DATASHEET

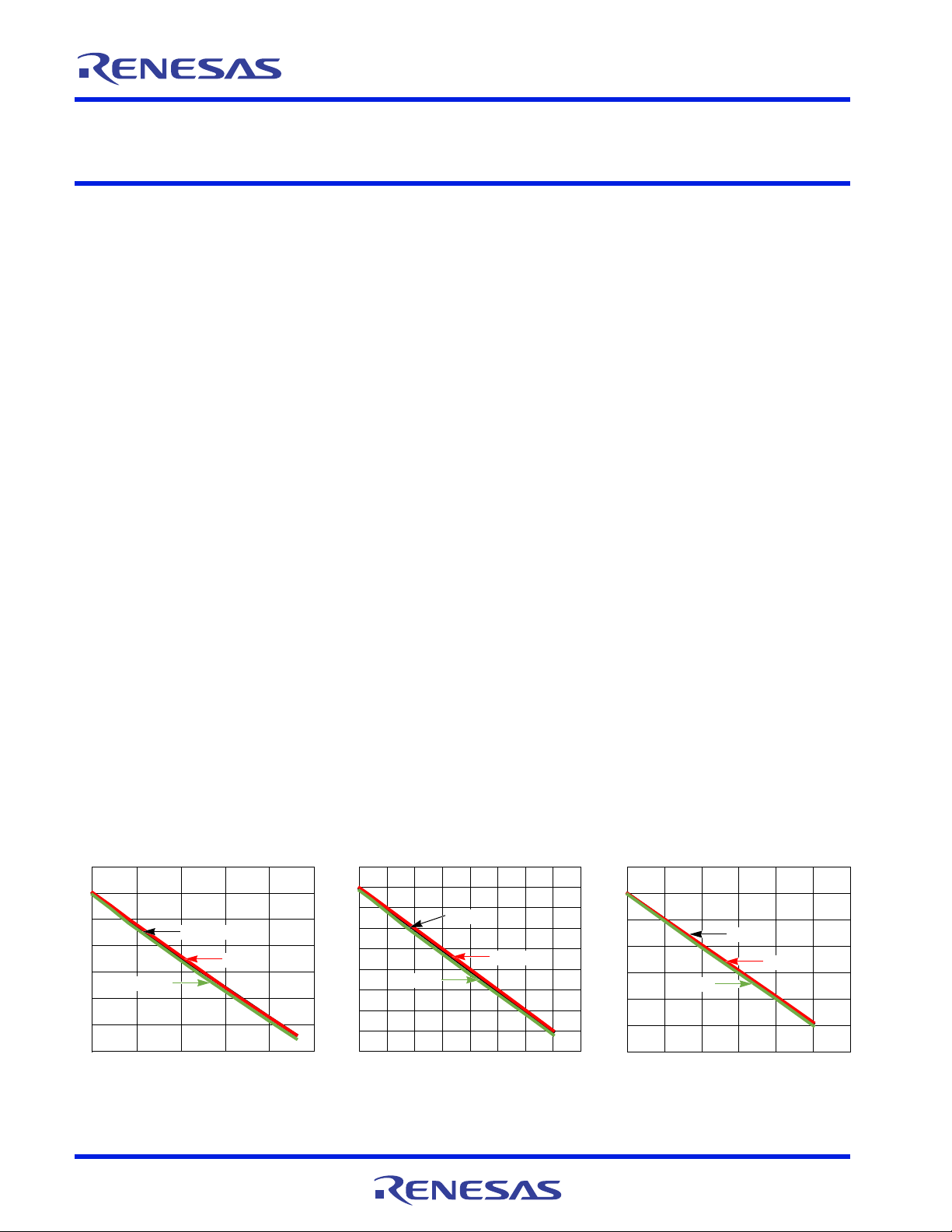

0.84

0.85

0.86

0.87

0.88

0.89

0.90

0.91

0 5 10 15 20 25

VIN = 12V

VIN = 6V

VIN = 21V

0.82

0.83

0.84

0.85

0.86

0.87

0.88

0.89

0.90

0.91

0 5 10 15 20 25 30 35 40

VIN = 12V

VIN = 6V

VIN = 21V

0.84

0.85

0.86

0.87

0.88

0.89

0.90

0.91

0123456

VIN = 12V

VIN = 6V

VIN = 21V

ISL95859C

1+2+1 Voltage Regulator With Expanded Iccmax Register Range Supporting

Intel IMVP8 CFL/CNL CPUs

The ISL95859C provides a complete power solution for

Intel microprocessors supporting core, graphics, and

system agent rails and is compliant with Intel IMVP8™.

The controller provides control and protection for three

Voltage Regulator (VR) outputs. The VR A and VR C

outputs support 1-phase operation only, while VR B is

configurable for 2- or 1-phase operation. The

programmable address options for these three outputs

allow for maximum flexibility in support of the IMVP8

CPU. All three VRs share a common serial control bus to

communicate with the CPU and achieve lower cost and

smaller board area compared with a two-chip approach.

Based on Intersil’s Robust Ripple Regulator (R3™)

technology, the R3 modulator has many advantages

compared to traditional modulators, including faster

transient settling time, variable switching frequency in

response to load transients, and improved light-load

efficiency due to Diode Emulation Mode (DEM) with

load-dependent low switching frequency.

The controller provides PWM outputs, which support Intel

CONFIDENTIAL

DrMOS power stages (or similar) and discrete power

stages using the Intersil ISL95808 high voltage

synchronous rectified buck MOSFET driver. The

controller complies with IMVP8 PS4 power requirements

and supports power stages and drivers, which are

compatible. The ISL95859C supports the system input

power monitor (PSYS) option. The controller supports

either DCR current sensing with a single NTC thermistor

for DCR temperature compensation or more precision

through resistor current sensing, if desired. All three

outputs feature remote voltage sense, programmable

I

, adjustable switching frequency, OC protection, and

MAX

a single VR_READY power-good indicator.

Features

• Supports the Intel serial data bus interface

• Fully supports PS4 Power Domain entry/exit

• Supports system input power monitor (PSYS)

• Three output controller

• VR A supports 1-phase VR design

• VR B configurable for 2- or 1-phase VR design

• VR C supports 1-phase VR design

• 0.5% system accuracy over temperature

• Low supply current in PS4 state

• Supports multiple current sensing methods

• Lossless inductor DCR current sensing

• Precision resistor current sensing

• Differential remote voltage sensing

• Programmable SVID address

• Programmable V

voltage at start-up

BOOT

• Resistor programmable address selection, I

switching frequency

• Adaptive body diode conduction time reduction

Applications

• IMVP8 compliant notebooks, desktops, Ultrabooks,

and tablets

FN8973

Rev.0.00

Oct 6, 2017

, and

MAX

Figure 1. V

Line = 2.4mΩ

CORE

/VR A Load

FN8973 Rev.0.00 Page 1 of 74

Oct 6, 2017

Figure 2. VGT/VR B Load Line = 2mΩ

Figure 3. VSA/VR C Load Line = 10.3mΩ

ISL95859C

Contents

1. Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Simplified Application Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4 Pin Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.5 Pin Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2. Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.1 Absolute Maximum Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2 Thermal Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3 Recommended Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.4 Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3. Typical Performance Curves for VR A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4. Typical Performance Curves for VR B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5. Typical Performance Curves for VR C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

CONFIDENTIAL

6. Theory of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.1 R3 Modulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.2 Multiphase Power Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.3 Diode Emulation and Period Stretching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.4 Adaptive Body Diode Conduction Time Reduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.5 Modes of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.6 Programming Resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.7 PSYS System Power Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7. General Design Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.1 Power Stages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.2 Output Filter Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.3 Input Capacitor Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.4 Inductor Current Sensing and Balancing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.5 Inductor DCR Current-Sensing Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.6 Current Sense Circuit Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.7 Voltage Regulation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

8. Fault Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

8.1 VR_HOT#/ALERT# Behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

FN8973 Rev.0.00 Page 2 of 74

Oct 6, 2017

ISL95859C

9. Serial VID (SVID) Supported Data and Configuration Registers . . . . . . . . . . . . . . . . . . . . . . . 67

10. Layout Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

11. Revision History. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

12. Package Outline Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

13. About Intersil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

CONFIDENTIAL

FN8973 Rev.0.00 Page 3 of 74

Oct 6, 2017

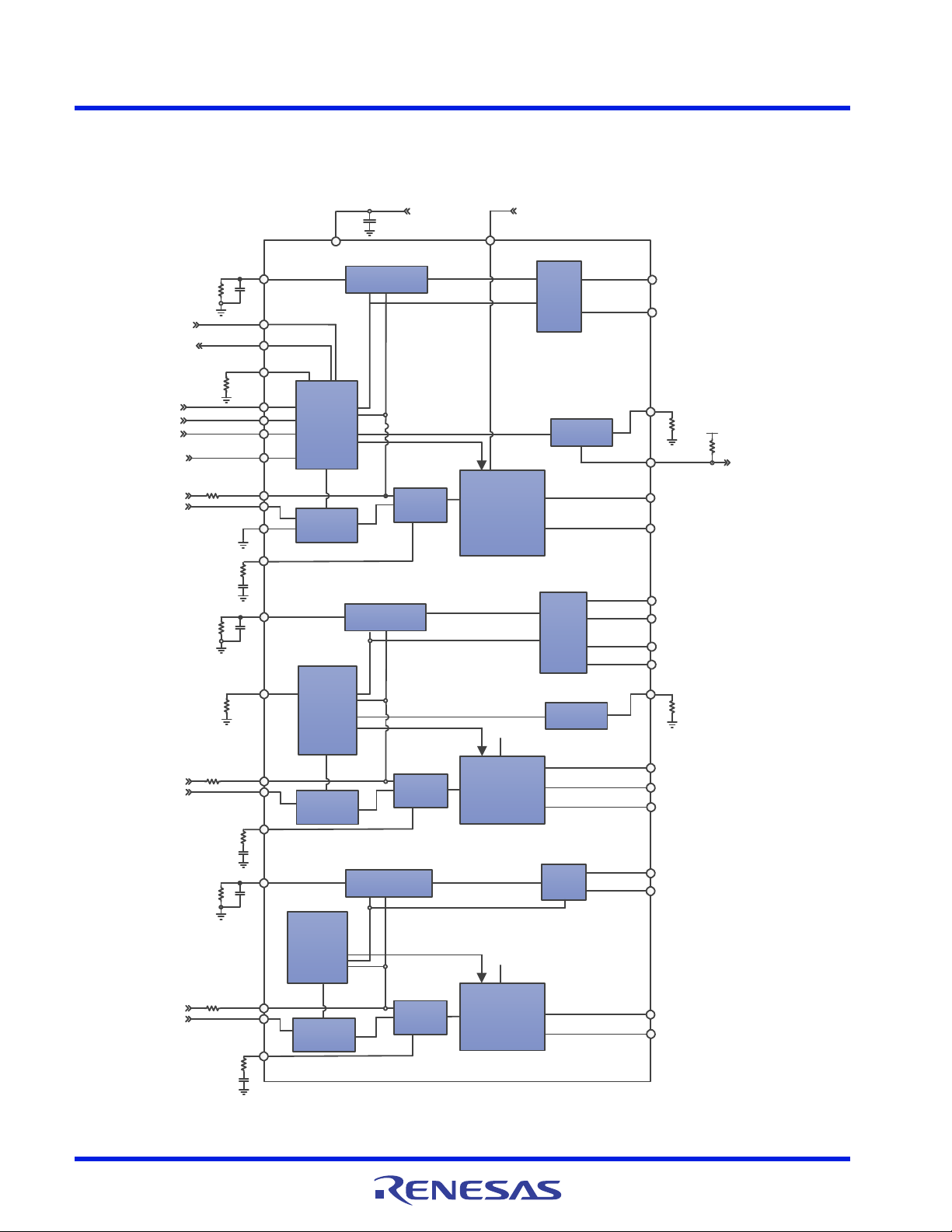

ISL95859C 1. Overview

- V

DROOP

+

FROM

CPU

COMP_A

PWM_A

VR A

R3

TM

MODULATOR

RTN_A

DIGITAL

BLOCK

SVID

START-UP

PROTECTION

TALRT

VTT

VIN

VRHOT#

NTC_A

VCC

FB_A

AGND

SCLK

SDA

ALRT#

PROG1

PSYS

VR_READY

IMON_A

VR_ENABLE

FROM

CPU

+5V

TO CPU

TO CPU

FROM

CHARGER

IMON AND DROOP

CIRCUITRY

OCP

DROOP

ERROR

AMPLIFIER

ISUMP_A

ISUMN_A

FCCM_A

- V

DROOP

+

FROM

CPU

COMP_B

PWM1_B

VR B

R3

TM

MODULATOR

RTN_B

DIGITAL

BLOCK

SVID

START-UP

PROTECTION

ISUMP_B

ISUMN_B

FB_B

PROG2

IMON_B

OCP

DROOP

ERROR

AMPLIFIER

PWM2_B

FCCM_B

ISEN2_B

ISEN1_B

VIN

- V

DROOP

+

FROM

CPU

COMP_C

VR C

R3

TM

MODULATOR

RTN_C

DIGITAL

BLOCK

SVID

START-UP

PROTECTION

ISUMP_C

ISUMN_C

FB_C

IMON_C

OCP

DROOP

ERROR

AMPLIFIER

PWM_C

FCCM_C

CURRENT

SENSE

VIN

CURRENT

SENSE

AND

BALANCE

CURRENT

SENSE

AND

BALANCE

TALRT

NTC_B

IC THERMAL

MONITOR

IC THERMAL

MONITOR

IMON AND DROOP

CIRCUITRY

DIFF REMOTE

SENSING

DIFF REMOTE

SENSING

IMON AND DROOP

CIRCUITRY

DIFF REMOTE

SENSING

1. Overview

1.1 Block Diagram

CONFIDENTIAL

FN8973 Rev.0.00 Page 4 of 74

Figure 4. Block Diagram

Oct 6, 2017

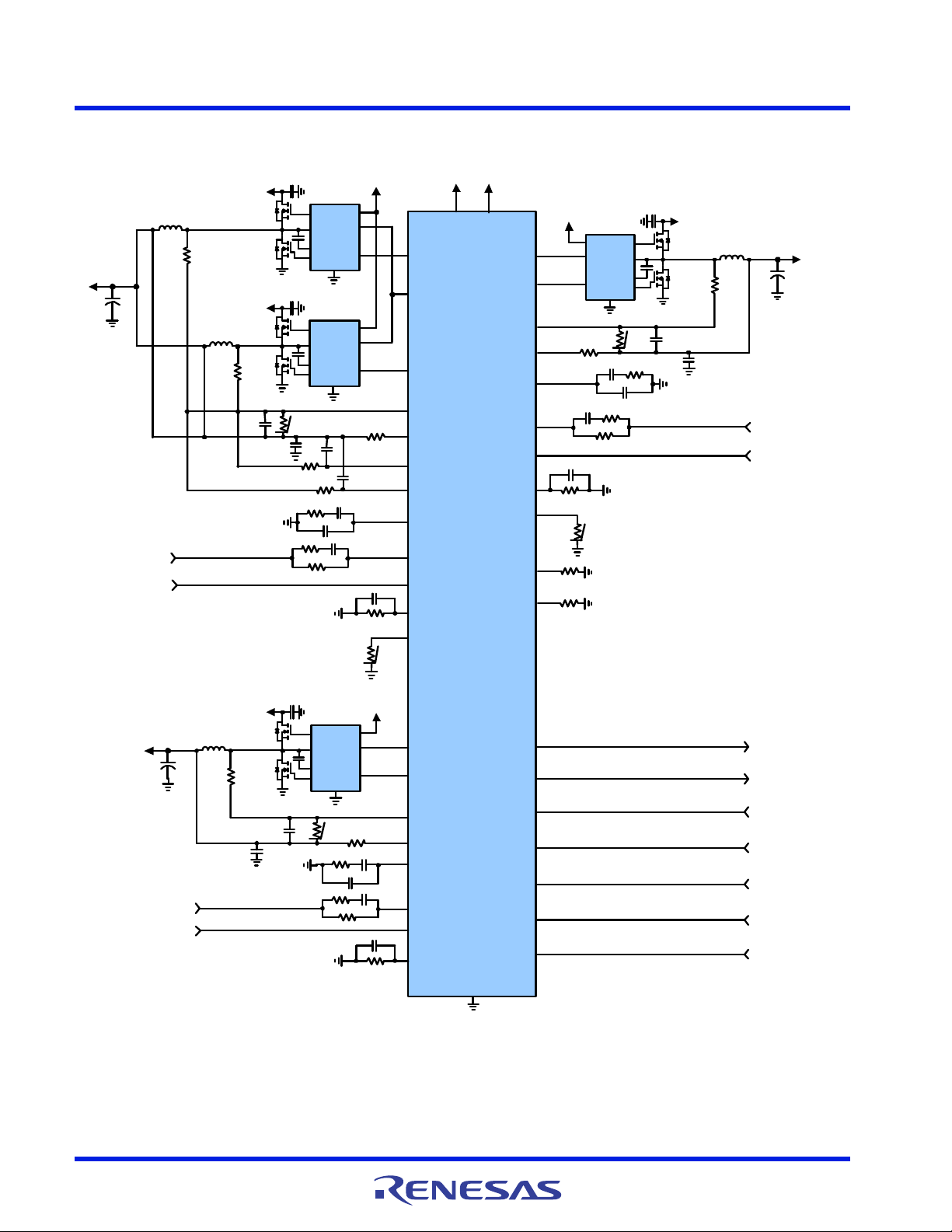

VR_ ENABLE

VR_READY

VCC

SENSE_CPU

VR_ ENABLE

VR_READY

SDA

SDA

ALERT #

ALERT #

SCLK

SCLK

GND

VCC

VR_HOT#

VR_HOT#

V+5

ISL95859C

PSYS

VSS

SENSE_CPU

VCC

SENSE_SA

VSS

SENSE_SA

SA

V

CORE

NTC_B

FCCM_B

PWM_C

FCCM_C

ISUMP_C

ISUMN_C

COMP_C

FB_C

RTN_ C

PSYS

VIN

VIN

PROG1

PROG2

PWM1_ B

UGATE

LGATE

PHASE

BOOT

PWM

FCCM

GND

ISL95808

VCC

VIN

°C

IMON_C

IMON_ A

FB_A

RTN_ A

VCC

SENSE_GT

GT

V

CORE

VSS

SENSE_GT

ISUMP_B

ISUMN_B

ISEN1_B

ISEN2_B

VIN

PWM2_B

VIN

UGATE

LGATE

PHASE

BOOT

PWM

FCCM

GND

ISL95808

VCC

V+5

UGATE

LGATE

PHASE

BOOT

PWM

FCCM

GND

ISL95808

VCC

COMP _B

FB_B

RTN_ B

°C

°C

V+5

IMON_B

NTC_ A

°C

SA

V

CORE

PWM_A

FCCM_ A

ISUMP_A

ISUM N_ A

COMP_ A

UGATE

LGATE

PHASE

BOOT

PWM

FCCM

GND

ISL95808

VCC

VIN

V+5

°C

ISL95859C 1. Overview

1.2 Simplified Application Circuits

CONFIDENTIAL

Figure 5. Typical ISL95859C Application Circuit Using Inductor DCR Current Sensing

FN8973 Rev.0.00 Page 5 of 74

Oct 6, 2017

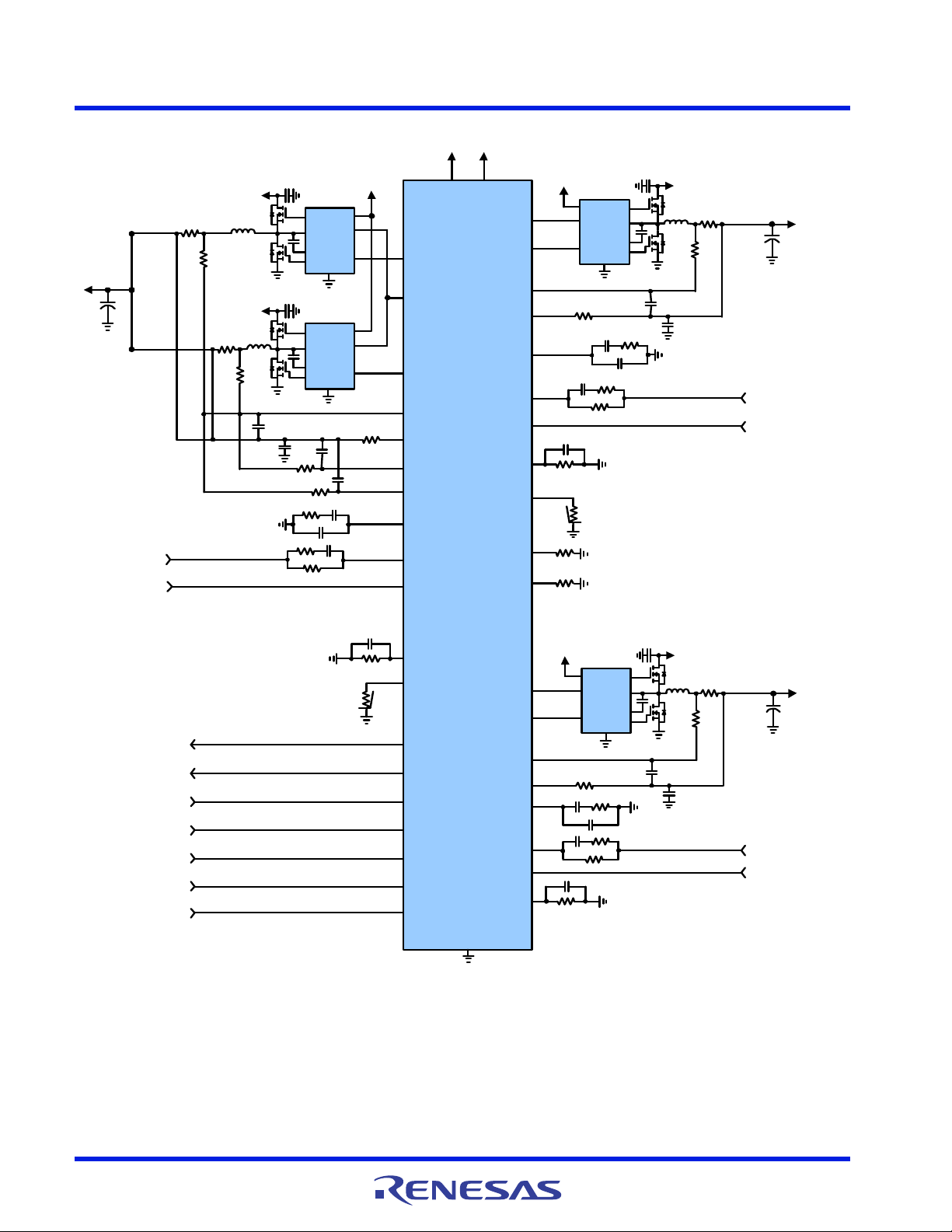

ISL95859C 1. Overview

VR_ ENABLE

VR_READY

VCC

SENSE_CPU

VR_ENABLE

VR_READY

SDA

SDA

ALERT #

ALERT #

SCLK

SCLK

GND

VCC

VR_HOT#

VR_HOT#

V+5

ISL95859 C

CPU

V

CORE

PSYS

VSS

SENSE_CPU

NTC _B

FCCM_B

PSYS

VIN

VIN

PROG1

PROG2

PWM1_B

IMON_ A

FB_A

RTN_A

VCC

SENSE_GT

GT

V

CORE

VSS

SENSE_GT

ISUMP_B

ISUMN_B

ISEN1_B

ISEN2_B

VIN

PWM2_B

VIN

UGATE

LGATE

PHASE

BOOT

PWM

FCCM

GND

ISL 9580 8

VCC

V+5

UGATE

LGATE

PHASE

BOOT

PWM

FCCM

GND

ISL 9580 8

VCC

COMP_B

FB_B

RTN _B

°C

IMON_ B

NTC_A

°C

PWM_A

FCCM_A

ISUMP_A

ISUMN_A

UGATE

LGATE

PHASE

BOOT

PWM

FCCM

GND

ISL 95808

VCC

VIN

V+5

VCC

SENSE_SA

VSS

SENSE_SA

SA

V

CORE

PWM_C

FCCM_C

ISUMP_C

ISUMN_C

COMP_ C

FB_C

RTN_C

UGATE

LGATE

PHASE

BOOT

PWM

FCCM

GND

ISL 95808

VCC

VIN

IMON_ C

V+5

COMP_ A

CONFIDENTIAL

Figure 6. Typical ISL95859C Application Circuit Using Resistor Sensing

FN8973 Rev.0.00 Page 6 of 74

Oct 6, 2017

ISL95859C 1. Overview

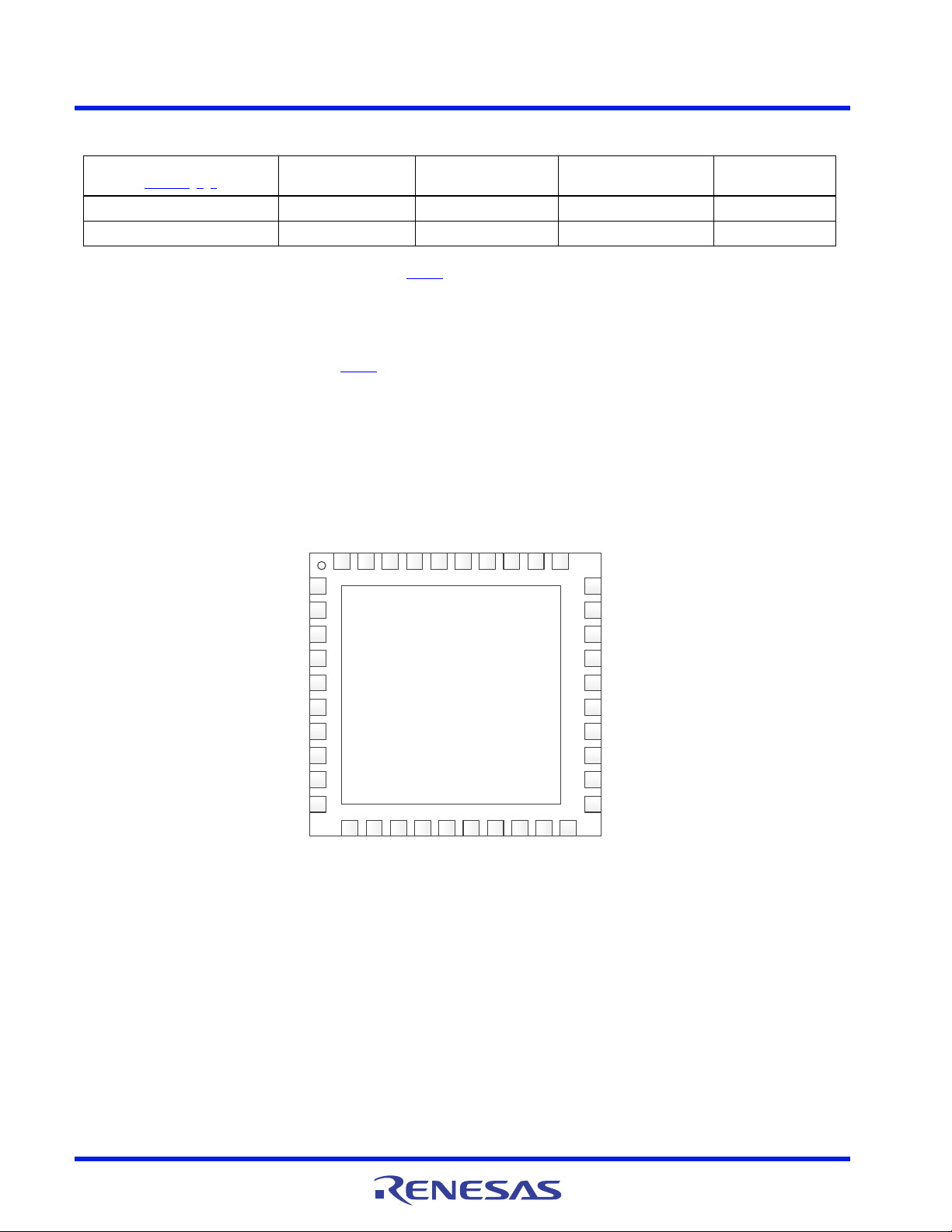

40 39 38 37 36 35 34 33 32 31

29

30

27

28

25

26

23

24

21

22

11 12 13 14 15 16 17 18 19

2

1

4

3

6

5

8

7

10

9

GND

(BOTTOM PAD)

NTC_B

COMP_B

FB_B

ISUMP_B

RTN_C

FB_C

COMP_C

ISUMP_C

ISUMN_C

SDA

SCLK

ALERT#

PROG2

PROG1

ISUMN_B

20

VR_HOT#

RTN_B

VR_ENABLE

FCCM_B

PWM1_B

PWM2_B

IMON_A

COMP_A

FB_A

RTN_A

ISUMP_A

NTC_A

ISEN 1_B

VR_READY

FCCM_A

ISUMN_A

FCCM_C

PWM_ C

PWM_ A

PSYS

IMON_B

IMON_C

VCC

ISEN 2_B

VIN

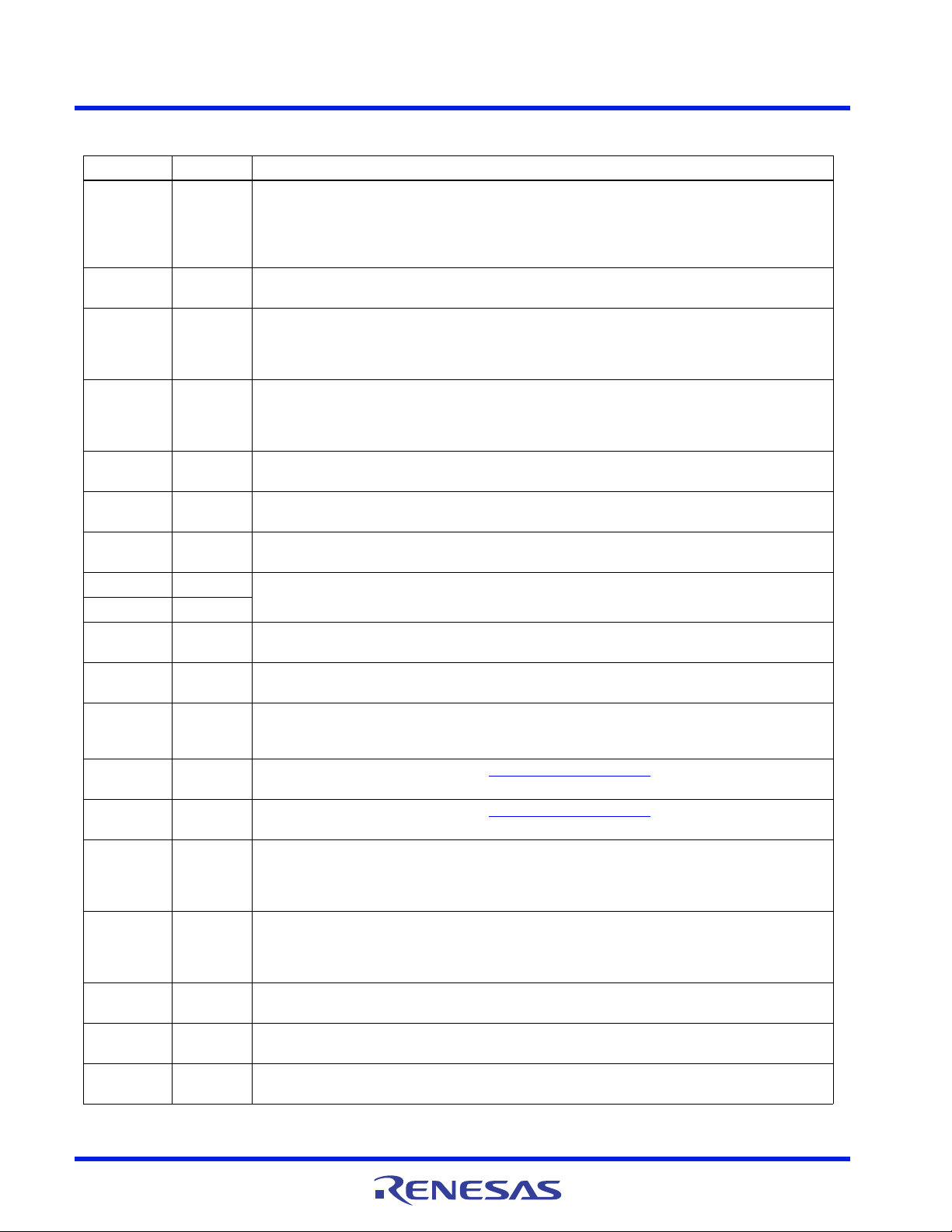

1.3 Ordering Information

Part Number

(Notes 1

ISL95859CHRTZ 95859C HRTZ -10 to +100 40 Ld 5x5 TQFN L40.5x5

ISL95859CIRTZ 95859C IRTZ -40 to +100 40 Ld 5x5 TQFN L40.5x5

Notes:

1. Add “-T” for 6k unit tape and reel options. Refer to TB347

2. These Intersil Pb-free plastic packaged products employ special Pb-free material sets, molding compounds/die attach materials

and 100% matte tin plate plus anneal (e3 termination finish, which is RoHS compliant and compatible with both SnPb and Pbfree soldering operations). Intersil

Pb-free products are MSL classified at Pb-free peak reflow temperatures that meet or exceed the Pb-free requirements of

IPC/JEDEC J STD-020.

3. For more information on MSL, refer to TB363

, 2, 3)Part Marking

.

Temp Range

(°C)

for details on reel specifications.

Package

(RoHS Compliant)

Pkg.

Dwg. #

1.4 Pin Configuration

ISL95859C

(40 LD TQFN)

Top View

CONFIDENTIAL

FN8973 Rev.0.00 Page 7 of 74

Oct 6, 2017

ISL95859C 1. Overview

1.5 Pin Descriptions

Pin Number Pin Name Description

BOTTOM PAD GND Signal common to the IC. Unless otherwise stated, all signals are referenced to the GND pad. It is also

the primary thermal conduction pad for heat removal. Connect this ground pad to the ground plane or

planes through a low impedance path. Best performance is obtained with an uninterrupted ground plane

under the ISL95859C and all associated components, signal sources, signal paths and extending from

the controller to the load. Do not attempt to isolate signal and power grounds.

1 PSYS Analog input from the platform battery charger that is proportional to real-time, total system power

dissipation. Information is to be digitized and stored by the controller to be read by the CPU from SVID.

2 IMON_B Regulator B current monitor. The IMON_B pin sources a current proportional to the regulator output

3 NTC_B Thermistor input from VR B to the temperature monitor circuit of the IC controlling the VR_HOT# output.

4 COMP_B Output of the transconductance error amplifier for VR B regulation and stability. Connect to ground

5 FB_B Output voltage feedback sensing input for regulation of Regulator B. Connect to the remote positive

6 RTN_B Ground return for differential remote output voltage sensing. Connect to the remote negative sense point

CONFIDENTIAL

7 ISUMP_B VR B droop current sensing inputs.

8ISUMN_B

9 ISEN1_B Individual current sensing for VR B Phase 1. This signal monitors and corrects for phase current

10 ISEN2_B Individual current sensing for VR B Phase 2. When ISEN2_B is pulled to VDD (+5V), the controller will

11 FCCM_B Driver control signal for Regulator B. When FCCM_B is high, continuous conduction mode is forced.

12 PWM1_B Regulator B, Channel 1 PWM output. See “

13 PWM2_B Regulator B, Channel 2 PWM output. See “

14 IMON_A Regulator A current monitor. The IMON_A pin sources a current proportional to the regulator output

15 NTC_A Thermistor input from VR A to the temperature monitor circuit of the IC controlling the VR_HOT# output.

16 COMP_A Output of the transconductance error amplifier for VR A regulation and stability. Connect to ground

17 FB_A Output voltage feedback sensing input for regulation of Regulator A. Connect to the remote positive

18 RTN_A Ground return for differential remote output voltage sensing. Connect to the remote negative sense point

current. A resistor connected from this pin to ground will set a voltage that is proportional to the load

current. This voltage is sampled internally to produce a digital IMON signal that is read through the serial

communication bus.

Connect this pin to a resistor network with a thermistor (NTC) to GND. A current is sourced from the pin

and generates a voltage, which is monitored versus an internal threshold to determine when the VR is too

hot.

through a type-II network to compensate the control loop.

sense point on the CPU through a resistor. The resistor value is used to scale droop for VR B.

on the CPU through a resistor.

Connecting ISUMN_B to VCC disables VR B.

imbalance. In 1-phase configurations, connect ISEN1_B to VCC or leave it open.

disable VR Phase 2. This signal is used to monitor and correct for phase current imbalance.

When FCCM_B is low, diode emulation is allowed. FCCM_B is high impedance and interfaces with the

ISL95808 or similar driver when entering a PS4 state.

Driver Selection” on page 35 for more information on

interfacing with the ISL95808 driver or compatible power stages.

Driver Selection” on page 35 for more information on

interfacing with the ISL95808 driver or compatible power stages.

current. A resistor connected from this pin to ground will set a voltage that is proportional to the load

current. This voltage is sampled internally to produce a digital IMON_A signal that is read through the

serial communication bus.

Connect this pin to a resistor network with a thermistor (NTC) to GND. A current is sourced from the pin

and generates a voltage, which is monitored versus an internal threshold to determine when the VR is too

hot.

through a type-II network to compensate the control loop.

sense point on the CPU through a resistor. The resistor value is used to scale droop for VR A.

on the CPU through a resistor.

FN8973 Rev.0.00 Page 8 of 74

Oct 6, 2017

ISL95859C 1. Overview

Pin Number Pin Name Description

19 ISUMP_A VR A droop current sensing inputs.

20 ISUMN_A

21 FCCM_A Driver control signal for Regulator A. When FCCM_A is high, Continuous Conduction Mode (CCM) is

22 PWM_A Regulator A, PWM output. See “

23 IMON_C Regulator C current monitor. The IMON_C pin sources a current proportional to the regulator output

24 COMP_C Output of the transconductance error amplifier for VR C regulation and stability. Connect to ground

25 FB_C Output voltage feedback sensing input for regulation of Regulator C. Connect to the remote positive

26 RTN_C Ground return for differential remote output voltage sensing. Connect to the remote negative sense point

27 ISUMP_C VR C droop current sensing inputs.

28 ISUMN_C

29 FCCM_C Driver control signal for Regulator C. When FCCM_C is high, Continuous Conduction Mode (CCM) is

CONFIDENTIAL

30 PWM_C Regulator C, PWM Output. See “

31 PROG2 Place a resistor from this pin to GND. The resistor value is selected based on programming options

32 PROG1 Place a resistor from this pin to GND. The resistor value is selected based on programming options

33 VIN Input supply voltage used for input voltage feed-forward.

34 VCC +5V bias supply input for the controller. Bypass to ground with a high quality 0.1µF ceramic capacitor.

35 SDA Communication bus between the CPU and the VRs.

36 ALERT#

37 SCLK

38 VR_HOT# Open-drain thermal overload output indicator. Considered part of the communication bus with the CPU.

39 VR_READY Power-good open-drain output indicating when controller is able to supply regulated voltage on all

40 VR_ENABLE Controller enable input. A high level logic signal on this pin enables the controller.

Connecting ISUMN_A to VCC disables VR A.

forced. When FCCM_A is low, diode emulation is allowed. FCCM_A is high impedance and interfaces

with the ISL95808 or similar driver when entering a PS4 state.

Driver Selection” on page 35 for more information on interfacing with the

ISL95808 driver or compatible power stages.

current. A resistor connected from this pin to ground will set a voltage that is proportional to the load

current. This voltage is sampled internally to produce a digital IMON signal that is read through the serial

communication bus.

through a type-II network to compensate the control loop.

sense point on the CPU through a resistor. The resistor value is used to scale droop for VR C.

on the CPU through a resistor.

Connecting ISUMN_C to VCC disables VR C.

forced. When FCCM_C is low, diode emulation is allowed. FCCM_C is high impedance and interfaces

with the ISL95808 or similar driver when entering a PS4 state.

Driver Selection” on page 35 for more information on interfacing with the

ISL95808 driver or compatible power stages.

defined in the controller option tables.

defined in the controller option tables.

This pin establishes the voltage reference for all PWM and FCCM driver interface outputs. To ensure

proper operation of drivers, especially during power-up and power-down sequencing, it is essential that

this pin be powered with the same +5V power supply as the VCC or VCCP pins of the Intersil gate

drivers.

outputs. Pull up externally with a 680Ω resistor to VCC or 1.9kΩ to 3.3V

FN8973 Rev.0.00 Page 9 of 74

Oct 6, 2017

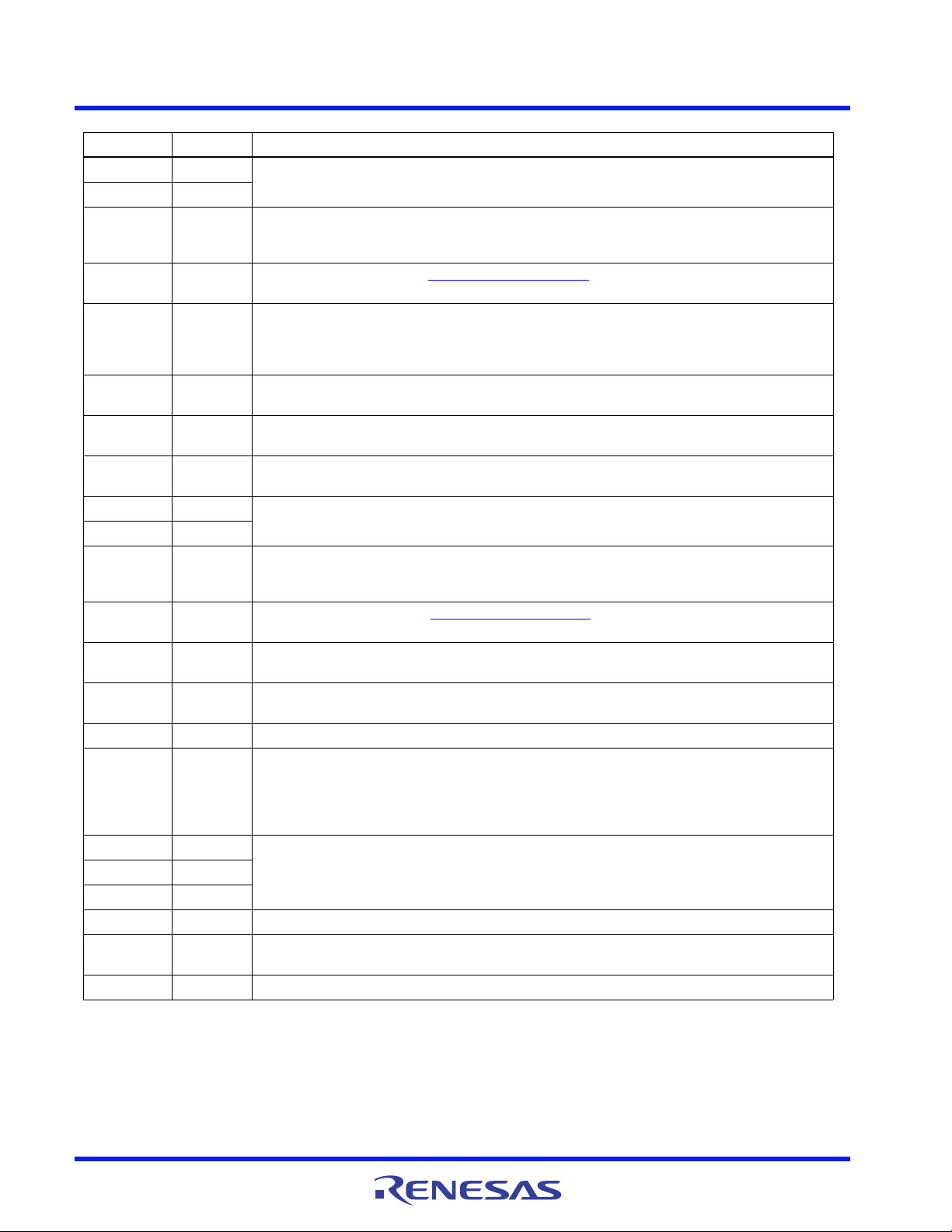

ISL95859C 2. Specifications

2. Specifications

2.1 Absolute Maximum Ratings

Parameter Minimum Maximum Unit

Supply Voltage, V

Battery Voltage, V

All Other Pins -0.3 V

Open-Drain Outputs, VR_READY, VR_HOT#, ALERT# -0.3 +6.5 V

Human Body Model (Tested per JESD22-A114E) 2 kV

Charged Device Model (Tested per JESD22-C101A) 1 kV

Latch-Up (Tested per JESD78B; Class 2, Level A) 100 mA

CAUTION: Do not operate at or near the maximum ratings listed for extended periods of time. Exposure to such conditions may

adversely impact product reliability and result in failures not covered by warranty.

CC

IN

ESD Rating Value Unit

2.2 Thermal Information

Thermal Resistance (Typical)

40 Ld TQFN Package (Notes 4, 5)30 1.5

Notes:

4.

is measured in free air with the component mounted on a high-effective thermal conductivity test board with “direct attach”

JA

CONFIDENTIAL

features. Refer to TB379

5. For

, the “case temp” location is the center of the exposed metal pad on the package underside.

JC

.

(°C/W) JC (°C/W)

JA

-0.3 +6.5 V

+28 V

+ 0.3 V

CC

Parameter Minimum Maximum Unit

Maximum Junction Temperature +150 °C

Maximum Storage Temperature Range -65 +150 °C

Maximum Junction Temperature (Plastic Package) +150 °C

Storage Temperature Range -65 +150 °C

Pb-Free Reflow Profile Refer to TB493

2.3 Recommended Operating Conditions

Parameter Minimum Maximum Unit

Supply Voltage, V

Input Voltage, VIN +4.5 25 V

Ambient Temperature

HRTZ -10 +100 °C

IRTZ -40 +100 °C

Junction Temperature

HRTZ -10 +125 °C

IRTZ -40 +125 °C

CC

+5V ±5% V

FN8973 Rev.0.00 Page 10 of 74

Oct 6, 2017

ISL95859C 2. Specifications

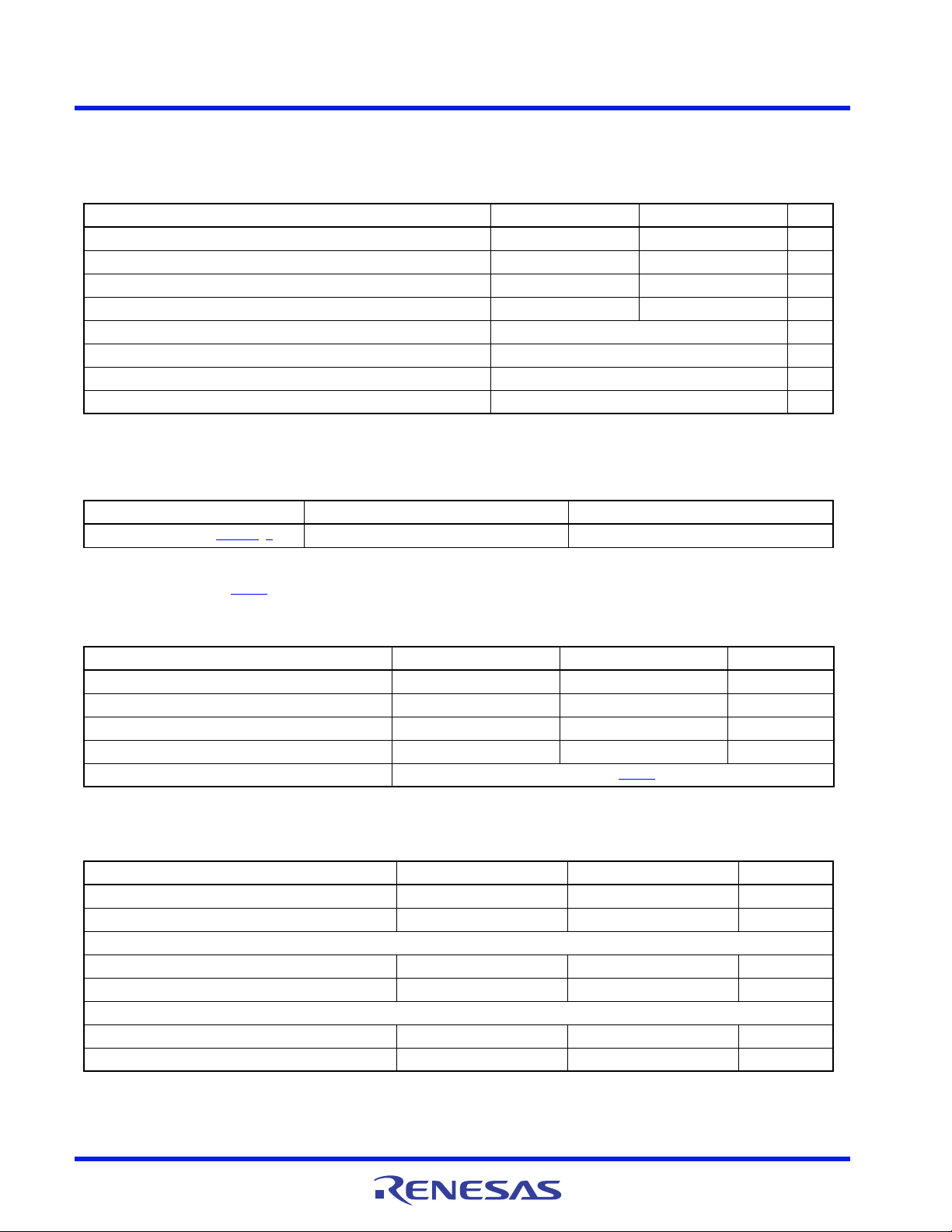

2.4 Electrical Specifications

V

= 5V, VIN = 15V, fSW = 583kHz, unless otherwise noted. Boldface limits apply across the operating temperature range

CC

T

= -40°C to +100°C for industrial (IRTZ) and TA = -10°C to +100°C for high temperature commercial (HRTZ).

A

Min

Symbol Parameter Test Conditions

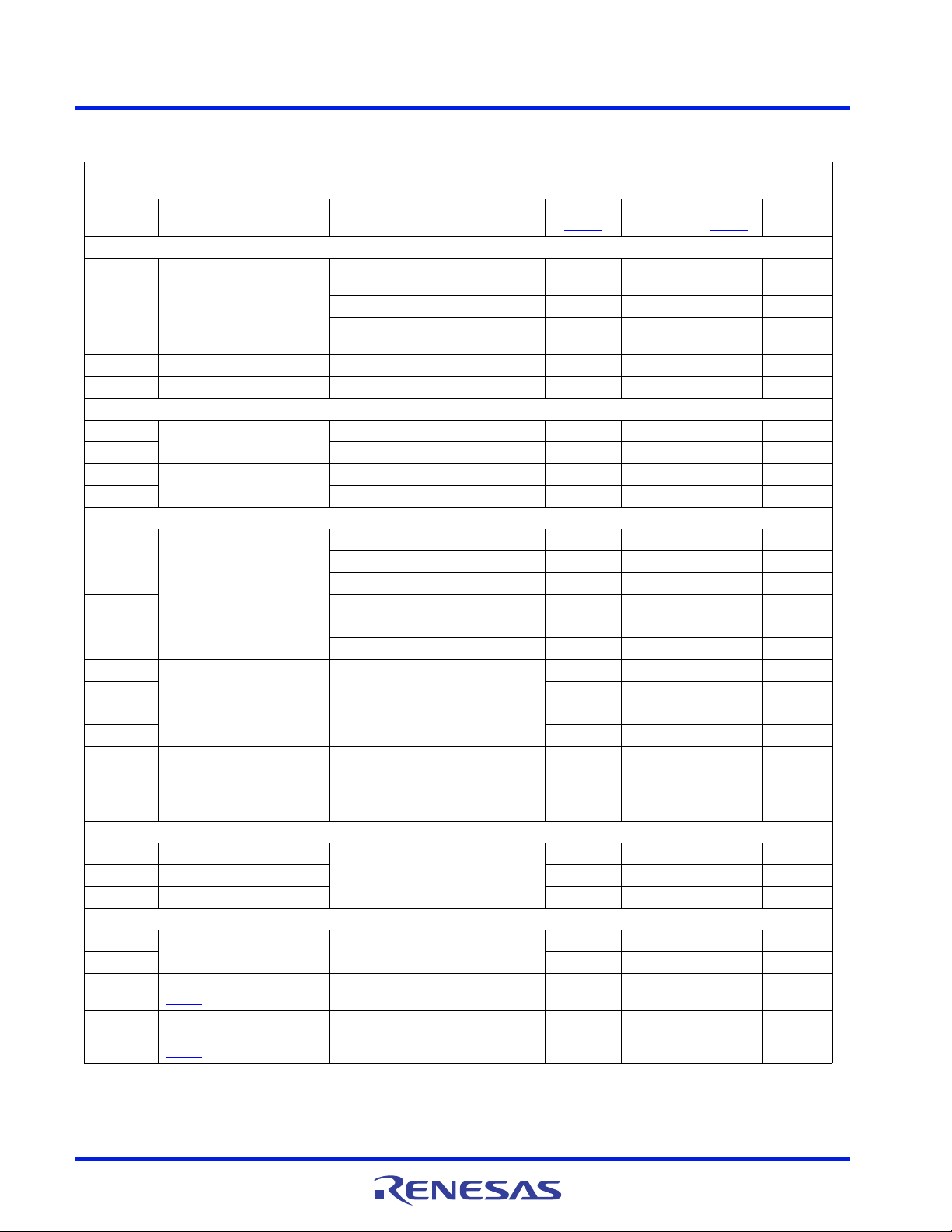

Input Power Supply

I

VCC

I

R

Power-on-Reset Thresholds

VCCPOR

VCCPOR

VINPOR

VINPOR

System and References

HRTZ System Accuracy VID = 0.75V to 1.52V -0.5 0.5 %

IRTZ VID = 0.75V to 1.52V -0.8 0.8 %

HRTZ SA Internal V

IRTZ 1.05 V

HRTZ IA, GT, GTUS Internal V

IRTZ 0V

V

OUT(max)

V

OUT(min)

Switching Frequency

f

SW_450k

f

SW_583k

f

SW_750k

Amplifiers

HRTZ Current-sense Amplifier Input

IRTZ -0.3 0.3 mV

A

GBW Error Amplifier

+5V Supply Current VR_ENABLE = 1V (PWMs are not

VIN Supply Current VR_ENABLE = 0V 1 µA

VIN

VIN Input Resistance VR_ENABLE = 1V 700 kΩ

VIN

Power-On Reset

rVCC

Threshold

f

Power-On Reset

rVIN

Threshold

f

CONFIDENTIAL

BOOT

Maximum Programmed

Output Voltage

Minimum Programmed

Output Voltage

450kHz Configuration Set by R_PROG1 and R_PROG2 415 500 kHz

583kHz Configuration 540 630 kHz

750kHz Configuration 685 795 kHz

Offset

Error Amplifier DC Gain

v0

(Note 7

)

Gain-Bandwidth Product

(Note 7

)

switching)

VR_ENABLE = 0V 1 µA

PS4 state for all VRs and input power

domain

VCC rising 4.40 4.50 V

VCC falling 4.00 4.15 V

VIN rising 4.00 4.35 V

VIN falling 2.90 3.40 V

VID = 0.5V to 0.745V -7 7 mV

VID = 0.25V to 0.495V -10 10 mV

VID = 0.5V to 0.745V -9 9 mV

VID = 0.25V to 0.495V -12 12 mV

BOOT

VI D = [11111111] 1. 52 V

VID = [00000001] 0.25 V

= 0A -0.2 0.2 mV

I

FB

C

= 20pF 30 MHz

L

(Note 6

)Typ

16 18 mA

80 140 µA

1.05 V

0V

38 dB

Max

(Note 6)Unit

FN8973 Rev.0.00 Page 11 of 74

Oct 6, 2017

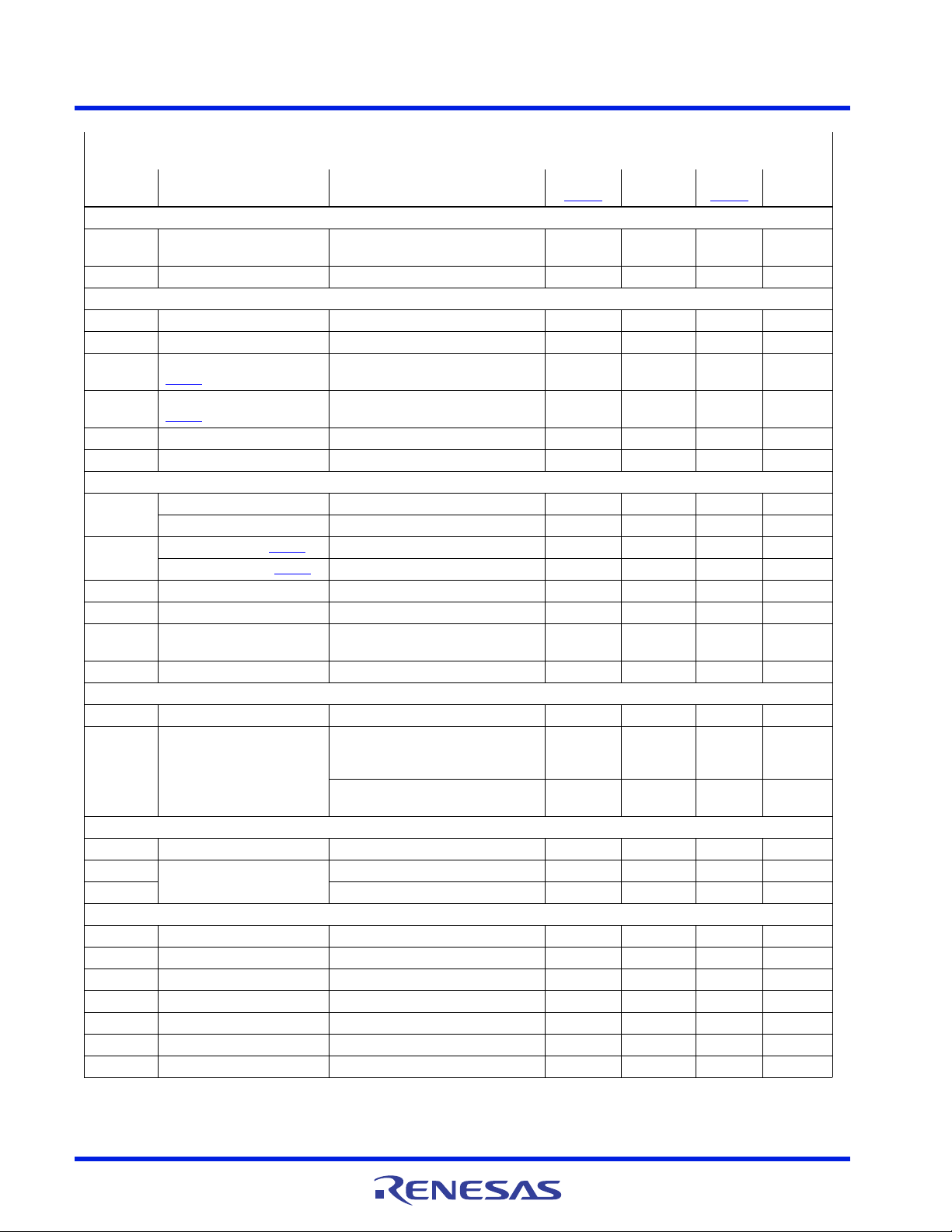

ISL95859C 2. Specifications

= 5V, VIN = 15V, fSW = 583kHz, unless otherwise noted. Boldface limits apply across the operating temperature range

V

CC

T

= -40°C to +100°C for industrial (IRTZ) and TA = -10°C to +100°C for high temperature commercial (HRTZ).

A

Symbol Parameter Test Conditions

ISEN

Imbalance Voltage Maximum of ISENs - minimum of

ISENs

Input Bias Current 20 nA

Power-Good and Protection Monitors

V

I

PWM and FCCM

V

V

t

PS4EXIT

Protection

OV

Logic Thresholds

V

V

V

Thermal Monitor

VR_READY Low Voltage I

OL

VR_READY Leakage Current VR_READY = 3.3V 1 µA

OH

ALERT# Low Voltage

(Note 7

VR_HOT# Low Voltage

(Note 7

ALERT# Leakage Current 1 µA

VR_HOT# Leakage Current 1 µA

PWM Output Low Sinking 5mA 0.6 0.9 V

0L

FCCM Output Low Sinking 4mA 0.6 0.9 V

PWM Output High (Note 7) Sourcing 5mA 3.5 4.2 V

0H

FCCM Output High (Note 7

CONFIDENTIAL

PWM Tri-State Voltage 2.5 V

FCCM Mid-State Voltage 2.5 V

PWM Tri-State and FCCM

High Impedance Leakage

PS4 Exit Latency VCC = 5V 50 100 µs

Overvoltage Threshold ISUMN rising above setpoint for >1µs 240 360 mV

H

Overcurrent Threshold

(ISUMN Pin Current)

VR_ENABLE Input Low 0.3 V

IL

VR_ENABLE Input High HRTZ 0.7 V

IH

IH

NTC Source Current NTC = 1.3V 9.5 10 10.5 µA

VR_HOT# Trip Voltage Falling 0.187 0.198 0.209 V

VR_HOT# Reset Voltage Rising 0.209 0.220 0.231 V

VR_HOT# Hysteresis 20 mV

Thermal Alert Trip Voltage Falling 0.203 0.214 0.225 V

Thermal Alert Reset Voltage Rising 0.225 0.236 0.247 V

Thermal Alert Hysteresis 20 mV

VR_READY

)

)

) Sourcing 4mA 3.3 3.6 V

PWM and FCCM = 2.5V -1 1 µA

2-phase configuration PS0 state or

1-phase configuration covering all

power states

2-phase configuration with 1-phase

operation in PS1, PS2 and PS3 states

IRTZ 0.75 V

= 4mA 0.15 0.40 V

Min

(Note 6

)Typ

7 12 Ω

7 12 Ω

56 60 64 µA

27 30 33 µA

Max

(Note 6)Unit

1 mV

FN8973 Rev.0.00 Page 12 of 74

Oct 6, 2017

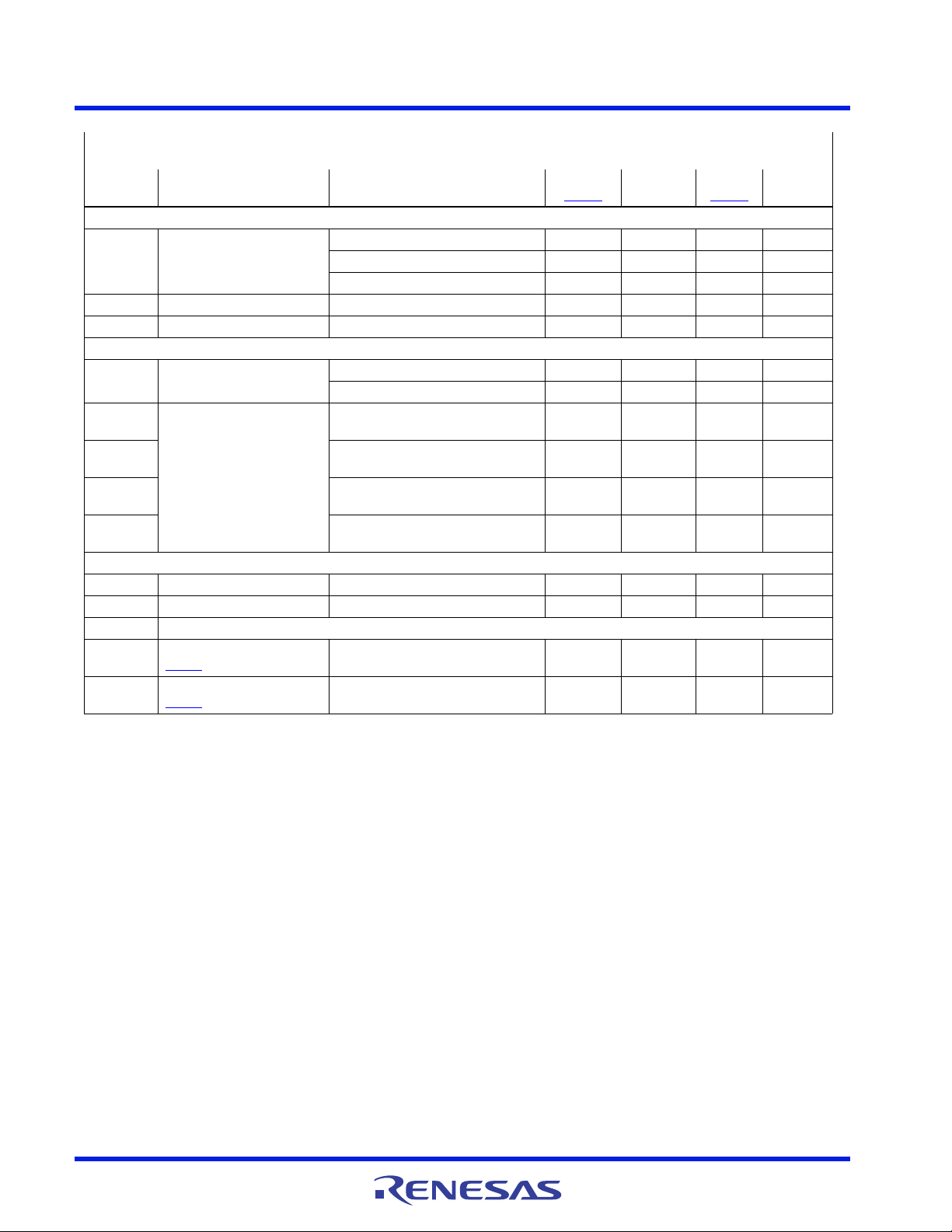

ISL95859C 2. Specifications

V

= 5V, VIN = 15V, fSW = 583kHz, unless otherwise noted. Boldface limits apply across the operating temperature range

CC

T

= -40°C to +100°C for industrial (IRTZ) and TA = -10°C to +100°C for high temperature commercial (HRTZ).

A

Symbol Parameter Test Conditions

Current Monitor

I

IMON

V

IMONrICCMAX

V

IMONf

Inputs

I

VR_ENABLE

Slew Rate (For VID Change)

Notes:

6. Parameters with MIN and/or MAX limits are 100% tested at +25°C, unless otherwise specified. Temperature limits established by

7. Limits established by characterization and are not production tested.

IMON Output Current ISUM- pin current = 40µA 9.7 10 10.3 µA

ISUM- pin current = 20µA 4.8 5 5.2 µA

ISUM- pin current = 4µA 0.875 1 1.125 µA

Alert Trip Voltage Rising 1.185 1.200 1.215 V

I

Alert Reset Voltage Falling 1.115 1.130 1.145 V

CCMAX

VR_ENABLE Leakage

Current

SCLK, SDA Leakage VR_ENABLE = 0V, SCLK and

CONFIDENTIAL

Fast Slew Rate 30 mV/µs

Slow Slew Rate 15 mV/µs

SVID

SVID CLK Maximum Speed

(Note 7

)

SVID CLK Minimum Speed

(Note 7

)

characterization and are not production tested.

VR_ENABLE = 0V -1 0µA

VR_ENABLE = 1V 3 5 µA

SDA = 0V and 1V

VR_ENABLE = 1V, SCLK and

SDA = 1V

VR_ENABLE = 1V, SCLK and

SDA = 0V, SCLK Leakage

VR_ENABLE = 1V, SCLK and

SDA = 0V, SDA Leakage

Min

(Note 6

)Typ

-1 1 µA

-5 1 µA

-42 µA

-24 µA

42 MHz

13 MHz

Max

(Note 6)Unit

FN8973 Rev.0.00 Page 13 of 74

Oct 6, 2017

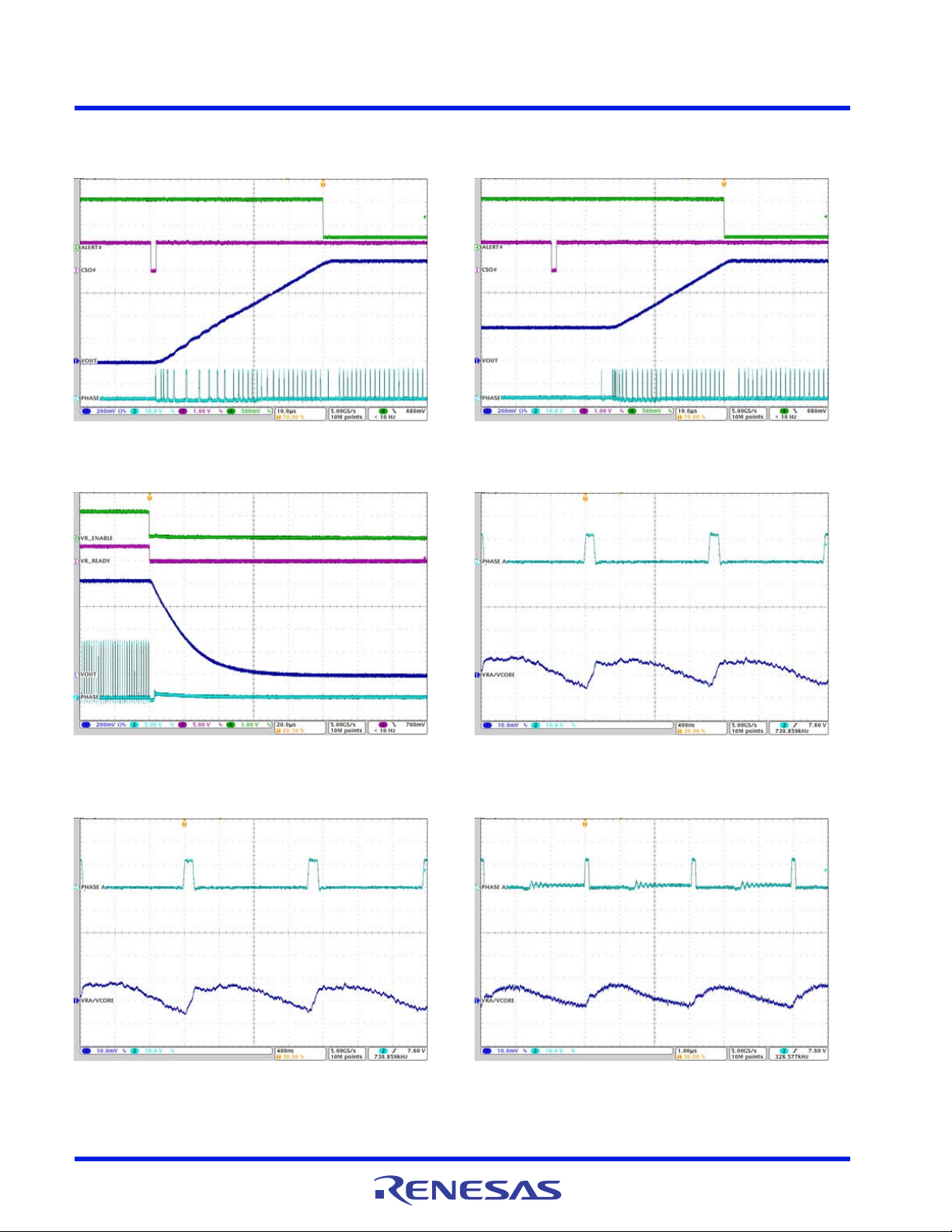

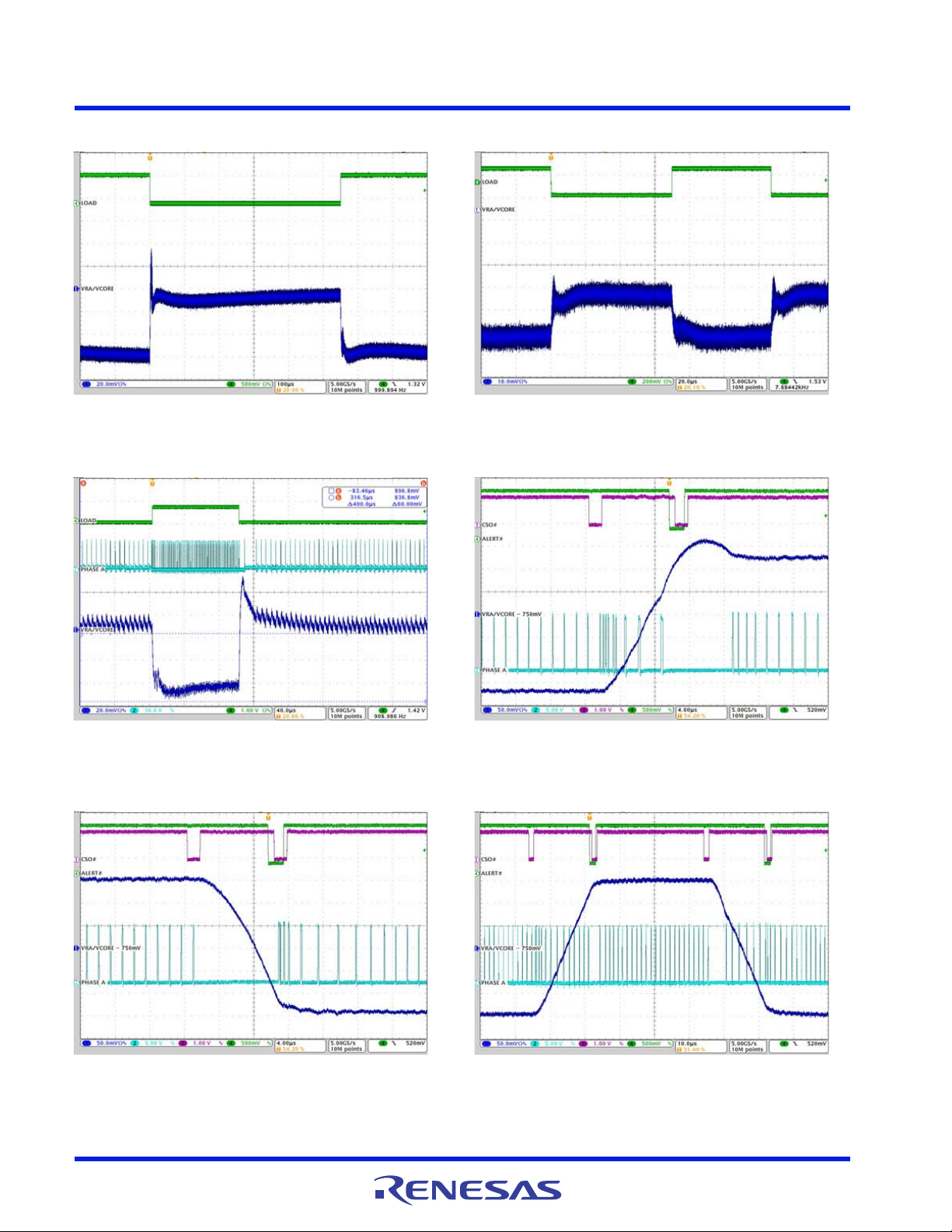

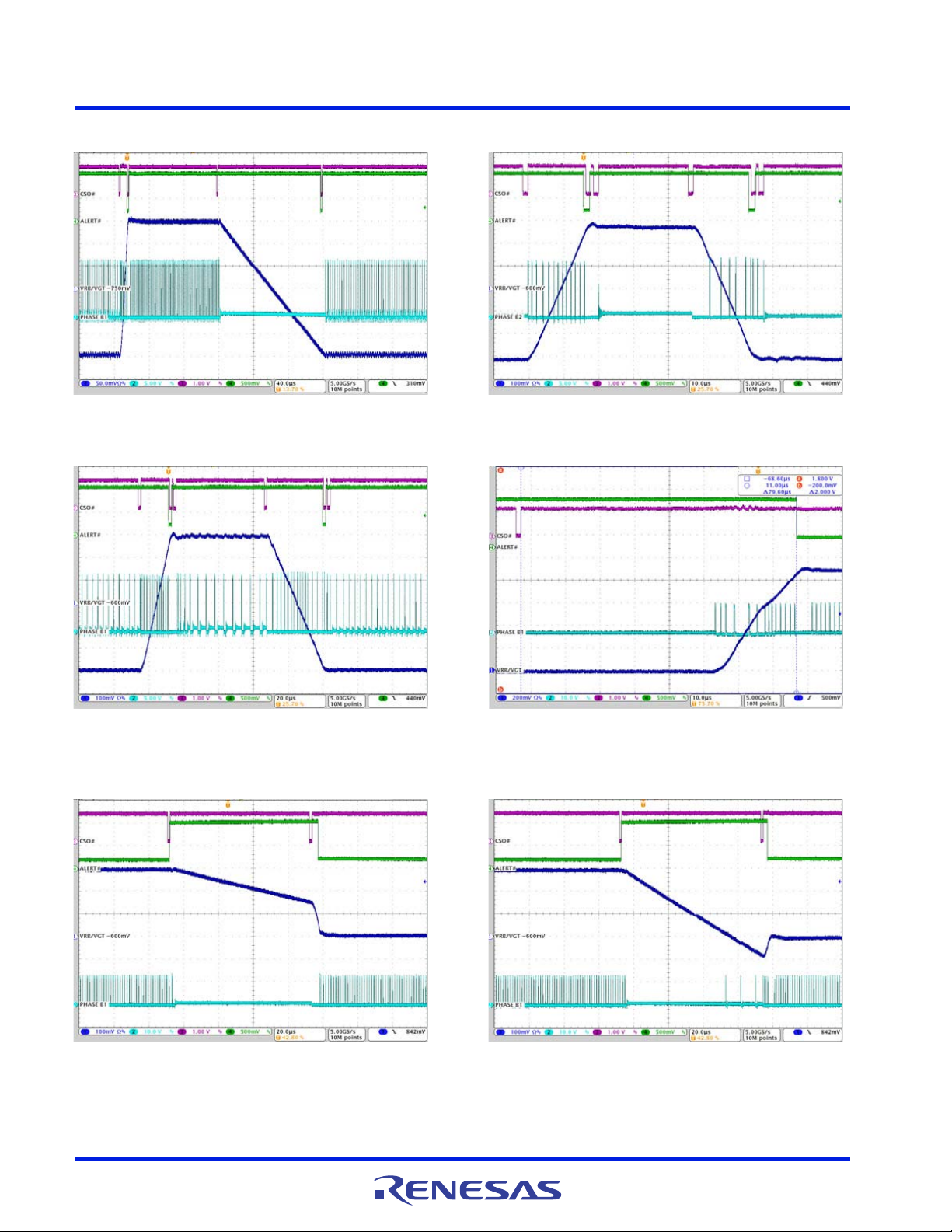

ISL95859C 3. Typical Performance Curves for VR A

3. Typical Performance Curves for VR A

Figure 7. V

Figure 9. V

/VR A Soft-Start, SetVID_fast 0V to 0.9V,

CORE

I

O

=0A

Figure 8. V

/VR A Soft-Start with Precharged Output,

CORE

SetVID_fast 0.9V, I

= 0A

O

CONFIDENTIAL

/VR A Shutdown, IO= 23A, VID = 0.9V

CORE

Figure 10. V

/VR A PS0 Steady-State Phase and

CORE

Ripple, IO= 23A, VID = 0.9V

Figure 11. V

FN8973 Rev.0.00 Page 14 of 74

Oct 6, 2017

/VR A PS1 Steady-State Phase and

CORE

Ripple, IO= 23A, VID = 0.9V

Figure 12. V

/VR A PS2 Steady-State Phase and

CORE

Ripple, IO= 2A, VID = 0.9V

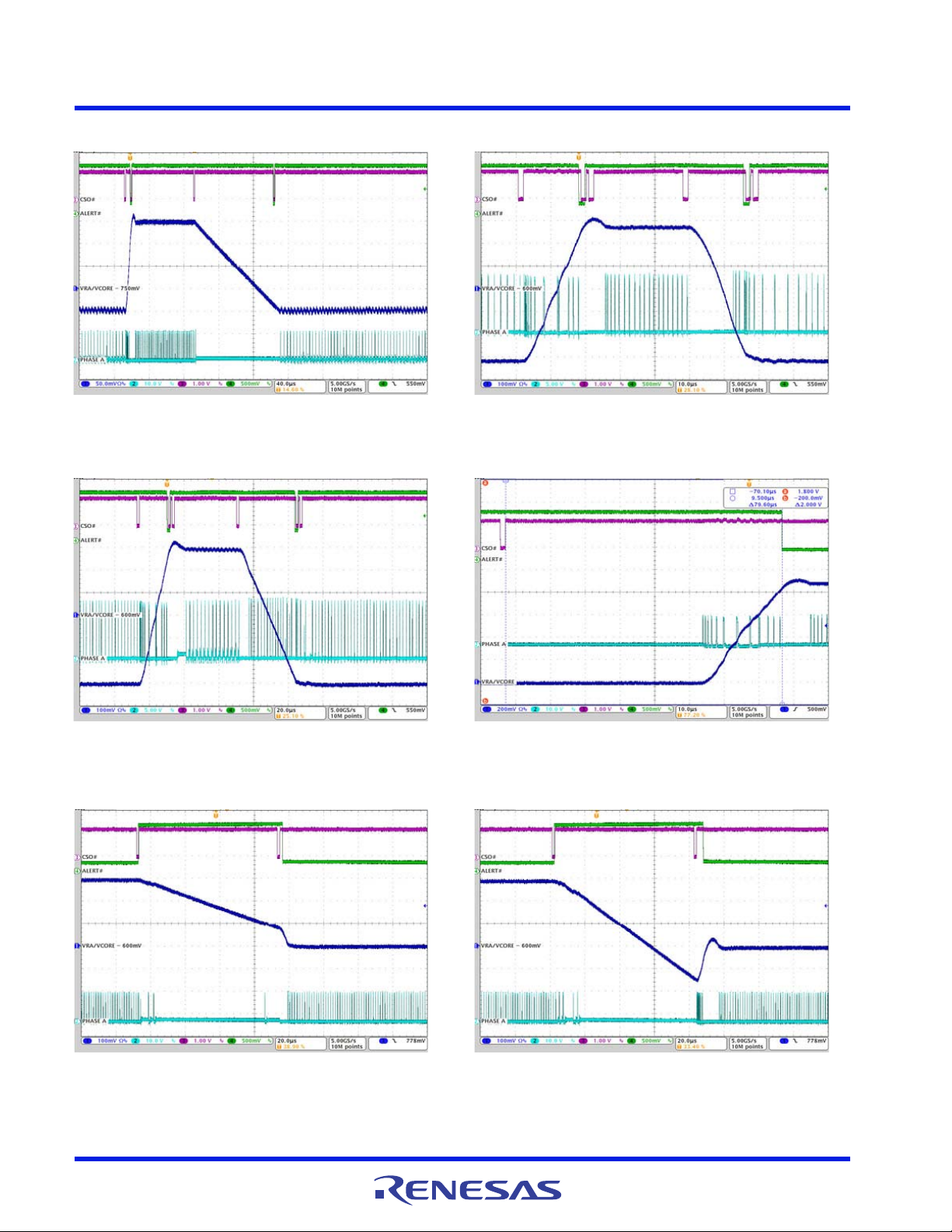

ISL95859C 3. Typical Performance Curves for VR A

Figure 13. V

CONFIDENTIAL

Figure 15. V

/VR A PS0 Load Step, IO = 4A to 29A,

CORE

VID = 0.9V, R_LL = 2.4mΩ

/VR A Load Step, IO = 1A IN PS2 to 26A

CORE

in PS0, VID = 0.9V, R_LL = 2.4mΩ

Figure 14. V

Figure 16. V

/VR A PS0 Load Step, IO = 18A to 28A,

CORE

VID = 0.9V, R_LL = 2.4mΩ

/VR A SetVID_fast, 0.6V to 0.9V, PS0,

CORE

IO= 7A, R_LL = 2.4mΩ

Figure 17. V

FN8973 Rev.0.00 Page 15 of 74

Oct 6, 2017

/VR A SetVID_fast, 0.9V to 0.6V, PS0,

CORE

IO= 7A, R_LL = 2.4mΩ

Figure 18. V

/VR A SetVID_slow, 0.6V to 0.9V to 0.6V,

CORE

PS0, IO= 7A, R_LL = 2.4mΩ

ISL95859C 3. Typical Performance Curves for VR A

Figure 19. V

SetVID_decay, 0.9V to 0.7V, IO = 1.5A, R_LL = 2.4mΩ

/VR A SetVID_fast, 0.7V to 0.9V, PS0,

CORE

CONFIDENTIAL

Figure 21. V

SetVID_slow to 0.3V, PS2, I

/VR A SetVID_fast, 0.3V to 0.9V,

CORE

= 1A, R_LL = 2.4mΩ

O

Figure 20. V

Figure 22. V

/VR A SetVID_fast, 0.3V to 0.9V to 0.3V,

CORE

PS1, IO= 7A, R_LL = 2.4mΩ

/VR A PS4 EXIT, SetVID_fast 0.9V, PS0,

CORE

= 0A, R_LL = 2.4mΩ

I

O

Figure 23. V

Pre-Empted Downward by SetVID_fast 0.6V, IO = 2.1A,

FN8973 Rev.0.00 Page 16 of 74

Oct 6, 2017

/VR A SetVID_decay 0.9V to 0.3V,

CORE

R_LL = 2.4mΩ

Figure 24. V

Pre-Empted Upward by SetVID_fast 0.6V, IO = 4.4A,

/VR A SetVID_decay 0.9V to 0.3V,

CORE

R_LL = 2.4mΩ

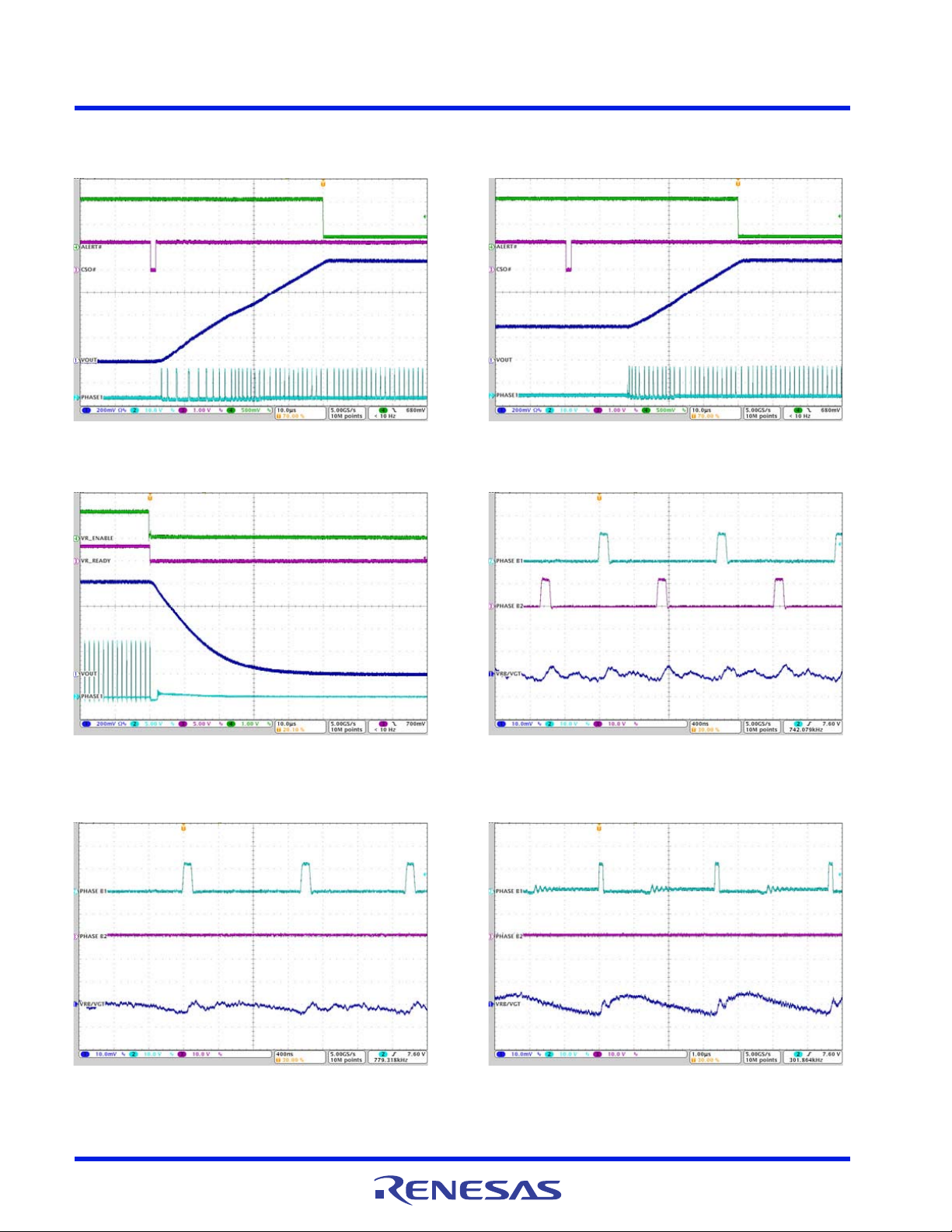

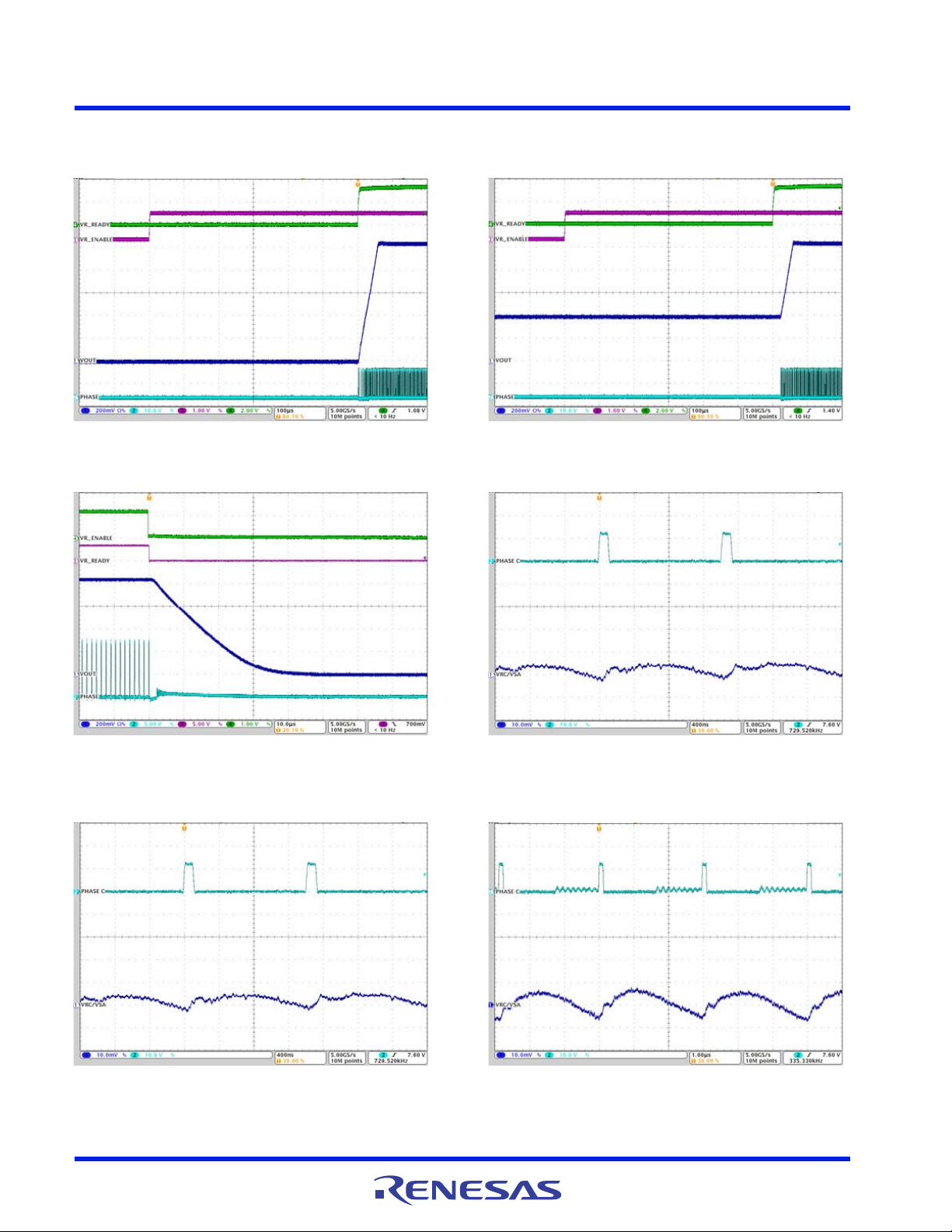

ISL95859C 4. Typical Performance Curves for VR B

4. Typical Performance Curves for VR B

Figure 25. VGT/VR B Soft-Start, SetVID_fast 0V to 0.9V,

=0A

I

O

CONFIDENTIAL

Figure 27. VGT/VR B Shutdown, IO= 35A, VID = 0.9V

Figure 26. VGT/VR B Soft-Start with Precharged Output,

SetVID_fast 0.9V, IO = 0A

Figure 28. VGT/VR B PS0 Steady-State Phase and Ripple,

I

= 35A, VID = 0.9V

O

Figure 29. VGT/VR B PS1 Steady-State Phase and Ripple,

= 10A, VID = 0.9V

I

O

FN8973 Rev.0.00 Page 17 of 74

Oct 6, 2017

Figure 30. VGT/VR B PS2 Steady-State Phase and Ripple,

= 2A, VID = 0.9V

I

O

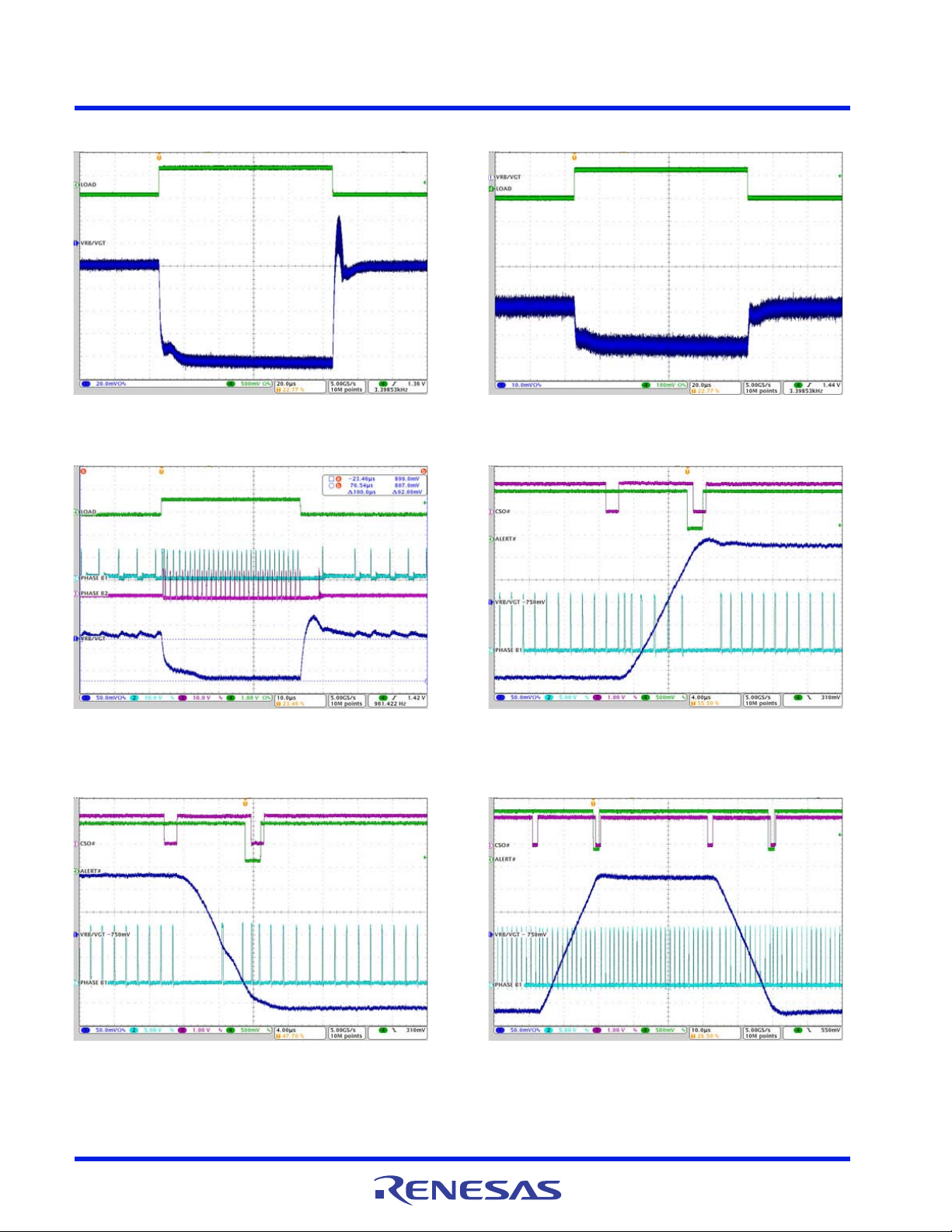

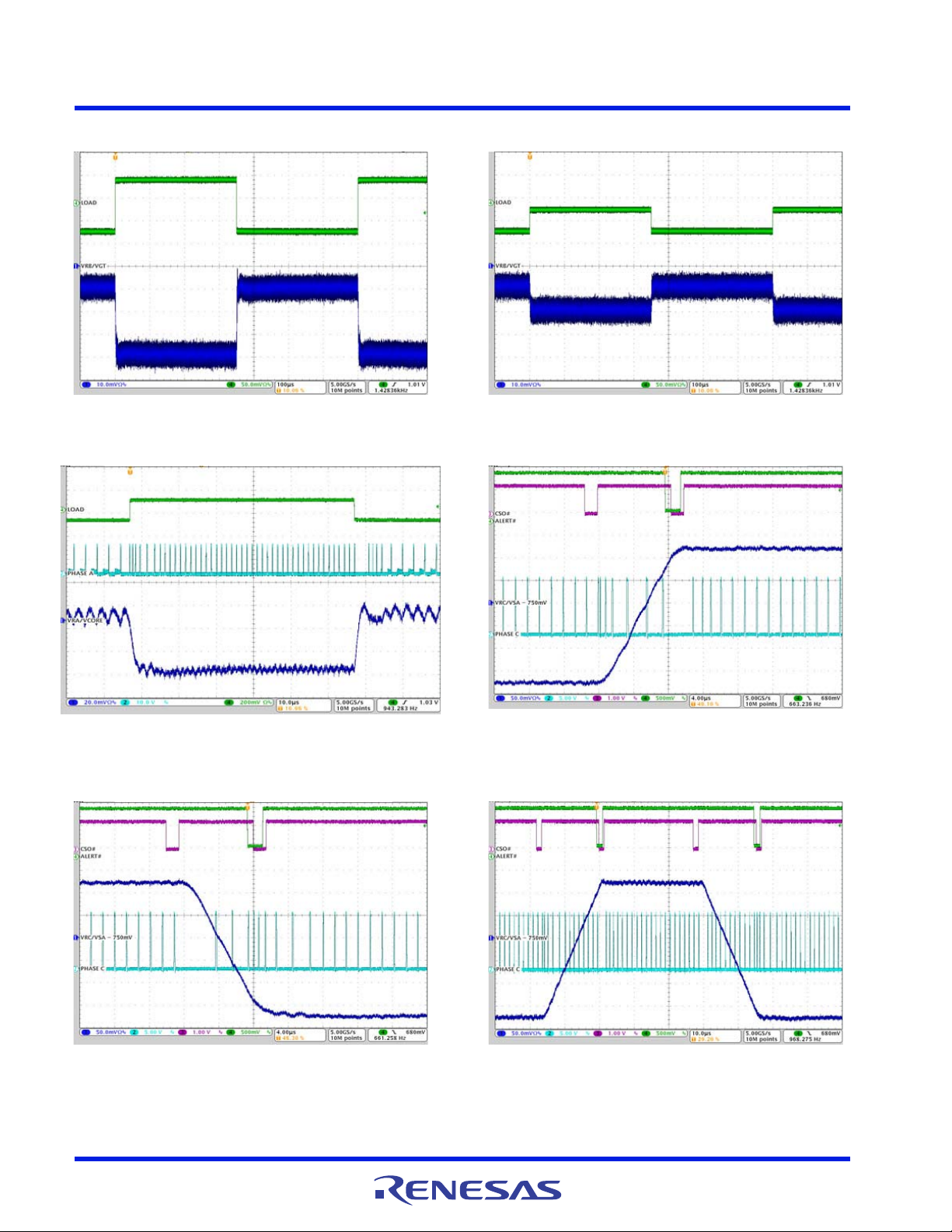

ISL95859C 4. Typical Performance Curves for VR B

Figure 31. VGT/VR B PS0 Load Step, IO = 11A to 57A,

VID = 0.9V, R_LL = 2.0mΩ

CONFIDENTIAL

Figure 33. VGT/VR B Load Step, I

PS0, VID = 0.9V, R_LL = 2.0mΩ

= 1A in PS2 to 47A in

O

Figure 32. IVGT/VR B PS0 Load Step, IO = 30A to 40A,

VID = 0.9V, R_LL = 2.0mΩ

Figure 34. VGT/VR B SetVID_fast, 0.6V to 0.9V, PS0,

= 11A, R_LL = 2.0mΩ

I

O

Figure 35. IVGT/VR B SetVID_fast, 0.9V to 0.6V, PS0,

= 11A, R_LL = 2.0mΩ

I

O

FN8973 Rev.0.00 Page 18 of 74

Oct 6, 2017

Figure 36. VGT/VR B SetVID_slow, 0.6V to 0.9V to 0.6V,

PS0, I

= 11A, R_LL = 2.0mΩ

O

ISL95859C 4. Typical Performance Curves for VR B

Figure 37. VGT/VR B SetVID_fast, 0.6V to 0.9V, PS0,

SetVID_decay, 0.9V to 0.6V, IO = 2A, R_LL = 2.0mΩ

CONFIDENTIAL

Figure 39. VGT/VR B SetVID_fast, 0.3V to 0.9V,

SetVID_slow to 0.3V, PS2, I

= 1A, R_LL = 2.0mΩ

O

Figure 38. VGT/VR B SetVID_fast, 0.3V to 0.9V to 0.3V, PS1,

IO= 10A, R_LL = 2.0mΩ

Figure 40. VGT/VR B PS4 Exit, SetVID_fast 0.9V, PS0,

= 0A, R_LL = 2.0mΩ

I

O

Figure 41. VGT/VR B SetVID_decay 0.9V to 0.3V,

Pre-Empted Downward by SetVID_fast 0.6V, I

R_LL = 2.0mΩ

FN8973 Rev.0.00 Page 19 of 74

Oct 6, 2017

= 1.5A,

O

Figure 42. VGT/VR B SetVID_decay 0.9V to 0.3V,

Pre-Empted Upward by SetVID_fast 0.6V, I

R_LL = 2.0mΩ

= 4A,

O

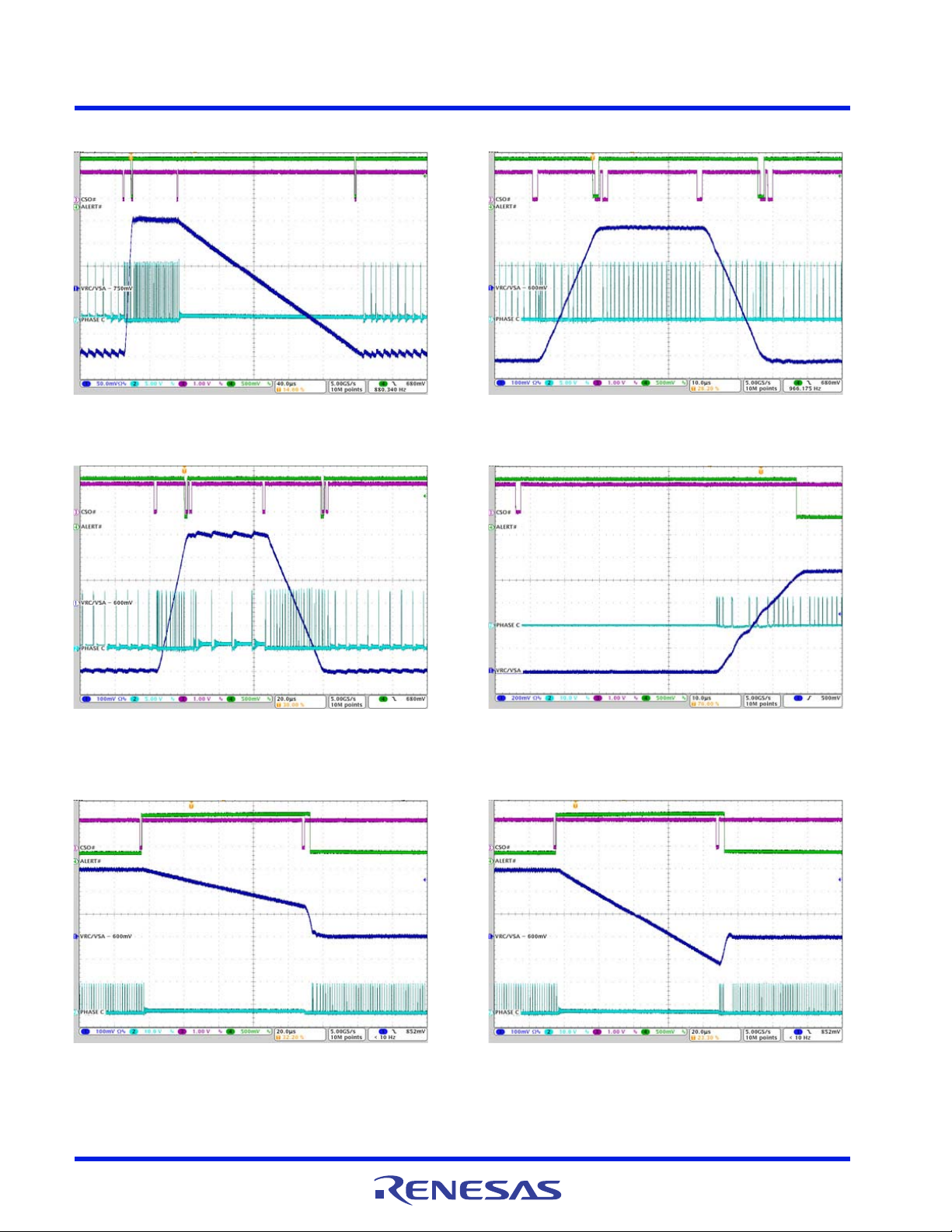

ISL95859C 5. Typical Performance Curves for VR C

5. Typical Performance Curves for VR C

Figure 43. VSA/VR C Soft-Start, 0V to V

=0A

I

O

BOOT

= 1.05V,

CONFIDENTIAL

Figure 45. VSA/VR C Shutdown, IO=5A, VID=0.9V

Figure 44. VSA/VR C Soft-Start with Precharged Output,

V

= 1.05V, IO = 0A

BOOT

Figure 46. VSA/VR C PS0 Steady-State Phase and Ripple,

I

= 5A, VID = 0.9V

O

Figure 47. VSA/VR C PS1 Steady-State Phase and Ripple,

= 5A, VID = 0.9V

I

O

FN8973 Rev.0.00 Page 20 of 74

Oct 6, 2017

Figure 48. VSA/VR C PS0 Steady-State Phase and Ripple,

IO= 1A, VID = 0.9V

ISL95859C 5. Typical Performance Curves for VR C

Figure 49. VSA/VR C PS0 Load Step, IO = 2A to 5A,

VID = 0.9V, R_LL = 10.3mΩ

CONFIDENTIAL

Figure 51. VSA/VR C Load Step, I

PS0, VID = 0.9V, R_LL = 10.3mΩ

= 1A in PS2 to 5A in

O

Figure 50. VSA/VR C PS0 Load Step, IO = 2A to 3A,

VID = 0.9V, R_LL = 10.3mΩ

Figure 52. VSA/VR C SetVID_fast, 0.6V to 0.9V, PS0,

IO= 3A, R_LL = 10.3mΩ

Figure 53. VSA/VR C SetVID_fast, 0.9V to 0.6V, PS0,

I

= 3A, R_LL = 10.3mΩ

O

FN8973 Rev.0.00 Page 21 of 74

Oct 6, 2017

Figure 54. VSA/VR C SetVID_slow, 0.6V to 0.9V to 0.6V,

PS0, I

= 3A, R_LL = 10.3mΩ

O

ISL95859C 5. Typical Performance Curves for VR C

Figure 55. VSA/VR C SetVID_fast, 0.6V to 0.9V, PS0,

SetVID_decay, 0.9V to 0.6V, IO = 200mA, R_LL = 10.3mΩ

CONFIDENTIAL

Figure 57. VSA/VR C SetVID_fast, 0.3V to 0.9V,

SetVID_slow to 0.3V, PS2, I

= 200mA, R_LL = 10.3mΩ

O

Figure 56. VSA/VR C SetVID_fast, 0.3V to 0.9V to 0.3V, PS1,

IO= 3A, R_LL = 10.3mΩ

Figure 58. VSA/VR C PS4 Exit, SetVID_fast 0.9V, PS0,

IO= 0A, R_LL = 10.3mΩ

Figure 59. VSA/VR C SetVID_decay 0.9V to 0.3V,

Pre-Empted Downward by SetVID_fast 0.6V, IO = 250mA,

R_LL = 10.3mΩ

FN8973 Rev.0.00 Page 22 of 74

Oct 6, 2017

Figure 60. VSA/VR C SetVID_decay 0.9V to 0.3V,

Pre-Empted Upward by SetVID_fast 0.6V, I

R_LL = 10.3mΩ

= 650mA,

O

ISL95859C 6. Theory of Operation

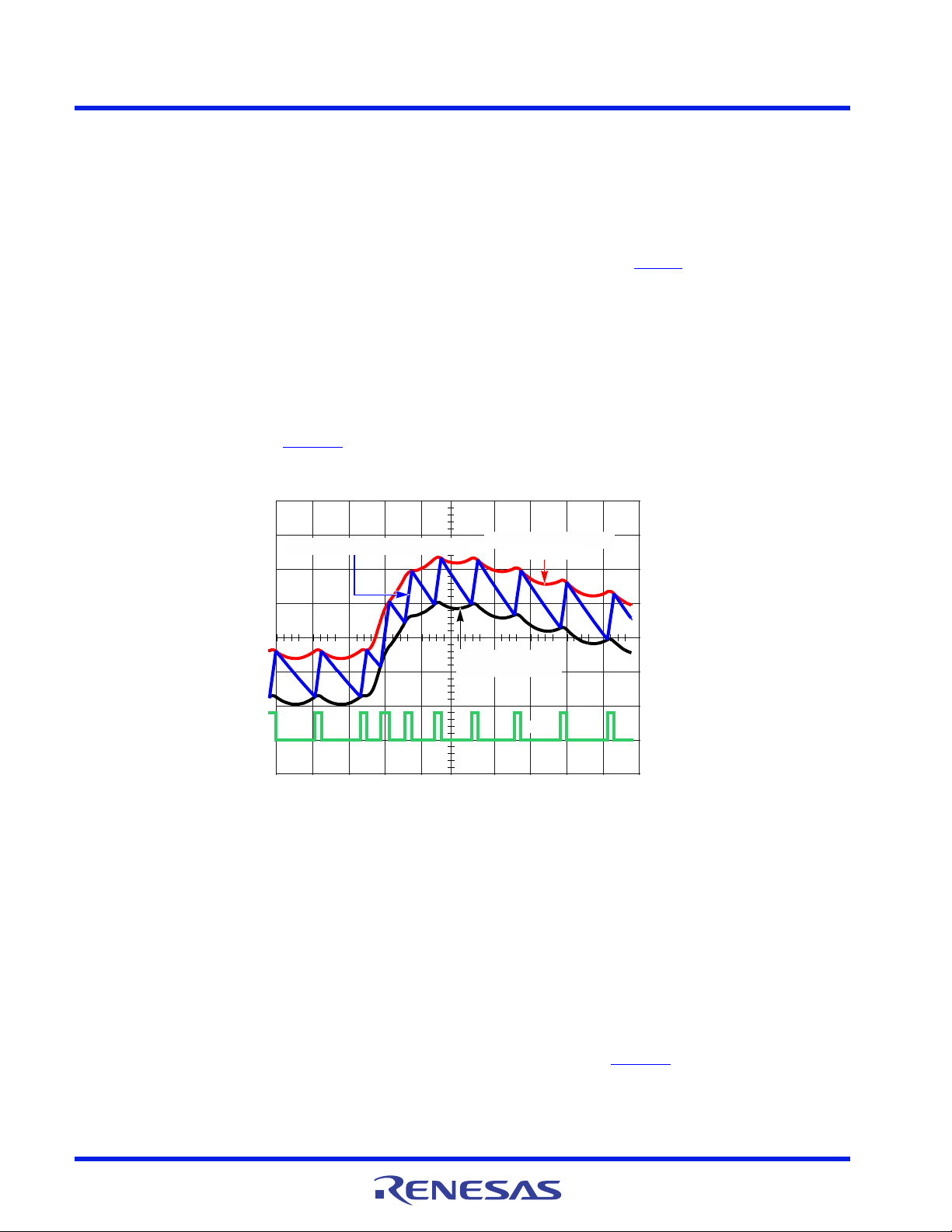

Figure 61. Modulator Waveforms During Load Transient

PWM

SYNTHETIC CURRENT SIGNAL

ERROR AMPLIFIER

WINDOW VOLTAGE V

W

(WRT V

COMP

)

VOLTAGE V

COMP

6. Theory of Operation

The ISL95859C is a three output, multiphase controller supporting Intel IMVP8 microprocessor Core (IA), Graphics

(GT), and System Agent (SA), or GTUS rails. The controller supports single-phase operation on outputs VR A and VR C.

Voltage regulator VR B supports 1- or 2-phase operation. The ISL95859C is compliant to Intel IMVP8 specifications with

SerialVID features. The system parameters and SVID required registers are programmable through 2 dedicated

programming pins. This greatly simplifies the system design for various platforms and lowers inventory complexity and

cost by using a single device. The “Typical Application Circuits” section beginning on page 14

view of configuring all three outputs using the ISL95859C controller.

6.1 R3 Modulator

The R3 modulator is Intersil’s proprietary synthetic current-mode hysteretic controller which blends both fixed

frequency PWM and variable frequency hysteretic control technologies. This modulator topology offers high noise

immunity and a rapid transient response to dynamic load scenarios. Under static conditions the desired switching

frequency is maintained within the entire specified range of input voltages, output voltages and load currents.

During load transients the controller will increase or decrease the PWM pulses and switching frequency to maintain

output voltage regulation. Figure 61

climb from a load step, the time between PWM pulses decreases as f

regulation.

illustrates this effect during a load insertion. As the window voltage starts to

increases to keep the output within

SW

provides a top level

CONFIDENTIAL

6.2 Multiphase Power Conversion

Microprocessor load current profiles have changed to the point that the advantages of multiphase power conversion

are impossible to ignore. Multiphase converters overcome the daunting technical challenges in producing a costeffective and thermally viable single-phase converter at the high Thermal Design Current (TDC) levels. The

ISL95859C controller VR B output reduces the complexity of multiphase implementation by integrating vital

functions and requiring minimal output components.

6.2.1 Interleaving

The switching of each channel in a multiphase converter is timed to be symmetrically out-of-phase with the

other channels. For the example of a 3-phase converter, each channel switches 1/3 cycle after the previous

channel and 1/3 cycle before the following channel. As a result, the 3-phase converter has a combined ripple

frequency 3x that of the ripple frequency of any one phase, as illustrated in Figure 62

currents (I

, IL2, and IL3) combine to form the AC ripple current and to supply the DC load current.

L1

. The three channel

FN8973 Rev.0.00 Page 23 of 74

Oct 6, 2017

ISL95859C 6. Theory of Operation

I

P-P

VINV

OUT

–V

OUT

Lf

SW

V

IN

----------------------------------------------------------=

(EQ. 1)

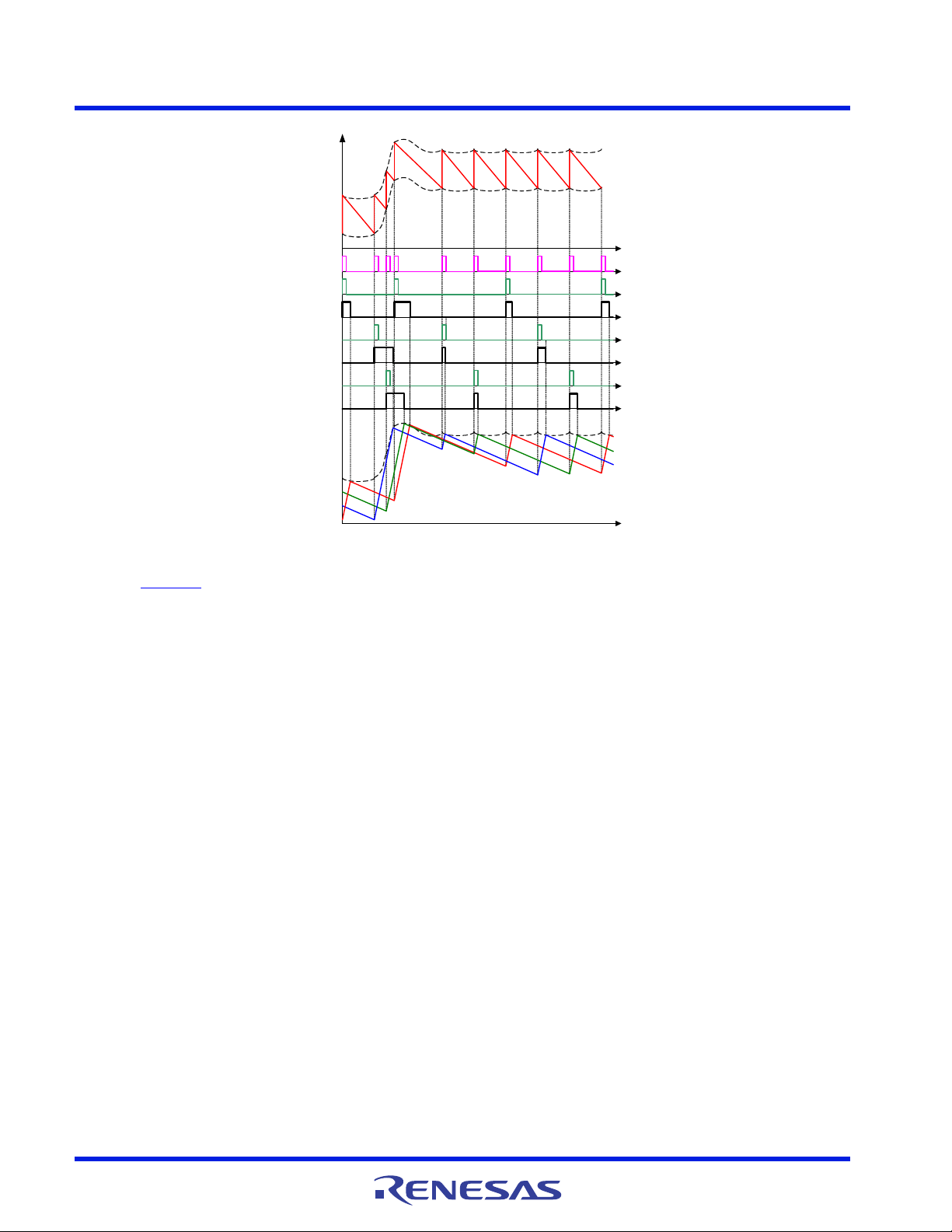

Figure 62. PWM and Inductor-Current Waveforms for

3-Phase Converter

1µs/DIV

PWM2, 5V/DIV

PWM3, 5V/DIV

IL2, 7A/DIV

IL3, 7A/DIV

IL1 + IL2 + IL3, 7A/DIV

IL1, 7A/DIV

PWM1, 5V/DIV

The ripple current of a multiphase converter is less than that of a single-phase converter supplying the same

load. To understand why, examine Equation 1

, which represents an individual channel’s peak-to-peak inductor

current.

In Equation 1

value, and f

, VIN and V

is the switching frequency.

SW

are the input and output voltages respectively, L is the single-channel inductor

OUT

CONFIDENTIAL

In a multiphase converter, the output capacitor current is the superposition of the ripple currents from each of the

individual phases. Compare Equation 1

(symmetrically phase-shifted inductor currents) in Equation 2

decreases with the increase in the number of channels, as shown in Figure 63

Ripple Current Multiplier (K

RCM

zero, the turn-off of one phase corresponds exactly with the turn-on of another phase, resulting in the sum of all phase

currents being always the (constant) load current and therefore there is no ripple current in this case.

The output voltage ripple is a function of capacitance, capacitor Equivalent Series Resistance (ESR), and the

summed inductor ripple current. Increased ripple frequency and lower ripple amplitude allow the designer to

use lower saturation-current inductors and fewer or less costly output capacitors for any performance

specification.

to the expression for the peak-to-peak current after the summation of N

. The peak-to-peak overall ripple current (I

C(P-P)

, which introduces the concept of the

). At the steady state duty cycles for which the ripple current and thus the K

)

RCM

is

FN8973 Rev.0.00 Page 24 of 74

Oct 6, 2017

ISL95859C 6. Theory of Operation

DUTY CYCLE (V

OUT/VIN

)

Figure 63. Ripple Current Multiplier vs Duty Cycle

RIPPLE CURRENT MULTIPLIER, K

RCM

N = 1

3

4

2

5

6

0

10 20 30 40 50 60 70 80 90 100

1.0

0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

(EQ. 2)

m ROUNDUP N D 0=

for

m1– ND m

I

C(P-P)

V

OUT

LfSW

------------------

K

RCM

=

K

RCM

ND m– 1+mND–

ND

------------------------------------------------------------- ----------------=

Figure 64. Channel Input Currents and Input-Capacitor

RMS Current for 3-phase Converter

CHANNEL 3

INPUT CURRENT

10A/DIV

CHANNEL 2

INPUT CURRENT

10A/DIV

CHANNEL 1

INPUT CURRENT

10A/DIV

INPUT-CAPACITOR CURRENT, 10A/DIV

1µs/DIV

CONFIDENTIAL

Another benefit of interleaving is to reduce the input ripple current. Input capacitance is determined in part by

the maximum input ripple current. Multiphase topologies can improve overall system cost and size by lowering

input ripple current and allowing the designer to reduce the cost of input capacitors. Figure 64

currents from a 3-phase converter combining to reduce the total input ripple current.

FN8973 Rev.0.00 Page 25 of 74

Oct 6, 2017

The converter depicted in Figure 64

current is 5.9A. Compare this to a single-phase converter also stepping down 12V to 1.5V at 36A. The singlephase converter has 11.9A

bank with twice the RMS current capacity as the equivalent 3-phase converter.

A more detailed explanation of input capacitor design is provided in “

input capacitor current. The single-phase converter must use an input capacitor

RMS

illustrates input

delivers 36A to a 1.5V load from a 12V input. The RMS input capacitor

Input Capacitor Selection” on page 37.

ISL95859C 6. Theory of Operation

Figure 65. R3 Modulator Circuit

C

rm

gmVo

MASTER

CLOCK

VW

COMP

MASTER

CLOCK

PHASE

SEQUENCER

CLOCK1

CLOCK2

R

I

L1

gm

CLOCK1

PHASE1

C

rs1

VW

S

Q

PWM1

L1

R

I

L2

gm

CLOCK2

PHASE2

C

rs2

VW

S

Q

PWM2

L2

Co

Vo

Vcrm

Vcrs1

Vcrs2

MASTER CLOCK CIRCUIT

SLAVE CIRCUIT 1

SLAVE CIRCUIT 2

R

I

L3

gm

CLOCK3

PHASE3

C

rs3

VW

S

Q

PWM3

L3

Vcrs3

SLAVE CIRCUIT 3

CLOCK3

+

-

+

-

+

-

+

-

+

-

+

-

+

-

6.2.2 Multiphase R3 Modulator

The Intersil ISL95859C VR B output uses the patented R3 (Robust Ripple Regulator) modulator. The R3

modulator combines the best features of fixed frequency PWM and hysteretic PWM while eliminating many of

their shortcomings. Figure 65

illustrates the operational principles.

shows the conceptual multiphase R3 modulator circuit and Figure 66 on page 27

CONFIDENTIAL

FN8973 Rev.0.00 Page 26 of 74

Oct 6, 2017

ISL95859C 6. Theory of Operation

Figure 66. R3 Modulator Operation Principles in

Steady State

COMP

V

crm

MASTER

CLOCK

PWM1

VW

CLOCK1

PWM2

CLOCK2

HYSTERETIC

WINDOW

PWM3

V

crs3

CLOCK3

V

crs2

V

crs1

VW

The internal modulator uses a master clock circuit to generate the clocks for the slave circuits, one per phase.

CONFIDENTIAL

The R3™ modulator master oscillator slews between two voltage signals; the COMP voltage (the output of the

voltage sense error amplifier, assuming the topology of Figure 76 on page 43

) and VW (Voltage Window), a

voltage positively offset from COMP by an offset voltage that is dependent on the nominal switching frequency.

The modulator discharges the master clock ripple capacitor C

with a current source equal to gmVo, where gm

rm

is a gain factor, dependent on the nominal switching frequency and also on the number of active phases. The

C

voltage V

rm

is a sawtooth waveform traversing between the VW and COMP voltages. It resets (charges

crm

quickly) to VW when it discharges (with discharge current gmVo) to COMP and generates a one-shot master

clock signal. A phase sequencer distributes the master clock signal to the active slave circuits. For example, if

the conceptual VR is in 4-phase mode, the master clock signal is distributed to the four phases 90° out-of-phase,

in 3-phase mode distributed to the three phases 120° out-of-phase, and in 2-phase mode distributed to Phases 1

and 2 180° out-of-phase. If VR is in 1-phase mode, the master clock signal is distributed to Phase 1 only and is

the Clock1 signal.

Each slave circuit has its own ripple capacitor C

, whose voltage mimics the inductor ripple current. A gm

rsn

amplifier converts the inductor voltage (or alternatively, series sense resistor voltage, indicative of that phase’s

inductor current) into a current source to charge and discharge C

upon receiving its respective clock signal Clockn and the current source charges C

proportional to its respective positive inductor voltage. When the C

circuit turns off the PWM pulse and the current source then discharges C

respective now-negative inductor voltage. C

Because the modulator works with the V

discharges until the next Clockn pulse and the cycle repeats.

rsn

, which are large-amplitude and noise-free synthesized signals, it

crsn

. The slave circuit turns on its PWM pulse

rsn

rsn

voltage (V

, with a current proportional to its

rsn

with a current

rsn

) rises to VW, the slave

Crsn

achieves lower phase jitter than conventional hysteretic mode and fixed PWM mode controllers. Unlike

conventional hysteretic mode converters, the ISL95859C uses an error amplifier that allows the controller

outputs to maintain a 0.5% output voltage accuracy.

FN8973 Rev.0.00 Page 27 of 74

Oct 6, 2017

ISL95859C 6. Theory of Operation

Figure 67. R3 Modulator Operation Principles in Load

Insertion Response

COMP

V

crm

MASTER

CLOCK

PWM1

V

crs1

VW

CLOCK1

PWM2

V

crs2

CLOCK2

PWM3

CLOCK3

V

crs3

VW

Figure 67 illustrates the operational principles during load insertion response. The COMP voltage rises during

CONFIDENTIAL

load insertion (due to the sudden discharge of the output capacitor driving the inverting input of the error

amplifier), generating the master clock signal more quickly. Thus, the PWM pulses turn on earlier, increasing

the effective switching frequency. This phenomenon allows for higher control loop bandwidth than

conventional fixed frequency PWM controllers. The VW voltage rises with the COMP voltage, making the

PWM on-time pulses wider. During load release response, the COMP voltage falls. It takes the master clock

circuit longer to generate the next master clock signal so the PWM pulse is held off until needed. The VW

voltage falls with the COMP voltage, reducing the current PWM pulse width. The inherent pulse frequency and

width increase due to an increasing load transient. Likewise, the pulse frequency and width reductions due to a

decreasing load transient produce the excellent load transient response of the R3 modulator.

Because all phases share the same VW window (master clock frequency generator) and threshold (slave pulse

width generator) voltage, dynamic current balance among phases is inherently ensured for the duration of any

load transient event.

The R3 modulator intrinsically has input voltage feed-forward control, due to the proportional dependence of the

clock generator slave transconductance gains on the input voltage. This dependence decreases the on-time

pulse-width of each phase in proportion to an increase in input voltage, making the output voltage insensitive to a fast

slew rate input voltage change.

FN8973 Rev.0.00 Page 28 of 74

Oct 6, 2017

ISL95859C 6. Theory of Operation

UGATE

PHASE

IL

LGATE

Figure 68. Diode Emulation

6.3 Diode Emulation and Period Stretching

The ISL95859C can operate each of its three rails in Diode Emulation Mode (DEM) to improve light-load efficiency.

Diode emulation is enabled in PS2 and PS3 power states. In DEM, the low-side MOSFET conducts while the current

is flowing from source-to-drain and blocks reverse current, emulating a diode. Figure 68

is on, the low-side MOSFET carries current, creating negative voltage on the phase node due to the voltage drop

across the ON-resistance. The controller monitors the inductor current by monitoring the phase node voltage. It turns

off LGATE when the phase node voltage reaches zero to prevent the inductor current from reversing the direction and

creating unnecessary power loss.

illustrates that, when LGATE

If the load current is light enough, as Figure 68

CONFIDENTIAL

next phase node pulse and the regulator is in Discontinuous Conduction Mode (DCM). If the load current is heavy

enough, the inductor current will never reach 0A and the regulator will appear to operate in Continuous Conduction

Mode (CCM), although the controller is nevertheless configured for DEM.

Figure 69

from top to bottom. The PWM on-time is determined by the VW window size, making the inductor current triangle

the same in the three cases (only the time between inductor current triangles changes). The controller clamps the ripple

capacitor voltage V

which produces master clock pulses, naturally stretching the switching period. The inductor current triangles move

further apart from each other such that the inductor current average value is equal to the load current. The reduced

switching frequency improves light-load efficiency.

Because the next clock pulse occurs when V

switching pulse frequency is responsive to load transient events in a manner similar to that of the multiphase CCM

operation.

shows the operation principle in DEM at light load. The load gets incrementally lighter in the three cases

in DEM to make it mimic the inductor current. It takes the COMP voltage longer to hit V

crs

illustrates, the inductor current will reach and stay at zero before the

(which tracks output voltage error) rises above V

COMP

CRM

, DEM

crm

,

FN8973 Rev.0.00 Page 29 of 74

Oct 6, 2017

ISL95859C 6. Theory of Operation

Figure 69. Period Stretching

I

L

I

L

V

crs

I

L

V

crs

V

crs

VW

CCM/DCM BOUNDARY

LIGHT DCM

DEEP DCM

VW

VW

6.4 Adaptive Body Diode Conduction Time Reduction

When in DCM, the controller ideally turns off the low-side MOSFET when the inductor current approaches zero.

CONFIDENTIAL

During on-time of the low-side MOSFET, phase voltage is negative, due to the product of the (negative) inductor

current and the low-side MOSFET r

, producing a voltage drop that is proportional to the inductor current. A

DS(ON)

phase comparator inside the controller monitors the phase voltage during on-time of the low-side MOSFET and

compares it with a threshold to determine the zero-crossing point of the inductor current. If the inductor current has

not reached zero when the low-side MOSFET turns off, it will flow through the low-side MOSFET body diode,

causing the phase node to have a larger voltage drop until it decays to zero. If the inductor current has crossed zero

and reversed the direction when the low-side MOSFET turns off, it will flow through the high-side MOSFET body

diode, causing the phase node to have a positive voltage spike (to V

plus a PN diode voltage drop) until the

IN

current decays to zero. The controller continues monitoring the phase voltage after turning off the low-side

MOSFET and adjusts the phase comparator threshold voltage accordingly in iterative steps such that the low-side

MOSFET body diode conducts for approximately 40ns (turning off 40ns before the inductor current zero-crossing)

to minimize the body diode-related loss.

6.5 Modes of Operation

The ISL95859C controller supports three voltage regulator outputs and each output is configured independently.

VR A and VR C are single-phase only regulators while VR B can support 2-phase or single-phase operation.

6.5.1 VR A Configuration and operation

Voltage Regulator A (VR A) operates only as a single-phase regulator. It operates in 1-phase CCM in PS0 and

PS1 and enters 1-phase DEM in PS2 and PS3. The overcurrent protection level is the same for all power states

as shown in Table 1

Power States Mode OCP Threshold (µA)

01-phase CCM 60

1

21-phase DE

3

FN8973 Rev.0.00 Page 30 of 74

Oct 6, 2017

.

Table 1. VR Modes of Operation VR C

ISL95859C 6. Theory of Operation

6.5.2 VR B Configuration and operation

Voltage Regulator B (VR B) can be configured for 2- or 1-phase operation. Ta ble 2 shows the VR B

configurations and operational modes, programmed by the ISEN2_B and ISEN1_B pin connections and by the

Power State (PS) command (SVID Register 32h). When configured for a 2-phase operation, the ISEN pins must

be connected through a low-pass filter to their respective PHASE node at the output inductor. For a 1-phase

configuration, tie both ISEN1_B and ISEN2_B to VCC. Phases are disabled in order, starting with the highest

numbered phase, as follows.

Table 2. VR Modes of Operation VR B

ISEN2_B Configuration PS Mode OCP Threshold (µA)

To Power Stage 2-phase VR B Configuration 0 2-phase CCM 60

1 1-phase CCM 30

2 1-phase DE

3

Tied to

VCC (+5V)

In a 2-phase configuration, all phases are active and the ISEN2_B and ISEN1_B pins are connected to their

associated PHASE nodes. For a 1-phase configuration, tie the ISEN2_B pin to VCC (+5V) and connect

ISEN1_B to VCC (+5V) or leave it open.

CONFIDENTIAL

In a 2-phase configuration, VR B operates in 2-phase CCM in PS0. It enters 1-phase mode in PS1, PS2, and

PS3 by dropping Phase 2 and reducing the overcurrent protection level to 1/2 of the initial value. PS1 operates

in CCM and PS2 and PS3 operate in DEM.

1-phase VR B Configuration

ISEN1_B open or tied to VCC (+5V)

0 1-phase CCM 60

1

2 1-phase DE

3

In a 1-phase configuration, VR A operates in 1-phase CCM in PS0 and PS1, and enters 1-phase DEM in PS2

and PS3. The overcurrent protection level is the same for all power states.

6.5.3 VR C Operation

Voltage Regulator C (VR C) supports 1-phase operation only. It operates in 1-phase CCM in PS0 and PS1 and

enters 1-phase DEM in PS2 and PS3. The overcurrent protection level is the same for all power states as shown

in Table 3

.

Table 3. VR Modes of Operation VR C

Power States Mode OCP Threshold (µA)

01-phase CCM 60

1

21-phase DE

3

6.5.4 Disabling outputs

Each of the ISL95859C outputs is disabled by connecting the ISUMN_x pin of the voltage regulator to +5V.

The controller will not acknowledge SVID communication to a disabled channel.

FN8973 Rev.0.00 Page 31 of 74

Oct 6, 2017

ISL95859C 6. Theory of Operation

6.6 Programming Resistors

Two programming resistors (R

to set the common switching frequency for the VR A and VR B outputs. The switching frequency options are

450kHz, 583kHz, and 750kHz. This provides flexibility in optimizing the regulators for a wide array of solutions.

R

PROG1

also sets the I

CC(MAX)

maximum current each VR can support. The CPU will read the individual VR I

that the VR current does not exceed the value specified.

Typical PROG1

Resistor

(±1%, KΩ)

1.87 450 21 24 40 18 18

5.62 450 30 30 60 20 20

9.31 450 33 35 40 18 18

13.3 450 34 35 67 18 18

16.9 450 35 40 70 20 20

20.5 450 40 40 75 25 25

24.3 583 21 24 40 18 18

28.0 583 30 30 60 20 20

34.0 583 33 35 40 18 18

41.2 583 34 35 67 18 18

CONFIDENTIAL

48.7 583 35 40 70 20 20

56.2 583 40 40 75 25 25

63.4 750 21 24 40 18 18

71.5 750 30 30 60 20 20

78.7 750 33 35 40 18 18

88.7 750 34 35 67 18 18

100 750 35 40 70 20 20

110 750 40 40 75 25 25

VR A and VR B

Switching Frequency

F

(kHz)

sw

PROG1

and R

) configure the ISL95859C. Table 4 shows how to select R

PROG2

register value for all three VRs. The I

Table 4. PROG1 Pin

VR A VR B VR C

IA/GT 1-ph (A) IA/GT 1-ph (A) IA/GT 2-ph (A) GTUS (A) SA or GTUS (A)

CC(MAX)

IMAX

register value determines the

CC(MAX)

register value and ensure

PROG1

R

sets the address registers for all three VRs (VR A, VR B, and VR C) on the ISL95859C. The three

PROG2

controller outputs can be configured to support three of the four potential processor rails required. The address

selections include Core (IA), Graphics slice (GT), Graphics Unslice (GTUS), and System Agent (SA) rails of the

Intel IMVP8™ processor. The selection should be based on the TDC requirements of the rail and the number of

phases required to support the overall current. Processor SKUs require support for all four processor rails, and the

ISL95859C can be used with the ISL95853 to support them all (see Table 5

R

also selects the switching frequency for VR C. The switching frequency options are 450kHz, 583kHz, and

PROG2

).

750kHz. This provides flexibility in optimizing the regulators for a wide array of solutions.

Table 5. PROG2 Pin

Typical PROG2

Resistor

(±1%, kΩ)

1.87 GT[01h] IA [00h] SA [02h] 450

5.62 GT[01h] IA [00h] SA [02h] 583

9.31 GT[01h] IA [00h] SA [02h] 750

20.5 GT[01h] IA [00h] GTUS [03h] 450

Address

Selection

Switching Frequency

f

SW

VR C

(kHz)VR A VR B VR C

FN8973 Rev.0.00 Page 32 of 74

Oct 6, 2017

ISL95859C 6. Theory of Operation

Table 5. PROG2 Pin (Continued)

Typical PROG2

Resistor

(±1%, kΩ)

24.3 GT[01h] IA [00h] GTUS [03h] 583

28.0 GT[01h] IA [00h] GTUS [03h] 750

48.7 IA [00h] GT[01h] SA [02h] 450

56.2 IA [00h] GT[01h] SA [02h] 583

63.4 IA [00h] GT[01h] SA [02h] 750

88.7 IA [00h] GT[01h] GTUS [03h] 450

100 IA [00h] GT[01h] GTUS [03h] 583

110 IA [00h] GT[01h] GTUS [03h] 750

150 IA [00h] GTUS [03h]] SA [02h] 450

165 IA [00h] GTUS [03h]] SA [02h] 583

182 IA [00h] GTUS [03h]] SA [02h] 750

Address

Selection

Switching Frequency

f

SW

VR C

(kHz)VR A VR B VR C

6.6.1 Switching Frequency Selection

There are a number of variables to consider when choosing switching frequency, as there are considerable effects on

the upper MOSFET loss calculation. These effects are outlined in “

upper limit for the switching frequency. The lower limit is established by the requirement for fast transient response

and small output voltage ripple as outlined in “

frequency that allows the regulator to meet the transient-response and output voltage ripple requirements.

CONFIDENTIAL

The resistors from PROG1 and PROG2 to GND select one of three available switching frequencies: 450kHz,

583kHz, and 750kHz. Note that when the ISL95859C is in Continuous Conduction Mode (CCM), the switching

frequency is not strictly constant due to the nature of the R3 modulator. As explained in “

Modulator” on page 26, the effective switching frequency will increase during load insertion and will decrease

during load release to achieve fast response. However, the switching frequency is nearly constant at constant

load. Variation is expected when the power stage condition, such as input voltage, output voltage, load, etc.

changes. The variation is usually less than 15% and does not have any significant effect on output voltage ripple

magnitude.

Output Filter Design” on page 36. Choose the lowest switching

MOSFETs” on page 34 and they establish the

Multiphase R3

6.7 PSYS System Power Monitoring

In an IMVP8 system the PSYS signal monitors the total system input power from either the battery or adapter.

When implemented according to Intel’s specifications, the PSYS voltage is a 1.2V full-scale analog signal sent into

the PSYS pin of the ISL95859C. The PSYS signal is then digitized and sent to the CPU over the SVID Bus.

This pin is designed to be used in conjunction with Intersil battery chargers. The full-scale current sent to the

ISL95859C PSYS pin from the charger IC should be scaled to a 1.2V full-scale voltage using the appropriate

resistor from the PSYS pin to GND.

FN8973 Rev.0.00 Page 33 of 74

Oct 6, 2017

ISL95859C 7. General Design Guide

P

LOW 1

r

DS ON

I

M

N

------

2

I

P-P

2

12

----------+1d–=

(EQ. 3)

P

LOW 2

V

DONfSW

I

M

N

------

I

P-P

2

----------

–

t

d1

I

M

N

------

I

P-P

2

----------

–

t

d2

+

=

(EQ. 4)

P

LOW 3,

2

3

---

V

IN

1.5

C

OSS_LOWVDS _LOW fSW

(EQ. 5)

7. General Design Guide

This design guide provides a high-level explanation of the steps necessary to design a multiphase power converter. It is

assumed that the reader is familiar with many of the basic skills and techniques referenced in the following. In addition

to this guide, Intersil provides complete reference designs, which include schematics, bills of materials, and example

board layouts for common microprocessor applications.

7.1 Power Stages

The first step in designing a multiphase converter is to determine the number of phases. This determination

depends heavily upon the cost analysis, which in turn depends on system constraints that differ from one design to

the next. Principally, the designer is concerned with whether components can be mounted on both sides of the

circuit board, whether through-hole components are permitted, and the total board space available for power supply

circuitry. Generally speaking, the most economical solutions are those in which each phase handles between 15A

and 25A. In cases where board space is the limiting constraint, current can be pushed as high as 40A per phase, but

these designs require heatsinks and forced air to cool the MOSFETs, inductors, and heat-dissipating surfaces.

7.1.1 MOSFETs

MOSFET choice depends on the current each MOSFET is required to conduct, the switching frequency, the

capability of the MOSFETs to dissipate heat and the availability and nature of heatsinking and air flow.

7.1.1.1 Lower MOSFET Power Calculation

The calculation for heat dissipated in the lower (alternatively called low-side) MOSFET of each phase is

simple, because virtually all of the heat loss in the lower MOSFET is due to current conducted through the

CONFIDENTIAL

channel resistance (r

peak inductor current per phase (see Equation 1 on page 24

channel inductance. Equation 3

). In Equation 3, IM is the maximum continuous output current; I

DS(ON)

); d is the duty cycle (V

shows the approximation.

OUT/VIN

is the peak-to-

P-P

); and L is the per-

A term can be added to the lower MOSFET loss equation to account for the loss during the dead time when

inductor current is flowing through the lower MOSFET body diode. This term is dependent on the diode

forward voltage at I

, V

M

; the switching frequency, fsw; and the length of dead times (td1 and t

D(ON)

d2)

beginning and end of the lower MOSFET conduction interval, respectively.

Finally, the power loss of output capacitance of the lower MOSFET is approximated in Equation 5

where C

OSS_LOW

is the output capacitance of the lower MOSFET at the test voltage of V

DS_LOW

:

. Depending

on the amount of ringing, the actual power dissipation is slightly higher than this.

Thus, the total maximum power dissipated in each lower MOSFET is approximated by the summation of

P

LOW,1

, P

LOW,2

and P

LOW,3

.

7.1.1.2 Upper MOSFET Power Calculation

In addition to r

input voltage (V

dependent on switching frequency, the power calculation is more complex. Upper MOSFET losses are divided

losses, a large portion of the upper MOSFET losses are due to currents conducted across the

DS(ON)

) during switching. Because a substantially higher portion of the upper MOSFET losses are

IN

at the

FN8973 Rev.0.00 Page 34 of 74

Oct 6, 2017

ISL95859C 7. General Design Guide

P

UP 1VIN

I

M

N

------

I

P-P

2

----------+

t

1

2

----

f

SW

(EQ. 6)

P

UP 2VIN

I

M

N

------

I

P-P

2

----------

–

t

2

2

----

f

SW

(EQ. 7)

P

UP 3VINQrrfSW

=

(EQ. 8)

(EQ. 9)

P

UP 4rDS ON

I

M

N

------

2

I

P-P

2

12

----------

+d

P

UP 5LDS

I

M

N

------

I

P-P

2

----------

+

2

(EQ. 10)

P

UP 6

2

3

---

V

IN

1.5

C

OSS_UPVDS_UP fSW

(EQ. 11)

into separate components involving the upper MOSFET switching times, the lower MOSFET body-diode

reverse-recovery charge Q

, and the upper MOSFET r

rr

conduction loss.

DS(ON)

When the upper MOSFET turns off, the lower MOSFET does not conduct any portion of the inductor current

until the voltage at the phase node falls below ground. When the lower MOSFET begins conducting, the current

in the upper MOSFET falls to zero as the current in the lower MOSFET ramps up to assume the full inductor

current. In Equation 6

is P

UP(1)

.

, the required time for this commutation is t1 and the approximated associated power loss

At turn on, the upper MOSFET begins to conduct and this transition occurs over a time (t

approximate power loss is P

A third component involves the lower MOSFET’s reverse-recovery charge, Q

UP(2)

.

. Because the inductor current

rr

). In Equation 7, the

2

has fully commutated to the upper MOSFET before the lower MOSFET’s body diode can draw all of Q

conducted through the upper MOSFET across V

approximated in Equation 8

The resistive part of the upper MOSFET is given in Equation 9

CONFIDENTIAL

Equation 10

accounts for some power loss due to the drain-to-source parasitic inductance (LDS, including PCB

.

. The power dissipated as a result is P

IN

as P

UP(4)

.

UP(3)

and is

parasitic inductance) of the upper MOSFET, although it is not exact:

Finally, the power loss of output capacitance of the upper MOSFET is approximated in Equation 11

:

, it is

rr

where C

is the output capacitance of the lower MOSFET at the V

OSS_UP

test voltage. Depending on the

DS_UP

amount of ringing, the actual power dissipation is slightly higher than this.

The total power dissipated by the upper MOSFET at full load can now be approximated as the summation of the

results from Equations 6

through 11. Because the power equations depend on MOSFET parameters, choosing

the correct MOSFET is an iterative process involving repetitive solutions to the loss equations for different

MOSFETs and different switching frequencies.

7.1.2 Driver Selection

The three voltage regulator outputs of the ISL95859C all feature PWM signals to drive external MOSFET

drivers. Based on the PS4 low quiescent current requirements of the Intel IMVP8 system, only the Intersil

ISL95808 driver or similar device is supported by the controller.

FN8973 Rev.0.00 Page 35 of 74

Oct 6, 2017

ISL95859C 7. General Design Guide

V ESL

di

dt

----- ESRI+

(EQ. 12)

L

ESR

V

OUT

K

RCM

f

SWVIN

V

P-P M A X

----------------------------------------------------------

(EQ. 13)

L

2NCV

OUT

I

2

----------------------------------------- V

MAX

IESR–

(EQ. 14)

L

1.25

NC

I

2

----------------------------- V

MAX

I ESR– VINV

OUT

–

(EQ. 15)

7.2 Output Filter Design

The output inductors and the output capacitor bank together to form a low-pass filter that smooths the pulsating

voltage at the phase nodes. The output filter also must provide the transient energy until the regulator can respond.

Because it has a low bandwidth compared to the switching frequency, the output filter necessarily limits the system

transient response. The output capacitor must supply or sink load current while the current in the output inductors

increases or decreases to meet the demand.

In high-speed converters, the output capacitor bank is usually the most costly (and often the largest) part of the circuit.

Output filter design begins with minimizing the cost of this part of the circuit. The critical load parameters in choosing

the output capacitors are the maximum size of the load step, I; the load-current slew rate, di/dt and the maximum

allowable output voltage deviation under transient loading, V

capacitance, Equivalent Series Resistance (ESR) and Equivalent Series Inductance (ESL).

At the beginning of the load transient, the output capacitors supply all of the transient current. The output voltage will

initially deviate by an amount approximated by the voltage drop across the ESL. As the load current increases, the

voltage drop across the ESR increases linearly until the load current reaches its final value. The capacitors selected must

have sufficiently low ESL and ESR so that the total output voltage deviation is less than the allowable maximum.

Neglecting the contribution of inductor current and regulator response, the output voltage initially deviates by an amount,

as shown in Equation 12

:

. Capacitors are characterized according to their

MAX

The filter capacitor must have sufficiently low ESL and ESR so that V < V

MAX

.

Most capacitor solutions rely on a mixture of high-frequency capacitors with relatively low capacitance in

combination with bulk capacitors having high capacitance but limited high-frequency performance. Minimizing the

CONFIDENTIAL

ESL of the high-frequency capacitors allows them to support the output voltage as the current increases.

Minimizing the ESR of the bulk capacitors allows them to supply the increased current with less output voltage

deviation.

The ESR of the bulk capacitors also creates the majority of the output voltage ripple. As the bulk capacitors sink

and source the inductor AC ripple current (see “

develops across the bulk-capacitor ESR equal to I

maximum allowable ripple voltage, V

Equation 13

.

P-P(MAX)

Interleaving” on page 23 and Equation 2 on page 25), a voltage

(ESR). Thus, when the output capacitors are selected, the

C(P-P)