Page 1

®

ISL9204

Data Sheet October 4, 2005

High Input Voltage Charger

The ISL9204 is a cost-effective, fully integrated high input

voltage single-cell Li-ion battery charger. This charger

performs the CC/CV charge function required by Li-ion

batteries. The charger accepts an input voltage up to 28V

but is disabled when the input voltage exceeds the OVP

threshold, minimum 10V, to prevent excessive power

dissipation. The 28V rating eliminates the overvoltage

protection circuit required in a low input voltage charger.

The charge current and the end-of-charge (EOC) current are

programmable with external resistors. When the battery

voltage is lower than a typical value of 2.8V, the charger

preconditions the battery with typically 17% of the

programmed charge current. When the charge current

reduces to the programmable EOC current level during the

CV charge phase, an EOC indication is provided by the CHG

pin, which is an open-drain output. An internal thermal

foldback function protects the charger from any thermal

failure.

Two indication pins (PPR and CHG) allow simple interface to

a microprocessor or LEDs. When no adapter is attached or

when disabled, the charger draws less than 1µA leakage

current from the battery.

FN9207.0

Features

• Complete Charger for Single-Cell Li-ion/Polymer Batteries

• Integrated Pass Element and Current Sensor

• No External Blocking Diode Required

• Low Component Count and Cost

• 1% Voltage Accuracy

• Programmable Charge Current

• Programmable End-of-Charge Current

• Charge Current Thermal Foldback for Thermal

Protection

• Trickle Charge for Fully Discharged Batteries

• 28V Maximum Voltage for the Power Input

• Power Presence and Charge Indications

• Less than 1µA Leakage Current Off the Battery when No

Input Power Attached or Charger Disabled

• Ambient Temperature Range: -40°C to 85°C

• 2x3 DFN 8 Ld Packages

• Pb-Free Plus Anneal Available (RoHS Compliant)

Ordering Information

PAR T

NUMBER

ISL9204IRZ-T

(Note)

Intersil Pb-free plus anneal products employ special Pb-free

material sets; molding compounds/die attach materials and 100%

matte tin plate termination finish, which are RoHS compliant and

compatible with both SnPb and Pb-free soldering operations.

Intersil Pb-free products are MSL classified at Pb-free peak reflow

temperatures that meet or exceed the Pb-free requirements of

IPC/JEDEC J STD-020.

PART

MARKING

04Z -40 to 85 8 Ld 2x3 DFN

TEMP.

RANGE (°C) PACKAGE

Tape and Reel

(Pb-free)

PKG.

DWG. #

L8.2x3

Applications

• Mobile Phones

• Blue-Tooth Devices

•PDAs

• MP3 Players

• Stand-alone Chargers

• Other Handheld Devices

Pinout

(8 LD 2x3 DFN)

VIN

1

2

PPR

3

CHG

4

EN

ISL9204

TOP VIEW

BAT

8

7

IREF

6

IMIN

5

GND

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

All other trademarks mentioned are the property of their respective owners.

Copyright © Intersil Americas Inc. 2005. All Rights Reserved

Page 2

ISL9204

Absolute Maximum Ratings (Reference to GND) Thermal Information

VIN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to 30V

IMIN, IREF, BAT, CHG, EN, PPR. . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to 7V

Recommended Operating Conditions

Ambient Temperature Range. . . . . . . . . . . . . . . . . . . .-40°C to 85°C

Maximum Supply Voltage (VIN Pin). . . . . . . . . . . . . . . . . . . . . . 28V

Operating Supply Voltage (VIN Pin). . . . . . . . . . . . . . . . 4.3V to 10V

Programmed Charge Current . . . . . . . . . . . . . . . . . 50mA to 350mA

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTES:

is measured in free air with the component mounted on a high effective thermal conductivity test board with “direct attach” features. See

1. θ

JA

Tech Brief TB379.

2. For theta θ

the "case temp." location is the center of the exposed metal pad on the package underside.

JC

Electrical Specifications Typical Values Are Tested at VIN = 5V and the Ambient Temperature at 25°C. All Maximum and Minimum

Values Are Guaranteed Under the Recommended Operating Supply Voltage Range and Ambient Temperature

Range, Unless Otherwise Noted.

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

POWER-ON RESET

Rising POR Threshold V

Falling POR Threshold V

VIN-BAT OFFSET VOLTAGE

Rising Edge V

Falling Edge V

OVER VOLTAGE PROTECTION

Over Voltage Protection Threshold V

OVP Threshold Hysteresis 200 400 500 mV

STANDBY CURRENT

BAT Pin Sink Current I

VIN Pin Supply Current I

VIN Pin Supply Current I

VOLTAGE REGULATION

Output Voltage V

PMOS On Resistance r

CHARGE CURRENT (Note 5)

IREF Pin Output Voltage I

Constant Charge Current I

Trickle Charge Current I

End-of-Charge Current I

EOC Rising Threshold R

PRECONDITIONING CHARGE THRESHOLD

Preconditioning Charge Threshold

Voltage

Preconditioning Voltage Hysteresis V

POR

POR

OVP

STANDBY

VIN

VIN

DS(ON)VBAT

IREF

CHG

TRK

MIN

V

MINHYS

V

output.

OS

V

output (Note 3)

OS

Use PPR to indicate the comparator output (Note 4)

Charger disabled or the input is floating - - 1.0 µA

Charger disabled - 300 400 µA

Charger enabled - 500 700 µA

4.3V < V

CH

Charge current = 20mA

V

R

R

R

MIN

= 3.0V, use PPR to indicate the comparator

BAT

= 4.0V, use CHG pin to indicate the comparator

BAT

< 10V

IN

= 3.8V, charge current = 0.3A - 0.6 - Ω

= 3.8V 1.165 1.210 1.245 V

BAT

= 29.4kΩ, V

IREF

= 29.4kΩ, V

IREF

= 137kΩ 20 30 40 mA

IMIN

= 29.4kΩ 90 110 130 mA

IREF

Thermal Resistance (Typical, Notes 1, 2) θ

(°C/W) θJC (°C/W)

JA

DFN Package. . . . . . . . . . . . . . . . . . . . 59 4.5

Maximum Junction Temperature (Plastic Package) . . . . . . . . 150°C

Maximum Storage Temperature Range. . . . . . . . . . .-65°C to 150°C

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . . 300°C

(SOIC, PLCC, etc. Lead Tips Only)

3.3 3.9 4.3 V

3.1 3.6 4.15 V

- 90 150 mV

10 50 - mV

10 10.5 13 V

4.158 4.20 4.242 V

= 2.8V - 4.0V 135 150 165 mA

BAT

= 2.4V 18 25 32 mA

BAT

2.7 2.8 2.9 V

40 100 150 mV

2

FN9207.0

October 4, 2005

Page 3

ISL9204

Electrical Specifications Typical Values Are Tested at VIN = 5V and the Ambient Temperature at 25°C. All Maximum and Minimum

Values Are Guaranteed Under the Recommended Operating Supply Voltage Range and Ambient Temperature

Range, Unless Otherwise Noted. (Continued)

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

INTERNAL TEMPERATURE MONITORING

Charge Current Foldback Threshold

(Note 6)

LOGIC INPUT AND OUTPUTS

EN Pin Logic Input High 1.3 - - V

EN Pin Logic Input Low --0.5V

EN Pin Internal Pull Down

Resistance

CHG Sink Current When LOW Pin Voltage = 1V 10 20 - mA

CHG Leakage Current When HIGH V

PPR Sink Current When LOW Pin Voltage = 1V 10 20 - mA

PPR Leakage Current When HIGH V

NOTES:

3. The 4.0V V

is selected so that the CHG output can be used as the indication for the offset comparator output indication. If the V

BAT

than the POR threshold, no output pin can be used for indication.

4. For junction temperature from -40°C to120°C.

5. The charge current can be affected by the thermal foldback function if the IC under the test setup cannot dissipate the heat.

6. Guaranteed by characterization or correlation to other test.

T

FOLD

100 115 130 °C

100 200 400 kΩ

= 6.5V - - 1 µA

CHG

= 6.5V - - 1 µA

PPR

BAT

is lower

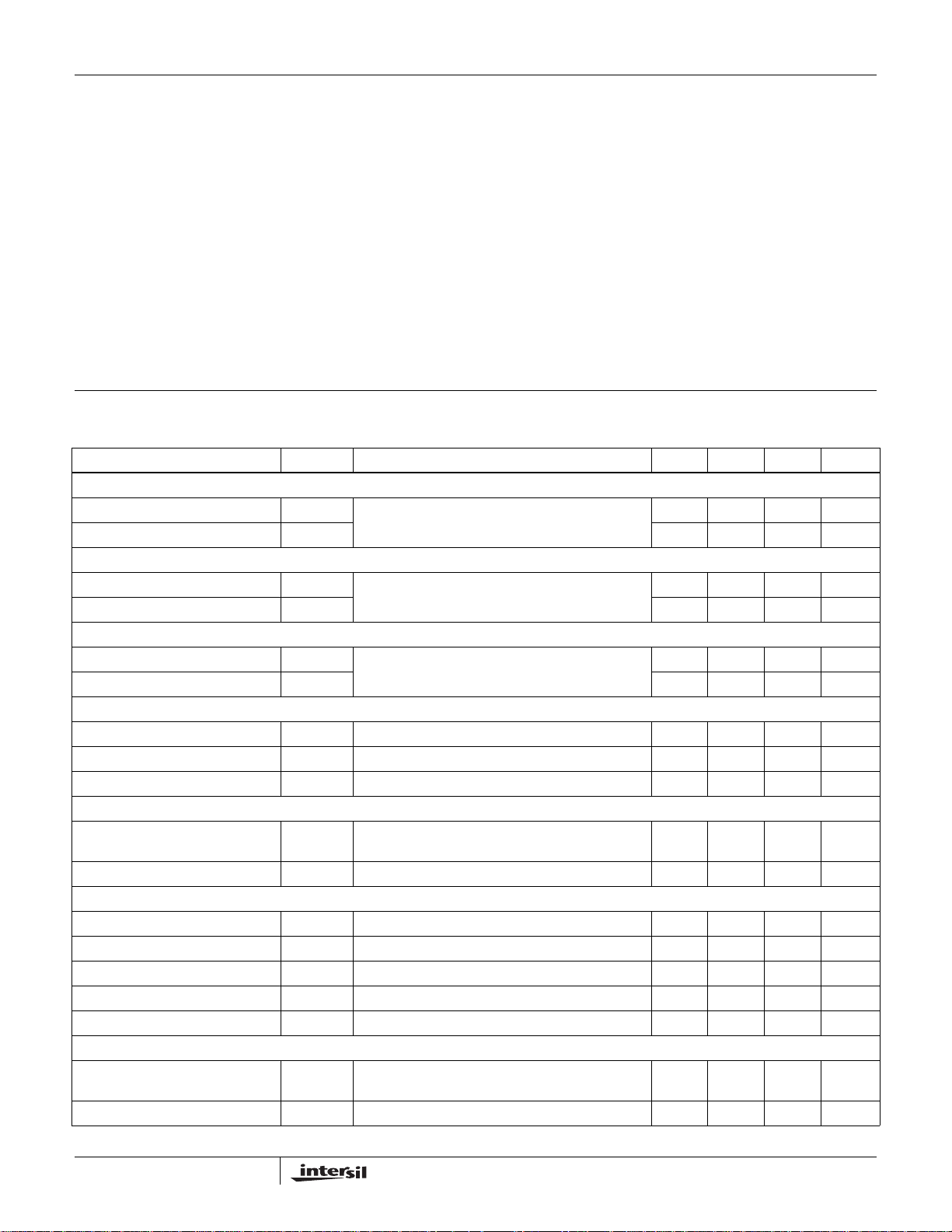

Typical Characteristics

4.5

4.3

4.1

3.9

3.7

CONSTANT

3.5

CURRENT

3.3

3.1

BAT VOLTAGE (V)

2.9

2.7

2.5

0 1K2K3K4K5K6K

CONSTANT

VOLTAGE

TIME (S)

0.20

0.18

0.16

0.14

0.12

0.10

0.08

0.06

0.04

0.02

0.00

Ichg (A)

FIGURE 1. COMPLETE CHARGE CYCLE (130mAh BATTERY) FIGURE 2. CONSTANT VOLTAGE vs CHARGE CURRENT

4.26

4.24

4.22

4.20

(V)

4.18

BAT

V

4.16

4.14

4.12

4.10

0 50 100 150 200 250 300 350

VIN = 5V

= 25°C

T

A

= 12.8K

R

IREF

(mA)

I

BAT

3

FN9207.0

October 4, 2005

Page 4

Typical Characteristics (Continued)

ISL9204

160.0

152.5

145.0

137.5

130.0

122.5

115.0

CHARGE CURRENT (mA)

107.5

100.0

456789101112

TA = 25°C

= 29.4K

R

IREF

= 3V

V

BAT

VIN (V)

FIGURE 3. CHARGE CURRENT vs VIN

240

210

VIN = 5V

180

150

120

90

60

CHARGE CURRENT (mA)

30

0

= 25°C

T

A

012345

V

BAT

(V)

R

IREF

19.5K

29.4K

= 59K

FIGURE 5. CHARGE CURRENT vs V

BAT

1.6

1.4

R

= 59K

IREF

1.2

1.0

0.8

VICDL (V)

0.6

0.4

0.2

0.0

0 50 100 150 200 250 300

29.4K 19.5K

VIN = 5V

= 25°C

T

A

= 3.9V

V

BAT

CHARGE CURRENT (mA)

FIGURE 4. VICDL vs CHARGE CURRENT

4.4

4.2

4.0

(V)

3.8

BAT

V

3.6

3.4

3.2

3.0

34567891011

FIGURE 6. V

VIN = 5V

T

I

VIN (V)

BAT

= 25°C

A

= 15mA

BAT

vs VIN

152

148

144

140

136

132

128

CHARGE CURRENT (mA)

124

120

-20-40 0 20 40 60 80 100 120

VIN = 5V

VB = 3.9V

= 29.4K

R

IREF

TEMPERATURE (°C)

FIGURE 7. CHARGE CURRENT vs TEMPERATURE

4

4.25

4.24

4.23

4.22

4.21

(V)

4.20

BAT

V

4.19

4.18

4.17

4.16

4.15

VIN = 5V

= 15mA

I

BAT

-20-40 0 20 40 60 80 100 120

TEMPERATURE (°C)

FIGURE 8. V

vs TEMPERATURE

BAT

FN9207.0

October 4, 2005

Page 5

ISL9204

Pin Descriptions

VIN - Power input. The absolute maximum input voltage is

28V. A 0.47µF or larger value X5R ceramic capacitor is

recommended to be placed very close to the input pin for

decoupling purpose. Additional capacitance may be required

to provide a stable input voltage.

PPR - Open-drain power presence indication. The opendrain MOSFET turns on when the input voltage is above the

POR threshold but below the OVP threshold and off

otherwise. This pin is capable to sink 10mA (minimum)

current to drive a LED. The maximum voltage rating for this

pin is 7V. This pin is independent on the EN-pin input.

CHG - Open-drain charge indication pin. This pin outputs a

logic LOW when a charge cycle starts and turns to HIGH

when the end-of-charge (EOC) condition is qualified. This

pin is capable to sink 10mA min. current to drive an LED.

When the charger is disabled, the CHG outputs high

impedance.

EN - Enable input. This is a logic input pin to disable or

enable the charger. Drive to HIGH to disable the charger.

When this pin is driven to LOW or left floating, the charger is

enabled. This pin has an internal 200kΩ pull-down resistor.

GND - System ground.

IMIN - End-of-charge (EOC) current program pin. Connect a

resistor between this pin and the GND pin to set the EOC

current. The EOC current IMIN can be programmed by the

following equation:

I

MIN

Where R

R

IMIN

is in kΩ. The programmable range covers 5%

IMIN

mA()=

4180

----------------

(or 10mA, whichever is higher) to 50% of IREF. When

programmed to less than 5% or 10mA, the stability is not

guaranteed.

IREF - Charge-current program and monitoring pin. Connect

a resistor between this pin and the GND pin to set the

charge current limit determined by the following equation:

I

REF

Where R

R

IREF

is in kΩ. The IREF pin voltage also monitors

IREF

mA()=

4400

-----------------

the actual charge current during the entire charge cycle,

including the trickle, constant-current, and constant-voltage

phases. When disabled, VIREF = 0V.

BAT - Charger output pin. Connect this pin to the battery. A

1µF or larger X5R ceramic capacitor is recommended for

decoupling and stability purposes. When the EN pin is pulled

to logic HIGH, the BAT output is disabled.

EPAD - Exposed pad. Connect as much as possible copper

to this pad either on the component layer or other layers

through thermal vias to enhance the thermal performance.

Typical Application

TO INPUT

C

1

ON

FIGURE 9. TYPICAL APPLICATION CIRCUIT INTERFACING TO INDICATION LEDS

OFF

VIN

EN

ISL9204

BAT

IREF

IMIN

CHG

PPR

GND

R

R

IREF

IMIN

TO BATTERY

1

D2

1

R2

C2

R

D

5

FN9207.0

October 4, 2005

Page 6

ISL9204

TABLE 1. COMPONENT DESCRIPTION FOR FIGURE 9

PART DESCRIPTION

R

D

R

R

C

C

IREF

IMIN

, R

1

, D

1

1

2

2

2

1µF X5R ceramic cap

1µF X5R ceramic cap

29.4kΩ, 1%, for 150mA charge current

137kΩ, 1%, for 30mA EOC current

300Ω, 5%

LEDs for indication

TO INPUT

VIN

C

1

OFF

EN

ON

ISL9204

TABLE 2. COMPONENT DESCRIPTION FOR FIGURE 10

PART DESCRIPTION

BAT

IREF

IMIN

CHG

R

R

R

C

C

IREF

IMIN

, R

1

1

2

R

R

2

IREF

IMIN

R1 R2

1µF X5R ceramic cap

1µF X5R ceramic cap

29.4kΩ, 1%, for 150mA charge current

137kΩ, 1%, for 30mA EOC current

100kΩ, 5%

TO BATTERY

C

2

VCC

VIN

PPR

EN

GND

GND

PPR

TO MCU

FIGURE 10. TYPICAL APPLICATION CIRCUIT WITH THE INDICATION SIGNALS INTERFACING TO A MCU

POR

PRE

REG

200kΩ

V

REF

VCC

VOS

BAT

CHARGE

CONTROL

EN

VCC

V

REF

DIE

TEMP

115°C

BAT

CHG

IMIN IREF

FIGURE 11. BLOCK DIAGRAM

6

FN9207.0

October 4, 2005

Page 7

ISL9204

TRICKLE CC CV

4.2V

I

REF

CHARGE

VOLTAGE

3.0V

17% I

REF

CHG

FIGURE 12. TYPICAL CHARGE PROFILE

Description

The ISL9204 charges a Li-ion battery with a constant current

(CC) or a constant voltage (CV). The constant current I

is set with the external resistor R

(see Figure 9) and the

IREF

constant voltage is fixed at 4.2V. If the battery voltage is

below a typical 2.8V trickle-charge threshold, the ISL9204

charges the battery with a trickle current until the battery

voltage rises above the trickle charge threshold. When the

battery voltage reaches 4.2V, the charger enters a CV mode

and regulates the battery voltage at 4.2V to fully charge the

battery without the risk of over charge. Upon reaching an

end-of-charge (EOC) current, the charger indicates the

charge completion with the CHG pin, but the charger

continues to output the 4.2V voltage. Figure 12 shows the

typical charge profile and the EOC/reset event.

The EOC current level I

external resistor R

IMIN

is programmable with the

MIN

(see Figure 9). The CHG signal turns

to LOW when the trickle charge starts and rises to HIGH at

the EOC. After the EOC is reached, the charge current has

to rise to typically 73% I

for the CHG signal to turn on

REF

again, as shown in Figure 12. The current surge after EOC

can be caused by a load connected to the battery.

A thermal foldback function reduces the charge current

anytime when the die temperature reaches typically 115°C.

This function guarantees safe operation when the printedcircuit board (PCB) is not capable of dissipating the heat

generated by the linear charger. The ISL9204 accepts an

input voltage up to 28V but disables charging when the input

voltage exceeds the OVP threshold, minimum 10V, to

protect against unqualified or faulty AC adapters.

PPR Indication

The PPR pin is an open-drain output to indicate the

presence of the AC adapter. Whenever the input voltage is

REF

CHARGE

CURRENT

I

MIN

CHG

INDICATION

73% I

TIME

REF

higher than the POR threshold, the PPR pin turns on the

internal open-drain MOSFET to indicate a logic LOW signal,

independent on the EN-pin input. When the internal opendrain FET is turned off, the PPR pin should leak less than

1µA current. When turned on, the PPR pin should be able to

sink at least 10mA current under all operating conditions.

The PPR pin can be used to drive an LED (see Figure 9) or

to interface with a microprocessor.

Power-Good Range

The power-good range is defined by the following three

conditions:

1. VIN > VPOR

2. VIN - VBAT > VOS

3. VIN < VOVP

where the VOS is the offset voltage for the input and output

voltage comparator, discussed shortly, and the VOVP is the

overvoltage protection threshold given in the Electrical

Specification. All V

, VOS, and V

POR

have hysteresis, as

OVP

given in the Electrical Specification table. The charger will

not charge the battery if the input voltage is not in the

power-good range.

Input and Output Comparator

The charger will not be enabled unless the input voltage is

higher than the battery voltage by an offset voltage VOS.

The purpose of this comparator is to ensure that the charger

is turned off when the input power is removed from the

charger. Without this comparator, it is possible that the

charger will fail to power down when the input is removed

and the current can leak through the PFET pass element to

continue biasing the POR and the Pre-Regulator blocks

shown in the Block Diagram.

7

FN9207.0

October 4, 2005

Page 8

ISL9204

CHG Indication

The CHG is an open-drain output capable to at least 10mA

current when the charger starts to charge and turns off when

the EOC current is reached. The CHG signal is interfaced

either with a micro-processor GPIO or an LED for indication.

EN Input

EN is an active-low logic input to enable the charger. Drive

the EN pin to LOW or leave it floating to enable the charger.

This pin has a 200kΩ internal pulldown resistor so when left

floating, the input is equivalent to logic LOW. Drive this pin to

HIGH to disable the charger. The threshold for HIGH is given

in the ES (Electrical Specification) table.

IREF Pin

The IREF pin has the two functions as described in the Pin

Description section. When setting the fast charge current,

the charge current is guaranteed to have 10% accuracy with

the charge current set at 150mA. When monitoring the

charge current, the accuracy of the IREF pin voltage vs. the

actual charge current has the same accuracy as the gain

from the IREF pin current to the actual charge current. The

accuracy is 10% at 150mA and is expected to drop to 30% of

the actual current (not the set constant charge current) when

the current drops to 50mA.

Operation Without the Battery

The ISL9204 relies on a battery for stability and is not

guaranteed to be stable if the battery is not connected. With

a battery, the charger will be stable with an output ceramic

decoupling capacitor in the range of 1µF to 200µF. The

maximum load current is limited by the dropout voltage or

the thermal foldback.

Dropout Voltage

The constant current may not be maintained due to the

r

resistance of the pass FET is 1.2Ω the maximum operating

temperature, thus if tested with 350mA current and 4.2V

battery voltage, constant current could not be maintained

when the input voltage is below 4.62V.

limit at a low input voltage. The worst case on

DS(ON)

Thermal Foldback

The thermal foldback function starts to reduce the charge

current when the internal temperature reaches a typical

value of 115°C.

Applications Information

Input Capacitor Selection

The input capacitor is required to suppress the power supply

transient response during transitions. Mainly this capacitor is

selected to avoid oscillation during the start up when the

input supply is passing the POR threshold and the VIN-BAT

comparator offset voltage. When the battery voltage is above

the POR threshold, the VIN-VBAT offset voltage dominates

the hysteresis value. Typically, a 1µF X5R ceramic capacitor

should be sufficient to suppress the power supply noise.

Output Capacitor Selection

The criteria for selecting the output capacitor is to maintain

the stability of the charger as well as to bypass any transient

load current. The minimum capacitance is a 1µF X5R

ceramic capacitor. The actual capacitance connected to the

output is dependent on the actual application requirement.

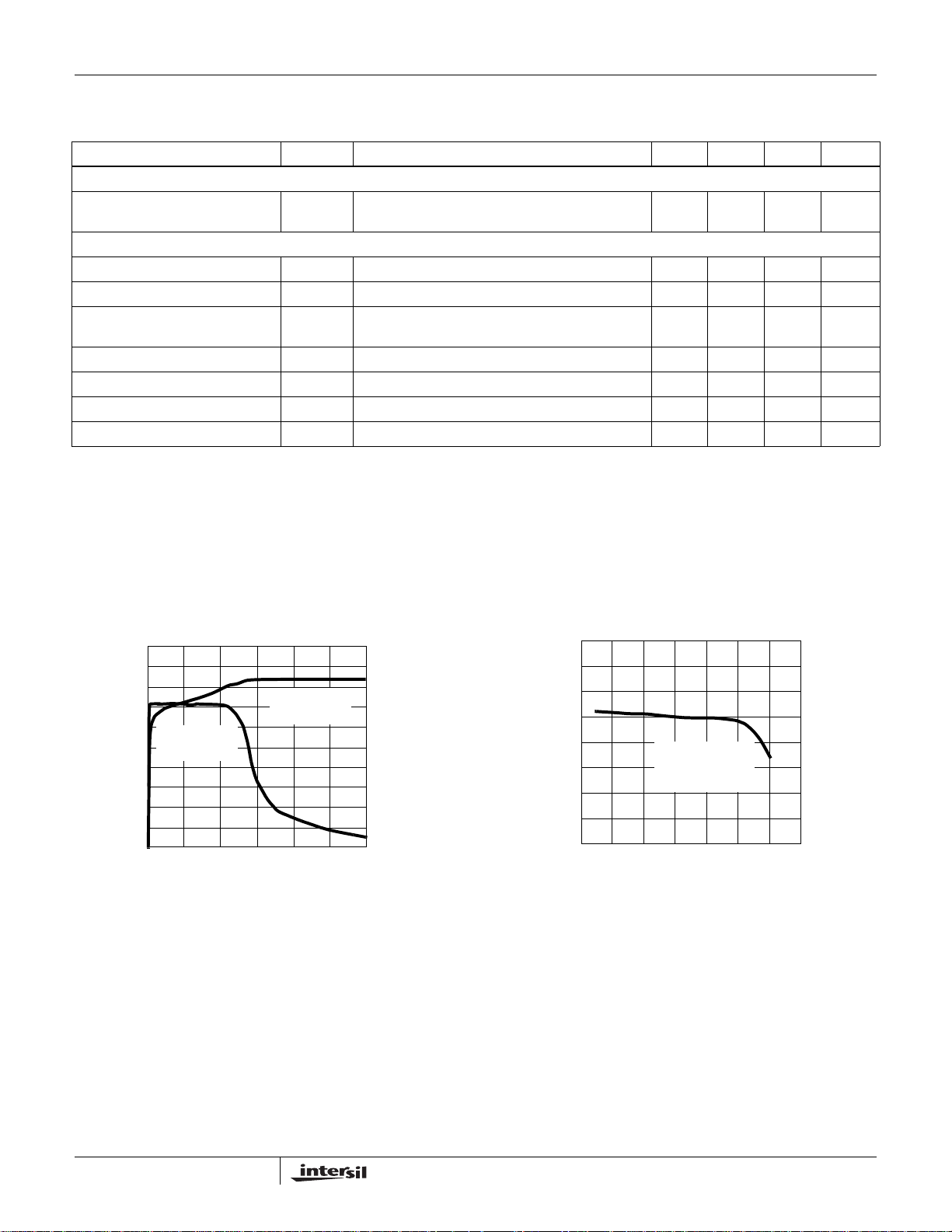

Charge Current Limit

The actual charge current in the CC mode is limited by

several factors in addition to the set I

three limits for the charge current in the CC mode. The

charge current is limited by the on resistance of the pass

element (power P-channel MOSFET) if the input and the

output voltage are too close to each other. The solid curve

shows a typical case when the battery voltage is 4.0V and

the charge current is set to 350mA. The non-linearity on the

R

-limited region is due to the increased resistance at

ON

higher die temperature. If the battery voltage increases to

higher than 4.0V, the entire curve moves towards right side.

As the input voltage increases, the charge current may be

reduced due to the thermal foldback function. The limit

caused by the thermal limit is dependent on the thermal

impedance. As the thermal impedance increases, the

thermal-limited curve moves towards left, as shown in

Figure 13.

Layout Guidance

The ISL9204 uses a thermally-enhanced DFN package that

has an exposed thermal pad at the bottom side of the

package. The layout should connect as much as possible to

copper on the exposed pad. Typically the component layer is

more effective in dissipating heat. The thermal impedance

can be further reduced by using other layers of copper

connecting to the exposed pad through a thermal via array.

Each thermal via is recommended to have 0.3mm diameter

and 1mm distance from other thermal vias.

. Figure 13 shows

REF

8

FN9207.0

October 4, 2005

Page 9

Input Power Sources

The input power source is typically a well-regulated wall

cube with 1-meter length wire or a USB port. The input

voltage ranges from 4.3V to 10V. The ISL9204 can withstand

up to 28V on the input without damaging the IC. If the input

voltage is higher than the OVP threshold, the charger stops

charging.

ISL9204

350

CHARGE CURRENT (mA)

R

ON

LIMITED

INCREASES

4.5 5.0 5.5

INPUT VOLTAGE (V)

INCREASES

V

BAT

R

IREF

THERMAL

LIMITED

θ

OR T

JA

INCREASES

A

\\

FIGURE 13. CHARGE CURRENT LIMITS IN CONSTANT

CURRENT MODE

10 4.0

9

FN9207.0

October 4, 2005

Page 10

Dual Flat No-Lead Plastic Package (DFN)

ISL9204

(DATUM A)

NX (b)

5

INDEX

AREA

SEATING

(DATUM B)

6

INDEX

AREA

NX L

8

A

6

C

PLANE

(A1)

D

TOP VIEW

SIDE VIEW

D2

D2/2

12

N

N-1

e

(Nd-1)Xe

REF.

BOTTOM VIEW

2X

A3

NX b

L8.2x3

ABC0.15

2X

0.15

CB

E

0.10

//

A

87

NX k

E2

E2/2

5

0.10

C

L

0.08

L

C

C

BAMC

8 LEAD DUAL FLAT NO-LEAD PLASTIC PACKAGE

MILLIMETERS

SYMBOL

NOTESMIN NOMINAL MAX

A 0.80 0.90 1.00 -

A1 - - 0.05 -

A3 0.20 REF -

b 0.20 0.25 0.32 5,8

D 2.00 BSC -

D2 1.50 1.65 1.75 7,8

E 3.00 BSC -

E2 1.65 1.80 1.90 7,8

e 0.50 BSC -

k0.20 - - -

L 0.30 0.40 0.50 8

N 8 2

Nd 4 3

Rev. 0 6/04

NOTES:

1. Dimensioning and tolerancing conform to ASME Y14.5-1994.

2. N is the number of terminals.

3. Nd refers to the number of terminals on D.

4. All dimensions are in millimeters. Angles are in degrees.

5. Dimension b applies to the metallized terminal and is measured

between 0.25mm and 0.30mm from the terminal tip.

6. The configuration of the pin #1 identifier is optional, but must be

located within the zone indicated. The pin #1 identifier may be

either a mold or mark feature.

7. Dimensions D2 and E2 are for the exposed pads which provide

improved electrical and thermal performance.

8. Nominal dimensions are provided to assist with PCB Land

Pattern Design efforts, see Intersil Technical Brief TB389.

SECTION "C-C"

FOR EVEN TERMINAL/SIDE

CC

e

TERMINAL TIP

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

10

FN9207.0

October 4, 2005

Loading...

Loading...