Page 1

®

ISL97635

Data Sheet December 22, 2008

SMBus 8-Channel LED Driver

The ISL97635 is a digitally controlled LED driver that

controls 8 channels of LED current for LCD backlight

applications. The ISL97635 is capable of driving typically 72

(8x9) pieces of 3.5V/30mA or 80 (8x10) pieces of

3.2V/20mA LEDs. The ISL97635’s 8 channels of voltage

controlled current sources with typical currents matching of

±1%, which compensate for the non-uniformity effect of

forward voltages variance in the LED stacks. T o minimize the

voltage headroom and power loss in the typical multi-strings

operation, the ISL97635 features a dynamic headroom

control that monitors the highest LED forward voltage string

and uses its feedback signal for output regulation.

The LED dimming control can be achieved through a

SMBus, an external PWM, or a variable DC (analog light

sensor) input. SMBus controlled dimming allows 256 levels

each of PWM and DC current adjustments. The SMBus

PWM dimming frequency can be adjusted from 100Hz to

5kHz by an external capacitor. External PWM input allows up

to 20kHz audio noise free PWM dimming. The SMBus PWM

setting and an external PWMI signal can also be combined

to provide a dynamic PWM dimming that complies with

Intel’s DPST (Display Power Saving Technology)

requirement.

One or more channels can be selected sequentially in any

order, allowing scrolling in RGB LED backlighting

applications.

The ISL97635 features extensi v e protection functions that

include string open and short circuit detections, OVP, OTP,

thermal shutdown and an optional input overcurrent

protection with master fault disconnect switch. The fault

conditions will be recorded in the Fault/Status register. There

are selectable short-circuit thresholds and the switching

frequency can be programmed between 600kHz and

1.2MHz.

Available in the 24 Ld 4mmx4mm QFN, the ISL97635

operates from -40°C to +85°C with input voltage ranging

from 6V to 24V.

FN6434.2

Features

• 8 Channels

• 6V to 24V Input

• 34.5V Output Max

• Drive Maximally 72 (3.5V/30mA each) or 80 (3.2V/20mA

each) LEDs

• Current Matching ±1% Typ

• Dynamic Headroom Control

• Dimming Controls

- SMBus 8-Bit PWM Current Control

- SMBus 8-Bit DC Current Control

- External PWM Input up to 20kHz Dimming

- SMBus and External PWM DPST Dimming Control

- DC-to-PWM Dimming Control

• Protections

- String Open Circuit Detection

- String Short Circuit Detection with Select able Thresho lds

- Over-Temperature Protection

- Overvoltage Protection

- Input Overcurrent Protection with Disconnect Switch

• 600kHz/1.2MHz Selectable f

SW

• Selectable Channels Allows Scrolling Backlight

• 24 Ld (4mmx4mm) QFN Package

• Pb-Free (RoHS compliant)

Applications

• Notebook Displays WLED or RGB LED Backlighting

• LCD Monitor LED Backlighting

• Automotive Displays LED Backlighting

• Automotive or Traffic Lighting

Ordering Information

PART NUMBER

(Note)

ISL97635IRZ* 976 35IRZ 24 Ld 4x4 QFN L24.4x4D

*Add “-T” or “-TK” suffix for tape and reel. Please refer to TB347 for

details on reel specifications.

NOTE: These Intersil Pb-free plastic packaged products employ

special Pb-free material sets, molding compounds/die attach

materials, and 100% matte tin plate plus anneal (e3 termination

finish, which is RoHS compliant and compatible with both SnPb and

Pb-free soldering operations). Intersil Pb-free products are MSL

classified at Pb-free peak reflow temperatures that meet or exceed

the Pb-free requirements of IPC/JEDEC J STD-020.

PART

MARKING

PACKAGE

(Pb-free)

PKG.

DWG. #

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

All other trademarks mentioned are the property of their respective owners.

Copyright Intersil Americas Inc. 2008. All Rights Reserved

Page 2

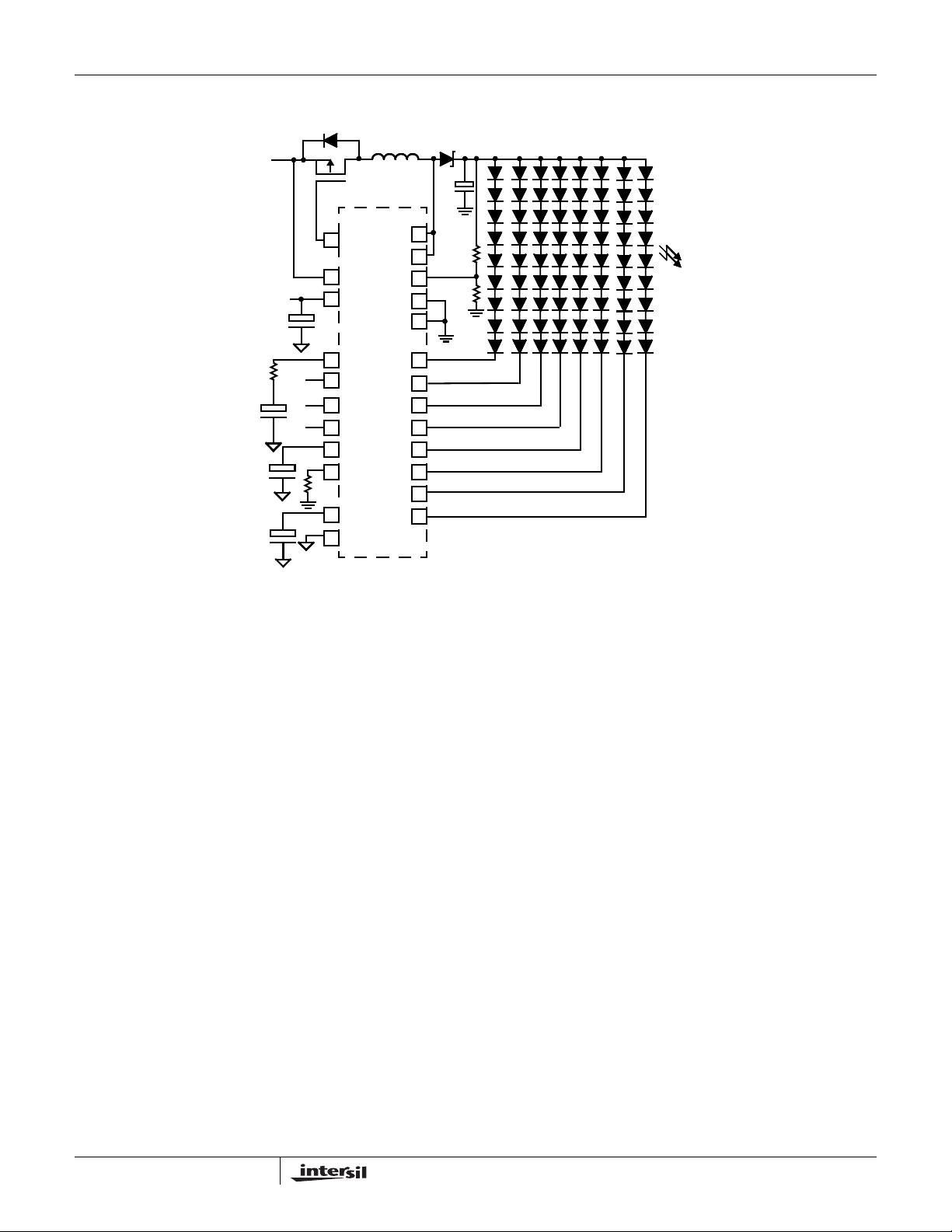

Typical Application Circuit

VBL+ = 6V TO 24V

21

23

24

ISL97635

FAULT

VIN

VDC

LX

LX

OVP

PGND

PGND 18

ISL97635

V

OUT

19

20

16

17

= 34.5V, 30mA PER STRING

22

1

2

6

4

11

3

5

COMP

SMBCLK

SMBDAT

PWMI/EN

PWMO

RSET

FPWM

GND

IIN0

IIN1

IIN2

IIN3

IIN4

IIN5

IIN6

IIN7

15

14

13

12

10

9

8

7

2

FN6434.2

December 22, 2008

Page 3

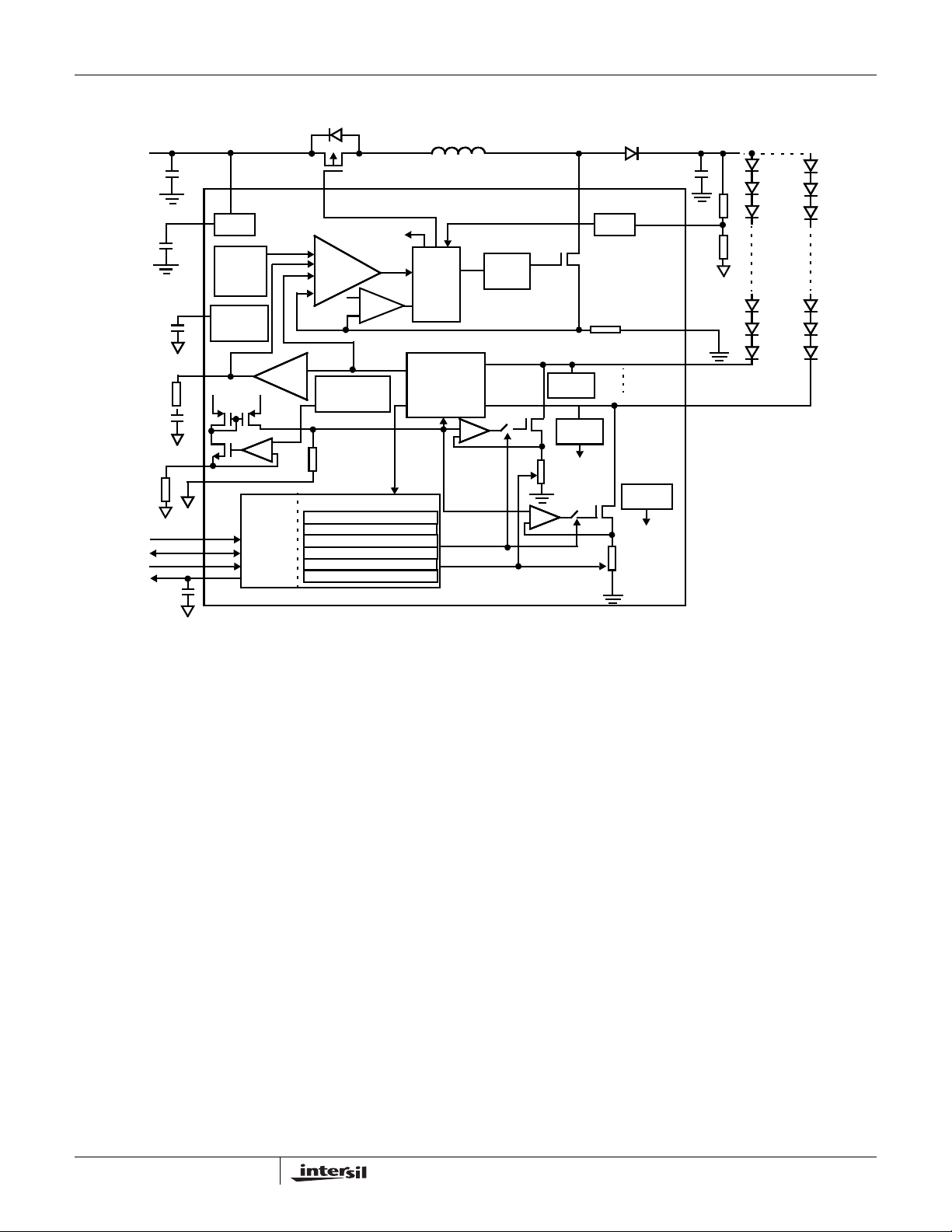

Block Diagram

VBL+ = 6V TO 24V

ISL97635

34.5V, 30mA PER STRING

(8x9 = 72 WHITE LEDS)

SMBCLK

SMBDAT

PWMI

PWMO

VDC

f

PWM

COMP

RSET

GND

VIN

VIN

REG

OSC AND

RAMP

COMP

LED PWM

CONTROL

SMBUS

INTERFACE

FAULT

FAULT/STATUS

REGISTER

Σ = 0

IMAX

GM

AMP

REFERENCE

GENERAT OR

+

+

-

-

REGISTERS

PWM BRIGHTNESS CONTROL

DEVICE CONTROL

FAULT/STATUS

IDENTIFICATION

DC BRIGHTNESS CONTROL

CONFIGURATION

ILIMIT

LOGIC

HIGHEST VF

STRING

DETECT

+

+

-

-

PWM/OC/SC

AM

ISL97635

FET

DRIVER

OC, SC

DETECT

OC, SC

DETECT

FAULT/STATUS

REGISTER

+

+

-

-

LX

LX

OVP

IIN0

IIN0

IIN7

TEMP

SENSOR

FAUL T/STATUS

REGISTER

PGND

FIGURE 1. ISL97635 BLOCK DIAGRAM

3

FN6434.2

December 22, 2008

Page 4

ISL97635

Absolute Maximum Ratings (T

VIN, FAULT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to 24V

VDC, COMP, RSET . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to 6.5V

SMBCLK, SMBDAT, FPWM, PWMO, EN/PWM . . . . . -0.3V to 6.5V

OVP, IIN0 - IIN7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-0.3V to 28V

LX. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-0.3V to 36V

PGND. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to +0.3V

Above voltage ratings are all with respect to GND pin

= +25°C) Thermal Information

A

Thermal Resistance (Typical, Notes 1, 2) θ

24 Ld QFN . . . . . . . . . . . . . . . . . . . . . . 39 2

Thermal Characterization (Typical, Note 3) PSI

24 Ld QFN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ~0.7

Maximum Continuous Junction Temperature . . . . . . . . . . . . +125°C

Storage Temperature . . . . . . . . . . . . . . . . . . . . . . .-65°C to +150°C

Pb-free Reflow Profile . . . . . . . . . . . . . . . . . . . . . . . . .see link below

(°C/W) θJC (°C/W)

JA

(°C/W)

JT

http://www.intersil.com/pbfree/Pb-FreeReflow.asp

Operating Conditions

Temperature Range. . . . . . . . . . . . . . . . . . . . . . . . . .-40°C to +85°C

IMPORTANT NOTE: All parameters having Min/Max specifications are guaranteed. Typical values are for information purposes only. Unless otherwise noted, all tests

are at the specified temperature and are pulsed tests, therefore: T

CAUTION: Do not operate at or near the maximum ratings listed for extended periods of time. Exposure to such conditions may adversely impact product reliability and

result in failures not covered by warranty.

NOTES:

is measured in free air with the component mounted on a high effective thermal conductivity test board with “direct attach” features. See T ech

1. θ

JA

Brief TB379.

2. For θ

3. PSI

, the “case temp” location is the center of the exposed metal pad on the package underside.

JC

is the PSI junction-to-top thermal characterization parameter. If the package top temperature can be measured with this rating then the

JT

die junction temperature can be estimated more accurately than the θ

4. Limits established by characterization and are not production tested.

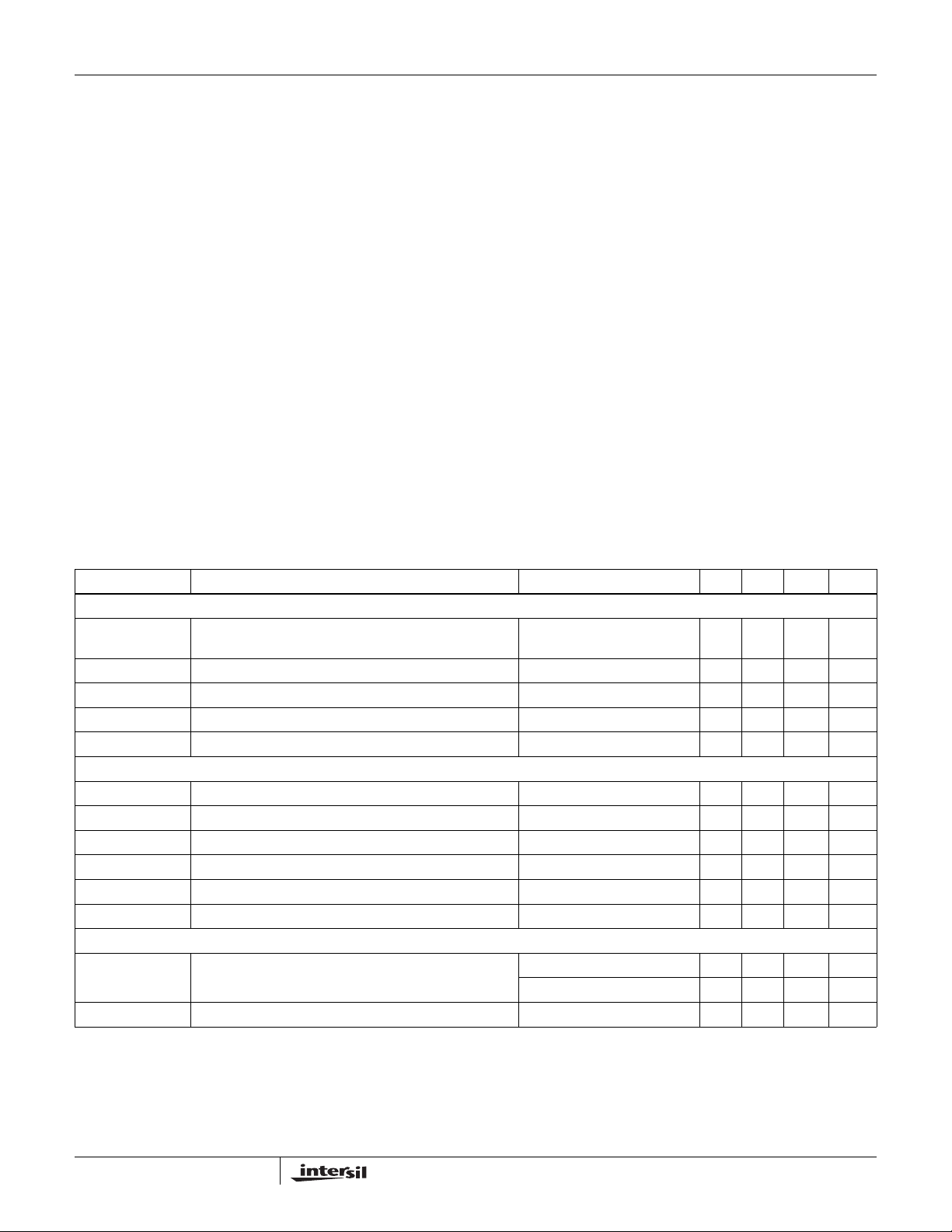

Electrical Specifications All specifications below are tested at T

unless otherwise noted. Parameters with MIN and/or MAX limits are 100% tested at +25°C, unless otherwise

specified. Temperature limits established by characterization and are not production tested.

PARAMETER DESCRIPTION CONDITION MIN TYP MAX UNIT

GENERAL

V

IN

I

VIN_STBY

V

OUT

V

UVLO

V

UVLO_HYS

REGULATOR

V

DC

I

VDC_STBY

I

VDC

V

LDO

SS Soft-Start 1ms

ENmin Minimum Enable Signal 40 µs

BOOST

SWILimit Boost FET Current Limit T

r

DS(ON)

Backlight Supply Voltage ≤ 9 LEDs per channel

VIN Shutdown Current 5µA

Output Voltage 34.5 V

Undervoltage Lockout Threshold 2.45 2.8 V

Undervoltage Lockout Hysteresis 300 mV

LDO Output Voltage VIN > 6V 5.0 5.5 V

Standby Current EN/PWM = 0V 20 µA

Active Current EN/PWM = 5V 10 mA

VDC LDO Dropout Voltage VIN > 5.5V, 30mA 30 200 mV

Internal Boost Switch ON-Resistance 130 260 mΩ

= TC = T

J

A

and θJC thermal resistance ratings.

JC

= -40°C to +85°C; VIN = 12V, EN = 5V, R

A

= 36.6kΩ,

SET

624V

(3.5V/30mA type)

= +25°C 2.3 3.2 A

A

= -40°C to +85°C 2.2 A

T

A

4

FN6434.2

December 22, 2008

Page 5

ISL97635

Electrical Specifications All specifications below are tested at T

unless otherwise noted. Parameters with MIN and/or MAX limits are 100% tested at +25°C, unless otherwise

= -40°C to +85°C; VIN = 12V, EN = 5V, R

A

= 36.6kΩ,

SET

specified. Temperature limits established by characterization and are not production tested. (Continued)

PARAMETER DESCRIPTION CONDITION MIN TYP MAX UNIT

Eff_peak Peak Efficiency VIN = 18V, 54 LEDs, 20mA

91 %

each, L = 8.2µH with DCR

106mΩ, T

VIN = 12V, 54 LEDs, 20mA

= +25°C

A

88 %

each, L = 8.2µH with DCR

106mΩ, T

VIN = 6V, 54 LEDs, 20mA

= +25°C

A

86 %

each, L = 8.2µH with DCR

ΔI

OUT

D

MAX

D

MIN

f

OSC_hi

f

OSC_lo

/ΔV

106mΩ, T

IN

Line Regulation 0.1 %

Boost Maximum Duty Cycle 82 %

Boost Minimum Duty Cycle 7%

Lx Frequency Register 0x08, fSW = 1 1.0 1.2 1.3 MHz

Lx Frequency Register 0x08, fSW = 0 550 600 650 kHz

= +25°C

A

ILX_leakage Lx Leakage Current VLX = 36V, EN = 0 10 µA

REFERENCE

I

MATCH

I

ACC

Channel-to-Channel Current Matching I

= 30mA, BRT = 255 -3.5 ±1 +3.5 %

OUT

Current Accuracy ±3 %

FAULT DETECTION

V

SC

Short Circuit Threshold Accuracy Reg0x08 = 0x0F or 0x0B

7.8 8 8.8 V

Reg0x00 = 0xFF

Reg0x08 = 0x0E or 0x0A

2.8 3.1 3.8 V

Reg0x00 = 0xFF

V

temp_acc

V

OVPlo

OVP

OVP

hys

fault

Over-Temperature Threshold Accuracy 5 °C

Overvoltage Limit on OVP Pin 1.17 1.2 1.23 V

OVP Hysteresis 20 mV

OVP Short Detection Fault Level 300 mV

SMBus INTERFACE

VIL Guaranteed Range for Data, Clock Input Low Voltage 0.8 V

VIH Guaranteed Range for Data, Clock Input High Voltage 2.1 VDD V

VOL SMBus Data Line Logic Low Voltage with 1.1kΩ series

resistor from data bus to SMBDAT pin

SMBus Data Line Logic Low Voltage without series resistor

from data bus to SMBDAT pin

I

LEAK

V

DD

Input Leakage On SMBData/SMBClk -1 1 µA

Nominal Bus Voltage 3V to 5V ±10% 2.7 5.5 V

I

= 350µA 0.4 V

PULLUP

= 4mA 0.17 V

I

PULLUP

SMBus TIMING SPECIFICATIONS (Note 4)

f

SMB

t

BUF

t

HD:STA

SMBus Clock Frequency 10 100 kHz

Bus Free Time Between Stop and Start Condition 4.7 µs

Hold Time After (Repeated) START Condition. After this

4.0 µs

Period, the First Clock is Generated

t

SU:STA

t

SU:STO

Repeated Start Condition Setup Time 4.7 µs

Stop Condition Setup Time 4.0 µs

5

FN6434.2

December 22, 2008

Page 6

ISL97635

Electrical Specifications All specifications below are tested at T

unless otherwise noted. Parameters with MIN and/or MAX limits are 100% tested at +25°C, unless otherwise

= -40°C to +85°C; VIN = 12V, EN = 5V, R

A

= 36.6kΩ,

SET

specified. Temperature limits established by characterization and are not production tested. (Continued)

PARAMETER DESCRIPTION CONDITION MIN TYP MAX UNIT

t

HD:DAT

t

SU:DAT

t

LOW

t

HIGH

t

F

t

R

Data Hold Time 300 ns

Data Setup Time 250 ns

Clock Low Period 4.7 µs

Clock High Period 4.0 50 µs

Clock/data Fall Time 300 ns

Clock/data Rise Time 1000 ns

GENERAL TIMING SPECIFICATIONS (Note 4)

t

1

t

2

t

3

t

4

t

5

t

6

t

7

t

8

t

9

t

10

t

11

Minimum Setup Time Between VIN Rising above VUVLO

with EN = 1 and SMBus Communications

Minimum Setup Time Between EN Going High with VIN

above VUVLO and SMBus Communications

Minimum Time Between VIN Rising above VUVLO with

EN = 1 to SMBus BL CTRL On

Minimum Time Between EN Going High with VIN above

VUVLO to SMBus BL CTRL On

Minimum Time for LED Output to Respond to SMBus Data at

any Levels

Response Time Between Backlight CTRL Off with Boost

Not Switching to Backlight CTRL On with Boost Switching

Response Time Between Backlight CTRL On with Boost

Switching to Backlight CTRL Off with Boost Not Switching

LED Channel Short Circuit Fault Detection to Status

Register Data Ready

V

Short Circuit Detection During Operation to

OUT-GND

Status Register Data Ready

Time Between VIN Rising Above VUVLO with EN = 1 and

V

Short being Reported in Status Register

OUT-GND

Time Between EN Going High with VIN Above VUVLO and

a V

OUT-GND

Short being Reported in Status Register

EN = 1, TA = +25°C, VDC

80 µs

capacitor < 10µF

VIN > VUVLO, TA= +25°C,

80 µs

VDC capacitor < 10µF

EN = 1, TA = +25°C 4.5 ms

VIN > VUVLO, TA = +25°C 4.5 ms

VIN > VUVLO, EN = 1,

T

= +25°C

A

VIN > VUVLO, EN = 1,

T

= +25°C

A

VIN > VUVLO, EN = 1,

T

= +25°C

A

VIN > VUVLO, EN = 1,

T

= +25°C, LEDs Active

A

VIN > VUVLO, EN = 1,

T

= +25°C, Fault FET used

A

EN = 1, VDC capacitor < 10µF,

5µs

5µs

5µs

6ms

5µs

30 ms

TA = +25°C, Fault FET used.

> VUVLO, VDC capacitor <

V

IN

10µF, T

used.

= +25°C, Fault FET

A

30 ms

CURRENT SOURCES

V

headroom

V

RSET

ILEDmax Maximum LED Current per Channel R

Dominant Channel Current Source Headroom at IIN Pin I

Voltage at RSET Pin R

= 20mA, TA = +25°C 100 mV

LED

= 36.6kΩ 680 700 720 mV

SET

= 20.9kΩ 35 mA

SET

PWM GENERATOR

FPWM Generated PWM Frequency C

DPWM Duty Cycle Of Generated PWM (DC-to-PWM) V

= 27nF

FPWM

C

= 220nF

PWMO

= 0.3V

PWMO

CFPWM = 27nF

= 1.1V

V

PWMO

CFPWM = 27nF

200 Hz

90 %

10 %

tMAX_PWM_OFF Maximum P WMI Off Time B efore Sh u tdown EN/PWMI toggles 28 ms

6

FN6434.2

December 22, 2008

Page 7

ISL97635

Electrical Specifications All specifications below are tested at T

unless otherwise noted. Parameters with MIN and/or MAX limits are 100% tested at +25°C, unless otherwise

= -40°C to +85°C; VIN = 12V, EN = 5V, R

A

= 36.6kΩ,

SET

specified. Temperature limits established by characterization and are not production tested. (Continued)

PARAMETER DESCRIPTION CONDITION MIN TYP MAX UNIT

FAULT PIN

I

FAULT

V

FAULT

Fault Pull-down Current VIN = 12V 10 18 30 µA

Fault Clamp Voltage with Respect to V

IN

VIN = 12, VIN-V

FAULT

7.5 V

IlxStart-up Lx Start-up Current VDC = 5.2V 1 2.7 7 mA

Typical Performance Curves

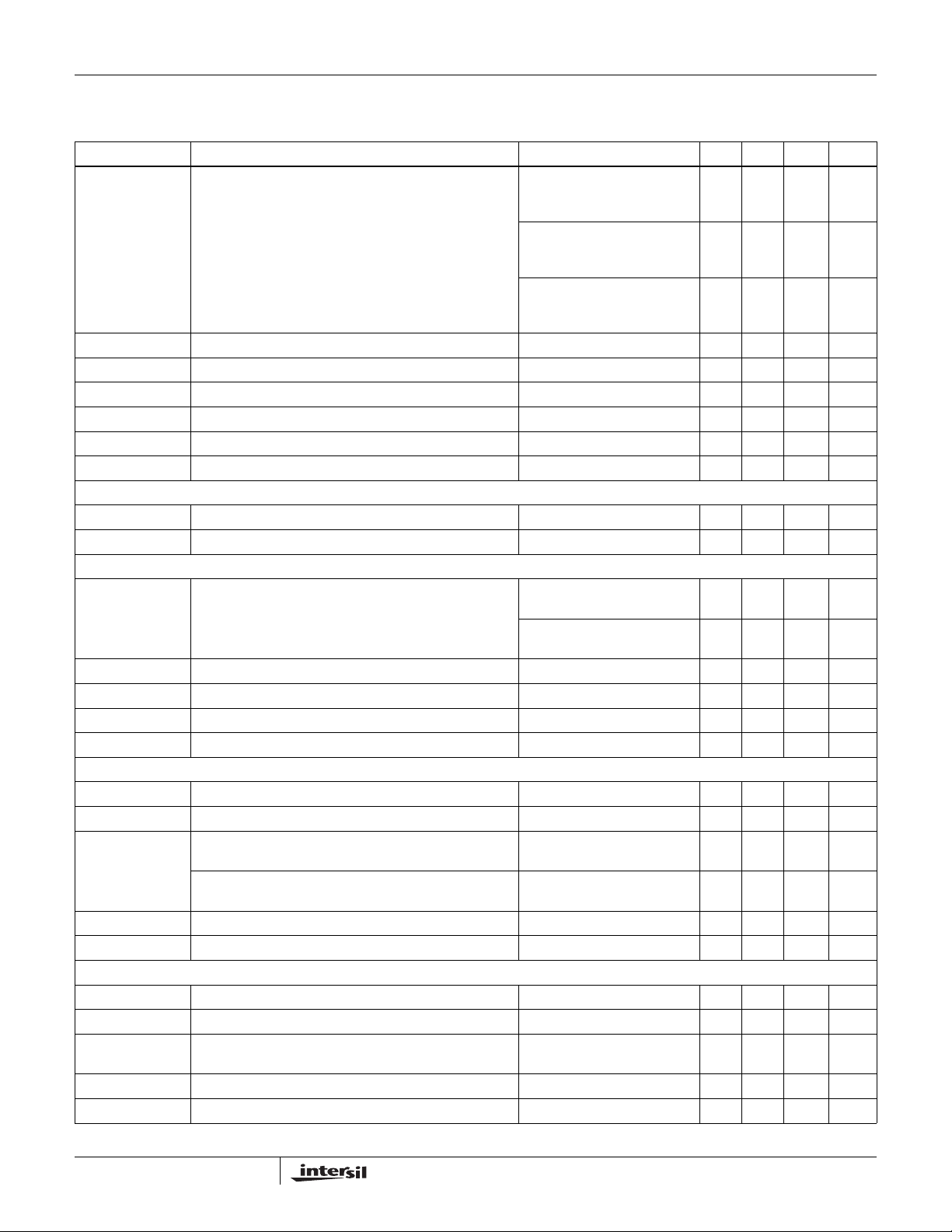

92

7S6P - 18V

90

88

86

84

82

80

78

76

EFFICIENCY (%)

74

72

70

68

66

0 20 40 60 80 100 120 140 160 180

9S6P - 6V

9S8P - 6V

7S8P - 6V

7S8P - 6V

9S6P - 12V

7S6P - 6V

9S8P - 12V

7S8P - 12V

7S6P - 12V

(mA)

I

O

9S8P - 18V

7S8P - 18V

9S6P - 18V

L = 8.2µH

IHLP-2525BD-01

DCR = 106mΩ

I

= 3A

SAT

FIGURE 2. EFFICIENCY, L = 8.2µH WITH DCR = 106mΩ,

C

= 4x4.7µF/50V

O

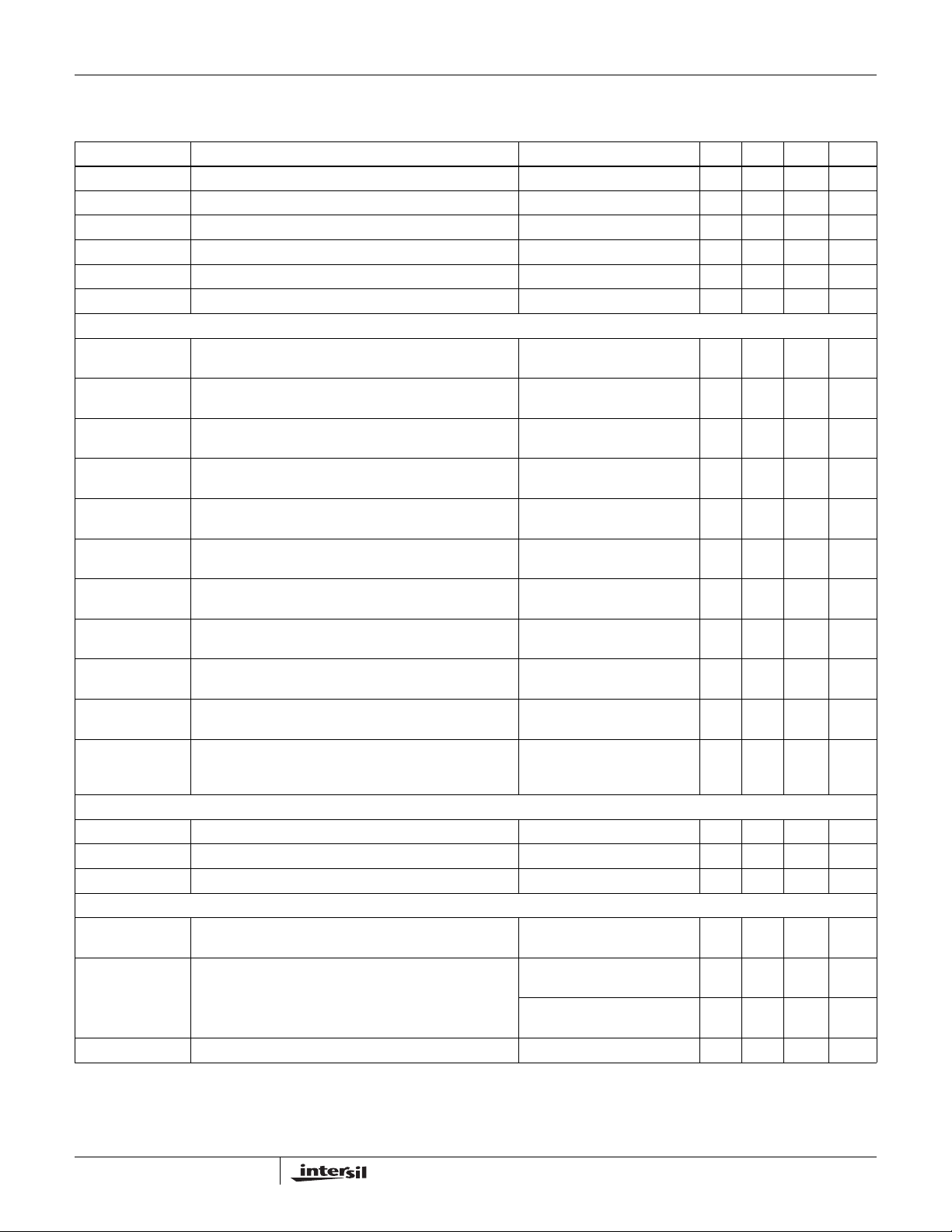

92

90

7S6P - 18V

88

86

84

82

80

78

76

74

EFFICIENCY (%)

72

70

68

9S8P - 6V

66

0 20 40 60 80 100 120 140 160 180

7S6P - 6V

7S8P - 6V

7S8P - 6V

9S6P - 6V

9S8P - 12V

9S6P - 18V

9S6P - 12V

IO (mA)

9S8P - 18V

7S6P - 12V

7S8P - 12V

7S8P - 18V

L = 10µH

IHLP-2525BD-01

DCR = 129mΩ

I

= 2.5A

SAT

FIGURE 3. EFFICIENCY, L = 10µH WITH DCR = 129mΩ,

CO= 4x4.7µF/50V

92

7S8P - 12V

90

7S6P - 12V

88

86

84

82

80

78

76

74

EFFICIENCY (%)

72

70

68

66

9S8P - 12V

9S8P - 6V

0 20 40 60 80 100 120 140 160 180

7S6P - 18V

9S8P - 18V

7S8P - 6V

7S8P - 6V

9S6P - 6V

9S6P - 18V

9S6P - 12V

7S6P - 6V

(mA)

I

O

7S8P - 18V

L = 10µH

DCR = ~500mΩ

<1mm HEIGHT

FIGURE 4. 3 EFFICIENCY, L = 10µH WITH DCR = 500mΩ,

1mm, C

= 4µFx4.7µF/50V

O

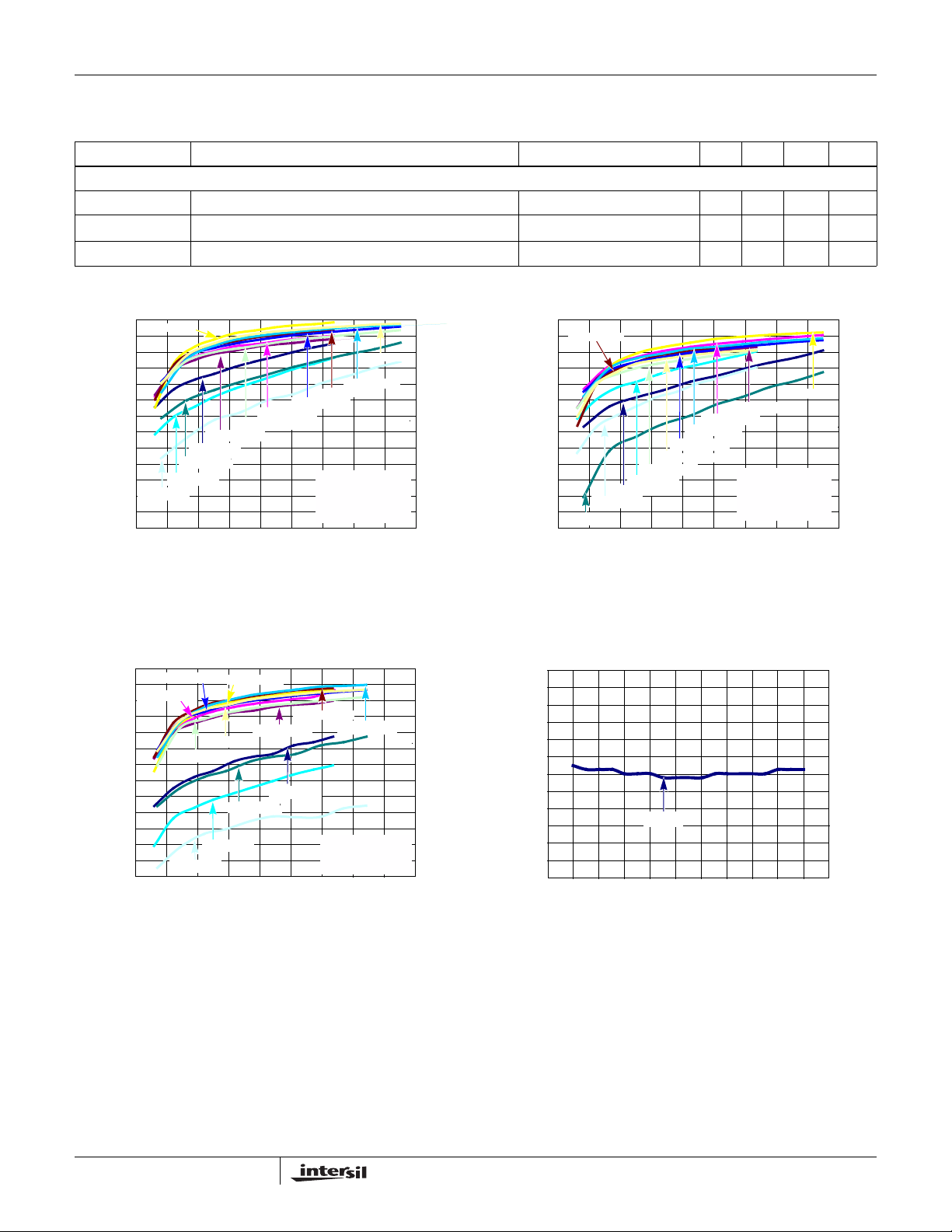

1.2

1.0

0.8

0.6

0.4

0.2

0.0

-0.2

-0.4

-0.6

CURRENT VARIATION (%)

-0.8

-1.0

-1.2

4 6 8 10 12 14 16 18 20 22 24 26

20mA

(V)

V

IN

FIGURE 5. CURRENT REGULATION

7

FN6434.2

December 22, 2008

Page 8

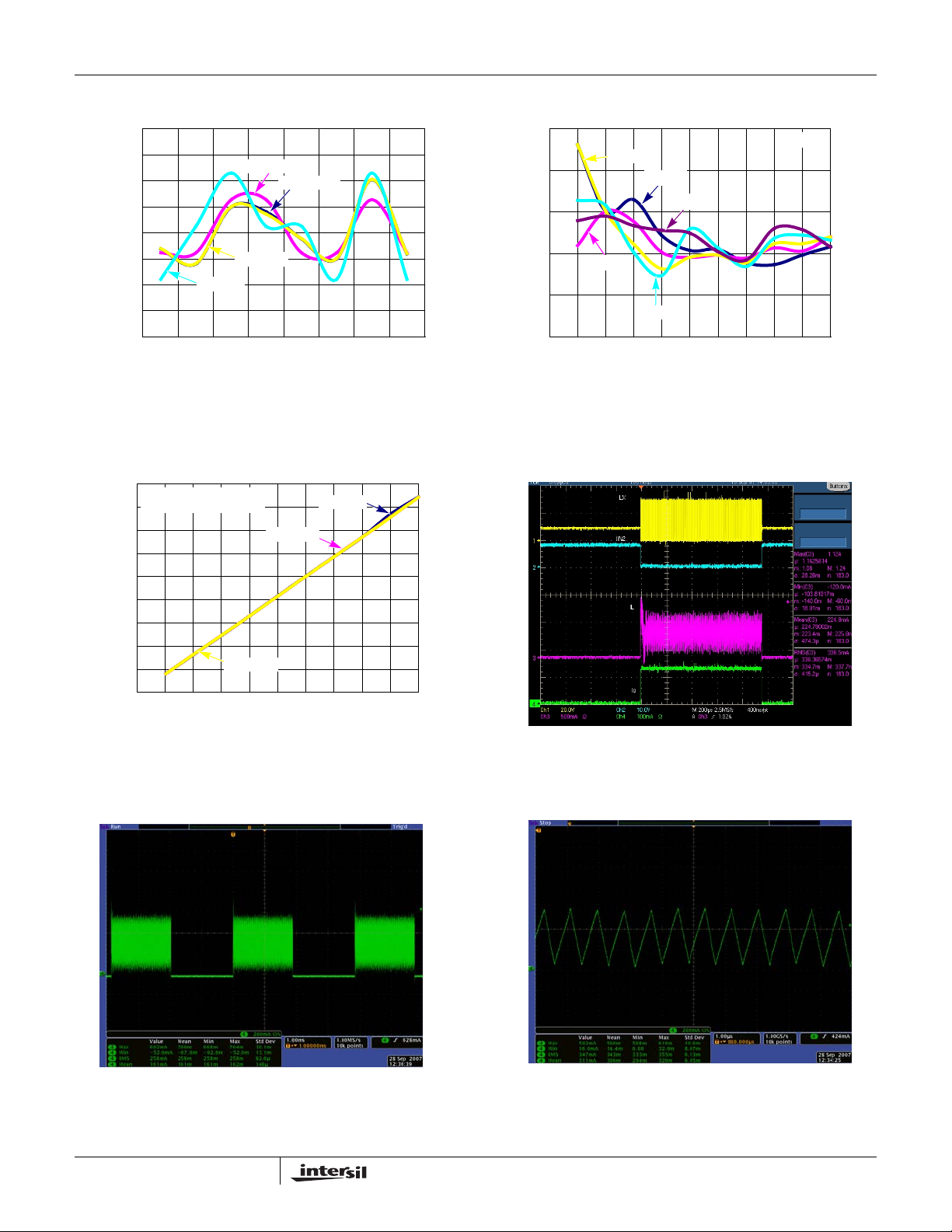

Typical Performance Curves (Continued)

2.0

1.5

1.0

0.5

0.0

-0.5

-1.0

CURRENT MATCHING (%)

-1.5

-2.0

CH 0 CH 1 CH 2 CH 3 CH 4 CH 5 CH 6 CH 7

6V/1mA

FIGURE 6. CHANNEL-TO-CHANNEL CURRENT MATCHING

180

8 CHANNELS

9 LEDS PER CHANNEL

160

140

120

100

80

60

40

TOTAL OUTPUT CURRENT (mA)

20

0

0 102030405060708090100

FIGURE 8. PWM DIMMING LINEARITY FIGURE 9. LX, VIIN, IL AND I

12V/1mA

12V/20mA

6V/20mA

CHANNELS

VIN = 6V

VIN = 12V

VIN = 18V

PWM DUTY CYCLE (%)

ISL97635

1.0

0.9

0.8

0.7

0.6

CURRENT MATCHING (%)

0.5

0 102030405060708090100

1kHz

100kHz

20kHz

200kHz

10kHz

PWM DUTY CYCLE (%)

VIN = 12V

FIGURE 7. CURRENT MATCHING vs DUTY CYCLE vs

DIMMING FREQUENCY

AT PWM DIMMING

O

FIGURE 10. I

AT 50% PWM DIMMING

L

8

FIGURE 11. I

ZOOM IN AT PWM DIMMING ZOOM IN

L

December 22, 2008

FN6434.2

Page 9

Typical Performance Curves (Continued)

ISL97635

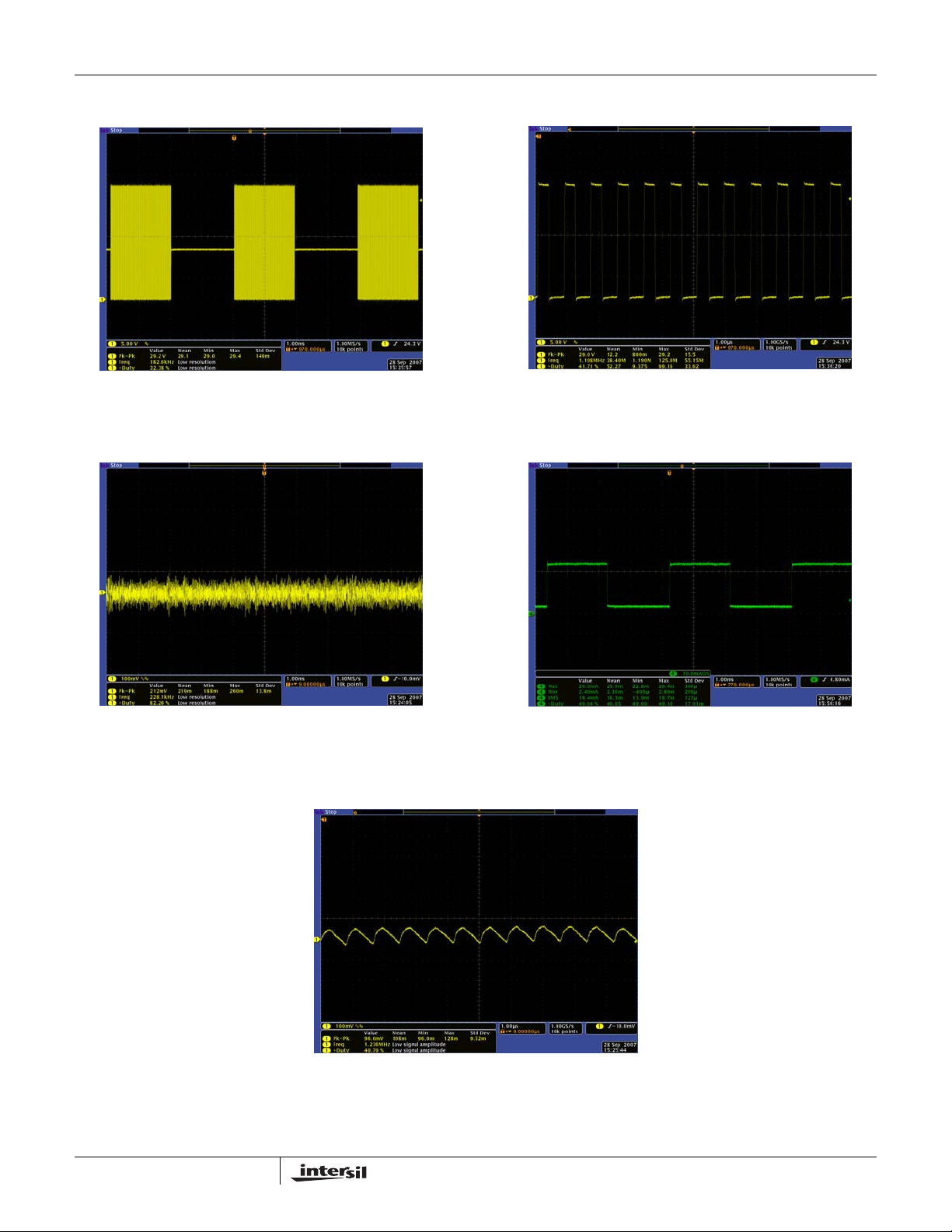

FIGURE 12. LX AT 50% PWM DIMMING

FIGURE 14. RIPPLE VOLTAGE

FIGURE 13. LX ZOOM IN AT 50% DIMMING

FIGURE 15. I

AT 50% PWM DIMMING

LED

FIGURE 16. RIPPLE VOLTAGE ZOOM IN

9

FN6434.2

December 22, 2008

Page 10

Pinout

SMBCLK

SMBDAT

PWMO

PWMI/EN

FPWM

GND

1

2

3

4

5

6

Pin Descriptions (I = Input, O = Output, S = Supply)

ISL97635

ISL97635

(24 LD QFN)

TOP VIEW

VDC

VIN

COMP

FAULT

LX

LX

24 23 22 21 20 19

789101112

IIN7

IIN6

IIN5

IIN4

RSET

IIN3

PGND

18

PGND

17

OVP

16

IIN0

15

IIN1

14

IIN2

13

PIN NAME TYPE DESCRIPTION

1 SMBCLK I SMBus serial clock input

2 SMBDAT I/O SMBus serial data input and output

3 FPWM I Connect a capacitor between FPWM and GND to set the DPWM frequency. FPWM = 5.4µ/C

If SMBus PWM or DPST mode is used, connect C

connect C

connect C

between V

PWMO

to set the dimming frequency and apply a 0.21V to 1.21V at V

FPWM

and GND pins for DPST operation. If DC-to-PWM mode is used,

PWMO

to GND to set the dimming frequency. Also,

FPWM

.

PWMO

FPWM

4 PWMO I/O PWMI buffered output. If one connects a capa citor betwee n PWMO and GND, it forms a lo w pass filter

with an internal 40kΩ resistor , which filters the PWMI signal for DPST operation when Reg 0x01 = 0x01.

If one applies a 0.2V to 1.2V DC input voltage, the output w ill be PWM with duty cycle proportional to the

DC input.

5 GND S Analog GND and LED power return

6 PWMI/EN I Dual Functions: Enable pin and PWM brightness control pin or DPST control input. DO NOT let

PWMI/EN floating. The device needs 4ms for initial power-up Enable, then this pin can be applied with

a PWM signal with off-time no longer than 28ms.

7 IIN7 I Input 7 to current source, FB, and monitoring

8 IIN6 I Input 6 to current source, FB, and monitoring

9 IIN5 I Input 5 to current source, FB, and monitoring

10 IIN4 I Input 4 to current source, FB, and monitoring

11 RSET I Resistor connection for setting LED current, (see Equation 1 for calculating the I

LEDmax

)

12 IIN3 I Input 3 to current source, FB, and monitoring

13 IIN2 I Input 2 to current source, FB, and monitoring

14 IIN1 I Input 1 to current source, FB, and monitoring

15 IIN0 I Input 0 to current source, FB, and monitoring

16 OVP I Overvoltage protection input

17, 18 PGND S Power ground (LX Power return)

19, 20 LX I Input to boost switch

21 FAULT O Fault disconnect switch

10

FN6434.2

December 22, 2008

Page 11

ISL97635

Pin Descriptions (I = Input, O = Output, S = Supply) (Continued)

PIN NAME TYPE DESCRIPTION

22 COMP O Boost compensation pin

23 VIN S Input voltage for the device and LED power

24 VDC S De-couple capacitor for internally generated supply rail. If 2.7V < VBL+ < 5.5V , apply VDC directly with

a supply voltage of 2.7V to 5.5V

Theory of Operation

PWM Boost Converter

The current mode PWM boost converter produces the

minimal voltage needed to enable the LED stack with the

highest forward voltage drop to run at the programmed

current. The ISL97635 employs current mode control boost

architecture that has a fast current sense loop and a slow

voltage feedback loop. Such architecture achieves a fast

transient response that is essential for the notebook

backlight application where the power can be a series of

drained batteries or instantly change to an AC/DC adapter

without rendering a noticable visual nuisance. The number

of LEDs that can be driven by ISL97635 depends on the

type of LED chosen in the application. The ISL97635 is

capable of boosting up to 34.5V and typically driving 9 LEDs

in series for each of the 8 channels, enabling a total of 72

pieces of the 3.5V/30mA type of LEDs.

+

REF

REF

-

RSET

RSET

PWM DIMMING

DC DIMMING

FIGURE 17. SIMPLIFIED CURRENT SOURCE CIRCUIT

+

+

-

-

+

+

-

-

Enable and PWMI

The EN/PWMI pin serves dual purposes; it is used as an

Enable signal and can be used as a PWM input signal for

dimming. If a PWM signal is applied to this pin, the first pulse of

minimum 40µs will be used as an Enable signal. If there is no

signal for longer than 28ms, the device will enter shutdown. The

EN/PWMI pin cannot be floating thus a 10kΩ pull-down resistor

may need to be added.

Current Matching and Current Accuracy

Each channel of the LED current is regulated by the current

source circuit, as shown in Figure 17.

The LED peak current is set by translating the R

to the output with a scaling factor of 733/R

SET

terminals of the current source MOSFETs are designed as

100mV to minimize the power loss. The sources of errors of

the channel-to-channel current matching come from the

op amp’s offset, internal layout, reference, and current

source resistors. These parameters are optimized for current

matching and absolute current accuracy. On the other hand,

the absolute accuracy is additionally determined by the

external R

, and therefore, additional tolerance will be

SET

contributed by the current setting resistor. A 1% tolerance

resistor is therefore recommended.

current

SET

. The source

Dynamic Headroom Control

The ISL97635 features a proprietary Dynamic Headroom

Control circuit that detects the highest forward voltage string

or effectively the lowest voltage from any of the IIN pins.

When this lowest I

threshold, V

SC

voltage is lower than the short circuit

IN

, such voltage will be used as the feedback

signal for the boost regulator. The boost makes the output to

the correct level such that the lowest IIN pin is at the target

headroom voltage. Since all LED stacks are connected to

the same output voltage, the other IIN pins will have a higher

voltage, but the regulated current source circuit on each

channel will ensure that each channel has the same

programmed current. The output voltage will regulate

cycle-by-cycle and is always referenced to the highest

forward voltage string in the architecture.

Dimming Controls

The ISL97635 allows two ways of controlling the LED

current, and therefore, the brightness. They are:

1. DC current adjustment

2. PWM chopping of the LED current defined in Step 1.

There are various ways to achieve DC or PWM current

control, which will be described in the following.

11

FN6434.2

December 22, 2008

Page 12

ISL97635

MAXIMUM DC CURRENT SETTING

The initial brightness should be set by choosing an

appropriate value for R

. This should be chosen to fix the

SET

maximum possible LED current, as shown in Equation 1:

733

I

LEDmax

=

---------------

R

SET

(EQ. 1)

DC CURRENT ADJUSTMENT

Once R

is fixed, the LED DC current can be adjusted

SET

through Register 0x07 (BRTDC), as shown in Equation 2:

I

LED

2.87 BRTDC R

⁄×=

SET

(EQ. 2)

BRTDC can be programmed from 0 to 255 in decimal and

defaults to 255 (0xFF). If left at the default value, LED

current will be fixed at I

. BRTDC can be adjusted

LEDmax

dynamically on the fly during operation. BRTDC = 0

disconnects all channels and I

is guaranteed to be <10µA

LED

at this state.

For example, if the maximum required LED current (I

LEDmax

is 20mA, rearranging Equation 1 yields Equation 3:

R

733 0.02⁄ 36.6kΩ==

SET

(EQ. 3)

If BRTDC is set to 200 then:

I

2.87 200 36600 15.4mA=ڥ=

LED

(EQ. 4)

PWM CONTROL

The ISL97635 provides four different PWM dimming

methods, as described in the following. Each of these

methods results in PWM chopping of the current in the LEDs

for all 8 channels to provide an average LED current. During

the On periods, the LED current will be defined by the value

of R

and BRTDC, as described in Equations 1 and 2. The

SET

source of the PWM signal can be described as follows:

1. Internally generated 256 step duty cycle programmed

through the SMBus.

2. External signal from PWMI.

3. DPST mode. Internally generated signal with a duty cycle

defined by the product of the external PWMI and SMBus

programmed PWM at the internal setting frequency.

4. DC-to-PWM control.

The default PWM dimming is in DPST mode. In all four

methods, the average LED current of each channel is

controlled by I

and the PWM duty cycle in percent, as

LED

shown in Equation 5:

I

LED ave()ILED

PWM×=

(EQ. 5)

Method 1 (Internal Mode, SMBus controlled PWM)

The average LED current of each channel is controlled by the

internally generated PWM signal, as shown in Equation 6:

I

LED ave()ILED

BRT 255⁄()×=

(EQ. 6)

where BRT is the PWM brightness level programmed in the

Register 0x00. BRT ranges from 0 to 255 in decimal and

defaults to 255 (0xFF). BRT = 0 disconnects all channels

and I

is guaranteed to be <10µA in this state.

LED

To use only the SMBus controlled PWM brightness control,

users need to set Register0x01 to 0x05 with EN/PWMI in

logic high.

The SMBus controlled PWM frequency is adjusted by a

capacitor at the FPWM pin, which will be described in “PWM

Dimming Frequency Adjustment” on page 13.

Method 2 (External Mode)

The average LED current of each channel can also be

controlled by an external PWMI signal, as shown in Equation 7:

)

I

LED ave()ILED

PWMI×=

(EQ. 7)

The PWM dimming frequency can be for example 20kHz but

there are a minimum on and off time requirements such that

the dimming will be in the range of 10% to 99.5%. If the

dimming frequency is below 5kHz, the dimming range can

be 1% to 99.5%. The PWM dimming off time cannot be

longer than 28ms or else the driver will enter shutdown.

To use PWMI only brightness control, users need to set

Register 0x01 to 0x03.

Method 3 (DPST Mode)

The average LED current of each channel can also be

controlled by the product of the SMBus controlled PWM and

the external PWMI signals as:

I

LED ave()ILED

xPWM

=

DPST

(EQ. 8)

Where:

PWM

DPST

BRT 255⁄ PWMI×=

(EQ. 9)

Therefore:

I

LED ave()ILED

BRT 255⁄× PWMI×=

(EQ. 10)

Where BRT is the value held in Register 0x00 (default

setting 0xFF) controlled by SMBus and PWMI is the duty

cycle of the incoming PWMI signal. In this way, the users can

change the PWM current in ratiometric manner to achieve

DPST compliance backlight dimming.

To use the DPST mode, users need to set Register 0x01 to

0x01 with external PWM signal.

12

The DPST mode PWM frequency is adjusted by a capacitor at

the FPWM pin. A C

capacitor , is also needed in the

PWMO

FN6434.2

December 22, 2008

Page 13

ISL97635

PWMO pin for DPST mode operation which will be described

in “PWM Dimming Frequency Adjustment” on page 13.

For example, if the SMBus controlled PWM duty is 80%

dimming at 200Hz (see C

Equation 12) and the

FPWM

external PWMI duty cycle is 60% dimming at 1kHz, the

resultant PWM duty cycle is 48% dimming at 200Hz.

Method 4 (Analog Mode, DC-to-PWM Mode)

By overdriving the PWMO pin with a DC voltage between

0.21V and 1.21V, the average LED current of each channel

is controlled by the internally generated PWM signal, as

shown in Equation 11:

I

LED ave()ILED

BRT 255 1 V PWMO()0.21–()–()×⁄×=

(EQ. 11)

Where BRT is the value held in Register 0x00 (default

setting 0xFF). The PWMO pin is internally driven to 0.21V

via a 40kΩ resistor when the EN/PWMI pin is in logic high,

any overdrive circuit will need to be able to drive up to 40µA

in order to overcome this.

The DC-to-PWM controlled PWM frequency is adjusted by a

capacitor at the FPWM pin, which will be described in “PWM

Dimming Frequency Adjustment” on page 13.

For example, if PWMO is applied with a DC voltage ≥ 1.21V,

the output will be zero. On the other hand, if the PWMO is

applied with a DC voltage ≤ 0.21V, the PWM duty cycle will

be at its maximum. If the PWMO pin is applied with a DC

voltage of 0.31V, the PWM duty cycle will be at 90% at

200Hz if C

FPWM

= 27nF.

PWM Dimming Frequency Adjustment

(Applicable to SMBus controlled PWM, DPST, and

DC-to-PWM Modes)

Except for the external PWM dimming mode where the

frequency follows the external signals, the dimming

frequencies of the other modes are set by an external

capacitor C

C

FPWM

where FPWM is the desirable PWM dimming frequency.

For example, if FPWM = 200Hz, C

The PWM dimming frequency can be for example 20kHz but

there are a minimum on and off time requirements such that

the dimming will be in the range of 10% to 99.5%. If the

dimming frequency is below 5kHz, the dimming range can

be 1% to 99.5%.

In the DPST and DC-to-PWM modes, a C

also needed. An internal 40kΩ and an external C

PWMO pin form a low pass network to filter the PWMI to an

averaged DC. As a result, the time constant of the 40kΩ and

at the FPWM pin, as shown in Equation 12:

FPWM

5.4μ FFPWM⁄=

= 5.4µF/200 = 27nF

FPWM

PWMO

(EQ. 12)

capacitor is

at the

PWMO

C

should be significantly larger than the external PWMI

PWMO

period, t, such that Equation 13 will show:

40kΩ x C

For example, if F

PWMO

>t

is 200Hz and an external PWMI is

PWM

1kHz and above, a 220nF C

can be chosen that allows

PWMO

(EQ. 13)

the external PWMI signal to be filtered as an averaged DC.

Also, the F

frequency in the DPST mode should be

PWM

limited between 100Hz to 2kHz and at least five times

smaller than the external PWMI frequency when DPST

mode is used.

Switching Frequency

An internal clock of 1.2MHz is used for the boost regulator

control of the LX pin in default. There are 2 levels of

switching frequencies: 600kHz or 1.2MHz. Each can be

programmed in the Configuration Register 0x08 bit 2. The

default switching frequency is at 1.2MHz.

5V Low Dropout Regulator

A 5.2V LDO regulator is present at the VDC pin to develop the

necessary low voltage supply, which is used by the chips

internal control circuitry. Because VDC is an LDO pin, it

requires a bypass capacitor of 1µF or more for the regulation.

For applications with an input voltage ≤ 5.5V, VIN and VDC

pins can be connected together . Low input voltage also all ows

only lower output voltage applications only with the maximum

boost ratio defined in “Components Selections” on page24.

The VDC pin can be used as a coarse reference with a few

mA sourcing capability.

In-rush Control and Soft-start

The ISL97635 has separately built-in independent inrush

control and soft-start functions. The inrush control function is

built around the short circuit protection FET, and is only

available in applications, which include this device. At

start-up, the fault protection FET is turned on slowly due to a

30µA pull-down current output from the FAULT pin. This

discharges the fault FET's gate-source capacitance, turning

on the FET in a controlled fashion. As this happens, the

output capacitor is charged slowly through the weakly turned

on FET before it becomes fully enhanced. This results in a

low in-rush current. This current can be further reduced by

adding a capacitor (in the 1nF to 5nF range) across the

gate-source terminals of the FET.

Once the chip detects that the fault protection FET is turned

on hard, it is assumed that in-rush has completed. At this

point, the boost regulator will begin to switch and the current

in the inductor will ramp-up. The current in the boost power

switch is monitored and the switching is terminated in any

cycle where the current exceeds the current limit. The

ISL97635 includes a soft-start feature where this current limit

starts at a low value (375mA). This is stepped up to the final

3A current limit in 7 further steps of 375mA. These steps will

happen over a 1ms total time, such that after 1ms, the final

limit will be reached. This allows the output capacitor to be

13

FN6434.2

December 22, 2008

Page 14

ISL97635

charged to the required value at a low current limit and

prevents high input current for systems that have only a low

to medium output current requirement.

For systems with no master fault protection FET, the inrush

current will flow towards C

determined by the ramp rate of VIN and the values of C

when VIN is applied and it is

OUT

OUT

and L.

Fault Protection and Monitoring

The ISL97635 features extensive protection functions to

cover all the perceivable failure conditions. The failure mode

of a LED can be either open circuit or as a short. The

behavior of an open circuited LED can additionally take the

form of either infinite resistance or, for some LEDs, a zener

diode, which is integrated into the device in parallel with the

now opened LED.

For basic LEDs (which do not have built-in zener diodes), an

open circuit failure of an LED will only result in the loss of

one channel of LEDs without affecting other channels.

Similarly, a short circuit condition on a channel that results in

that channel being turned off does not affect other channels

unless a similar fault is occurring. All LED faults are reported

via the SMBus interface to Register 0x02 (Fault/Status

register). The controller is able to determine which channels

have failed via Register 0x09 (Output Masking register). The

controller can also choose to use Register 0x09 to disable

faulty channels at start-up, resulting in only further faulty

channels being reported by Register 0x02.

Due to the lag in boost response to any load change at its

output, certain transient events (such as LED current steps

or significant step changes in LED duty cycle) can transiently

look like LED fault modes. The ISL97635 uses feedback

from the LEDs to determine when it is in a stable operating

region and prevents apparent faults during these transient

events from allowing any of the LED stacks to fault out. See

Table 1 for more details.

A fault condition that results in an input current that exceeds

the devices electrical limits will result in a shutdown of all

output channels. The control device logic will remain

functional such that the Fault/Status Register can be

interrogated by the system. The root cause of the failure will

be loaded to the volatile Fault/Status Register so that the

host processor can interrogate the data for failure

monitoring.

Short Circuit Protection (SCP)

The short circuit detection circuit monitors the voltage on

each channel and disables faulty channels which are

detected above the programmed short circuit threshold.

There are two selectable levels of short circuit threshold

(3.1V and 8.0V) that can be programmed through the

Configuration Register 0x08 bit 0. When an LED becomes

shorted, the action taken is described in T able 1. The default

short circuit threshold is 8V. The detection of this failure

mode can be disabled via Register 0x08 bit 1 if required.

Open Circuit Protection (OCP)

When one of the LEDs becomes open circuit, it can behave

as either an infinite resistance or a gradually increasing finite

resistance. The ISL97635 monitors the current in each

channel such that any string which reaches at least 75% of

the intended output current is considered “good”. Should the

current subsequently fall below 50% of the target, the

channel will be considered an “open circuit”. Furthermore,

should the boost output of the ISL97635 reach the OVP limit

or should the lower over-temperature threshold be reached,

all channels which are not “good” will immediately be

considered as “open circuit”. Detection of an “open circuit”

channel will result in a time-out before disabling of the

affected channel. This time-out is sped up when the device

is above the lower over-temperature threshold in an attempt

to prevent the upper over-temperature trip point from being

reached.

Some users employ some special types of LEDs that have

zener diode structure in parallel with the LED for ESD

enhancement, thus enabling open circuit operation. When this

type of LED goes open circuit, the effect is as if the LED

forward voltage has increased, but no lighting. Any af fecte d

string will not be disabled, unless the failure results in the

boost OVP limit being reached, allowing all other LEDs in the

string to remain functional. Care should be taken in th is case

that the boost OVP limit and SCP limit are set properly, so as

to make sure that multiple failures on one string do not cause

all other good channels to be faulted out. This is due to the

increased forward voltage of the faulty channel making all

other channel look as if they have LED shorts. See Table1 for

details for responses to fault conditions.

Overvoltage Protection (OVP)

The integrated OVP circuit monitors the output voltage and

keeps the voltage at a safe level. The OVP threshold is set as

Equation 14:

OVP 1.21V R

+()R

UPPERRLOWER

⁄×=

LOWER

(EQ. 14)

These resistors should be large to minimize the power loss.

For example, a 1MΩ R

to 32.2V. Large OVP resistors also allow C

UPPER

and 39kΩ R

LOWER

OUT

sets OVP

discharges

slowly during the PWM Off-time.

Undervoltage Lockout

If the input voltage falls below the UVLO level of 2.45V, the

device will stop switching and be reset. Operation will restart

when the voltage comes back into the operating range.

Input Overcurrent Protection

During normal switching operation, the current through the

internal boost power FET is monitored. If the current

exceeds the current limit, the internal switch will be turned

14

FN6434.2

December 22, 2008

Page 15

ISL97635

off. This monitoring happens on a cycle by cycle basis in a

self protecting way.

Additionally, the ISL97635 monitors the voltage at the LX

and OVP pins. At start-up, a fixed current is injected out of

the LX pins and into the output capacitor. The device will not

start-up unless the voltage at LX exceeds 1.2V . Furthermore,

should the voltage at LX not rise above this threshold during

any subsequent period where the power FET is not switched

on, it will immediately disable the input protection FET. The

OVP pin is also monitored such that if it rises above and

subsequently falls below 20% of the target OVP level, the

input protection FET will also be switched off.

Over-Temperature Protection (OTP)

The ISL97635 includes two over-temperature thresholds. The

lower threshold is set to +130°C. When this threshold is

reached, any channel which is outputting current at a level

significantly below the regulation target will be treated as “open

circuit” and disabled after a time-out period. This time-out

period is also reduced to 800µs when it is above the lower

threshold. The intention of the lower threshold is to allow bad

channels to be isolated and disabled before they cause enough

power dissipation (as a result of other channels having large

voltages across them) to hit the upper temperature threshold.

The upper threshold is set to +150°C. Each time this is

reached, the boost will stop switching and the output current

sources will be switched off. Once the device has cooled to

approximately +100°C, the device will restart with the DC

LED current level reduced to 77% of the initial setting. If the

dissipation problem persists, subsequent hitting of the limit

will cause identical behavior, with the current reduced in

steps to 53% and finally 30%. Hitting of the upper threshold

will also set the thermal fault bit of the Fault/Status register

0x02. Unless disabled via the EN pin, the device stays in an

active state throughout, allows the external processor to

interrogate the fault condition.

For the extensive fault protection conditions, please refer to

Figure 18 and Table 1 for details.

REG

VIN

IMAX

VSET/2

DRIVER

ILIMIT

REGISTER

FAULT

LOGIC

FAULT/

STATUS

O/P

SHORT

FET

DRIVER

THRM

THRM

SHDN

SHDN

SMBUS

CONTROL

LOGIC

OTP

OTP

VSET

PWM/OC0/SC0

LX

LX

OVP

VSC

VSC

+

-

DC CURRENT

REF

T2

TEMP

SENSOR

T1

VOUT

IIN0

VSET

Q0

PWM/OC7/SC7

IIN7

+

-

Q5

15

FIGURE 18. SIMPLIFIED FAULT PROTECTIONS

FN6434.2

December 22, 2008

Page 16

ISL97635

TABLE 1. PROTECTIONS TABLE

CASE FAILURE MODE DETECTION MODE FAILED CHANNEL ACTION GOOD CHANNELS ACTION

1 CH0 Short Circuit Upper

Over-Temperature

Protection limit (OTP)

not triggered and VIIN0

< VSC

2 CH0 Short Circuit Upper OTP triggered but

VIN0 < VSC

3 CH0 Short Circuit Upper OTP not triggered

but VIIN0 > VSC

4 CH0 Open Circuit

with infinite

Upper OTP not triggered

and VIIN0 < VSC

resistance

5 CH0 LED Open

Circuit but has

Upper OTP not triggered

and VIIN0 < VSC

paralleled Zener

6 CH0 LED Open

Circuit but has

Upper OTP triggered but

VIIN0 < VSC

paralleled Zener

7 CH0 LED Open

Circuit but has

paralleled Zener

Upper OTP not triggered

but VIIN0 > VSC

Upper OTP not triggered

but VIINx > VSC

8 Channel-to-Channel

ΔVF too high

9 Channel-to-Channel

ΔVF too high

10 Output LED stack

Lower OTP triggered but

VIINx < VSC

Upper OTP triggered but

VIINx < VSC

VOUT > VOVP Driven with normal current. Any channel that is below 50% of the target

voltage too high

11 VOUT/LX shorted to

GND

LX current and timing

are monitored.

OVP pin monitored for

excursions below 20% of

OVP threshold

CH0 ON and burns power CH1 through CH7 Normal Highest VF of

CH0 goes off until chip cooled and

Same as CH0 Highest VF of

then comes back on with current

reduced to 76%. Further OTP

triggers result in reduction to 53%,

then 30%. Thermal event reported

in Fault/Status Register.

CH0 doubled after 6ms time-out.

CH1 through CH7 Normal Highest VF of

Time-out reduced to 420µs if above

lower OTP limit

V

will ramp to OVP. CH0 will

OUT

CH1 through CH7 Normal Highest VF of

time-out after 6ms (800µs if above

lower OTP limit) and switch off.

V

will drop to normal level.

OUT

CH0 remains ON and has highest

VF, thus V

increases

OUT

CH0 goes off until chip cooled and

CH1 through CH7 ON, Q1

through Q7 burn power

Same as CH0 VF of CH0

then comes back on with current

reduced to 76%. Further OTP

triggers result in reduction to 53%,

then 30%. Thermal event reported

in Fault/Status Register.

CH0 OFF CH1 through CH7 Normal Highest VF of

CH0 remains ON and has highest

VF, thus V

increases.

OUT

increases then CH-X

V

OUT

switches OFF. This is an

unwanted shut off and can be

prevented by setting OVP and/or

VSC at an appropriate level.

Any channel at below 50% of the target current will fault out after

400µs.

Remaining channels driven with normal current.

All channels switched off until chip cooled and then comes back on

with current reduced to 76%. Further OTP triggers result in reduction

to 53%, then 30%. Thermal event reported in Fault/Status Register.

current will time-out after 6ms.

Fault switch disabled and system shutdown until fault goes away,

V

is checked at start-up with a low current from LX to check for

OUT

presence of short before the fault switch is enabled.

VOUT

REGULATED BY

CH1 through CH7

CH1 through CH7

CH1 through CH7

CH1 through CH7

VF of CH0

CH1 through CH7

VF of CH0

Highest VF of

CH0 through CH7

Highest VF of

CH0 through CH7

Highest VF of

CH0 through CH7

16

FN6434.2

December 22, 2008

Page 17

ISL97635

SMBCLK

V

IH

V

IL

SMBDAT

V

IH

V

IL

t

BUF

NOTES:

SMBus Description

S = Start condition

P = Stop condition

A = Acknowledge

A

= Not acknowledge

R/W

= Read enable at high; write enable at low

t

HD:STA

t

LOW

t

HIGH

t

F

t

t

SU:DAT

SU:STA

SSP

t

SU:STO

P

t

R

t

HD:DAT

FIGURE 19. SMBUS INTERFACE

171181811

S SLAVE ADDRESS W

A COMMAND CODE ADATA BYTEAP

Master to Slave

Slave to Master

FIGURE 20. WRITE BYTE PROTOCOL

1711811811811

S SLAVE ADDRESS W

A COMMAND CODE A S SLAVE ADDRESS R A DATA BYTE A P

Master to Slave

Slave to Master

FIGURE 21. READ BYTE PROTOCOL

17

FN6434.2

December 22, 2008

Page 18

ISL97635

Write Byte

The Write Byte protocol is only three bytes long. The first byte

starts with the slave address followed by the “command code,”

which translates to the “register index” being written. The third

byte contains the data byte that must be written into the register

selected by the “command code”. A shaded label is used on

cycles during which the slaved backlight controller “owns” or

“drives” the Data line. All other cycles are driven by the “host

master.”

Read Byte

As shown in the Figure 21, the four byte long Read Byte

protocol starts out with the slave address followed by the

“command code” which translates to the “register index.”

Subsequently, the bus direction turns around with the

re-broadcast of the slave address with bit 0 indicating a read

(“R”) cycle. The fourth byte contains the data being returned

by the backlight controller. That byte value in the dat a byte

reflects the value of the register being queried at the

“command code” index. Note the bus directions, which are

highlighted by the shaded label that is used on cycles during

which the slaved backlight controller “owns” or “drives” the

Data line. All other cycles are driven by the “host maste r.”

Slave Device Address

The slave address contains 7 MSB plus one LSB as R/W bit,

but these 8 bits are usually called Slave Aaddress bytes. As

shown in Figure 22, the high nibble of the Slave Address byte is

0x5 or 0101b to denote the “backlight controller class.” Bit 3 in

the lower nibble of the Slave Address byte is 1. Bit 0 is always

the R/W bit, as specified by the SMBus protocol. Note: In this

document, the device address will always be expressed as a

full 8-bit address instead of the shorter 7-bit address typically

used in other backlight controller specifications to avoid

confusion. Therefore, if the device is in the write mode where bit

0 is 0, the slave address byte is 0x58 or 0101 1000b. If the

device is in the read mode where bit 0 is 1, the slave address

byte is 0x59 or 01011001b.

The backlight controller may sense the state of the pins at POR

or during normal operation—the pins will not change state while

the device is in operation.

MSB

0101100R/W

DEVICE

IDENTIFIER

DEVICE

ADDRESS

FIGURE 22. SLAVE ADDRESS BYTE DEFINITION

LSB

T

I

B

E

T

I

R

W

/

D

A

E

R

SMBus Register Definitions

The backlight controller registers are Byte wide and

accessible via the SMBus Read/Write Byte protocols. Their

bit assignments are provided in the following sections with

reserved bits containing a default value of “0”.

TABLE 2A. REGISTER LISTING

ADDRESS REGISTER BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

0x00 PWM

0x01 Device Control

0x02 Fault/Status

0x03 Identification

0x07 DC Brightness

0x08 Configuration

0x09 Output Channel

Brightness

Control Register

Register

Register

Register

Control Register

Register

Register

BRT7 BRT6 BRT5 BRT4 BRT3 BRT2 BRT1 BRT0 0xFF Read and Write

Reserved Reserved Reserved Reserved Reserved PWM_MD PWM_SEL BL_CTL 0x00 Read and Write

Reserved Reserved 2_CH_SD 1_CH_SD BL_STAT OV_CURR THRM_SHDN FAULT 0x00 Read Only

LED

PANEL

BRTDC7 BRTDC6 BRTDC5 BRTDC4 BRTDC3 BRTDC2 BRTDC1 BRTDC0 0xFF Read and Write

Reserved Reserved Reserved Reserved Reserved FSW VSC1 VSC0 0xXF Read and Write

CH7 CH6 CH5 CH4 CH3 CH2 CH1 CH0 0xFF Read and W rite

MFG3 MFG2 MFG1 MFG0 REV2 REV1 REV0 0xC8 Read Only

18

DEFAULT

VALUE

SMBUS

PROTOCOL

FN6434.2

December 22, 2008

Page 19

ISL97635

TABLE 2B. DATA BIT DESCRIPTIONS

ADDRESS REGISTER DATA BIT DESCRIPTIONS

0x00 PWM Brightness Control Register BRT[7..0] = 256 steps of DPWM duty cycle brightness control

0x01 Device Contr ol Register PWM_MD = PWM mode select bit (1 = absolute brightness, 0 = % change), default = 0

PWM_SEL = Brightness control select bit (1 = control by PWMI, 0 = control by SMBus), default = 0

BL_CTL = BL On/Off (1 = On, 0 = Off), default = 0

PWM_MD PWM_SEL MODE

X 1 PWMI Mode

1 0 SMBus Mode

0 0 SMBus and PWMI mode with DPST

0x02 Fault/Status Register 2_CH_SD = Two LED output channels are shutdown (1 = shutdown, 0 = OK)

1_CH_SD = One LED output channel is shutdown (1 = shutdown, 0 = OK)

BL_STAT = BL status (1 = BL On, 0 = BL Off)

OV_CURR = Input overcurrent (1 = Overcurrent condition, 0 = Current OK)

THRM_SHDN = Thermal Shutdown (1 = Thermal fault, 0 = Thermal OK)

FAULT = Fault occurred (Logic “OR” of all of the fault conditions)

0x03 Identification Register MFG[3..0] = Manufacturer ID (16 vendors available. Intersil is vendor ID 9)

REV[2..0] = Silicon rev (Rev 0 through Rev 7 allowed for silicon spins)

0x07 DC Brightness Control Register BRTDC[7..0] = 256 steps of DC brightness control

0x08 Configuration Register VSC[1..0] = Short circuit thresholds selection

FSW[2] = Switching frequencies selection

VSC1 VSC0 OPERATION

0 X No VSC error detection

1 0 VSC = 3.1V ±15%

1 1 VSC = 8V ±15%

0x09 Output Channel Mask/Fault

Readout Register

CH[5..0] = Output Channel Read and Write. In Write, 1 = Channel Enabled, 0 = Channel Disabled.

In Read, 1 = Channel OK, 0 = Channel Not OK/Channel disabled

PWM Brightness Control Register (0x00)

The Brightness control resolution has 256 steps of PWM duty

cycle adjustment. The bit assignment is shown in Figure 23. All

of the bits in this Brightness Control Register can be read or

write. Step 0 corresponds to the minimum step where the

current is less than 10µA. Steps 1 to 255 represent the linear

steps between 0.39% and 100% duty cycle with approximately

0.39% duty cycle adjustment per step.

• An SMBus Write Byte cycle to Register 0x00 sets the

PWM brightness level only if the backlight controller is in

SMBus mode (see Table 3 Operating Modes selected by

Device Control Register Bits 1 and 2).

• An SMBus Read Byte cycle to Register 0x00 returns the

programmed PWM brightness level, regardless of the

value of PWM_SEL.

f

SW

0f

SW

1f

SW

OPERATION

= 600kHz

= 1.2MHz

• An SMBus setting of 0xFF for Register 0x00 sets the

backlight controller to the maximum brightness.

• An SMBus setting of 0x00 for Register 0x00 sets the

backlight controller to the minimum brightness output in

which the LED current is guaranteed to be less than 10µA.

• Default value for Register 0x00 is 0xFF.

Device Control Register (0x01)

This register has 2 bits that control the operating mode of the

backlight controller and a single bit that controls the BL

ON/OFF state. The remaining bits are reserved. The bit

assignment is shown in Figure 24. All other bits in the Device

Control Register will read as low unless otherwise written.

Bits 7 and 6 are not implemented and will always read low.

19

FN6434.2

December 22, 2008

Page 20

ISL97635

TABLE 3. OPERATING MODES SELECTED BY DEVICE

CONTROL REGISTER BITS 1 AND 2

PWM_MD PWM_SEL MODE

X 1 PWMI Mode

1 0 SMBus Mode

0 0 SMBus and PWMI Mode with DPST

The PWM_SEL bit determines whether the SMBus or PWMI

input should drive the output br ig h tness in terms of PWM

dimming. When PWM_SEL bit is 1, the PWMI drives the

output brightness regardless of what the PWM_MD is.

When the PWM_SEL bit is 0, the PWM_MD bit selects the

manner in which the PWM dimming is to be interpreted;

when this bit is 1, the PWM dimming is based on the SMBus

brightness setting. When this bit is 0, the PWM dimming

reflects a percentage change in the current brightness

programmed in the SMBus Register 0x00, i.e. DPST

(Display Power Saving Technology) mode, as shown in

Equation 15:

DPST Brightness Cbt PWMI×=

(EQ. 15)

Where:

Cbt = Current brightness setting from SMBus Register 0x00

without influence from the PWMI

PWMI = is the percent duty cycle of the PWMI

For example, the Cbt = 50% duty cycle programmed in the

SMBus Register 0x00 and the PWM frequency is tuned to be

200Hz with an appropriate capacitor at the FPWM pin. On the

other hand, PWMI is fed with a 1kHz 30% high PWM signal.

When PWM_SEL = 0 and PWM_MD = 0, the device is in DPST

operation where DPST brightness = 15% PWM dimming at

200Hz.

• All reserved bits return a “0” when read.

• All reserved bits have no functional effect when written.

• All defined control bits return their current, latched value

when read.

• A value of 1 written to BL_CTL turns on the BL in 4ms or less

after the write cycle completes. The BL is deemed to be on

when Bit 3 BL_ST AT of Register 0x02 is 1 and Register

0x09 is not 0. See Figures 23 and 24.

• A value of 0 written to BL_CTL immediately turns off the BL.

The BL is deemed to be off when Bit 3 BL_ST AT of Register

0x02 is 0 and Register 0x09 is 0. See Figures 23 and 24.

• **Note that the behavior of Register 0x00 (Brightness

Control Register) is affected by certain combinations of the

control bits, as shown in Table 3 “Operating Modes

Selected by Device Control Register Bits 1 and 2.”

REGISTER 0x00 PWM BRIGHTNESS CONTROL REGISTER

BRT7BRT6BRT5BRT4BRT3BRT2BRT1BRT0

Bit 7 (R/W) Bit 6 (R/W) Bit 5 (R/W) Bit 4 (R/W) Bit 3 (R/W) Bit 2 (R/W) Bit 1 (R/W) Bit 0 (R/W)

BIT ASSIGNMENT BIT FIELD DEFINITIONS

BRT[7..0]

REGISTER 0x01 DEVICE CONTROL REGISTER

RESERVED RESERVED RESERVED RESERVED RESERVED PWM_MD PWM_SEL BL_CTL

Bit 7 (R/W) Bit 6 (R/W) Bit 5 (R/W) Bit 4 (R/W) Bit 3 (R/W) Bit 2 (R/W) Bit 1 (R/W) Bit 0 (R/W)

BIT ASSIGNMENT BIT FIELD DEFINITIONS

PWM_MD = PWM mode select bit (1 = absolute brightness,

PWM_SEL = Brightness control select bit (1 = control by

BL_CTL = BL On/Off (1 = On, 0 = Off) default = 0

= 256 steps of PWM brightness levels

FIGURE 23. DESCRIPTIONS OF BRIGHTNESS CONTROL REGISTER

0 = % change) default = 0

PWMI, 0 = control by SMBus) default = 0

FIGURE 24. DESCRIPTIONS OF DEVICE CONTROL REGISTER

20

FN6434.2

December 22, 2008

Page 21

ISL97635

• When an SMBus mode is selected, Register 0x00 reflects

the last value written to it. But, when any non-SMBus

mode is selected, Register 0x00 reflects the current

brightness value based on the current mode of operation,

with the exception of SMBus mode with DPST, where

PWM_MD = 0 and PWM_SEL = 0.

• When SMBus mode with DPST is selected, Register 0x00

reflects the last value written to it from SMBus.

• When a write to Register 0x01 (Device Control Register)

causes the backlight controller to transition to an SMBus

mode, the brightness of the BL does not change. On the

other hand, when a write to Register 0x01causes the

backlight controller to transition to a non-SMBus mode,

the brightness of the BL changes as appropriate for the

new mode.

• The default value for Register 0x01 is 0x00.

Fault/Status Register (0x02)

This register has 6 status bits that allow monitoring of the

backlight controller’s operating state. Bit 0 is a logical “OR” of all

fault codes to simplify error detection. Not all of the bits in this

register are fault related (Bit 3 is a simple BL status indicator).

The remaining bits are reserved and return a “0” when read and

ignore the bit value when written. All of the bits in this register

are read-only, with the exception of bit 0, which can be cleared

by writing to it.

• A Read Byte cycle to Register 0x02 indicates the current

BL on/off status in BL_STAT (1 if the BL is on, 0 if the BL is

off).

• A Read Byte cycles to Register 0x2 also returns FAULT as

the logical OR of THRM_SHDN, OV_CURR, 2_CH_SD,

and 1_CH_SD should these events occur.

• 1_CH_SD returns a 1 if one or more channels have

faulted out.

• 2_CH_SD returns a 1 if two or more channels have faulted

out.

• When FAULT is set to 1, it will remain at 1 even if the

signal which sets it goes away. FAULT will be cleared

when the BL_CTL bit of the Device Control Register is

toggled or when written low. At that time, if the fault

condition is still present or reoccurs, FAULT will be set to 1

again. BL_STAT will not cause FAULT to be set.

• The controller will not indicate a fault if the VBL+ goes

away, whether or not the LEDs were on at the time of the

power loss. This can occur if there is some hang condition

that causes the user to force the system off by holding the

power button down for 4s.

• The default value for Register 0x02 is 0x00.

Identification Register (0x03)

The ID register contains 3-bit fields to denote the LED driver

(always set to 1), manufacturer and the silicon revision of the

controller IC. The bit field widths allow up to 16 vendors with up

to 8 silicon revisions each. In order to keep the number of

silicon revisions low, the revision field will not be updated unless

the part will make it out to the user’s factory. Thus, if during the

engineering development process, 3 silicon spins were

needed, the next available revision ID would be used for all 3

spins until that same ID made it to the factory. Except Bit 7,

which has to be 1, all of the bits in this register are read-only.

• Vendor ID 9 represents Intersil Corporation.

• The default value for Register 0x03 is 0xC8.

The initial value of REV shall be 0. Subsequent values of

REV will increment by 1.

• A fault will not be reported in the event that the BL is

commanded on and then immediately off by the system.

21

FN6434.2

December 22, 2008

Page 22

ISL97635

REGISTER 0x02 FAULT/STATUS REGISTER

RESERVED RESERVED 2_CH_SD 1_CH_SD BL_STAT OV_CURR THRM_SHDN FAULT

Bit 7 (R) Bit 6 (R) Bit 5 (R) Bit 4 (R) Bit 3 (R) Bit 2 (R) Bit 1 (R) Bit 0 (R)

BIT BIT ASSIGNMENT BIT FIELD DEFINITIONS

Bit 5 2_CH_SD = Two LED output channels are shutdown (1 = shutdown, 0 = OK)

Bit 4 1_CH_SD = One LED output channel is shutdown (1 = shutdown, 0 = OK)

Bit 3 BL_STAT = BL Status (1 = BL On, 0 = BL Off)

Bit 2 OV_CURR = Input Overcurrent (1 = Overcurrent condition, 0 = Current OK)

Bit 1 THRM_SHDN = Thermal Shutdown (1 = Thermal Fault, 0 = Thermal OK)

Bit 0 FAULT = Fault occurred (Logic “OR” of all of the fault conditions)

FIGURE 25. DESCRIPTIONS OF FAULT/STATUS REGISTER

REGISTER 0x03 ID REGISTER

LED PANEL MFG3 MFG2 MFG1 MFG0 REV2 REV1 REV0

Bit 7 = 1 Bit 6 (R) Bit 5 (R) Bit 4 (R) Bit 3 (R) Bit 2 (R) Bit 1 ( R) Bit 0 (R)

BIT ASSIGNMENT BIT FIELD DEFINITIONS

MFG[3..0]

REV[2..0] = Silicon rev (Rev 0 through Rev 7 allowed for

= Manufacturer ID. See “Identification Register

(0x03)” on page 21.

data 0 to 8 in decimal correspond to other vendors

data 9 in decimal represents Intersil ID

data 10 to 14 in decimal are reserved

data 15 in decimal Manufacturer ID is not

implemented

silicon spins)

FIGURE 26. DESCRIPTIONS OF ID REGISTER

22

FN6434.2

December 22, 2008

Page 23

ISL97635

REGISTER 0x07 DC BRIGHTNESS CONTROL REGISTER

BRTDC7 BRTDC6 BRTDC5 BRTDC4 BRTDC3 BRTDC2 BRTDC1 BRTDC0

Bit 7 (R/W) Bit 6 (R/W) Bit 5 (R/W) Bit 4 (R/W) Bit 3 (R/W) Bit 2 (R/W) Bit 1 (R/W) Bit 0 (R/W)

BIT ASSIGNMENT BIT FIELD DEFINITIONS

BRTDC[7..0]

= 256 steps of DC brightness levels

FIGURE 27. DESCRIPTIONS OF DC BRIGHTNESS CONTROL REGISTER

DC Brightness Control Register (0x07)

The DC Brightness Control Register 0x07 allows users to

have additional dimming flexibility by:

1. Effectively achieving 16 bits of dimming control when DC

dimming is combined with PWM dimming or,

2. Achieving visual or audio noise free 8-bit DC dimming

over potentially noisy PWM dimming.

The bit assignment is shown in Figure 27. All of the bits in

this Register can be read or write. Steps 0 to 255 represent

the linear steps of current adjustment in DC on the fly. It can

also be considered as the peak current factory calibration

feature to account for various LED production batch

variations, but external EEPROM settings storing and

restoring are required.

• An SMBus Write Byte cycle to Register 0x07 sets the

brightness level in DC only.

• An SMBus Read Byte cycle to Register 0x07 returns the

current DC brightness level.

• Default value for Register 0x07 is 0xFF.

users to set the boost conversion switching frequency

between 1.2MHz and 600kHz.

The bit assignment is shown in Figure 28. The default value

for Register 0x08 is 0xFF

Output Channel Mask/Fault Readout Register

(0x09)

This register can be read or write; the bit position

corresponds to the channel. For example, bit 0 corresponds

to Ch0 and bit 6 corresponds to Ch6 and so on. Writing data

to this register, it enables the channels of interest. When

reading data from this register, any disabled channel and

any faulted out channel will read as 0. This allows the user to

determine which channel is faulty and optionally not enabling

it in order to allow the rest of the system to continue to

function. Additionally, a faulted out channel can be disabled

and re-enabled in order to allow a retry for any faulty channel

without having to power-down the other channels.

The bit assignment is shown in Figure 29. The default for

Register 0x09 is 0xFF.

Configuration Register (0x08)

The Configuration Register allows users to set 2 levels of

channel Short-Circuit thresholds or disable it. It also allows

REGISTER 0x08 CONFIGURATION REGISTER

RESERVED RESERVED RESERVED RESERVED RESERVED FSW VSC1 VSC0

Bit 7 (R/W) Bit 6 (R/W) Bit 5 (R/W) Bit 4 (R/W) Bit 3 (R/W) Bit 2 (R/W) Bit 1 (R/W) Bit 0 (R/W)

BIT ASSIGNMENT BIT FIELD DEFINITIONS

VSC[1..0]

FSW[2] 2 levels of Switching Frequencies (1 = 1,200kHz, 0 = 600kHz)

2 levels of Short-Circuit Thresholds (1 = 8V , 0 = 3.1V, accuracy ±15%)

FIGURE 28. DESCRIPTIONS OF CONFIGURATION REGISTER

23

FN6434.2

December 22, 2008

Page 24

ISL97635

REGISTER 0x09 OUTPUT CHANNEL REGISTER

CH7 CH6 CH5 CH4 CH3 CH2 CH1 CH0

Bit 7 (R/W) Bit 6 (R/W) Bit 5 (R/W) Bit 4 (R/W) Bit 3 (R/W) Bit 2 (R/W) Bit 1 (R/W) Bit 0 (R/W)

BIT ASSIGNMENT BIT FIELD DEFINITIONS

CH[7..0] CH7 = Channel 7, CH6 = Channel 6 and so on

FIGURE 29. OUTPUT CHANNEL REGISTER

Components Selections

According to the inductor Voltage-Second Balance principle,

the change of inductor current during the switching regulator

On-time is equal to the change of inductor current during the

switching regulator Off-time. Since the voltage across an

inductor is as shown in Equation 16:

VLL Δ ILΔt⁄×=

and ΔI

@ On = ΔIL @ Off, therefore:

L

0) L⁄ DtS× VOVDVI––()=× L1( D) tS×–×⁄–

V(

I

where D is the switching duty cycle defined by the turn-on

time over the switching period. VD is Schottky diode forward

voltage that can be neglected for approximation.

Rearranging the terms without accounting for V

boost ratio and duty cycle respectively as Equations 18

and 19:

OVI

11D–()⁄=⁄

( VI) VO⁄–=

O

V

DV

Input Capacitor

Switching regulators require input capacitors to deliver peak

charging current and to reduce the impedance of the input

supply. This reduces interaction between the regulator and

input supply, thereby improving system stability. The high

switching frequency of the loop causes almost all ripple

current to flow in the input capacitor, which must be rated

accordingly.

A capacitor with low internal series resistance should be

chosen to minimize heating effects and improve system

efficiency, such as X5R or X7R ceramic capacitors, which

offer small size and a lower value of temperature and voltage

coefficient compared to other ceramic capacitors.

In Boost mode, input current flows continuously into the

inductor; AC ripple component is only proportional to the rate

of the inductor charging, thus, smaller value input capacitors

may be used. It is recommended that an input capacitor of at

least 10µF be used. Ensure the voltage rating of the input

capacitor is suitable to handle the full supply range.

(EQ. 16)

(EQ. 17)

gives the

D

(EQ. 18)

(EQ. 19)

Inductor

The selection of the inductor should be based on its

maximum current (I

) characteristics, power dissipation

SAT

(DCR), EMI susceptibility (shielded vs unshielded), and size.

Inductor type and value influence many key parameters,

including ripple current, current limit, efficiency, transient

performance and stability.

The inductor’s maximum current capability must be

adequate enough to handle the peak current at the worst

case condition. If an inductor core is chosen with too low a

current rating, saturation in the core will cause the effective

inductor value to fall, leading to an increase in peak to

average current level, poor efficiency and overheating in the

core. The series resistance, DCR, within the inductor causes

conduction loss and heat dissipation. A shielded inductor is

usually more suitable for EMI susceptible applications, such

as LED backlighting.

The peak current can be derived from the voltage across the

inductor during the Off-period, as expressed in Equation 20:

IL

peak

VO( IO) 85%( VI) 12VIVO( VI) L( VOfSW)××⁄–×[⁄+×⁄×=

(EQ. 20)

The choice of 85% is just an average term for the efficiency

approximation. The first term is the average current, which is

inversely proportional to the input voltage. The second term

is the inductor current change, which is inversely

proportional to L and f

. As a result, for a given switching

SW

frequency and minimum input voltage on which the system

operates, the inductor I

must be chosen carefully. At a

SAT

given inductor size, usually the larger the inductance, the

higher the series resistance because of the extra winding of

the coil. Thus, the higher the inductance, the lower the peak

current capability. The ISL97635 current limit should also

have to be taken into account.

Output Capacitors

The output capacitor acts to smooth the output voltage and

supplies load current directly during the conduction phase of

the power switch. Output ripple voltage consists of the

discharge of the output capacitor for I

and the voltage drop due to flowing through the ESR of the

during FET On

LPEAK

24

FN6434.2

December 22, 2008

Page 25

ISL97635

output capacitor. The ripple voltage can be shown as

Equation 21:

ΔV

COI(OCO

DfS) I(OESR×()+⁄×⁄=

(EQ. 21)

The conservation of charge principle also brings up the fact

that during the boost switch Off-period, the output capacitor

is charged with the inductor ripple current minus a relatively

small output current in boost topology. As a result, the user

needs to select an output capacitor with low ESD and

enough input ripple current capability.

Output Ripple

ΔVCo, can be reduced by increasing Co or fSW, or using

small ESR capacitors. In general, ceramic capacitors are the

best choice for output capacitors in small to medium sized

LCD backlight applications due to their cost, form factor, and

low ESR.

A larger output capacitor will also ease the driver response

during PWM dimming Off-period due to the longer sample

and hold effect of the output drooping. The driver does not

need to boost harder in the next On-period that minimizes

transient current. The output capacitor is also needed for

compensation, and, in general 2x4.7µF/50V ceramic

capacitors are suitable for notebook display backlight

applications.

Schottky Diode

A high speed rectifier diode is necessary to prevent

excessive voltage overshoot, especially in the boost

configuration. Low forward voltage and reverse leakage

current will minimize losses, making Schottky diodes the

preferred choice. Although the Schottky diode turns on only

during the boost switch Off-period, it carries the same peak

current as the inductor, and therefore, a suitable current

rated Schottky diode must be used.

Applications