intersil X9418 DATA SHEET

®

www.BDTIC.com/Intersil

X9418

Low Noise/Low Power/2-Wire Bus

Data Sheet FN8194.3October 12, 2006

Dual Digitally Controlled Potentiometers

(XDCP™)

FEATURES

• Two potentiometers in one package

• 2-wire serial interface

• Register oriented format

—Direct Read/Write/Transfer Wiper Position

—Store as many as Four Positions per

Potentiometer

• Power supplies

—V

—V+ = 2.7V to 5.5V

—V– = -2.7V to -5.5V

• Low power CMOS

—Standby current < 1µA

—Ideal for Battery Operated Applications

• High reliability

—Endurance–100,000 Data Changes per Bit per

—Register Data Retention–100 years

• 8-bytes of nonvolatile memory

•2.5kΩ, 10kΩ resistor array

• Resolution: 64 taps each potentiometer

• 24-pin plastic DIP, 24-lead TSSOP and 24-lead

SOIC packages

• Pb-Free plus anneal available (RoHS compliant)

= 2.7V to 5.5V

CC

Register

DESCRIPTION

The X9418 integrates two digitally controlled

potentiometers (XDCP) on a monolithic CMOS

integrated microcircuit.

The digitally controlled potentiometer is implemented

using 63 resistive elements in a series array. Between

each element are tap points connected to the wiper

terminal through switches. The position of the wiper on

the array is controlled by the user through the 2-wire

bus interface. Each potentiometer has associated with

it a volatile Wiper Counter Register (WCR) and 4

nonvolatile Data Registers (DR0:DR3) that can be

directly written to and read by the user. The contents

of the WCR controls the position of the wiper on the

resistor array through the switches. Power up recalls

the contents of DR0 to the WCR.

The XDCP can be used as a three-terminal

potentiometer or as a two-terminal variable resistor in

a wide variety of applications including control,

parameter adjustments, and signal processing.

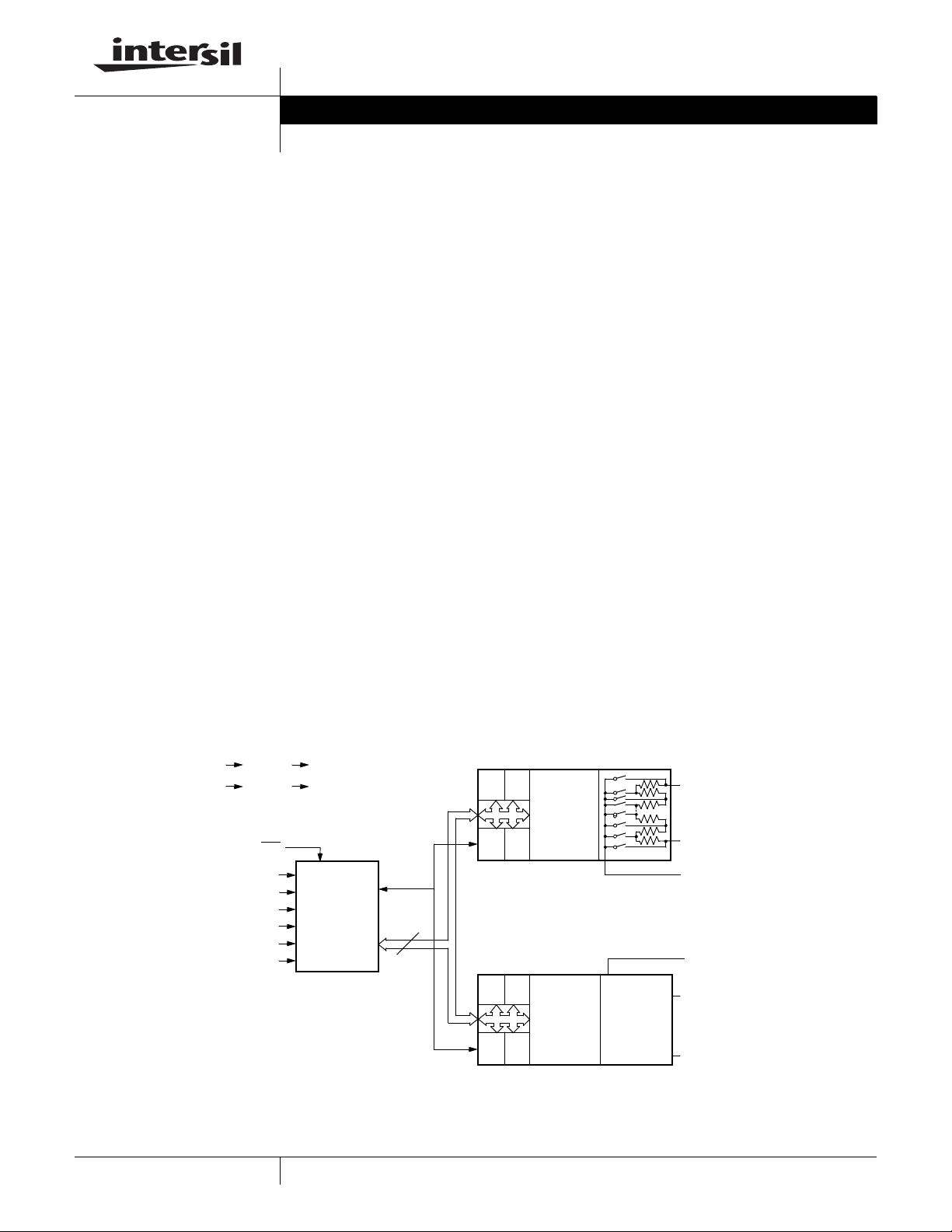

BLOCK DIAGRAM

V

CC

V

SS

SCL

SDA

A0

A1

A2

A3

V+

V-

WP

1

Interface

and

Control

Circuitry

R0 R1

R2 R3

8

Data

R0 R1

R2 R3

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

XDCP is a trademark of Intersil Americas Inc. Copyright Intersil Americas Inc. 2005, 2006. All Rights Reserved

Wiper

Counter

Register

(WCR)

Wiper

Counter

Register

(WCR)

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

All other trademarks mentioned are the property of their respective owners.

Resistor

Array

XDCP1

VH0/R

VL0/R

VW0/R

VW1/R

V

H1/RH1

VL1/R

H0

L0

W0

W1

L1

X9418

www.BDTIC.com/Intersil

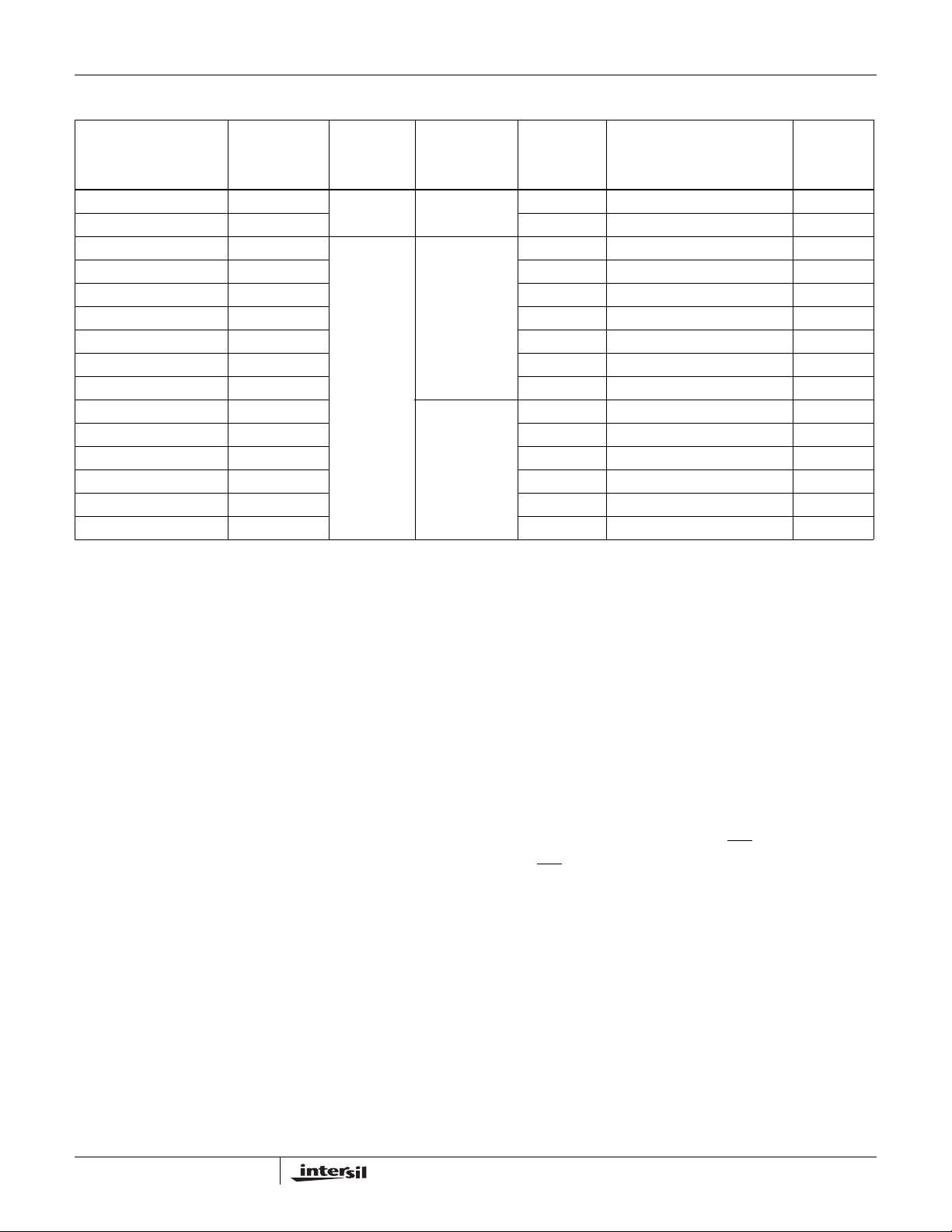

Ordering Information

POTENTIOMET

ER

V

LIMITS

PART NUMBER PART MARKING

X9418WV24* X9418WV 5 ±10% 10 0 to +70 24 Ld TSSOP (4.4MM) MDP0044

X9418WV24Z* (Note) X9418WV Z 0 to +70 24 Ld TSSOP (4.4MM) (Pb-free) MDP0044

X9418WP24I-2.7 X9418WP G 2.7 to 5.5 10 -40 to +85 24 Ld PDIP E24.6

X9418WS24I-2.7 X9418WS G -40 to +85 24 Ld SOIC (300MIL) M24.3

X9418WS24IZ-2.7 (Note) X9418WS ZG -40 to +85 24 Ld SOIC (300MIL) (Pb-free) M24.3

X9418WV24-2.7* X9418WV F 0 to +70 24 Ld TSSOP (4.4MM) MDP0044

X9418WV24Z-2.7* (Note) X9418WV ZF 0 to +70 24 Ld TSSOP (4.4MM) (Pb-free) MDP0044

X9418WV24I-2.7 X9418WV G -40 to +85 24 Ld TSSOP (4.4MM) MDP0044

X9418WV24IZ-2.7 (Note) X9418WV ZG -40 to +85 24 Ld TSSOP (4.4MM) (Pb-free) MDP0044

X9418YS24-2.7 X9418YS F 2.5 0 to +70 24 Ld SOIC (300MIL) M24.3

X9418YS24Z-2.7 (Note) X9418YS ZF 0 to +70 24 Ld SOIC (300MIL) (Pb-free) M24.3

X9418YS24I-2.7 X9418YS G -40 to +85 24 Ld SOIC (300MIL) M24.3

X9418YS24IZ-2.7 (Note) X9418YS ZG -40 to +85 24 Ld SOIC (300MIL) (Pb-free) M24.3

X9418YV24I-2.7* X9418YV G -40 to +85 24 Ld TSSOP (4.4MM) MDP0044

X9418YV24IZ-2.7* (Note) X9418YV ZG -40 to +85 24 Ld TSSOP (4.4MM) (Pb-free) MDP0044

*Add "T1" suffix for tape and reel.

NOTE: Intersil Pb-free plus anneal products employ special Pb-free material sets; molding compounds/die attach materials and 100% matte tin

plate termination finish, which are RoHS compliant and compatible with both SnPb and Pb-free soldering operations. Intersil Pb-free products are

MSL classified at Pb-free peak reflow temperatures that meet or exceed the Pb-free requirements of IPC/JEDEC J STD-020.

CC

(V)

ORGANIZATION

(kΩ)

TEMPERATU

RE RANGE

(°C) PACKAGE PKG . DWG. #

PIN DESCRIPTIONS

Host Interface Pins

Serial Clock (SCL)

The SCL input is used to clock data into and out of the

X9418.

Serial Data (SDA)

SDA is a bidirectional pin used to transfer data into

and out of the device. It is an open drain output and

may be wire-ORed with any number of open drain or

open collector outputs. An open drain output requires

the use of a pull-up resistor. For selecting typical

values, refer to the guidelines for calculating typical

values on the bus pull-up resistors graph.

Device Address (A

0

- A3)

The Address inputs are used to set the least

significant 4 bits of the 8-bit slave address. A match in

the slave address serial data stream must be made

with the Address input in order to initiate

communication with the X9418. A maximum of 16

devices may occupy the 2-wire serial bus.

Potentiometer Pins

V

H/RH

The V

(VH0/R

H/RH

- VH1/RH1), VL/RL (VL0/R

H0

- VL1/RL1)

L0

and VL/RL inputs are equivalent to the

terminal connections on either end of a mechanical

potentiometer.

V

W/RW

(VW0/R

- VW1/RW1)

W0

The wiper outputs are equivalent to the wiper output of

a mechanical potentiometer.

Hardware Write Protect Input (WP

The WP

pin when low prevents nonvolatile writes to

)

the Data Registers.

Analog Supplies V+, V-

The Analog Supplies V+, V- are the supply voltages

for the XDCP analog section.

2

FN8194.3

October 12, 2006

X9418

www.BDTIC.com/Intersil

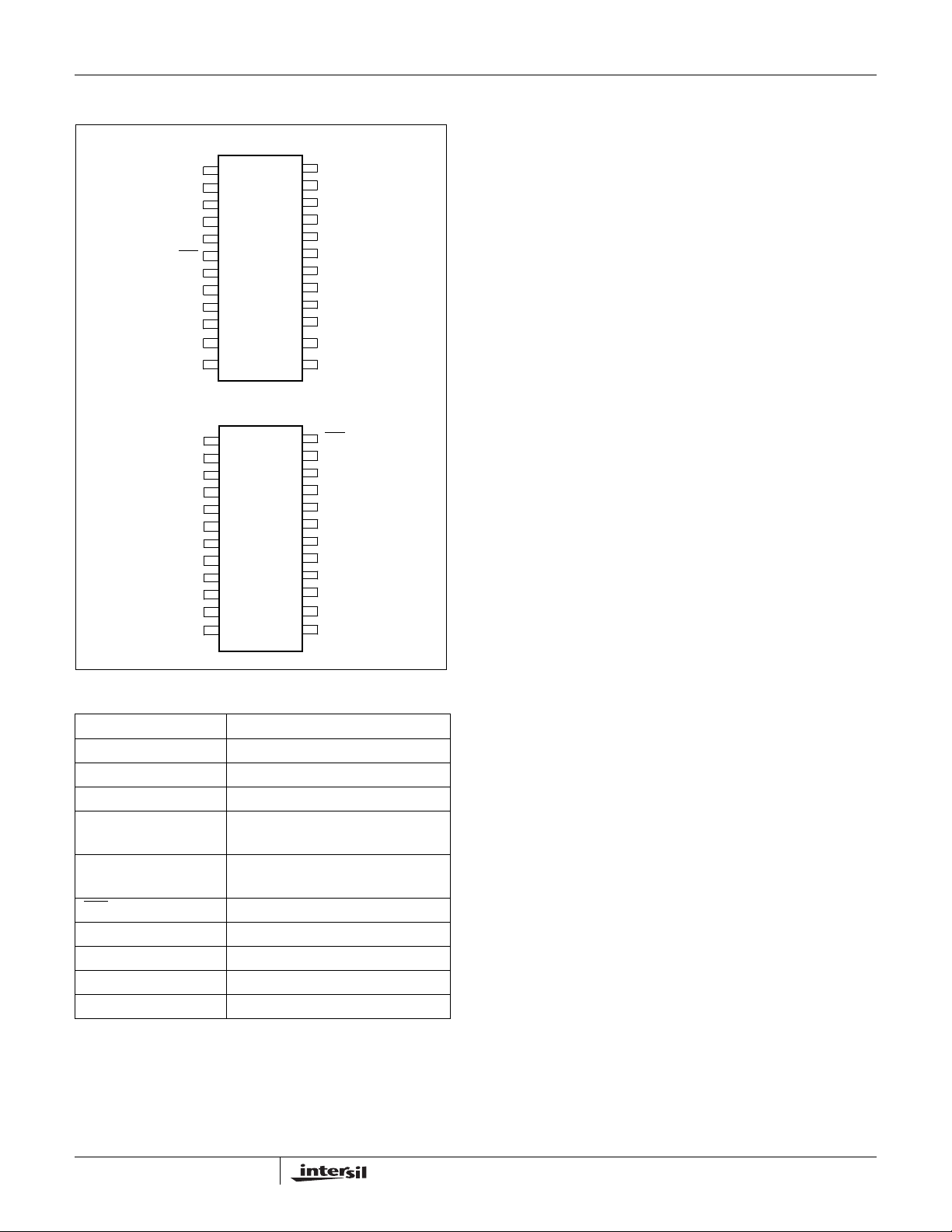

PIN CONFIGURATION

DIP/SOIC

RL0/V

RH0/V

RW0/V

R

L1/VL1

RH1/V

RW1/V

R

L1/VL1

R

H1/VH1

R

W1/VW1

V

WP

SDA

V

SDA

V

SCL

CC

L0

H0

W0

A2

A1

H1

W1

SS

A1

SS

NC

NC

NC

V-

A3

1

2

3

4

5

6

7

8

9

10

11

12

1

2

3

4

5

6

7

8

9

10

11

12

X9418

TSSOP

X9418

24

23

22

21

20

19

18

17

16

5

14

13

24

23

22

21

20

19

18

17

16

15

14

13

PIN NAMES

Symbol Description

SCL Serial Clock

SDA Serial Data

A0 - A3 Device Address

V

H0/RH0

V

L0/RL0

V

W0/RW0

V

W1/RW1

WP

- VH1/RH1,

- VL1/R

L1

-

Potentiometer Pins

(terminal equivalent)

Potentiometer Pins

(wiper equivalent)

Hardware Write Protection

V+,V- Analog Supplies

V

CC

V

SS

System Supply Voltage

System Ground

NC No Connection

V+

NC

NC

NC

A0

NC

A3

SCL

NC

NC

NC

V-

WP

A2

V

W0/RW0

VH0/R

VL0/R

V

CC

NC

NC

NC

V+

A0

NC

L0

H0

PRINCIPLES OF OPERATION

The X9418 is a highly integrated microcircuit

incorporating two resistor arrays and their associated

registers and counters and the serial interface logic

providing direct communication between the host and

the XDCP potentiometers.

Serial Interface

The X9418 supports a bidirectional bus oriented

protocol. The protocol defines any device that sends

data onto the bus as a transmitter and the receiving

device as the receiver. The device controlling the

transfer is a master and the device being controlled is

the slave. The master will always initiate data transfers

and provide the clock for both transmit and receive

operations. Therefore, the X9418 will be considered a

slave device in all applications.

Clock and Data Conventions

Data states on the SDA line can change only during

SCL LOW periods (t

). SDA state changes during

LOW

SCL HIGH are reserved for indicating start and stop

conditions.

Start Condition

All commands to the X9418 are preceded by the start

condition, which is a HIGH to LOW transition of SDA

while SCL is HIGH (t

). The X9418 continuously

HIGH

monitors the SDA and SCL lines for the start condition

and will not respond to any command until this

condition is met.

Stop Condition

All communications must be terminated by a stop

condition, which is a LOW to HIGH transition of SDA

while SCL is HIGH.

Acknowledge

Acknowledge is a software convention used to provide

a positive handshake between the master and slave

devices on the bus to indicate the successful receipt of

data. The transmitting device, either the master or the

slave, will release the SDA bus after transmitting eight

bits. The master generates a ninth clock cycle and

during this period the receiver pulls the SDA line LOW

to acknowledge that it successfully received the eight

bits of data.

3

FN8194.3

October 12, 2006

X9418

www.BDTIC.com/Intersil

The X9418 will respond with an acknowledge after

recognition of a start condition and its slave address

and once again after successful receipt of the

command byte. If the command is followed by a data

byte the X9418 will respond with a final acknowledge.

Array Description

The X9418 is comprised of two resistor arrays. Each

array contains 63 discrete resistive segments that are

connected in series. The physical ends of each array

are equivalent to the fixed terminals of a mechanical

potentiometer (V

and VL/RL inputs).

H/RH

At both ends of each array and between each resistor

segment is a CMOS switch connected to the wiper

(V

) output. Within each individual array only one

W/RW

switch may be turned on at a time. These switches are

controlled by the Wiper Counter Register (WCR). The

six bits of the WCR are decoded to select, and enable,

one of sixty-four switches.

The WCR may be written directly, or it can be changed

by transferring the contents of one of four associated

Data Registers into the WCR. These Data Registers

and the WCR can be read and written by the host

system.

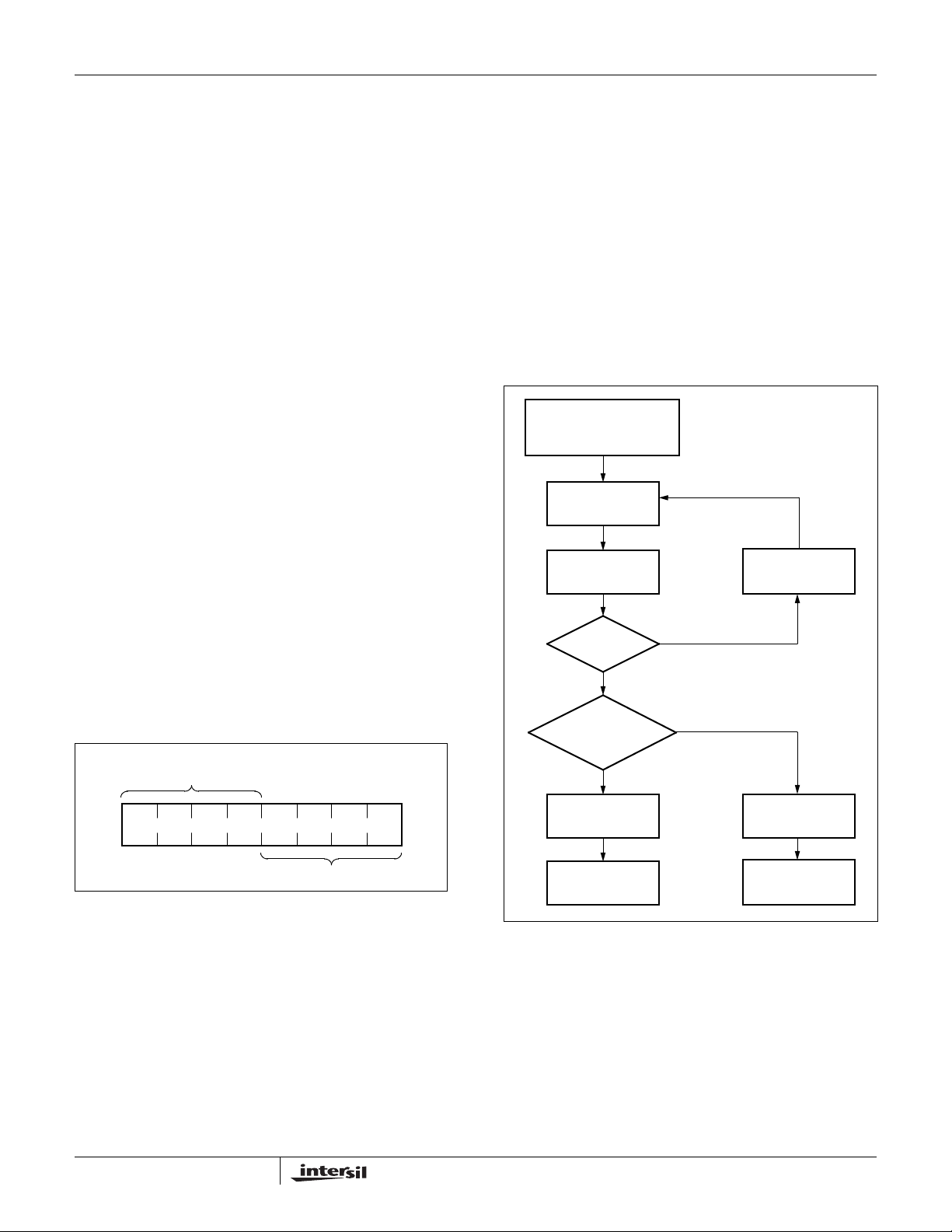

Device Addressing

Following a start condition the master must output the

address of the slave it is accessing. The most

significant four bits of the slave address are the device

type identifier (refer to Figure 1 below). For the X9418

this is fixed as 0101[B].

Acknowledge Polling

The disabling of the inputs, during the internal

nonvolatile write operation, can be used to take

advantage of the typical 5ms EEPROM write cycle

time. Once the stop condition is issued to indicate the

end of the nonvolatile write command the X9418

initiates the internal write cycle. ACK polling can be

initiated immediately. This involves issuing the start

condition followed by the device slave address. If the

X9418 is still busy with the write operation no ACK will

be returned. If the X9418 has completed the write

operation an ACK will be returned, and the master can

then proceed with the next operation.

Flow 1. ACK Polling Sequence

Nonvolatile Write

Command Completed

Enter ACK Polling

Issue

START

Issue Slave

Address

ACK

Returned?

YES

NO

Issue STOP

Figure 1. Slave Address

Device Type

Identifier

100

1

A3 A2 A1 A0

Device Address

The next four bits of the slave address are the device

address. The physical device address is defined by

the state of the A

- A3 inputs. The X9418 compares

0

the serial data stream with the address input state; a

successful compare of all four address bits is required

for the X9418 to respond with an acknowledge. The

- A3 inputs can be actively driven by CMOS input

A

0

signals or tied to V

or VSS.

CC

4

Further

Operation?

YES

Issue

Instruction

Proceed

NO

Issue STOP

Proceed

Instruction Structure

The next byte sent to the X9418 contains the instruction

and register pointer information. The four most

significant bits are the instruction. The next four bits

point to one of the two pots and when applicable they

point to one of four associated registers. The format is

shown Figure 2.

FN8194.3

October 12, 2006

X9418

www.BDTIC.com/Intersil

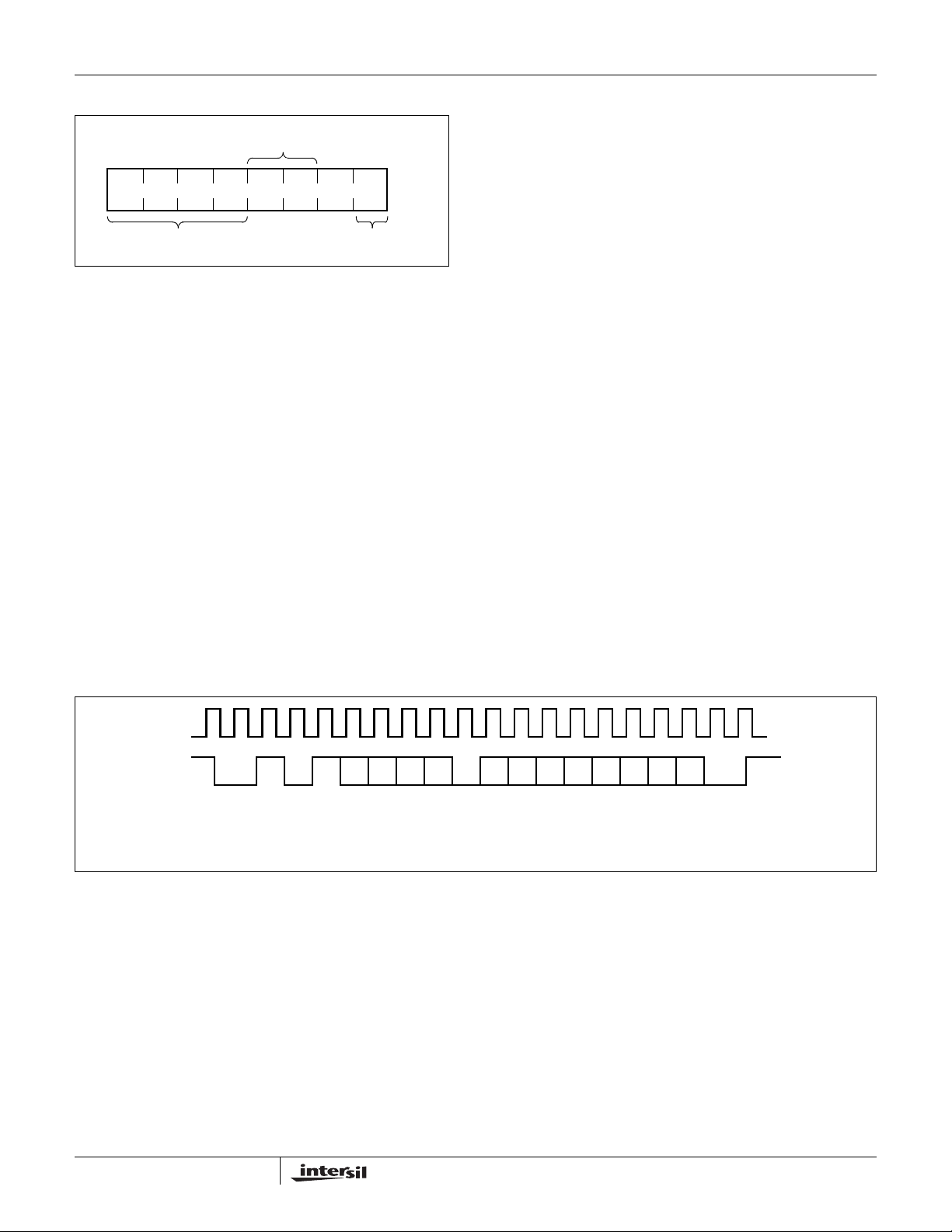

Figure 2. Instruction Byte Format

Register

Select

I1I2I3 I0 R1 R0 0 P0

Instructions

Wiper Counter

Register Select

The four high order bits define the instruction. The

next two bits (R1 and R0) select one of the four

registers that is to be acted upon when a register

oriented instruction is issued. The last bits (P0) select

which one of the two potentiometers is to be affected

by the instruction. Bit 1 is defined to be 0.

Four of the nine instructions end with the transmission

of the instruction byte. The basic sequence is

illustrated in Figure 3. These two-byte instructions

exchange data between the wiper counter register and

one of the data registers. A transfer from a Data

Register to a Wiper Counter Register is essentially a

write to a static RAM. The response of the wiper to this

action will be delayed t

. A transfer from the wiper

WRL

counter register (current wiper position), to a Data

Register is a write to nonvolatile memory and takes a

minimum of t

to complete. The transfer can occur

WR

between one of the two potentiometers and one of its

associated registers; or it may occur globally, wherein

the transfer occurs between both of the

potentiometers and one of their associated registers.

Four instructions require a three-byte sequence to

complete. These instructions transfer data between

the host and the X9418; either between the host and

one of the Data Registers or directly between the host

and the wiper counter register. These instructions are:

Read Wiper Counter Register (read the current wiper

position of the selected pot), write Wiper Counter

Register (change current wiper position of the selected

pot), read Data Register (read the contents of the

selected nonvolatile register) and write Data Register

(write a new value to the selected Data Register). The

sequence of operations is shown in Figure 4.

The Increment/Decrement command is different from

the other commands. Once the command is issued

and the X9418 has responded with an acknowledge,

the master can clock the selected wiper up and/or

down in one segment steps; thereby, providing a fine

tuning capability to the host. For each SCL clock pulse

) while SDA is HIGH, the selected wiper will

(t

HIGH

move one resistor segment towards the V

H/RH

terminal. Similarly, for each SCL clock pulse while

SDA is LOW, the selected wiper will move one resistor

segment towards the V

terminal. A detailed

L/RL

illustration of the sequence and timing for this

operation are shown in Figures 5 and 6 respectively.

Figure 3. Two-Byte Instruction Sequence

SCL

SDA

S

0101A3A2A1A0A

T

A

R

T

I3 I2 I1 I0 R1 R0 0 P0 A

C

K

S

C

T

K

O

P

5

FN8194.3

October 12, 2006

X9418

www.BDTIC.com/Intersil

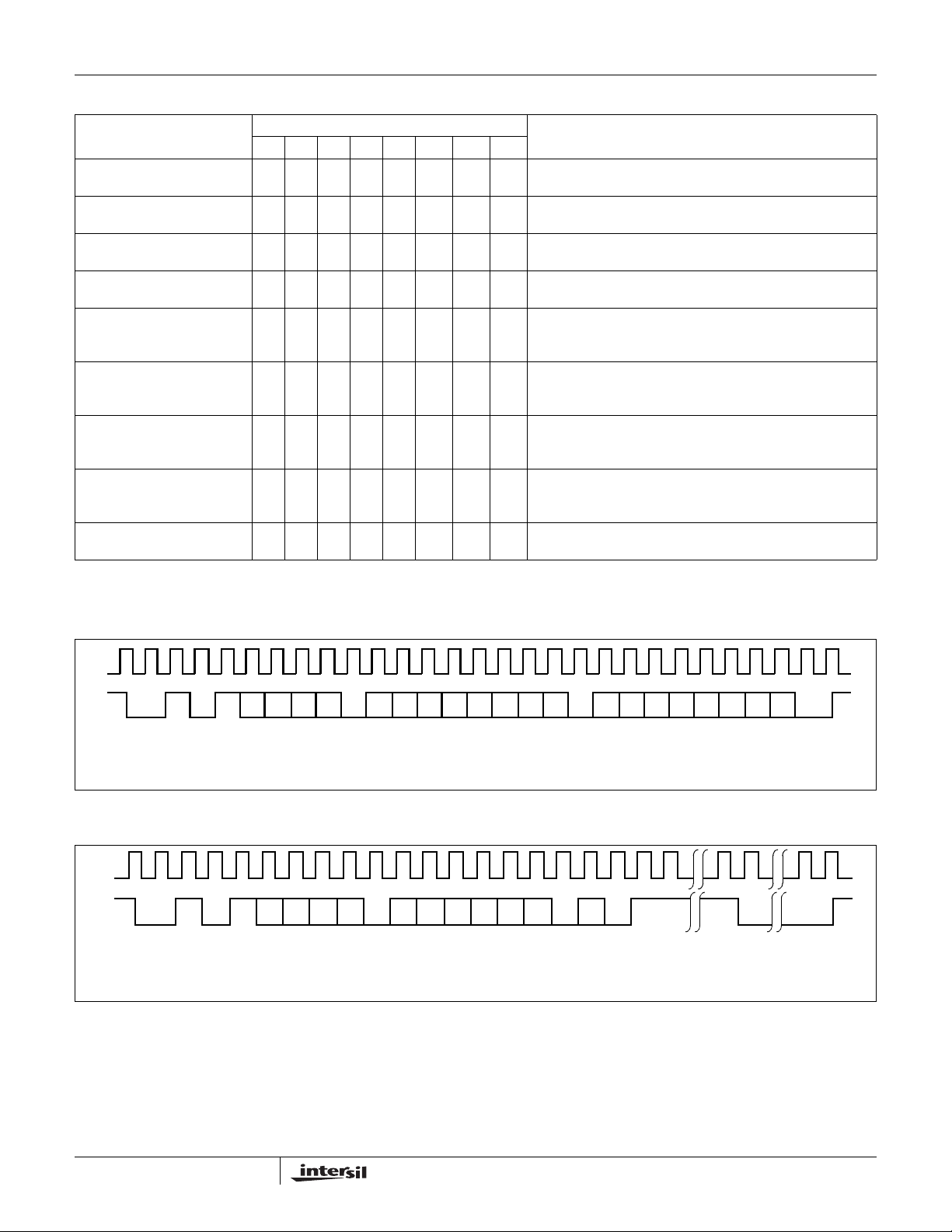

Table 1. Instruction Set

Instruction Set

Instruction

Read Wiper Counter

Register

Write Wiper Counter

Register

3I2I1I0R1R0P1P0

1 0 0 1 0 0 0 1/0 Read the contents of the Wiper Counter Register

pointed to by P

1 0 1 0 0 0 0 1/0 Write new value to the Wiper Counter Register

pointed to by P

Read Data Register 1 0 1 1 1/0 1/0 0 1/0 Read the contents of the Data Register pointed to by

and R1 - R

P

0

Write Data Register 1 1 0 0 1/0 1/0 0 1/0 Write new value to the Data Register pointed to by

and R1 - R

P

0

XFR Data Register to

Wiper Counter Register

1 1 0 1 1/0 1/0 0 1/0 Transfer the contents of the Data Register pointed to

and R1 - R0 to its associated Wiper Counter

by P

0

Register

XFR Wiper Counter

Register to Data Register

Global XFR Data

Registers to Wiper

Counter Registers

Global XFR Wiper

Counter Registers to

Data Register

Increment/Decrement

Wiper Counter Register

Note: (7) 1/0 = data is one or zero

1 1 1 0 1/0 1/0 0 1/0 Transfer the contents of the Wiper Counter Register

pointed to by P

- R

R

1

0

0 0 0 1 1/0 1/0 0 0 Transfer the contents of the Data Registers pointed

to by R

- R0 of both pots to their respective Wiper

1

Counter Registers

1 0 0 0 1/0 1/0 0 0 Transfer the contents of both Wiper Counter

Registers to their respective data Registers pointed

to by R

- R0 of both pots

1

0 0 1 0 0 0 0 1/0 Enable Increment/decrement of the Wiper Counter

Register pointed to by P

OperationI

0

0

0

0

to the Data Register pointed to by

0

0

Figure 4. Three-Byte Instruction Sequence

SCL

SDA

S

0 1 0 1 A3 A2 A1 A0 A

T

A

R

T

I3 I2 I1 I0 R1 R0 0 P0 A

C

K

Figure 5. Increment/Decrement Instruction Sequence

SCL

SDA

S

0 1 0 1 A3 A2 A1 A0 A

T

A

R

T

I3 I2 I1 I0 R0 0 P0 A

C

K

R1

0 0 D5 D4 D3 D2 D1 D0

C

K

XX

I

I

N

C

K

N

C

C

1

2

D

I

E

N

C

C

1

n

A

S

C

T

K

O

P

S

D

T

E

O

C

P

n

6

FN8194.3

October 12, 2006

Loading...

Loading...