t:00359 898 606 796 ||| f:00359 596 325 80 ||| info@intiel.com ||| www.intiel.com

9 Peter Beron Str, Pomorie 8000, Bulgaria

- 1 -

INTIEL

THE ELECTRONICS ON YOUR SIDE

Dynamic Boiler Controller

User’s Manual

t:00359 898 606 796 ||| f:00359 596 325 80 ||| info@intiel.com ||| www.intiel.com

9 Peter Beron Str, Pomorie 8000, Bulgaria

- 2 -

Application

The Dynamic Boiler Controller is very suitable for water heating installations in

family houses, small and large projects. It is designed to provide the desired heating comfort,

optimizing the fuel consumption by a control of the boiler operation. In fact it is able to

manage the operation of solid fuel, light fuel and gas boilers and as well the consumption of a

heating energy from accumulating reservoirs or other central heating sources.

The traditional heating controllers regulate the temperature of the water system in

relation to the ambient temperature. Compare with them, the Dynamic Boiler Controller can

manage the regulation processes by the real boiler temperature. If a right estimation of the

internal water temperature is available, the heating system will react to additional heating

sources like sun shine, people presence in the premises, working machines and so on.

The principle of dynamic regulation is that the Controller follows the room thermostat,

measures the temperature of the heating water in the heating circuit and the temperature in the

small boiler circuit and bases on all that data, regulates the position of the four-way mixed

valve and thus controls the boiler operation. The central heating systems equipped with a

four-way mixed valve provides protection against low temperature corrosion of the boiler

body. In this way the setting-up of the heating curve (something usual for an equithermal

regulation) with all negative consequences of the regulation is not necessary.

The Controller provides a domestic hot water preparation in the accumulating water

heater, which is being managed by the domestic hot water thermostat, installed in the water

heater (or in the accumulating reservoir), where also can be added a timer-switch. The

Controller provides the heating of the domestic hot water with same or higher priority

compare to the heating of the premises. The type of priority can be adjusted in compliance

with customer’s preferences.

1. Controller description

Basically the Controller can operate in two configurations as a dynamic regulator with

connected room thermostat and as an equi-thermal regulator without a room thermostat.

1.1 Main functions:

1.1.1 Measure the water temperature at three points: outlet boiler temperature (sensor K),

return boiler water (small boiler circuit sensor V) and the heating water (in the heating

circuit) after a mixed valve (sensor O).

1.1.2 Measure the outdoor temperature (sensor A)

1.1.3 Measure the room temperature by room thermostats with a contact output (RT)

1.1.4 Stops the boiler operation by a signal of the built-in operation boiler thermostat, when

the maximum working temperature exceeds (+750C)-(+900C) (sensor K).

1.1.5 Opens the mixed valve, switch on the circulation pump and switches off the boiler if

the outlet boiler temperature (sensor K) exceeds its emergency level of (+850C)-

(+1050C)

1.1.6 Closes the mixed valve and starts the boiler by force (only in a winter mode) if the

return boiler water temperature (sensor V) is lower than the settled one of (+250C)-

(+650C).

1.1.7 Open the mixed four-way valve and start by force the boiler operation if the water

temperature after the mixed valve in the heating circuit (sensor O) is lower than the

calculated one Thset. The operation threshold is changing automatically by the

outdoor temperature of the installed outdoor thermostat (A). If a room thermostat is

not mounted this function can be used for a central equi-thermal temperature

regulation of the water heating in multi-circuit and large systems.

t:00359 898 606 796 ||| f:00359 596 325 80 ||| info@intiel.com ||| www.intiel.com

9 Peter Beron Str, Pomorie 8000, Bulgaria

- 3 -

1.1.8 Protection against freezing of the whole heating system.

1.1.9 Closes by force the mixed valve in systems equipped with a room thermostat, despite

of its command in case the heating water exceeds its maximum assignation.

1.1.10 Controls the mixed valve in relation to the room thermostat. The room thermostat

option can be switched off, for example concerning large and multi-circuits systems.

1.1.11 Provides a domestic hot water preparation in a winter and a summer mode in relation

to the domestic hot water thermostat or timer.

1.1.12 Possibility for adjusting a priority, concerning domestic hot water preparation:

Same one with the heating of the premises or

Higher one by stopping the premises heating.

The customer is to adjust one of those two priorities.

1.1.13 Control a circulation pump, an actuator or a magnetic valve in the domestic hot water

circuit.

1.1.14 Automatically goes into a summer mode if the room thermostat or the sensor after the

mixed valve (“O”) does not send a command for a start in a period adjusted by the

customer of 12, 24, 36 or 48 hours after the last command is being sent.

1.1.15 The main distinguish of the summer mode is that the boiler cannot be started if the

return water temperature of the boiler is lower than the settled one Tkset, as circulation

pumps P1 and P2 are switched off.

1.1.16 Automatically goes into a winter mode if a command of the room thermostat is

available or if the heating water temperature (measured by sensor O) is lower than

Thset.

1.1.17 STOP mode can be fulfilled by the controller in two ways: automatically with the fuel

run out or manual, indication about which appears on the display (fig.2) . Going back to the

previous mode is to be done only manually.

1.1.18 Periodically starting the circulation pump in the heating circuit and the mixed valve

during summer and STOP mode in order to prevent their blocking after a long stop.

1.1.19 Manual assignation of the heating water temperature.

1.1.20 Timer and a weekly programmer for an economic operation programming.

On figure 1 is shown functional heating systems, managed by the controller.

Figure 1

K

М

SV

P2

O

RТ

Boiler

Controller

Start

Stop

P1

А

Water

Heater

P3

V

t:00359 898 606 796 ||| f:00359 596 325 80 ||| info@intiel.com ||| www.intiel.com

9 Peter Beron Str, Pomorie 8000, Bulgaria

- 4 -

1.2 Operation modes

1.2.1 Winter mode

The Controller automatically fix a winter mode in terms of switching on its power

supply. Then it is is able to goes into winter mode and to start the boiler only by two ways:

signal by a room thermostat or heating water temperature (measured with sensor O) lower

than Thset.

During that mode the Dynamic Boiler Controller manages with priority the temperatures at

above mentioned points 1.1.5 and 1.1.6. The control of the minimal temperature level of the

heating water according point 1.1.7 is of an importance if the heating system temperature falls

down bellow the adjusted one (for example at the programmable night drops). In fact, that

provides the optimum heating comfort in the building and quicker heating after switching

from economical to a comfort room temperature level. This function is very useful for

systems with a grate water contents and inertness. The regulated minimal temperature level of

the heating water is either permanent or controlled by the room temperature.

The desired room temperature is kept in compliance with the room thermostat

measurement and the Dynamic Boiler Controller manages the heating water temperature in

accordance with that temperature. The Controller reacts to the time of switching (ON/OFF) of

the room thermostat and thus the best results can be achieved by using proportional

thermostat with an integration control of the temperature. The precision class of the used

room thermostat directly affects to the precision in keeping the desired room temperature

level.

1.2.2 Summer mode

The transition to summer mode can be done automatically if the room thermostat or

sensor “O” does not send a command for starting in 12 hours (the adjustment can be done

within 12-48 hours) after the last stopping. That stop interval is to be fixed at menu

“OTHERS”. During the transition to a summer mode the Controller performs the following:

Stops the circulation pumps P1 and P2.

Stops the boiler.

Closes the mixed valve.

The Controller provides regular tests of the circulation pumps P1 and P2 and the

mixed valve in order to avoid the fur accumulating at the heating system mobile parts. The

first step of that test is the start of the circulation pumps and their subsequent stopping. The

next one is the opening and closing of the mixed valve. This prevents the hot water

penetration from the boiler circuit to the heating one during a summer mode.

The domestic hot water preparation during the summer is performed at a closed mixed

valve and a stopped circulation pump P2. The boiler starts operation by switching on the

domestic hot water thermostat or by a timer switch, connected to the domestic hot water

terminals of the Controller. In this way the boiler is being switched on if it is necessary,

keeping summer mode settings. In this mode as well, the boiler is being kept against

emergency overheating of the outlet boiler water or overcooling of the return one.

t:00359 898 606 796 ||| f:00359 596 325 80 ||| info@intiel.com ||| www.intiel.com

9 Peter Beron Str, Pomorie 8000, Bulgaria

- 5 -

1.2.3. Stop mode

STOP mode is being fixed automatically in case of fuel finish or manual (indication

about which is being shown on the display figure2), as again it is being performed stopping of

the circulation pumps, boiler and mixed valve closing.

STOP mode can be entered manual if button “stop” on the front panel is being pressed.

The controller goes automatically into STOP mode in case of fuel finish with gas, light oil or

solid fuel boilers (Tk<40 С for more than 30min.). Escaping STOP mode is able to be done

only manual by means of keeping pressed button “stop” as the Controller fix the previous

mode. During STOP mode is being observed only heating water, outlet boiler water and the

outdoor temperature. In case of very low heating water temperature (bellow 5 С) and fuel

presence, the boiler and pumps are being switched on as the valve starts opening in order to

prevent freezing (light indication 8 is being activated, figure3a). The previous goes on until

the heating water temperature reach 10 С.

1.2.4. Manual mode

In this mode the heating water assignation can be defined manually.

Mode settings and start are to be done in submenu “MANUAL

REGIME”. In case this mode is started a letter “m” appears in the

brackets where the temperature of the heating water is being indicated.

Returning to the previous mode is able to be done manually in the relevant submenu, or

automatically if the calculated temperature of the heating water in relation to the outdoor

temperature exceeds the manual assigned one. The Manual mode cannot be started if a

room thermostat operation is being selected.

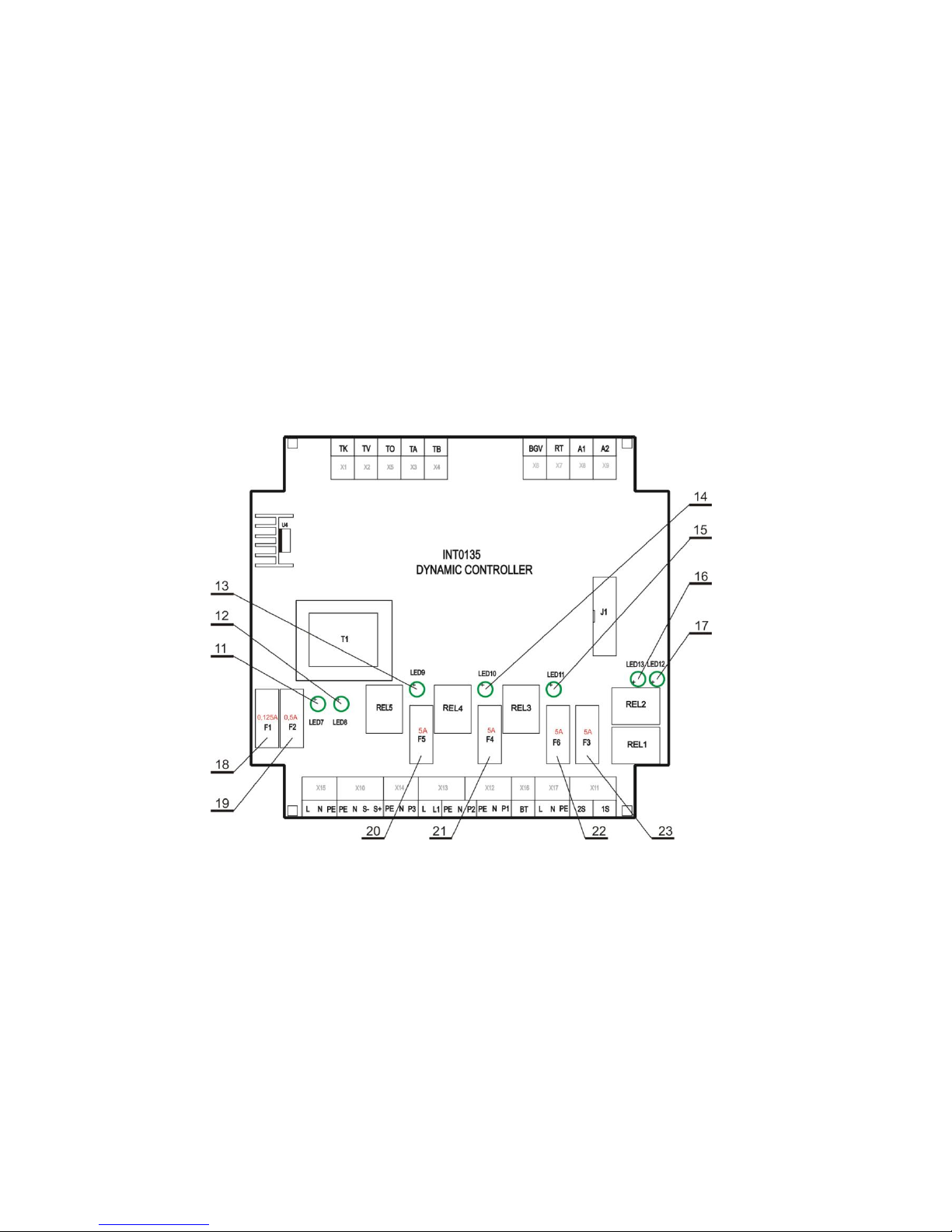

1.3 Controller basic elements

A general view of the Controller is shown at Figure 3, the Controller front panel at

Figure 3a and the Controller main board at Figure 3b.

Figure 3a

t:00359 898 606 796 ||| f:00359 596 325 80 ||| info@intiel.com ||| www.intiel.com

9 Peter Beron Str, Pomorie 8000, Bulgaria

- 6 -

Legend:

1. 4-raw digital LCD display

2. enter/escape button for STOP mode, used as well for allowing or prohibiting

the operation of the weekly programmer.

3. “+”(SCL) button, for forward navigation in the menu, as well for increasing of

the relevant value.

4. “-”(SEL) button, for forward navigation in the menu, as well for decreasing of

the relevant value.

5. SET button for a value confirmation and entering the main menu.

6. Indication for return temperature water decreasing, bellow the assigned value;

7. Control indication, showing exceeded emergency outlet boiler temperature.

8. Control indication, showing very low heating water temperature.

9. Summer mode indication.

10. Control indication, showing motor valve opening (>) and closing (<).

Figure 3.b

Legend

11. Service indication for motor valve closing

12. Service indication for motor valve opening

13. Service indication for switched on circulation pump 1

14. Service indication for switched on circulation pump 2

15. Service indication for switched on pump or motor actuator in the domestic hot water

circuit.

16. Service indication for 1st stage of the burner

17. Service indication for 2nd stage of the burner

t:00359 898 606 796 ||| f:00359 596 325 80 ||| info@intiel.com ||| www.intiel.com

9 Peter Beron Str, Pomorie 8000, Bulgaria

- 7 -

18 Fuse F1 – 0.125A about the controller electronic part

19. Fuse F2 – 0.5A about the motor actuator

20. Fuse F5 – 5A at the domestic hot water preparation output

21. Fuse F4 – 5A about circulation pump 2 in the heating circuit

22. Fuse F6 – 5A about circulation pump 1 in the small boiler circuit

23. Fuse F3 – 5A about burner power supply

1.4. Menus and settings

While the Controller is being set in one of the modes (summer, winter) on the display

are being indicated the current temperatures measured by the sensors, as well the adjusted

ones. By means of pressing “+”(SCL) button the following temperature groups are being

indicated.

Tk – current outlet boiler temperature, in brackets – the assigned temperature of the operation

thermostat about 1st stage of the burner.

Tr – current return boiler temperature, in brackets – the assigned one

Th – current heating water temperature measured after the mixed valve, in brackets – the

calculated one, or manual assigned one (m)

Tb – current water tank temperature, in brackets – the assigned one.

Ta – current outdoor temperature, in brackets – the assigned value at which the heating water

temperature has a maximum value Tou.min. (see point 1.5.5.1)

With temperatures below (20) С and above (+120) С, instead of values are being indicated

low and hi.

To enter the main menu button SET is to be pressed and kept for more than 3 sec., The Main

menu consists of four submenus, Manual Regime, Settings, Options and Other, which review

is able to be done by means of “+”(SCL) and “-” (SEL), as the selection by means of SEL

button.

Subnemu MANUAL REGIME:

- Define Thset – assignation of desired temperature of the heating water;

- Start and exit (Stор and exit) – start (stop) manual mode, escape directly to operation

mode.

Submenu SETTINGS

- Set limit Tk – setting the emergency value of the outlet boiler temperature

- Set return Tr – setting the return boiler temperature

- Heat min. Thmin – setting the lower border of the heating water temperature

- Heat max. Thmax – setting the upper border of the heating water temperature

- Set boiler Tb – setting the water tank temperature assignation

- Thermostat st1 – setting the operation thermostat 1st stage of the burner

- Thermostat st2 – setting the operation thermostat 2nd stage of the burner

Button SET is to be pressed in order to make some changes, as the value

starts blinking. Now the function of buttons “+”(SCL) and “-” (SEL) are

being changed to increasing and decreasing of the values. Once the desired

value is being selected then it has to be confirmed by means of SET button.

t:00359 898 606 796 ||| f:00359 596 325 80 ||| info@intiel.com ||| www.intiel.com

9 Peter Beron Str, Pomorie 8000, Bulgaria

- 8 -

Submenu OPTIONS

- Actuator speed - define the actuator speed (see point 3.1.7)

- Equi-thermal reg – selection of the lower border of the range about the

equithermal regulation. (Tout.min.)

- Night drop set – the value with which Thset drops during economic mode.

- Room thermostat – define if a room thermostat will be used. The setting come in

force after Controller switching on; In case of using a room thermostat Thmax is

being automatically limited up to 50 С if the room thermostat does not send a

signal for boiler starting.

- Boiler priority – defines whether the water tank is to be heated with an equal or

higher priority.

Press SET button in order to make some changes. By means of “+” button

it is able to go to the next option or by means of “-” to the previous one.

Submenu OTHER

- Summer regime – define the time within which if there is no signal from the room

thermostat or temperature sensor O, then the controller will automatically goes into

summer mode. It can be fixed within 12 – 48 hours;

- Kotel Type – define the boiler type, as boilers with gas and light oil (gas/liquid),

solid fuel boilers without their own controller (solid fuel 1) and solid fuel boilers

with their own controller (solid fuel 2), come in force after Controller switching

on;

- Restore settings – restore the default settings;

- Test actuator – it is being used for a control of correct wiring connection of the

actuator.

Press SET button in order to make some changes. By means of “+” button

it is able to go to the next option or by means of “-” to the previous one.

1.4.1. Weekly programmer – settings

The Controller is equipped with a built-in timer and a weekly programmer, for

programming of the night drops (economic mode) during which the calculated assignation of

the heating water drops with 5÷15 С. There could be assigned two time periods, which are to

be active during the whole week, during working or during weekend days (Saturday and

Sunday). By means of pressing SEL button (while on the display are being indicated the

current temperatures) it is being entered in timer and weekly programmer

menu, as escaping that menu can be done again with SEL button. On the

display are being indicated current date, hour, day of the week, as well the

status of the weekly programmer.

Status: stopped – weekly programmer function is prohibited;

Status: auto – the function is allowed, except in the case when about the two time

periods there are no selected days in the week, in which they are to be active.

The correction of date and time is to be done by means of pressing SET button, as

the status changing by means of “stop” button (button 2 of figure 3a).

Setting the time periods

By means of pressing SCL button, shows on the display the setting of the first time

period. There are no assigned time periods when the controller is primary started (a new one).

t:00359 898 606 796 ||| f:00359 596 325 80 ||| info@intiel.com ||| www.intiel.com

9 Peter Beron Str, Pomorie 8000, Bulgaria

- 9 -

Pressing SET button is to fix the hour and minutes for start and

stop. The values starts blinking as the change could be done by means of

SEL and SCL buttons, as the confirmation of the selected value can be done

by means of SET button. The next step is to select the days during which

the time period is to be active (whole week, working days, weekend). In

case no one day is selected means the time period is not active.

Button SCL is to be pressed in order to move to the second time

period. The setting about it is to be done in the same way. The settings will

be saved in the energy independent memory of the Controller, after pressing

SCL button again. To escape that menu SEL button is to be pressed.

If there is an active time period and the economic mode has been

modified the assignation of the heating water, then in the upper right corner

on the display a down arrow will appear.

The Controller is able to get back from any menu to regular operation status if no one

button is being pressed in 30 seconds time after the last used one.

1.5 Description of the sensors

The sensors are Pt-1000, interchangeable.

1.5.1 Temperature sensor ”K” of the outlet boiler water

The temperature sensor “K” is to be mounted on the outlet boiler pipe as much as

close to the boiler (Figure 1). It is designed to avoid emergency exceeding of the boundary

outlet boiler temperature. If the boiler outlet temperature exceeds the assigned one, the

Controller indicator 7 (Figure 3a) will light, the boiler will stop by force, the mixed valve will

be open and the circulation pumps P1 and P2 will start operation. That will be done despite of

the present working mode and the rest of the regulation parameters meaning. If the outlet

boiler temperature drops bellow the assigned boundary level the Controller automatically will

go into the previous working mode.

The assigned boundary outlet temperature of the boiler is to be fixed in the range of

(+850C) – (+1050C). That temperature must be fixed in relation with the boiler type and in

compliance with the settings of the boiler emergency thermostat. For example if the

emergency thermostat is fixed at 1000C, the necessary boundary outlet boiler temperature of

the Controller is to be decreased bellow that level and afterwards to test its functions. The

Controller must provide the limitation of the outlet boiler temperature level before the

emergency thermostat stops the boiler.

That protection is very important for wood gasification boilers, in case the mixed

valve is closed (for instance during a night drop) and the boiler is not able to decrease its

capacity.

1.5.2 Temperature sensor of the return boiler water “V”

The temperature sensor “V” is to be mounted on the return boiler pipe as much as

close to the boiler (Figure 1). It is designed to prevent the boiler corrosion in relation to the

low temperature boiler condense. In fact that can be happen during starting of the boiler when

the system is still cold and during the usual boiler operation if it is not provided a minimal

level of the return boiler water temperature.

t:00359 898 606 796 ||| f:00359 596 325 80 ||| info@intiel.com ||| www.intiel.com

9 Peter Beron Str, Pomorie 8000, Bulgaria

- 10 -

The mixed valve cannot be open by the Controller at systems with a bad gravitational

circulation in the small boiler circuit, because of low temperature of the return boiler water.

The indicator 6 (figure 3a) signalizes for low temperature return water. The decision about

such a situation is an additionally decreasing of the assigned minimal level of the return

water, even that will increase the low temperature condensation; or by increasing the boiler

temperature by means of the operation thermostat about 1st burner stage; or by turning the

mixed valve at 1800 that will release the circulation in the small boiler circuit to the heating

one by means of circulation pump P2. In order to obtain the above-mentioned the servoactuator and the mixed valve lever have to be dismantled, as the valve is to be turned at 1800.

It is not necessary the water in the heating systems to be drawn out. Generally all above

mentioned relates to heating systems with gravitation circulation in the small boiler circuit

and with an installed circulation pump at the heating circuit.

1.5.3 Temperature sensor of the heating water “O”

The temperature sensor “O” is to be mounted on the pipe after the mixed valve. Its

main function is to measure the inlet temperature of the heating water circuit. The

recommended sensor location is as much as far from the mixed valve. In fact the best location

is after the circulation pump P2 (Figure 1).

Sensor “O” provides an optimum heating comfort in the premises by uniform heating

during the time and it does not permit a drop of the heating water temperature bellow the

assigned level. The assigned heating water temperature can be constant or it can be defined in

relation to the outdoor temperature. Thus, there is no cooling of the radiators during

penetrating of a cold air through the windows towards the floor. If such function is not

available, the programming of not estimated room temperature drops will cause substantial

cooling of the water in the heating system. As a result of that the whole heating system and

the heating premises will get cold. Secondary heating of the system, up to desired temperature

comfort is an energy-waste and needs more time. That effect becomes stronger with

increasing the water contents in the heating system.

The heating water temperature is being regulated within 15 - 85 С, never mind the

regulation of the system is provided by outdoor temperature (equi-thermal regulation) or by a

room thermostat.

Sensor “O” prevents water heating in the second circuit above the maximum assigned

level, which is recommended to be 50 С concerning under-floor systems. That could be fixed

by submenu “SETTINGS” (see point 1.4)

1.5.4. Water tank temperature sensor “B”

Sensor B is to be mounted in the water tank at a place, recommended by the tank producer. It

sends a signal to the Controller about what thank heating if the following conditions have been

fulfilled:

- the water tank temperature is lower than assigned one Tbset,

- the outlet boiler temperature is grater than the one in the water tank;

- the return boiler temperature is not lower than the assigned one Trset,

Then the Controller starts the circulation in the water tank circuit by means of closing the

contact between terminals X6 (see point 2.3.2.). In case the water tank temperature exceeds

the assigned one Tbset, then the circulation in the water tank circuit is to be stopped. In case

the contact between terminals X6 is not closed, so the circulation in the water tank circuit is

not being switched on, even when the water tank temperature is cooler than the assigned one.

1.5.5. Outdoor temperature sensor “A”

t:00359 898 606 796 ||| f:00359 596 325 80 ||| info@intiel.com ||| www.intiel.com

9 Peter Beron Str, Pomorie 8000, Bulgaria

- 11 -

The outdoor temperature sensor is to be mounted at the outside north wall of the

building, in a way it is not exposed to direct sunrise or other type of heating radiation, which

can influences to the correct measurement of the outdoor temperature. The assignation of the

heating water is being calculated by means of sensor “A” measurement.

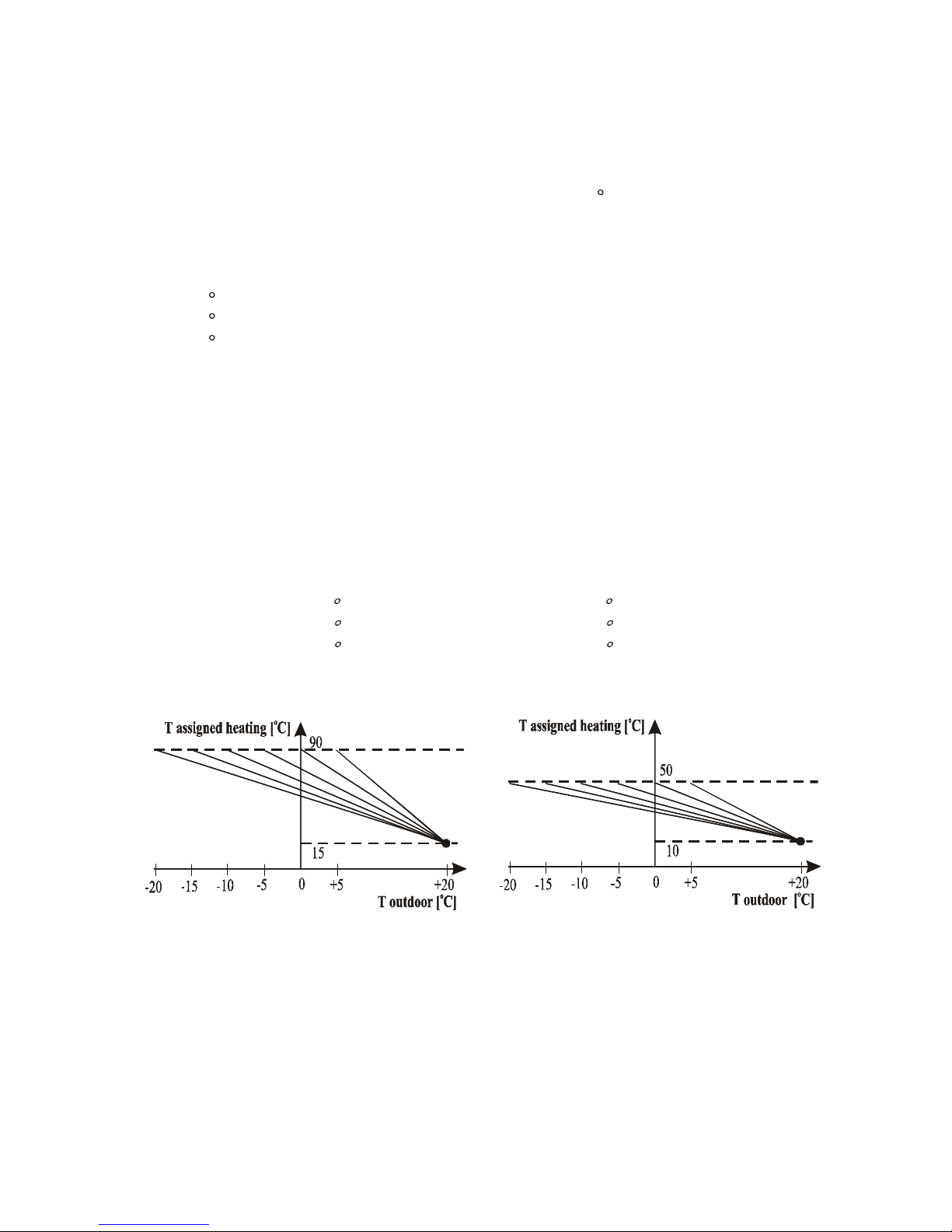

The decreasing of the outdoor temperature bellow +20 C leads to increasing of the

assignation of the heating water, which reaches it maximum level at the lower border range

for the equi-thermal regulation (Tout.min).

The maximum assignation of the heating water is being defined by means of heating type

or room thermostat presence, for example:

a) 85 C with radiator heating, without a room thermostat;

b) 50 C with under floor heating without a room thermostat;

c) 50 C with under floor heating with a room thermostat;

In case of under-floor heating system it is recommended an installation of mechanical

emergency thermostat which is to stop circulation pump P2, in case the heating temperature

exceeds the maximum assigned one. The previous mentioned could happen if the outlet boiler

temperature reaches its emergency value and the Controller has been opened the mixed valve.

1.5.5.1. Selection of the lower border of the equi-thermal regulation range

The desired temperature range depends of the premises insulation and it is being selected by

submenu „OPTIONS” -> „Equi-thermal reg” (see point 1.4). The first number in the range

shows the minimum outdoor temperature which corresponds to the highest (hottest) heating

one.

There are opportunity for assignation of 6 temperature ranges concerning the outdoor

temperature sensor:

from +5 up to +20 С; from –10 up to +20 С;

from 0 up to +20 С; from –15 up to +20 С;

from –5 up to +20 С; from –20 up to +20 С.

as the heating water assignation is being changed in compliance to figure4.

without room thermostat with room thermostat

The outdoor temperature range (-200C) – (+200C) has to be selected for buildings with small

heat losses where the heating water in the system reaches its maximum value if the outside

temperature is -200C. The ranges of (+50C) – (+200C) and (00C) – (+200C) have to be chosen

for premises with big heat losses like production halls, stores, etc., where the hottest heating

water can be obtained as soon as the outdoor temperature reaches +50C or 00C. Concerning

the factory settings, take into consideration that jumper J2 is placed at position (-100C) –

(+200C).

t:00359 898 606 796 ||| f:00359 596 325 80 ||| info@intiel.com ||| www.intiel.com

9 Peter Beron Str, Pomorie 8000, Bulgaria

- 12 -

Concerning each outside temperature:

- Tout.min. is to be increased in order to increase the heating water temperature;

- Tout.min. is to be decreased in order to decrease the heating water temperature;

1.6 Technical data

1. Power supply: ~230V/50Нz

2. Main board capacity without the servo-actuator: max. 4VA

3. Main board capacity with the servo-actuator: max. 10VA

4. Servo-actuator output: ~230V/50Hz, 5VА

5. Outputs for 1/first/ and 2/second/ stage of the burner:

2 (switching contacts) x 7A/250V/AC

6. Outputs for circulation pumps P1 and P2: phase 5A/250V/AC

7. Output for a circulation pump or a servo-actuator in the domestic hot water circuit:

switching contact 5A/250V/AC

8. Room thermostat input: switching contact

9. Loading of the room thermostat contact: 50mA/12Vss

10. Input for starting the domestic hot water preparation: switching contact

11. Loading of the domestic hot water switching on contact: 50mA/12Vss

12. Protection: IP00

2. Installation of the Controller

2.1 Introduction

The installation of the Controller must be done by a qualified staff. The connection of

the boiler, the mixed valve, servo-actuator and the circulation pump must be in compliance

with the requirements of their producers for a proper installation at central heating systems. It

must be provided enough circulation in the small boiler circuit and in the heating one, in order

to achieve a correct mixture of the water in the heating system. For systems that are equipped

with a circulation pump only in the heating circuit, it must be provided the necessary

gravitation circulation in the boiler circuit either. Therefore, at such systems the mixed valve

must be installed at a height of at least 0.8m above the return boiler water inlet and must be

used pipes and mixed valves with enough vertical section.

2.2 Temperature sensors installation

The Controller is equipped with five temperature sensors, which installation is not

related to an intervention to the existing heating pipe systems. Each sensor is equipped with a

50cm long cable. It can be shortened or connected by a terminal with prolonged two-core

cable with a vertical section for each of them of at least 0.35 mm2.

t:00359 898 606 796 ||| f:00359 596 325 80 ||| info@intiel.com ||| www.intiel.com

9 Peter Beron Str, Pomorie 8000, Bulgaria

- 13 -

At Figure 5 can be seen the schemes of the following systems:

a) System equipped with a four-way valve

b) System equipped with a three-way valve located at position 1 or 2.

The circulation of the water in the small boiler circuit cannot be provided separate

from the heating circuit in systems which are equipped with three-way mixed valve. Thus, if

the mixed valve is closed there is a circulation only in the heating circuit and cannot be

obtained mixture of the outlet boiler water with the returned one. As a result of that the return

boiler water gets cold in short time, that reflects to closing of the mixed valve and going

deeper into that process. In this way the mixed valve will not be opened again. The only

solution about avoiding the low temperature corrosion is to mount the temperature sensor of

the return boiler water “V” together with the sensor of the outlet water temperature “K” and in

the same time setting-up the minimal temperature of the return water at (+650C). In this way

the outlet boiler temperature will vary in the range of (+650C)-(+900C).

The above mentioned installation of the temperature sensors can be used in heating

systems with a gravitation circulation in the small boiler circuit, where incorrect connections

are done by choosing a mixed valve with not enough vertical section or mixed valve with not

enough installation height, or by using pipe system with not enough vertical section.

The temperature sensors must be covered with thermo insulation tape during their

installation on the pipe surface, in order to avoid the ambient temperature influence. The

proper installation gains only the measurement of the water, inside the pipe system.

2.3. Electrical connection of the Controller

The side two covers of the Controller are to be removed in order to provide access to the

terminals. The wiring connection is shown at Figure 6.

K

Boiler

Boiler

K

а) b)

Figure 5

Position .1

Position 2

t:00359 898 606 796 ||| f:00359 596 325 80 ||| info@intiel.com ||| www.intiel.com

9 Peter Beron Str, Pomorie 8000, Bulgaria

- 14 -

2.3.1. Connection of the room thermostat

The Controller can be connected to a different type room thermostat, having

independent switch circuit closer that is switched on, when the real room temperature is lower

than the assigned one. In fact the thermostats equipped with a relay on their outputs (which

are most of the programmable thermostats) and some of the electronics thermostats meet that

requirement. The thermostats having a phase of their output (result of the power supply) have

to be connected by means of a middle relay.

There is a safety voltage of 5 V between the Controller terminals, designed for a room

thermostat connection that allows the thermostat to be connected by a two-core regular cable

2x0.35mm2. The cable is intended to transfer two-digit information and therefore its length

has to be fixed only in relation with its resistance that can reach 100

The room thermostat location is something very important. It is suitable the thermostat

to be placed at the most occupied room in the house that will become a standard for the whole

house (premises) heating. Such areas could be the living-room and the kids’ room in the

family houses. The position of the room thermostat in the kitchen is not correct, because it can

be influenced by the cooking. The location in the corridors is incorrect either, because of its

temperature that differs from the room one. The room thermostat has to be mounted far from

radiators (or other heating elements) and any sun shine influence. It should not be installed on

the outer wall, where the cooling of the masonry will affect to the results of the thermostat

operation. Sometimes the above mentioned unfavorable influences can be used to improve the

thermostat functions, for example when a thermostat with a high hysteresis is getting closer to

the heating elements, providing quicker reaction to the temperature variation; or a thermostat

mounted on the outer wall can provide in time reaction to the variation of the outdoor

temperature.

t:00359 898 606 796 ||| f:00359 596 325 80 ||| info@intiel.com ||| www.intiel.com

9 Peter Beron Str, Pomorie 8000, Bulgaria

- 15 -

2.3.2. Connection of the domestic hot water timer and circulation pump (servo-motor)

For the connection of the domestic hot water thermostat or timer should be followed the same

instructions like for the room thermostat. The switching on contact of the domestic hot water

thermostat is to be connected to terminals X6. In case the domestic hot water preparation is

not provided by the boiler, the terminals have to remain unconnected.

The circulation pump (or the servo-motor) of the domestic hot water is connected by

independent switching contact at terminals X14 (Figure 6). It is protected by fuse F5 (5A). A

terminal X14 provides the neutral and a safety earth. To terminal X13 is to be provided

external phase L1. It can be used the internal phase by means of placing an electrical bridge

between L and L1 from the same terminal.

Some examples of hydraulic and electrical connection schemes for a domestic hot water

circuit are shown at Figure 7:

a) With four-way mixed valve and third circulation pump for domestic hot water circuit

(Figure 7a)

b) With four-way mixed valve and three-way magnet valve in the domestic hot water

circuit (Figure 7b)

a)

b)

Figure 7

Consider the meaning of the above mentioned abbreviations at Figure 7 as follows:

B – boiler

WH – water heater

Switching on the domestic hot water timer, when the water tank temperature is lower

than Tbset will cause the boiler start no matter of the boiler operation mode. It means that it

can be happened even during the summer regime when the mixed valve is closed and the

circulation pump P2 is stopped. The boiler protection against overheating is still active in the

regime of a domestic hot water preparation, as the Controller stops the boiler operation,

without stopping the circulation pump in the domestic hot water circuit, which actually stops

when the water tank temperature reaches 900C. The protection against overcooling of the

return boiler water is active during the domestic hot water preparation, stopping the pump in

the domestic hot water circuit without boiler stopping.

P2

14

13

12

L

N

P1

WH

B

Х2

P3

PE

P2

14

13

12

L

N РЕ

P1 B Х2

WH

t:00359 898 606 796 ||| f:00359 596 325 80 ||| info@intiel.com ||| www.intiel.com

9 Peter Beron Str, Pomorie 8000, Bulgaria

- 16 -

The domestic hot water preparation can be done with a higher priority or with same one

compare to the heating of the premises.

The heating with same priority means if the domestic hot water timer is being

switched on by time, while the heating of the premises is provided (open mixed

valve), then both of them will be provided in the same time. The boiler capacity is

to be shared between the water tank and the premises heating in a dynamic way, as

to the heating is to be sent only that part of the boiler capacity which is not able to

be utilized by the water tank. The gradually heating of the water tank corresponds

to directing grater part of the boiler capacity to the premises. It happens by means

of observing the outlet boiler temperature. In case it drops to 50C bellow the

assignation for the 2nd burner stage of the boiler due to not enough boiler capacity

(switched on 1st and 2nd stage), the four way mixed valve start proceeding closing

steps, thus closing the heating circuit. The consumed capacity is being decreased,

when the valve is being closed and the water tank heated, which referes to

increasing of the outlet boiler temperature. The controller allows mixed valve

opening to the heating circuit when the outlet boiler temperature excceds the

assigned one for the 2nd burner stage, but that happens only in case the room

thermostat or the heating circuit sensor send a command about that.

Heating with a higher priority means that if the domestic hot water timer is being

switched on by time, while the premises heating is being provided (opned mixed

valve), so the Controller will send a signal for a complete mixed valve closing in

order to direct the whole boiler capacity only to the water tank. The boiler capacity

is being decreased as it remains equal to the consumed one from the water tank.

After domestic hot water timer is being switched off or the assigned water tank

temperature is being reached, then the premises heating is to be restored.

The selection of the domestic hot water priority is to be done from submenu

„OPTIONS” -> „Boiler priority” (see point 1.4), where “YES” means high priority and “NO”

– equal priority.

It is possible the domestic hot water preparation to be provided in a combined way,

by means of a boiler and solar panels with a priority of last ones. In this case it is necessary

an additional differential thermostat which is to manage the operation of the solar system

and three way valve. In this case the output relay of the differential thermostat is to be

connected to terminal X6 instead of domestic hot water timer.

2.3.3 Connection the servo-actuator of the mixed valve

The Controller can be connected to a different type of servo-actuator that is in

compliance with mentioned requirements at point 1.6 (Technical data). The manufacture

requirements, concerning the regulation of the Controller output end switches must be

considered during the installation of the servo-actuator. The electrical connection is to be

done at terminals X10. To terminal X10(PE) is to be connected the actuator body, to terminal

X10(N) the common wire of both coils of actuator motor, to terminal X10(-S) the wire whish

is to close the valve, as to terminal X10(+S) the wire which is to open the valve.

t:00359 898 606 796 ||| f:00359 596 325 80 ||| info@intiel.com ||| www.intiel.com

9 Peter Beron Str, Pomorie 8000, Bulgaria

- 17 -

2.3.4 Connection of the boiler

2.3.4.1 Light oil/gas boilers equipped with one or two stage burners.

From menu „OTHER” -> „Kotel Type” is to be selected „gas/liquid fuel” (the option

is default). The burner is to be connected to terminal X17 and X11 (figure 6). By means of

terminal X17(L) a phase is provided to the burner, protected by fuse F3 – 5A. By means of

terminals Х17(N) and Х17(PE) are to be provided respectively a neutral and a protection

earth. Between terminals X11(1S) is placed a switching contact starting 1st burner stage, as

between terminals X11(2S) is placed a switching contact starting the 2nd burner stage.

2.3.4.2 Solid fuel boilers

The electrical managed solid fuel boilers are designed for a connection of a room

thermostat or a timer, as there are terminals for a contact thermostat (placed in the boiler

terminal box), connected in a short circuit by means of an outer electrical bridge. That bridge

is to be removed as the boiler controller is to be connected by means of a cable with the

Controller terminals.

Solid fuel boiler without their own controller

When the boiler is without its own controller, then the boiler operation is managed by

means of fan speed control in relation to the boiler water temperature within the range of 60 85 C.

The control of boiler fan is provided by means of relay switching contact for 1st stage

of the controller, placed on terminals X11(1S). From menu „Kotel Type” is to be selected

„solid fuel 1”.

The boiler operation in this case has the following characteristics. If the boiler

temperature is lower than 60 С the boiler fan operates constantly and it is managed by means

of the room or outdoor thermostat. During smooth increasing of the boiler temperature above

60 С (for example when the valve is too much open) even the room thermostat sends a start

command in the fan operation occurs forced pauses of 15 seconds which are being increased

together with the boiler temperature increasing, as the operation periods are being decreased.

In case the boiler temperature is being increased up to 85 С the pauses are being widen too

much, as the operation periods do not exceed 5 seconds. If the boiler temperature exceeds

85 С, the fan operation is permanently prohibited, despite of the room thermostat could send

a start command. In case the boiler temperature is being increased too fast, the fan operation

can be prohibited constantly after exceeding 60 С. It means the point for constant boiler

stopping depends as well on the speed of boiler temperature increasing as if the speed is faster

the boiler can stop completely within boiler temperature of 60 - 85 С. In this way the

Controller prevents the boiler overheating above the emergency boiler temperature and

emergency opening of the mixed valve, caused by the temperature inertial increasing after the

fan stopping.

Solid fuel boiler with their own controller

If the boiler is equipped with its own operation thermostat, the outlet boiler

temperature is being managed by the boiler thermostat, as the controller only starts or stops

the boiler fan in relation to the commands from the room thermostat, outdoor sensor, return

and outlet boiler temperature, as the last one now fulfils only protection stopping function in

case of boiler overheating above the emergency temperature. The boiler control is provided

by relay switching contact for 1st Controller stage, placed on terminals X11(1S). From menu

t:00359 898 606 796 ||| f:00359 596 325 80 ||| info@intiel.com ||| www.intiel.com

9 Peter Beron Str, Pomorie 8000, Bulgaria

- 18 -

„OTHER” -> „Kotel Type is to be selected „solid fuel 2”. In this case the settings of the

operation thermostats for 1st and 2nd stage does not affect to the fan operation.

2.3.5 Connection of the circulation pump

There is possibility for connection of two circulation pumps P1 and P2

respectively for the small boiler circuit and for the heating one, concerning

heating systems provided with four-way mixed valve. The circulation pump P1

can provide the circulation in the domestic hot water circuit either (see Figure

7b).

single phase circulation pump P1 is to be connected to terminal

X12(PE) – a protection earth, terminal X12(N) – a neutral and terminal

X12(P1) – a phase. The pump protection is provided by fuse F6 (5A).

single phase circulation pump P2 is to be connected to terminal X13(PE) – a

protection earth, terminal X13(N) – a neutral and terminal X13(P2) – a phase. The

pump protection is provided by fuse F4 (5A).

2.3.6 Connection of an emergency (blocking) thermostat.

The emergency (blocking) thermostat is to be connected between terminals X16. This

contact is being opened in case of boiler overheating.

If an emergency thermostat is not provided, so terminals X16 are to be connected in a

short circuit by means of outer electrical bridge.

3. Starting the Controller operation

After the Controller starting must be considered the following check-up:

Control the correctness of the servo-actuator connection.

Regulation of the assigned emergency temperature level of the outlet boiler

water.

Regulation of the assigned temperature level of the working thermostat for

Controller first stage.

Regulation of the assigned temperature level of the working thermostat for the

Controller second stage.

Regulation of the assigned minimal temperature level of the return boiler

water.

Regulation of the assigned minimal temperature level of the heating water.

Specification the boiler starting concerning the domestic hot water preparation.

Specification of the room thermostat control.

3.1 Start-up sequence

3.1.1 First start-up of the Controller

Switch off the burner by removing the cable from X17(L). Then the Controller is to be

switched on.

3.1.2 Control of the correct servo-actuator starting

From menu „OTHER” -> „Test actuator”the actuator can be opened and closed

manually. Press SET button to:

a) The actuator is being opened as light indication 10(>) appears – figure 3a;

t:00359 898 606 796 ||| f:00359 596 325 80 ||| info@intiel.com ||| www.intiel.com

9 Peter Beron Str, Pomorie 8000, Bulgaria

- 19 -

b) The actuator is being closed as light indication 10(<) appears – figure 3a .

The control of the actuator operation is being undertaken by the Controller when the

current menu is being escaped.

In the very beginning the servo-actuator has to be separated of the mixed valve. The

test of the correct direction run of the servo-actuator and the accurate operation of the end

circuit closers have to be done by switching positions “A” and “B”. In case the servo-actuator

moves in the opposite direction than the expected one, the cables of terminals (-S) and (+S)

from X10 are to be replaced.

After fixing the correct run direction of the servo-actuator it is necessary the servoactuator to be waited for to make it complete move until the end position (reaching the end

circuit closer for a “closed”). The regulation element of the mixed valve is to be turned

manually to a closed position, as this is the position for the servo-actuator mounting to the

mixed valve.

3.1.3 Fixing the assigned minimal temperature level of the return boiler water

The minimal temperature level of the boiler return water is to be fixed by submenu

„SETTINGS” -> „Set return Tr” (see point 1.4). The assigned temperature of the return boiler

water can be adjusted within the range of (+45 0C) – (+65 0C). When the real boiler return

water temperature decreases bellow the assigned level, indication 6 appears and the servoactuator starts closing the boiler water flow to the heating circuit.

The recommended levels of the fixed return boiler water temperature are as follows:

Boilers with steel heat-exchangers

from 55 up to 60

Boilers with die-cast heat-exchangers

from 45 up to 55

Solid fuel gasification boilers

from 60 up to 65

3.1.4. Fixing the heating water temperature

The assigned heating water temperature is being kept by the Controller only in winter

mode, but if the room thermostat is switched of for less than 12(24, 36 or 48) hours, or a room

thermostat is not installed. During that time the Controller keeps the heating water

temperature, assigned by transmitter of the outdoor temperature by means of outdoor

temperature sensor. Thus the heating water assignation can be changed in relation to the

outdoor temperature within upper and lower borders, which are to be fixed.

Setting the upper border of the heating water assignation:

It can be done from submenu „SETTINGS” -> „Heat min. Thmах” as it can be fixed within

30 - 85 С.

Setting the lower border of the heating water assignation:

It can be done from submenu „SETTINGS” -> „Heat min. Thmin” as it can be fixed within

15 - 30 С.

The Controller default settings regarding the heating water are as follows, lower border

20 С and upper border 85 С.

Depends on the Controller application there are two ways for keeping the heating water

temperature:

A) With a room thermostat – in case there is no a signal from the room thermostat, the

heating water temperature is being kept by the equithermal regulation, as the upper

border assignation of the heating water is 50 С.;

B) Without a room thermostat – equithermal regulation.

t:00359 898 606 796 ||| f:00359 596 325 80 ||| info@intiel.com ||| www.intiel.com

9 Peter Beron Str, Pomorie 8000, Bulgaria

- 20 -

3.1.5 Fixing the boundary temperature level of the outlet boiler water

The emergency opening of the servo-valve during exceeding of the boundary

temperature level of the boiler can be easily checked during boiler start-up. It can be carried

out when the mixed valve is not open yet, the working thermostat at a first burner stage is

fixed at its maximum level and the settled boundary level of the outlet boiler water is at its

minimal level. Mostly the boiler behavior is that if the working thermostat is switched off the

boiler temperature keeps increasing in case the heating water would not be leaded (for

example that could be happen at a closed mixed valve). When the boundary temperature level

of the heating water is reached the light indication 7 appears (see Figure 3a), the boiler must

be stopped, the mixed valve must be opened and the circulation pumps P1 and P2 must

operate, it is possible to start operation of the circulation pump in the domestic hot water

circuit in case the water tank temperature is less than 900C. The boundary emergency boiler

water temperature can be adjusted from menu „SETTINGS” -> „Set limit Tk” in the range of

(+90 0C) – (+105 0C). The setting is to be done in a way that after activating the first

stage, the boiler would not be stopped by the working thermostat, neither to be able to

reach the assigned boundary level of the outlet boiler temperature. That means the

lowest possible temperature setting is of the 1st stage of the working thermostat (for

example +800C), the fixed emergency boiler temperature is higher (for example +950C)

and the emergency thermostat has the most possible settings (for instance +1050C). The

boiler emergency thermostat is an automatic discharger of hot water during overheating

of the boiler and operates together with an automatic filling valve with a cold water of

the water-conduit.

If the boiler temperature of the outlet boiler water drops bellow the fixed boundary

temperature level, the indication 7 stops and the Controller goes independently into the settled

operation mode with a control of the servo-valve.

Figure 8 shows the adjusting of the outlet emergency water temperature of the boiler

at:

a) High temperature level Tp;

b) Correct temperature level Tp,

where:

Tn is a temperature of the emergency boiler thermostat

Tb is a boiler temperature (in our case an emergency one)

Tp is a temperature of 1st stage of the working thermostat

3.1.6 Adjusting the assignation of the working thermostats for 1st and 2nd burner stage

About 1st stage – from menu „SETTINGS” -> „Thermostat st1” is to be fixed an operation

temperature of 1st stage within 75 - 90 С;

Emergency boiler stopping

CONTROLLER safety

function

Without installed

controller

Тn

Тb

Тр

Тn

Тb

Тр

Т

t[min]

Т

t[min]

a)

b)

Figure 8

t:00359 898 606 796 ||| f:00359 596 325 80 ||| info@intiel.com ||| www.intiel.com

9 Peter Beron Str, Pomorie 8000, Bulgaria

- 21 -

About 2nd stage – from menu „SETTINGS” -> „Thermostat st2” is to be fixed an

operation temperature of 2nd stage within 60 - 75 С;

Regarding solid fuel boiler, managed by the switching contact of 1st stage (see point

2.3.4.2) thermostats about 1st and 2nd stages does not affect to the boiler operation.

3.1.7 Fixing the operation and stop time of the motor actuator

The actuator operation and stop time is to be fixed from submenu OPTIONS”->

„Actuator speed” within 1-100%, as 1% corresponds to 1 second. For example, is the setting

of “Actuator speed” is 10%, it means 10seconds operation and 90 seconds a pause. Regarding

faster actuators it is to be fixed less operation time and vice versa. The default setting is 20%.

3.1.8 Control of the domestic hot water thermostat operation

If no one of the indications 6, 7 appear (figure 3a) or Th is not bellow the assigned

value, then short circuit between terminals X4(TB), as well between terminals X6 (BGW) is

to start the boiler operation, as well the relay managed circulation pump P3.

3.1.9 Control of the room thermostat regulation

If no one of the indications 6, 7 (figure 3a) or Th is not bellow the assigned value, then

after a room thermostat switching on, the mixed valve is to start opening and the boiler is to

be started. After room thermostat switching off – the valve is to start closing as the boiler is to

be stopped. In case of constant switching of the room thermostat the controller move the

motor actuator in a step movement to positions “open” and “close”

t:00359 898 606 796 ||| f:00359 596 325 80 ||| info@intiel.com ||| www.intiel.com

9 Peter Beron Str, Pomorie 8000, Bulgaria

- 22 -

3.2 Detection of possible installation failures

Before looking for some occurred failures, it must be checked up the state of the

control indications 6 and 7, which lighting signalize, the Controller fulfils its priority

functions and its operation is in compliance with above mentioned.

Failure Indication

Possible Cause

Trouble-shooting

There is no activated light

indication on the front panel

A burned fuse F1 –

0.125A

Replace the fuse F1 with new

one after switching off the

power supply.

A circulation pump does not

operate.

A burned fuse F4 – 5A,

F5 – 5A, F6 – 5A

Replace the fuses F4, F5 or

F6 with new one after

switching off the power

supply.

The servo-actuator does not

operate

A burned fuse F2 – 0.5A

Replace the fuse F2 with new

one after switching off the

power supply.

The servo-actuator is turning in

a wrong direction.

Not correct connected

servo-actuator

Replace the positions of

cables at terminals X10(S+)

and (S-)

Any of the observed

temperatures is indicated with

“too high”

Not connected or

damaged sensor or

interrupted cable

The connection is to be

checked up or the sensor

replaced

Any of the observed

temperatures is indicated with

“too low”

Short circuit in the sensor

or temperature bellow

300C

The sensor is to be replaced

The premises cannot be heated

to the desired temperature

Low temperature of the

boiler water

Increase the assignation of

the working thermostat for

first burner stage.

Low heating water

temperature

Increase Tout.min.

Check up the heating system

settings from point 3.1.4.

4. The Controller maintenance

The system starts its operation by switching on the power supply button. The further

maintenance of the Controller can be done by the room thermostat and that provides only a

regulation of the desired room temperature level. The Controller keeps such a temperature of

the heating water that is able to provide reaching the assigned temperature level by the room

thermostat.

In case there is overheating in the rest of the rooms it is necessary to close the

regulation valves of their heating elements (radiators, bath radiators, etc.) Other decision that

can provide a proper regulation of the temperature in those rooms is the installation of

thermostatic valves. But in this way, the time programming of their temperature changes

cannot be used.

The Controller transition to a summer mode is being assigned by the room thermostat.

As it was mentioned the Controller periodically tests the circulation pumps and the mixed

valve and therefore it is not recommended it is to be switched off during the summer. An

undesired boiler switching during the summer can be avoided by switching off the room

t:00359 898 606 796 ||| f:00359 596 325 80 ||| info@intiel.com ||| www.intiel.com

9 Peter Beron Str, Pomorie 8000, Bulgaria

- 23 -

thermostat (in case it is equipped with such a switch) or by fixing a lowest possible room

temperature (for example anti-freezing temperature, which is preliminary adjusted with most

of the room thermostats). For example it can be a not-freezing temperature that is adjusted to

most of the room thermostats. Then to go back to winter mode is enough to get back to the

preliminary program settings.

The complete stopping of the heating system can be provided by switching off the Controller

and boiler power supply.

5. Opening of the Controller cover

5.1. Remove protective caps „ 1 ”

5.2. Press pin „2” as at the same time pick up cover „ 3 ”

t:00359 898 606 796 ||| f:00359 596 325 80 ||| info@intiel.com ||| www.intiel.com

9 Peter Beron Str, Pomorie 8000, Bulgaria

- 24 -

6. Storage

The Controller has to be kept in the provided by the manufacturer packages, at an

ambient temperature of (+5 0C) up to (+35 0C) and a maximal relative humidity of 65%.

SETTINGS and PARAMETERS

Symbols

Description

Range

Default setting

Customer’s settings

Set limit Tk

Assigned emergency boiler

temperature of the outlet water

85 ÷ 105° С

95° С

Set return Tr

Assigned minimum temperature

of the return boiler water

25 ÷ 65° С

45° С

Th min

Lower border of heating water

assignation

15 ÷ 30° С

20° С

Th max

Upper border of heating water

assignation

30 ÷ 85° С

85° С

Set boiler Tb

Assigned water tank

temperature

30 ÷ 80° С

60° С

Thermost-at

st1

Operation thermostat

assignation of 1st burner stage

75 ÷ 90° С

85° С

Thermost-at

st2

Operation thermostat

assignation of 2nd burner stage

60 ÷ 75° С

65° С

Твънш. мин

Outdoor temperature

corresponding to the hottest

heating water temperature

during equi-thermal regulation

5 ÷ -20° С

-10° С

Night

drop set

Temperature assignation

regarding the night drops

5÷ 15° С

5° С

Actuator speed

Servo actuator speed

1 ÷ 100%

20%

Room

thermostat

Presence of room thermostat

YES/NO

NO

Boiler priority

Heating the water tank with

equal or higher priority

YES/NO

NO

Summer

regime

Time after which the Controller

goes to a summer mode, in case

of no signal from a room

thermostat or sensor “O”

12 hours

24 hours

36 hours

48 hours

12 hours

Kotel Type

Defines the boiler type in

relation to the fuel and own

thermostat availability

gas/liquid fuel

solid fuel 1

solid fuel 2

gas/liquid

fuel

t:00359 898 606 796 ||| f:00359 596 325 80 ||| info@intiel.com ||| www.intiel.com

9 Peter Beron Str, Pomorie 8000, Bulgaria

- 25 -

7. Warranty

The warranty period is 24 months following the purchase date of the unit or its

installation by a qualified staff, but not exceeding 28 months after the production date. The

warranty is extended to the malfunctions that occur during the warranty period and are result

of the production reasons or defective used parts.

The warranty does not relate to malfunctions corresponding to not-qualified

installation, activities directed to the product body interference, not regular storage or

transport.

The repairs during the warranty period can be done after correct filling of the

manufacturer warranty card

Loading...

Loading...