INTORQ 14.105.12, 14.105.10, 14.105.16, 14.105.20, 14.105.25 Operating Instructions Manual

...Page 1

i

Operating Instructions

BA 14.0175-EN

13056569

Electromagnetic clutch and brake

INTORQ 14.105 and INTORQ 14.115

Page 2

2

i

BA 14.105/115 EN 2.0

Read Operating Instructions before set-up!

Manufacturer:

INTORQ GmbH & Co. KG Wülmser Weg 5

Postfach 11 03 D-31855 Aerzen

D-31849 Aerzen Phone: +49 (0) 51 54 / 95 39-01

Fax: +49 (0) 51 54 / 95 39-10

Email: info@intorq.de

Internet: www.intorq.de

Origin and year of manufacture:

See nameplate (page 4)

These Operating Instructions are only valid for:

Electromagnetic clutches Electromagnetic brakes

INTORQ 14.105.06..

INTORQ 14.105.08..

INTORQ 14.105.10..

INTORQ 14.105.12..

INTORQ 14.105.14..

INTORQ 14.105.16..

INTORQ 14.105.20..

INTORQ 14.105.25..

INTORQ 14.115.06..

INTORQ 14.115.08..

INTORQ 14.115.10..

INTORQ 14.115.12..

INTORQ 14.115.14..

INTORQ 14.115.16..

INTORQ 14.115.20..

INTORQ 14.115.25..

What is new / what has changed in the Operating Instructions ?

Material number Edition Important Content

00 178 685 1.0 12/1995 TD09 1st edition First edition for preseries

00 467 314 1.0 07/2002 TD09 1st edition

replaces 178 685

All chapters: Correction of faults and complete revision

13056569 2.0 05/2005 TD09 2nd edition

replaces 467 314

Changeofthefirm’snametoINTORQ

E 2005 INTORQ GmbH & Co. KG

No part of this documentation may be reproduced or made accessible to third parties without written consent by INTORQ GmbH & Co. KG.

All information given in this documentation has been carefully selected. Required corrections will be included in updates of this documentation.

Page 3

3

i

BA 14.105/115 EN 2.0

Product key

INTORQ 14.105 Electromagnetic clutches, 7.5 - 480 Nm

INTORQ 14.115 Electromagnetic brakes, 7.5 - 480 Nm

INTORQ 14.15.

. . - - ..V,

∅∅∅∅

..,

∅∅∅∅

..

Type

Size

Stator design

Armature design

Frame size Armature design

06, 08, 10, 12, 16, 1 - with outer flange hub

20, 25 2 - with inner flange hub (brakes only)

3 - without flange hub

5 - with flange hub bearing (for clutches only)

Stator design Variants

1 - Flange design Supply voltage

3 - with bearing Rotor bore

Armature bore

Variants

•

The specific ations in the product key, nameplate and packaging sticker are valid for electromagnetic

clutches and electromagnetic brakes.

Page 4

4

i

BA 14.105/115 EN 2.0

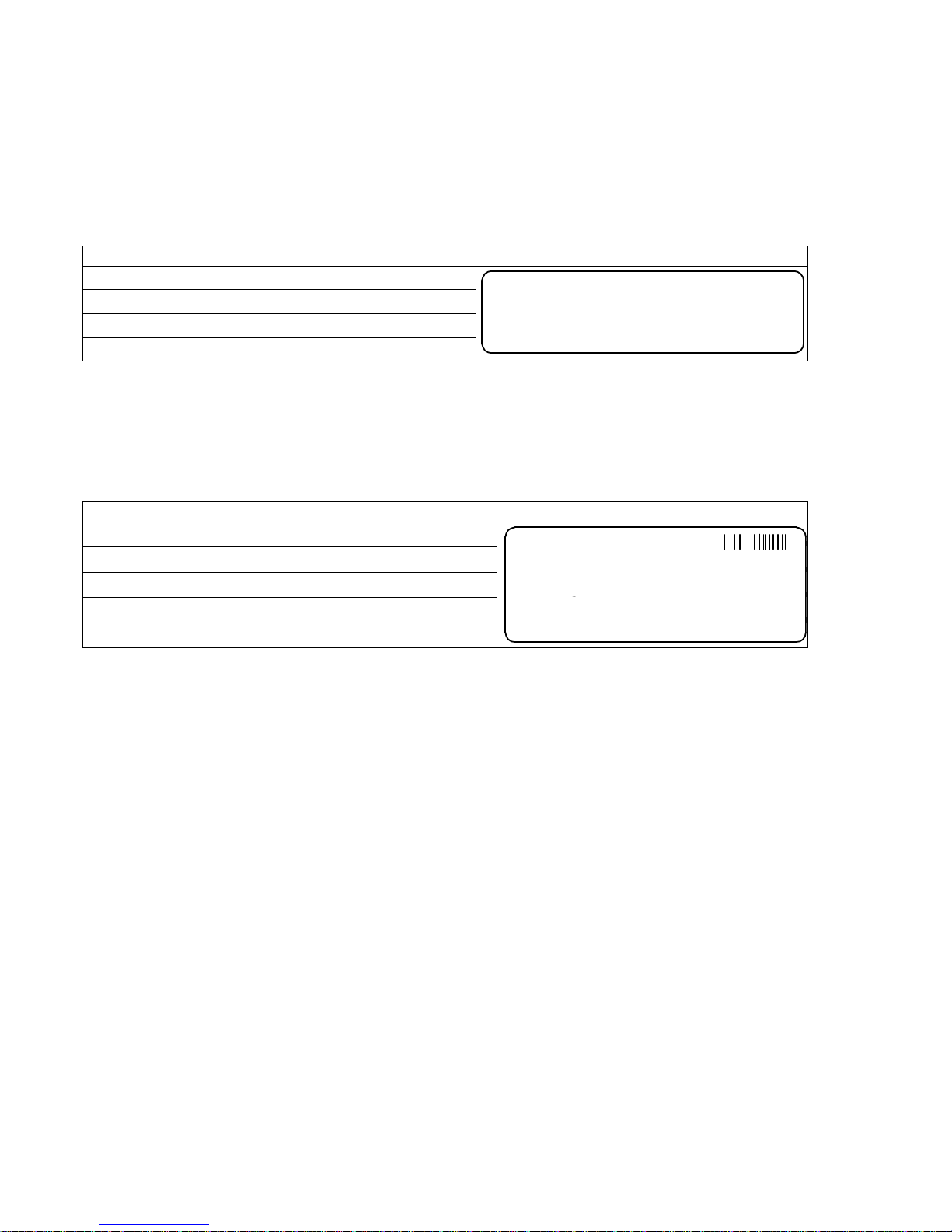

Nameplate

Structure

Field Content Example

1

Manufacturer

2

Brake type

14.115.06.1.0

j

DDDD

----

AAAA

eeee

r

r

r

rzzzzeeeennnn

3

Rated voltage Rated power

1

4.115.0

6.1.0

24 V DC 11,5 W

4

Ident no.

.

Rated brake torque

Date of manufacture

Nr. 00034106 7.5 NM 01.04.05

Packaging sticker

Assembly

Field Content Example

1 Manufacturer Barcode no.

----

2 Type see product key Type no.

T

y

p:14.115.06.1.0 Nr. 00034106

DDDD

----

AAAA

eeee

rrrr

zzzz

eeee

nnnn

j

3 Name Qty. per box

MAGNETTEIL KPL. 1 Stück

Ty:14.115.0

6.1.0Nr.0003410

6

4 Rated voltage Rated power Rated brake torque Date of packaging

24 V DC 11.5 W 7.5 NM 01.04.05

5 Note

Rostschutzverpackung-Reibflächen fettfrei halten!

Page 5

Contents

5

i

BA 14.105/115 EN 2.0

1 Preface and general information 6...........................................

1.1 About these Operating Instructions ... 6..................................................

1.1.1 T erminology used 6.........................................................

1.2 Items supplied 6...................................................................

1.3 Lenze drive systems 7...............................................................

1.3.1 Labelling 7................................................................

1.3.2 Application as directed 7.....................................................

1.3.3 Legal regulations 7..........................................................

2 Safety information 9.....................................................

2.1 Persons responsible for the safety 9....................................................

2.2 General safety information 9..........................................................

2.3 Layout of the safety information 11......................................................

3Data 13.................................................................

3.1 Product description 13...............................................................

3.1.1 Flange-mounted clutches 13....................................................

3.1.2 Shaft-mounted clutches 13.....................................................

3.1.3 Flange-mounted brakes 14.....................................................

3.2 Selection table of clutches 15..........................................................

3.3 Selection table of brakes 15...........................................................

4 Installation 16............................................................

4.1 Preparation 16.....................................................................

4.1.1 Product key 16..............................................................

4.1.2 Designs 17.................................................................

4.2 Assembly 18.......................................................................

4.2.1 Clutch and brake of design 1 18.................................................

4.2.2 Stator design 3 18...........................................................

4.2.3 Mounting of armature assembly of designs 1, 2 and 5 19..............................

4.2.4 Mounting of armature assembly of design 3 19......................................

4.3 Electrical connection 21..............................................................

5 Maintenance 22..........................................................

5.1 Disassembly 22....................................................................

5.2 Spare parts list 23..................................................................

Page 6

Preface and general information

6

i

BA 14.105/115 EN 2.0

1 Preface and general information

1.1 About these Operating Instructions ...

•

These Operating Instructions inform about safety-relevant w orking on and with

electromagnetic c lutches and brakes. They contain all safety information which must be

observed.

•

All persons working on or with the stated electromagnetic clutc hes and brakes must have

these Operating Instructions available and observe the information and notes relevant for their

work.

•

The Operating Instructions must alw ays be in a complete and perfectly readable state.

1.1.1 Terminology used

Clutches and brakes

The terms ”clutches” and ” brakes” will be used for ”electromagnetic clutches and brakes” in the

following text.

Drive system

The term ”drive system” will be used for drive systems with spring-applied brakes and other drive

components.

1.2 Items supplied

•

The drive systems are individually designed with modules. The list of all items supplied can be

obtained from the accompanying papers.

•

After receipt of the delivery, check immediately whether the items delivered match the

accompanying papers. INTORQ GmbH & Co. KG does not accept any liability for deficiencies

claimed subsequently. Claim

– visible transport damage immediately to the forwarder.

– visible defic iencies/ incompleteness immediately to your INTORQ representative.

Page 7

Preface and general information

7

i

BA 14.105/115 EN 2.0

1.3 Drive systems

1.3.1 Labelling

•

Drive systems and components are clearly labelled and defined by the indications on the

nameplates.

•

Manufacturer:

INTORQ GmbH & Co. KG

Postfach 11 03 Wülmser Weg 5

D-31849 Aerzen D-31855 Aerzen

•

Clutches and brakes are supplied as individual parts. The user combines them as desired.

Specifications, especially packing stickers, nameplate and type code are valid for the entire

stator.

•

If individual parts are supplied, there is no identification.

1.3.2 Application as directed

•

Drive systems

– are to be used in machines and systems.

– are only to be used for the ordered and acknowledged application conditions.

– must only be operated under the conditions prescribed in these Instructions.

– must not be used at powers higher or lower than indicated in these Instructions.

Any other use shall be deemed as inappropriate!

1.3.3 Legal regulations

Liability

•

The information, data, and not es in these Operating Instructions met the state of the art at the

time of printing. Claims on modifications referring to controllers which have already been

supplied cannot be derived from the information, illustrations, and descriptions.

•

Lenze does not accept any liability for damage and operating interference caused by:

– inappropriate use

– unauthorized modifications to the drive system

– improper working on and with the controller

– operating errors

– disregarding these Instructions

Warranty

•

Warranty conditions: see Sales and Delivery Conditions of INTORQ GmbH & Co. KG.

•

Warranty c laims must be made to the INTORQ representat ive responsible for you immediately

after detecting defects or faults.

•

The warranty is void in all cases where liability claims cannot be made.

Page 8

Safety information

8

i

BA 14.105/115 EN 2.0

2 Safety information

2.1 Persons responsible for the safety

Operators

•

An operator is any natural or legal person who uses the clutch or the brake or on whose behalf

the clutch or brake is used.

•

The operator or the safety personnel must ensure

– that all relevant regulations, instructions, notes and laws will be maintained.

– that only qualified personnel works on and with the clutch or brake.

– that the Operating Instructions are always available

– that unqualifed personnel is not allowed to work on and with the clutch or brake.

Qualified personnel

Qualified personnel are persons who, because of their training, experience and knowledge of all

applicable standards and regulations as well as of all operating circumstances, have been entitled

by the person responsible for the system to work on and with the system and to see and avoid all

possible dangers.

(Definition for qualified personnel to IEC 364)

2.2 General safety information

•

These safety notes do not claim to be complete. If any questions or problems occur, please

contac t your Lenze representative.

•

The clutches and brakes met the state of the technology at the time of delivery and are

generally safe to operate.

•

Clutches and brakes endanger persons, the clutches and brakes themselves and other

properties of the user if

– unqualified personnel works on and with clutches and brakes.

– the clutches and brakes are used for a purpose other than intended.

•

The clutches and brakes must be designed such that they perform their function and do not

cause danger for persons if they are installed correctly and used as intended in error-free

operation. This also applies to clutches and brakes integrated into a drive system.

•

Operate the clutches and brake only in a correc t state.

•

Retrofittings, modifications or changes of the clutch or brake are generally forbidden. In any

case, INTORQ GmbH & Co. KG must be contacted before.

•

The friction lining and the friction surfaces must by no means have contact to oil or grease

since even small amounts reduce the brake torque considerably.

•

Enclosure IP44, temperature class B (130°C).

Page 9

Safety information

9

i

BA 14.105/115 EN 2.0

Application range of the INTORQ clutches and brakes

•

No potentially-explosive or agressive atmosphere.

•

Humidity, no restrictions.

•

Ambient temperature -20°C to +40°C

•

Sparking in switching operation

– Especially at high speeds and high surface speeds of large clutches and brakes sparking

can occur during the switch-on slip phase. This is a completely normal phenomenon of pole

face clutches and brakes. If necessary, insulate the drive system depending on the ambient

conditions.

2.3 Layout of the safety information

•

All safety information given in these Operating Instructions have the same layout:

Signal word!

Note

– The icon characterizes the type of danger.

– The signal word characterizes the severity of danger.

– The note text describes the danger and gives information how to prevent dangerous

situations.

Warning of danger to persons

Icons used Signal words

Warning of hazardous

Danger! Warns of impending danger.

electricalvoltageConsequencesifdisregarde

d

:

Death or severe injuries.

Warning! Warns of potential, very hazardous situations.

Possible consequences if disregarded:

Warning of a general

danger

Death or severe injuries.

dange

r

Caution! Warns of potential, hazardous situations.

P

oss

ibl

e consequences

ifd

i

sregarded:

Light or minor injuries.

Warning of damage to material

Icons used Signal words

Stop! Warns of potential damage to material.

Possible consequences if disregarded:

Damage of the drive system/device or its environment

.

Other notes

Icons used Signal words

Tip! Designates a general, useful note.

If you observe it, handling of the drive system/controller will be made easier.

Page 10

Technical data

10

i

BA 14.105/115 EN 2.0

3Data

3.1 Product description

3.1.1 Flange-mounted clutches

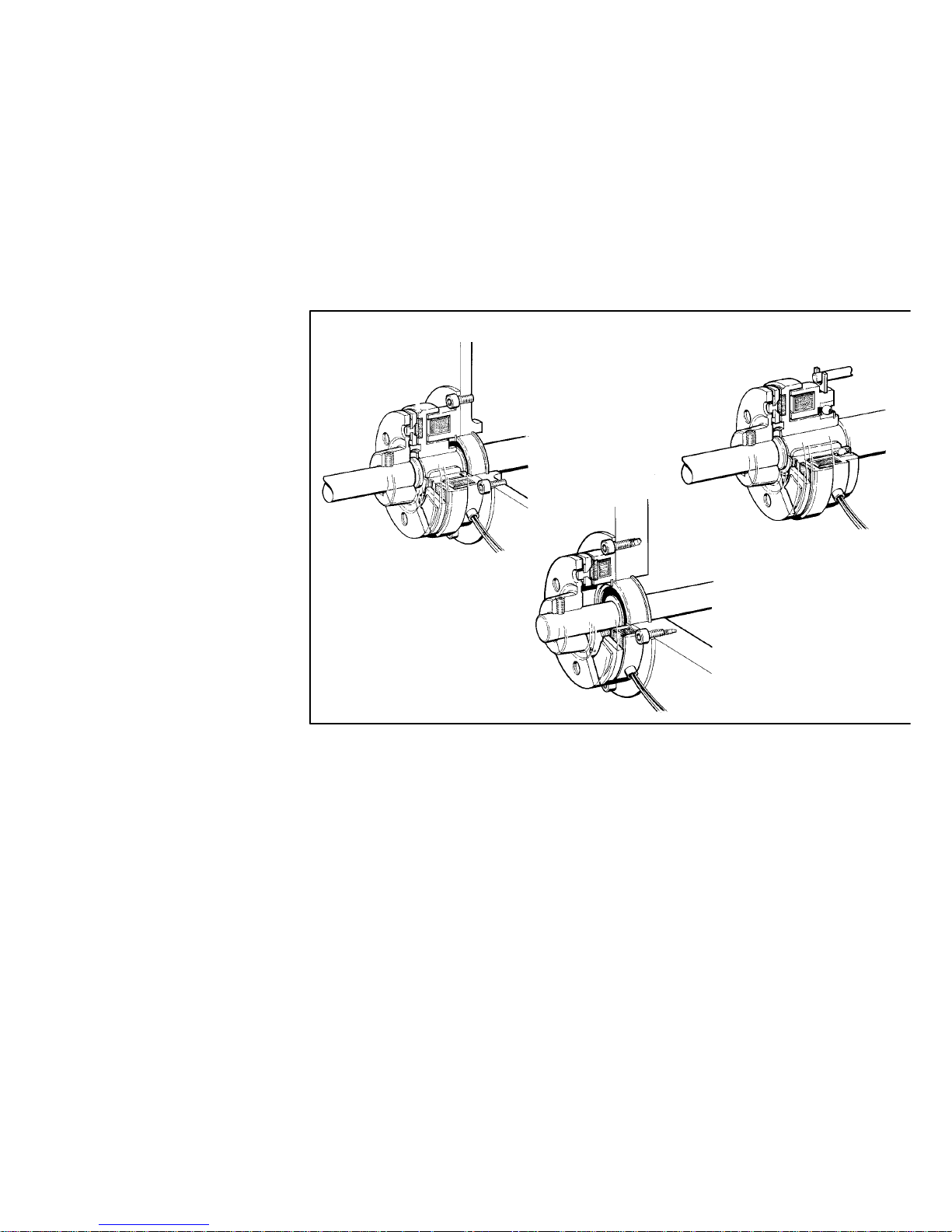

The clutch consists of the stator (1) with encapsulated coil, the rotor (2) with fixed friction lining

and an armature assembly (5,6,7) with armature plate and prestressed spring. The stator (1) is

centred to the shaft and mounted at the machine panel. The rotor (2) is connected to the shaft

using a key. Designs 1.1 and 1.5 are particularly suitable for through-shafts. The magnetic field

which is created when a DC voltage is applied attracts the armature plate against the friction face

of the rotor (2)via the air gap “sLü“. The torque is transmitted without backlash by the spring. The

prestressed springs draw the armature plate back to its initial position when the DC voltage is no

longer applied. The clutch is released without residual torque.

1 Stator

2 Rotor

5,6,7 Armature assembly

s

Lü

1

2

5,6,7

Fig. 1 Flange-mount ed clutch INTORQ 14.105..1.1

3.1.2 Shaft-mounted clutches

The clutch with magnet frame with bearing is particularly suitable for the mounting on

through-shafts. The stator (1) with encapsulated coil and sealed deep-groove ball bearing is

secured against torsion by a torque arm engaging into the lug at the stator. The torque arm must

only accept the bearing friction. A circlip holds the stator (1) on the rotor in axial direction. At the

same time the rotor (2)with fixed friction lining must be mounted outo the shaft. Centrings are not

necessary. If a DC voltage is applied the armature plate of the armature assembly (5,6,7) is

attracted against the friction surface of the rotor (2) by the magnetic field. The torque is

transmitted without backlash. When the DC voltage is switched off the prestressed spring pulls

the armature plate back to its initial position. It is released without residual torque.

Page 11

Technical data

11

i

BA 14.105/115 EN 2.0

s

Lü

1 Stator

2 Rotor

5,6,7 Armature assembly

1

2

5,6,7

Fig. 2 Shaft- mounted clut ch INTORQ 14.105..3.1

3.1.3 Flange-mounted brakes

The brake consists of the stator (1) with encapsulated coil and fixed friction lining and an

armature assembly (5,6,7) with armature plate and prestressed spring. The stator (1) is centred to

the shaft and mounted at the machine panel. The armature assembly is connected to the shaft to

be braked. If a DC voltage is applied the armature plate is attracted against the fric tion surface of

the stator by the magnetic field. The shaft is braked by friction locking. When the DC voltage is

switched off the prestressed patented spring pulls the armature plate back to its initial position. It

is released without residual torque.

1 Stator

5, 6, 8 Armature assembly

s

Lü

1

5, 6, 8

Fig. 3 Flange-mount ed brake INTORQ 14.115..1.2

Page 12

Technical data

12

i

BA 14.105/115 EN 2.0

3.2 Selection table of clutches

Typ e M

K

1)

[Nm]

r

max

[min-1]

P

20°C

[W]

Operating times

2)

[ms]

Q

E

[J]

Q

NA

[kWh]

S

hü

[h-1]

J[10-5kgm2]

Rotor Armature assembly

t

11

t

12

t

1

t

2

1 3 1/2 3 5

INTORQ

14.105.06..

7.5 8000 15 15 30 45 10 3,6x10310 72 11,9 13,3 6 4.2 9,2

INTORQ

14.105.08..

15 6000 20 20 55 75 15 6x10316.6 56 26.5 29.4 17.1 11.8 28.2

INTORQ

14.105.10..

30 5000 28 25 85 110 25 10x10334.7 43 78 86.6 66.4 47.2 92

INTORQ

14.105.12..

60 4000 35 35 105 140 40 16x10369.5 37 226 246 180 130 258

INTORQ

14.105.16..

120 3000 50 45 125 170 50 25x103130.5 36 630 690 633.3 480 868

INTORQ

14.105.20..

240 3000 68 60 140 200 60 40x103277.7 28 2050 2150 1900 1370 2580

INTORQ

14.105.25..

480 2000 85 75 155 230 70 65x103555.5 22 5470 5660 4800 3580 7200

Ta b . 1

3.3 Selection table of brakes

Typ e M

K

1)

[Nm]

r

max

[min-1]

P

20°C

[W]

Operating times

2)

[ms]

Q

E

[J]

Q

NA

[kWh]

S

hü

[h-1]

J[10-5kgm2]

Armature assembly

t

11

t

12

t

1

t

2

1/2 3

INTORQ

14.115.06..

7.5 8000 11,5 10 20 35 10 3,6x10

3

10 72 6 4.2

INTORQ

14.115.08..

15 6000 16 15 25 40 20 6x10

3

16.6 56 17.1 11.8

INTORQ

14.115.10..

30 5000 21 20 40 60 30 10x10334.7 43 66.4 47.2

INTORQ

14.115.12..

60 4000 28 25 55 80 45 16x10369.5 37 180 130

INTORQ

14.115.16..

120 3000 38 30 70 100 60 25x103130.5 36 633.3 480

INTORQ

14.115.20..

240 3000 45 35 80 115 70 40x103277.7 28 1900 1370

INTORQ

14.115.25..

480 2000 70 40 90 130 80 65x103555.5 22 4800 3580

Ta b . 2

1) referred to relative speed n = 100min

-1

2) Average values for switchi ng on the DC side with rated air gap and warm coil

Standard voltage 24V +5% / -10% acc. to VDE 0580

Temperature class B (130°C)

Page 13

Installation

13

i

BA 14.105/115 EN 2.0

4 Installation

4.1 Preparation

1. Unpack clutch or brake.

2. Check completely.

3. Check nameplate data, especially rated voltage.

4.1.1 Product key

Type

Size

Stator design

Armature design

Armature bore

Rotor bore

Connection voltge

Article no.

Example:

INTORQ 14.105. 16.1. 1. - 050480 - 24 - 25 - 30

Page 14

Installation

14

i

BA 14.105/115 EN 2.0

4.1.2 Designs

Size

Stator design

Armature design

INTORQ 14.105..

INTORQ 14.105..

INTORQ 14.105..

INTORQ 14.105..

INTORQ 14.105..

INTORQ 14.105..

1. 1

1. 3

1. 5

3. 1

3. 3

3. 5

Item 1; 2; 5

Item 1; 2; 6

Item 1; 2; 7

Item 3a; 3b; 5

Item 3a; 3b; 6

Item 3a; 3b; 7

INTORQ 14.115..

INTORQ 14.115..

INTORQ 14.115..

1. 1

1. 2

1. 3

Item 4; 5

Item 4; 8

Item 4; 6

7652 1

7653b 3a

85 46

Fig. 4

Page 15

Installation

15

i

BA 14.105/115 EN 2.0

4.2 Assembly

Stop!

•

Keep friction faces free of grease and oil!

•

Use oil- and grease-tight deep groove ball bearings only!

4.2.1 Clutch and brake of design 1

The stator of clutch or brake of design 1 must be mounted internally or externally centered

(observe dimension “tk” for max. centricity from Tab. 3). The mounting surface should not exceed

a maximum phase run-out “ x” (Tab. 3) and should not be convex. In the case of internal centring

the register diameter is machined to an oval clearance.

When the rotor is assembled, dimension “ b” (Tab. 3) must be observed maintained.

Stop!

The rotor must be secured axially!

Fig. 5 Internal centring External cent ring

4.2.2 Stator design 3

The stator design 3 does not need a mounting surface as the centring is performed by a deep

groove ball bearing on the rotor. A torque arm must be provided for the bearing fric tion. This

torque arm engages in the recess of the anti-rotation tag.

Stop!

The stator must not be strained in any case!

Page 16

Installation

16

i

BA 14.105/115 EN 2.0

4.2.3 Mounting of armature assembly of designs 1, 2 and 5

The armature assembly is shifted onto the shaft. The maximum permissible centre offset of the

shafts, dimension ” tw” can obtained from Tab. 3. The air gap “sLü” (Tab. 3) must be adjusted

using a feeler gauge.

Use shims for the exact air gap setting and for the compensation of wear.

Stop!

The armature assembly must be fixed axially.

14.105

14.115

Fig. 6

Size

s

Lü

x INTORQ 14.105 INTORQ 14.115

[mm] [mm] t

k

t

w

b [mm] t

w

b [mm]

06 0,2 ± 0.05 0.04 0.2 0.1 24 0.16 18

08 0,2 ±0.05 0.05 0.3 0.1 26.5 0.16 20

10 0,2 ±0.05 0.06 0.3 0.1 30 0.16 22

12 0.3 ± 0.1 0.07 0.3 0.1 33.5 0.2 24

16 0.3 ± 0.1 0.09 0.4 0.2 37.5 0.2 26

20 0.5 ± 0.15 0.11 0.4 0.2 44 0.2 30

25 0.5 ± 0.15 0.14 0.5 0.2 51 0.3 35

Ta b . 3

Page 17

Installation

17

i

BA 14.105/115 EN 2.0

4.2.4 Mounting of armature assembly of design 3

Use bolts with threads up to the head to fix the armature assembly.

•

For the tapped holes the clearance bores “ Ød” and the depth “t” (Tab. 4) must be observed

maintained in any case.

•

The rivet heads require a sufficient clearance hole.

Size Screws DIN Schnorr lock washer * Ø d [mm] t [mm]

06 M3x8 DIN 84 Schnorr lock washer 3 3.1 0.8

08 M4x10 DIN 84 Schnorr lock washer 4 4.1 1.0

10 M5x12 DIN 6912 Schnorr lock washer 5 5.1 3.5

12 M6x16 DIN 7984 Schnorr lock washer 6 6.1 2.8

16 M8x20 DIN 7984 Schnorr lock washer 8 8.2 3.5

20 M10x25 DIN 7984 Schnorr lock washer 10 10.2 3.5

25 M12x25 DIN 7984 Schnorr lock washer 12 12.2 3.8

Ta b . 4

1

2

3

4

5

1 Mounting surface

2Armatureplate

3Screw

4 Prestressed spring

5 Lock washer

d

t

Fig. 7

* Source of supply:

Adolf Schnorr GmbH & CO KG

Postfach 60 0162; D-71050 Sindelfingen

Phone: ++49 7031 - 3020; Fax: ++49 7031 - 382600

Page 18

Installation

18

i

BA 14.105/115 EN 2.0

4.3 Electrical connection

The device is connected to DC voltage (observe voltage specific ation on the stator). Permissible

voltage fluctuation acc. to VDE 0580: +6% to -10%.

The standard voltage is 24 V DC. If no DC voltage is available the voltage must be supplied via

transformers or rectifiers.

The clutches and brakes should be switched on the DC side to achieve short switch-off times.

secondary

primary

230V ~ 50Hz

230V ~ 50Hz

Universal spark suppressor

14.198.00.01 ... 04

Fig. 8 Switching on the DC side Switching on the AC side

When switching on the DC side use a spark suppressor to protect coil and contacts from

excessive inductive voltages.

Stop!

If there is no protective circuit the induc tive voltage can be higher than the values specified in

VDE 0580 and cause the coil to fail which destroys switching contacts.

The spark suppressor consists of a non-inductive pulse capacitor which accepts current peaks

during switching. When a spark suppressor is used the spark at the contact and thus the contact

erosion is considerably reduced.

Page 19

Maintenance

19

i

BA 14.105/115 EN 2.0

5 Maintenance

The clutches and brakes are largely free of maintenanc e. In applications requiring many switching

operations the air gap “sLü” must be checked and readjusted at certain periods. When t he air gap

has reached 250% of its rated value “sLü” at the latest it must be readjusted to the rated value at

the latest.

•

For air gap setting “sLü” after wear see chapter 5.1, Disassembly.

•

The shims mentioned in section 2 can be removed or the spacers can be reduced.

The friction face poles of the rotor or stator of clutches or brakes run into the armature plate.

Friction marks are thus normal and must not be re-worked!

Stop!

Friction faces must be kept absolutely free of oil and grease!

5.1 Disassembly

Remove the axial circlip or shaft locking plate Fig. 9 to disassemble the armature assembly of

design1or2ortherotor.Afterthatthearmatureassemblycanbewithdrawnfromtheshaftvia

the withdrawal thread “d” (see Fig. 9 and Tab. 5) provided for disassembly in the flange hub or

rotor of the corresponding part. After the armature assembly has been withdrawn, remove the

shims depending on the air gap size “sLü” (Fig. 6 and Tab. 3) and mount them afterwards between

circlip and flange hub.

d

e

d

c

Fig. 9

Size

06 08 10 12 16 20 25

øc 29 36 46 56 73 92 114

d M4 M4 M4 M4 M5 M6 M8

øe 31 37 47 56 73 93 120

Ta b . 5 D i m e n s i o n s i n m m

Page 20

Maintenance

20

i

BA 14.105/115 EN 2.0

5.2 Spare parts list

The clutches and brakes have a wear reserve of several millimeters. When these are used up after

several readjustments the rotor and armature assembly of clutches and the stator and armature

assembly of brakes must be replaced in pairs.

•

When ordering spare parts indicate the designation of the parts according to the illustration

and list below.

3

1

2

10

5

67

11

12 11

14 13 15

4

5

10

86

Item Name Item Name

1 Clutch-stator design 1 10 Setscrew

2 Rotor design 1 11 Deep-groove ball bearing 2RS

3 Clutch - stator + rotor 12 Spacer

4 Brake - stator 14.115 13 Circlip

5 Armature assembly design 1 14 Fitted key

6 Armature assembly design 3 15 Spring ring

7 Armature assembly design 5

8 Armature assembly design 2

Page 21

Maintenance

21

i

BA 14.105/115 EN 2.0

•

Spare parts should be ordered according to the following example:

Electromagnetic clutch

Type Size Spare part

Electromagnetic brake

Type Size Spare part

INTORQ 14.105. 10. Item 1 - 24V / 28W INTORQ 14.115. 16. Item 6

•

When you order stators you also have to indicate the coil voltage and power (see section

Electrical connection).

•

When ordering rotors, armature assemblies of designs 1 and 2 also specify the bore diameter.

Page 22

Hersteller

Head Office

INTORQ GmbH & Co. KG

Postfach 1103

D-31849 Aerzen

Wülmser Weg 5

D-31855 Aerzen

Telefon +49(0)5154 / 9539-01

Te lefax +49 (0)5154 /95 39-10

E-mail: info@intorq.de

http://www.intorq.de

Kundendienst /Service

Lenze Drive Systems GmbH

Extertal-Bösingfeld

Breslauer Straße 3

D-32699 Extertal

Telefon +49(0)5154 / 82-1215

Telefax +49 (0)5154/ 82-11 12

Der Vertrieb erfolgt über die

Lenze-Vertriebsorganisation

Sales are organized by

Lenze’s sales department

Deutschland

Germany

Lenze Vertrieb GmbH

Ludwig-Erhard-Straße 52-56

D-72760 Reutlingen

Telefon +49 (0)71 21 /9 3939-0

Telefax +49 (0)7121 / 9 3939-29

Region Nord

Dornenpark 1

31840 Hessisch Oldendorf

Telefon (051 52) 90 36-0

Telefax (0 51 52) 9036-33/44/55

Region West

Postfach 10 12 20

47497 Neukirchen-Vluyn

Kelvinstraße 7

47506 Neukirchen-Vluyn

Telefon (028 45) 95 93-0

Telefax (0 28 45) 9593 93

Region Mitte/Ost

Postfach 1463

35724 Herborn

Austraße 81

35745 Herborn

Telefon (027 72) 95 94-0

Telefax (0 27 72) 530 79

Region Südwest

Postfach 14 33

71304 Waiblingen

Schänzle 8

71332 Waiblingen

Telefon (071 51) 9 59 81 - 0

Telefax (0 71 51) 959 8150

Region Süd

Fraunhoferstraße 16

82152 Martinsried

Telefon (089) 89 56 14-0

Telefax (0 89) 89 5614 14

weltweit

worldwide

ALGERIA

see FRANCE

ARGENTINA

E.R.H.S.A.

Girardot 1368

1427 BUENOS AIRES

Phone +54 (0)11 / 45 54 32 32

Telefax +54 (0)11 / 45 52 3611

AUSTRALIA

FCR Motion Technology Pty. Ltd.

Unit 6, Automation Place

38-40 Little Boundary Rd.

Leverton North

3026 MELBOURNE, VIC.

Phone +61 (03) 9362 6800

Telefax +61 (03) 9314 3744

AUSTRIA

Lenze Antriebstechnik GmbH

Ipf-Landesstraße 1

4481 ASTEN

Phone +43 (0)7224 / 21 0-0

Telefax +43 (0)7224 / 2109 99

Office Dornbirn:

Lustenauer Straße 64

6850 DORNBIRN

Phone +43 (0)5572 / 26 789-0

Telefax +43 (0)5572 / 26 789-66

Office Wr. Neudorf:

Triester Straße 14/109

2351 WR. NEUDORF

Phone +43 (0)2236 / 2 5333-0

Telefax +43 (0)2236 / 2 53 33-66

Office Graz:

Seering 8

8141 UNTERPREMSTÄTTEN

Phone +43 (0)3135 / 56 900-0

Telefax +43 (0)3135 / 56 900 999

Lenze Verbindungstechnik GmbH

Ipf-Landesstraße 1

4481 ASTEN

Phone +43 (0)7224 / 21 1-0

Telefax +43 (0)7224 / 2119 98

Lenze Anlagentechnik GmbH

Mühlenstraße 3

4470 ENNS

Phone +43 (0)7223 / 886-0

Telefax +43 (0)7223 / 886-997

BELGIUM

Lenze b.v.b.a

Noorderlaan 133, bus 15

2030 ANTWERPEN

Phone +32 (0)3 / 54 26 20 0

Telefax +32 (0)3 / 54 13 75 4

BOSNIA-HERZEGOVINA

see AUSTRIA

BRAZIL

AC Control Ltda

Rua Gustavo da Silveira 1199

Vila Sta. Catarina

SÃO PAULO – S.P.

04376-000

Phone +55 (11) 55 64 65 79 ramal: 214

Telefax +55 (11) 56 79 75 10

BULGARIA

see MACEDONIA

CANADA

see USA

CHILE

Sargent S.A.

Tecnica Thomas C. Sargent

S.A.C.é.l., Casilla 166-D

SANTIAGO DE CHILE

Phone +56 (0)2 / 51 03 000

Telefax +56 (0)2 / 69 83 989

CHINA

Lenze Mechatronic Drives (Shanghai)

Co. Ltd., Section B, 50# building,

No.199 North Ri Ying Road,

Waigaoqiao Free Trade Zone

SHANGHAI, 200131

Phone +86-21-5046 0848

Telefax +86-21-5046 0850

Beijing Office

Rm. 401, Huaxin Mansion

No. 33 An Ding Road, Chaoyang District

BEIJING 100029

Phone +86-10-6441 1470

Telefax +86-10-6441 1467

CROATIA

Lenze Antriebstechnik GmbH

Predstavnista Zagreb

Ulica Grada Gospica 3

HR-1000 ZAGREB

Phone +385-1-2 49 8056

Telefax +385-1-2 4980 57

CZECH REPUBLIC

Lenze, s.r.o.

Central Trade Park D1

396 01 HUMPOLEC

Phone +420 565 507-111

Telefax +420 565 507-399

Büro âerven˘ Kostelec:

17. listopadu 510

549 41 âERVEN¯ KOSTELEC

Phone +420 491 467-111

Telefax +420 491 467-166

DENMARK

Lenze A/S

Vallensbækvej 18A,

2605 BRØNDBY

Phone +45 / 46 96 66 66

Telefax +45 / 46 96 6660

24 stunde service +45 / 40 9304 11

Buero Jylland:

Lenze A/S, Enebærvej 11

8653 THEM

Phone +45 / 46 96 66 66

Telefax +45 / 46 96 6680

EGYPT

WADI Co. for technologies

and development

P. O.Box 209, new center Ramses

11794 CAIRO, Egypt

11 Syria St., Mohandessin

GIZA, Egypt

Phone +20 (2) 347 6842

Telefax +20 (2) 347 6843

ESTONIA

see FINLAND

FINLAND

Lenze Drives

Rykmentintie 2 b, 20810 TURKU

Phone +358 2 2748180

Telefax +358 22748 189

FRANCE

Lenze S.A.

Siege

Z.A. de Chanteloup

Rue Albert Einstein

93603 AULNAY-SOUS-BOIS CEDEX

Services Commerciaux

Tel. 0825 086036

Fax 0 825 086 346

Centre de formation

E-Mail : semin.sidonie@lenze.fr

Questions générales / Documentation

E-Mail : info@lenze.fr

Service Après-vente /

assistance en ligne

Helpline 24/24 : 0 825 826 117

E-Mail:helpline@lenze.fr

Agences en France

Région France Nord :

Z.A. de Chanteloup

Rue Albert Einstein

93603 AULNAY-SOUS-BOIS CEDEX

Lille

59420 MOUVAUX

Strasbourg

67960 ENTZHEIM

Rouen

76500 ELBEUF

INTORQ – sales and service worldwide

Page 23

Région France Sud :

Rond point du sans souci

69578 LIMONEST Cedex

Toulouse

31400 TOULOUSE

Agen

47270 SAINT-PIERRE DE CLAIRAC

GREECE

George P. Alexandris S.A.

12K. Mavromichali Str.

185 45 PIRAEUS

Phone +30 (0)210 /41 1184 15

Telefax +30 (0)210/ 4 11 81 71

4127058

183 Monastiriou Str.

546 27 THESSALONIKI

Phone +30 (0)310 /5 5665 04

Telefax +30 (0)310/ 51 18 15

HUNGARY

Lenze Antriebstechnik

Handelsgesellschaft mbH

2040 BUDAÖRS

Gyár utca 2., P.O.Box 322.

Phone +36 (0)23 / 501-320

Telefax +36 (0)23 / 501-339

ICELAND

see DENMARK

INDIA

Electronic Service:

National Power Systems,

10, Saibaba Shopping Centre

Keshav Rao Kadam Marg,

Off Lamington Rd,

MUMBAI 400 008

Phone +91 22 / 2300 5667, 2301 3712

Telefax +91 22/ 2300 5668

V3 Controls Pvt. Ltd.

1, “Devyani”, Next to SBI,

Baner ITI Road, Sanewadi, Aundh,

PUNE 411 007, MS

Phone +91 20 /25 8868 62

Telefax +91 20/ 25 88 0350

Mechanical Service:

Emco Lenze Pvt. Ltd.

1st Floor, Sita Mauli

Madanlal Dhingra Road

Panch Pakhadi, Thane (West)

MAHARASHATRA 400602

Phone +91 22 /25 4054 88

+91 22/ 25452244

Telefax +91 22/ 25 45 2233

INDONESIA

P. T. Futurindo Globalsatya

Jl.: Prof. Dr. Latumenten No. 18

Kompleks Perkantoran

Kota Grogol Permai Blok A 35

JAKARTA 11460

Buero 1:

Phone +62 (0)21 /766 42 34

765 8623

Telefax +62 (0)21 / 766 4420

Buero 2:

Phone +62 (0)21 /567 96 31

567 9632

Telefax +62 (0)21 / 566 8750

IRAN

Tavan Ressan Co. Ltd.

P.O.Box. 19395-5177

No. 44, Habibi St.,

South Dastour St.,

Sadr EXP’Way,

TEHRAN 19396

Phone +98 21 / 260 2655

260 6766

260 9299

Telefax +98 21 / 200 28 83

ISRAEL

Greenshpon Engineering Works LTD

Bar-Lev Industrial Park

MISGAV 20179

Phone +972 4 99 13 18 1

Telefax +972 4 99 13 477

ITALY

Gerit Trasmissioni S.p.A.

Viale Monza 338, 20128 MILANO

Phone +39 02 / 270 98.1

Telefax +39 02 / 270 98 290

JAPAN

Miki Pulley Co., Ltd.

1-39-7 Komatsubara, Zama-c

ity

KANAGAWA 228-8577

Phone +81 (0)462 / 58 16 61

Telefax +81 (0)462 / 5817 04

LATVIA

see LITHUANIA

LITHUANIA

Lenze UAB

Breslaujos g.3, 44403 KAUNAS

Phone + 370 37 407174

Telefax +370 37 407175

LUXEMBOURG

see BELGIUM

MACEDONIA

Lenze Antriebstechnik GmbH

Pretstavnistvo Skopje

ul. Nikola Rusinski 3/A/2

1000 SKOPJE

Phone +389 2 30 90 090

Telefax +389 2 30 90091

MALAYSIA

D.S.C. Engineering SDN BHD

3A & 3B, Jalan SS21/56B

Damansara Utama

47400, PETALING JAYA

SELANGOR

Phone +60 (0)3 / 77 2562 43

77 2562 46

77 2865 30

Telefax +60 (0)3 / 77 29 5031

MAURITIUS

Automation & Controls Engineering Ltd

3, Royal Road

Le Hochet, Terre Rouge

MAURITIUS

Phone +230 248 8211

Telefax +230 248 8968

MEXICO

Automatización y Control

de Energía S.A. de C.V.

Av. 2 No. 89 Esq Calle 13

Col. San Pedro de los Pinos

C.P. 03800 MEXICO D.F.

Phone +52 (55)5277/5998

Telefax +52 (55)5277/5937

MOROCCO

GUORFET G.T.D.R

Automatisation Industrielle

Bd Chefchaouni Route 110 km, 11.500

No. 353-Aîn-Sabaâ

CASABLANCA

Phone +212/22-35 7078

Telefax +212/22-35 7104

NETHERLANDS

Lenze B.V., Postbus 31 01

5203 DC`S-HERTOGENBOSCH

Ploegweg 15

5232 BR`S-HERTOGENBOSCH

Phone +31 (0)73 / 64 56 50 0

Telefax +31 (0)73 / 64 56 51 0

NEW ZEALAND

Tranz Corporation

343 Church Street

P. O. Box 12-320, Penrose

AUCKLAND

Phone +64 (0)9 / 63 45 51 1

Telefax +64 (0)9 / 63 45 51 8

NORWAY

Dtc- Lenze as

Stallbakken 5, 2005 RAELINGEN

Phone +47 / 64 80 25 10

Telefax +47 / 64 80 25 11

PHILIPPINES

Jupp & Company Inc.

Unit 224 Cityland Pioneer Bldg.,

Pioneer Street

MANDALUYONG CITY

Phone +63 2 /687 7423

683 0042

683 0047

Telefax +63 2 / 6877421

POLAND

Lenze-Rotiw Sp. z o.o.

ul. Ro˝dzieƒskiego 188b

40-203 KATOWICE

Phone +48 (0)32 / 2 03 97 73

Telefax +48 (0)32 / 7 81 0180

Lenze Systemy Automatyki Sp. z o.o.

Ul. Rydygiera 47

87-100 TORU¡

Phone +48 (0)56 / 6 58 28 00

6453460

6453570

Telefax +48 (0)56 / 6 45 3356

PORTUGAL

Costa Leal el Victor

Electronica-Pneumatica, Lda.

Rua Prof. Augusto Lessa, 269,

Apart. 52053

4202-801 PORTO

Phone +351-22 / 550 8520

Telefax +351-22 /5 02 40 05

ROMANIA

see AUSTRIA

RUSSIA

Inteldrive

1 Buhvostova Street 12/11

Korpus 18, Office 322

MOSCOW 107258

Phone +7 (0)095 / 963 96 86

Telefax +7 (0)095 / 962 67 94

SERBIA-MONTENEGRO

see MACEDONIA

SINGAPORE

see MALAYSIA

SLOVAC REPUBLIC

ECS Sluzby spol. s.r.o.

Staromlynska 29

82106 BRATISLAVA

Phone +421 2 45 25 96 06

+421 2 45 64 31 47

+421 2 45 64 31 48

Telefax +421 2 45 64 3149

SLOVENIA

Lenze pogonska tehnika GmbH

Zbiljska Cesta 4

1215 MEDVODE

Phone +386 (0)1 361 61 41

Telefax +386 (0)1 361 2288

SOUTH AFRICA

S.A. Power Services (Pty.) Ltd.

Unit 14, Meadowbrook Business Estates

Jacaranda Ave, Olivedale, Randburg 2158

P. O.Box 1137, RANDBURG 2125

Phone +27(11) 462-8810

Telefax +27(11) 704-5775

SOUTH KOREA

Hankuk Mechatro Ltd.

Room# 1409 Samhwan officetel 830-295

Beomil-dong, Dong-Gu

PUSAN

Phone +82 (0)51-635-6663

Telefax +82 (0)51-635-6632

SPAIN

Lenze Transmisiones, S.A.

Mila i Fontanals, 135-139

08205 SABADELL (Barcelona)

Phone +34 93 / 72 07 68 0

Telefax +34 93 / 71 22 54 1

SWEDEN

Lenze Transmissioner AB

P.O.Box 10 74, Attorpsgatan

Tor nby Ind.

58110 LINKÖPING

Phone +46 (0)13 / 35 5800

Telefax+46 (0)13 / 10 36 23

SWITZERLAND

Lenze Bachofen AG

Ackerstrasse 45

8610 USTER

Phone +41 (0) 43 399 1414

Telefax+41 (0) 43 399 14 24

Vente Suisse Romande:

Route de Prilly 25

1023 CRISSIER

Phone +41 (0)21 / 63 72 19 0

Telefax +41 (0)21 / 63 72 19 9

SYRIA

Zahabi Co.

8/5 Shouhadaa Street

P. O . Box 8262

ALEPPO-SYRIA

Phone +963 21 21 22 23 5

Telefax +963 21 2122 237

TAIWAN

ACE Pillar Co. Ltd.

No.12, Lane 61, Sec. 1,

Kuanfu Road, San-Chung City

TAI PEI HSIEN

Phone +886 (0)2 / 299 58 40 0

Telefax +886 (0)2 / 299 53 46 6

THAILAND

PSG-WESCO CO., LTD.

429 Moo 7, Theparak Road,

Tambol Theparak

Amphur Muang

SAMUTPRAKARN 10270

Phone +66 (0)2 / 383 5633

Telefax +66 (0)2 / 3835637

TUNESIA

AMF Industrielle Sarl

Route de Gremda - Km 0,2

Immeuble El Madina,

Centre Bloc B - 5 ème - appt 52

3002 SFAX

Phone +216 74 403514

Telefax +216 74402 516

TURKEY

LSE Elektrik

Elektronik Makina, Otomasyon Mühendislik

San. Ve Tic. Ltd. Ωti.

Atatürk mah. Cumhuriyet cad.

Yurt sok. No:7

ÜMRANIYE /∑STANBUL

Phone +90 (0)216 / 316 5138 pbx

Telefax +90 (0)216 / 443 4277

Bursa Address:

Demirtaspasa Mh.

Ata Sk. Petek Bozkaya Is Merkezi

D Blok No :5 / A

OSMANGAZI / BURSA

Phone +90 (0)224-2733232 pbx

+90 (0)224-2734151

+90 (0)224-2733238

Telefax +90 (0)224-2734150

UKRAINE

SV Altera Ltd.

Ivana Lepse ave, 4

KIEV, 03067

Phone +38-044 496 1888

Telefax +38-044 496 18 18

UNITED KINGDOM/EIRE

Lenze Ltd.

Caxton Road

BEDFORD MK 41 OHT

Phone +44 (0)1234 / 32 13 21

Telefax +44 (0)1234 / 26 18 15

USA

AC Technology Corp.

630 Douglas Street

UXBRIDGE, MA 01569

Phone +1 508 /278-9100

Telefax +1 508/ 278-7873

Lenze Corporation

1730 East Logan Avenue

EMPORIA, KS 66 801

Phone +1 620 /343-8401

+1 888/ 269-2381

Telefax +1 620/ 342-2595

+1 800/ 469-0931

INTORQ – sales and service worldwide

Page 24

INTORQ GmbH & Co. KG

Postfach 1103

D-31849 Aerzen

Wülmser Weg 5

D-31855 Aerzen

Tel.: +49 (0) 5154 / 95 39- 01

Fax.: +49 (0) 5154 / 95 39-10

E-Mail: inf o@intorq.de

www.intorq.de

Loading...

Loading...