®

www.BDTIC.com/Intersil

ISL96017

Data Sheet April 17, 2006

128-Tap DCP, 16kbit EEPROM, and I2C

Serial Interface

This device integrates a 128-tap digitally controlled

potentiometer, 16kbit of EEPROM, and a 2-wire I

interface. The device is powered by a single 3.3V supply.

The potentiometer is available with total resistance of either

10kΩ or 50kΩ.

The memory is organized in 128 pages of 16 bytes each, to

reduce total programming time. All programming signals are

generated on-chip.

The potentiometer is implemented with a combination of

CMOS switches and resistor elements. The position of the

wiper can be stored in non-volatile memory an d th en be

recalled upon a subsequent power-up. The three terminals

of the potentiometer are available for use as either a variable

resistor or a resistor divider.

2

C serial

Pinout

ISL96017

(8 LD TDFN)

TOP VIEW

FN8243.1

Features

• Integrated Digitally Controlled Potentiometer

- 128-Tap Positions

-10kΩ, 50kΩ Total Resistance

- Monotonic Over Temperature

- Non-Volatile Wiper Position Storage

- 0 to VDD Terminal Voltage

2

C Serial Interface

•I

• 16kbit EEPROM

- 50 Years Retention @ ≤ 55°C

- 1,000,000 Cycles Endurance

• Single 3.3

• 3mm x 3mm Thin DFN Package – 0.8mm Max Thickness,

0.65mm Pitch

• Pb-Free Plus Anneal Available (RoHS Compliant)

±0.3V Supply

RH

RW

RL

VDD

1

2

3

4

8

WP

SCL

7

SDA

6

GND

5

Ordering Information

TEMP.

PART NUMBER PART MARKING R

ISL96017WIRT8Z* (Note) 96017WIZ 10 -40 to 85 8 Ld 3x3 TDFN (Pb-free) L8.3x3A

ISL96017UIRT8Z* (Note) 96017UIZ 50 -40 to 85 8 Ld 3x3 TDFN (Pb-free) L8.3x3A

*Add "-TK" suffix for 1000 units tape and reel.

NOTE: Intersil Pb-free plus anneal products employ special Pb-free material sets; molding compounds/die attach materials and 100% matte tin plate

termination finish, which are RoHS compliant and compatible with both SnPb and Pb-free soldering operations. Intersil Pb-free products are MSL

classified at Pb-free peak reflow temperatures that meet or exceed the Pb-free requirements of IPC/JEDEC J STD-020.

TOTAL

(kΩ)

RANGE (°C) PACKAGE

PKG.

DWG. #

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

All other trademarks mentioned are the property of their respective owners.

Copyright Intersil Americas Inc. 2005. All Rights Reserved

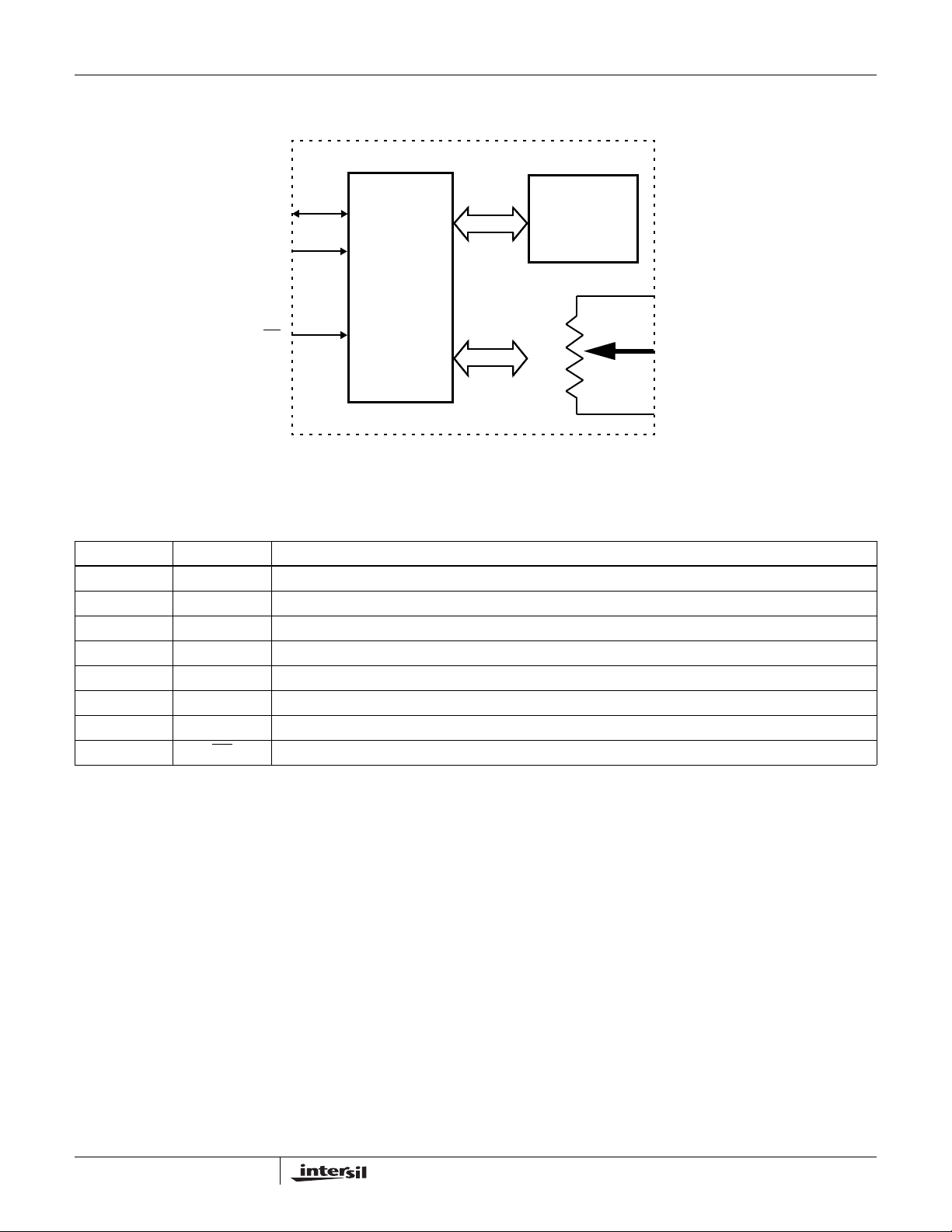

Block Diagram

www.BDTIC.com/Intersil

ISL96017

SDA

SCL

WP

POWER-UP,

INTERFACE,

AND

CONTROL

LOGIC

Pin Descriptions

PIN SYMBOL DESCRIPTION

1 RH “High” terminal of the DCP

2 RW “Wiper” terminal of the DCP

3 RL “Low” terminal of the DCP

4 VDD Power supply

5 GND Ground

6 SDA Open drain serial interface data input/output

7 SCL Open drain serial interface clock input

8WP

Hardware write protection pin. Active low. Prevents any “Write” operation to the device.

16kbit

EEPROM

RH

RW

RL

2

FN8243.1

April 17, 2006

ISL96017

www.BDTIC.com/Intersil

Absolute Maximum Ratings Thermal Information

Storage Temperature: . . . . . . . . . . . . . . . . . . . . . . . .-65°C to 150°C

Note: All Voltages with Respect to GND

Voltage at SCL, SDA, WP

Voltage at RH, RW, RL: . . . . . . . . . . . . . . . . . . . . . . . GND to VDD

VDD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to 4V

Lead Temperature (Soldering, 10s): . . . . . . . . . . . . . . . . . . . .300°C

Wiper Current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±6mA

ESD (MIL-STD-883B, Method 3014). . . . . . . . . . . . . . . . . . .>2000V

ESD (Machine Model) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .>150V

CAUTION: Stresses above those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress rating only; the functional

operation of the device, at these or any other conditions above those listed in the op erational se ctions of th is specification, is not implied. Exposure to abso lute maximum

rating conditions for extended periods may affect device reliability.

Note:

θ

is measured in free air with the component mounted on a high effective thermal conductivity test board with “direct attach” features. See

1.

JA

Tech Brief TB379 for details.

: . . . . . . . . . . . . . . . . . . . . .-0.3V to 4V

Thermal Resistance (Typical, Note 1)

8 Ld TDFN Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90(°C/W)

Moisture Sensitivity (see Technical Brief TB363). . . . . . . . . .Level 2

Maximum Junction Temperature (Plastic Package). . . . . . . . . .150°C

Recommended Operating Conditions

Ambient Temperature . . . . . . . . . . . . . . . . . . . . . . . . .-40°C to 85°C

VDD Voltage for DCP Operation . . . . . . . . . . . . . . . . . . 3.0V to 3.6V

Wiper Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -3mA to 3mA

Power Rating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5mW

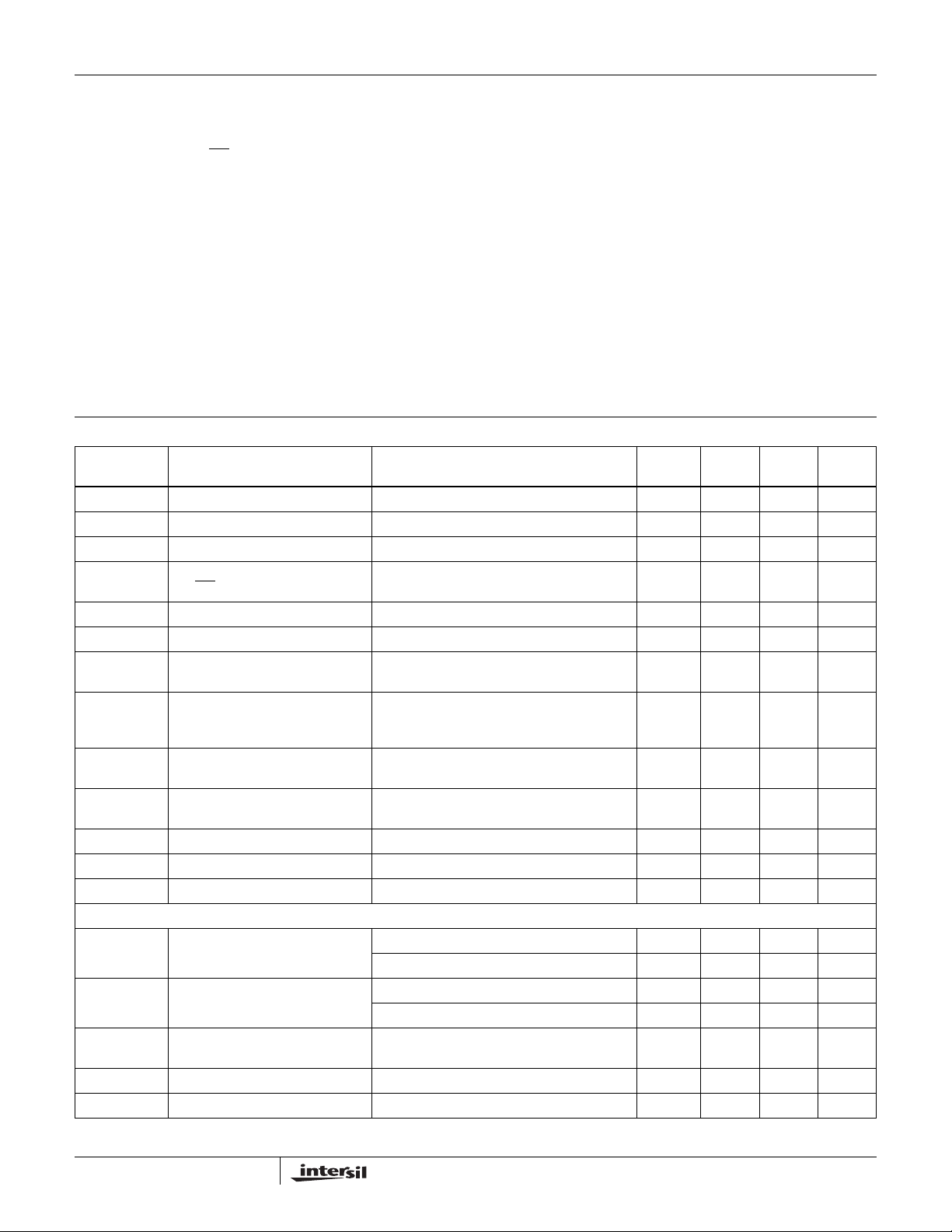

Electrical Specifications Over recommended operating conditions unless otherwise stated. All voltages with respect to GND.

TYP

SYMBOL PARAMETER TEST CONDITIONS MIN

IccdSby Standby Current at VDD Serial interface in standby 10 µA

IccdRd Read Current at VDD Reading with 400kHz at SCL 1 mA

IccdWr Write Current at VDD Writing to EEPROM 5 mA

I

LkgDig

I

LkgDCP

VDDRamp VDD Power-Up Ramp Rate 0.2 V/ms

t

DCP

(Note 13)

t

D

CH/CW/CL

(Note 13)

R

Total

R

Wiper

DCP IN VOLTAGE DIVIDER MODE (0V at RL, VCC at RH; measured at RW unloaded)

FSerror

(Note 2, 3)

ZSerror

(Note 2, 4)

TC

(Note 7, 13)

DNL (Note 2, 5) Differential Non-Linearity Monotonic over all tap positions -0.75 0.75 LSB

INL (Note 2, 6) Integral Non-Linearity -1 1 LSB

Leakage Current at Pins SDA, SCL,

and WP

Leakage Current at RH, RW, RL Pin voltage from GND to VDD -1 1 µA

DCP Wiper Response Time SCL falling edge of last bit of DCP Data Byte to

Power-Up Delay VDD above 2.6V, to DCP Initial Value Register

RH, RW, RL Pin Capacitance 10 pF

Total Resistance W and U versions, respectively. TA =25°C.

R

Tolerance TA = 25°C. Measured between RH and RL pins. -20 20 %

Total

Wiper Resistance VDD = 3.3V @ 25°C. Wiper current = VDD/R

DCP Resolution 7Bits

Full-Scale Error U option -2 -1 0 LSB

Zero-Scale Error U option 0 1 2 LSB

Ratiometric Temperature

V

Coefficient

Pin voltage from GND to VDD -10 10 µA

wiper change

2

recall completed, and I

state

Measured between R

W option -5 -1 0 LSB

W option 0 1 5 LSB

DCP Register between 10 hex and 6F hex ±4 ppm/°C

C Interface in standby

and RL pins.

H

Total

(Note 1) MAX UNIT

1.5 µs

3ms

10, 50 kΩ

100 300 Ω

JA

θ

3

FN8243.1

April 17, 2006

ISL96017

www.BDTIC.com/Intersil

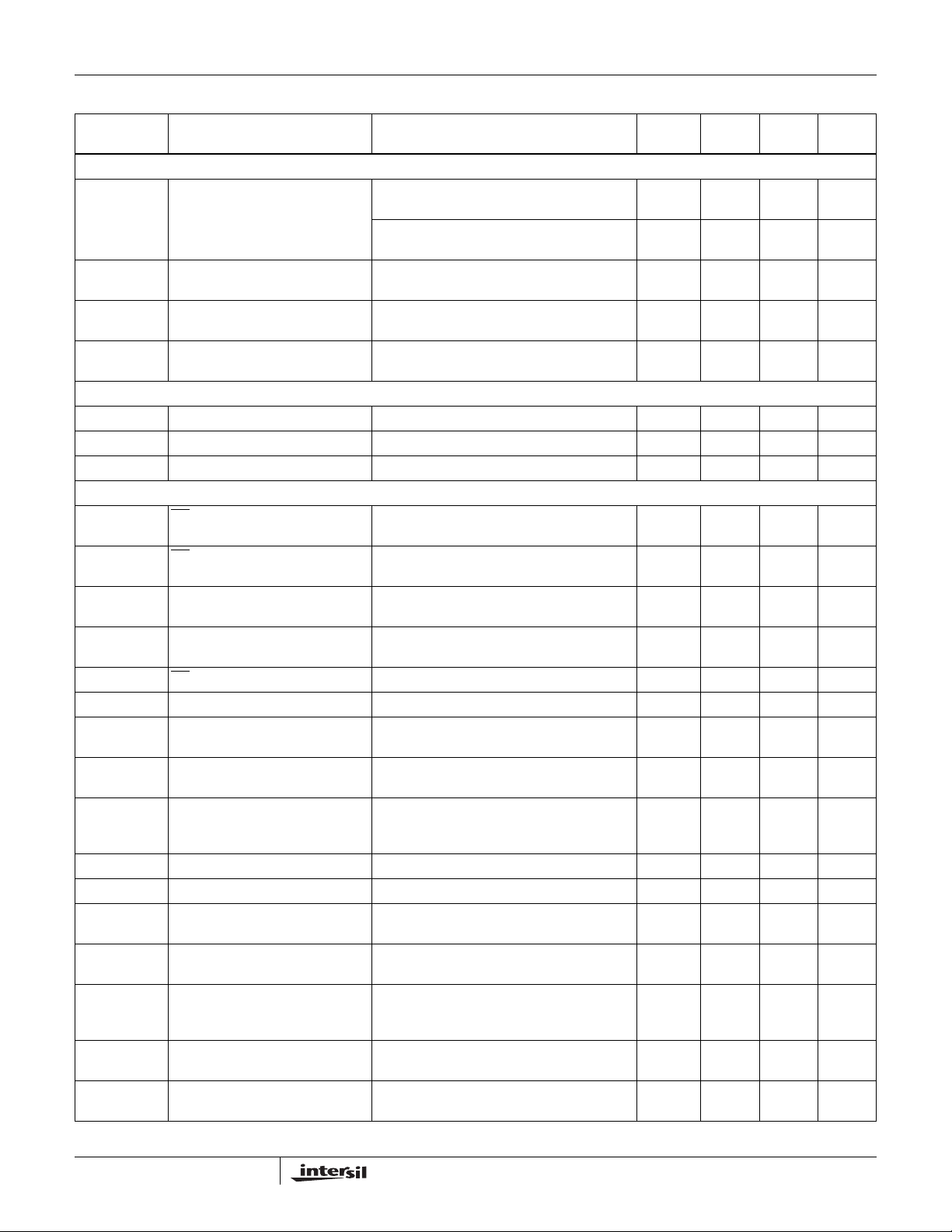

Electrical Specifications Over recommended operating conditions unless otherwise stated. All voltages with respect to GND. (Continued)

SYMBOL PARAMETER TEST CONDITIONS MIN

DCP IN RESISTOR MODE (Measurements between RH and RW with RL not connected)

(Note 8) Resistance Offset. U version - DCP Register set to 7F hex.

R

127

TC

(Note 11,13)

RDNL

(Note 8,9)

RINL

(Note 8,10)

EEPROM SPECS

(Note 12) Non-Volatile Write Cycle Time 6 12 ms

t

WC

SERIAL INTERFACE SPECS

V

IL

V

IH

Hysteresis SDA and SCL Input Buffer

V

OL

Cpin WP

f

SCL

t

IN

t

AA

t

BUF

t

LOW

t

HIGH

t

SU:STA

t

HD:STA

t

SU:DAT

t

HD:DAT

t

SU:STO

Resistance Temperature Coefficient ±100 ppm/°C

R

Resistance Differential NonLinearity

Resistance Integral Non-Linearity -1 1 MI

EEPROM Endurance 1,000,000 Cycles

EEPROM Retention At 55°C 50 Years

WP, SDA, and SCL Input Buffer

LOW Voltage

WP, SDA and SCL Input Buffer

HIGH Voltage

Hysteresis

SDA Output Buffer LOW Voltage,

Sinking 4mA

, SDA, and SCL Pin Capacitance 10 pF

SCL Frequency 400 kHz

Pulse Width Suppression Time at

SDA and SCL Inputs.

SCL Falling Edge to SDA Output

Data Valid

Time the Bus Must be Free Before

the Start of a New Transmission

Clock LOW Time Measured at the 30% of VDD crossing 1300 ns

Clock HIGH Time Measured at the 70% of VDD crossing 600 ns

START Condition Setup Time SCL rising edge to SDA falling edge. Both

STAR T Condition Hold Time From SDA falling edge crossing 30% of VDD to

Input Data Setup Time From SDA exiting the 30% to 70% of VDD

Input Data Hold Time From SCL rising edge crossing 70% of VDD to

STOP Condition Setup Time From SCL rising edge crossing 70% of VCC, to

Measured between R

W version - DCP Register set to 7F hex.

Measured between R

Any pulse narrower than the max spec is

suppressed

SCL falling edge crossing 30% of VDD, until

SDA exits the 30% to 70% of VDD window

SDA crossing 70% of VCC during a STOP

condition, to SDA crossing 70% of VDD during

the following START condition

crossing 70% of VDD

SCL falling edge crossing 70% of VDD

window, to SCL rising edge crossing 30% of

VDD

SDA entering the 30% to 70% of VDD window

SDA rising edge crossing 30% of VDD

and RW pins.

H

and RW pins.

H

00.52MI

-0.75 0.75 MI

-0.3 0.3*

0.7*

VDD

0.05*

VDD

00.4V

1300 ns

600 ns

600 ns

100 ns

0ns

600 ns

TYP

(Note 1) MAX UNIT

15MI

(Note 1)

(Note 1)

V

VDD

VDD

+0.3

50 ns

900 ns

V

V

4

FN8243.1

April 17, 2006

ISL96017

www.BDTIC.com/Intersil

Electrical Specifications Over recommended operating conditions unless otherwise stated. All voltages with respect to GND. (Continued)

SYMBOL PARAMETER TEST CONDITIONS MIN

t

HD:STO

STOP Condition Hold Time From SDA rising edge to SCL falling edge. Both

600 ns

crossing 70% of VDD

t

DH

Output Data Hold Time From SCL falling edge crossing 30% of VDD,

until SDA enters the 30% to 70% of VDD

0ns

window

t

R

t

F

SDA and SCL Rise Time From 30% to 70% of VDD 20+

0.1*Cb

SDA and SCL Fall Time From 70% to 30% of VDD 20+

0.1*Cb

Cb Capacitive Loading of SDA or SCL Total on-chip and off-chip 10 400 pF

Rpu SDA and SCL Bus Pull-Up Resistor

Off-Chip

Maximum is determined by t

For Cb = 400pF, max is about 2~2.5kΩ

and t

R

F

1kΩ

For Cb = 40pF, max is about 15~20kΩ

t

SU:WP

t

HD:WP

WP Setup Time Before START condition 600 ns

WP Hold Time After STOP condition 600 ns

NOTES:

2. Typical values are for T

3. LSB = (V(RW)

127

4. FSerror = (V(RW)

5. ZSerror = V(RW)

6. DNL = [(V(RW)

7. INL = [V(RW)

8. for i = 16 to 111, and T = -40°C to 85°C

TC

V

9. MI = (R

0

i

– i * LSB – V(RW)0]/LSB, for I = 1 to 127.

i

Max V RW()i()Min V RW()i()–[]

-----------------------------------------------------------------------------------------------

Max V RW()i()Min V RW()i()+()2⁄

– R

)/127. MI is minimum increment. R0 and R

127

= 25°C and VDD = 3.3V.

A

– V(RW)0)/127. V(RW)

– VDD)/LSB

127

/LSB

0

– V(RW)

)/LSB] – 1, for i from 1 to 127. i is the DCP Register setting.

i-1

and V(RW)0 are the voltage at pin RW for the DCP Register set to 7F hex and 00 hex respectively .

127

6

10

-----------------

×=

125° C

are the resistances between RH and RW with the DCP Register set to 00 hex and

127

7F hex, respectively.

– R

10. RDNL = (R

11. RINL = [R

12. ; for i = 1 to 111, and T = -40°C to 85°C

TC

13. t

WC

valid STOP condition at the end of a Write sequence of a I

i

Max Ri()Min Ri()–[]

--------------------------------------------------------------- -

R

Max Ri()Min Ri()+[]2⁄

is the minimum cycle time to be allowed for any non-volatile Write by the user, unless Acknowledge Polling is used. It is the time from a

)/MI – 1, for i from 1 to 111. i is the DCP Register setting.

i

i-1

– (MI * i) – R

]/MI, for i from 1 to 111.

127

6

110

×

-------------------

×=

125° C

2

C serial interface Write operation, to the end of the self-timed internal non-volatile

write cycle.

14. Parameter is not 100% tested.

TYP

(Note 1) MAX UNIT

250 ns

250 ns

I2C Timing Diagram

SCL

t

(INPUT TIMING)

(OUTPUT TIMING)

SDA

SDA

SU:STA

5

t

HD:STA

t

F

t

SU:DAT

t

HIGH

t

LOW

t

HD:DAT

t

R

t

SU:STO

t

t

DH

AA

t

BUF

FN8243.1

April 17, 2006

Typical Performance Curves

www.BDTIC.com/Intersil

ISL96017

140

WIPER RESISTANCE (Ω)

120

100

T = 25°C

80

60

40

20

0

0

20 40 60 80 100 120 140

TAP POSITION (DECIMAL)

VDD = 3.6V

VDD = 3.0V

FIGURE 1. WIPER RESISTANCE vs T AP POSITION

FOR 10kΩ (W)

0.2

0.15

0.05

INL (LSB)

-0.05

-0.15

T = 25°C

0.1

0

-0.1

-0.2

0 20 40 60 80 100 120 140

TAP POSITION (DECIMAL)

V

DD

VDD = 3.6V

= 3.0V

FIGURE 3. INL vs TAP POSITION FOR 10kΩ (W)

0.15

VDD = 3.0V

0.1

0.05

0

-0.05

-0.1

DNL (LSB)

-0.15

-0.2

T = 25°C

-0.25

0 20 40 60 80 100 120 140

= 3.6V

V

DD

TAP POSITION (DECIMAL)

FIGURE 2. DNL vs TAP POSITION FOR 10kΩ (W)

0.2

0.15

V

= 3.6V

DD

0.1

0.05

0

-0.05

RDNL (LSB)

-0.1

-0.15

-0.2

0 20 40 60 80 100 120 140

= 3.0V

V

DD

TAP POSITI ON (DECIMAL)

FIGURE 4. RDNL vs TAP POSITION FOR 10kΩ (W)

T = 25°C

0.4

0.3

0.2

0.1

0

RINL (LSB)

-0.1

-0.2

V

DD

-0.3

0 20 40 60 80 100 120 140

FIGURE 5.

= 3.6V

V

= 3.0V

DD

TAP POSITI ON (DECIMAL)

RINL vs TAP POSITION FOR 10kΩ (W)

6

T = 25°C

FN8243.1

April 17, 2006

Principles of Operation

www.BDTIC.com/Intersil

This device combines a DCP, 16kbit non-volatile memory,

and an I

between a host and the DCP and memory.

DCP Description

The DCP has 10kΩ or 50kΩ nominal total resistance and

128 taps. It is implemented with a combination of resistor

elements and CMOS switches. The physical ends of the

DCP, the RH and RL pins, are equivalent to the fixed

terminals of a mechanical potentiometer. The RW pin is

connected to intermediate nodes, and it is equivalent to the

wiper terminal of a mechanical potentiometer. The position

of the wiper terminal within the DCP is controlled by a 7-bit

volatile DCP Register. When the DCP Register contains all

zeroes (00 hex, or “R

its RL terminal. When the DCP Register contains all ones

(7F hex, or “R

terminal. As the value of the DCP Register increases from all

zeroes to all ones, the wiper moves monotonically from the

position closest to RL to the closest to RH. Therefore, the

resistance between RH and RW decreases monotonically

from R

increases monotonically from R

While the device is being powered up, the DCP Register is

reset to 40 hex (64 decimal). Soon after the power supply

voltage becomes large enough for reliable non-volatile

memory reading, the device reads the value stored on the

non-volatile Initial Value Register (IVR) and loads it into the

DCP Register.

2

C serial interface providing direct communication

”), its wiper terminal, RW, is closest to

0

”), its wiper terminal is closest to its RH

127

to R

0

, while the resistance between RW and RL

127

127

to R0.

ISL96017

controls the access to the DCP byte (See “Access to DCP

Register and IVR”). Bytes at addresses 7FC hex and 7FD

hex, are reserved, which means that they should not be

written, and their value should be ignored if they are read.

(See Table 1).

Access to DCP Register and IVR

The volatile DCP Register and the non-volatile (IVR) can be

read or written directly using the I

Address Byte 07FF hex.

The MSB of the byte at address 7FE hex is called

“OnlyVolatile” and controls the access to the DCP Register

and IVR. This bit is volatile and it’s reset to “0” at power up.

The Data Byte read from memory address 7FF hex, is from

the DCP register when the “OnlyVolatile” bit is “1”, and from

the IVR when this bit is “0”.

The Data Byte of a Write operation to memory address 7FF

hex is written only to the DCP Register when the

“OnlyVolatile” bit is “1”, and it’s written to both the DCP

Register and the IVR when this bit is “0”.

When writing to the “OnlyVolatile” bit at address 7FE hex,

the seven LSBs of the Data Byte must be all zeros.

Writing to address 7FE hex and 7FF hex can be done in two

Write operations, or one Write operation with two Data

Bytes.

See next sections for interface protocol description.

2

C serial interface, with

Memory Description

This device contains 2048 non-volatile bytes organized in

128 pages of 16 bytes each. This allows writing 16 bytes on

a single I

non-volatile write cycle. The memory is accessed by I

interface operations with addresses 000 hex through 7FF hex.

Bytes at addresses 000 hex through 7FB hex are available

to the user as general purpose memory. The byte at address

7FF hex, IVR, contains the initial value loaded at power-up

into the volatile DCP Register. The byte at address 7FE hex

2

C interface operation, followed by a single internal

TABLE 1. ISL96017 MEMORY MAP

2

C

Addres s Data B its Function

7FFh 0 D

6D5D4D3D2D1D0

7FEhOV0000000 Access Control

7FDh Res erved

7FCh Res erved

7FB h D

7D6D5D4D3D2D1D0

000h

Note: OV = “Only Volatile”. All other bits in register 7FEh must be 0.

IVR, DCP

General Purpos e M em ory

7

FN8243.1

April 17, 2006

ISL96017

www.BDTIC.com/Intersil

I2C Serial Interface

This device supports a bidirectional bus oriented protocol.

The protocol defines any device that sends data onto the

bus as a transmitter and the receiving device as the receiver.

The device controlling the transfer is a master and the

device being controlled is the slave. The master always

initiates data transfers and provides the clock for both

transmit and receive operations. Therefore, this device

operates as a slave device in all applications. All

communication over the I

sending the MSB of each byte of data first.

Protocol Conventions

Data states on the SDA line can change only during SCL

LOW periods. SDA state changes during SCL HIGH are

reserved for indicating START and STOP conditions (See

Figure 6). On power up, the SDA pin is in the input mode. All

2

I

C interface operations must begin with a START condition,

which is a HIGH to LOW transition of SDA while SCL is

HIGH. The device continuously monitors the SDA and SCL

lines for the START condition and does not respond to any

command until this condition is met (See Figure 6). A START

condition is ignored during the power up sequence and

during internal non-volatile write cycles. All I

operations must be terminated by a STOP condition, which

is a LOW to HIGH transition of SDA while SCL is HIGH (See

Figure 6). A STOP condition at the end of a Read operation,

or at the end of a Write operation to volatile bytes only

places the device in its standby mode. A STOP condition

during a Write operation to a non-volatile byte, initiates an

2

C interface is conducted by

2

C interface

internal non-volatile write cycle. The device enters its

standby state when the internal non-volatile write cycle is

completed.

An ACK, Acknowledge, is a software convention used to

indicate a successful data transfer. The transmitting device,

either master or slave, releases the SDA bus after

transmitting eight bits. During the ninth clock cycle, the

receiver pulls the SDA line LOW to acknowledge the

reception of the eight bits of data (See Figure 7). This device

responds with an ACK after recognition of a START

condition followed by a valid Identification Byte, and once

again after successful receipt of the Address Byte. This

device also responds with an ACK after receiving each Data

Byte of a Write operation. The master must respond with an

ACK after receiving each Data Byte of a read operation

except the last one. A valid Identification Byte contains 1010

as the four MSBs. The following three bits are the MSBs of

the memory address to be accessed. The LSB of the

Identification Byte is the Read/Write bit. Its value is “1” for a

Read operation, and “0” for a Write operation (See Table 2).

The complete memory address location to be accessed is a

11-bit word, since the memory has 2048 bytes. The eight

LSBs are in the Address Byte.

TABLE 2. IDENTIFICATION BYTE FORMAT

1010A10A9A8R/Wb

MSB LSB

SCL

SDA

SCL

SDA

START

DATA STABLE DATA CHANGE DATA STABLE

FIGURE 6. VALID DATA CHANGES, START AND STOP CONDITIONS

STOP

8

FN8243.1

April 17, 2006

SCL FROM MASTER

www.BDTIC.com/Intersil

ISL96017

81 9

SDA OUTPUT FROM

TRANSMITTER

SDA OUTPUT FROM

RECEIVER

START ACK

HIGH IMPEDANCE

FIGURE 7. ACKNOWLEDGE RESPONSE FROM RECEIVER

Write Operation

A Write operation requires a START condition, followed by a

valid Identification Byte, a valid Address Byte, one or more

Data Bytes, and a STOP condition (See Figure 8). After each

of the bytes, this device responds with an ACK. At this time,

if the operation is only writing to volatile registers, then the

device enters its standby state. If one or more Data Bytes

are to be written to non-volatile memory, the device begins

its internal write cycle to non-volatile memory. During this

cycle, the device ignores transitions at the SDA and SCL

pins, and the SDA output is at a high impedance state. When

the internal non-volatile write cycle is completed, the device

enters its standby state.

The memory is organized as 128 pages of 16 bytes each.

This allows writing 16 bytes on a single I

operation, followed by a single internal non-volatile write

cycle. The addresses of bytes within a page share the same

eight MSBs, and differ on the four LSBs. For example, the

first page is located at addresses 0 hex through F hex, the

second page is located at addresses 10 hex through 1F hex,

etc.

A Write operation with more than one Data Byte sends the

first Data Byte to the memory address indicated by the three

address bits of the Identification Byte plus the eight bits of

the Address Byte, the second Data Byte to the following

address, etc.

A single Write operation has to stay within a page. If the

Address Byte corresponds to the lowest address of a page,

then the Write operation can have anywhere from 1 to 16

Data Bytes. If the Address Byte corresponds to the highest

address of a page, then only one byte can be written with

that Write operation.

See “Access to DCP Register and IVR” for additional

information.

2

C interface

HIGH IMPEDANCE

respond to them with ACK, and instead, goes to its standby

state waiting for a new START condition.

A valid Identification Byte, Address Byte, and total number of

SCL pulses act as a protection of both volatile and nonvolatile registers.

During a Write sequence, Data Bytes are loaded into an

internal shift register as they are received. If the address bits

in the Identification Byte plus the bits in the Address Byte are

all ones, the Data Byte is transferred to the DCP Register at

the falling edge of the SCL pulse that loads the last bit (LSB)

of the Data Byte.

The STOP condition acts as a protection of non-volatile

memory. Non-volatile internal write cycles are started by

STOP conditions.

Read Operation

A Read operation consist of a three byte instruction followed

by one or more Data Bytes (See Figure 9). The master

initiates the operation issuing the following sequence: a

START, the Identification Byte with the R/W bit set to “0”, an

Address Byte which contains the LSBs of the memory

address, a second START, and a second Identification Byte

with the same address bits but with the R/W bit set to “1”.

After each of the three bytes, this device responds with an

ACK. Then this device transmits Data Bytes as long as the

master responds with an ACK during the SCL cycle following

the eighth bit of each byte. The master terminates the Read

operation (issuing a STOP condition) following the last bit of

the last Data Byte. The Data Bytes are from the memory

location indicated by an internal pointer. This pointer initial

value is determined by the address bits in the Identification

Byte plus the bits in the Address Byte in the Read operation

instruction, and increments by one during transmission of

each Data Byte.

Data Protection

The WP pin has to be at logic HIGH to perform any Write

operation to the device. When WP

device ignores Data Bytes of a Write operation, does not

is active (LOW) the

9

FN8243.1

April 17, 2006

ISL96017

www.BDTIC.com/Intersil

SIGNALS FROM

THE MASTER

SIGNAL AT SDA

SIGNALS FROM

SIGNALS

FROM THE

MASTER

SIGNAL AT SDA

SIGNALS FROM

THE SLAVE

THE SLAVE

S

T

A

R

ADDRESS WITH

T

1010

SLAVE

R/Wb=0

S

T

A

R

T

1010

0

SLAVE

ADDRESS

A

C

K

WRITE

ADDRESS

BYTE

0

A

C

K

FIGURE 8. WRITE SEQUENCE

S

T

A

ADDRESS

ADDRESS

BYTE

R

T

A

C

K

SLAVE

WITH

R/Wb=1

FIRST DATA BYTE

TO WRITE

A

C

K

READ

1

A

C

FIRST READ

K

DATA BYTE

LAST DATA BYTE

TO WRITE

A

C

K

A

A

C

C

K

K

S

T

O

P

A

C

K

LAST READ

DATA BYTE

S

T

A

O

C

P

K

FIGURE 9. READ SEQUENCE

Applications Information

The typical application diagram is shown on Figure 10. For

proper operation adding 0.1µF decoupling ceramic capacitor

to Vdd

is recommended. The capacitor value may vary

based on expected noise frequency of the design.

Vdd=3.3V

Rpu

Rpu

FIGURE 10. TYPICAL APPLICATION DIAGRAM FOR IMPLEMENTING ADJUSTABLE VOLTAGE REFERANCE

Vdd=3.3V

WP

SCL

SDA

ISL96017

0.1uF

Vdd=3.3V

RH

RW

RL

Vcc

0.1uF

Vout

R2

R1

10

FN8243.1

April 17, 2006

ISL96017

www.BDTIC.com/Intersil

Thin Dual Flat No-Lead Plastic Package (TDFN)

(DATUM B)

6

INDEX

AREA

(DATUM A)

NX L

8

NX (b)

5

SECTION "C-C"

A

6

INDEX

AREA

SEATING

PLANE

C

12

N

(A1)

D

TOP VIEW

SIDE VIEW

D2

D2/2

N-1

e

(Nd-1)Xe

REF .

BOTTOM VIEW

TERMINAL TIP

FOR EVEN TERMINAL/SIDE

2X

2X

ABC0.15

0.15

CB

L8.3x3A

8 LEAD THIN DUAL FLAT NO-LEAD PLASTIC PACKAGE

MILLIMETERS

SYMBOL

NOTESMIN NOMINAL MAX

A 0.70 0.75 0.80 -

E

A1 - 0.02 0.05 A3 0.20 REF -

b 0.25 0.30 0.35 5, 8

D 3.00 BSC -

D2 2.20 2.30 2.40 7, 8, 9

E 3.00 BSC -

E2 1.40 1.50 1.60 7, 8, 9

e 0.65 BSC -

k0.25 - - -

L 0.20 0.30 0.40 8

A3

//

A

0.10

0.08

C

C

N82

Nd 4 3

87

Rev. 3 11/04

NOTES:

1. Dimensioning and tolerancing conform to ASME Y14.5-1994.

2. N is the number of terminals.

NX k

3. Nd refers to the number of terminals on D.

4. All dimensions are in millimeters. Angles are in degrees.

E2

E2/2

5. Dimension b applies to the metallized terminal and is measured

between 0.15mm and 0.30mm from the terminal tip.

6. The configuration of the pin #1 identifier is optional, but must be

located within the zone indicated. The pin #1 identifier may be

NX b

5

0.10

BAMC

either a mold or mark feature.

7. Dimensions D2 and E2 are for the exposed pads which provide

improved electrical and thermal performance.

8. Nominal dimensions are provided to assist with PCB Land

Pattern Design efforts, see Intersil Technical Brief TB389.

C

L

L1

e

L

10

9. Compliant to JEDEC MO-WEEC-2 except for the “L” min

dimension.

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implic atio n or other wise u nde r any p a tent or patent rights of Intersil or its sub sidi aries.

For information regarding Intersil Corporation and its products, see www.intersil.com

11

FN8243.1

April 17, 2006

Loading...

Loading...