Page 1

Compatible with AC units, of most AC brands, provided with an IR receiver

Application’s Program version: 1.1

USER MANUAL

Issue date: 02/2020 r1.3 ENGLISH

Page 2

Intesis

TM

KNX – IR Universal AC

User's manual r1.3 EN

© HMS Industrial Networks S.L.U. - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

2 / 46

Important User Information

Disclaimer

The information in this document is for informational purposes only. Please inform HMS Industrial Networks of

any inaccuracies or omissions found in this document. HMS Industrial Networks disclaims any responsibility or

liability for any errors that may appear in this document.

HMS Industrial Networks reserves the right to modify its products in line with its policy of continuous product

development. The information in this document shall therefore not be construed as a commitment on the part

of HMS Industrial Networks and is subject to change without notice. HMS Industrial Networks makes no

commitment to update or keep current the information in this document.

The data, examples and illustrations found in this document are included for illustrative purposes and are only

intended to help improve understanding of the functionality and handling of the product. In view of the wide

range of possible applications of the product, and because of the many variables and requirements associated

with any particular implementation, HMS Industrial Networks cannot assume responsibility or liability for actual

use based on the data, examples or illustrations included in this document nor for any damages incurred during

installation of the product. Those responsible for the use of the product must acquire sufficient knowledge in

order to ensure that the product is used correctly in their specific application and that the application meets all

performance and safety requirements including any applicable laws, regulations, codes and standards. Further,

HMS Industrial Networks will under no circumstances assume liability or responsibility for any problems that

may arise as a result from the use of undocumented features or functional side effects found outside the

documented scope of the product. The effects caused by any direct or indirect use of such aspects of the product

are undefined and may include e.g. compatibility issues and stability issues.

Page 3

Intesis

TM

KNX – IR Universal AC

User's manual r1.3 EN

© HMS Industrial Networks S.L.U. - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

3 / 46

Gateway for integration of IR air conditioners into KNX TP-1

(EIB) control systems.

Compatible with AC units, of most AC brands, provided with an IR receiver.

Application’s Program Version: 1.1

ORDER CODE

LEGACY ORDER CODE

INKNXUNI001I000

IS-IR-KNX-1I

Page 4

Intesis

TM

KNX – IR Universal AC

User's manual r1.3 EN

© HMS Industrial Networks S.L.U. - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

4 / 46

Table of Contents

1 Presentation ............................................................................................................................................ 6

2 Quick setup .............................................................................................................................................. 7

3 Device Installation ................................................................................................................................... 8

Location selection ............................................................................................................................... 8

Connection to IR and location ............................................................................................................ 9

Connection of the device: KNX and USB connection ...................................................................... 11

3.3.1 KNX port connection .............................................................................................................. 11

3.3.2 USB port connection .............................................................................................................. 11

Binary Input connection .................................................................................................................... 12

4 Configuration and setup ........................................................................................................................ 14

5 ETS Parameters and Configuration ...................................................................................................... 15

General configuration ....................................................................................................................... 16

5.1.1 Manual configuration: AC brand and model ........................................................................... 16

5.1.2 Automatic configuration: Auto Learn ...................................................................................... 16

5.1.3 Delay before sending initial “Read” telegrams ....................................................................... 17

5.1.4 Scene to execute on bus recovery / startup........................................................................... 17

5.1.5 Enable “lock control” objects .................................................................................................. 18

5.1.6 Enable func “Operation time objects” ..................................................................................... 18

5.1.7 RGB LED mode ..................................................................................................................... 18

5.1.8 Error notification ..................................................................................................................... 19

AC supported features ..................................................................................................................... 19

Mode ................................................................................................................................................. 19

5.3.1 Enable use of bit-type Mode objects (for control) .................................................................. 20

5.3.2 Enable use of bit-type Mode objects (for status).................................................................... 20

5.3.3 Enable use of + / - object for Mode ........................................................................................ 21

5.3.4 Enable use of Text object for Mode ....................................................................................... 21

Fan Speed ........................................................................................................................................ 21

5.4.1 DPT object type for fan speed ............................................................................................... 22

5.4.2 Enable use of bit-type Fan Speed objects (for Control) ......................................................... 22

5.4.3 Enable use of bit-type Fan Speed objects (for Status) .......................................................... 23

5.4.4 Enable use of +/- object for Fan Speed ................................................................................. 23

5.4.5 Enable use of Text object for Fan Speed ............................................................................... 24

Up-Down vanes configuration dialog ............................................................................................... 24

5.5.1 DPT object type for Vane Up-Down ....................................................................................... 24

5.5.2 Enable use of bit-type Vane U-D objects (for Control) ........................................................... 25

5.5.3 Enable use of bit-type Vane U-D objects (for Status) ............................................................ 25

5.5.4 Enable use of +/- obj for Vane Up-Down ............................................................................... 26

5.5.5 Enable use of Text object for Vane U-D ................................................................................ 26

Left-Right vanes configuration dialog ............................................................................................... 26

5.6.1 DPT object type for Vane Left-Right ...................................................................................... 26

5.6.2 Enable use of bit-type Vane L-R objects (for Control) ........................................................... 27

5.6.3 Enable use of bit-type Vane U-D objects (for Status) ............................................................ 28

5.6.4 Enable use of +/- obj for Vane Left-Right ............................................................................... 28

5.6.5 Enable use of Text object for Vane U-D ................................................................................ 29

Temperature configuration dialog..................................................................................................... 29

5.7.1 Set Point - Enable use of +/- obj for Setp Temp .................................................................... 29

5.7.2 Set Point - Enable limits on Control_ Setpoint obj ................................................................. 30

5.7.3 Set Point - Periodic sending time ........................................................................................... 30

5.7.4 Ambient - Transmission of “Status_ Intesis Ref Temp” ......................................................... 30

5.7.5 Ambient - Periodic sending time ............................................................................................ 30

Scene Configuration dialog .............................................................................................................. 31

5.8.1 Enable use of scenes ............................................................................................................. 31

5.8.2 Scenes can be saved from KNX ............................................................................................ 31

5.8.3 Enable use of bit-field objects for save .................................................................................. 32

5.8.4 Enable use of bit-field objects for execute ............................................................................. 32

5.8.5 Scene “x” preset ..................................................................................................................... 32

Enable use of Open Window ............................................................................................................ 33

Enable use of Occupancy function ............................................................................................. 35

Page 5

Intesis

TM

KNX – IR Universal AC

User's manual r1.3 EN

© HMS Industrial Networks S.L.U. - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

5 / 46

Binary Input “x” configuration dialogs ......................................................................................... 36

5.11.1 Enable use of Input “x” ........................................................................................................... 37

5.11.2 Contact type ........................................................................................................................... 37

5.11.3 Debounce time ....................................................................................................................... 37

5.11.4 Disabling function ................................................................................................................... 37

5.11.5 Function.................................................................................................................................. 37

6 Electrical and Mechanical features ........................................................................................................ 39

7 List of compatible AC indoor units. ........................................................................................................ 40

8 Appendix A – Communication Objects Table ........................................................................................ 41

Page 6

Intesis

TM

KNX – IR Universal AC

User's manual r1.3 EN

© HMS Industrial Networks S.L.U. - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

6 / 46

1 Presentation

IntesisTM INKNXUNI001I000 allows monitoring and control of Air Conditioners

from KNX installations.

Compatible with most AC units with an IR receiver.

Great flexibility of integration into your KNX projects. Configuration is made directly from ETS, the

database of the device comes with a complete set of communication objects allowing, from a simple

and quick integration using the basic objects, allowing a simple and quick integration.

Main features:

• Reduced dimensions and quick installation.

• Includes a mini USB connector for fast programming download.

• Multiple objects for control and status (bit, byte, characters…) with KNX standard datapoint types.

• Status objects for every control available.

• Special Modes available (Power, Economy, Additional Heating and Additional Cooling).

• Timeout for Open Window and Occupancy. Sleep function also available.

• Control of the AC unit based in the ambient temperature read by the own AC unit, or in the ambient

temperature read by any KNX thermostat.

• Total Control and Monitoring of the AC unit from KNX, including monitoring of AC unit’s state of internal

variables, running hours’ counter (for filter maintenance control).

• AC unit can be controlled simultaneously by the remote controller of the AC unit and by KNX.

• Up to 5 scenes can be saved and executed from KNX, fixing the desired combination of Operation Mode,

Set Temperature, Fan Speed, Vane Position and Remote Controller Lock in any moment by using a

simple switching.

• Two binary inputs for potential-free contacts provide the possibility to integrate many types of external

devices for window status control (window contacts) and occupancy (presence sensor

Page 7

Intesis

TM

KNX – IR Universal AC

User's manual r1.3 EN

© HMS Industrial Networks S.L.U. - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

7 / 46

2 Quick setup

Figure 2.1 INKNXUNI001I000 integration example

1. Check the interface location that best fits the installation (More at 3.1 LOCATION SELECTION)

2. Connect the interface to the KNX bus.

3. Download the ETS database for this product, import it and add it to the current ETS project.

4. Access the parameter section of the Intesis device. Notice that parameters for this interface are

configured through a specific plugin (5 ETS PARAMETERS AND CONFIGURATION).

5. Select the communication objects to be used and other parameters. This step can be omitted if working

with the default objects and parameters.

6. Save the configuration file and download the application program.

7. Close the plugin and apply changes when asked.

8. Link the group address from the communication object of the KNX device with the communication object

inside the Intesis interface.

9. Download the ETS parameters as with any other standard KNX device.

Page 8

Intesis

TM

KNX – IR Universal AC

User's manual r1.3 EN

© HMS Industrial Networks S.L.U. - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

8 / 46

3 Device Installation

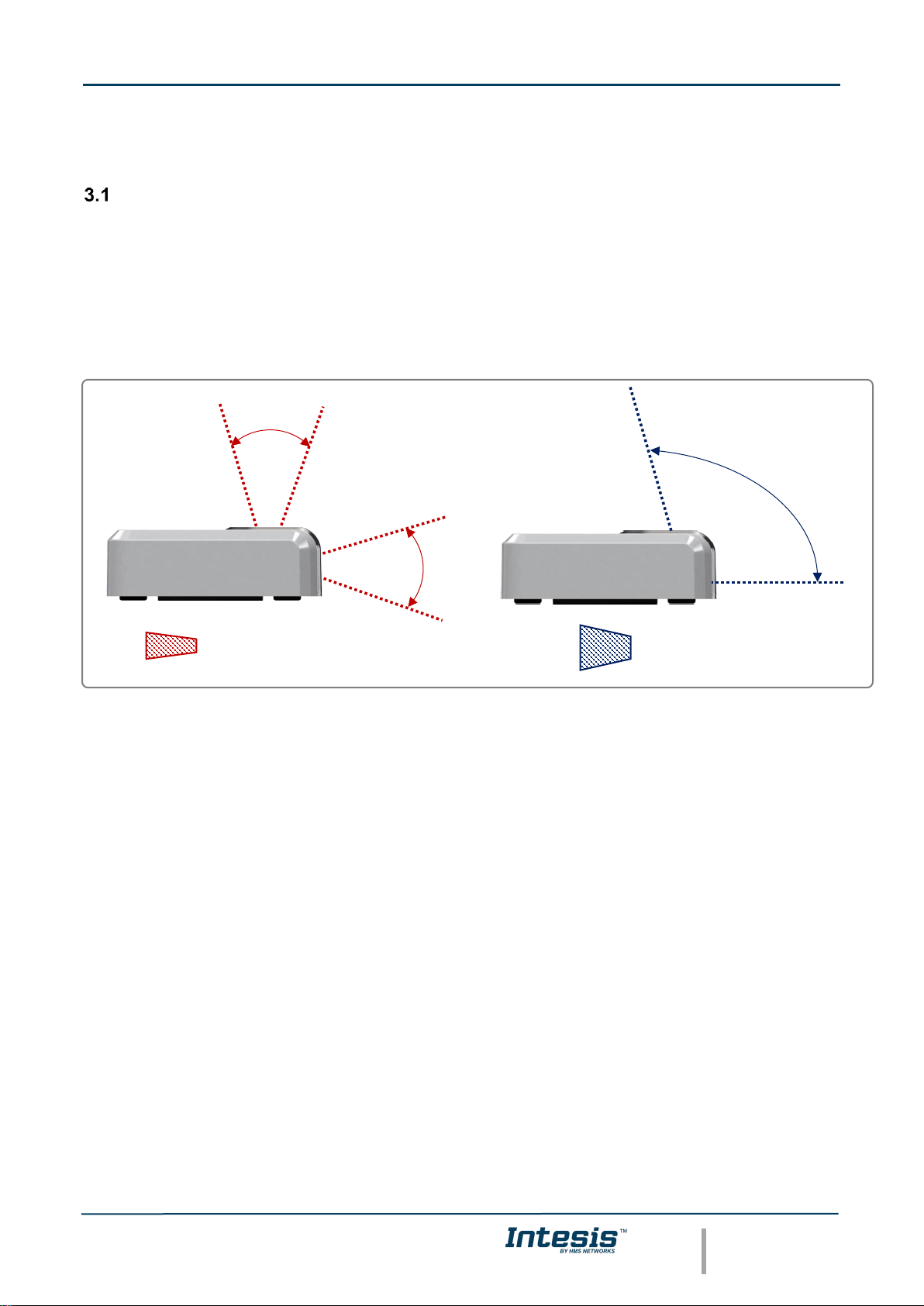

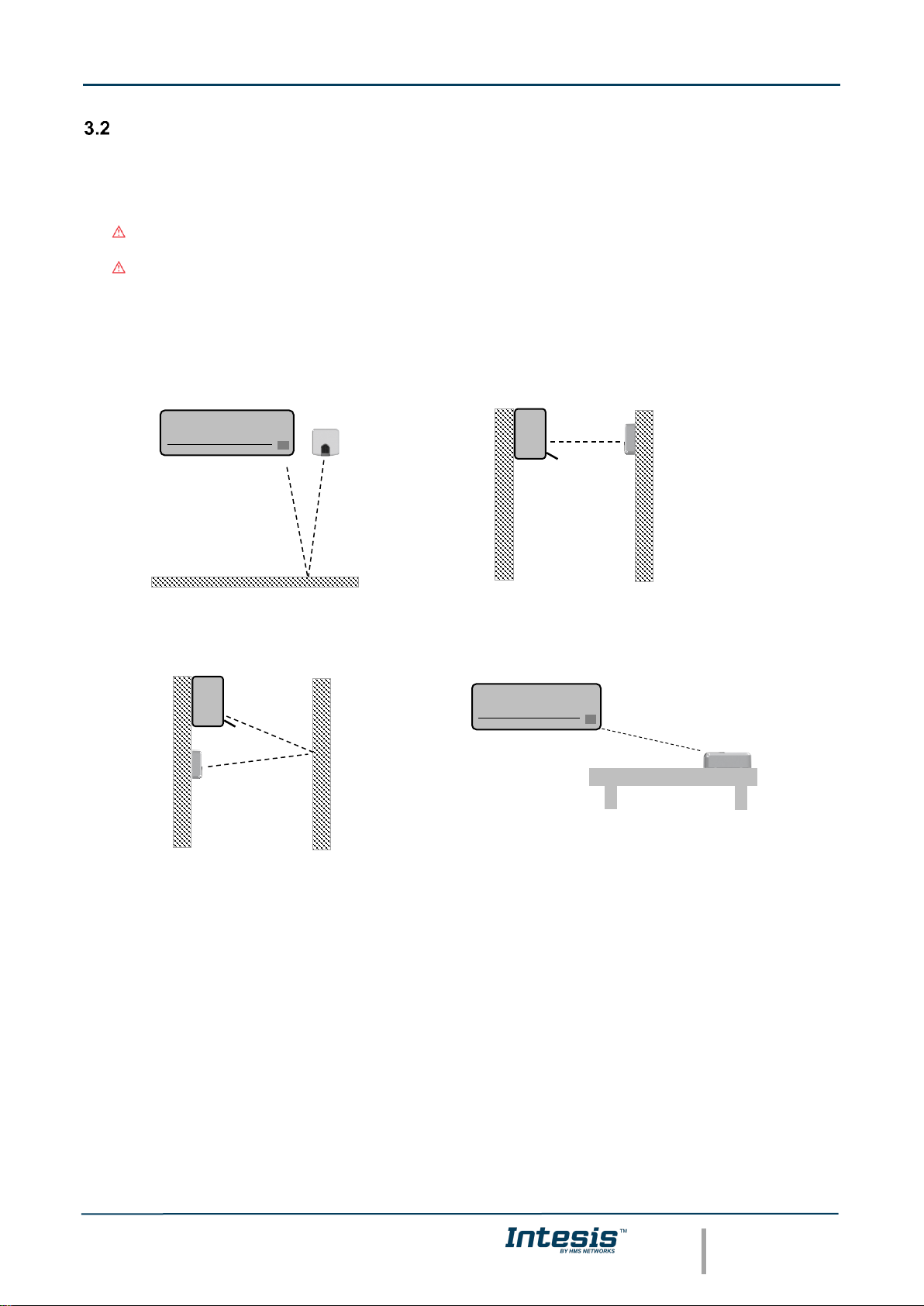

Location selection

Determining that the Intesis device will be working as expected in the installation location is an important stage.

To determine the best location for your Intesis device, use the Wireless Controller (the one of your AC unit).

When selecting the installation location, please keep in mind that the Intesis device has 2 IR emitters and 1 IR

receiver. The 2 emitters increase the installation possibilities allowing many different suitable positions for the

device location. On the other hand, the receiver offers the possibility to get the feedback from the IR wireless

remote controller so the KNX status objects can be updated with that feedback.

Figure 3.1 IR emitters and IR receiver location

IR reception area

IR transmission area

Page 9

Intesis

TM

KNX – IR Universal AC

User's manual r1.3 EN

© HMS Industrial Networks S.L.U. - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

9 / 46

Connection to IR and location

There is no special requirement to match the IR receiver and the Intesis INKNXUNI001I000 interface. Simply

select your model from the list present in the plugin. If your AC unit is not present, please check the compatibility

list as in section 7. You can find more information about the IR configuration in section 5.

Important: Keep in mind that some furniture and materials (carpets, curtains, glass, metal…) may affect

to the IR communication.

Important: The Intesis device has 2 IR emitters pointing at 2 different locations. Considering this and

IR reflections, valid locations for the Intesis device may be many and very different depending on each

installation. Check section 3.1 LOCATION SELECTION for more information.

Intesis INKNXUNI001I000 can be installed in many different locations.

A) Side-by-side with the AC unit B) In front of the AC unit

C) Under the AC unit D) Desktop position

Figure 3.2 IR emitters and IR receiver location

Case A: Installed side-by-side with the AC unit. In that case, the signal will travel from the Intesis device to the

AC unit tacking advantage of the rebounds on the floor or other furniture present in the room.

Case B: Installed in front of the AC unit. In that case, the signal will travel from the Intesis device directly to the

AC unit.

Case C: Installed below the AC unit. In that case, the signal will travel from the Intesis device to the AC unit

tacking advantage of the rebounds on the wall in front of it or other furniture present in the room.

Case D: If you want to place the device on your desktop or any other horizontal surface, please consider the

sketch below. In this case, the signal will travel directly from the Intesis device to the AC unit.

Page 10

Intesis

TM

KNX – IR Universal AC

User's manual r1.3 EN

© HMS Industrial Networks S.L.U. - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

10 / 46

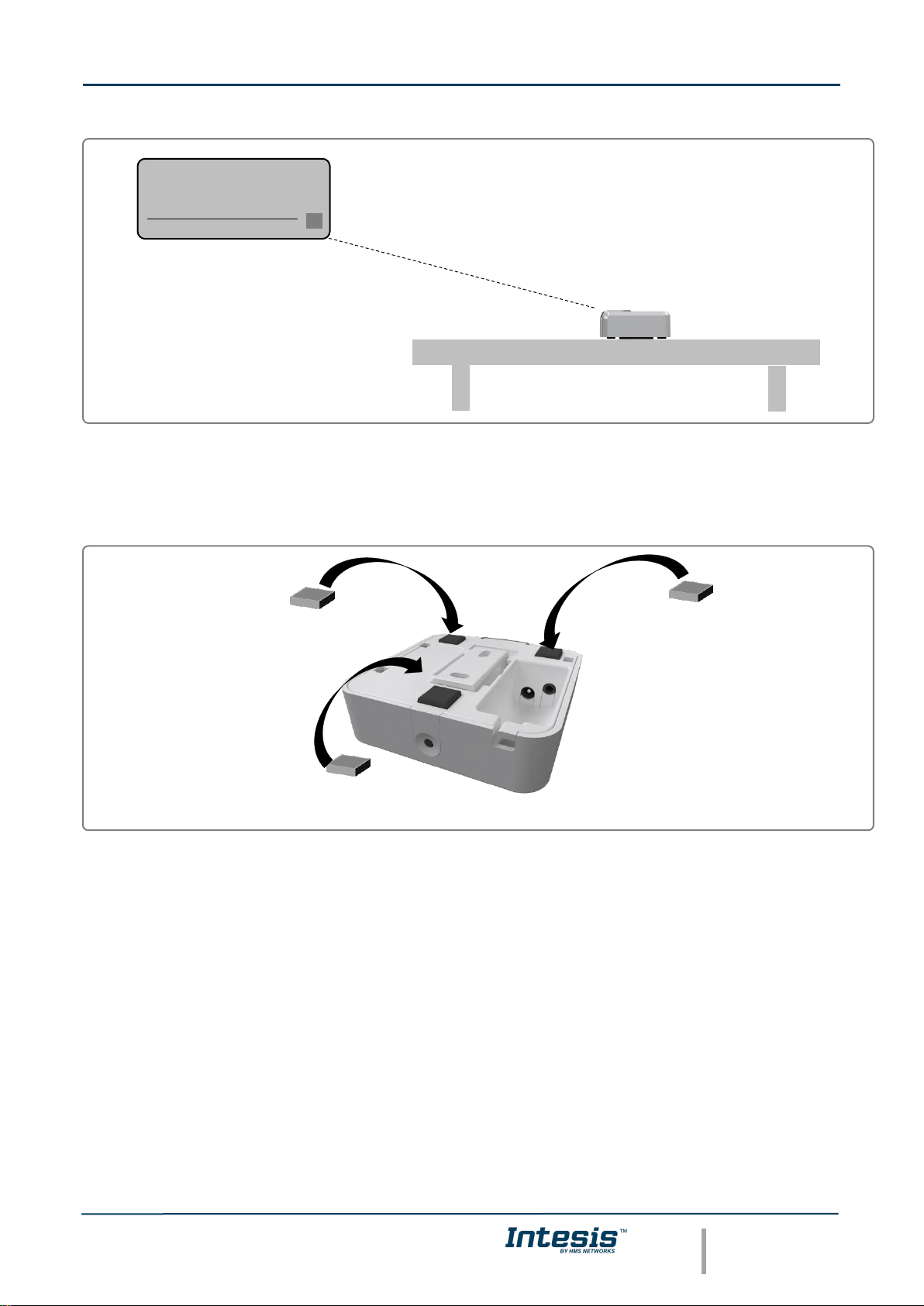

Figure 3.3 Desktop mounted position

In order not to produce marks or scratches on the surface and to improve the device stability, you can use the

rubber dumpers included in the package. Please, check Figure 3.4.

Figure 3.4 Rubber dumpers location

Page 11

Intesis

TM

KNX – IR Universal AC

User's manual r1.3 EN

© HMS Industrial Networks S.L.U. - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

11 / 46

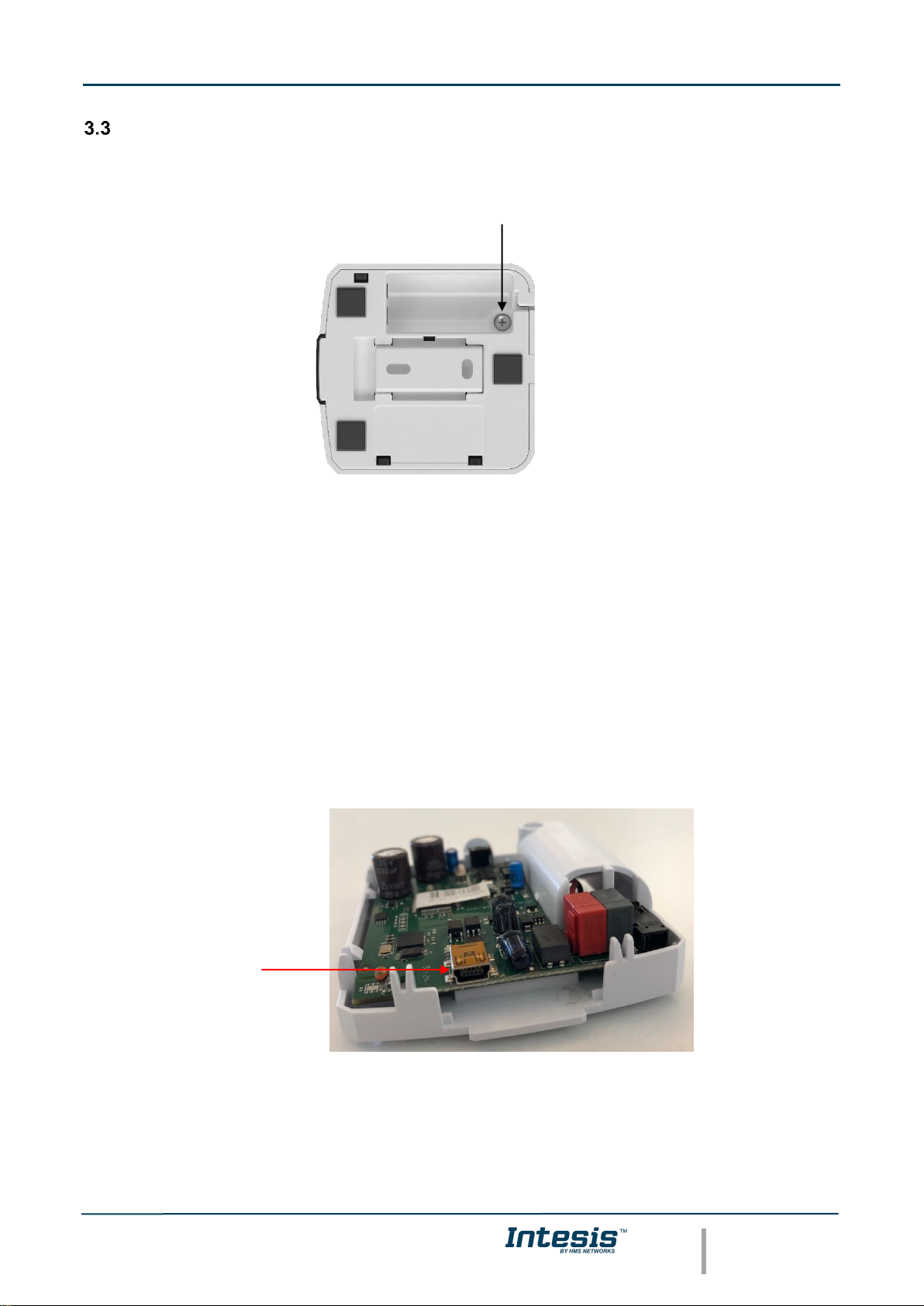

Connection of the device: KNX and USB connection

To get access to the KNX or mini USB connector, remove the screw as seen in Figure 3.5.

Figure 3.5 Top lid release and KNX connection

3.3.1 KNX port connection

Intesis device needs to be connected directly through a KNX TP-1 bus.

Disconnect power of the KNX bus. Connect the INKNXUNI001I000 to the KNX TP-1 (EIB) bus using the KNX

standard connector (red/grey) of the INKNXUNI001I000, respect polarity.

Reconnect power of the KNX bus, and mains power of the AC unit.

3.3.2 USB port connection

Intesis device allows a USB connection via mini USB port for the IR remote parameters or application program

version download. Please, refer to 4 CONFIGURATION AND SETUP for further information.

Figure 3.8 USB port connector

Make sure the device is not connected to power (KNX or USB) during the connection of the USB port.

Setscrew

USB port

Page 12

Intesis

TM

KNX – IR Universal AC

User's manual r1.3 EN

© HMS Industrial Networks S.L.U. - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

12 / 46

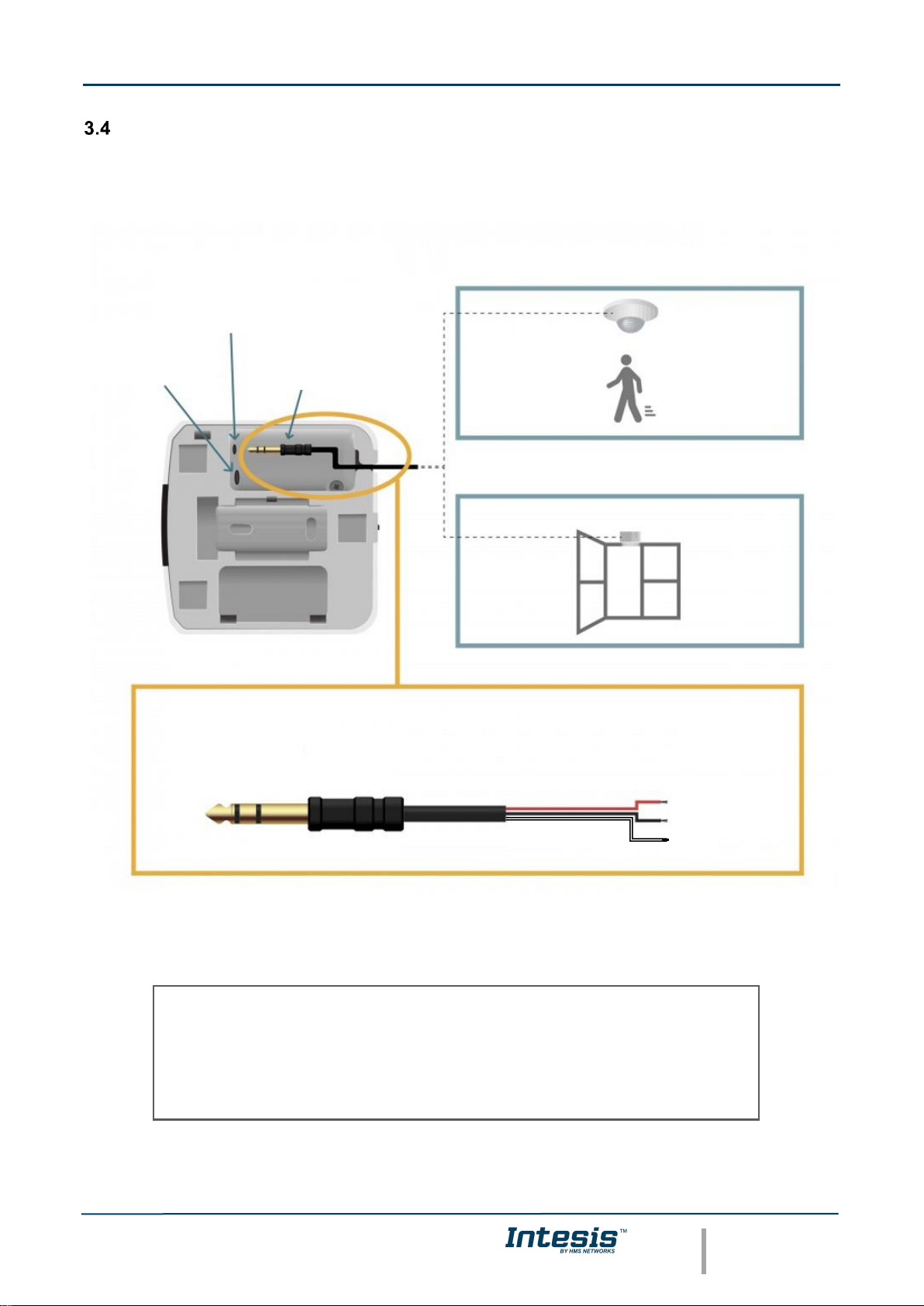

Binary Input connection

Intesis INKNXUNI001I000 interface is equipped with Binary Inputs from factory. To use the built-in binary inputs

in all the IR KNX Controllers, a standard 3,5mm stereo jack connector is required.

Connections will be as in the image below.

Figure 3.7 Binary Input connection

Before proceeding, please check the technical specification of the binary input below:

Once you are sure your installation is compliant with the specifications, please check the presence sensor or

window contact you would like to use. Basically, sensors only need to be equipped with a potential free external

CHANNEL 1: PRESENCE DETECTOR

CHANNEL 2: WINDOW CONTACT

STEREO JACK

(3,5 mm)

BINARY INPUT

CONNECTOR

KNX INPUT

CONNECTOR

CHANNEL 1

COMMON

CHANNEL 2

Potential free binary input

Signal cable length: 5m unshielded, may be extended up to 20m with twisted

Compliant with the following standards:

IEC61000-4-2: level 4 – 15kV (air discharge) - 8kV (contact discharge)

MIL STD 883E-Method 3015-7: class 3B

Page 13

Intesis

TM

KNX – IR Universal AC

User's manual r1.3 EN

© HMS Industrial Networks S.L.U. - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

13 / 46

contact. No matter if the contact is NO (Normally Open) or NC (Normally closed) as you will be able to configure

the contact type (NO or NC) of your sensor in the settings of the Binary Input function (Go to Settings menu in

the Intesis WEB Site).

IMPORTANT NOTE: Please, note that INKNXUNI001I000 interface will only react if the contact of your sensor

is opened or closed. In the case of the presence sensor, the installer needs to decide the specific settings of

the presence sensor to be applied. Intesis will be not responsible of the incorrect settings or incorrect

installations.

Recommendation: In some presence sensors or window contacts it is possible to setup a delay time to the

external contact. As you will see in this manual, Intesis Settings allow the user to setup a timer before starting

with the configured actions. Anyway, we recommend to setup a certain delay time in your presence sensor or

window contact to prevent continuous contact changes in a very short period of time.

Page 14

Intesis

TM

KNX – IR Universal AC

User's manual r1.3 EN

© HMS Industrial Networks S.L.U. - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

14 / 46

4 Configuration and setup

This is a fully compatible KNX device which must be configured and setup using standard KNX tool ETS.

Before starting with the configuration, please make sure that the binary inputs (if used) and the USB cable are

properly connected to the interface. Make sure as well, that the interface is connected to the KNX bus to allow

the proper download of the KNX programming.

To proceed with the configuration and setup, it is recommended to follow instructions next:

1. Download and install the latest version of the ETS data base (5 ETS Parameters and Configuration).

2. Open the product’s plugin.

3. Select your AC brand and model.

4. Download the infrared configuration to the Intesis pushing on the “Download IR parameters”.

NOTE: Check the current connection to the Intesis. Notice that to send the Infrared configuration, you

can use the standard KNX connection (the same used to program the device) or a USB connection. For

this purpose, a mini USB port is available by opening the device.

USB connection is faster than KNX connection. Notice that USB is only available for the IR

parameters download (see 5.1 General configuration).

5. Proceed with the rest of AC unit settings and other parameters in the plugin tab.

6. Finish the KNX programming: communication object links and device addressing.

7. Download the configuration to the device as usual KNX device.

Page 15

Intesis

TM

KNX – IR Universal AC

User's manual r1.3 EN

© HMS Industrial Networks S.L.U. - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

15 / 46

5 ETS Parameters and Configuration

The Intesis INKNXUNI001I000 interface is configured through ETS. General KNX parameters, such as the

physical address, group addresses or DPTs can be configured as usual using the ETS interface. For the specific

AC unit configuration and IR communication, the use of the specific plugin included in the ETS database is

required.

ETS database for this device can be downloaded from:

https://www.intesis.com/products/ac-interfaces/knx-gateways/universal-knx-ir-is-ir-knx-1

Please consult the README.txt file, located inside the downloaded zip file, to find instructions on how to install

the database.

Once the database is imported, the plugin can be accessed when editing parameters. To get access to

parameters edition, click on the Parameter tab, located in the project screen, and then press the specific

parameter dialog.

Figure 5.1 ETS Project managing and plugin screen

Remember that before start using the Intesis interface along with the AC unit, you need to set up at least the

brand and type of you AC unit. Check section 5.1 for more information about it.

Important: Please, update the Catalogue before proceeding with the device configuration and

programming. The laptop where ETS is running shall have Internet connection to update the catalogue.

Page 16

Intesis

TM

KNX – IR Universal AC

User's manual r1.3 EN

© HMS Industrial Networks S.L.U. - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

16 / 46

General configuration

The main view of this tab is the showed in the next figure. Parameter description will follow next:

Figure 5.2 General parameters

Configuration of the AC model

There are two possibilities to configure the AC model to control through INKNXUNI001I000: doing a manual

configuration, by including the AC brand and unit model, or doing an automatic configuration, by using Auto

Learn. To use the last option, it is mandatory the IR remote controller of the AC unit.

5.1.1 Manual configuration: AC brand and model

Use the dropdown menus to select the brand and model of the AC unit to control.

In case your AC unit brand or model were not available in the list, please select the INKNXUNI001I000 and

contact our support department for more information about the settings to select.

5.1.2 Automatic configuration: Auto Learn

The auto learn function is available for INKNXUNI001I000 using 1.1 application program version or newer. This

function allows to identify the infrared remote control automatically by only sending a command pointing to the

KNX device. Please note that internet connection is required for this function.

To launch the function, press the button “Auto Learn” and follow the instructions given in the pop-up window:

AC brand

AC unit model

Page 17

Intesis

TM

KNX – IR Universal AC

User's manual r1.3 EN

© HMS Industrial Networks S.L.U. - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

17 / 46

Once clicked on “Receive IR frame”, the following sequence will be executed:

1) The device will be prepared to receive the frame. During this period (up to 10s) no frame from IR

remote is expected and the device LED is OFF (sometimes a short red blink may be noticed).

2) Once the LED changes into steady white, the device is ready to receive the IR frame and a 30s

countdown will start. Kindly consider the following advices to do it in the proper way:

a. It is necessary to press ON/OFF once and wait for about 5s to let the device transmitting the

information to the PC. You can notice this transmission if the countdown freezes.

b. If ON/OFF button is pressed many times, the process may be enlarged till the user stops, as

the frame communication will not be the appropriate.

3) If the process finishes properly, the LED will switch OFF and a pop-up will be displayed with the

message "Frame Received". If the remote is available in the database, the remote will appear in

"Discovered RCF's" being highly recommended to use the "recomended remote" to match with the

integration needed.

In case the remote is not available in the database, you will get a pop-up warning with the following

message: "Frame could not be recognized". In this case, please, contact to our Support Team so that

they will inform you about the next steps.

Both manual or automatic remote configuration options need to press the button “Download IR parameters” to

download the current AC choice over INKNXUNI001I000. Please, make sure the option selected is the desired

one before starting this process as this process may last for some minutes. Refer to 4 ABOVE4 CONFIGURATION

AND SETUP for more information about IR parameter downloads available.

Other settings

5.1.3 Delay before sending initial “Read” telegrams

This parameter sets the delay before the interface will send READ telegrams for the group addresses associated

on its Control_ objects on bus recovery or application reset/start-up. All Control_ objects with both Transmit (T)

and Update (U) flags enabled will send READs and their values will be updated with the response when

received.

Valid values go from 10 to 60 seconds. This is to give time enough to other KNX devices on the bus to start-up

before sending the READs.

5.1.4 Scene to execute on bus recovery / startup

This parameter executes a selected scene on bus recovery or startup, only if the selected scene has an enabled

preset or values previously saved from KNX bus (see Scene Configuration dialog). You can select any of the 5

available scenes.

Page 18

Intesis

TM

KNX – IR Universal AC

User's manual r1.3 EN

© HMS Industrial Networks S.L.U. - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

18 / 46

5.1.5 Enable “lock control” objects

This parameter shows/hide the Control_ Lock Control Obj communication object which, depending on the sent

value, locks or unlocks ALL the Control_ communication objects except itself.

When a “1” value is sent to this communication object, the remote controller is locked. To be unlocked a “0”

value must be sent. The gateway remembers the last value received even if a KNX bus reset/failure happens.

Figure 5.3 Communication object detail

Important: If an initial scene is enabled and it has as Value for Remote Lock (unchanged) or unlocked,

this would unlock the remote controller because the initial scene has priority over the Control_ Lock Remote

Control communication object.

5.1.6 Enable func “Operation time objects”

This parameter shows/hides the Status_ Operating Hour Counter and Status_ Operating Second Counter

communication object which counts the number of operating hours for the INKNXUNI001I000.

Figure 5.4 Communication object detail

o If set to “no” the object will not be shown.

o If set to “yes” the Status_ Operation Hour Counter object will appear.

• This object can be read and sends its status every time an hour is counted. The gateway keeps that

count in memory and the status is sent also after a KNX bus reset/failure. Although this object is

marked as a Status_ object it also can be written to update the counter when needed. To reset the

counter should be written a “0” value.

Important: This object comes by default without the write (W) flag activated. If is necessary to write on it, this

flag must be activated.

Important: This object will also return its status, every time a value is written, only if it’s different from the

existing one.

Important: If the stored value is 0 hours, the gateway will not send the status to KNX.

5.1.7 RGB LED mode

This parameter determines the working mode of the interface LED.

o If set to “Always off” the LED will always be off.

o If set to “Always on” the LED will always be on.

o If set to “Only on changes” the LED will always change when there is a change of value in any of the

active communication objects.

Page 19

Intesis

TM

KNX – IR Universal AC

User's manual r1.3 EN

© HMS Industrial Networks S.L.U. - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

19 / 46

5.1.8 Error notification

This device uses three different error communication objects to report any issue of the device itself. These

errors are not related to the AC errors since the device do not receive information from the AC unit.

The 1-bit error notification object Status_ Error/Alarm is 1 when any error is active and 0 when no errors are

detected.

The 2 bytes error object Status_ Error Code reports the error code while the 14 bytes error object Status_ Error

Text code reports the information about the error code.

The information about the internal errors reported is the following:

Error code

(2 bytes)

Text code

(14 bytes object)

How to solve

-1

COMM ERROR

Open plug-in and Download IR parameters again

-3

WRONG IR-FW1

Open plug-in and Download IR parameters again

-4

WRONG IR-FW2

Open plug-in and Download IR parameters again

-5

#0005

Restart device

-200

SUPPLY2 FAIL

Device is not receiving enough supply

AC supported features

Select the AC features of your AC unit to match both: the AC unit features with the enabled communication

objects and parameters.

Please, select these parameters carefully, otherwise not expected behavior may occur.

Figure 5.5 AC supported features

Mode

All the parameters in this section are related with the different mode properties and communication objects.

Page 20

Intesis

TM

KNX – IR Universal AC

User's manual r1.3 EN

© HMS Industrial Networks S.L.U. - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

20 / 46

The byte-type communication object for Mode works with the DTP_20.105. Auto mode will be enabled with a

“0” value, Heat mode with a “1” value, Cool mode with a “3” value, Fan mode with a “9” value and Dry mode

with a “14” value.

Figure 5.6 AC mode additional communication objects

5.3.1 Enable use of bit-type Mode objects (for control)

This parameter shows/hides the bit-type Control_ Mode objects.

Figure 5.7 Communication object detail

o If set to “no” the objects will not be shown.

o If set to “yes” the Control_ Mode objects for Auto, Heat, Cool, Fan and Dry will appear. To activate a

mode by using these objects a “1” value has to be sent.

5.3.2 Enable use of bit-type Mode objects (for status)

This parameter shows/hides the bit-type Status_ Mode objects.

Figure 5.8 Communication object detail

o If set to “no” the objects will not be shown.

o If set to “yes” the Status_ Mode objects for Auto, Heat, Cool, Fan and Dry will appear. When enabled,

a mode will return a “1” through its bit-type object.

Page 21

Intesis

TM

KNX – IR Universal AC

User's manual r1.3 EN

© HMS Industrial Networks S.L.U. - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

21 / 46

5.3.3 Enable use of + / - object for Mode

This parameter shows/hides the Control_ Mode +/- communication object which lets change the indoor unit

mode by using two different datapoint types.

o If set to “no” the object will not be shown.

o If set to “yes” the Control_ Mode +/- object and a new parameter will appear.

➢ DPT type for +/- Mode Object

This parameter lets choose between the datapoints 0-Up / 1-Down [DPT_1.008] and 0-Decrease / 1-

Increase [DPT_1.007] for the Control_ Mode +/- object.

The sequence followed when using this object is shown below:

5.3.4 Enable use of Text object for Mode

This parameter shows/hides the Status_ Mode Text communication object.

o If set to “no” the object will not be shown.

o If set to “yes” the Status_ Mode Text object will appear.

Fan Speed

All the parameters in this section are related with the Fan Speed properties and communication objects.

Figure 5.9 Fan Speed parameters

▪ Up / Increase

▪ Down / Decrease

DRY

AUTO

HEAT

COOL

FAN

Page 22

Intesis

TM

KNX – IR Universal AC

User's manual r1.3 EN

© HMS Industrial Networks S.L.U. - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

22 / 46

5.4.1 DPT object type for fan speed

With this parameter is possible to change de DPT for the Control_ Fan Speed and Status_ Fan Speed bytetype communication objects. Datapoints Scaling (DPT_5.001) and Enumerated (DPT_5.010) can be selected.

o When “Enumerated [DPT 5.010]” is selected, Control_ Fan Speed and Status_ Fan Speed communication

objects for this DPT will appear. Also, depending on the number of fan speeds selected, these objects will

be different.

The first fan speed will be selected if a “1” is sent to the Control_ object. The second fan speed will be

selected sending a “2” and so on.

The Status_ object will always return the value for the fan speed selected.

Important: In both cases if a “0” value is sent to the Control_ object, the minimum fan speed will be

selected. If a value bigger than “2” (in case of 2 speeds) or bigger than “3” (in case of 3 fan speeds)

is sent to the Control_ object, then the maximum fan speed will be selected.

o When “Scaling [DPT 5.001]” is selected, Control_ Fan Speed and Status_ Fan Speed communication

objects for this DPT will appear. Also, depending on the number of fan speeds selected, these objects will

be different.

The formula used to calculate the value to be set in the Control object is ‘100*(n+0,5)/N %’, where n is the

current fan speed and N the maximum number of fan speeds.

On the other hand, the formula to calculate the status to be read according to the current value is ‘100*n/N’,

where n is the current fan speed and N the maximum number of fan speeds.

Check this example with 3 fan speeds:

When a value between 0% and 49% is sent to the Control_ object the first fan speed will be selected.

When a value between 50% and 83% is sent to the Control_ object, the second speed will be selected.

When a value between 84% and 100% is sent to the Control_ object, the third speed will be selected.

The Status_ object will return a 33% when the first speed is selected, a 67% for the second one and a 100%

for the third one.

5.4.2 Enable use of bit-type Fan Speed objects (for Control)

This parameter shows/hides the bit-type Control_ Fan Speed objects.

Fan Speed 1

Fan Speed 3

100%

Status_

0%

83%

50%

Control_

Control_

Status_

33%

67%

Fan Speed 2

Control_

Status_

Page 23

Intesis

TM

KNX – IR Universal AC

User's manual r1.3 EN

© HMS Industrial Networks S.L.U. - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

23 / 46

o If set to “no” the objects will not be shown.

o If set to “yes” the Control_ Fan Speed objects for Speed 1, Speed 2 and Speed 3 (if available) will

appear. To activate a Fan Speed by using these objects a “1” value has to be sent.

5.4.3 Enable use of bit-type Fan Speed objects (for Status)

This parameter shows/hides the bit-type Status_ Fan Speed objects.

o If set to “no” the objects will not be shown.

o If set to “yes” the Status_ Fan Speed objects for Speed 1, Speed 2 and Speed 3 (if available) will

appear. When a Fan Speed is enabled, a “1” value is returned through its bit-type object.

5.4.4 Enable use of +/- object for Fan Speed

This parameter shows/hides the Control_ Fan Speed +/- communication object which lets you

increase/decrease the indoor unit fan speed by using two different datapoint types.

o If set to “no” the object will not be shown.

o If set to “yes” the Control_ Fan Speed +/- object.

➢ DPT type for +/- Fan Speed Object

This parameter lets choose between the datapoints 0-Up / 1-Down [DPT_1.008] and 0-Decrease / 1-

Increase [DPT_1.007] for the Control_ Fan Speed +/- object.

➢ Roll-over Speed at upper/lower limit

This parameter lets choose if roll-over will be enabled (“yes”) or disabled (“no”) for the Control_ Fan

Speed +/- object.

Fan Speed 3

Fan Speed 1

Fan Speed 2

Only if Roll-over is enabled

Only if Roll-over is enabled

Page 24

Intesis

TM

KNX – IR Universal AC

User's manual r1.3 EN

© HMS Industrial Networks S.L.U. - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

24 / 46

5.4.5 Enable use of Text object for Fan Speed

This parameter shows/hides the Status_ Fan Speed Text communication object.

o If set to “no” the object will not be shown.

o If set to “yes” the Status_ Fan Speed Text object will appear.

Up-Down vanes configuration dialog

All the parameters in this section are related with the Vane Up-Down properties and communication objects.

5.5.1 DPT object type for Vane Up-Down

With this parameter is possible to change de DPT for the Control_ Vane Up-Down and Status_ Vane Up-Down

byte-type communication objects. Datapoints Scaling (DPT_5.001) and Enumerated (DPT_5.010) can be

selected.

o When “Enumerated [DPT 5.010]” is selected, Control_ Vane Up-Down and Status_ Vane Up-Down

communication objects for this DPT will appear.

To choose a vane position, values from “1” to “N” can be sent to the Control_ object. Each value will

correspond to the position (i.e. Value “3” = Position 3).

The Status_ object will always return the value for the vane position selected.

Important: If a “0” value is sent to the Control_ object, the Position 1 will be selected. If a value bigger

than “N” is sent to the Control_ object, then the Position N will be selected.

o When “Scaling [DPT 5.001]” is selected, Control_ Vane Up-Down and Status_ Vane Up-Down

communication objects for this DPT will appear.

The formula used to calculate the value to be set in the Control object is ‘100*(n+0,5)/N %’, where n is the

current fan speed and N the maximum number of fan speeds.

On the other hand, the formula to calculate the status to be read according to the current value is ‘100*n/N’,

where n is the current fan speed and N the maximum number of fan speeds.

Check the example with 5 positions:

When a value between 0% and 29% is sent to the Control_ object the first vane position will be selected.

▪ Up / Increase

▪ Down / Decrease

Page 25

Intesis

TM

KNX – IR Universal AC

User's manual r1.3 EN

© HMS Industrial Networks S.L.U. - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

25 / 46

When a value between 30% and 49% is sent to the Control_ object, the second vane position will be

selected.

When a value between 50% and 69% is sent to the Control_ object, the third vane position will be selected.

When a value between 70% and 89% is sent to the Control_ object, the fourth vane position will be selected.

When a value between 90% and 100% is sent to the Control_ object, the fifth vane position will be selected.

The Status_ object will return a 20% for the first vane position, a 40% for the second one, a 60% for the

third one, an 80% for the fourth one and a 100% for the fifth and last one.

5.5.2 Enable use of bit-type Vane U-D objects (for Control)

This parameter shows/hides the bit-type Control_ Vane Up-Down objects.

o If set to “no” the objects will not be shown.

o If set to “yes” the Control_ Vane Up-Down objects for each Position (1 to 5) will appear. To activate a

Vane Position by using these objects, a “1” value has to be sent.

5.5.3 Enable use of bit-type Vane U-D objects (for Status)

This parameter shows/hides the bit-type Status_ Vane Up-Down objects.

o If set to “no” the objects will not be shown.

o If set to “yes” the Status_ Vane Up-Down objects for each Position (1 to N) will appear. When a Vane

Position is enabled, a “1” value is returned through its bit-type object.

Pos. 1

Pos. 3

100%

Status_

0%

90%

50%

Control_

Control_

Status_

30%

70%

Pos. 2

Control_

Status_

Pos. 4

Pos. 5

Control_

Control_

20%

40%

60%

80%

Status_

Status_

Page 26

Intesis

TM

KNX – IR Universal AC

User's manual r1.3 EN

© HMS Industrial Networks S.L.U. - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

26 / 46

5.5.4 Enable use of +/- obj for Vane Up-Down

This parameter shows/hides the Control_ Vane Up-Down +/- communication object which lets you change the

indoor unit vane position by using two different datapoint types.

o If set to “no” the object will not be shown.

o If set to “yes” the Control_ Vane Up-Down +/- object.

➢ DPT type for +/- Vane Up-Down obj

This parameter lets choose between the datapoints 0-Up / 1-Down [DPT_1.008] and 0-Decrease / 1-

Increase [DPT_1.007] for the Control_ Vane Up-Down +/- object.

➢ Rollover Vane at upper/lower limit

This parameter lets choose if roll-over will be enabled (“yes”) or disabled (“no”) for the Vane Up-Down

+/- object.

5.5.5 Enable use of Text object for Vane U-D

This parameter shows/hides the Status_ Vane Up-Down Text communication object.

o If set to “no” the object will not be shown.

o If set to “yes” the Status_ Vane Up-Down Text object will appear.

Left-Right vanes configuration dialog

All the parameters in this section are related with the Vane Up-Down properties and communication objects.

5.6.1 DPT object type for Vane Left-Right

With this parameter is possible to change de DPT for the Control_ Vane Left-Right and Status_ Vane Left-Right

byte-type communication objects. Datapoints Scaling (DPT_5.001) and Enumerated (DPT_5.010) can be

selected.

o When “Enumerated [DPT 5.010]” is selected, Control_ Vane Left-Right and Status_ Vane Left-Right

communication objects for this DPT will appear.

▪ Up / Increase

▪ Down / Decrease

Pos. 3

Pos. 1

Pos. 2

Only if Roll-over is enabled

Only if Roll-over is enabled

Pos. 5

Pos. 4

SWING

Page 27

Intesis

TM

KNX – IR Universal AC

User's manual r1.3 EN

© HMS Industrial Networks S.L.U. - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

27 / 46

To choose a vane position, values from “1” to “N” can be sent to the Control_ object. Each value will

correspond to the position (i.e. Value “3” = Position 3).

The Status_ object will always return the value for the vane position selected.

Important: If a “0” value is sent to the Control_ object, the Position 1 will be selected. If a value bigger

than “N” is sent to the Control_ object, then the Position N will be selected.

o When “Scaling [DPT 5.001]” is selected, Control_ Vane Up-Down and Status_ Vane Up-Down

communication objects for this DPT will appear.

The formula used to calculate the value to be set in the Control object is ‘100*(n+0,5)/N %’, where n is the

current fan speed and N the maximum number of fan speeds.

On the other hand, the formula to calculate the status to be read according to the current value is ‘100*n/N’,

where n is the current fan speed and N the maximum number of fan speeds.

Check the example with 5 positions:

When a value between 0% and 29% is sent to the Control_ object the first vane position will be selected.

When a value between 30% and 49% is sent to the Control_ object, the second vane position will be

selected.

When a value between 50% and 69% is sent to the Control_ object, the third vane position will be selected.

When a value between 70% and 89% is sent to the Control_ object, the fourth vane position will be selected.

When a value between 90% and 100% is sent to the Control_ object, the fifth vane position will be selected.

The Status_ object will return a 20% for the first vane position, a 40% for the second one, a 60% for the

third one, an 80% for the fourth one and a 100% for the fifth and last one.

5.6.2 Enable use of bit-type Vane L-R objects (for Control)

This parameter shows/hides the bit-type Control_ Vane Left-Right objects.

Pos. 1

Pos. 3

100%

Status_

0%

90%

50%

Control_

Control_

Status_

30%

70%

Pos. 2

Control_

Status_

Pos. 4

Pos. 5

Control_

Control_

20%

40%

60%

80%

Status_

Status_

Page 28

Intesis

TM

KNX – IR Universal AC

User's manual r1.3 EN

© HMS Industrial Networks S.L.U. - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

28 / 46

o If set to “no” the objects will not be shown.

o If set to “yes” the Control_ Vane Up-Down objects for each Position (1 to N) will appear. To activate a

Vane Position by using these objects, a “1” value has to be sent.

5.6.3 Enable use of bit-type Vane U-D objects (for Status)

This parameter shows/hides the bit-type Status_ Vane Up-Down objects.

o If set to “no” the objects will not be shown.

o If set to “yes” the Status_ Vane Up-Down objects for each Position (1 to N) will appear. When a Vane

Position is enabled, a “1” value is returned through its bit-type object.

5.6.4 Enable use of +/- obj for Vane Left-Right

This parameter shows/hides the Control_ Vane Left-Right +/- communication object which lets you change the

indoor unit vane position by using two different datapoint types.

o If set to “no” the object will not be shown.

o If set to “yes” the Control_ Vane Left-Right +/- object.

➢ DPT type for +/- Vane Left-Right obj

This parameter lets choose between the datapoints 0-Up / 1-Down [DPT_1.008] and 0-Decrease / 1-

Increase [DPT_1.007] for the Control_ Vane Left-Right +/- object.

➢ Rollover Vane at upper/lower limit

This parameter lets choose if roll-over will be enabled (“yes”) or disabled (“no”) for the Vane Up-Down

+/- object.

Pos. 3

Pos. 1

Pos. 2

Only if Roll-over is enabled

Only if Roll-over is enabled

Pos. 5

Pos. 4

SWING

Page 29

Intesis

TM

KNX – IR Universal AC

User's manual r1.3 EN

© HMS Industrial Networks S.L.U. - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

29 / 46

5.6.5 Enable use of Text object for Vane U-D

This parameter shows/hides the Status_ Vane Up-Down Text communication object.

o If set to “no” the object will not be shown.

o If set to “yes” the Status_ Vane Up-Down Text object will appear.

Temperature configuration dialog

All the parameters in this section are related with the Temperature properties and communication objects.

Figure 5.10 Tempeature settings

5.7.1 Set Point - Enable use of +/- obj for Setp Temp

This parameter shows/hides the Control_ Setpoint Temp +/- communication object which lets you change the

indoor unit setpoint temperature by using two different datapoint types.

o If set to “no” the object will not be shown.

o If set to “yes” the Control_ Setpoint Temp +/- object.

➢ DPT type for +/- Setp Temp object

▪ Up / Increase

▪ Down / Decrease

Page 30

Intesis

TM

KNX – IR Universal AC

User's manual r1.3 EN

© HMS Industrial Networks S.L.U. - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

30 / 46

This parameter lets choose between the datapoints 0-Up / 1-Down [DPT_1.008] and 0-Decrease / 1Increase [DPT_1.007] for the Control_ Setpoint Temp +/- object.

5.7.2 Set Point - Enable limits on Control_ Setpoint obj

This parameter enables to define temperature limits for the Control_ Setpoint Temperature object.

o If set to “no” the setpoint temperature limits for the Control_ Setpoint Temperature object will be the

default: 16ºC for the lower limit and 32ºC for the upper limit.

o If set to “yes” it is possible to define temperature limits for the Control_ Setpoint Temperature object.

➢ Control_ Set Temp Lower limit (ºC)

This parameter lets to define the lower limit for the setpoint temperature.

➢ Control_ Set Temp Upper limit (ºC)

This parameter lets to define the upper limit for the setpoint temperature.

Important: If a setpoint temperature above the upper defined limit (or below the lower defined limit) is sent

through the Control_ Setpoint Temperature object, it will be ALWAYS applied the limit defined.

Important: When limits are enabled, any setpoint temperature sent to the AC (even through scenes, special

modes, etc.) will be limited.

5.7.3 Set Point - Periodic sending time

This parameter lets you change the interval of time (in seconds, from 0 to 255) at the end of which the AC

setpoint temperature is sent to the KNX bus. For a “0” value, the AC setpoint temperature will ONLY be sent

on change. The AC setpoint temperature is sent through the communication object Status_ AC Setpoint Temp.

5.7.4 Ambient - Transmission of “Status_ Intesis Ref Temp”

This parameter lets to you choose if the Intesis reference temperature will be sent “only cyclically”, “only on

change” or “cyclically and on change”. The Intesis reference temperature is sent through the communication

object Status_ Intesis Reference Temperature.

5.7.5 Ambient - Periodic sending time

This parameter will only be available for the “only cylically” and “cyclically and on change” options, and lets

you change the interval of time (in seconds, from 1 to 255) at the end of which the Intesis reference temperature

is sent to the KNX bus.

▪ Up / Increase

▪ Down / Decrease

…

16ºC

17ºC

32ºC

31ºC

(Upper limit)

(Lower limit)

Page 31

Intesis

TM

KNX – IR Universal AC

User's manual r1.3 EN

© HMS Industrial Networks S.L.U. - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

31 / 46

Scene Configuration dialog

All the parameters in this section are related with the Scene properties and communication objects. A scene

contains values of: On/Off, Mode, Fan speed, Vane position and Setpoint Temperature.

Figure 5.11 Scene configuration settings

5.8.1 Enable use of scenes

This parameter shows/hides the scene configuration parameters and communication objects.

o If set to “no” the scene parameters and communication objects will not be shown.

o If set to “yes” the scene parameters and communication objects will be shown. To execute a scene

through the byte-type object, a value from “0” to “4” has to be sent, correponding each one to a different

scene (i.e. “0” = Scene 1;… “4” = Scene 5).

5.8.2 Scenes can be saved from KNX

This parameter shows/hides the Control_ Save/Exec Scene and all the Control_ Save Scene (if enabled)

communication objects.

Page 32

Intesis

TM

KNX – IR Universal AC

User's manual r1.3 EN

© HMS Industrial Networks S.L.U. - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

32 / 46

o If set to “no” the communication objects will not be shown.

o If set to “yes” the communication objects and a new parameter will appear. To store a scene through

the byte-type object, a value from “128” to “132” has to be sent to the object, correponding each one

to a different scene (i.e. “128” = Scene 1;… “132” = Scene 5).

➢ Enable use of bit objects for storing scenes (from bus)

If set to “no” the objects will not be shown.

If set to “yes” the Control_ Store Scene objects for storing scenes will appear. To store a scene by

using these objects, a “1” value has to be sent to the scene’s object we want to store (i.e. to store scene

4, a “1” has to be sent to the Control_ Store Scene 4 object).

5.8.3 Enable use of bit-field objects for save

This parameter shows/hides the Control_ Execute Scene bit-type communication objects.

o If set to “no” the communication objects will not be shown.

o If set to “yes” the communication objects will appear. To execute a scene by using these objects, a

“1” value has to be sent to the scene’s object we want to execute (i.e. to execute scene 4, a “1” has to

be sent to the Control_ Execute Scene 4 object).

5.8.4 Enable use of bit-field objects for execute

This parameter shows/hides the Control_ Execute Scene bit-type communication objects.

o If set to “no” the communication objects will not be shown.

o If set to “yes” the communication objects will appear. To execute a scene by using these objects, a

“1” value has to be sent to the scene’s object we want to execute (i.e. to execute scene 4, a “1” has to

be sent to the Control_ Execute Scene 4 object).

5.8.5 Scene “x” preset

This parameter lets you define a preset for a scene (the following description is valid for all the scenes).

o If set to “no” the preset for the scene “x” will be disabled.

Page 33

Intesis

TM

KNX – IR Universal AC

User's manual r1.3 EN

© HMS Industrial Networks S.L.U. - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

33 / 46

o If set to “yes” the preset will be enabled. When a scene is executed the values configured in the preset

will be aplied.

Important: If a scene’s preset is enabled, will not be possible to modify (store) the scene from the KNX

bus.

➢ Scene “x” / Value for On-Off

This parameter lets you choose the power of the indoor unit when the scene is executed. The following

options are available: “ON”, “OFF” or “(unchanged)”.

➢ Scene “x” / Value for Mode

This parameter lets you choose the mode of the indoor unit when the scene is executed. The following

options are available: “AUTO”, “HEAT”, “COOL”, “FAN”, “DRY”, or “(unchanged)”.

➢ Scene “x” / Value for Fan Speed

This parameter lets you choose the fan speed of the indoor unit when the scene is executed. The

following options are available: “SPEED 1”, “SPEED 2”… “SPEED N”, or “(unchanged)”.

➢ Scene “x” / Value for Vane Up-Down

This parameter lets you choose the vane position of the indoor unit when the scene is executed. The

following options are available: “POSITION 1”, “POSITION 2”… “POSITION N”, “SWIRL”, “SWING”

or “(unchanged)”.

➢ Scene “x” / Value for Vane Left-Right

This parameter lets you choose the vane position of the indoor unit when the scene is executed. The

following options are available: “POSITION 1”, “POSITION 2”… “POSITION N”, “SWIRL”, “SWING”

or “(unchanged)”.

➢ Scene “x” / Value for Setp Temp (ºC)

This parameter lets you choose the setpoint temperature of the indoor unit when the scene is executed.

The following options are available: from “16ºC” to “32ºC” (both included), or “(unchanged)”.

Important: If any preset value is configured as “(unchanged)”, the execution of this scene will not

change current status of this feature in the AC unit.

Important: When a scene is executed, Status_ Current Scene object shows the number of this scene.

Any change in previous items does Status_ Current Scene show “No Scene”. Only changes on items

marked as “(unchanged)” will not disable current scene.

Enable use of Open Window

This parameter shows/hides the Control_ Window Contact Input communication object which lets you Start/Stop

a timeout to switch off the indoor unit.

Page 34

Intesis

TM

KNX – IR Universal AC

User's manual r1.3 EN

© HMS Industrial Networks S.L.U. - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

34 / 46

o If set to “no” the object will not be shown.

o If set to “yes” the Control_ Window Contact Input object will appear. If a “1” value is sent to this object,

and the indoor unit is already turned on, the switch-off timeout will begin. If a “0” value is sent to this

object, the switch-off timeout will stop.

➢ Input Object

This parameter lets you choose between the datapoints 0-Open / 1-Closed Window [DPT_1.009] and

0-Stop / 1-Start Timeout [DPT_1.010] for the Control_ Switch Off Timeout.

➢ Timeout (min)

This parameter lets you select how much time (in minutes) to wait before switching off the indoor unit.

➢ Reload last Value

If set to “no”, once the switch-off timeout is stopped, any value will be reloaded.

If set to “yes”, once the switch-off timeout is stopped, the last On/Off value sent will be reloaded.

• If a “1” value is sent to the Control_ Window Contact Input object after the timeout period, the

indoor unit will turn on.

• If a “0” value is sent to the Control_ Switch Off Timeout after the timeout period, no action will

be performed.

➢ Lock ON when Open

If set to “no”, On/Off commands while the window is open will be accepted.

• If a “1” value is sent to the Control_ Switch Off Timeout object the switch-off timeout period will

begin again.

• If a “0” value is sent to the Control_ Switch Off Timeout object, no action will be performed.

If set to “yes”, On/Off commands, while the window is open, will be saved (but not applied). These

commands will be used in the next parameter if set to “yes”.

Page 35

Intesis

TM

KNX – IR Universal AC

User's manual r1.3 EN

© HMS Industrial Networks S.L.U. - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

35 / 46

Enable use of Occupancy function

This parameter shows/hides the Control_ Occupancy Input communication object which lets you apply different

parameters to the indoor unit depending on the presence/no presence in the room.

o If set to “no” the object will not be shown.

o If set to “yes” the Control_ Occupancy object and new parameters will appear. If a “1” value is sent to

this object (no room occupancy), the timeout will begin. If a “0” value is sent to this object, the timeout

will stop.

➢ Timeout to apply action (minutes)

This parameter lets you choose how much time to wait (in minutes) before executing the action specified

in the next parameter (“Action after timeout elapsed”).

➢ Action

When Switch Off AC is selected, once the timeout has elapsed, the indoor unit will be turned off.

When Apply Preset Delta is selected, once the timeout has elapsed, a delta temperature will be applied

to save energy (decreasing the setpoint when in Heat mode or increasing the setpoint when in Cool

mode). Also new parameters will appear.

➢ Temp delta decreases (HEAT) or increase (COOL) (ºC)

This parameter lets configure the delta temperature (increase or decrease) that will be applied

when the timeout has elapsed.

Important: When there is occupancy again after the application of a delta, the same delta will be applied

inversely. (i.e. In a room with AC in cool mode and 25ºC setpoint temperature, a +2ºC delta is applied

after the occupancy timeout, setting the setpoint at 27ºC because there is no occupancy in the room. If

Page 36

Intesis

TM

KNX – IR Universal AC

User's manual r1.3 EN

© HMS Industrial Networks S.L.U. - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

36 / 46

the setpoint is raised to 29ºC during that period, when the room is occupied again, a -2ºC delta will be

applied and the final setpoint temperature will then be 27ºC).

➢ Second Action

If set to “no” nothing will be applied.

If set to “yes”, a new timeout will be enabled, and two new parameters will appear.

➢ Timeout (2nd)

This parameter lets you choose how much time to wait (in minutes) before executing the action specified

in the next parameter (“Action after timeout elapsed”).

➢ Action (2nd)

When Switch-Off is selected, once the timeout has elapsed, the indoor unit will turn off.

When Apply Preset Delta is selected, once the timeout configured is extinguished, a delta temperature

will be applied (decreasing the setpoint when in Heat mode or increasing the setpoint when in Cool

mode). Also new parameters will appear.

➢ Temp delta decreases (HEAT) or increase (COOL) (ºC)

This parameter lets configure the delta temperature that will be applied when the timeout is

extinguished.

Important: When there is occupancy again after the application of a delta, the same delta will

be applied inversely as explained above.

➢ Reload last On/Off value when Occupied

If set to “no”, once the switch-off timeout has elapsed, any value will be reloaded.

If set to “yes”, once the switch-off timeout has elapsed, the last On/Off value will be reloaded.

• If a “1” value is sent to the Control_ Occupancy object after the timeout period, the indoor unit

will turn on.

• If a “0” value is sent to the Control_ Occupancy after the timeout period no action will be

performed.

➢ Lock ON when occupied

If set to “no”, On/Off commands while the room is occupied will be accepted.

• If a “1” value is sent to the Control_ Switch Off Timeout object the switch-off timeout period will

begin again.

• If a “0” value is sent to the Control_ Switch Off Timeout object, no action will be performed.

If set to “yes”, On/Off commands, while the window is open, will be saved (but not applied). These

commands will be used in the next parameter if set to “yes”.

Binary Input “x” configuration dialogs

All the parameters in this section are related with the binary inputs properties and communication objects.

Page 37

Intesis

TM

KNX – IR Universal AC

User's manual r1.3 EN

© HMS Industrial Networks S.L.U. - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

37 / 46

5.11.1 Enable use of Input “x”

This parameter enables the use of the Input “x”.

o If set to “no” the objects will not be shown.

o If set to “yes” the Status_ Inx object(s) and new parameters will appear.

5.11.2 Contact type

This parameter lets choose the behavior that will have the binary input depending on if the contact is normally

open or normally closed.

o There are two possible options to configure the contact type: “NO: Normally Open” and “NC:

Normally Closed”.

5.11.3 Debounce time

This parameter lets choose a debounce time (in milliseconds) that will be applied to the contact.

5.11.4 Disabling function

This parameter shows/hides the Control_ Disable Input x communication object which will let disable/enable the

input x.

o If set to “no” any object will be shown.

o When “DPT 1.003: 0-Disable; 1-Enable” is selected, the input can be disabled using the value “0”

and enabled using the value “1”.

o When “DPT 1.002: 1-True (Disable); 0-False (Enable)” is selected, the input can be disabled using

the value “1” and enabled using the value “0”.

5.11.5 Function

This parameter lets choose the function that will have the binary input. There are 3 different functions available:

Occupancy (internal), On/Off and Window Contact (internal).

Page 38

Intesis

TM

KNX – IR Universal AC

User's manual r1.3 EN

© HMS Industrial Networks S.L.U. - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

38 / 46

o When “Occupancy” is selected, the binary input “x” will have the same behavior as configured in the

parameter “Occupanys” (section 5.10).

o When “On/Off” is selected, the AC unit will turn off when the binary inpyt “x” is active.

o When “Window Contact (internal)” is selected, the binary input “x” will have the same behavior as

configured in the parameter “Window Contact” (section 5.9).

Page 39

Intesis

TM

KNX – IR Universal AC

User's manual r1.3 EN

© HMS Industrial Networks S.L.U. - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

39 / 46

6 Electrical and Mechanical features

Enclosure

ABS (V-0). 2,1 mm thickness

PC (V-2). 1 mm thickness

Dimensions

81 x 78 x 28 mm

Weight

76 g

Color

Ivory white

Power supply

29V DC, 17mA

Supplied through KNX bus

Mounting

Wall and desktop

LED indicators

1 x Device status and KNX programming

Push buttons

1 x KNX programming.

Binary inputs

2 x binary inputs for potential-free contacts.

Signal cable length: 5m unshielded, may be extended up to 20m with twisted.

Compliant with the following standards:

IEC61000-4-2: level 4 - 15kV (air discharge) - 8kV (contact discharge)

MIL STD 883E-Method 3015-7: class3B

Console port

Mini USB port for console usage

Configuration

Configuration with ETS

Operating

Temperature

From 0ºC to 40ºC

Operating

humidity

<93% HR, no condensation

Stock humidity

<93% HR, no condensation

27 mm

78 mm

81 mm

28 mm

26 mm

3 mm

Page 40

Intesis

TM

KNX – IR Universal AC

User's manual r1.3 EN

© HMS Industrial Networks S.L.U. - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

40 / 46

7 List of compatible AC indoor units.

A list of indoor unit model references compatible with INKNXUNI001I000 and their available features can be

found in:

https://www.intesis.com/docs/compatibilities/inxxxuni001i000_universal_compatibility

Page 41

Intesis

TM

KNX – IR Universal AC

User's manual r1.2 eng

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

41 / 46

8 Appendix A – Communication Objects Table

TOPIC

OBJECT

NUMBER

NAME

LENGTH

DATAPOINT TYPE

FLAGS

FUNCTION

DPT_NAME

DPT_ID

R W T

U

CONTROL OBJECTS

On/Off

1

Control_ On/Off

1 bit

DPT_Switch

1.001

W T 0 - Off; 1-On

Mode

2

Control_ Mode

1 byte

DPT_HVACContrMode

20.105

W T 0 - Auto; 1 - Heat; 3 - Cool; 9 - Fan; 14 - Dry

3

Control_ Mode Cool/Heat

1 bit

DPT_Heat/Cool

1.100

W T 0 - Cool; 1 - Heat

4

Control_Mode Cool & On

1 byte

DPT_Scaling

5.001

W T 0 – OFF; 0,1%-100% ON + Cool

5

Control_Mode Heat & On

1 byte

DPT_Scaling

5.001

W T 0 – OFF; 0,1%-100% ON + Heat

6

Control_ Mode Auto

1 bit

DPT_Bool

1.002

W T 1 - Auto

7

Control_ Mode Heat

1 bit

DPT_Bool

1.002

W T 1 - Heat

8

Control_ Mode Cool

1 bit

DPT_Bool

1.002

W T 1 - Cool

9

Control_ Mode Fan

1 bit

DPT_Bool

1.002

W T 1 - Fan

10

Control_ Mode Dry

1 bit

DPT_Bool

1.002

W T 1 - Dry

11

Control_ Mode -/+

1 bit

DPT_Step

1.007

W 0 - Decrease; 1 - Increase

Control_ Mode +/-

1 bit

DPT_UpDown

1.008

W 0 - Up; 1 - Down

Fan Speed

12

Control_ Fan Speed / N Speeds

1 byte

DPT_Scaling

5.001

W T 100*(n+0,5)/N %

Control_ Fan Speed / N Speeds

1 byte

DPT_Enumerated

5.010

W T

1 - Speed1; 2 - Speed2; 3 - Speed3; 4 - Speed4;

5 - Speed5; 6 - Speed6; 7 - Speed7

13

Control_ Fan Speed Man/Auto

1 bit

DPT_Bool

1.002

W T 0 - Manual; 1 - Auto

14

Control_ Fan Speed 1

1 bit

DPT_Bool

1.002

W T 1 - Fan Speed 1

15

Control_ Fan Speed 2

1 bit

DPT_Bool

1.002

W T 1 - Fan Speed 2

16

Control_ Fan Speed 3

1 bit

DPT_Bool

1.002

W T 1 - Fan Speed 3

17

Control_ Fan Speed 4

1 bit

DPT_Bool

1.002

W T 1 - Fan Speed 4

18

Control_ Fan Speed 5

1 bit

DPT_Bool

1.002

W T 1 - Fan Speed 5

Page 42

Intesis

TM

KNX – IR Universal AC

User's manual r1.2 eng

© HMS Industrial Networks S.L.U - All rights reserved

This information is subject to change without notice

URL https://www.intesis.com

42 / 46

19

Control_ Fan Speed 6

1 bit

DPT_Bool

1.002

W T 1 - Fan Speed 6

20

Control_ Fan Speed 7

1 bit

DPT_Bool

1.002

W T 1 - Fan Speed 7

21

Control_ Fan Speed -/+

1 bit

DPT_Step

1.007

W T 0 - Decrease; 1 - Increase

Control_ Fan Speed +/-

1 bit

DPT_UpDown

1.008

W T 0 - Up; 1 - Down

Vanes

22

Control_ Vane Up-Down / N pos

1 byte

DPT_Scaling

5.001

W T 100*(n+0,5)/N %

Control_ Vane Up-Down / N pos

1 byte

DPT_Enumerated

5.010

W T

1 - Pos1; 2 - Pos2; 3 - Pos3; 4 - Pos4; 5 - Pos5;

6 - Pos6; 7 - Pos7; 8 - Pos8

23

Control_ Vane Up-Down Man/Auto

1 bit

DPT_Bool

1.002

W T 0 - Manual; 1 - Auto

24

Control_ Vane Up-Down Pos1

1 bit

DPT_Bool

1.002

W T 1 - Position 1

25

Control_ Vane Up-Down Pos2

1 bit

DPT_Bool

1.002

W T 1 - Position 2

26

Control_ Vane Up-Down Pos3

1 bit

DPT_Bool

1.002

W T 1 - Position 3

27

Control_ Vane Up-Down Pos4

1 bit

DPT_Bool

1.002

W T 1 - Position 4

28

Control_ Vane Up-Down Pos5

1 bit

DPT_Bool

1.002

W T 1 - Position 5

29

Control_ Vane Up-Down Pos6

1 bit

DPT_Bool

1.002

W T 1 - Position 6