Page 1

OPERATING INSTRUCTIONS MANUAL

(Please retain for future reference)

For

FRHR-100N/P/PQD RADIANT CONSTRUCTION HEATERS

INDOOR USE ONLY

CERTIFIED FOR USE IN CANADA AND U.S.A.

CSA 2.14 2000 Gas Fired Construction Heaters Unvented /Unattended Type.

As per Standard ANSI Z83.7 2000/

FLAGRO INDUSTRIES LIMITED

ST. CATHARINES, ONTARIO

CANADA

Page 2

GENERAL HAZARD WARNING:

FAILURE TO COMPLY WITH THE PRECAUTIONS AND INSTRUCTIONS

PROVIDED WITH THIS HEATER, CAN RESULT IN DEATH, SERIOUS BODILY

INJURY AND PROPERTY LOSS OR DAMAGE FROM HAZARDS OF FIRE,

EXPLOSION, BURN, ASPHYXIATION, CARBON MONOXIDE POISONING, AND/OR

ELECTRICAL SHOCK.

ONLY PERSONS WHO CAN UNDERSTAND AND FOLLOW THE INSTRUCTIONS

SHOULD USE OR SERVICE THIS HEATER.

IF YOU NEED ASSISTANCE OR HEATER INFORMATION SUCH AS AN

INSTRUCTIONS MANUAL, LABELS, ETC. CONTACT THE MANUFACTURER.

WARNING:

FIRE, BURN, INHALATION, AND EXPLOSION HAZARD. KEEP SOLID

COMBUSTIBLES, SUCH AS BUILDING MATERIALS, PAPER OR CARDBOARD, A

SAFE DISTANCE AWAY FROM THE HEATER AS RECOMMENDED BY THE

INSTRUCTIONS. NEVER USE THE HEATER IN SPACES WHICH DO OR MAY

CONTAIN VOLATILE OR AIRBORNE COMBUSTIBLES, OR PRODUCTS SUCH AS

GASOLINE, SOLVENTS, PAINT THINNER, DUST PARTICLES OR UNKNOWN

CHEMICALS.

WARNING:

NOT FOR HOME OR RECREATIONAL VEHICLE USE.

This heater is designed and approved for use as a

construction heater under ANSI Z83.7 2000 and

CSA 2.14 2000 Gas Fired Construction Heaters for indoor use

Only.

We cannot anticipate every use which may be made

of our heaters. CHECK WITH YOU LOCAL FIRE

SAFETY AUTHORITY IF YOU HAVE QUESTIONS

ABOUT APPLICATIONS.

Other standards govern the use of fuel gases and heat

producing products in specific applications. Your local

authority can advise you about these.

- 2 -

Page 3

WARNING:

INTENDED USE IS PRIMARILY THE TEMPORARY HEATING OF BUILDINGS

UNDER CONSTRUCTION, ALTERATION, REPAIR OR EMERGENCIES ONLY.

ALWAYS PROVIDE ADEQUATE VENTILATION. 1 SQ. IN. OF FRESH AIR MUST

BE SUPPLIED FOR EVERY 1000 BTUH OF HEAT.

THIS HEATER SHALL BE INSTALLED SUCH THAT IT IS NOT DIRECTLY

EXPOSED TO WATER SPRAY, RAIN AND/OR DRIPPING WATER.

MINIMUM CLEARANCE TO COMBUSTIBLES

TOP: 48 inches

SIDES: 30 inches

BOTTOM: 0 inches

INLET PRESSURES

FRHR-100N Natural gas MINIMUM Supply Pressure 7" W.C.

MAXIMUM Supply Pressure 14" W.C.

FRHR-100P/PQD Propane MINIMUM Supply Pressure 11" W.C.

MAXIMUM Supply Pressure 14" W.C.

MAINTENANCE

1. This construction heater should be inspected before each use. All burner ports should remain clear and the

valve should be inspected for any possible damage. The heater should be test fired before each use. High

pressure air may be used to blow out the inside of the burner.

2. The heater should be inspected annually by a qualified service person.

3. The heater must be kept clear and free from combustible materials, gasoline and other flammable vapors

and liquids.

4. The hose assembly shall be visually inspected prior to each use of the heater. If it is evident there is

excessive abrasion or wear, or the hose is cut, it must be replaced prior to the heater being put into

operation. The replacement hose assembly shall be supplied by Flagro Industries Limited. Please see Parts

List.

- 3 -

Page 4

INSTALLATION

All natural gas heaters must be installed by a qualified gas fitter and must conform to local installation codes or, in

the absence of local codes, with the National Fuel Gas Code ANSI Z223.1/NFPA 54 and the Natural Gas and

Propane Installation Code, CSA B149.1. The natural gas heater is provided with a ½" male quick disconnect fitting.

The hose assembly used to install this heater must be a Type 1 CGA/AGA approved hose assembly equipped with a

½" female quick disconnect socket to mate with the inlet fitting. Before lighting the heater, all connections must be

leak checked using a soap and water solution. The heater must be installed on a level surface.

FOR A HEATER CONNECTION TO AN LP-GAS SUPPLY CYLINDER

1. The installation must conform with local codes or, in the absence of local codes, to the Standard for the

Storage and Handling of Liquefied Petroleum Gases, ANSI/NFPA 58 and the Natural Gas and Propane

Installation Code, CSA B149.1.

2. The hose assembly used to install this heater must be a Type 1 CGA/AGA approved hose assembly. The

heater must be located at least 20-ft (6.10m) from any LP-gas cylinder.

3. The heater should be installed using a LP-gas cylinder with a minimum capacity of 30-lbs up to a

maximum capacity of 100-lbs.

4. The cylinders used to supply this heater must provide for vapor withdrawal only.

5. The heater must be connected with a “low pressure” regulator and POL inlet fitting. The POL fitting is

connected to the LP-gas cylinder by turning the POL nut counter clockwise and tightened using a wrench.

All connections must be checked for leaks using a soap and water solution or approved leak detector

solution. Use a wrench and turn the POL nut clockwise to disconnect the heater from the cylinder.

6. The cylinder must be disconnected from the heater when not in use.

7. The heater is to be stored indoors, the connection between the LP-gas supply cylinder(s) and the heater

must be disconnected and the cylinder(s) removed from the heater and stored in accordance with Chapter 5

of the Standard for the Storage and Handling of Liquefied Petroleum Gases, ANSI/NFPA 58 and CSA

B149.1, Natural Gas and Propane Installation Code.

- 4 -

Page 5

LIGHTING INSTRUCTIONS

1. Ensure the heater is connected to the proper source of gas and proper

inlet pressures are supplied. The heater must be installed by a

qualified installer.

2. Set thermostat knob (green button) to high position. Rotate the control

knob (black) counter clockwise to 'PILOT' position. Depress and hold

control knob.

3. Light the pilot burner using a long reach lighter through lighting hole

provided.

Release the knob after 60 seconds. Pilot will remain lit. Main burner

will remain off.

4. Turn control knob counterclockwise to 'ON' position. Main burner

will light.

5. If the main burner fails to light, turn the control knob clockwise to the

'OFF' position, wait 5 minutes and repeat step 3.

6. The green knob controls the thermostat option. This will light and

extinguish the main burner as the temperature fluctuates.

SHUT OFF INSTRUCTIONS

1. Turn the control knob clockwise to the 'OFF' position. Both main

burner and pilot burners will extinguish.

2. Turn off source of fuel.

- 5 -

Page 6

IMPORTANT NOTES FOR SUCCESSFUL LIGHTING AND OPERATIONAL SAFETY

1. For safety purposes, this heater model is equipped with a “tip over switch” which will prevent the heater from

operating or being lit if it is bumped, jarred, knocked over or positioned on an angle. In order to light and

operate properly, this heater MUST be placed on a flat horizontal surface in an upright position.

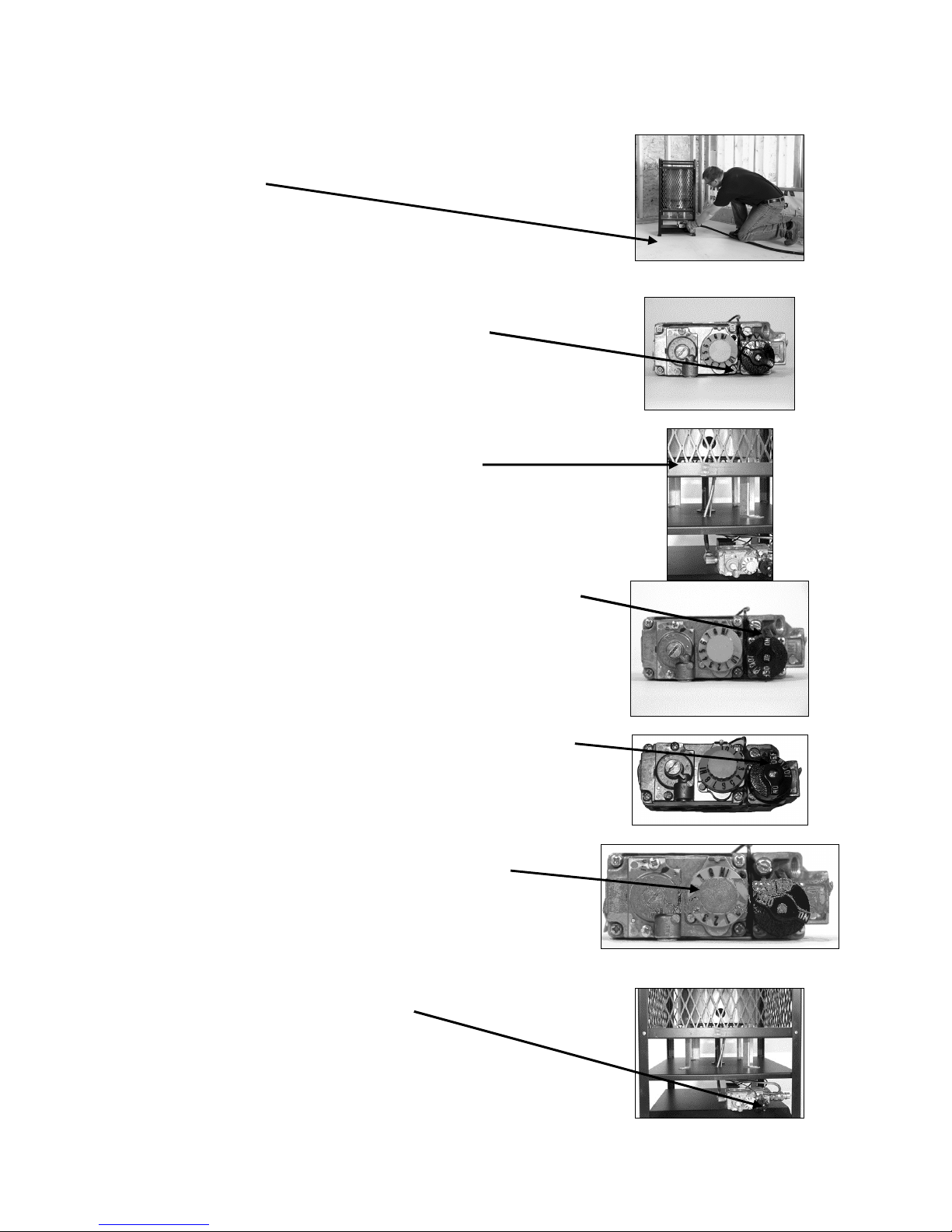

CORRECT POSITION

2. The tip over switch is interlocked with the

thermocouple. The connections on the

thermocouple switch must be kept clean and tight at

all times to ensure proper operation of these

components.

Thermocouple block

Tip over switch

3. While the heater unit does not require a filter, the unit must be kept clean and

the burner and pilot assembly must be kept free of dust and dirt to ensure

optimal and safe operation at all times

Store the unit in a clean environment and make sure that the unit is leak

checked and cleaned before every use. Do not clean the unit with volatile

substances. (see maintenance on Page 3)

INCORRECT POSITION

- 6 -

Page 7

PARTS DIAGRAM FRHR-100P/N

FRHP-08R

FRHP-12

T-18

FRHP-02LP

FRHP-02NG

FRHP-05RLP

FRHP-05RNG

FRHP-07RLP

FRHP-07RNG

Page 8

VALVE INLET - LP

VALVE INLET - NG

FRHP-01LP FRHP-01NG

FRHP-10

49-6C

T-18

FRHP-03A

FRHP-23

48-6C (SAE)

122-C/100-506

(QD)

122-DC/100-508

FRHP-04A

FRHP-09BR

FRHP-09

FRHP-18

Page 9

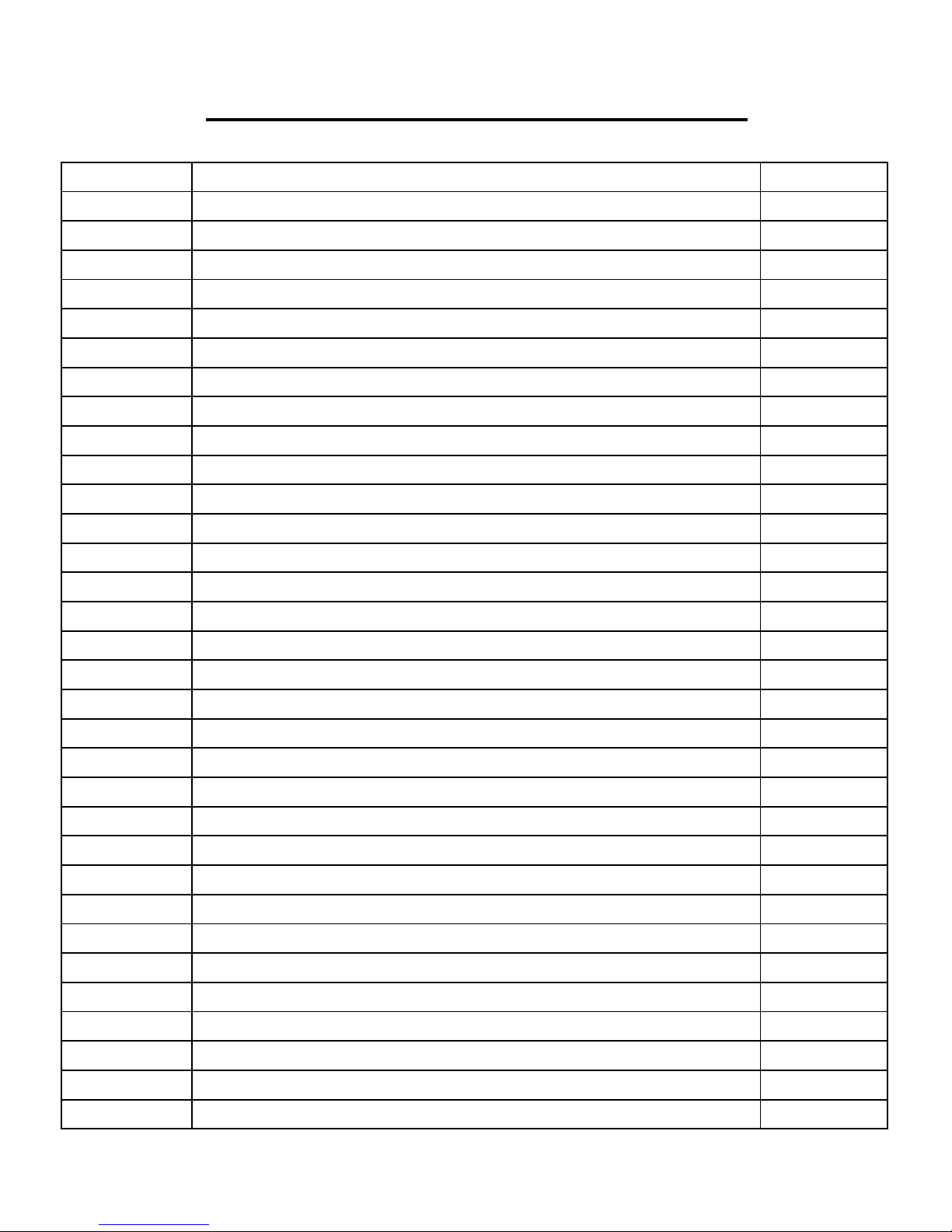

PARTS LIST FOR FRHR-100N/P/PQD

Part Number Part Description

FRHP-01NG GAS CONTROL VALVE C/W THERMOSTAT - NG

FRHP-01LP GAS CONTROL VALVE C/W THERMOSTAT - LP

FRHP-01WR GAS CONTROL VALVE NO THERMOSTAT

FRHP-02NG PILOT ASSEMBLY - NG

FRHP-02LP PILOT ASSEMBLY - LP

FRHP-03 PILOT LINE (1999 - 2003)

FRHP-03A PILOT LINE (CURRENT)

FRHP-03WR PILOT LINE (FOR USE WITH WR CONTROL)

FRHP-04A CUT-OFF SWITCH

T-18 18" THERMOCOUPLE

FRHP-05 BURNER ASSEMBLY (FOR OLD FRH-100)

FRHP-05RLP BURNER ORIFICE LP (CURRENT)

FRHP-05NG BURNER ORIFICE NG (CURRENT)

FRHP-06LP BURNER ORIFICE LP (FOR OLD FRH-100)

FRHP-06NG BURNER ORIFICE NG (FOR OLD FHH-100)

FRHP-07RLP BURNER ASSEMBLY- LP (CURRENT)

FRHP-07RNG BURNER ASSEMBLY - NG (CURRENT)

FRHP-08R STAINLESS EMITTER GRID (CURRENT)

FRHP-09 TIP-OVER SWITCH C/W WIRE

FRHP-10 3/8" LOW PRESSURE FIRE LINE C/W FLARE NUTS

FRHP-10WR

FRHP-11 REDUCING NIPPLE 1/2" X 3/8"

FRHP-12 SAFETY SCREEN ASSEMBLY (TWO REQUIRED)

FRHP-13A TWO STAGE REGULATRO - LP

FRHP-13A SINGLE STAGE REGULATOR - C/W POL

FRHP-14 BRASS ELBOW C/W TEST POINT (USE FOR WR CONTROL)

FRHP-15 NG REGULATOR (USE FOR W R CONTROL)

FRHP-16 3/8" X 5" NIPPLE (USE FOR WR CONTROL)

3/8" LOW PRESSURE FIRE LINE C/W FLARE NUTS (FOR W R CONTROL)

FRHP-17 1/2" NG REGULATOR (5PSI MAX)

FRHP-18 THERMO BULB BRACKET C/W GROMMETS

FRHP-19 BLACK CONTROL KNOB (FOR WR CONTROL)

FRHP-20 3/4" NG REGULATOR (5 PSI MAX)

Page 10

FRHP-21 1/4" COMPRESSION NUT & SLEEVE FOR PILOT LINE

FRHP-22 1/4" EXTENDED BREAKAWAY FOR PILOT LINE

FRHP-50 CONVERSION KIT FOR FRHR NG TO LP (CDN)

FRHP-51 CONVERSION KIT FOR FRHR LP TO NG (CDN)

FRHP-52 CONVERSION KIT FOR FRHR LP TO NG (USA)

FRHP-53 CONVERSION KIT FOR FRHR NG TO LP (USA)

S52600-12 3/4ID MNPT X MNPT 50FT HOSE ASSEMBLY

2103-E-CGA 3/4" FNPT BALL VALVE

100-006 3/8" QUICK DISCONNECT SOCKET - FEMALE

100-506 3/8" QUICK DISCONNECT PLUG - MALE

100-008 1/2" QUICK DISCONNECT SOCKET - FEMALE

100-508 1/2" QUICK DISCONNECT PLUG - MALE

100-010 3/4" QUICK DISCONNECT SOCKET - FEMALE

100-510 3/4" QUICK DISCONNECT PLUG - MALE

ACCESSORIES

NG HOSE ASSEMBLY - C/W 50FT X 3/4" TYPE 1 , 3/4" BALL VALVE, 1/2"

FRHP-101

FRHP-101600LP

MAN-E1 SINGLE MANIFOLD - ENBRIDGE

MAN-E2 DUAL MANIFOLD - EMBRIDGE

MAN-U1 SINGLE MANIFOLD - UNION GAS

MAN-U2 DUAL MANIFOLD - UNION GAS

FEMALE QD SOCKET & 3/4" MALE QD PLUG

LP HOSE ASSEMBLY - C/W 50FT 1/2" TYPE 1 HOSE, 1/2" BALL VALVE, 3/8"

FEMALE QD SOCKET & FITTED REGULATOR

Loading...

Loading...