Page 1

IntesisBox

®

KNX

Hitachi VRF Air Conditioning

User Manual

Issu Date: 01/2019

r1.1 EN

Page 2

IntesisBox® KNX – HITACHI VRF User Manual r1.1 EN

2/30

This information is subject to change without prior notice

IntesisBox is a registered trademark of Intesis Software S.L.U.

email: info@intesisbox.com

web: www.intesisbox.com

phone: +34 938047134

© Intesis Software S.L.U. 2019 All Rights Reserved.

Information in this document is subject to change without notice. The software described in this document is furnished

under a license agreement or nondisclosure agreement. The software may be used only in accordance with the terms

of those agreements. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any

form or any means electronic or mechanical, including photocopying and recording for any purpose other than the

purchaser’s personal use without the written permission of Intesis Software S.L.U.

Intesis Software S.L.U.

Milà i Fontanals, 1 bis

08700 Igualada

Spain

TRADEMARKS

All trademarks and tradenames used in this document are acknowledged to be the copyright of their respective holders.

Page 3

IntesisBox® KNX – HITACHI VRF User Manual r1.1 EN

3/30

This information is subject to change without prior notice

IntesisBox is a registered trademark of Intesis Software S.L.U.

email: info@intesisbox.com

web: www.intesisbox.com

phone: +34 938047134

Gateway for the integration of Hitachi VRF systems into KNX home

automation systems.

Order code:

IBKNXHIS016O000, 16 indoor units

IBKNXHIS064O000, 64 indoor units

Page 4

IntesisBox® KNX – HITACHI VRF User Manual r1.1 EN

4/30

This information is subject to change without prior notice

IntesisBox is a registered trademark of Intesis Software S.L.U.

email: info@intesisbox.com

web: www.intesisbox.com

phone: +34 938047134

INDEX

1 Description ............................................................................................................................................................ 5

Introduction .................................................................................................................................................... 5

1.1 Functionality...................................................................................................................................................... 6

Capacity of IntesisBox ................................................................................................................................... 7

2 KNX System .......................................................................................................................................................... 8

Description..................................................................................................................................................... 8

Points definition ............................................................................................................................................. 8

3 Connections .......................................................................................................................................................... 9

Power device ............................................................................................................................................... 10

Connect to Hitachi installation ..................................................................................................................... 10

Connection to KNX ...................................................................................................................................... 10

Connection to the configuration tool ............................................................................................................ 10

4 Set-up process and troubleshooting ................................................................................................................... 11

Pre-requisites .............................................................................................................................................. 11

IntesisBox MAPS. Configuration & monitoring tool for IntesisBox KNX series ........................................... 11

4.2.1 Introduction .......................................................................................................................................... 11

4.2.2 Connection ........................................................................................................................................... 11

4.2.3 Configuration tab ................................................................................................................................. 12

4.2.4 KNX configuration ................................................................................................................................ 12

4.2.5 Hitachi configuration ............................................................................................................................ 15

4.2.6 Signals ................................................................................................................................................. 17

4.2.7 Sending the configuration to IntesisBox .............................................................................................. 18

4.2.8 Diagnostic ............................................................................................................................................ 18

4.2.9 Set-up procedure ................................................................................................................................. 20

5 Electrical & Mechanical Features ........................................................................................................................ 21

6 Dimensions ......................................................................................................................................................... 22

7 AC Unit Types compatibility ................................................................................................................................ 23

8 Error codes for Indoor and Outdoor Units ........................................................................................................... 24

9 Appendix A – Communication Objects Table ..................................................................................................... 27

Page 5

IntesisBox® KNX – HITACHI VRF User Manual r1.1 EN

5/30

This information is subject to change without prior notice

IntesisBox is a registered trademark of Intesis Software S.L.U.

email: info@intesisbox.com

web: www.intesisbox.com

phone: +34 938047134

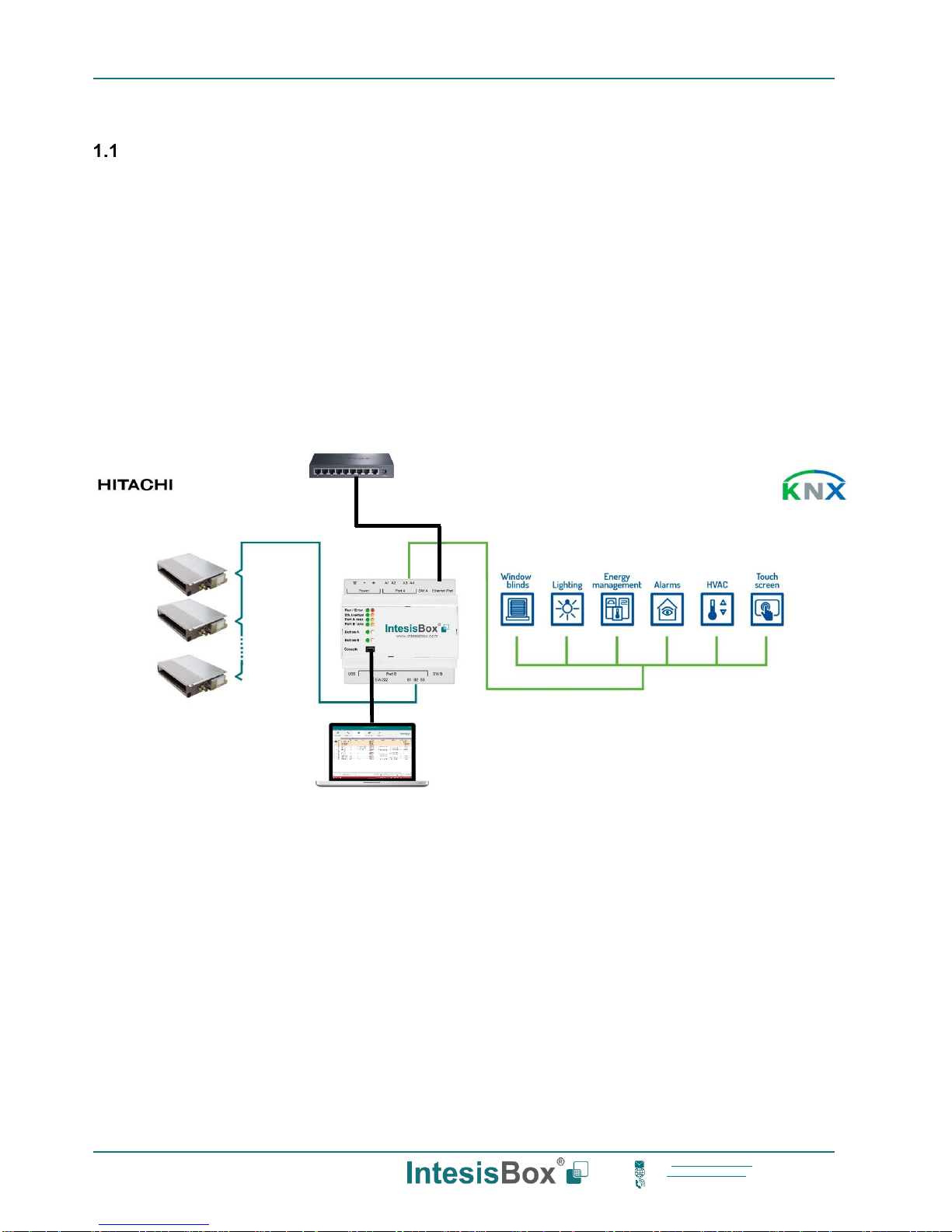

1 Description

Introduction

This document describes the integration of Hitachi VRF air conditioning systems into KNX home automation systems

using gateway IntesisBox KNX – Hitachi VRF.

The aim of this integration is to monitor and control your Hitachi air conditioning system, from your KNX TP-1 installation.

To do it so, IntesisBox performs as a one more KNX device, sending and receiving telegrams to group addresses in the

KNX network.

IntesisBox makes available the Hitachi air conditioning system indoor units’ datapoints through independent KNX

objects.

Up to 64 indoor units supported, depending on product version.

This document assumes that the user is familiar with KNX and Hitachi technologies and their technical terms.

Integration of Hitachi VRF systems into

KNX control systems

USB

configuration

Ethernet TCP

Ethernet

configuration

Page 6

IntesisBox® KNX – HITACHI VRF User Manual r1.1 EN

6/30

This information is subject to change without prior notice

IntesisBox is a registered trademark of Intesis Software S.L.U.

email: info@intesisbox.com

web: www.intesisbox.com

phone: +34 938047134

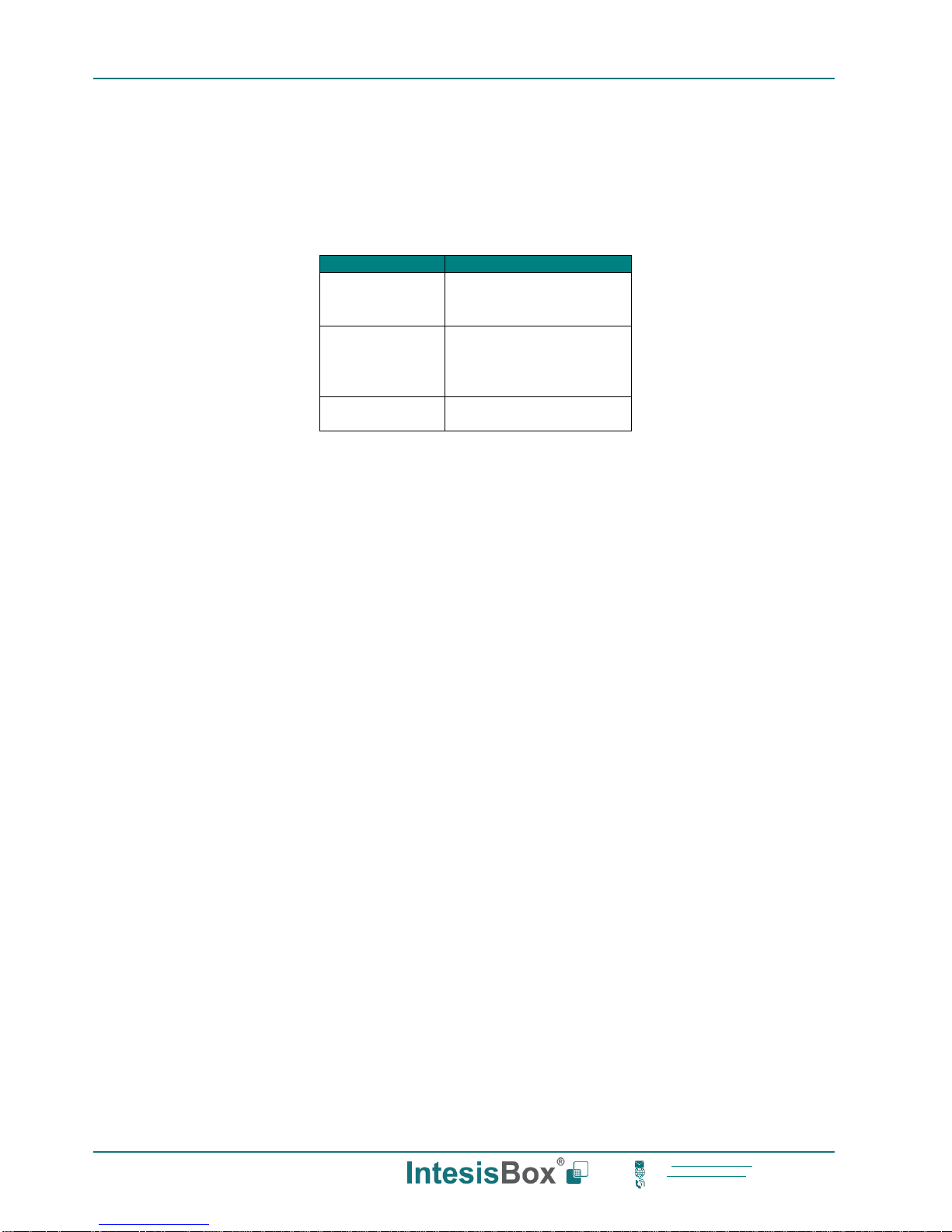

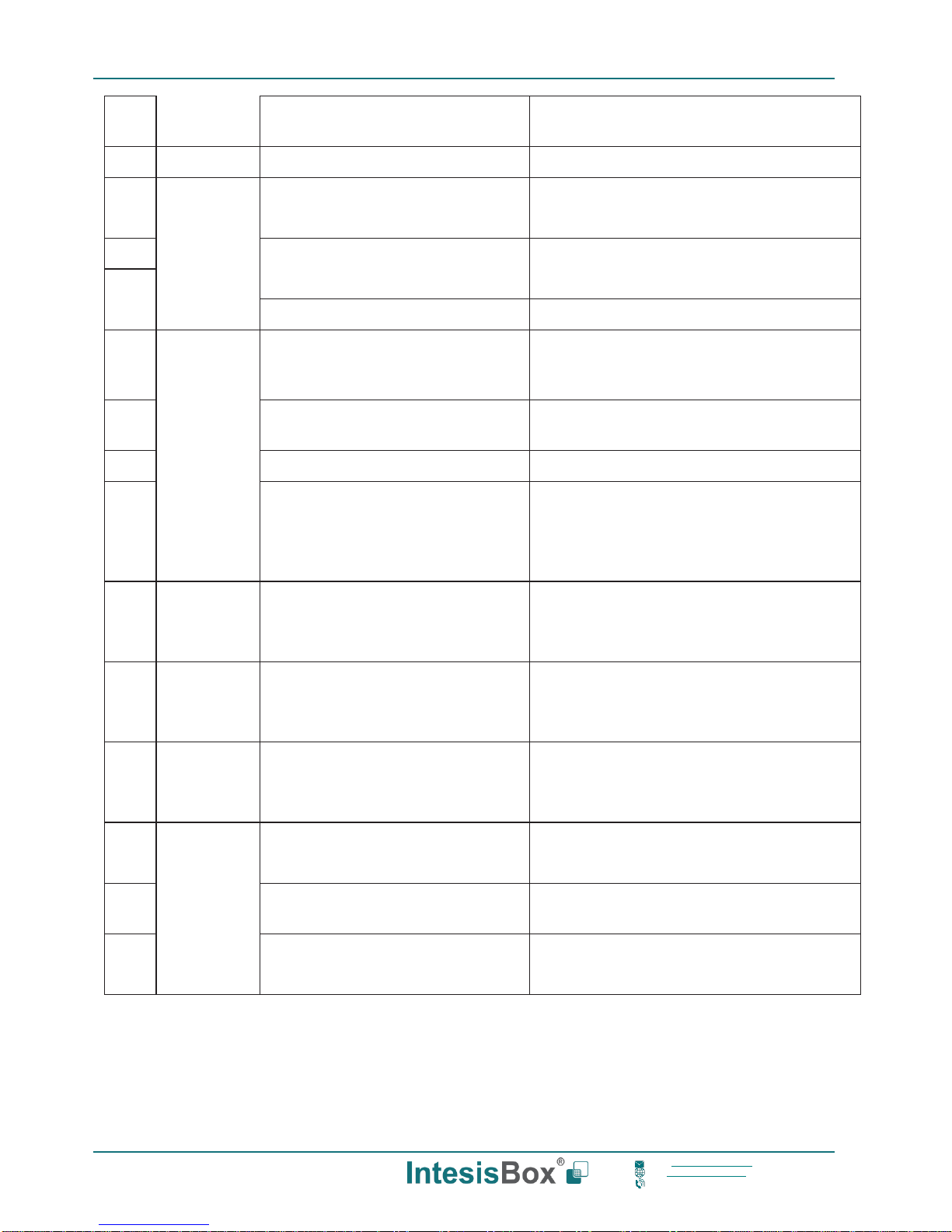

1.1 Functionality

IntesisBox® continuously monitors Hitachi VRF network for all configured signals and keeps the updated status of all of

them in its memory. It triggers updates on configured group addresses to KNX network on value change.

Commands toward the indoor unit communication adaptor are permitted.

Each indoor unit is offered as a set of KNX objects.

Element

Object supported

Outdoor Unit

• Communication

status

• Status

Indoor Unit

• Status

• Command

• Communication

status

General signals

(all units)

• Command

Page 7

IntesisBox® KNX – HITACHI VRF User Manual r1.1 EN

7/30

This information is subject to change without prior notice

IntesisBox is a registered trademark of Intesis Software S.L.U.

email: info@intesisbox.com

web: www.intesisbox.com

phone: +34 938047134

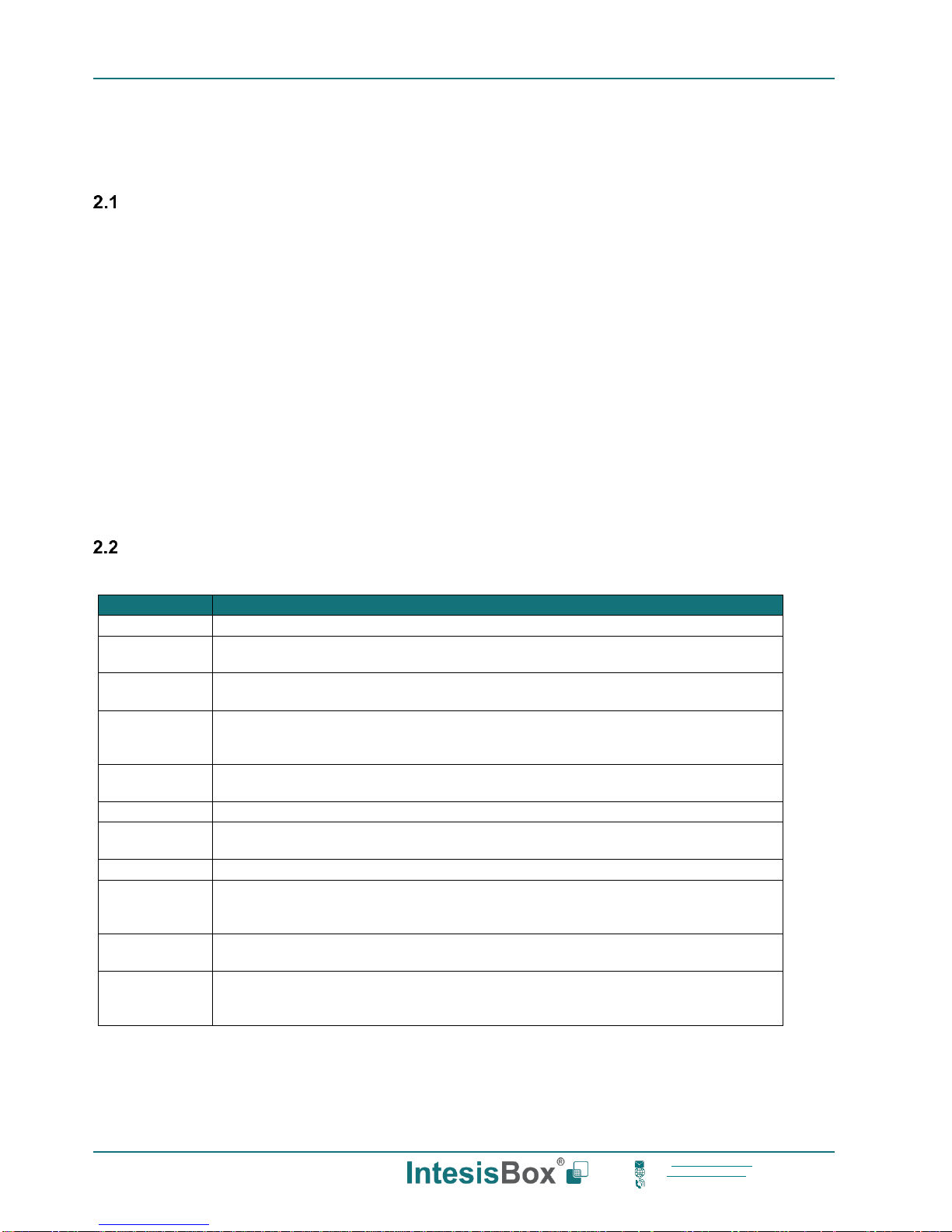

Capacity of IntesisBox

Element

Max.

Notes

Number of indoor units

64*

Number of indoor units that can be controlled through

IntesisBox

* There are different models of IntesisBox KNX – Hitachi VRF each one with different capacity. The table above shows

the capacity for the top model (with maximum capacity).

Their order codes are:

▪ IBKNXHIS016O000: Model supporting up to 16 indoor units

▪ IBKNXHIS064O000: Model supporting up to 64 indoor units

Page 8

IntesisBox® KNX – HITACHI VRF User Manual r1.1 EN

8/30

This information is subject to change without prior notice

IntesisBox is a registered trademark of Intesis Software S.L.U.

email: info@intesisbox.com

web: www.intesisbox.com

phone: +34 938047134

2 KNX System

In this section, a common description for all IntesisBox KNX series gateways is given, from the point of view of KNX

system which is called from now on internal system. Connection with the Hitachi system is also called from now on

external system.

Description

IntesisBox KNX connects directly to the KNX TP-1 bus and performs as one more device into the KNX system, with the

same configuration and operational characteristics as other KNX devices.

Internally, the circuit part connected to the KNX bus is opto-isolated from the rest of the electronics.

IntesisBox KNX receives, manages and sends all the telegrams related to its configuration to the KNX bus.

On receiving WRITE telegrams of KNX group addresses associated to communication objects, the corresponding

messages are sent to the external system (Hitachi installation).

When a change in a signal of the external system is detected, a WRITE telegram is sent to the KNX bus (addressed

with the group address associated to the corresponding group object), in order to maintain both systems synchronized

in every moment.

The status of the KNX bus is checked continuously and, if a bus drop-down is detected, for example due to failure in

the bus power supply, after the KNX bus is restored again, IntesisBox will send READ telegrams to group addresses of

all communication objects marked with flag ‘Ri’. The behavior of each individual point into IntesisBox is determined by

the flags configured for the communication object. See details below.

Points definition

Every group object in configuration has following KNX properties:

Property

Description

Description

Descriptive information about the communication object or signal.

Object

function

Information on range of values for the group object.

DPT

Datapoint type. It is the KNX data type used to encode the signal's value. It will depend

on the type of signal associated in the external system in every case.

Group

It is the KNX group to which the point is associated. It is also the group to which the

read (R), write (W), transmit (T), update (U) and read on init (Ri) flags are applied. It is

the sending group.

Listening

addresses

They are the addresses that can write on the group object, a part of the main group

address.

R

Read. If this flag is activated, READ telegrams of this group address will be accepted.

Ri

Read on Init. If this flag is activated, the object will trigger corresponding READ request

(on associated group address) on initialization.

W

Write. If this flag is activated, WRITE telegrams on this group object will be accepted.

T

Transmit. If this flag is activated, when the group object value changes, due to a change

in the external system, a WRITE telegram of the associated group address will be sent

to the KNX bus.

U

Update. If this flag is activated, UPDATE telegrams (response to READ telegrams) on

this group object will be accepted.

Active

If activated, the point will be active in IntesisBox, if not, the behavior will be as if the

point is not defined. This allows deactivating points without the need of delete them for

possible future use.

These properties are common for all IntesisBox KNX series gateways. Although each integration may have specific

properties according to the type of signals of the external system.

See list of communication objects in section 9 APPENDIX A – COMMUNICATION OBJECTS TABLE.

Page 9

IntesisBox® KNX – HITACHI VRF User Manual r1.1 EN

9/30

This information is subject to change without prior notice

IntesisBox is a registered trademark of Intesis Software S.L.U.

email: info@intesisbox.com

web: www.intesisbox.com

phone: +34 938047134

3 Connections

Find below information regarding the IntesisBox connections available.

Power Supply

Must use NEC Class 2 or Limited Power Source (LPS) and SELV rated

power supply.

If using DC power supply:

Respect polarity applied of terminals (+) and (-). Be sure the voltage

applied is within the range admitted (check table below). The power

supply can be connected to earth but only through the negative

terminal, never through the positive terminal.

If using AC power supply:

Make sure the voltage applied is of the value admitted (24 Vac). Do

not connect any of the terminals of the AC power supply to earth, and

make sure the same power supply is not supplying any other device.

Ethernet

Connect the cable coming from the IP network to the connector ETH of

the gateway. Use an Ethernet CAT5 cable. If communicating through the

LAN of the building, contact the network administrator and make sure

traffic on the port used is allowed through all the LAN path (check the

gateway user manual for more information). Default IP is

192.168.100.246. DHCP is enabled by default.

PortA / KNX

Connect the KNX TP1 bus to connectors A3 (+) and A4 (-) of gateway’s PortA. Respect the polarity.

PortB / H-Link Hitachi

Connect the H-Link terminals (TB2) of Hitachi Outdoor Unit to the connectors B1 and B2 of gateway’s

PortB. There is no polarity to be respected.

Console Port

Connect a mini-type B USB cable from your computer to the gateway to allow communication between the Configuration

Software and the gateway. Remember that Ethernet connection is also allowed. Check the user manual for more

information.

USB

Connect a USB storage device (not a HDD) if required. Check the user manual for more information.

Ensure proper space for all connectors when mounted (see section 6)

Page 10

IntesisBox® KNX – HITACHI VRF User Manual r1.1 EN

10/30

This information is subject to change without prior notice

IntesisBox is a registered trademark of Intesis Software S.L.U.

email: info@intesisbox.com

web: www.intesisbox.com

phone: +34 938047134

Power device

The first step to perform is to power up the device. To do so, a power supply working with any of the voltage range

allowed is needed (check section 5). Once connected the ON led will turn on.

WARNING! In order to avoid earth loops that can damage the gateway, and/or any other equipment connected to it, we

strongly recommend:

• The use of DC power supplies, floating or with the negative terminal connected to earth. Never use a DC

power supply with the positive terminal connected to earth.

• The use of AC power supplies only if they are floating and not powering any other device.

Connect to Hitachi installation

Use the Port B connector of the IntesisBox device to connect Hitachi H-Link bus to the IntesisBox. Remember to follow

all safety precautions indicated by Hitachi.

Connect the Hitachi H-Link bus to connectors B1 and B2 of gateway’s PortB. Bus is not sensitive to polarity.

Connection to KNX

Connect the KNX TP1 bus to connectors A3 (+) and A4 (-) of gateway’s PortA. Respect the polarity.

Connection to the configuration tool

This action allows the user to have access to configuration and monitoring of the device (more information can be found

in the configuration tool User Manual). Two methods to connect to the PC can be used:

• Ethernet: Using the Ethernet port of IntesisBox.

• USB: Using the console port of IntesisBox, connect a USB cable from the console port to the PC.

Page 11

IntesisBox® KNX – HITACHI VRF User Manual r1.1 EN

11/30

This information is subject to change without prior notice

IntesisBox is a registered trademark of Intesis Software S.L.U.

email: info@intesisbox.com

web: www.intesisbox.com

phone: +34 938047134

4 Set-up process and troubleshooting

Pre-requisites

It is necessary to have a KNX installation, device or interface operative and well connected to the corresponding KNX

port of IntesisBox. It is also required to have a Hitachi Air Conditioner installation, with accessible H-Link/TB2 port for

connection of IntesisBox.

Connectors, connection cables, PC to use the configuration tool and other auxiliary material, if needed, are not supplied

by Intesis Software SLU for this standard integration.

Items supplied by Intesis Software for this integration are:

• IntesisBox gateway.

• Link to download the configuration tool.

• USB Console cable to communicate with IntesisBox.

• Product documentation.

IntesisBox MAPS. Configuration & monitoring tool for IntesisBox KNX series

4.2.1 Introduction

IntesisBox MAPS is a Windows® compatible software developed specifically to monitor and configure IntesisBox new

generation gateways.

The installation procedure and main functions are explained in the IntesisBox MAPS KNX User Manual. This document

can be downloaded from the link indicated in the installation sheet supplied with the IntesisBox device or in the product

website at www.intesisbox.com

In this section, only the specific case of Hitachi to KNX systems will be covered.

Please check the IntesisBox MAPS KNX User Manual for specific information about the different parameters and how

to configure them.

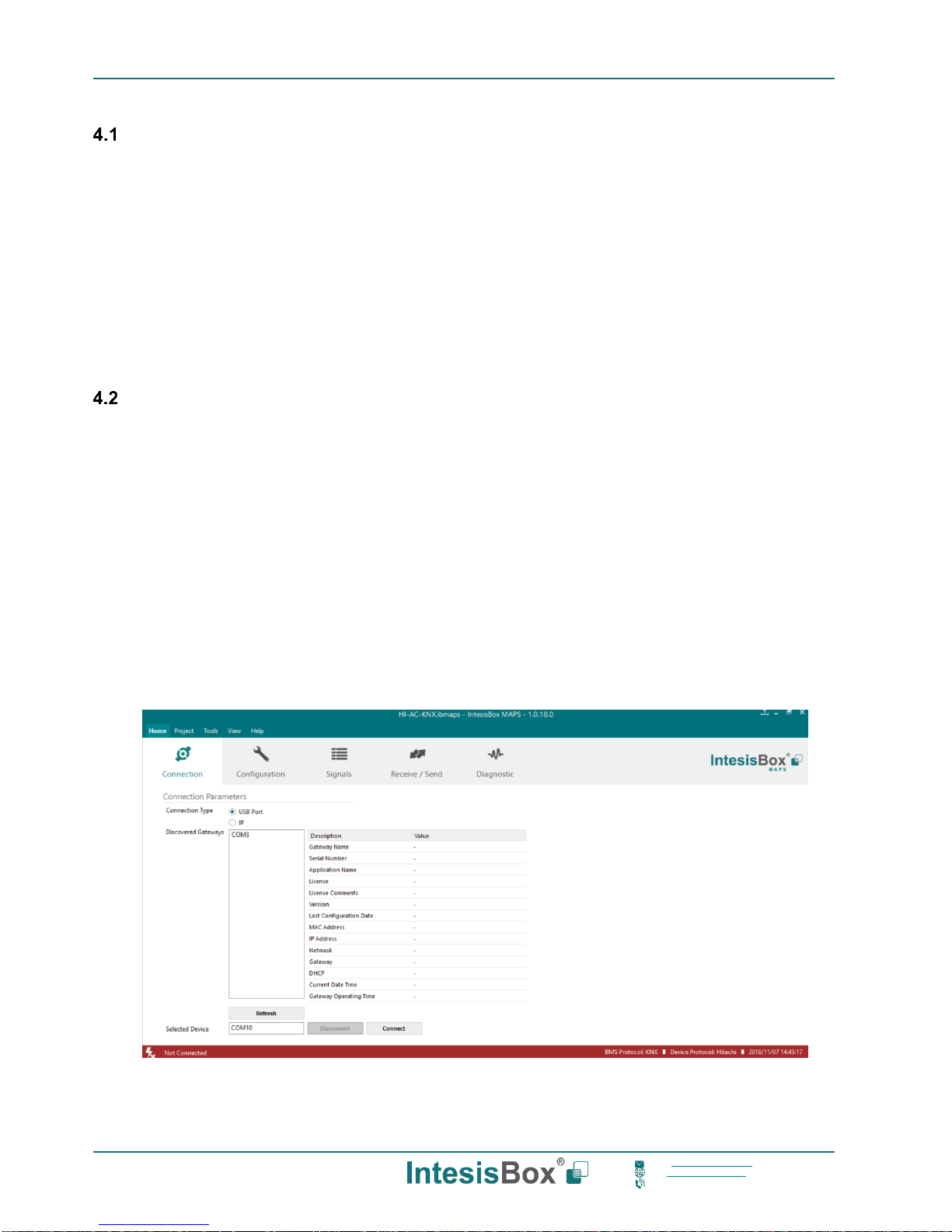

4.2.2 Connection

To configure the IntesisBox connection parameters press on the Connection button in the menu bar.

Figure 4.1 MAPS connection

Page 12

IntesisBox® KNX – HITACHI VRF User Manual r1.1 EN

12/30

This information is subject to change without prior notice

IntesisBox is a registered trademark of Intesis Software S.L.U.

email: info@intesisbox.com

web: www.intesisbox.com

phone: +34 938047134

4.2.3 Configuration tab

Select the Configuration tab to configure the connection parameters. Three subsets of information are shown in this

window: General (Gateway general parameters), KNX (KNX interface configuration) and Hitachi (Hitachi interface

parameters).

Figure 4.2 IntesisBox MAPS configuration tab

4.2.4 KNX configuration

Set parameters of KNX interface of IntesisBox.

Figure 4.3 IntesisBox MAPS KNX configuration tab

Page 13

IntesisBox® KNX – HITACHI VRF User Manual r1.1 EN

13/30

This information is subject to change without prior notice

IntesisBox is a registered trademark of Intesis Software S.L.U.

email: info@intesisbox.com

web: www.intesisbox.com

phone: +34 938047134

1. Device configuration

1.1. Physical Address. KNX physical address of the device in the network

1.2. Extended Addresses. Enables usage of KNX Extended addresses (range from 16/0/0 to 32/7/255).

2. Operating Mode. Settings related to KNX interface for control and feedback of AC unit’s operating mode.

2.1. KNX DPT for HVAC operation mode comm object. Base DPT. Base DPT to use for control/monitor the

operating mode. Following DPT types are offered:

o DPT_20.105. DPT_HVACContrMode: 0-Auto, 1-Heat, 3-Cool, 9-Fan, 14-Dry

o DPT_5.x (non-standarized): 0-Auto, 1-Heat, 2-Dry, 3-Fan, 4-Cool

2.2. KNX DPT for HVAC operation mode comm object. Extra DPT. Additional DPT to use for control/monitor

the operating mode.

o DPT_1.100. DPT_Heat/Cool: 0-Cool, 1-Heat.

o DPT_5.001. DPT_Scaling: Enables objects “Control_ Heat Mode & On” and “Control_ Cool Mode &

On”. Their type is DPT_Scaling (0..100%), and their ending is to be able to control parameters On/Off,

Cool/Heat of indoor unit from a single percentage object. They are meant to provide compatibility with

certain thermostats oriented to the operation of valves for Heating/Cooling. Whenever a value > 0% is

received at each of these two objects, the corresponding operating mode and ON operation is sent to

the indoor unit. Whenever both values are 0%, indoor unit is set to OFF

2.3. Use of 1-bit Operating Modes. 1-bit Control Objects. Enables a bit-type object for the control of each

operating mode.

2.4. Use of 1-bit Operating Modes. 1-bit Status Objects. Enables a bit-type object for monitoring each

operating mode.

3. Temperature Sensor.

3.1. Ambient temperature provided from KNX. Enables object Control_ KNX ambient temperature.

NOTE: Indoor unit does not accept, by itself, that an ambient temperature for control of operation

of the indoor unit is provided. To allow regulation of indoor unit according to a temperature reference

from KNX, what IntesisBox does is passing a different temperature setpoint to the indoor unit than

the one required by the user. The passed setpoint is such that the difference ‘Ambient temperature

reported by Hitachi IU – AC setpoint’ is equal to ‘Ambient temperature reported by KNX – AC

setpoint required by KNX’, using the following formula:

“AC Setp. Temp” = “AC Ret. Temp” - (“KNX Amb. Temp.” - “KNX Setp. Temp”)

Where:

▪ AC Setp. Temp: AC indoor unit setpoint temperature

▪ AC Ret. Temp: AC indoor unit return temperature

▪ KNX Amb. Temp.: Ambient temperature provided from KNX

▪ KNX Setp. Temp: Setpoint temperature provided from KNX

Consequently, when using this feature (Ambient temp provided from KNX), setpoint at AC and

setpoint in KNX will not necessarily be the same (actually, user will not be able to operate setpoint

from AC System controllers as the remote controller).

!

Page 14

IntesisBox® KNX – HITACHI VRF User Manual r1.1 EN

14/30

This information is subject to change without prior notice

IntesisBox is a registered trademark of Intesis Software S.L.U.

email: info@intesisbox.com

web: www.intesisbox.com

phone: +34 938047134

4. Fan Speed. Settings related to KNX interface for control and feedback of AC unit’s fan speed.

4.1. Auto Fan Speed. Configures availability of Auto Fan Speed control/monitoring objects. Necessary if your

indoor unit has auto fan speed.

4.2. KNX DPT for Fan Speed comm objects. DPT_5.001, DPT_Scaling. Control/monitoring of Fan Speed is

performed by means of scaling (percentage) objects. Thresholds for control object and values for status object

will vary according to number of fanspeeds of the unit.

4.2. KNX DPT for Fan Speed comm objects. DPT_5.010, DPT_Value_1_Ucount. Control/monitoring of Fan

Speed is performed by means of enumerated values.

4.4. Use of 1-bit Fan Speed. 1-bit Control Objects. Enables a bit-type object for control of fan speed.

4.5. Use of 1-bit Fan Speed. 1-bit Status Objects. Enables a bit-type object for monitoring of each fan speed.

5. Vanes Position. Settings related to KNX interface for control and feedback of AC unit’s vanes position.

4.1. Auto&Swing Vanes. Configures availability of Auto and Swing control/monitoring objects.

4.2. KNX DPT for Vane Position comm objects. DPT_5.001, DPT_Scaling. Control/monitoring of Vanes

Positions is performed by means of scaling (percentage) objects. Thresholds for control object and values for

status object will vary according to number of vanes positions of the unit.

4.2. KNX DPT for Vane Position comm objects. DPT_5.010, DPT_Value_1_Ucount. Control/monitoring of

Vanes Positions is performed by means of enumerated values.

4.4. Use of 1-bit Fan Speed. 1-bit Control Objects. Enables a bit-type object for control of Vanes Positions.

4.5. Use of 1-bit Fan Speed. 1-bit Status Objects. Enables a bit-type object for monitoring of each Vanes

Position.

Page 15

IntesisBox® KNX – HITACHI VRF User Manual r1.1 EN

15/30

This information is subject to change without prior notice

IntesisBox is a registered trademark of Intesis Software S.L.U.

email: info@intesisbox.com

web: www.intesisbox.com

phone: +34 938047134

4.2.5 Hitachi configuration

Set parameters for connection with Hitachi’s installation.

Figure 4.4 IntesisBox MAPS Hitachi configuration tab

In Units Configuration section you need to enter, for each unit:

• Active. If it’s active (checkbox at Unit xx), ranging from 1 to 64 indoor units that will be integrated (maximum

number of units will depend on IntesisBox model)

• IU address. Address 1..64 of Unit in Hitachi H-Link bus.

• OU address. Address 1..64 of Outdoor Unit in Hitachi H-Link bus.

• Description. Descriptive name to easy identification of the unit (for example, ‘living room floor 1 unit’, etc).

Additional to manual entry of each unit, autodiscover of present units in an H-Link installation is possible. To do so, click

button Scan. Following window will appear:

Page 16

IntesisBox® KNX – HITACHI VRF User Manual r1.1 EN

16/30

This information is subject to change without prior notice

IntesisBox is a registered trademark of Intesis Software S.L.U.

email: info@intesisbox.com

web: www.intesisbox.com

phone: +34 938047134

Figure 4.5 IntesisBox MAPS Scan Hitachi Units window

By pressing Scan button, connected Hitachi H-Link bus will be scanned for available units. Error window will appear if

there is a problem in the connection with H-Link bus (units not powered, bus not connected, …).

A progress bar will appear during the scan, which will take up to a few minutes. After scan is completed, detected units

will be shown in available units as follows:

Figure 4.6 IntesisBox MAPS Scan Hitachi Units window with scan results

Select with its checkbox units to add (or replace) in installation, according to selection Replace Units / Add Units.

After units to be integrated are selected, click button Apply, and changes will appear in previous Units Configuration

window.

Page 17

IntesisBox® KNX – HITACHI VRF User Manual r1.1 EN

17/30

This information is subject to change without prior notice

IntesisBox is a registered trademark of Intesis Software S.L.U.

email: info@intesisbox.com

web: www.intesisbox.com

phone: +34 938047134

Figure 4.7 IntesisBox MAPS Hitachi configuration tab after importing scan results

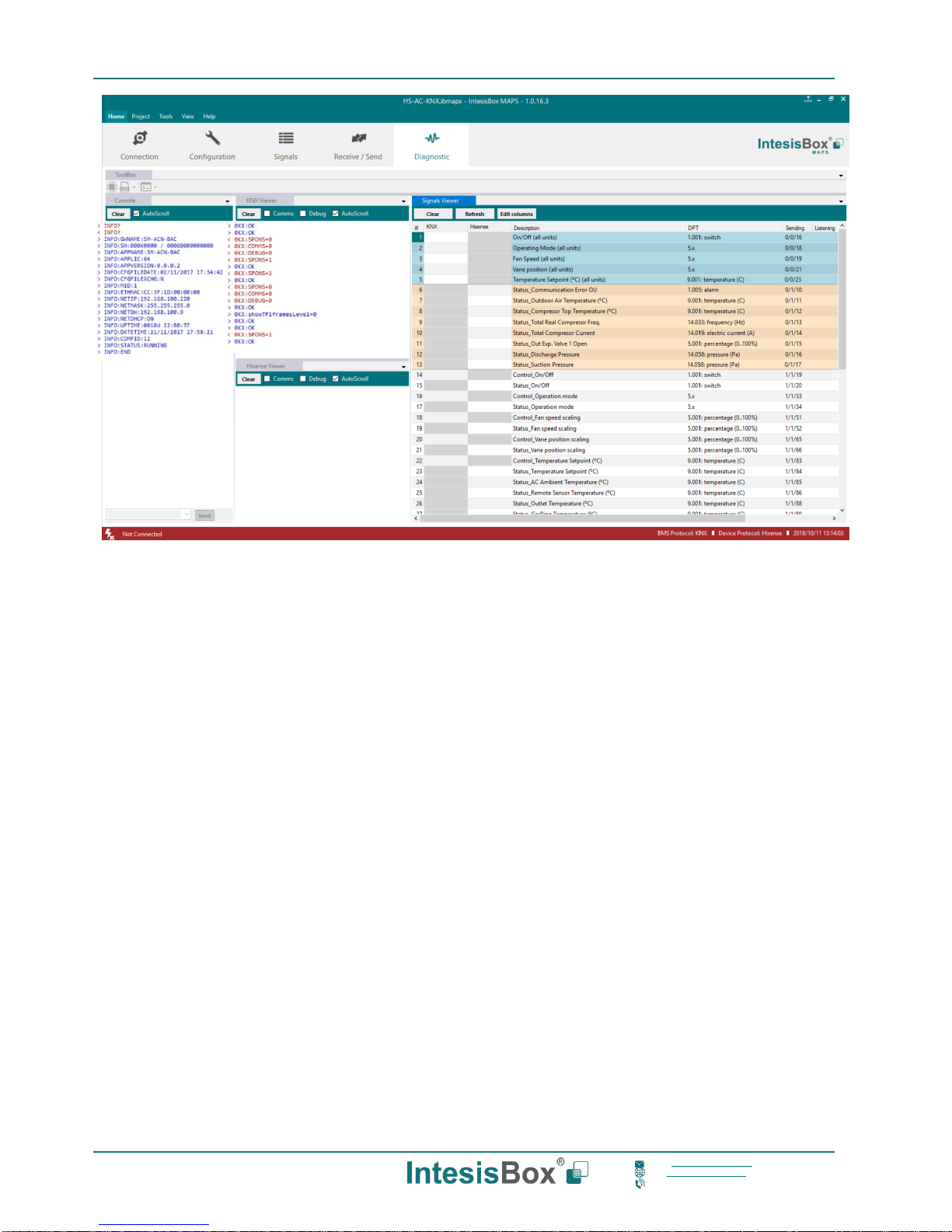

4.2.6 Signals

All available KNX objects, its corresponding description and other main parameters are listed in the signals tab.

Figure 4.8 IntesisBox MAPS Signals tab

Page 18

IntesisBox® KNX – HITACHI VRF User Manual r1.1 EN

18/30

This information is subject to change without prior notice

IntesisBox is a registered trademark of Intesis Software S.L.U.

email: info@intesisbox.com

web: www.intesisbox.com

phone: +34 938047134

4.2.7 Sending the configuration to IntesisBox

When the configuration is finished, follow the next steps.

1.- Save the project (Menu option Project->Save) on your hard disk (more information in IntesisBox MAPS User

Manual).

2.- Go to tab ‘Receive / Send’ of MAPS, and in Send section, press Send button. IntesisBox will reboot

automatically once the new configuration is loaded.

Figure 4.9 IntesisBox MAPS Receive/Send tab

After any configuration change, do not forget to send the configuration file to the IntesisBox using the

Send button in the Receive / Send section.

4.2.8 Diagnostic

To help integrators in the commissioning tasks and troubleshooting, the Configuration Tool offers some specific tools

and viewers.

In order to start using the diagnostic tools, connection with the Gateway is required.

The Diagnostic section is composed by two main parts: Tools and Viewers.

• Tools

Use the tools section to check the current hardware status of the box, log communications into

compressed files to be sent to the support, change the Diagnostic panels’ view or send commands to

the gateway.

• Viewers

In order to check the current status, viewer for the Internal and External protocols are available. It is

also available a generic Console viewer for general information about communications and the gateway

status and finally a Signals Viewer to simulate the BMS behavior or to check the current values in the

system.

Page 19

IntesisBox® KNX – HITACHI VRF User Manual r1.1 EN

19/30

This information is subject to change without prior notice

IntesisBox is a registered trademark of Intesis Software S.L.U.

email: info@intesisbox.com

web: www.intesisbox.com

phone: +34 938047134

Figure 4.10 Diagnostic

More information about the Diagnostic section can be found in the Configuration Tool manual.

Page 20

IntesisBox® KNX – HITACHI VRF User Manual r1.1 EN

20/30

This information is subject to change without prior notice

IntesisBox is a registered trademark of Intesis Software S.L.U.

email: info@intesisbox.com

web: www.intesisbox.com

phone: +34 938047134

4.2.9 Set-up procedure

1. Install IntesisBox MAPS on your laptop, use the setup program supplied for this and follow the instructions given by

the Installation wizard.

2. Install IntesisBox in the desired installation site. Installation can be on DIN rail or on a stable not vibrating surface

(DIN rail mounted inside a metallic industrial cabinet connected to ground is recommended).

3. Connect the KNX communication cable coming from the KNX network to the port marked as Port A on IntesisBox

(More details in section 3).

4. Connect the communication cable coming from the Hitachi H-Link installation to the port marked as Port B of

IntesisBox (More details in section 3).

5. Power up IntesisBox. The supply voltage can be 9 to 36 Vdc or just 24 Vac. Take care of the polarity of the supply

voltage applied.

WARNING! In order to avoid earth loops that can damage IntesisBox and/or any other equipment connected to

it, we strongly recommend:

• The use of DC power supplies, floating or with the negative terminal connected to earth. Never use a DC

power supply with the positive terminal connected to earth.

• The use of AC power supplies only if they are floating and not powering any other device.

6. If you want to connect using IP, connect the Ethernet cable from the laptop PC to the port marked as Ethernet of

IntesisBox (More details in section 3).

If you want to connect using USB, connect the USB cable from the laptop PC to the port marked as Console of

IntesisBox (More details in section 3).

7. Open IntesisBox MAPS, create a new project selecting a copy of the one named IBOX-KNX-HI.

8. Modify the configuration as desired, save it and download the configuration file to IntesisBox as explained in the

IntesisBox MAPS user manual.

9. Visit the Diagnostic section and check that there is communication activity, some TX frames and some other RX

frames. This means that the communication with the KNX installation and Hitachi installation is OK. In case there is

no communication activity between IntesisBox and the KNX side and/or Hitachi units, check that those are operative:

check communication cable used to connect all devices and any other communication parameter.

Figure 4.11 Enable COMMS

Page 21

IntesisBox® KNX – HITACHI VRF User Manual r1.1 EN

21/30

This information is subject to change without prior notice

IntesisBox is a registered trademark of Intesis Software S.L.U.

email: info@intesisbox.com

web: www.intesisbox.com

phone: +34 938047134

5 Electrical & Mechanical Features

Enclosure

Plastic, type PC (UL 94 V-0)

Net dimensions (dxwxh): 90x88x56 mm

Recommended space for installation (dxwxh): 130x100x100mm

Color: Light Grey. RAL 7035

Battery

Size: Coin 20mm x 3.2mm

Capacity: 3V / 225mAh

Type: Manganese Dioxide Lithium

Mounting

Wall.

DIN rail EN60715 TH35.

Console Port

Mini Type-B USB 2.0 compliant

1500VDC isolation

Terminal Wiring

(for power supply and

low-voltage signals)

Per terminal: solid wires or stranded wires (twisted or with

ferrule)

1 core: 0.5mm2… 2.5mm2

2 cores: 0.5mm2… 1.5mm2

3 cores: not permitted

USB port

Type-A USB 2.0 compliant

Only for USB flash storage device

(USB pen drive)

Power consumption limited to 150mA

(HDD connection not allowed)

Power

1 x Plug-in screw terminal block (3 poles)

9 to 36VDC +/-10%, Max.: 140mA.

24VAC +/-10% 50-60Hz, Max.: 127mA

Recommended: 24VDC

Push Button

Button A: Check the user manual

Button B: Check the user manual

Operation

Temperature

0°C to +60°C

Ethernet

1 x Ethernet 10/100 Mbps RJ45

2 x Ethernet LED: port link and activity

Operational

Humidity

5 to 95%, no condensation

Port A

1 x KNX TP-1 Plug-in screw terminal block orange (2 poles)

2500VDC isolation from other ports

KNX power consumption: 5mA

Voltage rating: 29VDC

1 x Plug-in screw terminal block green (2 poles)

Reserved for future use

Protection

IP20 (IEC60529)

LED

Indicators

10 x Onboard LED indicators

2 x Run (Power)/Error

2 x Ethernet Link/Speed

2 x Port A TX/RX

2 x Port B TX/RX

1 x Button A indicator

1 x Button B indicator

Switch A

(SWA)

1 x DIP-Switch for PORT A configuration:

Reserved for future use

PORT B

1 x Serial EIA232 (SUB-D9 male connector)

Reserved for future use

1 x H-Link Plug-in screw terminal block (3 poles)

1500VDC isolation from other ports

Switch B

(SWB)

1 x DIP-Switch for PORT B configuration:

Reserved for future use (leave OFF, default)

Page 22

IntesisBox® KNX – HITACHI VRF User Manual r1.1 EN

22/30

This information is subject to change without prior notice

IntesisBox is a registered trademark of Intesis Software S.L.U.

email: info@intesisbox.com

web: www.intesisbox.com

phone: +34 938047134

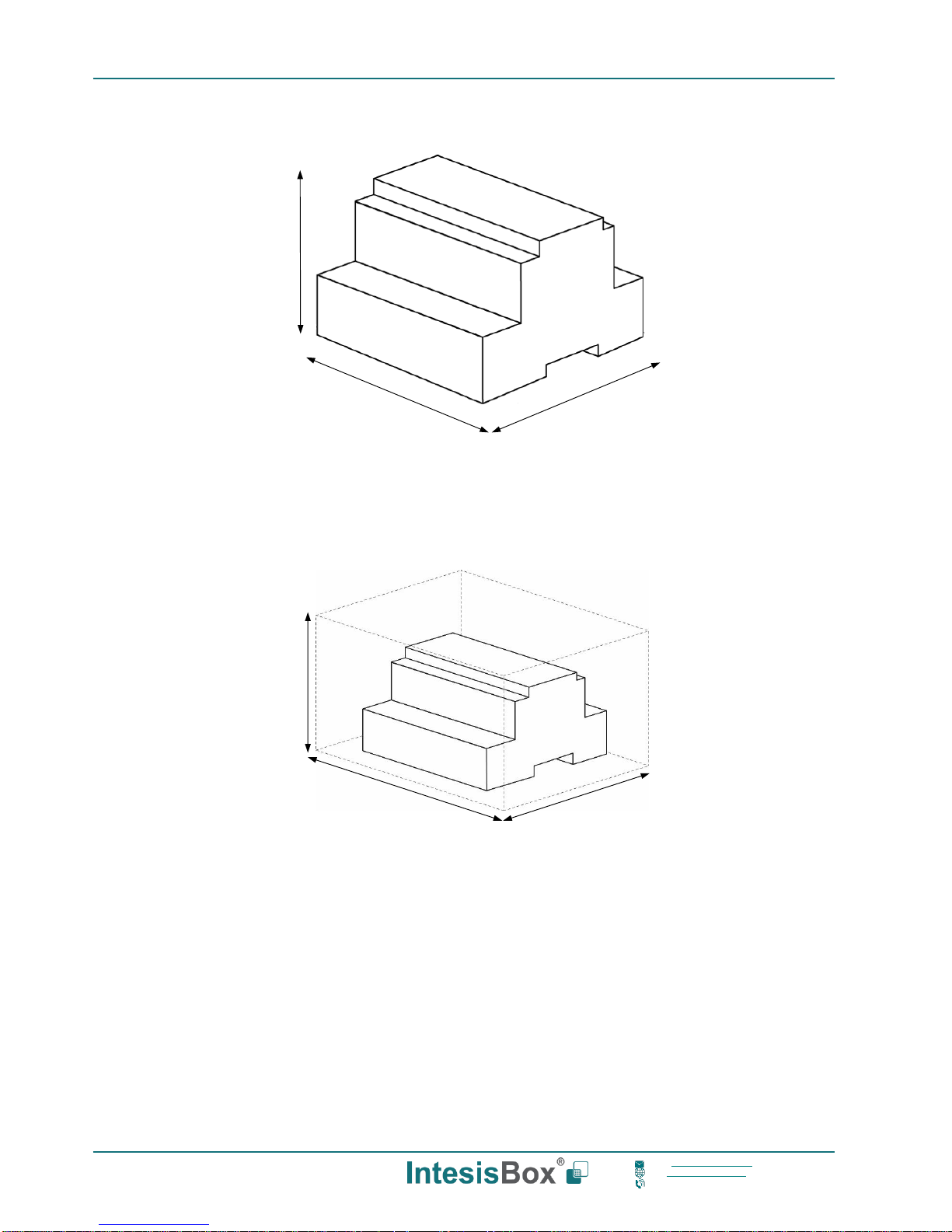

6 Dimensions

Recommended available space for its installation into a cabinet (wall or DIN rail mounting), with space enough for

external connections

100 mm (h)

100 mm (w)

130 mm (d)

56 mm (h)

88 mm (w)

90 mm (d)

Page 23

IntesisBox® KNX – HITACHI VRF User Manual r1.1 EN

23/30

This information is subject to change without prior notice

IntesisBox is a registered trademark of Intesis Software S.L.U.

email: info@intesisbox.com

web: www.intesisbox.com

phone: +34 938047134

7 AC Unit Types compatibility

A list of Hitachi unit model references compatible with HI-AC-KNX-16/64 and their available features can be found in:

http://intesis.com/pdf/IntesisBox_HI-AC-xxx-MIU_AC_Compatibility.pdf

Page 24

IntesisBox® KNX – HITACHI VRF User Manual r1.1 EN

24/30

This information is subject to change without prior notice

IntesisBox is a registered trademark of Intesis Software S.L.U.

email: info@intesisbox.com

web: www.intesisbox.com

phone: +34 938047134

8 Error codes for Indoor and Outdoor Units

This list contains all possible values shown in KNX Object for “Error Code” for each indoor unit and outdoor unit.

It must be taken into account that Outdoor Units are only able to reflect a single error for each indoor / outdoor unit in

the system. Thus, a unit having two or more active errors from that list will only report a single error code – the one of

the first error that has been detected.

Error

Code

Category

Content of Abnormality

Leading Cause

01

lndoor Unit

Activation of Protection Device (Float

Switch)

Activation of Float Switch

(High Water Level in Drain Pan,

Abnormality of Drain Pipe, Float Switch or

Drain Pan)

02

Outdoor Unit

Activation of Protection

Device (High Pressure

Cut)

Activation of PSH (Pipe Clogging,

Excessive Refrigerant! lnert Gas

Mixing)

03

Transmission

Abnormality between lndoor and

Outdoor

incorrect Wiring, Loose Terminals,

Disconnect Wire, Blowout of Fuse,

Outdoor Unit Power OFF

04

Abnormality between lnverter PCB

and Outdoor PCB

lnverter PCB - Outdoor PCB

Transmission Failure (Loose Connector,

Wire Breaking, Blowout of Fuse)

04.

Abnormality between Fan Controller

and Outdoor PCB

Fan Controller - Outdoor PCB

Transmission Failure (Loose Connector,

Wire Breaking, Blowout of Fuse)

05

Supply Phase

Abnormality Power Source Phases

lncorrect Power Source,

Connection to Reversed

Phase, Open-Phase

06

Voltage

Abnormal lnverter Voltage

Outdoor Voltage Drop, insufficient Power

Capacity

06. Abnormal Fan Controller Voltage

Outdoor Voltage Drop, lnsufficient Power

Capacity

07

Cycle

Decrease in Discharge Gas Superheat

Excessive Refrigerant! Charge, Failure of

Thermistor, lncorrect Wiring, lncorrect

Piping Connection, Expansion Valve

Locking at Opened Position (Disconnect

Connector)

08

lncrease in Discharge Gas

Temperature

lnsufficient Refrigerant! Charge,

Pipe Clogging, Failure of

Thermistor, lncorrect Wiring,

lncorrect Piping Connection, Expansion

Valve Locking at Closed Position

(Disconnect Connector)

0A

Transmission

Abnormality between Outdoor and

Outdoor

lncorrect Wiring, Breaking Wire, Loose Terminals

0b

Outdoor Unit

lncorrect Outdoor Unit Address

Setting

Duplication of Address Setting for

Outdoor Units (Sub Units) in Same

Refrigerant! Cycle System

0c

lncorrect Outdoor Unit Main Unit

Two (or more) Outdoor Units Set

Page 25

IntesisBox® KNX – HITACHI VRF User Manual r1.1 EN

25/30

This information is subject to change without prior notice

IntesisBox is a registered trademark of Intesis Software S.L.U.

email: info@intesisbox.com

web: www.intesisbox.com

phone: +34 938047134

Setting

as "Main Unit" Exist in Same

Refrigerant! Cycle System

11

Sensoron

lndoor Unit

lnlet Air Thermistor

lncorrect Wiring,

Disconnecting Wiring Breaking

Wire, Short Circuit

12

Outlet Air Thermistor

13

Freeze Protection Thermistor

14

Gas Piping Thermistor

19

Fan Motor

Activation of Protection Device for

lndoor Fan

Fan Motor Overheat, Locking

21

Sensor on

Outdoor Unit

High Pressure Sensor

lncorrect Wiring,

Disconnecting Wiring Breaking

Wire, Short Circuit

22

Outdoor Air Thermistor

23

Discharge Gas Thermistor on Top of

Compressor

24

Heat Exchanger Liquid Pipe Thermistor

25

Heat Exchanger Gas Pipe Thermistor

29

Low Pressure Sensor

31

System

lncorrect Capacity Setting of Outdoor

Unit and lndoor Unit

lncorrect Capacity Code Setting of Combination

Excessive or lnsufficient lndoor Unit Total

Capacity Code

35

lncorrect Setting of lndoor Unit No.

Duplication of lndoor Unit No. in same Ref. Gr.

36

lncorrect of lndoor Unit Combination

lndoor Unit is Designed for R22

38

Abnormality of Picking up Circuit for

Protection in Outdoor Unit

Failure of Protection Detecting Device

(lncorrect Wiring of Outdoor PCB)

39 Compressor

Abnormality Running Current at

Constant! Speed Compressor

Overcurrent, Blowout Fuse, Current Sensor

Failure, instantaneous Power Failure, Voltage

Drop, Abnormal Power Supply

3A

Outdoor Unit

Abnormality of Outdoor Unit Capacity

Outdoor Unit Capacity > 510kBtu/h

3b

lncorrect Setting of Outdoor Unit

Models Combination or Voltage

lncorrect Setting of Main and Sub Unit(s)

Combination or Voltage

3d

Abnormality Transmission between

Main Unit and Sub Unit(s)

lncorrect Wiring, Disconnect Wire, Breaking Wire,

PCB Failure

43

Protection

Device

Activation of Low Compression Ratio

Protection Device

Defective Compression (Failure of Compressor of

lnverter, Loose Power Supply Connection)

44

Activation of Low Pressure lncrease

Protection Device

Overload at Cooling, High Temperature at

Heating, Expansion Valve Locking (Loose

Connector)

45

Activation of High Pressure lncrease

Protection Device

Overload Operation (Clogging, Short-Pass), Pipe

Clogging, Excessive Refrigerant!, lnert Gas Mixing

47

Activation of Low Pressure Decrease

Protection Device (Vacuum Operation

Protection)

lnsuffcient Refrigerant!, Refrigerant! Piping,

Clogging, Expansion Valve Locking at Open

Position (Loose Connector)

Page 26

IntesisBox® KNX – HITACHI VRF User Manual r1.1 EN

26/30

This information is subject to change without prior notice

IntesisBox is a registered trademark of Intesis Software S.L.U.

email: info@intesisbox.com

web: www.intesisbox.com

phone: +34 938047134

48

Activation of lnverter Overcurrent

Protection Device

Overload Operation, Compressor Failure

51

Sensor

Abnormal lnverter Current! Sensor

Current! Sensor Failure

53

lnverter

lnverter Error Signal Detection

Driver IC Error Signal Detection (Protection for

Overcurrent, Low Voltage, Short Circuit)

54

Abnormality of lnverter Fin

Temperature

Abnormal lnverter Fin Thermistor,

Heat Exchanger Clogging, Fan Motor Failure

55

lnverter Failure

lnverter PCB Failure

57

Fan Controller

Activation of Fan Controller Protection

Driver IC Error Signal Detection (Protection for

Overcurrent, Low Voltage, Short Circuit),

lnstantaneous Overcurrent

5A

Abnormality of Fan Controller Fin

Temperature

Fin Thermistor Failure, Heat Exchanger Clogging,

Fan Motor Failure

5b

Activation of Overcurrent Protection

Fan Motor Failure

5C Abnormality of Fan Controller Sensor

Failure of Current! Sensor (lnstantaneous

Overcurrent,

lncrease of Fin Temperature, Low Voltage, Earth

Fault, Step-Out)

EE Compressor

Compressor Protection Alarm

(lt is cannot be reset from remote

Controller)

This alarm code appears when the following

alarms• occurs three times within 6 hours.

*02, 07, 08, 39, 43 to 45, 47

b1

Outdoor Unit

No. Setting

lncorrect Setting of Unit and

Refrigerant! Cycle No.

Over 64 Number is Set for Address or Refrigerant!

Cycle.

b5

lndoor Unit

No. Setting

lncorrect lndoor Unit Connection

Number Setting

More than 17 Non-Corresponding to Hi-NET Units

are Connected to One System.

C1

Switch Box

Unit

lncorrect lndoor Unit Connection

2 or more Switch Box Units are connected

between outdoor unit and indoor unit.

C2

lncorrect lndoor Unit Connection No.

Setting

9 or More lndoor Units Connected to Switch Box

Unit

C3 lncorrect lndoor Unit Connection

The indoor units of different refrigerant! cycle is

connected to Switch Box unit.

Page 27

IntesisBox® KNX – HITACHI VRF User Manual r1.1 EN

27/30

This information is subject to change without prior notice

IntesisBox is a registered trademark of Intesis Software S.L.U.

email: info@intesisbox.com

web: www.intesisbox.com

phone: +34 938047134

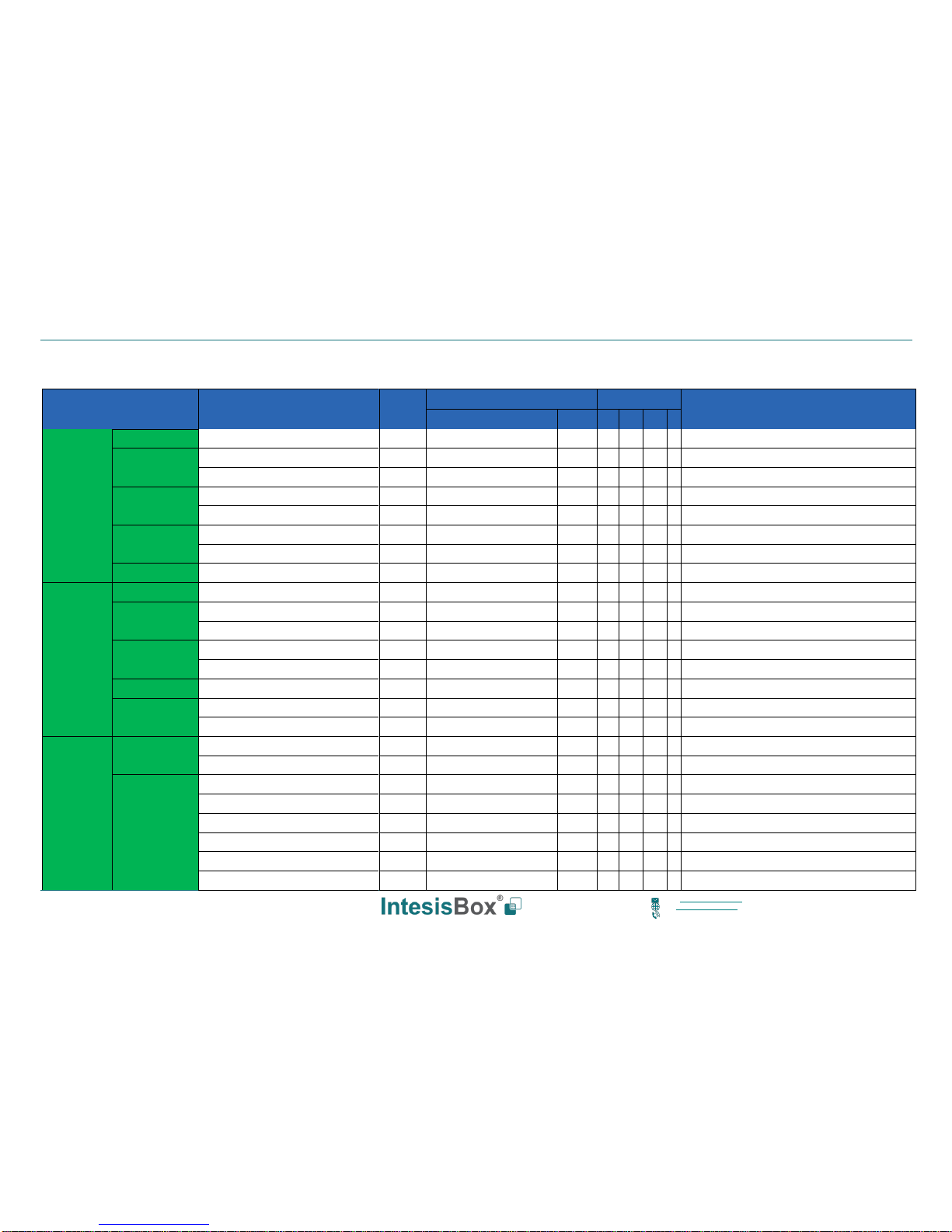

9 Appendix A – Communication Objects Table

TOPIC

NAME

LEN

DATAPOINT TYPE

FLAGS

FUNCTION

DPT_NAME

DPT_ID R W T U

GLOBAL

SIGNALS

ON/OFF

On/Off (all units)

1 bit

DPT_Switch

1.001 W

0-Off, 1-On

OP MODE

Operating Mode (all units)

1 byte

DPT_HVACContrMode

20.105 W

0-Auto, 1-Heat, 3-Cool, 9-Fan, 14-Dry

Operating Mode (all units)

1 byte

Non-standarized

5.x W

0-Auto, 1-Heat, 2-Dry, 3-Fan, 4-Cool

FAN SPEED

Fan Speed (all units)

1 byte

Non-standarized

5.x W

1-Low, 2-Mid, 3-High, 4-High+

Fan Speed AUTO (all units)

1 bit

DPT_Switch

1.001 W

1-Set auto fan; 0-Stop auto fan

VANE POSITION

Vane position (all units)

1 byte

Non-standarized

5.x W

1-Position 1...7-Position 7

Vane position AUTO (all units)

1 bit

DPT_Switch

1.001 W

1-Set auto vane; 0-Stop auto vane

SETP TEMP

Temperature Setpoint (ºC) (all units)

2 byte

DPT_Value_Temp

9.001 W

Cool:19..30 ºC; Heat:17..30 ºC

OUTDOOR

UNIT

SIGNALS

COMM ERROR

Status_Communication Error OU

1 bit

DPT_Alarm

1.005 R T

0-No error, 1-Error

TEMPERATURES

Status_Outdoor Air Temperature (ºC)

2 byte

DPT_Value_Temp

9.001 R T

-50..99 ºC

Status_Compresor Top Temperature (ºC)

2 byte

DPT_Value_Temp

9.001 R T

0..200 ºC

COMPRESOR

Status_Total Real Compresor Freq.

4 byte

DPT_Value_Frequency

14.033 R T

0..255 Hz

Status_Total Compresor Current

4 byte

DPT_Value_Electric_Current

14.019 R T

0..255 A

VALVE

Status_Out Exp. Valve 1 Open

1 byte

DPT_Scaling

5.001 R T

0..100 %

PRESSURE

Status_Discharge Pressure

4 byte

DPT_Value_Pressure

14.058 R T

-5.0..9.9 Mpa

Status_Suction Pressure

4 byte

DPT_Value_Pressure

14.058 R T

-5.0..9.9 Mpa

ON / OFF

Control _On/Off

1 bit

DPT_Switch

1.001 W

0-Off,1-On

Status _On/Off

1 bit

DPT_Switch

1.001 R T

0-Off,1-On

OP MODE

Control _Operation mode

1 byte

DPT_HVACContrMode

20.105 W

0-Auto, 1-Heat, 3-Cool, 9-Fan, 14-Dry

Status _Operation mode

1 byte

DPT_HVACContrMode

20.105 R T

0-Auto, 1-Heat, 3-Cool, 9-Fan, 14-Dry

Control _Operation mode

1 byte

Non-standarized

5.x W

0-Auto, 1-Heat, 2-Dry, 3-Fan, 4-Cool

Status _Operation mode

1 byte

Non-standarized

5.x R T

0-Auto, 1-Heat, 2-Dry, 3-Fan, 4-Cool

Control _Mode Cool/Heat

1 bit

DPT_Heat/Cool

1.100 W

0-Cool, 1-Heat

Status _Mode Cool/Heat

1 bit

DPT_Heat/Cool

1.100 R T

0-Cool, 1-Heat

Page 28

IntesisBox® KNX – HITACHI VRF User Manual r1.1 EN

28/30

This information is subject to change without prior notice

IntesisBox is a registered trademark of Intesis Software S.L.U.

email: info@intesisbox.com

web: www.intesisbox.com

phone: +34 938047134

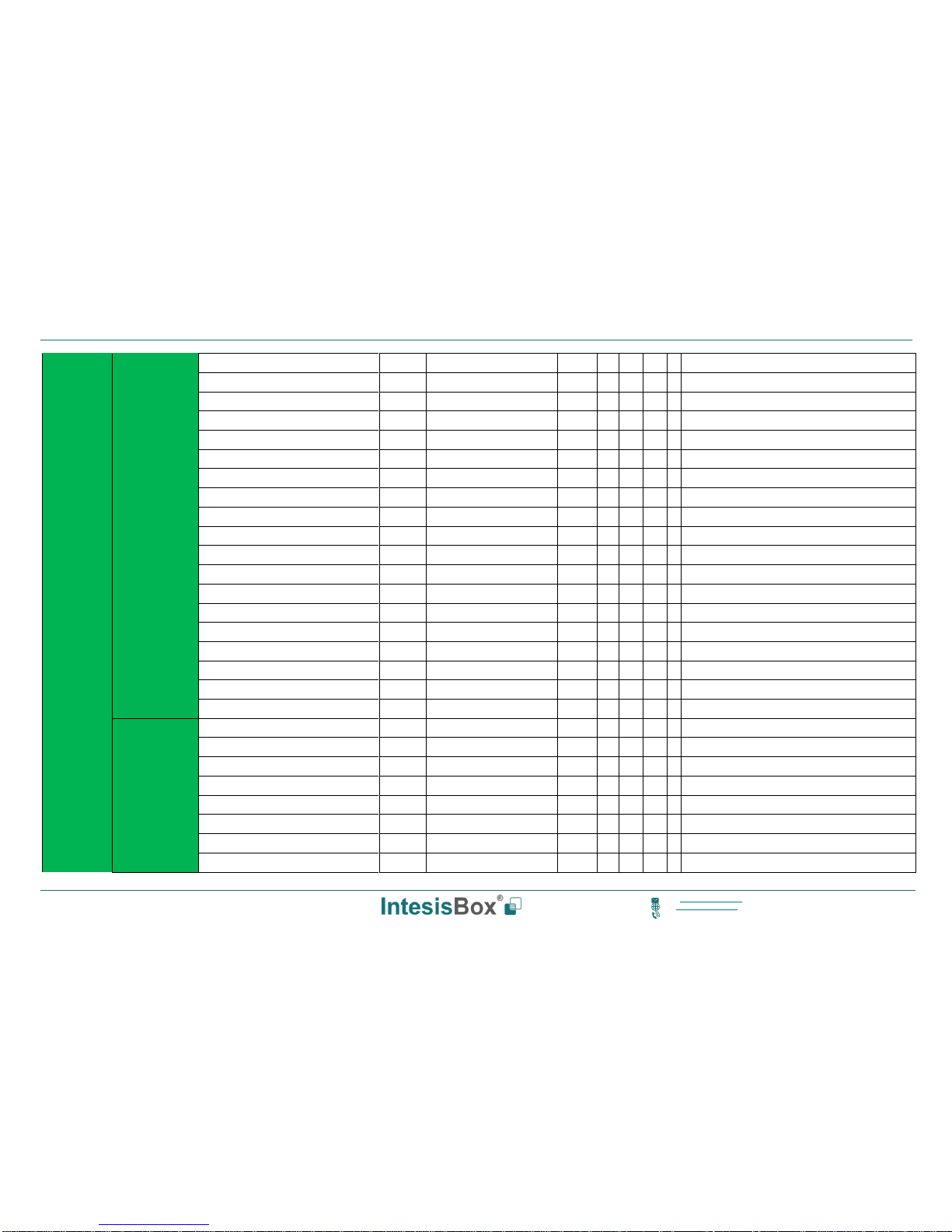

INDOOR UNIT

SIGNALS

Control _Heat mode&ON

1 byte

DPT_Scaling

5.001 W

0%-Off, 1%-100%-On+Heat

Control _Cool mode&ON

1 byte

DPT_Scaling

5.001 W

0%-Off, 1%-100%-On+Cool

Control _Auto mode

1 bit

DPT_Switch

1.001 W

1-Set auto mode

Status _Auto mode

1 bit

DPT_Switch

1.001 R T

1-Auto mode active, 0-Auto mode not active

Control _Heat mode

1 bit

DPT_Switch

1.001 W

1-Set heat mode

Status _Heat mode

1 bit

DPT_Switch

1.001 R T

1-Heat mode active, 0-Heat mode not active

Control _Cool mode

1 bit

DPT_Switch

1.001 W

1-Set cool mode

Status _Cool mode

1 bit

DPT_Switch

1.001 R T

1-Cool mode active, 0-Cool mode not active

Control _Fan mode

1 bit

DPT_Switch

1.001 W

1-Set fan mode

Status _Fan mode

1 bit

DPT_Switch

1.001 R T

1-Fan mode active, 0-Fan mode not active

Control _Dry mode

1 bit

DPT_Switch

1.001 W

1-Set dry mode

Status _Dry mode

1 bit

DPT_Switch

1.001 R T

1-Dry mode active, 0-Dry mode not active

Control_Fan speed enumerated

1 byte

Non-standarized

5.x W

1-Low, 2-Mid, 3-High, 4-High+

FAN SPEED

Status _Fan speed enumerated

1 byte

Non-standarized

5.x R T

1-Low, 2-Mid, 3-High, 4-High+

Control _Fan speed scaling

1 byte

DPT_Scaling

5.001 W

Thersholds (0%..37%; 38%..62%; 63%..87%;

Status _Fan speed scaling

1 byte

DPT_Scaling

5.001 R T

Thersholds (25%; 50%; 75%; 100%)

Control_ Fan speed low

1 bit

DPT_Switch

1.001 W

1-Set fan speed low

Status_Fan speed low

1 bit

DPT_Switch

1.001 R T

1-Speed low active, 0-Speed low not active

Control_Fan speed mid

1 bit

DPT_Switch

1.001 W

1-Set fan speed mid

Status_Fan speed mid

1 bit

DPT_Switch

1.001 R T

1-Speed mid active, 0-Speed mid not active

Control_Fan speed high

1 bit

DPT_Switch

1.001 W

1-Set fan speed high

Status_Fan speed high

1 bit

DPT_Switch

1.001 R T

1-Speed high active, 0-Speed high not active

Control_Fan speed high+

1 bit

DPT_Switch

1.001 W

1-Set fan speed high+

Status_Fan speed high+

1 bit

DPT_Switch

1.001 R T

1-Speed high+ active, 0-Speed high+ not active

Control_Fan speed Man/Auto

1 bit

DPT_Switch

1.001 W

0-Manual; 1-Auto

Status_Fan speed Man/Auto

1 bit

DPT_Switch

1.001 R T

0-Manual; 1-Auto

VANE POS

Control_Vane position enumerated

1 byte

Non-standarized

5.x W

1-Position 1..7-Position 7

Page 29

IntesisBox® KNX – HITACHI VRF User Manual r1.1 EN

29/30

This information is subject to change without prior notice

IntesisBox is a registered trademark of Intesis Software S.L.U.

email: info@intesisbox.com

web: www.intesisbox.com

phone: +34 938047134

INDOOR UNIT

SIGNALS

Status_Vane position enumerated

1 byte

Non-standarized

5.x R T

1-Position 1..7-Position 7

Control_Vane position scaling

1 byte

DPT_Scaling

5.001 W

Thersholds(0..21%;22..36%;37..50%;51..64%;65..79%;8

Status_Vane position scaling

1 byte

DPT_Scaling

5.001 R T

Thersholds(0..14%;15..29%;30..43%;44..57%;58..71%;7

Control_Vane position auto

1 bit

DPT_Switch

1.001 R T

1-Set auto vane, 0-Stop auto vane

Status_Vane position auto

1 bit

DPT_Switch

1.001 W

1-Vane auto active, 0-Vane auto not active

Control_Vane position position-1

1 bit

DPT_Switch

1.001 R T

1-Set position-1 vane

Status_Vane position position-1

1 bit

DPT_Switch

1.001 W

1-Vane position-1 active, 0-Vane position-1 not active

Control_Vane position position-2

1 bit

DPT_Switch

1.001 R T

1-Set position-2 vane

Status_Vane position position-2

1 bit

DPT_Switch

1.001 W

1-Vane position-2 active, 0-Vane position-2 not active

Control_Vane position position-3

1 bit

DPT_Switch

1.001 R T

1-Set position-3 vane

Status_Vane position position-3

1 bit

DPT_Switch

1.001 W

1-Vane position-3 active, 0-Vane position-3 not active

Control_Vane position position-4

1 bit

DPT_Switch

1.001 R T

1-Set position-4 vane

Status_Vane position position-4

1 bit

DPT_Switch

1.001 W

1-Vane position-4 active, 0-Vane position-4 not active

Control_Vane position position-5

1 bit

DPT_Switch

1.001 R T

1-Set position-5 vane

Status_Vane position position-5

1 bit

DPT_Switch

1.001 W

1-Vane position-5 active, 0-Vane position-5 not active

Control_Vane position position-6

1 bit

DPT_Switch

1.001 R T

1-Set position-6 vane

Status_Vane position position-6

1 bit

DPT_Switch

1.001 W

1-Vane position-6 active, 0-Vane position-6 not active

Control_Vane position position-7

1 bit

DPT_Switch

1.001 R T

1-Set position-7 vane

Status_Vane position position-7

1 bit

DPT_Switch

1.001 W

1-Vane position-7 active, 0-Vane position-7 not active

TEMPERATURES

Control_Temperature Setpoint (ºC)

2 byte

DPT_Value_Temp

9.001 W

Cool:19..30 ºC; Heat:17..30 ºC

Status_Temperature Setpoint (ºC)

2 byte

DPT_Value_Temp

9.001 R T

Cool:19..30 ºC; Heat:17..30 ºC

Status_AC Ambient Temperature (ºC)

2 byte

DPT_Value_Temp

9.001 R T

-63..63 ºC

Status_Remote Sensor Temperature (ºC)

2 byte

DPT_Value_Temp

9.001 R T

-63..63 ºC

Control_KNX ambient Temperature (ºC)

2 byte

DPT_Value_Temp

9.001 W

ºC

Status_Outlet Temperature (ºC)

2 byte

DPT_Value_Temp

9.001 W

-63..63 ºC

Status_GasPipe Temperature (ºC)

2 byte

DPT_Value_Temp

9.001 R T

-63..63 ºC

Status_LiquidPipe Temperature (ºC)

2 byte

DPT_Value_Temp

9.001 W

-63..63 ºC

Page 30

IntesisBox® KNX – HITACHI VRF User Manual r1.1 EN

30/30

This information is subject to change without prior notice

IntesisBox is a registered trademark of Intesis Software S.L.U.

email: info@intesisbox.com

web: www.intesisbox.com

phone: +34 938047134

INDOOR UNIT

SIGNALS

ERROR CODE

Status_Unit error

1 bit

1.005-DPT_Alarm

1.005 R T

0-No error, 1-Error

Status_Unit error code

2 byte

Non-standarized

8.x R T

0-No Error, X-Error (100..999)

FILTER

Status_FilterSign

1 bit

DPT_Alarm

1.005 R T

0-Normal, 1-Alarm

Control _FilterReset

1 bit

DPT_Reset

1.015 W

0-No reset, 1-Reset

COMM STATUS

Status_Communication status

1 bit

DPT_Switch

1.001 R T

0-Not exist, 1-Exist

REMOC.

Control_On/Off Remote controll

disablement

1 bit

DPT_Bool

1.002 W

0-No disabled, 1-Disabled

Status_On/Off Remote controll

disablement

1 bit

DPT_Bool

1.002 R T

0-No disabled, 1-Disabled

Control_Mode Remote controll

disablement

1 bit

DPT_Bool

1.002 W

0-No disabled, 1-Disabled

Status_Mode Remote controll disablement

1 bit

DPT_Bool

1.002 R T

0-No disabled, 1-Disabled

Control_Setpoint Remote controll

disablement

1 bit

DPT_Bool

1.002 W

0-No disabled, 1-Disabled

Status_Setpoint Remote controll

disablement

1 bit

DPT_Bool

1.002 R T

0-No disabled, 1-Disabled

Control_Fan Remote controll disablement

1 bit

DPT_Bool

1.002 W

0-No disabled, 1-Disabled

Status_Fan Remote controll disablement

1 bit

DPT_Bool

1.002 R T

0-No disabled, 1-Disabled

SYSTEM INFO

Status_Unit type

1 byte

DPT_Value_1_Ucount

5.010 R T

1-SS, 2-FC, 3-VRF, 4-IU, 5-ES, 13-Not Defined

Status_Unit adress

1 byte

DPT_Value_1_Ucount

5.010 R T

1..64

Status_System adress

1 byte

DPT_Value_1_Ucount

5.010 R T

1..64

DEHUMIDIFICATION

Status_Dehumidification

1 bit

DPT_Switch

1.001 R T

0-Off,1-On

Control_Dehumidification correction

1 byte

DPT_Value_1_Ucount

5.010 W

0..2

Status_Dehumidification correction

1 byte

DPT_Value_1_Ucount

5.010 R T

0..2

OTHERS

Status_Compresor stop cause

2 byte

Non-standarized

8.x R T

X-Cause (0-254), 255-Operation Off

Status_Expansion valve open

1 byte

DPT_Scaling

5.001 R T

0..100 %

Status_Operation condition

1 byte

Non-standarized

5.x R T

0-Off, 1-Thermo Off, 2-Thermo On, 3-Alarm

Status_RC SW Temperature (ºC)

2 byte

DPT_Value_Temp

9.001 R T

-63..63 ºC

Status_RC SW Configuration

1 bit

DPT_Switch

1.001 R T

0-Without RCS, 1-With RCS

Loading...

Loading...