Intertek Tasman 40000 insert, Tasman 40000 free standing Operating & Installation Instructions Manual

Page 1

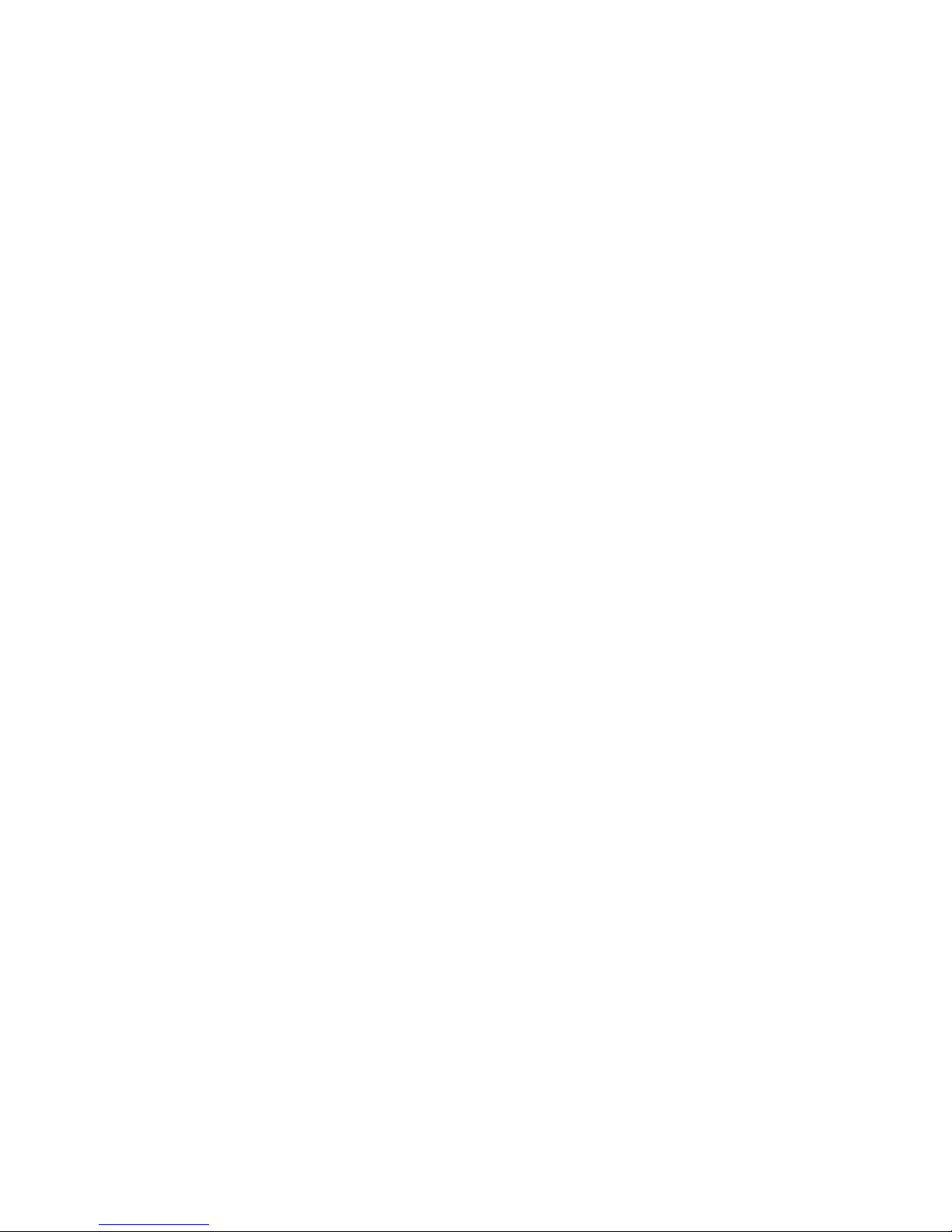

PELLET STOVE

OPERATING & INSTALLATION INSTRUCTIONS

14142

Tasman 40,000

Tasman 40,000

Free Standing

Model

Please read this entire manual before installation and use of this pellet fuel burning room

heater. Failure to follow these instructions could result in property damage, bodily injury or

even death.

Contact your local building officials about restrictions and installation inspection

requirements in your area.

Save these instructions.

Inca Metal Cutting

#100 – 11091 Bridgeport Road

Richmond, B.C. V6X 1T3

Canada

Page 2

TABLE OF CONTENTS

Introduction..................................................................................................... 3

Safety Information.....................................................................................4 - 5

Specifications.................................................................................................. 6

Dimensions ................................................................................................6 - 7

Operating Instructions..............................................................................8 - 12

Thermostat Installation ................................................................................. 13

Clearances to Combustibles...................................................................14 - 15

Installing Your Room Heater................................................................. 16 - 24

Mobile Home Installations............................................................................ 25

Insert Pellet Stove..................................................................................26 - 28

Vent Termination Locations......................................................................... 29

Maintenance........................................................................................... 30 - 33

Optional Accessories .................................................................................... 34

Troubleshooting.................................................................................... 35 – 41

Circuit Board Auger Timing……………………………………………….42

Wiring Diagram............................................................................................ 43

Replacement Parts List ................................................................................. 44

Warranty ................................................................................................45 - 47

Installation Information Sheet……………………………………………...48

Service & Maintenance Log………………………………………………..49

2

Page 3

INTRODUCTION

Thank you for purchasing the Tasman 40,000 pellet stove. The Tasman 40,000 is

available as an insert or a freestanding stove. The Tasman 40,000 has been tested and

listed for installation in residential, mobile homes and alcove installations.

This heater has been certified to ASTM E1509-04 Standard Specification for Room

Heaters, Pellet Fuel-Burning Type.

The performance of you pellet stove can be affected by the type of pellet fuel burnt in the

appliance. It is important to use only pellet fuel that is dry and free from dirt or other

impurities.

The Pellet Fuel Industry has established standards for wood pellet manufacturers. It is

recommended that the fuel used in this appliance meet or exceed the following

specifications:

Fines (fine particles)…….1% maximum through a 1/8" screen

Bulk Density…………….minimum 40 lbs per cubic foot

Size……………………...maximum 3/8" diameter by 1-1/2" long

Ash Content……………..1% maximum (Premium grade)

……………..3% maximum (Standard grade)

Moisture Content………..8% maximum

Heat Content…………….minimum 8,200 btu/hr

It is important to note that the ash content of the fuel (and frequency of operation)

determine the frequency of cleaning required for your unit. A high ash fuel may result in

your unit having to be cleaned daily while a low ash content fuel may permit a longer

time between cleaning.

Occasionally impurities in the fuel will cause a hard mass build up in the burn pot. This

build up may block the air flow through the burn pot affecting the performance of your

unit. Check the burn pot daily for any blockage. If necessary remove the burn pot liner

(once unit has cooled) and clean the liner and the burn pot.

Since Inca Metal has no control over the quality of pellet fuel used in this unit they

assume no responsibility for the end users choice in wood pellets.

Caution: Be sure to store the pellet fuel a minimum of 3' (0.9 m) away from the pellet

stove.

Please note that the rating label may be found on the inside of the hopper lid for the

freestanding unit and on the hopper cover for the insert.

3

Page 4

SAFETY INFORMATION

Be sure to read the entire owner’s manual prior to installing and operating this pellet fuel

burning heater.

Failure to follow these instructions could result in property damage, bodily injury or even

death.

This stove’s exhaust system works with negative combustion chamber pressure and a

slight positive chimney pressure, it is extremely important to ensure that the exhaust

system be sealed and airtight. The ash pan and viewing door must be securely fastened in

order for the unit to be airtight. This appliance will not operate using natural draft or

without a power source for the blowers.

The use of grates or other methods of supporting the fuel is not permitted.

This unit is designed to burn pellet wood fuel only. Do not use any other type of fuel,

this will void any warranties stated in this manual. THE USE OF CORDWOOD IS

PROHIBTED BY LAW.

This appliance is designed for residential installation according to current national and

local building codes. It is also approved as a mobile home heater which is designed for

connection to an outside combustion air source.

It is recommended that the exhaust vent be cleaned bi-annually or after every two tons of

pellets.

Soot or creosote may accumulate when the stove is operated under incorrect conditions

such as an extremely rich burn (black tipped lazy orange flames). Do not operate the

stove if the flame becomes dark or sooty or if the burn pot overfills with pellets. Turn the

stove off and call your dealer.

The grounded electrical cord should be connected to a standard 120 volt, 60 hertz

electrical outlet. Ensure that the electrical cord is not trapped under the appliance and

that it is clear of any hot surfaces or sharp edges.

Be sure that the structural integrity of the home is maintained when passing venting

through walls, ceilings or roofs.

The ash pan and viewing door must be locked securely for proper and safe operation of

the pellet stove.

DO NOT PLACE UNBURNED OR NEW PELLET FUEL IN ASH PAN. A fire in the

ash pan may occur.

Do not abuse the glass by striking or slamming the door. Do not attempt to operate the

unit with broken glass. Replacement glass must be purchased from an Inca Metal dealer.

Do not attempt to clean the glass while unit is hot. To clean the glass, use a soft cotton

cloth and mild window cleaner, gas or woodstove cleaner.

4

Page 5

SAFETY INFORMATION (continued)

Do not operate your stove if you smell smoke coming from it. Turn it off, monitor it and

call your dealer.

Repair and servicing of your stove may only be done by a qualified technician.

Disconnect the power cord before performing any maintenance or repair. NOTE:

Turning the stove to "off" does not disconnect all power from the unit.

The stove will not operate during a power outage, if this happens check for smoke

spillage and open a house window if necessary.

Keep foreign objects out of the hopper.

Contact your local building officials to obtain a permit and information on any

installation restrictions or inspection requirements in your area. Notify your insurance

company of your new stove.

Allow the stove to cool before performing any maintenance.

Ashes must be disposed of in a metal container with a tight lid and placed on a noncombustible surface well away from your home.

Check the venting system, at least twice a year, for creosote build up.

CAUTION:

DO NOT CONNECT TO ANY AIR DISTRIBUTION DUCT OR SYSTEM.

NEVER USE GASOLINE, GASOLINE TYPE LANTERN FUEL, KEROSENE,

CHARCOAL LIGHTER FLUID, OR SIMILAR LIQUIDS TO START OR

FRESHEN UP A FIRE IN THE HEATER. KEEP ALL SUCH LIQUIDS WELL

AWAY FROM THE HEATER WHILE IT IS IN USE.

HOT WHILE IN OPERATION. KEEP CHILDREN, CLOTHING AND

FURNITURE AWAY FROM THE HEATER. CONTACT MAY CAUSE SKIN

BURNS. YOUNG CHILDREN SHOULD BE SUPERVISED WHEN THEY ARE

IN THE SAME ROOM AS THE STOVE.

A SURGE PROTECTOR IS RECOMMENDED ON THE POWER SOURCE TO

YOUR PELLET STOVE

5

Page 6

SPECIFICATIONS

Heating Specifications:

Burn Rate…………………………………*40,000 btu/hr or 4.8 lbs. of fuel per hour

Hopper Capacity………………………….50 lbs.

Heating Efficiency………………………..*75-79%

*Depends on quality and heating value of pellet fuel.

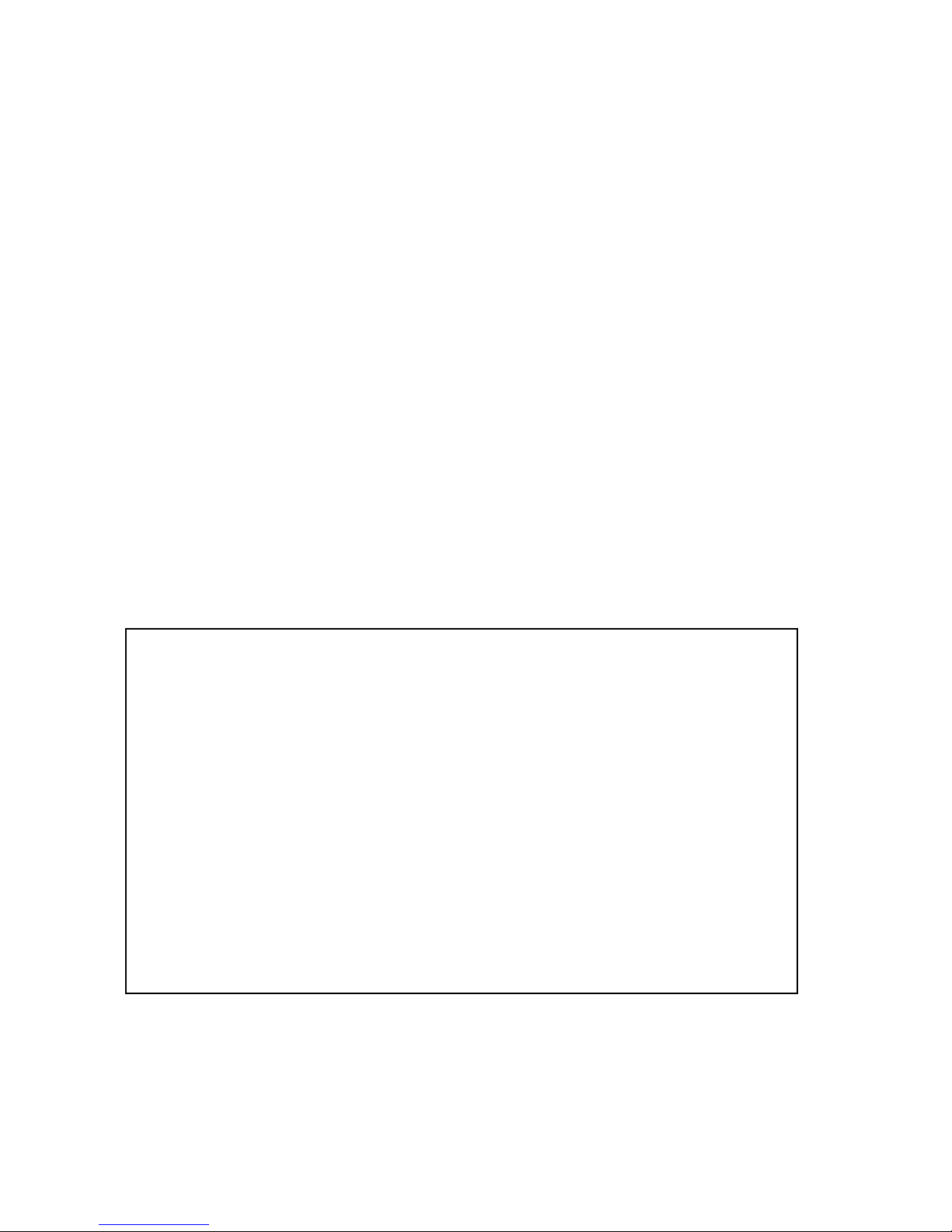

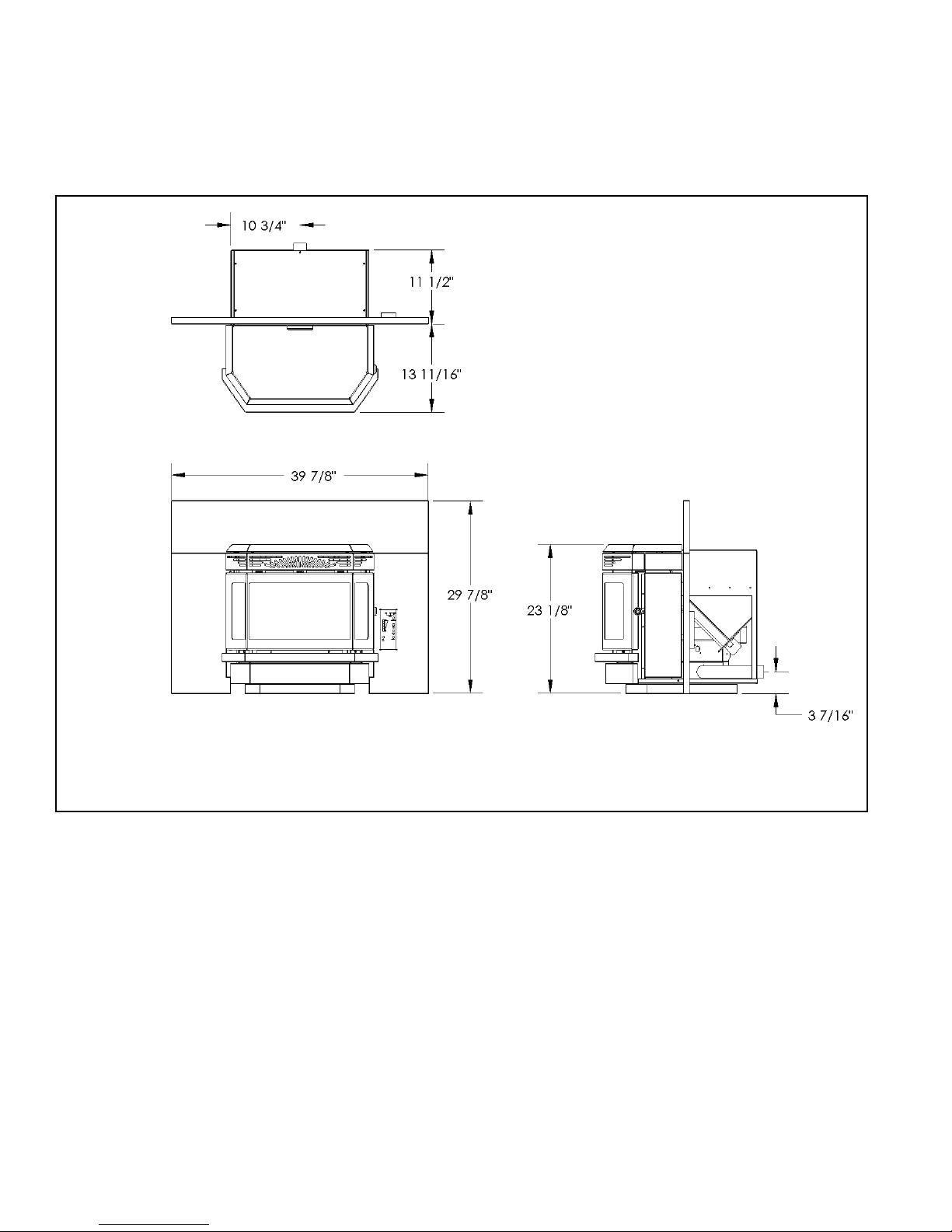

DIMENSIONS

Figure 1

6

Page 7

DIMENSIONS

The minimum installation dimensions, of the insert opening, are 22” (558.80 mm) wide x

22-3/4” (578 mm) high x 17-1/2” (444.50 mm) deep.

Figure 2

15”

7

Page 8

OPERATING INSTRUCTIONS

Filling the Hopper

This pellet stove is available as a freestanding unit or as an insert, therefore there is a

different method of filling the hopper for each type of unit.

To open the hopper lid, on the insert, pull slightly forward and up. To open the hopper

lid on the freestanding unit simply lift up.

CAUTION: Do not overfill the hopper.

Pre-start check up

Remove the burn pot (only if unit is cool) and clean out any ash debris. Be sure to install

the burn pot in the correct position (see page 30).

The blowers and automatic fuel supply are controlled from a panel located on the right

hand side of the stove.

Note: During the first time your unit is fired it may omit an odor as high temperature

paint cures. Maintaining a smaller fire (for the first few hours) will help to minimize this.

Avoid placing any items on the stove top during this period as the unit's paint could be

permanently damaged.

Lighting Instructions

When first operating the pellet stove, switch it to manual mode, so you can have full

control of the pellet stoves control board functions and familiarize yourself with how the

pellet stove works. It is in this mode that the heat level for the T-STAT mode is set.

To Start up a Cold Stove

Press and release the On/Off button. The green light above the On/Off button will flash

to indicate that the start up cycle has started. The light above the Auger button will turn

on, intermittently, indicating the activation of the auger which is feeding the pellets into

the burn pot. At this time the electric igniter is activated. The igniter takes a few minutes

to heat up enough to ignite the pellets in the burn pot. This may take as little as 3 minutes

or as much as 8 minutes. If no flames appear within 15 minutes the stove will attempt

to restart for a further 7 minutes. If it still does not start a full shut down will occur

and the stove will need to be turned back on again.

Once the flame has been established, the start up cycle will end, this takes between 10 22 minutes. At this point, if the stove is in the manual mode, it will default to the lowest

heat level setting. If the stove is in the T-STAT mode the heat output will vary in

accordance with the commands from the thermostat.

8

Page 9

OPERATING INSTRUCTIONS

To Start up a Hot Stove

If the stove is warm at re-start, the On/Off button must be pressed down and held for 2

seconds or more until the Heat Level light is lit.

When first starting a new pellet stove, or when you completely empty the hopper of

pellets, you can press and hold the AUGER button to get the pellets into the burn pot

quicker. See AUGER button description on page 10.

The convection air flow will change in accordance with the heat setting. Convection air

flow is at maximum when the heat setting is at maximum. Air flow will be at a minimum

when the heat setting is at a minimum. If the user wishes to turn the convection fan on

maximum, at any heat setting, they may do so by pressing the FAN button.

If the flame goes out, use the AUGER TRIM button to make adjustments. See the

AUGER TRIM button description on page 11.

To Shutdown Stove

Turn off the unit by pressing the On/Off button. The stove will enter the shutdown cycle

where the pellets will stop feeding to allow the fuel in the burn pot to be used up. The

exhaust blower and convection fan will continue to operate until the flames are out and

the unit has cooled down. Once this has been accomplished the stove will shut down

completely.

In the T-STAT mode turning the thermostat all the way down can also be used to turn off

the stove.

DO NOT TURN OFF THE UNIT BY DISCONNECTING THE ELECTRICAL

POWER TO THE UNIT. THIS WILL CAUSE THE UNIT TO MISS THE

PROPER SHUTDOWN CYCLE, CAUSING THE RELEASE OF SMOKE INTO

THE HOUSE AND OVERHEATING OF THE STOVE.

9

Page 10

OPERATING INSTRUCTIONS

Control Board Functions

T-STAT/Manual Control: The mode button selects the pellet stove operation to either

T-Stat or Manual. Set to Manual to be able to manually select the heat settings and

controls.

If you have a remote thermostat attached and wish to have the pellet stove controlled by

the thermostat, set to T-STAT to operate the pellet stove in variable heat mode. The

thermostat will control the heat output of the pellet stove alternating between the lowest

heat level and the highest heat level pre-selected by the user.

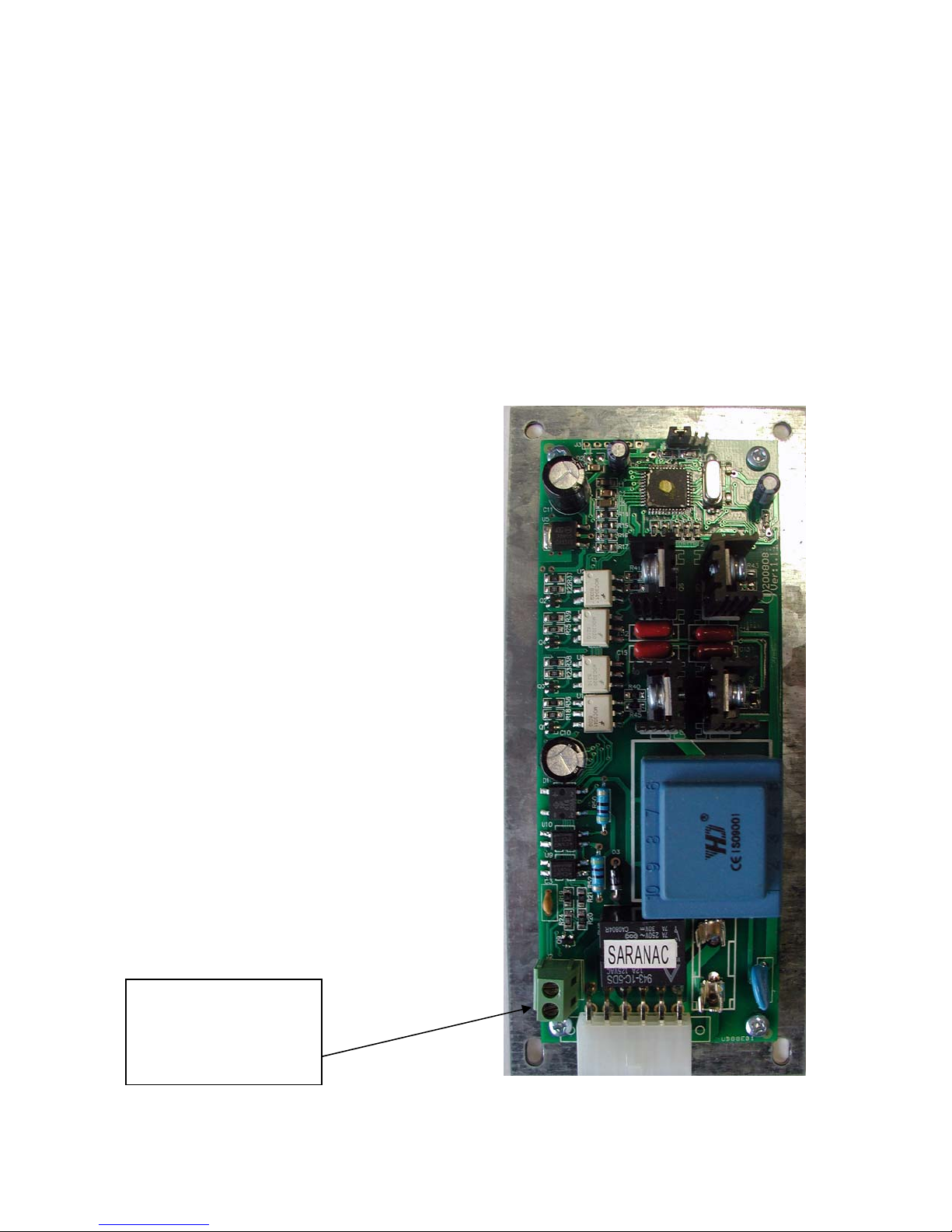

When you first plug in the Saranac board the only light that will be on will be the manual

mode light. If you push the start button in that mode this will start the pellet stove in the

manual mode only. You cannot move from the manual mode to the thermostat mode once

you have switched the stove on.

What you need to do is plug the stove in, before turning on the control push in the mode

button on the control board. With the thermostat light on if you set the wall thermostat to

require heat this will automatically start the pellet stove once the room temperature drops

below heat required. You do not need to start the pellet stove from the control board it

will automatically start through the wall thermostat.

This is the way it will work. Plug Pellet stove in and press mode button select T-STAT.

The wall thermostat will be set to your preferred heat setting, once the room temp drops

below that level the pellet stove will automatically start up. Once the stove starts up it

will run for 3 or 4 minutes and the red light will come on and show the feed rate on level

1. At this point you can push the heat level button and set to desired feed rate setting (2-

5). This only needs to be done once and then the stove will automatically cycle using the

wall thermostat. If the wall thermostat doesn’t call for heat within 30 minutes the stove

will go to full shut down mode and will shut itself off. You do not need to touch the

control board at this point, as soon as the room temperature drops to call for heat the

pellet stove will automatically start up again. If you want to stop this function then the

wall thermostat should be turned off. To restart turn the wall thermostat back up to

desired temperature.

If you unplug the stove or turn it off on the pellet stove control board you will need to

restart as above for wall thermostat use.

After switching between modes the stove should be turned Off and back On to reset

the control to operate in that mode.

On/Off Button: This button is used to turn the unit on and off. If the stove is cold prior

to start-up press and release the On/Off button. The green light above the On/Off switch

will flash to indicate start up cycle has started. Fuel pellets will start to feed into the burn

pot. The electric ignition system will be automatically activated, flames in the burn pot

will normally appear between 3 - 8 minutes. Once the flame has been established, the

start up cycle will end, this takes between 10 -17 minutes. At this point the user will be

able to make heat level adjustments.

If the stove is warm at restart the On/Off button must be pressed down and held for 2

seconds, or more, until the minimum heat level setting light is lit.

Heat Level: When pressed this increases the heat level setting one level. Pressing the

button will cycle the heat setting from minimum to maximum and back again. The

10

Page 11

convection fan speed will also increase with the heat level setting. When the light is

flashing during the start up cycle the heat level button will not respond to the

adjustments. When the light is solid, indicating the start up cycle is finished, it will then

respond (only in manual mode).

Fan: Use this button to override the automatic fan speed control to turn the convection

fan on high. The smart control on this pellet stove will vary the fan speed in accordance

with the heat level setting. It is recommended to let the controller automatically adjust

the speed of the fan for optimum efficiency and minimal fan noise.

Auger: Pressing and holding this button will turn on the auger to speed feeding of pellets

into the burn pot, when first using the pellet stove or when you completely empty the

hopper of pellets and restarting after reloading the hopper. You can load the auger faster

by pressing and holding this button (until you see pellets dropping into the burn pot).

This button will turn off after 1 minute and must be released and pressed again if you

want to continue to manually operate the auger.

Auger Trim: This is used to change the feed rate on the minimum heat level for various

quality of pellet fuel. This will help to keep the flames from extinguishing on the

minimum heat level setting..

Push and release the Auger Trim button once and the heat level 1 and 5 lights appear.

This will slightly increase the feed rate on the minimum heat level setting to keep the

burn pot flames from going out.

Push and release the button until just the heat level 1 setting light is on, this is the factory

setting and works for most types of fuel.

11

Page 12

OPERATING INSTRUCTIONS

Figure 3 Control Panel

Open Door

If the door is opened, while the unit is operating, it must be

closed within 30 seconds or the unit will go into vacuum

error mode. If this happens, close the door, turn the control

panel switch to "OFF" then back to the setting it was

previously at.

Refueling

For maximum performance we recommend that you do not

let the hopper drop below 1/4 full. KEEP LID CLOSED

AT ALL TIMES EXCEPT WHEN REFILLING. DO

NOT OVERFILL HOPPER.

Safety Features

1. Your unit is equipped with a "high temperature

2. If the combustion fan malfunctions a vacuum

If either of these situations occur contact your dealer as a service call may be

required.

limit" thermo snap disc. This snap disc serves to

shutdown the auger in the case of an over

temperature situation (such as convection fan

failure). This disc has a manual reset button that

will have to be reactivated once the unit has cooled

down.

switch will automatically shut down the auger (see

also Open Door section above).

12

Page 13

THERMOSTAT INSTALLATION

An optional thermostat is available for use with this unit. A thermostat can help you

maintain a constant room temperature. A milli-volt thermostat is required.

NOTE: Your thermostat should be installed by an authorized dealer or service person.

To Install Thermostat:

Disconnect unit from power supply.

Open right side panel to gain access to rear of control panel.

Take the thermostat wires and connect to the green screw terminal on the rear of

the control panel (see Figure 4).

When the room cools to below the thermostat setting the stove will automatically restart

and run at the last feed rate setting. When the room is warm enough the unit will shut

off. The exhaust fan will continue to run until the stove cools.

Figure 4

screw connection for

thermostat

13

Page 14

CLEARANCES TO COMBUSTIBLES

INSTALL VENT AT CLEARANCES SPECIFIED BY THE VENT

MANUFACTURER.

When the unit is being installed on a combustible floor a 1/2" thick non-combustible

hearth pad must be installed under the unit. The pad must extend at least the width of the

appliance and at least the depth of the appliance plus 6" (152 mm) in front of the

appliance. This applies for both the freestanding unit and the insert.

Figure 5

Alcove Dimensions

Figure 6

14

Page 15

CLEARANCES TO COMBUSTIBLES

Mantle Clearances to Combustibles

A combustible mantle may be installed if its dimensions fall within the chart below.

Figure 7

Mantle Depth Mantle Height from

10” (254 mm) 40” (1016 mm)

8-7/8” (222 mm) 39” (991 mm)

7-13/16” (197 mm) 38” (965 mm)

6-11/16” (171 mm) 37” (940 mm)

5-5/8” (143 mm) 36” (914 mm)

4-1/2” (114 mm) 35” (889 mm)

3-7/16” (88 mm) 34” (864 mm)

2-5/16” (57 mm) 33” (838 mm)

1-1/4” (32 mm) 32” (813 mm)

Floor

15

Page 16

INSTALLING YOUR ROOM HEATER

Your first step is to decide where to install your pellet stove. In order to get the best use

of circulated heat we recommend too install it in a large open room centrally located in

the house.

Next it is very important to check that clearances to combustibles are maintained, these

can be found on page 14 & 15 of this manual and on the rating label of the pellet stove.

The pellet stove can be vented through an exterior wall or into an existing masonry or

metal chimney. The chimney must be lined if over 6” (150 mm) in diameter or if it has a

cross sectional area of over 28 square inches. Venting can pass through the ceiling and

roof if listed pipe is used.

Do not obtain combustion air from the attic, garage or any other unventilated area. You

may obtain combustion air from a ventilated crawlspace.

DO NOT INSTALL A FLUE DAMPER IN THE EXHAUST VENTING SYSTEM OF

THIS UNIT.

DO NOT CONNECT THIS UNIT TO A CHIMNEY FLUE SERVING ANOTHER

APPLIANCE.

INSTALL VENT AT CLEARANCES SPECIFIED BY THE VENT

MANUFACTURER.

This appliance is certified for use with listed “PL” or “L” pellet venting products as well

as Selkirk’s Direct-Temp Vent system for pellet burning appliances..

16

Page 17

INSTALLING YOUR ROOM HEATER

HORIZONTAL EXHAUST VENT INSTALLATION

1. Locate your appliance in a location which meets the requirements of this manual

and where it does not interfere with the house framing, wiring, etc..

2. Install a non-combustible hearth pad underneath the unit. This pad should extend

at least 6” (152 mm) in front of the unit.

3. Place your stove at the approximate installation site allowing yourself room for

working, the stove will be pushed into position once the venting has been

installed, see item 10/ below for minimum clearances to combustibles.

4. Locate the center of the exhaust pipe of your unit. This point should then be

extended to the interior wall of your house. Once you have located the center

point, on the interior wall, cut a 7” (175 mm) diameter hole through the wall.

5. The next step is to install the wall thimble, refer to the instructions which come

with the wall thimble for this step.

6. Install the appropriate length of exhaust vent pipe into the wall thimble. See step

11 when determining the correct length of exhaust vent to use.

7. Install the combustion air intake pipe. The unit is to use outside air for

combustion. Be sure that the outside air vent has a proper cap on it to prevent

rodents from entering and also is installed where it won’t become blocked with

snow, etc..

8. Connect the exhaust vent pipe to the exhaust outlet of your appliance.

9. Secure all vent joint connections with 3 screws. Seal the exhaust vent joint

connections with high temperature silicone sealant.

10. Push the unit straight back to the interior wall but be sure to m aintain the

minimum clearances to combustibles 6” (152 mm) to the back of the unit and 8”

(204mm) to the side walls of the unit. If your installation is to be at 45 degrees to

the corner the minimum clearance is 6” (152mm) from the back corners of the

unit to the walls (see figure 5). Seal the annular space, of the wall thimble,

around the vent pipe with high temperature silicone sealant.

11. The exhaust vent pipe must extend at least 12” (300 mm) out past the exterior

wall. Seal the annular space, of the wall thimble, around the vent pipe with high

temperature silicone sealant.

12. Install a listed horizontal termination cap or if necessary install a 90 elbow and

appropriate length of vertical venting. A listed vertical vent cap is recommended

however (if local codes allow) when the vent terminates several feet above ground

level and there are no trees, plants, etc. within several feet a 45 elbow can be

used as a termination. The elbow must be turned down to prevent rain from

entering.

17

Page 18

HORIZONTAL EXHAUST VENT INSTALLATION

(continued)

Figure 8

Figure 9

18

Page 19

FREESTANDING INTERIOR VERTICAL INSTALLATION

1. Choose the location for your pellet stove, see item 1 of the Horizontal Exhaust

Vent Installation (page 17) for help in determining the correct location.

2. Install the non-combustible hearth pad.

3. Place your pellet stove on the hearth pad and locate the unit in manner that will

leave the exhaust vent with a minimum of 3” (75 mm) clearance to any

combustible wall.

4. Locate the center of the combustion air intake pipe at the back of your unit. Line

up the center with the same spot on your exterior wall and cut a hole 2-1/2” (64

mm) in diameter through the wall.

5. Secure all vent joint connections with 3 screws. Seal the exhaust vent joint

connections with high temperature silicone sealant.

6. Install the combustion air intake pipe.

7. Install a tee, with a cleanout, on the exhaust pipe found at the rear of your unit.

8. Install listed vent upward through the ceiling. When you pass through the

combustible framing ensure that the appropriate ceiling is used. You must

maintain a minimum 3” (75 mm) clearance to combustibles and keep any

insulation away from the exhaust vent.

9. Extend the exhaust vent through the roof flashing and ensure that the vertical cap

is approximately 36” (900 mm) above the roof.

Figure 10

19

Page 20

FREESTANDING EXTERIOR VERTICAL INSTALLATION

1. Follow steps 1 – 5 from previous page.

2. Locate the center of the exhaust pipe, at the back of the unit. Line up the center

with the same spot on the exterior wall a cut a 7” (175 mm) diameter hole through

the wall.

3. Install the wall thimble, refer to the instructions which come with the wall thimble

for this step.

4. Install a listed exhaust vent through the wall, be sure to make sure that 3” (75

mm) clearances to combustibles are maintained.

5. Secure all vent joint connections with 3 screws. Seal the exhaust vent joint

connections with high temperature silicone sealant.

6. Install a Tee with a cleanout on the end of the exhaust pipe, then install listed

venting upward from there. Be sure to install support brackets every 5’ (1500

mm) to keep the venting straight and secure.

7. Extend the exhaust vent through the roof flashing and ensure that the vertical cap

is approximately 36” (900 mm) above the roof.

Figure 11

20

Page 21

SELKIRK DIRECT-TEMP VENT SYSTEM FOR PELLET

APPLIANCES

Images courtesy of Selkirk

21

Page 22

SELKIRK DIRECT-TEMP VENT SYSTEM FOR PELLET

APPLIANCES

Images courtesy of Selkirk

UP & OUT HORIZONTAL TERMINATION KIT

Figure 12

22

Page 23

SELKIRK DIRECT-TEMP VENT SYSTEM FOR PELLET

APPLIANCES

Images courtesy of Selkirk

STRAIGHT OUT HORIZONTAL TERMINATION KIT

Figure 13

23

Page 24

SELKIRK DIRECT-TEMP VENT SYSTEM FOR PELLET

APPLIANCES

Images courtesy of Selkirk

THROUGH THE ROOF VERTICAL TERMINATION KIT

Figure 14

24

Page 25

MOBILE HOME INSTALLATION

Mobile home installation should be done in accordance with the Manufactured Home and

Safety Standard (HUD), CFR 3280, Part 24.

In order for this unit to be installed in a mobile home the following criteria must be met:

The unit must be secured to the floor using lag bolts in the holes provided in the

pedestal base.

Ensure that the unit is permanently electrically grounded to the chassis of your

home.

IT IS MANDATORY TO TAKE THE COMBUSTION AIR FROM THE OUTSIDE

WHEN INSTALLING THIS UNIT IN AIR TIGHT OR MANUFACTURED/MOBILE

HOMES.

CAUTION:

THE STRUCTURAL INTEGRITY OF THE MANUFACTURED HOME FLOOR,

WALL, AND CEILING/ROOF MUST BE MAINTIANED.

WARNING:

DO NOT INSTALL IN SLEEPING ROOM.

Figure 15

HEARTH PAD

FLOORING

STEEL FRAME

1/4" LAG BOLTS,

SECURELY FASTENED

NOTE: Only the freestanding model is for installation into a mobile home.

GROUND WIRE, DIRECTLY

TO METAL CHASSIS

25

Page 26

INSERT PELLET STOVE

The pellet stove is also available as an insert. There is a small amount of assembly

required when installing this model.

The steps are as follows:

Note: The shroud must be installed before unit is set into its final position.

Step 1: Shroud Side

Facing the back of the unit take the left shroud side piece (no control panel hole) and

fasten, as shown, with 2 screws provided.

Step 2: Shroud Side

Facing the back of the unit take the right shroud side piece (control panel hole) and

fasten, as shown, with 2 screws provided.

Figure 16

Figure 17

26

Page 27

INSERT PELLET STOVE (continued)

Step 3: Shroud Top

Facing the back of the unit take the top shroud side piece and fasten, as shown, with 4

screws provided.

Step 4: Control Board

Take the control board and insert it from the back of the right shroud side (facing front of

unit). Fasten control board in place with 4 screws provided (top & bottom of board).

Figure 19

Figure 18

27

Page 28

INSERT PELLET STOVE (continued)

g

Exhaust Cap Air Inlet

Steel Plate or Flashin

Rigid Vent Pipe

Damper Removed or

Fastened Open (for

Canada) or sealed off

(United States)

90º elbow or clean out Tee

Minimum 6” (150 mm) noncombustible Floor Protection

** Please note either flexible exhaust

vent, rigid exhaust vent or a combination

of the two is allowable when installing in

a masonry chimney.

Figure 20

Flexible Exhaust

Vent

Mantle

Installation into a Masonry Fireplace:

1. Have the masonry chimney inspected by a certified

chimney sweep or installer to determine its structural

condition.

2. Determine the amount of venting required to reach

the top of the chimney and then add 14” to ensure the

termination is an adequate distance above the roofline.

3. The first 5’ of your exhaust vent will be Simpson

Dura Vent pellet stove flex vent the remainder will be

rigid pipe. For each joint subtract 1-1/2” to allow for

the overlap. You may need an adjustable length

section to achieve the correct height. The air intake

may be 2” aluminum flex vent.

4. Assemble the first rigid section (of the exhaust

pipe) to the pellet stove flex vent insuring that the

“UP” arrows shown on the pipe labels are pointing up.

Push the sections together and twist to lock. Repeat

the process for the remainder of the pipe sections and

lower the assembly down the chimney. Lower the

intake and exhaust pipes below their normal position

in order to connect the to the back of the appliance. It

may be necessary to tie a line to the top section, of

venting, to pull it back up to the correct position after.

5. In order to connect to the exhaust of the stove you

will need to install a pipe adapter to the exhaust fan

and the either a 90º elbow or a clean out tee with cap.

The air intake can be attached, to the appliance, by

using a hose clamp.

6. Connect the stove to the coupling on the bottom of

the exhaust flex vent and twist to the locked position.

Push the appliance into the fireplace to its final

position. Go to the top of the chimney and pull the

vent system up to the desired height.

7. For the exhaust termination of the pellet vent use a

tall cone flashing and a storm collar. This requires

14” of pipe above the top of the masonry chimney.

Pull the pipe up through the flashing to the desired

height and mark where the storm collar will go. Slip

the storm collar down over the pipe and fasten it to the

pipe with a 1/4” stainless steel sheet metal screw. The

storm collar will then support the entire exhaust vent

system.

8. To install the air intake vent through the chimney

cap you may cut a hole and install cap as shown or

attach air intake vent to a flashing and cap. The

chimney top must be properly sealed to prevent rain

and or snow from entering the chimney.

9. Install the cap and seal around the joint of the

storm collar and any other joints that are visible.

10. This completes the masonry chimney installation.

28

Page 29

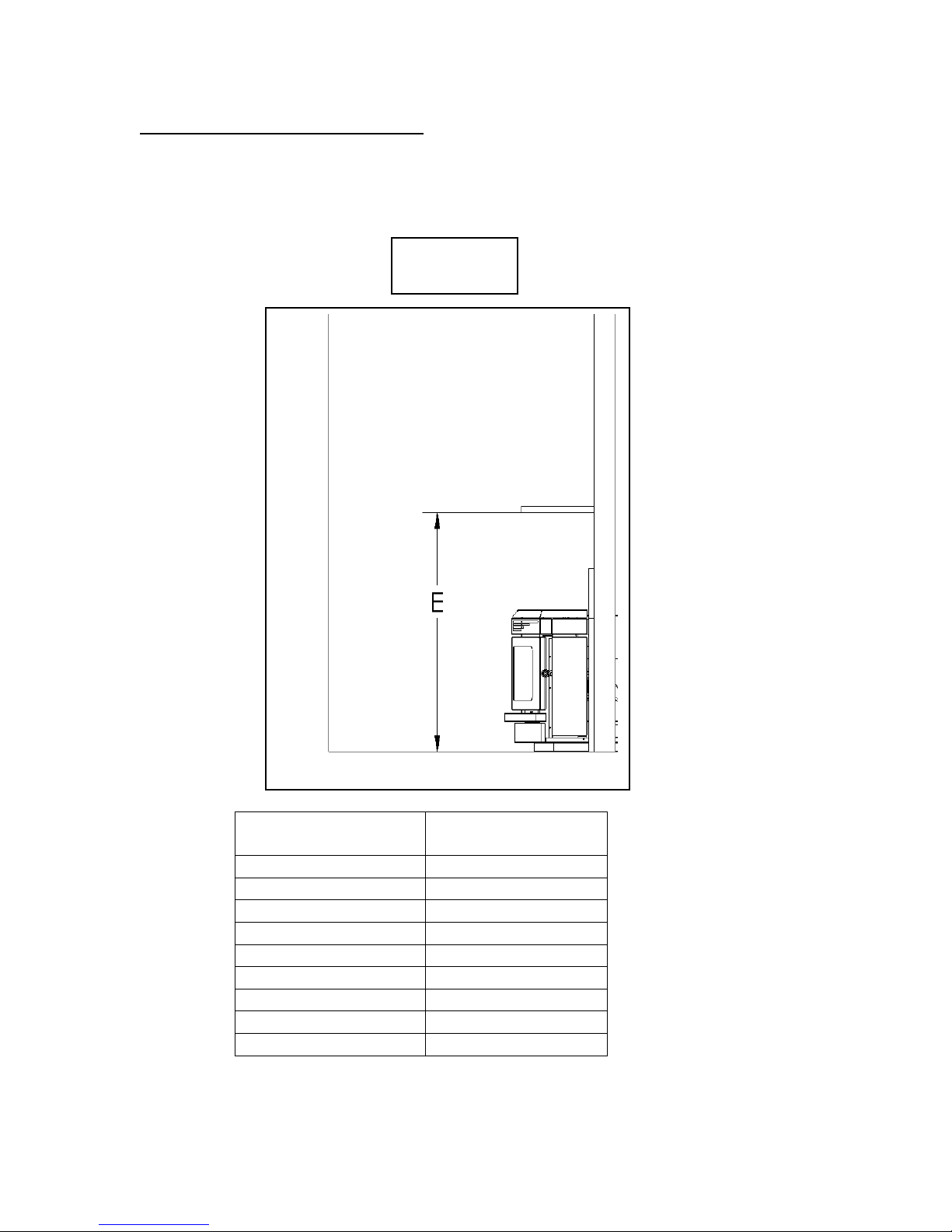

Figure 21

Letter Minimum Clearance Description

A 24" (60 cm) Above grass, top of plants wood, or any other

B 48" (122 cm) From beside/below any door or window that may be

C 24" (60 cm) From any door or window that may be opened.

D 24" (60 cm) To any adjacent building, fence and protruding parts

E 24" (60 cm) Below any eave or roof overhang.

F 12" (30 cm) To outside corner.

G 12" (30 cm) To inside corner, combustible wall.

H 3' (91 cm) within a height of 15' (4.5 m)

above the meter/regulator assembly

I 3' (91 cm) From any forced air intake or other appliance.

J 12" (30 cm) Clearance to non-mechanical air supply inlet to

K 24" (60 cm) Clearance above roof line for vertical terminations.

L 7' (2.13 m) Clearance above paved sidewalk or paved driveway

VENT TERMINATION LOCATIONS

combustible material.

opened.

of the structure.

To each side of center line extended above natural

gas or propane meter/regulator assembly or

mechanical vent.

building, or the combustion air inlet to any appliance.

located on public property.

29

Page 30

MAINTENANCE

FAILURE TO CLEAN AND MAINTAIN THIS UNIT AS INDICATED MAY

RESULT IN POOR PERFORMANCE AND HAZARDOUS SITUATIONS. NEVER

CLEAN THE UNIT WHEN HOT.

Burn Pot

Note: Let the unit cool to room temperature before inspecting the burn pot.

Inspect the burn pot regularly to check that the holes have not become plugged. If

necessary clean thoroughly. It is imperative that the burn pot be re-installed the correct

way or the unit will not light. The end of the burn pot with an igniter hole in it (see

Figure 22) must be installed facing the rear of the unit. This hole allows the igniter to

heat up the pellets to the point of ignition.

Figure 23

Figure 22

Igniter Hole

Burn Pot

Installed

Ash Pan

Burn Pot

Removed

30

Page 31

MAINTENANCE - continued

Ash Removal - Freestanding Unit

If left neglected ashes will eventually fill the ash pan. Remove the ashes periodically to

avoid unnecessary ash build up. Ash removal is as follows:

1. Let fire run out and unit cool to room temperature.

2. Clean the heat exchanger tubes (see Heat Exchanger Cleaning section).

3. Open the ash pan door, remove the burn pot and burn pot liner and empty into

metal container.

4. Vacuum to remove ashes from the firebox. BE SURE THAT ASHES ARE

COOL TO THE TOUCH BEFORE VACUUMING. Some regular vacuums

and shop vacs may leak ash into the room. Your vacuum or shop vac may have a

special filter or bag available to eliminate this leakage.

5. Remove ash pan and dispose of ashes into metal container.

6. Reinstall ash pan.

7. Reinstall burn pot and burn pot liner.

Ash Removal

Ash Disposal

Ashes should be placed in a metal container with a tight fitting lid. The closed ash

container should be placed on a non-combustible surface or on the ground well away

from all combustible materials, pending final disposal. If the ashes are disposed of by

burial in soil or otherwise locally dispersed, they should be retained in the closed

container until all cinders have been thoroughly cooled.

Ash Pan Door

1. Let the unit cool to room temperature then lift the ash pan door up and pull out.

2. Follow directions for freestanding unit on previous page.

- Insert Unit

Figure 24

31

Page 32

MAINTENANCE - continued

Cleaning

Heat Exchanger Tubes – Your unit is designed with a built in heat exchanger tube

cleaner. This should be used every 2 or 3 days to remove ash build up on the heat

exchanger tubes, which can reduce heat transfer. The handle, for the heat exchanger tube

cleaner, is located inside the firebox. Slide the rod front to back several times to clean

the tubes then follow the instructions for ash removal.

Figure 25

Heat

Exchanger

Cleaner

Handle

Fans – DANGER: RISK OF ELECTRIC SHOCK. DISCONNECT POWER BEFORE

SERVICING UNIT.

Over time ash or dust may accumulate on the blades of the convection & combustion

fans. The fans should be inspected, periodically, and if any accumulation is present

vacuumed clean as the ash or dust can impede the fans performance. It is also possible

that creosote may accumulate in the combustion fan, this must be brushed clean.

The combustion fan can be found behind the left side panel (facing the front of the unit),

the convection fan can be found behind the right side panel. To access the igniter you

must remove the air inlet tube and cover (2 screws).

Note: When cleaning be careful not to damage the fan blades.

Figure 26

32

Page 33

MAINTENANCE - continued

Chimney Cleaning:

1. Creosote Formation – When wood is burned slowly it produces tar and other

organic vapors which combine with expelled moisture to form creosote. The

creosote vapors condense in the relatively cool chimney flue, as a result creosote

residue accumulates on the chimney lining. When ignited creosote makes an

extremely hot fire which can damage the chimney or cause a house fire.

2. Fly Ash – This can accumulate in the horizontal sections of a vent run. Fly ash is

non-combustible although if allowed to build up, continuously, it may impede the

exhaust flow.

3. Inspection of Vent System – The chimney/venting system should be inspected

should be inspected annually or per ton of fuel to determine if creosote or fly ash

build up has occurred. To clean the chimney, detach the vent where it attaches to

the combustion blower. If creosote has accumulated it should be removed.

Inspect the entire vent system from unit exhaust to termination. Creosote should

be removed with a brush specifically designed for the type of chimney in use. It

is recommended that a qualified service technician perform the inspection and

required maintenance.

Glass Doors:

Gaskets around the door and window panes should be inspected, cleaned and repaired

when necessary.

Door Removal and Replacement:

If glass is broken carefully remove (once unit has cooled, also be sure to wear gloves)

any loose pieces of glass from the door frame.

Combustion Chamber weekly

Heat Exchanger Tubes bi-weekly

Convection Fan Blades annually

Combustion Fan Blades annually

Task Maintenance Schedule

Burn Pot check daily

Ash Pan bi-weekly or every 10 bags of fuel

Hopper bi-weekly or every 10 bags of fuel

Venting System annually

Glass as needed

Gaskets annually

33

Page 34

OPTIONAL ACCESSORIES

d

This pellet stove is available with an optional firebox decorative liner as well as a

ceramic log set.

Decorative Liner Installation:

1. Install the center panel, be sure to line up the hole with the drop tube.

2. Install the left and right panels.

Left Panel Right Panel

All Panels Installe

Figure 27

34

Page 35

TROUBLE SHOOTING

See figure 26, page 32, for component locations.

Condition 1: The unit will not light.

Check that the unit is plugged in and that the wall outlet has power.

Unplug the unit then check all electrical connections against the Wiring Diagram

in this manual.

Check the fuse on the circuit board.

If a thermostat is used, ensure it is calling for heat.

If your unit still does not light contact your local dealer for service.

Condition 2: The stove will not operate when hot.

Check the hopper has fuel.

Check that the combustion air inlet is not blocked. Insufficient air supply may

cause the fire to burn cold and may cause fuel build up, in the pot, and smother

the fire.

Check that the exhaust fan is operating, if the fan is not operating properly it may

not generate enough vacuum in the firebox.

Check the vacuum switch by shorting out the vacuum switch then turn the control

panel to "OFF" and back to “ON”. If the unit starts to operate change the vacuum

switch.

Check the exhaust temperature switch (located on the exhaust blower) by shorting

out the exhaust temperature switch then turn the control panel to "OFF" and back

to “ON”. If the unit starts to operate change the exhaust temperature switch.

Check the 250F high limit switch. This switch is manually reset, check if it has

tripped, if so let cool and reset switch. Check for cause of overheating, if switch

trips again contact your local dealer for service.

Condition 3: Exhaust blower does not operate normally.

Check all wiring connections.

Apply 120 volts directly to the exhaust blower, if the blower does not run replace

the blower.

Condition 4: Convection blower does not operate normally.

Check all wiring connections.

Apply 120 volts directly to the convection blower, if the blower does not run

replace the blower.

35

Page 36

TROUBLE SHOOTING

Condition 5: Igniter will not light fuel.

Check electrical connections (including fuse) to the igniter.

Check the igniter tube, which touches the burn pot, is not plugged with ash. If it

is plugged remove the debris (be sure to wait until everything has cooled to room

temperature).

Check burn pot is installed correctly (see page 30).

If igniter still does not work, replace it.

Note: The igniter should be glowing orange when in operation.

Condition 6: The auger motor does not function normally.

If the auger shaft does not turn but the motors armature tries to spin then this is a

sign your auger is jammed. Try to remove the blockage by poking at the fuel in

the drop tube. If this does not work then empty the hopper and remove the auger

cover and clear the blockage (Note: Before removing the auger cover

disconnect power to the unit).

Check for voltage at the auger motor, if none check circuit board fuse.

Ensure the exhaust blower is operating.

Check the vacuum hose is connected or damaged.

Bypass the vacuum switch by placing a jumper wire on the two electrical

connections. If the auger motor starts to function normally replace the vacuum

switch.

Check the manual reset on the 250 F high limit switch. If the switch has been

tripped, check for the cause of the overheating, reset the switch and check if the

auger operates normally.

Bypass the 250 F high switch by placing a jumper wire on the two electrical

connections. If the auger motor starts to function normally replace the high limit

switch.

If the auger is not jammed and you have tried the other possible causes, connect

120 volts directly to the auger motor. If the auger motor does not work replace

the auger motor.

Condition 7: The 250 F high limit switch has tripped.

Reset the switch and determine the cause. It is normally a faulty convection fan.

If the convection fan does not operate apply 120volts directly to the convection

fan, if it still does not operate replace the convection fan.

36

Page 37

TROUBLE SHOOTING

Condition 8: The stove will not shut off.

Ensure that the room thermostat (if a thermostat is used) is turned down below the

room temperature.

Disconnect one of the wires to the exhaust temperature sensor, the unit should

then shut off.

Turn the control board to "OFF"

If the unit will still not shut off, disconnect power to the unit and call your local dealer for

servicing.

Condition 9: The unit keeps going out on "LOW" setting.

If the unit goes out and leaves fresh unburned pellets in the burn pot liner then the fire is

going out before the unit shuts off.

On the control panel, turn the heat level up to the next setting, poorer quality

pellets require a slightly higher setting.

Condition 10: Glass soots up at a fast rate, flame is lazy.

The vent pipe (including air intake) may be dirty or partially blocked restricting

airflow to the unit.

Burn pot holes are blocked. Let the unit cool and clean burn pot and burn pot

liner (be sure to follow instructions for disposal of ashes found on page 31).

Circuit board malfunction. Time the fuel feed light at each setting (after the stove

has completed the initial "Start Up" sequence. Check the timing against the

timing chart (found below), if the auger motor runs constantly there is a problem

with the circuit board.

Combustion blower is not operating. Check the exhaust blower is operating, if

not bypass the exhaust temperature switch, if the motor operates replace the

exhaust temperature switch. If the exhaust blower still does not work apply 120

volts directly to the exhaust blower motor, if the motor does not work replace the

exhaust blower motor.

Poor fuel quality. The type of pellets being used may be of poor quality, if

possible try a different brand of pellets (refer to fuel type information on page 3).

37

Page 38

TROUBLE SHOOTING

SARANAC & WESTPOINT PELLET STOVES

TROUBLE SHOOTING DURING THE START UP CYCLE:

*WE RECOMMEND PUTTING A HANDFUL OF PELLETS IN THE POT

WHEN STARTING YOUR PELLET STOVE TO AID WITH IGNITION.

Auger motor not feeding:

Start up cycle should be 5 second on & 11 seconds off

Check wiring is attached properly.

Check high limit switch has not been tripped, if so reset it.

Disconnect power to the stove.

Plug in auger motor directly to see if it works, if not replace auger

motor.

All of the above are OK then replace the board.

Exhaust fan not on:

Check wires are attached properly.

Disconnect power to the stove.

Plug in fan direct.

If it runs on direct power the fan is good, DO NOT CHANGE THE

FAN, change the board.

If it does not run on direct power then change out the fan.

Stove times out on start up cycle & goes to shut down:

Stove is not getting to temperature in time and therefore goes to

automatic shut down; everything will turn off including the

convection fan.

If it is an old board (12 minute cycle), start again and wiggle low

limit switch.

If you have to wiggle switch more than once then change low limit

switch.

If problem persists then switch old board with new board (15 & 7

minute start up cycle).

Stove smokes:

Usually because it is timing out on start up cycle.

Make sure you have exhaust and intake running to the outside;

otherwise it is inevitable that you will get smoke in your home.

If your intake is inside the house and not run outside then change

board to new board with 10 minute exhaust fan shut down cycle.

Convection fan not on after start up:

Disconnect power to stove.

Plug in fan and test it direct.

If the fan does not work on direct power then replace the fan.

38

Page 39

If the fan works then it is NOT a problem with the fan, DO NOT

CHANGE THE FAN.

Check the low limit switch; wiggle it on start up to see if the fan

kicks in.

If that does not work then once the stove is warm bypass the low

limit switch (see attached Figure 1). Only do this after the stove

is warm, if you attempt to bypass the low limit switch before

starting your stove you will fault out the board, the low limit

switch can not be bypassed before you start the stove.

If the fan comes on with the switch bypassed then replace the low

limit switch.

If the fan does not come on then replace the board and leave the

low limit switch.

Stove shuts down & flashes level 2:

If the Vacuum switch fails it will go into full shut down and flash

on level 2 on the board.

Disconnect power to the stove.

Bypass the vacuum switch and fire up the stove.

If the stove fires up and runs for more than 1 minute (1 minute

until vacuum failure & 10 minute shut down cycle) then replace

the vacuum switch.

Stove shuts down & flashes level 3:

This indicates that the stove was starved for fuel.

Check that the auger is functioning properly and that there is fuel

in the pot and hopper.

Make sure there are no jams.

If the fuel is being feed properly then restart the stove by holding

down the start button for 5 seconds. It should fire up the second

time.

If the problem persists then change the board for one with the new

extended start up cycles.

Blowing fuses:

Check to make sure nothing is shorting out.

Check the ignitor rod and make sure there is not a bare spot on the

wire; this could cause the stove to short out.

Ignitor rod not coming on:

Disconnect power to the stove.

Hook up the ignitor rod directly.

If it does not heat up on direct power then replace the ignitor rod.

If it does then replace the board.

Convection fan cycles from high to low:

Get stove hot and bypass low limit switch.

If the fan stops cycling it is a bad thermostat, replace the low limit

switch.

39

Page 40

If it does not stop then disconnect power to the stove and plug in

fan direct.

If it still cycles then it is a bad fan and must be replaced.

If it does not cycle when plugged in direct then change the board.

TROUBLE SHOOTING DURING THE RUN CYCLE:

*THE QUALITY OF PELLETS YOU USE WILL DIRECTLY INFLUENCE THE

PERFORMANCE OF YOUR STOVE.

*PELLET STOVES ARE NOT MEANT TO RUN ON HIGH FOR LONG

PERIODS OF TIME, THE HIGH LEVELS ARE ONLY MEANT TO INITIALLY

BRING THE ROOM UP TO A DESIRED HEAT.

*YOU MUST CLEAN OUT YOUR PELLET STOVE REGULARLY IN ORDER

FOR IT TO PERFORM EFFECTIVELY.

*ALL TESTING OF THE STOVE IN THIS SECTION SHOULD BE

PERFORMED AFTER THE START UP CYCLE AND DURING THE RUN

CYCLE.

The stove is smoking into the house:

If you have a power failure or an exhaust fan failure and you do

not have a fresh air intake hooked up then you may get smoke in

the house.

If both the intake and exhaust are installed and you are still getting

smoke in the house then you will want to check that your exhaust

is hooked up properly to code and that it is COMPLETELY

SEALED (this is very important, this is the main cause of most

smoke issues).

Check to make sure your intake is going to the outside and is

sealed properly.

If problem persists then get a new board with the extended shut

down cycle on it and the exhaust fan will stay on for 10 minutes

after shut down to ensure everything is exhausted out.

High limit switch keeps tripping:

As we stated above no pellet stove is designed to run on high for

long periods of time. It is like running your car; you would never

drive it all out peddle to the metal everywhere you go, it is not

designed for that. The same thing with your pellet stove, use the

high levels to bring the room up to heat and then turn the stove

down.

The convection fan has a fail safe at 210 degrees Fahrenheit; it will

shut down if it gets that hot. If the convection fan shuts down then

the stove heats up to an unsafe temperature and the high limit trips.

That is what it is supposed to do. The pellets will stop feeding and

the stove will shut down and flash level 3.

40

Page 41

That being said, if the stove continually trips the high limit switch

before getting up to unsafe heat then check the convection fan by

disconnecting power to the stove and plugging the fan in direct.

If the fan cuts out while plugged in direct then change the fan.

If the fan runs without fail when plugged in direct then it is not the

fan.

Bypass the high limit switch while the power to the stove is

disconnected and then plug in and see if the stove runs properly. If

the stove runs longer than it previously was when tripping the high

limit switch then replace the high limit switch.

Pellets stop feeding:

Check the auger shaft for a jam. Unfortunately, auger jams are

unavoidable when operating a pellet stove. However, if your stove

is experiencing a high regularity of auger shaft pellet jams then

check the quality of your pellets. Pellets are like anything else, you

get what you pay for. You want to use high quality pellets with

little or no sawdust and with a low ash content. Use of poor

grade pellets is the main issue with most pellet jams.

If there is no pellet jam then check the high limit switch, if it is

tripped it will stop the pellets from feeding as well.

Burn pot is clogging up:

You must clean pot regularly, how regularly depends on usage.

Failure to clean out the burn pot will cause build up and clogging.

It could also lead to a hopper fire should the pot clog up and back

up the drop tube. IT IS VERY IMPORTANT TO CLEAN OUT

THE BURN POT REGULARLY!

Failure to clean out the burn pot and allowing it to clog up will also

negatively affect the performance of your stove. You are limiting

the amount of air that can be feed into the pot to feed the fire.

Different altitudes can affect the burn off your stove and cause the

pot to clog. Higher altitudes require a different board setting;

change the board if this is an issue.

The burn pot is warped:

This is again a result of not cleaning out the pot. If you allow build

up in your pot and do not clean out your pot from one use to the

next your burn pot will experience hotter than acceptable

temperatures and your pot may warp. This is not covered under

warranty!

*YOU CAN ALSO CONSULT YOUR MANUAL FOR ADDITIONAL TROUBLE

SHOOTING AND GENERAL INFORMATION ON YOUR STOVE.

41

Page 42

CIRCUIT BOARD AUGER TIMING

SARANAC CIRCUIT BOARD #1A

MODE: A

*8 SECOND CYCLE

SETTING TIME ON TIME OFF

START UP 2.5 5.5

LEVEL 1 2 6

LEVEL 2 2.5 5.5

LEVEL 3 4 4

LEVEL 4 4.5 3.5

LEVEL 5 5.5 2.5

MODE: B

*8 SECOND CYCLE

SETTING TIME ON TIME OFF

START UP 2.5 5.5

LEVEL 1 2 6

LEVEL 2 2.5 5.5

LEVEL 3 3.5 4.5

LEVEL 4 4 4

LEVEL 5 5 3

MODE: C

*8 SECOND CYCLE

(SHOULD SHIP IN THIS MODE)

PIN POSITION

PIN POSITION

SETTING TIME ON TIME OFF

START UP 2.5 5.5

LEVEL 1 2 6

LEVEL 2 2.5 5.5

LEVEL 3 3 5

LEVEL 4 3.5 4.5

LEVEL 5 4 4

PIN POSITION

42

Page 43

WIRING DIAGRAM

43

Page 44

REPLACEMENT PARTS

Contact an authorized Inca Metal pellet stove dealer to obtain any of these parts. Never

use substitute materials. Use of non-approved parts can result in poor performance and

possible safety hazards as well as voiding the Warranty.

Item Part #

control panel circuit board SPSS 1007

auger motor SPSS 1005

250 F, normally open

high limit snap disc

140 F, normally open

exhaust temperature snap disc

convection fan SPSS 1002

exhaust fan SPSS 1000

0.1" w.c. normally open

vacuum switch

silicone tube for vacuum switch SPSA 1011

hot rod ignitor SPSA 1012

door gasket

door glass (front panel) SPSS 1017

door glass (side panel) SPSS 1018

removable door handle

brick panel set – optional

SPSA 1016

SPSA 1015

SPSA 1010

44

Page 45

LIMITED 5 YEAR WARRANTY

Products manufactured by Inca Metal Cutting Ltd (“Inca Metal”) are designed with

superior components and materials, assembled by trained craftsmen who take great pride

in their work. Once assembled the complete fireplace is thoroughly inspected by a

qualified technician, before packaging, to ensure that you, the customer, receives the

quality product that you expect from Inca Metal. With that in mind every stove is fully

burned for a minimum of one hour before leaving Inca Metal to ensure the stove is in full

working condition.

The pellet stoves manufactured by Inca Metal are warranted for (5) years on all nonelectrical components excluding the burn pot. The burn pot is warranted for the lifetime

of the pellet stove. Electrical components, which include the control board, auger motor,

combustion and convection blowers and ignitor, are warranted for (1) year.

There is specifically no warranty on glass, paint, brick panels and all gaskets. There is no

written or implied performance warranty on the stove as the manufacturer has no control

over the installation, daily operations, maintenance or the type of fuel burned.

Warranty coverage begins on the date of the original installation. The warranty is only

valid if the unit remains at the site of original installation. The warranty is

nontransferable and is made only to the original purchaser. The warranty shall commence

no later than 24 months following the date of product shipment from Inca Metal,

regardless of the installation or occupancy date.

It is strongly recommended that this appliance be installed by a licensed and qualified

installer. It must be installed, operated and maintained at all times in accordance with the

instructions in the Owner’s Manual. This warranty does not cover damage or breakage

caused by improper handling, misuse, abuse, over-firing, disassembly, unauthorized

modification or other circumstances that are beyond Inca’s control.

This warranty is void if:

The appliance has been over-fired or operated in atmospheres contaminated

by chlorine, fluorine or other damaging chemicals. Over-firing can be

identified, but not limited to, warped plates or tubes, rust coloured cast iron,

bubbling, cracking and discoloration of steel or enamel panels.

Any damages that occur to fireplace, combustion chamber, brass or chrome

trim or other component due to water, weather damage, long periods of

dampness, condensation, damaging chemicals or cleaners.

There is any damage to the appliance or other components due to water or

weather damage which is the result of, but not limited to, improper chimney

or venting installation.

This limited warranty further does not cover any scratches, dents, corrosion or

discoloring caused by excessive heat, abrasives, chemical cleaners nor any

venting components used in the installation of the fireplace.

45

Page 46

Important note:

Burning anything other than high quality wood pellets that meet A.P.F.I. specifications

may cause stove damage and could void the warranty.

Inca stresses that only high quality premium pellets should be

burnt in our stoves!

Inca Metal Ltd. is not responsible for the performance of any stove that is being run on

poor quality pellets. It is the responsibility of the homeowner to ensure the stove is run on

high quality pellets. It is important to remember that the stove will only perform as well

as the fuel that is used.

Warranty procedure:

An Installation Information Sheet is provided in the manual; it is to be filled out by the

installer on the installation date. A Service & Maintenance Log is also provided in the

manual and it is to be filled out by the dealer when any work is done on the stove after

the date of installation. These may be requested by the manufacturer on any claim. If

these forms can not be provided upon request a claim may be denied.

Homeowner: Contact the dealer where you purchased the stove for any and all concerns

regarding the stove.

Dealer: A Warranty Claim Form will be provided to the dealer by the distributor. This

Warranty Claim Form must be accurately filled out by the dealer and sent to the

distributor along with any parts being claimed.

Distributor: The distributor must sign and verify the information is correct for any and

all warranty claims then send a copy of the Warranty Claim Form to the manufacturer for

review (keep original form w/ part). If this sheet is not filled out correctly and entirely

when returned to Inca then a claim may be denied. DO NOT SEND ANY PARTS

BACK TO THE MANUFACTURER WITHOUT RMA #.

Any claims under this warranty must be made by the dealer to the distributor. If an

inspection by the distributor indicates that a warranty claim is justified, and that all

conditions of this warranty have been met, the manufacturer’s total responsibilities and

liabilities shall be to repair or replace, at the manufacturer’s option, the defective part(s).

Limited labour claims can be made under warranty so long as the stove was installed

professionally by the dealer who originally sold the stove. No labour will be covered by

the manufacturer on any stove where the installation was done by anyone other than the

dealer who originally sold the stove.

Any installation, construction, transportation or other related costs or expenses arising

from defective part(s), repair or replacement or otherwise of same, will not be covered by

this warranty nor shall Inca Metal assume responsibility for same. Further, Inca Metal

will not be responsible for any incidental, indirect or consequent damages, except as

provided by law, and in no event shall damages exceed the original purchase price.

Final note:

Notwithstanding any provisions contained in this warranty, Inca’s responsibility under

this warranty is defined as above and it shall not in any event extend to any incidental,

consequential or indirect damages.

46

Page 47

This warranty defines the obligations and liability of Inca Metal with respect to the Inca

Metal fireplace and any other warranties expressed or implied with respect to this

product, its components or accessories are excluded.

Inca Metal neither assumes, nor authorizes any third party to assume, on its behalf, any

other liabilities with respect to the sale of this product. Inca Metal will not be responsible

for: over firing, downdrafts, spillage howsoever caused and including but not limited to

environmental conditions such as rooftops, buildings, nearby trees, hills, mountains,

inadequate vents, excessive venting configurations, insufficient make up air, or negative

air pressures which may or may not be caused by mechanical systems such as exhaust

fans, furnaces, clothes dryers, etc. Inca metal does not accept responsibility, legal or

otherwise, for incidental or consequential damage to property or persons resulting from

the use of this product.

Inca Metal reserves the right to have its representative inspect any product or part thereof

prior to honoring any warranty claim.

Manufactured by

Inca Metal Cutting Ltd

Richmond, BC

Canada

47

Page 48

INSTALLATION INFORMATION SHEET

The following page must be filled out by the installer when the unit is installed for warranty

purposes and future reference. Failure to properly fill out this sheet will void all future warranties.

NAME OF

ADDRESS: ADDRESS:

PHONE #: PHONE #:

OWNER:

NAME OF

DEALER:

MODEL NAME: NAME OF INSTALLER:

SERIAL #: SIGNATURE:

DATE OF PURCHASE:

DATE OF INSTALLATION

MANUFACTURED BY:

INCA METAL PRODUCTS LTD

RICHMOND, BC

48

Page 49

SERVICE AND MAINTENANCE LOG

SERIAL # OF STOVE:_______________

DATE SERVICED PERFORME D BY DESCRIPTION OF SERVICE

12/2009

49

Loading...

Loading...