Page 1

Gateway for integration of Mitsubishi Heavy Industries air conditioning

systems into KNX TP-1 (EIB) control systems

Application’s Program Version: 2.1

USER MANUAL

Issue date: 07/2012 r1.2 ENGLISH

Page 2

IntesisTM KNX – Mitsubishi Heavy Industries AC

User’s Manual r1.2 eng

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

2 / 26

Important User Information

Disclaimer

The information in this document is for informational purposes only. Please inform HMS Industrial

Networks of any inaccuracies or omissions found in this document. HMS Industrial Networks disclaims

any responsibility or liability for any errors that may appear in this document.

HMS Industrial Networks reserves the right to modify its products in line with its policy of continuous

product development. The information in this document shall therefore not be construed as a

commitment on the part of HMS Industrial Networks and is subject to change without notice. HMS

Industrial Networks makes no commitment to update or keep current the information in this document.

The data, examples and illustrations found in this document are included for illustrative purposes and are

only intended to help improve understanding of the functionality and handling of the product. In view of

the wide range of possible applications of the product, and because of the many variables and

requirements associated with any particular implementation, HMS Industrial Networks cannot assume

responsibility or liability for actual use based on the data, examples or illustrations included in this

document nor for any damages incurred during installation of the product. Those responsible for the use

of the product must acquire sufficient knowledge in order to ensure that the product is used correctly in

their specific application and that the application meets all performance and safety requirements

including any applicable laws, regulations, codes and standards. Further, HMS Industrial Networks will

under no circumstances assume liability or responsibility for any problems that may arise as a result from

the use of undocumented features or functional side effects found outside the documented scope of the

product. The effects caused by any direct or indirect use of such aspects of the product are undefined and

may include e.g. compatibility issues and stability issues.

Page 3

IntesisTM KNX – Mitsubishi Heavy Industries AC

User’s Manual r1.2 eng

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

3 / 26

Gateway for integration of Mitsubishi Heavy

Industries air conditioning systems into KNX TP-1

(EIB) control systems.

ORDER CODE

LEGACY ORDER CODE

INKNXMHI048O000

MH-AC-KNX-48

INKNXMHI128O000

MH-AC-KNX-128

Page 4

IntesisTM KNX – Mitsubishi Heavy Industries AC

User’s Manual r1.2 eng

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

4 / 26

Index

Description ....................................................................................................... 5

Introduction .................................................................................................... 5

Integration signals ........................................................................................... 5

Functionality ................................................................................................... 6

Capacity of Intesis

TM

........................................................................................ 7

KNX interface of Intesis

TM

................................................................................... 8

Description ..................................................................................................... 8

Communication objects available ....................................................................... 9

2.2.1 Communication objects per each indoor unit: .............................................. 10

2.2.2 Controlling all units at a time .................................................................... 11

Intesis

TM

Device Connections ............................................................................. 12

Connect to Mitsubishi Heavy Industries Interface ............................................... 13

Connect to KNX Interface ............................................................................... 14

Connect to PC (LinkBoxEIB) ............................................................................ 14

Power Device ................................................................................................ 14

LinkBoxEIB. Configuration & monitoring tool for Intesis

TM

KNX series ..................... 15

Introduction .................................................................................................. 15

Connections configuration ............................................................................... 15

4.2.1 Configuration tab ..................................................................................... 15

4.2.2 Signals ................................................................................................... 18

Sending the configuration to Intesis

TM

.............................................................. 19

Signals viewer ............................................................................................... 19

Files ............................................................................................................. 20

Intesis

TM

and ETS............................................................................................. 21

Integration of Intesis

TM

in ETS ......................................................................... 21

Setup process and troubleshooting .................................................................... 22

Pre-requisites ................................................................................................ 22

Setup procedure ............................................................................................ 22

Troubleshooting ............................................................................................. 22

6.3.1 Physical checking ..................................................................................... 22

6.3.2 Software checking ................................................................................... 23

Mechanical & Electrical characteristics ................................................................ 24

AC Unit Types compatibility .............................................................................. 25

Error codes ..................................................................................................... 26

Page 5

IntesisTM KNX – Mitsubishi Heavy Industries AC

User’s Manual r1.2 eng

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

5 / 26

Description

Introduction

IntesisTM KNX – Mitsubishi Heavy Industries AC is a communication gateway for the

integration of Mitsubishi Heavy Industries air conditioning (AC) systems into KNX TP-1

(EIB).

This gateway allows integrating a Mitsubishi Heavy Industries AC system inside a

supervision/control/automation system through PLC, SCADA and, in general, through any

device or system with a KNX TP-1 (EIB) interface.

The aim of this integration is to make accessible several Mitsubishi Heavy Industries air

conditioning indoor units communicating with the Superlink protocol as if they were part of

a KNX TP-1 (EIB) system. Therefore, the IntesisTM KNX acts as a KNX device in the KNX TP1 (EIB) interface, allowing the KNX system read and write in the communication objects.

Moreover, IntesisTM includes all hardware required to manage/control Mitsubishi Heavy

Industries indoor units without extra components needed.

Integration signals

Following is the list of parameters that can be monitored/controlled on the indoor units

using IntesisTM:

▪ For each indoor unit in the system:

o Communication Status (read-only)

o On/Off (R/W)

o Operation Mode (R/W)

o SetPoint Temperature (R/W)

o Fan Speed (R/W)

o Remocon Lock/Unlock (R/W)

o Louver Control (R/W)

o Room Temperature (read-only)

o Filter Sign Status (read-only)

o Error Code (read-only)

o Compressor Status (read-only)

o Filter Sign Reset (write-only)

o Remocon Error Reset (write-only)

o Thermo On/Off Status (read-only)

Apart from these, the IntesisTM also implements some extra signals (functions):

▪ For all indoor units

1

in the system:

o HW Communication Status (read-only)

o On/Off (write-only)

o Operation Mode (write-only)

o SetPoint Temperature (write-only)

o Fan Speed (write-only)

o Remocon Lock/Unlock (write-only)

1

These signals work as master signals controlling all connected units at the same time

Page 6

IntesisTM KNX – Mitsubishi Heavy Industries AC

User’s Manual r1.2 eng

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

6 / 26

Functionality

IntesisTM continuously polls (reads) the Superlink network for all configured signals and

keeps the updated status of all of them in its memory ready to be served when requested

from KNX.

When a change of status is detected in a MHI’s AC signal, a write telegram is sent to the

KNX bus, of the associated KNX Group.

When it is received a telegram from the KNX bus, and if its KNX Group address is associated

to an MHI’s AC signal, a message is sent immediately to the Superlink network to perform

the corresponding action in the MHI’s AC system.

In the continuous polling if no response is detected, the corresponding virtual signal inside

the gateway will be activated indicating communication error. There is a virtual signal for

each AC indoor unit indicating communication error with the indoor unit – this signal will be

normally activated if the indoor unit is not properly setup.

Each of the mentioned signals in section 1.2 has to be associated to a KNX group address,

with this, all the system is seen as another KNX device, with the same configuration and

functioning characteristics. These addresses are not fixed and can be configured using the

LinkBoxEIB tool (see 4.2.2)

IntesisTM includes all hardware needed to connect directly with the Mitsubishi Heavy

Industries indoor units connecting with Superlink network.

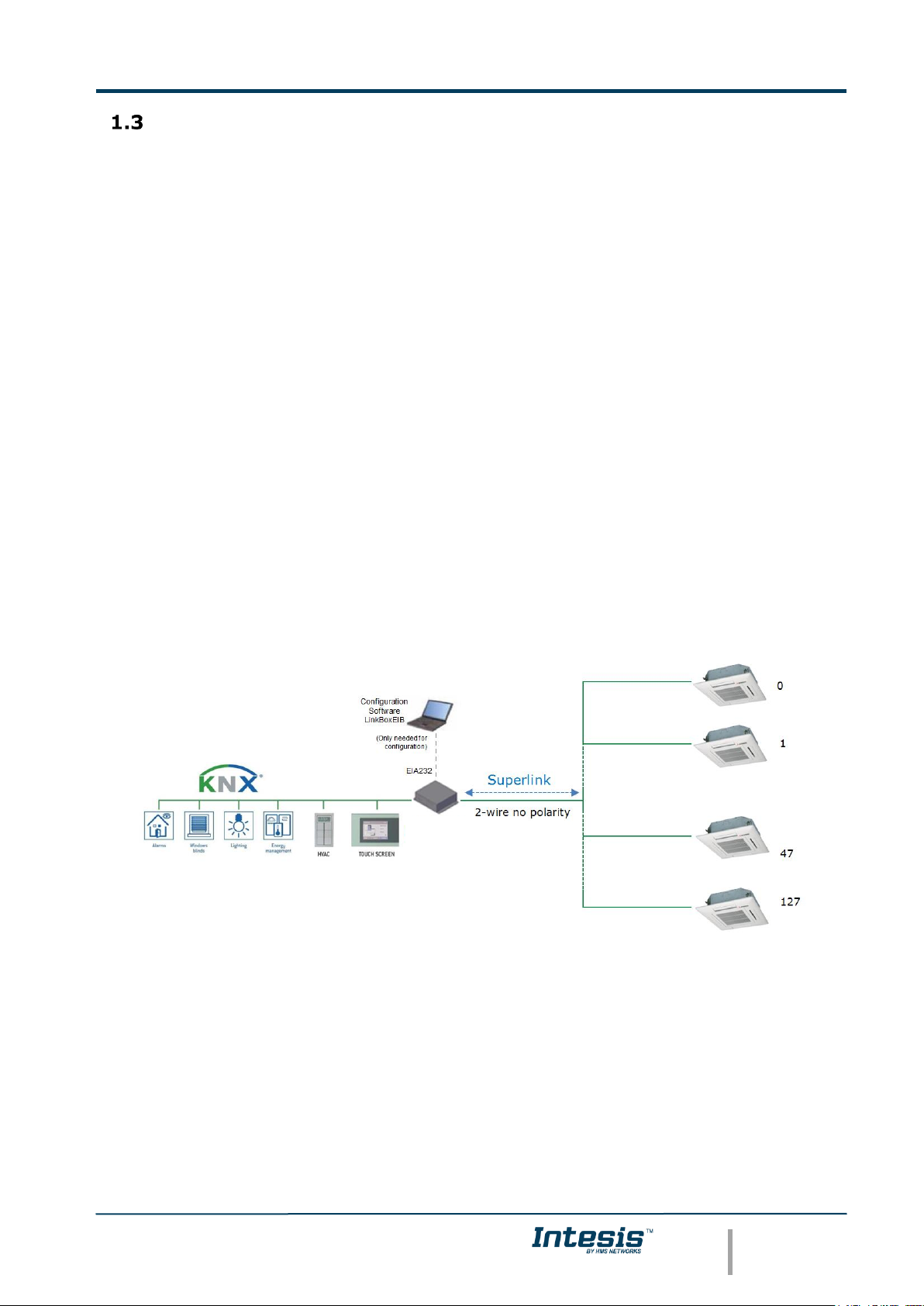

Figure 1.1 Integration of Mitsubishi Heavy Industries AC into KNX TP-1 (EIB) system

Page 7

IntesisTM KNX – Mitsubishi Heavy Industries AC

User’s Manual r1.2 eng

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

7 / 26

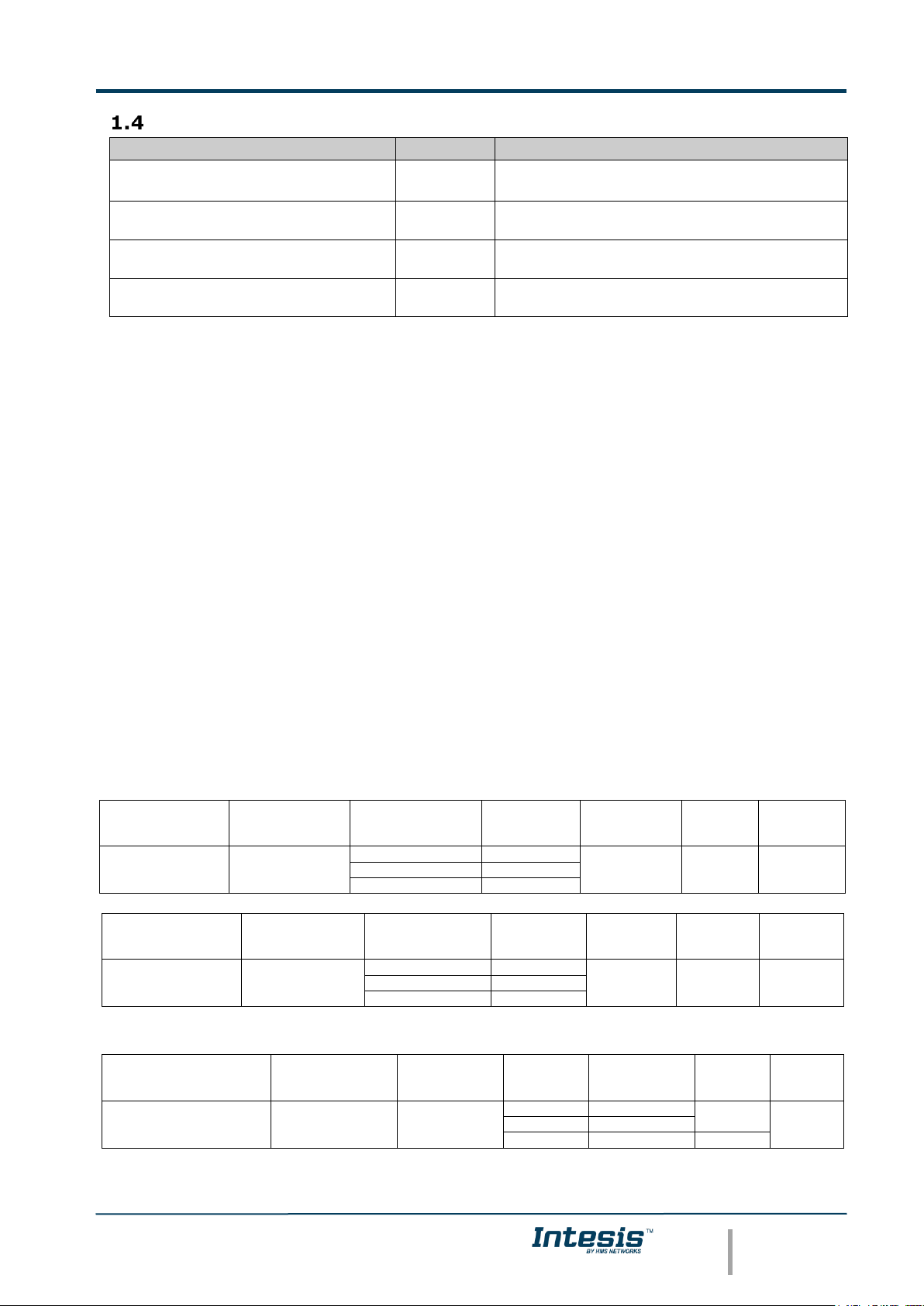

Capacity of Intesis

TM

Element

Max.

Notes

Number of indoor units

128 *

Maximum number of AC indoor units that

can be controlled

Main Group Address

3000

Maximum number of communication

objects

Total number of listening group

addresses

1000

Number of KNX groups that can be used as

listening addresses

Num. of listening addresses per

communication object

255

Number of listening addresses that can be

associated to an KNX group address

Table 1.1 IntesisTM capacity

* There are two different models of IntesisTM KNX – Mitsubishi Heavy Industries AC each

one with different capacity. The table above shows the capacity for the top model (with

maximum capacity).

Their order codes are:

▪ INKNXMHI048O000:

▪ Model supporting up to 48 indoor units

▪ For Superlink-I (Previous Superlink) or Superlink-II (New Superlink).

▪ Indoor Unit actual address range is 00 to 47

▪ INKNXMHI128O000:

▪ Model supporting up to 128 indoor units

▪ For Superlink-II (New Superlink)

▪ Indoor Unit actual address range is 000 to 127

Check available combination of Mitsubishi Heavy Industries Central Control and BMS

interface units in the next tables.

In the case of SL2NA or SL3NA, it is necessary to erase registration of non-connected indoor

unit. For SL2NA and SL3NA, change is required for the setup deprived of the rights of

instruction of Remocon control Lock/Unlock.

New Superlink connections:

MH-AC-MBS-128

INKNXMHI128O0

00

SC-LGWNA-A

SC-BGWNA-A/B

etc.

SC-SL3NA-AE/BE

etc.

SC-SL2NA-E

etc.

SC-SL1N-E

etc.

Max

Indoor

Units

Address

No.

1

Non connect

2

0

0-8

128

000-127

1

0-2 0 0-4

MH-AC-MBS-48

INKNXMHI048O000

SC-LGWNA-A

SC-BGWNA-A/B

etc.

SC-SL3NA-AE/BE

etc.

SC-SL2NA-E

etc.

SC-SL1N-E

etc.

Max

Indoor

Units

Address

No.

1

Non connect

2

0

0-8

48

00-47

1

0-2 0 0-4

Previous Superlink connections:

MH-AC-MBS-48/128

INKNXMHI048O000/128

SC-LGWNA-A

SC-BGWNA-A/B

etc.

SC-SL3NA-

AE/BE

etc.

SC-

SL2NA-E

etc.

SC-SL1N-E

etc.

Max

Indoor

Units

Address

No.

1

Non connect

Non connect

1

0

32

00-47

0

1,2 0 0

48

Page 8

IntesisTM KNX – Mitsubishi Heavy Industries AC

User’s Manual r1.2 eng

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

8 / 26

KNX interface of Intesis

TM

Description

IntesisTM KNX - Mitsubishi Heavy Industries supports the KNX TP-1 (EIB) physical layer, as

defined in the KNX standard. It behaves as another device of the KNX system, with the

same configuration and functional characteristics as other KNX devices.

KNX TP-1 (EIB) bus provides a 30V DC current, which can even directly power certain lowconsumption KNX devices. IntesisTM does not drain any significant current from the KNX bus

- it has a separate own power supply. Another important electrical aspect is that the KNX

TP-1 (EIB) port of IntesisTM is optically isolated (~2500Vrms AC) from all its other ports

(EIA232, EIA485, Ethernet) and power supply.

At a logical level, all KNX devices feature an interface of communication objects, by which

their functionality is abstracted. As a basic example, a KNX interface of an AC indoor unit

would typically consist of an interface of datapoints such as “On/Off”, “Setpoint

temperature”, “Operating mode”, etc.

Associations between communication objects from different KNX devices are actually done

by means of so-called group addresses.

KNX telegrams within a working KNX installation are always addressed to a certain KNX

group address. Typically, whenever a communication object on a KNX device changes its

value, the new value is updated to the bus, by sending a “write” telegram addressed to its

associated group address. The rest of KNX devices in the installation that have a

communication object associated to this group address will act accordingly on reception of

the new value.

Other operations are possible. KNX devices can also decide to read the current value of the

communication objects, by sending a “read” telegram to a certain group address (previously

known to be associated to the targeted comm. object). This operation is performed by many

devices on bus start-up or recovery – in this way, the device gets the latest value of the

group addresses it has associated right from its start-up.

Each datapoint defined in IntesisTM KNX configuration needs at least a single KNX group

address associated with it. This group address will be used either for sending updates to

KNX of the datapoint value (that have been generated on the other MHI interface of the

IntesisTM), or receiving updates from KNX of the datapoint value (that will be propagated to

the MHI side in this case)

From the point of view of KNX functionality, each datapoint of IntesisTM can hold following

group address associations:

• A single KNX group address with which update/write telegrams will be sent,

whenever the datapoint changes (as a result of a change coming from the other

interface of IntesisTM, MHI in this case).

• One or more KNX group addresses from which this datapoint of Intesis

TM

will be

updated/written from the KNX installation (resulting in a change to the other side of

IntesisTM, MHI in this case).

A single KNX group address from which IntesisTM will read the object value on KNX bus

recovery / IntesisTM start-up.

Page 9

IntesisTM KNX – Mitsubishi Heavy Industries AC

User’s Manual r1.2 eng

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

9 / 26

Behavior of IntesisTM datapoints with regard to their associated group addresses is defined

by means of flags (R, W, T, U and U2), explained in section 4.2.2.

Additional to the binding aspect commented above, it is also important to notice that each

KNX communication object has a defined EIS type. The EIS type of a communication object

defines the bit length and coding of the data it represents. Communication objects

associated by means of a group address need to match the same EIS type, in order to

communicate consistently.

So, at configuration time it is required that for each datapoint configured on IntesisTM an EIS

type is defined. Datapoints on IntesisTM KNX support the following EIS-types:

• EIS1 - Switching (1bit raw)

• EIS2 - Dimming (4bit raw)

• EIS5 – Value (16bit – floating type)

• EIS6 – Scaling (8bit – scaled 0%-100% in values 0-255)

• EIS7 – Drive Control (1bit raw)

• EIS8 – Priority (2bit raw)

• EIS9 – IEEE 754 float (32bit – floating type)

• EIS10 – 16bit Counter (16bit raw)

• EIS11 – 32bit Counter (32bit raw)

• EIS13 – ASCII char (8bit raw)

• EIS14 – 8bit Counter (8bit raw)

ETS3 or ETS4 software tools are not used to configure IntesisTM. Though, it’s typical that the

choice of which KNX group addresses to use is restricted or defined by an ETS-based

project. If that’s the case, the KNX installer/integrator needs to provide the set of group

addresses prior to doing the configuration of datapoints in LinkBoxEIB.

Also, a dummy ETS application is provided by HMS Networks (section 5), which can be

imported into ETS. This application is nor downloadable into IntesisTM KNX neither usable for

IntesisTM configuration. Rather, it poses as a means of having a device in the ETS project

representing the IntesisTM KNX and its own datapoints/communication objects, and to which

group addresses are associated.

Communication objects available

Address map is configurable for each indoor unit and can be modified through the supplied

software LinkBoxEIB. Next, there are two tables showing different

datapoints/communication objects available either for each indoor unit control or all indoor

units control at a time. Please, remember that in the tables R/W stands for Read and Write,

R stands for Read Only and W stands for Write Only.

Page 10

IntesisTM KNX – Mitsubishi Heavy Industries AC

User’s Manual r1.2 eng

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

10 / 26

2.2.1 Communication objects per each indoor unit:

Property

EIS type

Signal

type

(R/W)

Description / Status

Communication Error

1 – Switching (1bit)

R

Communication Status

0 – Communication OK, 1 – Communication ERROR

OnOff

1 – Switching (1bit)

R/W

Indoor Unit On/Off

0 – Off, 1 – On

Mode

14 – Counter (8bit)

R/W

Operation Mode

0 – Auto, 1 – Heat, 2 – Cool, 3 – Fan, 4 – Dry

DPT 20.105 (8bit)

R/W

Operation Mode

0 – Auto, 1 – Heat, 3 – Cool, 9 – Fan, 14 – Dry

DPT 1.100 (1bit)

R/W

Operation Mode

0 – Cool, 1 – Heat

Mode::Cool

1 – Switching (1bit)

R/W

0 – Inactive, 1 – Active

Only one of these objects will

be set / read to “1” at the

same time (all objects will be

updated on bus upon a Mode

change)

Mode::Heat

1 – Switching (1bit)

R/W

0 – Inactive, 1 – Active

Mode::Fan

1 – Switching (1bit)

R/W

0 – Inactive, 1 – Active

Mode::Auto

1 – Switching (1bit)

R/W

0 – Inactive, 1 – Active

Mode::Dry

1 – Switching (1bit)

R/W

0 – Inactive, 1 – Active

SetPoint

5 – Float (2byte)

R/W

Set Point Temperature (only integer numbers allowed)

16..30 ºC

Read/Write: If the option of virtual ambient temperature

and SetPoint is deactivated (see in section 4.2.1of this

document).

Write: If the option of virtual ambient temperature and

SetPoint is activated, to be configured from extern KNX

sensor (see in section 4.2.1of this document).

Fan Speed

14 – Counter (8bit)

R/W

Fan Speed

0 – Low, 1 – Medium, 2 – High, 3 – Powerful

FanSpeed::Low

1 – Switching (1bit)

R/W

0 – Inactive, 1 – Active

Only one of these objects will be

set / read to “1” at the same

time (all objects will be updated

on bus upon a FanSpeed change)

FanSpeed::Mid

1 – Switching (1bit)

R/W

0 – Inactive, 1 – Active

FanSpeed::High

1 – Switching (1bit)

R/W

0 – Inactive, 1 – Active

FanSpeed::Powerful

1 – Switching (1bit)

R/W

0 – Inactive, 1 – Active

RemoConLock

1 – Switching (1bit)

R/W

Remote Controller Lock/ Unlock

0 – Remote Controller Locked, 1 – Remote Controller

Unlocked

Louver

14 – Counter (8bit)

R/W

Louver Control1

0 – Swing, 1 – Pos1, 2 – Pos2, 3 – Pos3, 4 – Pos4

Room Temp

5 – Float (2byte)

R/W

Ambient Temperature (only integer numbers)

Read: 10ºC to 40ºC

Read: If the option of virtual ambient temperature and

SetPoint is deactivated (see in section 4.2.1of this

document).

Write: If the option of virtual ambient temperature and

SetPoint is activated, to be measured from extern KNX

sensor (see in section 4.2.1of this document).

Filter Sign

1 – Switching (1bit)

R

Filter Sign Status

0 – Off, 1 - On

ErrorCode

10 – Counter (16bit)

R

Error Code

0 – No Error, 1..99 – Error Code2

1

During transition between positions, Swing signal will turn on indicating the Louver is moving

2

See list of indoor unit error codes and their meaning in section 9.

Page 11

IntesisTM KNX – Mitsubishi Heavy Industries AC

User’s Manual r1.2 eng

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

11 / 26

CompressorStatus

1 – Switching (1bit)

R

Compressor Status

0 – Off, 1 - On

FilterSignReset

1 – Switching (1bit)

W

Filter Sign Reset

1 – Clear Filter Alarm (When reading always 0)

RemoConErrorReset

1 – Switching (1bit)

W

Remote Controller Error Reset

1 – Clear Filter Alarm (When reading always 0)

ThermoOnOff

1 – Switching (1bit)

R

Thermo On/Off Status (Inverter Type Only)

0 – Off, 1 - On

2.2.2 Controlling all units at a time

Property

EIS type

Signal

type

(R/W)

Description / Status

HW Error Com

1 – Switching (1bit)

R

HW Communication Status

0 – Communication OK, 1 – Communication ERROR

OnOff_All

1 – Switching (1bit)

R/W

Indoor Unit On/Off

0 – Off, 1 – On

Mode_All

14 – Counter (8bit)

R/W

Operation Mode

0 – Auto, 1 – Heat, 2 – Cool, 3 – Fan, 4 – Dry

DPT 20.105 (8bit)

R/W

Operation Mode

0 – Auto, 1 – Heat, 3 – Cool, 9 – Fan, 14 – Dry

DPT 1.100 (1bit)

R/W

Operation Mode

0 – Cool, 1 – Heat

Mode_All::Cool

1 – Switching (1bit)

R/W

0–Inactive, 1–Active

Only one of these objects will be

set / read to “1” at the same time

(all objects will be updated on bus

upon a Mode change)

Mode_All::Heat

1 – Switching (1bit)

R/W

0–Inactive, 1–Active

Mode_All::Fan

1 – Switching (1bit)

R/W

0–Inactive, 1–Active

Mode_All::Auto

1 – Switching (1bit)

R/W

0–Inactive, 1–Active

SetPoint_All

5 – Float (2byte)

R/W

Set Point Temperature (only integer numbers allowed)

16..30 ºC

Fan Speed_All

14 – Counter (8bit)

R/W

Fan Speed

0 – Low, 1 – Medium, 2 – High, 3 – Powerful

FanSpeed_All::Low

1 – Switching (1bit)

R/W

0–Inactive, 1–Active

Only one of these objects will be

set / read to “1” at the same time

(all objects will be updated on bus

upon a FanSpeed change)

FanSpeed_All::Mid

1 – Switching (1bit)

R/W

0–Inactive, 1–Active

FanSpeed_All::High

1 – Switching (1bit)

R/W

0–Inactive, 1–Active

FanSpeed_All::Powerful

1 – Switching (1bit)

R/W

0–Inactive, 1–Active

RemoconLock_All

1 – Switching (1bit)

W

Remote Controller Lock/Unlock

0 – Unlock, 1 - Lock

Page 12

IntesisTM KNX – Mitsubishi Heavy Industries AC

User’s Manual r1.2 eng

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

12 / 26

Intesis

TM

KNX Device Connections

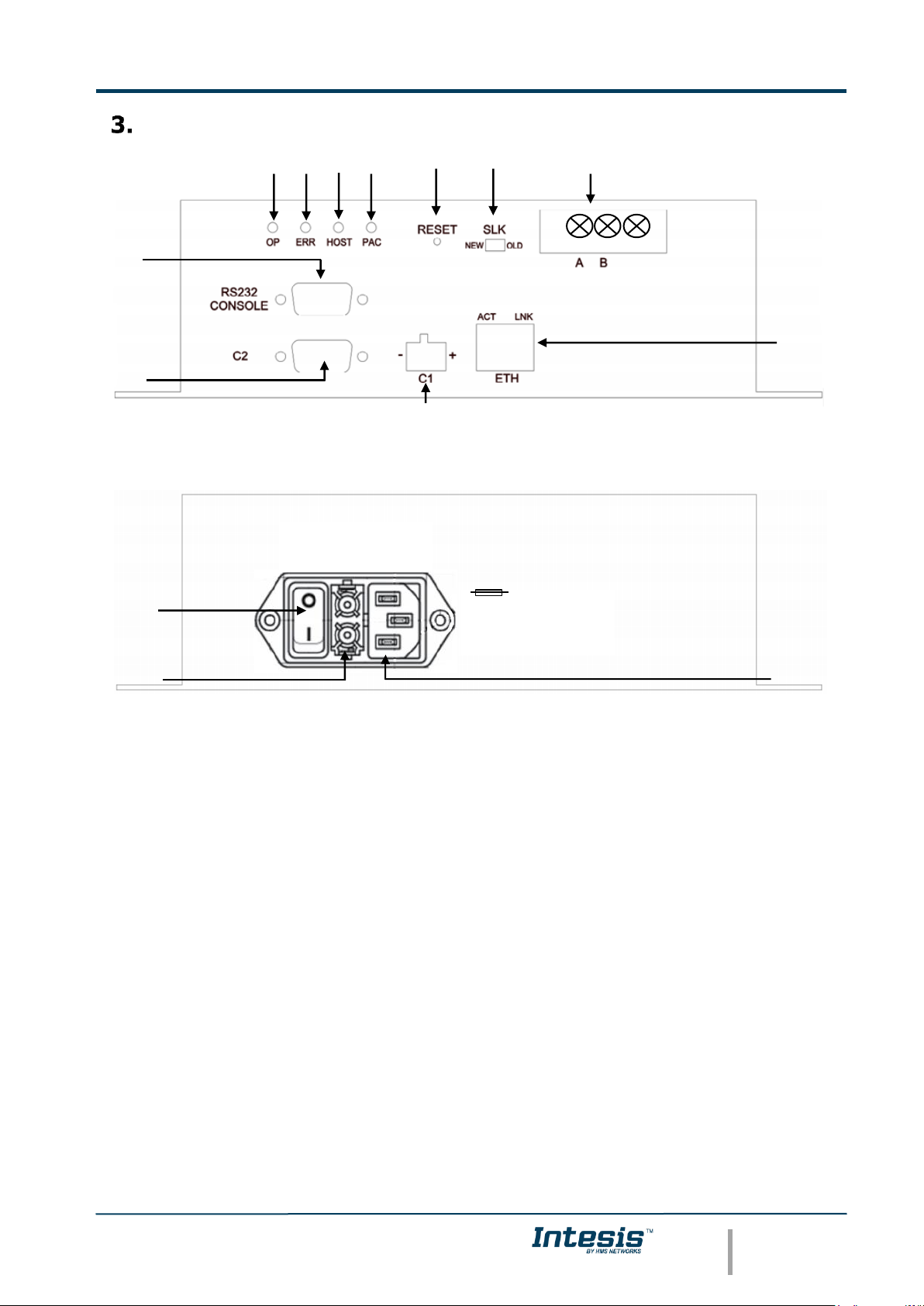

Figure 3.1 IntesisTM KNX device front view

Next, there is the list with the device physical interface connector’s description

1.- KNX configuration Port (C1)

8.- Reset button (Non supported)

2.- Non supported (C2)

9.- Superlink selector (SLK)

New: Superlink-II

Old: Superlink-I

3.- Console serial port EIA232

10.- A-B connector (for Superlink, no polarity)

4.- Operation LED

11.- IP configuration Ethernet (ETH)

5.- Error LED

12.- Power supply On/Off button

6.- Host LED

13.- Power supply fuse (250V, 1.5A)

7.- Pac LED

14.- Power supply connector

2

3

4 5 6

7 8 9

10

11

1

Figure 3.2 IntesisTM KNX device back view

12

14

13

100-240VAC~

50-60Hz 5W max

FUSE:

250V 1.5A(T)

Page 13

IntesisTM KNX – Mitsubishi Heavy Industries AC

User’s Manual r1.2 eng

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

13 / 26

Connect to Mitsubishi Heavy Industries Interface

Use the A-B connector in the right top corner of the front side of the IntesisTM device in

order to connect the Mitsubishi Heavy Industries network (Superlink) to the IntesisTM.

Recommended specifications of the cable for the Superlink are shown as follows:

• Size of cable : 0.75 to 1.25 square mm

• Max length of wiring : total 1000m (loop wiring is not allowed)

• Cable materials :

Twisted Vinyl Cabtyre Cable

VCTF 2 core 0.75 to 1.25 square mm

Twisted Vinyl Cabtyre Cable

VCT 2 core 0.75 to 1.25 square mm

Twisted Vinyl Cable for Control

CVV 2 core 0.75 to 1.25 square mm

Table 3.1 Cable types recommended for Superlink connection

• For prevention of electromagnetic noise malfunctions, parallel wiring with the power

line should be avoided

Select the appropriate Superlink mode in the SLK selector. If you are using latest Air

Conditioner of the Mitsubishi Heavy Industries network (New Superlink) select NEW, if not

select OLD.

LEDs placed in the top left corner will show connection status as follows:

LED

Status

IntesisTM behavior

OP

Blinking

Power supply OK

ERR

Off

No error

HOST

Blinking

Internal communication OK

PAC

Blinking

Communication with the Superlink network OK

Table 3.2 IntesisTM LED status information

OP LED behavior must defer depending on the Superlink version, as shown in Figure 3.3

Figure 3.3 OP LED blinking behavior depending on Superlink version

If LEDs (except ERR) are not in the states described above, check section 6.3.

For further information about the Superlink network, look up the Mitsubishi Heavy

Industries Manual or contact your nearest Mitsubishi Heavy Industries supplier.

Superlink-II

Superlink-I

On

Off

On

Off

1 sec

Page 14

IntesisTM KNX – Mitsubishi Heavy Industries AC

User’s Manual r1.2 eng

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

14 / 26

Connect to KNX Interface

Connect + and – terminals of the KNX bus to the IntesisTM KNX connector (C1). The polarity

is important.

How to check if there is communication with the KNX bus is explained in the LinkBoxEIB

Manual (section 6.3).

To check connectivity and correct functioning, use LinkBoxEIB software (see LinkBoxEIB

User Manual).

Connect to PC (LinkBoxEIB)

This action allows the user to have access to configuration and monitoring of the device

(more information can be found in the LinkBoxEIB User Manual).Two methods to connect to

the PC can be used:

• Ethernet: Using the ETH port (Figure 3.1) of Intesis

TM

. How to check connectivity is

explained in section 6.3.

• Serial cable: Connect the Intesis

TM

device to the PC serial port using the serial cable

provided. One end should be connected to the Console EIA232 port of the IntesisTM

device (Figure 3.1) and the other end to the PC serial port.

IntesisTM

(DB9 F)

EIA232

Serial

Console

PC Connection (LinkBoxEIB)

PC

(DB9 M)

Cable

(DB9 M)

EIA232

(Straight)

Cable

(DB9 F)

TX

2

2

RX

RX

3

3

TX

GND

5

5

GND

Table 3.3 EIA232 serial connection pin assign

Power Device

To power up the device, what you need is to plug properly the Power Supply connector to

the IntesisTM device using a proper cable and connecting one end to the power supply

connector (see Figure 3.2) and the other end to the power line. After that, just press the

power supply On/Off button to turn it on.

Page 15

IntesisTM KNX – Mitsubishi Heavy Industries AC

User’s Manual r1.2 eng

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

15 / 26

LinkBoxEIB. Configuration & monitoring tool for Intesis

TM

KNX series

Introduction

LinkBoxEIB is a Windows® compatible software developed specifically to monitor and

configure IntesisTM KNX series.

The installation procedure and main functions are explained in the LinkBoxEIB User Manual.

This document can be found in the Doc folder or can be downloaded from the link indicated

in the installation sheet supplied with the IntesisTM device.

In this section, only the specific case of Mitsubishi Heavy Industries indoor unit’s integration

to KNX networks will be covered.

Connections configuration

To configure the IntesisTM connection parameters and to see the points list, press on the

Config button in the menu bar (see Figure 4.1). The Mitsubishi Heavy Industries

Configuration window will open (see Figure 4.2). For integrations with large number of

points, there is available an alternative CSV installation procedure explained in the

LinkBoxEIB User Manual.

Figure 4.1 LinkBoxEIB menu bar

4.2.1 Configuration tab

Select the Connection tab to configure the connection parameters. Three subsets of

information are shown in this window: EIB (KNX interface), Intesis IP (IP interface for

configuration) and Mitsubishi Heavy Industries interface parameters (see Figure 4.2).

Figure 4.2 LinkBoxEIB configuration tab

Next, there is an explanation for each of the configuration parameters in each mode.

• KNX interface configuration parameters:

KNX

interface

configuration

MHI

interface

configuration

Intesis IP

interface

configuration

Page 16

IntesisTM KNX – Mitsubishi Heavy Industries AC

User’s Manual r1.2 eng

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

16 / 26

Figure 4.3 KNX interface configuration

1. Physical Address: Enter the KNX physical address for the gateway.

2. Force update after a KNX bus reset: Affects to the KNX groups with the Update

feature activated (U).

3. Delay for update after bus reset: Enter the desired delay after a bus reset. It is

expressed in seconds.

• IntesisIP interface configuration parameters:

Figure 4.4 IntesisIP interface configuration

1. IP: Enter the KNX physical address for the gateway.

2. NetMask: Enter the Intesis

TM

net mask address.

3. Gateway: Enter the router or default gateway address if needed. In case you don’t

want to use it, left blank.

• Mitsubishi Heavy Industries interface configuration parameters:

Figure 4.5 Mitsubishi Heavy Industries interface configuration

1. Indoor Units: In this list, you can individually enable each of the 128 indoor units

available on the system. The index in the column “Indoor Units” (i.e. the number

1 2 3 1 3 2 6 8 7 5 4

1 3 2

9

Page 17

IntesisTM KNX – Mitsubishi Heavy Industries AC

User’s Manual r1.2 eng

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

17 / 26

x in “Indoor Unit xxx”) is the reference that will be used later on (in tab “Signals”)

to refer to this AC indoor unit. You can also change the description name of the

Indoor Unit and its address to facilitate integration tasks using Add and Name

text boxes.

2. Add: Enter here the desired Indoor Unit address.

3. Name: Enter here the desired descriptive Indoor Unit name (optional).

4. KNX Datapoint type for HVAC Mode communication object: Select the

desired codification so the Mode object matches your integration needs.

5. Gateway version: Selection of the Intesis

TM

KNX – Mitsubishi Heavy Industries

gateway you are setting up (128AC for INKNXMHI128O000, 48AC for

INKNXMHI048O000).

6. Timeout response: Maximum amount of time permitted before activating the

Communication Error signal. It is expressed in milliseconds (ms) and ranges can

vary from 2000 ms to 10000 ms.

7. Delay interframe: Maximum amount of time permitted between End Of

Transmission (EOT) and a new frame. It is expressed in milliseconds (ms) and

ranges can vary from 500 ms to 3000 ms.

8. Monitoring cadence: Cadence of monitoring and subscription. It is expressed in

seconds (s) and ranges can vary from 60 s to 600 s.

9. Virtual ambient temperature and setpoint: Meant to be enabled when you

want the temperature provided by a KNX sensor to be the reference ambient

temperature for the air conditioner. Then, the following formula applies for

calculation of real Control_ Setpoint Temperature sent to the AC unit:

As an example, consider the following situation:

User wants: 19ºC (“KNX Setp. Temp.”)

User sensor (a KNX sensor) reads: 21ºC (“KNX Amb Temp.”)

Ambient temp. read by MHI system is: 24ºC (“AC Ret. Temp”)

In this example, the final setpoint temperature that INKNXMHI048O000/128 will

send out to the indoor unit (shown in “Setp. Temp.”) will become 24ºC – (21ºC 19ºC) = 22ºC. This is the setpoint that will actually be requested to MHI unit.

This formula will be applied as soon as the Control_ Setpoint Temperature and

Control_ Ambient Temperature objects are written at least once from the KNX

installation. After that, they are kept always consistent.

Note that this formula will always drive the AC indoor unit demand in the right

direction, regardless of the operation mode (Heat, Cool or Auto). Due to the use

of this functionality, temperature showed in the KNX device and in the MHI remote

controller (in case it exist) may differ.

“AC Setp. Temp” = “AC Ret. Temp” - (“KNX Amb. Temp.” - “KNX Setp. Temp”)

▪ AC Setp. Temp: AC indoor unit setpoint temperature

▪ AC Ret. Temp: AC indoor unit return temperature

▪ KNX Amb. Temp.: Ambient temperature provided from KNX

▪ KNX Setp. Temp: Setpoint temperature provided from KNX

Page 18

IntesisTM KNX – Mitsubishi Heavy Industries AC

User’s Manual r1.2 eng

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

18 / 26

Additional configuration parameters should generally be left to their default value. They only

might need to be tuned in some very specific cases (installations with large number of units,

scenarios with large bursts of commands sent at once …)

4.2.2 Signals

Select the Signals tab to configure the signals list (the IntesisTM internal points).

Figure 4.6 Signal list

1. IU: Indoor Unit identifier.

2. Property: Identifies the different signals available per every MHI group. An

identification code is given to every different signal into the MHI group, identifying

every signal with an individual code. In section 2.2, an explanation of every signal

is given. A contextual menu appears using mouse right button click over the

column showing all the possible signal codes.

3. Signal: Signal's descriptive name (optional). Useful to identify the signal. The

default descriptive name corresponds to the signal's code, but can be edited or

modified.

4. EIS: KNX data type (Data point) to encode the signal’s value. It will depend on

the MHI type of signal associated to it in every case. Edit using the mouse rightbutton-click pop-up menu available on the column. Only the EIS defined in values

are allowed.

5. Group: Main KNX group address for the signal. Flags R,W,T,U explained below will

only apply for this main KNX group address, not for listening addresses. Formats

supported are P/I/S and P/S.

6. Listening addresses: KNX group addresses that will be listened by Intesis

TM

for

this signal. If IntesisTM receives a KNX telegram whose destination is one of these

listening addresses, the telegram will be taken into account and the corresponding

action will be performed on this signal (if W is active). Formats supported are

P/I/S and P/S, comma separated.

7. Communication object flags:

7.1 R: Indicates if this signal is allowed to be read from KNX system (“R” flag

activated, “blank” flag not activated).

1 2 3 4 5 6 7

8

Page 19

IntesisTM KNX – Mitsubishi Heavy Industries AC

User’s Manual r1.2 eng

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

19 / 26

7.2 W: Indicates if this signal is allowed to be written from KNX system (“W”

flag activated, “blank” flag not activated).

7.3 T: Indicates if this signal will generate a telegram sending to the KNX

system following a change of the signal’s value, that is to say, any change

of value of this signal in MHI side will be transmitted to the KNX system if

this flag is activated (“T” flag activated, “blank” flag not activated).

7.4 U: Indicates if this signal will be updated (sending read requests)

whenever IntesisTM starts up or after a KNX bus reset (“U” flag activated

for the main group address, “U2” activated for the listening group

address, “blank” flag not activated).1

8. Active: Indicates if the signal is active or not for the current configuration (“1-

Yes” signal active, “0-No” signal not active).

See section 2.2 for further detail on available signals and the possible values on each one.

Sending the configuration to Intesis

TM

When the configuration is finished, follow the next steps.

1.- Click on Save button to save the project to the project folder on your hard disk

(more information in LinkBoxEIB User Manual).

2.- You will be prompted to generate the configuration file to be sent to the gateway.

a.- If Yes is selected, the binary file (MHI.Lbox) containing the configuration

for the gateway will be generated and saved also into the project folder.

b.- If NO is selected, remember that the binary file with the project needs to

be generated before the IntesisTM starts to work as expected.

3.- Once in the configuration window again, click on exit. Configuration file is ready

to be sent to the IntesisTM device.

4.- Press the Send File button to send the binary file to the IntesisTM device. The

process of file transmission can be monitored in the IntesisTM Communication

Console window. IntesisTM will reboot automatically once the new configuration is

loaded.

After any configuration change, do not forget to send the configuration file

to the IntesisTM using button Send File.

Signals viewer

Once the gateway is running with the correct configuration, to supervise the status of the

configured signals, press the Signals button on the menu bar (see Figure 4.1). The Signals

Viewer window will open (see Figure 4.7).

This window shows all signals active within the gateway with its main configuration

parameters and its real time value2 in the Value column.

1

DO NOT BE CONFUSED: Philosophy of Intesis

TM

point's U flag is not the same as KNX device's U flag. In KNX

devices, U flag means that the point's value will be updated whenever a write telegram for the group address is

received by the device.

2

In case you connect to the Intesis

TM

when it’s been running for a certain time, you should press the Refresh

button to get updated values. After pressing Refresh, all signal values will keep continuously updated until the

connection is closed.

Page 20

IntesisTM KNX – Mitsubishi Heavy Industries AC

User’s Manual r1.2 eng

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

20 / 26

Figure 4.7 LinkBoxEIB Signals Viewer

The signals viewer can be used even though only one system is connected to the IntesisTM,

KNX or Mitsubishi Heavy Industries AC. Therefore, it becomes convenient for supervision

and testing the system.

In order to force a specific value to a signal, double-click its row in the table. This will

display a dialog in which the desired value can be entered (see Figure 4.8). Changing its

value in this way, will make:

• The content of the corresponding KNX group address will be changed to this value.

• If the signal is write-enabled, it will trigger a suitable command to Mitsubishi Heavy

Industries AC system.

Figure 4.8 Signal value change window

Files

LinkBoxEIB saves the integration configuration in the following files inside the project

folder:

PROJECT.INI

INI file containing general information related to the project.

Page 21

IntesisTM KNX – Mitsubishi Heavy Industries AC

User’s Manual r1.2 eng

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

21 / 26

MHI.INI

INI file containing information related with the values configured

through the “Connection” tab in IntesisTM configuration.

MHI.LBOX

Binary file created from the information in the files described

above. This is the file downloaded to the IntesisTM.

MHI.dat

ASCII file containing the configuration of the project signals. It is

the one to be used for bulk point configuration.

Table 4.1 LinkBoxEIB generated files during Project creation

It is strongly recommended to back up the project folder containing these files in external

media, once the installation process is finished. This way you will be able to do future

configuration changes in case of reinstallation of LinkBoxEIB due, for example, to a failure

of the hard disk in the PC where LinkBoxEIB was installed.

The configuration cannot be uploaded from the gateway to LinkBoxEIB, it can only

be downloaded.

IntesisTM and ETS

Integration of Intesis

TM

in ETS

As explained the IntesisTM is configured with the LinkBoxEIB but in some projects it might

be needed to integrate the gateway in the ETS project, for example to allow the line

couplers have a correct configuration of their filter tables. To do so a Dummy device can be

used in ETS to simulate the IntesisTM and associate also to this Dummy device all group

addresses used in IntesisTM.

The dummy device can be downloaded from:

https://intesis.com/docs/software/setupv_linkboxmb

Page 22

IntesisTM KNX – Mitsubishi Heavy Industries AC

User’s Manual r1.2 eng

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

22 / 26

Setup process and troubleshooting

Pre-requisites

It is necessary to have the KNX bus operative and well connected to the KNX port of

IntesisTM.

Connectors, connection cables, PC for LinkBoxEIB, and other auxiliary material, if needed,

are not supplied by HMS Networks for this standard integration. Items supplied by HMS

Networks for this integration are:

• Intesis

TM

KNX device with full Mitsubishi Heavy Industries AC compatibility without

extra components.

• Standard plug-in 220Vac 50Hz power supply to power Intesis

TM

(European plug

type).

• Access to LinkBoxEIB software download site to configure Intesis

TM

.

• Console cable needed to download the configuration to Intesis

TM

.

• Product documentation.

Setup procedure

1. Install LinkBoxEIB on your laptop, use the setup program supplied for this and follow the

instructions given by the Installation Wizard.

2. Install Intesis

TM

in the desired installation site. For your convenience, check external

enclosure measures (see 7) before deciding where to place the IntesisTM device.

3. Connect the communication cable coming from the KNX bus to the Intesis

TM

KNX port

(See 3 for more information on connection procedure).

4. Connect the Superlink network cable to the Intesis

TM

port marked as AB (see 3.1).

5. Select the appropriate Superlink mode in the SLK selector. If you are using latest Air

Conditioner of the Mitsubishi Heavy Industries network select NEW, if not select OLD.

Contact your nearest Mitsubishi Heavy Industries supplier in case of doubt.

6. Connect the Intesis

TM

device to the power line (see 3.4) and press the On/Off button to

turn it on.

7. Connect the communication cable coming from the serial port of your laptop/desktop PC

to the IntesisTM port marked as EIA232 Console (see 3.3).

8. Open LinkBoxEIB and proceed as explained in section 4.

Troubleshooting

If IntesisTM is not working properly or even not working at all, please check the following

conditions to be accomplished.

6.3.1 Physical checking

First point to look at to make sure that IntesisTM is not working properly is to check physical

connections:

1.- Make sure that the power plug is correctly connected and current is available in

the power line.

Page 23

IntesisTM KNX – Mitsubishi Heavy Industries AC

User’s Manual r1.2 eng

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

23 / 26

2.- Check IntesisTM LED status:

LED

Status

Explanation

Solution

OP

Off

No power reaching the

internal device

Check power connection

Check fuse status (see part 13 in Figure 3.2)

ERR

Blinking once

periodically

Superlink

communication failure

Check Superlink cables and terminals

(connectors, length of cables, etc.)

HOST

Off

Configuration error

Download the binary file again (see 4.3)

PAC

Off

Communication error in

the Superlink network

Check the Mitsubishi Heavy Industries

Superlink network and its connections

Table 6.1 IntesisTM LED status information

6.3.2 Software checking

Once physical connections have been checked, if functioning problems still remain, please

use the LinkBoxEIB tool to monitor the working status of the device.

• To check the KNX communication status, click on the KNX button in the menu

bar (see Figure 4.1).

• To check the MHI communication status, click on the MHI button, also in the

menu bar (see Figure 4.1).

• To check the signal values in the KNX communication objects, click on the

Signals button, also in the menu bar (see Figure 4.1).

Further information regarding the monitoring procedure and the information provided in

each window can be consulted in the LinkBoxEIB Manual.

Page 24

IntesisTM KNX – Mitsubishi Heavy Industries AC

User’s Manual r1.2 eng

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

24 / 26

Mechanical & Electrical characteristics

1

Device can be installed in any position.

Ø 5 mm

195 mm

138 mm

10 mm

15 mm

Figure 7.1 External dimensions – Perspective view

Figure 7.3 Top view1 (screw holes size)

167 mm

65 mm

179 mm

61 mm

65 mm

Figure 7.2 External dimensions – Front view

61 mm

Page 25

IntesisTM KNX – Mitsubishi Heavy Industries AC

User’s Manual r1.2 eng

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

25 / 26

Enclosure

Industrial sheet metal.

Size: 215mm x 167mm x 61mm.

Weight: 2.025 Kg

Color

Gray metalized.

Power

100 to 240VAC~

50 to 60Hz

5W max.

Power connector: C14 (male) 1

Fuse

250V

1.5A

Dimensions: 20x5mm

Terminal wiring

(for low-voltage

signals)

Per terminal: solid wires or stranded wires (twisted or with ferrule)

1 core: 0.75 … 1.25mm2

2 cores: 0.75 … 1.25mm2

3 cores: not permitted

Mounting

Wall (see Figure 7.3)

KNX port

1 x KNX TP1 (EIB) opto-isolated (Plug-in screw terminal block 2

poles)

A-B port

1 x Superlink terminals (Plug-in screw terminal block 2 poles “A”

“B”). SELV

ETH port

1 x Ethernet 10Base-T (RJ45)

LED indicators

2 x Ethernet port link and activity (LNK, ACT).

4 x MHI Interface (OP, ERR, HOST, PAC)

Push buttons

1 x Reset Device

Selectors

1 x SLK selector

Console port

EIA232. (DB9 female DCE). SELV

Configuration

Via console port. 2

Firmware

Allows upgrades via console port.

Operational

temperature range

0°C to +40°C

Operational

humidity range

5% to 95%, non condensing

Protection

IP20 (IEC60529).

RoHS conformity

Compliant with RoHS directive (2002/95/CE).

Norms and

standards

CE conformity to EMC directive (2004/108/EC) and Low-voltage

directive (2006/95/EC)

EN 61000-6-2

EN 61000-6-3

EN 60950-1

EN 50491-3

Table 7.1 IntesisTM Mechanical and Electrical Characteristics

AC Unit Types compatibility

Indoor units compatible with the IntesisTM KNX – Mitsubishi Heavy Industries are those

included in the Mitsubishi Heavy Industries KX family and so on.

1

A power cable with connector C14 male 1.6 meters long is supplied with the device.

2

Standard cable DB9male-DB9female 1.8 meters long is supplied with the device for connection to a PC COM port for configuring

and monitoring the device. The configuration software, compatible with WindowsTM operating systems, is also supplied.

Page 26

IntesisTM KNX – Mitsubishi Heavy Industries AC

User’s Manual r1.2 eng

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

26 / 26

Error codes

This list contains all possible values shown in KNX communication objects for “Error Code”

for each indoor unit.

Error

Code

KNX

Error in

Remote

Controller

Error Description

0

N/A

No active error

1

E1

Remote controller communication error

2

E2

Duplicated indoor unit address

3

E3

Outdoor unit signal line error

5

E5

Communication error during operation

6

E6

Indoor heat exchanger temperature thermistor anomaly

7

E7

Indoor return air temperature thermistor anomaly

8

E8

Heating overload operation

9

E9

Drain trouble

10

E10

Excessive number of indoor units (more than 17) by controlling one remote

controller

12

E12

Address setting error by mixed setting method

14

E14

Communication error between master and slave indoor units

16

E16

Indoor fan motor anomaly

19

E19

Indoor unit operation check, drain motor check setting error

28

E28

Remote controller temperature thermistor anomaly

30

E30

Unmatched connection of indoor and outdoor unit

31

E31

Duplicated outdoor unit address No.

32

E32

Open L3 Phase on power supply at primary side

33

E33

Inverter primary current error

35

E35

Cooling overload operation

36

E36

Discharge pipe temperature error

37

E37

Outdoor heat exchanger temperature thermistor anomaly

38

E38

Outdoor/Ambient air temperature thermistor anomaly

39

E39

Discharge pipe temperature thermistor anomaly

40

E40

High pressure error

41

E41

Power transistor overheat

42

E42

Current cut

43

E43

Excessive number of indoor units connected, excessive total capacity of connection

45

E45

Communication error between inverter PCB and outdoor control PCB

46

E46

Mixed address setting methods coexistent in same network

47

E47

Inverter over-current error

48

E48

Outdoor DC fan motor anomaly

49

E49

Low pressure anomaly

51

E51

Inverter anomaly

53

E53

Suction pipe temperature thermistor anomaly

54

E54

High/Low pressure sensor anomaly

55

E55

Underneath temperature thermistor anomaly

56

E56

Power transistor temperature thermistor anomaly

57

E57

Insufficient in refrigerant amount or detection of service valve closure

58

E58

Anomalous compressor by loss of synchronism

59

E59

Compressor startup failure

60

E60

Rotor position detection failure / Anomalous compressor rotor lock

61

E61

Communication error between the master unit and slave units

63

E63

Emergency stop

Table 9.1 Error codes

In case you detect an error code not listed, contact your nearest MITSUBISHI HEAVY

INDUSTRIES technical support service.

Loading...

Loading...