Intesity IDIC-024KF-3, IDIC-024KC-3, IDIC-048KC-3, IDIC-036KF-3, IDIC-060KF-3 Installation Instructions Manual

...

IDIC-024KF-3 - IDIC-024KC-3 / IDIC-036KF-3 - IDIC-036KC-3,

IDIC-048KF-3 - IDIC-048KC-3 / IDIC-060KF-3 - IDIC-060KC-3.

INSTALLATION INSTRUCIONS

intensity.mx

MAN-I-IDC-1214

SPLIT SYSTEM HEAT PUMP & AIR CONDITIONER

2, 3, 4 Y 5 TR.

FEATURING R-410A REFRIGERANT

18 SEER

TABLE OF CONTENTS

1.0 SAFETY..................................................................................................................3

1.1 INSPECTION.................

................................................................................

...4

1.2 LIMITATIONS..........................................................

..............................

............4

2.0 GENERAL..............................................................................................................4

3.0 UNIT INSTALLATION............................................................................................6

3.1 LOCATION.......................................................................................................6

3.2 GROUND INSTALLATION...............................................................................6

3.3 ROOF INSTALLATION.............................

........................................................

6

3.4 UNIT PLACEMENT..........................................................................................6

3.5 UNIT LOCATION CONSIDERATIONS............................................................7

3.6 UNIT MOUNTING............................................................................................8

3.7 FACTORY-PREFERRED TIE-DOWN METHOD.............................................9

3.8 PRECAUTIONS DURING LINE INSTALLATION.............................................9

3.9 PRECAUTIONS DURING BRAZING OF LINES...

..........................................11

3.10 PRECAUTIONS DURING BRAZING SERVICE VALVE...............................11

4.0 INTERCONNECTING TUBING............................................................................12

4.1 SUCTION AND LIQUID LINES .....................................................................12

4.2 MAXIMUM LENGTH OF LINES ....................................................................13

4.3 VERTICAL LIFT ............................................................................................13

5.0 EVACUATION......................................................................................................13

6.0 ELECTRICAL CONNECTIONS...........................................................................14

6.1 GENERAL INFORMATION & GROUNDING ............

...............................

......14

6.2 FIELD CONNECTIONS POWER WIRING ..............................

......................

14

6.3 REMOVING THE TOP PANEL AND MOTOR................................................15

7.0 CHECKING REFRIGERANT CHARGE .............................................................16

7.1 CHARGING BY LIQUID PRESSURE............................................................16

7.2 CHARGING BY WEIGHT ..............................................................................16

7.3 FINAL LEAK TESTING .................................................................................16

8.0 SYSTEM OPERATION........................................................................................18

8.1 COMPRESSOR CRANKCASE HEATER (CCH)...........................................19

8.2 REVERSING VALVE INTRODUCTION .......................................................20

8.3 PROTECTION FUNCTION INTRODUCTION...............................................20

8.4 SENSORS.....................................................................................................20

8.5 ERROR CODE TABLE..................................................................................24

8.6 PARAMETER POINT CHECK TABLE...........................................................25

9.0 WARRANTY.........................................................................................................26

9.1 MAINTENANCE.............................................................................................26

10.0 WIRING DIAGRAM............................................................................................26

10.1 CONTROL WIRING FOR UNITS.................................................................26

2

WARNING

These instructions are intended as an aid to qualified

licensed service personnel for proper installation, adjustment and operation of this unit. Read these instructions

thoroughly before attempting installation or operation.

Failure to follow these instructions may result in improper

installation, adjustment, service or maintenance possibly

resulting in fire, electrical shock, property damage,

personal injury or death.

RECOGNIZE THIS SYMBOL AS AN INDICATION OF IMPORTANT SAFETY INFORMATION

DO NOT DESTROY THIS MANUAL

Please read carefully and keep in a safe place for future reference by a serviceman.

1.0 SAFETY

This is a safety alert symbol. When you see this symbol on labels or in

manuals, be alert to the potential for personal injury.

Understand and pay particular attention to the signal words DANGER, WARNING, or

CAUTION.

DANGER indicates an imminently hazardous situation, which, if not avoided, will result

in death or serious injury.

WARNING indicates a potentially hazardous situation, which, if not avoided, could result

in death or serious injury.

CAUTION indicates a potentially hazardous situation, which, if not avoided may result

in minor or moderate injury. It is also used to alert against unsafe practices and hazards

involving only property damage.

This is an attention alert symbol. When you see this symbol on labels or in

manuals, be alert to the potential for personal injury.

This document is customer property and is to remain with this unit.

These instructions do not cover all the different variations of systems nor does

it provide for every possible contingency to be met in connection with installation.

All phases of this installation must comply with NATIONAL, STATE, AND LOCAL

CODES. If additional information is required please contact your local distributor.

3

WARNING

Improper installation may create a condition where the operation of the product

could cause personal injury or property damage.

Improper installation, adjustment, alteration, service or maintenance can cause

injury or property damage. Refer to this manual for assistance or for additional

information, consult a qualified contractor, installer or service agency.

CAUTION

This product must be installed in strict compliance with the installation instructions and any applicable local, state, and national codes including, but not

limited to building, electrical, and mechanical codes.

WARNING

FIRE OR ELECTRICAL HAZARD

Failure to follow the safety warnings exactly could result in serious injury, death

or property damage.

A fire or electrical hazard may result causing property damage, personal injury

or loss of life.

CAUTION

If using existing refrigerant lines make certain that all joints are brazed, not

soldered.

CAUTION

Scroll compressor dome temperatures may be hot. Do not touch the top of compressor; it may cause minor to severe burning.

The outdoor units are designed to be connected to a matching indoor coil with braze

connect lines. Units are factory charged with refrigerant for a matching indoor coil

plus 15 feet of field supplied lines.

Matching indoor coils are available with a thermostatic expansion valve or an orifice

for the most common usage. The orifice size and/or refrigerant charge may need to

be changed for some indoor-outdoor unit combinations, elevation differences or

total line lengths.

2.0 GENERAL

1.Limitations for the indoor unit, coil and appropriate accessories must also be observed.

2.The outdoor unit must not be installed with any duct work in the air stream. The outdoor fan is

the propeller type and is not designed to operate against any additional external static pressure.

3.The maximum and minimum conditions for operation must be observed to assure a system

that will give maximum performance with minimum service.

4.This unit is not designed to operate with a low ambient kit. Do not modify the control system to

operate with any kind of Iow ambient kit.

5.The maximum allowable line length for this product is 100 feet.

1.2 LIMITATIONS

The unit should be installed in accordance with all National, State, and Local Safety

Codes and the limitations listed below:

As soon as a unit is received, it should be inspected for possible damage during transit.

If damage is evident, the extent of the damage should be noted on the carrier's delivery

receipt. A separate request for inspection by the carrier's agent should be made in

writing. See Local distributor for more information.

1.1 INSPECTION

4

Requirements For Installing/Servicing R410A Equipment

Gauge sets, hoses, refrigerant containers, and recovery system must be designed

to handle the POE or PVE type oils.

Manifold sets should be 800 PSIG high side and 250 PSIG low side with 550 PSIG

Iow side restart.

All hoses must have a 700 PSIG service pressure rating.

Leak detectors should be designed to detect R410A.

Recovery equipment (including refrigerant recovery containers) must be specifi-

cally designed to handle R410A.

Do not use an R-22 TXV.

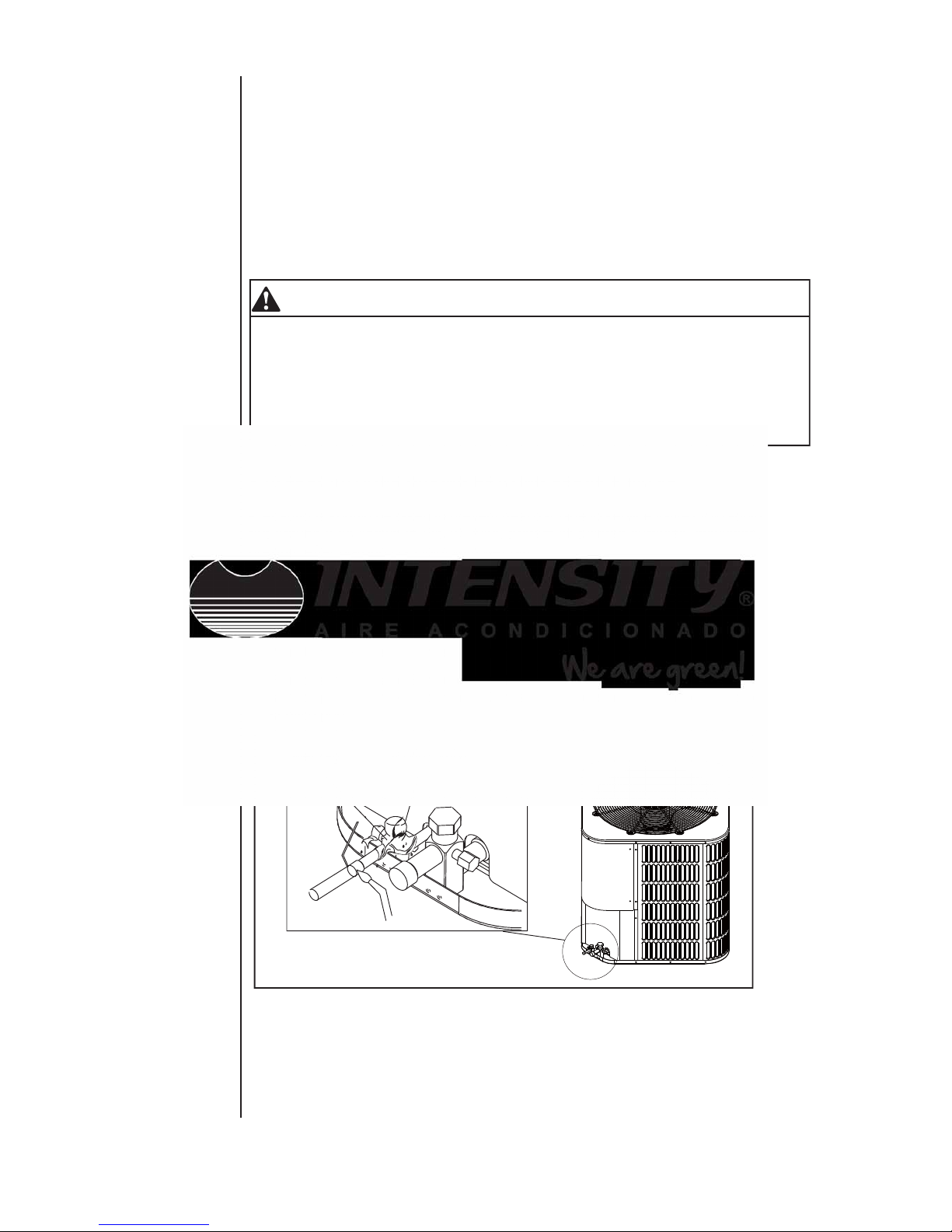

Good Refrigeration practices require the installation of a field supplied liquid line

drier, as shown in Fig.1.

Fig.1 Filter-Drier installation

LIQUID-LINE FILTER-DRIER

It will be more convenient to open

the Service valve after removing

the Underside Clapboard.

NOTE

LARGE SERVICE VALVE

SMALL SERVICE VALVE

FIELD SUPPLIED AND INSTALLED

5

DIMENSIONAL DATA

"H" in. [mm] "W" in. [mm]

"L" in. [mm]

Liquid in.

Suction in.

29-1/8[740] 29-1/8[740]

29-1/8[740] 29-1/8[740]

29-1/8[740] 29-1/8[740]

29-1/8[740] 29-1/8[740]

MODEL SIZE

Dimensions (Inches)

Refrigerant Connection

Service Valve Size

24-15/16[633]

3/8

3/8

3/8

3/8

3/4

3/4

7/8

7/8

24-15/16[633]

33-3/16[843]

33-3/16[843]

36

36

AC HP

24 24

48

48

60

60

FIG.2 DIMENSIONS

SUCTION LINE

CONNECTION

CONTROL WIRING

7/8” (22.2mm)

KNOCKOUT

1-11/32” (34.5mm)

LIQUID LINE

CONNECTION

SERVICE

FITTING

SERVICE

FITTING

POWER WIRING

SEE DETAIL A

DETAIL A

HOLE

1-3/32” (27.8mm)

NOTE: GRILL APPEARANCE

MAY VARY.

NOTES: 1 AC: Air Condition er ; HP: Heat Pump;

AIR DISCHARGE: ALLOW 60”

MINIMUM CLEARANCE.

SERVICE ACCESS

ALLOW 24” CLEARANCE

AIR INLETS

LOUVERED PANELS

ALLOW 18”

MINIMUM

CLEARANCE

W

3.0 UNIT INSTALLATION

3.1 LOCATION

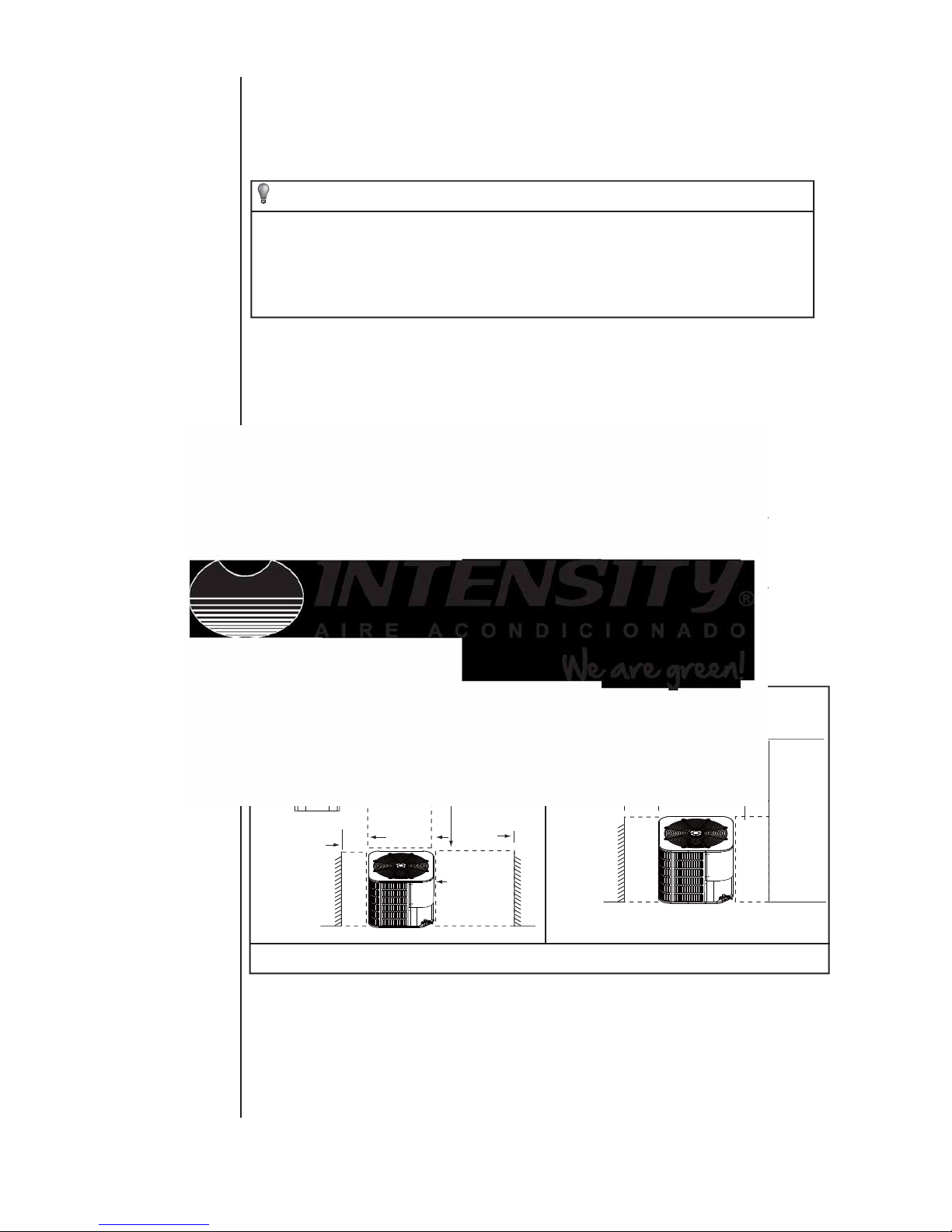

Before starting the installation, select and check the suitability of the location for both

the indoor and outdoor unit. Observe all limitations and clearance requirements. The

outdoor unit must have sufficient clearance for air entrance to the condenser coil, for air

discharge and for service access. See Fig.2

NOTE

For multiple unit installations, units must be spaced a minimum of 18 inches

apart. (Coil face to coil face.)

If the unit is to be installed on a hot sun exposed roof or a black-topped ground area, the

unit should be raised sufficiently above the roof or ground to avoid taking the accumulated layer of hot air into the outdoor unit.

Provide an adequate structural support.

WARNING

The outdoor unit should not be installed in an area where mud or ice could cause

personal injury or system damage.

Elevate the unit sufficiently to prevent any blockage of the air entrances by snow in

areas where there will be snow accumulation. Check the local weather bureau for the

expected snow accumulation in your area. Isolate the unit from rain gutters to avoid any

possible wash out of the foundation.

When installing units on a roof, the structure must be capable of supporting the total

weight of the unit, including a padded frame unit, rails, etc., which should be used to

minimize the transmission of sound or vibration into the conditioned space.

3.3 ROOF INSTALLATION

3.4 UNIT PLACEMENT

1. Provide a base in the pre-determined location.

2. Remove the shipping carton and inspect for possible damage.

3. Compressor tie-down nuts should remain tightened.

4. Position the unit on the base provided.

The unit may be installed at ground level on a solid base that will not shift or settle, causing strain on the refrigerant lines and possible leaks. Maintain the clearances shown in

Fig.2 and install the unit in a level position.

3.2 GROUND INSTALLATION

Normal operating sound levels may be objectionable if the unit is placed directly under

windows of certain rooms (bedrooms, study, etc.).

Top of unit discharge area must be unrestricted for at least 60 inches above the unit.

6

CAUTION

This system uses R410A refrigerant which operates at higher pressure than

R-22. No other refrigerant may be used in this system. Gauge sets, hoses,

refrigerant containers, and recovery system must be designed to handle

R410A. If you are unsure, consult the equipment manufacturer.

The outdoor unit must be connected to the indoor coil using field supplied refrigerant

grade copper tubing that is internally clean and dry. Units should be installed only with

the tubing sizes for approved system combinations. The refrigerant charge shown in

the nameplate is for standard size interconnecting liquid line lengths up to 15 feet.

7

NOTE

Using a larger than specified line size could result in oil return problems. Using a

too small line will result in loss of capacity and other problems caused by insufficient refrigerant flow. Slope horizontal suction lines at least 1" every 20 feet

toward the outdoor unit to facilitate proper oil return.

3.5 Unit Location Considerations

• Ensure the top discharge area is unrestricted for at least 5 feet above the unlt.

• Provide at least 3 feet clearance in front of the control box (access panels) and any other

side requiring service.

• Do not locate close to bedrooms as operational sounds may be objectionable.

• Avoid locations near windows and similar areas where condensation and freezing defrost

vapor can annoy a customer.

• Position the outdoor unit a minimum of 12" from any wall or surrounding shrubbery to

ensure adequate airflow.

• Outdoor unit location must be far enough away from any structure to prevent excess roof

runoff water or Icicles from ralling directly on the unit.

• Position the outdoor unit a minimum of 12" from any wall or surrounding shrubbery to

ensure adequate airflow.

• Outdoor unit location must be far enough away from any structure to prevent excess roof

runoff water or icides from ralling directly on the unit.

Avoid install

near bedrooms

Min 5 feet unrestricted

Min 3 feet

unrestricted

Min 12"

to wall

Min 20 inches

to shrubbery

Min 12" to

shrubbery

Access panel

1. suggested Locations for Best Reliability

Fig. 3 suggested Locations for Best Reliability

8

3.6 UNIT MOUNTING

2 . If elevating a unit on a flat roof , use 4”× 4”(or equivalent) stringers

positioned to distribute unit weight evenly and prevent noise and vibration (See Fig.3).

NOTE:Do not block drain openings shown in Fig.5.

3. If unit must be elevated because of anticipated snow fall, secure unit and

elevating stand such that unit and/or stand will not tip over or fall off.

If elevating the heat pump, either on a flat roof or on a slab, observe the following guidelines.

1. The base pan provided elevates the heat pump 2” above the base pad.

NOTE: To tie down unit, see 3.6.

BASE PAD

(CONCRETE OR

OTHER SUITABLE

MATERIAL)

Note: It is recommended that these precautions be taken for units being installed in areas

where snow accumulation and prolonged below-freezing temperatures occur.

• Units should be elevated 3-12 inches above the pad or rooftop, depending on local

weather. This additional height will allow drainage of snow and ice melted durIng defrost

cycle prior to its refreezlng. Ensure that drain holes in unit base pan are not obstructed,

preventing drainage of defrost water.

• If possible, avoid locations that are likely to accumulate snow drifts. if not possible, a snow

drift barrier should be installed around the unit to prevent a build-up of snow on the sides of

the unit.

Min 12"

Snow

barrier

3- 12" Elevation

Snow legs

pad

2. Cold Climate Considerations (Heat Pump Only)

Fig.4 Cold Climate Considerations (Heat Pump Only)

BASE PAN (BOTTOM

VIEW) DO NOT OBSTRUCT

DRAIN HOLES

(SHADED)

ELEVATION ABOVE

ANTICIPATED

SNOW IS NECESSARY

Fig.5 RECOMMENDED ELEVATED INSTALLATION

1. Install the lines with as few bends as possible. Care must be taken not to damage

the couplings or kink the tubing. Use clean hard drawn copper tubing where no

appreciable amount of bending around obstruction is necessary, if soft copper must

be used, care must be taken to avoid sharp bends which may cause a restriction.

2. The lines should be installed so that they will not obstruct service access to the coil,

air handling system or filter.

3.8 PRECAUTIONS DURING LINE INSTALLATION

9

3.7 FACTORY-PREFERRED TIE-DOWN METHOD

Step 3: Using field supplied L-shaped bracket to locate holes on concrete and drill pilot

holes which is at least 1/4” deeper than fastener being used.

IMPORTANT

Self drilling screws to base pan should not exceed 3/8” long to avoid damaging

coil.

Step 4: Using conventional practices to install brackets, tighten concrete fasteners and

self-tapping screws (See Fig.6).

NOTE

NOTE

: 1. One bracket for each side. For extra stability, 2 brackets for each side.

2. Do not over-tighten the concrete fastener to avoid weakening the concrete.

Step 1: Prior to installing clear pad of debris.

IMPORTANT

Then cement pad must meet local codes and must be the proper thickness to

accommodate fasteners.

Step 2: Center and level unit onto pad.

IMPORTANT NOTE:

These instructions are intended to provide a method to tie-down system to cement slab

as a securing procedure for high wind areas. It is recommended to check Local Codes

for tie-down methods and protocols.

REQUIRED PARTS LIST

SEE DETAIL B

#7 X 3/8” Self Tapping Screws

(Don’t Exceed 3/8” long)

1/4” 1-1/2” Hex Washer Head Concrete Screws

(3/16” Pilot Hole Needed. Pilot Hole Should Be1/4” Deeper

Than The Fastener Embedment)

Fig.6 PREFERRED TIE-DOWN METHOD

DETAIL B

Brackets:

2” width, 1/16” thickness,

height as required.

Available from distributor

or in market place.

The dimension see FIG.2

3. Care must also be taken to isolate the refrigerant lines to minimize noise transmis sion from the equipment to the structure.

4. The suction line must be insulated. Tape and suspend the refrigerant lines as shown.

DO NOT allow tube metal-to-metal contact. See Fig.7.

5. Use PVC piping as a conduit for all underground installations as shown in Fig.8.

Buried lines should be kept as short as possible to minimize the build up of liquid

refrigerant in the suction line during long periods of shutdown.

6. Pack a sealing material such as perma gum around refrigerant lines where they

penetrate a wall to reduce vibration and to retain some flexibility.

Insu la ted Liquid Line

Tape

Shee t Me tal Hanger

opt iona l

Sug gest ed

Incorrect

Fig.7 Tubing Hanger

Fig.8 Underground Installation

10

Insu la ted Suction Line

Fig.9

Typical Installation

TO

INDO OR

BLOW ER

TO

POWE R

SUPPLY

TO

COIL

WEATHERPR OOF

DISCONNECT

SWIT CH

Seal o pening(s) with

perm agum or equivalen t

24V co ntrol signal

NOTE :All outdoor wiri ng m ust be weather proo f

All outdoor unit and evaporator coil connections are copper-to-copper and should be

brazed with a phosphorous-copper alloy material such as Silfos-5 or equivalent. DO

NOT use soft solder. The outdoor units have reusable service valves on both the liquid

and suction connections. The total system refrigerant charge is retained within the

outdoor unit during shipping and installation. The reusable service valves are provided

to evacuate and charge per this instruction.

Serious service problems can be avoided by taking adequate precautions to assure an

internally clean and dry system.

3.9 PRECAUTIONS DURING BRAZING OF LINES

CAUTION

Dry nitrogen should always be supplied through the tubing while it is being

brazed, because the temperature required is high enough to cause oxidation

of the copper unless an inert atmosphere is provide. The flow of dry nitrogen

should continue until the joint has cooled. Always use a pressure regulator

and safety valve to insure that only low pressure dry nitrogen is introduced into

the tubing.Only a small flow is necessary to displace air and prevent oxidation.

Precautions should be taken to prevent heat damage to service valve by wrapping a wet

rag around it as shown in Fig.10. Also, protect all painted surfaces, insulation, during

brazing. After brazing cool joint with wet rag.

3.10 PRECAUTIONS DURING BRAZING SERVICE VALVE

The valve can be opened by removing the plunger cap and fully inserting a hex wrench

into the stem and backing out counter-clockwise until valve stem just touches the chamfered retaining wall.

11

1. Remove the cap and Schrader core from both the liquid and suction service valve

service ports at the outdoor unit. Connect Iow pressure nitrogen to the liquid line

service port.

Connect the refrigerant lines using the following procedure:

2. Braze the liquid line to the liquid valve at the outdoor unit. Be sure to wrap the valve

body with a wet rag. Allow the nitrogen to continue flowing. Refer to the Tabular Data

Sheet for proper liquid line sizing.

3. Carefully remove the rubber plugs from the evaporator liquid and suction connections

at the indoor coil.

Fig.10 Heat Protection

service valve

wet rag

4. Braze the liquid line to the evaporator liquid connection. Nitrogen should be flowing

through the evaporator coil.

5. Slide the plastic cap away from the suction connection at the indoor coil. Braze the

suction line to the evaporator suction connection. Refer to the Table 1 for proper

suction line sizing.

6. Protect the suction valve with a wet rag and braze the suction line connection to the

outdoor unit. The nitrogen flow should be exiting the system from the suction service

port connection. After this connection has cooled, remove the nitrogen source from

the liquid fitting service port.

7. Replace the Schrader core in the liquid and suction valves.

8. Leak test all refrigerant piping connections including the service port flare caps to be

sure they are leak tight. DO NOT OVER TIGHTEN (between 40 and 60 inch -lbs.

maximum).

9. Evacuate the suction line, evaporator, and the liquid line, to 350 microns or less.

Table 1: Recommended Liquid and Suction Tube Diameters (ln.)

MODEL

SIZE

LIQUID

SUCTION

Tube Diameter

Tube Diameter

24 3/8 3/4

36 3/8 3/4

48 3/8

60 3/8 7/8

12

7/8

10. Replace cap on service ports. Do not remove the flare caps from the service ports

except when necessary for servicing the system.

11. Release the refrigerant charge into the system. Open both the liquid and suction

valves by removing the plunger cap and with an hex wrench back out counter

-clockwise until valve stem just touches the chamfered retaining wall.

12. Replace plunger cap finger tight, then tighten an additional 1/12 turn (1/2 hex flat).

Cap must be replaced to prevent leaks.

WARNING

Never attempt to repair any brazed connections while the system is under pressure. Personal injury could result.

See "System Charge" section for checking and recording system charge.

4.0 INTERCONNECTING TUBING

4.1 SUCTION AND LIQUID LINES

Keep all lines sealed until connection is made.

Make connections at the indoor coil first.

Refer to Li ne Size Information in Ta bles 2 and 3 for correct size and multipliers to be

used to determine capacity for various suction line diameters and lengths of run. The

losses due to the lines being exposed to outdoor conditions are not included.

The factory refrigerant charge in the outdoor unit is sufficient for 15 feet of standard

size interconnecting liquid line. Calculate actual charge required with installed liquid

line size and length as below.

5/16” ± .4 oz. per foot

3/8” ± .6 oz . per foot

1/2” ± 1.2 oz . per foot

It will be necessary to evacuate the system to 350 microns or less. If a leak is

suspected, leak test with dry nitrogen to locate the leak. Repair the leak and test again.

To verify that the system has no leaks, simply close the valve to the vacuum pump

suction to isolate the pump and hold the system under vacuum. Watch the micron

gauge for a few minutes. If the micron gauge indicates a steady and continuous rise,

it's an indication of a leak. If the gauge shows a rise, then levels off after a few minutes

and remains fairly constant, its an indication that the system is leak free but still

contains moisture and may require further evacuation if the reading is above 350

microns.

5.0 EVACUATION

13

4.2 MAXIMUM LENGTH OF LINES

T h e maximum length of interconnecting line is 100 feet .

Always use the shortest length possible with a minimu m number of bends.

N

NOTE

: Excessively long refrigerant lines cause loss of equipment capacity.

4.3 VERTICAL LIFT

Keep the vertical lift to a minimum. Use the following guidelines when installing

the unit:

1. DO NOT exceed the vertical lift as indicated on Table 3.

2. It is recommended to use the smallest liquid line size permitted to minimize sys t

em charge which will maximize compressor reliability.

3. Table 3

may be used for sizing horizontal runs.

TABLE 2: SUCTION LINE LENGTH/SIZE VS CAPACITY MULTIPLIER(R410A)

2 Ton 3 Ton 4 Ton 5 Ton

3/4" O.D. 3/4" O.D. 7/8" O.D. 7/8" O.D.

5/8 Opt. 5/8 Opt. 3/4 Opt. 1 1/8 Opt.

3/4* Std. 3/4* Std. 7/8* Std. 7/8* Std.

Optional 1.00 1.00 1.00 1.00

Standard 1.00 1.00 1.00 0.99

Optional 0.97 0.97 0.98 0.99

Standard 0.98 0.99 0.98 0.98

Optional 0.94 0.94 0.95 0.98

Standard 0.95 0.97 0.97 0.94

Suction Line Connection Size

Model Size

Suction Line Run - Feet

NOTES:

* Standard size

Using suction line larger than shown in chart will result in poor oil return and is not recommended.

25'

50'

100'

Optional 0.90 0.90 0.92 0.97

Standard 0.92 0.96 0.96 0.90

150'

LINE SIZING

6.1 GENERAL INFORMATION & GROUNDING

Check the electrical supply to be sure that it meets the values specified on the unit

nameplate and wiring label.

Power wiring, control (Iow voltage) wiring, disconnect switches and over current

protection must be supplied by the installer. Wire size should be sized per requirements.

CAUTION

All field wiring must USE COPPER CONDUCTORS ONLY and be in accordance

with Local, National Fire, Safety & Electrical Codes. This unit must be grounded

with a separate ground wire in accordance with the above codes.

The complete connection diagram and schematic wiring label is located on the inside

surface of the unit service access panel and this instruction.

1. Install the proper size weatherproof disconnect switch outdoors and within sight of

the unit.

2. Remove the screws at the side of the corner panel. Slide corner panel down and

remove from unit. See Fig. 9.

3. Run power wiring from the disconnect switch to the unit.

4. Route wires from disconnect through power wiring opening provided and into the

unit control box.

5. Install the proper size time-delay fuses or circuit breaker, and make the power

supply connections.

6. Energize the crankcase heater if equipped to save time by preheating the compres sor oil while the remaining installation is completed.

6.2 FIELD CONNECTIONS POWER WIRING

6.0 ELECTRICAL CONNECTIONS

14

NOTE: When changing the motor, remove top cover first.

TABLE 3: LIQUID LINE SIZE (R410A)

25 50 75 100 125 150

1/4 23 N/A N/A N/A N/A N/A

5/16 25 36 29 23 16 9

3/8* 25 50 60 60 40 30

Rotary 3/8* 25 30 30 24

5/16 25 50 37 22 7 N/A

3/8* 25 50 60 60 40 30

3/8* 25 46 38 30 22 15

1/2 25 50 56 55 40 30

3/8* 25 50 56 44 32 20

1/2 25 50 60 60 40 30

Liquid Line Size

Outdoor unit above or below indoor coil

3/8"

3/8"

3 Ton

Total Equivalent Length - Feet

Model Size

Line Size

Connection And

Line Size

(Inch O.D.)

Maximum Vertical Separation - Feet

Line Size

Connection Size

(Inch O.D.)

Compressor

Type

Scroll

2 Ton 3/8"

NOTES:

* Standard line size

N/A Application not recommended.

Scroll

Scroll

Scroll

4 Ton

5 Ton

3/8"

N/A N/A

15

1/2” nut

5/16” nuts

Fig.12 COVER AND FAN

6.3 REMOVING THE TOP PANEL AND MOTOR

When motor requires changing follow the steps below:

Step 1: Go into electrical panel, disconnect motor power lines.

IMPORTANT NOTE

Disconnect main power to unit. Severe burns and electrical shock will occur if

you do not disconnect main power.

Step 2: Remove cover (be careful of motor wires)

Step 3: Be sure to place fan cover unit on the ground as indicated in Fig. 12

IMPROTANT NOTE

Do not place or lean fan blades on ground or against surface.

Step 4: Remove fan motor by removing 5/16” nuts from cover.

Step 5: Remove fan blade from motor by removing 1/2” nut and place fan on the ground.

Step 6: Reverse removal process to reinstall the fan and motor.

IMPROTANT NOTE

When connecting motor wires be sure to check motor direction.

Damage will occur to condenser unit

if you remove fan nuts prior to cover removal.

NOTE:

Fig.11 Typical Field Wiring

CORNER

PANEL

HIGH VOLTAGE WIRING

LOW VOLTAGE WIRING

16

7.2 CHARGING BY WEIGHT

7.3 FINAL LEAK TESTING

After the unit has been properly evacuated and charged, a halogen leak detector

should be used to detect leaks in the system. All piping within the condensing unit,

evaporator, and interconnec ting tubing should be checked for leaks. If a leak is

detected, the refrigerant should be recovered before repairing the leak. The Clean Air

Act prohibits releasing refrigerant into the atmosphere .

Charge for all systems should be checked against the Charging Chart inside the

access corner panel or Charging by weight.

IMPORTANT:Do not operate the compressor without charge in system. Additio n of

R - 410A will raise pressures (suction, liquid and discharge).

7.1 CHARGING BY LIQUID PRESSURE

7.0 CHECKING REFRIGERANT CHARGE

In order to properly charge the system, the following conditions must be met:

1) Outdoor temperature above 60°F.

2) Indoor temperature between 70°F to 100°F.

3) Installation must be complete with brazed joints and drier visually inspected.

4) The unit electrical installation must be checked and unit powered for one (I) hour if

crank case heater is used or five (5) minutes if no crankcase heater is used.

Follow these steps:

1. Run in Force cooling mode(click the FORCE button in cooling mode )at least 20

minutes.

2. Measure OUTDOOR AMBIENT TEMPERATURE within 6 inches of coil.

3. Measure SUCTION LINE PRESSURE AND TEMPERATURE.

4.According to the superheat of suction line, confirm that the TXV is working

properly(Usually the superheat is between 10 to 15). If not, it should be adjusted.

5. Find the TARGET LIQUID PRESSURE at the intersection between the SUCTION

LINE PRESSURE and the OUTDOOR AMBIENT TEMPERATURE, if falls between

rows or columns then estimate the TARGET LIQUID PRESSURE or SUCTION LINE

PRESSURE falls between rows or columns then estimate the TARGET LIQUID PRESSURE between the rows and columns.

5. Compare the measured LIQUID LINE PRESSURE to the TARGET LIQUID PRESSURE, add charge to raise the pressure or recover charge to lower it.

6. After running unit for 10 minutes if the SUCTION LINE PRESSURE changes, go

back to step 2 otherwise remove test equipment and cover the valves.

For a new installation,evacuation of interconnecting tubing and indoor coil is adequate;

otherwise,evacuate the entire system. The factory refrigerant charge in the outdoor

unit is sufficient for 15 feet of standard size interconnecting liquid line. Calculate

actual charge required with installed liquid line size and lengthplease see 4.1 of

instruction.

With an accurate scale (+/- 1 oz.) adjust charge difference between that shown on

the unit data plate and that calculated for the new system Installation. if the entire

system has been evacuated, add the total calculated charge.

17

charging: weigh-In Method

weigh-In Method can be used for the Initial installation, or anytime a system charge is being

replaced. weigh-In Method can also be used when power is not available to the equipment

site or operating conditions (indoor/Outdoor temperatures) are not In range to verify with

the subcooling charging method.

Note: The only mode aperoved for setting validating system charge Is using Charging

Mode-cooling. Charging Mode-cooling is a variable speed test mode found in the 950

comfort control Technician Menu. Outdoor Temperature must be between 55

O

F and

120OF with Indoor Temperature kept between 70OF and 80OF.

Table 17. Heat Pumps

D C A

Model

charge

adder for

Indoor Coil

charge

multiplier for

interconnecting

refrigerant tube

length

024 7 lb. 6 oz. 6 oz. 0.6 oz/f t

036 8 Ib. 3 oz. 8 oz. 0.6 oz/ft

037 9 lb. 8 oz. 12 oz. 0.6 oz/ft

048 9 lb. 13 oz. 13 oz. 0.6 oz/ft

049 10 lb. 12 oz. 15 oz. 0.6 oz/ft

060 11 lb. 14 oz. 1 lb., 2 oz. 0.6 oz/ft

Factory

Charge

B

Table 18. Air Conditioners

D C A

Model

charge

adder for

Indoor Coil

charge

multiplier for

interconnecting

refrigerant tube

length

024 7 lb. 6 oz. 6 oz. 0.6 oz/f t

036 7 Ib. 14 oz. 7 oz. 0.6 oz/ft

048 11 lb. 1 oz. 1 lb., 0 oz. 0.6 oz/ft

060 11 lb. 14 oz. 0.6 oz/ft

Factory

Charge

B

Table 19. New Installations — calculating charge using the weigh-In method

1. Measure in feet the distance between the

outdoor unit and the indoor unit and record on Line

1. Include the entire length of the line from the

servIce valve to the IDU.

2. Enter the charge multiplier from column D.

3. Muitply the total length of refrigerant tubing (Line

1) tImes the value on step 2. Record the result on

Line 3 of the worksheet.

4. Locate the outdoor equipment size in column A.

Record the value shown In column c of Table 16 for

Heat Pumps or Table 17 for Air conditioners.

5. Add the values from step 3 and step 4 and

record the resulting value. This Is the amount of

refrigerant to weigh-in prior to opening the service

valves.

New Installation weigh-In Method worksheet

1. Line Length (ft)

2. value from Column D x

3. Step1 x Step2 =

4. charge Adder (column C) +

5. Refrlgerant(Steps 3+4) =

Table 20. Sealed-System Repairs — calculating charge using the weigh-In method.

1. Meisure in feet the distance between the

outdoor unit and the indoor unit and record on

Line 1 Include the entire length of the line from the

service valve to the IDU.

2. Enter the charge multiplIer from cotumn D.

3. MultIply the total length of refhgerant tubing

(Line 1) times the value on Line 2. Record the

result on Line 3 of the worksheet.

4. Locate the outdoor equipment size in column A.

Record the value shown in column C of Table 16

for Heat Pumps or Table 17 for Air conditioners.

5. Record the value in column B to Line 5 of the

worksheet.

6. Add the values from step 3, step 4, and step 5

and record the resulting value on Line 6. ThIs is

the amount of refrigerant to weigh-in.

New Installation weigh-In Method worksheet

1. Line Length (ft)

2. value from ColumnD x

3. Step 1 x step 2 =

4. charge Adder (column C) +

5. Factory charge (column B) +

6. RefrIgerant (steps 3+4+5) =

1 lb., 0 oz.

18

8.0 SYSTEM OPERATION

1. Control logic description

2.Sensor description

This frequency conversion system adopts the exactly same control logic as that of

common fixed frequency unit. Start-up demand signal is sent by wired controller or

indoor unit and when outdoor unit receives the signal, it will start required mode according to demand. Start-up demand signal is the common 24V control signal.

Compressor operating frequency is controlled by outdoor unit completely.

To ensure stable and adequate power output, target control low pressure evaporating

temperature Te when cooling and target control high pressure condensing temperature

Tc when heating, control and adjust compressor PI according to control target demand.

Meanwhile, Te and Tc target demand has the function of self-study according to compressor operating frequency, start/stop times so that to adjust power output autonomously ensure to well satisfy power demand load.

It can choose the initial settings of Te and Tc according to dehumidification and high

capacity demands by manually adjusting the dial code as well so that to satisfy relative

demands.

A working T3 Sensor is required for:

Operating protection (high temp./low temp.)

Outdoor fan control(cooling)

Heat pump onlyDefrost Heat pump only

Ambient temp forecast Cooling only

A working T4 Sensor is required forHeat pump only:

Operating condition permission

Defrosting condition determination

Outdoor fan control(heating mode, Heat pump only)

A working T5 Sensor is required for:

Protection(high temp./low temp.)

Outside EEV control valve Heat pump only

A working Tf Sensor is required for:

Module temp. protection(high temp.)

A working Pressure Transducer Sensor is required for:

Operating frequency control

Outside EEV control valve Heat pump only

High pressure protection(heating mode, Heat pump only)

Low pressure protection(cooling mode)

2Defrost description

Outdoor defrost control needs to measure T4 ambient temp. sensor and T3 coil temp.

sensor. When difference value between the two sensors has satisfied some condition,

defrosting will begin. Meanwhile, Meanwhile when operating in the condition of a low

ambient temp.for a certain period or system high pressure side pressure is lower than a

certain value, the system will enter defrosting mode.

19

Refrigerant migration during the off cycle can result in a noisy start up. Add a crankcase

heater to minimize refrigeration migration, and to help eliminate any start up noise or

bearing “wash out”.

All heaters must be located on the lower half of the compressor shell. Its purpose is to

drive refrigerant from the compressor shell during long off cycles, thus preventing

damage to the compressor during start-up.

The crankcase heating start condition:

1.The crankcase heating start must meet two conditions:

A. Outdoor temperature 37.4° F.

B. Compressor stops working more than 3 hours.

2. Outdoor temperature 37.4° F and just connected to the power source.

The crankcase heating stop must meet condition:

Outdoor temperature 44.6° F or compressor start.

At initial start-up or after extended shutdown periods, make sure the heater is energized

for at least 12 hours before the compressor is started. (Disconnect switch on and wall

thermostat off.)

2Crankcase heating zone description

Dial code SW5

Defrosting quit

According to outdoor coil temp.T3 is up to 18and lasts for 1 min. Or defrosting time

is up to 8 min.

Defrosting control choice

Dial code SW5 can adjust and set the time that enters and quits defrosting

In general, adjust dial code to ON can enhance the ability of defrosting.

Manual defrosting:

The system must operate in heating mode.

Enter into this mode after 5 min when system starts(It is suggest that stably running for

30 min, then enter )

Press Force button and hold for at least 6s to enter into defrosting.

It is suggest that manual defrost time interval is 15min above.

Start if crankcase heating zone can satisfy one of the 3 conditions,

1. First time to power on

2. In process of defrosting

3Compressor stops running for 4h and the outdoor ambient temp. T4 once lower than

50.

Stop crankcase heating zone satisfy the following conditions

Air discharge temp. T5113

Defrosting enter

The following 3 situations were determined to enter into defrosting: Outdoor coil temp.

T31, and satisfy a certain correspondence of T4 ambient temp.

When operating time accumulates to a certain value. Because of ambient temp. T4

time settings are different, when T4<-5 , cumulative time is 4h, when T4-5 and T4

4 , the cumulative time is 2h to determine. When high pressure lasts low, the

situation that high pressure saturation temperature lower than 28 lasts for 20 min

determines to enter into defrosting.

Defrosting choice SW5-1 SW5-2 Remarks

ON

Oper ating time

shorten q0%

Def r os ti ng time is

becoming longer

OFF Normal Normal Default OFF

Remarks

En te r in t o t h e

situation

Quit situation

ON

OFF

1 2

8.1 COMPRESSOR CRANKCASE HEATER (CCH) (Heat pump only,optional)

20

8.3 PROTECTION FUNCTION INTRODUCTION (Heat pump only)

Sensor T3 (condenser pipe temperature) and T4 (outdoor ambient temperature)

When open-circuit, compressor, outdoor fan motor and reverse valve will be OFF.

T3149°F,compressor stop working ; T3140°F,compressor start working.

When T4 < 5 °F, compressor will stop.If the electrical heater kit is installed in the

indoor unit, the outdoor unit would provide a signal to drive up the heater.

When T4 > 10.4 °F, compressor will restart.

Discharge temperature protection (optional)

When discharge temp. > 275 °

F, the compressor will stop.

When discharge temp. < 194 °F, the compressor will restart.

High pressure protection (optional)

When high pressure > 638 PSIG, the compressor and outdoor fan motor will stop.

When high pressure < 464 PSIG, the compressor and outdoor fan motor will restart

(3 minutes delay necessary).

Low pressure protection

Low pressure < 21 PSIG, the compressor and outdoor fan motor will stop.

Low pressure > 44 PSIG, the compressor and outdoor fan motor will restart

(3 minutes delay necessary).

In stand-by status, the compressor will not start in low pressure protection.

Within 30 mins, if 4 protection cycles occurs.The system will be locked. It will

be restore after power cycle.

8.4 SENSORS

Start-up conditions of defrost mode:

When JUMP switch is set to “1”(See in Fig 11), the mode will start up in either of

the two following conditions:

1. Compressor operating, when T4 is > 28.4 °F and T3 is < 32 °F last for 40 minutes;

2. Compressor operating, when T4 is < 28.4 °F and T3 is < 32 °F last for 50 minutes.

When JUMP switch is set to “0”:

Compressor operating, when T3 is < 32 °F last for 30 minutes.

Shut-down conditions of defrost mode:

The mode will shut down in either of the two following conditions:

1. The defrosted time lasting for 10 minutes;

2. T3 is 77 °F.

8.2 REVERSING VALVE INTRODUCTION (Heat pump only)

Reversing valve energizes at the heating conditions, and cut off at the cooling condition.

When the compressor has been running more than 10 minutes in the heating mode,

holding down the FORCE button for at least 6 seconds, the systementers to the

defrost mode, and then exits the defrost mode normally by itself.

1. T3(condenser pipe temperature) and T4(outdoor ambient temperature, heat pump

only) see TABLE 4

2.T5(compressor discharge temperature) and Tf(IPM radiator fin temperature) see

TABLE 5.

3. Pressure sensor(cooling only) see TABLE 6, Pressure sensor(heat pump only) see

TABLE 7.

21

TABLE 4

TABLE 5

TEMP F TEMP C

RESISTANCE k VOLTS DC TEMP F TEMP C

RESISTANCE

k

VOLTS DC

-5 -20.6 600.134 4.93 140 60 13.643 3.14

0 -17.8 505.551 4.92 145 62.8 12.359 3.03

5 -15 427.463 4.91 150 65.6 11.214 2.91

10 -12.2 362.739 4.89 155 68.3 10.227 2.8

15 -9.4 308.891 4.87 160 71.1 9.308 2.68

20 -6.7 265.398 4.85 165 73.9 8.485 2.56

25 -3.9 227.481 4.83 170 76.7 7.746 2.45

30 -1.1 195.601 4.8 175 79.4 7.105 2.34

35 1.7 168.707 4.77 180 82.2 6.504 2.23

40 4.4 146.695 4.74 185 85 5.963 2.13

45 7.2 127.258 4.7 190 87.8 5.474 2.02

50 10 110.707 4.66 195 90.6 5.032 1.92

55 12.8 96.572 4.61 200 93.3 4.645 1.83

60 15.6 84.465 4.56 205 96.1 4.28 1.73

65 18.3 74.411 4.51 210 98.9 3.949 1.64

70 21.1 65.408 4.45 215 101.7 3.648 1.56

75 23.9 57.634 4.39 220 104.4 3.383 1.48

80 26.7 50.904 4.32 225 107.2 3.133 1.4

85 29.4 45.258 4.24 230 110 2.904 1.32

90 32.2 40.152 4.16 235 112.8 2.694 1.25

95 35 35.699 4.08 240 115.6 2.503 1.18

100 37.8 31.807 3.99 245 118.3 2.334 1.12

105 40.6 28.398 3.89 250 121.1 2.172 1.06

110 43.3 25.506 3.8 255 123.9 2.024 1

115 46.1 22.861 3.7 260 126.7 1.888 0.95

120 48.9 20.529 3.59 265 129.4 1.767 0.9

125 51.7 18.47 3.48 270 132.2 1.651 0.85

130 54.4 16.708 3.37 275 135 1.544 0.8

135 57.2 15.085 3.26 280 137.8 1.446 0.76

TEMP F TEMP C

RESISTANCE k VOLTS DC TEMP F TEMP C RESISTANCE k VOLTS DC

-5 -20.6 107.732 4.65 90 32.2 7.225 2.36

0 -17.8 93.535 4.6 95 35 6.401 2.21

5 -15 79.521 4.54 100 37.8 5.683 2.07

10 -12.2 67.795 4.47 105 40.6 5.057 1.93

15 -9.4 57.948 4.39 110 43.3 4.509 1.79

20 -6.7 49.652 4.3 115 46.1 4.028 1.67

25 -3.9 42.645 4.21 120 48.9 3.606 1.55

30 -1.1 36.710 4.1 125 51.7 3.233 1.43

40 4.4 27.386 3.86 130 54.4 2.902 1.32

45 7.2 23.732 3.73 135 57.2 2.610 1.22

50 10 20.610 3.59 140 60 2.350 1.13

55 12.8 17.939 3.45 145 62.8 2.119 1.04

60 15.6 15.648 3.3 150 65.6 1.914 0.96

65 18.3 13.681 3.15 155 68.3 1.731 0.88

70 21.1 11.987 2.99 160 71.1 1.574 0.82

75 23.9 10.527 2.83 165 73.9 1.416 0.75

80 26.7 9.265 2.67 170 76.7 1.276 0.68

85 29.4 8.172 2.52

22

TABLE 6

Te Pe

MPa

1 1.04 -22 0.27 47 2

2 1.07 -21 0.28 48 2.02

3 1.1 -20 0.3 49 2.05

4 1.11 -19.5 0.31 50 2.08

5 1.13 -19 0.31 51 2.11

6 1.14 -18.5 0.32 52 2.14

7 1.16 -18 0.33 53 2.16

8 1.17 -17.5 0.34 54 2.19

9 1.19 -17 0.35 55 2.22

10 1.21 -16.5 0.35 56 2.25

11 1.22 -16 0.36 57 2.28

12 1.24 -15.5 0.37 58 2.31

13 1.26 -15 0.38 59 2.34

14 1.27 -14.5 0.39 60 2.37

15 1.29 -14 0.4 61 2.4

16 1.31 -13.5 0.41 62 2.44

17 1.33 -13 0.41 63 2.47

18 1.35 -12.5 0.42 64 2.5

19 1.37 -12 0.43 65 2.53

20 1.38 -11.5 0.44 66 2.56

21 1.4 -11 0.45 67 2.6

22 1.42 -10.5 0.46 68 2.63

23 1.44 -10 0.47 69 2.67

24 1.46 -9.5 0.48 70 2.7

25 1.48 -9 0.49 71 2.74

26 1.5 -8.5 0.5 72 2.77

27 1.52 -8 0.51 73 2.81

28 1.54 -7.5 0.52 74 2.84

29 1.57 -7 0.53 75 2.88

30 1.59 -6.5 0.54 76 2.92

31 1.61 -6 0.55 77 2.95

32 1.63 -5.5 0.57 78 2.99

33 1.65 -5 0.58 79 3.03

34 1.68 -4.5 0.59 80 3.07

35 1.7 -4 0.6 81 3.1

36 1.72 -3.5 0.61 82 3.14

37 1.75 -3 0.62 83 3.18

38 1.77 -2.5 0.64 84 3.22

39 1.79 -2 0.65 85 3.26

40 1.82 -1.5 0.66 86 3.3

41 1.84 -1 0.67 87 3.35

42 1.87 -0.5 0.68 88 3.39

43 1.89 0 0.7 89 3.43

44 1.92 0.5 0.71 90 3.47

45 1.94 1 0.72 91 3.51

46 1.97 1.5 0.74 92 3.56

17 80.2376 74 8.4881 132 1.4937

18 76.6616 75 8.166 133 1.4551

19 73.2636 76 7.8945 134 1.4177

20 70.0337 77 7.6334 135 1.3813

21 66.9628 78 7.382 136 1.3461

22 64.0424 79 7.1401 137 1.3118

23 61.2643 80 6.9072 138 1.2786

24 58.6208 81 6.683 139 1.2463

25 56.1048 82 6.467 140 1.215

26 53.7095 83 6.259

For AC model: NSK-BD020I V=2*MPa+0.5

No. V No.

V

23

TABLE 7

Te/ Tc Pe/Pc Te/ Tc Pe/Pc Te/ Tc Pe/Pc

MPa

MPa

MPa

1 0.69 -30 0.17 56 1.37 2.5 0.76 111 2.54 30 1.78

2 0.7 -29 0.18 57 1.39 3 0.78 112 2.56 30.5 1.81

3 0.72 -28 0.19 58 1.4 3.5 0.79 113 2.59 31 1.83

4 0.73 -27 0.2 59 1.42 4 0.8 114 2.62 31.5 1.86

5 0.75 -26 0.22 60 1.43 4.5 0.82 115 2.65 32 1.88

6 0.76 -25 0.23 61 1.45 5 0.83 116 2.68 32.5 1.91

7 0.78 -24 0.24 62 1.47 5.5 0.85 117 2.71 33 1.93

8 0.79 -23 0.25 63 1.48 6 0.86 118 2.74 33.5 1.96

9 0.81 -22 0.27 64 1.5 6.5 0.88 119 2.77 34 1.98

10 0.82 -21 0.28 65 1.52 7 0.89 120 2.8 34.5 2.01

11 0.84 -20 0.3 66 1.53 7.5 0.91 121 2.83 35 2.04

12 0.85 -19.5 0.31 67 1.55 8 0.92 122 2.86 35.5 2.06

13 0.86 -19 0.31 68 1.57 8.5 0.94 123 2.89 36 2.09

14 0.87 -18.5 0.32 69 1.59 9 0.95 124 2.92 36.5 2.12

15 0.88 -18 0.33 70 1.61 9.5 0.97 125 2.95 37 2.15

16 0.89 -17.5 0.34 71 1.62 10 0.98 126 2.98 37.5 2.17

17 0.89 -17 0.35 72 1.64 10.5 1 127 3.02 38 2.2

18 0.9 -16.5 0.35 73 1.66 11 1.02 128 3.05 38.5 2.23

19 0.91 -16 0.36 74 1.68 11.5 1.03 129 3.08 39 2.26

20 0.92 -15.5 0.37 75 1.7 12 1.05 130 3.12 39.5 2.29

21 0.93 -15 0.38 76 1.72 12.5 1.07 131 3.15 40 2.32

22 0.94 -14.5 0.39 77 1.74 13 1.08 132 3.18 40.5 2.35

23 0.95 -14 0.4 78 1.76 13.5 1.1 133 3.22 41 2.38

24 0.96 -13.5 0.41 79 1.78 14 1.12 134 3.25 41.5 2.41

25 0.97 -13 0.41 80 1.8 14.5 1.14 135 3.29 42 2.44

26 0.98 -12.5 0.42 81 1.82 15 1.15 136 3.32 42.5 2.47

27 0.99 -12 0.43 82 1.84 15.5 1.17 137 3.36 43 2.5

28 1.01 -11.5 0.44 83 1.86 16 1.19 138 3.39 43.5 2.53

29 1.02 -11 0.45 84 1.88 16.5 1.21 139 3.43 44 2.56

30 1.03 -10.5 0.46 85 1.9 17 1.23 140 3.46 44.5 2.59

31 1.04 -10 0.47 86 1.92 17.5 1.24 141 3.5 45 2.62

32 1.05 -9.5 0.48 87 1.94 18 1.26 142 3.54 45.5 2.66

33 1.06 -9 0.49 88 1.97 18.5 1.28 143 3.57 46 2.69

34 1.07 -8.5 0.5 89 1.99 19 1.3 144 3.61 46.5 2.72

35 1.09 -8 0.51 90 2.01 19.5 1.32 145 3.65 47 2.76

36 1.1 -7.5 0.52 91 2.03 20 1.34 146 3.69 47.5 2.79

37 1.11 -7 0.53 92 2.06 20.5 1.36 147 3.73 48 2.82

38 1.12 -6.5 0.54 93 2.08 21 1.38 148 3.77 48.5 2.86

39 1.13 -6 0.55 94 2.1 21.5 1.4 149 3.8 49 2.89

40 1.15 -5.5 0.57 95 2.13 22 1.42 150 3.84 49.5 2.93

41 1.16 -5 0.58 96 2.15 22.5 1.44 151 3.88 50 2.96

42 1.17 -4.5 0.59 97 2.17 23 1.46 152 3.93 50.5 3

43 1.19 -4 0.6 98 2.2 23.5 1.49 153 3.97 51 3.03

44 1.2 -3.5 0.61 99 2.22 24 1.51 154 4.01 51.5 3.07

45 1.21 -3 0.62 100 2.25 24.5 1.53 155 4.05 52 3.1

46 1.23 -2.5 0.64 101 2.27 25 1.55 156 4.09 52.5 3.14

47 1.24 -2 0.65 102 2.3 25.5 1.57 157 4.13 53 3.18

48 1.25 -1.5 0.66 103 2.32 26 1.6 158 4.18 53.5 3.22

49 1.27 -1 0.67 104 2.35 26.5 1.62 159 4.22 54 3.25

50 1.28 -0.5 0.68 105 2.38 27 1.64 160 4.26 54.5 3.29

51 1.3 0 0.7 106 2.4 27.5 1.66 161 4.31 55 3.33

52 1.31 0.5 0.71 107 2.43 28 1.69 162 4.35 55.5 3.37

53 1.33 1 0.72 108 2.45 28.5 1.71 163 4.39 56 3.41

54 1.34 1.5 0.74 109 2.48 29 1.73 164 4.44 56.5 3.45

55 1.36 2 0.75 110 2.51 29.5 1.76 165 4.48 57 3.49

For HP model: NSK-BD035I V=(8/7)*MPa+0.5

No.

V

No.

V

No.

V

24

krameR noitinifed noitcetorp ro rorrE tnetnoc yalpsiD

E4 Temp. sensor error

E5 Voltage protection(overvoltage and undervoltage)

Self-recovery for the first v oltage protection, second voltage

protection needs to be powered on and then recover.

E6 DC motor error

niaga no nehw revoceR nim 01 ni snoitcetorp 6E 2 bE

E7 Air discharge sensor T5 loosely-inserted error

H0 Main control chip and comm. Chip comm. error

niaga no gnirewop nehw revoceR nim 021 ni snoitcetorp )3P( 3 3H

H4 3 (P6) protec tions in 60 min

Recover when powering on again

H5 5 (P2) protec tions in 100 min

Recover when powering on again

H6 3 (P4) protec tions in 100 min

Recover when powering on again

H8 Pressure sensor error

Hb Heating high pressure protection

HH PH standby in 200 min.

Recover when powering on again

P0 Module radiator tem p. Tf protection

P1 High pressure protection

P2 Low pressure protection

P3 f requency-conversion over-current protection

P4 Air discharge overtemperature protection

Cooling high pressure protection

(T3 pipe high temp.)

P6 Compressor instant over-cu

rrent protection

PH Compressor liquid –return protection

.sutats lamron ot revocer lliw ti ,nim 2 retfA noitcetorp noohpyt naf CD 8P

C3 T3 sensor loosely-inserted error

CE 5 P1 protections in 150min

Recover when powering on again

F1 High pressure protection switch error

F3 5 P5 protec tions in 180min

Recover when powering on again

F4 3 P0 protec tions in 120min

Recover when powering on again

5 Hb protections in 180min

Recover when powering on again

Frequency limited/status definition

D T5 high temp. protection frequency limit

P Compression ratio protection frequenc y limit

F Module temp. protection frequency lim

it

C Current protection frequency limit

U V oltage protection frequency limit

H Condensing pressure protection frequency limit

A Oil return

dF Defrost

T3 high temp. protection frequenc y limit L

F5

P5

8.5 Error code table

powering

twice

25

krameR elpmaxE tnetnoc kcehc tnioP .oN

TR+ledoM 3C yticapac tinu roodtuO 0

2 edom tinu roodtuO 1

0 standby,2

cooling

3heating

2 Outdoor unit set frequenc y

eulav lautcA eerged gninepo VXE 3

4 T3 tube temp.

5 T4 ambient temp.

6 T5 air discharge temp.

7 Reserved

8 Te low pressure temp.(air return saturation)

9 Tc high pressure temp.(Air dischage saturation)

10 Tf module temp.

Actual value

*10

Actual value

*10

13 Air discharge s uperheat

14 Reserved

15 Reserved

16 Frequency c onversion current

17 Voltage value

18 Air speed

19 Reserved

20 Reserved

21 Reserved

Spit oil quantity

Actual value

/10

23 The last time error code

24 Software version

25 Remark“--”

22

Pc high pressure (air discharge pressure) 12

Pe low pressure (air return pressure) 11

1Shift to display content of data code pipe when pressing point check key shortly(check key).

Display the next set of data when press the key once. The display content is accordance with the

sequence.

2There’re 3 digits for LED. The first digit is sequence(only display units digit, recycling display), the

second and third digits are values. For example, the 8th item is operating low pressure saturation

temperature. The 11th item is operating low pressure. For detailed meanings, please refer to the point

check table.3. After staying for 20s, it will recover to the normal status display

4For normal status display, the last 2 digits of nixie tube will display ambient temp when the unit is in

standby status(the first nixie tube has no display). When operating, last 2 digits of nixie tube will display

operating frequency.(If there’s system protection, the first digit of nixie tube will display status code,

details for code meaning, please refer to the error code table )

8.6 Parameter point check table

10.0 WIRING DIAGRAM

26

9.0 WARRANTY

9.1 MAINTENANCE

1. Dirt should not be allowed to accumulate on the indoor or outdoor coils or other parts

in the air circuit. Clean as often as necessary to keep the unit clean. Use a brush,

vacuum cleaner attachment, or other suitable means.

2.

The outdoor fan motor is permanently lubricated and does not require periodic oiling.

3. Refer to the furnace or air handler instructions for filter and blower motor maintenance.

4. The indoor coil and drain pan should be inspected and cleaned regularly to assure

proper drainage.

Assist owner with processing Warranty cards and/or online registration.

CAUTION

Thes e un its must be wired and insta ll ed in accordance with all N at ional and

Loca l Sa fety Codes.

CAUTION

It is unlawful to knowingly vent, release or discharge refrigerant into the open air

during repair, service, maintenance or the final disposal of this unit. When the

system is functioning properly and the owner has been fully instructed, secure the

owner’s approval.

10.1 CONTROL WIRING FOR UNITS

TH ERMOSTAT

C

C

R E

D

D

YE LLO

W

W

GREE

N

N

Y

Y

R

R

G

G

INDOOR UNIT

INDOOR UNIT

OUTDOOR UNIT

OUTDOOR UNIT

G

G

C

C

Y

Y

B

LACK

LACK

R

R

C

C

Fig.12 Control Wiring for A/C Systems.

B

LACK

LACK

27

Fig.1 4 Outdo or Unit W iring D ia gra m fo r Syste ms

(2 08/23 0V 1P 60H z) (24/ 36 K).

THERMOSTAT

C

RED

GREEN

INDOOR UNIT

OUTDOOR UNIT

Y

R

G

R Y

YELLOW

BLACK

BLACK

G

C

C

B

R

B

RED

BLUE

Fig.13 Control Wiring for H/P Systems.

W2

D

PURPLE

w1

WHITE

F T

5 T

F T

L - C F P

1 L

2 L

N O

4 T

C P H

V E E

Y W C

B

S P

1 V S

U

V

W

P

V

W

U

V

W

U

2 P

4 P

H C C

N W O R B

W O L L E Y

G / Y

H

L

M O C

: G N I N R A W

Y L T N E M N A M R E P E B T S U M T E N I B A C

M R O F N O C O T G N I R I W L L A D N A D E D N U O G

L A C O L D N A , C . L . C , C . E . C , C . E . N , C . E . I O T

T N E M E C A L P E R E L B A C I L P P A S A S E D O C

D N A E G U A G E M A S E H T E B T S U M E R I W

E R I W L A N I G I R O S A E P Y T N O I T A L U S N I

Y L N O S R O T C U D N O C R E P P O C E S U

D D I I S S P

P

4

4

4

4

1 - 5 W S

2 - 5 W S

F F O

N O

F F O

F F O

N O

S 0 6 : g n i t s o r f e d d n e e h t f o y a l e D e m i T

g n i t s o r f e d l a m r o N

g n i t s o r f e d e h t o t n i e c n a v d A

P M O C

P A C

E C N A T I C A P A C

H C C

E V L A V Y A W - 4

V E E

E V L A V E V I S N A P X E C I R T C E L E

C P H

H C T I W S E R U S S E R P H G I H

3 T

5 T

4 T

R O S N E S E R U T A R E P M E T R E S N E D N O C

R O S N E S E R U T A R E P M E T T N E I B M A R O O D T U O

G N I T A E H E S A C K N A R C

R O S N E S E R U T A R E P M E T E G R A H C S I D . P M O C

1 V S

L - C F P

E C N A T C U D N I C F P

S P

R O S N E S E R U S S E R P

L E D O M P H R O F Y L N O

L E D O M P H R O F Y L N O : 1 J

L E D O M P H R O F Y L N O W D N A B

L E D O M P H R O F Y L N O

W O L L E Y W O L L E Y

K C A L B

E U L B

E G N A R O

E G N A R O

E G N A R O

E G N A R O

N

N W O R B

R O S N E S . P M E T R O T A I D A R

R O S S E R P M O C

3

3

3

3

+

-

2 - 4 W S

3 - 4 W S

d e s u t o N

4 - 4 W S

F F O

N O

g n i t a e h / g n i l o o c y l l a m r o N

F F O

N O

g n i t a e h / g n i l o o c d e t a r e l e c c A

e l b a s i d t u p t u o y t i c a p a c e v i t p a d A

t u p t u o y t i c a p a c e v i t p a d A

1 - 4 W S

d e s u t o N

4 H

5 H

6 H

s e t u n i m 0 0 1 n i n o i t c e t o r p ) 4 P ( s e m i t 3

C H

t l u a f r o s n e s e r u t a r e p m e t l a t n e m n o r i v n E

b H

g n i t a e H n i n o i t c e t o r p e r u s s e r p h g i h

H H

s e t u n i m 0 8 1 n i s e m i t 3 g n i n n u r t e W

5 E

7 E

6 E

n o i t c e t o r p e g a t l o V

d e v r e s e R

t l u a f d e t a e s t o n s i r o s n e s s a g t s u a h x e e h T

4 E

E D O C

0 H

p i h c l o r t n o c n i a m n i t l u a f n o i t a c i n u m m o C

s e t u n i m 0 6 n i n o i t c e t o r p ) 6 P ( s e m i t 3

s e t u n i m 0 0 1 n i n o i t c e t o r p ) 2 P ( s e m i t 3

6 P

H P

E C

n o i t c e t o r p e r u s s e r p h g i H

3 C

t l u a f d e t a e s t o n s i r o s n e s 3 T e h T

4 F

s e t u n i m 0 8 1 n i n o i t c e t o r p . p m e t h g i h 3 T s e m i t 3

2 P

4 P

3 P

n o i t c e t o r P e r u s s e r p w o L

n o i t c e t o r p t n e r r u c r e v O

s e t u n i m 0 0 1 n i n o i t c e t o r p ) 1 P ( s e m i t 3

t l u a f d e t a e s t o n s i r o s n e s s a g t s u a h x e e h T

1 P

0 P

n o i t c e t o r P . p m o c e h t f o . p m e t t s u a h x e e h T

5 P

n o i t c e t o r p . p m e t e b u t e h T h g i H

n o i t c e t o r p e l u d o m M P I e h T

y b d n a t s g n i n n u r t e W

3 F

n o i t p i r c s e d t l u a F

8 H

t l u a f r o s n e s e r u s s e r P

9 H

s e t u n i m 0 6 n i n o i t c e t o r p ) 9 P ( s e m i t 3

d e v r e s e R

s e t u n i m 0 2 1 n i n o i t c e t o r p ) 0 P ( s e m i t 3

S 0 2 1 : g n i t s o r f e d d n e e h t f o y a l e D e m i T

N O

F F O

D E L N E E R G

t l u a f d r a o b l o r t n o c c i r t c e l E

y b d n a t S

9

9

8

8

4

4

t l u a f n o i t a c i n u m m o C

n o i t c e t o r p e l u d o m M P I e h T

n o i t c e t o r p e g a t l o v c d w o L

r o r r e e s a h p r o s s e r p m o C

t l u a f l o r t n o c M P I e h T

H A S L F D E L D E R

0

0

n o i t a r e p o r o s s e r p m o C

O O N

N

O O F F F

F

8 4 7 0 9 5 5 7 0 2 0 2

1 J

F F O

N O

F F O

N O

y l n o g n i l o o C

2 J

m e t s y s P H

n o t 3

n o t 5 . 2

S G N I T T E S Y R O T C A F

3 T

28

Fig.1 5 Outdo or Unit W iring D ia gra m fo r Syste ms

(2 08/23 0V 1P 60H z) (48/ 60 K).

TF

T5

TF

L1

L2

T4

HPC

EEV

PS

CCH

WARNING: CABINET MU ST BE PERMANMENTLY

GOUNDED AND ALL WI RING TO CONFORM TO

I.E.C,N.E.C, C.E.C,C.L.C,AND LOCAL C ODES AS APPLIC ABLE

REPLACEMENT WIRE MUST BE THE SAME GAUGE AND

INSULATION TYP E AS ORIGINAL WIRE

USE C OPPE R CON DUCTORS ONLY

COMP

CAP

CAPAC ITAN CE

CC H

4-WAY VALVE

EEV

ELECTRIC EXPANSI VE VALVE

HP C

HIGH PRES SURE SWITCH

T3

T5

T4

CONDENSER TEMPERATURE SENSOR

CRANKCASE HEATING

COMP. DISCHARGE TEMPERATURE SENSO R

SV1

PFC-L

PFC INDUCTANCE

PS

PRES SUR E SEN SOR

RADIAT OR TEMP. SENSO R

COM PR ESSOR

+

-

+

-

DB 1

H4

H5

H6

3 tim es (P4 ) prote ction in 10 0 minutes

F1

Temperature sensor fault(T3 T4 T5 TF)

Hb

High pressure protection in Heating

HH

Wet ru nni ng 2 times in 200 minu tes

E5

Eb

E6

Voltage protection

DC fan motor fault

The exhaust gas sensor(T5) is not seated fault

E4

CODE

H0

Communication fault in main control chip

3 t i m e s (P6) pr otection in 60 minutes

5 t i m e s (P2) pr ote ctio n in 100 min ute s

P6

PH

P8

Typhoon pro tec tion of t he fan moto r

CE

High pressure protection

C3

The T3 sensor is not seated fault

F5

P2

P4

P3

Low pressure Pro tection

5 times (P1) protection in 150 minutes

P1

P0

The exhaust temp. Of the comp. Protection

(T5)

P5

H i gh The tub e temp. (T3) pr otection

Th e IPM modu le p rotectio n

Wet running standby

F3

Fault descrip tion

H8

Pre ssure s ensor(PS) faul t

2 times (E6) protection in 10 minutes

Hig h p

ressure swi tch (HPC) fault

5 ti mes (Hb) protectio n in 180 min utes

Com pr es so r ov e r current protection

5 t im es ( P5 ) pro tection in 180 mi nute s

F4

3 tim es (P 0) protectio n in 120 minutes

The module radiator temperature (TF)protection

ON

SW5-1

SW5-2

OFF

ON

OFF

OFF

ON

Time D elay of the end defrosting:60S

Normal defrosting

A dva nce into t he d efrosting

SW4-2

SW4-3

Not used

SW4-4

OFF

ON

Normally cooling/heating

OFF

ON

A cce lerated cooling/heating

Adaptive cap acit y output di sabl e

A daptive cap acity out pu t en abl e

SW4-1

Not used

Time D elay of the end defrosting:120S

ON

OFF

GREEN LED

Electric control board fault

St an dby

The IPM mo dul e protectio n

Low dc vol ta ge p rotection

Compressor phase error

The IPM control fault

RED LED FLSAH

Compressor operation

Co mmuni cation f au lt

T3

AM B IE NT TEMPERA TU R E S ENSO R( FOR HP SYS TEM)

10 K RESISTANCE ( FOR COOLING ONLY SYSTEM)

COMP

202075890714

E7

29

Function description for the corresponding position

6

5

7

8

9

10

11

12

13

17

19

20

21

22

23

1

2

3

14

4

15

16

18

24

tnetnoC .oN tnetnoC .oN

trop gnitcennoc rellortnoc .pmeT 31 lanimret gniriw rosserpmoC 1

2 Reactor wiring terminal(connect a reactor between 2 and 3 ) 14 Function dial code SW4

3 Reactor wiring terminal(connect a reactor between 2 and 3 ) 15 Spot check button

nottub noitarepo decroF 61 5WSedoc laid noitcnuf gnitsorfeD 4

devreseR 71 trop rosnes erusserP 5

yalpsid ebut eixiN 81 trop rosnes.pmet egrahcsid riA 6

trop lortnoc naF 91 )ylno PH(trop rosnes.pmet roodtuO 7

lanimret lortnoc enoz gnitaeh esacknarC 02 trop rosnes.pmet resnednoC 8

eriw trohS 12 trop rosnes.pmet rotaidaR 9

lanimret gnitcennoc ylppus rewoP 22 trop hctiws erusserp hgiH 01

lanimret gnitcennoc ylppus rewoP 32 )ylno PH(trop evird VXE 11

pmal rotacidnI 42 trop evlav yaw-4 21

30

REFRIGERANT CHARGE FOR AC SYSTEM

55 60 65 70 75 80 85 90 95 100 105 110 115

177

173

169

165

161

157

153

149

145

141

137

133

129

125

121

117

113

109

Suct ion Pressure at

Large Serv ice Valve(psig)

Cooling Mode

18 SEER R410A AC Charge Chart 2 TON

Outdoor Ambient Temperature(°F)

Lipuid Pr essure at Small Service Valve(psig)

55 60 65 70 75 80 85 90 95 100 105 110 115

177

173

169

165

161

157

153

149

145

141

137

133

129

125

121

117

113

109

Suct ion Pressure at

Large Serv ice Valve(psig)

Cooling Mode

18 SEER R410A AC Charge Chart 3 TON

Outdoor Ambient Temperature(°F)

Lipuid Pr essure at Small Service Valve(psig)

55 60 65 70 75 80 85 90 95 100 105 110 115

177

173

169

165

161

157

153

149

145

141

137

133

129

125

121

117

113

109

Suct ion Pressure at

Large Serv ice Valve(psig)

Cooling Mode

18 SEER R410A AC Charge Chart 5 TON

Outdoor Ambient Temperature(°F)

Lipuid Pr essure at Small Service Valve(psig)

55 60 65 70 75 80 85 90 95 100 105 110 115

177

173

169

165

161

157

153

149

145

141

137

133

129

125

121

117

113

109

Suct ion Pressure at

Large Serv ice Valve(psig)

Cooling Mode

18 SEER R410A AC Charge Chart 4 TON

Outdoor Ambient Temperature(°F)

Lipuid Pr essure at Small Service Valve(psig)

307 330 353 376 403 430 457 484

286 306 329 352 375 402 429 456 483

266 285 305 328 351 374 401 428 455 482

245 265 284 304 327 350 372 400 427 454 481

224 244 264 283 303 326 349 371 399 426 453 480

203 223 243 263 282 302 325 347 370 398 425 452 479

202 222 242 262 281 301 324 346 369 396 423 450 478

201 221 241 261 280 300 323 345 368 395 422 449 477

200 220 240 260 279 299 322 344 367 394 421 448 476

199 219 239 259 278 298 321 343 366 393 420 447 475

198 218 238 258 277 297 320 342 365 392 419 446 473

197 217 237 257 276 296 319 341 364 391 418 445 472

196 216 236 256 275 295 318 340 363 390 417 444 471

195 215 235 255 274 294 316 339 361 389 416 443 470

194 214 234 254 273 293 315 338 360 388 415 442 469

193 213 233 253 272 292 314 337 359 387 414 441 468

192 212 232 252 271 291 313 336 358 385 412 439 467

191 211 231 251 270 290 312 335 357 384 411 438 466

312 334 357 379 404 430 456 482

291 311 333 355 378 403 429 455 481

271 290 310 332 354 376 402 428 454 480

250 269 289 309 331 353 375 401 427 453 478

229 249 268 288 307 329 352 374 399 425 451 477

209 228 247 267 286 306 328 350 373 398 424 450 476

206 226 246 266 285 305 327 349 371 397 423 449 474

207 226 245 264 284 304 326 348 370 396 422 448 473

205 224 244 263 283 302 324 347 369 394 420 446 472

204 223 242 262 281 301 323 345 367 393 419 445 471

201 221 241 261 280 300 322 344 366 392 418 444 469

202 221 240 259 279 298 321 343 365 390 416 442 468

200 219 239 258 278 297 319 341 364 389 415 441 467

199 218 237 257 276 296 318 340 362 388 414 440 465

196 216 236 256 275 295 317 339 361 386 412 438 464

195 215 235 254 274 293 315 337 360 385 411 437 463

195 214 233 253 272 292 314 336 358 384 410 436 461

192 212 232 252 271 291 313 335 357 383 409 435 460

304 327 349 372 398 424 450 475

284 303 326 348 371 396 422 448 474

264 283 302 325 347 370 395 421 447 473

243 263 282 301 323 346 368 394 420 446 472

223 242 261 281 300 322 345 367 393 419 445 471

203 222 241 260 280 299 321 344 366 392 418 444 470

202 221 240 259 279 298 320 343 365 391 417 443 469

201 220 239 258 278 297 319 342 364 390 416 442 468

198 218 238 257 277 296 318 341 363 389 415 441 467

197 217 237 256 276 295 317 340 362 388 414 440 466

197 216 235 255 274 294 316 338 361 387 413 439 464

196 215 234 254 273 293 315 337 360 385 411 437 463

193 213 233 253 272 292 314 336 359 384 410 436 462

192 212 232 252 271 291 313 335 357 383 409 435 461

191 211 231 251 270 290 312 334 356 382 408 434 460

190 210 230 250 269 289 311 333 355 381 407 433 459

189 209 229 249 268 288 310 332 354 380 406 432 458

188 208 228 247 267 287 309 331 353 379 405 431 457

303 325 347 369 394 418 443 468

284 302 324 346 368 393 418 442 467

264 283 301 323 345 368 392 417 441 466

244 263 282 300 322 345 367 391 416 440 465

224 243 262 281 300 322 344 366 390 415 440 464

204 223 242 261 280 299 321 343 365 389 414 439 463

203 222 241 260 279 298 320 342 364 388 413 438 462

200 220 240 259 278 297 319 341 363 388 412 437 461

199 219 239 258 277 296 318 340 362 387 411 436 460

199 218 238 257 276 295 317 339 361 386 410 435 460

198 217 236 256 275 294 316 338 360 385 409 434 459

197 216 235 255 274 293 315 337 359 384 409 433 458

194 214 234 254 273 292 314 336 359 383 408 432 457

193 213 233 253 272 291 313 336 358 382 407 431 456

192 212 232 252 271 291 313 335 357 381 406 431 455

193 212 231 250 270 290 312 334 356 380 405 430 454

192 211 230 249 269 289 311 333 355 379 404 429 453

189 209 229 248 268 288 310 332 354 379 403 428 452

31

REFRIGERANT CHARGE FOR HP SYSTEM

55 60 65 70 75 80 85 90 95 100 105 110 115

177

173

169

165

161

157

153

149

145

141

137

133

129

125

121

117

113

109

Coo lin g Mo de

18 SEER R410A HP Charge Chart 2 TON (cooling mode)

Outdoor Ambient Temperature(°F)

Lipuid Pr essure at Small Service Valve(psig)

Suct ion Pressure at

Large Serv ice Valve(psig)

55 60 65 70 75 80 85 90 95 100 105 110 115

177

173

169

165

161

157

153

149

145

141

137

133

129

125

121

117

113

109

Coo lin g Mo de

18 SEER R410A HP Charge Chart 3 TON (cooling mode)

Outdoor Ambient Temperature(°F)

Lipuid Pr essure at Small Service Valve(psig)

Suct ion Pressure at

Large Serv ice Valve(psig)

55 60 65 70 75 80 85 90 95 100 105 110 115

177 322 346 371 395 424 452 480 508

173 301 320 344 369 393 422 450 478 506

169 279 299 318 342 367 391 420 448 476 504

165 258 277 297 316 340 365 389 418 446 474 502

161 237 256 275 295 314 338 363 387 416 444 472 500

157 216 235 254 273 293 312 336 361 385 414 442 470 498

153 214 233 252 271 291 310 334 359 383 412 440 468 496

149 212 231 250 269 289 308 332 357 381 410 438 466 494

145 210 229 248 267 287 306 330 355 379 408 436 464 492

141 208 227 246 265 285 304 328 353 377 406 434 462 490

137 206 225 244 263 283 302 326 351 375 404 432 460 488

133 204 223 242 261 281 300 324 349 373 402 430 458 486

129 202 221 240 259 279 298 322 347 371 400 428 456 484

125 200 219 238 257 277 296 320 345 369 398 426 454 482

121 198 217 236 255 275 294 318 343 367 396 424 452 480

117 196 215 234 253 273 292 316 341 365 394 422 450 478