Intertec Data Systems WST Series, WST50 EL, WST80 EL, WST119 EL Installation And Maintenance Instructions Manual

Solar DHW Tank / Ballon d'eau chaude solaire

WST Series

Notice:

The heat transfer medium must be nontoxic water with Toxicity Class 1 as

listed in "Clinical Toxicology of Commercial Products," 5th edition.

The heat transfer medium must be limited to a maximum pressure of 30 PSIG

by an approved safety or pressure relief valve.

Avis :

Le liquide caloporteur doit être de l'eau non toxique de classe 1 telle que

précisé dans la 5e édition de « Clinical Toxicology of Commercial Products ».

Le liquide caloporteur doit être limité à une pression maximale de 30 PSIG par

une soupape de sécurité ou de surpression homologuée.

6 720 648 083-00.1ITL

WST50 EL / WST80 EL / WST119 EL

[en] Installation and maintenance instructions for the contractor 2

[fr] Notice d'installation et d'entretien pour installateurs professionnels 20

WARNING:

These installation instructions are intended solely for use by a licensed heating

contractor or service technician. Read all

instructions before installing. Perform

steps exactly in the order given. Failure to

follow these instructions can result in severe injury, death or property damage.

6 720 648 081 (2012/09) US/CA

Conforms to UL 174, IAS 1-91

Certified to CSA C22.2 no. 110

AVERTISSEMENT:

Cette notice d'installation doit être utilisée

uniquement par des installateurs chauffagistes ou des techniciens de maintenance

qualifiés. Lisez attentivement toutes les

consignes avant l'installation. Exécutez les

actions en respectant scrupuleusement

l'ordre indiqué. En cas de non-respect,

vous risquez de subir de sérieuses blessures pouvant conduire à la mort ou d'entraîner de lourds dommages matériels.

Table of Contents

Table of Contents

1 Explanation of symbols and safety information . . . . . . . . 2

1.1 Explanation of symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 Important safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 Product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1 Pack contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.4 Rating plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.5 Tools, Materials and Accessories . . . . . . . . . . . . . . . . . . . . . . 5

2.6 Symbols and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.7 Dimensions and connections . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.8 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.9 Pressure Drop Curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Moving the Solar Storage Tank . . . . . . . . . . . . . . . . . . . . . . 9

4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1 Solar Storage Tank Installation . . . . . . . . . . . . . . . . . . . . . . . 9

4.1.1 Requirements for installation location . . . . . . . . . . . . . . . . . . 9

4.1.2 Positioning the DHW tank . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.2 Attaching the Bosch solar pump station (optional) . . . . . 10

4.3 Water connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.3.1 Installation example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.3.2 Pipe connections to the heat source and DHW network . 11

4.3.3 Temperature and Pressure Relief Valve (TPR)

Blow-off Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.3.4 Checking for leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.4 Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.4.1 Making electrical connections . . . . . . . . . . . . . . . . . . . . . . 13

4.4.2 Grounding Instructions / Connecting the electric heating

element electrically . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.4.3 Setting the electric heating element . . . . . . . . . . . . . . . . . 13

4.4.4 Installing the DHW temperature sensor . . . . . . . . . . . . . . . 14

10 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

10.1 Additional terms and conditions of the limited warranty

for domestic hot water tanks (for all applications) . . . . . . 18

10.2 Limited warranty for domestic hot water tank installed

in a commercial application . . . . . . . . . . . . . . . . . . . . . . . . 18

10.3 Additional terms and conditions of the limited warranty

for domestic hot water tanks (for all applications) . . . . . . 18

1 Explanation of symbols and safety

information

1.1 Explanation of symbols

Warnings

Warnings are indicated in the text by a warning triangle

and a gray background.

In case of danger due to electric shock, the exclamation

point on the warning triangle is replaced with a lightning

symbol.

Signal words at the beginning of a warning are used to indicate the type

and seriousness of the ensuing risk if measures for minimizing damage

are not taken.

• NOTICE indicates that minor damage to property may occur.

• CAUTION indicates possible minor to medium personal injury.

• WARNING indicates possible severe personal injury.

• DANGER indicates that severe personal injury may occur.

Important information

Important information that presents no risk to people or

property is indicated with this symbol. It is separated by

horizontal lines above and below the text.

5 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.1 Commissioning the solar storage tank . . . . . . . . . . . . . . . . 14

5.2 System installer to inform the owner/operator . . . . . . . . . 14

6 Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.1 Shutting down the solar storage tank . . . . . . . . . . . . . . . . 15

6.2 Shutting down the solar storage tank when there is a

risk of frost . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7 Environmental Protection / Disposal . . . . . . . . . . . . . . . 15

8 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

8.1 Checking the magnesium anodes . . . . . . . . . . . . . . . . . . . 15

8.2 Restarting the solar storage tank after maintenance . . . . 16

9 Spare parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2

Additional symbols

Symbol Meaning

B Sequence of steps

Æ Cross-reference to other points in this document or to

other documents

• Listing/list entry

– Listing/list entry (2nd level)

Table 1

1.2 Important safety instructions

WARNING – When using electrical appliances, basic safety precautions

to reduce the risk of fire, electric shock, or injury to persons should be

followed, including:

1. READ ALL INSTRUCTIONS BEFORE USING THIS WATER HEATER.

2. This water heater must be grounded. Connect only to properly

grounded outlet. See "GROUNDING INSTRUCTIONS" found on section

4.4.2.

3. Install or locate this water heater only in accordance with the provided

installation instructions.

4. Use this water heater only for its intended use as described in this

manual.

WST50 EL / WST80 EL / WST119 EL – 6 720 648 081 (2012/09)

Explanation of symbols and safety information

5. Do not use an extension cord set with this water heater. If no

receptacle is available adjacent to the water heater, contact a qualified

electrician to have one properly installed.

6. As with any appliance, close supervision is necessary when used by

children.

7. Do not operate this water heater if it has a damaged cord or plug, if it

is not working properly, or if it has been damaged or dropped.

8. This water heater should be serviced only by qualified service

personnel. Contact nearest authorized service facility for examination,

repair, or adjustment.

SAVE THESE INSTRUCTIONS

Read all instructions before installing. Perform steps in the order given.

Have this indirect water heater serviced/inspected by a qualified service

technician, at least annually. Failure to comply with the above could

result in severe personal injury, death or substantial property damage.

Installation and conversion

B Risk of fire through soldering and welding!

Take appropriate protective measures when soldering and welding as

the thermal insulation is flammable; for example, cover the thermal

insulation.

B Ensure that the solar storage tank is installed or converted only by an

authorized contractor.

B Use installation materials that are sufficiently heat-resistant.

Installation and commissioning

B In the Commonwealth of Massachusetts this tank must be installed by

a licensed plumber or gas fitter.

B The power supply must be connected by a licensed electrician. The

wiring diagram must be followed.

B Do not install this device in rooms with high moisture exposure (e.g.

bathrooms, saunas).

Function

B Observe these installation and maintenance instructions to ensure

trouble-free operation.

B Never close the blow-off line of the safety relief valve. During heating,

water may be ejected for safety reasons.

Danger from electric shock

B Ensure that all electrical work is carried out only by a licensed

electrician.

B Before removing the jacket, disconnect all poles from the solar

storage tank and secure against unintentional reconnection.

Risk of burns due to hot surfaces!

B Ensure that the piping of the solar thermal system is insulated

adequately.

Using the electric heating element

B Ensure that all electrical work is carried out only by a licensed

electrician.

B Before starting electrical work, disconnect all poles from the power

supply and secure against unintentional reconnection.

B Ensure the system has been disconnected from the power supply.

Risk of scalding at the hot water taps

B When the solar storage tank is in operation, temperatures in excess of

122 °F (50 °C) can occur. To limit the temperature at the tap, install a

thermal DHW tempering valve.

B Water heated to temperatures for clothes washing, dish washing, and

other sanitizing needs can scald and cause permanent injury.

B Children, elderly, and handicapped persons are more likely to be

permanently injured by hot water. Never leave them unattended in a

bathtub or shower. Never allow small children to use a hot water tap

or draw their own bath.

B If anyone using hot water in the building fits the above description, or

if state laws or local codes require certain water temperatures at hot

water taps, you must take special precautions:

– Use lowest possible temperature setting.

– To prevent scalding, install a tempering device, such as an

automatic mixing valve, at the hot water tap or the water heater.

Automatic mixing valves must be selected and installed according

to valve manufacturers recommendations and instructions.

B Water exiting from drain valves may be extremely hot. To avoid injury:

– Make sure all connections are tight.

– Direct water flow away from any person.

B Measures must be taken to protect against excessive temperature and

pressure! Installation of a temperature and pressure relief valve (TPR)

is required.

The following chart details the relationship between water temperature

and time for a scalding injury to occur. It can be used to determine the

safest water temperature for your application.

Temperature Time to produce serious burn

120 °F (48 °C) More than 5 minutes

125 °F (51 °C) 1.5 to 2 minutes

130 °F (54 °C) About 30 seconds

135 °F (57 °C) About 10 seconds

140 °F (60 °C) Less than 5 seconds

145 °F (62 °C) Less than 3 seconds

150 °F (65 °C) About 1.5 seconds

155 °F (68 °C) About 1 second

Table 2 Approximate time / temperature relationship for scalding to

occur

For operation with the electric heating element observe the following

points in order to maintain the corrosion protection and to adhere to the

guidelines for electrical safety:

B Do not operate electrically heated solar storage tanks with an inert

anode.

B Use metal connection fittings in potable water heating systems with

plastic lines.

B Use only the original electric heating element.

B When installation of the tank is complete, inspect the ground

conductor (including metal connection fittings).

Maintenance

Customers are advised to:

B Sign a maintenance and inspection contract with an authorized

contractor. Have the solar storage tank inspected and, if required,

serviced annually.

B Only use genuine spare parts.

Overheating

Should overheating occur or the solar supply fail to shut off,

B Do not turn off or disconnect electrical supply to circulator.

B Do not operate the appliance if any part has been under water.

The possible damage to a flooded appliance can be extensive and

present numerous safety hazards.

B Any appliance that has been under water must be replaced.

WST50 EL / WST80 EL / WST119 EL – 6 720 648 081 (2012/09)

3

Product description

2 Product description

2.1 Pack contents

The solar storage tank is delivered fully assembled on a pallet.

The following parts of the standard delivery are packed separately in a

plastic bag:

• Feet for the solar storage tank

• Technical documentation

• 2x M6 Screws and washers for installing the solar pump station

• Clamping spring for DHW temperature sensor

2.2 Product description

The solar storage tank is equipped with an electric heating element.

Alternatively, the solar storage tank can be operated with a downstream

external tankless water heater.

When operated with an external tankless water heater, the electric

heating element must not be connected.

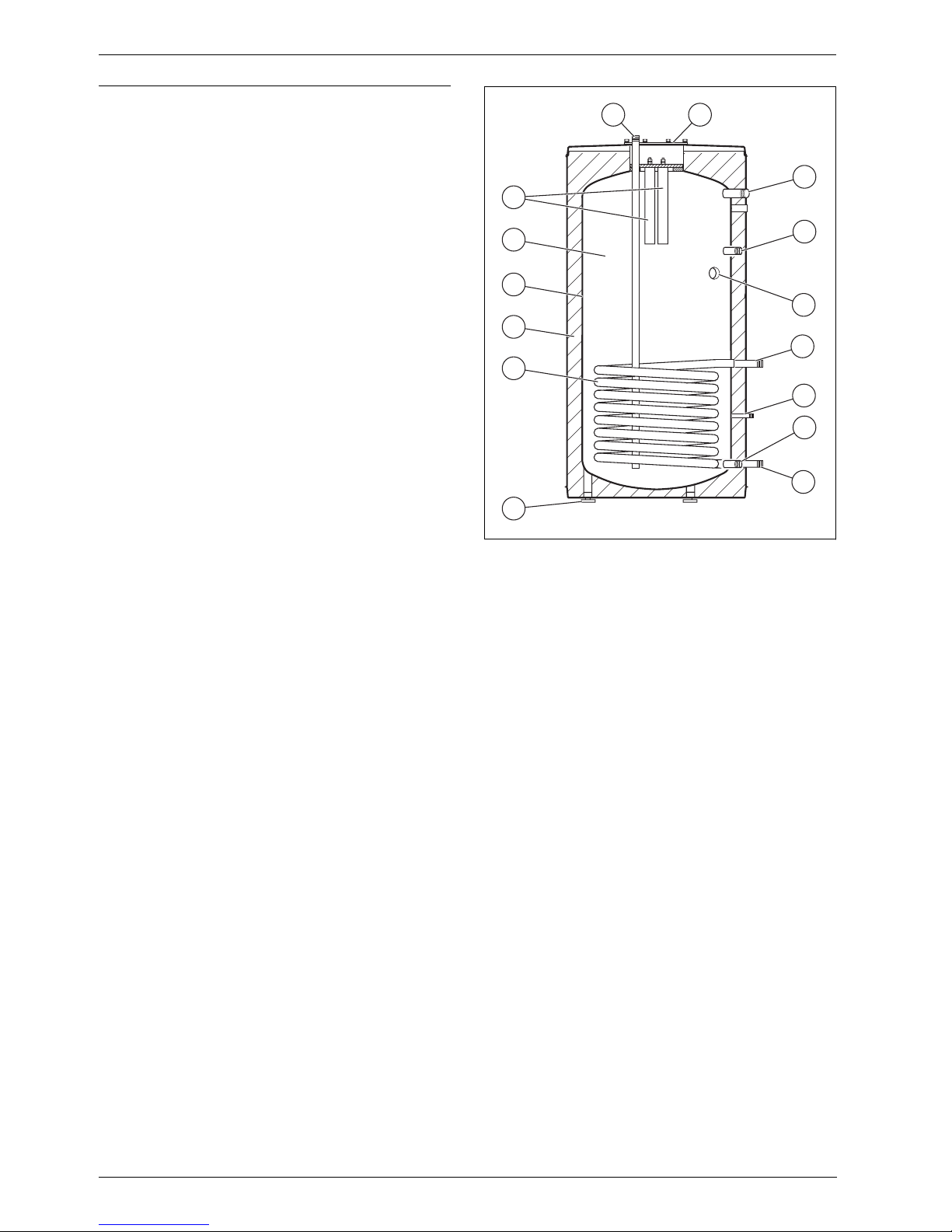

The main components of the solar storage tank are:

• Storage tank with corrosion protection

The cathodic corrosion protection comprises the hygienic thermo

glaze and two magnesium anodes.

• Smooth tube heat exchanger

The smooth tube heat exchanger transfers the energy from the solar

circuit to the DHW inside the storage tank. The potable water is

heated uniformly.

• Thermal insulation

The thermal insulation, made from CFC-free hard polyurethane foam,

is directly applied to the storage tank and insulates against heat loss.

• Sensor well with DHW temperature sensor

The optional DHW temperature sensor supplies temperature

information to an optional controller.

• Electric heating element

In addition to the solar thermal system, the electric heating element is

a backup heat source for DHW heating.

• Drain valve

The drain valve is used to drain the storage tank completely.

• Temperature and pressure relief valve (TPR)

The temperature and pressure relief valve protects the storage tank

against overheating and overpressure.

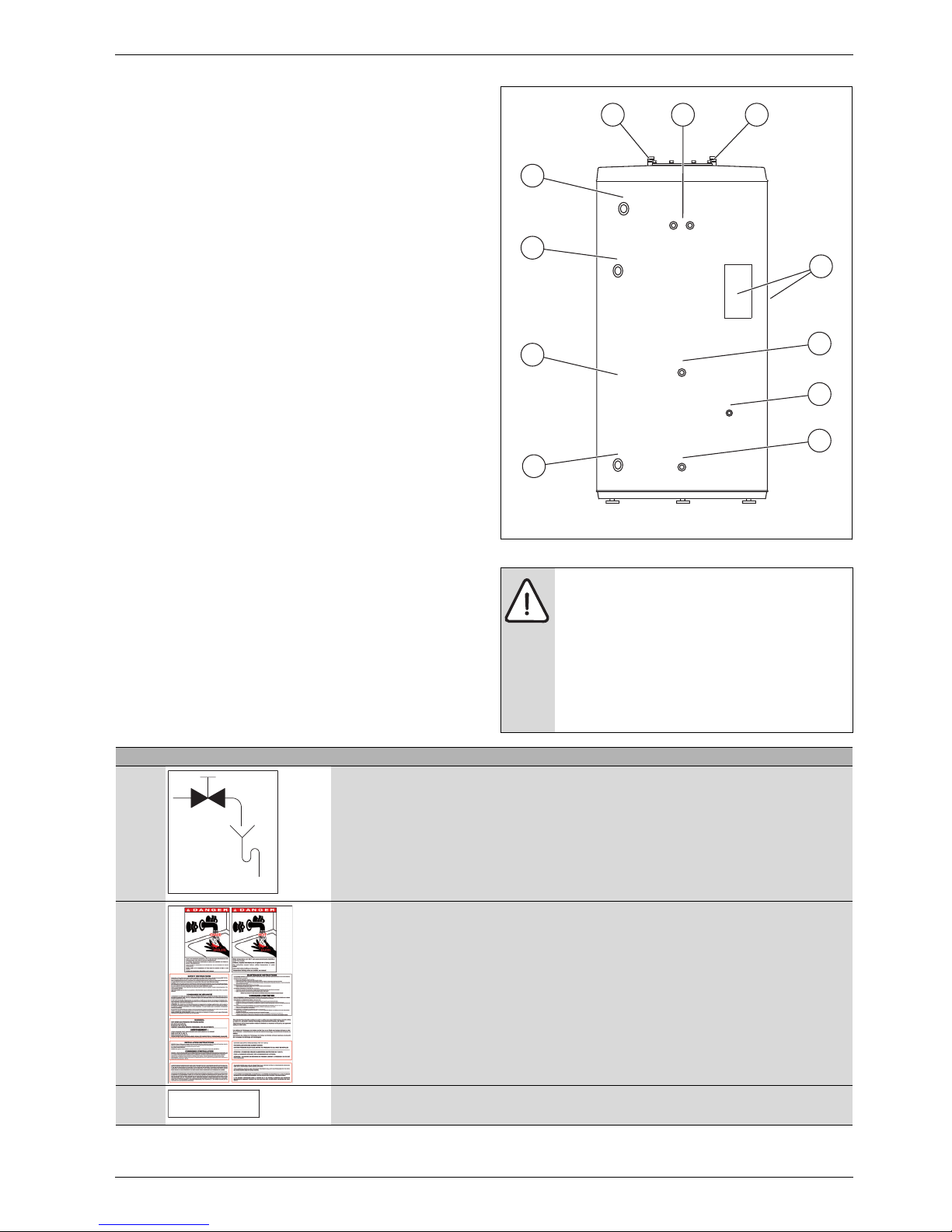

87

6

5

4

3

2

1

Fig. 1 Sectional view of solar storage tank

[1] Feet for the solar storage tank

[2] Smooth tube heat exchanger (solar thermal system)

[3] Thermal insulation

[4] Thermo glaze

[5] Storage tank

[6] Magnesium anodes

[7] Cold water inlet (EK) and hot water outlet (AW)

[8] Inspection cover

[9] Connection temperature and pressure relief valve (TPR)

[10] Connection DHW recirculation return

[11] Connection electric heating element

[12] Supply from solar thermal system

[13] DHW temperature sensor

[14] Drain valve

[15] Return to solar thermal system

6 720 648 083-01.3ITL

9

10

11

12

13

14

15

4

2.3 Intended use

The solar storage tank is used to heat and store potable water to supply

single- and multi-family homes. Please observe national, regional, and

local codes, regulations, guidelines and standards for potable water.

Heat the solar storage tank only by means of a heat transfer medium

(mixing ratio: heat transfer medium/water max 50/50) and only in

closed systems.

Install the solar storage tank only inside a building. The room must not be

exposed to freezing temperatures and the floor must be level.

Observe the specifications (Æ Chapter 2.8) to ensure proper use.

Any other purpose is considered improper use. Any resulting damage is

excluded from the manufacturer's warranty.

WST50 EL / WST80 EL / WST119 EL – 6 720 648 081 (2012/09)

2.4 Rating plate

The nameplate is located at the lower right on the front of the tank and

contains the following information.

• Model

• Type

• Serial no.

• Contents

• Maximum supply pressure

• Maximum operating pressure

• Maximum hot water operating temperature

• Mixing ratio: heat transfer medium/water

• Maximum operating pressure of solar thermal system

• Maximum heat transfer medium temperature

• Preset value for electric heating element

• Output of electric heating element

• Voltage for electric heating element

• Manufacturer's address

Product description

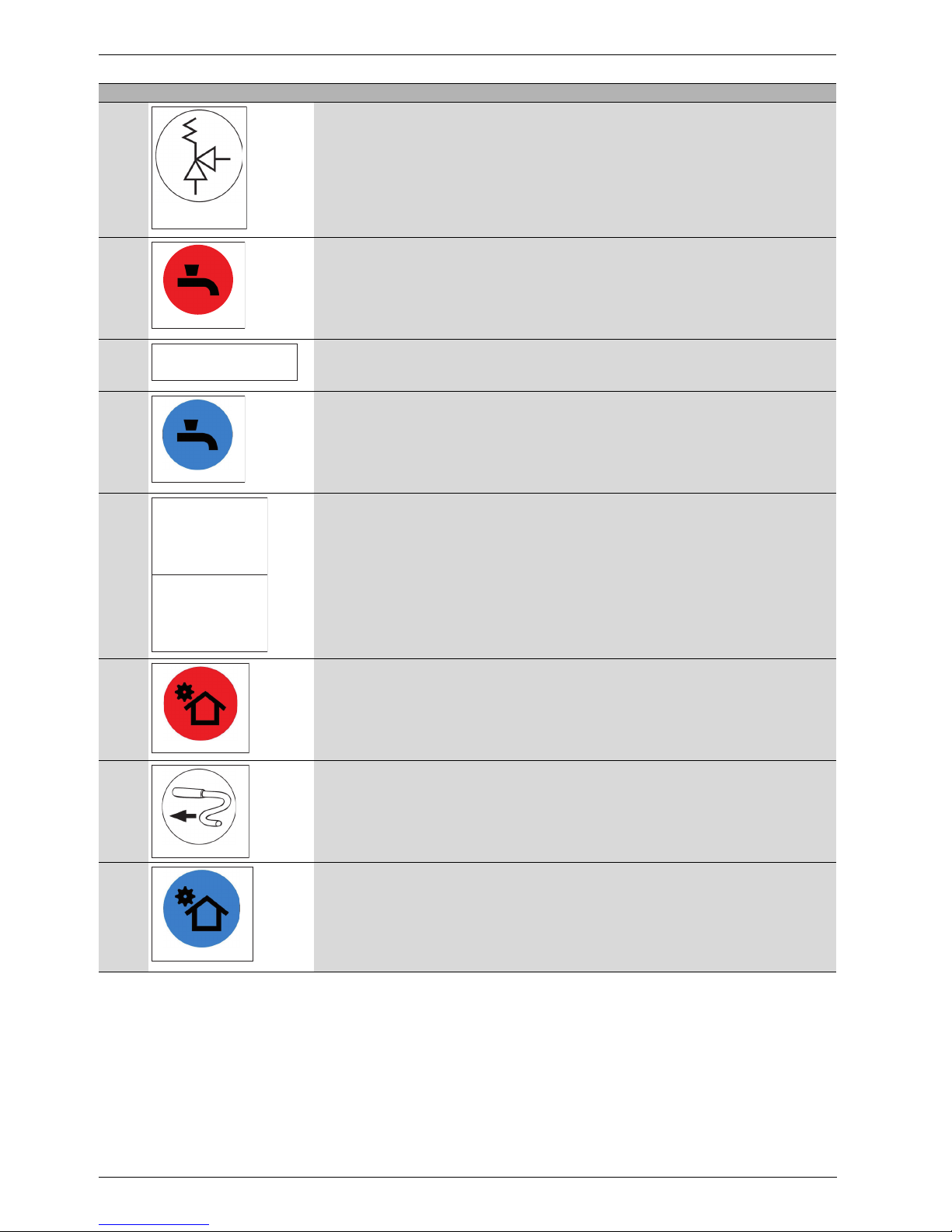

5 7

6

4

3

8

2

9

2.5 Tools, Materials and Accessories

You need only the standard tools typically used in gas and water

installations to install and maintain the solar storage tank.

A dolly with straps may also be useful.

2.6 Symbols and Warnings

The following symbols and warnings are attached to the storage tank.

They refer to their immediate surroundings.

Fig. 2 Symbol and warning locations

Pos. Symbol/warning Location on the storage tank

1 This symbol identifies the drain valve.

10

11

1

6 720 648 083-26.2ITL

WARNING: Risk of injury from illegible symbols and

warnings!

Labels and signs can become dirty or covered over time.

Dangers can then not be recognized or the necessary

procedures observed. This poses a risk of injury.

B All safety, warning and operating instructions must be

observed at all times and kept in legible condition.

B Damaged signs or labels must be replaced

immediately.

Drain valve

2 The warning label is located on the front of the solar storage tank and contains important information

3 This label is located at the recirculation connection.

Table 3 Symbols and Warnings

WST50 EL / WST80 EL / WST119 EL – 6 720 648 081 (2012/09)

Recirculation

about safe installation, use and maintenance of the storage tank.

5

Product description

Pos. Symbol/warning Location on the storage tank

4 This symbol is located at the temperature and pressure relief valve.

TPR-valve

5 This symbol is located at the upper left on the storage tank, next to the hot water outlet (AW).

Hot water out

6 This label is located at the position where the optional solar pump station is attached.

Optional: Solar station

7 This symbol is located at the upper right on the storage tank, next to the cold water inlet.

Cold water in

8 This warning label is located on the panel covering the electric heating element and on the distribution

Warning

Power supply to the

appliance should be

isolated before

removing this panel

box.

Avertissement

Alimentation de

l'appareil doivent

être isolés avant

de retirer ce panneau

9 This symbol is located at the supply from the solar thermal system.

From collector

10 This symbol is located at the position for the DHW temperature sensor of the solar controller.

Solar sensor

11 This symbol is located at the return to the solar thermal system.

To collector

Table 3 Symbols and Warnings

6

WST50 EL / WST80 EL / WST119 EL – 6 720 648 081 (2012/09)

Product description

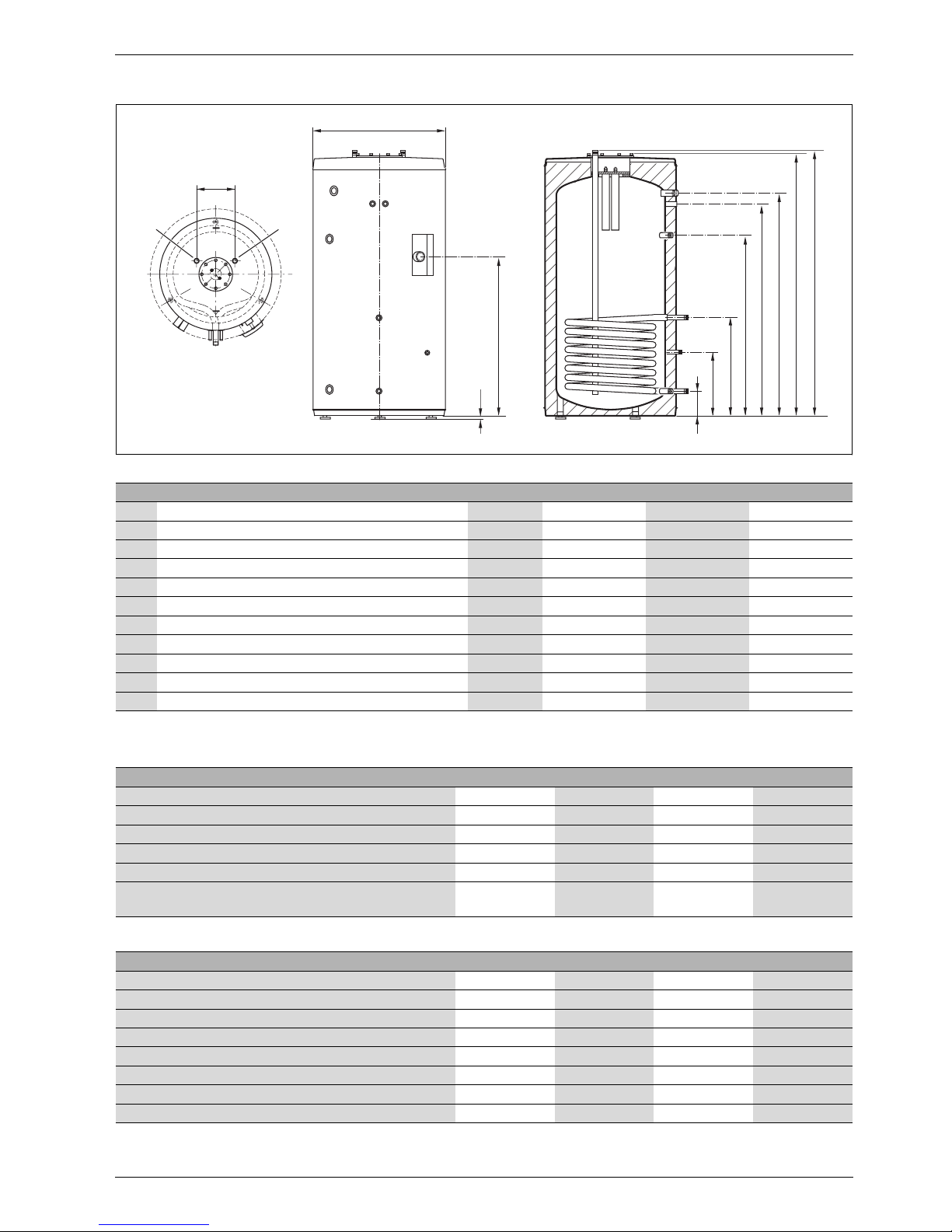

2.7 Dimensions and connections

A

205

8"

K

1

K

2

J

I

H

D

1

D

2

C

G

F

E

B

D

6 720 648 083-02.3ITL

Fig. 3 Connections and dimensions: (WST80 EL)

Dimension Unit WST50 EL WST80 EL WST119 EL

ADiameter in (mm) 23.6 (600) 27.6" (700) 29.5" (750)

B Feet for the solar storage tank in (mm) 0.6-2" (15-50) 0.6-2" (15-50) 0.6-2" (15-50)

C Electric heating element in (mm) 26.0" (660) 29.5" (750) 35.7" (908)

DD1 = Drain valve, D2 = Return to solar thermal system in (mm) 4.3" (110) 5.3" (135) 5.4" (138)

E DHW temperature sensor in (mm) 11.8" (300) 19.1" (485) 19.2" (488)

F Supply from solar thermal system in (mm) 16.1" (410) 19.1" (485) 19.2" (488)

G DHW circulation in (mm) 29.3" (745) 33.5" (850) 39.3" (998)

H Attachment location for solar pump station in (mm) 36.6" (930) 41.2" (1046) 52.3" (1328)

I Temperature and pressure relief valve in (mm) 39.4" (1000) 43.9" (1115) 55.0" (1398)

J Height without storage tank feet in (mm) 45.2" (1147) 50.6" (1285) 61.9" (1572)

KK1 = Hot water outlet (AW), K2 = Cold water inlet (EK) in (mm) 45.9" (1166) 51.3" (1304) 62.6" (1590)

Table 4 Dimensions for Fig. 3

K

2.8 Specifications

Performance data Unit WST50 EL WST80 EL WST119 EL

Recommended number of Bosch solar collectors – 1-2 2-3 3-4

Standby heat loss kWh/24 h 1.4 1.8 2.3

Standby heat loss °F/h (°C/h) 0.7 (0.39) 0.6 (0.32) 0.5 (0.27)

Standby capacity when drawing water (first hour supply) Gal (L) 45 (170.3) 57 (215.8) 74 (280.1)

Thermal insulation (R-value, design) °F ft²h/BTU 12.5 - 31.8 12.5 - 31.8 12.5 - 31.8

Thermal insulation (R-value, measured over entire tank surface

area)

Table 5 Performance data

Dimensions and general specifications Unit WST50 EL WST80 EL WST119 EL

Tank capacity Gal (L) 50 (189.3) 80 (302.8) 119 (450.5)

Diameter in (mm) 23.6" (600) 27.6" (700) 29.5" (750)

Height without tank feet

Minimum height of the installation room

1)

2)

Shipping weight lbs (kg) 234 (106) 320 (145) 428 (194)

Empty weight lbs (kg) 187(85) 271 (123) 375 (170)

Standby capacity for electric heating element Gal (L) 20 (76) 32 (121) 48 (180)

Electric heating element voltage V 240 240 240

Table 6 Dimensions and general specifications

WST50 EL / WST80 EL / WST119 EL – 6 720 648 081 (2012/09)

°F ft²h/BTU 12.11 12.31 12.22

in (mm) 45.2" (1147) 50.6" (1285) 61.9" (1572)

in (mm) 78.7" (2000) 78.7" (2000) 78.7" (2000)

7

Product description

Dimensions and general specifications Unit WST50 EL WST80 EL WST119 EL

Electric heating element rating kW 4.5 4.5 4.5

Cold water inlet (EK) Inches NPT m 3/4" NPT m 3/4" NPT m 1"

Hot water outlet (AW) Inches NPT m 3/4" NPT m 3/4" NPT m 1"

Supply to storage tank (solar thermal system) Inches NPT m 3/4" NPT m 3/4" NPT m 3/4"

Return from storage tank (solar thermal system) Inches NPT m 3/4" NPT m 3/4" NPT m 3/4"

Length of solar coil in (m) 338" (8.6) 485" (12.3) 485" (12.3)

Surface area of solar coil ft² (m²) 9.8 (0.9) 14 (1.3) 14 (1.3)

Capacity of solar coil Gal (L) 1.6 (6) 2.2 (8.5) 2.2 (8.5)

Recirculation inlet Inches NPT fm 3/4" NPT fm 3/4" NPT fm 3/4"

Temperature and pressure relief valve Inches NPT fm 3/4" NPT fm 3/4" NPT fm 3/4"

Table 6 Dimensions and general specifications

1) Without storage tank feet.

2) Minimum height of the installation room required for replacement of the magnesium anode.

Permissible maximum values Unit WST50 EL, WST80 EL, WST119 EL

Voltage V 240

Heat transfer medium temperature °F (°C) 275 (135)

DHW temperature °F (°C) 203 (95)

Hot water operating pressure

1)

PSI (bar) 100 (6.89)

Hot water operating temperature PSI (bar) 150 (10.34)

Heat transfer medium operating pressure PSI (bar) 116 (8)

Water connection pressure PSI (bar) 90 (6.2)

Mixing ratio: heat transfer medium/water – 50/50

Table 7 Permissible maximum values

1) With factory-installed temperature and pressure relief valve

Requirements for potable water Unit WST50 EL, WST80 EL, WST119 EL

Water hardness, min. ppm 36

grain/US gallon

°dH

2.1

2

pH value, min. – 6.5

pH value, max. – 9.5

Conductivity, min. S/cm 130

Conductivity, max. S/cm 1500

Table 8 Requirements for potable water

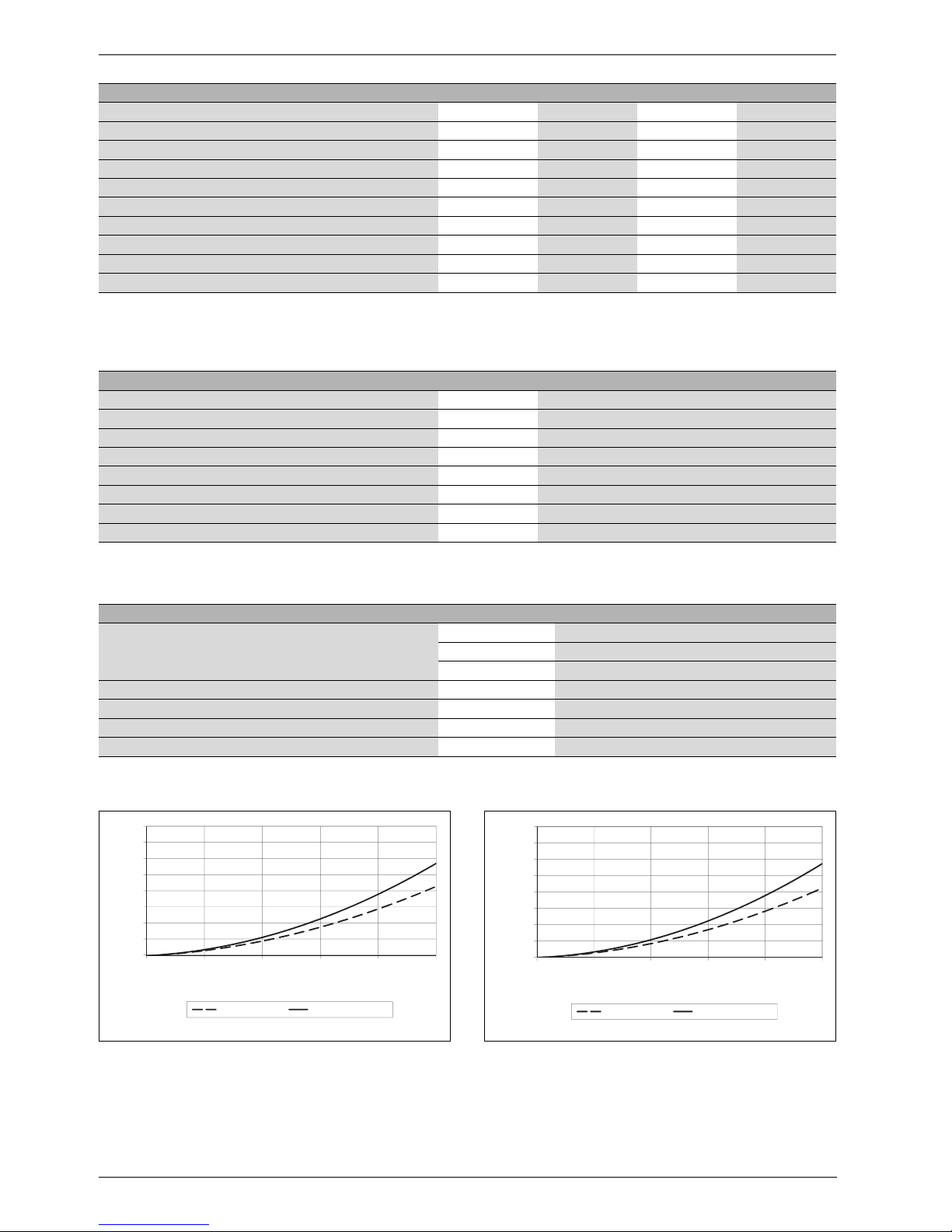

2.9 Pressure Drop Curve

4.0

4,0

3.5

3,5

3.0

3,0

O]

2.5

2,5

2

2.0

2,0

1.5

1,5

1.0

1,0

[feet of H

[feet of head]

0.5

0,5

0.0

0,0

02 46 810

[gal/min]

WST50 EL WST80/119 EL

6 720 648 083-28.1ITL

Fig. 4 Pressure drop curve Fig. 5 Pressure drop curve

200

175

150

125

100

[mbar]

75

50

25

0

01020304050

[l/min]

WST50 EL

WST80/119 EL

6 720 648 083-29.1ITL

8

WST50 EL / WST80 EL / WST119 EL – 6 720 648 081 (2012/09)

Moving the Solar Storage Tank

Model Pressure drop in feet of head (mbar)

2 GPM

(10 l/min)

WST50 EL 0.14 (6.58) 0.44 (20.84) 0.87 (42.11) 1.43 (70.37) 2.13 (105.64)

WST80 EL, WST119 EL 0.17 (8.09) 0.55 (26.81) 1.13 (55.56) 1.89 (94.35) 2.85 (143.19)

Table 9 Pressure drop values

4 GPM

(20 l/min)

6 GPM

(30 l/min)

8 GPM

(40 l/min)

10 GPM

(50 l/min)

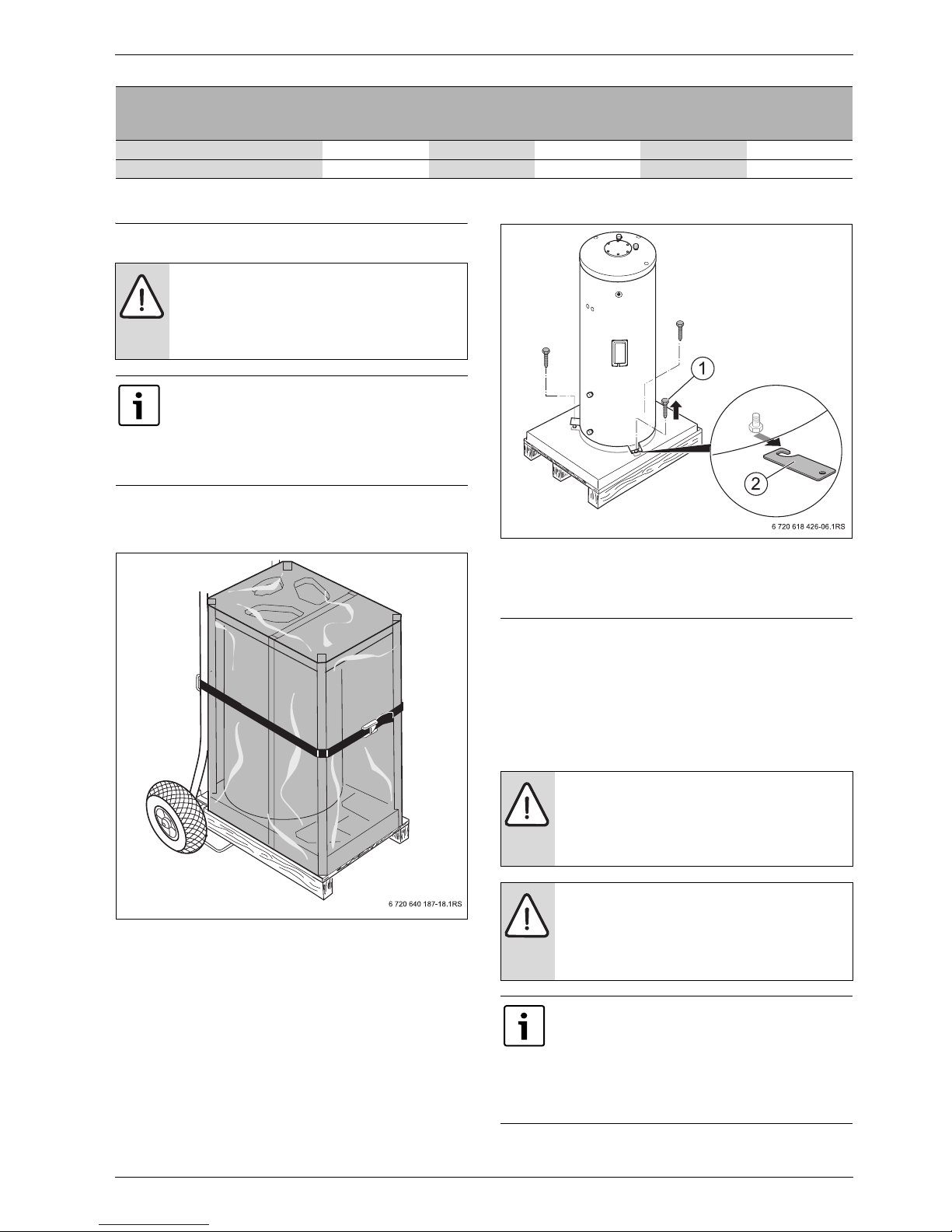

3 Moving the Solar Storage Tank

WARNING: Risk of injury from carrying heavy loads and

inadequately securing loads for transport.

B Use suitable means of transportation, e.g. a dolly with

strap.

B Secure the solar storage tank to prevent slipping.

Where possible, do not remove the tank from its

packaging until it has reached the installation location.

This keeps it protected.

If you are transporting the solar storage tank unpacked,

use a transport net. Protect the connections against

damage.

B Position the dolly at the back of the packed solar storage tank.

B Secure the solar storage tank to the means of transportation with a

strap.

Fig. 6 Securing the solar storage tank for transport

B Transport the solar storage tank to the installation location.

B Remove packaging and dispose of it.

B Remove wood screws [1] from transport bracket [2].

B Unscrew and remove transport bracket.

Fig. 7 Removing the transport brackets

[1] Wood screws

[2] Securing plate

4Installation

The solar storage tank is delivered fully assembled.

B Check that the delivered package(s) are complete and in perfect

condition (Æ Chapter2.1, page 4).

4.1 Solar Storage Tank Installation

4.1.1 Requirements for installation location

NOTICE: Risk of damage from inadequate load-bearing

capacity of the supporting surface or unsuitable

substrate.

B Make sure that the surface on which the solar storage

tank stands has sufficient load-bearing capacity.

NOTICE: Risk of damage from corrosion.

B Install the solar storage tank at a dry location.

B Install this solar storage tank only in closed, unvented

systems.

B Never use open, vented expansion vessels.

At least 20" (500 mm) clearance above and in front of

the solar storage tank is required for the replacement of

the magnesium anode and the electric heating element

(during maintenance).

B Maintain the minimum height and minimum wall

clearances in the installation room (Æ Tab. 6, page 7

and Fig. 8 ).

WST50 EL / WST80 EL / WST119 EL – 6 720 648 081 (2012/09)

9

Installation

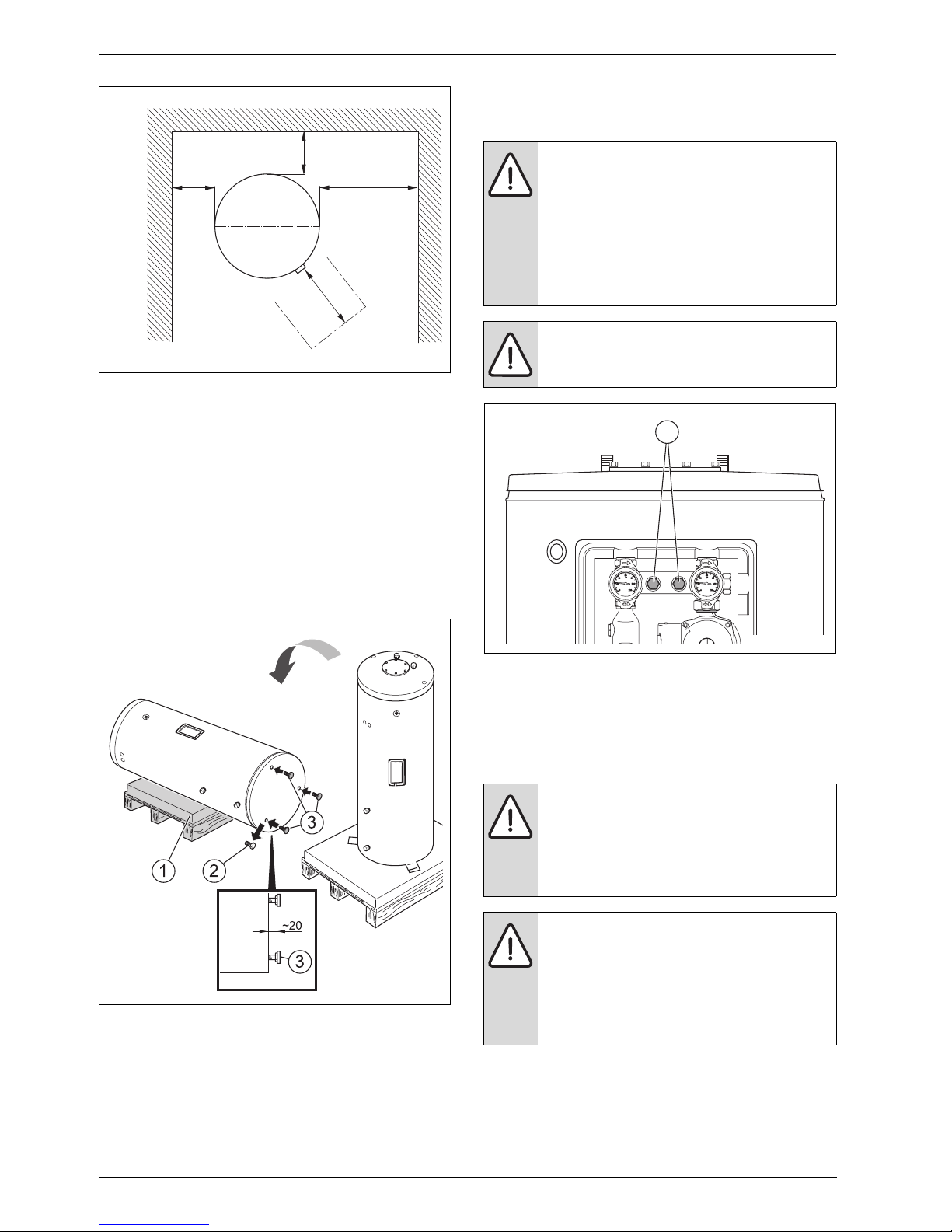

4.2 Attaching the Bosch solar pump station (optional)

To save space, the solar pump station can be attached to the solar

storage tank.

A

A

B

C

6 720 648 083-05.1ITL

Fig. 8 Minimum wall clearances

[A] 2" (50 mm)

[B] 12" (300 mm)

[C] 20" (500 mm)

4.1.2 Positioning the DHW tank

B Lift the solar storage tank from the pallet and position it on a level floor

that has adequate load-bearing capacity.

B Tilt the solar storage tank slowly onto the pallet [1].

B Remove the hex bolts [2].

B Pre-assemble the storage tank feet [3] to approx. 3/4" (20 mm).

B Stand the solar storage tank upright at the installation location and

level it using the feet.

B Maintain minimum wall clearances.

CAUTION: Risk of injury from use of the wrong bolts to

attach the solar pump station.

The bolts of the solar pump station do not match the

threads in the bracket on the solar storage tank. These

bolts can destroy the threads in the bracket, preventing

secure attachment of the solar pump station.

B Use only the bolts included with the solar storage tank

to attach solar pump station

(Æ Chapter 2.1, page 4).

CAUTION: Risk of injury from falling parts.

B Ensure that the solar pump station is secured to

prevent it from dropping while being attached.

1

Fig. 9 Installing the storage tank feet

[1] Suitable surface (e.g. pallet)

[2] Hex-head bolts

[3] Feet of the solar storage tank

6 720 648 083-06.1ITL

6 720 648 083-07.1ITL

Fig. 10 Attaching the solar pump station

[1] Mounting holes

B Use the bolts included with the solar storage tank to attach the solar

pump station.

B Refer to the separate manual for the solar pump station.

4.3 Water connections

DANGER: Risk of fire from soldering and welding!

B Take appropriate protective measures when

soldering and welding as the thermal insulation is

flammable; for example, cover the thermal insulation.

B Check the integrity of the thermal insulation after

completing work.

WARNING: Risk to health from contaminated water!

Work carried out without due care for cleanliness

contaminates the potable water.

B Install and equip the solar storage tank hygienically in

accordance with national standards and guidelines.

B Flush the solar storage tank and pipework thoroughly

with potable water after installation.

10

WST50 EL / WST80 EL / WST119 EL – 6 720 648 081 (2012/09)

Installation

NOTICE: Risk of damage from incorrect connections!

B Use installation material that is heat-resistant to

302 °F (150 °C).

B Use metal connection fittings in water heating

systems with plastic lines.

B When using an electric heating element: Once

installation of the solar storage tank is complete,

inspect the ground conductor (including metal

connection fittings).

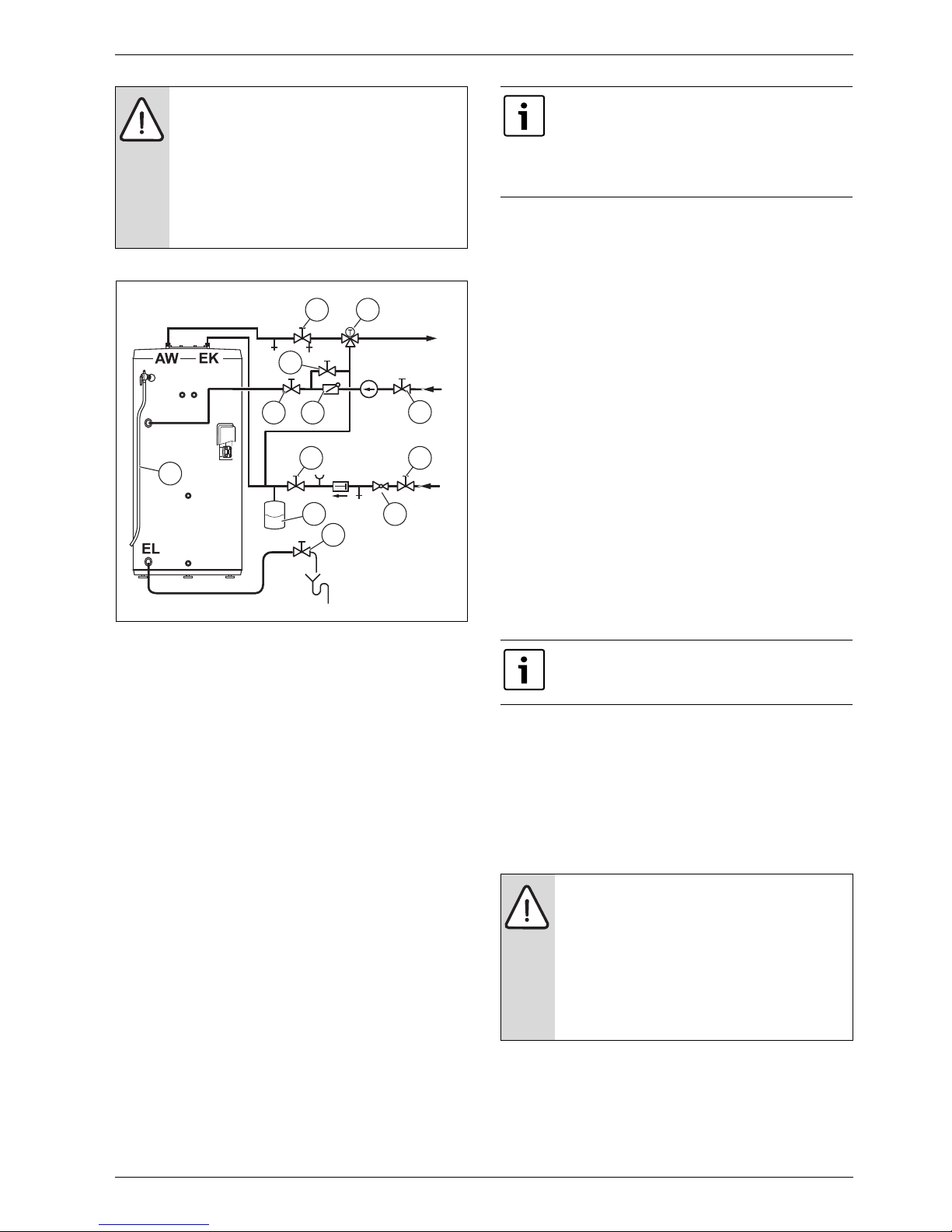

4.3.1 Installation example

2 3

AW

TPR

445

EZ

4

EZ

4

1

VS

7

4

EK

6

8

RS

6 720 648 083-03.3ITL

Fig. 11 Recommended piping for potable water

[1 Blow-off line of the pressure and temperature relief valve]

[2] Shut-off and drain valve

[3 Thermostatic DHW mixing valve ]

[4] Shut-off valve

[5] Flow-check valve

[6] Pressure reducer (if required)

[7] Expansion tank

[8] Drain valve (factory-installed)

[AW] Hot water outlet

[EK] Cold water inlet

[EZ] Recirculation inlet

[EL] Drain port

[VS] Supply to storage tank (solar thermal system)

[RS] Return from storage tank (solar thermal system)

[TPR] Temperature and pressure relief valve

Example of typical piping layout for a solar storage tank

Fig. 11 shows typical domestic water piping for a solar storage tank.

The function of the components shown are as follows:

• Shut-off valves (recommended) – Used to isolate the tank for

servicing.

• Flow-check valve (required by some codes) – Used to prevent water

from flowing back out of the tank in the event that inlet water pressure

drops.

• Drain (required) – Used to drain the tank for inspection or servicing.

• Expansion tank (required when a flow-check valve is used) – This

expansion tank absorbs the increased volume caused by heating

water.

Use an expansion tank designed for use on domestic

water systems. Refer to the expansion tank

manufacturer’s literature for the proper size expansion

tank to use.

B If an expansion tank is used, do not install any valves

between the expansion tank and tank inlet.

Domestic Water Piping for Distant Fixtures

In some cases, the furthest fixture may be quite distant from the tank.

Such an installation would result in an unacceptable delay before hot

water reaches these distant fixtures. Even if all the fixtures are relatively

close to the tank, the building owner may want hot water at all fixtures as

soon as they are opened.

A solution to this problem is to run a pipe from the furthest fixture on

each branch back to the recirculation return of the tank (Æ Fig. 11 ).

A small recirculation pump is installed in this line and wired to run

continuously, intermittently, or on demand. A flow-check valve in this

line permits flow only towards the tank inlet.

When no fixtures are drawing water, the recirculation pump moves hot

water from the tank to the end of the branch just below the last fixture,

then back to the inlet of the tank via the return pipe. When a fixture is

opened, hot water is already out in the branch very close to the fixture

and hot water appears at it almost immediately. The flow-check valve

prevents cold water in the tank’s inlet pipe from passing around the tank

and heading directly to the fixture. Because hot water is always

circulating in the hot water branch the entire branch should be insulated

to prevent excessive heat loss.

Anti-scald Valves (Tempering Valves)

Anti-scald valves used with water heaters are also called tempering

valves or mixing valves. An anti-scald valve mixes cold water with the

outgoing hot water to assure that hot water reaching a building fixture is

at a temperature low enough to be safe (Æ Fig. 11 , [3]).

As solar thermal systems can produce high

temperatures, it is strongly recommended and

considered best practice to fit a DHW tempering valve!

Usually, the maximum temperature of the outlet water will stay near the

setting of the tank controller. In some cases, however, hot water usage

patterns can cause the outlet water temperature to rise significantly

above the control setting.

The temperature of water going to the fixtures can be more carefully

controlled through the use of a thermostatic mixing valve. This device

blends a controlled amount of cold water with the hot water leaving the

tank so that water exits the mixing valve at a more constant temperature,

resulting also in increased comfort.

WARNING: Hot water can scald!

An anti-scald mixing valve does not eliminate the risk of

scalding.

B Set the tank thermostat as low as practical.

B Feel water before bathing or showering.

B If anti-scald or anti-chill protection is required, use

devices specifically designed for such purpose. Install

these devices in accordance with their

manufacturer’s instructions.

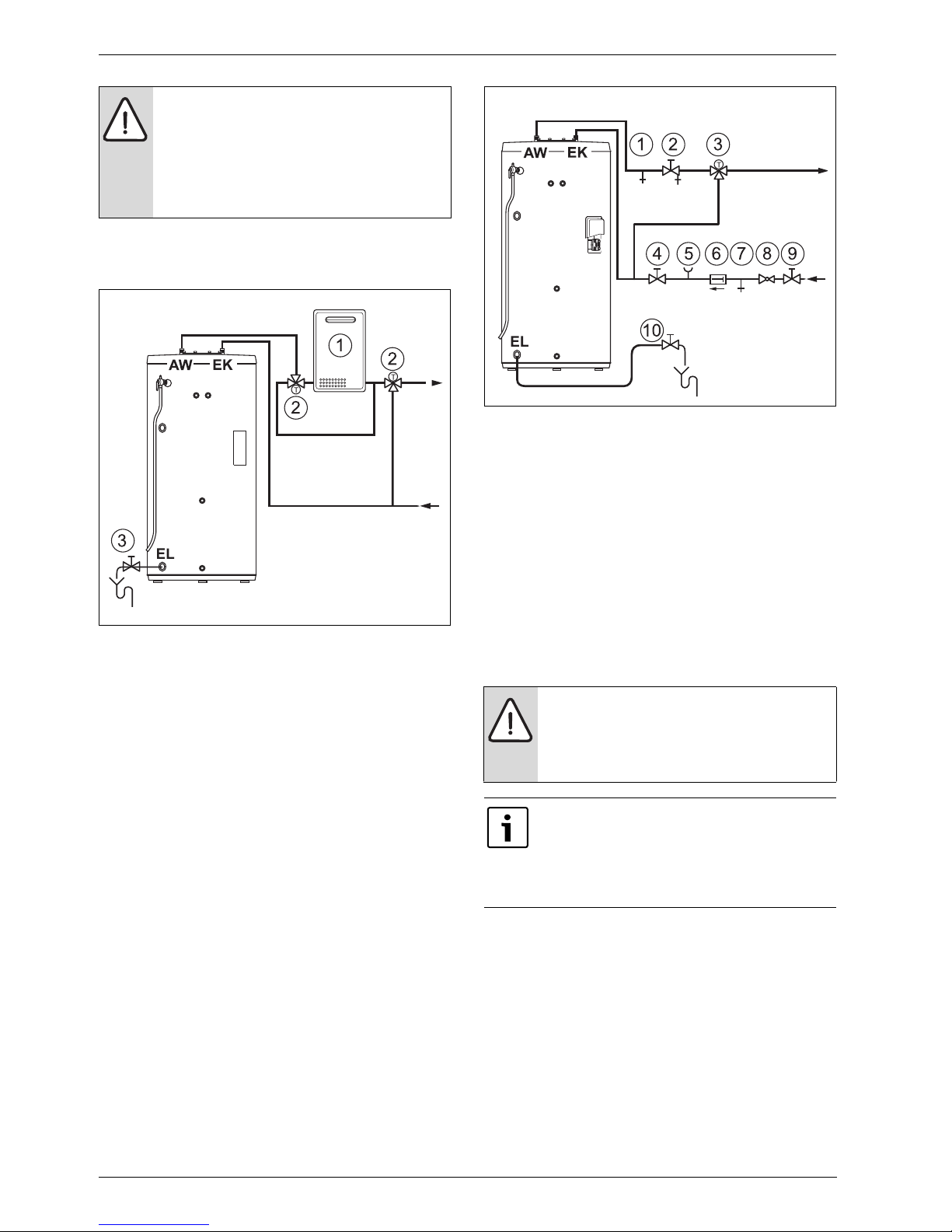

4.3.2 Pipe connections to the heat source and DHW network

When operated with an external water heater, the electric heating

element must not be connected.

B Use only threaded fittings, with shut-off valves as required, to connect

lines to the tank. Connect tank to piping on site.

WST50 EL / WST80 EL / WST119 EL – 6 720 648 081 (2012/09)

11

Installation

WARNING: Risk of scalding from hot water!

The water temperature can be as high as 194 °F (90 °C)

in solar mode.

B To limit the temperature at the tap to a maximum of

122 °F (50 °C), install a thermostatic hot water mixer

(accessory) in the hot water line (Æ Fig. 12 , [2])

and Fig. 13 , [3]).

B To facilitate debris removal, never install bends in the drain line.

B Install all pipes free of stress.

B Plug all unused tank connections (e.g. recirculation).

6 720 648 083-08.2ITL

Fig. 12 Connection diagram on the DHW side when using an external

water heater

[1] External water heater

[2] Thermostatic DHW mixing valve

[3] Drain valve (factory-installed)

[AW] Hot water outlet

[EK] Cold water inlet

[EL] Port

6 720 648 083-09.1ITL

Fig. 13 Connection diagram on the DHW side when using the internal

electric heating element (no external water heater)

[1] Air bleeder valve

[2] Shut-off and drain valve

[3] Thermostatic DHW mixing valve

[4] Shut-off valve

[5] Pressure gauge connection (optional)

[6] Flow-check valve

[7] Purge valve

[8] Pressure reducer (if required)

[9] Shut-off valve

[10] Drain valve (factory-installed)

[AW] Hot water outlet

[EK] Cold water inlet

[EL] Port

4.3.3 Temperature and Pressure Relief Valve (TPR) Blow-off Line

WARNING: Improper placement and piping of the TPR

valve can cause severe personal injury, death or

substantial property damage.

B Do not install any valve between the TPR valve and the

tank connection or on the TPR valve blow-off line.

12

The TPR valve is not intended for constant duty, such as

relief of pressure due to repeated normal system

expansion. Correct this condition in a domestic hot

water system by installing a properly sized expansion

tank. Refer to the expansion tank manufacturer’s

installation instructions for proper sizing.

The temperature and pressure relief valve (TPR) blow-off line must

be:

• Made of material capable of withstanding a temperature of 250 °F

(121 °C) or higher

• Directed so that hot water flows away from all persons

• Directed to a suitable place for drainage.

• Installed so as to allow complete draining of the temperature and

pressure relief valve (TPR) and blow-off line.

• Terminated no more than 6" (150 mm) above the floor or as required

by code (Æ Fig. 14 , [X]).

WST50 EL / WST80 EL / WST119 EL – 6 720 648 081 (2012/09)

Loading...

Loading...