intersil X80000, X80001 DATA SHEET

查询X80000供应商

®

X80000, X80001

Data Sheet March 18, 2005

Smart Power Plug™ Penta-Power

Sequence Controller with Hot Swap

The X80000 contains three major functions: a power

communications controller, a power sequencing controller,

and a hotswap controller.

The power communications controller allows smart power

supply control via the backplane using the SMBus protocol.

The system can check for voltage, current, and

manufacturing ID compliance before board insertion. The

power distribution network can monitor the status of the

negative voltage supply, DC voltage supplies, and hardshort

events by accessing the Fault Detection Register and

General Purpose EEPROM of the device. Each device has a

unique slave address for identification.

The power sequencer controller time sequences up to five

DC-DC modules. The X80000 allows for various hardwired

configurations, either parallel or relay sequencing modes.

The power good, enable and voltage good signals provide

for flexible DC-DC timing configurations. Each voltage

enable signal has a programmable delay. In addition, the

voltage good signals can be monitored remotely via the fault

detection register (thru the SMBus).

The hot swap controller allows a board to be safely inserted

and removed from a live backplane without turning off the

main power supply. The X80000 family of devices offers a

modular, power distribution approach by providing flexibility

to solve the hotswap and power sequencing issues for

insertion, operations, and extraction. Hardshort Detection

and Retry with Delay, Noise filtering, Insertion Overcurrent

Bypass, and Gate Current selection are some of the

programmable features of the device.

During insertion, the gate of an external power MOSFET is

clamped low to suppress contact bounce. The

undervoltage/overvoltage circuits and the power on reset

circuitry suppress the gate turn on until the mechanical

bounce has ended. The X80000 turns on the gate with a

user set slew rate to limit the inrush current and incorporates

an electronic circuit breaker set by a sense resistor. After the

load is successfully charged, the PWRGD signal is asserted;

indicating that the device is ready to power sequence the

DC-DC power bricks.

FN8148.0

Features

• Integrates Three Major Functions

- Smart Power Plug communications

- Programmable power sequencing

- Programmable Hot Swap controller

• Smart Power Plug™

- Intelligent board insertion allows verification of board

and power supply resources prior to system insertion.

- Fault detection register records the cause of the faults

- Soft extraction

- Soft re-insertion

- Remote gate shutdown/turn on

- Power ID/manufacturing ID memory (2kb of EEPROM)

• Programmable Power Sequencing

- Sequence up to 5 DC/DC converters.

- Four independent voltage enable pins

- Four programmable time delay circuits

- Soft Power Sequencing - restart sequence without

power cycling.

• Hot Swap Controller

- Programmable overvoltage and undervoltage protection

- Undervoltage lockout for battery/redundant supplies

- Programmable slew rate for external FET gate control

- Electronic circuit breaker - overcurrent detection and

gate shut-off

- Programmable overcurrent limit during Insertion

- Programmable hardshort retry with retry failure flag

- Typically operates from -30V to -80V. Tolerates

transients to -200V (limited by external components)

• Available Packages

- 32-lead Quad No-Lead Frame (QFN)

Applications

• -48V Hot Swap Power Backplane/Distribution Central

Office, Ethernet for VOIP

• Card Insertion Detection

• Power Sequencing DC-DC/Power Bricks

• IP Phone Applications

• Databus Power Interfacing

• Custom Industrial Power Backplanes

• Distributed Power Systems

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 321-724-7143

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

All other trademarks mentioned are the property of their respective owners.

Copyright Intersil Americas Inc. 2005. All Rights Reserved

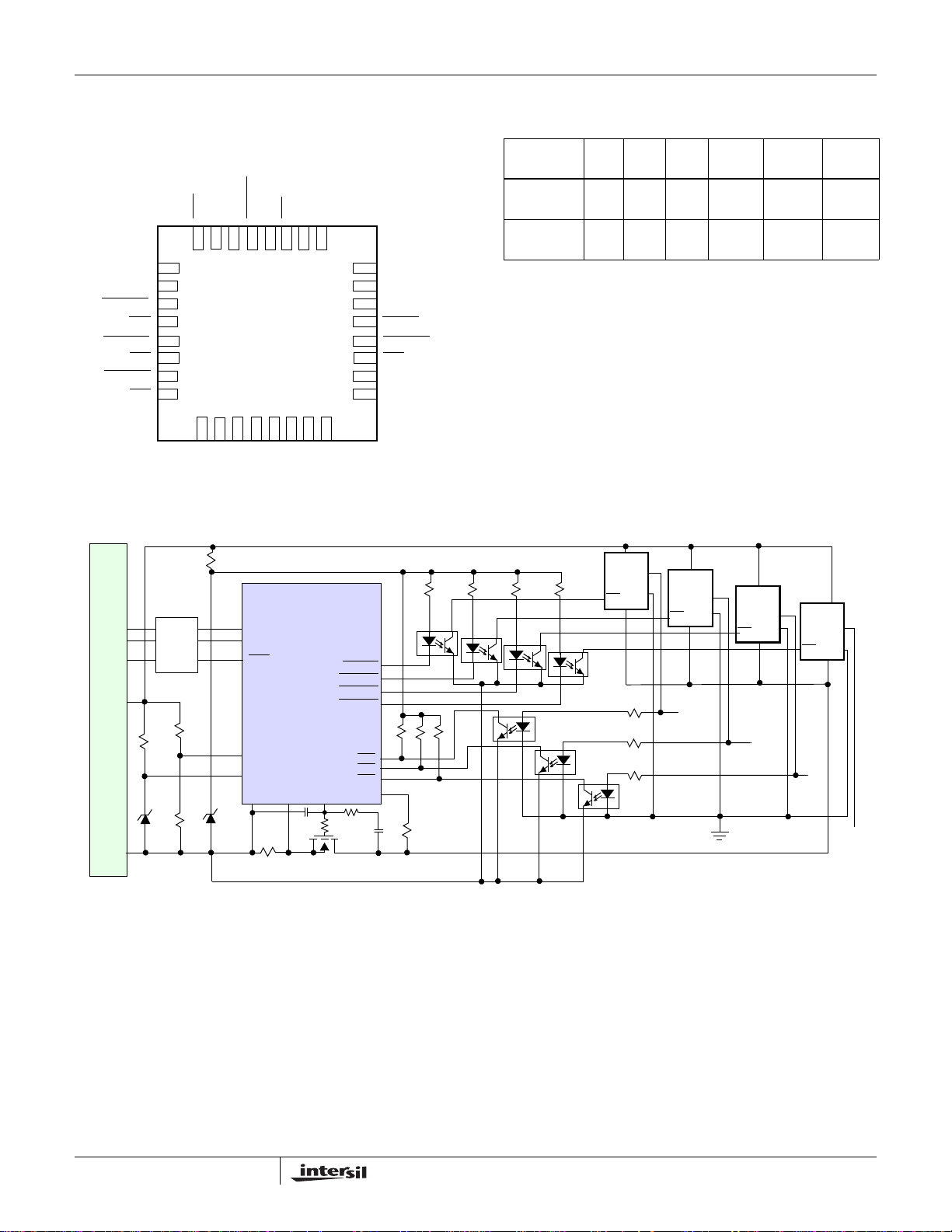

Pinout

V4GOOD

V3GOOD

V2GOOD

V

RGO

A0

EN4

EN3

EN2

X80000, X80001

X80000, X80001

(7X7 QFN)

TOP VIEW

GQ0

GQ1

PWRGD

I

MRH

32

1

BATT-ON

I

2

3

4

(7mm x 7mm)

5

6

7

817

910111213 14

EE

FAR

NC

V

262728293031

25

NC

24

MRC

23

WP

22

RESET

21

20

V1GOOD

EN1

19

SCL

18

SDA

15

16

Ordering Information

PAR T

NUMBER OV UV1 UV2

X80000Q32I 74.9 42.4 33.2 I 32 Ld

X80001Q32I 68.0 42.4 33.2 I 32 Ld

TEMP

RANGE PKG

QFN

QFN

PART

MARK

80000I

80001I

EE

DD

V

V

Typical Application

BackPlane

SCL

SDA

Insert

Control

-48V

RTN

-48V

Opto-

Isolation

R5

30K

1%

12V

R4

182K

1%

R6

10K

1%

4.7V

V

UV/OV

V

V

SCL

SDA

MRH

UV/OV

DD

V

EE

0.02Ω

SENSE

Rs

5%

GATE

OV=71V

UV=37V

SENSE

NC

DRAIN

X80000

X80001

GATE

0.1µF

IRFR120

Q1

A1

PWRGD

V1GOOD

V2GOOD

V3GOOD

DRAIN

100

EN1

EN2

EN3

4.7K

3.3n

100K

DC-DC

Module

1

ON/OFF

DC-DC

Module

2

ON/OFF

V1

DC-DC

Module

3

ON/OFF

V2

DC-DC

Module

4

ON/OFF

V3

V4

2

FN8148.0

March 18, 2005

X80000, X80001

Absolute Maximum Ratings Recommended Operating Conditions

Temperature under bias . . . . . . . . . . . . . . . . . . . . . –65°C to +135°C

Storage temperature . . . . . . . . . . . . . . . . . . . . . . . –65°C to +150°C

Voltage on given pin (Hot Side Functions):

V

ov/uv pin

SENSE pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 400mV + V

VEE pin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -80V

DRAIN pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48V + V

PWRGD pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7V + V

GATE pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . VDD + V

FAR pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7V + V

MRH pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.5V + V

BATT_ON pin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5.5V + V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.5V + V

EE

EE

EE

EE

EE

EE

EE

EE

Voltage on given pin (Cold Side Functions):

ENi

pins (i = 1 to 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5V

ViGOOD

RESET pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5.5V + V

SDA, SCL, WP, A0, A1 pins . . . . . . . . . . . . . . . . . . . . . 5.5V + V

MRC pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.5V + V

IGQ1 and IGQ0 pins . . . . . . . . . . . . . . . . . . . . . . . . . .5.5V + V

VDD pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14V + V

D.C. output current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5mA

pins (i = 1 to 4) . . . . . . . . . . . . . . . . . . . . . . .5.5V + V

EE

EE

EE

EE

EE

EE

Lead temperature (soldering, 10 seconds) . . . . . . . . . . . . . . .300°C

CAUTION: Stresses above those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress rating only; functional

operation of the device (at these or any other conditions above those listed in the operational sections of this specification) is not implied. Exposure to absolute maximum

rating conditions for extended periods may affect device reliability.

Temperature Range (Industrial) . . . . . . . . . . . . . . . . . . -40°C to 85°C

Supply Voltage (V

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12V

DD

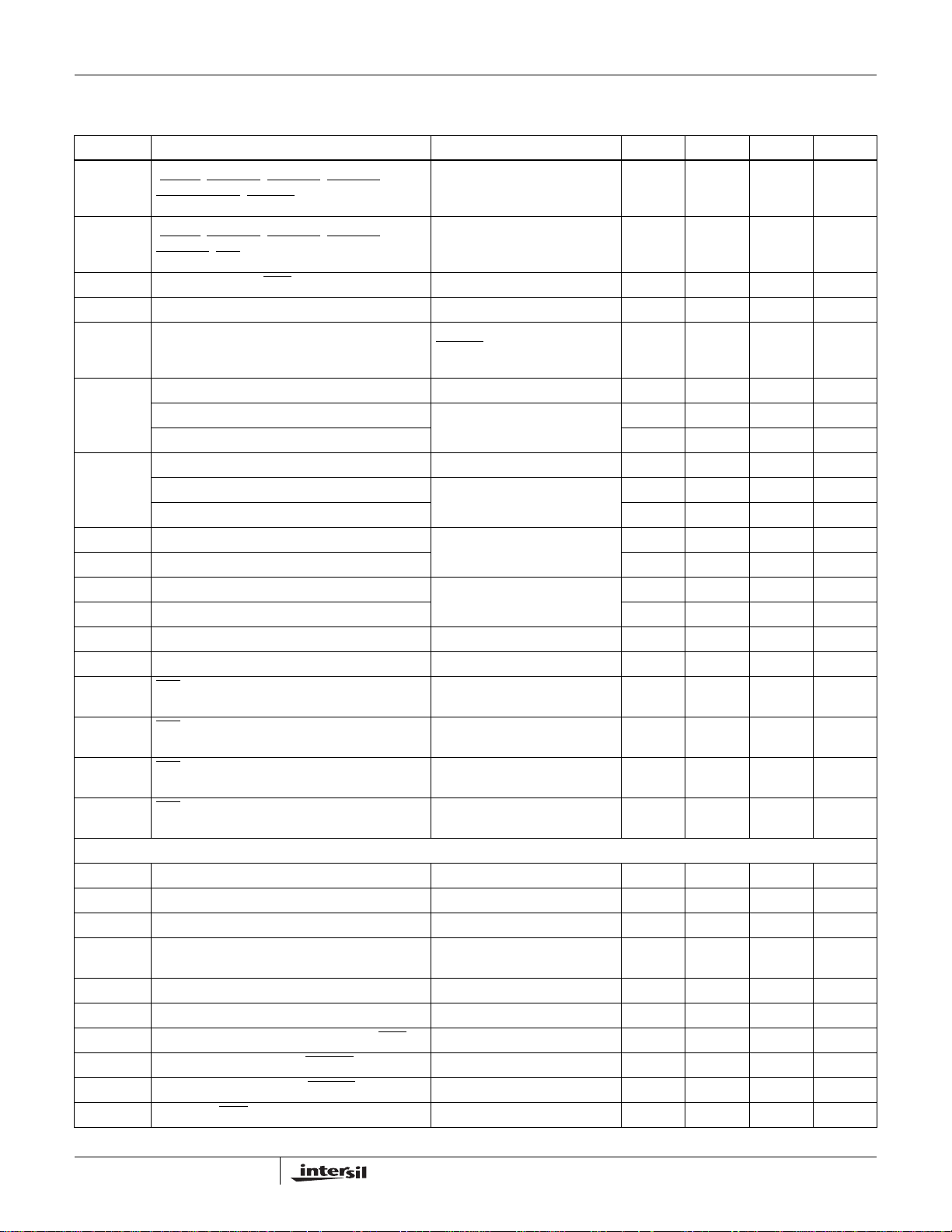

Electrical Specifications Standard Settings

Over the recommended operating conditions unless otherwise specified.

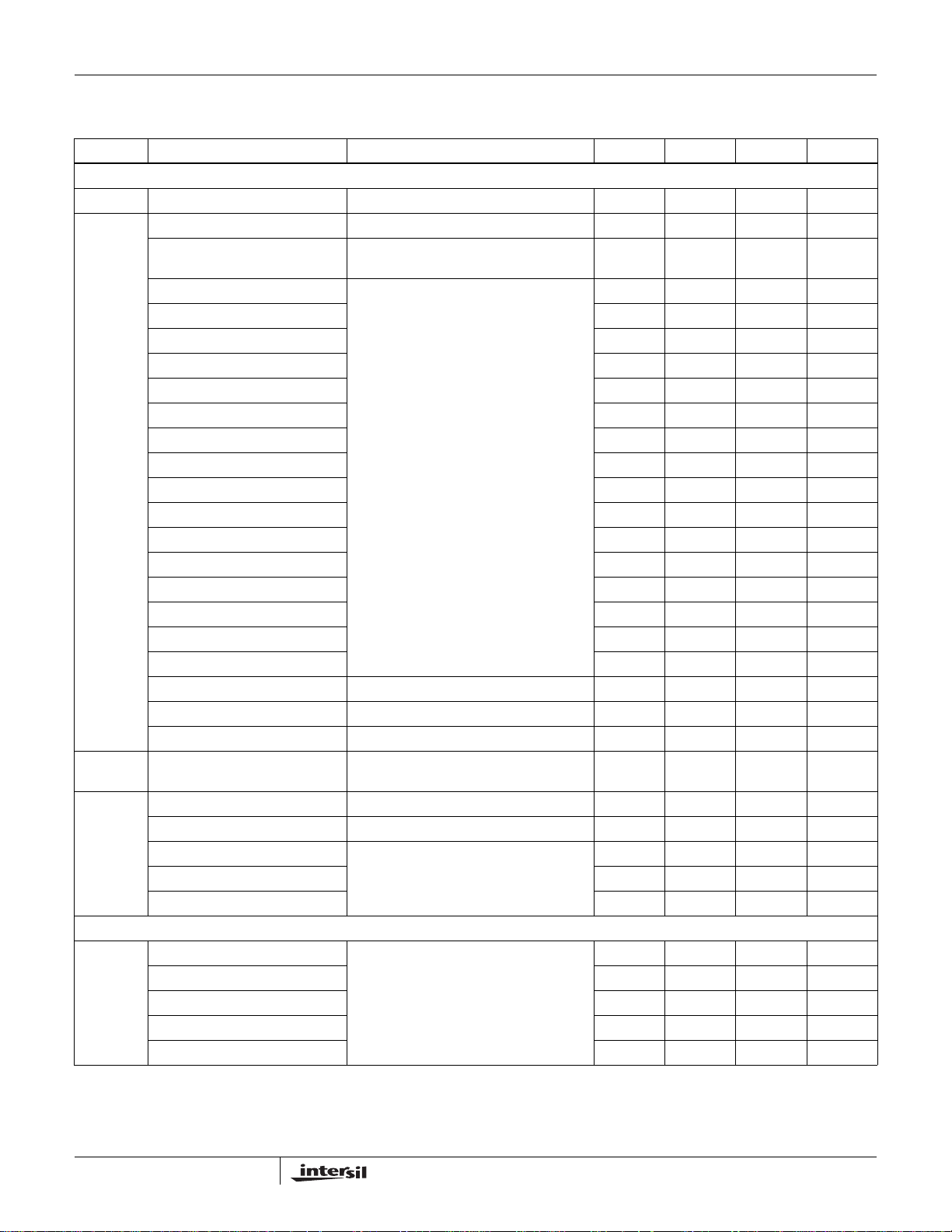

SYMBOL PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

DC CHARACTERISTICS

V

I

DD

V

RGO

I

RGO

I

GATE

V

GATE

V

PGA

V

V

I

I

LO

V

V

DD

IHB

ILB

Supply Operating Range 10 12 14 V

Supply Current 2.5 5 mA

Regulated 5V output I

V

current output 50 µA

RGO

Gate Pin Current Gate Drive On,

External Gate Drive (Slew Rate Control) I

Power Good Threshold (PWRGD High to Low) Referenced to V

= 10µA 4.5 5.5

RGO

46.2 52.5 58.8 µA

V

= VEE,

GATE

V

= V

SENSE

- VEE = 3V

V

GATE

V

SENSE-VEE

= 50µA VDD-0.01 V

GATE

V

< V

UV1

(sourcing)

EE

= 0.1V (sinking)

EE

< V

UV/OV

0.9 1 1.1 V

OV

9mA

Voltage Input High (BATT_ON) VEE + 4 VEE + 5 V

Voltage Input Low (BATT_ON) VEE + 2 V

Input Leakage Current (MRH, MRC) VIL = GND to V

LI

Output Leakage Current

(V1GOOD

RESET

Input LOW Voltage (MRH, MRC, IGQ0, IGQ1) -0.5 +

IL

Input HIGH Voltage (MRH, MRC, IGQ0, IGQ1) (VEE + 5)

IH

, V2GOOD, V3GOOD, V4GOOD,

)

All ENi

= V

CC

for i = 1 to 4 10 µA

RGO

V

EE

x 0.7

DD

10 µA

(VEE + 5)

x 0.3

+ 5)

(V

EE

+ 0.5

V

V

V

3

FN8148.0

March 18, 2005

X80000, X80001

Electrical Specifications Standard Settings

Over the recommended operating conditions unless otherwise specified. (Continued)

SYMBOL PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

C

OUT

(Note 1)

(Note 1) Input Capacitance (MRH, MRC) VIN = 0V 6 pF

C

IN

V

OC

V

OCI

V

OVR

Output LOW Voltage

OL

(RESET

, V1GOOD, V2GOOD, V3GOOD,

V4GOOD, FAR

, PWRGD)

Output Capacitance

(RESET, V1GOOD, V2GOOD, V3GOOD,

V4GOOD

, FAR)

Overcurrent threshold VOC = V

Overcurrent threshold (Insertion) VOC = V

Overvoltage threshold (rising)

X80000 Referenced to V

X80001 3.49 3.54 3.59 V

V

OVF

Overvoltage threshold (falling)

X80000 Referenced to V

X80001 3.46 3.51 3.56 V

V

UV1R

V

UV1F

V

UV2R

V

UV2F

V

DRAINF

V

DRAINR

V

TRIP1

(Note 1)

V

TRIP2

(Note 1)

V

TRIP3

Undervoltage 1 threshold (rising) Referenced to V

Undervoltage 1 threshold (falling) 2.16 2.21 2.26 V

Undervoltage 2 threshold (rising) Referenced to V

Undervoltage 2 threshold (falling) 1.68 1.73 1.78 V

Drain sense voltage threshold (falling) Referenced to V

Drain sense voltage threshold (rising) Referenced to V

Trip Point Voltage Referenced to V

EN1

Trip Point Voltage Referenced to V

EN2

Trip Point Voltage Referenced to V

EN3

(Note 1)

V

TRIP4

(Note 1)

Trip Point Voltage Referenced to V

EN4

AC CHARACTERISTICS

t

FOC

t

FUV

t

FOV

t

VFR

t

BATT_ON

t

MRC

t

MRH

t

MRCE

t

MRCD

t

MRHE

Sense High to Gate Low 1.5 2.5 3.5 µs

Under Voltage conditions to Gate Low 0.5 1 1.5 µs

Overvoltage Conditions to Gate Low 1.0 1.5 2 µs

Overvoltage/undervoltage failure recovery time to

Gate =1V.

Delay BATT_ON Valid 100 ns

Minimum time high for reset valid on the MRC pin 5 µs

Minimum time high for reset valid on the MRH pin 5 µs

Delay from MRC enable to PWRGD HIGH No Load 1.0 1.6 µs

Delay from MRC disable to PWRGD LOW Gate is On, No Load 200 400 ns

Delay from MRH enable to Gate Pin LOW I

I

= 4.0mA VEE + 0.4 V

OL

V

= 0V 8 pF

OUT

SENSE

SENSE

- V

- V

EE

EE

45 50 55 mV

135 150 165 mV

PWRGD = HIGH

Initial Power Up condition

EE

EE

BATT-ON = V

BATT-ON = V

EE

EE

EE

RGO

EE

EE

EE

EE

EE

EE

VDD does not drop below 3V, No

3.85 3.90 3.95 V

3.82 3.87 3.92 V

2.19 2.24 2.29 V

1.71 1.76 1.81 V

0.9 1 1.1 V

1.2 1.3 1.4 V

V

÷ 2 V

RGO

1.2 1.6 2 µs

other failure conditions.

= 60µA, No Load 1.0 1.6 2.4 µs

GATE

V

V

V

4

FN8148.0

March 18, 2005

X80000, X80001

Electrical Specifications Standard Settings

Over the recommended operating conditions unless otherwise specified. (Continued)

SYMBOL PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

t

MRHD

t

RESET_E

t

QC

t

SC_RETRY

t

NF

t

DPOR

t

SPOR

t

TO

t

PDHLPG

(Note 1)

t

PDLHPG

(Note 1)

t

PGHLPG

(Note 1)

t

PGLHPG

(Note 1)

NOTE:

1. This parameter is based on characterization data.

Delay from MRH disable to GATE reaching 1V I

Delay from PWRGD or ViGOOD to RESET valid

= 60µA, No Load 1.8 2.6 µs

GATE

1 µs

LOW

Delay from IGQ1 and IGQ0 to valid Gate pin

1 µs

current

Delay between retries TSC1 = 0; TSC0 = 0 90 100 110 ms

Noise Filter for Overcurrent TF1 = 0; TF0 = 1 4.5 5 5.5 µs

Device Delay before Gate assertion 45 50 55 ms

Delay after PWRGD and all ViGOOD signals are

active before RESET

assertion

TPOR1 = 0; TPOR0 = 0 90 100 110 ms

ViGOOD turn off time 50 ns

Delay from Drain good to PWRGD

Delay from Drain fail to PWRGD

Delay from Gate good to PWRGD

Delay from Gate fail to PWRGD

HIGH Drain = V

LOW Gate = V

HIGH Gate = V

LOW Drain = V

DD

DD

EE

EE

1 µs

1 µs

1 µs

1 µs

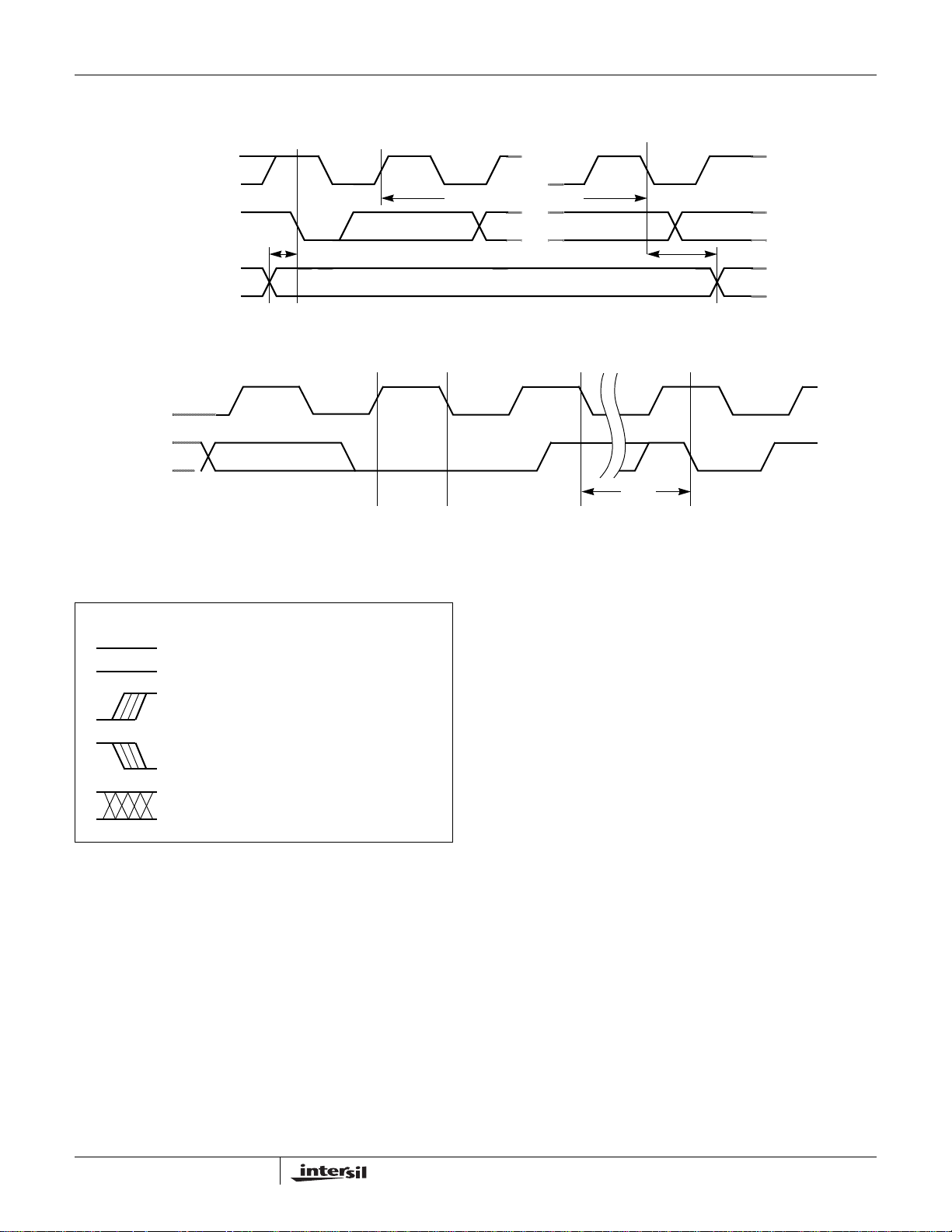

Equivalent A.C. Output Load Circuit

5V

,

,

SDA

5V

4.6kΩ

30pF

RESET

FAR

PWRGD

5V

4.6kΩ

30pF

V1GOOD,

V2GOOD,

V3GOOD

V4GOOD

A.C. Test Conditions

Input pulse levels VCC x 0.1 to VCC x 0.9

Input rise and fall times 10ns

Input and output timing levels V

Output load Standard output load

CC

x 0.5

4.6kΩ

30pF

5

FN8148.0

March 18, 2005

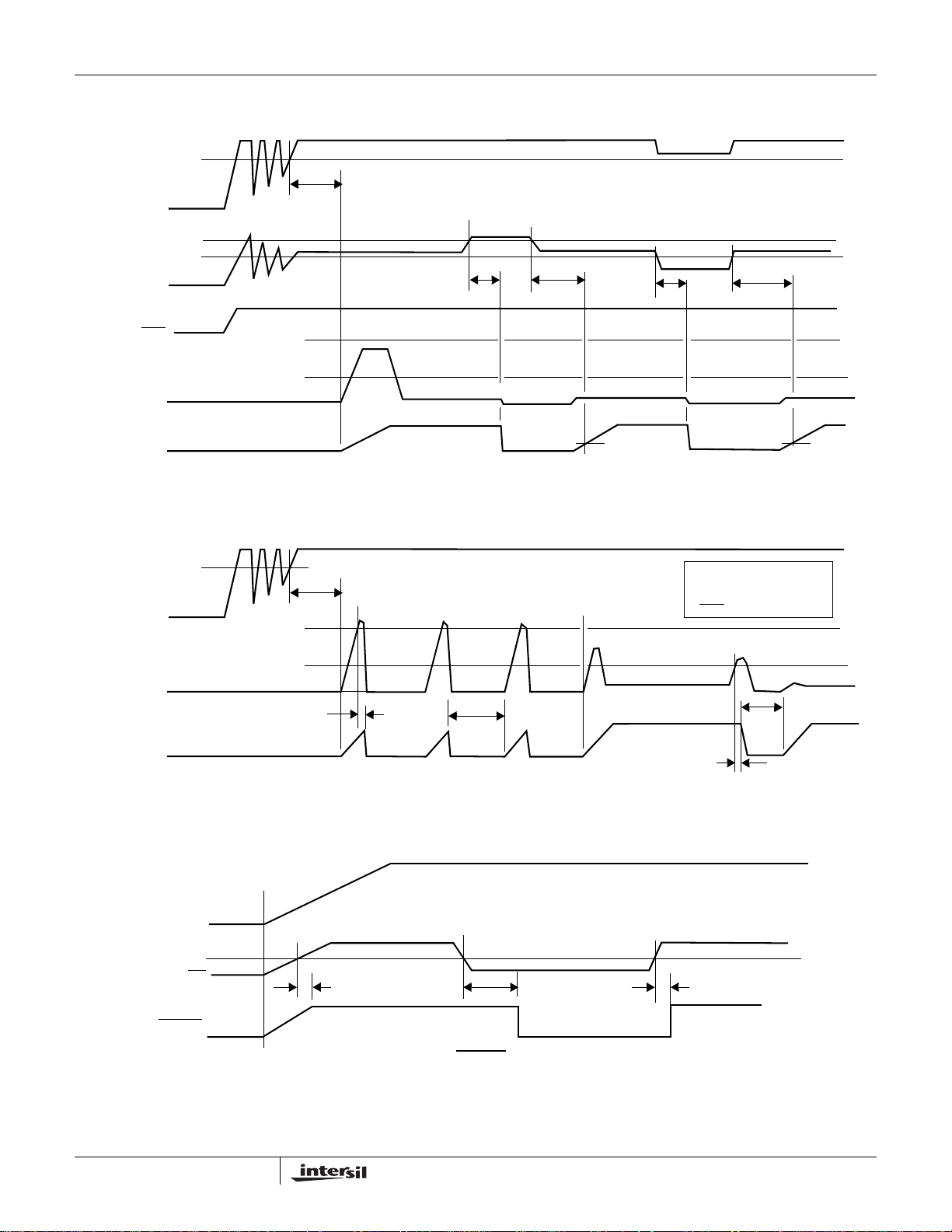

V

UV/OV

VDD

X80000, X80001

V

TH

t

DPOR

V

OV

V

UV

t

FOV

t

VFR

t

FUV

t

VFR

MRH

SENSE

GATE

VDD

SENSE

GATE

V

OCI

V

OC

1V 1V

FIGURE 1. OVERVOLTAGE/UNDERVOLTAGE GATE TIMING

V

TH

t

DPOR

V

OCI

V

OC

t

FOC

t

SC_RETRY

Always Retry

V

< V

UV

MRH = HIGH

t

FOC

UV/OV

< V

OV

t

SC_RETRY

VDD

V

TRIPi

ENi

ViGOOD

Initial

Power-up

6

FIGURE 2. OVERCURRENT GATE TIMING

t

TO

t

DELAYi

Enable DC/DC supply

FIGURE 3. ViGOOD TIMINGS

t

TO

i = 1, 2, 3, 4

FN8148.0

March 18, 2005

MRH

t

MRH

X80000, X80001

MRC

t

MRC

GATE

t

MRHE

FIGURE 4. MANUAL RESET (HOT SIDE) MRH

V

DRAIN

V

GATE

PWRGD

ENi

V1GOOD

V2GOOD

t

DHLPG

t

GLHPG

1V

t

MRHD

t

DELAY1

t

DELAY2

PWRGD

t

MRCE

FIGURE 5. MANUAL RESET (COLD SIDE) MRC

t

DLHPG

t

GHLPG

t

MRCD

V3GOOD

V4GOOD

RESET

t

DELAY3

t

DELAY4

t

SPOR

PWRGD or

any ENi

(1st occurance)

FIGURE 6. PWRGD AND RESET TIMINGS

LOW to HIGH

t

RESET_E

7

FN8148.0

March 18, 2005

X80000, X80001

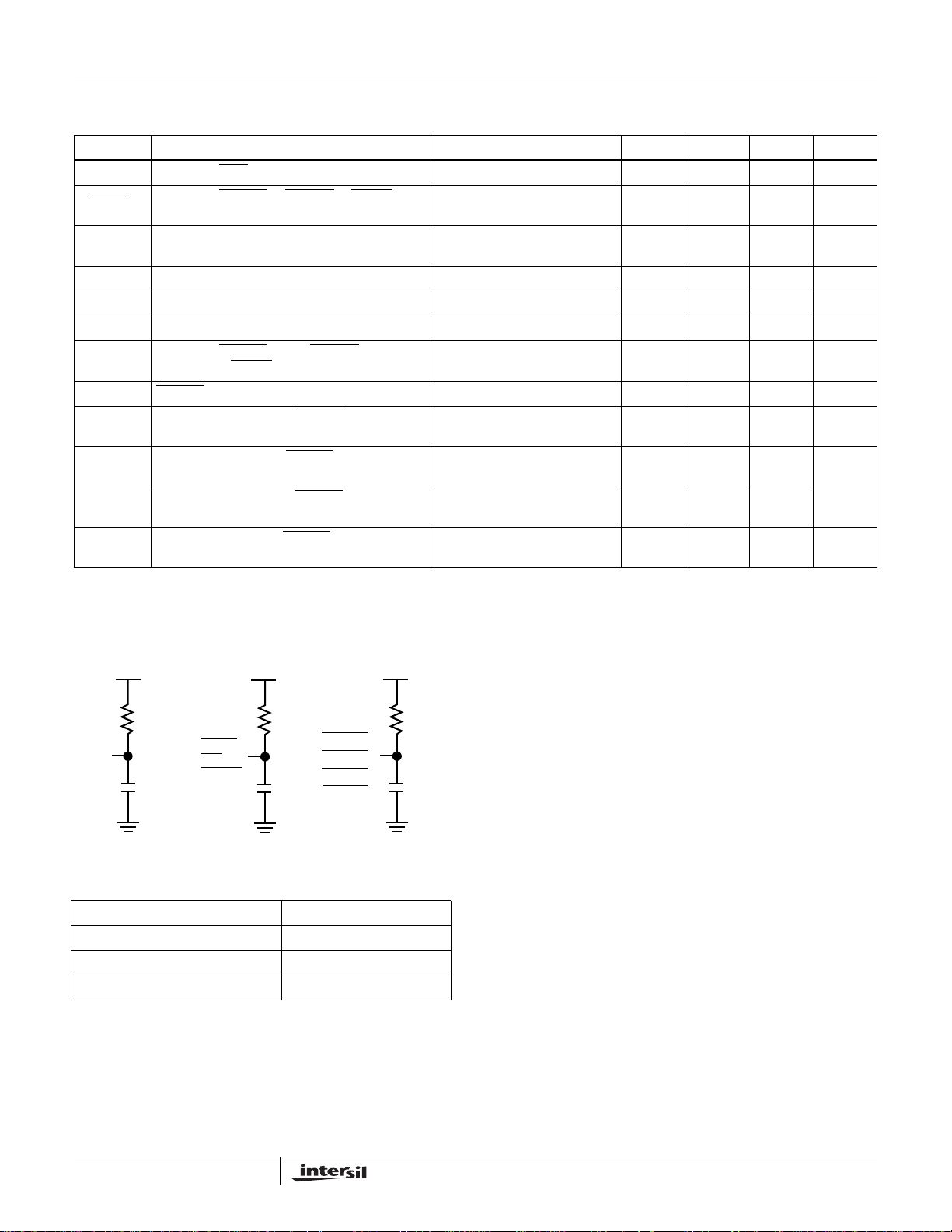

Electrical Specifications Programmable Parameters

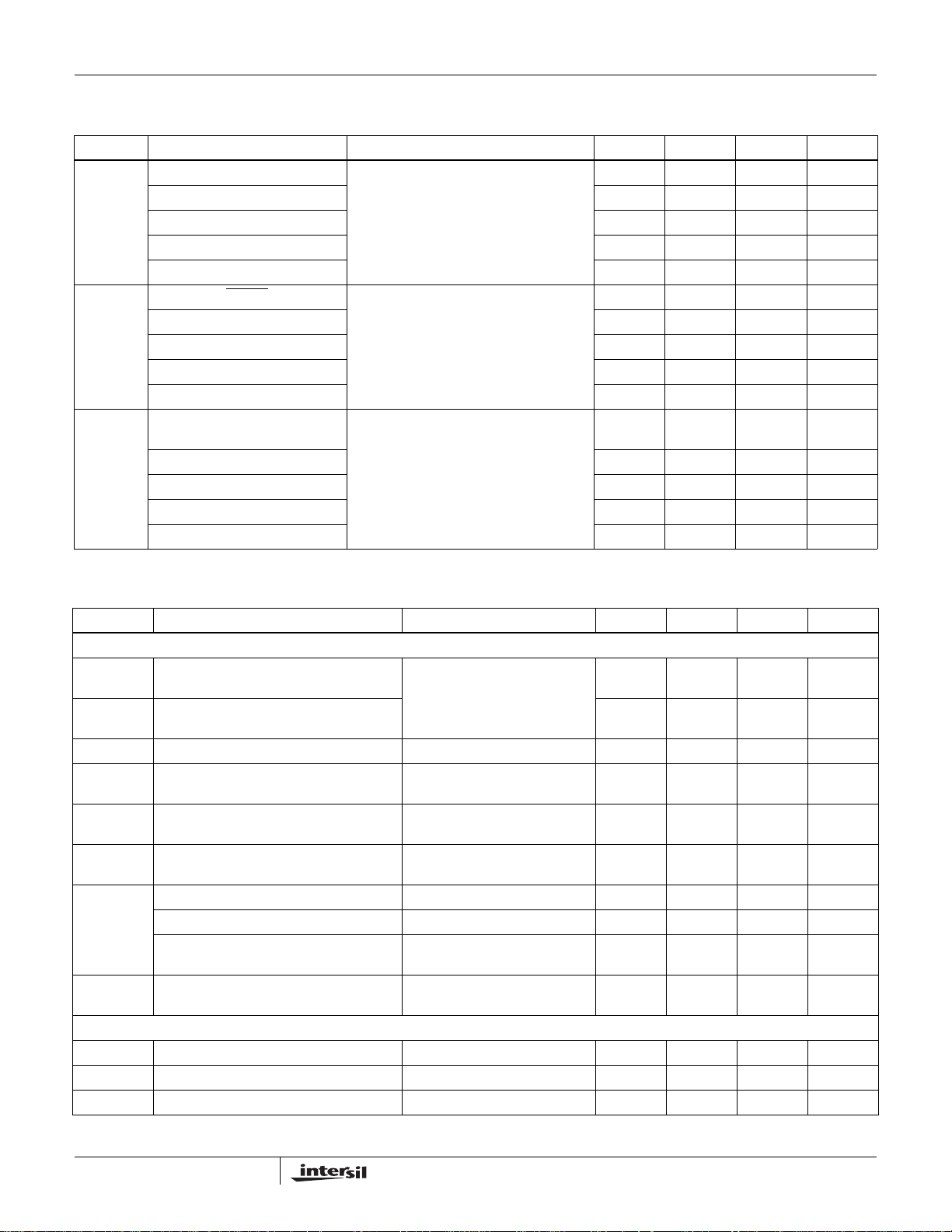

Over the recommended operating conditions unless otherwise specified.

SYMBOL PARAMETER TEST CONDITIONS MIN. TYP. MAX. UNIT

DC CHARACTERISTICS

VCB Over Current Trip Voltage Range Factory Setting is 50mV (see VOCI). 30 100 mV

I

GATE

V

PGA

V

OCI

AC CHARACTERISTICS

t

SC_RETRY

(VCB = V

Gate Pin Pull-Up Current. (error)

(current)

- VEE) For other options, contact Intersil. -12 12 %

SENSE

Gate Drive On; V

= VEE, IGQ1=0;

GATE

IGQ0=0

IG3 = 0; IG2= 0; IG1 = 0; IG0 = 0 Factory Default 9.2 10.5 11.8 µA

IG3 = 0; IG2= 0; IG1 = 0; IG0 = 1 21.0 µA

IG3 = 0; IG2= 0; IG1 = 1; IG0 = 0 31.5 µA

IG3 = 0; IG2= 0; IG1 = 1; IG0 = 1 42.0 µA

IG3 = 0; IG2= 1; IG1 = 0; IG0 = 0 46.2 52.5 58.5 µA

IG3 = 0; IG2= 1; IG1 = 0; IG0 = 1 63.0 µA

IG3 = 0; IG2= 1; IG1 = 1; IG0 = 0 64.7 73.5 82.3 µA

IG3 = 0; IG2= 1; IG1 = 1; IG0 = 1 84.0 µA

IG3 = 1; IG2= 0; IG1 = 0; IG0 = 0 94.5 µA

IG3 = 1; IG2= 0; IG1 = 0; IG0 = 1 105.0 µA

IG3 = 1; IG2= 0; IG1 = 1; IG0 = 0 115.5 µA

IG3 = 1; IG2= 0; IG1 = 1; IG0 = 1 126.0 µA

IG3 = 1; IG2= 1; IG1 = 0; IG0 = 0 136.5 µA

IG3 = 1; IG2= 1; IG1 = 0; IG0 = 1 147.0 µA

IG3 = 1; IG2= 1; IG1 = 1; IG0 = 0 138.6 157.5 176.4 µA

IG3 = 1; IG2= 1; IG1 = 1; IG0 = 1 168.0 µA

IG3-IG0 = Don’t Care IGQ1=0; IGQ0=1 9.2 10.57 11.8 µA

IG3-IG0 = Don’t Care IGQ1=1; IGQ0=0 64.7 73.5 82.3 µA

IG3-IG0 = Don’t Care IGQ1=1; IGQ0=1 138.6 157.5 176.4 µA

Power Good Threshold Accuracy V

- VEE, High to Low Transition.

DRAIN

Default Factory Setting is 47V.

±400 mV

Over current threshold (Insertion) Referenced to VEE

VS1 = 0 VS0 = 0 PWRGD = HIGH 45 50 55 mV

VS1 = 0 VS0 = 1 Factory Default 90 100 110 mV

VS1 = 1 VS0 = 0 135 150 165 mV

VS1 = 1 VS0 = 1 180 200 220 mV

Delay between Retries Factory Default

TSC1 = 0 TSC0 = 0 90 100 110 ms

TSC1 = 0 TSC0 = 1 450 500 550 ms

TSC1 = 1 TSC0 = 0 0.9 1 1.1 s

TSC1 = 1 TSC0 = 1 4.5 5 5.5 s

8

FN8148.0

March 18, 2005

X80000, X80001

Electrical Specifications Programmable Parameters

Over the recommended operating conditions unless otherwise specified. (Continued)

SYMBOL PARAMETER TEST CONDITIONS MIN. TYP. MAX. UNIT

t

NF

t

SPOR

t

DELAYi

Noise Filter for Overcurrents Factory Default

F1 = 0 F0 = 0 0µs

F1 = 0 F0 = 1 4.5 5 5.5 µs

F1 = 1 F0 = 0 9 10 11 µs

F1 = 1 F0 = 1 18 20 22 µs

Delay before RESET assertion Factory Default

TPOR1 = 0 TPOR0 = 0 90 100 110 ms

TPOR1 = 0 TPOR0 = 1 450 500 550 ms

TPOR1 = 1 TPOR0 = 0 0.9 1 1.1 s

TPOR1 = 1 TPOR0 = 1 4.5 5 5.5 s

Time Delay used in Power

Factory Default

Sequencing (i = 1 to 4)

TiD1 = 0 TiD0 = 0 90 100 110 ms

TiD1 = 0 TiD0 = 1 450 500 550 ms

TiD1 = 1 TiD0 = 0 0.9 1 1.1 s

TiD1 = 1 TiD0 = 1 4.5 5 5.5 s

Serial Interface

Over the recommended operating conditions unless otherwise specified.

SYMBOL PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

DC CHARACTERISTICS

I

CC1

(Note 1)

I

CC2

(Note 1)

I

LI

I

LO

V

(Note 3) Input LOW Voltage (SDA, SCL, WP, A0, A1) -0.5 + VEE (VEE + 5) x

IL

V

(Note 3) Input HIGH Voltage (SDA, SCL, WP, A0, A1) (VEE + 5) x

IH

V

HYS

Active Supply Current (VDD) Read to

Memory or CRs

Active Supply Current (VDD)

Write to Memory or CRs

Input Leakage Current (SCL, WP, A0, A1) VIL = GND to V

Output Leakage Current (SDA) V

Schmitt Trigger Input Hysteresis

Fixed input level V

V

related level .05 x

CC

V

OL

Output LOW Voltage (SDA) IOL = 4.0mA (2.7-5.5V)

VIL = VCC x 0.1

V

= VCC x 0.9,

IH

f

= 400kHz

SCL

CC

= GND to V

SDA

Device is in Standby (Note 2)

I

= 2.0mA (2.4-3.6V)

OL

CC

0.7

+ 0.2 V

EE

(V

+ 5)

EE

AC CHARACTERISTICS

f

SCL

t

t

AA

IN

SCL Clock Frequency 400 kHz

Pulse width Suppression Time at inputs 50 ns

SCL LOW to SDA Data Out Valid 0.1 1.5 µs

2.5 mA

3.0 mA

10 µA

10 µA

0.3

(VEE + 5) +

0.5

+ 0.4 V

V

EE

V

V

V

9

FN8148.0

March 18, 2005

X80000, X80001

Serial Interface (Continued)

Over the recommended operating conditions unless otherwise specified.

SYMBOL PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

t

BUF

t

LOW

t

HIGH

t

SU:STA

t

HD:STA

t

SU:DAT

t

HD:DAT

t

SU:STO

t

DH

t

R

t

F

t

SU:WP

t

HD:WP

Cb Capacitive load for each bus line 400 pF

t

(Note 2) EEPROM Write Cycle Time 5 10 ms

WC

NOTE:

2. t

WC

minimum cycle time to be allowed for any nonvolatile write by the user, unless Acknowledge Polling is used.

Time the bus is free before start of new

1.3 µs

transmission

Clock LOW Time 1.3 µs

Clock HIGH Time 0.6 µs

Start Condition Setup Time 0.6 µs

Start Condition Hold Time 0.6 µs

Data In Setup Time 100 ns

Data In Hold Time 0 µs

Stop Condition Setup Time 0.6 µs

Data Output Hold Time 50 ns

SDA and SCL Rise Time 20 +.1Cb

300 ns

(Note 1)

SDA and SCL Fall Time 20 +.1Cb

300 ns

(Note 1)

WP Setup Time 0.6 µs

WP Hold Time 0 µs

is the time from a valid stop condition at the end of a write sequence to the end of the self-timed internal nonvolatile write cycle. It is the

Timing Diagrams

t

BUF

SCL

t

SU:STA

SDA IN

SDA OUT

t

F

t

HD:STA

t

SU:DAT

t

HIGH

t

LOW

t

HD:DAT

FIGURE 7. BUS TIMING

t

R

t

SU:STO

t

t

DH

AA

t

BUF

t

HD:STO

t

HD:DAT

10

FN8148.0

March 18, 2005

START

X80000, X80001

SCL

SDA

Symbol Table

SCL

SDA IN

WP

t

8th Bit of Last Byte

SU:WP

Clk 1 Clk 9

Slave Address Byte

FIGURE 8. WP PIN TIMING

ACK

Stop

Condition

FIGURE 9. WRITE CYCLE TIMING

t

HD:WP

t

WC

Start

Condition

WAVEFORM INPUTS OUTPUTS

Must be

steady

May change

from LOW

to HIGH

May change

from HIGH

to LOW

Don’t Care:

Changes

Allowed

Will be

steady

Will change

from LOW

to HIGH

Will change

from HIGH

to LOW

Changing:

State Not

Known

11

FN8148.0

March 18, 2005

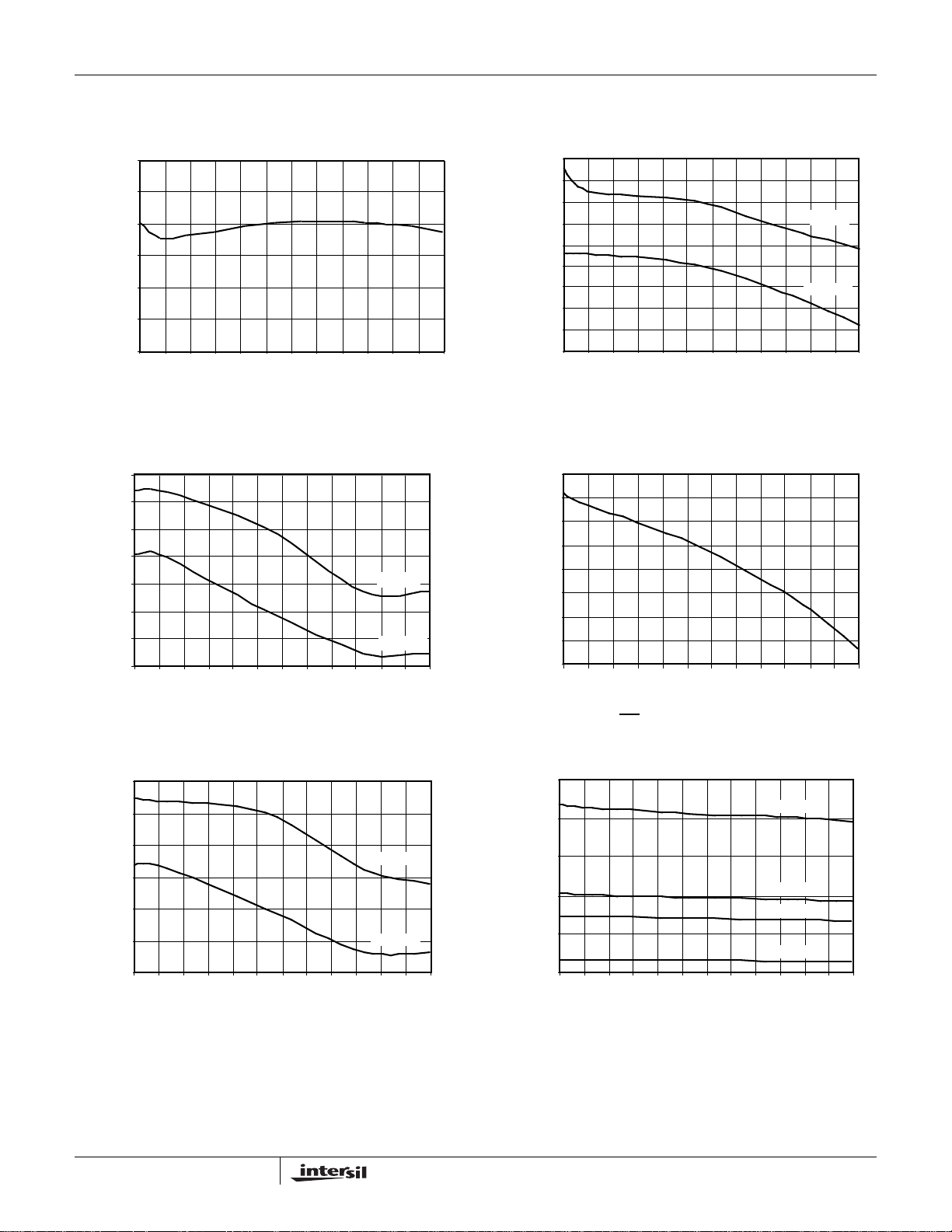

Typical Performance Characteristics

X80000, X80001

52.000

51.000

50.000

49.000

48.000

47.000

INRUSH CURRENT LIMIT (mV)

46.000

-55 -40 -25 -10 5 20 35 50 65 80 95 110 12

TEMPERATURE

1.780

1.770

1.760

1.750

1.740

1.730

1.720

1.710

1.700

UNDERVOLTAGE 2 THRESHOLD (V)

1.690

-55 -40 -25 -10 5 20 35 50 65 80 95 110 125

TEMPERATURE

FIGURE 10. OVERCURRENT THRESHOLD vs TEMPERATURE FIGURE 11. UNDERVOLTAGE 1 THRESHOLD vs

TEMPERATURE

3.92

3.91

3.90

3.89

3.88

3.87

OV THRESHOLD (V)

3.86

3.85

-55 -40 -25 -10 5 20 35 50 65 80 95 110 125

TEMPERATURE

RISING

FALLING

FIGURE 12. OVERVOLTAGE THRESHOLD vs TEMPERATURE FIGURE 13. ENi

2.515

2.510

2.505

2.500

2.495

2.490

2.485

ENi THRESHOLD (V)

2.480

2.475

-55 -40 -25 -10 5 20 35 50 65 80 95 110 125

TEMPERATURE

THRESHOLD vs TEMPERATURE

RISING

FALLING

2.250

2.240

2.230

2.220

2.210

2.200

UNDERVOLTAGE 1 THRESHOLD (V)

2.190

-55 -40 -25 -10 5 20 35 50 65 80 95 110 125

TEMPERATURE

FIGURE 14. UNDERVOLTAGE 1 THRESHOLD vs

TEMPERATURE

12

RISING

FALLING

200

160

120

80

GATE CURRENT (µA)

40

0

-55 -40 -25 -10 5 20 35 50 65 80 95 110 125

TEMPERATURE

FIGURE 15. I

(SOURCE) vs TEMPERATURE

GATE

150µA

70µA

50µA

10µA

FN8148.0

March 18, 2005