Page 1

TheatreCue

User Manual

Cueing and Presentation Control Specialists

Page 2

Contents

Introduction 3

Safety Instructions 4

Setting Up 5

Operating Instructions 7

Programming Outstations 7

Main Unit Setup 9

Giving Cues 10

Testing and Faults 12

Certificate of Conformity 14

Environmental 15

Technical Support Contact 15

2

Page 3

Introduction

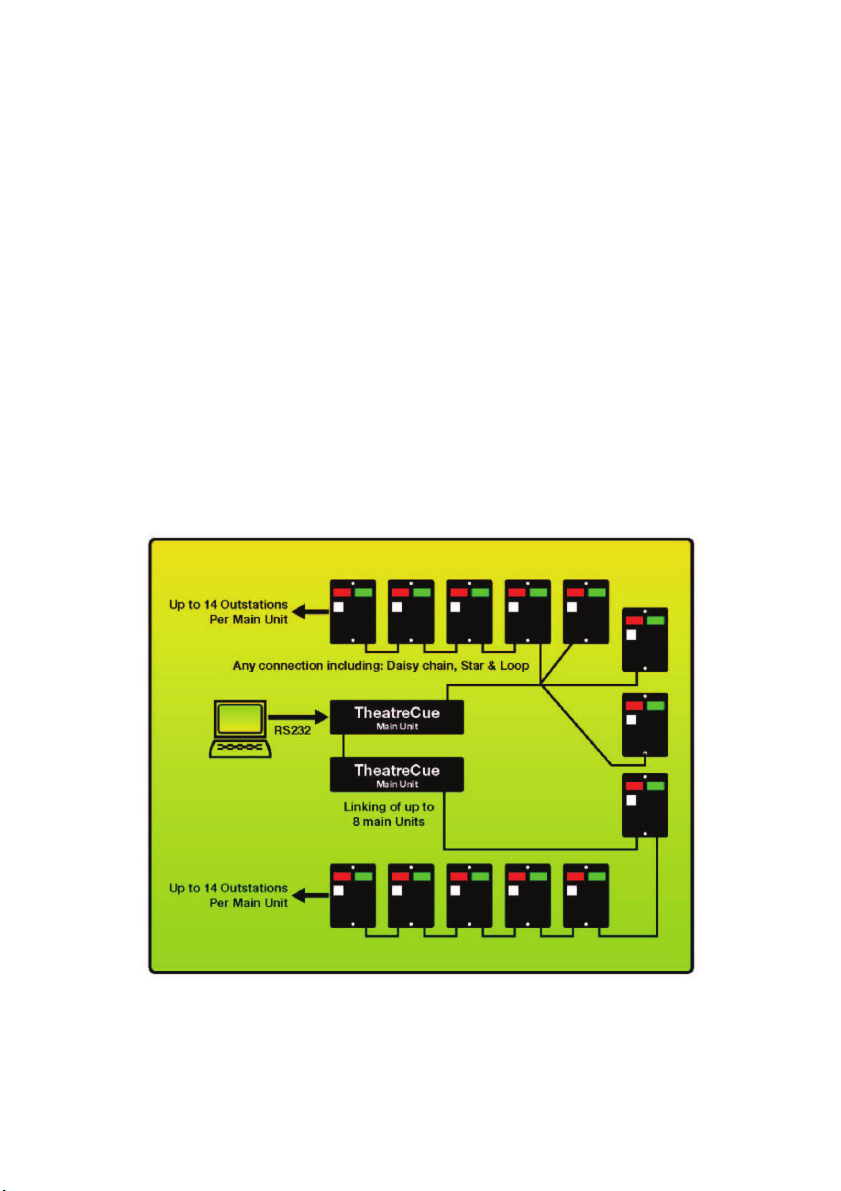

TheatreCue provides for cueing of remote Outstations, each acting as an

interactive cuelight or as a direct controller of stage equipment. Each Main

Unit controls up to 14 Outstations and the system is designed so that up to

8 Main Units can be linked, thus providing for the control of up to 112

Outstations if required. The system is easily set up using standard XLR

(mic) cables and allows for any combination of daisy chain, star or looping

configuration.

System operators are able to quickly set-up and assign remote stations in

any preferred order, and to either of two groups for the easy simultaneous

cueing of multiple actions. Stage managers are then able to give ‘standby’

commands, which Outstation operators are able to confirm prior to the

stage manager giving the ‘go’ command. TheatreCue can be RS232

computer controlled and features numerous continuous system fault alert

functions; for the fast diagnosis of any cabling or system failures.

Simple, Effective Live Event Cueing

We hope that TheatreCue

feedback that you have about this or any of our products.

Thank you.

The Interspace Industries Team

www.interspaceind.com

exceeds your expectations and welcome any

3

Page 4

Safety Instructions

All safety and operating instructions should be read before this product is

operated and should be retained for further reference. Please adhere to

all the warnings on this product and in these operating instructions. Please

follow these instructions carefully.

Power. Only use the power source indicated on the device. Devices

equipped with a grounded plug should only be used with a grounded type

outlet. In no way should this grounding be disconnected, modified or

suppressed.

Power Supply Lead. To unplug the device always pull by the plug itself,

not the power supply lead. The power source outlet should always be near

the TheatreCue Main Unit and easily accessible. Ensure the power supply

lead cannot be walked on or damaged by items placed on or against it. Do

not use if the power supply lead is damaged. Using the device with a

damaged power supply lead may expose you to electric shock or other

hazards. Check the condition of the power supply lead regularly. Contact

your dealer or service centre immediately for a replacement if damaged.

Keep Away From Harmful Substances

To prevent the risk of electric shock and fire, do not expose this device to

rain, humidity or intense heat sources (such as radiators or direct

sunlight). Avoid using this equipment in environments where there is

excessive heat, dust, moisture, chemicals, vibration or mechanical

shocks.

Slots and Openings. These are designed into the device for ventilation

and to avoid overheating. Always ensure these openings remain clear. Do

not attempt to insert anything into these openings under any

circumstances. If liquids have been spilled on, or objects have fallen into

the product it must be checked by a qualified technician before re-using.

Connections. All inputs and outputs (except for power input) are TBTS

defined under EN60950.

4

Page 5

• DO NOT OPEN SYSTEM DUE TO HIGH VOLTAGE.

• DO NOT IMMERSE IN WATER.

If you have any queries regarding these safety instructions or how to

maintain the unit please do not hesitate to contact us on:

+44 (0) 870 770 8088

Servicing. Do not attempt to service this product yourself. Opening or

removing covers and screws may expose you to electric shocks or other

hazards. Refer all servicing to qualified service personnel.

Setting Up

Figure 1 Connections Diagram

5

Page 6

Figure 2 Linking Main Units

All connections to Outstations can be made using standard 3-pin XLR

(mic) cables. TheatreCue

can be set up and operated over a combined

total distance of up to 1000 metres (3000ft) when using the highest possible quality cable. 14 Outstations per Main Unit can be connected in any

combination of star, daisy-chain or loop configuration. The loop configuration allows the whole system to keep working even when a break in the

cable exists.

Up to 8 Main Units can be linked also, providing for control of up to 112

Outstations if required (refer figure 2).

Cuelight Outstations function as interactive visual cue signals (where talent or crew can ‘confirm’ standby signals). The beeper type Outstation

provides for audible cue signals as well as the interactive cuelight functionality, and relay-type Outstations can directly control electrical equip-

6

Page 7

ment. Relay-type Outstations are rated up to 1A, 48V and are NOT DESIGNED FOR MAINS SWITCHING.

The Main Units can be controlled by computer via the RS232 interface

also.

Unpacking and Connections. Unpack the Main Unit and place on a flat

surface within easy reach of the operator. Set up the preferred mounting of

the Main Unit by removing the bracket securing screws on each side of the

Main Unit and repositioning each bracket for either 19” 2RU rack mounting

or freestanding, and then replace and tighten the bracket securing screws.

Mount the Main Unit in the rack unit if this is the preferred mounting configuration.

If multiple Main Units are being used and linked, mount these also and

connect to each other using the RS232 (serial) connectors (loop output

from Main Unit one to input of Main Unit two etc).

Unpack the Outstations and install where required. Connect these to the

Main Unit using high quality, standard 3 pin XLR (mic) cables (refer fig 1

for connection options).

Apply power to the Main Unit/s using the 12V DC power adaptor/s provided and switch on the mains power. All LEDs in the system illuminate

briefly to confirm that all are operational. The system is now ready for programming or operation.

Operating Instructions

Programming Outstations

1. With the system fully powered up, unplug the XLR input cable

which is providing power to the Outstation and wait 10 seconds for

the Outstation to fully power down (i.e. until all LED lamps on the

Outstation are fully extinguished).

2. While holding down the ‘Confirm’ button, reconnect power to the

Outstation. Release the ‘Confirm’ button and the ‘Standby’ light will

flash to confirm the Outstation is now in programme mode

7

Page 8

3. Press the ‘Confirm’ button as many times as the number you want

to assign to this Outstation. For example; to programme the Outstation to be number 11, press the ‘Confirm’ button 11 times. If

you want to programme the Outstation to be number 6, press the

‘Confirm’ button only 6 times. The ‘Standby’ light will then confirm

your programming by flashing the same number times.

4. If the Outstation has been programmed correctly, you can simply

leave it and move to the next Outstation (whereupon after 30 seconds the ‘Standby’ LED will stop flashing and the Outstation will

then remain programmed accordingly), or press and hold the

’Confirm’ button to re-boot the Outstation, or you can disconnect

the power cable (as in 1. above), wait for the Outstation to fully

power down, then reconnect. The Outstation will then be programmed to the new assigned number and the Main Unit will be

updated immediately.

5. If when the Outstation confirms the programming the number is

incorrect and you need to change the number it is programmed to,

simply press the ‘Confirm’ button the required number of times

again and check the number of replayed flashes once more. When

correct, perform the confirmation by following the steps in 4.

above.

Dimming of Outstations

To dim the LEDs on Outstations, hold down the ‘Dimmer’ button on the

Main Unit and press the ‘Standby’ button on the channel assigned to the

Outstation in question. Each press of the ‘Standby’ button dims the LEDs

on the Outstation by 20%. When the illumination level is correct, simply

release all buttons on the Main Unit and the dimming programming is complete. This process needs to be repeated for each additional Outstation

requiring dimming also.

IMPORTANT NOTE:

When enabled, the ‘Dimmer’ button

is also a master reset of all cues!

If any cues have already been given (i.e. Standby, Confirmed and/or Go),

these will be cancelled instantly whenever the ‘Dimmer’ button is pressed.

8

Page 9

Main Unit Setup

To enter the Main Unit setup mode, press and hold all 3 buttons of channel 1 while turning on the mains power. When all setup programming has

been completed, press the ‘Group B Go’ button to exit and save changes.

Set Main Unit Address.

The current Main Unit address is displayed using the fault LEDs of channels 1 to 8. If address #5 is programmed, then fault LED #5 will be on.

Change the address by pressing the ‘Dimmer’ button. Valid addresses are

1 to 8. Unless the RS232 adaptor unit is used, the address can be set to

any value. Factory default address is #1

Calls from Outstations.

The ability for the Main Unit to receive calls from Outstations can be

turned off or on (i.e. when the ‘Confirm’ button is pressed at any Outstation, the ‘Standby’ and ’Go’ buttons assigned to that Outstation will flash

on the Main Unit . When the Main Unit is in setup mode, the status of this

function is displayed by the channel 2 ‘Go’ button. The factory default =

LED on (enabled). Use the channel 2 ‘Go’ button to toggle this on and off.

Enable/disable the Beep Button.

When the Main Unit is in setup mode, the status of this function is displayed by the channel 3 ‘Go’ button. The factory default = LED on

(enabled). Use the channel 3 ‘Go’ Button to toggle this on and off.

Link/unlink the Master Group A and B Buttons.

The Master Group buttons are normally linked between multiple Main

Units. When the RS232 Interface Unit is connected, it may be desirable to

have the Main Units not linked. This option is only possible when the

RS232 Interface Unit is connected. When the Main Unit is in setup mode,

the current status of this function is displayed by the channel 4 ‘Go’ button.

The factory default = LED on (linking enabled). Use the channel 4 ‘Go’

Button to toggle this on and off.

9

Page 10

Giving Cues

Standby, Confirm, Go.

To send a ‘Standby’ cue to an Outstation, the Main Unit operator presses

the ‘Standby’ button for the required Outstation. Once the standby cue has

been given, both the ‘Standby’ button on the Main Unit and the ‘Standby’

LED on the Outstation will flash continuously. Once given, the standby cue

can be cancelled at any time by the Main Unit operator simply by pressing

the ‘Standby’ button again.

Cast or crew can confirm they have received the standby cue if required

by pressing the ‘Confirm’ button on the Outstation. This is not mandatory

however as the go cue can still be given without the standby cue being

confirmed. Once confirmed, both the ‘Standby’ LED on the Outstation and

the ‘Standby’ button on the Main Unit will remain lit continuously.

When required, the Main Unit operator can signal a ‘Go’ cue by pressing

the ‘Go’ button for the required Outstation. Once a Go cue is given, the

Outstation ‘Standby‘ LED and Main Unit buttons will be extinguished and

both the green ‘Go’ LED on the Outstation and the ‘Go’ button on the Main

Unit will remain lit continuously for 5-6 seconds, then flash for 10-14 seconds and then the Go cue expires. This gives a combined Go cue duration

of at least 15 seconds. If the cue hasn’t been acted on by then, it is certain

to be too late but the Main Unit operator can repeat the Go cue by pressing the ’Go’ button again once the cue has expired, as many times as they

need to. A Go cue can be cancelled anytime before the cue expires by

pressing the ‘Go’ button again.

Grouping.

Any or all of the TheatreCue channels can be assigned to the group master ‘Go’ and ‘Standby’ buttons A and B. The group assignment for any

channel is controlled by the dual LED ‘Group A B’ button on the Main Unit.

Pressing any of the channel ‘Group A B’ buttons cycles through the four

possible group assignments: A, B, A+B and none.

Once each required channel has been assigned to either of the A, B or

A+B groups, these channels can all be controlled simultaneously using

10

Page 11

just the Group A and B master ‘Go’ or ‘Standby’ buttons. All group assigning remains stored in memory, even during power down. The assignments

will therefore be restored whenever the Main Unit is powered up again and

remain active until reassigned.

Any channels not assigned to either Group A, B, or A+B will still need to

be controlled as individual channels. Any channels that have been assigned to Group A, B, or A+B can still be manually controlled at any time if

required also.

When multiple Main Units are linked via the RS232 ports, the system can

be programmed to also link the group master buttons. In this configuration,

pressing any of the ‘Go’ or ‘Standby’ group master buttons on any Main

Unit will simultaneously cue all assigned channels on all Main Units accordingly. Up to 8 Main Units can be linked for larger systems providing for

up to 112 Outstations. See ‘Main Unit Setup’ for more information on linking Main Units.

Using the Beeper.

The Main Unit operator can give audible cues to beeper-type Outstations.

When the operator holds down the ‘Beep’ button on the Main Unit and

simultaneously presses the ’Standby’ button on the channel assigned to

the required beeper-type Outstation, the Outstation will emit a discrete

“click” sound (a very short beep). By pressing both the ‘Beep’ and ‘Go’

buttons, the Outstation sounds a long beep for as long as the button is

pressed - up to a maximum of two seconds. The ’Standby’ LED on the

cued Outstation flashes also while the beeper operates. Beeper-type Outstations function just like standard cuelight Outstations when not giving

audible cues.

The Beep button can also be used in conjunction with the group master

buttons to give audible cues to groups of beeper-type Outstations.

The beep button can be disabled on the Main Unit. See “Main Unit Setup”

for details.

11

Page 12

Testing and Faults

Positive Monitoring.

TheatreCue has been designed to continuously check for, and signal, any

possible fault condition. This means that operators are provided with the

maximum possible advance warning if there is any risk that a cue cannot

be given. As an example, all feedback given by the Main Unit is driven

entirely by the Outstations themselves. The ‘Standby’ and ‘Go’ buttons on

the Main Unit therefore will not illuminate unless the respective Outstation

has signalled to the Main Unit to do so. This ensures that not only complete cable or Outstation failures can be detected instantly but intermittent

or ‘noisy’ circuits likely to impair the optimum performance of TheatreCue

will be detected and the operator alerted.

Fault LED.

The fault LED on each channel of the Main Unit can be in either of 3

states; ON (continuously), OFF or FLASHING. If all connections and system functions are normal, the fault LED will remain OFF. If there has never

been an Outstation connected to that channel since initial power up, the

fault LED will remain ON continuously. If no signal can be received from

an Outstation, there is an intermittent or ‘noisy’ connection or an Outstation has been unplugged, the fault LED will FLASH. Once the source of

the fault has been identified and rectified, power down the Main Unit, wait

10 seconds then power it up again. Test the channel again by sending

several cues to the Outstation. If the fault LED remains OFF, the fault has

been cleared. If it remains ON continuously, the Outstation has become

completely disconnected. If it is still flashing, a fault still exists.

Short LED.

If there is a short circuit anywhere on the Outstation circuit; power is removed from all Outstations, the system will commence testing at between

2 and 8 second intervals to see if the short has been cleared and the

‘Short’ LED will illuminate continuously. Whilst in this state, all cabling and

connections can be checked ‘live’ to see when the fault clears and the

‘Short’ LED goes out.

12

Page 13

System Lamp Test.

The Main Unit conducts a short lamp test on start up but a lamp test of the

entire system (including Outstations) can be carried out during set up and

prior to the commencement of the event if required. With the system powered up, hold down the ‘Dimmer’ Group B, ‘Standby’ and ‘Go’ buttons all

together until all the Main Unit LEDs illuminate. Release the buttons and

the Main Unit LEDs will now flash slowly across all channels. The red

‘Short’ LED will flash also and the power LED will remain illuminated constantly. This test will verify that all LEDs are functioning properly. Whilst in

this mode, all LEDs and lamps on all Outstations will flash also so each

can be checked for full functionality. To cancel lamp test mode, hold down

the ‘Dimmer’ Group B, ‘Standby’ and ‘Go’ buttons all together again or

power down the Main Unit.

Individual Outstation Lamp Test.

To lamp test any Outstation, disconnect the power input XLR cable from

the Outstation, wait 10 seconds for the Outstation to fully power down,

then reconnect the power again. The Outstation performs a short lamp test

whenever it is powered up.

Diagnostic Mode.

This mode allows the operation of the LEDs and data communications to

be verified. Enter the diagnostic mode by pressing both of the Group B

‘Standby’ and ‘Go’ buttons for approximately 4 seconds, until all LEDs on

the Main Unit illuminate. Release the buttons and the ‘Go’ and ‘Standby’

LEDs on all Outstations flash alternately. Any ‘Fault’ LEDs illuminating

briefly is an indication of data communication errors. The usual causes for

this are excessive cable lengths and/or too many Outstations at the end

of a long cable run. Exit the Diagnostic Mode by pressing either of the

Group B ‘Standby’ or ‘Go’ buttons ,or by powering down the Main Unit.

13

Page 14

DECLARATION OF CONFORMITY

We (Interspace Industries 28 High Street, Arlesey, Bedfordshire SG15 6RA , UK) declare

under our sole responsibility that the products:

TheatreCue

(Part Nos: CUERACK14, CUEOUT, CUERELAY, CUEBEEP, CUE232)

Conform to the following standards:

EN60950-1:2002,

BS EN 55103-1:1997

BS EN 55103-2:1997

Following the provision of:

The Low Voltage Directive 73/23/EEC and

The Electromagnetic Compatibility Directive 89/336/EEC

Issued on: 25th January 2008

Dave Humphrys,

Managing Director, Interspace Industries

14

Page 15

WEEE and RoHS Compliance. TheatreCue and its associated

accessories have been manufactured and sold in accordance with the

requirements of the EC WEEE and RoHS directives. Please return all endof-life items to your supplier, or your local Interspace Industries

representative directly, for appropriate disposal.

Packaging Materials:

Cardboard box: Grade 150 K/T ‘B’ (Single Walled Corrugated - Brown

Kraft)

Protective Foam: Grade HLB 22 Grey Foam (High Load Bearing)

Equipment Supplied

• 1 x TheatreCue Main Unit

• Outstations to order

• 12v DC power supply

Available Accessories

• Additional TheatreCue Main Units

• Additional Cuelight Outstations

• Relay-type Outstations

• Beeper-type Outstations

• RS232 Adaptor

For Technical Support or Sales Enquiries:

Interspace Industries Head Office:

+44 (0) 870 770 8088

Emergency Technical Support Hot Line:

+44 (0) 7976 385 046

Website:

www.interspaceind.com

Environmental

15

Page 16

28 High Street

Arlesey

Bedfordshire

SG15 6RA

UK

Tel: +44 (0) 870 770 8088

Fax: +44 (0) 870 770 8089

Email: moreinfo@interspaceind.com

www.interspaceind.com

16

Loading...

Loading...