Intersil ISL95831HRTZ, ISL95831IRTZ Schematic [ru]

3+1 Voltage Regulator for IMVP-7/VR12™ CPUs

ISL95831

Compliant with IMVP-7/VR12™, the ISL95831 provides a

complete solution for microprocessor and graphic processor

core power supply. It provides two Voltage Regulators (VRs)

with three integrated gate drivers. The first VR can be

configured as 3-, 2- or 1-phase VR while the second output is 1phase VR, providing maximum flexibility. The two VRs share the

serial control bus to communicate with the CPU and achieve

lower cost and smaller board area compared with the two-chip

approach.

Based on Intersil’s Robust Ripple Regulator (R3) technology™,

the PWM modulator compared to traditional modulators, has

faster transient settling time, variable switching frequency

during load transients and has improved light load efficiency

with it’s ability to automatically change switching frequency.

The ISL95831 has several other key features. Both outputs

support DCR current sensing with single NTC thermistor for

DCR temperature compensation or accurate resistor current

sensing. Both outputs come with remote voltage sense,

programmable V

voltage, programmable I

BOOT

MAX

, T

MAX

,

adjustable switching frequency, OC protection and separate

Power-Good.

Load Line Regulation

0.91

0.90

0.89

0.88

0.87

0.86

(V)

0.85

OUT

V

0.84

0.83

0.82

0.81

0.80

VIN = 19V

0 6 12 18 24

Features

•Serial Data Bus

•Dual Outputs:

- Configurable 3-, 2- or 1-phase for the 1st Output using 2

integrated Gate Drivers

- 1-phase for the 2nd Output using an Integrated Gate

Driver

• 0.5% System Accuracy Over-Temperature

• Supports Multiple Current Sensing Methods

- Lossless Inductor DCR Current Sensing

- Precision Resistor Current Sensing

• Differential Remote Voltage Sensing

•Programmable V

• Resistor Programmable I

Voltage at Start-up

BOOT

MAX

, T

for Both Outputs

MAX

• Adaptive Body Diode Conduction Time Reduction

Applications

• IMVP-7/VR12 Compliant Computers

VIN = 12V

VIN = 8V

30 36 42 48 54 60 66

(A)

I

OUT

Ordering Information

PART NUMBER

(Notes 1, 2, 3) PART MARKING

ISL95831HRTZ 95831 HRTZ -10 to +100 48 Ld 6x6 TQFN L48.6x6

ISL95831IRTZ 95831 IRTZ -40 to +100 48 Ld 6x6 TQFN L48.6x6

NOTES:

1. Add “-T*” suffix for tape and reel. Please refer to TB347

2. These Intersil Pb-free plastic packaged products employ special Pb-free material sets, molding compounds/die attach materials, and 100% matte

tin plate plus anneal (e3 termination finish, which is RoHS compliant and compatible with both SnPb and Pb-free soldering operations). Intersil Pbfree products are MSL classified at Pb-free peak reflow temperatures that meet or exceed the Pb-free requirements of IPC/JEDEC J STD-020.

3. For Moisture Sensitivity Level (MSL), please see device information page for ISL95831

January 21, 2011

FN7613.0

1

for details on reel specifications.

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

TEMP. RANGE

(°C)

. For more information on MSL please see techbrief TB363.

Intersil (and design) is a trademark owned by Intersil Corporation or one of its subsidiaries.

All other trademarks mentioned are the property of their respective owners.

|Copyright Intersil Americas Inc. 2011. All Rights Reserved

PACKAGE

(Pb-Free)

PKG.

DWG. #

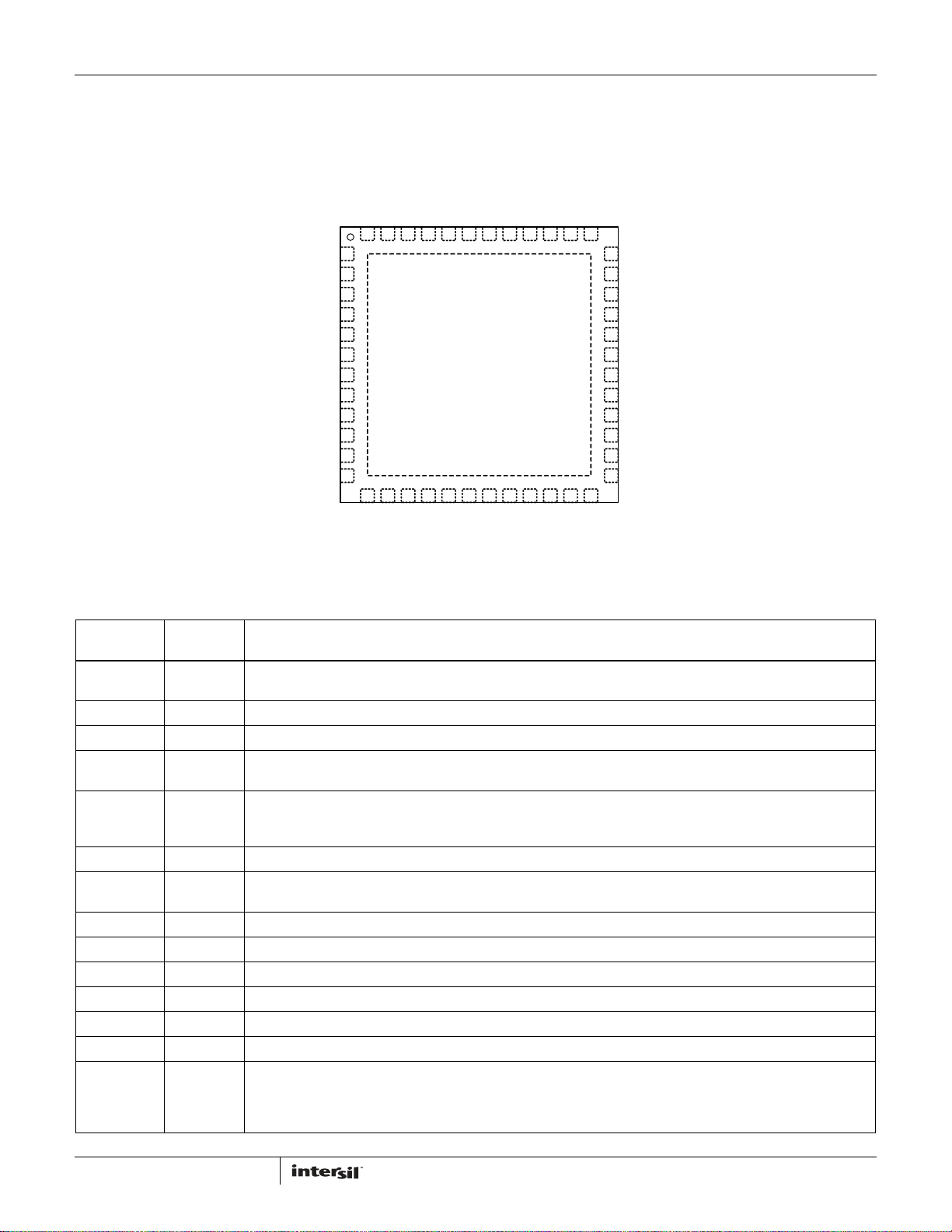

Pin Configuration

VWG

IMONG

PGOODG

SDA

ALERT#

SCLK

VR_ON

PGOOD

IMON

VR_HOT#

NTC

VW

ISL95831

ISL95831

(48 LD TQFN)

TOP VIEW

RTNG

ISUMPG

GND PAD

(BOTTOM)

ISEN2

ISEN1

ISUMNG

VSEN

NTCG

RTN

FBG

COMPG

48 47 46 45 44 43 42 41 40 39

1

2

3

4

5

6

7

8

9

10

11

12

13 14 15 16 17 18 19 20 21 22

VSENG

FB

COMP

ISEN3/FB2

PROG2

BOOTG

UGATEGVDD

PHASEG

LGATEG

38 37

36

BOOT2

35

UGATE2

PHASE2

34

VSSP2

33

32

LGATE2

VCCP

31

30

PWM3

29

LGATE1

VSSP1

28

PHASE1

27

UGATE1

26

25

BOOT1

23 24

VIN

ISUMP

ISUMN

PROG1

Pin Descriptions

ISL95831

PIN NUMBER SYMBOL DESCRIPTION

BOTTOM PAD GND Signal common of the IC. Unless otherwise stated, signals are referenced to the GND pin. It should also be used as the

thermal pad for heat removal.

1 VWG A resistor from this pin to COMPG programs the switching frequency for VR2 (8kΩ gives approximately 300kHz).

2 IMONG An analog output. IMONG outputs a current proportional to VR2 output current.

3 PGOODG Power-Good open-drain output indicating when VR2 is able to supply regulated voltage. Pull up externally with a 680Ω

4, 5, 6 SDA,

ALERT#,

SCLK

7 VR_ON Controller enable input. A high level logic signal on this pin enables the controller.

8 PGOOD Power-Good open-drain output indicating when VR1 is able to supply regulated voltage. Pull up externally with a 680Ω

9 IMON An analog output. IMON outputs a current proportional to VR1 output current.

10 VR_HOT# Open drain thermal overload output indicator. Can be considered part of communication bus with CPU.

11 NTC One of the thermistor inputs to VR_HOT# circuit. Use it to monitor VR1 temperature.

12 VW A resistor from this pin to COMP programs the switching frequency for VR1 (8kΩ gives approximately 300kHz).

13 COMP This pin is the output of the error amplifier for VR1.

14 FB This pin is the inverting input of the error amplifier for VR1.

15 ISEN3/FB2 When the VR1 is configured in 3-phase mode, this pin is ISEN3. ISEN3 is the individual current sensing for VR1 phase 3.

resistor to VCCP or 1.9kΩ to 3.3V.

Communication bus between the CPU and the VRs.

resistor to VCCP or 1.9kΩ to 3.3V.

When VR1 is configured in 2-phase mode, this pin is FB2. There is a switch between the FB2 pin and the FB pin. The

switch is on when VR1 is in 2-phase mode and is off in 1-phase mode. The components connecting to FB2 are used to

adjust the compensation in 1-phase mode to achieve optimum performance for VR1.

2

FN7613.0

January 21, 2011

ISL95831

Pin Descriptions (Continued)

ISL95831

PIN NUMBER SYMBOL DESCRIPTION

16 ISEN2 Individual current sensing for VR1 Phase 2. When ISEN2 and PWM3 are both pulled to 5V VDD, the controller will

disable VR1 Phases 3 and 2.

17 ISEN1 Individual current sensing for VR1 Phase 1.

18 VSEN VR1 remote voltage sense input.

19 RTN VR1 remote voltage sense return.

20, 21 ISUMN and

ISUMP

22 VDD 5V bias power.

23 VIN This pin is connected to the power stage input voltage and used for feed-forward.

24 PROG1 A resistor from this pin to GND programs Imax for VR1, and V

25 BOOT1 Connect an MLCC capacitor across the BOOT1 and the PHASE1 pins. The boot capacitor is charged through an internal

26 UGATE1 Output of VR1 Phase-1 high-side MOSFET gate driver. Connect the UGATE1 pin to the gate of the Phase-1 high-side

27 PHASE1 Current return path for the VR1 Phase-1 high-side MOSFET gate driver. Connect the PHASE1 pin to the node consisting

28 VSSP1 Current return path for VR1 Phase-1 low-side MOSFET gate driver. Connect the VSSP1 pin to the source of VR1 Phase-

29 LGATE1 Output of VR1 Phase-1 low-side MOSFET gate driver. Connect the LGATE1 pin to the gate of VR1 Phase-1 low-side

30 PWM3 PWM output for VR1 Phase 3. When PWM3 is pulled to 5V VDD, the controller will disable VR1 Phase 3.

31 VCCP Input voltage bias for the internal gate drivers. Connect +5V to the VCCP pin. Decouple with at least 1µF of an MLCC

32 LGATE2 Output of VR1 Phase-2 low-side MOSFET gate driver. Connect the LGATE2 pin to the gate of VR1 Phase-2 low-side

33 VSSP2 Current return path for VR1 Phase-2 low-side MOSFET gate driver. Connect the VSSP2 pin to the source of VR1 Phase-2

34 PHASE2 Current return path for VR1 Phase-2 high-side MOSFET gate driver. Connect the PHASE2 pin to the node consisting of

35 UGATE2 Output of VR1 Phase-2 high-side MOSFET gate driver. Connect the UGATE2 pin to the gate of VR1 Phase-2 high-side

36 BOOT2 Connect an MLCC capacitor across the BOOT2 and the PHASE2 pins. The boot capacitor is charged through an internal

37 LGATEG Output of VR2 low-side MOSFET gate driver. Connect the LGATEG pin to the gate of VR2 low-side MOSFET.

38 PHASEG Current return path for VR2 high-side MOSFET gate driver. Connect the PHASEG pin to the node consisting of the

39 UGATEG Output of VR2 high-side MOSFET gate driver. Connect the UGATEG pin to the gate of VR2 high-side MOSFET.

40 BOOTG Connect an MLCC capacitor across the BOOTG and the PHASEG pins. The boot capacitor is charged through an internal

41 PROG2 A resistor from this pin to GND programs I

42 NTCG The second thermistor input to VR_HOT# circuit. Use it to monitor VR2 temperature.

VR1 droop current sense input.

for both VR1 and VR2.

BOOT

boot diode connected from the VCCP pin to the BOOT1 pin, each time the PHASE1 pin drops below VCCP minus the

voltage dropped across the internal boot diode.

MOSFET.

of the high-side MOSFET source, the low-side MOSFET drain, and the output inductor of VR1 Phase 1.

1 low-side MOSFET through a low impedance path, preferably in parallel with the traces connecting the LGATE1 pin to

the gates of the Phase-1 low-side MOSFET.

MOSFET.

capacitor.

MOSFET.

low-side MOSFET through a low impedance path, preferably in parallel with the traces connecting the LGATE2 pin to

the gates of the Phase-2 low-side MOSFET.

the high-side MOSFET source, the low-side MOSFET drain, and the output inductor of VR1 Phase 2.

MOSFET.

boot diode connected from the VCCP pin to the BOOT2 pin, each time the PHASE2 pin drops below VCCP minus the

voltage dropped across the internal boot diode.

high-side MOSFET source, the low-side MOSFET drain, and the output inductor of VR2.

boot diode connected from the VCCP pin to the BOOTG pin, each time the PHASEG pin drops below VCCP minus the

voltage dropped across the internal boot diode.

for VR2 and T

MAX

for both VR1 and VR2.

MAX

3

FN7613.0

January 21, 2011

ISL95831

Pin Descriptions (Continued)

ISL95831

PIN NUMBER SYMBOL DESCRIPTION

43, 44 ISUMNG and

ISUMPG

45 RTNG VR2 remote voltage sense return.

46 VSENG VR2 remote voltage sense input.

47 FBG This pin is the inverting input of the error amplifier for VR2.

48 COMPG This pin is the output of the error amplifier for VR2. Also, a resistor from COMPG to GND can program the operational

VR2 droop current sense input. When ISUMNG is pulled to 5V VDD, VR2 is disabled and all communication to VR2 is

rejected.

modes of VR2.

4

FN7613.0

January 21, 2011

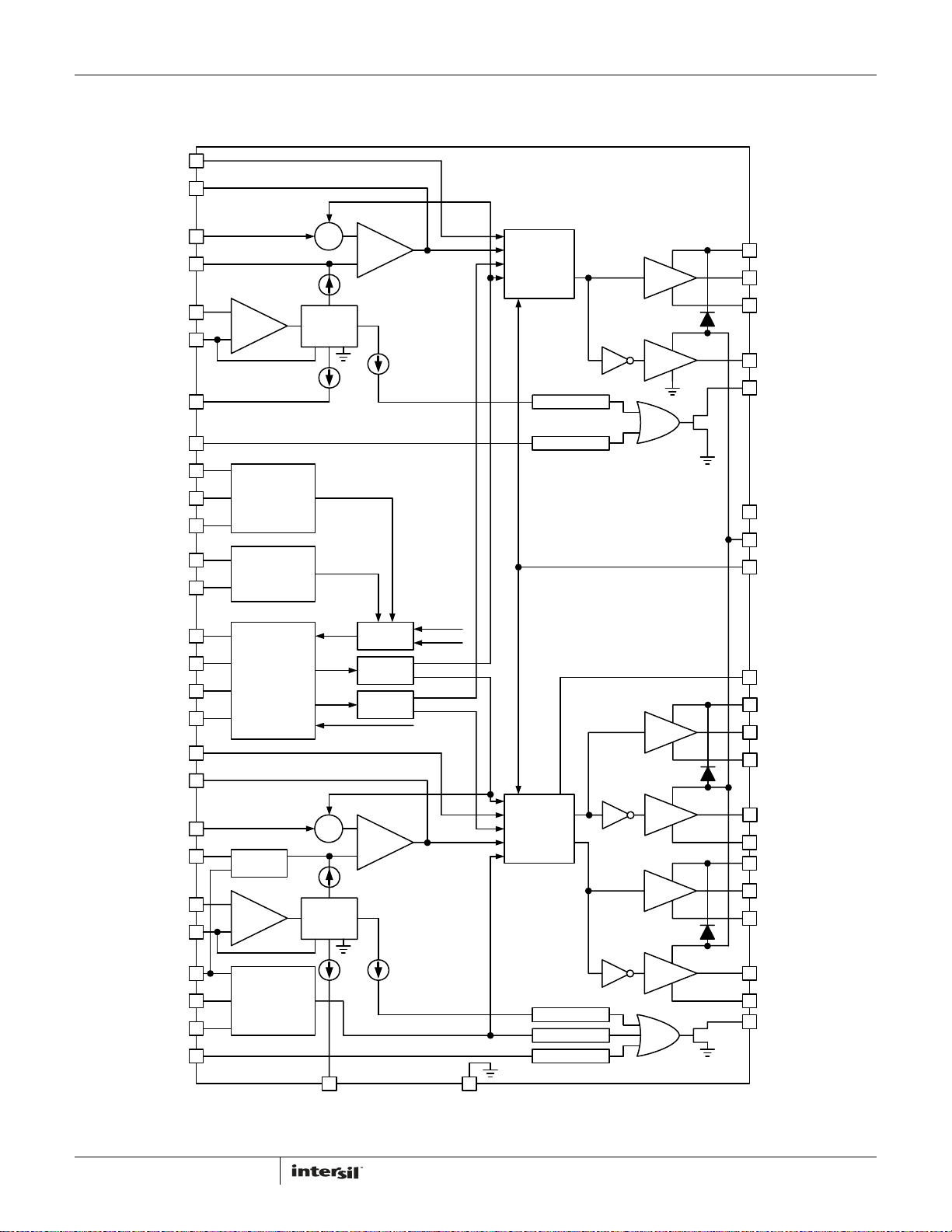

Block Diagram

VWG

COMPG

RTNG

FBG

ISUMPG

ISUMNG

ISL95831

+

+

+

_

CURRENT

SENSE

Σ

+

E/A

_

IDROOPG

VR2

MODULATOR

DRIVER

DRIVER

BOOTG

UGATEG

PHASEG

LGATEG

IMONG

VSENG

NTCG

NTC

VR_HOT#

PROG2

PROG1

VR_ON

SDA

ALERT#

SCLK

VW

COMP

RTN

FB

ISUMP

ISUMN

TEMP

MONITOR

IMAX

VBOOT

TMAX

SET (A/D)

DIGITAL

INTERFACE

FB2

CIRCUIT

+

_

T_MONITOR

PROG

+

+

Σ

CURRENT

SENSE

MODE

+

E/A

_

IDROOP

IMONG

A/D IMON

DAC2

DAC1

D/A

MODE2

MODE1

VREADY

OC FAULT

OV FAULT

VR1

MODULATOR

DRIVER

DRIVER

DRIVER

PGOODG

VDD

VCCP

VIN

PWM3

BOOT2

UGATE2

PHASE2

LGATE2

VSSP2

BOOT1

UGATE1

PHASE1

ISEN3/FB2

ISEN2

ISEN1

VSEN

CURRENT

BALANCING

5

DRIVER

OC FAULT

IBAL FAULT

OV FAULT

GNDIMON

LGATE1

VSSP1

PGOOD

January 21, 2011

FN7613.0

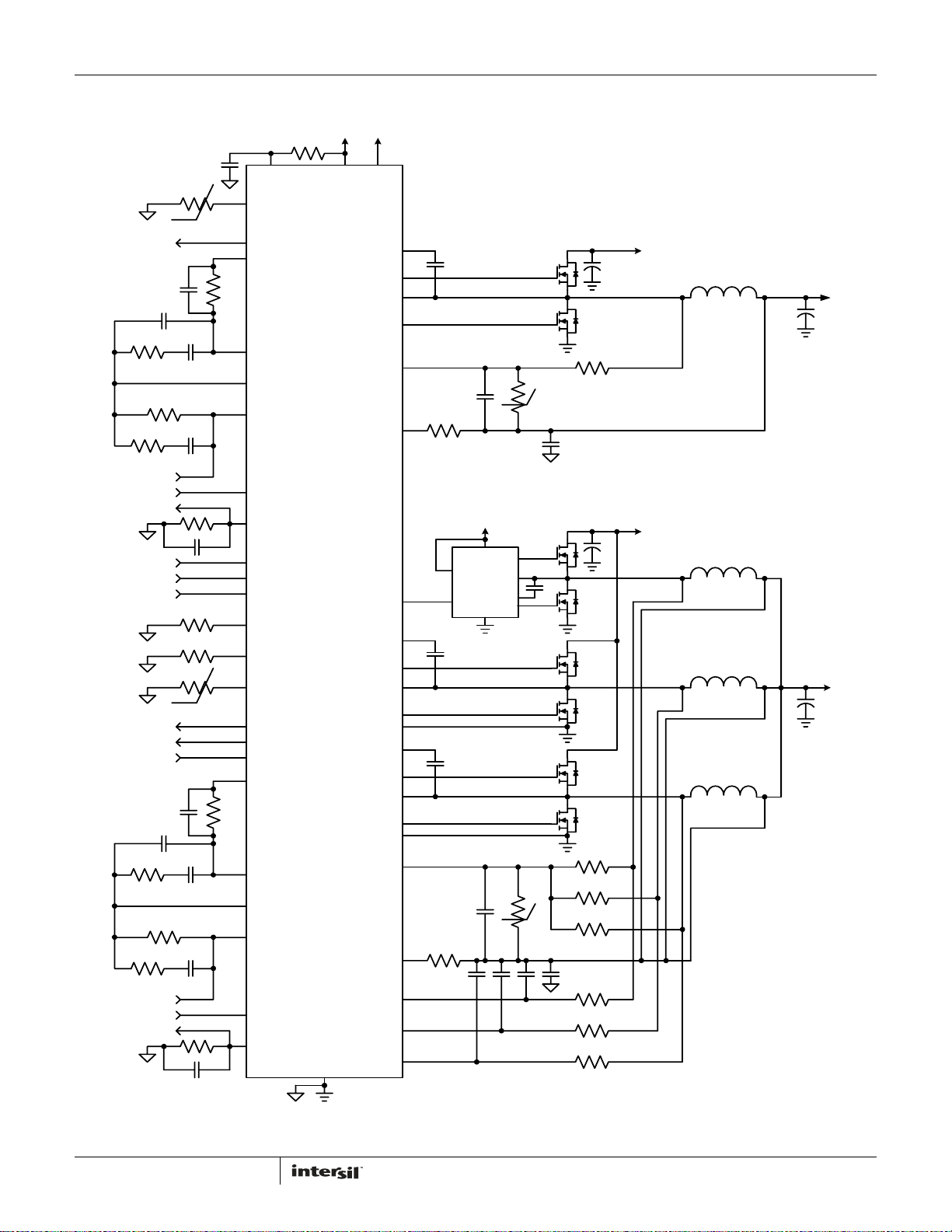

Simplified Application Circuit

V+5

ISL95831

VIN

Rntcg

°c

PGOODG PGOODG

Rdroopg

VCCSENSEG

VSSSENSEG

IMONG

SDA SDA

ALERT# ALERT#

SCLK SCLK

Rprog2

Rprog1

Rntc

°c

VR_HOT# VR_HOT#

PGOOD

VR_ON

Rdroop

VCCSENSE

VSSSENSE

IMON

NTCG

VWG

Rfsetg

COMPG

FBG

VSENG

RTNG

IMONG

PROG2

PROG1

NTC

PGOOD

VR_ON

VW

Rfset

COMP

FB

VSEN

RTN

IMON

VDD

ISL95831

GND

PVCC

VIN

BOOTG

UGATEG

PHASEG

LGATEG

ISUMPG

ISUMNG

PWM3

BOOT2

UGATE2

PHASE2

LGATE2

VSSP2

BOOT1

UGATE1

PHASE1

LGATE1

VSSP1

ISUMP

ISUMN

ISEN3/FB2

ISEN2

ISEN1

Rig

Ri

Cng

FCCM

ISL6208

PWM

Cn

V+5

VCC

GND

°c

UGATE

PHASE

BOOT

LGATE

°c

Cisen3Cisen2Cisen1

Rng

Vsumng

Rn

Cvsumng

Vsumn

Cvsumv

Rsum4

Rsum3

Rsum2

Rsum1

Risen3

Risen2

Risen1

Vin

Vin

L4

L3

L2

L1

AXG Vcore

CPU Vcore

FIGURE 1. TYPICAL ISL95831 APPLICATION CIRCUIT USING INDUCTOR DCR SENSING

6

FN7613.0

January 21, 2011

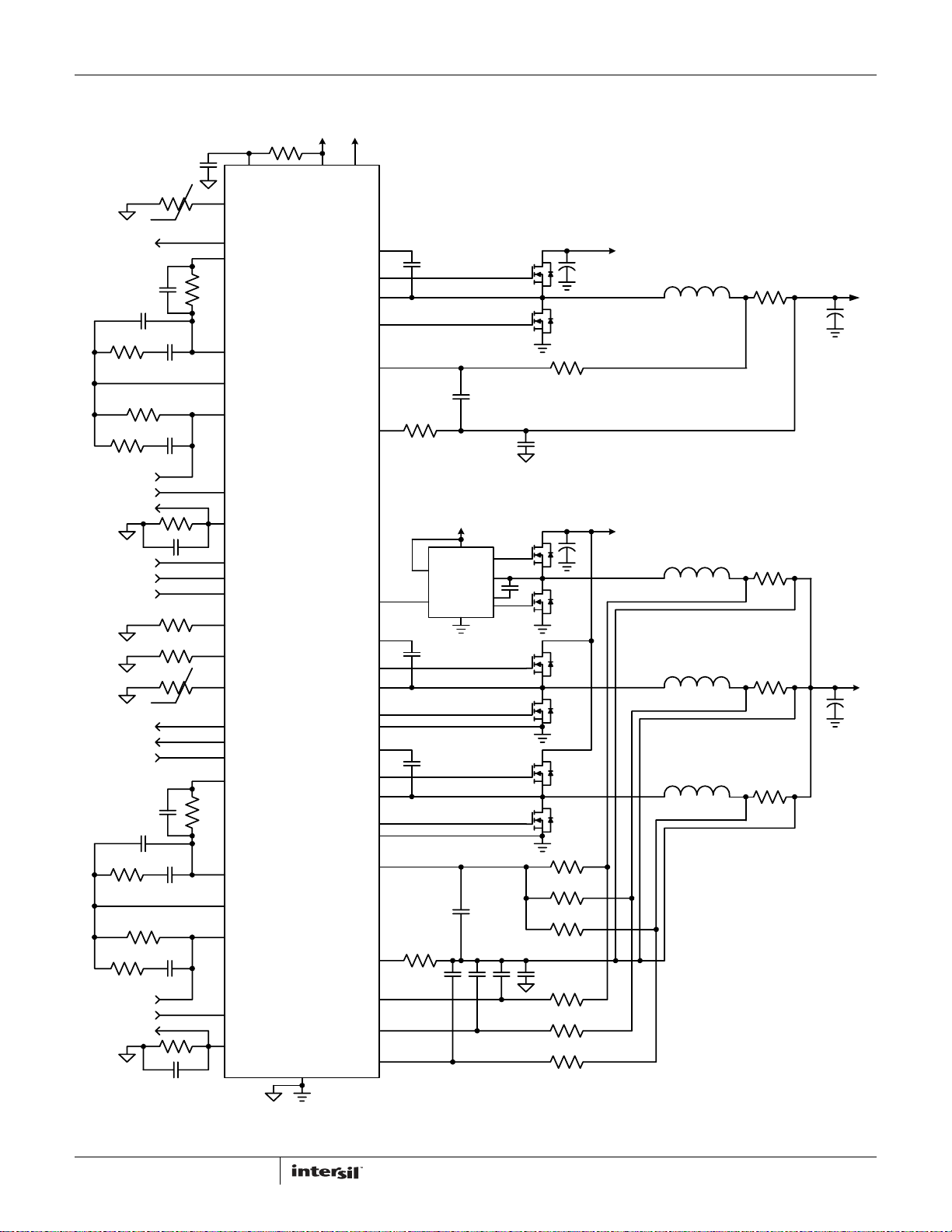

Simplified Application Circuit

V+5

VIN

PVCC

VDD

Rntcg

°C

NTCG

VIN

ISL95831

PGOODG PGOODG

Rfsetg

Rdroopg

VCCSENSEG

VSSSENSEG

IMONG

SDA SDA

ALERT# ALERT#

SCLK SCLK

Rprog2

Rprog1

Rntc

°C

VR_HOT# VR_HOT#

PGOOD

VR_ON

Rfset

Rdroop

VCCSENSE

VSSSENSE

IMON

VWG

COMPG

FBG

VSENG

RTNG

IMONG

PROG2

PROG1

NTC

PGOOD

VR_ON

VW

COMP

FB

VSEN

RTN

IMON

ISL95831

GND

BOOTG

UGATEG

PHASEG

LGATEG

ISUMPG

ISUMNG

PWM3

BOOT2

UGATE2

PHASE2

LGATE2

VSSP2

BOOT1

UGATE1

PHASE1

LGATE1

VSSP1

ISUMP

ISUMN

ISEN3/FB2

ISEN2

ISEN1

Vin

L4

Rsum4

Cng

Rig

V+5

VCC

FCCM

ISL6208

PWM

GND

Cn

Ri

UGATE

PHASE

BOOT

LGATE

Cisen3Cisen2Cisen1

Vsumng

Cvsumng

Vin

L3

L2

L1

Rsum3

Rsum2

Rsum1

Vsumn

Cvsumn

Risen3

Risen2

Risen1

Rsen4

Rsen3

Rsen2

Rsen1

AXG Vcore

CPU Vcore

FIGURE 2. TYPICAL ISL95831 APPLICATION CIRCUIT USING RESISTOR SENSING

7

FN7613.0

January 21, 2011

ISL95831

Table of Contents

Load Line Regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Pin Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Simplified Application Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Simplified Application Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Absolute Maximum Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Thermal Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Recommended Operating Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Gate Driver Timing Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Multiphase R3™ Modulator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Diode Emulation and Period Stretching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Start-up Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Voltage Regulation and Load Line Implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Differential Voltage Sensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Phase Current Balancing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

CCM Switching Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Modes of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Dynamic Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

VR_HOT#/ALERT# Behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Current Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

FB2 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Adaptive Body Diode Conduction Time Reduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Protections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Supported Data And Configuration Registers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Key Component Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Inductor DCR Current-Sensing Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Resistor Current-Sensing Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Overcurrent Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Compensator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Programming Resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Current Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Current Balancing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Slew Rate Compensation Circuit For VID Transition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Layout Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Typical Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Package Outline Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8

FN7613.0

January 21, 2011

ISL95831

Absolute Maximum Ratings Thermal Information

Supply Voltage, VDD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to +7V

Battery Voltage, VIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +28V

Boot Voltage (BOOT). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to +33V

Boot-to-Phase Voltage

(BOOT-PHASE) -0.3V to +7V(DC) . . . . . . . . . . . . . . -0.3V to +9V(<10ns)

Phase Voltage (PHASE) . . . . . . . . . . . . . . . . -7V (<20ns Pulse Width, 10µJ)

UGATE Voltage (UGATE) . . . . . . . . . . . . . . . . . . . PHASE - 0.3V (DC) to BOOT

. . . . . . . . . . . . . . . . . . . . PHASE - 5V (<20ns Pulse Width, 10µJ) to BOOT

LGATE Voltage

. . . . . . . . . . . . . . . . . . . . . . . . -2.5V (<20ns Pulse Width, 5µJ) to VDD+0.3V

All Other Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to (VDD +0.3V)

Open Drain Outputs, PGOOD, VR_HOT#, ALERT#. . . . . . . . . . -0.3V to +7V

ESD Rating

Human Body Model (Tested per JESD22-A114E). . . . . . . . . . . . . . . . 2kV

Machine Model (Tested per JESD22-A115-A) . . . . . . . . . . . . . . . . . 200V

Charged Device Model (Tested per JESD22-C101A) . . . . . . . . . . . . . . 1k

Latch Up (Tested per JESD-78B; Class 2, Level A) . . . . . . . . . . . . . . 100mA

CAUTION: Do not operate at or near the maximum ratings listed for extended periods of time. Exposure to such conditions may adversely impact product

reliability and result in failures not covered by warranty.

NOTES:

4. θ

is measured in free air with the component mounted on a high effective thermal conductivity test board with “direct attach” features. See Tech

JA

Brief TB379.

5. For θ

, the “case temp” location is the center of the exposed metal pad on the package underside.

JC

Thermal Resistance (Typical) θ

48 Ld TQFN Package (Notes 4, 5) . . . . . . . 29 1

Maximum Junction Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . .+150°C

Maximum Storage Temperature Range . . . . . . . . . . . . . .-65°C to +150°C

Maximum Junction Temperature (Plastic Package) . . . . . . . . . . . .+150°C

Storage Temperature Range. . . . . . . . . . . . . . . . . . . . . . . .-65°C to +150°C

Pb-Free Reflow Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . see link below

http://www.intersil.com/pbfree/Pb-FreeReflow.asp

(°C/W) θJC (°C/W)

JA

Recommended Operating Conditions

Supply Voltage, VDD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +5V ±5%

Battery Voltage, VIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +4.5V to 25V

Ambient Temperature

HRTZ. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -10°C to +100°C

IRTZ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-40°C to +100°C

Junction Temperature

HRTZ. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-10°C to +125°C

IRTZ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-40°C to +125°C

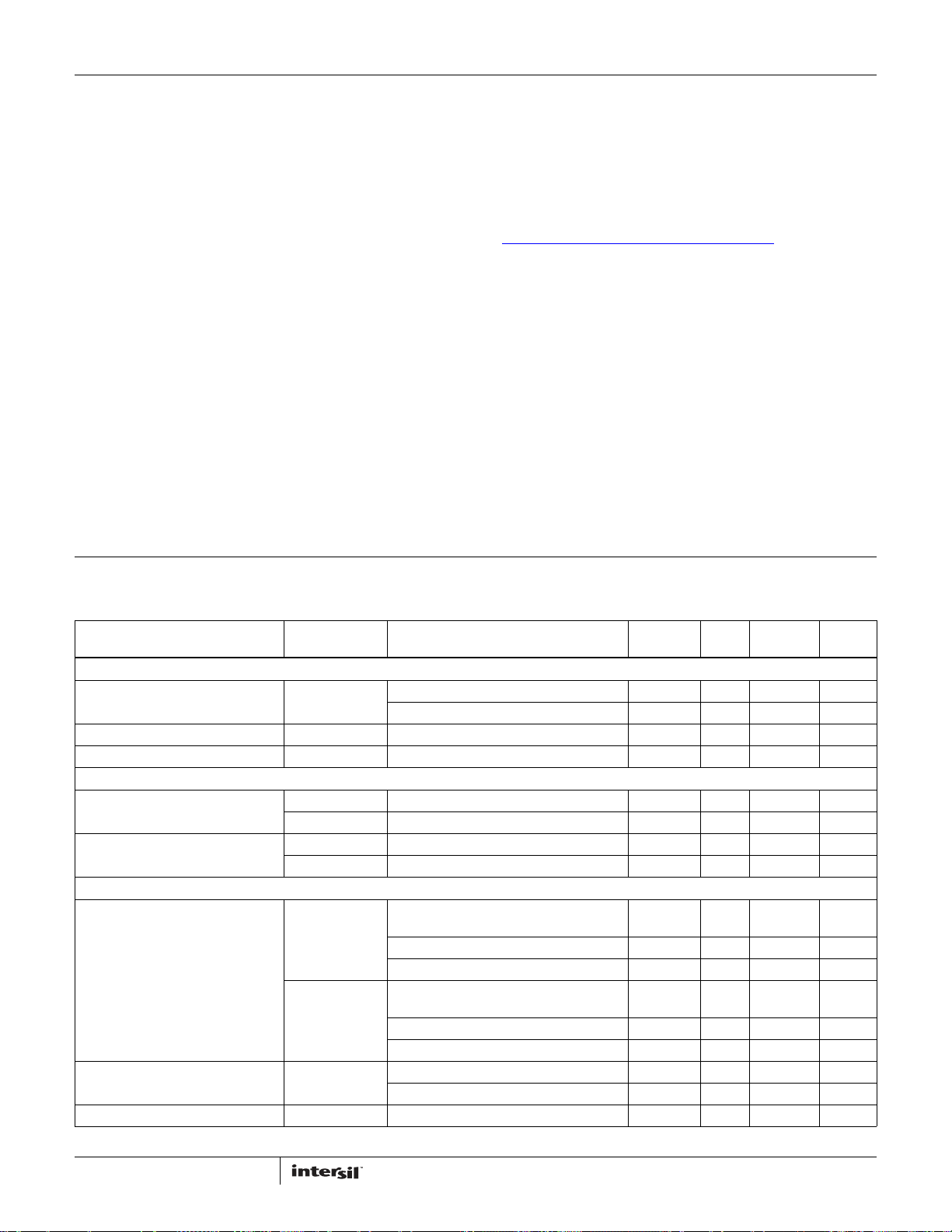

Electrical Specifications "Operating Conditions: VDD = 5V, T

(ISL95831HRTZ), fSW = 300kHz, unless otherwise noted." Boldface limits apply over the operating temperature ranges, -10°C to +100°C or

= -40°C to +100°C (ISL95831IRTZ), TA = -10°C to +100°C

A

-40°C to +100°C.

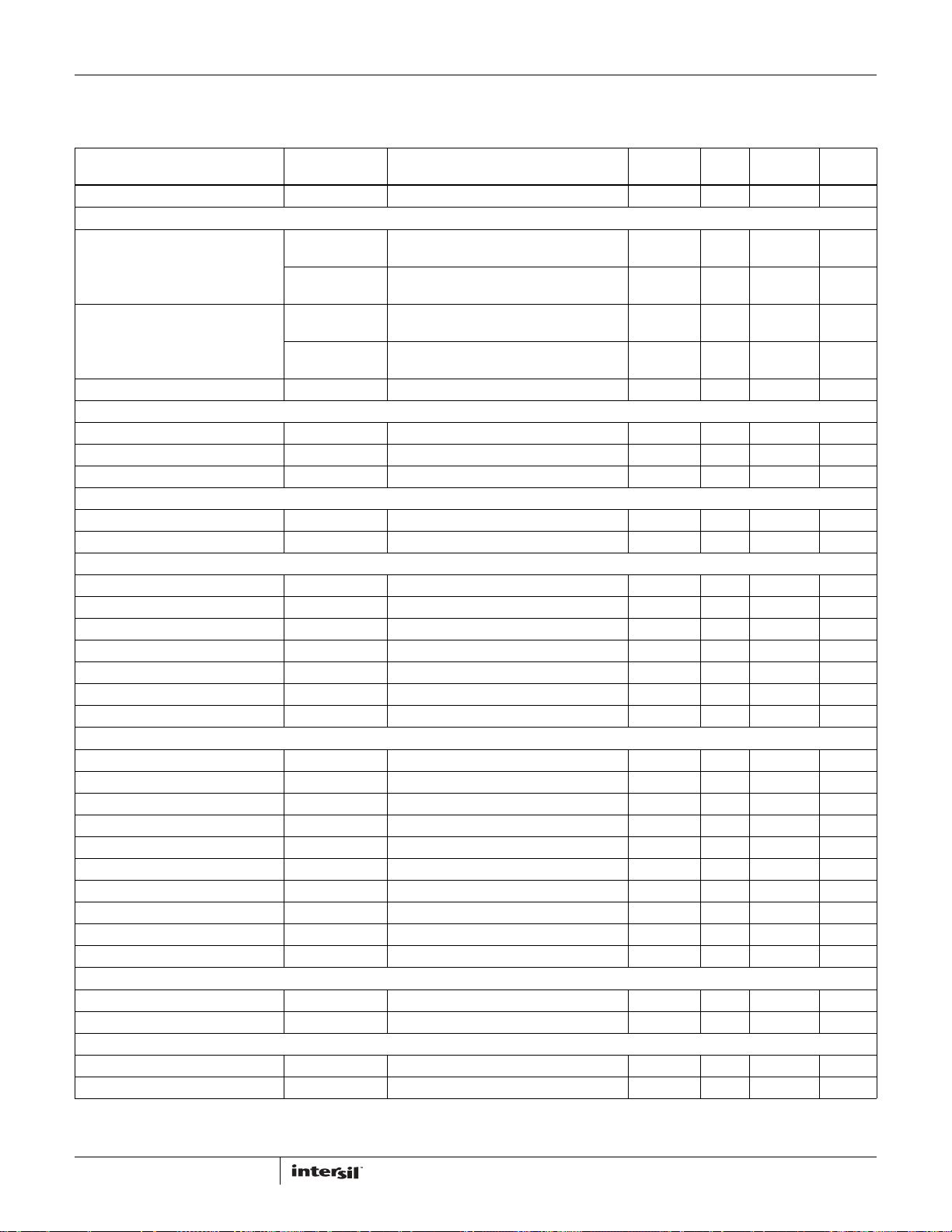

PARAMETER SYMBOL TEST CONDITIONS

MIN

(Note 6) TYP

MAX

(Note 6) UNITS

INPUT POWER SUPPLY

+5V Supply Current I

Battery Supply Current I

Input Resistance R

V

IN

VDD

VIN

VIN

VR_ON = 1V 9.2 10.5 mA

VR_ON = 0V 1 µA

VR_ON = 0V 1 µA

VR_ON = 1V 550 kΩ

POWER-ON-RESET THRESHOLDS

VDD Power-On-Reset Threshold VDDPOR

VDDPOR

VIN Power-On-Reset Threshold VINPOR

VINPOR

VDD rising 4.35 4.5 V

r

VDD falling 4.00 4.15 V

f

VIN rising 4.00 4.35 V

r

VIN falling 2.8 3.3 V

f

SYSTEM AND REFERENCES

System Accuracy HRTZ

%Error (V

IRTZ

%Error (V

Internal V

Maximum Output Voltage V

BOOT

OUT(max)

No load; closed loop, active mode range,

VID = 0.75V to 1.52V, -0.5 +0.5 %

OUT)

VID = 0.5V to 0.745V -8 +8 mV

VID = 0.25V to 0.495V -15 +15 mV

No load; closed loop, active mode range,

)

VID = 0.75V to 1.52V -0.8 +0.8 %

OUT

VID = 0.5V to 0.745V -10 +10 mV

VID = 0.25V to 0.495V -18 +18 mV

HRTZ 1.0945 1.100 1.1055 V

IRTZ 1.0912 1.100 1.1088 V

VID = [11111111] 1.52 V

9

FN7613.0

January 21, 2011

ISL95831

Electrical Specifications "Operating Conditions: VDD = 5V, T

(ISL95831HRTZ), fSW = 300kHz, unless otherwise noted." Boldface limits apply over the operating temperature ranges, -10°C to +100°C or

= -40°C to +100°C (ISL95831IRTZ), TA = -10°C to +100°C

A

-40°C to +100°C. (Continued)

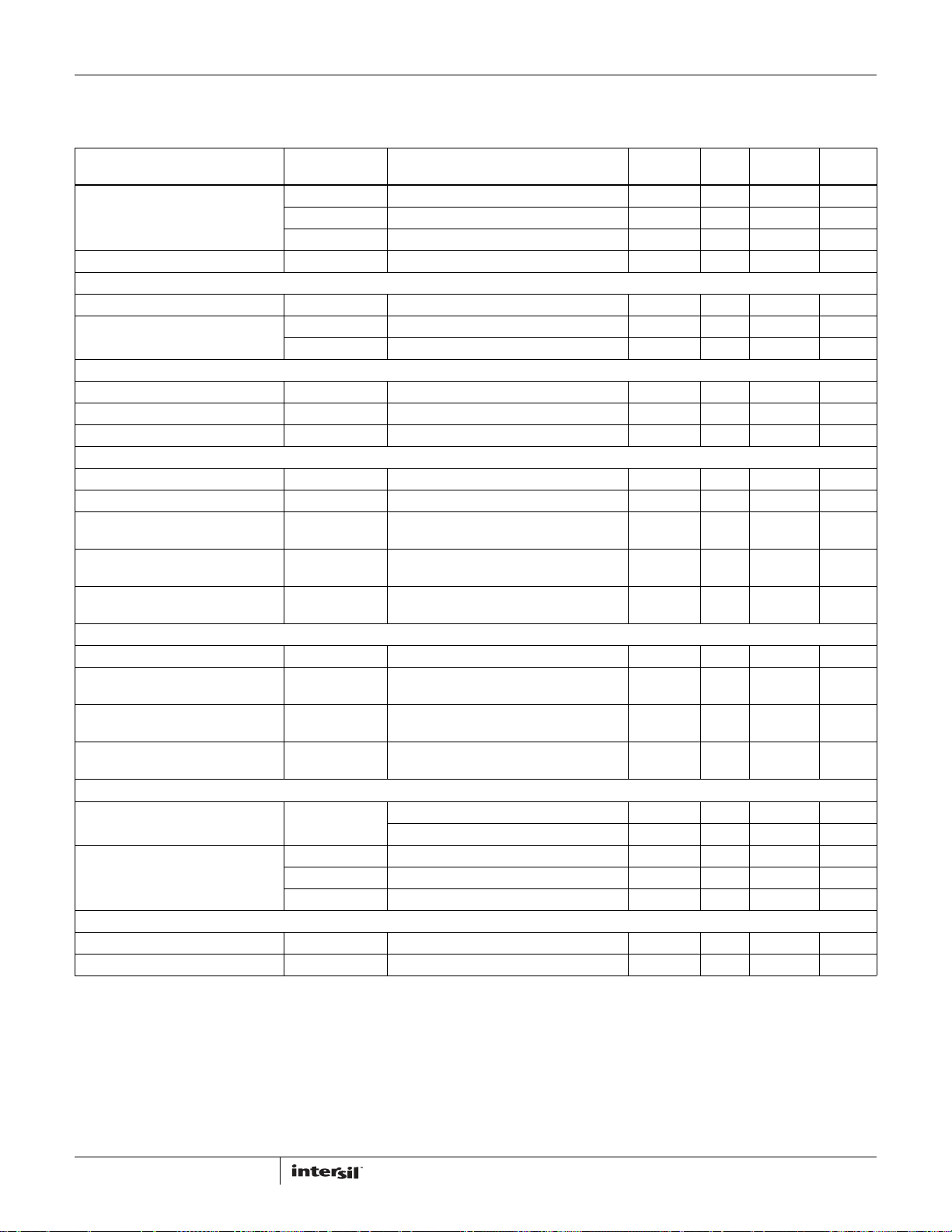

PARAMETER SYMBOL TEST CONDITIONS

Minimum Output Voltage V

OUT(min)

MIN

(Note 6) TYP

VID = [00000001] 0.25 V

MAX

(Note 6) UNITS

CHANNEL FREQUENCY

Nominal Channel Frequency-HRTZ HRTZ_VR1

fSW(nom)

HRTZ_VR2

fSW(nom)

Nominal Channel Frequency-IRTZ IRTZ_VR1

fSW(nom)

IRTZ_VR2

fSW(nom)

R

= 8.66kΩ, 2-channel operation,

fset

V

= 1.1V

COMP

= 9.09kΩ, V

R

fset

R

= 8.66kΩ, 2-channel operation,

fset

V

= 1.1V

COMP

= 9.09kΩ, V

R

fset

= 1.1V 285 300 315 kHz

COMP

= 1.1V 280 300 320 kHz

COMP

285 300 315 kHz

280 300 320 kHz

Adjustment Range 200 500 kHz

AMPLIFIERS

Current-Sense Amplifier Input Offset I

Error Amp DC Gain A

v0

Error Amp Gain-Bandwidth Product GBW C

= 0A -0.15 +0.15 mV

FB

90 dB

= 20pF 18 MHz

L

ISEN

Imbalance Voltage Maximum of ISENs - Minimum of ISENs 1 mV

Input Bias Current 20 nA

POWER-GOOD AND PROTECTION MONITORS

I

PGOOD Low Voltage V

PGOOD Leakage Current I

OL

OH

= 4mA 0.15 0.4 V

PGOOD

PGOOD = 3.3V 1 µA

PGOOD Delay tpgd 1.2 ms

ALERT# Low Voltage 7 12 Ω

VR_HOT# Low Voltage 7 12 Ω

ALERT# Leakage Current 1 µA

VR_HOT# Leakage Current 1 µA

GATE DRIVER

UGATE Pull-Up Resistance R

UGATE Source Current I

UGATE Sink Resistance R

UGATE Sink Current I

LGATE Pull-Up Resistance R

LGATE Source Current I

LGATE Sink Resistance R

LGATE Sink Current I

UGATE to LGATE De adt ime t

LGATE to UGATE De adt ime t

UGPU

UGSRC

UGPD

UGSNK

LGPU

LGSRC

LGPD

LGSNK

UGFLGR

LGFUGR

200mA Source Current 1.0 1.5 Ω

UGATE - PHASE = 2.5V 2.0 A

250mA Sink Current 1.0 1.5 Ω

UGATE - PHASE = 2.5V 2.0 A

250mA Source Current 1.0 1.5 Ω

LGATE - VSSP = 2.5V 2.0 A

250mA Sink Current 0.5 0.9 Ω

LGATE - VSSP = 2.5V 4.0 A

UGATE falling to LGATE rising, no load 23 ns

LGATE falling to UGATE rising, no load 28 ns

BOOTSTRAP DIODE

Forward Voltage V

Reverse Leakage I

F

R

PVCC = 5V, IF = 2mA 0.58 V

VR = 25V 0.2 µA

PROTECTION

Overvoltage Threshold OV

H

VSEN rising above setpoint for >1µs 120 155 200 mV

Current Imbalance Threshold One ISEN above another ISEN for >1.2ms 9 mV

10

FN7613.0

January 21, 2011

ISL95831

Electrical Specifications "Operating Conditions: VDD = 5V, T

(ISL95831HRTZ), fSW = 300kHz, unless otherwise noted." Boldface limits apply over the operating temperature ranges, -10°C to +100°C or

= -40°C to +100°C (ISL95831IRTZ), TA = -10°C to +100°C

A

-40°C to +100°C. (Continued)

PARAMETER SYMBOL TEST CONDITIONS

VR1 Overcurrent Threshold 3-Phase - PS0 and 1-Phase - all states 25.5 30.6 35.5 µA

3-Phase - PS1, 2-Phase - PS0 16.75 20.6 24.25 µA

3-Phase - PS2, 2-Phase - PS1 and PS2 8.5 10.6 12.75 µA

VR2 Overcurrent Threshold All states 28.5 30.6 33.5 µA

LOGIC THRESHOLDS

VR_ON Input Low V

VR_ON Input High V

PWM

PWM Output Low V

PWM Output High V

PWM Tri-State Leakage PWM = 2.5V 2 µA

THERMAL MONITOR

NTC Source Current NTC = 1.3V 59 60 61 µA

VR_HOT# Trip Voltage (VR1 and VR2) Falling 0.86 0.873 0.89 V

VR_HOT# Reset Voltage (VR1

and VR2)

Therm_Alert Trip Voltage (VR1

and VR2)

Therm_Alert Reset Voltage (VR1

and VR2)

CURRENT MONITOR

IMON Output Current (VR1 and VR2) ISUM- pin current = 25µA 147 150 153 µA

IMON Current Sinking Capability

(VR1 and VR2)

IccMax_Alert Trip Voltage (VR1

and VR2)

IccMax_Alert Reset Voltage (VR1

and VR2)

IL

IH

V

IH

0L

0H

HRTZ 0.7 V

IRTZ 0.75 V

Sinking 5mA 1.0 V

Sourcing 5mA 3.5 4.2 V

Rising 0.905 0.929 0.935 V

Falling 0.9 0.913 0.93 V

Rising 0.945 0.961 0.975 V

Rising 2.63 2.66 2.69 V

Falling 2.585 2.62 2.655 V

MIN

(Note 6) TYP

370 µA

MAX

(Note 6) UNITS

0.3 V

INPUTS

VR_ON Leakage Current I

SCLK, SDA Leakage VR_ON = 0V, SCLK & SDA = 0V & 1V -1 1 µA

SLEW RATE (For VID Change)

Fast Slew Rate 10 mV/µs

Slow Slew Rate 2.5 mV/µs

NOTES:

6. Compliance to datasheet limits is assured by one or more methods: production test, characterization and/or design.

VR_ON

VR_ON = 0V -1 0µA

VR_ON = 1V 18 35 µA

VR_ON = 1V, SCLK & SDA = 1V -5 1 µA

VR_ON = 1V, SCLK & SDA = 0V -85 -60 -30 µA

11

FN7613.0

January 21, 2011

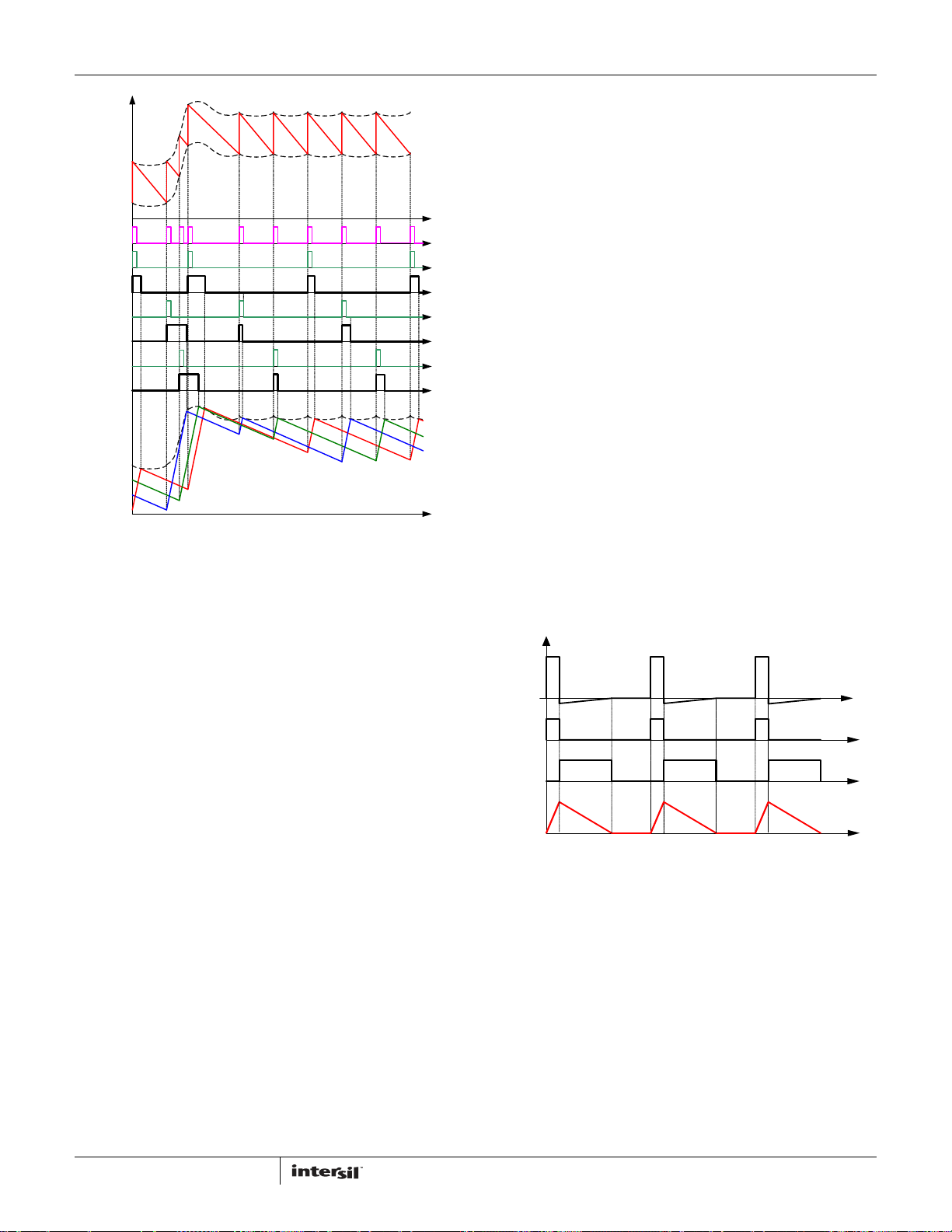

Gate Driver Timing Diagram

PWM

t

LGFUGR

UGATE

t

RU

ISL95831

t

FU

1V

LGATE

t

FL

1V

Theory of Operation

Multiphase R3™ Modulator

MASTER CLOCK CIRCUIT

gmVo

Crs1

Crs2

Crs3

MASTER

CLOCK

Vcrs1

Vcrs2

Vcrs3

VW

COMP

Vcrm

Crm

VW

VW

VW

MASTER

CLOCK

SLAVE CIRCUIT 1

Clock1

gm

SLAVE CIRCUIT 2

Clock2

gm

SLAVE CIRCUIT 3

Clock3

gm

S

Q

R

S

Q

R

S

Q

R

Phase

Sequencer

PWM1

PWM2

PWM3

Phase1

Phase2

Phase3

Clock1

Clock2

Clock3

L1

I

L1

L2

I

L2

L3

I

L3

Vo

Co

t

UGFLGR

t

VW

Vcrm

COMP

Master

Clock

Clock1

PWM1

Clock2

PWM2

Clock3

PWM3

FIGURE 4. R

RL

VW

Vcrs3

Vcrs2 V crs1

3

™ MODULATOR OPERATION PRINCIPLES IN

STEADY STATE

Hysteretic

Window

FIGURE 3. R

3

™ MODULATOR CIRCUIT

12

FN7613.0

January 21, 2011

ISL95831

VW

COMP

Vcrm

Master

Clock

Clock1

PWM1

Clock2

PWM2

Clock3

PWM3

VW

Vcrs1

Vcrs3

Vcrs2

FIGURE 5. R

3

™ MODULATOR OPERATION PRINCIPLES IN LOAD

INSERTION RESPONSE

The ISL95831 is a multiphase regulator implementing Intel™

IMVP-7/VR12™ protocol. It has two voltage regulators, VR1 and

VR2, on one chip. VR1 can be programmed for 1-, 2- or 3-phase

operation, and VR2 is dedicated to 1-phase operation. The

following description is based on VR1, but also applies to VR2

because they are based on the same architecture.

3

The ISL95831 uses Intersil patented R

Regulator™) modulator. The R

3

™ modulator combines the best

™ (Robust Ripple

features of fixed frequency PWM and hysteretic PWM while

eliminating many of their shortcomings. Figure 3 conceptually

shows the multiphase R

3

™ modulator circuit, and Figure 4 shows

the operation principles.

Each slave circuit has its own ripple capacitor C

, whose voltage

rs

mimics the inductor ripple current. A gm amplifier converts the

inductor voltage into a current source to charge and discharge

. The slave circuit turns on its PWM pulse upon receiving the

C

rs

clock signal, and the current source charges Crs. When Crs

voltage V

and the current source discharges C

Since the controller works with V

hits VW, the slave circuit turns off the PWM pulse,

Crs

.

rs

, which are large-amplitude

crs

and noise-free synthesized signals, it achieves lower phase jitter

than conventional hysteretic mode and fixed PWM mode

controllers. Unlike conventional hysteretic mode converters, the

ISL95831 uses an error amplifier that allows the controller to

maintain a 0.5% output voltage accuracy.

Figure 5 shows the operation principles during load insertion

response. The COMP voltage rises during load insertion,

generating the master clock signal more quickly, so the PWM

pulses turn on earlier, increasing the effective switching

frequency, which allows for higher control loop bandwidth than

conventional fixed frequency PWM controllers. The VW voltage

rises as the COMP voltage rises, making the PWM pulses wider.

During load release response, the COMP voltage falls. It takes

the master clock circuit longer to generate the next master clock

signal so the PWM pulse is held off until needed. The VW voltage

falls as the COMP voltage falls, reducing the current PWM pulse

width. This kind of behavior gives the controller excellent

response speed.

The fact that all the phases share the same VW window voltage

also ensures excellent dynamic current balance among phases.

Diode Emulation and Period Stretching

Phase

UGATE

LGATE

A current source flows from the VW pin to the COMP pin, creating

a voltage window set by the resistor between the two pins. This

voltage window is called VW window in the following discussion.

Inside the IC, the modulator uses the master clock circuit to

generate the clocks for the slave circuits. The modulator

discharges the ripple capacitor C

to g

, where gm is a gain factor. Crm voltage V

mVo

with a current source equal

rm

crm

is a

sawtooth waveform traversing between the VW and COMP

voltages. It resets to VW when it hits COMP, and generates a

one-shot master clock signal. A phase sequencer distributes the

master clock signal to the slave circuits. If VR1 is in 3-phase

mode, the master clock signal will be distributed to the three

phases, and the Clock1~3 signals will be 120° out-of-phase. If

VR1 is in 2-phase mode, the master clock signal will be

distributed to Phases 1 and 2, and the Clock1 and Clock2 signals

will be 180° out-of-phase. If VR1 is in 1-phase mode, the master

clock signal will be distributed to Phases 1 only and be the

Clock1 signal.

13

IL

FIGURE 6. DIODE EMULATION

ISL95831 can operate in diode emulation (DE) mode to improve

light load efficiency. In DE mode, the low-side MOSFET conducts

when the current is flowing from source to drain and doesn’t allow

reverse current, emulating a diode. As Figure 6 shows, when

LGATE is on, the low-side MOSFET carries current, creating

negative voltage on the phase node due to the voltage drop across

the ON-resistance. The controller monitors the current through

monitoring the phase node voltage. It turns off LGATE when the

phase node voltage reaches zero to prevent the inductor current

from reversing the direction and creating unnecessary power loss.

If the load current is light enough, as Figure 6 shows, the inductor

current will reach and stay at zero before the next phase node

pulse and the regulator is in discontinuous conduction mode

(DCM). If the load current is heavy enough, the inductor current

FN7613.0

January 21, 2011

Loading...

Loading...