor must not rotate.

Danger!

Live connections must not be touched.

1. Remove two bridges from the motor terminals. Do not switch off the DC voltage for

the brake. When connecting the rectifier to the neutral point of the motor, the PE

conductor must also be connected to this point.

"

2. Set air gap to "s

. Description 23 worksteps 8−11.

Lmax.

3. Connect the mains supply.

4. Measure the AC voltage at the motor terminals and the DC voltage at the brake. Both

must be zero.

5. Switch off the current.

6. Set air gap to "s

7. Connect the mains supply.

8. Measure the AC voltage at the motor terminals. It must be the same as the mains

voltage.

9. Measure the DC voltage at the brake.

– The DC voltage measured after the overexcitation time (see bridge/half−wave

rectifier) must be half the voltage indicated on the nameplate. A 10 % deviation is

permissible.

10. Check air gap "s

11. Switch off the current for the brake.

12. Bolt bridges to the motor terminals. Remove additional PEN conductor.

". Description 23 worksteps 8−11.

LN

". It must be zero and the rotor must rotate freely.

L

36

Page 37

i

j | BA 14.0190 | 11/2012

Commissioning and operation6

6.1.4 Manual release

Stop!

This operational test is to be carried out additionally!

Danger!

The brake must be free of residual torque. The motor must not rotate.

1. Pull the lever (Fig. 18) with approx. 250 N until the resistance increases strongly.

Stop!

Additional tools to facilitate brake release are not allowed! (e.g. extension piece)

2. The rotor must rotate freely. Small residual torques are permissible.

3. Release the lever.

37

Page 38

j | BA 14.0190 | 11/2012

Commissioning and operation6

6.2 Reducing the brake torque

M−

M+

BFK46825−010−a.iso BFK46820−012.iso

Fig. 18 Braking torque adjustment

1 Stator

31 Torque adjustment ring

1. Turn the adjuster nut (8) counterclockwise using the hook wrench.

– Observe the notches. Positions between notches are impermissible. (Values for the

brake torque reduction see chapter 3.2.1).

– The maximum permissible projection "h

is to be observed (values for "h

" see chapter 3.3).

Emax.

" of the adjuster nut (8) to the stator (7)

Emax.

Danger!

The reduction of the brake torque does not increase the maximum permissible

air gap "s

Do not change the manual release setting for models with manual release.

Lmax.

".

38

Page 39

i

j | BA 14.0190 | 11/2012

Commissioning and operation6

6.3 During operation

| Check the brake regularly during operation. Take special care of:

– unusual noises or temperatures

– loose fixing elements

– the condition of the electrical cables.

| The armature plate must be attracted and the drive must move without residual

torque.

| Measure the DC voltage at the brake.

– Compare the DC voltage measured with the voltage specified on the nameplate. A

±10 % deviation is permissible.

39

Page 40

j | BA 14.0190 | 11/2012

Maintenance/repair7

7 Maintenance/repair

7.1 Wear of spring−applied brakes

The following table describes the different causes of wear and their effects on the components

of the spring−applied brake. The important influencing factors must be quantified so that the

service life of the rotor and brake can be calculated and that the maintenance intervals to be

prescribed can be specified precisely. The most important factors in this context are the

applied friction energy, the initial speed of braking and the operating frequency. If several of

the causes of friction lining wear occur in an application at the same time, the influencing

factors are to be added together when the amount of wear is calculated.

Component Cause Effect Influencing factors

Friction lining Braking during operation

Emergency stops

Overlapping wear during start and

stop of drive

Active braking via the drive motor

with support of brake (quick stop)

Starting wear in case of motor

mounting position with vertical

shaft, even when the brake is not

applied

Armature plate and

counter friction face

Brake support Load alternation and jerks in the

Springs Axial load cycle and shear stress of

Rubbing of brake lining Run−in of armature plate and

backlash between armature plate,

sleeve bolts and guide bolt

springs through radial backlash on

reversal of armature plate

Wear of friction lining

counter friction face

Breaking of armature plate, sleeve

bolts and guide bolt

Reduced spring force or fatigue

failure

Friction work

Number of start/stop cycles

Friction work

Number of start/stop cycles,

braking torque

Number of switching operations of

brake

Tab. 8 Causes for wear

40

Page 41

i

j | BA 14.0190 | 11/2012

Maintenance/repair7

7.2 Inspections

7.2.1 Important notes

To ensure safe and trouble−free operation, spring−applied brakes must be checked and

maintained at regular intervals. Servicing can be made easier if good accessibility of the

brakes is provided in the plant. This must be considered when installing the drives in the plant.

Primarily, the necessary maintenance intervals for industrial brakes result from the load during

operation. When calculating the maintenance interval, all causes for wear must be taken into

account, ( 40). For brakes with low loads such as holding brakes with emergency stop, we

recommend a regular inspection at a fixed time interval. To reduce the cost, the inspection

can be carried out along with other regular maintenance work in the plant if necessary.

If the brakes are not maintained, failures, production losses or damage to the system may

occur. Therefore, a maintenance concept adapted to the particular operating conditions and

brake loads must be defined for every application. For the spring−applied brakes, the

maintenance intervals and maintenance operations listed in the below table must be provided.

The maintenance operations must be carried out as described in the detailed descriptions.

Danger!

The live connections and the rotating rotor must not be touched.

The drive must not be running when checking the brake.

7.2.2 Checking the rotor thickness

1. Remove the motor cover and seal ring, if mounted.

2. Measure the rotor thickness using a caliper gauge.

3. Compare the measured rotor thickness with the minimally permissible rotor thickness,

( 16).

4. If required, replace rotor completely, ( 43).

7.2.3 Checking the air gap

Danger!

Disconnect the drive from the load to prevent accidents. During the next

inspection steps of the spring−applied brake, the motor must not

run!

1. Check the air gap "s

using a feeler gauge ( 16).

2. Compare air gap measured to maximally permissible air gap "s

3. If required, set air gap to "s

" near the fixing screws between the armature plate and stator

L

" ( 42).

LN

L max.

" ( 16).

41

Page 42

j | BA 14.0190 | 11/2012

Maintenance/repair7

7.2.4 Release / voltage

Danger!

The running rotor must not be touched.

Danger!

Live connections must not be touched.

7.3 Maintenance operations

7.3.1 Adjusting the air gap

Danger!

The brake must be free of residual torque.

Stop!

Please observe when mounting the flange with additional screws:

Behind the threaded holes for the screws in the flange there must be clearing

holes in the endshield. Without clearing holes the minimum rotor thickness

cannot be used. Under no circumstances may the screws be pressed against

the endshield.

1. Unbolt screws (Fig. 10).

2. Screw the threaded sleeves into the stator by using a spanner.

the air gap by approx. 0.15 mm.

3. Tighten screws, torques 16.

4. Check air gap "s

5. If the difference between the measured air gap and "s

readjustment.

" near the screws using a feeler gauge, "sLN" 16.

L

" is too large, repeat the

LN

1

/6 revolution reduces

42

Page 43

i

j | BA 14.0190 | 11/2012

Maintenance/repair7

7.3.2 Rotor replacement

Danger!

The brake must be free of residual torque.

1. Switch off voltage!

2. Disconnect the supply cable.

3. Loosen the screws evenly and remove them completely.

4. Remove the complete stator from the end shield. Observe the supply cable.

5. Pull the complete rotor off the hub.

6. Check hub teeth.

7. Replace the hub as well if worn.

8. Check the friction surface at the end shield. In case of strong scoring at the flange,

replace the flange. If scoring occurs at the end shield, re−finish end shield.

9. Measure rotor thickness (new rotor) and sleeve bolt head with a caliper gauge.

10. Calculate the gap between the stator and the armature plate as follows:

Gap = rotor thickness + s

" 16)

("s

LN

11. Unscrew the sleeve bolts evenly until the calculated gap between stator and armature

plate is reached.

12. Install and adjust new rotor and stator, 23.

13. Reconnect the supply cable.

− head height

LN

43

Page 44

j | BA 14.0190 | 11/2012

Maintenance/repair7

7.4 Spare−parts list

| Only parts with item numbers are available.

– The item numbers are only valid for the standard design.

| Please include the following information with the order:

– Order number of the brake

– Position number of the spare part

7.4.1 Brakes BFK468−18 to 31

Fig. 19 BFK468−18 spring−applied brake to 31

Pos. Name Variant

Complete stator, module E

1

Complete stator, module N

Complete rotor

3

Complete rotor, noise−reduced

4 Hub Bore

Flange

6

Hartchromed flange

Set of fastening screws

10

Cheese head screw DIN 912 10.9

12 Manual release

13 Cover ring

Voltage / braking torque

for mounting to the motor

for flange with through hole

BFK45825−011.iso/dms

44

Page 45

i

j | BA 14.0190 | 11/2012

Maintenance/repair7

7.5 Spare parts order

INTORQ BFK468−LLL / complete stator

Size 18 20 25 31

Design:

Voltage

Brake torque

Cable length

Manual release mounted (not available for size 31)

Armature plate Standard Hardchromed

Microswitch

Switching noises Low−noise

E (with adjuster nut, sizes 18, 20,25)

N (without adjuster nut)

205 V / 103 V (not available for size 31)

360 V / 180 V

___________ Nm (see torque ranges)

Standard

___________mm (from 100 mm to 1000 mm in 100 mm steps,

from 1000 mm to 2500 mm in 250 mm steps)

Monitoring of the operation

Wear monitoring

Accessories

Rotor Aluminium Noise−reduced (rotor with sleeve)

Hub _________ mm (for hole diameter see dimensions)

Flange

Fixing screw set For mounting to the motor

For mounting to the flange with through holes

Sealing Cover ring

Shaft seal (shaft diameter on request)

Cap

Brake cover 18 20 25

Electrical accessories

Rectifier type AC voltage Coil voltage

[V AC] [V DC]

BEG−561−255−030

BEG−561−255−130 BFK468−25

BEG−561−440−030−1

BEG−561−440−130

230

400

±10%

±10%

release/holding

205 / 103

360 / 180

Assigned brake

BFK468−18

BFK468−20

BFK468−18

BFK468−20

BFK468−25

BFK468−31

45

Page 46

j | BA 14.0190 | 11/2012

Troubleshooting and fault elimination8

8 Troubleshooting and fault elimination

If any malfunctions should occur during operation, please check the possible causes using the

following table. If the fault cannot be eliminated by one of the listed measures, please contact

the aftersales service.

Fault Cause Remedy

Brake does not release

Rotor cannot rotate freely

Coil interruption | Measure coil resistance using multimeter:

– If resistance is too high, replace the complete

Coil has interturn fault or short circuit to

ground

Wiring incorrect or defective | Check and correct wiring.

Rectifier defective or wrong | Measure rectifier DC voltage using a multimeter.

Incorrect microswitch wiring Check microswitch wiring and correct it.

Incorrect microswitch setting Replace the complete stator and complain about the

Air gap too big Adjust air gap ( 42)

Wrong setting of manual release Check dimension "s+sL" with energised brake. The

Air gap "sL" too small Check air gap "sL" and, if required, readjust it (

| Measure coil resistance using multimeter:

– Compare measured resistance to rated

| Check coil for short circuit to ground using a

multimeter:

– Replace the complete stator if short circuit to

| Check brake voltage (see "defective rectifier,

voltage too low").

| Check cable continuity using a multimeter:

– Replace defective cable.

If DC voltage is zero:

| Check AC rectifier voltage.

If AC voltage is zero:

– Apply voltage,

– check fuse,

– check wiring

If AC voltage is ok:

– Check rectifier

– replace defective rectifier

| Check coil for fault between turns and short

circuit to ground.

| If the rectifier defect occurs again, replace the

complete stator, even if no fault between turns or

short circuit to ground can be detected. The fault

may only occur when warm.

incorrect microswitch setting to the manufacturer.

Measure rotor thickness and compare with minimum

rotor thickness ( 16). If necessary, replace rotor.

dimension must be identical on both sides. Correct if

necessary.

42).

stator.

resistance. For values, see 16. If the

resistance is too low, replace the complete

stator.

ground is detected.

46

Page 47

i

j | BA 14.0190 | 11/2012

Troubleshooting and fault elimination8

RemedyCauseFault

Rotor not thick enough Rotor has not been replaced in time Replace rotor ( 43)

Voltage is not zero during functional

test (chapter 6.1)

Voltage too high Brake voltage does not match the

Voltage too low Brake voltage does not match the

AC voltage is not mains voltage

Incorrect wiring of microswitch Check and correct the microswitch wiring.

Defective microswitch or incorrect

setting

rectifier

rectifier

Fuse missing or defective Select a connection with proper fusing.

Incorrect wiring of microswitch Check the microswitch wiring and correct it.

Defective microswitch or incorrect

setting

Replace the entire stator and send the defective

stator to the manufacturer.

Adapt rectifier and brake voltage to each other.

Adapt rectifier and brake voltage to each other.

Replace the entire stator and send the defective

stator to the manufacturer.

47

Page 48

F INTORQ GmbH & Co KG

Germany

Postfach 1103

D−31849 Aerzen

Wülmser Weg 5

D−31855 Aerzen

( +49515470534−444

Ê +49515470534−200

info@intorq.com

INTORQ (SHANGHAI) Co., Ltd

F

China

No. 600, Xin Yuan Road

Building No. 6 / Zone B

Nan Hui District, Lingang

Shanghai, China 201306

60061B

201306

( +86 21 20363−810

Ê +86 21 20363−805

info@cn.intorq.com

INTORQ US Inc.

F

USA

300 Lake Ridge Drive SE

Smyrna, GA 30082

( +1 678 309−1155

Ê +1 678 309−1157

info@us.intorq.com

33002357 | BA 14.0190 | EN | 2.0 | ©11.2012 | TD09 | 10 9 8 7 6 5 4 3 2 1

www.intorq.com

Loading...

Loading...