RHR1K160D

[ /Title

(RHR1

K160D

)

/Subject

(1A,

600V

Hyperfast

Dual

Diode)

/Autho

r ()

/Keywords

(Intersil

Corporation,

semiconductor,

Avalanche

Energy

Rated,

Switch

ing

Power

Supplies,

Power

Switch

ing

Circuits,

Rectifiers,

Data Sheet January 2000

1A, 600V Hyperfast Dual Diode

The RHR1K160D is a hyperfastdual diode withsoft recovery

characteristics (t

time of ultrafast diodes and is silicon nitride passivated ionimplanted epitaxial planar construction.

This device is intended for use as freewheeling/clamping

diodes and rectifiers in a variety of switching power supplies

and other power switching applications. Itslow stored charge

and hyperfast soft recovery minimize ringing and electrical

noise in many power switching circuits reducing power loss

in the switching transistors.

Formerly developmental type TA49185.

< 25ns). It has about half the recovery

rr

Features

• Hyperfast with Soft Recovery. . . . . . . . . . . . . . . . . .<25ns

• Operating Temperature. . . . . . . . . . . . . . . . . . . . . . .150

• Reverse Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . .600V

• Thermal Impedance SPICE® Model

• Thermal Impedance SABER© Model

• Avalanche Energy Rated

• Planar Construction

• Related Literature

- TB334, “Guidelines for Soldering Surface Mount

Components to PC Boards”

Ordering Information

PART NUMBER PACKAGE BRAND

RHR1K160D MS-012AA RHR1K160D

NOTE: When ordering, use the entire part number. For ordering in

tape and reel, add the suffix 96 to the part number, i.e.,

RHR1K160D96.

Packaging

JEDEC MS-012AA

BRANDING DASH

5

1

2

3

4

Absolute Maximum Ratings (Per Leg) T

Peak Repetitive Reverse Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .V

Working Peak Reverse Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .V

DC Blocking Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V

Average Rectified Forward Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I

TA = 65oC

Repetitive Peak Surge Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I

Square Wave, 20kHz

Nonrepetitive Peak Surge Current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I

Halfwave, 1 phase, 60Hz

Maximum Power Dissipation (Note 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P

Avalanche Energy (See Figures 11 and 12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E

Operating and Storage Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . T

Maximum Temperature for Soldering

Leads at 0.063in (1.6mm) from Case for 10s. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . T

Package Body for 10s, See Techbrief 334 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .T

= 25oC, Unless Otherwise Specified

A

Applications

• Switching Power Supplies

• Power Switching Circuits

• General Purpose

Symbol

ANODE 1 (2)

ANODE 2 (3)

RRM

RWM

F(AV)

FRM

FSM

STG,TJ

AVL

pkg

R

D

L

NC (1)

NC (4)

File Number 4788

o

C

CATHODE 1 (8)

CATHODE 1 (7)

CATHODE 2 (6)

CATHODE 2 (5)

RHR1K160D UNITS

600 V

600 V

600 V

1A

2A

10 A

2.5 W

5mJ

-55 to 150

300

260

o

C

o

C

o

C

1

1-888-INTERSIL or 321-724-7143 | Copyright © Intersil Corporation 2000

SABER is a Copyright of Analogy, Inc.

RHR1K160D

Electrical Specifications (Per Leg) T

= 25oC, Unless Otherwise Specified

A

SYMBOL TEST CONDITION MIN TYP MAX UNITS

V

F

IF = 1A - - 2.1 V

IF = 1A, TA = 150oC - - 1.7 V

I

R

VR = 600V - - 100 µA

VR = 600V, TA = 150oC - - 500 µA

t

rr

t

a

t

b

Q

RR

C

J

R

θJA

IF = 1A, dIF/dt = 200A/µs--25ns

IF = 1A, dIF/dt = 200A/µs - 10.5 - ns

IF = 1A, dIF/dt = 200A/µs-5-ns

IF = 1A, dIF/dt = 200A/µs - 20 - nC

VR = 10V, IF = 0A - 10 - pf

Pad Area = 0.483 in2(Note 1) - - 50

Pad Area = 0.027 in2(Note 2) (Figure 13) - - 201

Pad Area = 0.006 in2(Note 2) (Figure 13) - - 239

DEFINITIONS

VF = Instantaneous forward voltage (pw = 300µs, D = 2%).

IR = Instantaneous reverse current.

trr= Reverse recovery time (See Figure 10), summation of ta+tb.

ta = Time to reach peak reverse current (See Figure 10).

tb = Time from peak IRM to projected zero crossing of IRM based on a straight line from peak IRM through 25% of IRM (See Figure 10).

Qrr = Reverse recovery charge.

CJ = Junction Capacitance.

R

= Thermal resistance junction to ambient.

θJA

pw = Pulse width.

D = Duty cycle.

NOTES:

1. Measured using FR-4 copper board at 0.8 seconds.

2. 2. Measured using FR-4 copper board at 1000 seconds.

o

o

o

C/W

C/W

C/W

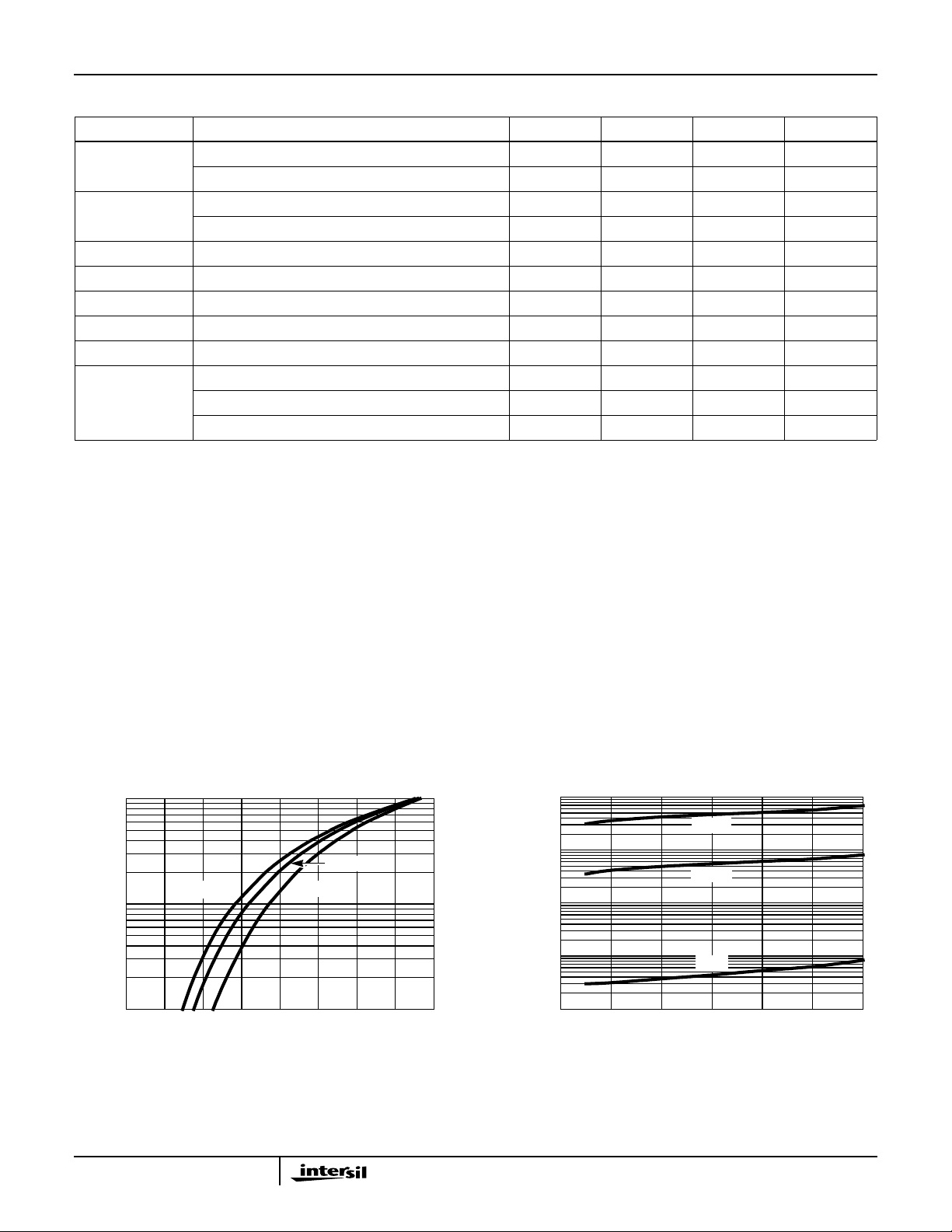

Typical Performance Curve

10

100oC

1

, FORWARD CURRENT (A)

F

I

0.1

0 0.5 1 1.5 2 2.5 4

150oC

VF, FORWARD VOLTAGE (V)

25oC

3.53

FIGURE 1. FORWARD CURRENT vs FORWARD VOLTAGE FIGURE 2. REVERSE CURRENT vs REVERSE VOLTAGE

2

10

1

0.1

REVERSE CURRENT ( A)

0.01

R,

I

0.001

0 600100 500200

o

C

150

o

100

C

25oC

300 400

VR, REVERSE VOLTAGE (V)

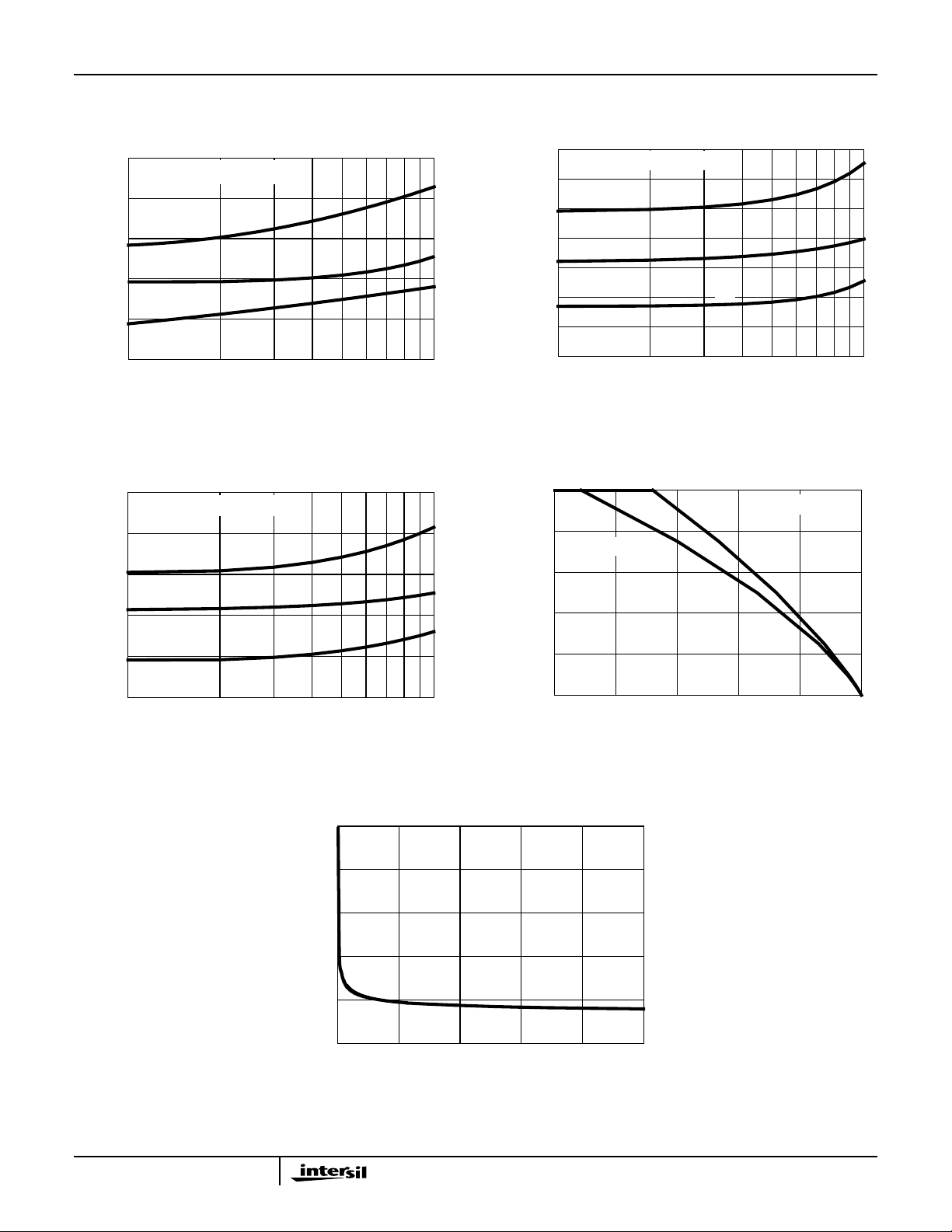

Typical Performance Curve (Continued)

RHR1K160D

20

TA = 25oC, dIF/dt = 200A/µs

16

12

8

4

t, RECOVERY TIMES (ns)

0

0.1

t

rr

t

a

t

b

0.5

IF, FORWARD CURRENT (A)

1

35

TA = 100oC, dIF/dt = 200A/µs

30

25

20

15

10

t, RECOVERY TIMES (ns)

5

0

0.1

t

rr

t

b

t

a

0.5

IF, FORWARD CURRENT (A)

FIGURE 3. trr,taAND tbCURVES vs FORWARD CURRENT FIGURE 4. trr,taAND tbCURVES vs FORWARD CURRENT

50

TA = 150oC, dIF/dt = 200A/µs

40

30

20

t

rr

t

b

1.0

0.8

0.6

0.4

SQ. WAVE

DC

R

θJA

= 50oC/W

1

t, RECOVERY TIMES (ns)

10

0

0.1

a

0.5

IF, FORWARD CURRENT (A)

1

0.2

, AVERAGE FORWARD CURRENT (A)

0

F(AV)

I

50 75 12525 150100

T

, AMBIENT TEMPERATURE (oC)

A

t

FIGURE 5. trr,taAND tbCURVES vs FORWARD CURRENT FIGURE 6. CURRENT DERATING CURVE

50

40

30

20

10

, JUNCTION CAPACITANCE (pF)

J

C

0

0 20 40 60 10080

V

, REVERSE VOLTAGE (V)

R

FIGURE 7. JUNCTION CAPACITANCE vs REVERSE VOLTAGE

3

Typical Performance Curve (Continued)

RHR1K160D

10

DUTY CYCLE - DESCENDING ORDER

0.5

0.2

0.1

0.05

1

0.02

0.01

, NORMALIZED

0.1

θJA

Z

THERMAL IMPEDANCE

SINGLE PULSE

0.01

-5

10

-4

10

FIGURE 8. NORMALIZED MAXIMUM TRANSIENT THERMAL IMPEDANCE

Test Circuits and Waveforms

VGE AMPLITUDE AND

RG CONTROL dIF/dt

AND t2CONTROL I

t

1

F

L

R

= 50oC/W

θJA

P

DM

t

1

t

NOTES:

DUTY FACTOR: D = t

PEAK TJ = PDM x Z

-3

10

-2

10

-1

10

0

10

1

10

θJA

1/t2

10

x R

2

θJA

2

+ T

A

3

10

t, RECTANGULAR PULSE DURATION (s)

DUT

CURRENT

R

G

V

GE

t

1

t

2

IGBT

SENSE

dI

+

V

DD

-

0

F

I

F

dt

t

rr

t

a

FIGURE 9. trr TEST CIRCUIT FIGURE 10. trr WAVEFORMS AND DEFINITIONS

L = 20mH

R < 0.1Ω

E

AVL

Q

= IGBT (BV

1

= 1/2LI2 [V

R(AVL)

CES

/(V

> DUT V

R(AVL)

R(AVL)

- VDD)]

)

LR

V

CURRENT

SENSE

Q

1

DUT

+

V

DD

I

L

IV

V

DD

t

0

AVL

I

L

t

1

t

2

FIGURE 11. AVALANCHE ENERGY TEST CIRCUIT FIGURE 12. AVALANCHE CURRENT AND VOLTAGE

WAVEFORMS

t

b

0.25 I

RM

I

RM

t

4

RHR1K160D

Thermal Resistance vs Mounting Pad Area

The maximum rated junction temperature, TJM, and the

thermal resistance of the heat dissipating path determines

the maximum allowable device power dissipation, P

application.Thereforetheapplication’sambienttemperature,

T

(oC), and thermal resistance R

A

reviewed to ensure that T

JM

is never exceeded. Equation 1

(oC/W) must be

θJA

mathematically represents the relationship and serves as

the basis for establishing the rating of the part.

P

TJMTA–()

-----------------------------=

DM

Z

θJA

In using surface mount devicessuch as the SOP-8 package,

the environment in which it is applied will have a significant

influence on the part’s current and maximum power

dissipation ratings. Precise determination of P

DM

and influenced by many factors:

1. Mounting pad areaonto which the device is attached and

whether there is copper on one side or both sides of the

board.

2. The number of copper layersand the thickness of the

board.

3. The use of external heat sinks.

4. The use of thermal vias.

5. Air flow and board orientation.

6. For non steady state applications, the pulse width, the

duty cycle and the transientthermal response of thepart,

the board and the environment they are in.

Intersil provides thermal information to assist the designer’s

preliminary application evaluation. Figure 13 defines the

R

for the device as a function of the top copper

θJA

(component side) area. This is for a horizontally positioned

FR-4 board with 2 oz. copper after 1000 seconds of steady

state power with no air flow. This graph provides the

necessary information for calculation of the steady state

junction temperature or power dissipation. Pulse

applications can be evaluated using the Intersil device

SPICE thermal model or manually utilizing the normalized

maximum transient thermal impedance curve.

,inan

DM

(EQ. 1)

is complex

350

R

= 110.2 - 25.24 x ln (AREA)

θJA

300

C/W)

o

250

200

150

, THERMAL IMPEDANCE

θJA

100

R

JUNCTION TO AMBIENT (

Rθβ= 43.81 - 22.66 x ln (AREA)

50

0.001

FIGURE 13. THERMAL RESISTANCE vs MOUNTING PAD AREA

Displayed on the curve are R

239oC/W - 0.006in

0.01 0.1

AREA, TOP COPPER AREA (in2)

values listed in the

θJA

2

201oC/W - 0.027in

2

Electrical Specifications table. These points were chosen to

depict the compromise between the copper board area, the

thermal resistance and ultimately the power dissipation,

P

. Thermal resistances corresponding to other

DM

component side copper areas can be obtained from Figure

13 or by calculation using Equation 2. The area, in square

inches is the top copper board area, the thermal resistance

and ultimately the power dissipation, P

θJA

110.18 25.24 Area()ln×–=

R

DM

.

(EQ. 2)

While Equation 2 describes the thermal resistance of a

single die, the dual die SOP-8 package introduces an

additional thermal component, thermal coupling resistance,

R

. Equation 3 describes Rθβ as a function of the top

θβ

copper mounting pad area.

R

θβ

43.81 22.66 Area()ln×–=

(EQ. 3)

The thermal coupling resistance vs. copper area is also

graphically depicted in Figure 13. It is important to note the

thermal resistance (R

(

R

) are equivalent for both die. For example at 0.1 square

θβ

) and thermal coupling resistance

θJA

inches of copper:

R

R

θJA1

θβ1

= R

= R

θJA2

= 96oC/W

θβ2

= 168oC/W

TJ1 and TJ2 define the junction temperature of the

respective die. Similarly, P

and P2 define the power

1

dissipated in each die. The steady state junction

temperature can be calculated using Equation 4 for die 1

and Equation 5 for die 2.

Example: Use Equation 4 to calculate T

calculate T

with the following conditions. Die 2 is

J2

and Equation 5 to

J1

dissipating 0.5W; die 1 is dissipating 0W; the ambient

temperature is 60

o

C; the package is mounted to a top

copper area of 0.1 square inches per die.

5

RHR1K160D

.

T

J1P1RθJAP2RθβTA

++=

(EQ. 4)

TJ1 = (0W)(168oC/W) + (0.5W)(96oC/W) + 60oC

TJ1 = 108oC

T

J2P2RθJAP1RθβTA

T

= (0.5W)(168oC/W) + (0W)(96oC/W) + 60oC

J2

++=

(EQ. 5)

TJ2 = 144oC

The transient thermal impedance (Z

) is also effected by

θJA

varied top copper board area. Figure 14 shows the effect of

200

COPPER BOARD AREA - DESCENDING ORDER

2

0.020 in

2

0.140 in

150

C/W)

o

100

, THERMAL

θJA

Z

IMPEDANCE (

50

0.257 in

0.380 in

0.483 in

2

2

2

copper pad area on single pulse transient thermal

impedance. Each trace represents a copper pad area in

square inches corresponding to the descending list in the

graph. SPICE and SABER thermal models are provided for

each of the listed pad areas.

Copper pad area has no perceivable effect on transient

thermal impedance for pulse widths less than 100ms. For

pulse widths less than 100ms the transient thermal

impedance is determinedby the die andpackage.Therefore,

CTHERM1 through CTHERM6 and RTHERM1 through

RTHERM5 remain constant for each of the thermal models.

A listing of the model component values is availab le in Table 1.

0

-1

10

0

10

t, RECTANGULAR PULSE DURATION (s)

1

10

2

10

3

10

FIGURE 14. TRANSIENT THERMAL IMPEDANCE vs MOUNTING PAD AREA

6

RHR1K160D

SPICE Thermal Model

REV October 1998

RHR1K160D

Copper Area = 0.483 in

2

CTHERM1 th 8 6e-6

CTHERM2 8 7 4e-5

CTHERM3 7 6 1.5e-4

CTHERM4 6 5 7.5e-4

CTHERM5 5 4 7e-3

CTHERM6 4 3 2e-2

CTHERM7 3 2 8e-2

CTHERM8 2 tl 2.5

RTHERM1 th 8 5e-2

RTHERM2 8 7 2.5e-1

RTHERM3 7 6 1.5

RTHERM4 6 5 2.5

RTHERM5 5 4 7.5

RTHERM6 4 3 22

RTHERM7 3 2 38

RTHERM8 2 tl 38

SABER Thermal Model

Copper Area = 0.483 in

template thermal_model th tl

thermal_c th, tl

{

ctherm.ctherm1 th 8 = 6e-6

ctherm.ctherm2 8 7 = 4e-5

ctherm.ctherm3 7 6 = 1.5e-4

ctherm.ctherm4 6 5 = 7.5e-4

ctherm.ctherm5 5 4 = 7e-3

ctherm.ctherm6 4 3 = 2e-2

ctherm.ctherm7 3 2 = 8e-2

ctherm.ctherm8 2 tl = 2.5

rtherm.rtherm1 th 8 = 5e-2

rtherm.rtherm2 8 7 = 2.5e-1

rtherm.rtherm3 7 6 = 1.5

rtherm.rtherm4 6 5 = 2.5

rtherm.rtherm5 5 4 = 7.5

rtherm.rtherm6 4 3 = 22

rtherm.rtherm7 3 2 = 38

rtherm.rtherm8 2 tl = 38

}

2

RTHERM1

RTHERM2

RTHERM3

RTHERM4

RTHERM5

RTHERM6

RTHERM7

RTHERM8

th

8

7

6

5

4

3

2

t

l

JUNCTION

CTHERM1

CTHERM2

CTHERM3

CTHERM4

CTHERM5

CTHERM6

CTHERM7

CTHERM8

AMBIENT

TABLE 1. THERMAL MODELS

COMPONENT 0.02 in

2

0.14 in

2

0.257 in

2

0.38 in

2

0.483 in

CTHERM7 7.5e-2 8e-2 8e-2 8e-2 8e-2

CTHERM8 1 1.5 2 2 2.5

RTHERM6 25 22 22 22 22

RTHERM7 65 45 40 38 38

RTHERM8 70 55 48 43 38

7

2

RHR1K160D

MS-012AA

8 LEAD JEDEC MS-012AA SMALL OUTLINE PLASTIC PACKAGE

E

E

1

1

2

D

56

o

h x 45

L

0.060

1.52

0.155

4.0

0.275

7.0

MINIMUM RECOMMENDED FOOTPRINT FOR

SURFACE-MOUNTED APPLICATIONS

A

A

1

SYMBOL

INCHES MILLIMETERS

NOTESMIN MAX MIN MAX

A 0.0532 0.0688 1.35 1.75 -

e

A

1

0.004 0.0098 0.10 0.25 b 0.013 0.020 0.33 0.51 c 0.0075 0.0098 0.19 0.25 -

D 0.189 0.1968 4.80 5.00 2

b

E 0.2284 0.244 5.80 6.20 -

E

1

0.1497 0.1574 3.80 4.00 3

e 0.050 BSC 1.27 BSC -

H 0.0099 0.0196 0.25 0.50 -

c

L 0.016 0.050 0.40 1.27 4

NOTES:

1. All dimensions are within allowabledimensions of Rev.C of

JEDEC MS-012AA outline dated 5-90.

2. Dimension “D” does not include mold flash, protrusions or gate

burrs. Mold flash, protrusions or gate burrs shall not exceed

0o-8

0.004 IN

0.10 mm

o

0.006 inches (0.15mm) per side.

3. Dimension “E1” does not include inter-lead flash or protrusions.

Inter-lead flash and protrusions shall not exceed 0.010 inches

(0.25mm) per side.

0.050

1.27

4. “L” is the length of terminal for soldering.

5. The chamferon the bodyis optional. Ifit is notpresent, a visualindex

feature must be located within the crosshatched area.

0.024

0.6

1.5mm

DIA. HOLE

6. Controlling dimension: Millimeter.

7. Revision 8 dated 5-99.

4.0mm

USER DIRECTION OF FEED

2.0mm

1.75mm

MS-012AA

12mm TAPE AND REEL

C

L

12mm

8.0mm

40mm MIN.

ACCESS HOLE

18.4mm

COVER TAPE

13mm

330mm

GENERAL INFORMATION

1. 2500 PIECES PER REEL.

2. ORDER IN MULTIPLES OF FULL REELS ONLY.

3. MEETS EIA-481 REVISION “A” SPECIFICATIONS.

50mm

12.4mm

8

RHR1K160D

All Intersil semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Intersil semiconductor products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design and/or specifications at any time without notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see web site www.intersil.com

Sales Office Headquarters

NORTH AMERICA

Intersil Corporation

P. O. Box 883, Mail Stop 53-204

Melbourne, FL 32902

TEL: (321) 724-7000

FAX: (321) 724-7240

9

EUROPE

Intersil SA

Mercure Center

100, Rue de la Fusee

1130 Brussels, Belgium

TEL: (32) 2.724.2111

FAX: (32) 2.724.22.05

ASIA

Intersil (Taiwan) Ltd.

7F-6, No. 101 Fu Hsing North Road

Taipei, Taiwan

Republic of China

TEL: (886) 2 2716 9310

FAX: (886) 2 2715 3029

Loading...

Loading...