Page 1

Direct Vent Fireplace Insert

Jøtul GI 535 DV IPI

New Harbor

High Altitude Adjustment

Instructions

Kit 157886 Manual Valve - LP

Kit 157887 Manual Valve - NG

This kit shall be installed by

a qualified service agency in

accordance with the manufacturer’s

instructions and all applicable

codes and requirements of the

authority having jurisdiction. If the

information in these instructions

is not followed exactly, a fire,

explosion, or production of carbon

monoxide may result causing

property damage, personal

injury or loss of life. The qualified

service agency is responsible for

the proper installation of this kit.

The installation is not proper and

complete until the operation of

the adjusted appliance is checked

as specified in the manufacturer’s

instructions supplied with the kit.

Cet équipement de conversion sera

installé par une agence qualifiée de

service conformément aux instructions du fabricant et toutes exigences

et codes applicables de l’autorisés

avoir la juridiction. Si l’information

dans cette Instruction n’est pas suivie

exactement, un feu, explosion ou production de protoxyde de carbone peut

résulter le dommages causer de propriété, pert ou blessure personnelle

de vie. L’agence qualifiée do service

est esponsable de l’installation propre de cet équipemetn. L’installation

n’est pas propre et complète jusqu’à

l’operation de l’appareil converi est

chéque suivant les critères établis

dans les instruction de propriétaire

provision nées avel l’équipement.

CAUTION: Before proceeding

with this conversion, the gas

supply must be shut off prior to

disconnecting the electrical power.

Jøtul North America, Inc. 55 Hutcherson Dr. Gorham, Maine 04038

ATTENTION: Avant de procéder à cette

conversion, l’approvisionnement en

gaz doit être coupée avant de débrancher l’alimentation électrique.

May, 2016 139778_R01

Page 2

High Altitude Adjustment

When installing this appliance at altitude above 2000

feet, it is necessary to compensate for the thinner air

(less volume of air per cubic foot). Higher altitudes affect

the atmospheric pressure and heat value of gaseous

fuels. The lower oxygen content in the air and the lower

gas viscosity require the use of a different orifice to

achieve efficient, clean combustion at the burner tube.

In the U.S.

THE DERATING KIT MUST BE INSTALLED BY AN AUTHORIZED SERVICE TECHNICIAN IN ACCORDANCE WITH THE

MANUFACTURER’S INSTRUCTIONS AND ALL CODES AND

REQUIREMENTS OF THE AUTHORITY HAVING JURISDICTION. THE INFORMATION STICKER MUST BE FILLED OUT

BY THE INSTALLER AND APPLIED TO THE APPLIANCE AT

THE TIME OF THE CONVERSION. THE QUALIFIED SERVICE

AGENCY PERFORMING THIS WORK ASSUMES RESPONSIBILITY FOR THIS DE-RATING.

In Canada

This unit has been tested for installation at high altitudes in accordance with Canadian test standard CAN/

CGA-2.17. THE DERATING SHALL BE CARRIED OUT IN

ACCORDANCE WITH THE REQUIREMENTS OF THE PROVINCIAL AUTHORITIES HAVING JURISDICTION AND IN

ACCORDANCE WITH THE REQUIREMENTS OF THE CAN1B-149.1 AND .2 INSTALLATION CODE.

GAS

NATURAL

GAS

PROPANE

Table 1. High Altitude Orifice Chart.

THIS APPLIANCE HAS BEEN CONVERTED FOR USE

AT AN ALTITUDE OF ______________________

Orifice Size: _______ Manifold Press: ________

Input, BTU/Hr: ________ Fuel Type: _________

Date of Conversion: ______ / _______ / ______

Figure 1. High Altitude Conversion Notice Label

ORIFICE SIZE

#48 - Left

#49 - Right

#56 - Left

#57 - Right

ELEVATION

2001’- 4500’

(611 - 1170 m)

2001’- 4500’

(611 - 1170 m)

220977 - Right

A

JØTUL PART

NO.

229407 - Left

129411 - Right

129466- Left

A

High Altitude Installations:

2000 ft. to 4500 ft. installations (or 610 m - 1370 m)

See Table 1.

For high altitude installations consult the local gas

distributor or the authority having jurisdiction for proper

rating methods. If the installer must convert the unit

to adjust for varying altitudes, the information label

included with this kit must be completed by the installer

and applied to the appliance at the time of the conversion. See fig. 1.

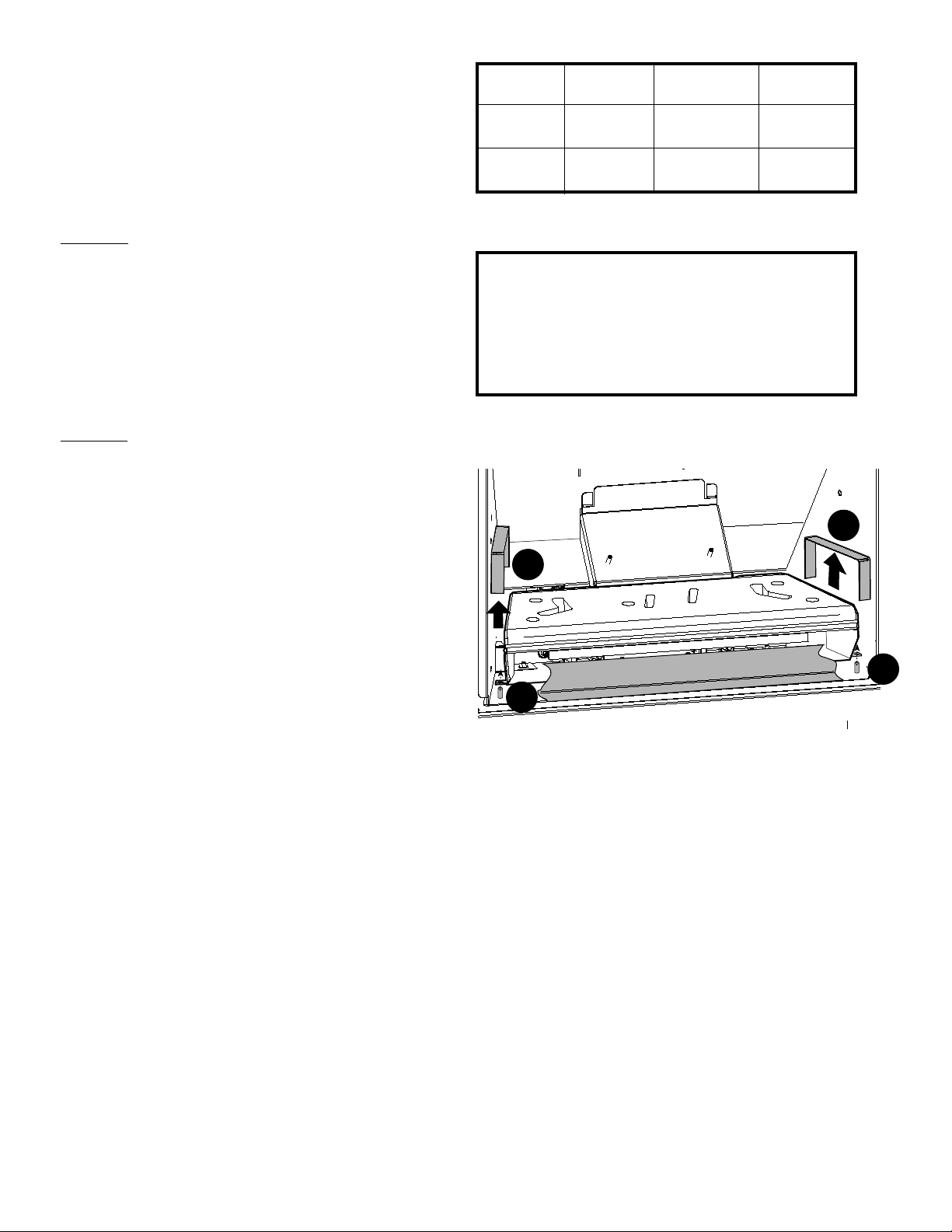

Derating procedure

1. Turn off the gas supply and electrical power to the

appliance.

2. Use the Latch Tool to remove the glass frame.

3. RETRACT THE AIR SHUTTERS: Locate the Air Shutter

cables on the floor in each side compartment - push each

cable fully in. This action retracts the shutters and allows

the burner to be disengaged from the firebox. See fig. 3.

4. REMOVE THE BURNER:

Lift out the two steel support shelves, fig. 2, (A),

located at each side of the burner. Grasp the burner

assembly at the sides, lifting it straight up, then tilt

it back to disengage it from the injectors and front

locator studs (B). Pull the assembly up out of the

firebox.

B

B

Figure 2. Burner removal and replacement.

5. Use a 1/2” deep well socket or open end wrench to

remove the original injectors and replace with the

appropriate ones from this kit as specified in Table 1

above.

6. Attach the high altitude conversion sticker provided to

the rating plate on the appliance. See figure 1.

7. REINSTALL THE BURNER ASSEMBLY. Tilt the back of

the burner down to engage the air shutters with the

injectors. Set the burner in place, engaging the front

brackets with the studs in the firebox floor, fig. 1, (B).

Replace the steel side support shelves, fig. 1, (A).

BE CERTAIN THE BURNER IS LEVEL AND SECURELY

SEATED ON THE FIREBOX FLOOR. Properly located, it

should not be able to move in any direction.

8. Use an electronic gas detector or soap solution to test

for leaks at the pilot head and all gas line joints.

NEVER USE AN OPEN FLAME TO CHECK FOR GAS LEAKS.

2

Page 3

Figure 3. Injector conversion.

Pilot Assembly

Front Burner Air

Shutter Cable

Front Burner

Injector

Air Shutter

Adjustor Trays

Rear Burner

Injector

Rear Burner Air

Shutter Cable

Gas Pressure Check

Correct gas pressure is essential for efficient and safe

operation of the stove. It is important that the correct

pressure is established at the time of the installation.

Proper gas pressure provides a consistent flow of gas to

the appliance and is instrumental in checking for gas

leaks.

Pressure Test: Attach a manometer to the

appropriate test point on the valve. See fig. 4. The

gauge connections are located on the front of the valve.

Connections are identified by:

E - for Inlet or Supply Pressure (the amount of gas

coming to the valve.)

A - for Manifold Pressure (the amount of gas that

is coming out of the valve to the burner.)

Figure 4.

Pressure test points.

ManifoldInlet

OUT

INLET GAS PRESSURES

(inches water column)

MIN MAX

NATURAL GAS 5.0 7.0

PROPANE 12.0 14.0

The appliance and its appliance main gas valve

must be disconnected from the gas supply piping

system during any pressure testing on that system

at test pressures in excess of 1/2 psig (3.5 kPa).

The appliance must be isolated from the gas

supply line by closing its individual manual gas

shut-off valve (gas cock) during any pressure testing

of the gas supply piping system that is equal to or

exceeds pressures of 1/2 psig (3.5 kPa).

MANIFOLD PRESSURES

(inches water column)

MIN MAX

NATURAL GAS 1.1 3.8

PROPANE 2.9 11.0

Integrated Gas Cock

An in-line gas cock is built into the left side firebox

compartment, just upstream from the gas valve. Use

the fireplace Latch Tool to open and close the gas cock.

See figs. 5 an 6 on page 4.

Pilot Adjustment

3

Page 4

Figure 5.

Insert the Latch Tool into the receiver hole in

the gas cock.

Fig. 6. Pull the tool forward toward you to open the gas

cock. Push it back to close the gas cock.

4

Loading...

Loading...