Page 1

IntesisBox

®

KNX

HA-AC-KNX-8/16/64 v1.0

User's Manual

r1 eng

Issue Date: 11/2017

Page 2

IntesisBox® KNX - Haier A.C. (VRF line)

User's manual r1.0 EN

© Intesis Software S.L.U. - All rights reserved

This information is subject to change without notice

IntesisBox is a registred trademark of Intesis Software SLU

URL

email

tel

http://www.intesisbox.com

info@intesisbox.com

+34 938047134

2 / 31

Interface for integration of Haier air conditioners

into KNX TP-1 (EIB) control systems.

Compatible with VRF air conditioners line commercialized by Haier.

Application’s Program Version: 1.0

Order Code: HA-AC-KNX-8

HA-AC-KNX-16

HA-AC-KNX-64

Page 3

IntesisBox® KNX - Haier A.C. (VRF line)

User's manual r1.0 EN

© Intesis Software S.L.U. - All rights reserved

This information is subject to change without notice

IntesisBox is a registred trademark of Intesis Software SLU

URL

email

tel

http://www.intesisbox.com

info@intesisbox.com

+34 938047134

3 / 31

© Intesis Software S.L.U. 2017 All Rights Reserved.

Information in this document is subject to change without notice. The software described in this

document is furnished under a license agreement or nondisclosure agreement. The software

may be used only in accordance with the terms of those agreements. No part of this publication

may be reproduced, stored in a retrieval system or transmitted in any form or any means

electronic or mechanical, including photocopying and recording for any purpose other than the

purchaser’s personal use without the written permission of Intesis Software S.L.

Intesis Software S.L.U.

Milà i Fontanals, 1 bis

08700 Igualada

Spain

TRADEMARKS

All trademarks and trade names used in this document are acknowledged to be the copyright of

their respective holders.

Page 4

IntesisBox® KNX - Haier A.C. (VRF line)

User's manual r1.0 EN

© Intesis Software S.L.U. - All rights reserved

This information is subject to change without notice

IntesisBox is a registred trademark of Intesis Software SLU

URL

email

tel

http://www.intesisbox.com

info@intesisbox.com

+34 938047134

4 / 31

INDEX

1 Presentation.............................................................................................................. 5

2 Connection ............................................................................................................... 6

3 Configuration and setup ............................................................................................. 7

4 ETS Parameters ......................................................................................................... 8

4.1 General configuration .......................................................................................... 9

4.1.1 Download latest database entry for this product and its User Manual from: .......... 9

4.1.2 Intesis Product ............................................................................................. 9

4.1.3 Number of Indoor Units in ETS ....................................................................... 9

4.1.4 First Status Updated to KNX ......................................................................... 10

4.1.5 Enable object “Error Code [2byte]” ............................................................... 10

4.1.6 Enable object “Error Text Code [14byte]” ....................................................... 10

4.2 Global mode configuration.................................................................................. 11

4.2.1 Enable use of “Operating Mode” objects ......................................................... 11

4.2.2 Enable use of Mode Heat/Cool objects ........................................................... 11

4.2.3 Enable use of + / - object for Mode ............................................................... 12

4.2.4 Enable use of bit-type Mode objects (for control) ............................................ 12

4.2.5 Enable use of bit-type Mode objects (for status) ............................................. 13

4.2.6 Enable use of Text object for Mode................................................................ 13

4.3 Global Fan Speed Configuration dialog ................................................................. 14

4.3.1 DPT object type for fan speed ....................................................................... 14

4.3.2 Enable use of “Fan Speed Man/Auto” objects (for Control and Status) ............... 15

4.3.3 Enable use of +/- object for Fan Speed .......................................................... 15

4.3.4 Enable use of bit-type Fan Speed objects (for Control) .................................... 16

4.3.5 Enable use of bit-type Fan Speed objects (for Status) ..................................... 17

4.3.6 Enable use of Text object for Fan Speed ........................................................ 17

4.4 Global temperature configuration ........................................................................ 18

4.4.1 Enable use of +/- obj for Setpoint ................................................................. 18

4.4.2 Ambient Ref. Temp. is provided from KNX ...................................................... 18

4.5 Control Mode configuration ................................................................................. 20

4.5.1 Enable use of Control Mode objects (for Control and Status) ............................ 20

4.5.1 Initial state of Control Mode ......................................................................... 20

4.6 Addressing of Indoor Units ................................................................................. 22

4.7 License ............................................................................................................ 23

5 Technical Specifications ............................................................................................ 24

6 AC Unit Types compatibility. ..................................................................................... 25

7 Error Codes............................................................................................................. 26

Appendix A – Communication Objects Table ..................................................................... 29

Page 5

IntesisBox® KNX - Haier A.C. (VRF line)

User's manual r1.0 EN

© Intesis Software S.L.U. - All rights reserved

This information is subject to change without notice

IntesisBox is a registred trademark of Intesis Software SLU

URL

email

tel

http://www.intesisbox.com

info@intesisbox.com

+34 938047134

5 / 31

1 Presentation

HA-AC-KNX-8/16/64 allows a complete and natural integration of

Haier air conditioners with KNX control systems.

Compatible with all models of VRF line of Haier air conditioners.

Main features:

• Reduced dimensions. Installation even inside the A.C. indoor unit.

• Quick and non-visible installation.

• External power not required.

• Direct connection to the KNX EIB bus.

• Direct connection to the AC indoor unit.

• Fully KNX interoperable, configuration from ETS.

• Multiple objects for control (of different types: bit, byte, characters…).

• Control of the AC unit based in the ambient temperature read by the own AC unit, or in the

ambient temperature read by any KNX thermostat.

• Total Control and Monitoring of the AC unit from KNX, including monitoring of AC unit’s state

of internal variables, running hours counter (for filter maintenance control), and error

indication and error code.

• AC unit can be controlled simultaneously by the IR remote control of the AC unit and by

KNX.

Page 6

IntesisBox® KNX - Haier A.C. (VRF line)

User's manual r1.0 EN

© Intesis Software S.L.U. - All rights reserved

This information is subject to change without notice

IntesisBox is a registred trademark of Intesis Software SLU

URL

email

tel

http://www.intesisbox.com

info@intesisbox.com

+34 938047134

6 / 31

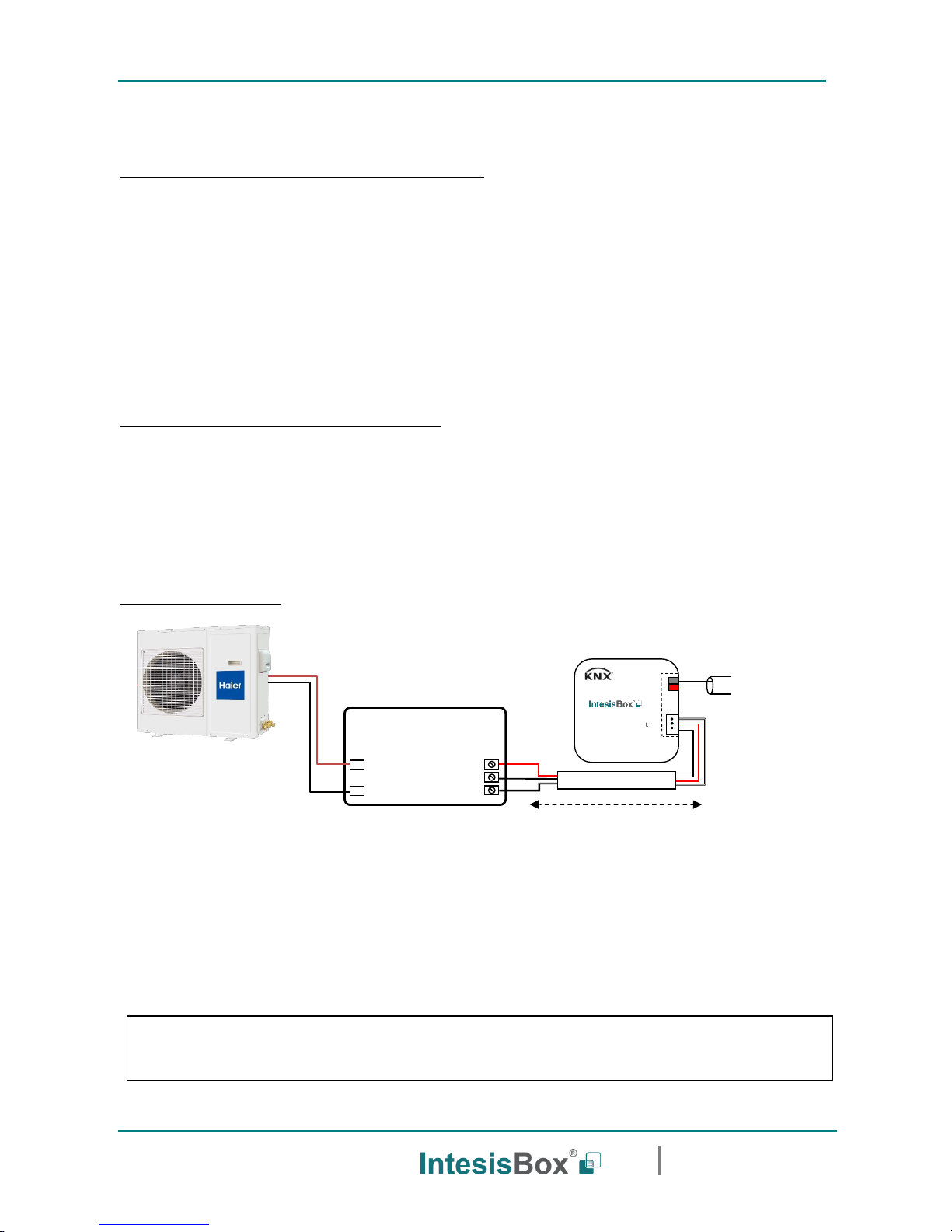

2 Connection

Connection of the interface to the AC indoor unit:

Disconnect mains power from the AC unit. Open the front cover of the indoor unit in order to

have access to the internal control board. In the control board locate the socket connector

marked as ABG1.

Using a 3-wire cable, connect the ABG1 connector from the HA-AC-KNX-8/16/64 to the A B G1

connector of the AC unit's control board.

Fix the HA-AC-KNX-8/16/64 inside or outside the AC indoor unit depending on your needs –

remember that HA-AC-KNX-8/16/64 must be also connected to the KNX bus. Close the AC

indoor unit's front cover again.

Connection of the interface to the KNX bus:

Disconnect power of the KNX bus. Connect the interface to the KNX TP-1 (EIB) bus using the

KNX standard connector (red/grey) of the interface, respect polarity. Reconnect power of the

KNX bus.

Connections diagram:

Figure 2.1 Default parameter configuration

Each Haier Communication Adaptor connects to a single Outdoor Unit.

The HA-AC-KNX-8-16-64 can be connected to more than one Haier Communication Adaptor

simultaneously.

NOTE: More than one Haier Communication Adaptor can be present in the installation.

Please make sure that the address of the Haier Communication Adaptor is correctly set in

the ETS. Check section 4.6 for more information.

Max. 500 m

A

U2 B

G1

Internal electronic

control board

A

U3

B

Haier Outdoor Unit

Unidad Exterior Haier

KNX TP-1

(EIB) bus

Connection to ABG1

bus. Three wires

cable.

Conexión al bus ABG1.

Cable de tres hilos.

G1

A

B

HA-AC-KNX-x

www.intesisbox.com

PROG

Haier Communication Adaptor

Adaptador de Comunicación Haier

HA-MA164AD

HA-MB164AD

HA-MC164AD

Page 7

IntesisBox® KNX - Haier A.C. (VRF line)

User's manual r1.0 EN

© Intesis Software S.L.U. - All rights reserved

This information is subject to change without notice

IntesisBox is a registred trademark of Intesis Software SLU

URL

email

tel

http://www.intesisbox.com

info@intesisbox.com

+34 938047134

7 / 31

3 Configuration and setup

This is a fully compatible KNX device which must be configured and setup using standard KNX

tool ETS.

ETS project for this device can be downloaded from:

https://www.intesisbox.com/en/haier-knx-ac-ha-ac-knx-8_16_64/gateway/

Please consult the README.txt file, located inside the downloaded zip file, to find instructions on

how to install the database.

Page 8

IntesisBox® KNX - Haier A.C. (VRF line)

User's manual r1.0 EN

© Intesis Software S.L.U. - All rights reserved

This information is subject to change without notice

IntesisBox is a registred trademark of Intesis Software SLU

URL

email

tel

http://www.intesisbox.com

info@intesisbox.com

+34 938047134

8 / 31

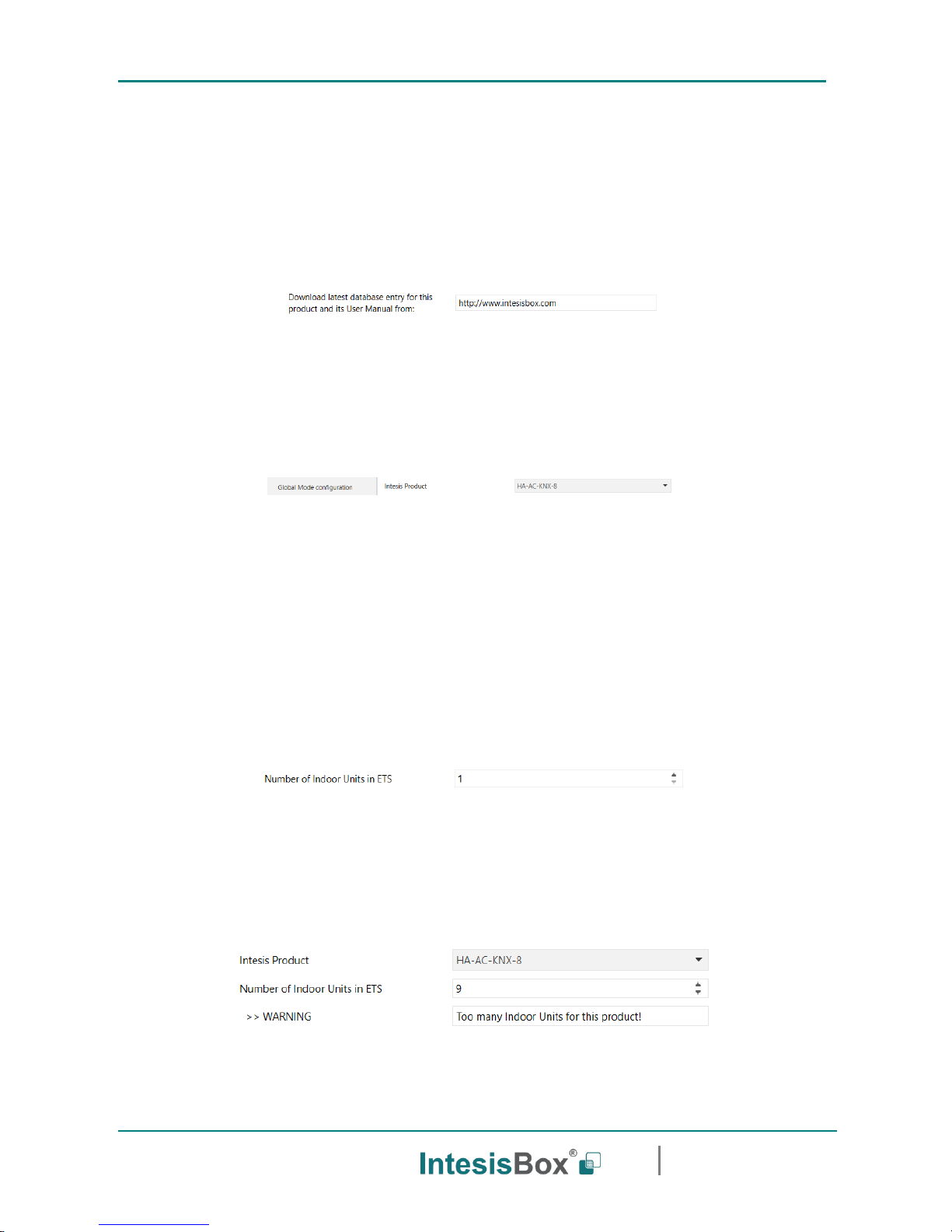

4 ETS Parameters

When imported to the ETS software for the first time, the gateway shows the following default

parameter configuration:

Figure 4.1 Default parameter configuration

With this configuration it’s possible to send On/Off (Control_ On/Off), change the AC Mode

(Control_ Mode), the Fan Speed (Control_ Fan Speed) and also the Setpoint Temperature

(Control_ Setpoint Temperature). The Status_ objects, for the mentioned Control_ objects, are

also available to use if needed. Objects Status_ AC Ambient Reference Temperature and

Status_ Error/Alarm are shown too.

Figure 4.2 Default communication objects

Page 9

IntesisBox® KNX - Haier A.C. (VRF line)

User's manual r1.0 EN

© Intesis Software S.L.U. - All rights reserved

This information is subject to change without notice

IntesisBox is a registred trademark of Intesis Software SLU

URL

email

tel

http://www.intesisbox.com

info@intesisbox.com

+34 938047134

9 / 31

4.1 General configuration

Inside this parameter’s dialog it is possible to activate or change the parameters shown in the

Figure 4.1.

4.1.1 Download latest database entry for this product and its User Manual from:

The first field shows the URL where to download the database and the user manual for the

product.

Figure 4.3 Parameter detail

4.1.2 Intesis Product

This parameter is used to check, before sending the programing, the maximum number of AC

units your device supports.

Figure 4.4 Parameter detail

Select the version of the gateway that you have:

• HA-AC-KNX-8, if you only want to control up to 8 AC unit.

• HA-AC-KNX-16, if you only want to control up to 16 AC units.

• HA-AC-KNX-64, if you only want to control up to 64 AC units.

4.1.3 Number of Indoor Units in ETS

This parameter is used to hide/show communication object according to the number of AC units

you need to configure. Value ranges go from 1 to 64.

Figure 4.5 Parameter detail

In case you introduce a number higher than the maximum number of units allowed by your

license, you will get a warning message. This is just for information and will not block the

configuration process. Configurations with more indoor units configured than the ones allowed

by the license will not be downloaded correctly.

Figure 4.6 Parameter detail

Page 10

IntesisBox® KNX - Haier A.C. (VRF line)

User's manual r1.0 EN

© Intesis Software S.L.U. - All rights reserved

This information is subject to change without notice

IntesisBox is a registred trademark of Intesis Software SLU

URL

email

tel

http://www.intesisbox.com

info@intesisbox.com

+34 938047134

10 / 31

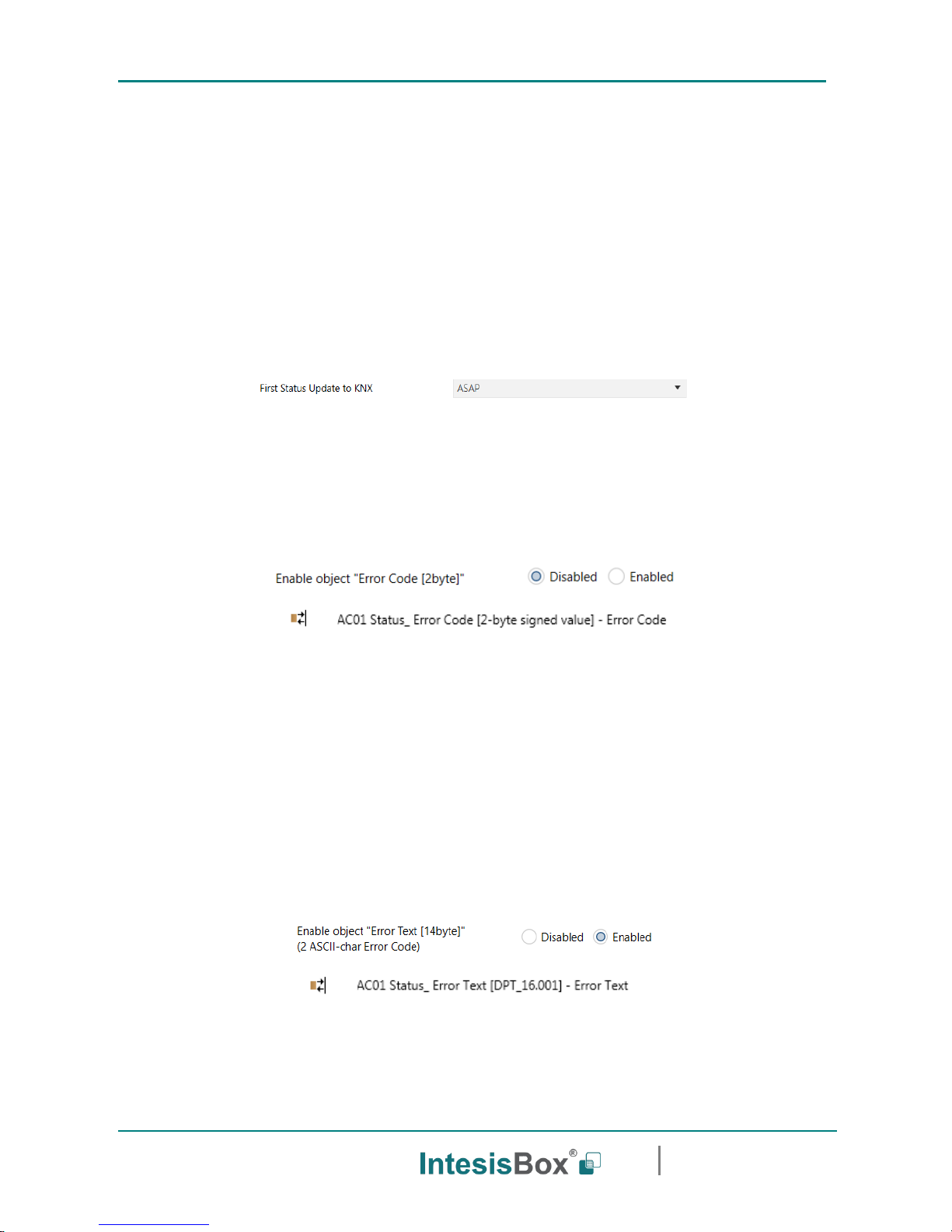

4.1.4 First Status Updated to KNX

This parameter defines how fast the status is updated to KNX. Depending on the value selected,

more or less priority will be assigned to this action. As there are so many parameters available,

it is important to consider carefully how to set this parameter.

o If set to “ASAP”, all status communication objects will send its value (if needed).

o If set to “Slow”, all status communication objects will send its value (if needed), but slower

than in the previous option (ASAP).

o If set to “Super Slow”, all status communication objects will send its value (if needed), but

slower than in the previous option (Slow).

Figure 4.7 Parameter detail

4.1.5 Enable object “Error Code [2byte]”

This parameter shows/hides the Status_ Error Code communication object which shows the

indoor unit errors, if occurred, in numeric format.

43:

Figure 4.8 Communication object and parameter detail

o If set to “Disabled” the object will not be shown.

o If set to “Enabled” the Status_ Error Code [2byte signed value] object will appear.

• This object can be read and also sends the indoor unit error, if occurred, in

numeric format. If a “0” value is shown that means no error.

4.1.6 Enable object “Error Text Code [14byte]”

This parameter shows/hides the Status_ Error Text Code communication object which shows

the indoor unit errors, if occurred, in text format.

44:

Figure 4.9 Communication object and parameter detail

o If set to “Disabled” the object will not be shown.

o If set to “Enabled” the Status_ Error Text Code object will appear.

Page 11

IntesisBox® KNX - Haier A.C. (VRF line)

User's manual r1.0 EN

© Intesis Software S.L.U. - All rights reserved

This information is subject to change without notice

IntesisBox is a registred trademark of Intesis Software SLU

URL

email

tel

http://www.intesisbox.com

info@intesisbox.com

+34 938047134

11 / 31

• This object can be read and also sends the indoor unit error, if occurred, in text

format. The errors shown have the same format as in the remote controller and in

the error list from the indoor unit manufacturer. If the object’s value is empty,

that means there is no error.

4.2 Global mode configuration

Figure 4.10 Default Mode Configuration dialog

All the parameters in this section are related with the different mode properties and

communication objects.

3:

26:

The byte-type communication object for Mode works with the DTP_20.105. Auto mode will be

enabled with a “0” value, Heat mode with a “1” value, Cool mode with a “3” value, Fan mode

with a “9” value and Dry mode with a “14” value.

4.2.1 Enable use of “Operating Mode” objects

This parameter shows/hides the Control_ and Status_ Mode Operating Mode communication

objects.

2:

25:

4.2.2 Enable use of Mode Heat/Cool objects

This parameter shows/hides the Control_ and Status_ Mode Cool/Heat communication objects.

4:

27:

o If set to “Disabled” the objects will not be shown.

Page 12

IntesisBox® KNX - Haier A.C. (VRF line)

User's manual r1.0 EN

© Intesis Software S.L.U. - All rights reserved

This information is subject to change without notice

IntesisBox is a registred trademark of Intesis Software SLU

URL

email

tel

http://www.intesisbox.com

info@intesisbox.com

+34 938047134

12 / 31

o If set to “Enabled” the Control_ and Status_ Mode Cool/Heat objects will appear.

• When a “1” value is sent to the Control_ communication object, Heat mode

will be enabled in the indoor unit, and the Status_ object will return this value.

• When a “0” value is sent to the Control_ communication object, Cool mode

will be enabled in the indoor unit, and the Status_ object will return this value.

4.2.3 Enable use of + / - object for Mode

This parameter shows/hides the Control_ Mode +/- communication object which let’s you

change the indoor unit mode by using two different datapoint types.

10:

o If set to “Disabled” the object will not be shown.

o If set to “Enabled” the Control_ Mode +/- object and a new parameter will appear.

Figure 4.11 Parameter detail

➢ DPT type for +/- Mode Object

This parameter lets choose between the datapoints 0-Up / 1-Down [DPT_1.008] and

0-Decrease / 1-Increase [DPT_1.007] for the Control_ Mode +/- object.

The sequence followed when using this object is shown below:

Keep in mind that depending on the indoor unit you have and the available features,

Auto mode and Dry mode may not be present.

4.2.4 Enable use of bit-type Mode objects (for control)

This parameter shows/hides the bit-type Control_ Mode objects.

5:

6:

7:

8:

▪ Up / Increase

▪ Down / Decrease

DRY

AUTO

HEAT

COOL

FAN

Page 13

IntesisBox® KNX - Haier A.C. (VRF line)

User's manual r1.0 EN

© Intesis Software S.L.U. - All rights reserved

This information is subject to change without notice

IntesisBox is a registred trademark of Intesis Software SLU

URL

email

tel

http://www.intesisbox.com

info@intesisbox.com

+34 938047134

13 / 31

9:

o If set to “no” the objects will not be shown.

o If set to “yes” the Control_ Mode objects for Auto, Heat, Cool, Fan and Dry will appear. To

activate a mode by using these objects a “1” value has to be sent.

4.2.5 Enable use of bit-type Mode objects (for status)

This parameter shows/hides the bit-type Status_ Mode objects.

28:

29:

30:

31:

32:

o If set to “no” the objects will not be shown.

o If set to “yes” the Status_ Mode objects for Auto, Heat, Cool, Fan and Dry will appear.

When enabled, a mode will return a “1” through its bit-type object.

4.2.6 Enable use of Text object for Mode

This parameter shows/hides the Status_ Mode Text communication object.

33:

o If set to “no” the object will not be shown.

o If set to “yes” the Status_ Mode Text object will appear. Also, in the parameters, will be

shown five text fields, one for each mode, that will let modify the text string displayed by

the Status_ Mode Text when changing mode.

Figure 4.12 Parameter detail

Page 14

IntesisBox® KNX - Haier A.C. (VRF line)

User's manual r1.0 EN

© Intesis Software S.L.U. - All rights reserved

This information is subject to change without notice

IntesisBox is a registred trademark of Intesis Software SLU

URL

email

tel

http://www.intesisbox.com

info@intesisbox.com

+34 938047134

14 / 31

4.3 Global Fan Speed Configuration dialog

Figure 4.13 Default Fan Speed Configuration dialog

All the parameters in this section are related with the Fan Speed properties and communication

objects.

4.3.1 DPT object type for fan speed

With this parameter is possible to change de DPT for the Control_ Fan Speed and Status_ Fan

Speed byte-type communication objects. Datapoints Scaling (DPT_5.001) and Enumerated

(DPT_5.010) can be selected.

o When “Enumerated [DPT 5.010]” is selected, Control_ Fan Speed and Status_ Fan Speed

communication objects for this DPT will appear. Also, depending on the number of fan

speeds selected, these objects will be different.

11:

34:

The first fan speed will be selected if a “1” is sent to the Control_ object. The second

one will be selected sending a “2”, and the last one sending a “3”.

The Status_ object will always return the value for the fan speed selected.

Important: If a “0” value is sent to the Control_ object, the minimum fan speed will be

selected. If a value bigger than “3” is sent to the Control_ object, then the maximum

fan speed will be selected.

o When “Scaling [DPT 5.001]” is selected, Control_ Fan Speed and Status_ Fan Speed

communication objects for this DPT will appear. Also, depending on the number of fan

speeds selected, these objects will be different.

11:

34:

Page 15

IntesisBox® KNX - Haier A.C. (VRF line)

User's manual r1.0 EN

© Intesis Software S.L.U. - All rights reserved

This information is subject to change without notice

IntesisBox is a registred trademark of Intesis Software SLU

URL

email

tel

http://www.intesisbox.com

info@intesisbox.com

+34 938047134

15 / 31

When a value between 0% and 49% is sent to the Control_ object the first fan speed will

be selected.

When a value between 50% and 83% is sent to the Control_ object, the second speed will

be selected.

When a value between 84% and 100% is sent to the Control_ object, the third speed will

be selected.

The Status_ object will return a 33% when the first speed is selected, a 67% for the

second one and a 100% for the third one.

4.3.2 Enable use of “Fan Speed Man/Auto” objects (for Control and Status)

This parameter shows/hides the Control_ Fan Speed Man/Auto and Status_ Fan Speed

Man/Auto communication object which lets you set the Fan Speed into Manual or Auto mode.

12:

35:

4.3.3 Enable use of +/- object for Fan Speed

This parameter shows/hides the Control_ Fan Speed +/- communication object which lets you

increase/decrease the indoor unit fan speed by using two different datapoint types.

16:

o If set to “no” the object will not be shown.

o If set to “yes” the Control_ Fan Speed +/- object and a new parameter will appear.

Figure 4.14 Parameter detail

➢ Fan speed +/- operation

This parameter lets choose between the datapoints 0-Up / 1-Down [DPT_1.008] and

0-Decrease / 1-Increase [DPT_1.007] for the Control_ Fan Speed +/- object.

Fan Speed 1

Fan Speed 3

100%

Status_

0%

83%

50%

Control_

Control_

Status_

33%

67%

Fan Speed 2

Control_

Status_

Page 16

IntesisBox® KNX - Haier A.C. (VRF line)

User's manual r1.0 EN

© Intesis Software S.L.U. - All rights reserved

This information is subject to change without notice

IntesisBox is a registred trademark of Intesis Software SLU

URL

email

tel

http://www.intesisbox.com

info@intesisbox.com

+34 938047134

16 / 31

➢ Sequence for +/- object

This parameter lets choose between the different modes available:

• S1>S2>….>SN

Select this option if you don’t have Auto mode and you don’t want roll-over to be

enabled.

• S1>S2>….>SN>S1>…

Select this option if you don’t have Auto mode and you want roll-over to be

enabled.

• Auto>S1>S2>….>SN

Select this option if you have Auto mode and you don’t want roll-over to be

enabled.

• Auto>S1>S2>….>SN>Auto>S1>…

Select this option if you have Auto mode and you want roll-over to be enabled.

4.3.4 Enable use of bit-type Fan Speed objects (for Control)

This parameter shows/hides the bit-type Control_ Fan Speed objects.

13:

14:

15:

o If set to “no” the objects will not be shown.

o If set to “yes” the Control_ Fan Speed objects for Speed 1, Speed 2 and Speed 3 (if

available) will appear. To activate a Fan Speed by using these objects a “1” value has to be

sent.

▪ Up / Increase

▪ Down / Decrease

Fan Speed 3

Fan Speed 1

Fan Speed 2

Only if Roll-over is enabled

Only if Roll-over is enabled

Page 17

IntesisBox® KNX - Haier A.C. (VRF line)

User's manual r1.0 EN

© Intesis Software S.L.U. - All rights reserved

This information is subject to change without notice

IntesisBox is a registred trademark of Intesis Software SLU

URL

email

tel

http://www.intesisbox.com

info@intesisbox.com

+34 938047134

17 / 31

4.3.5 Enable use of bit-type Fan Speed objects (for Status)

This parameter shows/hides the bit-type Status_ Fan Speed objects.

36:

37:

38:

o If set to “no” the objects will not be shown.

o If set to “yes” the Status_ Fan Speed objects for Speed 1, Speed 2 and Speed 3 (if

available) will appear. When a Fan Speed is enabled, a “1” value is returned through its bittype object.

4.3.6 Enable use of Text object for Fan Speed

This parameter shows/hides the Status_ Fan Speed Text communication object.

39:

o If set to “no” the object will not be shown.

o If set to “yes” the Status_ Fan Speed Text object will appear. Also, in the parameters, will

be shown two (or three, depending on the number of fan speeds selected) text fields, one

for each Fan Speed, that will let modify the text string displayed by the Status_ Fan Speed

Text when changing a fan speed.

Figure 4.15 Parameter detail

Page 18

IntesisBox® KNX - Haier A.C. (VRF line)

User's manual r1.0 EN

© Intesis Software S.L.U. - All rights reserved

This information is subject to change without notice

IntesisBox is a registred trademark of Intesis Software SLU

URL

email

tel

http://www.intesisbox.com

info@intesisbox.com

+34 938047134

18 / 31

4.4 Global temperature configuration

Figure 4.20 Default Temperature Configuration dialog

All the parameters in this section are related with the Temperature properties and

communication objects.

4.4.1 Enable use of +/- obj for Setpoint

This parameter shows/hides the Control_ Setpoint Temp +/- communication object which lets

you change the indoor unit setpoint temperature by using two different datapoint types.

18:

o If set to “no” the object will not be shown.

o If set to “yes” the Control_ Setpoint Temp +/- object and a new parameter will appear.

Figure 4.23 Parameter detail

➢ DPT type for +/- Setp Temp object

This parameter lets choose between the datapoints 0-Up / 1-Down [DPT_1.008] and

0-Decrease / 1-Increase [DPT_1.007] for the Control_ Setpoint Temp +/- object.

4.4.2 Ambient Ref. Temp. is provided from KNX

▪ Up / Increase

▪ Down / Decrease

…

16ºC

17ºC

32ºC

31ºC

(Upper limit)

(Lower limit)

Page 19

IntesisBox® KNX - Haier A.C. (VRF line)

User's manual r1.0 EN

© Intesis Software S.L.U. - All rights reserved

This information is subject to change without notice

IntesisBox is a registred trademark of Intesis Software SLU

URL

email

tel

http://www.intesisbox.com

info@intesisbox.com

+34 938047134

19 / 31

This parameter shows/hides the Control_ Ambient Temperature communication object which

lets you use an ambient temperature reference provided by a KNX device.

19:

o If set to “no” the object will not be shown.

o If set to “yes” the Control_ Ambient Temperature object will appear. Meant to be enabled

when you want the temperature provided by a KNX sensor to be the reference ambient

temperature for the air conditioner. Then, the following formula applies for the calculation of

real Control_ Setpoint Temperature sent ot the AC unit:

As an example, consider the following situation:

User wants: 19ºC (“KNX Setp. Temp.”)

User sensor (a KNX sensor) reads: 21ºC (“KNX Amb Temp.”)

Ambient temp. read by Haier system is: 24ºC (“Ambient Ref. Temp”)

In this example, the final setpoint temperature that HA-AC-KNX-8/16/64 will send

out to the indoor unit (shown in “Setp. Temp.”) will become 24ºC – (21ºC - 19ºC)

= 22ºC. This is the setpoint that will actually be requested to Haier unit.

This formula will be applied as soon as the Control_ Setpoint Temperature and

Control_ Ambient Temperature objects are written at least once from the KNX

installation. After that, they are kept always consistent.

Note that this formula will always drive the AC indoor unit demand in the right

direction, regardless of the operation mode (Heat, Cool or Auto).

“AC Setp. Temp” = “Ambient ref. Temp” - (“KNX Amb. Temp.” - “KNX Setp Temp.”)

▪ AC Setp. Temp: AC indoor unit setpoint temperature

▪ Ambient Ref. Temp: AC indoor unit return temperature

▪ KNX Amb. Temp.: Ambient temperature provided from KNX

▪ KNX Setp. Temp: Setpoint temperature provided from KNX

Page 20

IntesisBox® KNX - Haier A.C. (VRF line)

User's manual r1.0 EN

© Intesis Software S.L.U. - All rights reserved

This information is subject to change without notice

IntesisBox is a registred trademark of Intesis Software SLU

URL

email

tel

http://www.intesisbox.com

info@intesisbox.com

+34 938047134

20 / 31

4.5 Control Mode configuration

Figure 4.20 Control Mode Configuration dialog

All the parameters in this section are related with the Mode properties and communication

objects.

4.5.1 Enable use of Control Mode objects (for Control and Status)

This parameter shows/hides the Control_ Control Mode and Status_ Control Mode

communication objects which lets you change the indoor unit control: No Central, LIFO (Last

Input First Output), Central Controller and Lock Central Controller.

20:

21:

22:

23:

45:

46:

47:

48:

o If set to “no” the objects will not be shown.

o If set to “yes” the Control_ and Status_ Control Mode objects for No Central, LIFO (Last

Input First Output), Central Controller, Lock Central Controller will appear.

4.5.1 Initial state of Control Mode

This parameter sets the initial value for the Control Mode: No Central, LIFO (Last Input First

Output), Central Controller, Lock Central Controller or Do not initialize.

Page 21

IntesisBox® KNX - Haier A.C. (VRF line)

User's manual r1.0 EN

© Intesis Software S.L.U. - All rights reserved

This information is subject to change without notice

IntesisBox is a registred trademark of Intesis Software SLU

URL

email

tel

http://www.intesisbox.com

info@intesisbox.com

+34 938047134

21 / 31

Figure 4.24 Parameter detail

o If set to “Apply same initial state to all Indoor Units”, the parameter option selected

will apply to all indoor units.

o If set to “Initial state for each Indoor Unit might differ”, you will be able to set this

parameter for each Indoor Unit individually.

Page 22

IntesisBox® KNX - Haier A.C. (VRF line)

User's manual r1.0 EN

© Intesis Software S.L.U. - All rights reserved

This information is subject to change without notice

IntesisBox is a registred trademark of Intesis Software SLU

URL

email

tel

http://www.intesisbox.com

info@intesisbox.com

+34 938047134

22 / 31

4.6 Addressing of Indoor Units

Figure 4.24 Parameter detail

In this section you will be able to set the AC addressing for each AC unit present in the

installation.

o Modbus GW address of ACxx refers to the addres of the Haier Communication Addapters.

o IDU index (in Modbus GW) of ACxx refers to the AC system address of the Indoor Unit.

Page 23

IntesisBox® KNX - Haier A.C. (VRF line)

User's manual r1.0 EN

© Intesis Software S.L.U. - All rights reserved

This information is subject to change without notice

IntesisBox is a registred trademark of Intesis Software SLU

URL

email

tel

http://www.intesisbox.com

info@intesisbox.com

+34 938047134

23 / 31

4.7 License

Figure 4.24 Parameter detail

Use this section to introduce the migration code in case you need to update your box from

another version different from the factory default one.

Page 24

IntesisBox® KNX - Haier A.C. (VRF line)

User's manual r1.0 EN

© Intesis Software S.L.U. - All rights reserved

This information is subject to change without notice

IntesisBox is a registred trademark of Intesis Software SLU

URL

email

tel

http://www.intesisbox.com

info@intesisbox.com

+34 938047134

24 / 31

5 Technical Specifications

Enclosure

ABS (UL 94 HB) de 2,5 mm / 1” thick

Net dimensions (dxwxh):

70 x 70 x 28 mm / 2.8” x 2.8” x 1.1”

Color: Ivory White

Operation

Temperature

0ºC to +60ºC

Weight

42 g.

Stock

Temperature

-20ºC to +85ºC

Power supply

Power is supplied by:

1 x KNX bus (29V DC, 7mA)

Operational

Humidity

<90% RH, non-condensing

Terminal Wiring

(for low-voltage

signals)

For terminal: solid wires or stranded wires

(twisted or with ferrule)

1 core: 0.5mm2… 2.5mm2

2 cores: 0.5mm2… 1.5mm2

3 cores: not permitted

Stock Humidity

<90% RH, non-condensing

KNX port

1 x KNX TP1 (EIB) port opto-isolated.

Plug-in terminal block (2 poles). TNV-1

Isolation voltage

1500 VDC

AC unit port

1 x Specific connector

Plug-in terminal block (3 poles)

Isolation

resistance

1000 MΩ

Configuration

Configuration with ETS

Protection

IP20 (IEC60529)

LED indicators

1 x Onboard LED - Operational status

70 mm

70 mm

28 mm

Programming LED

AC Indoor unit Haier

bus connection

KNX bus

connection

Programming button

Page 25

IntesisBox® KNX - Haier A.C. (VRF line)

User's manual r1.0 EN

© Intesis Software S.L.U. - All rights reserved

This information is subject to change without notice

IntesisBox is a registred trademark of Intesis Software SLU

URL

email

tel

http://www.intesisbox.com

info@intesisbox.com

+34 938047134

25 / 31

6 AC Unit Types compatibility.

A list of Haier indoor unit model references compatible with HA-AC-KNX-8/16/64 and their

available features can be found in:

https://www.intesisbox.com/intesis/support/compatibilities/IntesisBox_HA-AC-xxx-yy_AC_Compatibility.pdf

Page 26

IntesisBox® KNX - Haier A.C. (VRF line)

User's manual r1.0 EN

© Intesis Software S.L.U. - All rights reserved

This information is subject to change without notice

IntesisBox is a registred trademark of Intesis Software SLU

URL

email

tel

http://www.intesisbox.com

info@intesisbox.com

+34 938047134

26 / 31

7 Error Codes

Error Code

in

KNX Object

Error in

Remote

Controller

Category

Error Name

1

1

Indoor Unit

Indoor ambient temp.sensor TA (Tas) failure

2

2

Indoor gas pipe temp. sensor TC1 failure

3

3

Indoor liquid pipe temp. sensor TC2 failure

4

4

Dual heat source sensor TW failure

5

5

Indoor EEPROM failure

6

6

Communication between indoor and outdoor failure

7

7

Communication between indoor and wired controller failure

8

8

Indoor float switch failure

9

9

Indoor address repeated failure

10

10

Reserved

11

11

Reserved

12

12

No 50 Hz zero passage signal

13

13

Coil sensor TC3 failure

14

14

DC motor failure

15

15

Indoor ambient temp.sensor TA (Taf) failure

16

16 - 17

17

Outdoor Unit

-

18

18 - 19

19

-

20

20

Defrosting temp. sensor Tdef1 failure

Defrosting temp. sensor Tdef2 failure

21

21

Ambient temp. sensor Ta failure

22

22

Suction temp. sensor Ts1 failure

Suction temp. sensor Ts2 failure

Suction temp. sensor Tsacc failure

Suction temp. sensor Tsuc failure

23

23

Discharging temp. sensor Tdi failure

Discharging temp. sensor Td1 failure

Discharging temp. sensor Td2 failure

24

24

Oil temp. sensor Toilp failure

Oil temp. sensor Toil failure

25

25

Inlet temp. of heat exchanger Toci1 failure

Inlet temp. of heat exchanger Toci2 failure

26

26

indoor communication failure

Reduce the number of indoor units failure

Increase the number of indoor units failure

27

27

Oil temp. too high protection (Toil)

Oil temp. too high protection (Toi2)

28

28

High pressure sensor Pd1 failure

High pressure sensor Pd2 failure

29

29

Low pressure sensor Ps failure

30

30

High pressure switch HPSi failure

High pressure switch HPS1 failure

High pressure switch HPS2 failure

31

31

Liquid pipe pressure Pl failure

32

32

Outlet temp. of subcooler Tsco failure

Liquid pipe SC temp. of subcooler Tliqsc failure

33

33

EEPROM (AT24C04) failure

34

34

Discharging temp. too high protection (Tdi)

Discharging temp. too high protection (Td1)

Discharging temp. too high protection (Td2)

35

35

4-way valve reversing failure

4-way valve reversing failure

36

36

Oil temp. too low protection (Toil)

Oil temp. too low protection (Toi2)

37

37

Lack of phase of 3N power supply or wrong phase sequence

38

38

High pressure sensor Pd too low protection

39

39

Low pressure sensor Ps too low protection

Compression ratio too high protection

Compression 1 ratio too low protection

Compression 2 ratio too low protection

40

40

High pressure sensor Pd1 too high protection

High pressure sensor Pd2 too high protection

41

41

Water temp. Twi too low protection

Water temp. Twi too high protection

42

42

Frost protection of water system

Water system out of water freeze protection

Water flow of Water system is too small to protect

43

43

Discharging temp. sensor Tdi too low protection

Discharging temp. sensor Td1 too low protection

Discharging temp. sensor Td2 too low protection

Page 27

IntesisBox® KNX - Haier A.C. (VRF line)

User's manual r1.0 EN

© Intesis Software S.L.U. - All rights reserved

This information is subject to change without notice

IntesisBox is a registred trademark of Intesis Software SLU

URL

email

tel

http://www.intesisbox.com

info@intesisbox.com

+34 938047134

27 / 31

44

44

Low pressure sensor PS too high protection

45

45

Communication among outdoors failure

46

46

Communication with inverter board 1 failure

Communication with inverter board 2failure

47

47 - 48

48

Unloading valve SV1 failure

49

49 - 50

50 51

51 - 52

52 - 53

53

Current detector CT1 failure

54

54

Communication with Thermal storage module failure

55

55

Thermal storage module LEV failure

56

56

Thermal storage module too hot failure

57

57

Communication between Thermal storage module and host computer

58

58

Thermal storage module Tc1 temp. sensor failure

59

59

Thermal storage module Tc2 temp. sensor failure

60

60

Reserved

61

61

Reserved

62

62

Reserved

63

63

Thermal storage module DIP setting failure

64

64

CT1 over current

CT2 over current

65

65

-

66

66

-

67

67

Communication with motor driving board failure

68

68

-

69

69

-

70

70

-

71

71

Left DC motor blocked

Right DC motor blocked

72

72

Left DC motor reversed

Right DC motor reversed

73

73

Left DC motor current too high

Right DC motor current too high

74

74

-

75

75

No pressure drop between high pressure and low one

Pressure too low between high pressure and low one

76

76

Incorrect outdoor address or capacity setting

77

77

Oil equalization protection among outdoors

78

78

Lack of refrigerant in cooling

Lack of refrigerant in heating

79

79

Incorrect wiring

80

80

Indoor and outdoor do not match

81

81

Model temp. too high protection

82

82

Compressor current protection

83

83

Wrong model selection

84

84 - 85

85 - 86

86 - 87

87 - 88

88 - 89

89 - 90

90 - 91

91 - 92

92 - 93

93 - 94

94 - 95

95 - 96

96 - 97

97 - 98

98 - 99

99

Program self-test failure

100

100

DC motor driving board IPM alarm

101

101

DC motor driving board detecting out of control

102

102

DC motor driving board EEPROM faulty

103

103

DC motor driving board over current or current detector damaged

104

104

Voltage too low protection of DC motor driving board

105

105

Voltage too high protection of DC motor driving board

106

106

DC motor driving board blocked

107

107

Protection of motor rate over Limitation

108

108

-

109

109

-

110

110

model 1 Over current

model 2 Over current

Page 28

IntesisBox® KNX - Haier A.C. (VRF line)

User's manual r1.0 EN

© Intesis Software S.L.U. - All rights reserved

This information is subject to change without notice

IntesisBox is a registred trademark of Intesis Software SLU

URL

email

tel

http://www.intesisbox.com

info@intesisbox.com

+34 938047134

28 / 31

111

111

Compressor 1 out of control

Compressor 2 out of control

112

112

Radiator of model 1 temp. too high

Radiator of model 2 temp. too high

113

113

model 1 overload

model 2 overload

114

114

Voltage too low of model 1

Voltage too low of model 2

115

115

Voltage too high of model 1

Voltage too high of model 2

116

116

Communication abnormal with model 1

Communication abnormal with model 2

117

117

Model 1 Over current (software)

Model 1 Over current (software)

118

118

Model 1 startup failure

Model 2 startup failure

119

119

Current Detecting Circuit Abnormal of transducer 1

Current Detecting Circuit Abnormal of transducer 2

120

120

Power supply of transducer 1 abnormal

Power supply of transducer 2 abnormal

121

121

Power supply of inverter board 1 is abnormal

Power supply of inverter board 2 is abnormal

122

122

Radiator temp. sensor of transducer 1 abnormal

Radiator temp. sensor of transducer 2 abnormal

123

123 - 124

124

-

125

125

Compressor 1 frequency not match

Compressor 2 frequency not match

126

126

-

127

127

MCU reset abnormal

128

128

MCU Program needs to be upgraded

0

N/A

KNX interface

No error

65535 (-1)

N/A

KNX interface

Indoor Units not ready for communication

65436 (-100)

N/A

KNX interface

License Error / indoor unit not supported by current license

65336 (-200)

N/A

KNX interface

Overconsumption error in EXY bus

In case you detect an error code not listed, contact your nearest Haier technical support service

for more information on the error meaning.

Page 29

IntesisBox® KNX - Haier A.C. (VRF line)

User's manual r1.0 EN

© Intesis Software S.L.U. - All rights reserved

This information is subject to change without notice

IntesisBox® is a registered trademark of Intesis Software SLU

URL

Email

tel

http://www.intesisbox.com

info@intesisbox.com

+34 938047134

29 / 31

Appendix A – Communication Objects Table

SECTION

OBJECT

NUMBER

NAME

LENGTH

DATAPOINT TYPE

FLAGS

FUNCTION

DPT_NAME

DPT_ID

R W T

U

On/Off

1

Control_ On/Off

1 bit

DPT_Switch

1.001

W T 0 - Off; 1-On

Mode

2

Control_ Operating Mode

1 byte

DPT_HVACMode

20.102

W T 0 - Auto; 1 - Com; 2 - Stan; 3 - Eco; 4 – Pro

3

Control_ Mode

1 byte

DPT_HVACControl

20.105

W T 0 - Auto; 1 - Heat; 3 - Cool; 9 - Fan; 14 - Dry

4

Control_ Mode Cool/Heat

1 bit

DPT_Cool/Heat

1.100

W T 0 - Cool; 1 – Heat

5

Control_ Mode Auto

1 byte

DPT_Scaling

5.001

W T 1 - Auto

6

Control_ Mode Heat

1 byte

DPT_Scaling

5.001

W T 1 - Heat

7

Control_ Mode Cool

1 bit

DPT_Bool

1.002

W T 1 - Cool

8

Control_ Mode Fan

1 bit

DPT_Bool

1.002

W T 1 – Dry

9

Control_ Mode Dry

1 bit

DPT_Bool

1.002

W T 1 – Fan

10

Control_ Mode +/-

1 bit

DPT_Step

1.007

W 0 - Decrease; 1 - Increase

Control_ Mode +/-

1 bit

DPT_UpDown

1.008

W 0 - Up; 1 - Down

Fan Speed

11

Control_ Fan Speed / 3 Speeds

1 byte

DPT_Scaling

5.001

W T

0%-49% - Speed 1; 50%-83% - Speed 2;

84%-100% Speed 3

Control_ Fan Speed / 3 Speeds

1 byte

DPT_Enumerated

5.010

W T 1 - Speed 1; 2 - Speed 2; 3 Speed 3

12

Control_ Fan Speed Man/Auto

1 bit

DPT_Bool

1.002

W T 0 – Manual; 1 – Auto

13

Control_ Fan Speed 1

1 bit

DPT_Bool

1.002

W T 1 - Fan Speed 1

14

Control_ Fan Speed 2

1 bit

DPT_Bool

1.002

W T 1 - Fan Speed 2

15

Control_ Fan Speed 3

1 bit

DPT_Bool

1.002

W T 1 - Fan Speed 3

16

Control_ Fan Speed +/-

1 bit

DPT_Step

1.007

W T 0 - Decrease; 1 - Increase

Control_ Fan Speed +/-

1 bit

DPT_UpDown

1.008

W T 0 - Up; 1 - Down

Page 30

IntesisBox® KNX - Haier A.C. (VRF line)

User's manual r1.0 EN

© Intesis Software S.L.U. - All rights reserved

This information is subject to change without notice

IntesisBox® is a registered trademark of Intesis Software SLU

URL

Email

tel

http://www.intesisbox.com

info@intesisbox.com

+34 938047134

30 / 31

Temperature

17

Control_ Setpoint Temperature

2 byte

DPT_Value_Temp

9.001

W T 17ºC to 30ºC

18

Control_ Setpoint Temp +/-

1 bit

DPT_Step

1.007

W 0 - Decrease; 1 - Increase

Control_ Setpoint Temp +/-

1 bit

DPT_UpDown

1.008

W 0 - Up; 1 - Down

19

Control_ Ambient Temperature

2 byte

DPT_Value_Temp

9.001

W T ºC value in EIS5 format

Control Mode

20

Control_ Control Mode No Central

1 bit

DPT_Bool

1.002

W T 1 – No Central Controller

21

Control_ Control Mode LIFO

1 bit

DPT_Bool

1.002

W T 1 – Last Input First Output (LIFO)

22

Control_ Control Mode Central

1 bit

DPT_Bool

1.002

W T 1 – Central Controller

23

Control_ Control Mode Lock

1 bit

DPT_Bool

1.002

W T 1 – Lock Central Controller

On/Off

24

Status_ On/Off

1 bit

DPT_Switch

1.001

R T 0 - Off; 1-On

Mode

25

Status_ Operating Mode

1 byte

DPT_HVACMode

20.102

R T 0 - Auto; 1 - Com; 2 - Stan; 3 - Eco; 4 – Pro

26

Status_ Mode

1 byte

DPT_HVACContrMode

20.105

R T 0 - Auto; 1 - Heat; 3 - Cool; 9 - Fan; 14 - Dry

27

Status_ Mode Cool/Heat

1 bit

DPT_Heat/Cool

1.100

R T 0 - Cool; 1 - Heat

28

Status_ Mode Auto

1 bit

DPT_Bool

1.002

R T 1 - Auto

29

Status_ Mode Heat

1 bit

DPT_Bool

1.002

R T 1 - Heat

30

Status_ Mode Cool

1 bit

DPT_Bool

1.002

R T 1 - Cool

31

Status_ Mode Fan

1 bit

DPT_Bool

1.002

R T 1 - Fan

32

Status_ Mode Dry

1 bit

DPT_Bool

1.002

R T 1 - Dry

33

Status_ Mode Text

14 byte

DPT_String_8859_1

16.001

R T ASCII String

Fan Speed

34

Status_ Fan Speed / 3 Speeds

1 byte

DPT_Scaling

5.001

R T 33% - Speed 1; 67% - Speed 2; 100% - Speed 3

Status_ Fan Speed / 3 Speeds

1 byte

DPT_Enumerated

5.010

R T 1 - Speed 1; 2 - Speed 2; 3 - Speed 3

35

Status_ Fan Speed Man/Auto

1 bit

DPT_Bool

1.002

R T 0 – Manual; 1 – Auto

Page 31

IntesisBox® KNX - Haier A.C. (VRF line)

User's manual r1.0 EN

© Intesis Software S.L.U. - All rights reserved

This information is subject to change without notice

IntesisBox® is a registered trademark of Intesis Software SLU

URL

Email

tel

http://www.intesisbox.com

info@intesisbox.com

+34 938047134

31 / 31

36

Status_ Fan Speed 1

1 bit

DPT_Bool

1.002

R T 1 - Speed 1

37

Status_ Fan Speed 2

1 bit

DPT_Bool

1.002

R T 1 - Speed 2

38

Status_ Fan Speed 3

1 bit

DPT_Bool

1.002

R T 1 - Speed 3

39

Status_ Fan Speed Text

14 byte

DPT_String_8859_1

16.001

R T ASCII String

Temperature

40

Status_ AC Setpoint Temp

2 byte

DPT_Value_Temp

9.001

R T 16ºC to 32ºC

41

Status_ AC Ambient Ref Temp

2 byte

DPT_Value_Temp

9.001

R T ºC value in EIS5 format

Error

42

Status_ Error/Alarm

1 bit

DTP_Alarm

1.005

R T 0 - No Alarm; 1 - Alarm

43

Status_ Error Code

2 byte

Enumerated

R T 0 - No Error; Any other see user's manual

44

Status_ Error Text code

14 byte

DPT_String_8859_1

16.001

R T 2 char Haier Error; Empty - none

Control Mode

45

Control_ Control Mode No Central

1 bit

DPT_Bool

1.002

W T 1 – No Central Controller

46

Control_ Control Mode LIFO

1 bit

DPT_Bool

1.002

W T 1 – Last Input First Output (LIFO)

47

Control_ Control Mode Central

1 bit

DPT_Bool

1.002

W T 1 – Central Controller

48

Control_ Control Mode Lock

1 bit

DPT_Bool

1.002

W T 1 – Lock Central Controller

NOTE: This addressing corresponds to the first AC indoor unit of the configuration. Communication objects for the rest of AC units are

consecutively listed.

Loading...

Loading...