查询X80010供应商

®

X80010, X80011, X80012, X80013

PRELIMINARY

Data Sheet January 13, 2005

Penta-Power Sequence Controller

with Hot swap and System Management

The X80010, X80011, X80012, X80013 contain three major

functions: a power sequencing controller, a hotswap

controller, and systems management support.

The power sequencer controller time sequences up to five

DC/DC modules. The device allows various DC/DC power

sequencing configurations, either parallel or relay modes.

The power good, enable, and voltage good signals provide

for flexible DC/DC timing configurations. Each voltage

enable signal has a built-in delay while additional delay can

be added with simple external passive components.

The hot swap controller allows a board to be safely inserted

and removed from a live backplane without turning off the

main power supply. The X80010 family of devices offers a

modular, power distribution approach by providing flexibility

to solve the hotswap and power sequencing issues for

insertion, operations, and extraction. Hardshort Detection

and Retry with Delay, Noise filtering, Insertion Overcurrent

Bypass, and Gate Current selection are some of the

integrated features of the device. During insertion, the gate

of an external power MOSFET is clamped low to suppress

contact bounce. The undervoltage/overvoltage circuits and

the power on reset circuitry suppress the gate turn on until

the mechanical bounce has ended. The X80010 turns on the

gate with a user set slew rate to limit the inrush current and

incorporates an electronic circuit breaker set by a sense

resistor. After the load is successfully charged, the PWRGD

signal is asserted; indicating that the device is ready to

power sequence the DC/DC power bricks.

FN8149.0

Features

• Integrates Three Major Functions

- Power Sequencing

- Hot Swap Controller

- System Management Functions

• Penta-Power Sequencing

- Sequence up to 5 DC/DC converters.

- Four independent voltage enable pins

- Four time delay circuits

- Soft Power Sequencing - MRC pin restarts sequence

without power cycling.

• Hot Swap Controller

- Programmable overvoltage and undervoltage protection

- Undervoltage lockout for battery/redundant supplies

- Electronic circuit breaker - Overcurrent Detection and

Gate Shut-off

- Overcurrent limit during Insertion

- Hardshort retry with retry failure flag

- Selectable gate current using IGQ pins (10, 70, 150µA)

- MRH pin controls board insertion/extraction.

- Typically operates from -30V to -80V. Tolerates

transients to -200V (limited by external components)

• System Management

- Reset output, with delay, holds off host until all supplies

are good

- Host control of reinsertion with MRH input

- Host control of resequencing using MRC input

• Available packages

- 32-lead Quad No-Lead Frame (QFN)

Systems management function provides a reset signal

indicating that the power good and all the voltage good

signals are active. The reset signal is asserted after a wait

state delay. This signal is used to coordinate the hotswap

and DC/DC module latencies during power up to avoid

"power hang up". In addition, the CPU host can initiate soft

insertion or DC voltage module re-sequencing.

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 321-724-7143

Applications

• -48V Hot Swap Power Backplane/Distribution Central

Office, Ethernet for VOIP

• Card Insertion Detection

• Power Sequencing DC/DC/Power Bricks

• IP Phone Applications

• Databus Power Interfacing

• Custom Industrial Power Backplanes

• Distributed Power Systems

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

All other trademarks mentioned are the property of their respective owners.

Copyright Intersil Americas Inc. 2005. All Rights Reserved

Pinout

QFN package

(Top view)

GQ0

I

MRH

I

32

V

RGO

NA1

V4GOOD

EN4

V3GOOD

EN3

V2GOOD

EN2 817

1

2

3

4

(7mm x 7mm)

5

6

7

91011121314

EE

DD

V

V

Ordering Information

X80010, X80011, X80012, X80013

GQ1

PWRGD

UV/OV

V

SENSE

EE

V

FAR

BA TT-ON

NC

262728293031

GATE

25

15

16

NA1

DRAIN

24

23

22

21

20

19

18

NA1

NC

MRC

NA1

RESET

V1GOOD

EN1

NA2

NA2

RETRY

DELAY

(ms)

I

GATE

(µA)

T

DELAY

(ms)

t

POR

(ms)

TEMP RANGE

(°C)

MARK

ORDER

NUMBER

OV

(V)

UV1

(V)

UV2

(V)

t

NF

(us)

V

OC

(mV)

V

OCI

(mV)

OVER

CURRENT

RETRY

X80010Q32I 74.9 42.4 33.2 5 50 150 Always 100 50 100 100 -40 to 85 80010I

X80011Q32I 68.0 42.4 33.2 5 50 150 Always 100 50 100 100 -40 to 85 80011I

X80012Q32I 74.9 42.4 33.2 5 50 150 5 retries 100 50 100 100 -40 to 85 80012I

X80013Q32I 68.0 42.4 33.2 5 50 150 5 retries 100 50 100 100 -40 to 85 80013I

Typical Application

BackPlane

-48V

RTN

-48V

R5

30k

1%

12V

R4

182k

1%

R6

10k

1%

4.7V

X80010, X80011,

X80012, X80013

OV=71V

V

UV/OV

UV=37V

V

DD

V

SENSE

EE

0.1uF

Rs

0.02Ω

5%

IRFR120

GATE

Q1

PWRGD

V1GOOD

V2GOOD

V3GOOD

DRAIN

100

EN1

EN2

EN3

4.7K

3.3n

100K

DC/DC

Module

1

ON/OFF

DC/DC

Module

2

ON/OFF

V1

DC/DC

Module

3

ON/OFF

V2

DC/DC

Module

4

ON/OFF

V3

PAR T

V4

2

FN8149.0

January 13, 2005

X80010, X80011, X80012, X80013

Absolute Maximum Ratings Recommended Operating Conditions

Temperature under bias . . . . . . . . . . . . . . . . . . . . . –65°C to +135°C

Storage temperature . . . . . . . . . . . . . . . . . . . . . . . –65°C to +150°C

Voltage on given pin (Hot Side Functions):

V

ov/uv pin

SENSE pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 400mV + V

VEE pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -80V

DRAIN pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48V + V

PWRGD pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7V + V

GATE pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . VDD + V

FAR pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7V + V

MRH pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.5V + V

BATT_ON pin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.5V + V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.5V + V

EE

EE

EE

EE

EE

EE

EE

EE

Voltage on given pin (Cold Side Functions):

ENi

pins (i = 1 to 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5V

ViGOOD

RESET pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5.5V + V

MRC pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.5V + V

IGQ1 and IGQ0 pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.5V + V

VDD pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14V + V

D.C. output current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5mA

pins (i = 1 to 4) . . . . . . . . . . . . . . . . . . . . . . . . . 5.5V + V

EE

EE

EE

EE

EE

Lead temperature (soldering, 10 seconds) . . . . . . . . . . . . . . .300°C

CAUTION: Stresses above those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress rating only; functional

operation of the device (at these or any other conditions above those listed in the operational sections of this specification) is not implied. Exposure to absolute maximum

rating conditions for extended periods may affect device reliability.

Temperature Range (Industrial) . . . . . . . . . . . . . . . . . . -40°C to 85°C

Supply Voltage (V

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12V

DD

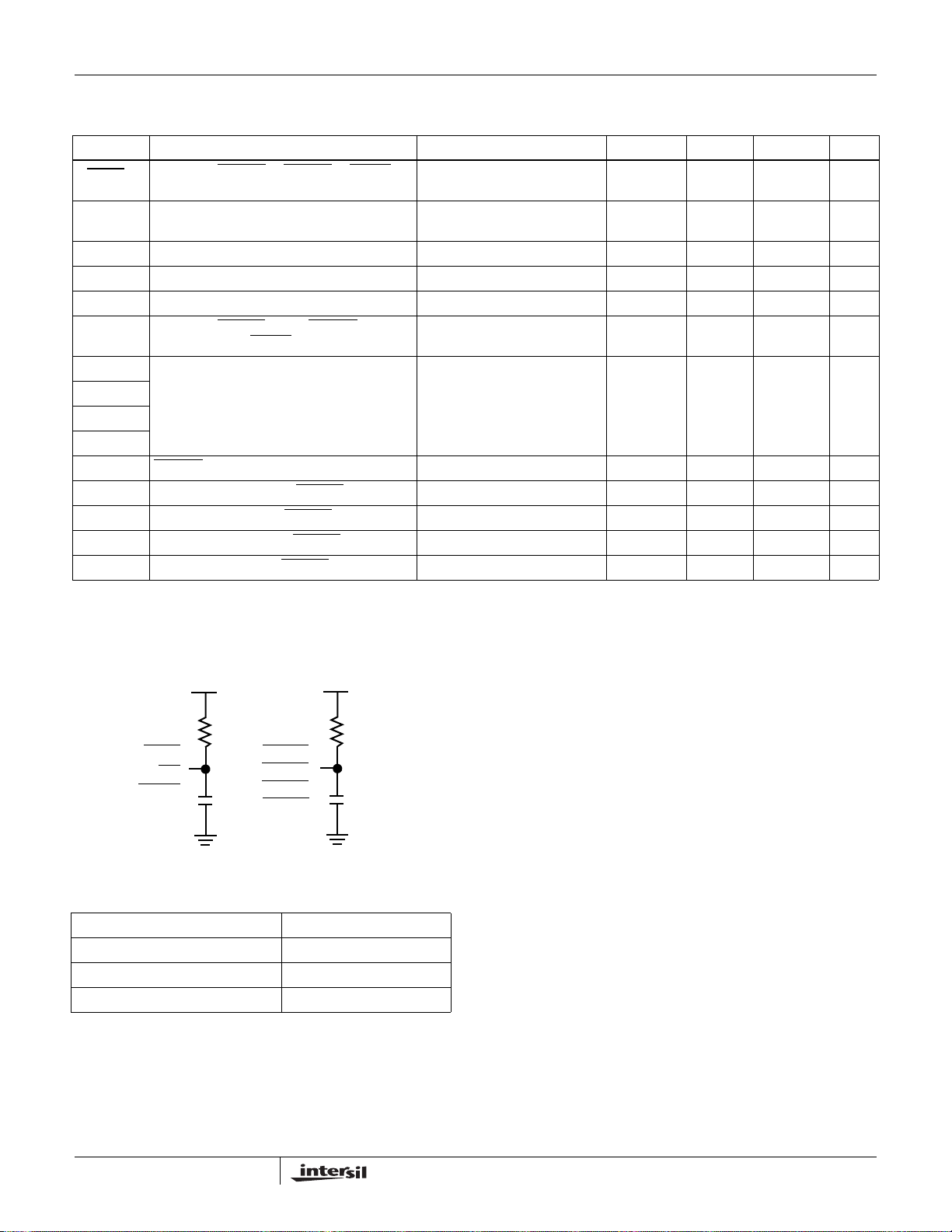

Electrical Specifications (Standard Settings)

Over the recommended operating conditions unless otherwise specified.

SYMBOL PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

DC CHARACTERISTICS

V

I

V

I

RGO

I

GATE

V

GATE

V

V

V

I

V

V

DD

RGO

PGA

IHB

ILB

I

LO

IL

IH

Supply Operating Range 10 12 14 V

DD

Supply Current 2.5 5 mA

Regulated 5V output I

V

current output 50 µA

RGO

Gate Pin Current Gate Drive On,

External Gate Drive (Slew Rate Control) I

Power Good Threshold

(PWRGD

High to Low)

= 10µA 4.5 6.0

RGO

46.2 52.5 58.8 µA

V

= VEE,

GATE

V

= V

SENSE

- VEE = 3V

V

GATE

V

SENSE-VEE

= 50µA VDD-1 V

GATE

Referenced to V

V

< V

UV1

(sourcing)

EE

= 0.1V (sinking)

EE

< V

UV/OV

9mA

0.9 1 1.1 V

OV

Voltage Input High (BATT_ON) VEE + 4 VEE + 5 V

Voltage Input Low (BATT_ON) VEE + 2 V

Input Leakage Current (MRH, MRC) VIL = GND to V

LI

Output Leakage Current

(V1GOOD

RESET

(3)

Input LOW Voltage (MRH, MRC, IGQ0, IGQ1) -0.5 + V

(3)

Input HIGH Voltage (MRH, MRC, IGQ0, IGQ1) (VEE + 5) x

, V2GOOD, V3GOOD, V4GOOD,

)

All ENi

= V

CC

for i = 1 to 4 10 µA

RGO

EE

0.7

DD

10 µA

(VEE + 5) x

0.3

(VEE + 5) +

0.5

V

V

V

3

FN8149.0

January 13, 2005

X80010, X80011, X80012, X80013

Electrical Specifications (Standard Settings)

Over the recommended operating conditions unless otherwise specified. (Continued)

SYMBOL PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

Output LOW Voltage

OL

(RESET, RESET

V3GOOD

(1)

C

OUT

Output Capacitance

(RESET

, V1GOOD, V2GOOD, V3GOOD,

V4GOOD

(1)

C

IN

V

V

OCI

V

OVR

V

OVH

V

UV1H

V

UV1F

V

UV2H

V

UV2F

V

DRAINF

V

DRAINR

V

TRIP1

V

TRIP2

V

TRIP3

V

TRIP4

OC

Input Capacitance (MRH, MRC) VIN = 0V 6 pF

Over-current threshold VOC = V

Over-current threshold (Insertion) VOC = V

Overvoltage threshold (rising)

Overvoltage hysteresis Referenced to V

Undervoltage 1 hysteresis Referenced to V

Undervoltage 1 threshold (falling) 2.16 2.21 2.26 V

Undervoltage 2 hysteresis Referenced to V

Undervoltage 2 threshold (falling) 1.68 1.73 1.78 V

Drain sense voltage threshold

(falling)

Drain sense voltage threshold

(rising)

EN1 Trip Point Voltage Referenced to V

EN2 Trip Point Voltage Referenced to V

EN3 Trip Point Voltage Referenced to V

EN4 Trip Point Voltage Referenced to V

AC CHARACTERISTICS

t

FOC

t

FUV

t

FOV

t

VFR

t

BATT_ON

t

MRC

t

MRH

t

MRCE

t

MRCD

t

MRHE

t

MRHD

Sense High to Gate Low 1.5 2.5 3.5 µs

Under Voltage conditions to Gate Low 0.5 1.0 1.5 µs

Overvoltage Conditions to Gate Low 1.0 1.5 2 µs

Overvoltage/undervoltage failure recovery time

to Gate =1V.

Delay BATT_ON Valid 100 ns

Minimum time high for reset valid on the MRC

pin

Minimum time high for reset valid on the MRH

pin

Delay from MRC enable to PWRGD HIGH No Load 1.0 1.6 µs

Delay from MRC disable to PWRGD LOW Gate is On, No Load 200 400 µs

Delay from MRH enable to Gate Pin LOW I

Delay from MRH disable to GATE reaching 1V I

, V1GOOD, V2GOOD,

, V4GOOD, FAR, PWRGD)

, FAR)

X80010, X80012

X80011, X80013

I

= 4.0mA

OL

(V

+ 2.7 to VEE + 5.5V)

EE

I

= 2.0mA

OL

(V

+ 2.7 to VEE + 3.6V)

EE

V

= 0V 8 pF

OUT

SENSE

PWRGD = HIGH

SENSE

- V

- V

EE

EE

45 50 55 mV

135 150 165 mV

Initial Power Up condition

Referenced to V

BATT-ON = V

BATT-ON = V

Referenced to V

Referenced to V

EE

EE

EE

EE

EE

RGO

EE

EE

EE

EE

EE

EE

VDD does not drop below 3V, No

3.85

3.49

3.90

3.54

12 18 24 mV

12 18 24 mV

12 18 24 mV

0.9 1 1.1 V

1.2 1.3 1.4 V

2.25 2.5 2.75 V

2.25 2.5 2.75 V

2.25 2.5 2.75 V

2.25 2.5 2.75 V

1.2 1.6 2 µs

other failure conditions.

5 µs

5 µs

= 60µA, No Load 1.0 1.6 2.4 µs

GATE

= 60µA, No Load 1.8 2.6 µs

GATE

V

+ 0.4 V

EE

3.95

3.59

V

4

FN8149.0

January 13, 2005

X80010, X80011, X80012, X80013

Electrical Specifications (Standard Settings)

Over the recommended operating conditions unless otherwise specified. (Continued)

SYMBOL PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

t

RESET_E

t

QC

t

SC_RETRY

t

NF

t

DPOR

t

SPOR

t

DELAY1

t

DELAY2

t

DELAY3

t

DELAY4

t

TO

t

PDHLPG

t

PDLHPG

t

PGHLPG

t

PGLHPG

NOTE:

1. This parameter is based on characterization data.

Delay from PWRGD or ViGOOD to RESET

1 µs

valid LOW

Delay from IGQ1 and IGQ0 to valid Gate pin

1 µs

current

Delay between Retries 85 100 115 ms

Noise Filter for Overcurrent 4.5 5 5.5 µs

Device Delay before Gate assertion 45 50 55 ms

Delay after PWRGD and all ViGOOD signals

are active before RESET

assertion

Power Sequencing Time Delay

85 100 115 ms

85 100 115 ms

TiD1 = 0; TiD0 = 0

ViGOOD turn off time 50 ns

(1)

Delay from Drain good to PWRGD LOW Gate = V

(1)

Delay from Drain fail to PWRGD HIGH Gate = V

(1)

Delay from Gate good to PWRGD LOW Drain = V

(1)

Delay from Gate fail to PWRGD HIGH Drain = V

DD

DD

EE

EE

1 µs

1 µs

1 µs

1 µs

Equivalent A.C. Output Load Circuit

5V

4.6kΩ

,

30pF

RESET

FAR

PWRGD

5V

4.6kΩ

30pF

V1GOOD,

V2GOOD,

V3GOOD

V4GOOD

A.C. Test Conditions

Input pulse levels VCC x 0.1 to VCC x 0.9

Input rise and fall times 10ns

Input and output timing levels V

Output load Standard output load

CC

x 0.5

5

FN8149.0

January 13, 2005

V

UV/OV

VDD

X80010, X80011, X80012, X80013

V

TH

t

DPOR

V

OV

V

UV

t

FOV

t

VFR

t

FUV

t

VFR

MRH

SENSE

GATE

VDD

SENSE

GATE

V

OCI

V

OC

1V 1V

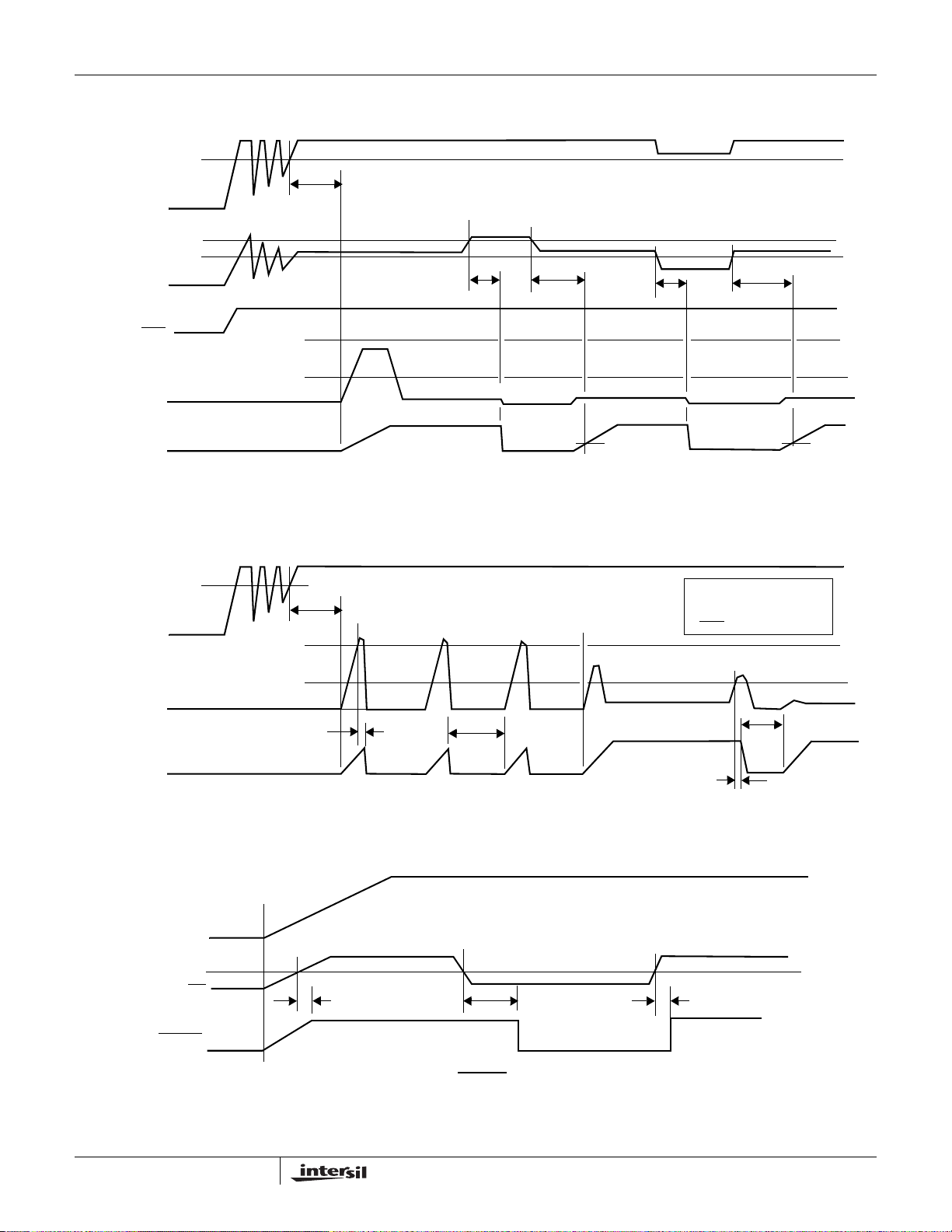

FIGURE 1. OVERVOLTAGE/UNDERVOLTAGE GATE TIMING

V

TH

t

DPOR

Always Retry

< V

V

UV

UV/OV < VOV

MRH = HIGH

V

OCI

V

OC

t

t

FOC

t

SC_RETRY

t

FOC

SC_RETRY

FIGURE 2. OVERCURRENT GATE TIMING

VDD

V

TRIPi

ENi

ViGOOD

Initial

Power-up

6

t

TO

t

DELAYi

Enable DC/DC supply

t

TO

i = 1, 2, 3, 4

FIGURE 3. ViGOOD TIMINGS

FN8149.0

January 13, 2005

MRH

t

MRH

X80010, X80011, X80012, X80013

MRC

t

MRC

GATE

t

MRHE

FIGURE 4. MANUAL RESET (HOT SIDE) MRH

V

DRAIN

V

GATE

PWRGD

ENi

V1GOOD

V2GOOD

1V

t

DHLPG

t

GLHPG

t

MRHD

t

DELAY1

t

DELAY2

PWRGD

t

MRCE

FIGURE 5. MANUAL RESET (COLD SIDE) MRC

t

DLHPG

t

GHLPG

t

MRCD

V3GOOD

V4GOOD

RESET

t

DELAY3

t

DELAY4

t

SPOR

FIGURE 6. RESET TIMINGS

PWRGD or

any ENi LOW to HIGH

(1st occurance)

t

RESET_E

7

FN8149.0

January 13, 2005

X80010, X80011, X80012, X80013

Typical Performance Characteristics

52.000

51.000

50.000

49.000

48.000

47.000

INRUSH CURRENT LIMIT (mV)

46.000

-55 -40 -25 -10 5 20 35 50 65 80 95 110 125

TEMPERATURE

FIGURE 7. OVER CURRENT THRESHOLD vs

TEMPERATURE

3.92

3.91

3.90

3.89

3.88

3.87

OV THRESHOLD (V)

3.86

3.85

-55 -40 -25 -10 5 20 35 50 65 80 95 110 125

TEMPERATURE

Rising

Falling

FIGURE 9. OVERVOLTAGE THRESHOLD vs TEMPERATURE

1.780

1.770

1.760

1.750

1.740

1.730

1.720

1.710

1.700

1.690

UNDER VOLTAGE 2 THRESHOLD (V)

-55 -40 -25 -10 5 20 35 50 65 80 95 110 125

TEMPERATURE

FIGURE 8. UNDERVOLTAGE 2 THRESHOLD vs

TEMPERATURE

2.515

2.510

2.505

2.500

2.495

2.490

2.485

ENi THRESHOLD (V)

2.480

2.475

-55 -40 -25 -10 5 20 35 50 65 80 95 110 125

TEMPERATURE

FIGURE 10. ENi

THRESHOLD vs TEMPERATURE

Rising

Falling

2.250

2.240

2.230

2.220

2.210

2.200

UNDER VOLTAGE 1 THRESHOLD (V)

2.190

-55 -40 -25 -10 5 20 35 50 65 80 95 110 125

TEMPERATURE

FIGURE 11. UNDERVOLTAGE 1 THRESHOLD vs

TEMPERATURE

8

Rising

Falling

200

160

120

80

GATE CURRENT (µA)

40

0

-55 -40 -25 -10 5 20 35 50 65 80 95 110 125

TEMPERATURE

FIGURE 12. I

(SOURCE) vs TEMPERATURE

GATE

150µA

70µA

50µA

10µA

FN8149.0

January 13, 2005

X80010, X80011, X80012, X80013

Typical Performance Characteristics (Continued)

11.0

10.5

10.0

9.5

9.0

8.5

8.0

7.5

GATE CURRENT - SINK (mA)

7.0

-55 -40 -25 -10 5 20 35 50 65 80 95 110 125

TEMPERATURE

(µs)

UV

t

0.800

0.750

0.700

0.650

0.600

0.550

FIGURE 13. I

(SINK) vs TEMPERATURE

GATE

tUV2

tUV1

2.5

2.4

2.3

2.2

(µs)

2.1

OC

t

2.0

1.9

1.8

1.7

-55 -40 -25 -10 5 20 35 50 65 80 95 110 125

TEMPERATURE

FIGURE 14. T

1.02

1.00

0.98

0.96

(NORMALIZED)

0.94

DELAY

t

0.92

vs TEMPERATURE

FOC

0.500

-55-40-25-105 203550658095110125

TEMPERATURE

FIGURE 15. t

1.4

1.4

1.3

1.3

(µs)

1.2

OV

t

1.2

1.1

1.1

1.0

-55-40-25-105 203550658095110125

FIGURE 17. t

vs TEMPERATURE

FUV

TEMPERATURE

vs TEMPERATURE

FOV

0.90

-55 -35 -15 5 25 45 65 85

TEMPERATURE

FIGURE 16. t

vs TEMPERATURE

DELAYi

9

FN8149.0

January 13, 2005

X80010, X80011, X80012, X80013

Typical Performance Characteristics (Continued)

52.000

51.000

50.000

49.000

48.000

47.000

INRUSH CURRENT LIMIT (mV)

46.000

-55 -40 -25 -10 5 20 35 50 65 80 95 110 125

TEMPERATURE

FIGURE 18. OVER CURRENT THRESHOLD vs TEMPERATURE

3.92

3.91

3.90

3.89

3.88

3.87

OV THRESHOLD (V)

3.86

3.85

-55 -40 -25 -10 5 20 35 50 65 80 95 110 125

TEMPERATURE

Rising

Falling

1.780

1.770

1.760

1.750

1.740

1.730

1.720

1.710

1.700

UNDER VOLTAGE 2 THRESHOLD (V)

1.690

-55 -40 -25 -10 5 20 35 50 65 80 95 110 125

TEMPERATURE

FIGURE 19. UNDERVOLTAGE 2 THRESHOLD vs

TEMPERATURE

2.515

2.510

2.505

2.500

2.495

2.490

2.485

ENi THRESHOLD (V)

2.480

2.475

-55 -40 -25 -10 5 20 35 50 65 80 95 110 125

TEMPERATURE

Rising

Falling

FIGURE 20. OVERVOLTAGE THRESHOLD vs TEMPERATURE

2.250

2.240

2.230

2.220

2.210

2.200

UNDER VOLTAGE 1 THRESHOLD (V)

2.190

-55 -40 -25 -10 5 20 35 50 65 80 95 110 125

TEMPERATURE

Rising

Falling

FIGURE 22. UNDERVOLTAGE 1 THRESHOLD vs

TEMPERATURE

10

FIGURE 21. ENi

200

160

120

80

GATE CURRENT (µA)

40

0

-55 -40 -25 -10 5 20 35 50 65 80 95 110 125

FIGURE 23. I

THRESHOLD vs TEMPERATURE

150µA

70µA

50µA

10µA

TEMPERATURE

(SOURCE) vs TEMPERATURE

GATE

FN8149.0

January 13, 2005

X80010, X80011, X80012, X80013

Typical Performance Characteristics (Continued)

11.0

10.5

10.0

9.5

9.0

8.5

8.0

7.5

GATE CURRENT - SINK (mA)

7.0

-55 -40 -25 -10 5 20 35 50 65 80 95 110 125

TEMPERATURE

(µs)

t

0.800

0.750

0.700

0.650

UV

0.600

0.550

FIGURE 24. I

(SINK) vs TEMPERATURE

GATE

tUV2

tUV1

2.5

2.4

2.3

2.2

(µs)

2.1

OC

t

2.0

1.9

1.8

1.7

-55 -40 -25 -10 5 20 35 50 65 80 95 110 125

TEMPERATURE

FIGURE 25. t

1.02

1.00

0.98

0.96

(NORMALIZED)

0.94

DELAY

t

0.92

vs TEMPERATURE

FOC

0.500

-55-40-25-105 203550658095110125

TEMPERATURE

FIGURE 26. t

1.4

1.4

1.3

1.3

(µs)

1.2

OV

t

1.2

1.1

1.1

1.0

-55-40-25-105 203550658095110125

FIGURE 28. t

vs TEMPERATURE

FUV

TEMPERATURE

vs TEMPERATURE

FOV

0.90

-55 -35 -15 5 25 45 65 85

TEMPERATURE

FIGURE 27. t

vs TEMPERATURE

DELAYi

11

FN8149.0

January 13, 2005

V

UV/OV

BATT-ON

DRAIN

GATE

X80010, X80011, X80012, X80013

PWRGD

V

Ref

OV

V

Ref

UV1

V

Ref

UV2

V

V

EE

1V Ref

RGO

2:1

MUX

50µA

V

DD

Power Good

Logic

Over current

logic, Hard short

relay, Retry logic

status and delay

V

EE

FAR

V

EE

V

DD

IGQ1

IGQ0

SENSE

V

EE

MRH

MRC

EN1

EN2

EN3

EN4

Slew Rate

Selection

Gate

Control

POR

5V reg.

V

RGO

RESET

V

EE

3R

V

EE

VOC REF

V

RGO

38R

OSC

Divider

Reset

4

repeated 4 times

4

Select

0.1s

0.5s

1s

5s

delay1

delay2

delay3

delay4

Delay circuit

Reset Logic

and Delay

Sequence

and Timing

Control logic

V

EE

V

EE

V1GOOD

V2GOOD

V3GOOD

V4GOOD

12

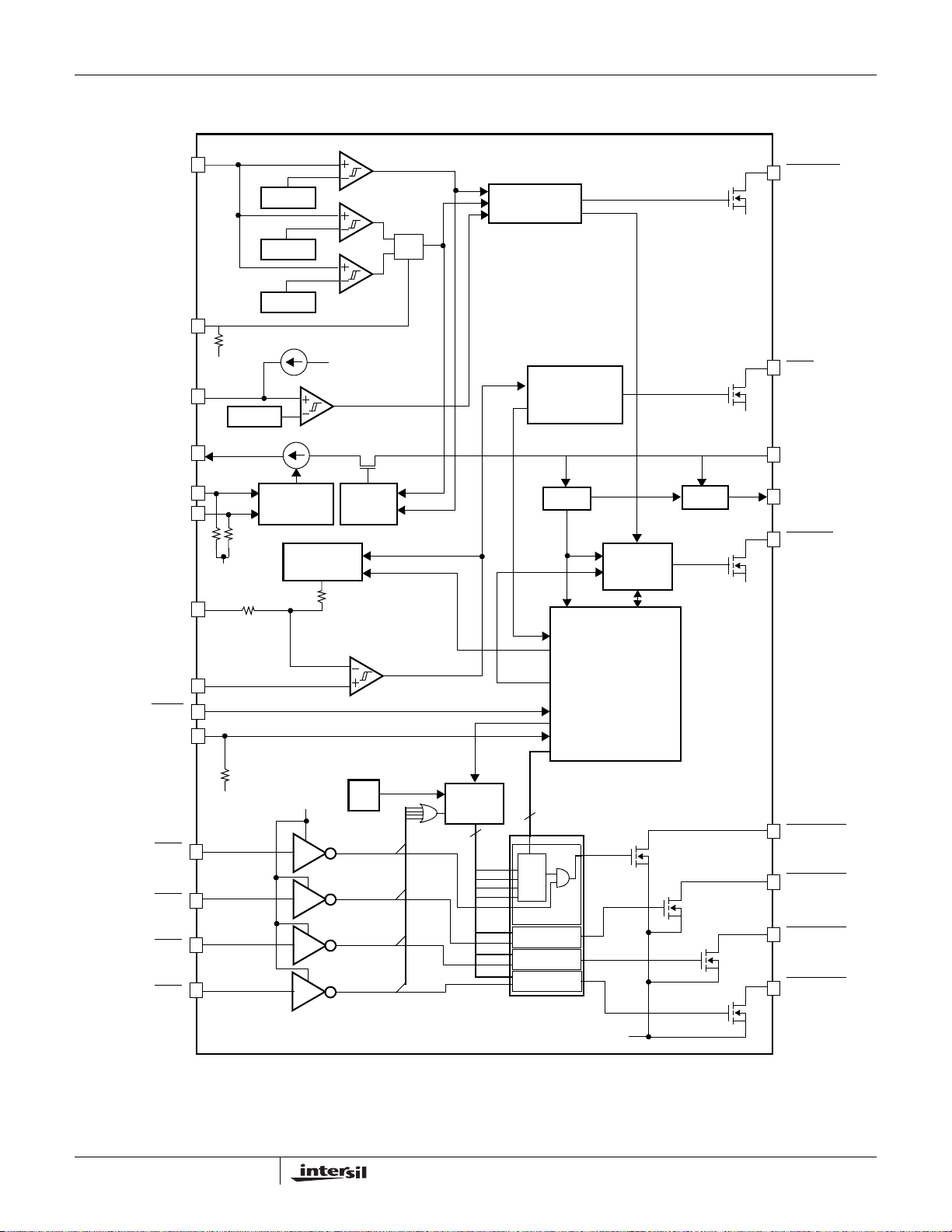

FIGURE 29. BLOCK DIAGRAM

FN8149.0

January 13, 2005

X80010, X80011, X80012, X80013

Pin Configuration

X80010, X80011, X80012, X80013

32-lead QFN Quad Package

EE

GQ0

GQ1

I

MRH

I

32

V

RGO

NA1

V4GOOD

EN4

V3GOOD

EN3 EN1

V2GOOD

EN2

1

2

3

4

(7mm x 7mm)

5

6

7

817

910111213 14

EE

DD

V

V

UV/OV

V

FAR

NC

GATE

V

262728293031

25

15

16

NA1

NA1

DRAIN

NC

24

MRC

23

NA1

22

RESET

21

20

V1GOOD

19

NA2

18

NA2

BATT-ON

PWRGD

SENSE

Pin Descriptions

PIN NAME DESCRIPTION

1V

RGO

2NA1Not Available. Do not connect to this pin.

3 V4GOOD

4EN4V4 Voltage Enable Input. Fourth voltage enable pin. If unused connect to V

5 V3GOOD

6EN3V3 Voltage Enable Input. Third voltage enable pin. If unused connect to V

7 V2GOOD

8EN2

9V

DD

10 V

11 V

UV/OV

12 SENSE Circuit Breaker Sense Input. This input pin detects the overcurrent condition.

13 GATE Gate Drive Output. Gate drive output for the external N-channel MOSFET.

14 DRAIN Drain. Drain sense input of the external N-channel MOSFET.

15 NA1 Not Available. Do not connect to this pin.

16 NA1 Not Available. Do not connect to this pin.

17 NA2 Not Available. Connect to V

18 NA2 Not Available. Connect to V

19 EN1

20 V1GOOD

Regulated 5V output. Used to pull-up

user programmable inputs IGQ0, IGQ1, BATT-ON (if needed).

V4 Voltage Good Output. This open drain output goes LOW when EN4 is less than V

greater than V

. There is a user selectable delay circuitry on this pin.

TRIP4

V3 Voltage Good Output (Active Low). This open drain output goes LOW when EN3 is less than V

when EN3

is greater than V

. There is a user selectable delay circuitry on this pin.

TRIP3

V2 Voltage Good Output (Active Low). This open drain output goes LOW when EN2 is less than V

when EN2

is greater than V

. There is a user selectable delay circuitry on this pin.

TRIP2

V2 Voltage Enable Input. Second voltage enable pin. If unused connect to V

Positive Supply Voltage Input.

Negative Supply Voltage Input.

EE

Analog Undervoltage and Overvoltage Input. Turns off the external N-channel MOSFET when there is an undervoltage or

overvoltage condition.

.

RGO

.

RGO

V1 Voltage Enable Input. First voltage enable pin. If unused connect to V

V1 Voltage Good Output (Active Low).This open drain output goes LOW when EN1 is less than V

when EN1

is greater than V

. There is a user selectable delay circuitry on this pin.

TRIP1

RGO

RGO

RGO

.

RGO

.

and goes HIGH when EN4 is

TRIP4

.

and goes HIGH

TRIP3

and goes HIGH

TRIP2

.

and goes HIGH

TRIP1

13

FN8149.0

January 13, 2005

X80010, X80011, X80012, X80013

Pin Descriptions (Continued)

PIN NAME DESCRIPTION

21 RESET RESET Output. This open drain pin is an active LOW output. This pin will be active until PWRGD goes active and the power

22 NA1 Not Available. Do not connect to this pin.

23 MRC Manual Reset Input Cold-side. Pulling the MRC pin HIGH initiates a system side RESET. The MRC signal must be held HIGH

24 NC No Connect. No internal connections.

25 V

26 NC No Connect. No internal connections.

27 FAR

28 BATT-ON Battery On Input. This input signals that the battery backup (or secondary supply) is supplying power to the backplane. It has

29 PWRGD

30 IGQ1 Gate Current Quick Select Bit 1 Input. This pin is used to change the gate current drive and is intended to allow for current

31 IGQ0 Gate Current Quick Select Bit 0 Input. This pin is used to change the gate current drive and is intended to allow for current

32 MRH

sequencing is complete. This pin will be released after a programmable delay.

for 5µs. It has an internal pulldown resistor. (>10mΩ typical)

Negative Supply Voltage Input.

EE

Failure After Re-try (FAR) output signal. Failure After Re-try (FAR) is asserted after a number of retries. Used for Overcurrent

and hardshort detection.

an internal pulldown resistor. (>10mΩ typical)

Power Good Output. This output pin enables a power module.

ramp rate control of the gate pin of an external FET. It has an internal pulldown resistor. (>10mΩ typical)

ramp rate control of the gate pin of an external FET. It has an internal pulldown resistor. (>10mΩ typical)

Manual Reset Input Hot-side. Pulling the MRH pin LOW initiates a GATE pin reset (GATE pin pulled LOW). The MRH signal

must be held LOW for 5µs (minimum).

Functional Description

Hot Circuit Insertion

When circuit boards are inserted into a live backplane, the

bypass capacitors at the input of the board’s power module

or DC/DC converter can draw huge transient currents as

they charge up (See Figure 30). This transient current can

cause permanent damage to the board’s components and

cause transients on the system power supply.

-48V

Return

R4

182K

1%

R5

30k

-48V

1%

R6

10K

1%

V

UV/OV

V

DD

V

EE

0.02Ω

I

inrush

UV=37V

OV=71V

SENSE

Rs

5%

0.1µF

Q1

X80010

X80011

X80012

X80013

GATE

100

IRFR120

4.7k

3.3n

DRAIN

100K

FIGURE 30. TYPICAL -48V HOTSWAP APPLICATION CIRCUIT

The X80010 is designed to turn on a board’s supply voltage

in a controlled manner (see Figure 31), allowing the board to

be safely inserted or removed from a live backplane. The

device also provides undervoltage, overvoltage and

overcurrent protection while keeping the power module

DC/DC

Converter

DC/DC

Converter

-48V

(DC/DC converter) off until the backplane input voltage is

stable and within tolerance.

FIGURE 31. TYPICAL INRUSH WITH GATE SLEW RATE

CONTROL

Overvoltage and Undervoltage Shutdown

The X80010 provides overvoltage and undervoltage

protection circuits. When an overvoltage (V

undervoltage (V

UV1

and V

) condition is detected, the

UV2

GATE pin immediately pulls low. The undervoltage threshold

V

applies to the normal operation with a mains supply.

UV1

The undervoltage threshold V

assumes the system is

UV2

powered by a battery. When using a battery backup, the

OV

) or

14

FN8149.0

January 13, 2005

X80010, X80011, X80012, X80013

BATT-ON pin is pulled to V

. The default thresholds have

RGO

been set so the external resistance values in Figure 30

provide an overvoltage threshold of 74.9V (X80010/X80012)

or 68V (X80011/X80013), a main undervoltage threshold of

43V and a battery undervoltage threshold of 33.8V.

As shown in Figure 34, this circuit block contains

comparators and voltage references to monitor for a single

overvoltage and dual undervoltage trip points. The

overvoltage and undervoltage trip points as shown in Table 1.

TABLE 1. OVERVOLTAGE/UNDERVOLTAGE DEFAULT

SYMBOL DESCRIPTION FALLING RISING

V

OV

V

OV

V

UV1

V

UV2

Notes: 1: Max/Min Voltage is the maximum and minimum operat-

THRESHOLDS

THRESHOLD

Overvoltage

MAX/MIN

VO LTAGE

3.87V 3.9V 74.3 74.9

LOCKOUT

1

VOLTAGE

(X80010/12)

Overvoltage

3.51V 3.54V 67.4 68

(X80011/13)

Undervoltage 1 2.21V 2.24V 43.0 42.4

Undervoltage 2 1.73V 1.76V 33.8 33.2

ing voltage assuming the recommended V

tor divider.

UV/OV

resis-

2: Lockout voltage is the voltage where the X8001x turns

off the FET.

A resistor divider connected between the plus and minus

input voltages and the V

pin (see Figure 32)

UV/OV

determines the overvoltage and undervoltage shutdown

voltages and the operating voltage range. Using the

thresholds in Table and the equations of Figure 32 the

desired operating voltage can be determined. Figure 33

shows the resistance values for various operating voltages

(X80010 and X80012).

100

90

80

V

OV

70

60

50

40

30

20

10

OPERATING VOLTAGE (V)

0

150

V

V

UV1

UV2

158

BATT-ON = V

166

175

R1 in kΩ (for R2=10K)

182

EE

190

Operating

Voltage

BATT-ON = V

198

206

214

RGO

222

FIGURE 33. OPERATING VOLTAGe vs RESISTOR RATIO

2

Battery Back Up Operations

An external signal, BATT_ON is provided to switch the

undervoltage trip point. The BATT_ON signal is a LOGIC

HIGH if V

+ 2V. The time from a BATT_ON input change to a valid new

undervoltage threshold is 100ns. See Electrical

Specifications for more details.

Note: The V

5.5V in worst case conditions. Values for R1 and R2 must be

chosen such that this condition is met. Intersil recommends

R1 = 182kΩ and R2 = 10kΩ to conform to factory settings.

TABLE 2. SELECTING BETWEEN UNDERVOLTAGE TRIP

PIN DESCRIPTION TRIP POINT SELECTION

BATT_ON Undervoltage Trip

V

UV1

> VEE + 4V and is a LOGIC LOW if V

IHB

pin must be limited to less than VEE +

UV/OV

POINTS

If BATT_ON = 0,

V

UV1

If BATT_ON = 1,

V

UV2

and V

Point

Selection Pin

are undervoltage thresholds.

UV2

ILB

trip point is selected;

trip point is selected.

< V

EE

V

P

R1

R2

V

UV/OV

V

S

V

N

Voltage divider:

UV OV⁄

=

V

or:

V

=

SVUV OV⁄

R2

----------------------

V

S

R1 R2+

R1 R2+

----------------------

R2

FIGURE 32. OVERVOLTAGE UNDERVOLTAGE DIVIDER

15

R1

182K

V

UV/OV

R2

10K

-48V

BATT_ON

+

V

OV

Voltage

Reference

+

V

UV1

Voltage

Reference

+

V

UV2

Voltage

Reference

2:1

Mux

To Gate

Control

To Gate

Control

FIGURE 34. OVERVOLTAGE UNDERVOLTAGE FOR PRIMARY

AND BATTERY BACKUP

FN8149.0

January 13, 2005

X80010, X80011, X80012, X80013

Overcurrent Protection (Circuit Breaker Function)

The X80010 over-current circuit provides the following

functions:

- Over-current shut-down of the power FET and external

power good indicators.

- Noise filtering of the current monitor input.

- Relaxed over-current limits for initial board insertion.

- Over-current recovery retry operation.

A sense resistor, placed in the supply path between VEE and

SENSE (see Figure 30) generates a voltage internal to the

X80010. When this voltage exceeds 50mV an over current

condition exists and an internal “circuit breaker” trips, turning

off the gate drive to the external FET. The actual overcurrent level is dependent on the value of the current sense

resistor. For example a 20mΩ sense resistor sets the overcurrent level to 2.5A.

Intersil’s X80010 provides a safety mechanism during

insertion of the board into the back plane. During insertion of

the board into the backplane large currents may be induced.

In order to prevent premature shut down, the overcurrent

detect circuit of the X80010 allows up to 3 times the standard

overcurrent setting during insertion.

After the PWRGD

signal is asserted, the X80010 switches

back to the normal overcurrent setting. The over-current

threshold voltage during insertion is 150mV.

After the Power FET turns off due to an over-current

condition, a retry circuit turns the FET back on after a delay

of 100ms. If the over-current condition remains, the FET

again turns off. For the X80010 and X80012, this sequence

repeats indefinitely until the over-current condition is

released. For the X80011 and X80013, the X80010 retries

five times, then, sets an output signal, FAR

, to indicate a

failure after retry.

Over-current shut-down

As shown in Figure 35, this circuit block contains a resistor

divider, a comparator, a noise filter and a voltage reference

to monitor for over-current conditions.

Voltage

Reference

38R

–

3R

-48V

FIGURE 35. OVERCURRENT DETECTION/SHORT CIRCUIT

R

Overcurrent Event

PROTECTION

Sense

+

noise

filtering

5µs

The overcurrent voltage threshold (V

Gate

Control

ock

Bl

Overcurrent/

Short-Circuit

Retry Logic

RETRY

Delay

) is 50mV. This can

OC

be factory set, by special order, to any setting between

30mV and 100mV. V

and V

pins and across the R

EE

is the voltage between the SENSE

OC

SENSE

resistor. If the

selected sense resistor is 20mW, then 50mV corresponds to

an overcurrent of 2.5A.

If an over-current condition is detected, the GATE is turned

off and all power good indicators go inactive.

Overcurrent Noise Filter

The X80010 has a noise (low pass) filter built into the overcurrent comparator. The comparator will thus require the

current spikes to exceed the overcurrent limit for more than

5µs.

Overcurrent During Insertion

Insertion is defined as the first plug-in of the board to the

backplane. In this case, the X80010 is initially fully powered

off prior to the hot plug connection to the mains supply. This

condition is different from a situation where the mains supply

has temporarily failed resulting in a partial recycle of the

power. This second condition will be referred to as a power

cycle.

16

During insertion, the board can experience high levels of

current for short periods of time as power supply capacitors

charge up on the power bus. To prevent the over-current

sensor from turning off the FET inadvertently, the X80010

has the ability to allow more current to flow through the

powerFET and the sense resistor for a short period of time

until the FET turns on and the PWRGD

signal goes active. In

the X80010, 150mV is allowed across sense resistor the

during insertion (10A assuming a 20mΩ resistor). This

provides a mechanism to reduce insertion issues associated

with huge current surges.

FN8149.0

January 13, 2005

X80010, X80011, X80012, X80013

Hardshort Protection - FET Turn-on Retry

In the event on an over-current or hard short condition, the

X80010 includes a retry circuit. This circuit waits for 100ms,

then attempts to again turn on the FET. If the fault condition

still exists, the FET turns off and the sequence repeats. For

the X80010 and X80012, this process continues indefinitely

until the overcurrent condition does not exist. For the X80011

and X80013, this process repeats five times, only then will

keep the FET off and set the FAR

pin active. After FAR is

asserted, it can be cleared using the master reset pin, MRH

(upon MRH

the power on V

assertion the FAR output is cleared) or cycling

.

DD

If an overcurrent condition does not occur on any retry, the

gate pin proceeds to open at the user defined slew rate.

Gate Drive Output Slew Rate (Inrush Current)

Control

The gate output drives an external N-Channel FET. The

GATE pin goes high when no overcurrent, undervoltage or

overvoltage conditions exist.

The X80010 provides an I

on-chip slew rate control to minimize inrush current. This

I

current limits the inrush current and provides the best

GATE

charge time for a given load, while avoiding overcurrent

conditions.

For applications that require different ramp rates during

insertion and start-up and operations modes, the X80010

provides two external pins, IGQ1 and IGQ0, that allow the

user to switch to different GATE currents on-the-fly by

selecting one of four pre-selected I

IGQ0 and IGQ1 are left unconnected, the gate current is

50µA. The other three settings are 10µA, 70µA and 150µA

(See Figure 36). Typically, the delay from IGQ1 and IGQ0

selection to a change in the GATE pin current is less than

1µs.

I

=

150µA

GATE

70µA

50µA

10µA

Inrush Current

current of 50µA to provide

GATE

currents. When

GATE

overcurrent

I

GATE

For applications that require different ramp rates during

insertion and operation or for applications where a different

gate current is desired, the X80010 provides two external

pins, IGQ1 and IGQ0, that allow the system to switch to a

different GATE current with pre-selected options.

The IGQ1 and IGQ0 pins can be used to select from one of

four set values.

IGQ1

IGQ0

PIN

PIN CONTENTS

0 0 Defaults to gate current 50µA

0 1 Gate Current is 10µA

1 0 Gate Current is 70µA

1 1 Gate Current is 150µA

Typically, the delay from IGQ1 and IGQ0 selection to a

change in the GATE pin current is less than 1µs.

Gate Current

I

INRUSH

Quick Select

Logic

Control

Registers

C2

3.3nF

100K

V

=12V

DD

Slew

100*

Selection

Logic

DRAIN

R2

22K

Rate

10µA

50µA

70µA

150µA

SENSEV

EE

-48V

R

SENSE

FIGURE 37. SLEW RATE (INRUSH CURRENT) CONTROL

GATE

100nF*

* Optional Components

See Section “Gate Capacitor, Filtering and Feedback”

IGQ1

IGQ0

LOAD

Gate Capacitor, Filtering and Feedback

In Figure 37, the FET control circuit includes an FET

feedback capacitor C

FET during turn on. The capacitor value depends on the

load, the FET gate current, and the maximum desired inrush

current.

, which provides compensation for the

2

T1

FIGURE 36. SELECTING I

CONTROL ON THE GATE PIN

T2 T3

Time, ms

CURRENT FOR SLEW RATE

GATE

T4

T5

Slew Rate (Gate) Control

As shown in Figure 37, this circuit block contains a current

source (I

pin. This current provides a controlled slew rate for the FET.

) that drives the 50µA current into the GATE

GATE

17

The value of C2 can be selected with the following formula.

C2

I

-------------------------------------------=

GATE

I

C×

LOAD

INRUSH

Where:

I

= FET Gate current

GATE

I

INRUSH

C

= Maximum desired inrush current

= DC/DC bulk capacitance

LOAD

FN8149.0

January 13, 2005

X80010, X80011, X80012, X80013

With the X80010, there is some control of the gate current

with the IGQ pins, so one selection of C2 can cover a wide

range of possible loading conditions. Typical values for C2

range from 2.2 to 4.7nF.

When power is applied to the system, the FET tries to turn

on due to its internal gate to drain capacitance (Cgd) and the

feedback capacitor C2 (see Figure 37.) The X80010 device,

when powered, pulls the gate output low to prevent the gate

voltage from rising and keep the FET from turning on.

However, unless V

powers up very quickly, there will be a

DD

brief period of time during initial application of power when

the X80010 circuits cannot hold the gate low. The use of an

external capacitor (C1) prevents this. Capacitors C1 and C2

form a voltage divider to prevent the gate voltage from rising

above the FET turn on threshold before the X80010 can hold

the gate low. Use the following formula for choosing C1.

V1 V2–

C1

--------------------- C 2=

V2

Where:

V1 = Maximum input voltage,

V2 = FET threshold voltage,

C1 = Gate capacitor,

C2 = Feedback capacitor.

In a system where V

rises very fast, a smaller value of C1

DD

may suffice as the X80010 will control voltage at the gate

before the voltage can rise to the FET turn on threshold. The

circuit of Figure 37 assumes that the input voltage can rise to

80V before the X80010 sees operational voltage on V

DD

. If

C1 is used then the series resistor R1 will be required to

prevent high frequency oscillations.

Drain Sense and Power Good Indicator

The X80010 provides a drain sense and power good

indicator circuit. The PWRGD

there is no overvoltage, no undervoltage, and no overcurrent

condition, the Gate voltage exceeds VDD-1V, and the

voltage at the DRAIN pin is less V

As shown in Figure 38, this circuit block contains a drain

sense voltage trip point (∆V

point (∆V

), two comparators, and internal voltage

GATE

references. These provide both a drain sense and a gate

sense circuit to determine the whether the FET has turned

on as requested. If so, the power good indicator (PWRGD

goes active.

signal asserts LOW when

EE+VDRAIN

) and a gate voltage trip

DRAIN

.

)

The PWRGD

signal asserts (Logic LOW) only when all of the

below conditions are true:

- there is no overvoltage or no undervoltage condition,

(i.e. undervoltage < V

- There is no overcurrent condition (i.e. V

< overvoltage.)

EE

EE

- V

SENSE

<

VOC.)

- The FET is turned on (i.e. V

V

> VDD - 1V).

GATE

∆V

DRAIN

–

+

1V

(Factory

Programmable)

∆V

GATE

–

+

VDD-1V

SENSEV

EE

-48V

R

SENSE

FIGURE 38. DRAIN SENSE AND POWER GOOD INDICATOR

GATE

DRAIN

100K

< VEE + 1V and

DRAIN

Power

Good

Logic

Control/Status

Registers

LOAD

PWRGD

V

EE

Power On/System Reset and Delay

Application of power to the X80010 activates a Power On

Reset circuit that pulls the RESET

used, provides several benefits.

- It prevents the system microprocessor from starting to

operate with insufficient voltage.

- It prevents the processor from operating prior to

stabilization of the oscillator.

- It allows time for an FPGA to download its configuration

prior to initialization of the circuit.

The POR/RESET circuit is activated when all voltages are

within specified ranges and the following time-out conditions

are met: PWRGD

V4GOOD

. The POR/RESET circuit will then wait 100ms and

assert the RESET

and V1GOOD, V2GOOD, V3GOOD, and

pin.

pin active. This signal, if

The drain sense circuit checks the DRAIN pin. If the voltage

on this pin is greater that 1V above V

, then a fault

EE

condition exists.

The gate sense circuit checks the GATE pin. If the voltage

on this pin is less than V

- 1V, then a fault condition exists.

EE

18

FN8149.0

January 13, 2005

X80010, X80011, X80012, X80013

Drain Sense

& Power

Good Logic

Enable

Logic

ViGOOD

i = 1 to 4

PWRGD

SPOR

V

DD

RESET

µP

RESET Logic

t

Delay

SPOR

Control

Registers

V

EE

MRC

FIGURE 39. POWER ON/SYSTEM RESET AND DELAY

Quad Voltage Monitoring

X80010 monitors 4 voltage enable inputs. When the ENi

(i=1-4) input is detected to be below the input threshold, the

output ViGOOD

signal is asserted after a delay of 100ms. The ViGOOD

signal remains active until ENi

(i = 1 to 4) goes active LOW. The ViGOOD

rises above threshold.

Once the PWRGD

of the DC/DC modules can commence. RESET

100ms after all ViGOOD

signal is asserted, the power sequencing

goes active

(i=1 to 4) outputs are asserted (See

Figure 39).

As shown in Figure 40, this circuit block contains four

separate voltage enable pins, a time delay circuit, and an

output driver.

EN1

EN2

EN3

EN4

V

RGO

OSC

Divider

Reset

4

repeated 4 times

4

Select

0.1s

0.5s

1s

5s

delay1

delay2

delay3

delay4

Delay circuit

Control Register

V

EE

FIGURE 40. VOLTAGE MONITORS AND VGOOD OUTPUTS

V1GOOD

V2GOOD

V3GOOD

V4GOOD

19

FN8149.0

January 13, 2005

X80010, X80011, X80012, X80013

Manual Reset (Hot Side and Cold Side)

The manual reset option allows a hardware reset of either

the Gate control or the PWRGD

used to recover the system in the event of an abnormal

operating condition.The X80010 has two manual reset pins:

MRH

(manual reset hot side) and MRC (manual reset cold

side). The MRH

signal is used as a manual reset for the

GATE pin. This pin is used to initiate Soft Reinsert. When

MRH

is pulled LOW the GATE pin will be pulled LOW. It also

clears the FAR

signal. When the MRH pin goes HIGH, it

removes the override signal and the gate will turn on based

on the selected gate control mechanism.

TABLE 3. MANUAL RESET OF THE HOT SIDE (GATE SIGNAL)

MRH GATE PIN REQUIREMENTS

1 Operational When MRH

(Hot) function is disabled

0OFFMRH

indicator. These can be

is HIGH the Manual Reset

must be held LOW minimum of 5µs

The MRC signal is used as a manual reset for the PWRGD

signal. This pin is used to initiate a Soft Restart. When the

MRC is pulled HIGH, the PWRGD

When MRC pin goes LOW, the PWRGD

signal is pulled HIGH.

pin goes

operational. It will go LOW if all constraints on the GATE are

within limits.

TABLE 4. MANUAL RESET OF THE COLD SIDE (PWRGD

SIGNAL)

MRC PWRGD REQUIREMENTS

1 HIGH MRC must be held HIGH minimum of 5µs

0 Operational When MRC is LOW the MRC

function is disabled

Flexible Power Sequencing of Multiple Power

Supplies

The X80010 provides several circuits such as multiple

voltage enable pins, programmable delays, and a power

good signals can be used to set up flexible power

sequencing schemes for downstream DC/DC supplies.

Below are examples of parallel and relay sequencing.

1. Power Up of DC/DC Supplies In Parallel Sequencing

Using Programmable Delays on Power Good (See Figure

41 and Figure 42).

Several DC/DC power supplies and their respective

power up start times can be controlled using the X80010

such that each of the DC/DC power supplies will start up

following the issue of the PWRGD

signal is fed into the ENi

PWRGD

ViGOOD

control the ON

is valid, the internal voltage enable circuits issue

signals after a time delay. The ViGOOD signals

/OFF pins of the DC/DC supplies. Each

inputs to the X80010. When

signal. The PWRGD

DC/DC converter is instructed to turn on 100ms after the

PWRGD goes active. However, each ViGOOD delay can

be increased with the use of external R-C circuits.

20

FN8149.0

January 13, 2005

X80010, X80011, X80012, X80013

-48V

Return

GND

GND

R5

30k

1%

-48V

R4

182k

1%

R6

10k

1%

V

UV/OV

OV=71V

V

DD

V

EE

0.02

C3

0.1µF

100V

C6

0.1µF

100V

MRH

UV=37V

Rs

Ω

5%

+

+

SENSE

0.1µF

Q1

IRFR120

C4

100µF

100V

C7

100µF

100V

X80010, X80011,

X80013, X80014

100

1

4

1

4

GATE

4.7K

V

V

V

V

3.3n

IN+

IN-

IN+

IN-

ON/OFF

V

SENSE+

SENSE-

ON/OFF

V

SENSE+

SENSE-

DRAIN

OUT

TRIM

V

OUT

TRIM

V

OUT

OUT

MRC

100K

+

+

RESET

9

8

7

6

5

9

8

7

6

5

V4GOOD

V3GOOD

V2GOOD

V1GOOD

PWRGD

OPTO

COUPLER

RESET ‘

C5

+

100µF

16V

C8

+

100µF

16V

EN4

EN3

EN2

EN1

OPTO

COUPLER

3.3V

2.5V

PWRGD

RESET

V

CC1

V

CC2

µC

V

CC1

V

CC2

FPGA

GND

GND

C9

0.1µF

100V

C12

0.1µF

100V

ON/OFF

1

V

IN+

V

V

V

SENSE+

IN-

ON/OFF

IN+

IN-

C10

+

100µF

100V

4

1

C13

+

100µF

100V

4

V

OUT

TRIM

SENSE-

V

OUT

V

OUT

SENSE+

TRIM

SENSE-

V

OUT

9

+

8

7

6

+

C11

100µF

16V

5

9

+

8

7

6

+

C14

100µF

16V

5

1.8V

1.2V

FIGURE 41. TYPICAL APPLICATION OF HOTSWAP AND DC/DC PARALLEL POWER SEQUENCING

21

V

CC1

V

CC2

ASIC

FN8149.0

January 13, 2005

X80010, X80011, X80012, X80013

EN1

(from PWRGD)

t

V1GDO

Power Supply

#1 OUTPUT

(3.3V)

EN2

(from PWRGD)

t

DELAY2

V2GDO

Power Supply

#2 OUTPUT

(2.5V)

EN3

(from PWRGD

t

DELAY3

V3GDO

Power Supply

#3 OUTPUT

(1.8V)

Main FET

turns ON

DELAY1

)

100ms

100ms

100ms

Power Supply

#1 turns ON

Power Supply

#2 turns ON

Power Supply

#3 turns ON

the X80010 EN1

input to sequence the next supply. An

opto-coupler is recommended in this connection for

isolation. This configuration ensures that each

subsequent DC/DC supply will power up after the

preceding DC/DC supply voltage output is valid.

EN4

(from PWRGD

V4GDO

Power Supply

#4 OUTPUT

(1.2V)

RESET

t

DELAY4

t

SPOR

)

100ms

Power Supply

#4 turns ON

100ms

All ViGOOD=LOW

FIGURE 42. PARALLEL SEQUENCING OF DC/DC SUPPLIES.

(TIMING)

1. Power Up of DC/DC Supplies Via Relay Sequencing

Using Power Good and Voltage Monitors (see Figure 43

and Figure 44).

Several DC/DC power supplies and their respective

power up start times can be controlled using the X80010

such that each of the DC/DC power supplies will start in

a relay sequencing fashion. The 1st DC/DC supply will

power up when PWRGD

is LOW after a 100ms delay.

Subsequent DC/DC supplies will power up after the prior

supply has reached its operating voltage. One way to do

this is by using an external CPU Supervisor (for example

the Intersil X40430) to monitor the DC/DC output. When

the DC/DC voltage is good, the supervisor output signals

22

FN8149.0

January 13, 2005

X80010, X80011, X80012, X80013

-48V

Return

R5

30k

1%

-48V

GND

GND

R4

182k

1%

R6

10k

1%

V

UV/OV

V

DD

V

0.02Ω

0.1µF

100V

0.1µF

100V

UV=37V

OV=71V

EE

Rs

5%

C3

C6

MRH

SENSE

+

+

X80010, X80011,

X80012, X80013

0.1µF

100

Q1

IRFR120

1

C4

100µF

100V

4

1

C7

100µF

100V

4

GATE

4.7K

V

IN+

V

V

IN+

V

3.3n

ON/OFF

IN-

ON/OFF

IN-

DRAIN

100K

V

OUT

SENSE+

TRIM

SENSE-

V

OUT

V

OUT

SENSE+

TRIM

SENSE-

V

OUT

MRC

+

+

RESET

OPTO

COUPLER

9

8

7

6

5

9

8

7

6

5

V4GOOD

V3GOOD

V2GOOD

V1GOOD

PWRGD

C5

+

100µF

16V

C8

+

100µF

16V

EN4

EN3

EN2

EN1

OPTO

COUPLER

3.3V

2.5V

OPTO

COUPLER

VFAIL<1:3>

X40430

VMON<1:3>

PWRGD

RESET

RESET

V

CC1

V

CC2

µC

V

CC1

V

CC2

FPGA

GND

GND

C9

0.1µF

100V

C12

0.1µF

100V

ON/OFF

1

V

IN+

V

V

V

SENSE+

IN-

ON/OFF

IN+

IN-

C10

+

100µF

100V

4

1

C13

+

100µF

100V

4

V

OUT

TRIM

SENSE-

V

OUT

V

OUT

SENSE+

TRIM

SENSE-

V

OUT

9

+

8

7

6

+

C11

100µF

16V

5

9

+

8

7

6

+

C14

100µF

16V

5

1.8V

1.2V

FIGURE 43. TYPICAL APPLICATION OF HOTSWAP AND DC/DC RELAY SEQUENCING

23

V

CC1

V

CC2

ASIC

FN8149.0

January 13, 2005

EN2 In

(from PWRGD)

t

V1GDO

Power Supply

#1 OUTPUT

(3.3V)

EN2

V2GDO

Power Supply

#2 OUTPUT

(2.5V)

EN3

FET

turns ON

DELAY1

100ms

t

DELAY2

X80010, X80011, X80012, X80013

Power Supply

#1 turns ON

V2MON

threshold

100ms

Power Supply

#2 turns ON

V3MON

threshold

V3GDO

Power Supply

#3 OUTPUT

(1.8V)

EN4

V4GDO

Power Supply

#4 OUTPUT

(1.2V)

RESET

t

DELAY3

100ms

t

DELAY4

Power Supply

#3 turns ON

V4MON

threshold

100ms

t

RESET

FIGURE 44. RELAY SEQUENCING OF DC/DC SUPPLIES. (TIMING)

Power Supply

#4 turns ON

100ms

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

24

FN8149.0

January 13, 2005

Packaging Information

0.007 (0.19)

0.009 (0.25)

0.000 (0.00)

0.002 (0.05)

X80010, X80011, X80012, X80013

32-Lead Very Very Thin Quad Flat No Lead Package

7mm x 7mm Body with 0.65mm Lead Pitch

0.009 (0.23)

0.015 (0.38)

0.185

(4.70)

0.271 (6.90)

0.279 (7.10)

0.027 (0.70)

0.031 (0.80)

0.000 (0.00)

0.030 (0.76)

0.271 (6.90)

0.279 (7.10)

PIN 1 INDENT

0.185

(4.70)

(4.70)

0.014 (0.35)

0.029 (0.75)

25

0.271 (6.90)

0.279 (7.10)

FN8149.0

January 13, 2005

Loading...

Loading...