Intersil JANSR2N7440 Datasheet

JANSR2N7440

Data Sheet November 1999 File Number 4803

Formerly Available as FSS913A0R4,

Radiation Hardened, SEGR Resistant,

P-Channel Power MOSFETs

The Discrete Products Operation of Intersil has developeda

series of Radiation Hardened MOSFETs specifically

designed for commercial and military space applications.

Enhanced Power MOSFET immunity to Single Event Effects

(SEE), Single Event Gate Rupture (SEGR) in particular, is

combined with100K RADS of total dose hardness to provide

devices which are ideally suited to harsh space

environments. The dose rate and neutron tolerance

necessary for military applications have not been sacrificed.

The Intersil portfolio of SEGR resistant radiation hardened

MOSFETs includes N-Channel and P-Channel devices in a

variety of voltage, current and on-resistance ratings.

Numerous packaging options are also available.

This MOSFET is an enhancement-mode silicon-gate power

field-effect transistor of the vertical DMOS (VDMOS)

structure. It is specially designed and processed to be

radiation tolerant. The MOSFET is well suited for

applications exposed to radiation environments such as

switching regulation, switching converters, motor drives,

relay drivers and drivers for high-power bipolar switching

transistors requiring high speed and low gate drive power.

This type can be operated directly from integrated circuits.

Also availableat other radiation and screening levels.Seeus

on the web, Intersil’s home page: http://www.intersil.com.

Contact y our local Intersil Sales Office f or additional

information.

Ordering Information

PART NUMBER PACKAGE BRAND

JANSR2N7440 TO-257AA JANSR2N7440

Features

• 10A, -100V, r

• Total Dose

- Meets Pre-RAD Specifications to 100K RAD (Si)

• Single Event

- Safe Operating Area Curve for Single Event Effects

- SEE Immunity for LET of 36MeV/mg/cm

V

up to 80% of Rated Breakdown and

DS

V

of 10V Off-Bias

GS

• Dose Rate

- Typically Survives 3E9 RAD (Si)/s at 80% BV

- Typically Survives 2E12 if Current Limited to I

• Photo Current

- 1.5nA Per-RAD(Si)/s Typically

• Neutron

- Maintain Pre-RAD Specifications

for 3E13 Neutrons/cm

- Usable to 3E14 Neutrons/cm

DS(ON)

= 0.280Ω

2

2

with

2

Symbol

D

G

S

Packaging

TO-257AA

S

D

G

DSS

DM

Die Family TA17796.

MIL-PRF-19500/659.

CAUTION: Beryllia Warning per MIL-S-19500

refer to package specifications.

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 321-724-7143

| Copyright © Intersil Corporation 1999

JANSR2N7440

Absolute Maximum Ratings T

= 25oC, Unless Otherwise Specified

C

JANSR2N7440 UNITS

Drain to Source Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V

Drain to Gate Voltage (RGS = 20kΩ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V

DS

DGR

-100 V

-100 V

Continuous Drain Current

TC = 25oC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I

TC = 100oC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I

Pulsed Drain Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I

Gate to Source Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V

D

D

DM

GS

10 A

6A

30 A

±20 V

Maximum Power Dissipation

TC = 25oC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P

TC = 100oC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P

T

T

56 W

22 W

Linear Derating Factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.45 W/oC

Single Pulsed Avalanche Current, L = 100µH, (See Test Figure) . . . . . . . . . . . . . . . . . . . . . . . . I

Continuous Source Current (Body Diode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I

Pulsed Source Current (Body Diode). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I

Operating and Storage Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .TJ, T

STG

Lead Temperature (During Soldering) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . T

AS

S

SM

L

30 A

10 A

30 A

-55 to 150

300

o

C

o

C

(Distance >0.063in (1.6mm) from Case, 10s Max)

Weight (Typical) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

Electrical Specifications T

= 25oC, Unless Otherwise Specified

C

4.4

g

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

Drain to Source Breakdown Voltage BV

Gate Threshold Voltage V

DSSID

GS(TH)VGS

= 1mA, VGS = 0V -100 - - V

= VDS,

ID = 1mA

TC = -55oC - - -7.0 V

TC = 25oC -2.0 - -6.0 V

TC = 125oC -1.0 - - V

Zero Gate Voltage Drain Current I

Gate to Source Leakage Current I

DSS

GSS

VDS = -80V,

VGS = 0V

TC = 25oC--25µA

TC = 125oC - - 250 µA

VGS = ±20V TC = 25oC - - 100 nA

TC = 125oC - - 200 nA

Drain to Source On-State Voltage V

Drain to Source On Resistance r

Turn-On Delay Time t

DS(ON)VGS

DS(ON)12ID

d(ON)

Rise Time t

Turn-Off Delay Time t

d(OFF)

Fall Time t

Total Gate Charge (Not on slash sheet) Q

g(TOT)VGS

Gate Charge at 12V Q

Threshold Gate Charge (Not on slash sheet) Q

Gate Charge Source Q

Gate Charge Drain Q

Thermal Resistance Junction to Case R

Thermal Resistance Junction to Ambient R

r

f

g(12)

g(TH)

gs

gd

JC

θ

JA

θ

= -12V, ID = 10A - - -3.10 V

= 6A,

VGS = -12V

VDD = -50V, ID = 10A,

RL = 5.0Ω, VGS = -12V,

RGS = 7.5Ω

TC = 25oC - 0.190 0.280 Ω

TC = 125oC - - 0.500 Ω

- - 20 ns

- - 55 ns

- - 45 ns

- - 35 ns

= 0V to -20V VDD = -50V,

VGS = 0V to -12V - 36 40 nC

ID = 10A

- - 60 nC

VGS = 0V to -2V - - 2.5 nC

- 6.6 7.4 nC

-1719nC

- - 2.2

o

C/W

--60oC/W

2

Source to Drain Diode Specifications

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

Forward Voltage V

Reverse Recovery Time t

SD

rr

JANSR2N7440

ISD = 10A -0.6 - -1.8 V

ISD = 10A,dISD/dt = 100A/µs - - 160 ns

Electrical Specifications up to 100K RAD T

= 25oC, Unless Otherwise Specified

C

PARAMETER SYMBOL TEST CONDITIONS MIN MAX UNITS

Drain to Source Breakdown Volts (Note 3) BV

Gate to Source Threshold Volts (Note 3) V

Gate to Body Leakage (Notes 2, 3) I

Zero Gate Leakage (Note 3) I

Drain to Source On-State Volts (Notes 1, 3) V

Drain to Source On Resistance (Notes 1, 3) r

DS(ON)12VGS

DSS

GS(TH)VGS

GSS

DSS

DS(ON)VGS

VGS = 0, ID = 1mA -100 - V

= VDS, ID = 1mA -2.0 -6.0 V

VGS = ±20V, VDS = 0V - 100 nA

VGS = 0, VDS = -80V - 25 µA

= -12V, ID = 10A - -3.10 V

= -12V, ID = 6A - 0.280 Ω

NOTES:

1. Pulse test, 300µs Max.

2. Absolute value.

3. Insitu Gamma bias must be sampled for both VGS = -12V, VDS = 0V and VGS = 0V, VDS = 80% BV

DSS

.

Single Event Effects (SEB, SEGR) Note 4

ENVIRONMENT (NOTE 5)

TEST SYMBOL

ION

SPECIES

TYPICAL LET

(MeV/mg/cm)

TYPICAL

RANGE (µ)

Single Event Effects Safe Operating Area SEESOA Ni 26 43 20 -100

Br 37 36 10 -100

Br 37 36 15 -80

Br 37 36 20 -50

NOTES:

4. Testing conducted at Brookhaven National Labs; sponsored by Naval Surface Warfare Center (NSWC), Crane, IN.

5. Fluence = 1E5 ions/cm2 (typical), TC = 25oC.

6. Does not exhibit Single Event Burnout (SEB) or Single Event Gate Rupture (SEGR).

APPLIED

V

BIAS

GS

(V)

(NOTE 6)

MAXIMUM

VDSBIAS (V)

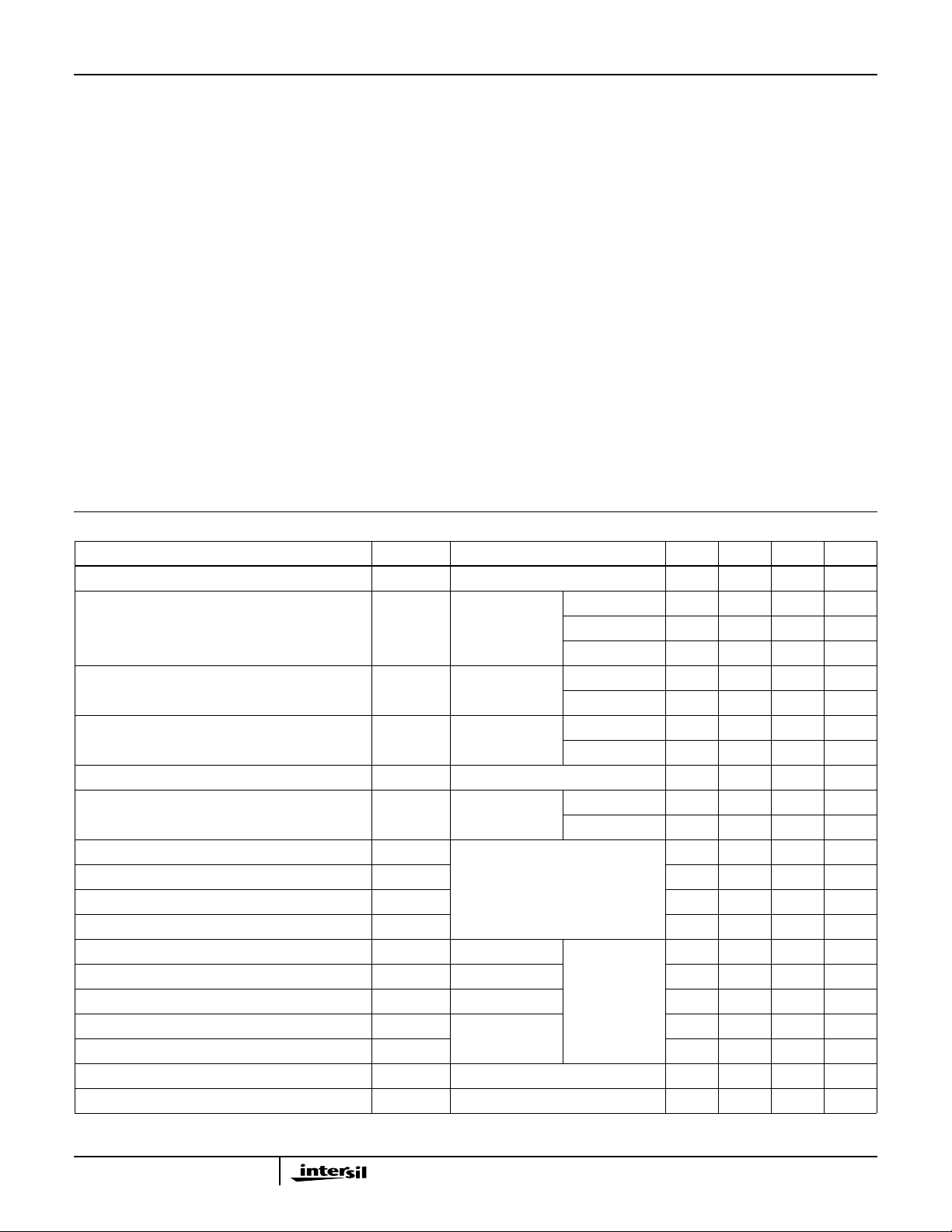

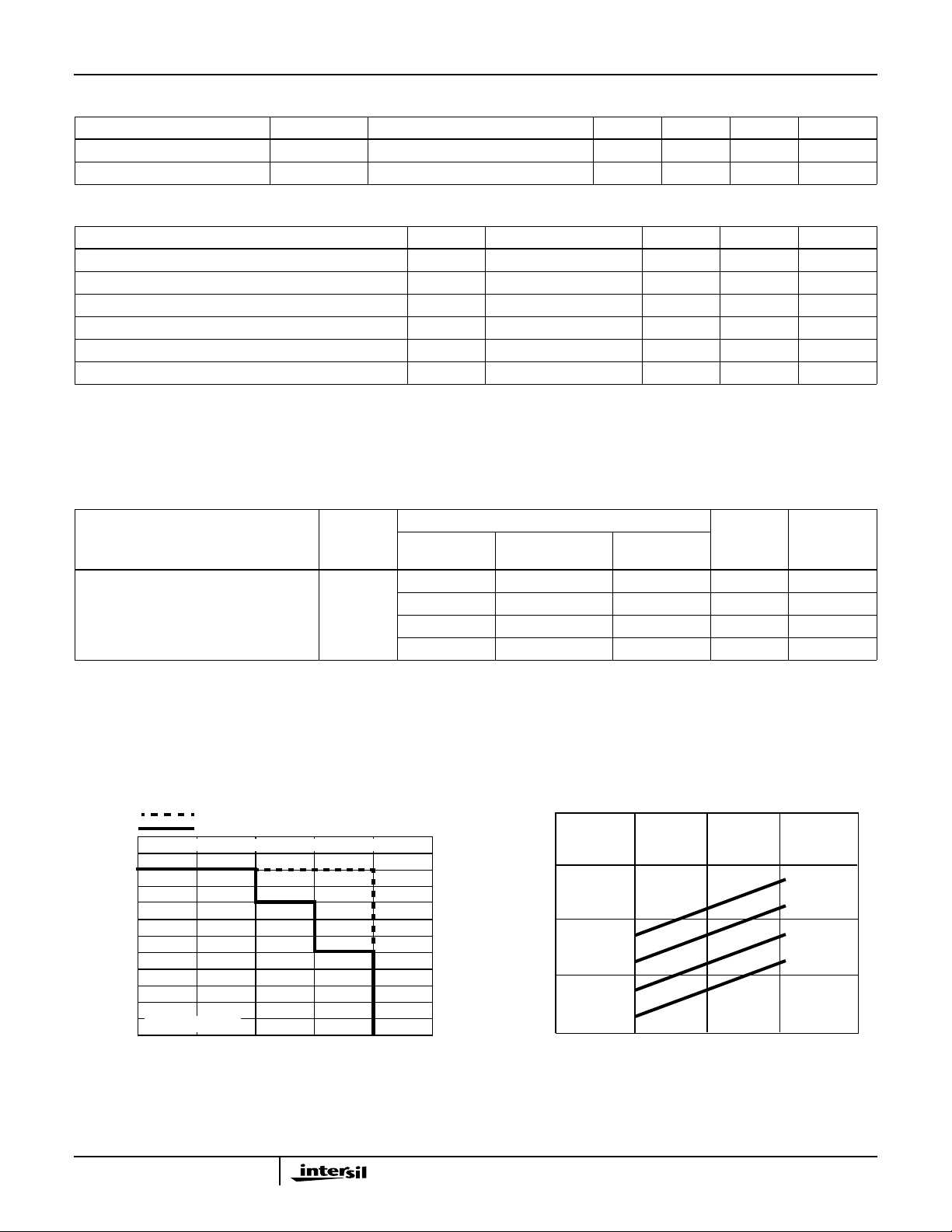

Performance Curves

LIMITING INDUCTANCE (HENRY)

1E-3

1E-4

1E-5

1E-6

1E-7

-30

DRAIN SUPPLY (V)

-300-100-10

LIMIT GAMMA DOT CURRENT TO I

ILM = 10A

30A

100A

300A

AS

LET = 26MeV/mg/cm2, RANGE = 43µ

LET = 37MeV/mg/cm2, RANGE = 36µ

V

(V)

GS

(V)

DS

V

-120

FLUENCE = 1E5 IONS/cm2 (TYPICAL)

-100

-80

-60

-40

-20

TEMP = 25oC

0

0101520255

FIGURE 1. SINGLE EVENT EFFECTS SAFE OPERATING AREA FIGURE 2. TYPICALDRAIN INDUCTANCEREQUIRED TO

3

-1000

Loading...

Loading...