Page 1

Compatible with Domestic line models

USER MANUAL

Issue date: 12/2017 r2.3 ENGLISH

Page 2

Intesis

TM

INMBSDAI001I000

User’s Manual r2.3 EN

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

2 / 22

Important User Information

Disclaimer

The information in this document is for informational purposes only. Please inform HMS Industrial

Networks of any inaccuracies or omissions found in this document. HMS Industrial Networks disclaims

any responsibility or liability for any errors that may appear in this document.

HMS Industrial Networks reserves the right to modify its products in line with its policy of continuous

product development. The information in this document shall therefore not be construed as a

commitment on the part of HMS Industrial Networks and is subject to change without notice. HMS

Industrial Networks makes no commitment to update or keep current the information in this document.

The data, examples and illustrations found in this document are included for illustrative purposes and are

only intended to help improve understanding of the functionality and handling of the product. In view of

the wide range of possible applications of the product, and because of the many variables and

requirements associated with any particular implementation, HMS Industrial Networks cannot assume

responsibility or liability for actual use based on the data, examples or illustrations included in this

document nor for any damages incurred during installation of the product. Those responsible for the use

of the product must acquire sufficient knowledge in order to ensure that the product is used correctly in

their specific application and that the application meets all performance and safety requirements

including any applicable laws, regulations, codes and standards. Further, HMS Industrial Networks will

under no circumstances assume liability or responsibility for any problems that may arise as a result from

the use of undocumented features or functional side effects found outside the documented scope of the

product. The effects caused by any direct or indirect use of such aspects of the product are undefined and

may include e.g. compatibility issues and stability issues.

Page 3

Intesis

TM

INMBSDAI001I000

User’s Manual r2.3 EN

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

3 / 22

Modbus RTU (EIA-485) Interface for Daikin air conditioners.

Compatible with Domestic line models.

ORDER CODE

LEGACY ORDER CODE

INMBSDAI001I000

DK-AC-MBS-1

Page 4

Intesis

TM

INMBSDAI001I000

User’s Manual r2.3 EN

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

4 / 22

INDEX

1. Presentation ........................................................................................................ 5

2. Connection .......................................................................................................... 6

2.1 Connect to the AC indoor unit ........................................................................... 6

2.2 Connection to the EIA-485 bus .......................................................................... 6

3. Quick Start Guide ................................................................................................. 7

4. Modbus Interface Specification ............................................................................... 8

4.1 Modbus physical layer ...................................................................................... 8

4.2 Modbus Registers ............................................................................................ 8

4.2.1 Control and status registers .......................................................................... 8

4.2.2 Configuration Registers .............................................................................. 10

4.2.3 Considerations on Temperature Registers ..................................................... 10

4.3 DIP-switch Configuration Interface .................................................................. 13

4.4 Implemented Functions .................................................................................. 16

4.5 Device LED indicator ...................................................................................... 16

4.6 EIA-485 bus. Termination resistors and Fail-Safe Biasing mechanism ................... 16

5. Mechanical and electrical features .......................................................................... 17

6. List of supported AC Unit Types ............................................................................. 18

7. Error Codes ........................................................................................................ 19

Page 5

Intesis

TM

INMBSDAI001I000

User’s Manual r2.3 EN

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

5 / 22

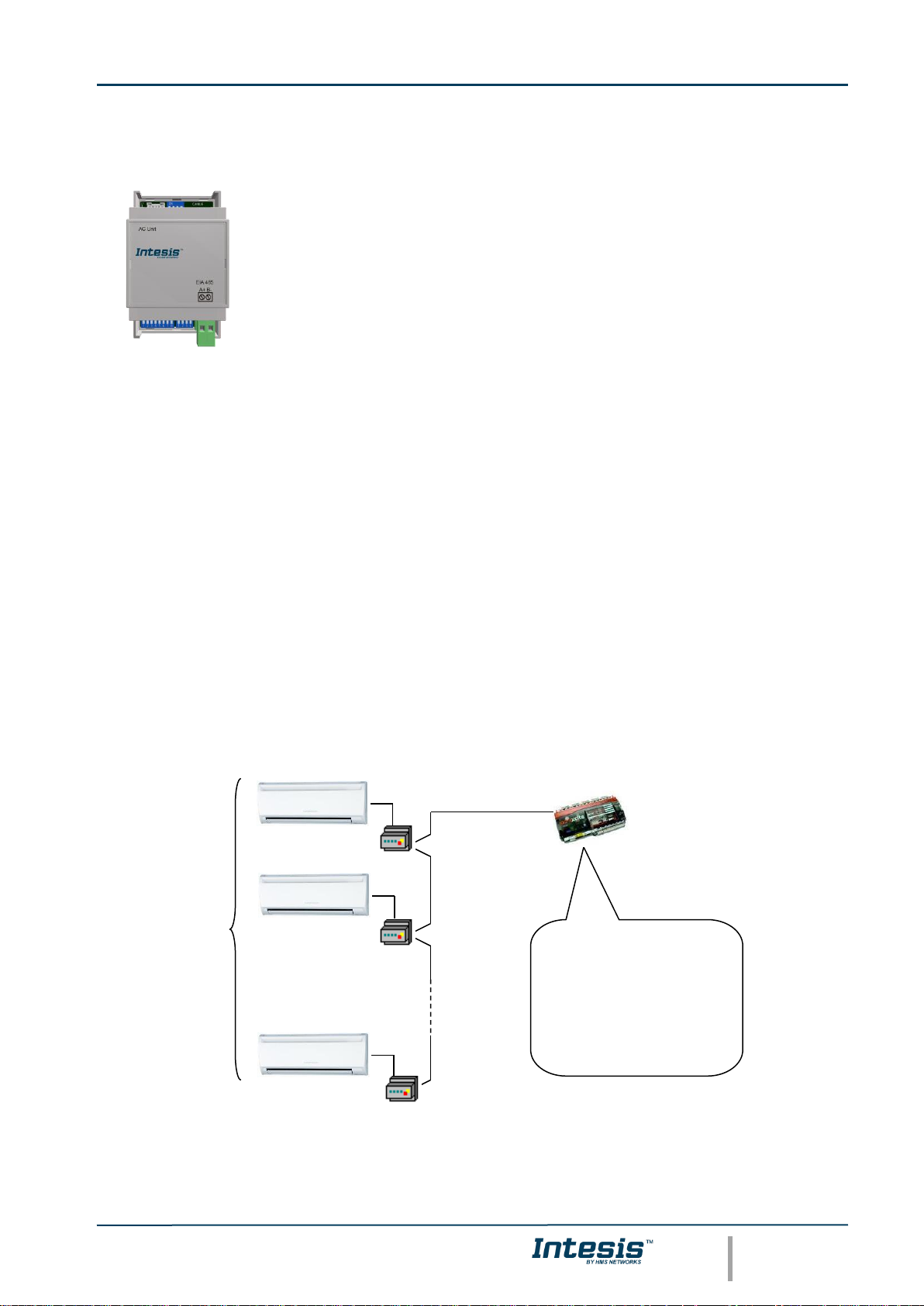

1. Presentation

The INMBSDAI001I000 interface allows a complete and natural integration of

Daikin air conditioners into Modbus RTU (EIA-485) networks.

Compatible with Domestic line models.

Reduced dimensions. 93 x 53 x 58 mm

3.7” x 2.1” x 2.3”

• Quick and easy installation.

Mountable on DIN rail, wall, or even inside the indoor unit on some models of AC.

• External power not required.

• Direct connection to Modbus RTU (EIA-485) networks. Up to 63 INMBSDAI001I000

devices can be connected on the same network.

INMBSDAI001I000 is a Modbus slave device.

• Direct connection to the AC indoor unit. Up to 1 AC indoor units can be connected to

INMBSDAI001I000. The cable for this connection is also supplied.

• Configuration from both on-board DIP-switches and Modbus RTU.

• Total Control and Supervision.

• Real states of the AC unit's internal variables.

• Allows simultaneous use of the AC’s remote controls and Modbus RTU.

* Up to 63 Intesis devices can be installed in the same Modbus RTU bus. However, depending on the configured speed, the

installation of Modbus Repeaters may be required

• SCADA

• PLC

• DDC

• BMS

• HMI

• Controller

• etc

Up to 63

AC indoor

units*

Modbus RTU

EIA-485 network

Modbus RTU

Master

device

INMBSDAI001I000

INMBSDAI001I000

INMBSDAI001I000

Page 6

Intesis

TM

INMBSDAI001I000

User’s Manual r2.3 EN

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

6 / 22

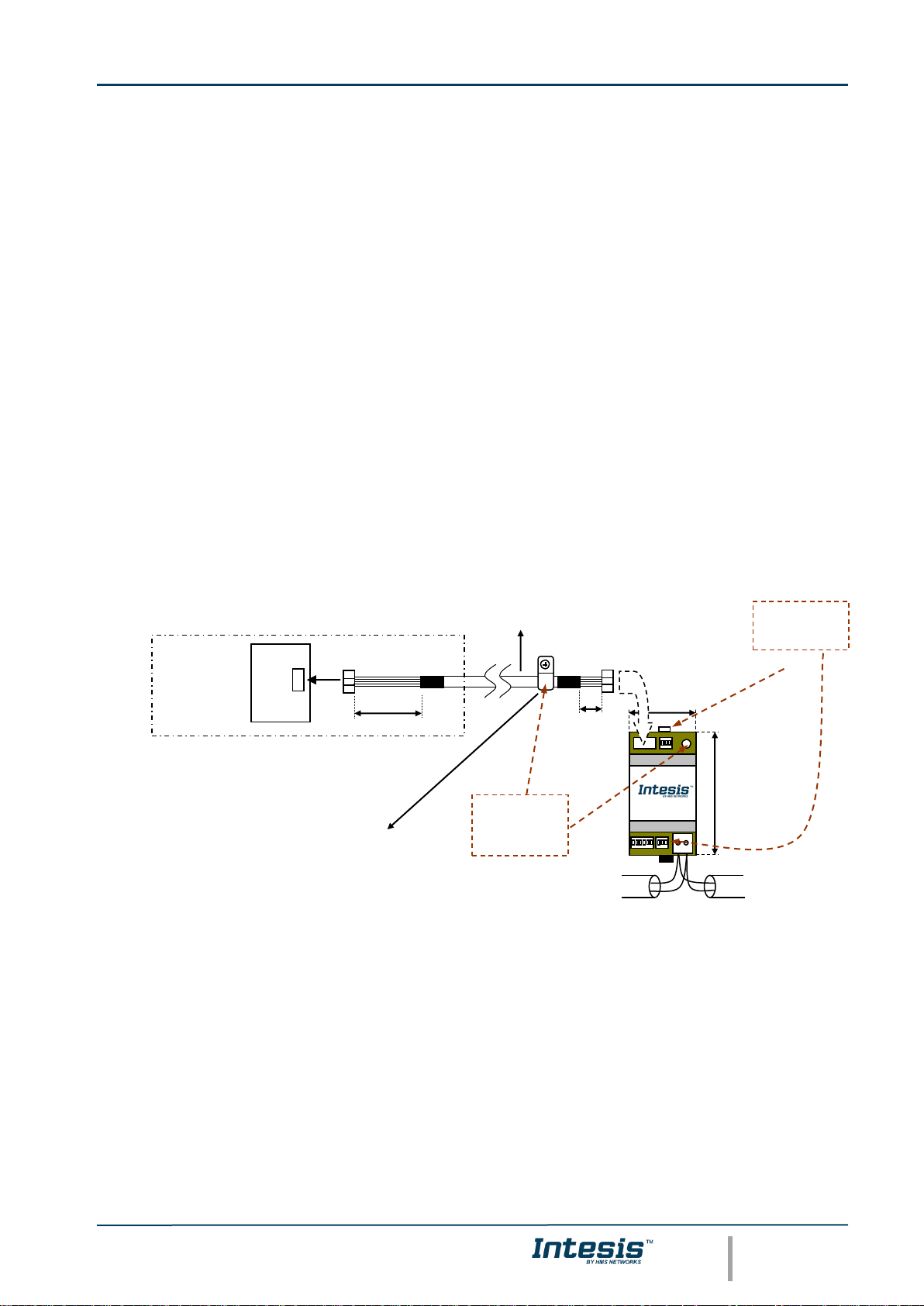

2. Connection

The interface comes with a specific cable and connectors to establish direct connection to the

AC indoor unit. It comes as well with a plug-in terminal block of 2 poles to establish direct

connection with the Modbus RTU EIA-485 network.

2.1 Connect to the AC indoor unit

To connect the INMBSDAI001I000 interface with the AC indoor unit you must follow these

steps:

Disconnect Mains Power from the AC unit. Open the front cover of the indoor unit to have

access to the electronic circuit. Once you arrive at the electronic circuit, locate the socket

connector marked as S21.

Take the cable that comes with the interface, insert one of its connectors (the one installed in

the shortest uncovered part) into the socket of the INMBSDAI001I000, and the other

connector (the one installed in the largest uncovered part) to the socket S21 of the AC unit's

electronic circuit. Remember that the INMBSDAI001I000 must also be connected to the

Modbus RTU EIA-485 network. Close the AC indoor unit's front cover again to finish the

connection.

Do not modify the length of the cable supplied with the interface, it may affect the correct

interface´s operation.

2.2 Connection to the EIA-485 bus

Connect the EIA-485 bus wires to the plug-in terminal block (the one of two poles) of

INMBSDAI001I000 and keep the polarity on this connection (A+ and B-). Make sure that the

maximum distance to the bus is 1,200 meters (3,937 ft). The loop or star typologies are not

allowed in the case of the EIA-485. A terminator resistor of 120Ω must be present at each

end of the bus to avoid signal reflections. The bus needs a fail-safe biasing mechanism (see

section 4.6 for more details).

S21

AC indoor unit

Electronic circuit board

200 mm / 7.9”

40 mm / 1.6”

Connection cable

supplied within the

interface.

90 mm / 3.5”

Modbus RTU

EIA-485

Bus

EIA485

A B

AC Unit

53 mm / 2.1”

Use these holes to

attach the cable

using the staple and

screw provided with

the interface.

For wall mounting,

extract the upper and

lower staples until

you listen the "click".

Fixing screw

Page 7

Intesis

TM

INMBSDAI001I000

User’s Manual r2.3 EN

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

7 / 22

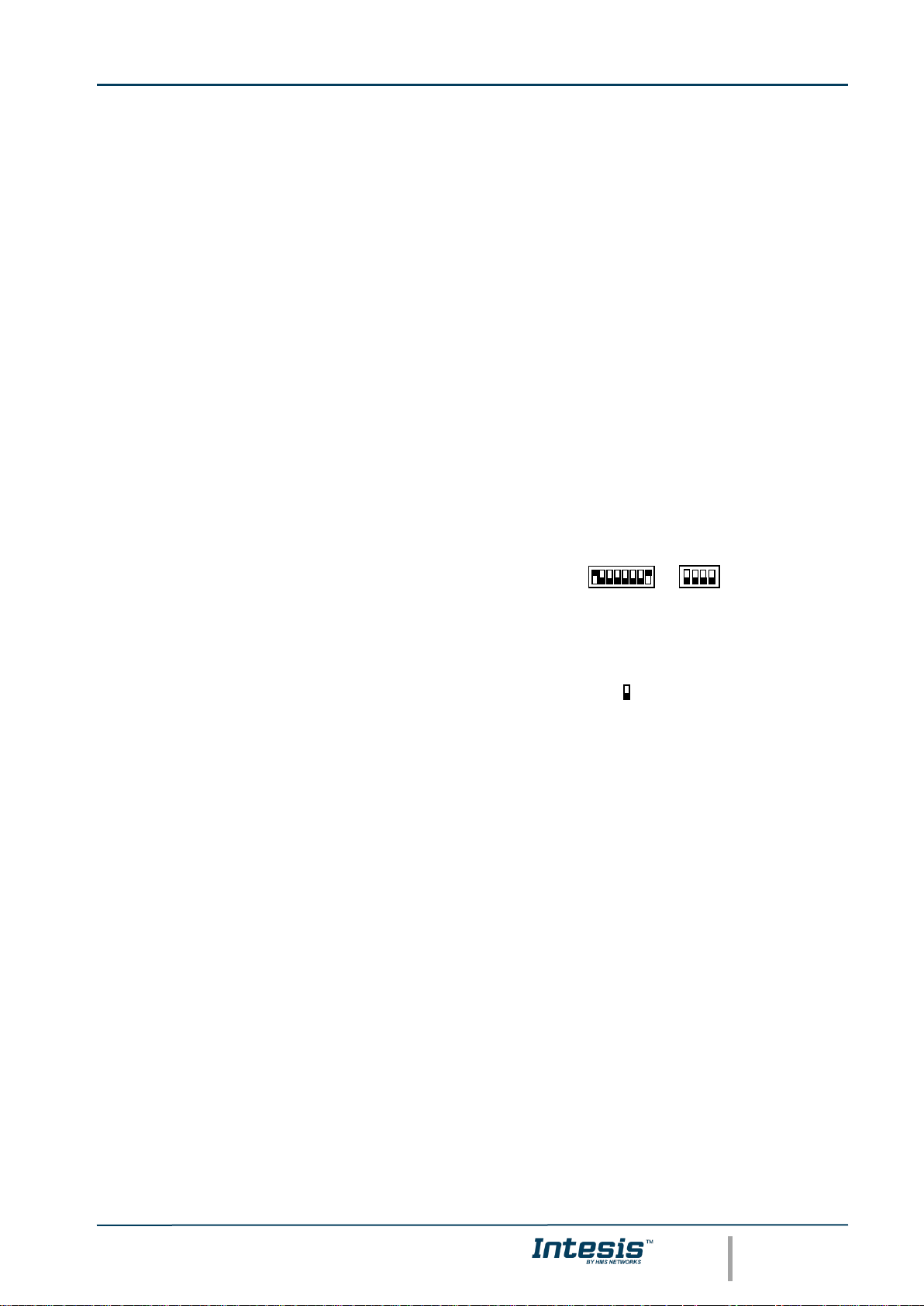

3. Quick Start Guide

1. Disconnect the air conditioning from the Mains Power.

2. Attach the interface next to the AC indoor unit (wall mounting) following the

instructions of the diagram below or install it inside the AC indoor unit (respect the

safety instructions given above).

3. Connect the connection cable included with the interface between the interface and

the AC indoor unit following the instructions of the diagram.

4. Connect the EIA-485 bus to the connector EIA485 of the interface.

5. Close the AC indoor unit.

6. Check the DIP-Switch configuration of the Intesis interface and make sure it matches

the current installation’s parameters (see section 4.3).

By default, the interface is set to:

▪ Modbus Slave Address ➔ 1

▪ Modbus baud rate ➔ 9600 bps

These parameters can be modified from SW4 and SW3 DIP-Switches.

All other switch positions are set at low level (Off position ) by default.

NOTE: All changes on the DIP-Switch configuration require a system power cycle to

be applied.

7. Connect the AC system to Mains Power.

IMPORTANT: The Intesis interface requires to be connected to the AC unit

(powered) to start communicating.

ON

ON

SW3

SW4

Page 8

Intesis

TM

INMBSDAI001I000

User’s Manual r2.3 EN

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

8 / 22

4. Modbus Interface Specification

4.1 Modbus physical layer

INMBSDAI001I000 implements a Modbus RTU (Slave) interface, to be connected to an EIA485 line. It performs an 8N2 communication (8 data bits, no parity and 2 stop bit) with

several available baud rates (2400 bps, 4800 bps, 9600 bps -default-, 19200 bps, 38400

bps, 57600 bps, 76800 bps and 115200 bps). It also supports 8N1 communication (8 data

bits, no parity and 1 stop bit).

4.2 Modbus Registers

All registers are type “16-bit unsigned Holding Register” and they use the standard ModBus

big endian notation.

4.2.1 Control and status registers

Register Address

(protocol address)

Register Address

(PLC address)

R/W

Description

0

1

R/W

AC unit On/Off

▪ 0: Off

▪ 1: On

1

2

R/W

AC unit Mode 1

▪ 0: Auto

▪ 1: Heat

▪ 2: Dry

▪ 3: Fan

▪ 4: Cool

2

3

R/W

AC unit Fan Speed 1

▪ 0: Auto

▪ 1: Low

▪ 2: Mid-1

▪ 3: Mid-2

▪ 4: Mid-3

▪ 5: High

3

4

R/W

AC unit Up/Down Vane Position 1

▪ 0: Off (Default)

▪ 10: Swing

4

5

R/W

AC unit Temperature setpoint

1,2,3

▪ -32678 (Initialization value)

COOL

▪ 18..32 ºC (ºC/x10ºC)

▪ 64..92 ºF

HEAT

▪ 16..30 ºC (ºC/x10ºC)

▪ 61..88 ºF

AUTO

▪ 18..30 ºC (ºC/x10ºC)

▪ 64..88 ºF

1

Available values will depend on the AC unit mode. Check the AC unit model functions in its user manual to know the possible

values for this register.

2

Magnitude for this register can be adjusted to Celsius x 1ºC, Celsius x 10ºC (default) or Fahrenheit. See section 4.2.3 for more

information

3

It is not possible turn to x10 the value shown in Fahrenheit.

Page 9

Intesis

TM

INMBSDAI001I000

User’s Manual r2.3 EN

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

9 / 22

Register Address

(protocol address)

Register Address

(PLC address)

R/W

Description

5

6

R

AC unit Temperature reference

1,2,3

▪ -32678 (Initialization value)

▪ 10..38 ºC (ºC/x10ºC)

▪ 50..100 ºF

6

7

R/W

Window Contact

▪ 0: Closed (Default Value)

▪ 1: Open

7

8

R/W

INMBSDAI001I000 Disablement 4

▪ 0: INMBSDAI001I000 enabled (Default

Value)

▪ 1: INMBSDAI001I000 disabled

8

9

R/W

AC Remote Control Disablement 4

▪ 0: Remote Control enabled (Default)

▪ 1: Remote Control disabled

9

10

R/W

AC unit Operation Time 4

▪ 0..65535 (hours). Counts the time the

AC unit is in “On” state.

10

11

R

AC unit Alarm Status

▪ 0: No alarm condition

▪ 1: Alarm condition

11

12

R

Error Code 5

▪ 0: No error present

▪ 65535 (-1 if it is read as signed value):

Error in the communication of

INMBSDAI001I000 with the AC unit

▪ Any other error present, see the table at

the end of this document.

22

23

R/W

Indoor unit ambient temperature from

external sensor (at Modbus side)

1,2,3,6

▪ -32768: (Initialization value). No

temperature is being provided from an

external sensor.

▪ Any other: (ºC/x10ºC/ºF)

23

24

R

AC Real temperature setpoint

1,2,3,6

▪ -32678 (Initialization value)

COOL

▪ 18..32 ºC (ºC/x10ºC)

▪ 64..92 ºF

HEAT

▪ 16..30 ºC (ºC/x10ºC)

▪ 61..88 ºF

AUTO

▪ 18..30 ºC (ºC/x10ºC)

▪ 64..88 ºF

26

27

R/W

AC unit Left/Right Vane Position 1

▪ 0: Auto (Default Value)

▪ 10: Swing

28 29

R/W

AC Humidification Value 1

▪ 0: Off

▪ 1: Low Humidification

▪ 2: Medium Humidification

▪ 3: High Humidification

4

This value is stored in non-volatile memory

5

See section 7 for possible error codes and their explanation

6

See section 4.2.3 for more information

Page 10

Intesis

TM

INMBSDAI001I000

User’s Manual r2.3 EN

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

10 / 22

▪ 4: Continuous

97

98

R/W

Block Periodic Sendings

4,7,8

▪ 0: Non-blocked (Default value)

▪ 1: Blocked

4.2.2 Configuration Registers

Register Address

(protocol address)

Register Address

(PLC address)

R/W

Description

13

14

R/W

“Open Window” switch-off timeout 9

▪ 0..30 (minutes)

▪ Factory setting: 30 (minutes)

14

15

R

Modbus RTU Baud rate

▪ 2400bps

▪ 4800bps

▪ 9600bps (Default)

▪ 19200bps

▪ 38400bps

▪ 57600bps

▪ 76800bps

▪ 115200bps

15

16

R

Device's Modbus Slave address

▪ 1..63

21

22

R

Max number of fan speeds

▪ Value is always 5

49

50

R

Device ID: 0x0701

50

51

R

Software version

4.2.3 Considerations on Temperature Registers

• AC unit temperature setpoint (R/W)

(register 4 – in Protocol address / register 5 – in PLC address):

This is the adjustable temperature setpoint value that must be required by the User.

This register can be read (Modbus function 3 or 4) or written (Modbus functions 6 or

16). A Remote Controller connected to the Daikin indoor unit will report the same

temperature setpoint value as this register. This will apply when no AC unit’s

external reference temperature is provided from INMBSDAI001I000 (see details for

register 22/23 below).

• AC unit temperature reference (R)

(register 5 – in Protocol address / register 6 – in PLC address):

7

If the register is configured as “0:Non-blocked”, all commands received from Modbus will be sent to the AC system. If “1:

Blocked”, commands from Modbus will only be sent to the AC system if they differ from the previous value (values sent on chan ge).

8

The register applies to firmware version 1.5 onwards

9

Once window contact is open, a count-down to switch off the AC Unit will start from this configured value.

Page 11

Intesis

TM

INMBSDAI001I000

User’s Manual r2.3 EN

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

11 / 22

This register reports the temperature that is currently used by the Daikin indoor unit

as the reference of its own control loop. Depending on the configuration of the indoor

unit, this value can be the temperature reported by the sensor on the return path of

the Daikin indoor unit or the sensor of its Remote Controller. It is a read-only

register (Modbus functions 3 or 4).

• AC unit external temperature reference (Modbus) (R/W)

(register 22 – in Protocol address / register 23 – in PLC address):

This register allows us to provide an external temperature’s sensor from the Modbus

side. Daikin indoor unit does not allow, on devices like INMBSDAI001I000, to provide

directly a temperature to be used as a reference of the control loop of the AC indoor

unit. In order to overcome this limitation and enable the usage of an external

temperature sensor (e.g. from Modbus side), INMBSDAI001I000 applies the

following mechanism (only if “external temperature’s reference” is being used):

o After a couple of values have been entered in the “AC unit external

temperature’s reference” (register 22/23) and the “AC unit temperature set

point” (register 4/5), INMBSDAI001I000 calculates the corresponding

temperature’s demand (e.g., if a “temperature setpoint (register 4/5)” of

22ºC, and an “external temperature reference (register 22/23)” of 20ºC are

entered, INMBSDAI001I000 will assume that the user is demanding a +2ºC

increase in temperature).

o By knowing at any time, the ambient temperature currently used by the

indoor unit to control its own operation (register 5/6), INMBSDAI001I000 can

calculate the required temperature setpoint needed to apply the

decrease/increase on the real temperature and reach the temperature chosen

by the user (following the example above, if INMBSDAI001I000 reads an

“ambient temperature” (register 5/6) of 24ºC in the indoor unit, it will apply

a final setpoint of 24ºC + 2ºC = 26ºC).

o At this moment, each time that INMBSDAI001I000 detects a change on the

ambient temperature reported by the indoor unit (register 5/6), it will also

change the required setpoint, in order to keep the temperature required by

the User at any time. If we follow the last example, when INMBSDAI001I000

receives a new temperature´s value coming from the indoor unit of 25ºC,

INMBSDAI001I000 will automatically adjust the temperature setpoint required

of the AC indoor unit to 25ºC + 2ºC = 27ºC).

o In general, INMBSDAI001I000 is constantly applying the “Virtual

Temperature” formula:

SAC = Su – ( Tu – T

AC

)

Where:

SAC - setpoint value currently applied to the indoor unit

Su - setpoint value written at Modbus side (register 4/5)

Tu - external temperature reference written at Modbus side (register 22/23)

TAC - ambient temperature that the indoor unit is using as the reference of

its own control loop (register 5/6)

When INMBSDAI001I000 detects a change in any of the values of

{ Su , Tu , TAC }, it will send the new setpoint (SAC) to the indoor unit.

o After the startup, the value for “external temperature’s reference” (register

22/23) has a value -32768 (0x8000). This value means that no external

temperature reference is being provided through INMBSDAI001I000. In this

Page 12

Intesis

TM

INMBSDAI001I000

User’s Manual r2.3 EN

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

12 / 22

scenario, the setpoint value shown or written in register 4/5 will always be

the same as the current setpoint value of the indoor unit.

o Notice that, the use of the “external temperature reference” (register 22/23)

(e.g., writing a value different from -32768 / 0x8000 in it) has the following

relevant consequences:

▪ The mechanism of “Virtual Temperature” is applied. The temperature

setpoint’s value shown by the Remote Controller or other Control

System from Daikin connected to the indoor unit may show a different

value from the value shown in register 4/5.

▪ The User is not be able to change the setpoint using any Remote

Controller from Daikin, as setpoint of the indoor unit becomes

exclusively controlled by the “Virtual Temperature” mechanism.

• AC Real temperature setpoint (R)

(register 23 – In Protocol address / register 24 – in PLC address):

As it has been detailed on the previous point, the real temperature setpoint in the

indoor unit and the temperature setpoint requested from INMBSDAI001I000 might

differ (when a value in register 22/23 – “external temperature reference” is

entered). This register always informs about the current temperature setpoint which

is being used by the indoor unit – it is also includes the temperature setpoint that

will be shown by an additional remote controller from Daikin connected to the indoor

unit, if it is present on the system.

Moreover, notice that temperature’s values of all these three registers are expressed

according to the temperature’s format configured through its onboard DIP-Switches

(See 4.3). The following formats are possible:

• Celsius value: Value in Modbus register is the temperature value in Celsius (i.e.

a value “22” in the Modbus register must be interpreted as 22ºC).

• Decicelsius value: Value in Modbus register is the temperature value in

decicelsius (i.e. a value “220” in the Modbus register must be interpreted as

22.0ºC).

• Fahrenheit value: Value in Modbus register is the temperature value in

Fahrenheit (i.e. a value “72” in the Modbus register must be interpreted as 72ºF

(~22ºC).

Page 13

Intesis

TM

INMBSDAI001I000

User’s Manual r2.3 EN

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

13 / 22

4.3 DIP-switch Configuration Interface

All the configuration values on INMBSDAI001I000 can be written and read from Modbus

interface. Otherwise, some of them can also be setup from its on-board DIP-switch interface.

The device has DIP-switches SW1*, SW3 and SW4 on the following locations:

The following tables apply to the interface’s configuration through DIP-switches:

SW4 –Degrees/Decidegrees (x10), temperature magnitude (ºC/ºF) and EIA-485 termination

resistor.

Table 4.1 SW4: Temperature and termination resistor configuration

SW4-P1..2-4

Description

Temperature values in Modbus register are represented in degrees (x1) (Default value)

Temperature values in Modbus register are represented in decidegrees (x10)

Temperature values in Modbus register are represented in Celsius degrees (Default value)

Temperature values in Modbus register are represented in Fahrenheit degrees

EIA-485 bus without termination resistor (Default value)

Internal termination resistor of 120Ω connected to EIA-485 bus

SW3

SW4

* DIP-Switch SW1 is

not used by the

current version of

DK-AC-MBS-1

SW3 SW4

K1

FIXING

CABLE

EIA485

A B

AC Unit

SW1*

ON

1 2 3 4

SW1*

ON

ON

1 2 3 4

1 2 3 4 5 6 7 8

SW3

SW4

ON

ON

ON

ON

ON

ON

Page 14

Intesis

TM

INMBSDAI001I000

User’s Manual r2.3 EN

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

14 / 22

SW3/SW4 – Baud rate configuration

SW3-P7..8

SW4-P3

Description

2400bps

4800bps

9600bps (Default value)

19200bps

38400bps

57600bps

76800bps

115200bps

Table 4.2 SW3-SW4: Modbus baud rate

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

Page 15

Intesis

TM

INMBSDAI001I000

User’s Manual r2.3 EN

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

15 / 22

SW3 – Modbus Slave address

Table 4.3 SW3: Modbus Slave address

Add SW3-P1..6

Add SW3-P1..6

Add

SW3-P1..6

Add

SW3-P1..6

Add

SW3-P1..6

0

13

26

39

52

1

14

27

40

53

2

15

28

41

54

3

16

29

42

55

4

17

30

43

56

5

18

31

44

57

6

19

32

45

58

7

20

33

46

59

8

21

34

47

60

9

22

35

48

61

10

23

36

49

62

11 24 37 50 63

12 25 38 51

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

Page 16

Intesis

TM

INMBSDAI001I000

User’s Manual r2.3 EN

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

16 / 22

4.4 Implemented Functions

INMBSDAI001I000 implements the following standard Modbus functions:

▪ 3: Read Holding Registers

▪ 4: Read Input Registers

▪ 6: Write Single Register

▪ 16: Write Multiple Registers (Despite this function is allowed, the interface does not

allow to write operations on more than 1 register with the same request, this means

that length field should always be 1 when this function is being used in case of

writing)

4.5 Device LED indicator

The device includes a LED indicator to show all the possible operational states. In the

following table there are written the indicators which can be performed and its meaning.

Device status

LED indication

ON / OFF Period

Description

On power-up

LED pulse

ON for 5 seconds / OFF after

Device reset / power-up

During normal

operation

LED flashing

200ms ON / 2s OFF

Device correctly

configured and working

During normal

operation

LED OFF

OFF continuously

No Modbus Slave address

configured

During normal

operation

LED blinking

200ms ON / 200ms OFF

Communication Error with

the AC unit

4.6 EIA-485 bus. Termination resistors and Fail-Safe Biasing

mechanism

EIA-485 bus requires a 120Ω terminator resistor at each end of the bus to avoid signal

reflections.

In order to prevent fail status detections by the receivers, which are "listening" the bus, when

all the transmitters’ outputs are in three-state (high impedance), it is also required a fail-safe

biasing mechanism. This mechanism provides a safe status (a correct voltage level) in the

bus when all the transmitters’ outputs are in three-state.

The INMBSDAI001I000 device includes an on-board terminator resistor of 120Ω that can be

connected to the EIA-485 bus by using DIP-switch SW4.

Some Modbus RTU EIA-485 Master devices can provide also internal 120Ω terminator resistor

and/or fail-safe biasing. Check the technical documentation of the Master device connected to

the EIA-485 network in each case.

Page 17

Intesis

TM

INMBSDAI001I000

User’s Manual r2.3 EN

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

17 / 22

5. Mechanical and electrical features

Enclosure

Plastic, type PC (UL 94 V-0)

Net dimensions (dxwxh):

93 x 53 x 58 mm / 3.7” x 2.1” x 2.3”

Color: Light Grey. RAL 7035

Operation

Temperature

0ºC to +60ºC

Weight

85 g.

Stock

Temperature

-20ºC to +85ºC

Mounting

Wall

DIN rail EN60715 TH35.

Operational

Humidity

<95% RH, non-condensing

Terminal Wiring

(for lowvoltage signals)

For terminal: solid wires or stranded wires

(twisted or with ferrule)

1 core: 0.5mm2… 2.5mm2

2 cores: 0.5mm2… 1.5mm2

3 cores: not permitted

Stock Humidity

<95% RH, non-condensing

Modbus RTU

port

1 x Serial EIA485 Plug-in screw terminal block

(2 poles)

A, B

Compatible with Modbus RTU EIA-485 networks

Isolation

voltage

1500 VDC

AC unit port

1 x Specific connector

Specific cable included

Isolation

resistance

1000 MΩ

Switch 1

(SW1)

1 x DIP-Switch

Protection

IP20 (IEC60529)

Switch 3

(SW3)

1 x DIP-Switch for Modbus RTU settings

LED indicators

1 x Onboard LED - Operational

status

Switch 4

(SW4)

1 x DIP-Switch for extra functions

EIA-485

Port

DIP

Switch SW1

DIP Switch

SW3

LED

indicator

DIP Switch

SW4

AC Unit

connector

Page 18

Intesis

TM

INMBSDAI001I000

User’s Manual r2.3 EN

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

18 / 22

6. List of supported AC Unit Types

A list of Daikin indoor unit model´s references compatible with INMBSDAI001I000 and its

available features can be found in:

https://www.intesis.com/docs/compatibilities/inxxxdai001xx00_compatibility

Page 19

Intesis

TM

INMBSDAI001I000

User’s Manual r2.3 EN

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

19 / 22

7. Error Codes

Error

Code

Error in

Remote

Controller

Error category

Error Description

0

N/A

INMBSDAI001I000

No active error

17

A0

Indoor Unit

External protection devices activated

18

A1

Indoor unit PCB assembly failure

19

A2

Interlock error for fan

20

A3

Drain level system error

21

A4

Temperature of heat exchanger (1) error

22

A5

Temperature of heat exchanger (2) error

23

A6

Fan motor locked, overload, over current

24

A7

Swing flap motor error

25

A8

Overcurrent of AC input

26

A9

Electronic expansion valve drive error

27

AA

Heater overheat

28

AH

Dust collector error / No-maintenance filter error

30

AJ

Capacity setting error (indoor)

31

AE

Shortage of water supply

32

AF

Malfunctions of a humidifier system (water leaking)

33

C0

Malfunctions in a sensor system

36

C3

Sensor system of drain water error

37

C4

Heat exchanger (1) (Liquid pipe) thermistor system error

38

C5

Heat exchanger (1) (Gas pipe) thermistor system error

39

C6

Sensor system error of fan motor locked, overload

40

C7

Sensor system of swing flag motor error

41

C8

Sensor system of over-current of AC input

42

C9

Suction air thermistor error

43

CA

Discharge air thermistor system error

44

CH

Contamination sensor error

45

CC

Humidity sensor error

46

CJ

Remote control thermistor error

47

CE

Radiation sensor error

48

CF

High pressure switch sensor

49

E0

Outdoor Unit

Protection devices activated

50

E1

Outdoor uni9t PCB assembly failure

52

E3

High pressure switch (HPS) activated

53

E4

Low pressure switch (LPS) activated

54

E5

Overload of inverter compressor motor

55

E6

Over current of STD compressor motor

56

E7

Overload of fan motor / Over current of fan motor

57

E8

Over current of AC input

58

E9

Electronic expansion valve drive error

59

EA

Four-way valve error

60

EH

Pump motor over current

61

EC

Water temperature abnormal

62

EJ

(Site installed) Protection device activated

63

EE

Malfunctions in a drain water

64

EF

Ice thermal storage unit error

65

H0

Malfunctions in a sensor system

66

H1

Air temperature thermistor error

67

H2

Sensor system of power supply error

68

H3

High Pressure switch is faulty

69

H4

Low pressure switch is faulty

70

H5

Compressor motor overload sensor is abnormal

71

H6

Compressor motor over current sensor is abnormal

72

H7

Overload or over current sensor of fan motor is abnormal

Page 20

Intesis

TM

INMBSDAI001I000

User’s Manual r2.3 EN

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

20 / 22

73

H8

Sensor system of over-current of AC input

74

H9

Outdoor air thermistor system error

75

HA

Discharge air thermistor system error

76

HH

Pump motor sensor system of over current is abnormal

77

HC

Water temperature sensor system error

79

HE

Sensor system of drain water is abnormal

80

HF

Ice thermal storage unit error (alarm)

81

F0

No.1 and No.2 common protection device operates.

82

F1

No.1 protection device operates.

83

F2

No.2 protection device operates

84

F3

Discharge pipe temperature is abnormal

87

F6

Temperature of heat exchanger(1) abnormal

91

FA

Discharge pressure abnormal

92

FH

Oil temperature is abnormally high

93

FC

Suction pressure abnormal

95

FE

Oil pressure abnormal

96

FF

Oil level abnormal

97

J0

Sensor system error of refrigerant temperature

98

J1

Pressure sensor error

99

J2

Current sensor error

100

J3

Discharge pipe thermistor system error

101

J4

Low pressure equivalent saturated temperature sensor

system error

102

J5

Suction pipe thermistor system error

103

J6

Heat exchanger(1) thermistor system error

104

J7

Heat exchanger(2) thermistor system error

105

J8

Oil equalizer pipe or liquid pipe thermistor system error

106

J9

Double tube heat exchanger outlet or gas pipe thermistor

system error

107

JA

Discharge pipe pressure sensor error

108

JH

Oil temperature sensor error

109

JC

Suction pipe pressure sensor error

111

JE

Oil pressure sensor error

112

JF

Oil level sensor error

113

L0

Inverter system error

116

L3

Temperature rise in a switch box

117

L4

Radiation fin (power transistor) temperature is too high

118

L5

Compressor motor grounded or short circuit, inverter PCB

fault

119

L6

Compressor motor grounded or short circuit, inverter PCB

fault

120

L7

Over current of all inputs

121

L8

Compressor over current, compressor motor wire cut

122

L9

Stall prevention error (start-up error) Compressor locked,

etc.

123

LA

Power transistor error

125

LC

Communication error between inverter and outdoor control

unit

129

P0

Shortage of refrigerant (thermal storage unit)

130

P1

Power voltage imbalance, open phase

132

P3

Sensor error of temperature rise in a switch box

133

P4

Radiation fin temperature sensor error

134

SW4

DC current sensor system error

135

SW1

AC or DC output current sensor system error

136

SW3

Total input current sensor error

142

PJ

Capacity setting error (outdoor)

145

U0

System

Low pressure drop due to insufficient refrigerant or electronic

Page 21

Intesis

TM

INMBSDAI001I000

User’s Manual r2.3 EN

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

21 / 22

expansion valve error, etc.

146

U1

Reverse phase, Open phase

147

U2

Power voltage failure / Instantaneous power failure

148

U3

Failure to carry out check operation, transmission error

149

U4

Communication error between indoor unit and outdoor unit,

communication error between outdoor unit and BS unit

150

U5

Communication error between remote control and indoor unit

/ Remote control board failure or setting error for remote

control

151

U6

Communication error between indoor units

152

U7

Communication error between outdoor units /

Communication error between outdoor unit and ice thermal

storage unit

153

U8

Communication error between main and sub remote

controllers (sub remote control error) / Combination error of

other indoor unit / remote control in the same system

(model)

154

U9

Communication error between other indoor unit and outdoor

unit in the same system / Communication error between

other BS unit and indoor/outdoor unit

155

UA

Combination error of indoor/BS/outdoor unit (model,

quantity, etc.), setting error of spare parts PCB when

replaced

156

UH

Improper connection of transmission wiring between outdoor

and outdoor unit outside control adaptor

157

UC

Centralized address duplicated

158

UJ

Attached equipment transmission error

159

UE

Communication error between indoor unit and centralized

control device

160

UF

Failure to carry out check operation Indoor-outdoor, outdooroutdoor communication error, etc.

209

60

Others

All system error

210

61

PC board error

211

62

Ozone density abnormal

212

63

Contamination sensor error

213

64

Indoor air thermistor system error

214

65

Outdoor air thermistor system error

217

68

HVU error (Venti-air dust-collecting unit)

219

6A

Dumper system error

220

6H

Door switch error

221

6C

Replace the humidity element

222

6J

Replace the high efficiency filter

223

6E

Replace the deodorization catalyst

224

6F

Simplified remote controller error

226

51

Fan motor of supply air over current or overload

227

52

Fan motor of return air over current / Fan motor of return air

overload

228

53

Inverter system error (supply air side)

229

54

Inverter system error (return air side)

241

40

Humidifying valve error

242

41

Chilled water valve error

243

42

Hot water valve error

244

43

Heat exchanger of chilled water error

245

44

Heat exchanger of hot water error

258

31

The humidity sensor of return air sensor

259

32

Outdoor air humidity sensor error

260

33

Supply air temperature sensor error

261

34

Return air temperature sensor error

262

35

Outdoor air temperature sensor error

Page 22

Intesis

TM

INMBSDAI001I000

User’s Manual r2.3 EN

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

22 / 22

263

36

Remote controller temperature sensor error

267

3A

Water leakage sensor 1 error

268

3H

Water leakage sensor 2 error

269

3C

Dew condensation error

339

M2

Centralized remote controller PCB error

345

M8

Communication error between centralized remote control

devices

347

MA

Centralized remote control devices inappropriate combination

349

MC

Centralized remote controller address setting error

65535

(-1)

N/A

INMBSDAI001I000

Error in the communication of INMBSDAI001I000 with the AC

unit

In case you detect an error code not listed, contact your nearest Daikin technical support

service.

Loading...

Loading...