查询ISL21007CFB820Z供应商

®

ISL97653A

Data Sheet December 6, 2007

5-Channel Integrated LCD Supply

The ISL97653A represents a fully integrated supply IC for

LCD-TV applications. With an input operating range of 4V to

14V, both commonly used LCD-TV input supplies, 5V and

12V, are supported. An A

supply up to 20V is generated

VDD

by a high-performance PWM BOOST converter with an

integrated 4.4A FET. V

is generated using an integrated

ON

charge pump with on-chip diodes and can be modulated using

an on-chip V

slice control circuit. V

ON

is generated using

OFF

an integrated charge pump controller . Addi tional ly, the chip

allows for two logic supplies. A buck regulator with an

included 2.5A high side switch is used for the main logic

output and an internal LDO controller can be used to generate

a second logic LDO output.

To facilitate production test, an integrated HVS circuit is

included which can provide high voltage stress of the LCD

panel.

An on-board temperature sensor is also provided for system

thermal management control.

The ISL97653A is packaged in a 40 Ld 6mmx6mm QFN

package and is specified for operation over the -40°C to

+105°C temperature range.

Ordering Information

FN6367.0

Features

• 5V to 14V Input Supply

• Integrated 4.4A Boost Converter

• Integrated VON Charge Pump and VON Slice Circuit

• Integrated V

Charge Pump Output

OFF

• Integrated 2.5A Buck Converter

• LDO Controller for an Additional Logic Supply

• High Voltage Stress (HVS) Test Mode

• Thermal Shutdown

• 40 Ld QFN (6mmx6mm) Package

• Pb-Free (RoHS Compliant)

Applications

•LCD-TVs

• Industrial/Medical LCD Displays

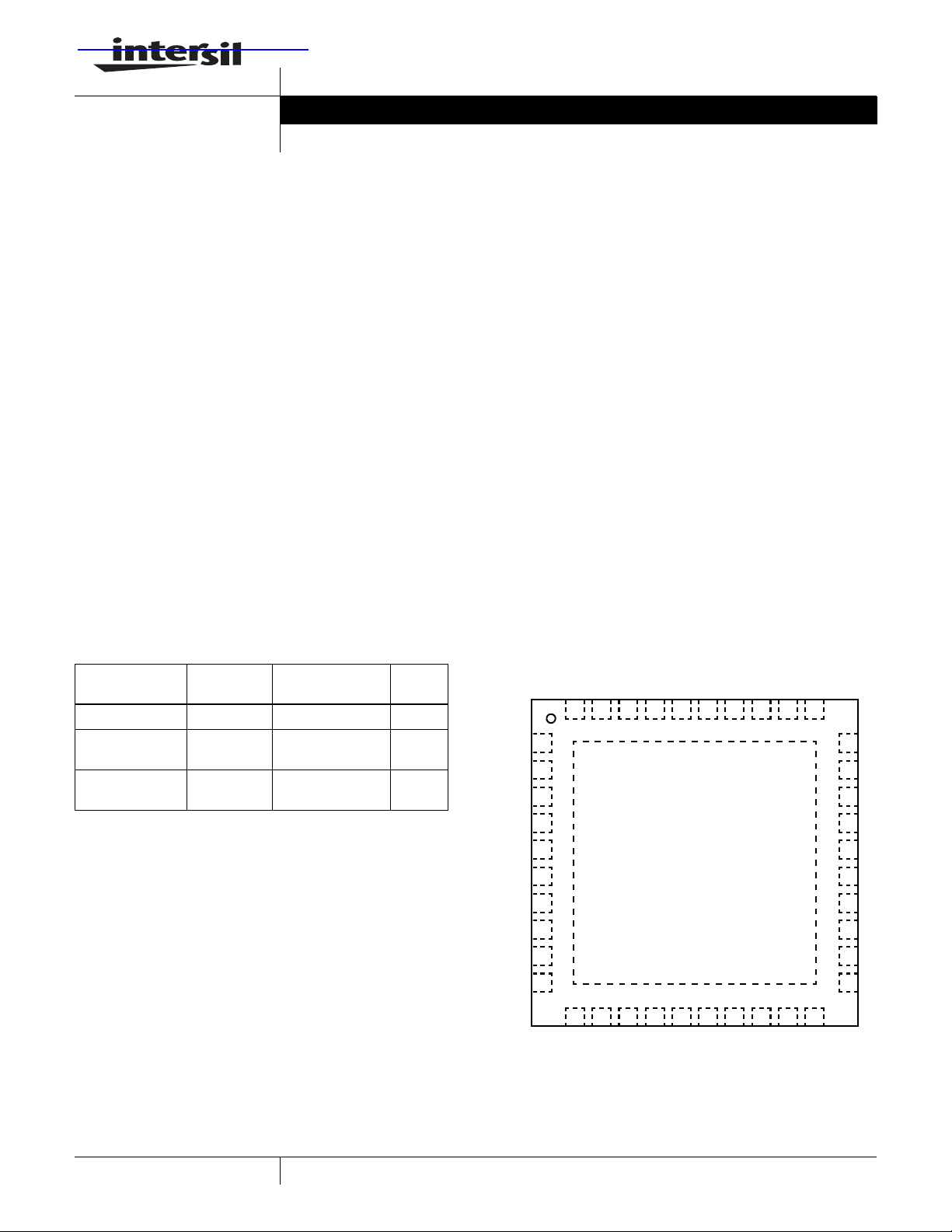

Pinout

ISL97653A

40 LD 6X6 QFN

TOP VIEW

PART NUMBER

(Note)

ISL97653AIRZ ISL97 653A 40 Ld 6 X6 QFN L40.6X6

ISL97653AIRZ-T* ISL97 653A 40 Ld 6 X 6 QFN

ISL97653AIRZ-TK* ISL97 653A 40 Ld 6 X 6 QFN

*Please refer to TB347 for details on reel specifications.

NOTE: These Intersil Pb-free plastic packaged products employ

special Pb-free material sets; molding compounds/die attach

materials and 100% matte tin plate PLUS ANNEAL - e3 termination

finish, which is RoHS compliant and compatible with both SnPb and

Pb-free soldering operations. Intersil Pb-free products are MSL

classified at Pb-free peak reflow temperatures that meet or exceed

the Pb-free requirements of IPC/JEDEC J STD-020.

PART

MARKING

PACKAGE

(Pb-Free)

Tape and Reel

Tape and Reel

PKG.

DWG. #

L40.6X6

L40.6X6

PVIN2

CB

LXL1

LXL2

PGND3

PGND4

CM2

FBL

VL

VREF

LDO-CTL

LDO-FB

PVIN1

AGND

PROT

LX2

LX1

40

39 38 37 36 35 34 33 32 31

1

2

3

4

5

6

7

8

9

10

11 12 13 14 15 16 17 18 19 20

FBN

SUPN

NOUT

C1P

PGND5

C2P

C1N

PGND2

C2N

PGND1

SUPP

TEMP

FBP

30

COMP

29

FBB

28

RSET

27

HVS

26

EN

CDEL

25

CTL

24

DRN

23

COM

22

21

POUT

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

All other trademarks mentioned are the property of their respective owners.

Copyright Intersil Americas Inc. 2007. All Rights Reserved

ISL97653A

Absolute Maximum Ratings (T

Maximum Pin Voltages, all pins except below. . . . . . . . . . . . . . 6.5V

LX1, LX2, SUPP, SUPN, NOUT, PROT, C1N, C2N . . . . . . . . .24V

PVIN1, PVIN2, LXL1, LXL2 . . . . . . . . . . . . . . . . . . . . . . . . . 16.8V

EN, CTL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16.5V

= +25°C) Thermal Information

A

Operating Ambient Temperature Range . . . . . . . . -40°C to +105°C

Operating Junction Temperature . . . . . . . . . . . . . . -40°C to +150°C

Pb-free reflow profile . . . . . . . . . . . . . . . . . . . . . . . . . .see link below

http://www.intersil.com/pbfree/Pb-FreeReflow.asp

DRN, POUT, COM, C1P, C2P. . . . . . . . . . . . . . . . . . . . . . . . . .33V

CB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21V

Recommended Operating Conditions

Input Voltage Range, VIN . . . . . . . . . . . . . . . . . . . . . . . . 4V to 14V

Input Capacitance, C

Boost Output Voltage Range, A

Output Capacitance, C

Boost Inductor, L1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.3µH-10µH

V

Output Range, VON . . . . . . . . . . . . . . . . . . . . . . +15V to +30V

ON

V

Output Range, V

OFF

Logic Output Voltage Range, V

Buck Inductor, L2. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.3µH to 10µH

CAUTION: Do not operate at or near the maximum ratings listed for extended periods of time. Exposure to such conditions may adversely impact product reliability and

result in failures not covered by warranty.

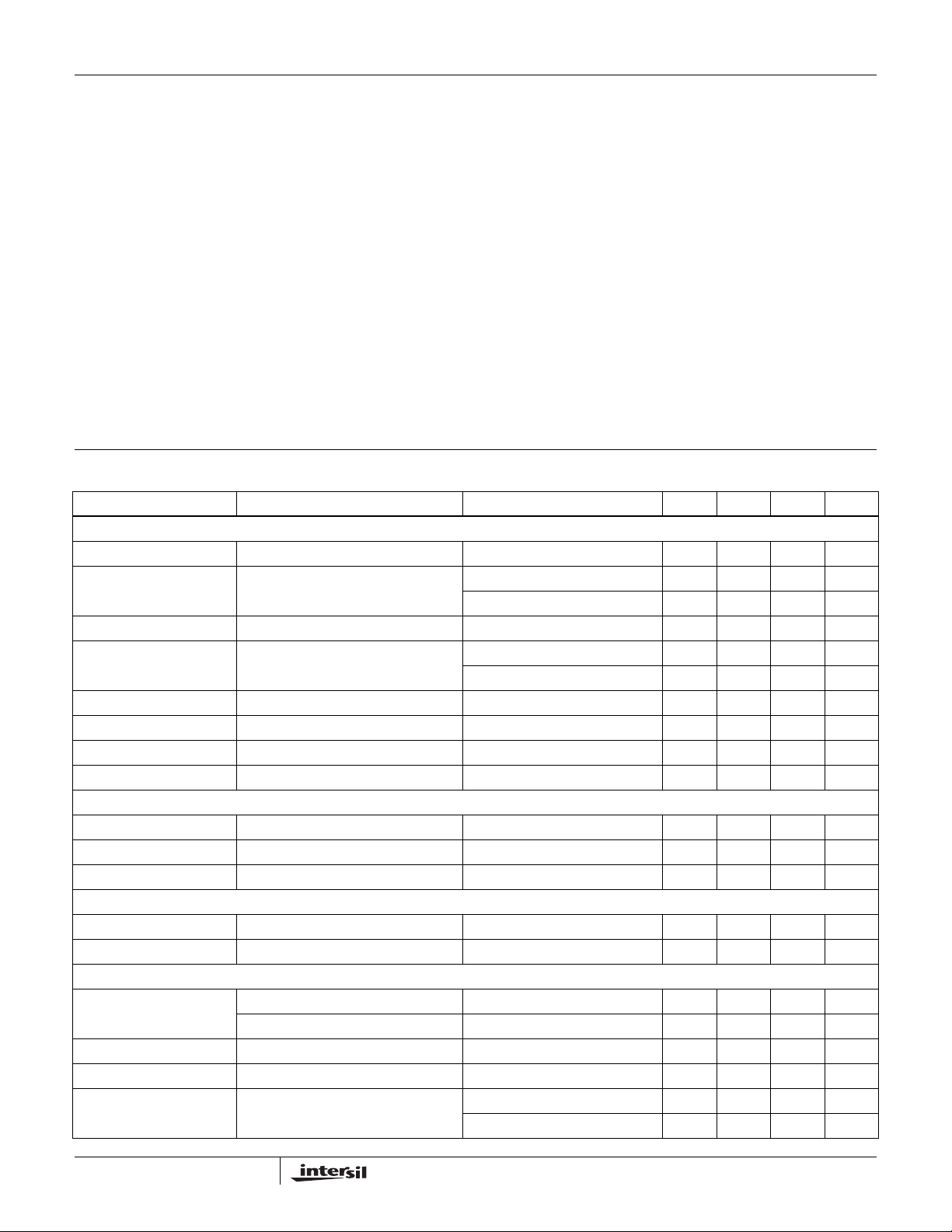

Electrical Specifications V

PARAMETER DESCRIPTION CONDITIONS MIN TYP MAX UNIT

SUPPLY PINS

V

IN

I

S

F

SW

V

REF

VLOR Undervoltage Lockout Threshold V

VLOF Undervoltage Lockout Threshold V

LOGIC SIGNALS HVS, EN, CTL

Logic Input High 2.0 V

Logic Input Low 0.4 V

Pull-down Resistance 130 174 215 kΩ

HVS, RSET

RSET RSET Pull-down Resistance HVS = HIGH 200 Ω

I

RSET

A

BOOST

VDD

DLIM Min Duty Cycle 8.5 12 %

V

BOOST

EFF

BOOST

V

FB

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .2x10µF

IN

. . . . . . . . . . . . . . . . . . . . . . . . . .3x22µF

OUT

. . . . . . . . . . . . . . . . . . . . . . .-15V to -5V

OFF

. . . . . . . . . . . . . . . . . . . . +20V

VDD

. . . . . . . . . . . .+1.5V to +3.3V

LOGIC

= 12V , V

IN

unless otherwise stated.

BOOST

= V

SUPN

Supply Voltage 4 14 V

Quiescent Current Enabled, no switching 4 5 mA

Switching Frequency 580 680 780 kHz

Reference Voltage TA = +25°C 1.190 1.215 1.240 V

Thermal Shutdown Temperature rising 150 °C

Thermal Shutdown Hysteresis 20 °C

RSET Leakage Current HVS = LOW, V

Max Duty Cycle 90 %

Boost Output Range 20 V

Boost Efficiency VIN = 12V, V

Boost Feedback Voltage TA = +25°C 1.203 1.215 1.227 V

= V

= 15V , VON = 25V , V

SUPP

= -8V , over temperature from -40°C to +105°C,

OFF

Disabled 2.7 3.5 mA

1.187 1.215 1.243 V

rising 3.4 3.55 3.7 V

L

falling 2.9 3.0 3.2 V

L

= 1.2V 0.4 µA

RSET

= 15V 90+ %

BOOST

1.198 1.215 1.232 V

2

FN6367.0

December 6, 2007

ISL97653A

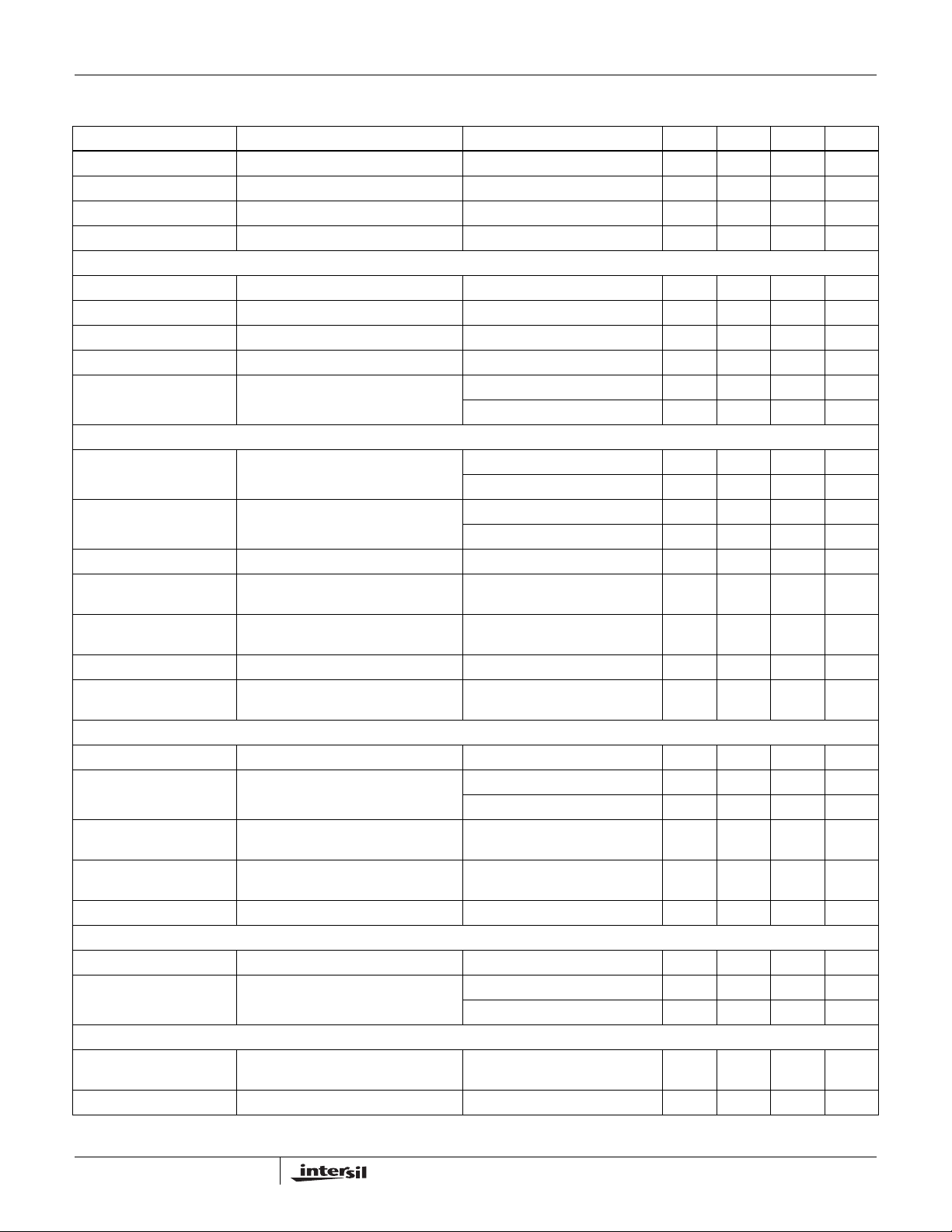

Electrical Specifications V

= 12V , V

IN

unless otherwise stated. (Continued)

BOOST

= V

SUPN

= V

SUPP

= 15V , VON = 25V , V

= -8V , over temperature from -40°C to +105°C,

OFF

PARAMETER DESCRIPTION CONDITIONS MIN TYP MAX UNIT

I

BOOST

R

DSON-BOOST

ΔV

BOOST

ΔV

BOOST

/ΔV

/ΔI

IN

OUT

Boost FET Current Limit 3.7 4.4 4.95 A

Switch On Resistance 93 200 mΩ

Line Regulation - Boost 0.08 0.15 %

Load Regulation - Boost Load 100mA to 200mA 0.004 1 %

LOGIC BUCK

EFF

BUCK

I

BUCK

R

DSON-BUCK

ΔV

/ΔI

LDO

V

FL

OUT

Buck Efficiency VIN = 5V, V

= 3.3V 90+ %

LOGIC

Buck FET Current Limit 1.9 4.0 A

Switch On Resistance 150 210 mΩ

Load Regulation - Buck Load 100mA to 500mA 0.5 1 %

Feedback Voltage TA = +25°C 1.195 1.215 1.235 V

1.189 1.215 1.241 V

V

CHARGE PUMP

ON

ILoad_PCP_min External Load Driving Capability V

= 24V (2X Charge Pump) 40 mA

ON

VON = 28V (3X Charge Pump) 40 mA

V

FBP

Feedback Voltage, ION = 1mA TA = +25°C 1.195 1.215 1.235 V

1.189 1.215 1.241 V

R

(VSUP_SW) ON Resistance of V

ON

R

(C1/2-)H High-Side Driver ON Resistance at

ON

(C1/2-)L Low-Side Driver ON Resistance at

R

ON

V

Load Reg VON Output Load Regulation ION = 10mA to 40mA +1 %

ON

C1- and C2-

C1- and C2-

V(diode) Internal Schottky Diode Forward Voltage

Input Switch I(switch) = +40mA 10 17 Ω

SUP

I(C1/2-) = +40mA 30 Ω

I(C1/2-) = -40mA 4 10 Ω

I(diode) = +40mA 700 800 mV

Drop

V

CHARGE PUMP

OFF

ILoad_NCP_min External Load Driving Capability SUPN>13.5V VOFF=-8V 100 120 mA

V

FBN

Feedback Voltage, I

= 10mA TA = +25°C 0.173 0.203 0.233 V

OFF

0.171 0.203 0.235 V

R

(NOUT)H High-Side Driver ON Resistance at

ON

R

(NOUT)L Low-Side Driver ON Resistance at

ON

NOUT

I(NOUT) = +60mA 10 Ω

I(NOUT) = -60mA 5 Ω

NOUT

V

Load Reg V

OFF

Output Load Reg I

OFF

= 10mA to 100mA, TA = +25°C 2.4 %

OFF

LDO Controller

I

DRVP

LDO-FB Feedback Voltage w/transistor load 1mA T

Sink Current V

= 1.1V, V

FBP

= +25°C 1.191 1.215 1.239 V

A

LDO_CTL

= 10V 12 15 mA

1.189 1.215 1.241 V

FAULT DETECTION THRESHOLDS

T_off Thermal Shut-Down (latched and reset

Temperature rising 150 °C

by power cycle or EN cycle)

Vth_A

(FBB) A

VDD

Boost Short Detection V(FBB) falling less than 0.9 V

VDD

3

FN6367.0

December 6, 2007

ISL97653A

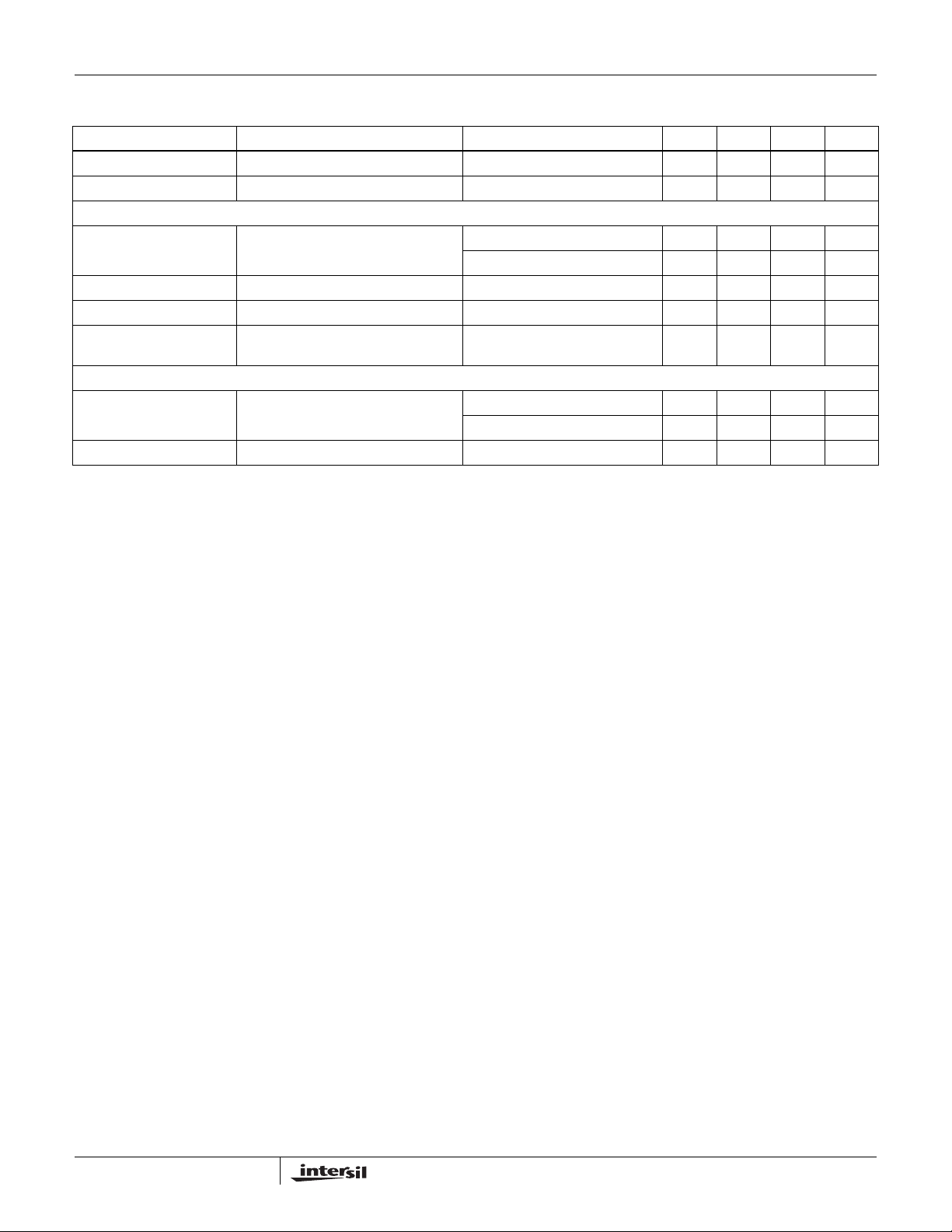

Electrical Specifications V

= 12V , V

IN

unless otherwise stated. (Continued)

BOOST

= V

SUPN

= V

SUPP

= 15V , VON = 25V , V

= -8V , over temperature from -40°C to +105°C,

OFF

PARAMETER DESCRIPTION CONDITIONS MIN TYP MAX UNIT

Vth_POUT (FBP) P

Vth_NOUT (FBN) N

V

Slice POSITIVE SUPPLY = V(POUT)

ON

I(POUT)_slice V

Charge Pump Short Detection V(FBP) falling less than 0.9 V

OUT

Charge Pump Short Detection V(FBN) rising more than 0.4 V

OUT

Slice Current from POUT Supply CTL = VDD, sequence complete 400 500 µA

ON

CTL = AGND, sequence complete 150 200 µA

R

(POUT-COM) ON Resistance between POUT-COM CTL = VDD, sequence complete 5 10 Ω

ON

R

(DRN-COM) ON Resistance between DRN-COM CTL = AGND, sequence complete 30 60 Ω

ON

RON_COM ON Resistance between DRN-COM and

200 260 400 Ω

PGND

PROT

I

PROT_ON

I

PROT_OFF

PROT Pull-Down Current or Resistance

when Enabled by the Start-U

PROT Pull-Up Current when Disabled V

V

> 0.9V 38 50 60 µA

PROT

V

< 0.9V 500 760 1000 Ω

PROT

< 20V 2 3 4 mA

PROT

4

FN6367.0

December 6, 2007

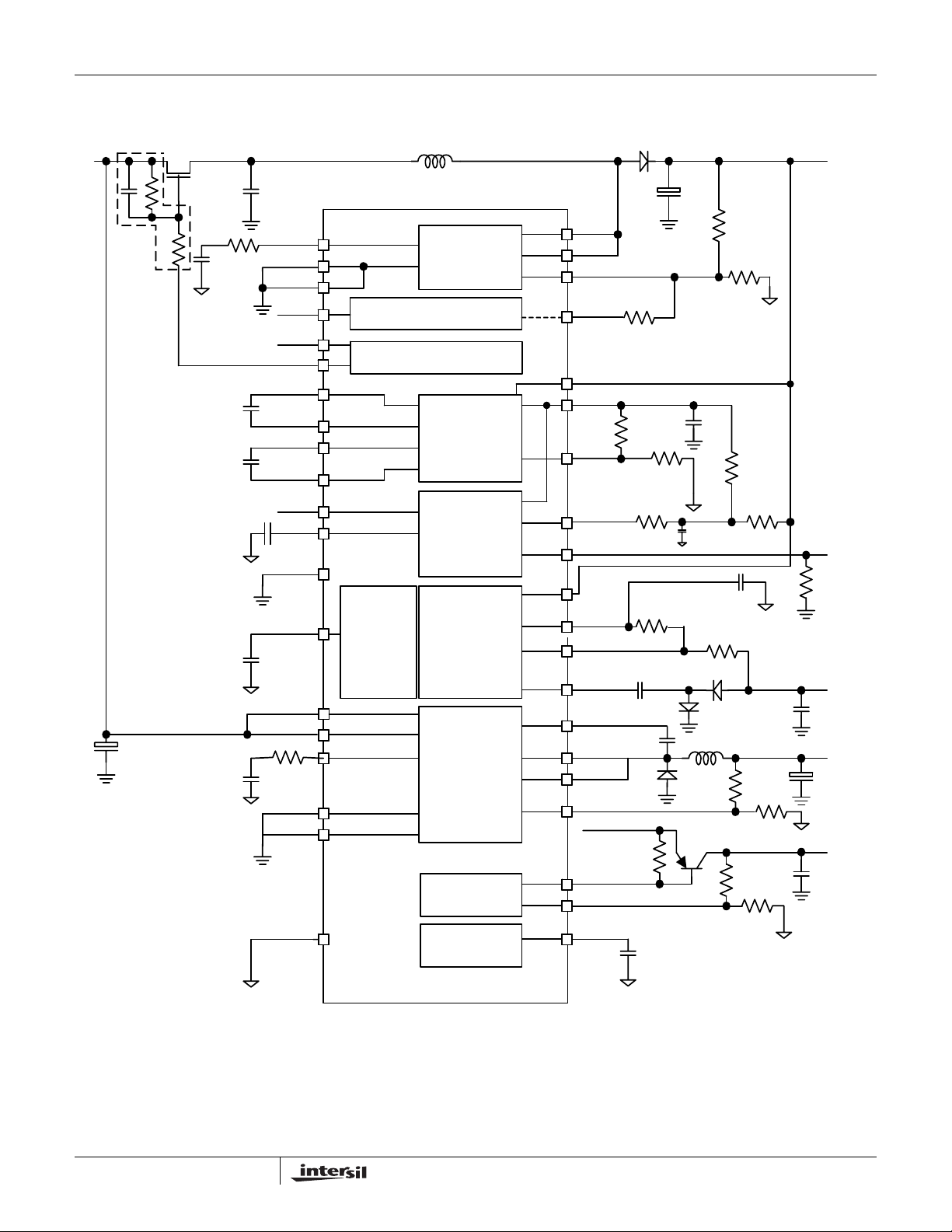

Typical Application Diagrams

ISL97653A

V

IN

C30

Optional

R21 75k

C0

10µF

M0

R22 75k

C2

4.7nF

220nF

220nF

C4

C5

C6

0.22µF

C7

4.7µF

C8

4.7nF

R2

0

C1

2.2µF

COMP

PGND1

PGND2

HVS

PROT

C1P

C1N

C2P

C2N

CTL

CDEL

PGND5

PVIN1

PVIN2

CM2

R20 10k

PGND3

PGND4

AGND

EN

VL

L

L1

6.8µH

30

32

33

27

HVS

26

SEQUENCING/FAULT CONTROL

36

15

16

17

18

24

25

VON SLICE

14

9

INTERNAL

REGULATOR

38

1

7

5

6

LDO CONTROLLER

37

TEMP SENSOR

BOOST

VON CP

V

CP

OFF

BUCK

D1

A

VDD

C3

22µF

x3

LX1

34

LX2

35

FBB

29

RSET

28

R3

55k

R4

5k

R5 20k

19

SUPP

21

POUT

V

R6

983k

20

FBP

470nF

R7, 50k

DRN

23

COM

22

12

SUPN

10

VREF

FBN

11

NOUT

13

R10

15

R11 40k

C22 0.1µF

C11

220nF

CB

2

C13

LXL1

3

LXL2

4

FBL

8

V

1µF

D4

LOGIC

D3

L

L2

6.8µH

R17

LDO-CTL

40

39

LDO-FB

TEMP

31

Q1

C9

R13

2k

R8

1k

C19

220nF

D2

R15

5.4k

R16

5k

ON

R9

1k

R12

328k

470nF

R14

1.2k

C12

C14

20µF

V

V

V

LOGIC

LOGIC2

R17

100k

OFF

C15

4.7µF

C16

10nF

5

FN6367.0

December 6, 2007

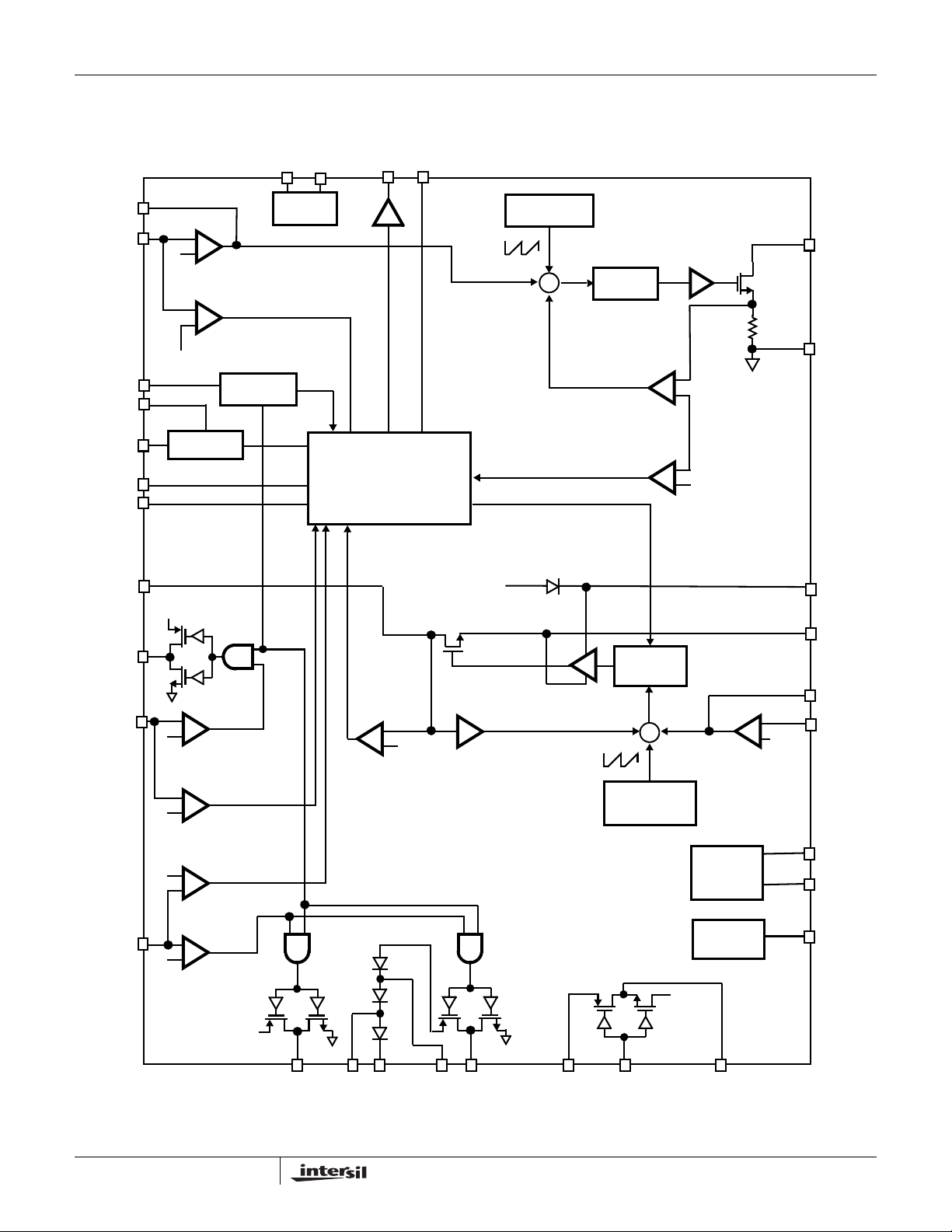

Typical Application Diagrams (Continued)

ISL97653A

FREQ

P

VIN1,2

CDEL

P

VIN1,2

N

CM1

FBB

VL

EN

OUT

FBN

GM AMPLIFIER

+

V

REF

UVLO COMPARATOR

+

0.75 V

REF

OSCILLATOR

REGULATOR

SUPN

+

0.2V

UVLO COMPARATOR

+

0.4V

RSET HVS PROT

HVS

LOGIC

680kHz

REFERENCE BIAS

SEQUENCE CONTROLLER

CURRENT

COMPARATOR

V

REF

AND

LIMIT

-

+

CURRENT LIMIT

THRESHOLD

SAWTOOTH

GENERATOR

SLOPE

COMPENSATION

Ε

VL

CURRENT AMPLIFIER

CONTROL

BUFFER

LOGIC

CURRENT

AMPLIFIER

CURRENT LIMIT

COMPARATOR

CONTROL

LOGIC

Ε

SLOPE

COMPENSATION

SAWTOOTH

GENERATOR

BUFFER

CURRENT LIMIT

THRESHOLD

GM AMPLIFIER

LX1

LX2

R

SENSE

-

+

V

REF

PGND1

PGND2

CB

LXL1

LXL2

CM2

FBL

FBP

0.75 V

V

REF

REF

+

+

SUPP

C1- C1+ C2+ C2-P

6

SUPP

OUT

DRN

LDO

CONTROL

LOGIC2

TEMP

SENSOR

P

OUT

CTL COM

LDO-CTL

LDO-FB

TEMP

FN6367.0

December 6, 2007

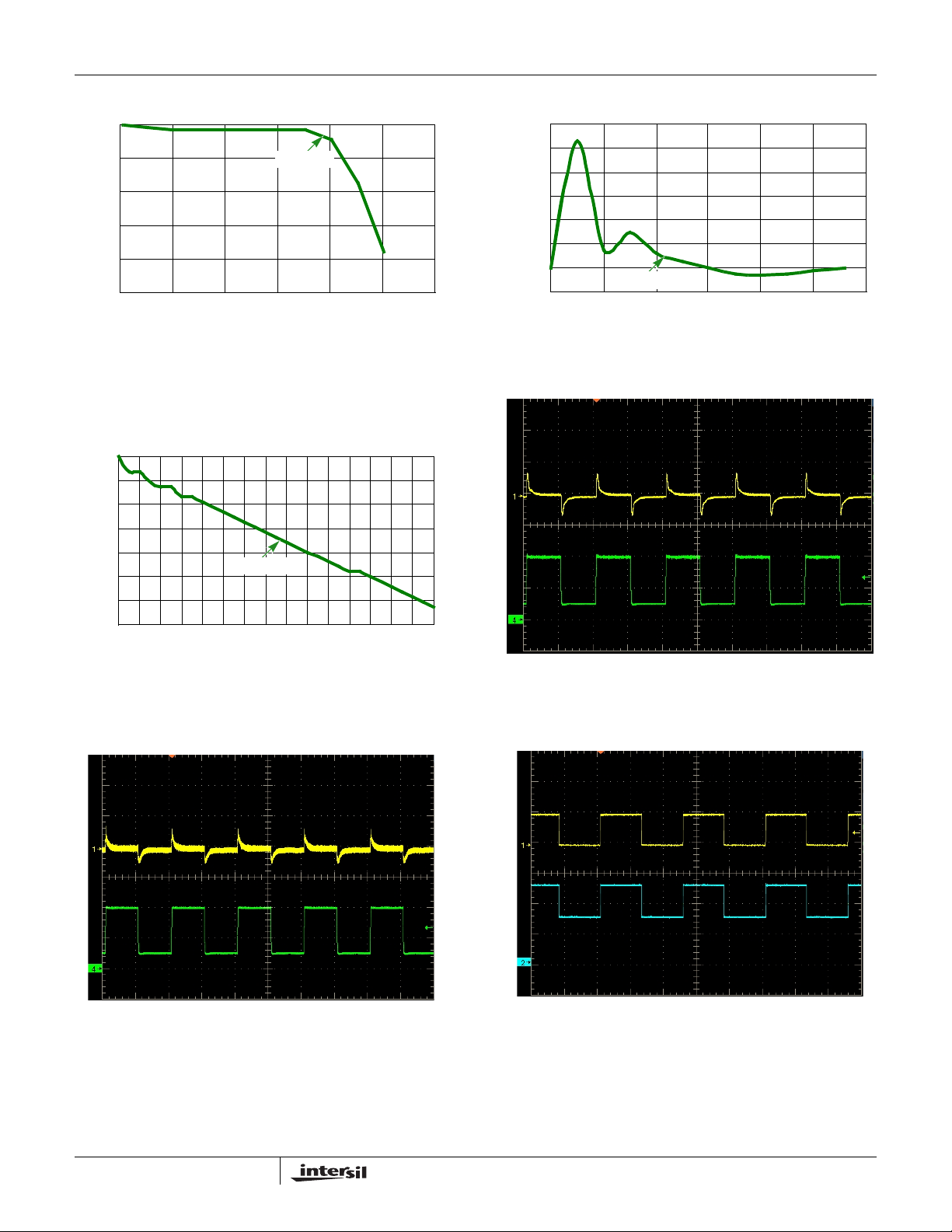

Typical Performance Curves

100

ISL97653A

0.5

90

VIN = 5V

80

EFFICIENCY (%)

70

0 500 1000 1500

VIN = 8V

(mA)

I

O

VIN = 12V

FIGURE 1. BOOST EFFICIENCY FIGURE 2. BOOST LOAD REGULATION

0.08

0.06

0.04

0.02

0.00

LINE REGULATION (%)

-0.02

-0.04

5 6 7 8 9 1011 121314

IO = 100mA

IO = 400mA

(V)

V

IN

FIGURE 3. BOOST LINE REGULATION FIGURE 4. BUCK EFFICIENCY

I

VIN = 8V

I

VIN = 8V

(mA)

O

(mA)

O

VIN = 12V

VIN = 12V

0.4

0.3

VIN = 5V

0.2

0.1

LOAD REGULATION (%)

0.0

0 500 1000 1500

100

90

80

70

EFFICIENCY (%)

60

50

0 500 1000 1500 2000

VIN = 5V

0.3

0.2

0.1

0.0

-0.1

-0.2

LOAD REGULATION (%)

-0.3

0 500 1000 1500 2000

VIN = 5V

VIN = 8V

I

O

VIN = 12V

(mA)

FIGURE 5. BUCK LOAD REGULATION FIGURE 6. BUCK LINE REGULATION

7

0.10

0.08

0.06

0.04

0.02

LINE REGULATION (%)

0.00

5678 9

IO = 100mA

V

IO = 400mA

10 11 12 13 14

(V)

IN

December 6, 2007

FN6367.0

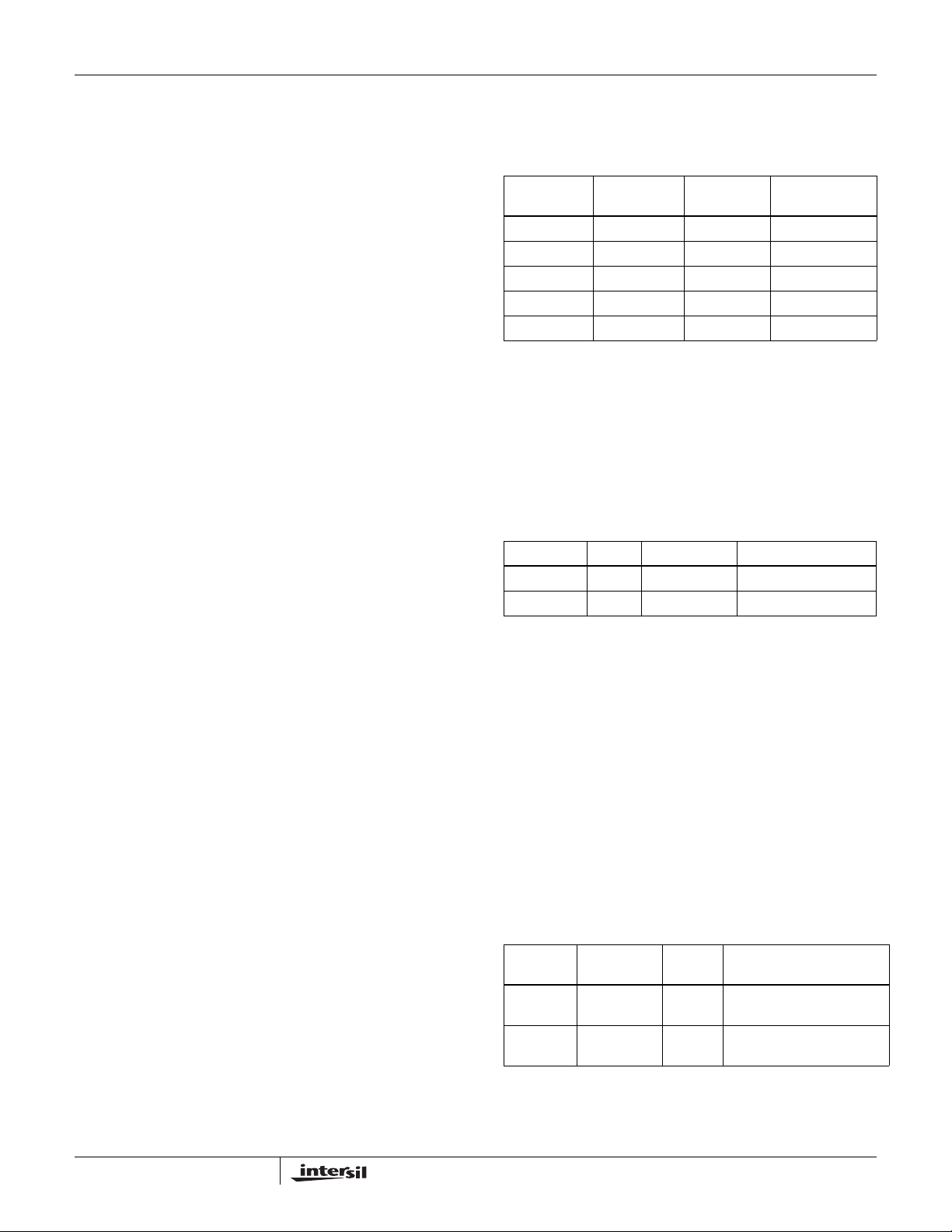

Typical Performance Curves (Continued)

0

I

ON

VON = 25V

(mA)

-1

-2

-3

-4

LOAD REGULATION (%)

-5

0 102030405060

FIGURE 7. VON LOAD REGULATION FIGURE 8. VOFF LOAD REGULATION

ISL97653A

1.2

1.0

0.8

0.6

0.4

0.2

0.0

LOAD REGULATION (%)

-0.2

0 102030405060

VON = 25V

(mA)

I

ON

0.0

-0.2

-0.4

-0.6

-0.8

-1.0

-1.2

LOAD REGULATION (%)

-1.4

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150

V

LOGIC

I

LDO

= 2.3V

(mA)

FIGURE 9. LOGIC LDO LOAD REGULATION

CH1 = A

CH2 = I

VDD (VBOOST

(BOOST) (100mA/DIV)

O

) (100mV/DIV)

CH1 = A

CH2 = I

VDD (VBOOST

(BOOST)(200mA/DIV)

O

)(500mV/DIV)

1ms/DIV

FIGURE 10. BOOST TRANSIENT RESPONSE

CH1 = VCTL (5V/DIV)

CH2 = COM (10V/DIV)

1ms/DIV

40µs/DIV

FIGURE 11. BUCK TRANSIENT RESPONSE FIGURE 12. VON SLICE OPERATION

8

FN6367.0

December 6, 2007

ISL97653A

Typical Performance Curves (Continued)

Ch1 = LXL (400ns/DIV)

Ch2 = ILXL (400ns/DIV)

FIGURE 13. BOOST CURRENT LIMIT FIGURE 14. BUCK CURRENT LIMIT

Pin Descriptions

PIN NUMBER PIN NAME DESCRIPTION

1 PVIN2 Logic buck supply voltage. This is also the analog supply from which the VL is generated. Needs at

least 1µF bypassing.

2 CB Logic buck boot strap pin. Generate the gate drive voltage for the N-Channel MOSFET by connecting

a 1µF cap to the switching node LXL1,2.

3, 4 LXL1, 2 Logic buck switching node. Source of the high side internal power N-Channel MOSFET for the Buck.

5, 6 PGND3,4 Logic buck ground pin.

7 CM2 Buck compensation pin. An RC network is recommended. Increase R for better transient response at

the expense of stability.

8 FBL Logic buck feedback pin. High impedance input to regulate at 1.215V.

9 VL 5.25V internal regulator output. Bypass with a 4.7µF cap. Ref voltage is generated from VL.

10 VREF Reference voltage output. Bypass with a low valued cap for transients - recommend 220nF. Should not

11 FBN Negative charge pump feedback pin. High impedance input to regulate to 0.203V.

12 SUPN Negative charge pump supply voltage. Can be the same as or different from A

13 NOUT Negative charge pump driver output.

14 PGND5 Charge pump ground pin.

15 C1P Charge pump capacitor 1, positive connection.

16 C1N Charge pump capacitor 1, negative connection.

17 C2P Charge pump capacitor 2, positive connection.

18 C2N Charge pump capacitor 2, negative connection.

19 SUPP Positive charge pump supply. Can be the same as or different from A

20 FBP Positive charge pump feedback pin. High impedance input to regulate at 1.215V

21 POUT V

22 COM High voltage switch control output. V

23 DRN Lower reference voltage for V

24 CTL Input control pin for V

be greater than 5 times CDEL cap to ensure correct start-up sequence.

charge pump output.

ON

slice output.

ON

slice output. Usually connected to A

ON

slice output.

ON

Ch1 = LXL (400ns/DIV)

Ch2 = ILXL (400ns/DIV)

VDD.

.

VDD

VDD.

9

FN6367.0

December 6, 2007

ISL97653A

Pin Descriptions (Continued)

PIN NUMBER PIN NAME DESCRIPTION

25 CDEL V

26 EN Chip enable (active high). Can be driven to VIN levels.

27 HVS High-voltage stress input select pin. High selects high voltage mode.

28 RSET Voltage set pin for HVS test. RSET connects to ground in the high voltage mode - RSET high.

29 FBB A

30 COMP Boost compensation network pin. An RC network is recommended. Increase R for better transient

31 TEMP Temperature sensor output voltage. An analog voltage from 0V to 3V for temperatures of -40°C to

32, 33 PGND1, 2 Boost ground pins.

34, 35 LX1, 2 Boost switch output. Drain of the internal power NMOS for the Boost.

36 PROT Gate driver of the Input protection switch. Goes low when EN is high. Can be used to modulate the

37 AGND Analog ground. Separate from PGND’s and star under the chip.

38 PVIN1 Logic buck supply voltage.This is also the analog supply from which the VL is generated. Needs at least

39 LDO-FB LDO controller feedback. High impedance input to regulate at 1.215V.

40 LDO-CTL LDO control pin. Gate drive for the external PNP BJT.

slice control delay input. Minimum 47nF . Recommend 220nF but is only limited by leakage in the

ON

cap reaching µA levels.

boost feedback pin. High impedance input to regulate at 1.215V.

VDD

response at the expense of stability. An R = 0Ω is recommended for 4.4A Boost requirements.

+150°C.

passive input inrush current as shown by R

1µF bypassing.

, and C30 in the typical application diagram.

21,R22

10

FN6367.0

December 6, 2007

Δ

ISL97653A

Application Information

A

Boost Converter

VDD

The A

boost FET. The regulator uses a current mode PI control

scheme which provides good line regulation and good

transient response. It can operate in both discontinuous

conduction mode (DCM) at light loads and continuous mode

(CCM). In continuous current mode, current flows

continuously in the inductor during the entire switching cycle

in steady state operation. The voltage conversion ratio in

continuous current mode is given by Equation 1:

V

boost

------------------

V

where D is the duty cycle of the switching MOSFET.

The boost soft-start function is digitally controlled within a

fixed 10ms time frame during which the current limit is

increased in eight linear steps.

The boost converter uses a summing amplifier architecture

for voltage feedback, current feedback, and slope

compensation. A comparator looks at the peak inductor

current cycle by cycle and terminates the PWM cycle if the

current limit is triggered. Since this comparison is cycle

based, the PWM output will be released after the peak

current goes below the current limit threshold.

An external resistor divider is required to divide the output

voltage down to the nominal reference voltage. Current

drawn by the resistor network should be limited to maintain

the overall converter efficiency. The maximum value of the

resistor network is limited by the feedback input bias current

and the potential for noise being coupled into the feedback

pin. A resistor network in the order of 60kΩ is recommended.

The boost converter output voltage is determined by

Equation 2:

A

VDD

where R

stated, component variables referred to in equations refer to

the Typical Application Diagram.

The current through the MOSFET is limited to 4.4A peak.

This restricts the maximum output current (average) based

on Equation 3:

I

OMAXILMT

Where ΔIL is peak to peak inductor ripple current, and is set

by Equation 4. f

I

boost converter features a fully integrated 4.4A

VDD

1

-------------

=

1D–

IN

R3R4+

---------------------

3

V

IN

---------

L

L

×=

V

R

FBB

4

and R4 are in the “” on page 5. Unless otherwise

ΔI

V

L

--------

IN

---------

×=

2

V

O

⎛⎞

–

⎝⎠

is the switching frequency (680kHz).

s

D

---- -

×=

f

S

(EQ. 1)

(EQ. 2)

(EQ. 3)

(EQ. 4)

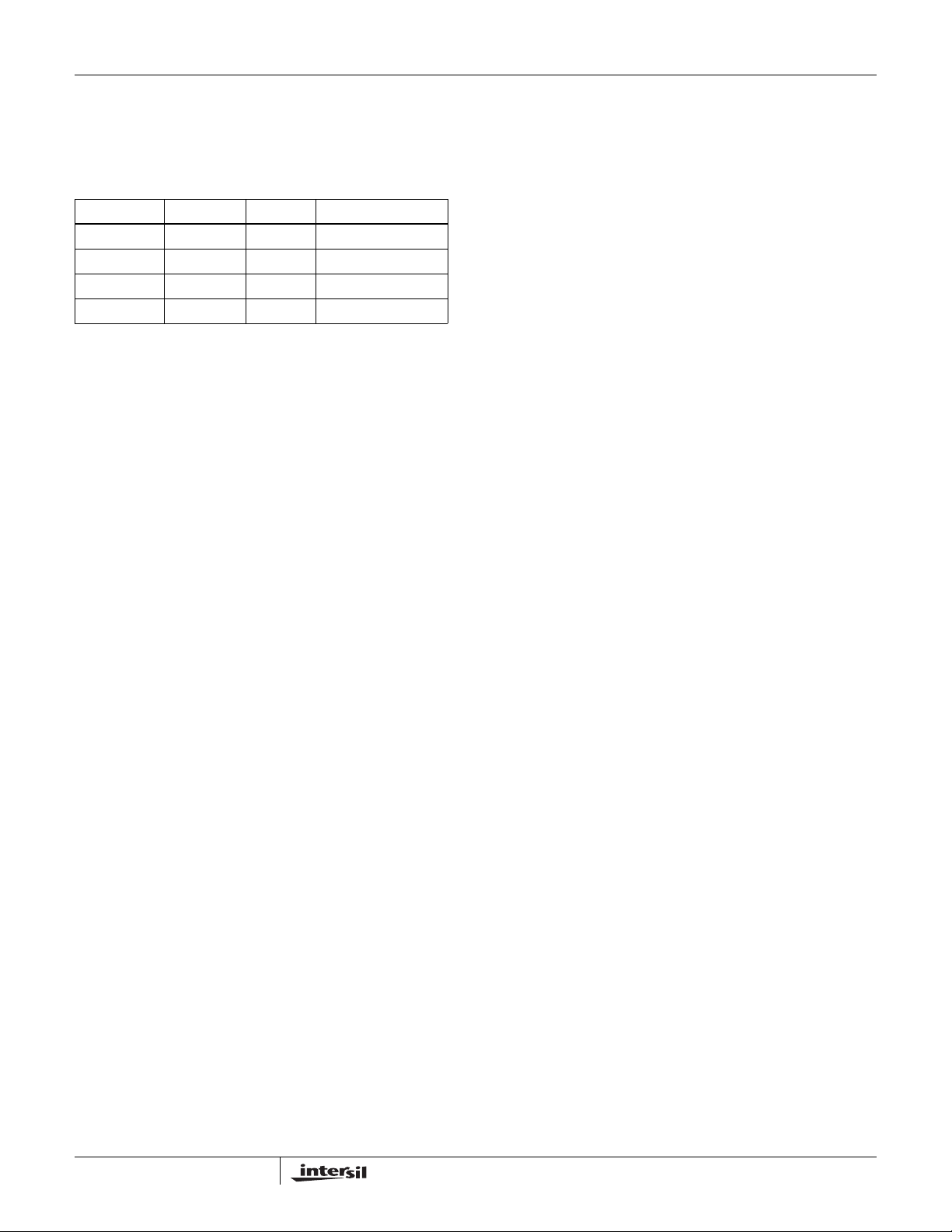

Table 1 gives typical values (worst case margins are

considered 10%, 3%, 20%, 10% and 15% on V

F

and I

SW

TABLE 1. MAXIMUM OUTPUT CURRENT CALCULATION

V

IN

(V)

5 9 6.8 2215

5 12 6.8 1673

5 15 6.8 1344

12 15 6.8 3254

12 18 6.8 2670

OMAX

):

V

(V)

O

L

(µH)

, VO, L,

IN

I

OMAX

(mA)

Boost Converter Input Capacitor

An input capacitor is used to suppress the voltage ripple

injected into the boost converter. A ceramic capacitor with

capacitance larger than 10µF is recommended. The voltage

rating of input capacitor should be larger than the maximum

input voltage. Some capacitors are recommended in Table 2

for input capacitor.

TABLE 2. BOOST CONVERTER INPUT CAP ACITOR

RECOMMENDATION

CAPACITOR SIZE VENDOR PART NUMBER

10µF/25V 1210 TDK C3225X7R1E106M

10µF/25V 1210 Murata GRM32DR61E106K

Boost Inductor

The boost inductor is a critical part which influences the

output voltage ripple, transient response, and efficiency.

Values of 3.3µH to 10µH are recommended to match the

internal slope compensation as well as to maintain a good

transient response performance. The inductor must be able

to handle the average and peak currents expressed in

Equations 5 and 6:

I

O

I

LAVG

I

LPKILAVG

Some inductors are recommended in Table 3.

INDUCTOR

5.1A

-------------

=

1D–

ΔI

L

--------

+=

2

TABLE 3. BOOST INDUCTOR RECOMMENDATION

DIMENSIONS

(mm) VENDOR PART NUMBER

10µH/

PEAK

5.9µH/

6A

PEAK

13x13x4.5 TDK RLF12545T-100M5R1

12.9X12.9X4 Sumida CDEP12D38NP-5R9MB-120

(EQ. 5)

(EQ. 6)

11

FN6367.0

December 6, 2007

ISL97653A

Rectifier Diode (Boost Converter)

A high-speed diode is necessary due to the high switching

frequency. Schottky diodes are recommended because of

their fast recovery time and low forward voltage. The reverse

voltage rating of this diode should be higher than the

maximum output voltage. The rectifier diode must meet the

output current and peak inductor current requirements. The

following table lists two recommendations for boost

converter diode.

TABLE 4. BOOST CONVERTER RECTIFIER DIODE

DIODE

FYD0504SA 50V/2A DPAK Fairchild

30WQ04FN 40V/3.5A DPAK International

RECOMMENDATION

V

R/IAVG

RATING PACKAGE VENDOR

Semiconductor

Rectifier

Output Capacitor

Integrating output capacitors supply the load directly and

reduce the ripple voltage at the output. Output ripple voltage

consists of two components: the voltage drop due to the

inductor ripple current flowing through the ESR of output

capacitor, and the charging and discharging of the output

capacitor.

V

RIPPLEILPK

ESR

V

–

OVIN

----------------------- -

V

O

I

O

----------------

C

OUT

1

----

××+×=

f

s

(EQ. 7)

Stability can be examined by repeatedly changing the load

between 100mA and a max level that is likely to be used in

the system being used. The A

voltage should be

VDD

examined with an oscilloscope set to AC 100mV/DIV and the

amount of ringing observed when the load current changes.

Reduce excessive ringing by reducing the value of the

resistor in series with the CM1 pin capacitor.

Cascaded MOSFET Application

A 20V N-Channel MOSFET is integrated in the boost

regulator. For applications requiring output voltages greater

than 20V, an external cascaded MOSFET is needed as

shown in Figure 15. The voltage rating of the external

MOSFET should be greater than A

VIN

LX1, LX2

INTERSIL

ISL97653A

FIGURE 15. CASCADED MOSFET TOPOLOGY FOR HIGH

OUTPUT VOLTAGE APPLICATIONS

VDD

FBB

.

A

VDD

For low ESR ceramic capacitors, the output ripple is

dominated by the charging and discharging of the output

capacitor. The voltage rating of the output capacitor should

be greater than the maximum output voltage.

Note: Capacitors have a voltage coefficient that makes their

effective capacitance drop as the voltage across them

increases. C

in Equation 7 assumes the effective value

OUT

of the capacitor at a particular voltage and not the

manufacturer's stated value, measured at zero volts.

Table 5 shows some selections of output capacitors.

TABLE 5. BOOST OUTPUT CAPACITOR RECOMMENDATION

CAPACITOR SIZE VENDOR PART NUMBER

10µF/25V 1210 TDK C3225X7R1E106M

10µF/25V 1210 Murata GRM32DR61E106K

PI Loop Compensation (Boost Converter)

The boost converter of ISL97653A can be compensated by

a RC network connected from COMP pin to ground.

C

= 4.7nF and R2 = 0Ω to 10Ω. A RC network is used in the

2

demo board. A higher capacitor value can be used to

increase system stability.

V

Protection

IN

A series external P-FET can be used to prevent passive

power-up inrush current from the Boost output caps charging

to V

IN

- V

SCHOTTKY

via the boost inductor and Schottky

diode. This FET also adds protection in the event of a short

circuit on A

The gate of the PFET (shown as M0 in the “”

VDD.

on page 5) is controlled by PROT. When EN is low, PROT is

pulled internally to PVIN1, thus M0 is switched off. When EN

goes high, PROT is pulled down slowly via a 50µA current

source, switching M0 on.

If the device is powered up with EN tied to high, M0 will

remain switched off until the voltage on VL exceeds the

VLOR threshold. Once the voltage on PROT falls below 0.6V

and the step-up regulator is within 90% of its target voltage,

PROT is pulled down to ground via a 1.3kΩ impedance. If

A

falls 10% below regulation, the drive to PROT reverts

VDD

to a 50µA current source. If a timed fault is detected, M0 is

actively switched off.

Several additional external components can optionally be

used to fine-tune the function of pin PROT (shown in the

dashed box near M0 in application diagram). PROT ramp

rate can be controlled by adding a capacitor C30 between

gate and source of M0. M0 gate voltage can be limited

during soft-start by adding a resistor (~75kΩ) between gate

12

FN6367.0

December 6, 2007

ISL97653A

and source of M0. In addition, a resistor can be connected

between PROT and the gate of M0, in order to limit the

maximum V

of M0 at all times.

GS

Buck Converter

The buck converter is a step down converter supplying

power to the logic circuit of the LCD system. The ISL97653A

integrates a high voltage N-channel MOSFET to save cost

and reduce external component count. In the continuous

current mode, the relationship between input voltage and

output voltage as expressed in Equation 8:

V

LOGIC

--------------------- -

V

IN

D=

(EQ. 8)

Where D is the duty cycle of the switching MOSFET.

Because D is always less than 1, the output voltage of a

buck converter is lower than input voltage.

The peak current limit of buck converter is set to 2.5A, which

restricts the maximum output current (average) based on

Equation 9:

2.5A ΔI

I

OMAX

Where ΔI

–=

P-P

is the ripple current in the buck inductor as

P-P

(EQ. 9)

shown in Equation 10:

V

LOGIC

--------------------- -

ΔI

pp

Lfs⋅

Where L is the buck inductor, f

1D–()⋅=

is the switching frequency

s

(EQ. 10)

(680kHz).

Feedback Resistors

The buck converter output voltage is determined by

Equation 11:

R14R13+

V

LOGIC

-------------------------- -

×=

V

R

14

FBL

(EQ. 11)

Where I

is the output current of the buck converter. Table 6

o

shows some recommendations for input capacitor.

TABLE 6. INPUT CAPACITOR (BUCK) RECOMMENDATION

CAPACITOR SIZE VENDOR PART NUMBER

10µF/16V 1206 TDK C3216X7R1C106M

10µF/10V 0805 Murata GRM21BR61A106K

22µF/16V 1210 Murata C3225X7R1C226M

Buck Inductor

A 3.3µH to 10µH inductor range is recommended for the

buck converter. Besides the inductance, the DC resistance

and the saturation current are also factors that need to be

considered when choosing a buck inductor. Low DC

resistance can help maintain high efficiency. Saturation

current rating should be higher than 2A. Here are some

recommendations for buck inductor.

TABLE 7. BUCK INDUCTOR RECOMMENDATION

DIMENSIONS

INDUCTOR

4.7µH/

2.7A

PEAK

6.8µH/

3A

PEAK

(mm) VENDOR PART NUMBER

5.7x5.0x4.7 Murata LQH55DN4R7M01K

7.3x6.8x3.2 TDK RLF7030T-6R8M2R8

Rectifier Diode (Buck Converter)

A Schottky diode is recommended for fast recovery and low

forward voltage. The reverse voltage rating should be higher

than the maximum input voltage. The peak current rating is

2.5A, and the average current is given by Equation 13:

I

Where I

following table shows some diode recommended.

avg

1D–()*I

=

o

is the output current of buck converter. The

o

(EQ. 13)

Where R

and R

13

are the feedback resistors in the buck

14

converter loop to set the output voltage Current drawn by

the resistor network should be limited to maintain the overall

converter efficiency. The maximum value of the resistor

network is limited by the feedback input bias current and the

potential for noise being coupled into the feedback pin. A

resistor network in the order of 1kΩ is recommended.

Buck Converter Input Capacitor

Input capacitance should support the maximum AC RMS

current which occurs at D = 0.5 and maximum output

current.

I

() D1D–()⋅ IO⋅=

acrmsCIN

13

(EQ. 12)

TABLE 8. BUCK RECTIFIER DIODE RECOMMENDATION

V

DIODE

PMEG2020EJ 20V/2A SOD323F Philips

SS22 20V/2A SMB Fairchild

R/IAVG

RATING PACKAGE VENDOR

Semiconductors

Semiconductor

December 6, 2007

FN6367.0

ISL97653A

Output Capacitor (Buck Converter)

Four 10µF or two 22µF ceramic capacitors are recommended

for this part. The overshoot and undershoot will be reduced

with more capacitance, but the recovery time wi ll be longer.

TABLE 9. BUCK OUTPUT CAPACITOR RECOMMENDATION

CAPACITOR SIZE VENDOR PART NUMBER

10µF/6.3V 0805 TDK C2012X5R0J106M

10µF/6.3V 0805 Murata GRM21BR60J106K

22µF/6.3V 1210 TDK C3216X5R0J226M

100µF/6.3V 1206 Murata GRM31CR60J107M

PI Loop Compensation (Buck Converter)

The buck converter of ISL97653A can be compensated by a

RC network connected from CM2 pin to ground. C

and R

= 10k RC network is used in the demo board. A

20

= 4.7nF

8

larger value resistor can lower the transient overshoot,

however, at the expense of stability of the loop.

The stability can be optimized in a similar manner to that

described in “PI Loop Compensation (Boost Converter)” on

page 12.

Bootstrap Capacitor (C13)

This capacitor provides the supply to the high driver circuitry

for the buck MOSFET. The bootstrap supply is formed by an

internal diode and capacitor combination. A 1µF is

recommended for ISL97653A. A low value capacitor can

lead to overcharging and in turn damage the part.

During very light loads, the on-time of the low side diode

may be insufficient to replenish the bootstrap capacitor

voltage. Additionally, if V

MOSFET pull-up device may be unable to turn-on until

V

falls. Hence, there is a minimum load requirement in

LOGIC

this case. The minimum load can be adjusted by the

feedback resistors to FBL.

IN

- V

< 1.5V , the internal

BUCK

Positive Charge Pump Design Consideration

All positive charge pump diodes (D1, D2 and D3 shown in

the “NEGATIVE CHARGE PUMP BLOCK DIAGRAM” on

page 16) for x2 (doubler) and x3 (Tripler) modes of operation

are included in the ISL97653A. During the chip start-up

sequence the mode of operation is automatically detected

when the charge pump is enabled. With both C

present, the x3 mode of operation is detected. With C

present, C

open and with C1+ shorted to C2+, the x2 mode

8

of operation will be detected.

Internal switches M1, M2 and M3 isolate P

until the charge pump is enabled. This is important for TFT

applications that require the negative charge pump output

(V

) and A

OFF

The maximum P

supplies to be established prior to P

VDD

charge pump current can be estimated

OUT

from the following equations assuming a 50% switching

duty:

I

2x()min of 40mA or

MAX

2V•

--------------------------------------------------------------------------------------------------------------------------

I

MAX

3V•

--------------------------------------------------------------------------------------------------------------------------

Note: V

function of I

∼

2– V

SUPP

3x()min of 40mA or

SUP·P

DIODE

DIODE

22R

∼

3– V

DIODE

23R

ONH

(2 • I

and V

MAX

ONHRONL

MAX

2I

•()VVON()–•

MAX

+•()•()

2I

•()VVON()–•

MAX

2R•

+•()•()

ONL

) is the on-chip diode voltage as a

(40mA) < 0.7V.

DIODE

and C8

7

from SUPP

OUT

0.95A•

0.95V•

7

OUT

(EQ. 14)

.

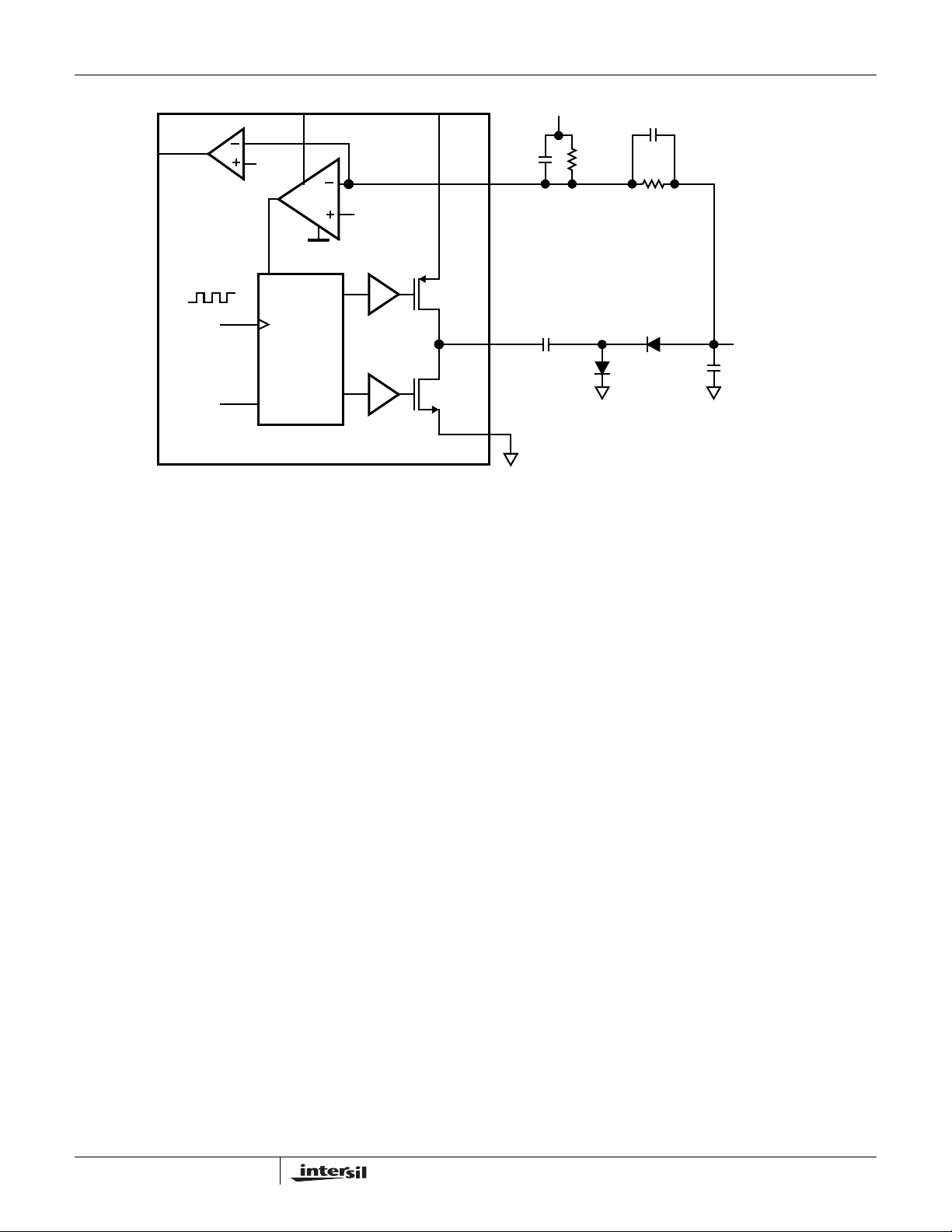

Charge Pump Controllers (VON and V

OFF

)

The ISL97653A includes 2 independent charge pumps (see

charge pump block and connection diagram). The negative

charge pump inverts the SUPN voltage and provides a

regulated negative output voltage. The positive charge pump

doubles or triples the SUPP voltage and provides a

regulated positive output voltage. The regulation of both the

negative and positive charge pumps is controlled by internal

comparators that sense the output voltage. These sensed

voltages are then compared to scaled internal reference

voltages.

Charge pumps use pulse width modulation to adjust the

pump period, depending on the load present. The pumps

can provide 100mA for V

and 40mA for VON.

OFF

14

FN6367.0

December 6, 2007

ISL97653A

680KHz

0.9V

V

REF

Control

Error

FB

SUPP

SUPP

M2

M4

M1

D3 D2 D1

SUPP

M3

M5

C1-

C1+

POUT

C2+

C2-

FBP

External Connections

and Components

C7

C14

C8

C21

C22

x2 Mode

x3 Mode

Both

R8

R9

FIGURE 16. VON FUNCTION DIAGRAM

In voltage doubler configuration, the maximum VON is as

given by the following equation:

V

ON_MAX(2x)

2V

SUPPVDIODE

–()• 2I

OUT

2R

ONHRONL

For Voltage Tripler:

V

ON_MAX(3x)

V

output voltage is determined by the following equation:

ON

V

ONVFBP

3V

⎛⎞

1

+

•=

⎜⎟

⎝⎠

–()• 2I

SUPPVDIODE

R

8

-------

R

9

OUT

3R

ONH

2R

Negative Charge Pump Design Consideration

The negative charge pump consists of an internal switcher

M1, M2 which drives external steering diodes D2 and D3 via

a pump capacitor (C

supply. An internal comparator (A1) senses the feedback

voltage on FBN and turns on M1 for a period up to half a

CLK period to maintain V

0.2V. External feedback resistor R

Faults on V

OFF

are detected by comparator (A2) and cause the fault

detection system to start the internal fault timer which will

cause the chip to power down if the fault persists.

) to generate the negative V

12

in regulated operation at

(FBN)

6

which cause V

to rise to more than 0.4V,

FBN

OFF

is referenced to V

REF

.

+•()••–=

(EQ. 15)

•+•(••–=

ONL

(EQ. 16)

(EQ. 17)

The maximum V

output voltage of a single stage charge

OFF

pump is:

V

OFF_MAX

R

ON

NOUT()HRONNOUT()L+()•

– V

SUPP

DIODE

2I

•++=

OUT

(EQ. 18)

2x() V

R6 and R7 in the Typical Application Diagram determine

V

output voltage.

OFF

R7

⎛⎞

V

OFFVFBN

*Although in the given typical application diagram, SUPP and SUPN are

connected to A

could be connected to either A

VDD

------- -

1

⎝⎠

, depending on a specific application, SUPN and/or SUPP

–•

+

R6

V

VDD

REF

or V

R7

⎛⎞

------- -

•=

⎝⎠

R6

IN.

(EQ. 19)

15

FN6367.0

December 6, 2007

ISL97653A

VDD

A1

STOP

PWM

CONTROL

FIGURE 17. NEGATIVE CHARGE PUMP BLOCK DIAGRAM

0.2V

M2

M1

V

Slice Circuit

ON

A2

FAULT

0.4V

1.2MHz

CLK

EN

The VON slice circuit functions as a three way multiplexer,

switching the voltage on COM between ground, DRN and

POUT, under control of the start-up sequence and the CTL pin.

During the start-up sequence, COM is pulled to ground via

an NDMOS FET with R

of 260 ohms. After the start-up

DS(on)

sequence has completed, CTL is enabled and acts as a

multiplexer control such that if CTL is low, COM connects to

DRN through a 30Ω internal MOSFET, and if CTL is high,

COM connects to P

internally via a 5Ω MOSFET.

OUT

The slew rate of the switch control circuit is mainly restricted

by the load capacitance at COM pin and is given by

Equation 20:

ΔV

------- -

Δt

Where V

P

OUT

between COM and DRN or P

MOSFET r

inserted, R

C

is the load capacitance of switch control circuit.

L

V

g

-------------------------------------

=

||

RiR

()C

×

L

L

is the supply voltage applied to DRN or voltage at

g

, which range is from 0V to 30V. Ri is the resistance

including the internal

, the trace resistance and the resistor

DS(on)

is the load resistance of VON slice circuit, and

L

OUT

(EQ. 20)

In the Typical Application Circuit, R8, R9 and C22 give the

bias to DRN based on Equation 21:

VONR9+AVDD R8⋅⋅

---------------------------------------------------------

=

V

DRN

And R

R+

R

9

8

can be adjusted to adjust the slew rate.

10

(EQ. 21)

SUPN

FBN

NOUT

PGND

C20

820pF

C12

220nF

V

LOGIC2

V

REF

R6

40k

LDO

D3

C19

100pF

R7

328k

D2

V

C13

470nF

OFF

(-8V)

An LDO controller is also integrated to provide a second

logic supply. The LDO-CTL pin drives the base of an

external transistor which should be sized for the current

required. A resistor divider is used to set the output voltage

by feeding back a reference voltage to LDO-FB. The internal

feedback reference is 1.215V.

HVS Operation

When the HVS input is taken high, the ISL97653A enters

HVS test mode. In this mode, the output of A

VDD

is

increased by switching RSET to ground, and the AVDD is

set to:

R3Rx+

VDD

-------------------- -

×=

V

R

is the value of R4 in parallel with R5. A VDD

x

FBB

x

(EQ. 22)

A

Where R

voltage higher than the maximum rating of the boost

MOSFET may damage the part.

Fault Protection

The ISL97653A incorporates a number of fault protection

schemes. A VDD, VON, and VOFF are constantly monitored.

If fault conditions are detected for longer than 1ms on these

FB inputs, the device stops switching and the outputs are

disconnected. The ISL97653A also integrates over temp and

over current protection.

Supply Sequencing

When the input voltage VIN is higher than 4V(UVLO), V

V

LOGIC,

fixed soft-start at start-up. A

and V

LOGIC2

are turned on. V

, VON, and V

VDD

LOGIC

has a 9ms

OFF

dependant on the EN pin.

REF

are

,

16

FN6367.0

December 6, 2007

ISL97653A

When EN is taken high, voltage of pin PROT and V

OFF

start

ramping down. Once the PROT voltage falls below 0.9V,

A

starts up with a 9ms fixed soft-start time. Please note if

VDD

V

is to start earlier than A

OFF

connect to Vin, and Vin voltage should be larger than V

absolute value. The delay between V

, then the SUPN needs to

VDD

and A

OFF

VDD

OFF

can be

controlled by C30 in the typical application diagram and is

given by Equation 23:

T

DELAY

The successful completion of the A

triggers two simultaneous events. V

VIN0.9V–()C30× 50μA()⁄=

soft-start cycle

VDD

begins to ramp up

ON

(EQ. 23)

and the voltage on CDEL starts ramping up. When the

voltage reaches 1.215V, V

V

IN

VREF

V

LOGIC

EN

PROT

A

VDD

V

ON

V

OFF

CDEL

V

Slice

ON

* For demonstration only, not to scale

slice starts.

ON

0.9V

FIGURE 18.

2.8V

1.215V

Temperature Sensor

The ISL97653A also includes a temperature output for use

in system thermal management control. The integrated

sensor measures the die temperature over the -40°C to

+150°C range. Output is in the form of an analog voltage on

the TEMP pin in the range of 0V to 3V, which is proportional

to the sensed die temperature. Temperature accuracy is

±8.5°C over the -40°C to +150°C temperature range.

The device should be disabled by the user when the TEMP

pin output reaches 3V ( = +150°C die junction). Operation of

the device between +125°C and +150°C can be tolerated for

short periods, however in order to maximize the life of the IC,

it is recommended that the effective continuous operating

junction temperature of the die should not exceed +125°C.

Fault Sequencing

The ISL97653A has advanced overall fault detection

systems including Over Current Protection (OCP) for both

boost and buck converters, Under Voltage Lockout

Protection (UVLP) and Over-Temperature Protection.

Once the peak current flowing through the switching

MOSFET of the boost and buck converters triggers the

current limit threshold, the PWM comparator will disable the

output, cycle by cycle, until the current is back to normal.

Layout Recommendation

The device's performance including efficiency, output noise,

transient response and control loop stability is dramatically

affected by the PCB layout. PCB layout is critical, especially

at high switching frequency.

There are some general guidelines for layout:

1. Place the external power components (the input

capacitors, output capacitors, boost inductor and output

diodes, etc.) in close proximity to the device. Traces to

these components should be kept as short and wide as

possible to minimize parasitic inductance and resistance.

2. Place V

3. Reduce the loop with large AC amplitudes and fast slew

rate.

4. The feedback network should sense the output voltage

directly from the point of load, and be as far away from LX

node as possible.

5. The power ground (PGND) and signal ground (SGND)

pins should be connected at only one point.

6. The exposed die plate, on the underneath of the

package, should be sold ered to an equivalent area of

metal on the PCB. This contact area should have multiple

via connections to the back of the PCB as well as

connections to intermediate PCB layers, if available, to

maximize thermal dissipation away from the IC.

7. To minimize the thermal resistance of the package when

soldered to a multi-layer PCB, the amount of copper track

and ground plane area connected to the exposed die

plate should be maximized and spread out as far as

possible from the IC. The bottom and top PCB areas

especially should be maximized to allow thermal

dissipation to the surrounding air.

8. Minimize feedback input track lengths to avoid switching

noise pick-up.

A demo board is available to illustrate the proper layout

implementation.

and VL bypass capacitors close to the pins.

REF

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implicat ion or oth erwise u nde r any p a tent or p at ent r ights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

17

FN6367.0

December 6, 2007

Package Outline Drawing

L40.6x6

40 LEAD QUAD FLAT NO-LEAD PLASTIC PACKAGE

Rev 3, 10/06

6.00

6

PIN 1

INDEX AREA

ISL97653A

A

B

6.00

4X

4.5

0.50

36X

31

30

40

6

PIN #1 INDEX AREA

1

4 . 10 ± 0 . 15

(4X)

( 5 . 8 TYP )

( 4 . 10 )

0.15

TOP VIEW

TYPICAL RECOMMENDED LAND PATTERN

0 . 90 ± 0 . 1

( 36X 0 . 5 )

( 40X 0 . 23 )

( 40X 0 . 6 )

21

20

40X 0 . 4 ± 0 . 1

BOTTOM VIEW

SIDE VIEW

C

0 . 2 REF

0 . 00 MIN.

0 . 05 MAX.

DETAIL "X"

5

10

4

0 . 23 +0 . 07 / -0 . 05

SEE DETAIL "X"

C

0.10

BASE PLANE

SEATING PLANE

B0.1011MAC

C

0.08

C

18

NOTES:

Dimensions are in millimeters.1.

Dimensions in ( ) for Reference Only.

2.

Dimensioning and tolerancing conform to AMSE Y14.5m-1994.

3.

Unless otherwise specified, tolerance : Decimal ± 0.05

4.

Dimension b applies to the metallized terminal and is measured

between 0.15mm and 0.30mm from the terminal tip.

Tiebar shown (if present) is a non-functional feature.

5.

The configuration of the pin #1 identifier is optional, but must be

6.

located within the zone indicated. The pin #1 identifier may be

either a mold or mark feature.

FN6367.0

December 6, 2007

Loading...

Loading...