RFT3055LE

Data Sheet August 1999

2.0A, 60V, 0.150 Ohm, N-Channel, Logic

Level, ESD Rated, Power MOSFET

This product is an N-Channel powerMOSFETmanufactured

using the MegaFET process. This process, which uses

feature sizes approaching those of LSI circuits, gives

optimum utilization of silicon, resulting in outstanding

performance. It was designed foruse in applications such as

switching regulators, switching converters, motor drivers,

and relay drivers. These transistors can be operated directly

from integrated circuits.

Formerly developmental type TA49158.

Ordering Information

PART NUMBER PACKAGE BRAND

RFT3055LE SOT-223 3055L

NOTE: RFT3055LE is available only in tape and reel.

File Number

Features

• 2.0A, 60V

•r

• 2kV ESD Protected

• Temperature Compensating PSPICE

• Thermal Impedance SPICE Model

• Peak Current vs Pulse Width Curve

• UIS Rating Curve

• Related Literature

- TB334, “Guidelines for Soldering Surface Mount

= 0.150Ω

DS(ON)

Components to PC Boards”

®

Model

Symbol

D

G

4537.3

Packaging

S

SOT-223

DRAIN

(FLANGE)

SOURCE

DRAIN

GATE

8-143

CAUTION: These devices are sensitive to electrostatic discharge; follow proper ESD Handling Procedures.

PSPICE® is a registered trademark of MicroSim Corporation.

http://www.intersil.com or 407-727-9207

| Copyright © Intersil Corporation 1999

RFT3055LE

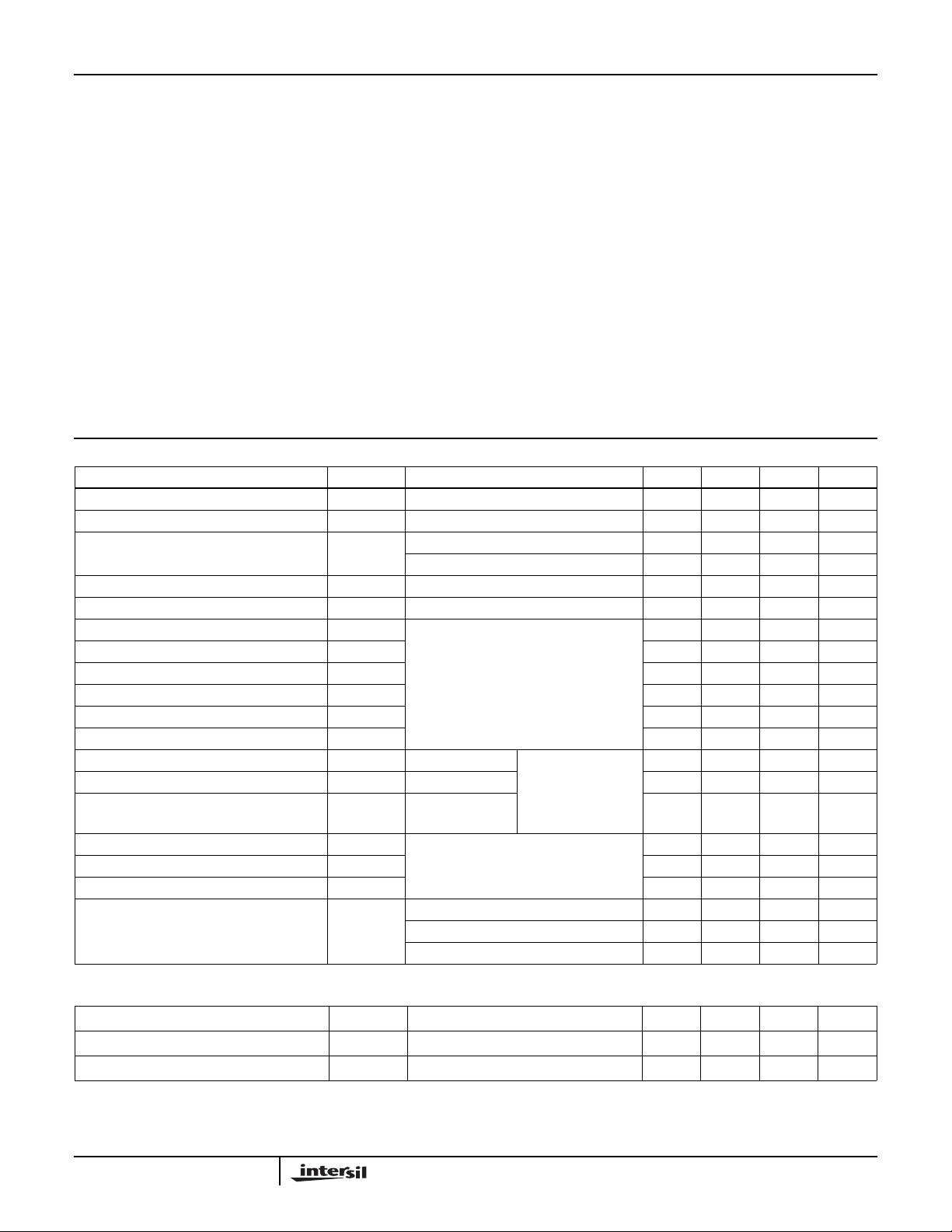

Absolute Maximum Ratings T

= 25oC, Unless Otherwise Specified

A

RFT3055LE UNITS

Drain to Source Voltage (Note 1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .V

Drain to Gate Voltage (RGS = 20kΩ) (Note 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .V

Gate to Source Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V

DSS

DGR

GS

60 V

60 V

±10 V

Drain Current

Continuous (Figure 2) (Note 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I

Pulsed Drain Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I

Pulsed Avalanche Rating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E

Power Dissipation (Note 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P

D

DM

AS

D

Derate Above 25oC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating and Storage Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TJ, T

STG

Maximum Temperature for Soldering

Leads at 0.063in (1.6mm) from Case for 10s. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . T

Package Body for 10s, See Techbrief 334 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .T

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operationofthe

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

L

pkg

2.0

Figure 5

Figures 6, 16, 17

1.1

9.09

-55 to 150

300

260

A

W

mW/oC

o

C

o

C

o

C

NOTE:

1. TJ = 25oC to 125oC.

Electrical Specifications T

= 25oC, Unless Otherwise Specified

A

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

Drain to Source Breakdown Voltage BV

Gate to Source Threshold Voltage V

Zero Gate Voltage Drain Current I

DSSID

GS(TH)VGS

DSS

= 250µA, VGS = 0V (Figure 11) 60 - - V

= VDS, ID = 250µA (Figure 10) 1 - 2 V

VDS = 60V, VGS = 0V - - 1 µA

VDS = 60V, VGS = 0V, TA = 150oC--50µA

Gate to Source Leakage Current I

Drain to Source On Resistance r

DS(ON)ID

Turn-On Time t

Turn-On Delay Time t

d(ON)

Rise Time t

Turn-Off Delay Time t

d(OFF)

Fall Time t

Turn-Off Time t

Total Gate Charge Q

g(TOT)VGS

Gate Charge at 10V Q

Threshold Gate Charge Q

GSS

ON

OFF

g(5)

g(TH)

VGS = ±10V - - 10 µA

= 2.0A, VGS = 5V (Figure 9) - 0.110 0.150 Ω

VDD = 30V, ID≅ 2.0A,

RL = 15Ω, VGS= 5V,

RGS = 5Ω

(Figure 12)

r

- - 120 ns

-10-ns

-70-ns

-30-ns

f

-25-ns

- - 85 ns

= 0V to 10V VDD = 30V,

VGS = 0V to 5V - 15 18 nC

VGS = 0V to 1V - 1.0 1.2 nC

ID≅ 2.0A,

RL = 15Ω

I

= 1.0mA

g(REF)

-2835nC

(Figure 15)

Input Capacitance C

Output Capacitance C

Reverse Transfer Capacitance C

Thermal Resistance Junction to Ambient R

ISS

OSS

RSS

θJA

VDS = 25V, VGS = 0V,

f = 1MHz

(Figure 12)

- 850 - pF

- 170 - pF

- 100 - pF

Pad Area = 0.171 in2 (see note 2) - - 110

Pad Area = 0.068 in

Pad Area = 0.026 in

2

2

- - 128

- - 147

o

o

o

C/W

C/W

C/W

Source to Drain Diode Specifications

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

Source to Drain Diode Voltage V

SD

Reverse Recovery Time t

NOTE:

2. 110oC/W measured using FR-4 board with 0.171in2 footprint for 1000 seconds.

8-144

ISD = 2.0A - - 1.5 V

ISD = 2.0A, dISD/dt = 100A/µs - - 100 ns

rr

RFT3055LE

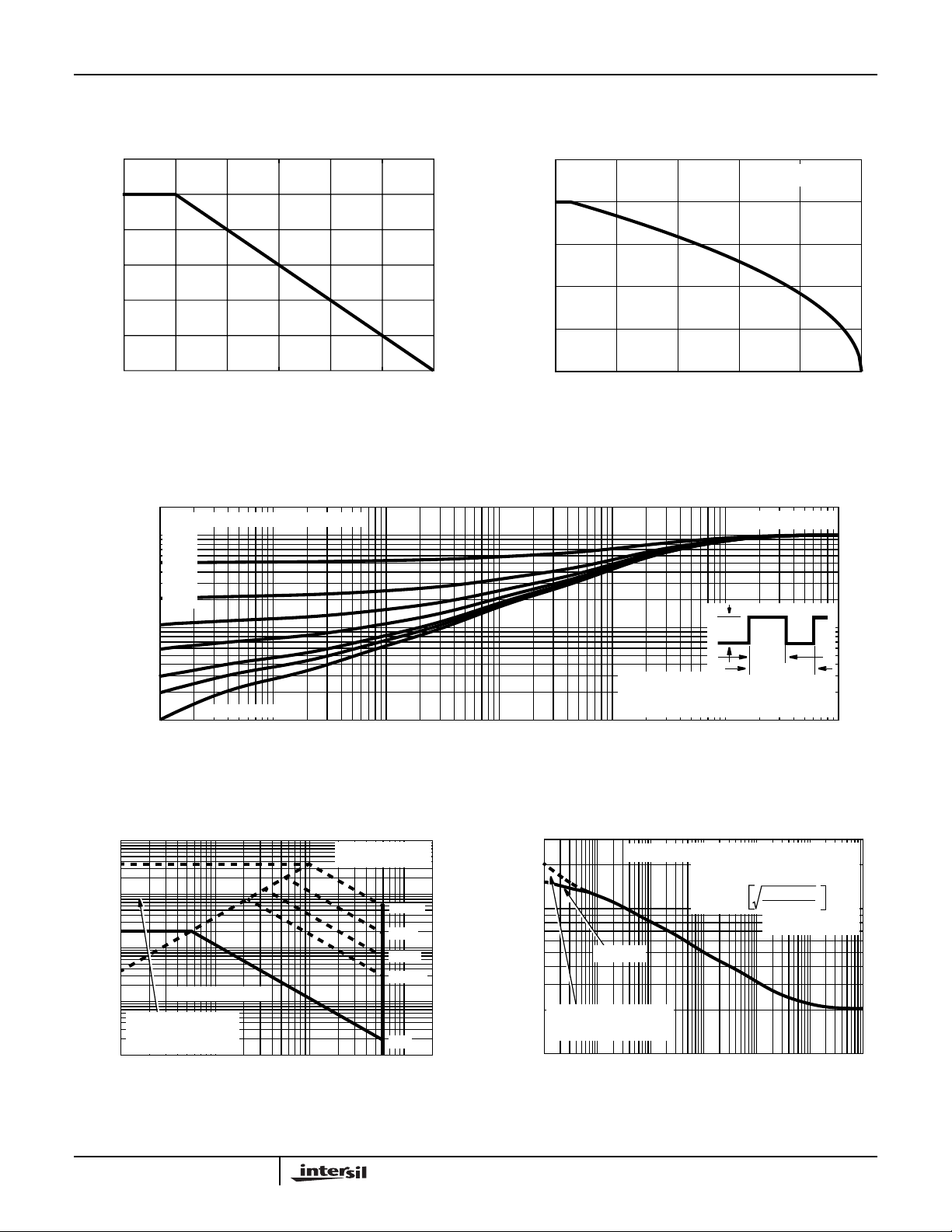

Typical Performance Curves

Unless otherwise specified

1.2

1.0

0.8

0.6

0.4

0.2

POWER DISSIPATION MULTIPLIER

0

0 25 50 75 100 150

125

TA, AMBIENT TEMPERATURE (oC)

FIGURE 1. NORMALIZED POWER DISSIPATION vs AMBIENT

TEMPERATURE

2

DUTY CYCLE - DESCENDING ORDER

0.5

1

0.2

0.1

0.05

0.02

0.01

2.5

R

= 110oC/W

θJA

2.0

1.5

1.0

, DRAIN CURRENT (A)

D

I

0.5

0

25 50 75 100 125 150

TA, AMBIENT TEMPERATURE (oC)

FIGURE 2. MAXIMUM CONTINUOUS DRAIN CURRENT vs

AMBIENT TEMPERATURE

R

= 110oC/W

θJA

0.1

, NORMALIZED

JA

θ

Z

THERMAL IMPEDANCE

-3

SINGLE PULSE

-2

10

0.01

10

FIGURE 3. NORMALIZED MAXIMUM TRANSIENT THERMAL IMPEDANCE

100

10

1

R

= 110oC/W

, DRAIN CURRENT (A)

0.1

D

I

OPERATION IN THIS

AREA MAY BE

LIMITED BY r

0.01

θJA

DS(ON)

0.1 1 10 100

VDS, DRAIN TO SOURCE VOLTAGE (V)

TJ = MAX RATED

TA = 25oC

-1

10

0

10

t, RECTANGULAR PULSE DURATION (s)

30

100µs

10

1ms

10ms

100ms

DC

200

, PEAK CURRENT (A)

DM

I

TRANSCONDUCTANCE

MAY LIMIT CURRENT

IN THIS REGION

1

-3

10

NOTES:

DUTY FACTOR: D = t

PEAK TJ = PDM x Z

1

10

TA = 25oC

VGS = 5V

-2

10

10

P

DM

1/t2

x R

JA

θ

2

10

FOR TEMPERATURES

ABOVE 25oC DERATE PEAK

CURRENT AS FOLLOWS:

I = I

25

-1

0

10

t, PULSE WIDTH (s)

10

t

JA

θ

1

1

t

2

+ T

150 - T

125

R

θJA

A

10

A

= 110oC/W

2

10

3

3

10

FIGURE 4. FORWARD BIAS SAFE OPERATING AREA FIGURE 5. PEAK CURRENT CAPABILITY

8-145

RFT3055LE

Typical Performance Curves

20

If R = 0

tAV = (L)(IAS)/(1.3*RATED BV

10

If R ≠ 0

t

= (L/R)ln[(IAS*R)/(1.3*RATED BV

AV

1

, AVALANCHE CURRENT (A)

AS

I

0.1

0.01 0.1 1 10 100

STARTING TJ = 150oC

tAV, TIME IN AVALANCHE (ms)

DSS

Unless otherwise specified (Continued)

- VDD)

- VDD) +1]

DSS

STARTING TJ = 25oC

NOTE: Refer to Intersil Application Notes AN9321 and AN9322.

FIGURE 6. UNCLAMPED INDUCTIVE SWITCHING CAPABILITY

20

PULSE DURATION = 80µs

DUTY CYCLE = 0.5% MAX

V

= 15V

DD

16

-55oC

12

8

DRAIN CURRENT (A)

D,

I

4

0

0 1.5 3.0 4.5 6.0

VGS, GATE TO SOURCE VOLTAGE (V)

150oC

o

25

C

20

16

12

8

, DRAIN CURRENT (A)

D

I

4

0

VGS = 10V

012345

VDS, DRAIN TO SOURCE VOLTAGE (V)

VGS = 5V

VGS = 4.5V

V

= 4V

GS

PULSE DURATION = 80µs

DUTY CYCLE = 0.5% MAX

TA = 25oC

V

= 3V

GS

FIGURE 7. SATURATION CHARACTERISTICS

2.0

PULSE DURATION = 80µs

DUTY CYCLE = 0.5% MAX

V

1.75

1.5

1.25

1.0

ON RESISTANCE

0.75

NORMALIZED DRAIN TO SOURCE

0.5

= 5V, ID = 2A

GS

-80 -40 0 40 80 120 160

TJ, JUNCTION TEMPERATURE (oC)

FIGURE 8. TRANSFER CHARACTERISTICS FIGURE 9. NORMALIZED DRAIN TOSOURCE ON

1.2

1.1

1.0

0.9

NORMALIZED GATE

THRESHOLD VOLTAGE

0.8

0.7

-80 -40 0 40 80 120 160

TJ, JUNCTION TEMPERATURE (oC)

VGS = VDS, ID = 250µA

FIGURE 10. NORMALIZED GATETHRESHOLD VOLTAGE vs

JUNCTION TEMPERATURE

8-146

RESISTANCE vs JUNCTION TEMPERATURE

1.15

ID = 250µA

1.1

1.05

1.0

BREAKDOWN VOLTAGE

0.95

NORMALIZED DRAIN TO SOURCE

0.9

-80 -40 0 40 80 120 160

TJ, JUNCTION TEMPERATURE (oC)

FIGURE 11. NORMALIZED DRAIN TOSOURCE BREAKDOWN

VOLTAGE vs JUNCTION TEMPERATURE

RFT3055LE

Typical Performance Curves

200

VDD = 30V, ID = 2A, RL = 15Ω

150

100

SWITCHING TIME (ns)

50

0

010

RGS, GATE TO SOURCE RESISTANCE (Ω)

20

Unless otherwise specified (Continued)

t

R

t

F

t

D(OFF)

t

D(ON)

30

40

50

250

200

150

100

, ON-STATE RESISTANCE (mΩ)

DS(ON)

r

50

246810

ID = 2A

I

= 0.5A

D

, GATE TO SOURCE VOLTAGE (V)

V

GS

PULSE DURATION = 80µs

DUTY CYCLE = 0.5% MAX

FIGURE 12. SWITCHING TIME vs GATE RESISTANCE FIGURE 13. SOURCE TO DRAIN ON RESISTANCE vs GATE

VOLTAGE AND DRAIN CURRENT

1200

C

ISS

900

VGS = 0V, f = 1MHz

= CGS + C

C

600

C

300

C, CAPACITANCE (pF)

0

0 5 10 15 20 25 30

OSS

C

RSS

VDS, DRAIN TO SOURCE VOLTAGE (V)

C

C

ISS

RSS

OSS

= C

= CDS + C

GD

GD

GD

10

WAVEFORMS IN

DESCENDING ORDER:

ID = 2A

8

I

= 0.5A

D

6

4

2

, GATE TO SOURCE VOLTAGE (V)

GS

V

0

0 6 12 18 24 30

Q

g

VDD = 15V

, GATE CHARGE (nC)

NOTE: Refer to Intersil Application Notes AN7254 and AN7260.

FIGURE 14. CAPACITANCE vs DRAIN TO SOURCE VOLTAGE

FIGURE 15. GATE CHARGE WAVEFORMS FOR CONSTANT

GATE CURRENT

8-147

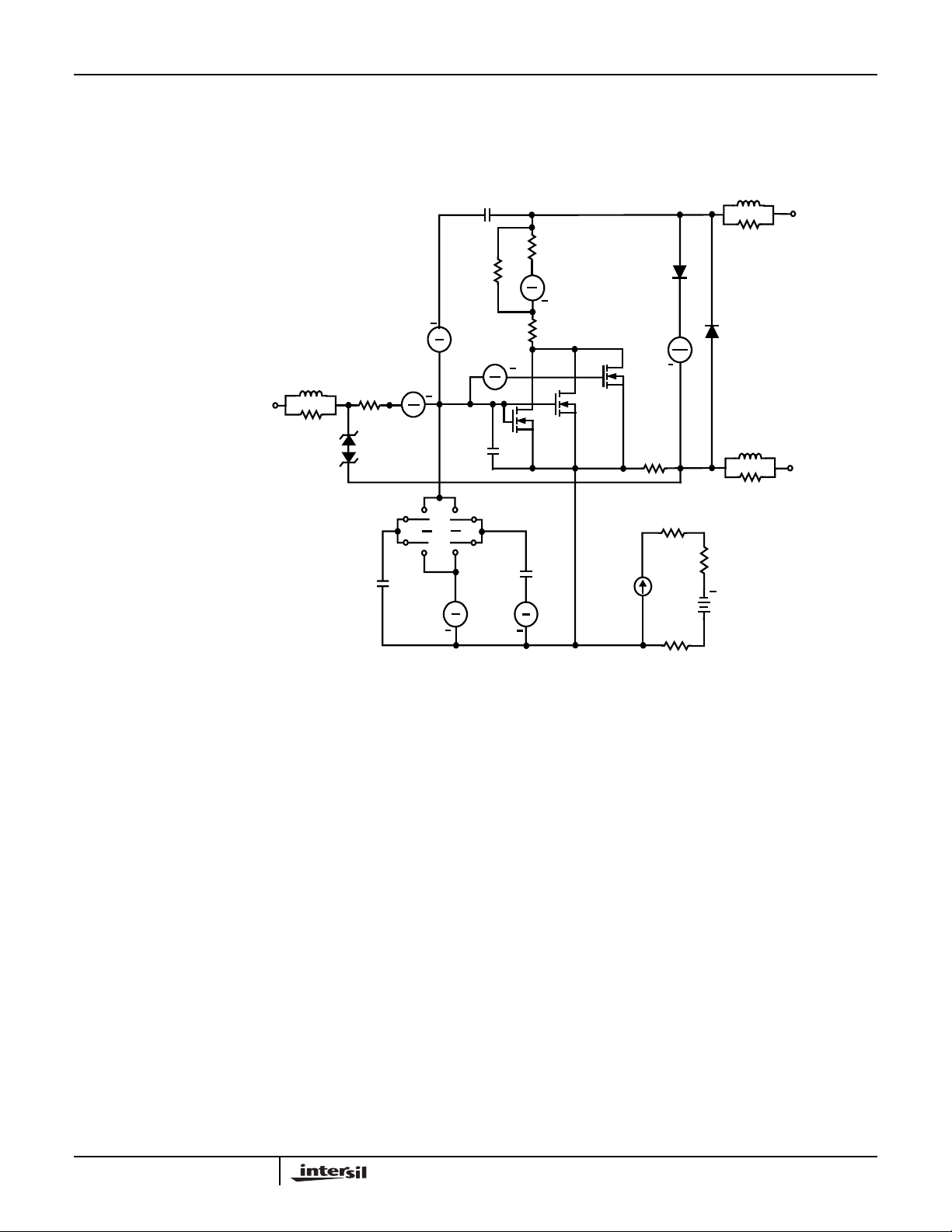

RFT3055LE

Test Circuits and Waveforms

V

DS

BV

DSS

L

VARY tP TO OBTAIN

REQUIRED PEAK I

V

GS

AS

R

G

+

V

DD

-

DUT

0V

P

I

AS

0.01Ω

0

t

FIGURE 16. UNCLAMPED ENERGY TEST CIRCUIT FIGURE 17. UNCLAMPED ENERGY WAVEFORMS

V

I

g(REF)

DS

R

L

V

GS

+

V

DD

-

DUT

V

DD

VGS= 1V

0

V

GS

Q

g(TH)

t

P

I

AS

t

AV

Q

g(TOT)

V

DS

Q

g(5)

VGS= 5V

V

DS

V

DD

VGS= 10V

I

g(REF)

0

FIGURE 18. GATE CHARGE TEST CIRCUIT FIGURE 19. GATE CHARGE WAVEFORM

t

ON

t

d(ON)

90%

10%

t

r

R

L

V

DS

V

GS

V

GS

+

-

V

DS

0

t

d(OFF)

0V

R

GS

DUT

V

GS

10%

0

50%

PULSE WIDTH

90%

FIGURE 20. SWITCHING TIME TEST CIRCUIT FIGURE 21. RESISTIVE SWITCHING WAVEFORMS

t

OFF

50%

t

f

90%

10%

8-148

RFT3055LE

Thermal Resistance vs. Mounting Pad

Area

The maximum rated junction temperature, T

thermal resistance of the heat dissipating path determines

the maximum allowable device power dissipation, P

in an application. Therefore the application’s ambient

temperature, T

must be reviewed to ensure that T

(oC), and thermal impedance R

A

is neverexceeded.

J(MAX)

Equation 1 mathematically represents the relationship and

serves as the basis for establishing the rating of the part.

P

D MAX()

T

--------------------------------------------=

–()

JMAX()TA

R

θJA

In using surface mount devices such as the SOT-223

package, the environment in which it is applied will have a

significant influence on the part’s current and maximum

power dissipation ratings. Precise determination of the

P

is complex and influenced by many factors:

D(MAX)

1. Mounting pad areaonto which the deviceis attached and

whether there is copper on one side or both sides of the

board.

2. The number of copper layersand the thickness of the

board.

3. The use of external heat sinks.

4. The use of thermal vias.

5. Air flow and board orientation.

6. For non steady state applications, the pulse width, the

duty cycle and the transientthermalresponse of thepart,

the board and the environment they are in.

Intersil provides thermal information to assist the designer’s

preliminary application evaluation. Figure 22 defines the

for the device as a function of the top copper

R

θJA

(component side) area. This is for a horizontally positioned

FR-4 board with 1oz copper after 1000 seconds of steady

state power with no air flow.This graph provides the

necessary information for calculation of the steady state

junction temperature or power dissipation. Pulse

applications can be evaluated using the Intersil device Spice

thermal model ormanually utilizing the normalized maximum

transient thermal impedance curve.

J(MAX)

θJA

, and the

D(MAX)

(oC/W)

(EQ. 1)

200

,

150

C/W)

o

(

θJA

R

100

50

FIGURE 22. THERMAL RESISTANCEvs MOUNTING PAD

147oC/W - 0.026in

0.01 0.1 1.0

AREA, TOP COPPER AREA (in2)

AREA

Displayed on the curve are the three R

R

= 75.9 - 19.3 * ln(AREA)

θJA

2

128oC/W - 0.068in

110oC/W - 0.171in

2

values listed in

θJA

2

the Electrical Specifications table. The three points were

chosen to depict the compromise between the copper board

area, the thermal resistance and ultimately the power

dissipation, P

. Thermal resistances corresponding to

D(MAX)

other component side copper areas can be obtained from

Figure 22 or by calculation using Equation 2. The area, in

square inches is the top copper area including the gate and

source pads.

θJA

75.9 19.3 Area()ln×–=

(EQ. 2)

R

8-149

RFT3055LE

PSPICE Electrical Model

.SUBCKT RFT3055LE 2 1 3 ; REV May 98

CA 12 8 1.68e-9

CB 15 14 1.78e-9

CIN 6 8 7.69e-10

DBODY 7 5 DBODYMOD

DBREAK 5 11 DBREAKMOD

DESD1 91 9 DESD1MOD

DESD2 91 7 DESD2MOD

DPLCAP 10 5 DPLCAPMOD

EBREAK 11 7 17 18 64.28

EDS 14 8 5 8 1

EGS 13 8 6 8 1

ESG 6 10 6 8 1

EVTHRES 6 21 19 8 1

EVTEMP 20 6 18 22 1

IT 8 17 1

LDRAIN 2 5 1e-9

LGATE 1 9 4.6e-9

LSOURCE 3 7 4.6e-9

MMED 16 6 8 8 MMEDMOD

MSTRO 16 6 8 8 MSTROMOD

GATE

1

LGATE

RLGATE

RGATE

9

DESD1

91

DESD2

ESG

EVTEMP

+

20

18

22

MWEAK 16 21 8 8 MWEAKMOD

RBREAK 17 18 RBREAKMOD 1

RDRAIN 50 16 RDRAINMOD 24e-3

RGATE 9 20 9.84

RLDRAIN 2 5 10

RLGATE 1 9 46

RLSOURCE 3 7 46

RSLC1 5 51 RSLCMOD 1e-6

S1A

12

13

S1B

CA

RSLC2 5 50 1e3

RSOURCE 8 7 RSOURCEMOD 49e-3

RVTHRES 22 8 RVTHRESMOD 1

EGS

RVTEMP 18 19 RVTEMPMOD 1

S1A 6 12 13 8 S1AMOD

S1B 13 12 13 8 S1BMOD

S2A 6 15 14 13 S2AMOD

S2B 13 15 14 13 S2BMOD

VBAT 22 19 DC 1

ESLC 51 50 VALUE={(V(5,51)/ABS(V(5,51)))*(PWR(V(5,51)/(1e-6*45),4))}

.MODEL DBODYMOD D (IS = 3.61e-13 RS = 1.78e-2 TRS1 = 1.7e-2 TRS2 = -4.69e-6 CJO = 3.88e-10 TT = 3.6e-8)

.MODEL DBREAKMOD D (RS = 4.73e-1 TRS1 = -2.19e-3 TRS2 = 4.7e-5)

.MODEL DESD1MOD D (BV = 12.5 NBV = 17.5 IBV = 2.5e-4 RS = 22)

.MODEL DESD2MOD D (BV = 12.86 NBV = 22 IBV = 2.5e-4 RS = 0)

.MODEL DPLCAPMOD D (CJO = 4.803e-10 IS = 1e-30 N = 10)

.MODEL MMEDMOD NMOS (VTO = 1.78 KP = 1.5 IS = 1e-30 N = 10 TOX = 1 L = 1u W = 1u RG = 9.84)

.MODEL MSTROMOD NMOS (VTO = 2.08 KP = 10.5 IS = 1e-30 N = 10 TOX = 1 L = 1u W = 1u)

.MODEL MWEAKMOD NMOS (VTO = 1.55 KP = 0.1 IS = 1e-30 N = 10 TOX = 1 L = 1u W = 1u RG = 98.4 RS = 0.1)

.MODEL RBREAKMOD RES (TC1 = 1.06e-3 TC2 = -6.22e-7)

.MODEL RDRAINMOD RES (TC1 = 4.5e-3 TC2 = 6e-5)

.MODEL RSLCMOD RES (TC1 = 0 TC2 = 0)

.MODEL RSOURCEMOD RES (TC1 = 0 TC2 = 0)

.MODEL RVTHRESMOD RES (TC = 0 TC2 = -4e-6)

.MODEL RVTEMPMOD RES (TC1 = -1.9e-3 TC2 = 1.3e-7)

.MODEL S1AMOD VSWITCH (RON = 1e-5 ROFF = 0.1 VON = -4.4 VOFF= -2.4)

.MODEL S1BMOD VSWITCH (RON = 1e-5 ROFF = 0.1 VON = -2.4 VOFF= -4.4)

.MODEL S2AMOD VSWITCH (RON = 1e-5 ROFF = 0.1 VON = -2.0 VOFF= 1.15)

.MODEL S2AMOD VSWITCH (RON = 1e-5 ROFF = 0.1 VON = 1.15 VOFF= -2.0)

.ENDS

DPLCAP

10

RSLC2

6

8

+

EVTHRES

+

6

S2A

14

8

13

S2B

13

+

6

8

19

8

15

EDS

CIN

CB

+

5

5

5

51

MSTRO

14

8

RSLC1

51

+

ESLC

50

RDRAIN

16

21

8

MMED

8

DBREAK

EBREAK

MWEAK

RSOURCE

RBREAK

17

IT

RVTHRES

11

+

17

18

7

18

RVTEMP

19

+

22

LDRAIN

RLDRAIN

DBODY

LSOURCE

RLSOURCE

VBAT

DRAIN

2

SOURCE

3

NOTE: For further discussion of the PSPICE model, consult A New PSPICE Sub-Circuit for the Power MOSFET Featuring Global

Temperature Options; IEEE Power Electronics Specialist Conference Records, 1991, written by William J. Hepp and C. Frank Wheatley.

8-150

SPICE Thermal Model

REV May 98

RFT3055LE

9

JUNCTION

RFT3055LE

Copper Area = 0.077in

CTHERM1 9 8 7.5e-5

CTHERM2 8 7 3.5e-4

CTHERM3 7 6 1.2e-3

CTHERM4 6 5 1.5e-2

CTHERM5 5 4 6.0e-2

CTHERM6 4 3 3.0e-1

CTHERM7 3 2 1.6

CTHERM8 2 1 6

RTHERM1 9 8 8.2e-2

RTHERM2 8 7 2.7e-1

RTHERM3 7 6 1.9

RTHERM4 6 5 3.1

RTHERM5 5 4 12

RTHERM6 4 3 38

RTHERM7 3 2 32

RTHERM8 2 1 22

2

RTHERM1

8

RTHERM2

7

RTHERM3

6

RTHERM4

5

CTHERM1

CTHERM2

CTHERM3

CTHERM4

RTHERM5

RTHERM6

RTHERM7

RTHERM8

CTHERM5

4

CTHERM6

3

CTHERM7

2

CTHERM8

1

AMBIENT

8-151

RFT3055LE

All Intersil semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Intersil semiconductor products are sold by description only. Intersil Corporationreserves the right to make changes in circuit design and/or specifications at any time without notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see web site http://www.intersil.com

Sales Office Headquarters

NORTH AMERICA

Intersil Corporation

P. O. Box 883, Mail Stop 53-204

Melbourne, FL 32902

TEL: (407) 724-7000

FAX: (407) 724-7240

8-152

EUROPE

Intersil SA

Mercure Center

100, Rue de la Fusee

1130 Brussels, Belgium

TEL: (32) 2.724.2111

FAX: (32) 2.724.22.05

ASIA

Intersil (Taiwan) Ltd.

7F-6, No. 101 Fu Hsing North Road

Taipei, Taiwan

Republic of China

TEL: (886) 2 2716 9310

FAX: (886) 2 2715 3029

Loading...

Loading...